Patents

Literature

203results about How to "Improve the tension effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

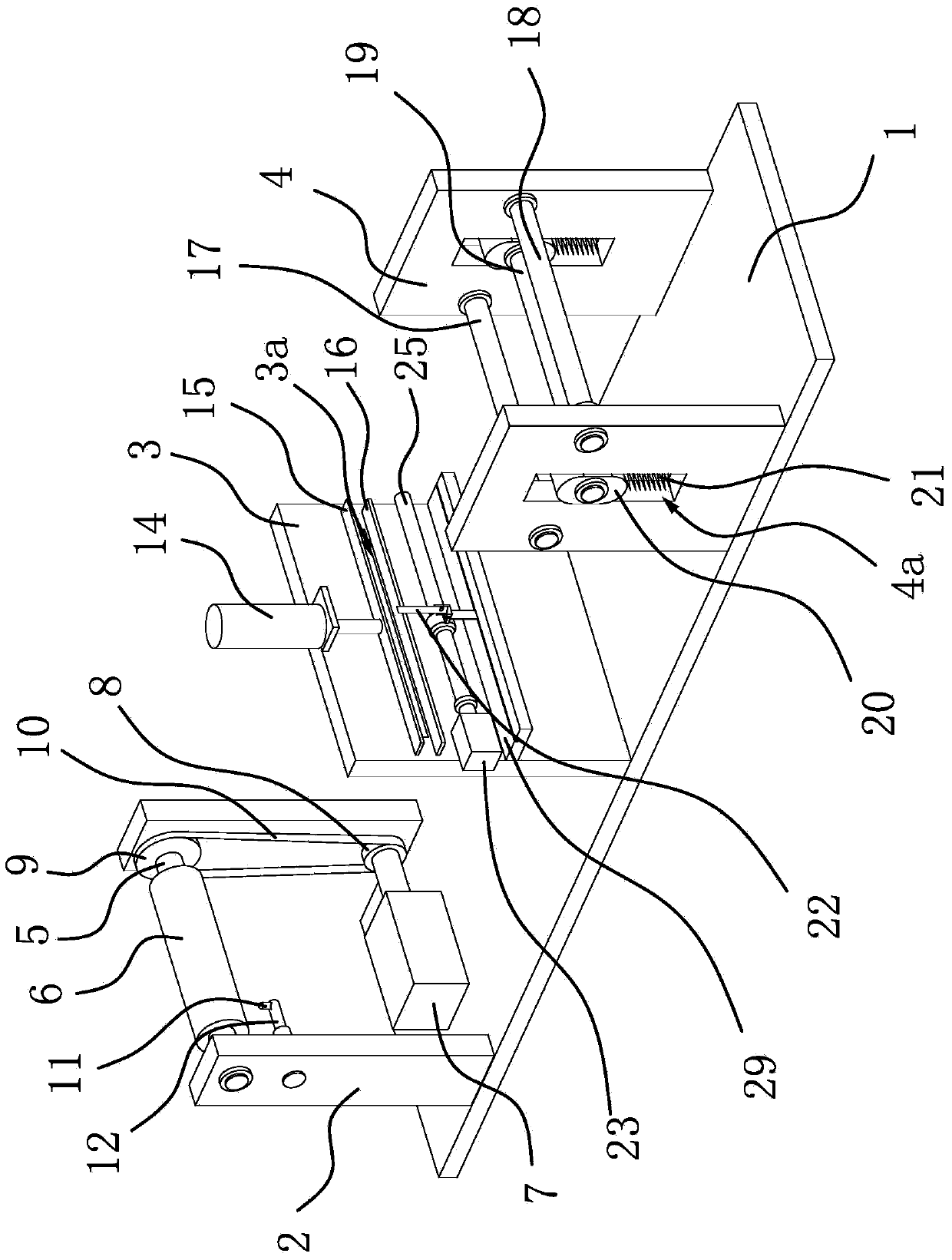

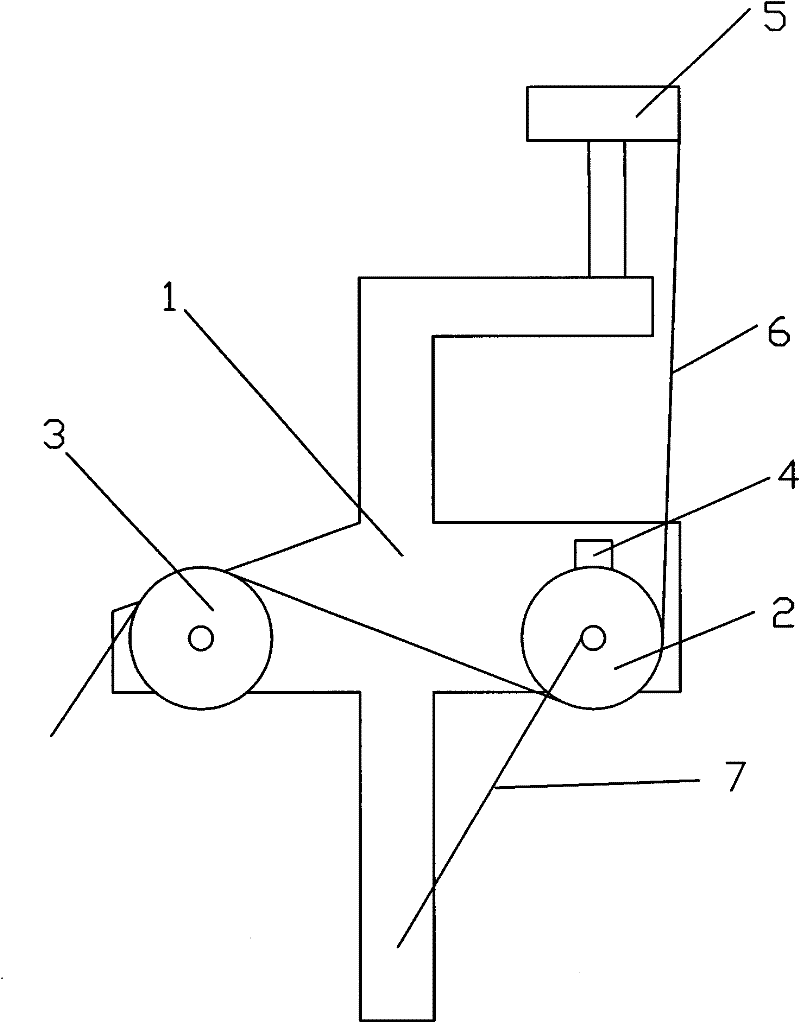

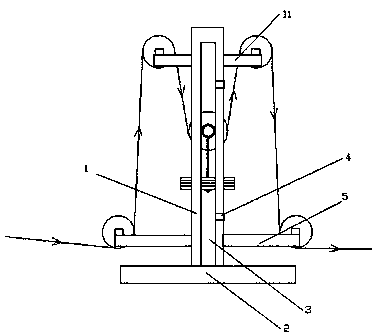

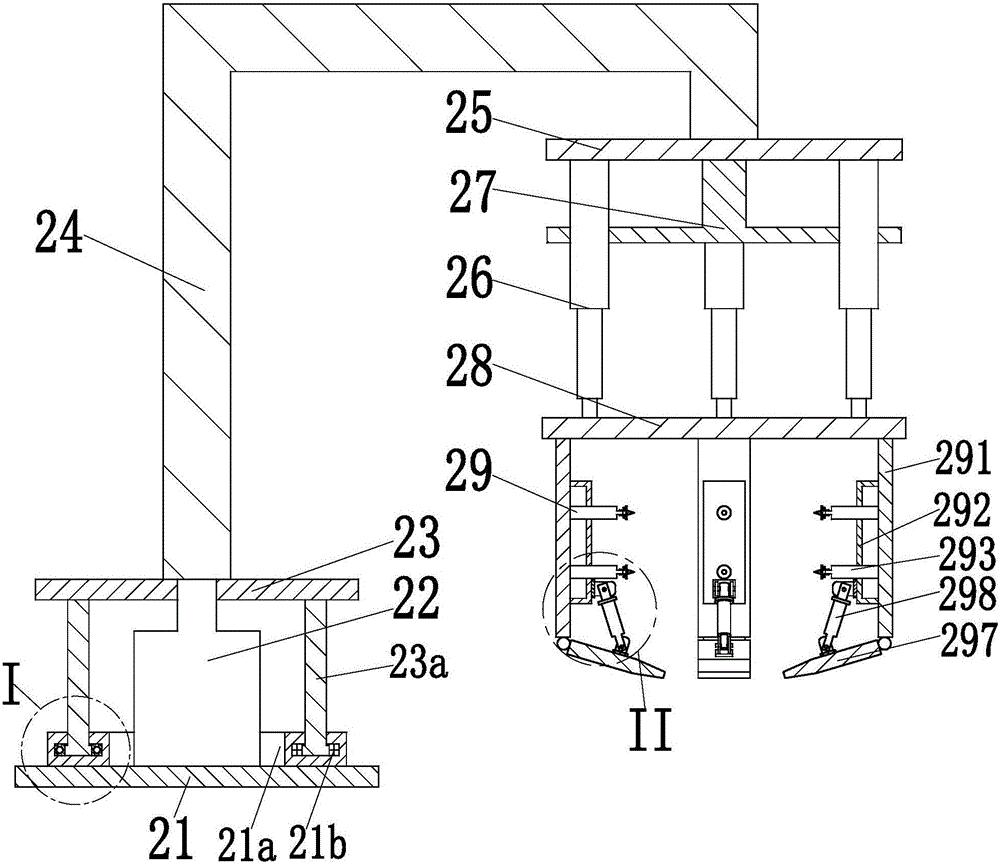

Ceramic cutting and conveying device with automatic correction function

ActiveCN105668142AImprove the tension effectTransportation safetyConveyorsMechanical engineeringEngineering

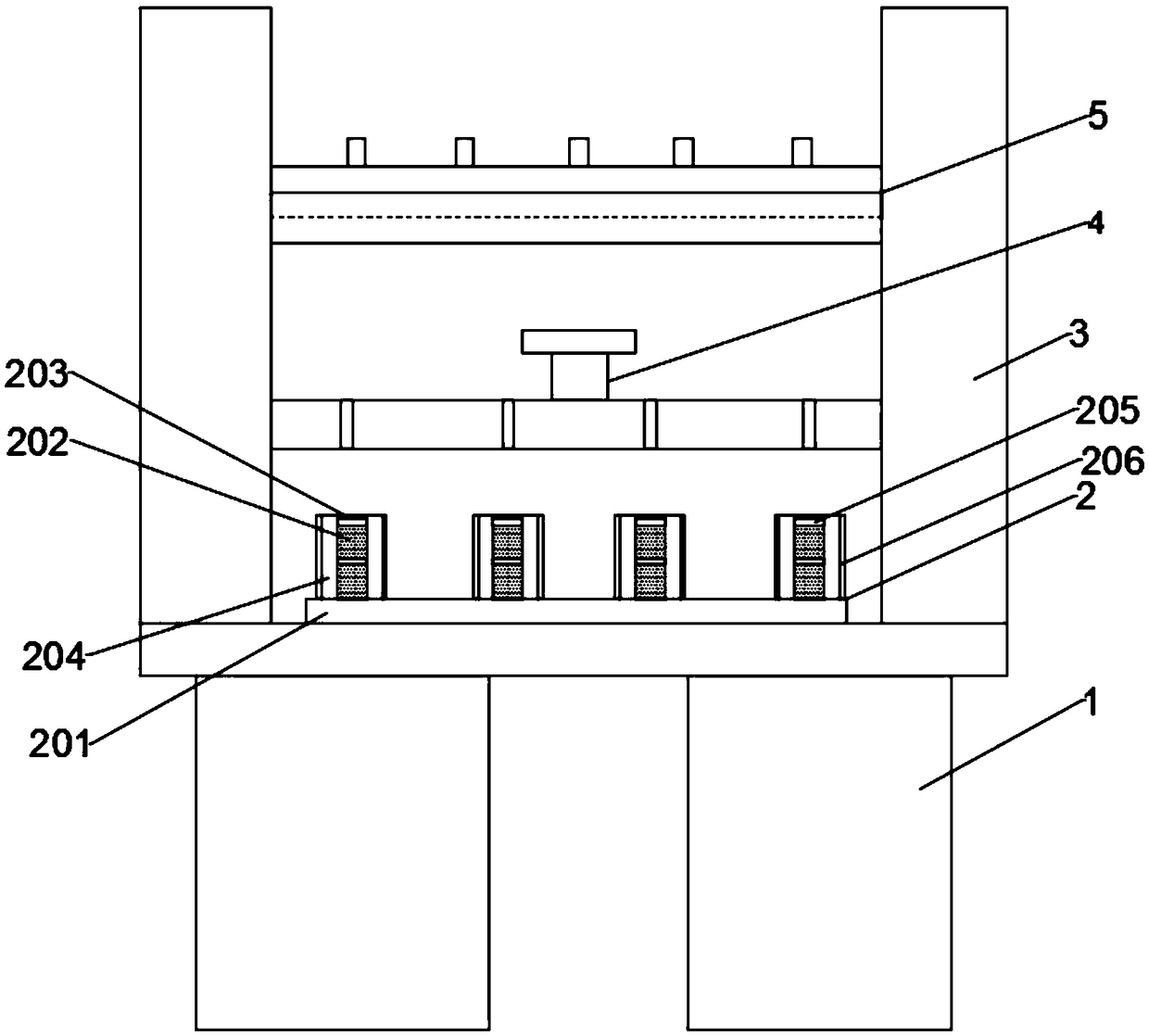

The invention discloses a ceramic cutting and conveying device with an automatic correction function. The ceramic cutting and conveying device comprises a rack. The rack comprises a middle shell. Supporting plates are fixed to the front end and the rear end of the left outer side wall of the middle shell and the front end and the rear end of the right outer side wall of the middle shell. The two ends of each driving roller are hinged to the two corresponding supporting plates. A conveying belt is tensioned on the two driving rollers. Landing legs are fixed to the bottom faces of the supporting plates. An upper supporting plate is arranged on the top face of the middle shell and pressed on the inner wall face of the upper part of the conveying belt in an abutting manner. Vertical plates are further fixed to the front side and the rear side of the top face of the middle shell, the two vertical plates are located on the two sides of the conveying belt, and a plurality of guide air cylinders are fixed to the vertical plates. Push rods of the guide air cylinders penetrate the vertical plates and are fixedly provided with guide plates. The positions of the two driving rollers are fixed, and relative movement is avoided. Meanwhile, ceramic products can be moved to the middle of the conveying belt through guide wheels arranged on the guide plates and front guide plates of the ceramic cutting and conveying device, and it is guaranteed that the ceramic products are conveyed normally and safely.

Owner:NANTONG BAOTIAN PACKING MACHINERY

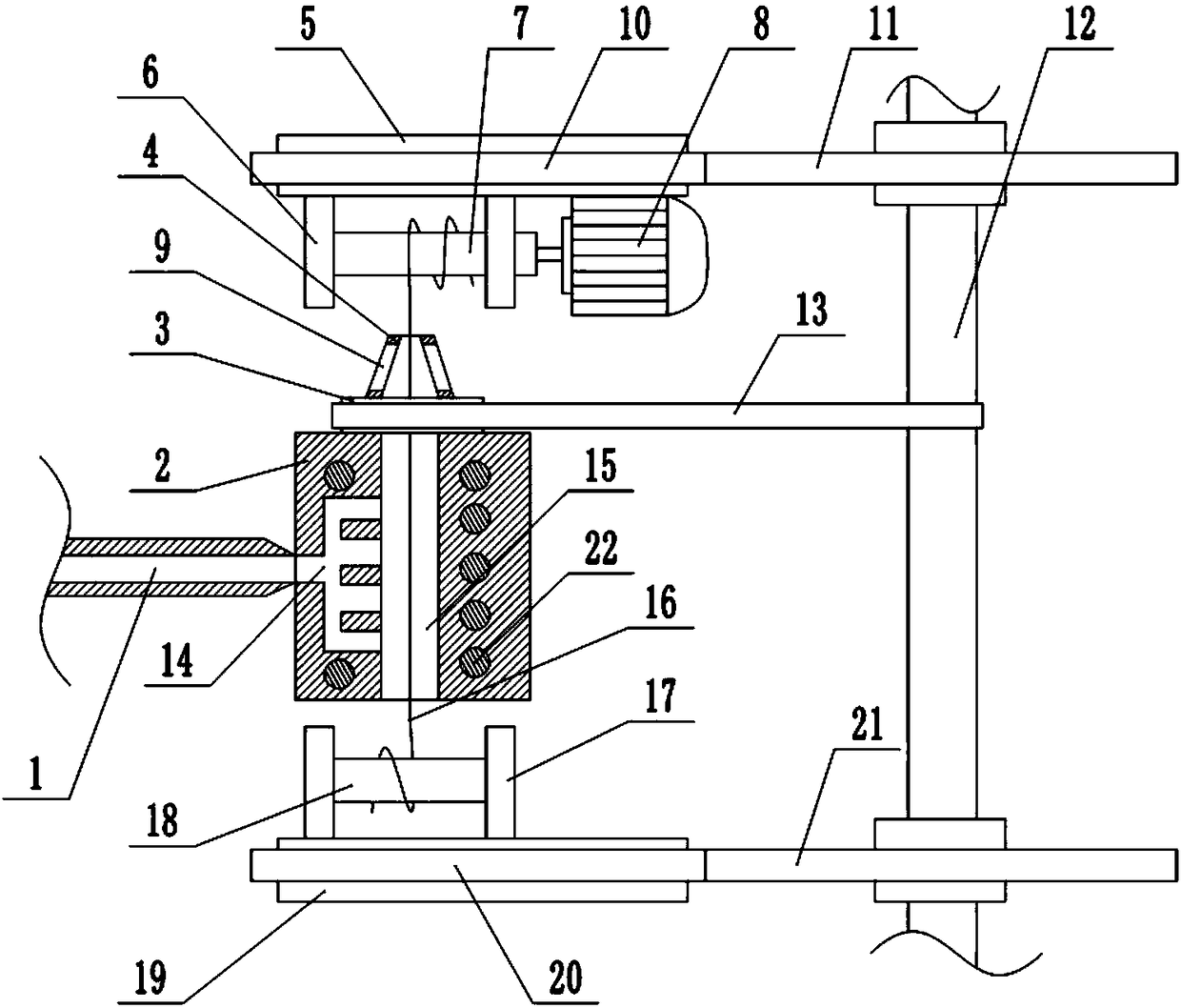

Winding device of BOPP thin film

The invention provides a winding device of a BOPP thin film, and belongs to the technical field of machines. The winding device solves the problems that in the prior art, the thin film needs to be manually cut off after being wound, and time and labor are wasted. The winding device of the BOPP thin film comprises a base and a first support arranged on the base; the first support comprises two stand columns; a winding shaft is arranged between the two stand columns, and a winding cylinder is arranged on the winding shaft; a power mechanism is arranged at one end of the winding shaft; a second support is arranged on the right side of the first support; the second support comprises a fixed plate; a clamping mechanism and a slitting blade are arranged on the fixed plate; the slitting blade is connected with a sliding mechanism which can drive the slitting blade to horizontally slide; a third support is arranged on the right side of the second support; the third support comprises two mounting plates; a tensioning mechanism which enables the thin film to be tensioned is arranged between the two mounting plates. According to the winding device, the aim that the thin film is cut off by the device after being wound can be achieved through the clamping mechanism.

Owner:湖南泰利恒友科技开发有限公司

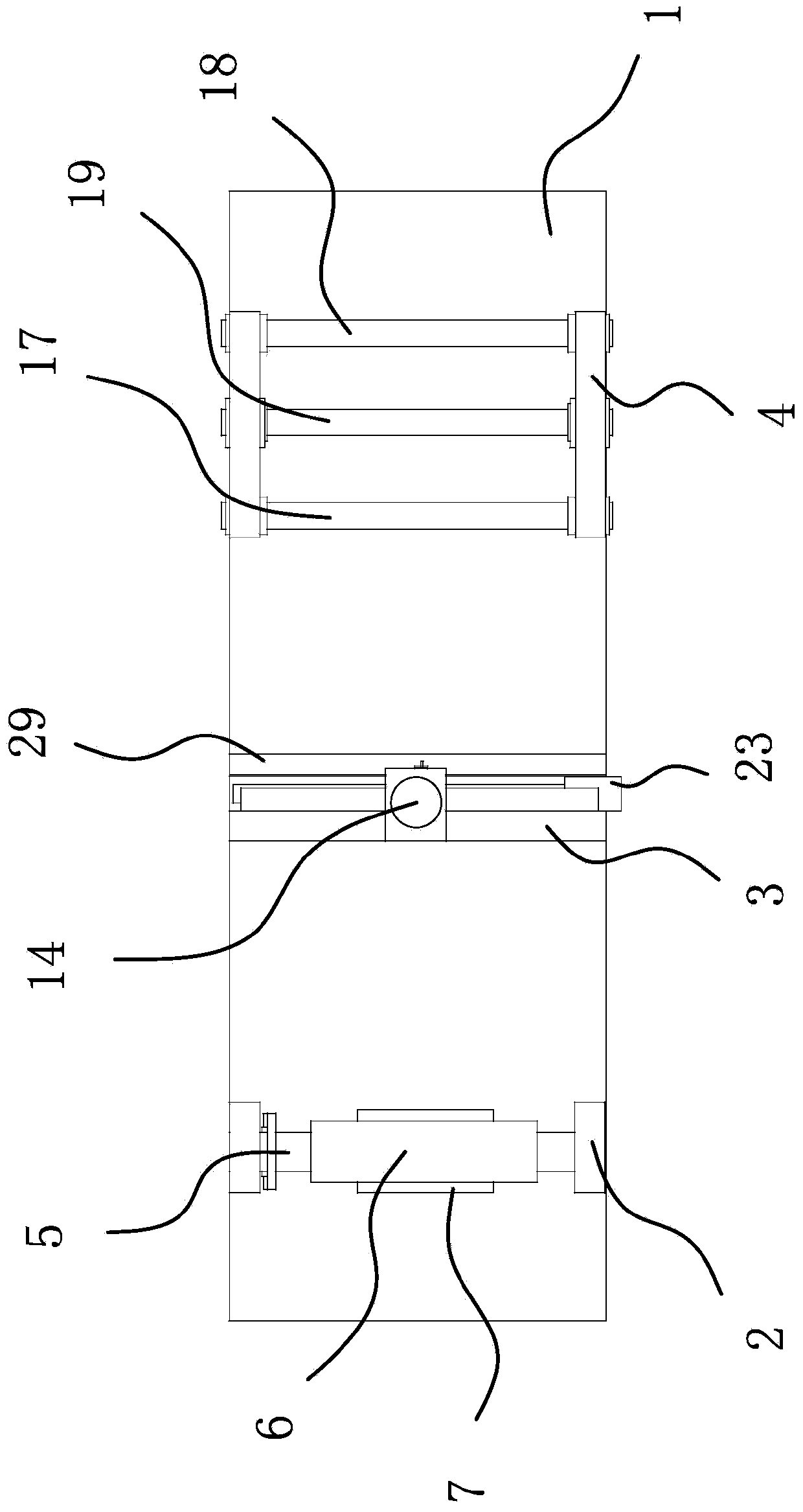

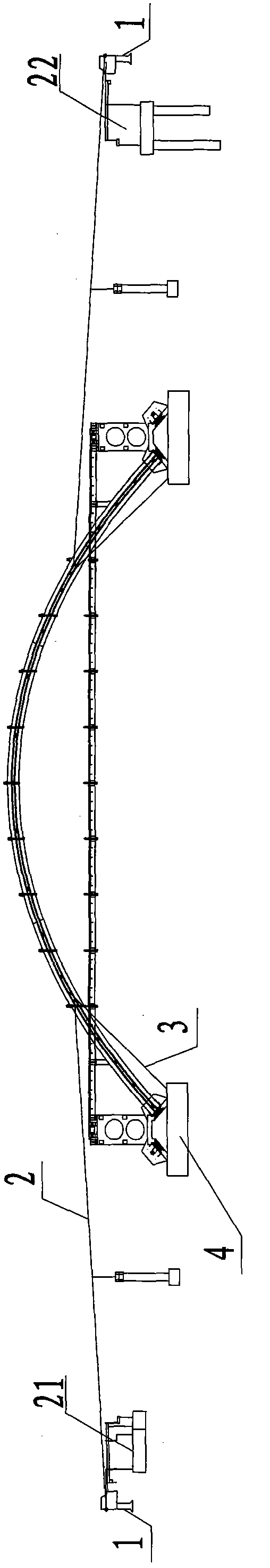

Steel tube arch bridge towerless buckling three-section type double-rib folding hoisting construction method

InactiveCN103437296AImprove the tension effectHigh control precisionBridge erection/assemblyArch-type bridgeEdge segmentSteel tube

The invention relates to a steel tube concrete arch bridge hoisting construction method, belongs to the technical field of bridge construction, and discloses a steel tube arch bridge towerless buckling three-section type double-rib folding hoisting construction method. The method includes the following steps of 1, arch rib pre-assembly, 2, ground anchor arrangement, 3, single-floating-crane transportation, 4, single-edge segment adjustment to be close to design angles through a floating crane, 5, buckling system installation, 6, repetition of the steps 3, 4 and 5 and installation of the other section of a single-edge segment, 7, double-floating-crane transportation, and 8, folding and welding. The method improves production efficiency, accelerates construction, saves engineering cost, and guarantees arch rib installation quality.

Owner:中天交通建设投资集团有限公司

Temporary winding device with cleaning function and used for gauze production and machining

InactiveCN110626838AGood cleaning effectGuaranteed cleanlinessCleaning using toolsCleaning using gasesMachiningBlow out

The invention relates to the field of gauze production and machining devices, and specifically relates to a temporary winding device with a cleaning function and used for gauze production and machining. The temporary winding device with the cleaning function and used for gauze production and machining comprises a bottom plate, a winding structure, a fixed plate, a compression structure, a flatly-laying structure, a guide structure, a cleaning structure and a side plate. The winding structure is capable of synchronously driving the cleaning structure to work during working, so that a better cleaning effect of the cleaning structure can be achieved; two oppositely-arranged brush plates are fixed into a cleaning sleeve, and cleaning working can be carried out on a gauze being wound, so that impurities on the surface of the gauze can be cleaned, and then the cleanliness of the wound gauze can be ensured; gas blowing holes communicate with the interior of a gas storage groove separately, and therefore, gas in the gas storage groove is blown out via the gas blowing holes, so that ash blowing cleaning working can be carried out before the gauze enters the two brush plates, and then the cleanliness of the wound gauze can be ensured.

Owner:LIXIN FUYA GAUZE CO LTD

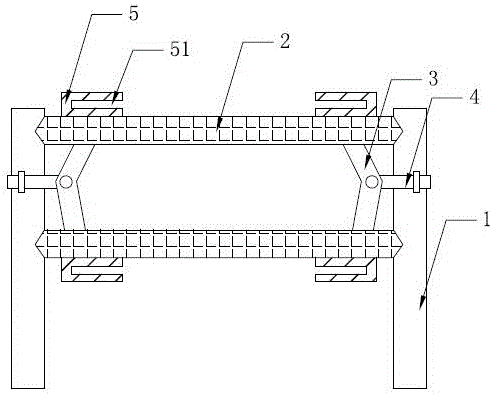

Tensioning gear for belt type conveyor

InactiveCN107973067AReduce tensionTo achieve tensionConveyorsSupporting framesMotor driveArchitectural engineering

The invention provides a tensioning gear for a belt type conveyor, and relates to the field of belt tensioning equipment. The tensioning gear for the belt type conveyor includes a base plate, fixing rods are fixedly installed at two sides of the bottom of the base plate, the two fixing rods are fixedly connected with each other through a cross rod, and a baffle plate is fixedly installed at the rear surface of the inner wall of the base plate; and the bottom portions of the fixing rods are provided with supporting legs in an inserting mode, first grooves are formed in two sides of the blockingplate, and a first motor is fixedly installed at the top of the inner wall of each of the first grooves. According to the tensioning gear for the belt type conveyor, the first motor drives a second angle gear to rotate through a first angle gear, so that a moving sliding block can be moved left and right with the rotating of a threaded rod to achieve the effect of regulating the distance of the fixing block and the blocking plate, and the effect of tensioning a slack belt can be achieved; and a first hydraulic pushing rod and a contacting wheel are cooperatively used to reinforce the tensioning effect, workers are convenient to tension the belt, the time and the labor can be saved, and the work efficiency can be improved.

Owner:无锡市内河装卸机械有限公司

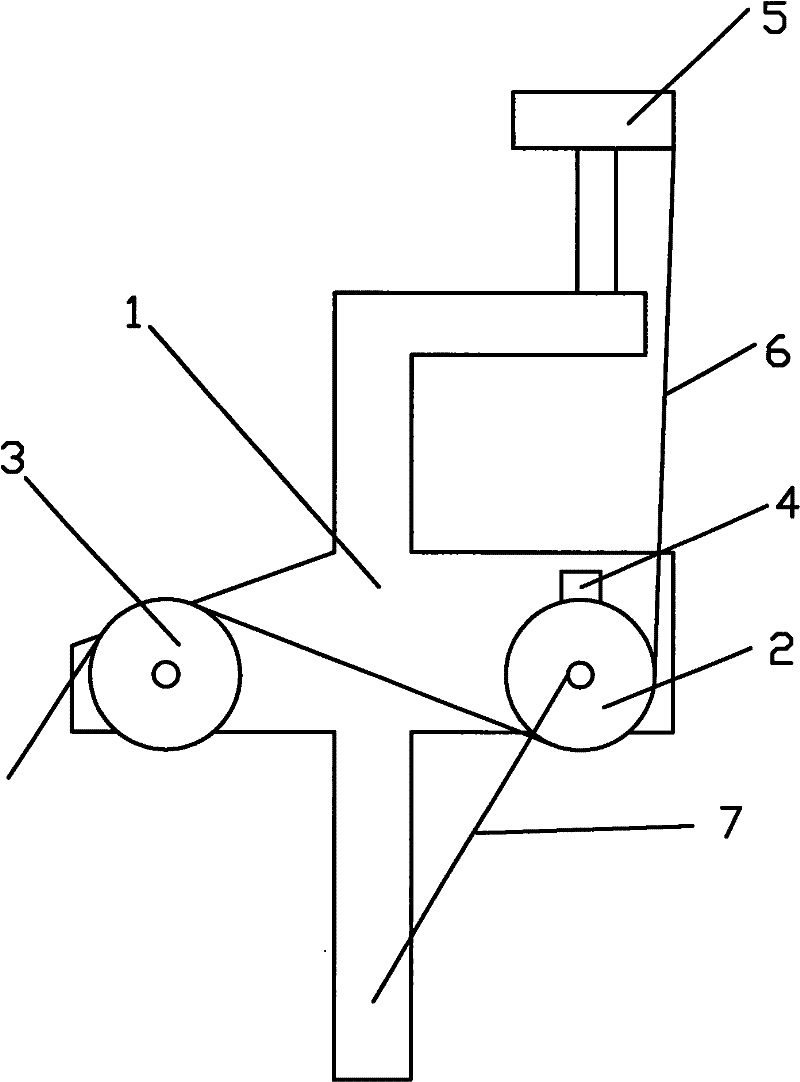

Yarn guiding device

InactiveCN102345200ASimple structureImprove the tension effectWeft knittingWarp knittingYarnEngineering

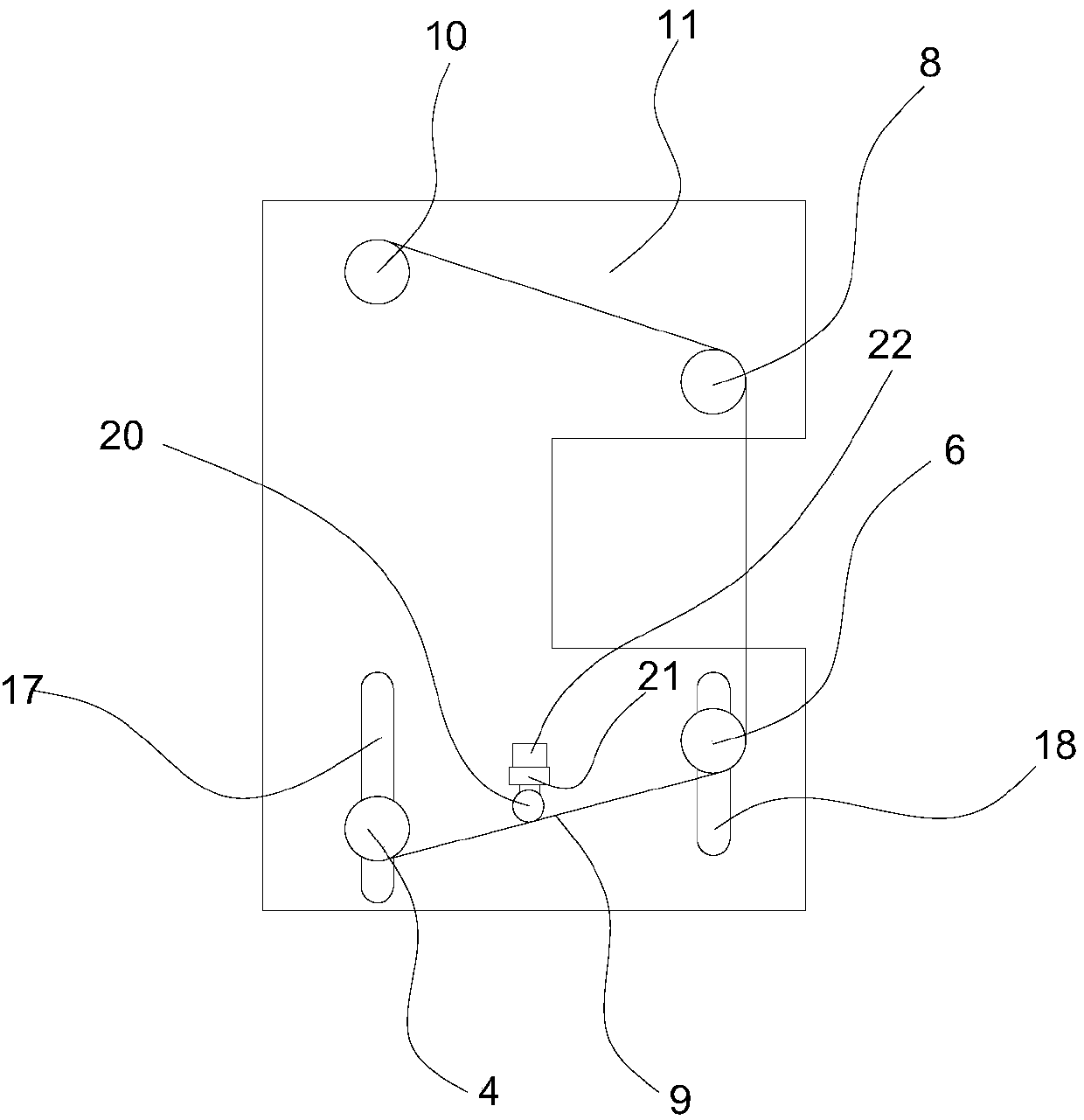

The invention discloses a yarn guiding device, which comprises a bracket, wherein an unwinding disc is arranged on the bracket. The yarn guiding device is characterized in that: a first yarn guiding wheel and a second yarn guiding wheel are arranged in the middle of the bracket; a vertical or inclined guide groove is formed on the bracket; the first yarn guiding wheel is arranged in the guide groove and is connected with a spring; the other end of the spring is fixed at the lower end of the bracket; the first yarn guiding wheel can move up and down in the guide groove under the action of the spring; and the first yarn guiding wheel and the second yarn guiding wheel are arranged in the same plane and have the same diameter. Compared with prior art, the invention has the advantages that: the guide groove is formed on the bracket, and the first yarn guiding wheel is arranged in the guide groove and is connected with the spring to adjust the distance between the first yarn guiding wheel and the second yarn guiding wheel, so that yarns which bypass the yarn guiding wheels are tensioned; and the yarn guiding device has a simple structure and a good tensioning effect and meets requirements well.

Owner:NANTONG SIFANG TEXTILE MACHINERY

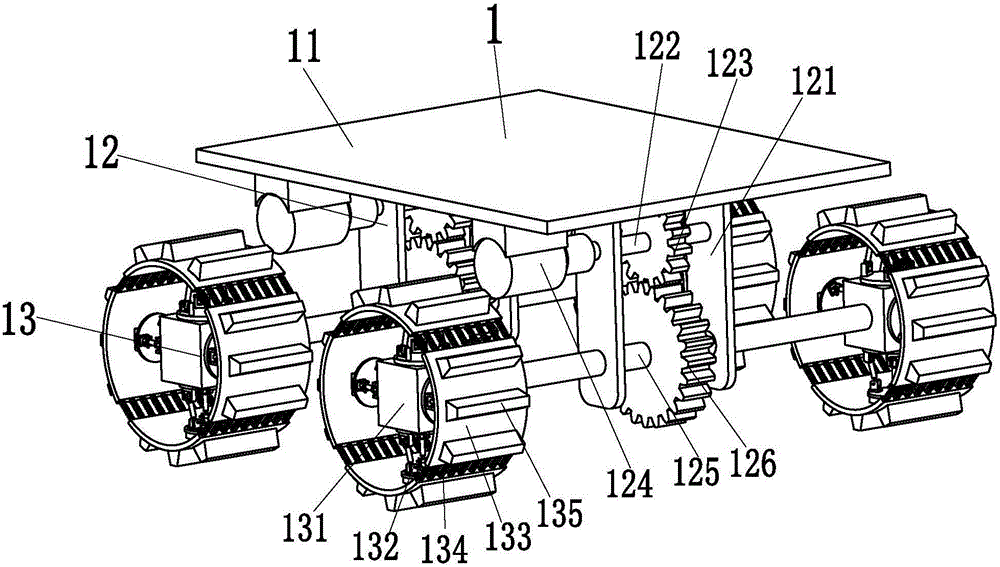

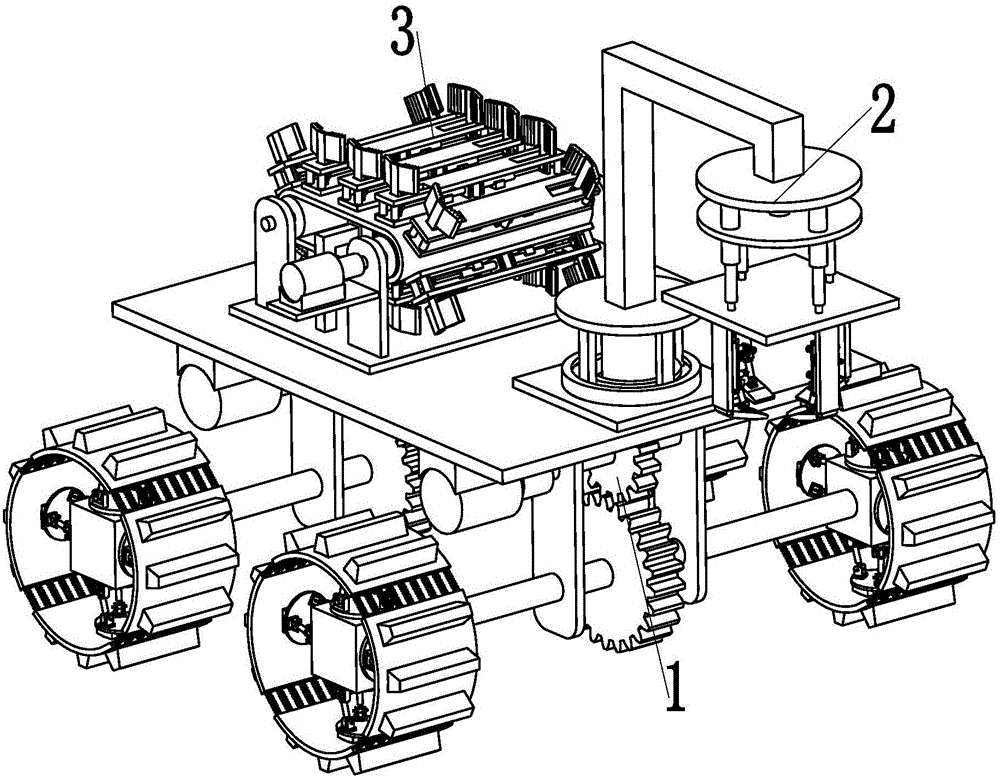

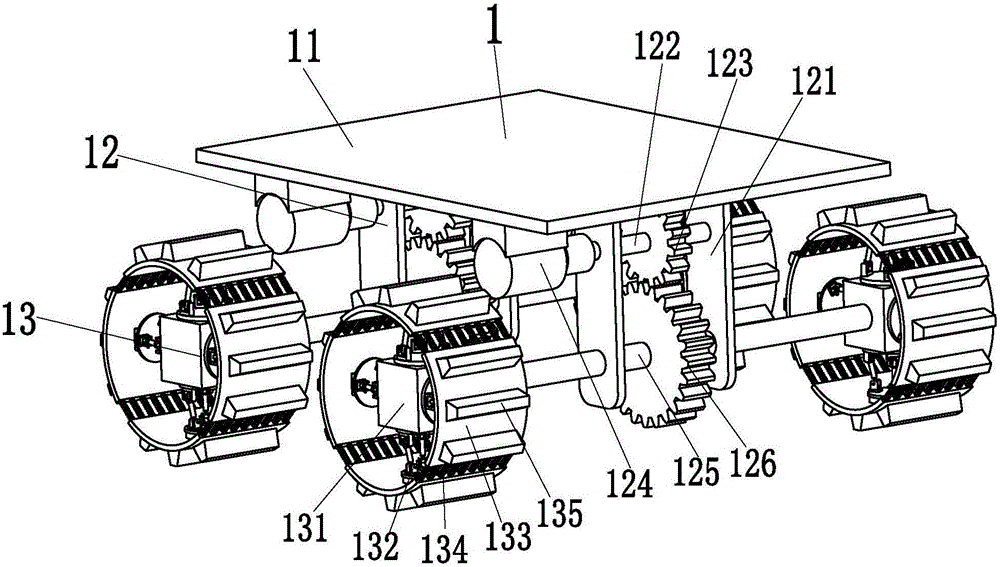

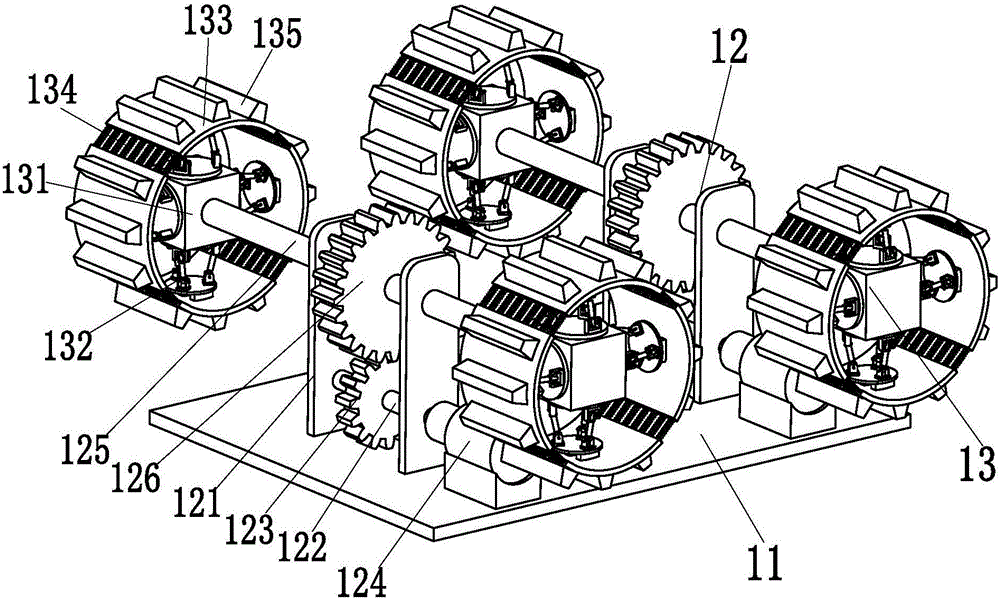

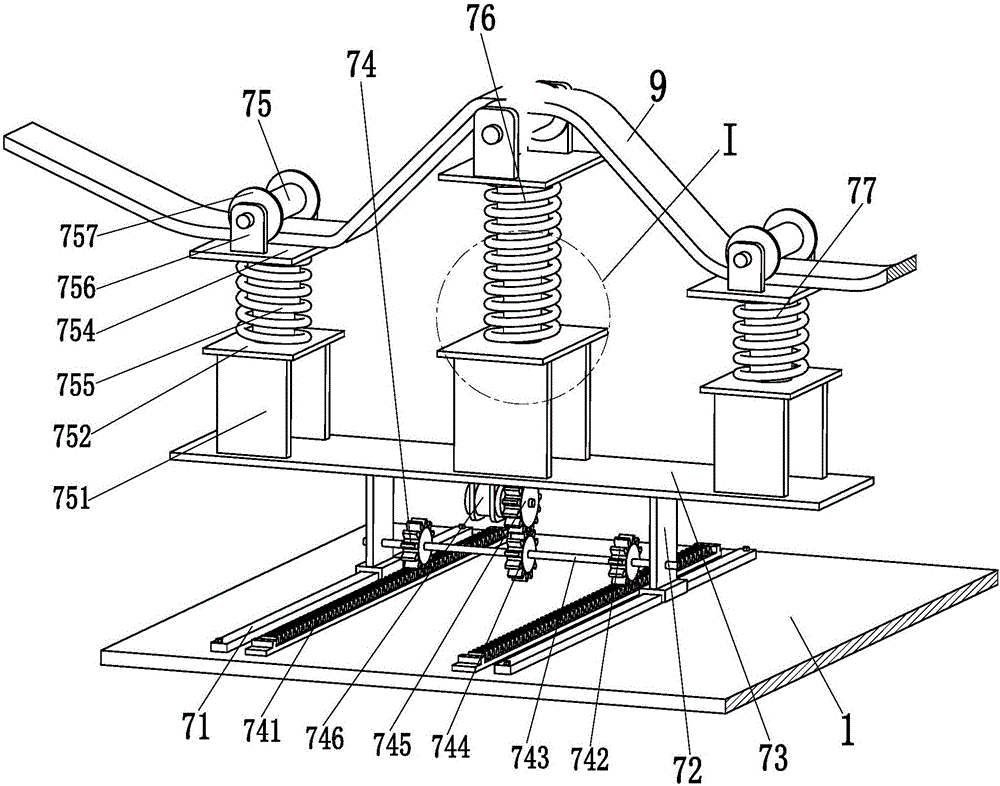

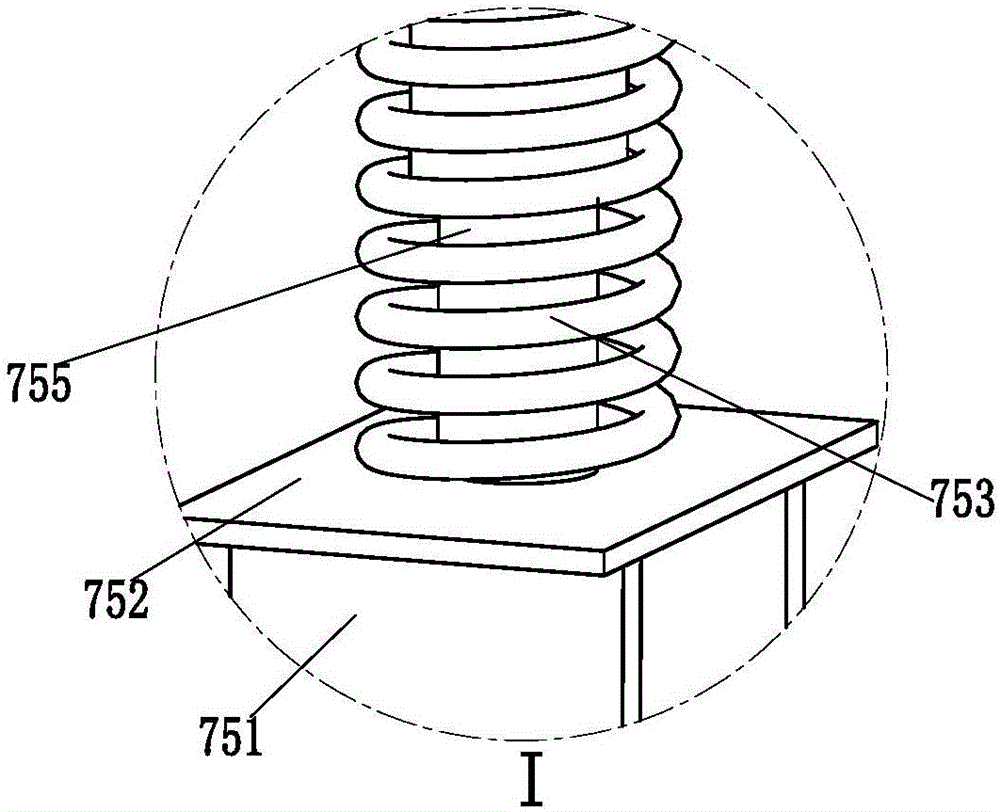

Intelligent retaining wall constructor for geotechnical engineering

ActiveCN106149754AImprove stabilityGood dynamic responseArtificial islandsUnderwater structuresSelf-stabilizationWork productivity

The invention relates to an intelligent retaining wall constructor for geotechnical engineering. The intelligent retaining wall constructor for geotechnical engineering comprises a self-stabilization traveling platform; the self-stabilization traveling platform is excellent in vibration reducing performance and stability performance, eliminates the up-down shaking or left-right shaking phenomenon in the grouted rubbles carrying process, so that the constructor is suitable for working at an uneven or muddy construction site; a limiting conveying device is mounted on the right side of the upper end surface of the self-stabilization traveling platform, and can realize a function of stable limiting conveying of grouted rubbles; the left-right position limiting always exists in the whole conveying process of the grouted rubbles, so that the hidden danger of rolling in the conveying process of the grouted rubbles is eliminated, and the conveying effect is good; and a lifting pushing and placing device is mounted on the left side of the upper end surface of the self-stabilization traveling platform, and can realize a function of automatic lifting carrying of the grouted rubbles, so that the manual up-down carrying is not needed, the carrying speed is fast, and the working efficiency is high. The constructor can realize a function of automatic forming of a retaining wall, and provides a new approach to automatic quick forming of the retaining wall.

Owner:广东广强基础工程有限公司

Chain transmission tensioning device

InactiveCN107514446AImprove the tension effectAccurate Watch Movement ValuesGearingDrive shaftSlide plate

The invention is mainly applied to the field of chain transmission equipment in the mining industry, and particularly relates to a chain transmission tensioning device, which includes a tensioning wheel, the tensioning wheel is connected to a connecting rod, the connecting rod is connected to a rack, and a slider is arranged at the bottom of the rack. Installed on the skateboard, the slider on the skateboard is provided with a chute, the rack and the gear are meshed, the gear is connected to the driving device through the transmission shaft, the transmission shaft is installed on the bearing seat through the bearing, and the bearing seat and the driving device are installed on the skateboard. A mounting plate is provided at the bottom, a sliding assembly is provided between the sliding plate and the mounting plate, a cylinder is provided on one side of the sliding plate, and the cylinder is installed on the mounting plate. The invention drives the gear to rotate through the driving device, and then drives the rack to move, realizes the movement of the upper and lower positions of the tension wheel, achieves the purpose of tensioning the chain, improves work efficiency and work quality, and can precisely control the tension.

Owner:SHANDONG HUALIAN MINING

Belt collecting and winding machine structure

InactiveCN103043483AConsistent tightnessGood belt tensioning effectWebs handlingWinding machineConductor Coil

The invention relates to a belt collecting and winding machine structure. The belt collecting and winding machine structure comprises a support, a collecting barrel and a collecting driving mechanism, wherein the collecting barrel is arranged on the support, and the collecting driving mechanism controls the collecting barrel to rotate. The belt collecting and winding machine structure is characterized by further comprising a first roller, a first limit switch, a second limit switch, a second roller, an upper press plate, a lower press plate, a third roller and a fourth roller, wherein the first roller is fixed at a first end of a swing rod, the middle of the swing rod is rotationally arranged on the support, conveyed belts firstly wind on the first roller, the upper press plate and the lower press plate are fixed on the support, the lower press plate is arranged below the upper press plate and tightly arranged with the upper press plate, the third roller and the fourth roller are fixed on the support, the axis of the fourth roller is lower than the axis of the collecting barrel, and output ends of both the first limit switch and the second limit switch are connected with the collecting driving mechanism. Compared with the prior art, the belt collecting and winding machine structure can always guarantee constant tightness degree of belt winding.

Owner:NINGBO NINGCHUANG AUTOMATION DEVICE

Cable insulation layer coating machine

ActiveCN108320861AUniform pressureLow costApparatus for heat treatmentInsulating conductors/cablesInsulation layerCopper wire

The invention belongs to the cable processing field and especially discloses a cable insulation layer coating machine. The machine comprises a die. The die is provided with a glue flowing chamber connecting a plastic extruding machine discharge end. A line passing channel connected to the glue flowing chamber is arranged in the die. A glue scraping unit comprises a pedestal which is in a circulardisc shape and is rotatably connected to the die. The pedestal is fixedly provided with a circular-bench-shaped and hollow glue scraping seat whose upper end is a small diameter end. The side wall ofthe glue scraping seat is provided with several bar-shaped through holes which are along a circular bench bus direction and pass through the side wall of the glue scraping seat. A rolling unit is arranged above a glue scraping unit. The lower end of a first rotating disk is fixedly provided with a first motor used for driving a first sleeve to rotate. A paying-off unit is arranged below the die. Arack is rotatably connected to a rotating shaft and a second motor used for driving the rotating shaft to rotate. The rotating shaft is provided with a first driving gear and a second driving gear located below the first driving gear. In the scheme, a requirement of timely processing a redundant insulating glue solution on a copper wire during a coating process is satisfied.

Owner:重庆博创知识产权运营有限公司

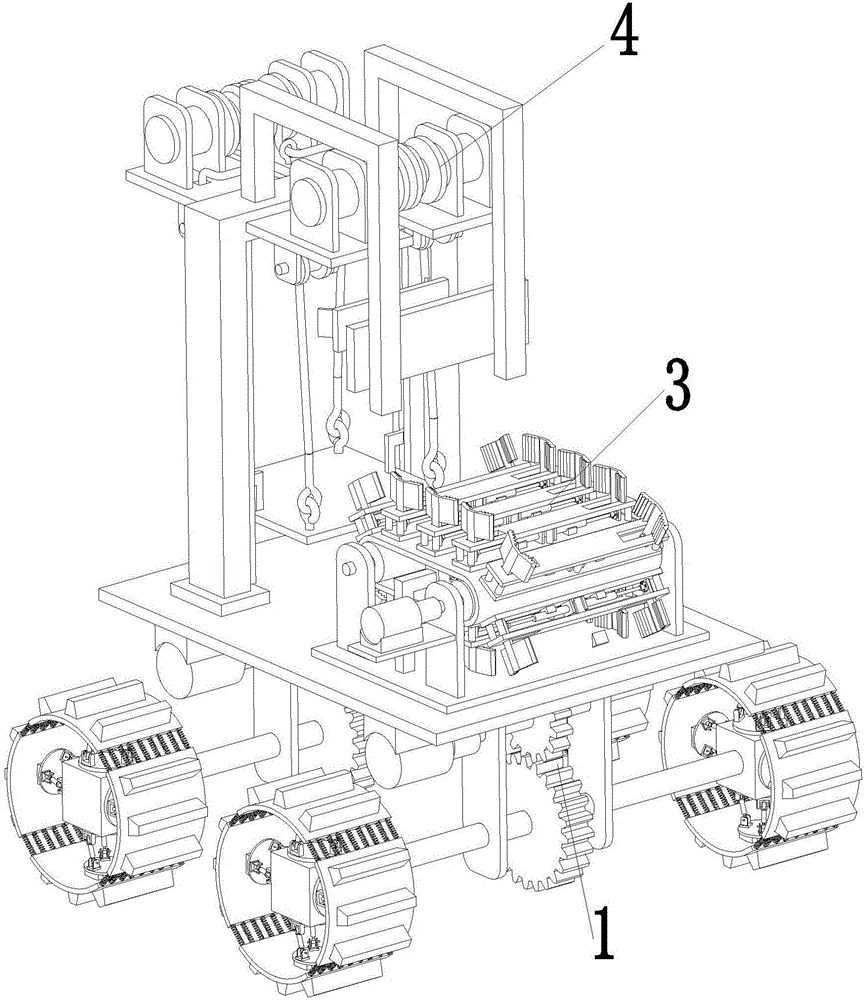

Grabbing and conveying robot for road retaining wall

ActiveCN106112954ANo manual operationImprove work efficiencyProgramme-controlled manipulatorGripping headsEngineeringRetaining wall

The invention relates to a grabbing and conveying robot for a road retaining wall. The robot comprises a self-stabilization walking platform, the self-stabilization walking platform has the good damping performance and the good stabilization performance, vertical shaking or left-and-right shaking phenomena appearing in the masonry carrying process are avoided, and therefore the robot is suitable for being work in uneven or muddy construction sites. A hydraulic grabbing device is arranged on the right side of the upper end face of the self-stabilization walking platform and can achieve the automatic hydraulic grabbing function of the masonry, manual grabbing and putting are not needed, a limiting conveying device is mounted in the middle of the upper rend of the self-stabilization walking platform, the limiting conveying device can achieve stable limiting conveying functions of the masonry, left-and-right limiting of the whole masonry conveying process is achieved, and the rolling hidden danger existing in the masonry conveying process can be removed. The automatic grabbing and conveying function of the masonry can be achieved, the vertical shaking or left-and-right shaking phenomena appearing in the masonry carrying process are avoided, and stable performance is good.

Owner:山东严格产业发展有限公司

Cloth feeding and fastening mechanism of numerically controlled single heedle quilter

InactiveCN1986935ASolve the problem of cutting fabric smoothlySimple structureWorkpiece carriersWork-feeding meansEngineeringPulley

Owner:李德锵

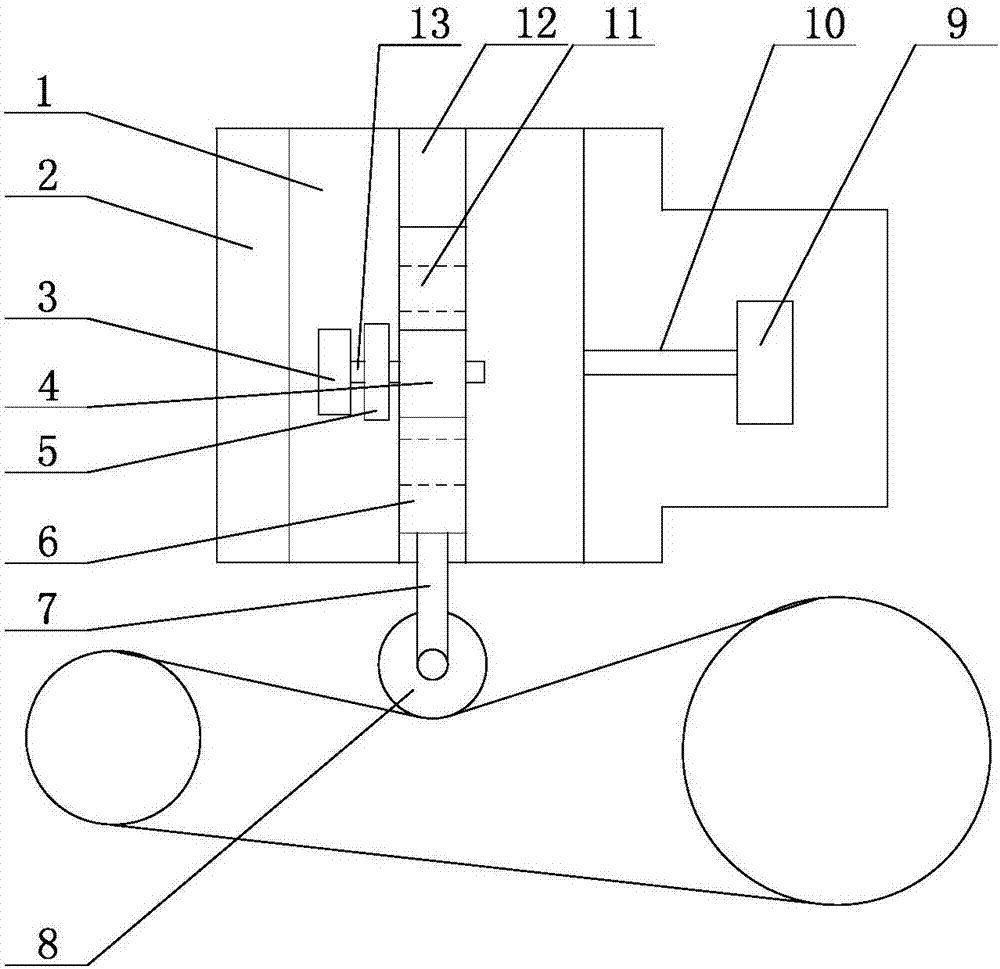

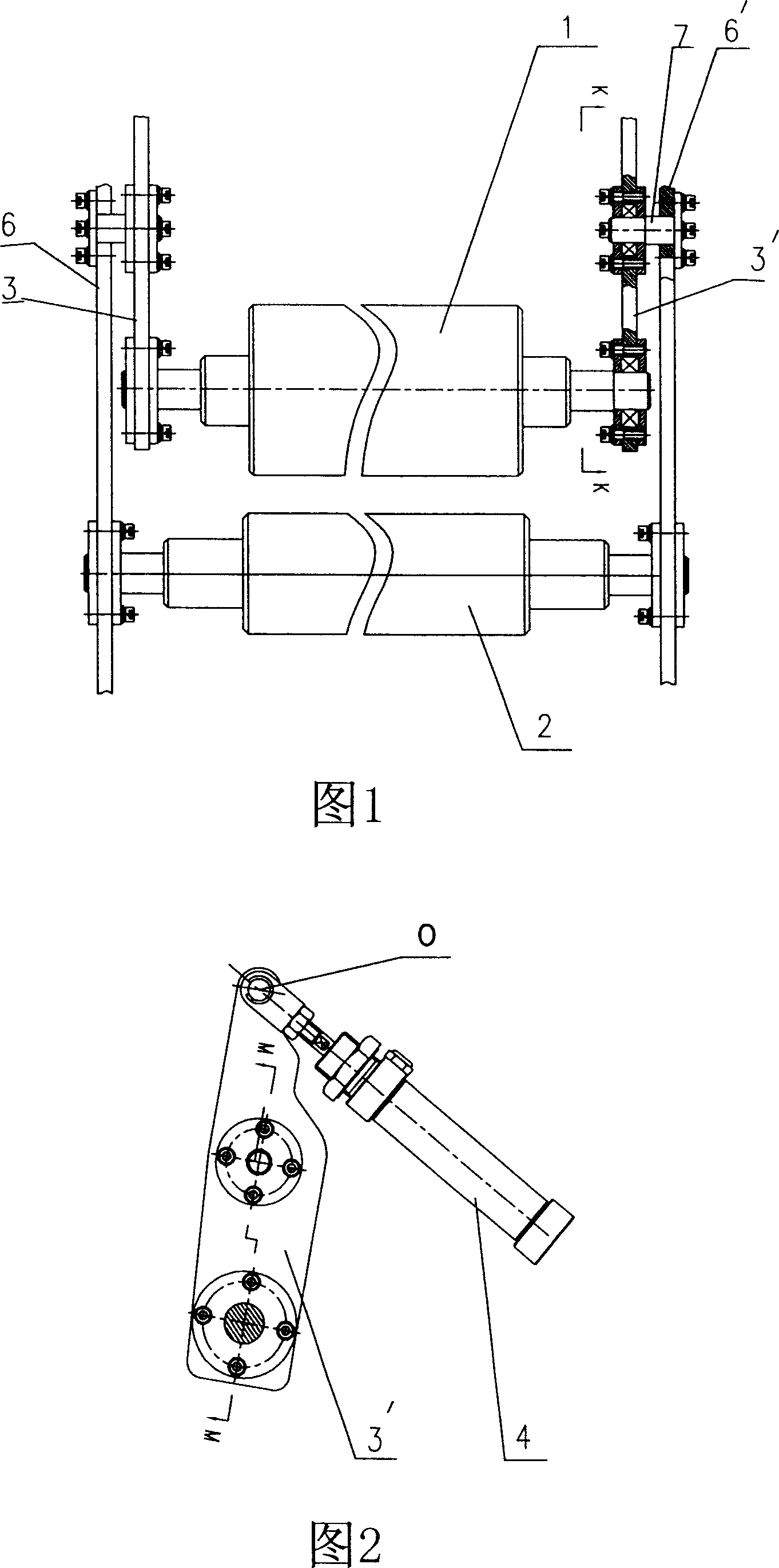

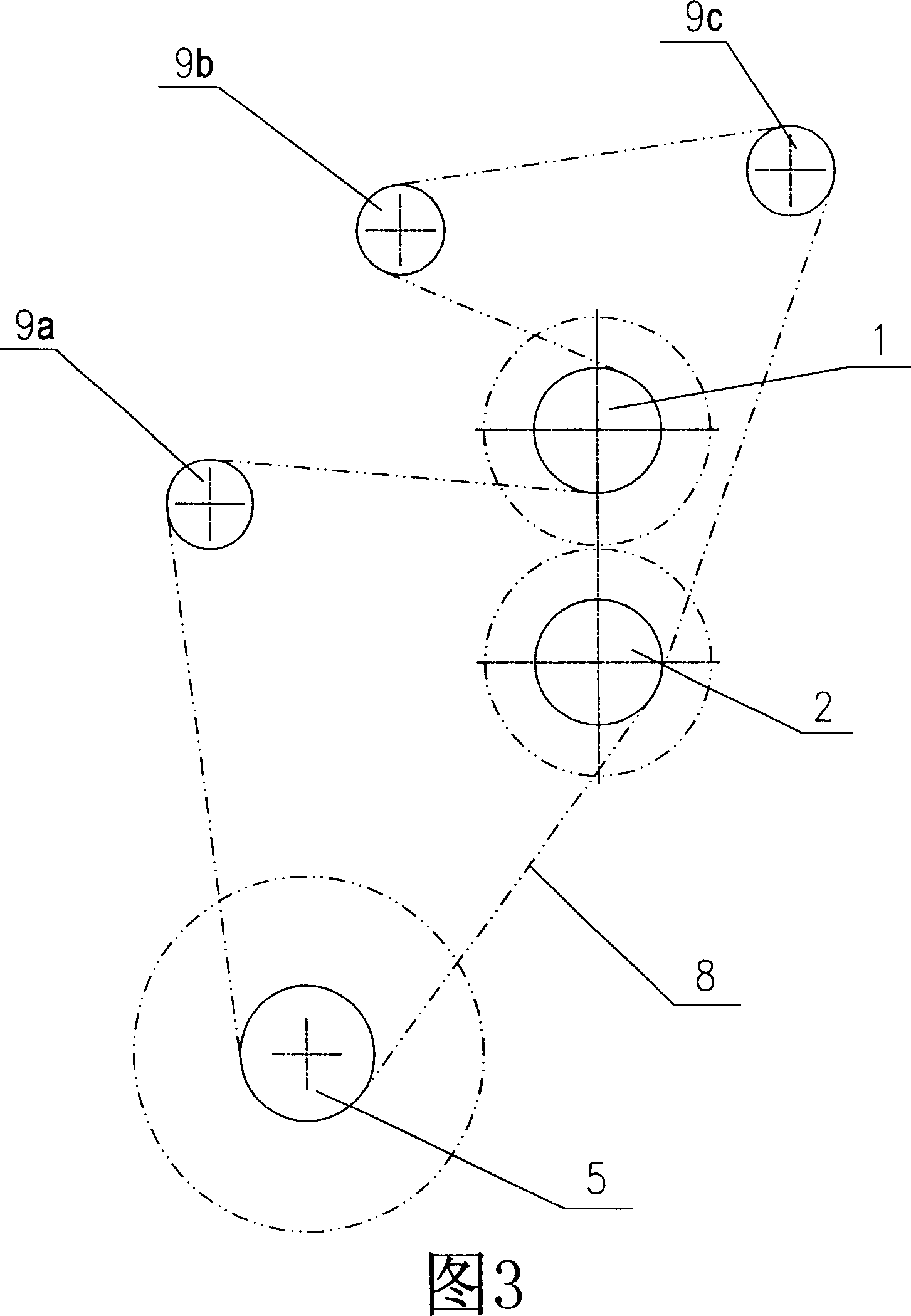

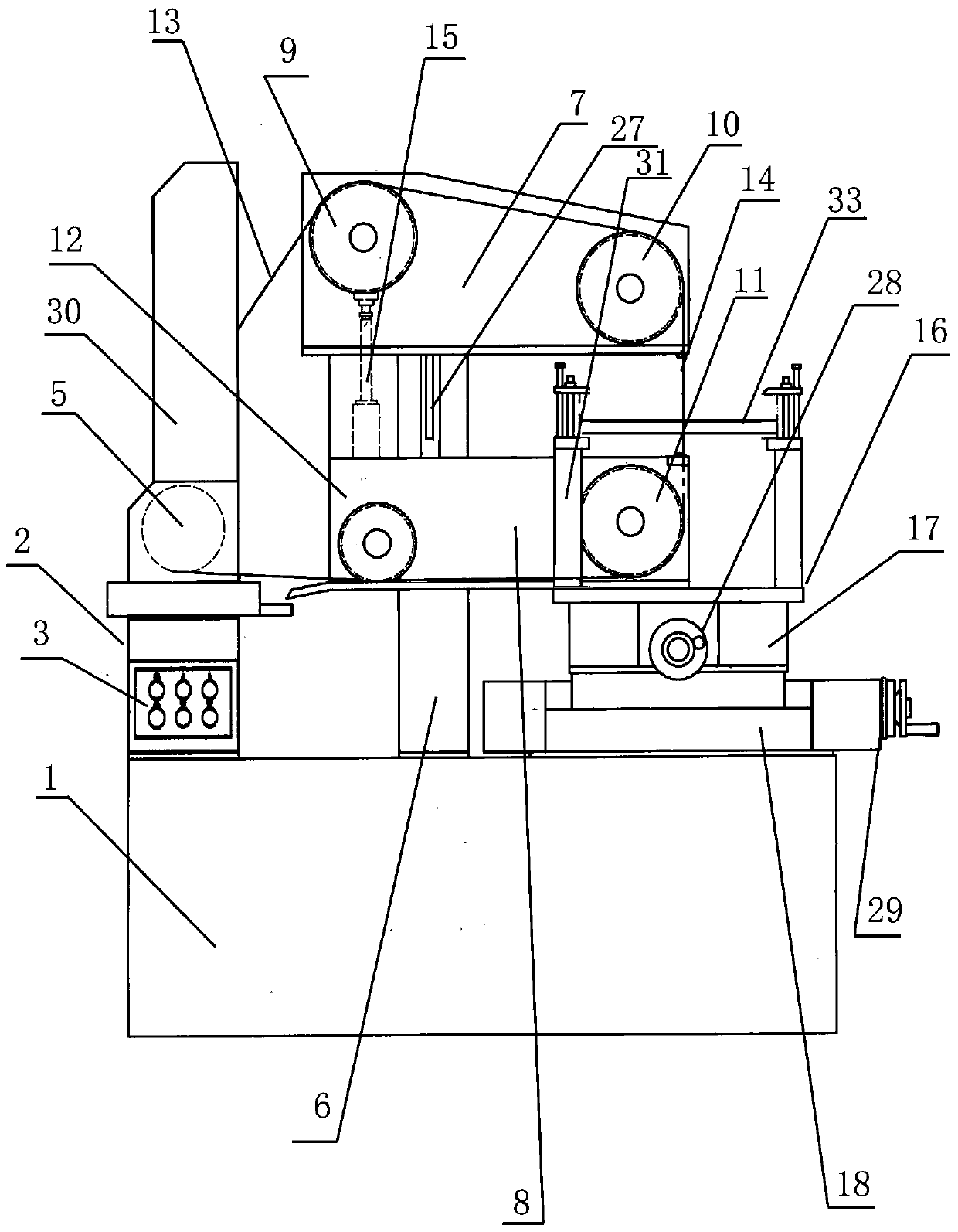

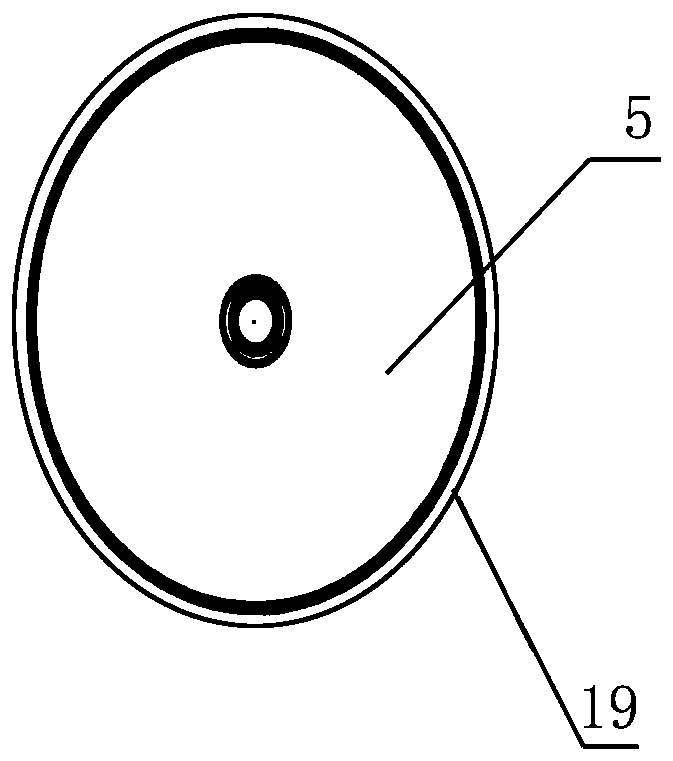

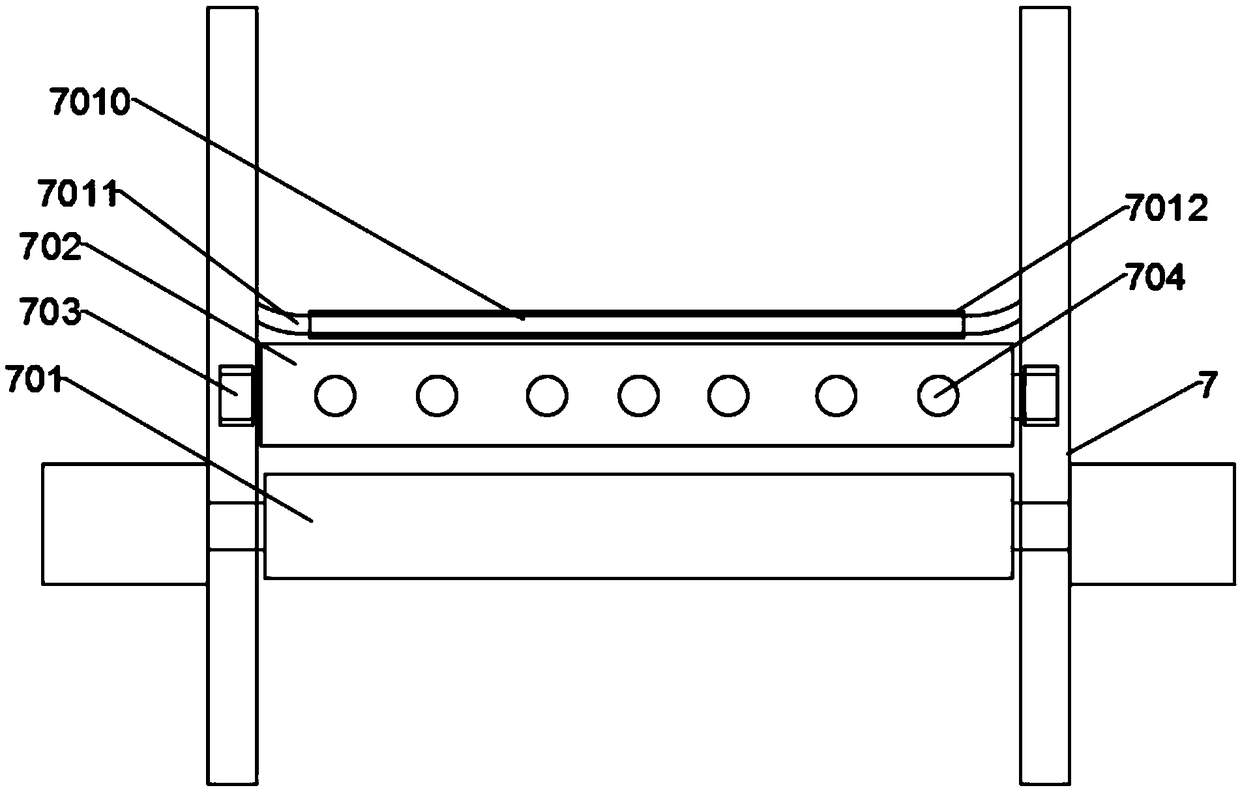

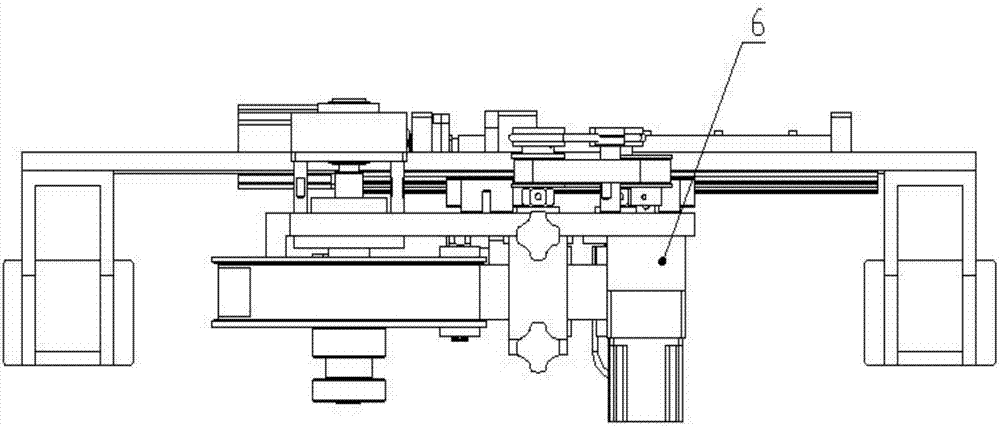

Numerical control diamond abrasive wire sawing machine

PendingCN107584396AImprove the tension effectImprove wear resistanceGrinding machinesNumerical controlDrive wheel

The invention discloses a numerical control diamond abrasive wire sawing machine. The outer surface of a wire storage barrel (5) of a wire transporting mechanism of the numerical control diamond abrasive wire sawing machine is covered with a wire barrel outer ring protecting glue layer, and an upper wire frame (7) and a lower wire frame (8) are arranged on a column (6) from top to bottom. An outerring of a tensioning wheel (9), an outer ring of a driving wheel I (10), an outer ring of a driving wheel II (11) and an outer ring of a transition wheel (12) are sleeved with protective sleeves, a diamond wire (13) is wound around the wire storage barrel (5), the driving wheel II (11) is vertically connected with a pneumatic tensioning device (15), the pneumatic tensioning device (15) pushes thetensioning wheel (9) to move up and down to adjust the position of the tensioning wheel (9) to enable the diamond wire to maintain a constant tension state, the other side of a lathe bed (1) is provided with a cutting working table (16), and the bottom of the cutting working table (16) is provided with a driving assembly. The numerical control diamond abrasive wire sawing machine not only is goodin use effect and wide in applied range, but also is resistant to abrasion and long in service life.

Owner:泰州市南光机械电子有限公司

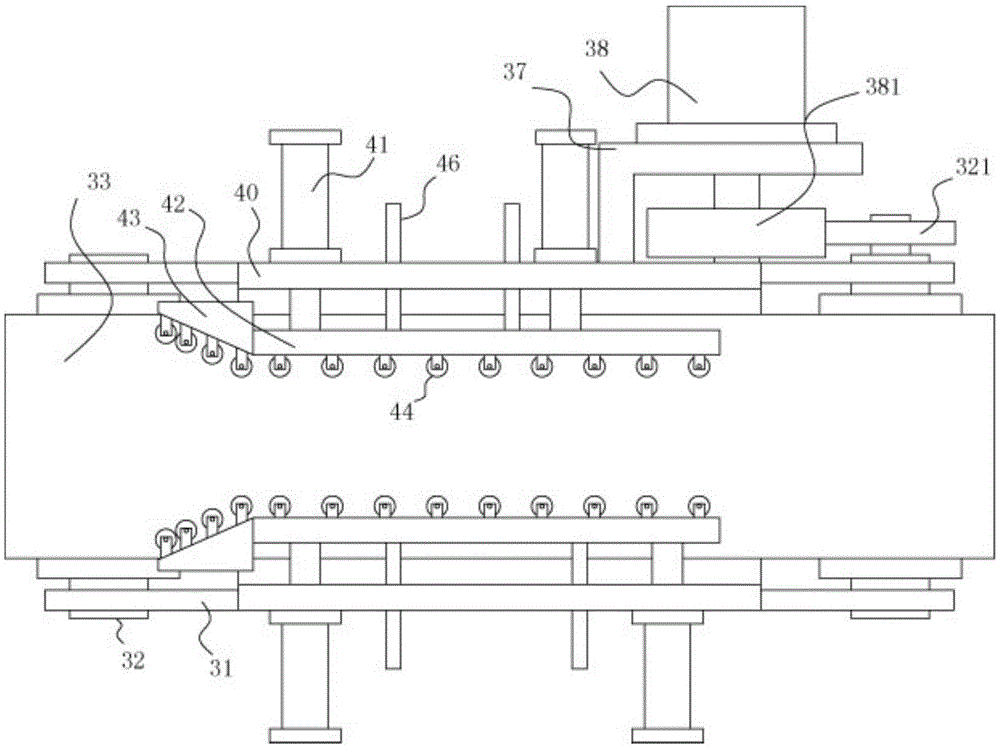

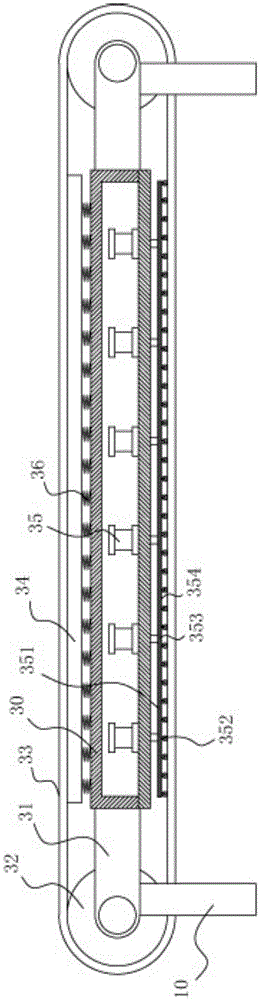

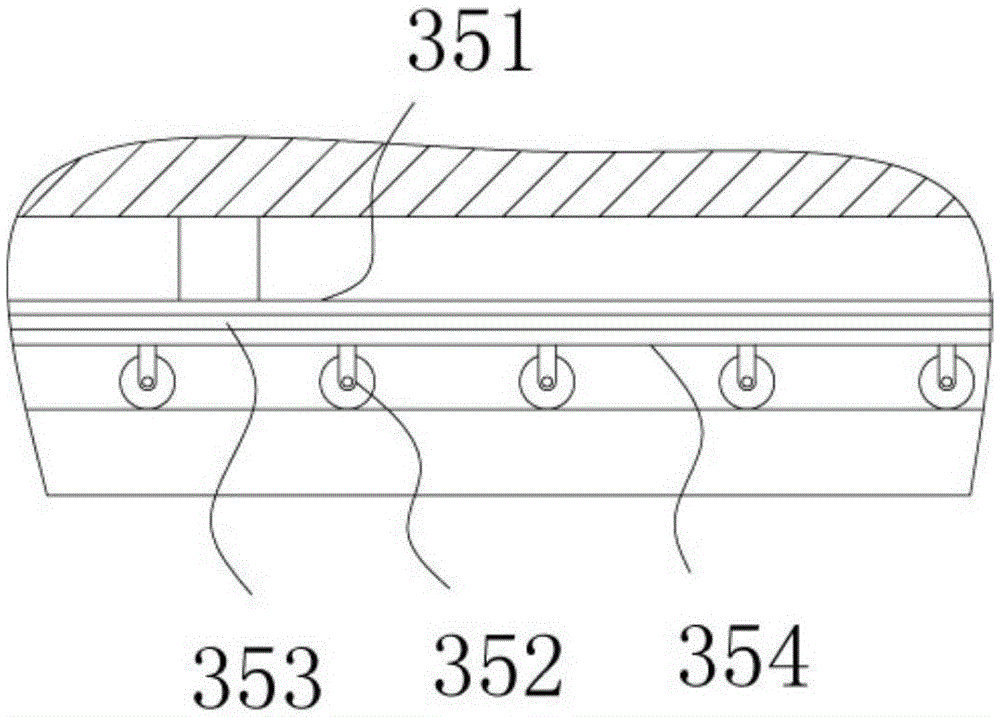

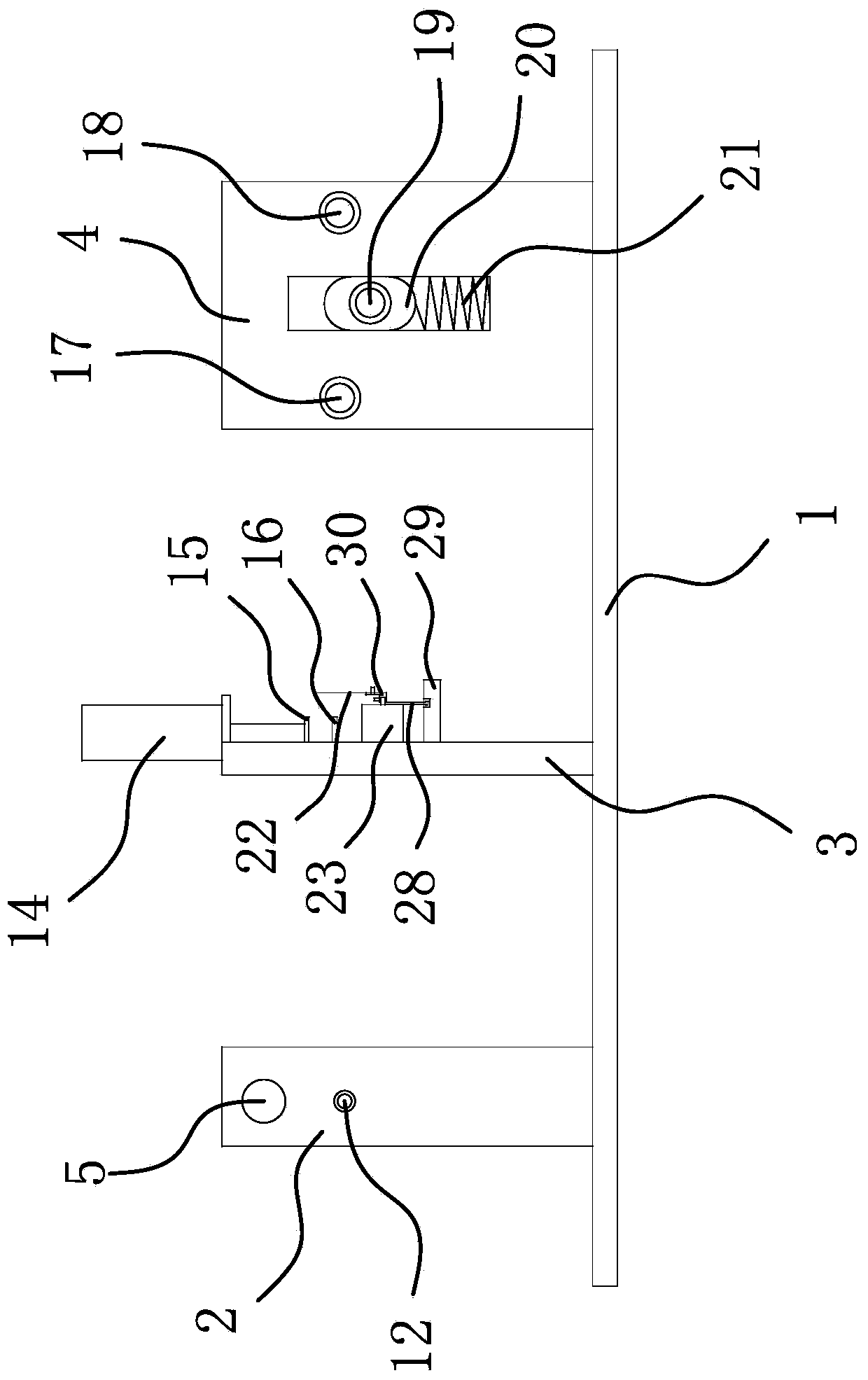

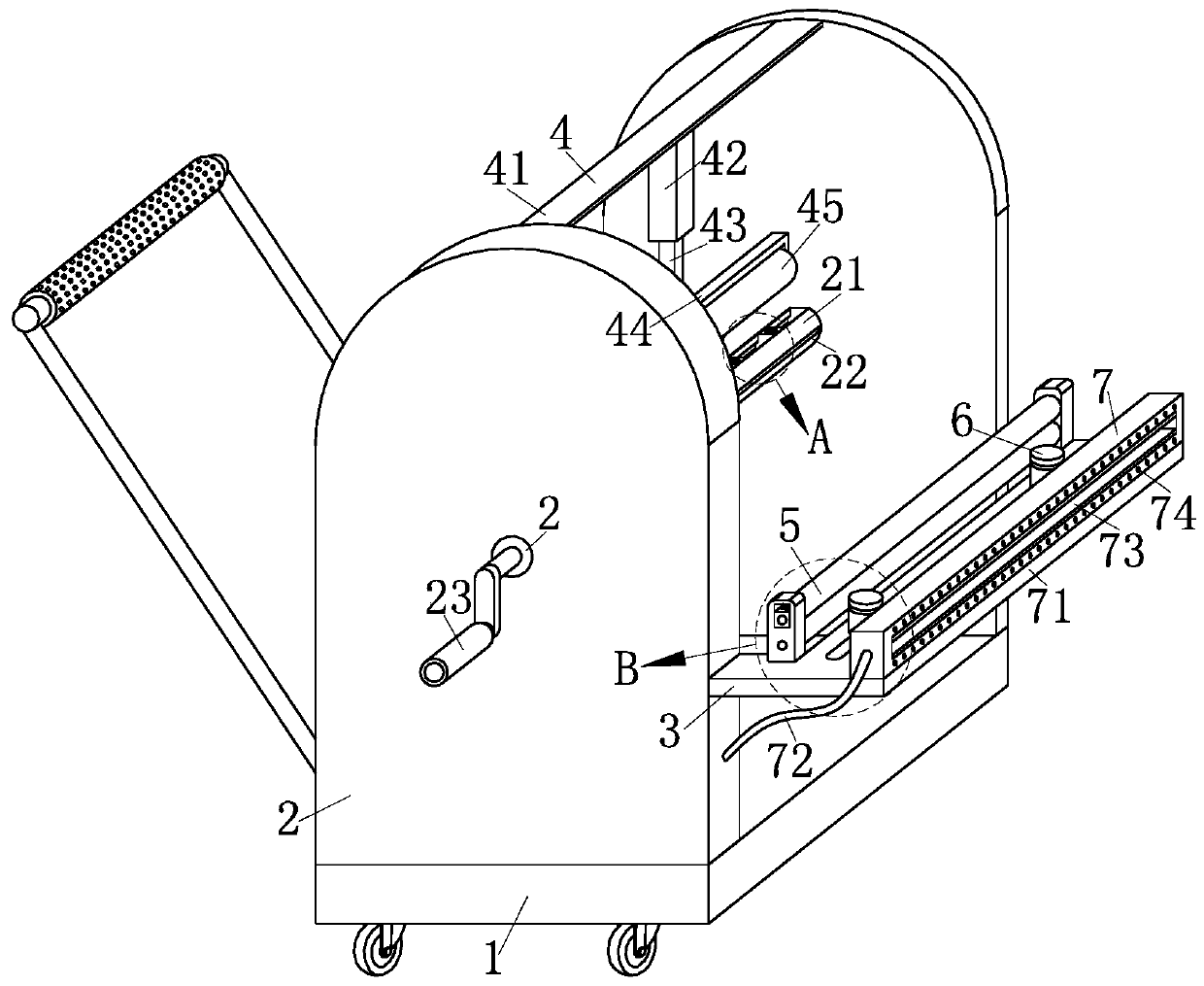

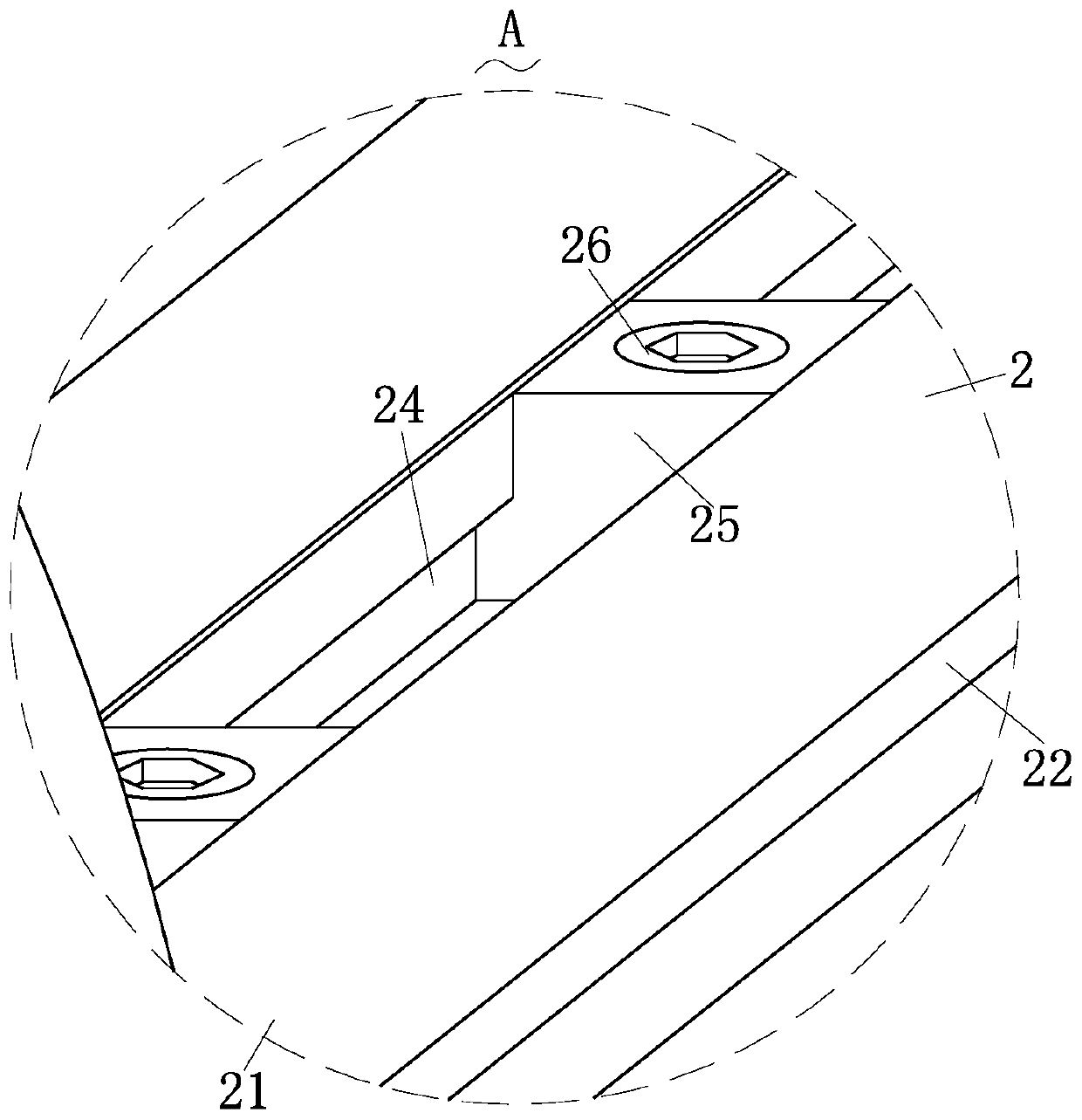

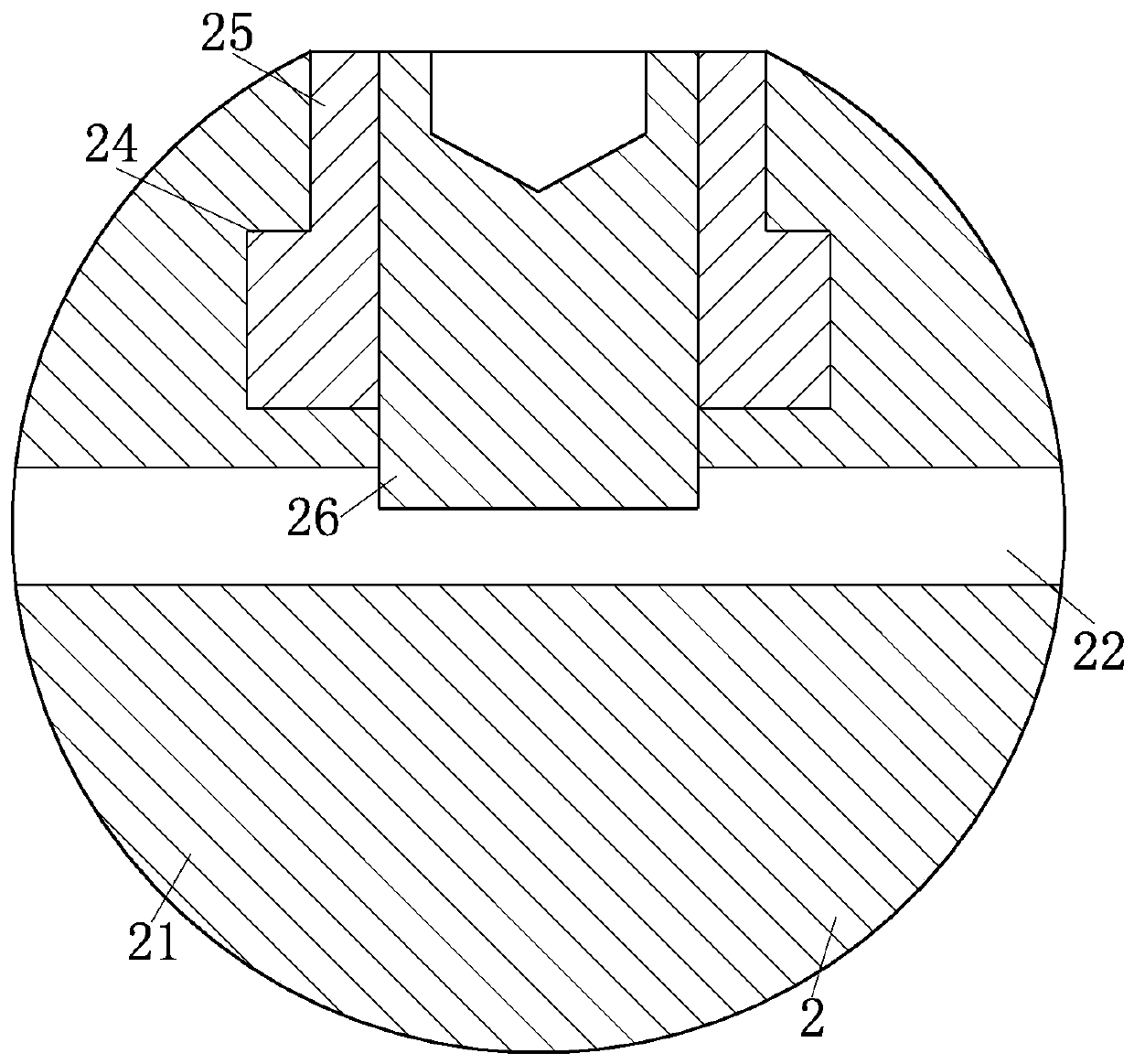

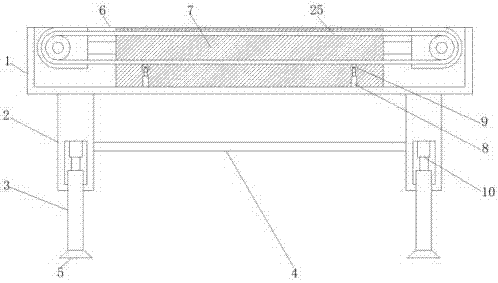

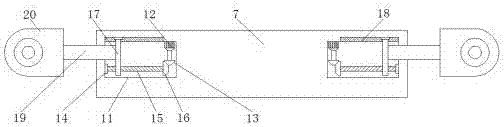

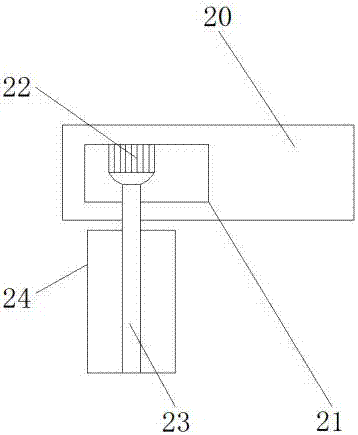

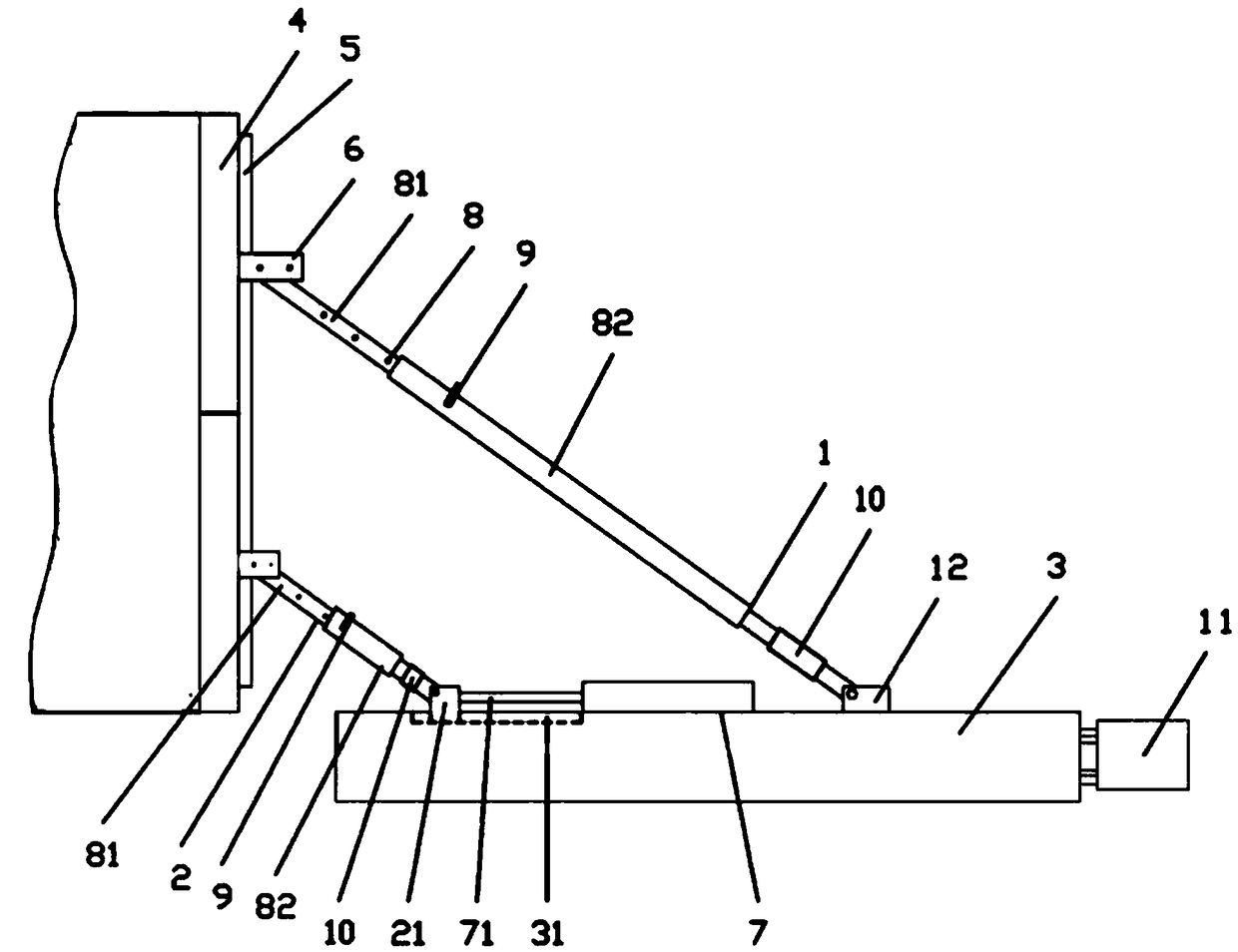

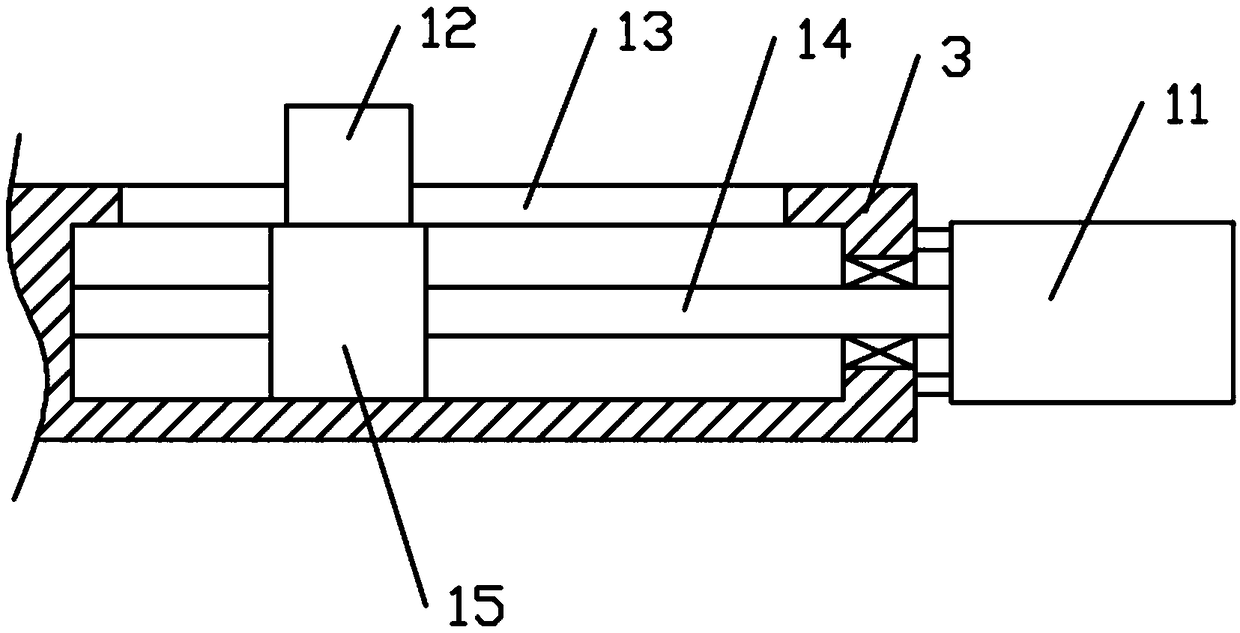

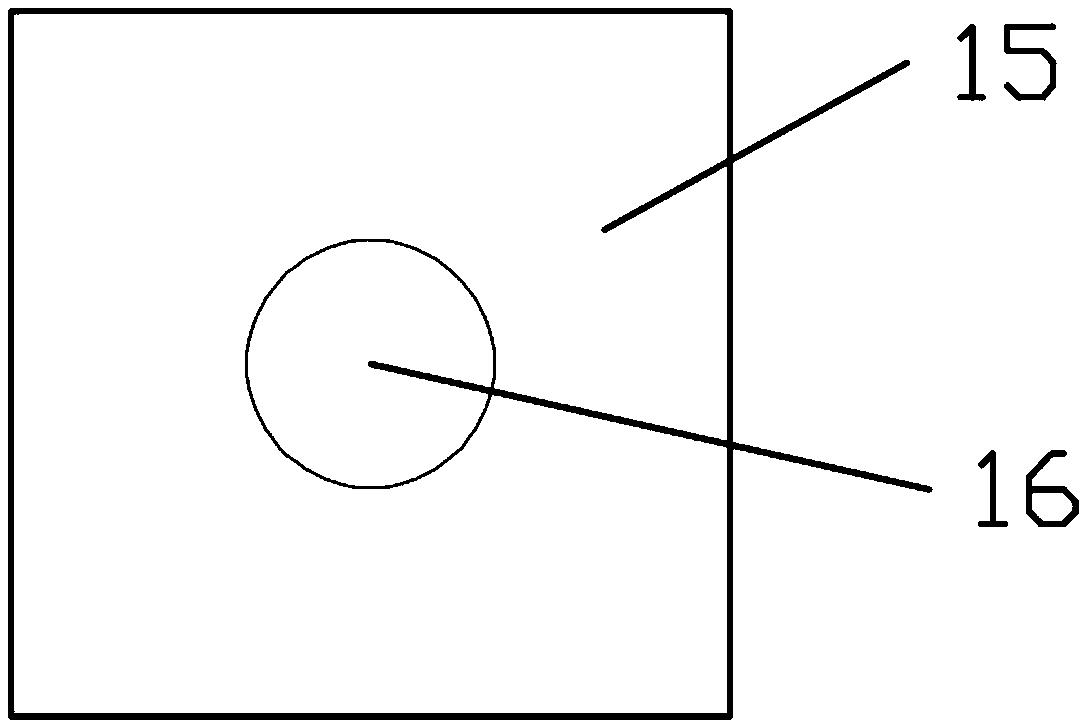

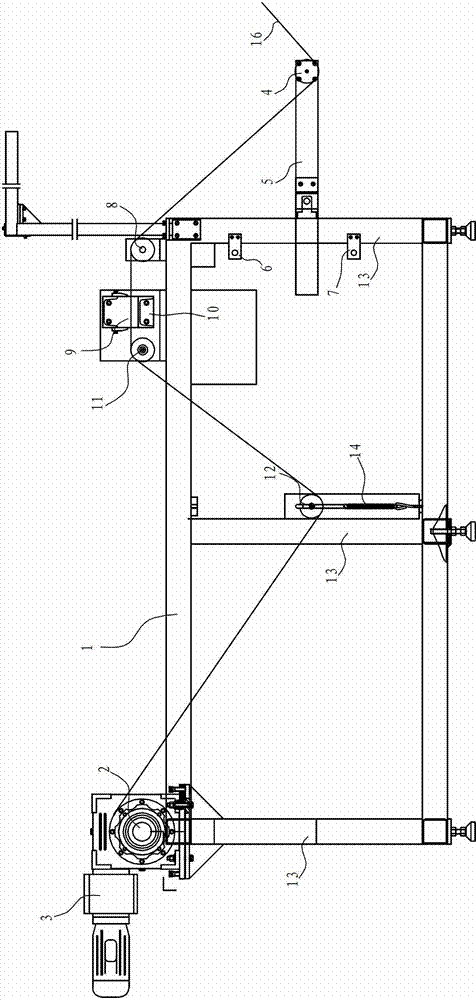

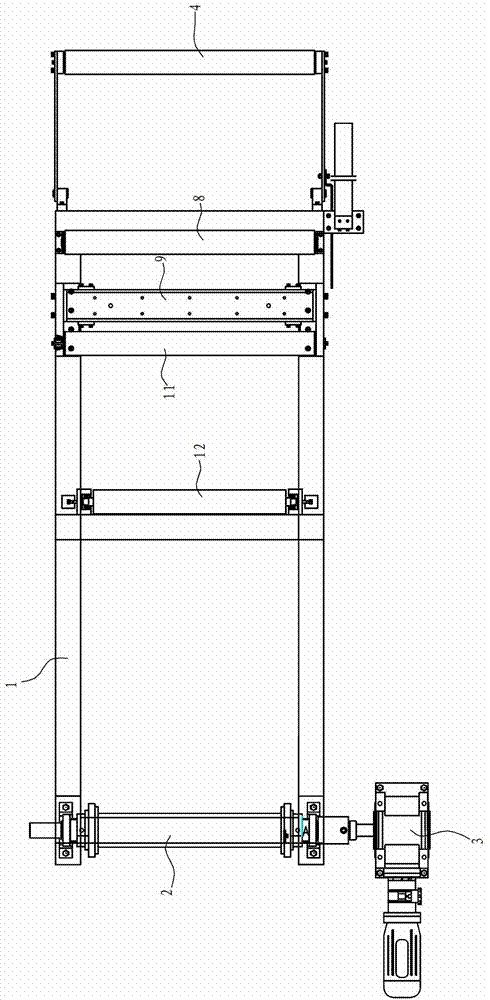

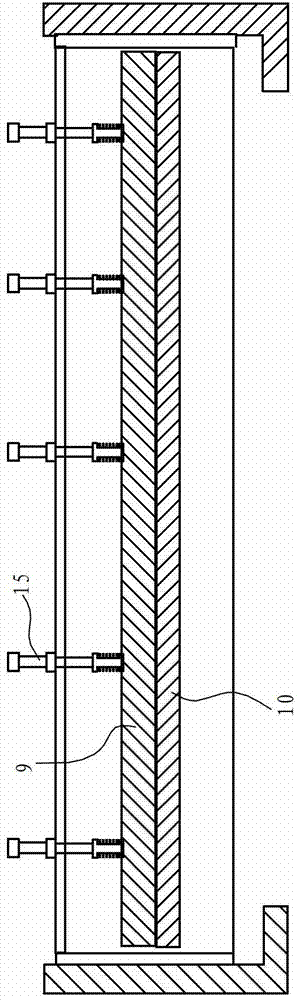

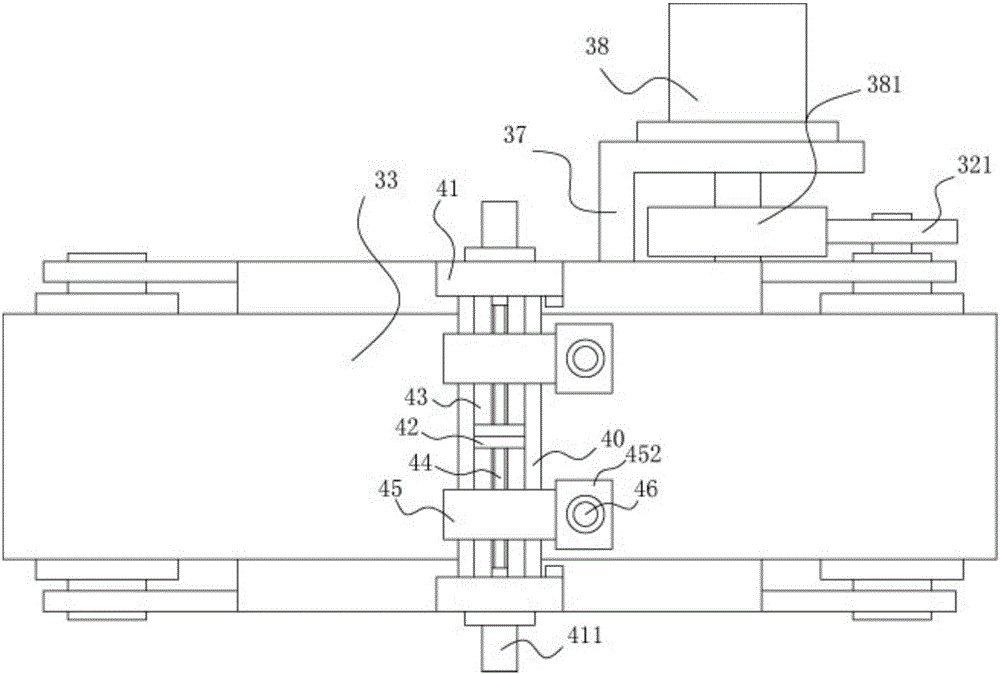

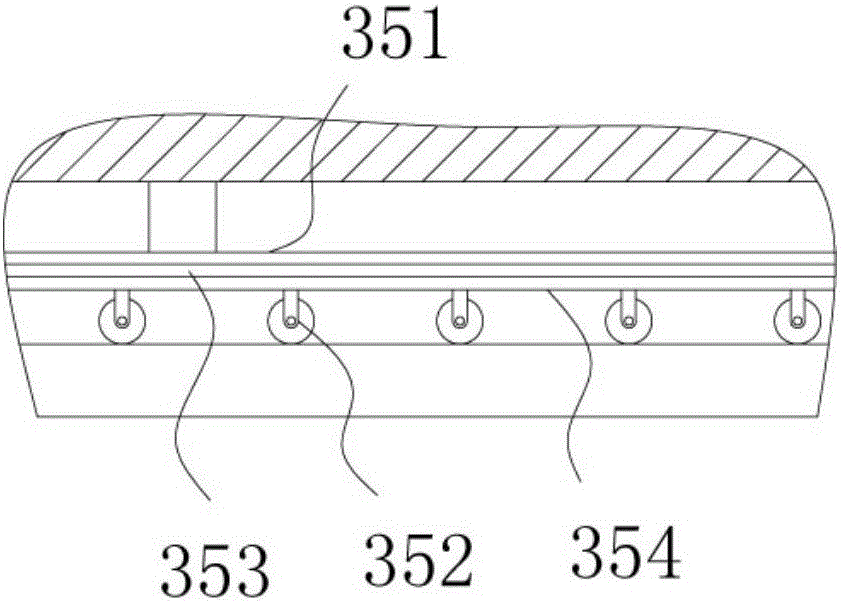

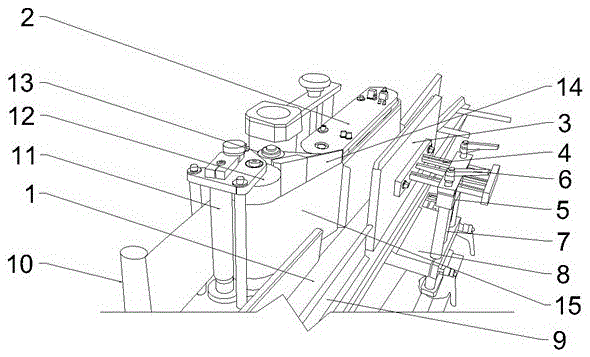

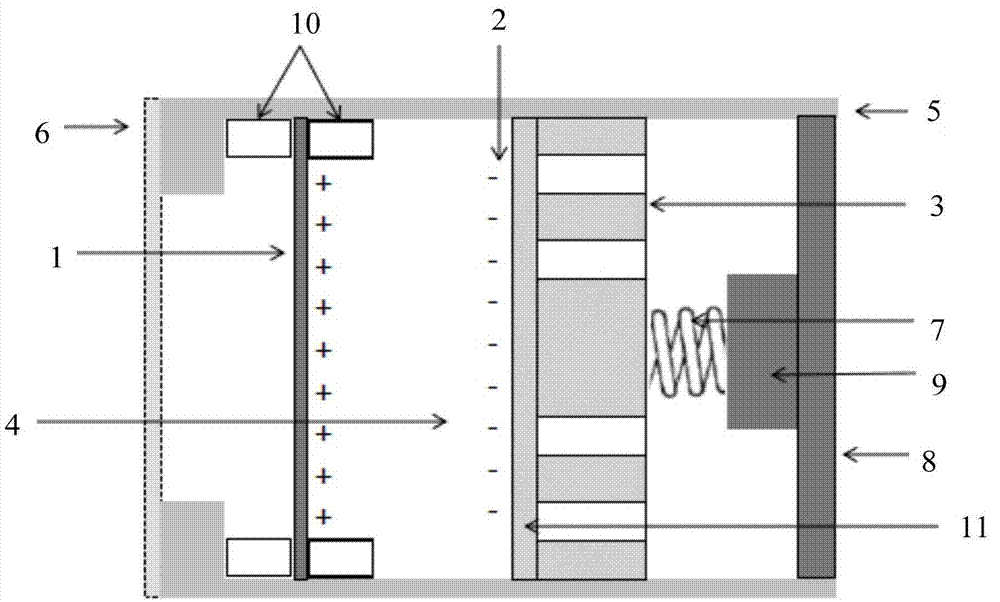

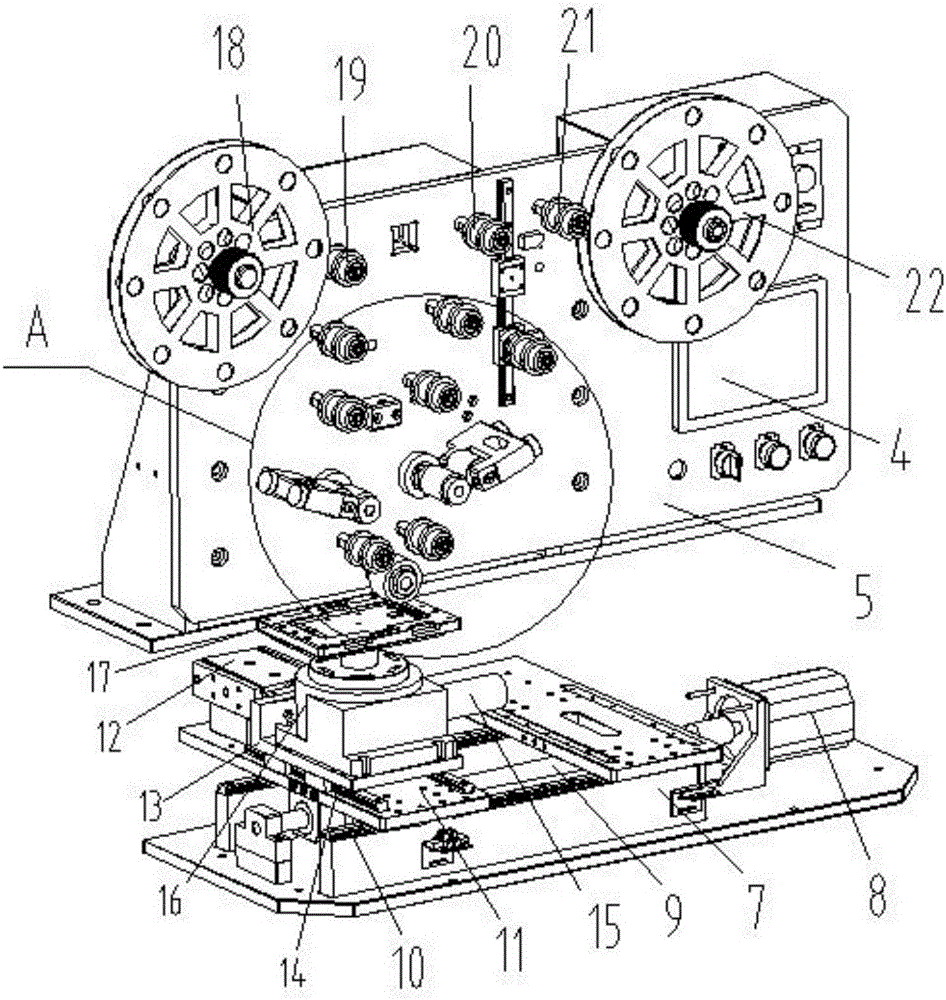

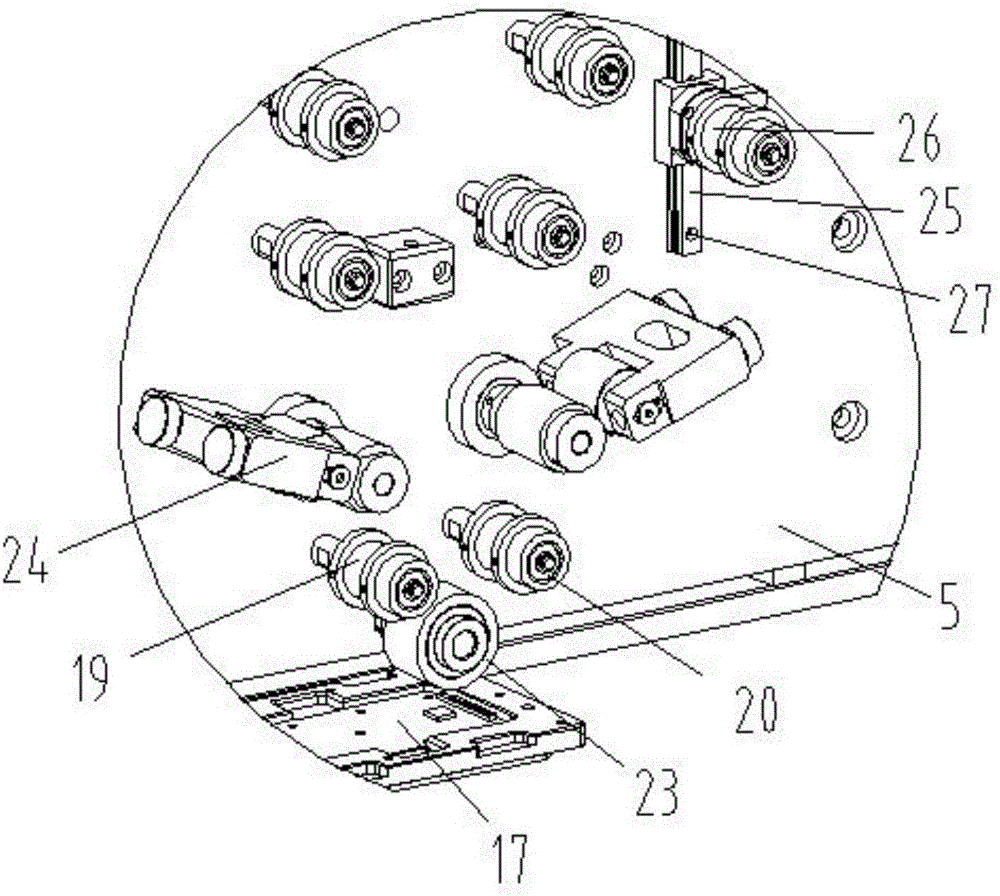

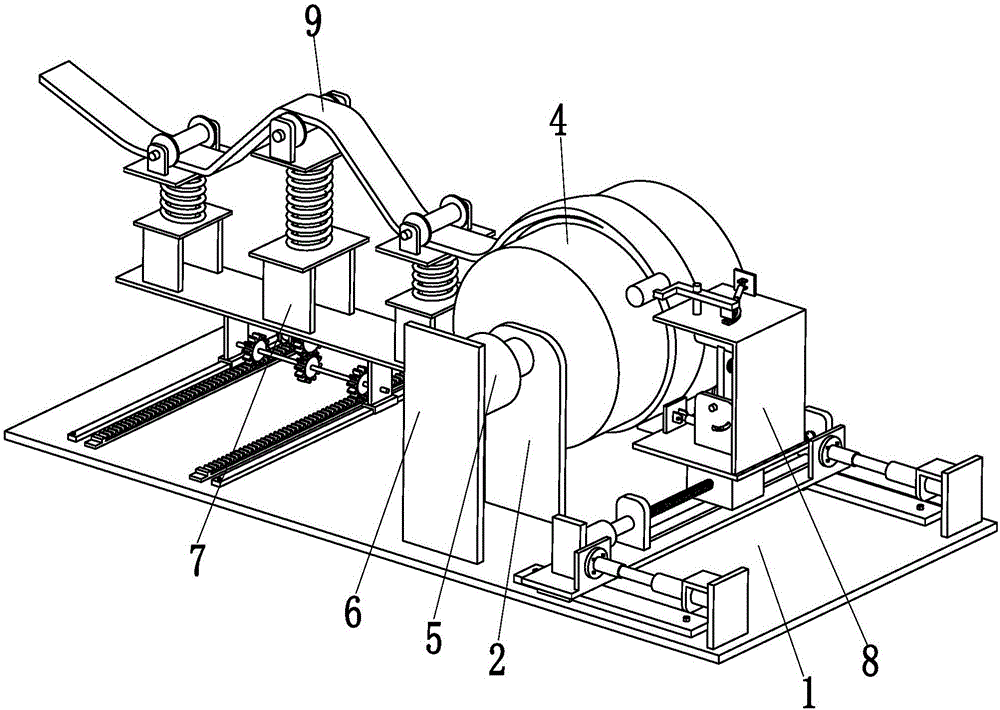

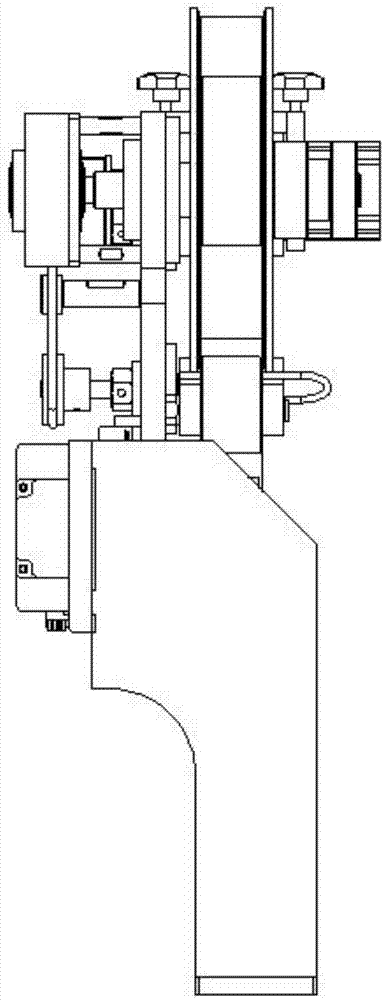

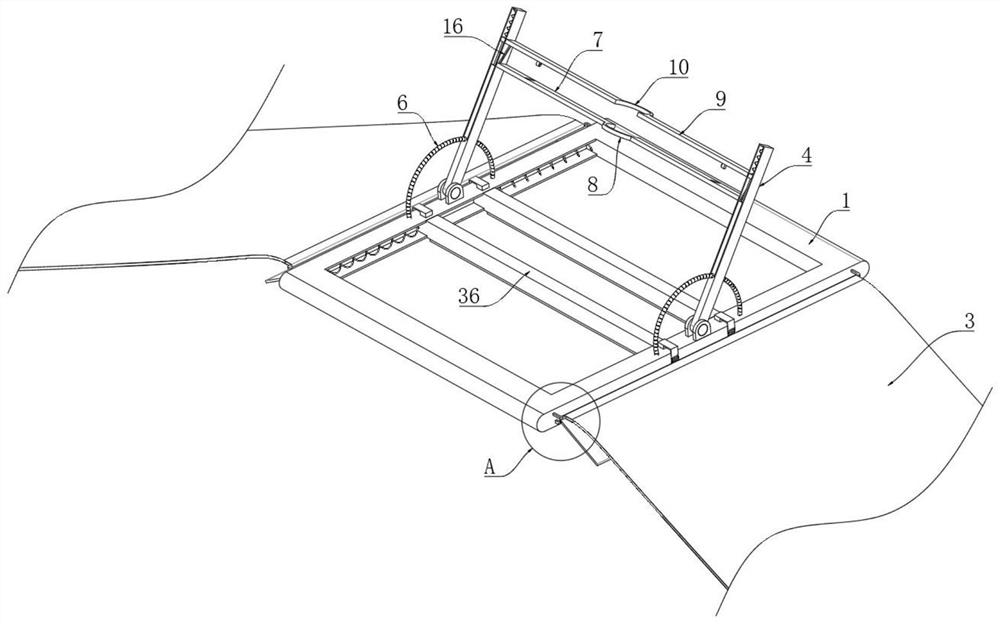

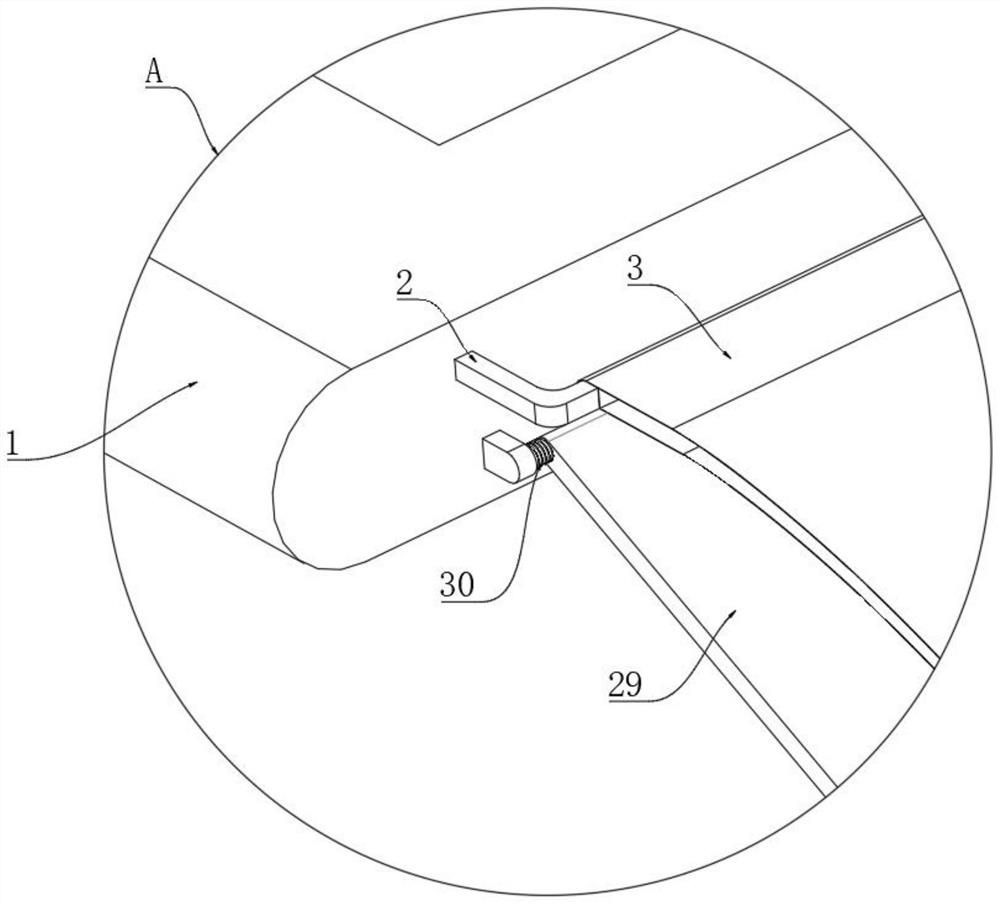

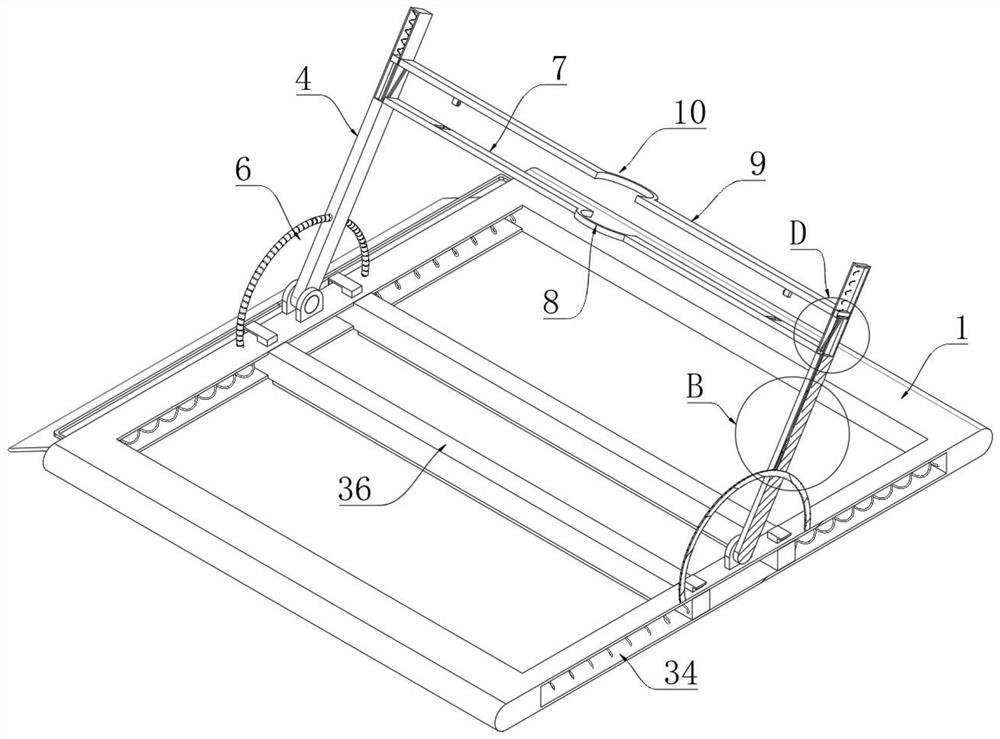

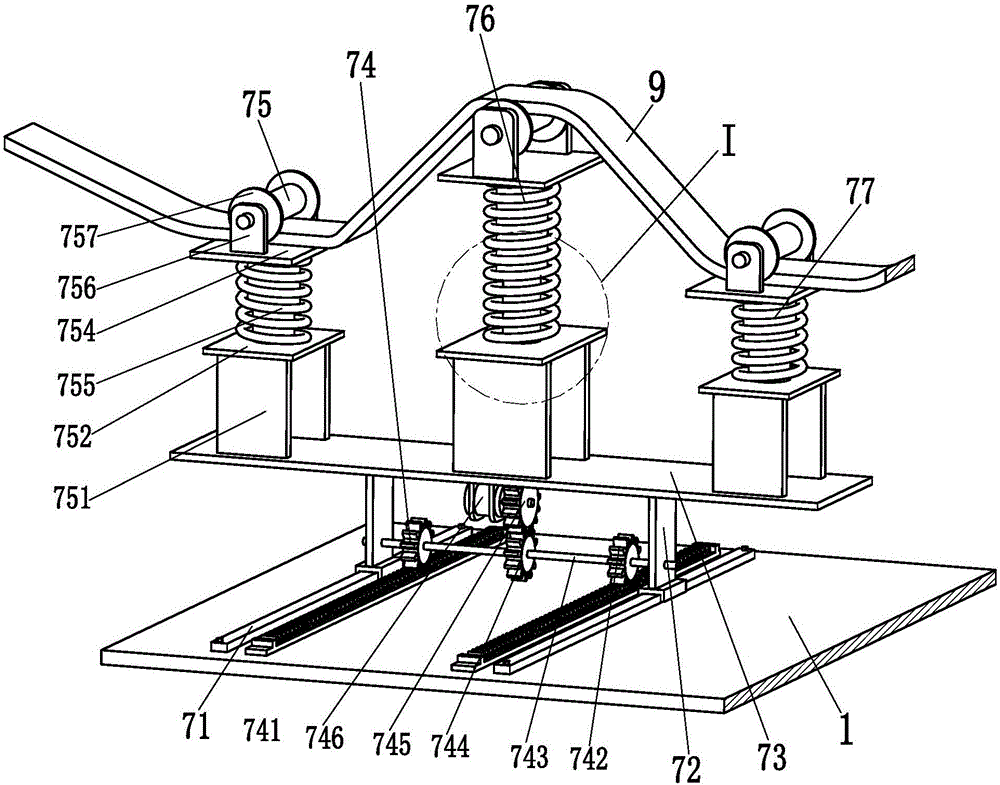

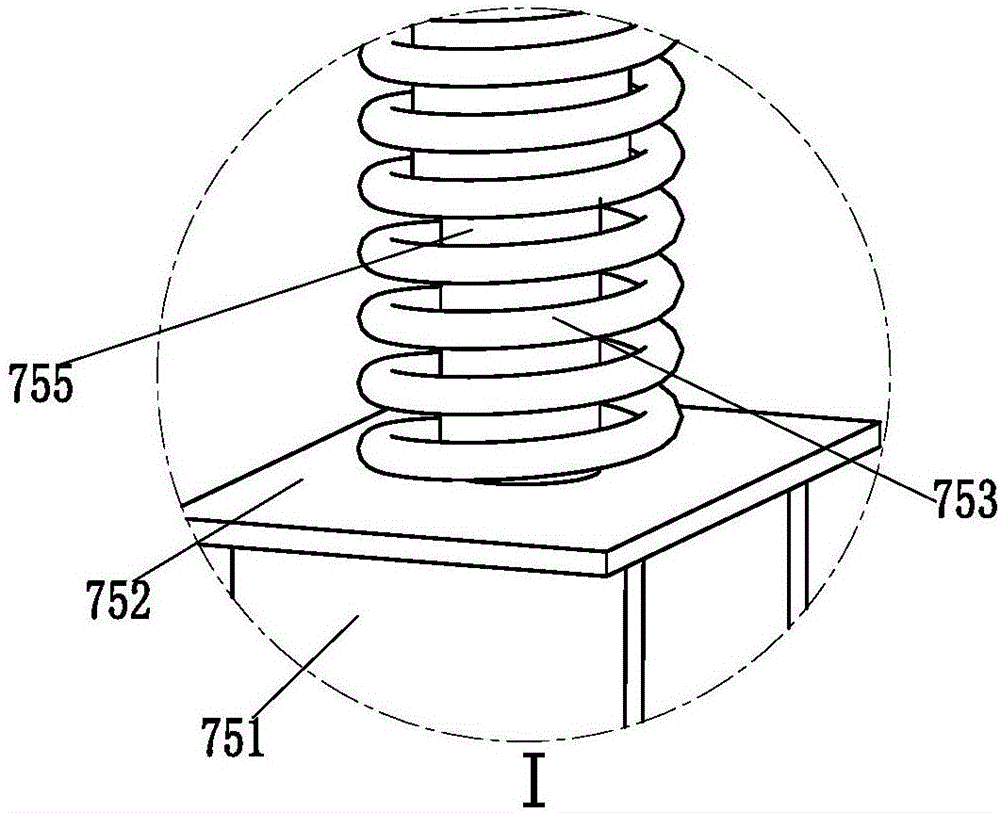

Conveying and pressing device for ceramic cutting

The invention discloses a conveying and pressing device for ceramic cutting. The conveying and pressing device comprises a rack. Supporting legs of the rack are fixed to a bottom supporting plate. The rack comprises a middle shell. Supporting plate bodies are fixed to the positions of the front end and the rear end of the left outer side wall and the right outer side wall of the middle shell. The two ends of each transmission roller are hinged to the corresponding two supporting plate bodies. A conveying belt is tensioned on the two transmission rollers. Vertical supporting plates are fixed to the front side and the rear side of the top face of the middle shell. Upper connecting beams are fixed to the two vertical supporting plates. A partition plate is fixed to the middle portions of the upper connecting beams. A sliding groove is formed among the partition plate and the front ends of the upper connecting beams, and a sliding groove is formed among the partition plate and the rear ends of the upper connecting beams. An adjusting screw is located under the sliding grooves. One end of the adjusting screw is hinged to the partition plate, and the other end of the adjusting screw is hinged to the corresponding vertical supporting plate. A pressing block is located above the upper connecting beams. The positions of the two transmission rollers are fixed and the two transmission rollers cannot move relatively, a push air cylinder is used for pushing wheels to achieve tensioning, the tensioning effect of the conveying and pressing device is good, and a pressing air cylinder of the conveying and pressing device conducts pressing firmly.

Owner:许仙福

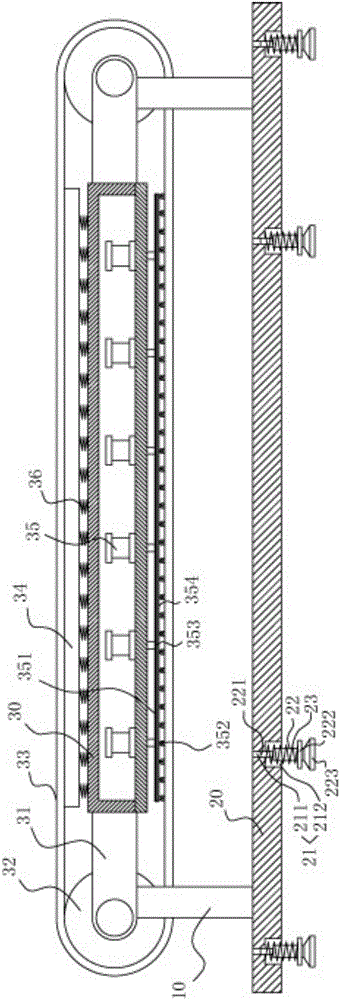

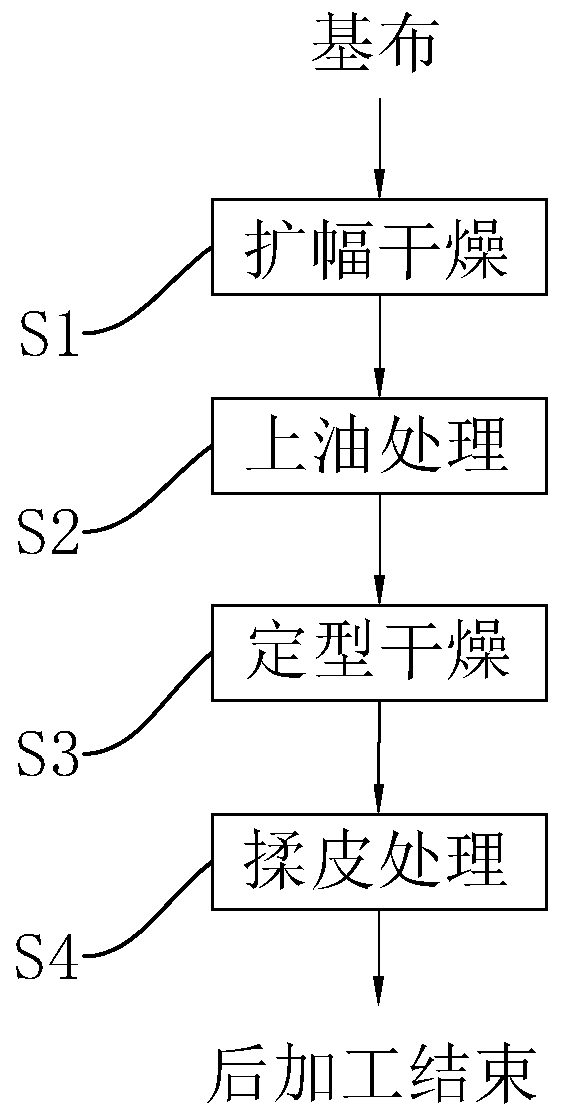

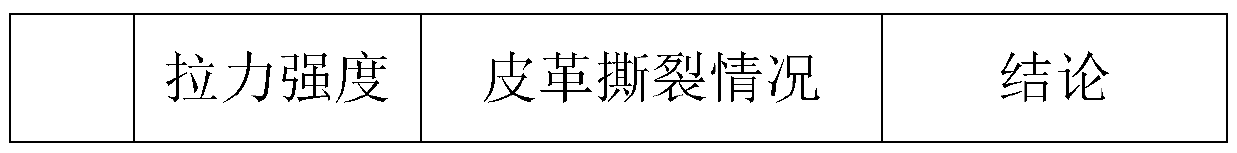

Base fabric post-processing technology for superfine fiber synthetic leather

ActiveCN110306315AHigh tear strengthAvoid wrinklesFabric breaking/softeningGrip property fibresKojic acidFiber

The invention relates to the technical field of preparation methods of superfine fiber synthetic leather, and discloses a base fabric post-processing technology of superfine fiber synthetic leather. Adecreased base fabric is treated by the technology comprising the following steps: S1, expanding and drying; S2, oiling, wherein the base fabric which is expanded and dried in step S1 is repeatedly soaked in an oiling agent. The oiling agent comprises the following chemical components in parts by weight: 40-60 parts of amino silicone oil, 30-50 parts of aminopropanol kojic acid phosphate, 6-9 parts of diatomite, 3-7 parts of talcum powder and 10-14 parts of a surfactant; S3, shaping and drying; and S4, carrying out puffing treatment. By using the oiling agent mentioned above, the tearing strength of the base fabric is improved.

Owner:浙江永祥合成材料有限公司

Tensioning device for label strip of bottle

InactiveCN105620840ANot easy to wrinkleImprove the tension effectLabelling machinesEngineeringBottle

The invention provides a tensioning device for a label strip of a bottle. The tensioning device comprises a conveying belt, a labeling mechanism and an adjusting pushing plate; the labeling mechanism is arranged on one side of the conveying belt, the adjusting pushing plate is arranged on the other side of the conveying belt, a horizontal adjusting guide column is arranged on the outer side of the adjusting pushing plate, and the adjusting pushing plate is movably assembled on a horizontal adjusting base through the horizontal adjusting guide column; a vertical adjusting guide column is arranged at the bottom of the horizontal adjusting base, and the horizontal adjusting base is movably assembled on a vertical adjusting base through the vertical adjusting guide column; a labeling channel is formed between the adjusting pushing plate and the labeling mechanism which are assembled; and guide baffles are arranged at the positions, at the two ends of the labeling channel, of the conveying belt. According to the scheme, folding is not prone to occurrence, and the tensioning effect is good.

Owner:DEQING AOYUAN BIOTECH CO LTD

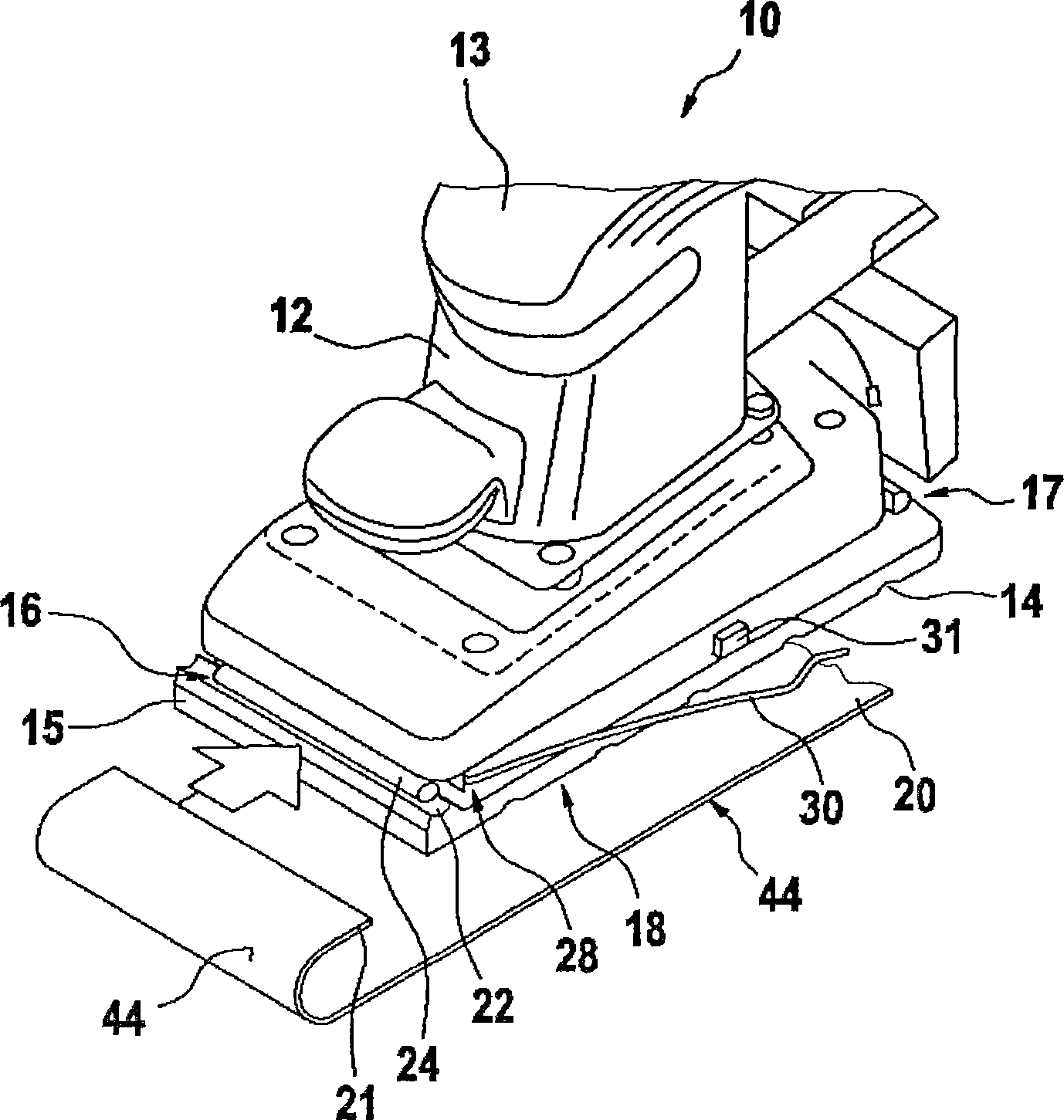

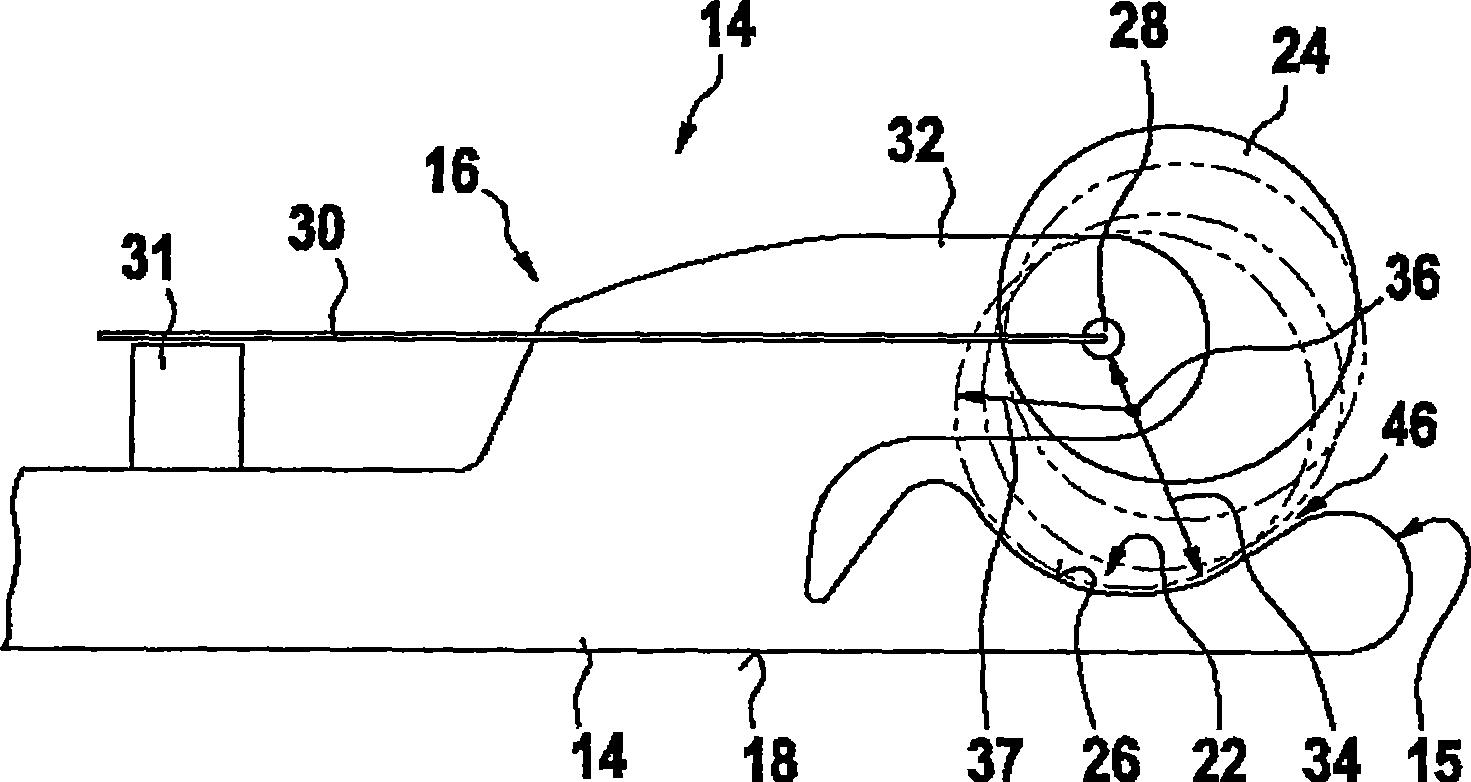

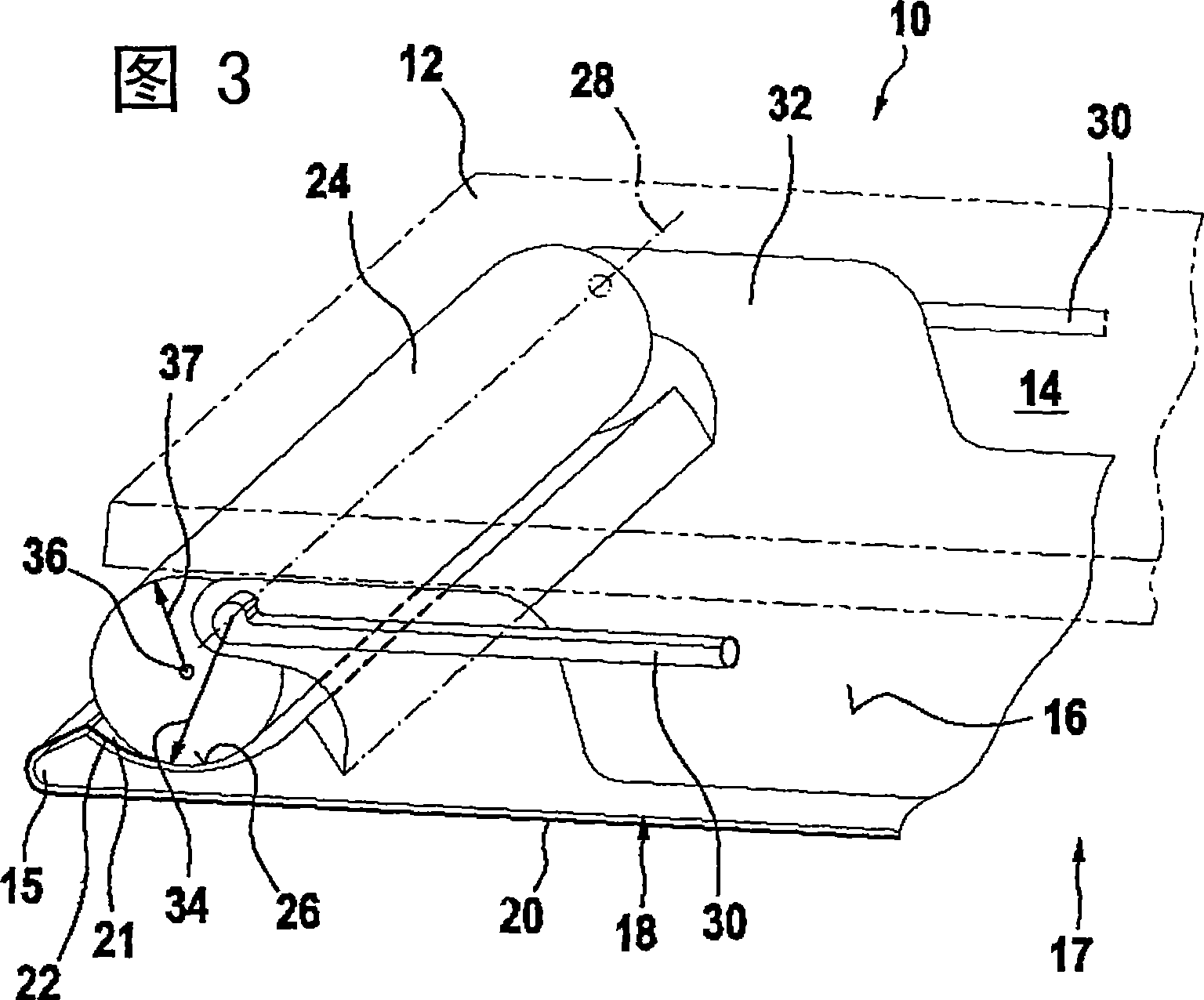

Hand sanding tool

InactiveCN1882415AStrong pressing forceLarge locking forcePortable grinding machinesGrinding/polishing hand toolsMechanical engineeringEngineering

Owner:ROBERT BOSCH GMBH

Deviation-preventing tensioning device

InactiveCN105692302AAvoid deformationConducive to maintaining the qualityWebs handlingEngineeringElectrical and Electronics engineering

The invention discloses an anti-running tensioning device, which is characterized by comprising a bracket and a plurality of pairs of tensioning rollers arranged in parallel on the bracket. When the cylinder is jacked up, the coupling piece is driven to move, and after the coupling piece moves, each pair of tensioning rollers is driven to move, and the positioning pieces are arranged at both ends of the tensioning rollers. The invention has novel structure design, strong practicability and good tensioning effect, can effectively prevent the film from deviating during the transmission process, and greatly improves the preparation or processing efficiency of the film.

Owner:JIANGYIN LICHNEG MACHINERY CO LTD

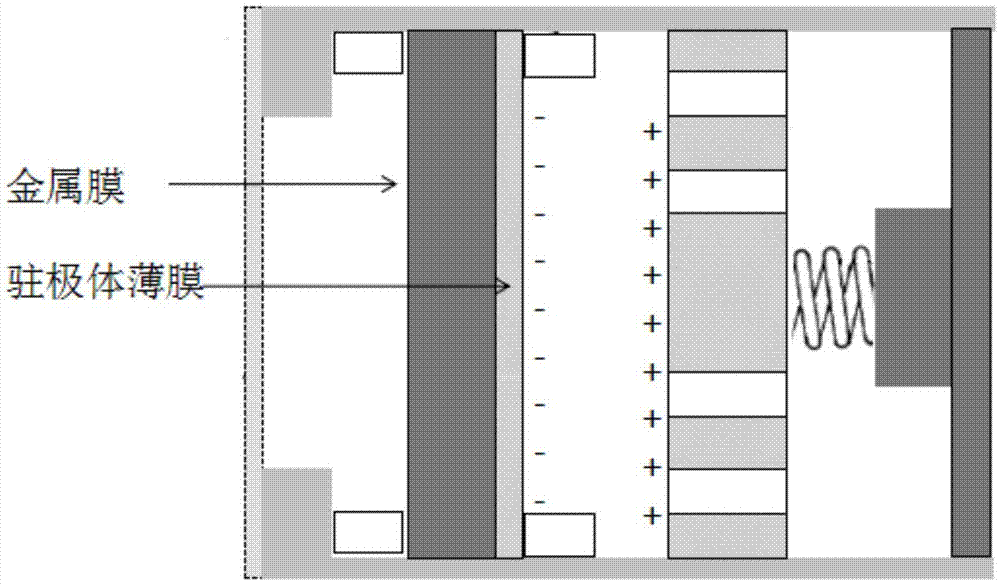

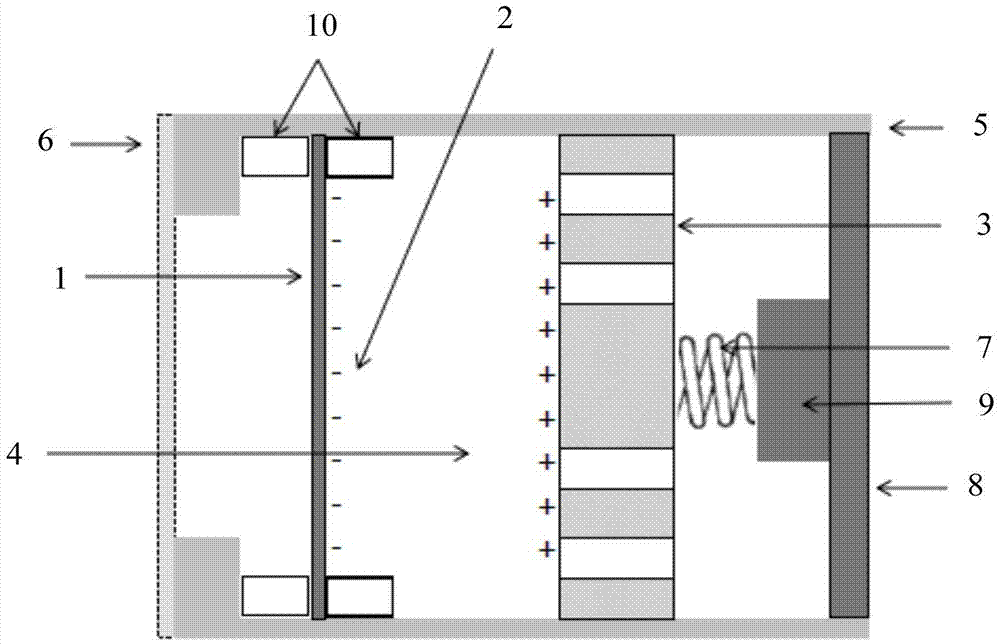

Capacitive sound acquisition device and microphone

InactiveCN106937229ACompact structureHigh sensitivityElectrostatic transducer microphonesEngineeringGraphene

The invention provides a capacitive sound acquisition device. The capacitive sound acquisition device comprises a graphene vibrating diaphragm and a back electrode parallel to the graphene vibrating diaphragm. A prepolarized electric field is generated between the graphene vibrating diaphragm and the back electrode. The capacitive sound acquisition device is arranged in an inner cavity formed by a shell of a microphone. One side of the shell is provided with an opening and a dust cover covers the opening. The graphene vibrating diaphragm is located between the dust cover and the back electrode. In the invention, under an equal tension intensity condition, sound acquisition sensitivity is greatly increased, or under a same sensitivity condition, high tension strength is acquired, which means that a maximum tolerable sound pressure characteristic is increased, and simultaneously a wide frequency width is possessed.

Owner:BEIJING SAIBIN TECH

Wire belt tensioning device of instant freezer

PendingCN109677850AAchieve tensionImprove the tension effectConveyorsControl devices for conveyorsSupport planeEngineering

Owner:NANTONG EXPEDITIONICESOURCE REFRIGERATION EQUIP

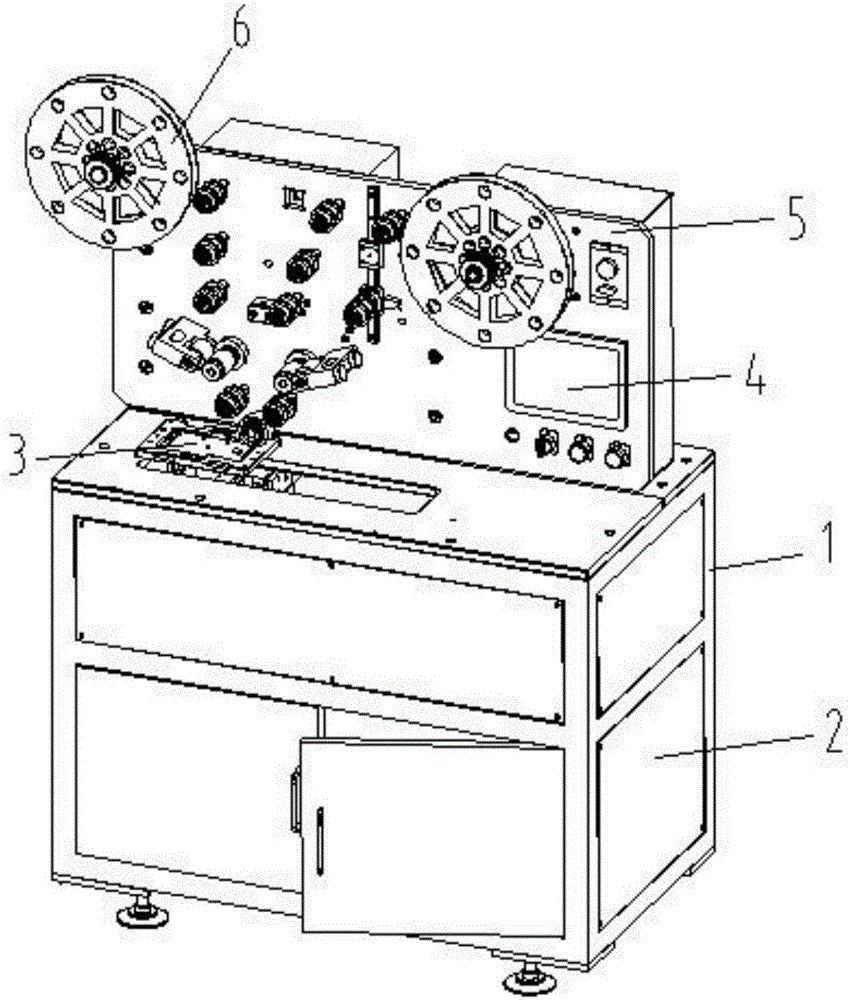

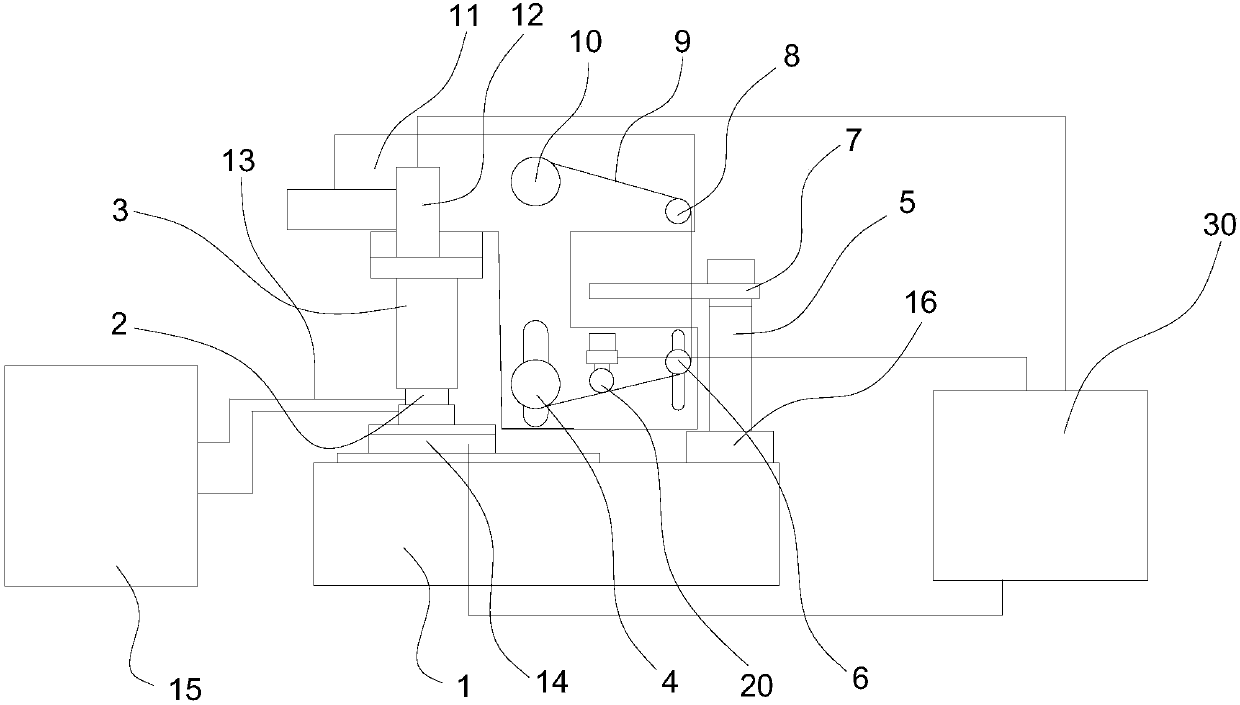

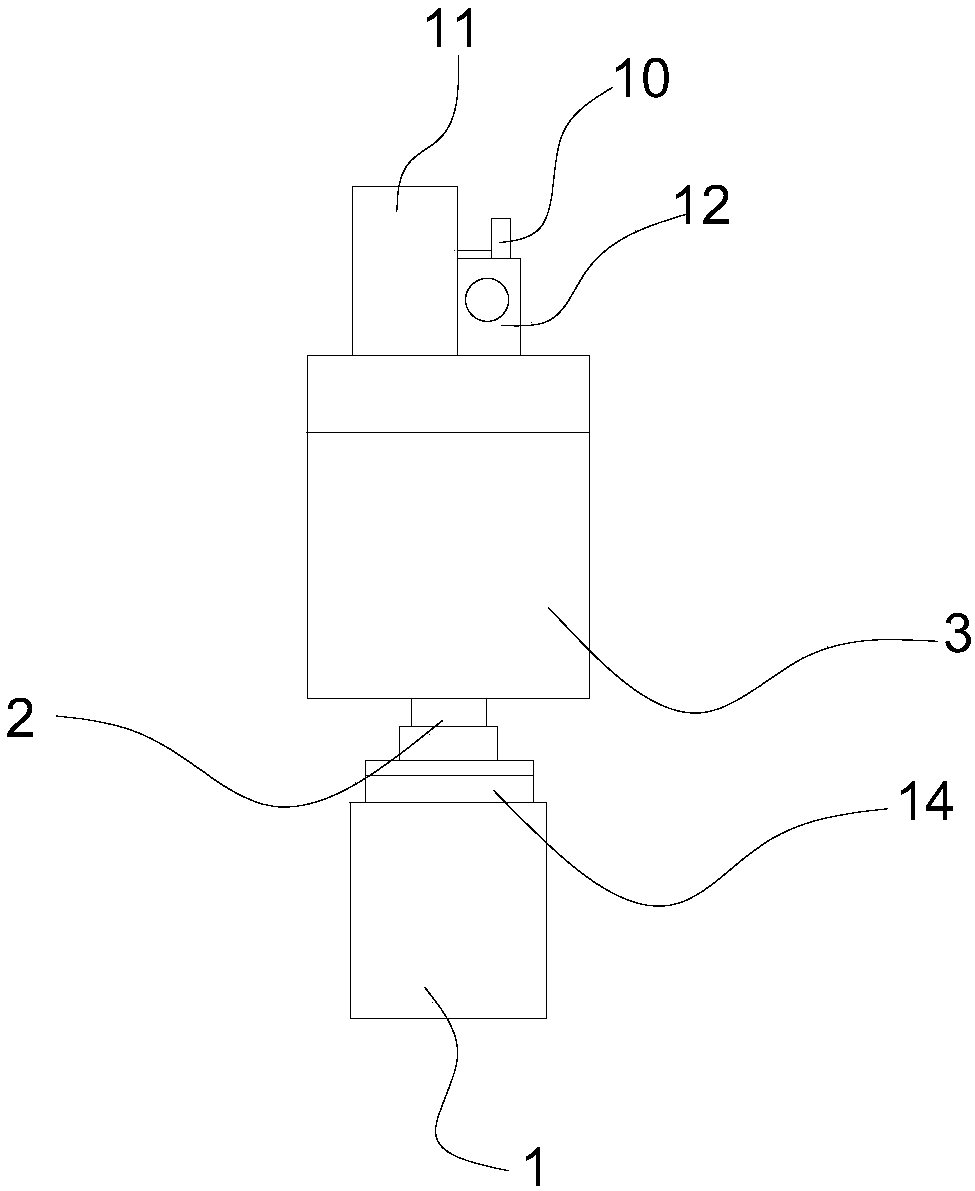

Automatic frictioning machine for panel

InactiveCN106824845ARealize the effect of wiping glueImprove glue wiping efficiencyCleaning using toolsDistribution controlEngineering

The invention relates to an automatic frictioning machine for a panel. The automatic frictioning machine comprises a rack and a power distribution control cabinet, wherein a material carrying mechanism matched with the panel is arranged on the rack; a vertical mounting plate is arranged on the rack; an operation display matched with the power distribution control cabinet and a frictioning mechanism matched with the material carrying mechanism are arranged on the mounting plate; the frictioning mechanism comprises an unwinding drum, a winding drum and a frictioning drum matched with the unwinding drum and the winding drum; the unwinding drum, the winding drum and the frictioning drum are arranged on the mounting plate; the frictioning drum is matched with the material carrying mechanism; the winding drum is connected with a winding motor through a synchronizing wheel; and the winding motor and the material carrying mechanism are connected to the power distribution control cabinet. According to the automatic frictioning machine for the panel provided by the invention, the unwinding drum and the winding drum of a frictioning strip are arranged, the frictioning drum matched with the unwinding drum and the winding drum is arranged, a panel carrier is arranged below the frictioning drum, the frictioning strip and the panel are in contact through the frictioning drum, the frictioning effect is achieved, the frictioning efficiency is high, the frictioning strip continuously moves, the frictioning effect is not affected by too large viscose glue, and good frictioning precision can be guaranteed.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

Three-axis high-speed cutting machine capable of detecting fracture of diamond wires

ActiveCN107626980AAchieve rotationAvoid Disassembly of FixturesMetal sawing devicesMetal sawing accessoriesLinear driveDiamond

The invention discloses a three-axis high-speed cutting machine capable of detecting fracture of diamond wires. By means of the three-axis high-speed cutting machine capable of detecting fracture of the diamond wires, three-axis movement of the diamond wires can be achieved, the tensioning state of the diamond wires can be adjusted, and whether the diamond wires are snapped or not can be detected.The three-axis high-speed cutting machine capable of detecting fracture of the diamond wires comprises a base, a servo control cabinet and an adjusting device; a supporting platform is arranged on the base; a horizontal linear drive device for driving the supporting platform to move on the base in the horizontal direction is arranged between the supporting platform and the base; the horizontal linear drive device is provided with a supporting block, a vertical telescopic device is arranged on the supporting block, and the supporting platform is installed at the upper end of the vertical telescopic device; and a longitudinal working platform is slidably installed on the supporting platform through a longitudinal linear drive device and provided with a cutting device. By adoption of the three-axis high-speed cutting machine capable of detecting fracture of the diamond wires, the operation stability, safety and cutting efficiency can be improved, and the service life of the diamond wirescan be prolonged.

Owner:LESHAN TOPRAYCELL

Spinning traction device for modified fiber

The invention discloses a spinning traction device for modified fiber. The device comprises a supporting main frame and a bobbin fixing mechanism, an H-shaped plate frame fixedly connected with the supporting main frame is arranged above the bobbin fixing mechanism, a silk yarn winding mechanism is arranged on the H-shaped plate frame, a tensioning waxing mechanism and a reel mechanism are arranged above the silk yarn winding mechanism, the H-shaped plate frame comprises two vertical supporting plates and a cavity rotating disc, the side curve face of the cavity rotating disc is provided withmultiple polishing inclined cutting grooves, a C-shaped clamping groove is formed in the inner wall of the upper end of the cavity rotating disc, a rotating round plate is arranged in the C-shaped annular clamping groove, the silk yarn winding mechanism comprises a coiling plate and threading holes which are formed in the edge of the coiling plate and are annularly distributed, a drive motor is arranged in the cavity rotating disc, an output shaft of the drive motor is fixedly connected with the rotating round plate, winding disorder between spinning bobbins can be prevented, under the large external force, the bobbins can be subject to self-adjusting rotation, and the breakage of spinning in the traction process can be reduced.

Owner:ANHUI HEBANG TEXTILE TECH CO LTD

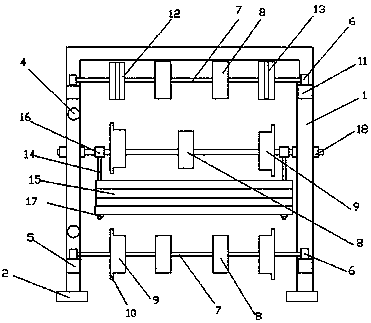

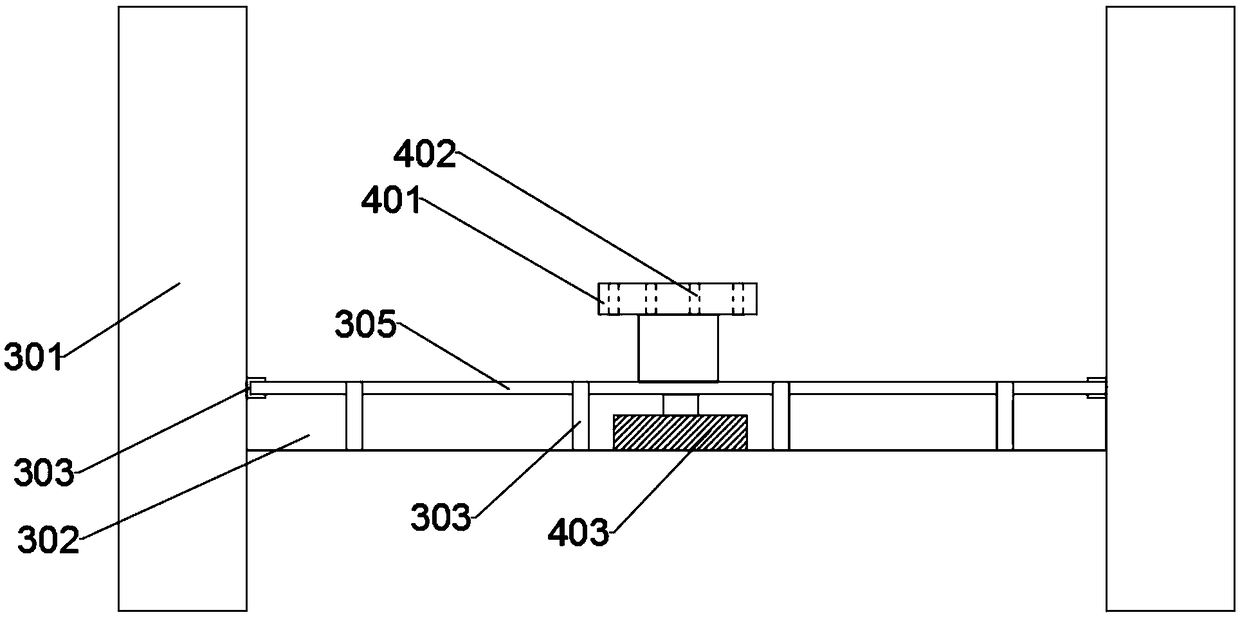

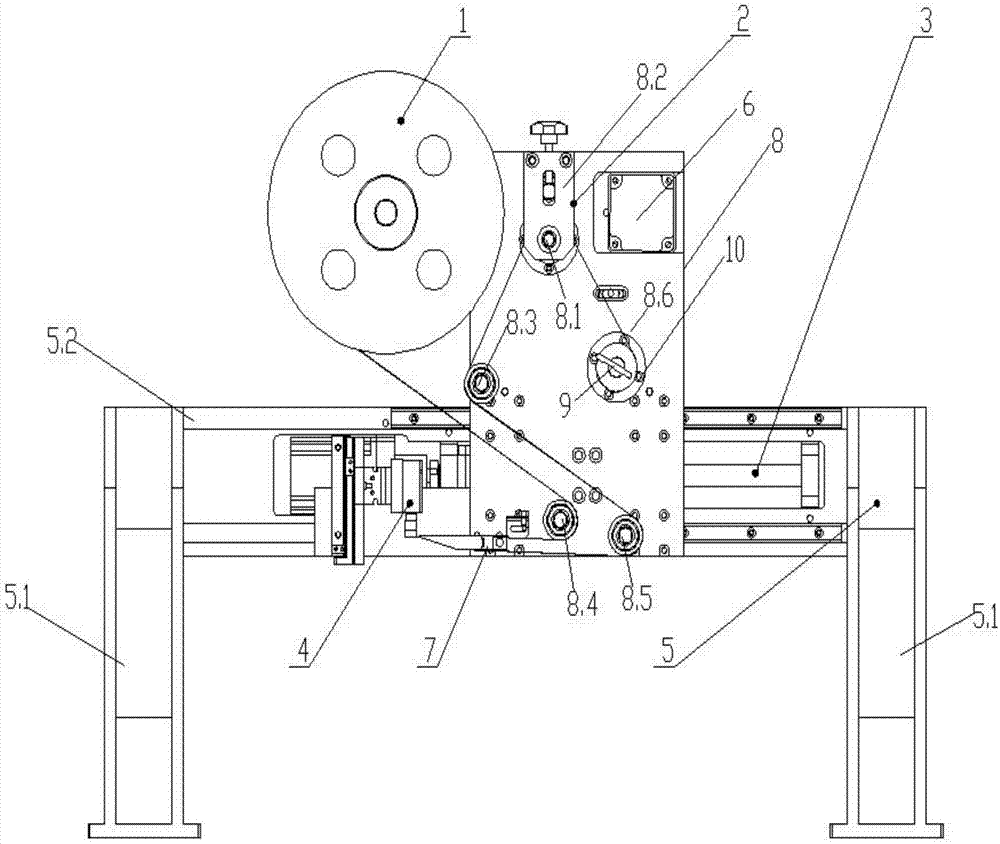

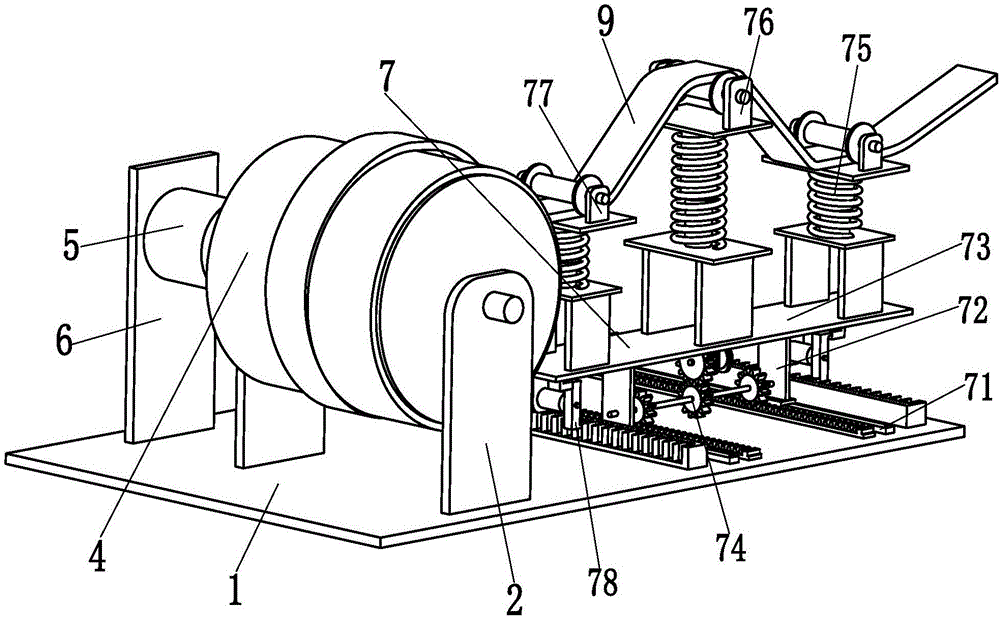

Cylindrical winding processing equipment for distribution network transformer and transformer

ActiveCN106783155AEvenly tensionedNo manual adjustmentTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureTransformerCoupling

The invention relates to cylindrical winding processing equipment for a distribution network transformer and the transformer. The cylindrical winding processing equipment comprises a base plates, two mounting lugs are symmetrically mounted on the upper end face of the base plate, an insulating barrel is mounted between the mounting lugs through a bearing, a winding motor is mounted at the front end of the insulating barrel through a coupler, the bottom of the winding motor is mounted on a vertical plate through a motor base, the vertical plate is welded on the base plate, the insulating barrel is driven to rotate on the mounting lugs through the insulating barrel, a moving tension device is mounted at the left end of the base plate, an auxiliary tightening device is mounted at the right end of the base plate, the moving tension device is wound with a wire guiding strip, the starting end of the wire guiding strip winds the insulating barrel, the wire guiding strip winding the right end of the insulating barrel is abutted against the auxiliary tightening device, and the wire guiding strip winds on the outer wall of the insulating barrel for a plurality of times to form a cylindrical winding. By the arrangement, the function of full-automatic tensioning and patting winding of the cylindrical winding can be realized, and the high-performance transformer with the cylindrical winding can be produced.

Owner:YANCHENG POWER SUPPLY CO STATE GRID JIANGSU ELECTRIC POWER CO +4

Package label attaching device

PendingCN107972943ANot easy to wrinkleImprove the tension effectLabelling machinesWebs handlingEngineeringElectrical and Electronics engineering

The invention provides a package label attaching device. The package label attaching device comprises a label storage mechanism, a pressing mechanism, a label processing mechanism, a translation mechanism and a rack, wherein the rack comprises two vertical brackets which are arranged on the left and right sides and a cross beam between the two vertical brackets, the translation mechanism is arranged on the cross beam in a transverse direction, the label processing mechanism is perpendicularly arranged on the translation mechanism, the label storage mechanism is arranged on one side of the label processing mechanism, and the pressing mechanism is arranged on the cross beam below the label storage mechanism; the pressing mechanism is a label attaching cylinder; the translation mechanism is ascrew rod translation mechanism; and the label processing mechanism comprises a processing box body, tensioning devices, a label arrangement device and a feeding motor are arranged on the box body, the label arrangement device is arranged at the bottom of the box body, and the protruding end of the label arrangement device is over against the lower pressing part of the label attaching cylinder. Aplurality of tensioning rollers and tension adjusting devices are arranged, so that the tension of labels is adjusted, the labels are difficult to fold, and the tensioning effect is good.

Owner:WUXI TEHENG TECH CO LTD

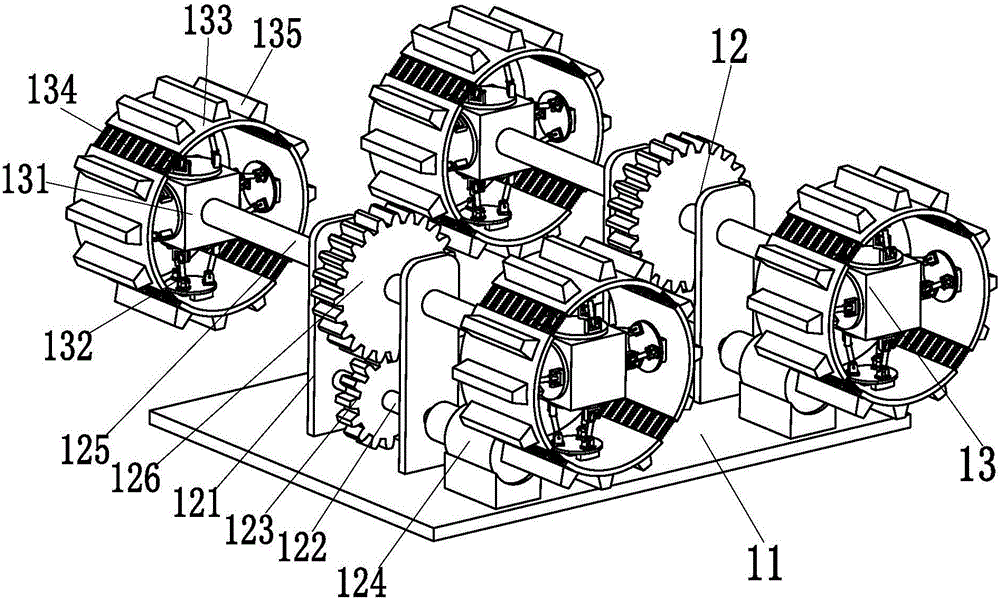

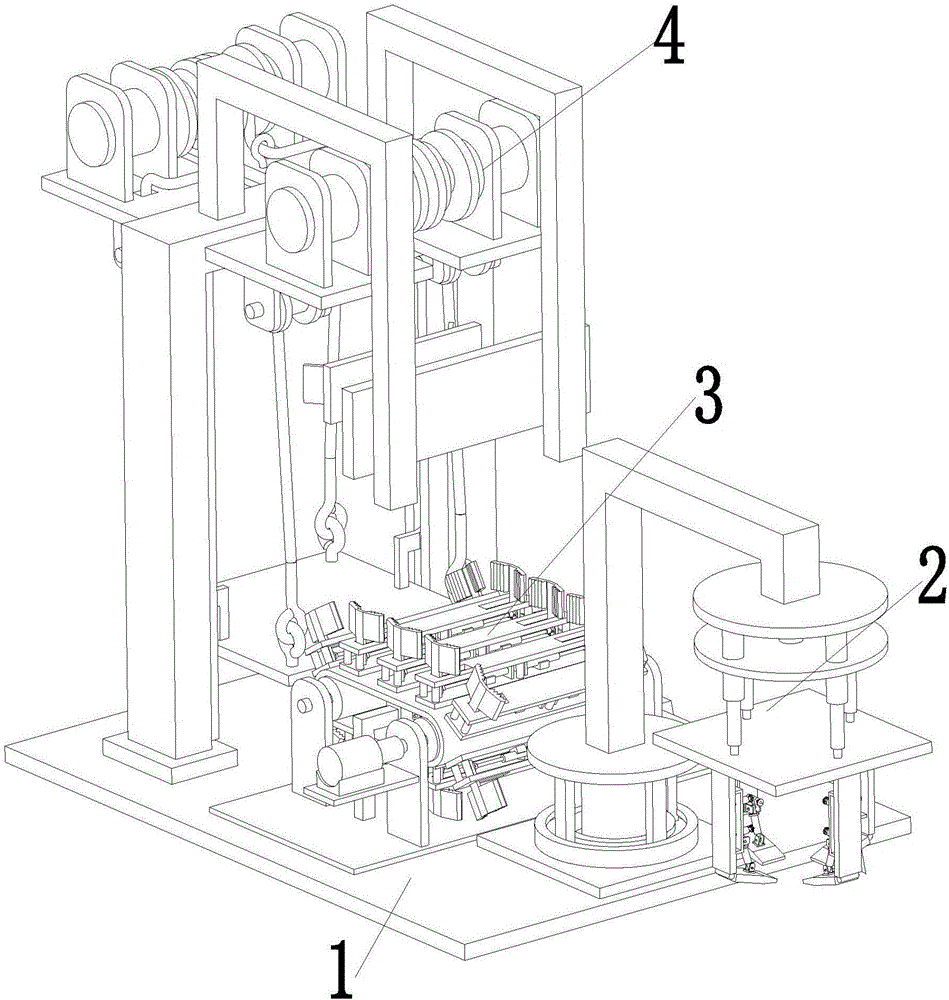

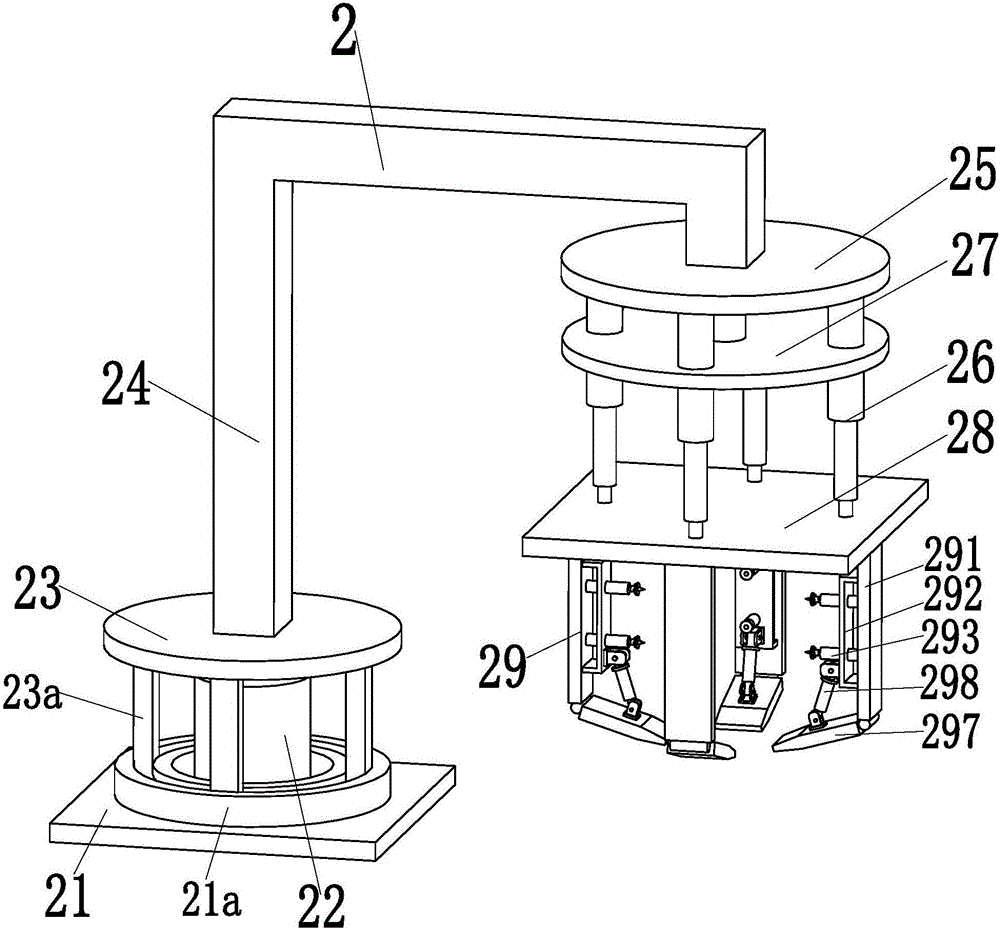

City highway retaining wall intelligent moulding integrated machine

InactiveCN106193107APrevent the phenomenon of falling due to excessive gravityRealize hydraulic automatic grabbing functionArtificial islandsMechanical machines/dredgersMechanical engineeringRetaining wall

The invention relates to a city highway retaining wall intelligent moulding integrated machine. The city highway retaining wall intelligent moulding integrated machine comprises a base, wherein a hydraulic grabbing device is arranged on the right side of the upper end of the base; a hydraulic automatic grabbing function for grouted rubble can be realized through the hydraulic grabbing device; manual grabbing and placing are not needed; the grabbing speed is high; the grabbing efficiency is high; a limiting conveying device is arranged on the middle part of the upper end surface of the base; a stable limiting conveying function for the grouted rubble can be realized through the limiting conveying device; left limiting and right limiting are realized during the whole conveying process of the grouted rubble; tumbling hidden danger existing in the conveying process of the grouted rubble is eradicated; the conveying effect is good; manual operation is not needed; a lifting pushing and placing device is arranged on the left side of the upper end surface of the base; an automatic lifting pushing and placing function for the grouted rubble can be realized through the lifting pushing and placing device; manual up and down conveying is not needed; the conveying speed is high; and the working efficiency is high. By adopting the city highway retaining wall intelligent moulding integrated machine, an automatic moulding function for a retaining wall can be realized; and a new means is provided for automatic rapid moulding of the retaining wall.

Owner:王俊磊

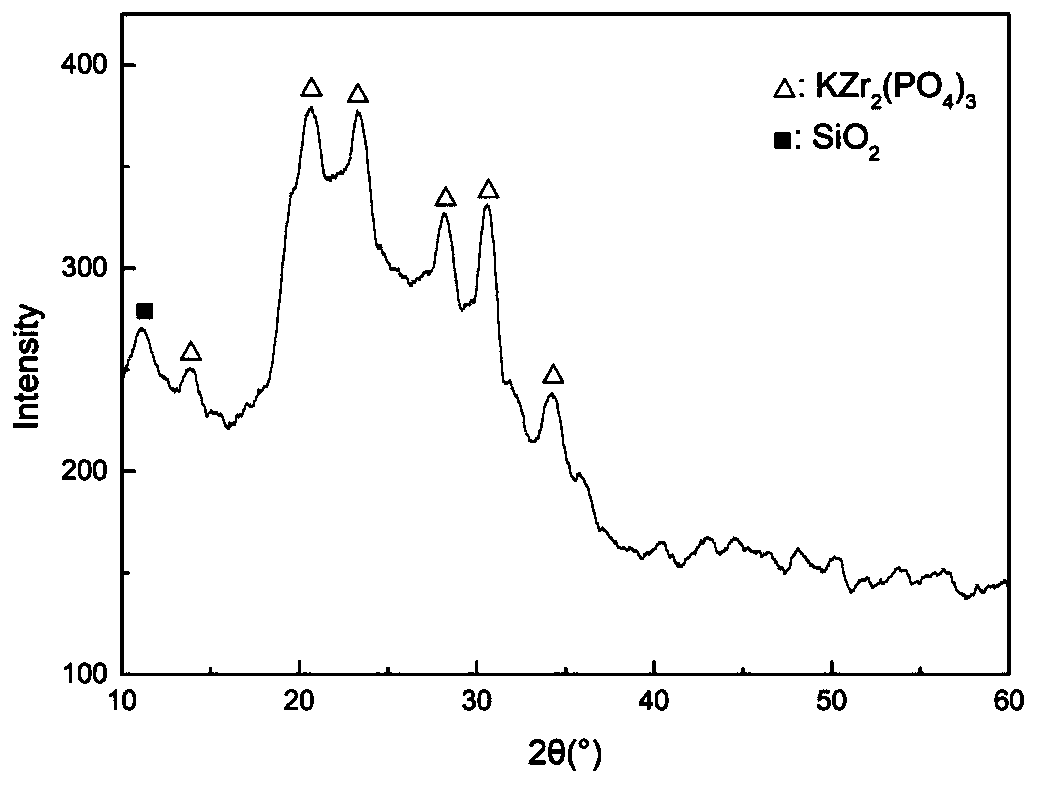

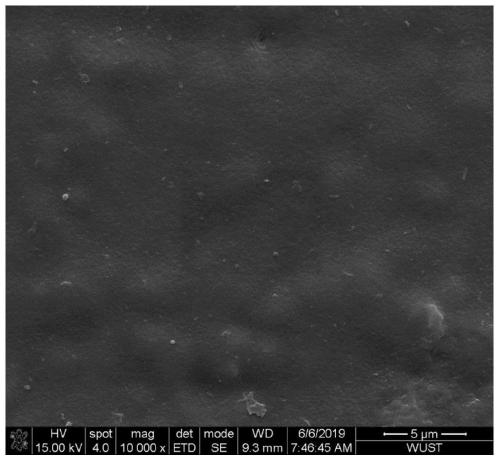

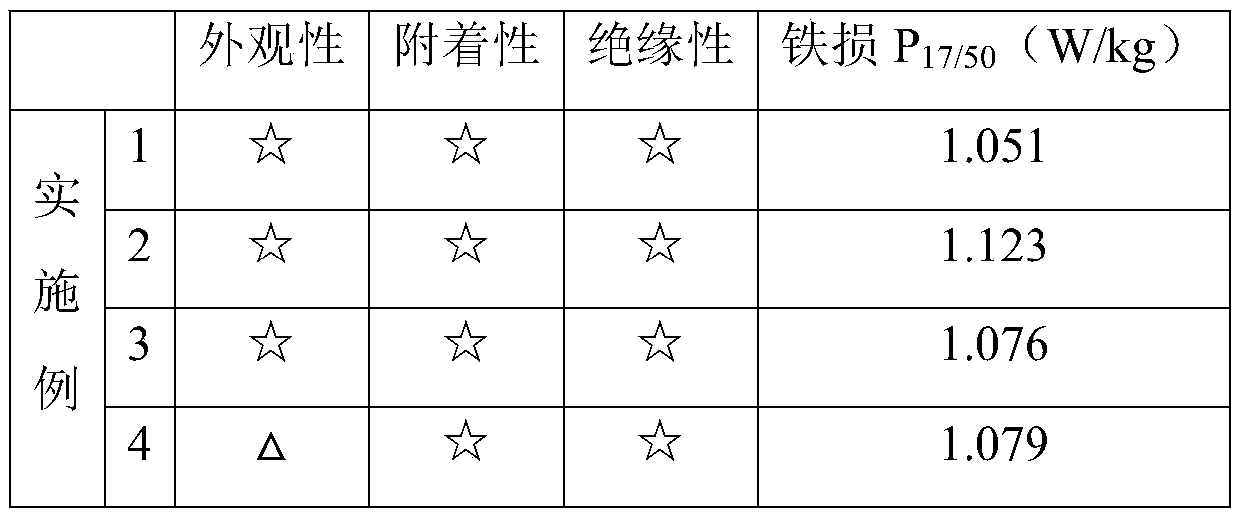

Preparation method of high tension coating for oriented silicon steel

InactiveCN110240815AHigh bonding strengthAnti-stripping insulation performanceAnti-corrosive paintsIonPhosphate

The invention relates to a preparation method of a high tension coating for oriented silicon steel. The technical scheme is as follows: components of a high-tension coating solution are as follows: 20-40 wt% of aluminum dihydrogen phosphate, 25-45 wt% of silica sol, 2-4 wt% of chromic anhydride, 0.8-4.0 wt% of potassium dihydrogen phosphate, 1.3-6.4 wt% of zirconium oxychloride, and 20-30 wt% of deionized water; according to the component and content of the high tension coating solution, firstly aluminum dihydrogen phosphate, silicon sol and chromic anhydride are added into a reaction kettle, uniform mixing is performed, then potassium dihydrogen phosphate and a zirconium oxychloride solution obtained by mixing zirconium oxychloride with deionized water is sequentially added, stirring is performed, then the high tension coating solution for oriented silicon steel obtained by stirring is smeared on the surface of oriented silicon steel, baking is performed in a protective atmosphere, and high temperature solidification is performed to obtain the high tension coating for oriented silicon steel. The method has the characteristics of low cost, simple process and easy industrial production, and the prepared high tension coating for oriented silicon steel has good tensile effects and excellent performance.

Owner:WUHAN UNIV OF SCI & TECH

Adjusting and fixing support for deep vein puncture needle for anesthesia

The invention relates to the technical field of puncture needle supports, in particular to an adjusting and fixing support for for a deep vein puncture needle for anesthesia. The adjusting and fixing support comprises a rectangular frame, two U-shaped frames are symmetrically fixed to the two sides of the rectangular frame, binding belts are bound and fixed to the interiors of the two U-shaped frames, and transverse tensioning mechanisms used for tensioning the skin are arranged on the two sides of the rectangular frame. Two supporting rods are symmetrically and rotationally connected to the top face of the rectangular frame, guide rail holes are formed in the supporting rods, semicircular guide rail rings are inserted into the guide rail holes, the two ends of each guide rail ring are fixed to the top face of the rectangular frame, and elastic positioning mechanisms used for temporarily fixing the supporting rods to the guide rail rings are arranged in the supporting rods. According to the scheme, the skin at the puncture position is tensioned through the transverse tensioning mechanism, so that the loose skin is tightened, a doctor can see the meridians at the puncture position clearly, puncture is facilitated, the needle tube is clamped and fixed stably, the needle tube does not need to be held manually, and puncture operation is facilitated.

Owner:何家璇

Bobbin winding processing device and transformer comprising bobbin winding

ActiveCN106783138AEvenly tensionedNo manual adjustmentInductances/transformers/magnets manufactureBobbinTransformer

The invention relates to a bobbin winding processing device and a transformer comprising a bobbin winding. The bobbin winding processing device comprises a bottom plate, wherein two mounting lugs are symmetrically installed on the upper end face of the bottom plate, an insulating cylinder is installed between the two mounting lugs through a bearing, a winding motor is installed at the front end of the insulating cylinder through a coupler, the bottom of the winding motor is installed on a vertical plate through a motor base, the vertical plate is welded on the bottom plate, the insulating cylinder is driven by the winding motor to rotate on the two mounting lugs, a mobile tensioning device is installed at the left end of the bottom plate, a guide line strip is wound around the mobile tensioning device in V-shaped structure, the mobile tensioning device can adjust the position in real time according to the winding position of the guide line strip, and does not need manual adjustment on tensioning positions, the initial end of the guide line strip is wound around the insulating cylinder, and a bobbin winding is formed by winding the guide line strip on the outer wall of the insulating cylinder more than once. The bobbin winding processing device not only can achieve a full-automatic tensioning winding function of the bobbin winding, but also can be prepared into the high performance transformer comprising the bobbin winding.

Owner:HUNAN XIANGBIAN ELECTRIC LIMITED LIABILITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com