Patents

Literature

255results about How to "No manual adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

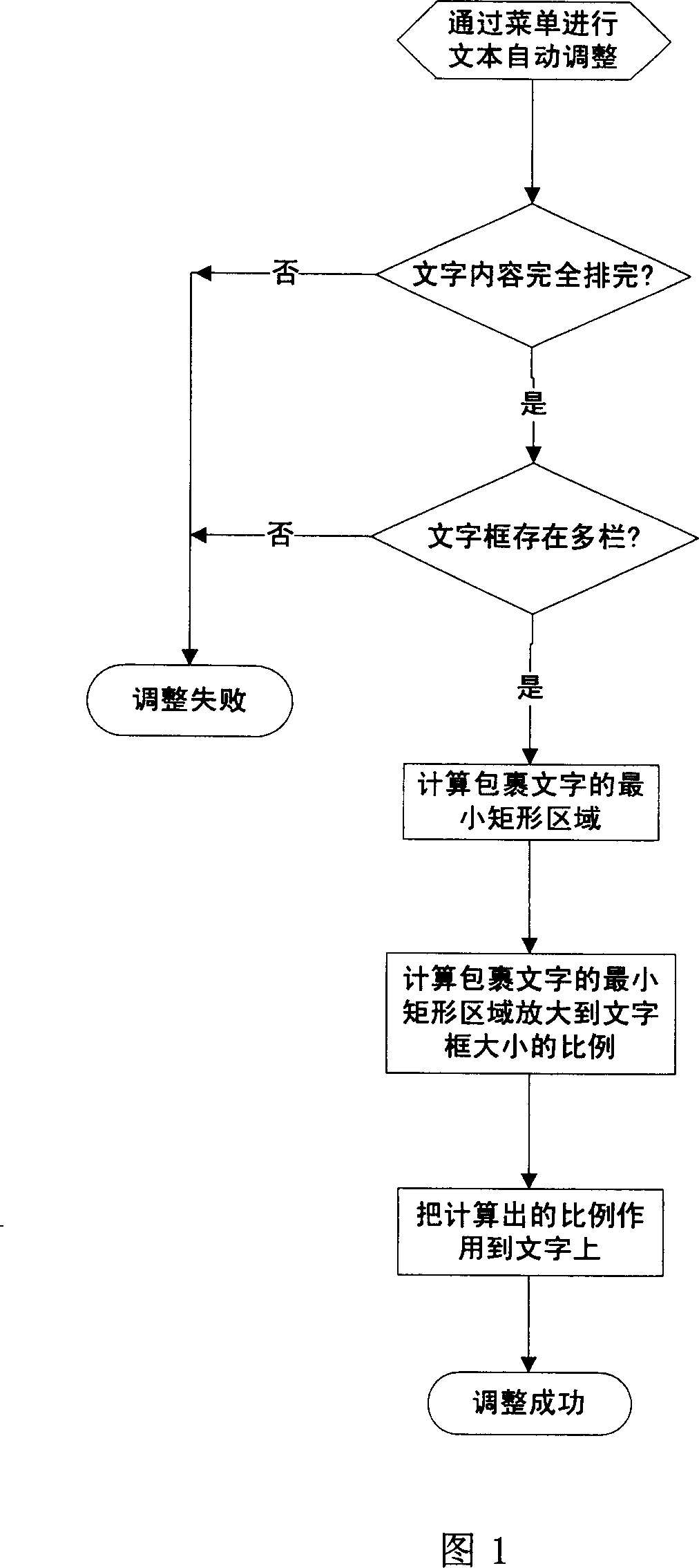

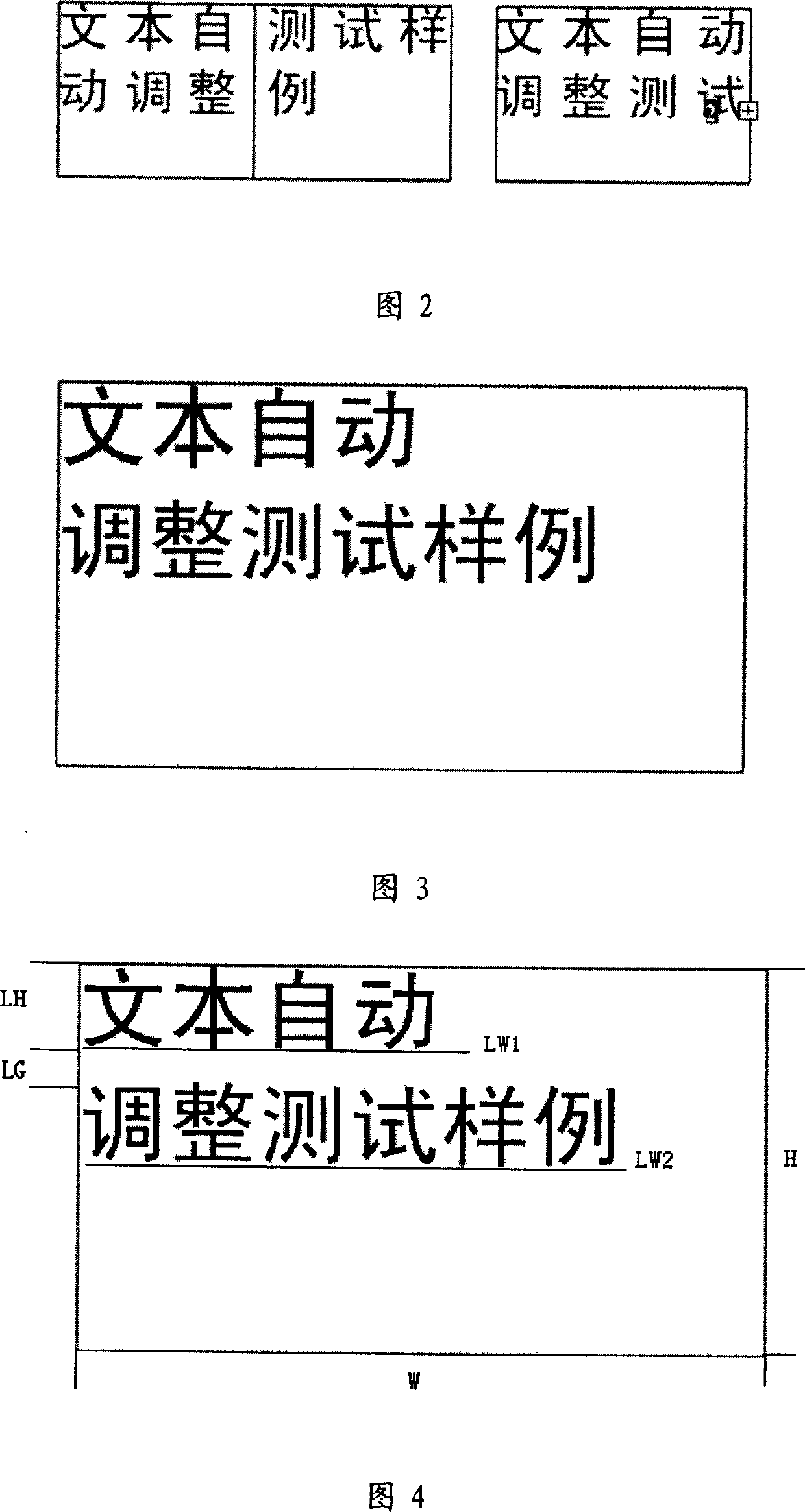

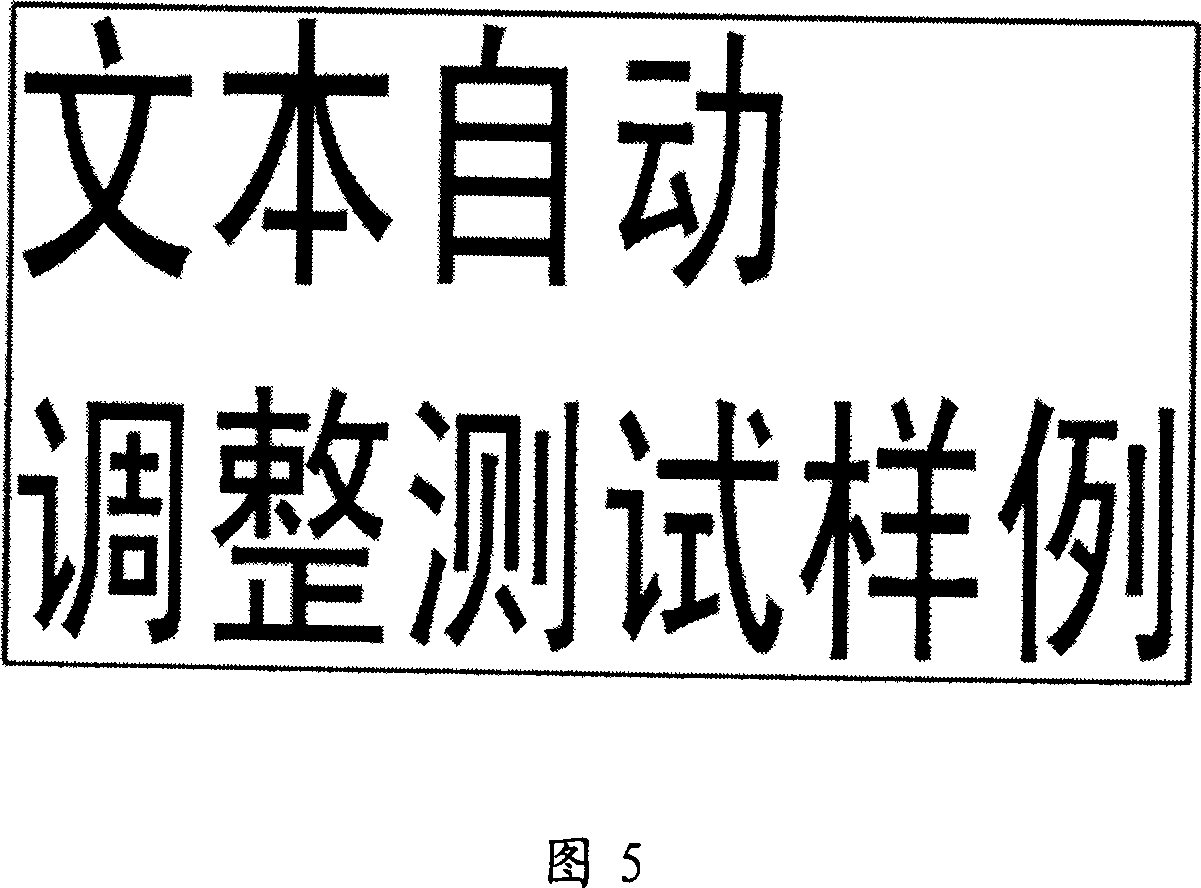

Layout method for word content fitting rectangular words frame

InactiveCN1828581AImprove work efficiencyNo manual adjustmentNatural language data processingSpecial data processing applicationsState of artAlgorithm

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +1

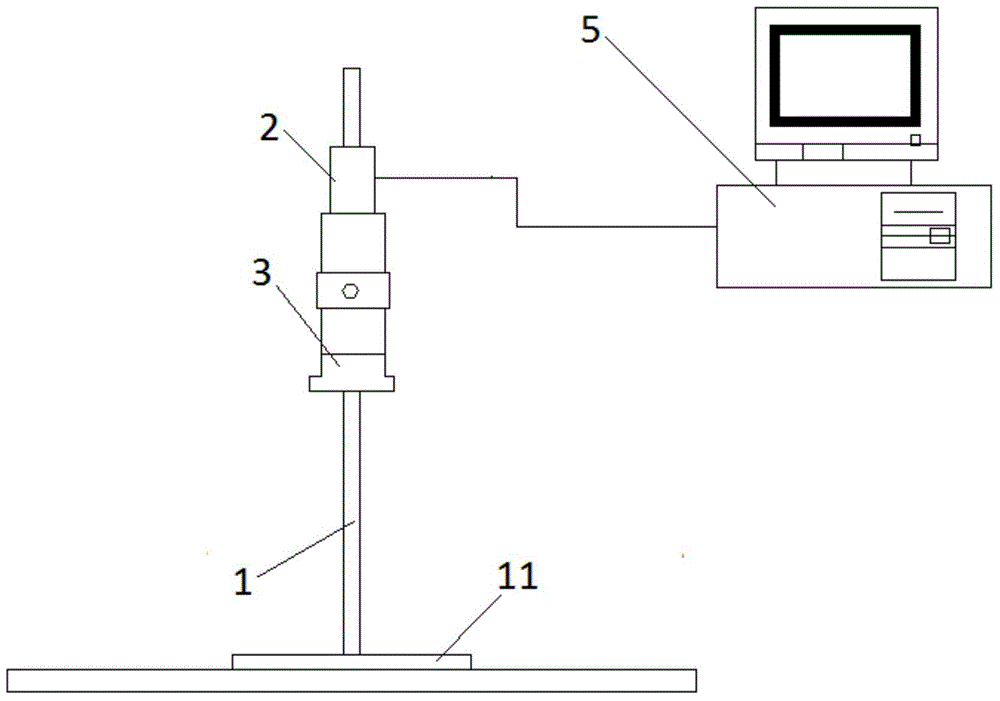

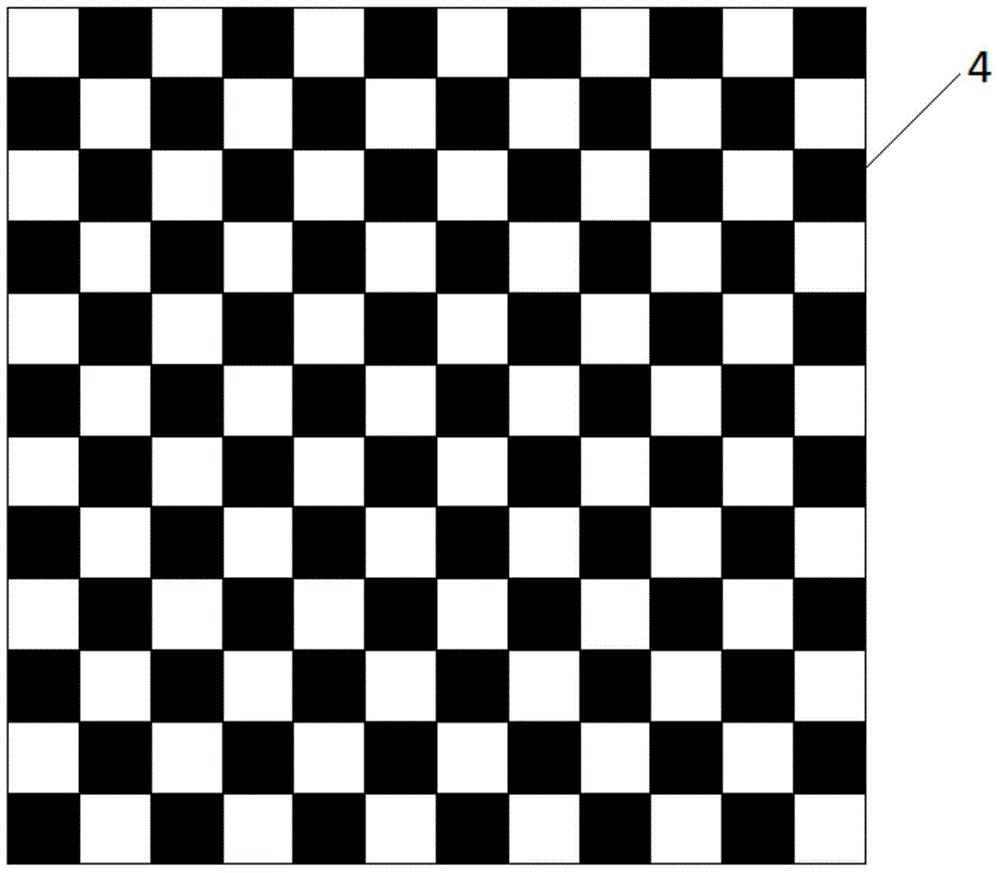

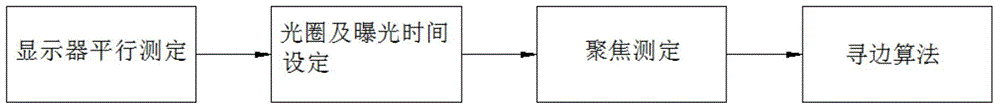

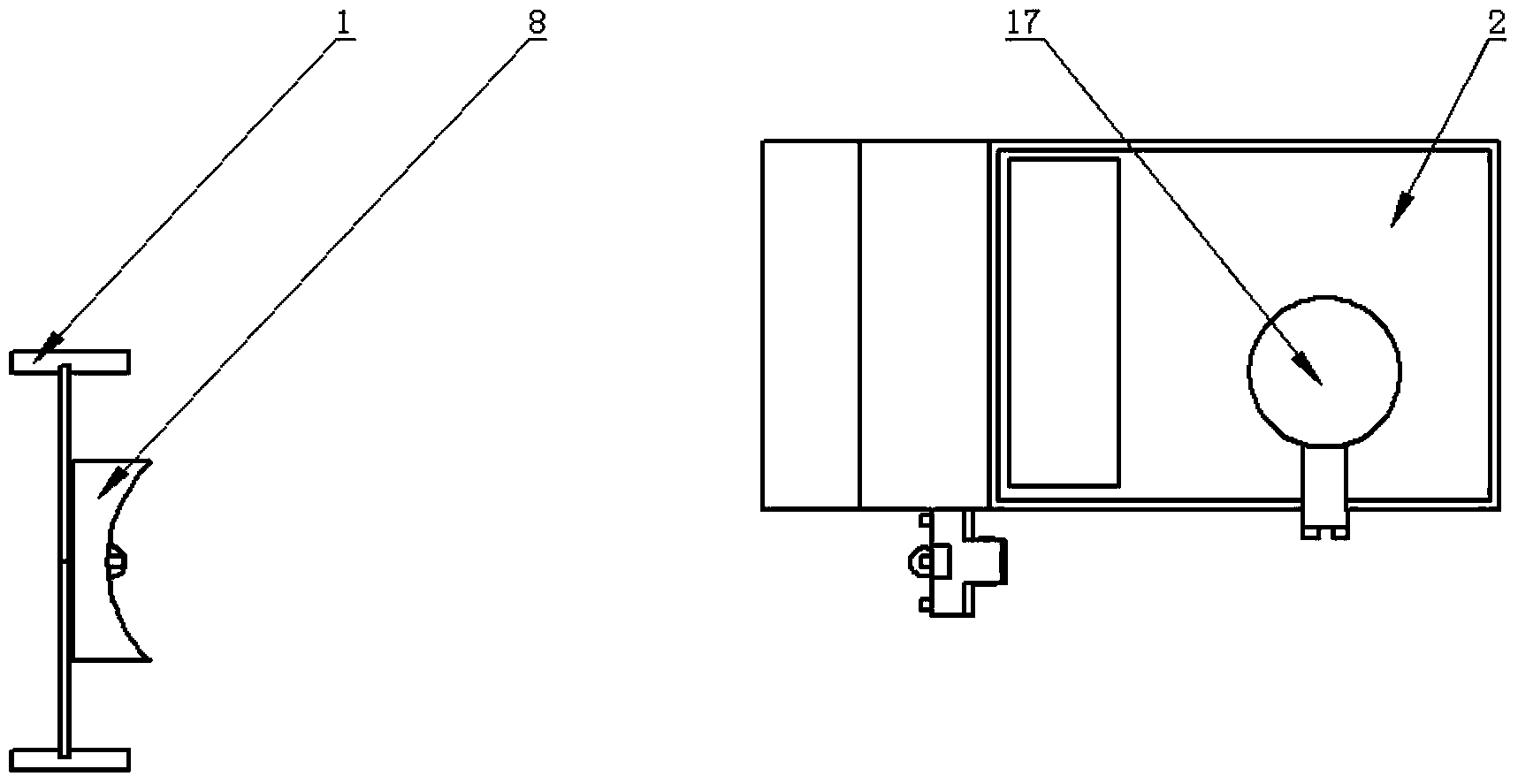

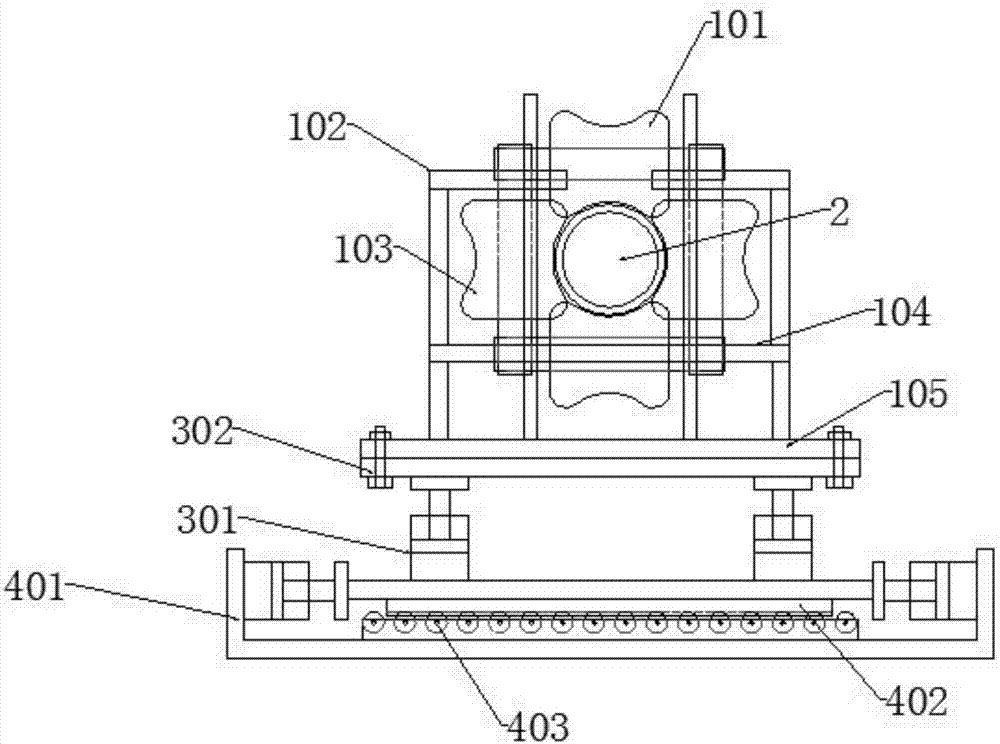

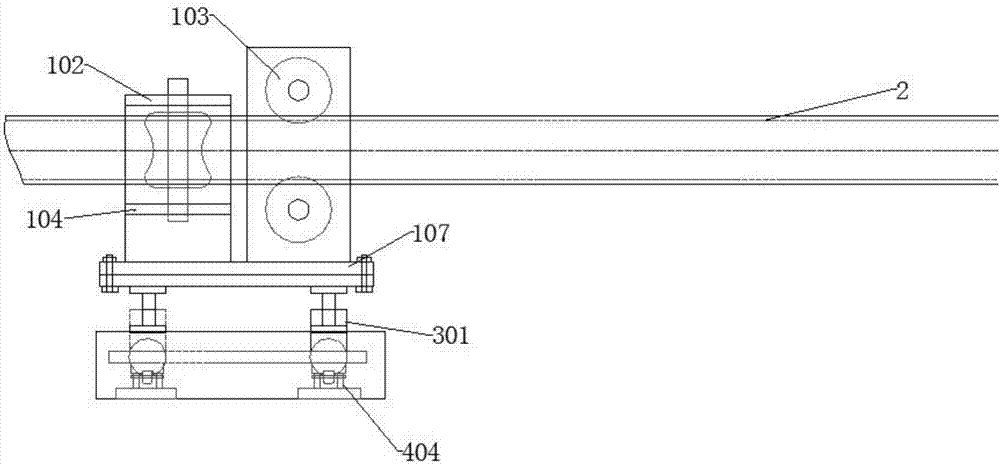

Automatic visual detection method and device for Mura defects of thin film transistor liquid crystal display (TFT-LCD) process

ActiveCN103558229ANo manual adjustmentReduce labor costsOptically investigating flaws/contaminationNon-linear opticsEngineeringThin-film-transistor liquid-crystal display

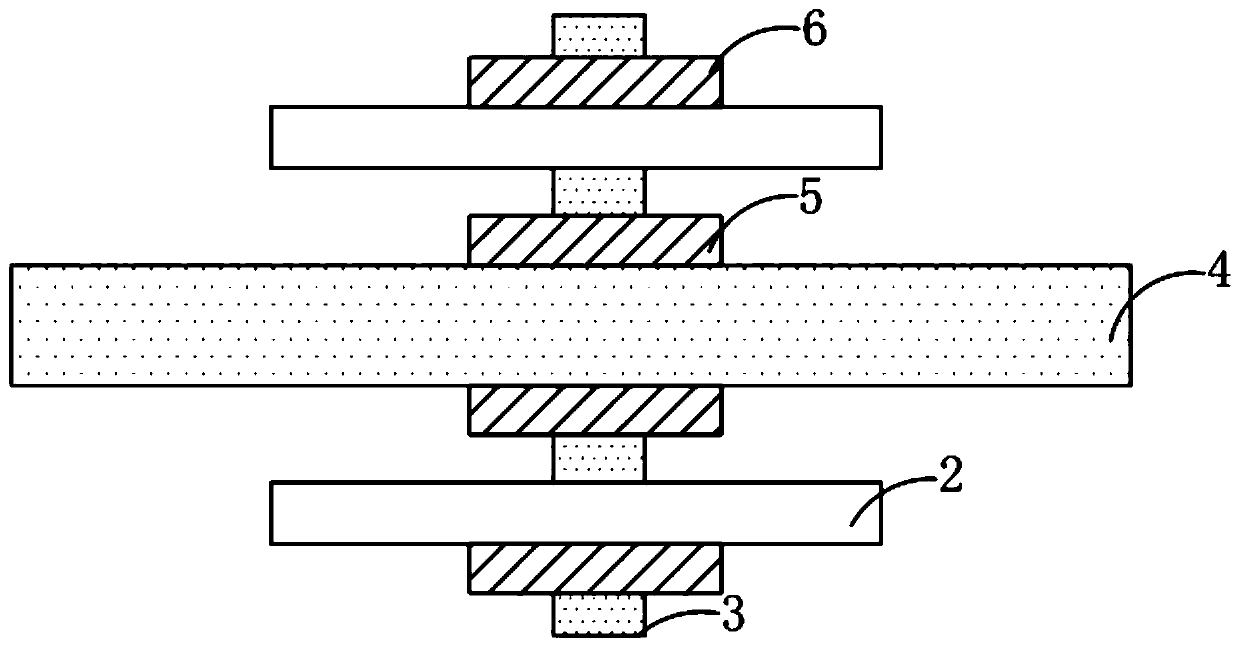

The invention discloses an automatic visual detection device for Mura defects of a thin film transistor liquid crystal display (TFT-LCD) process. The device comprises a fixing device, a charge coupled device (CCD) photographic device, a lens and a square angle standard graph, wherein the fixing device is provided with a detected object fixing tool; the square angle standard graph is laid on the upper surface of the detected object fixing tool; the CCD photographic device is arranged on the fixing device and is arranged above the detected object fixing tool; the lens is arranged on the CCD photographic device; the CCD photographic device is connected with an operation card, which is arranged on a computer, through a connecting line. Different types and sizes of the Mura defects of the TFT-LCD process can be indentified by operating different environments in a compatible manner, intelligent detection is realized, and the labor cost is reduced.

Owner:苏州富鑫林光电科技有限公司

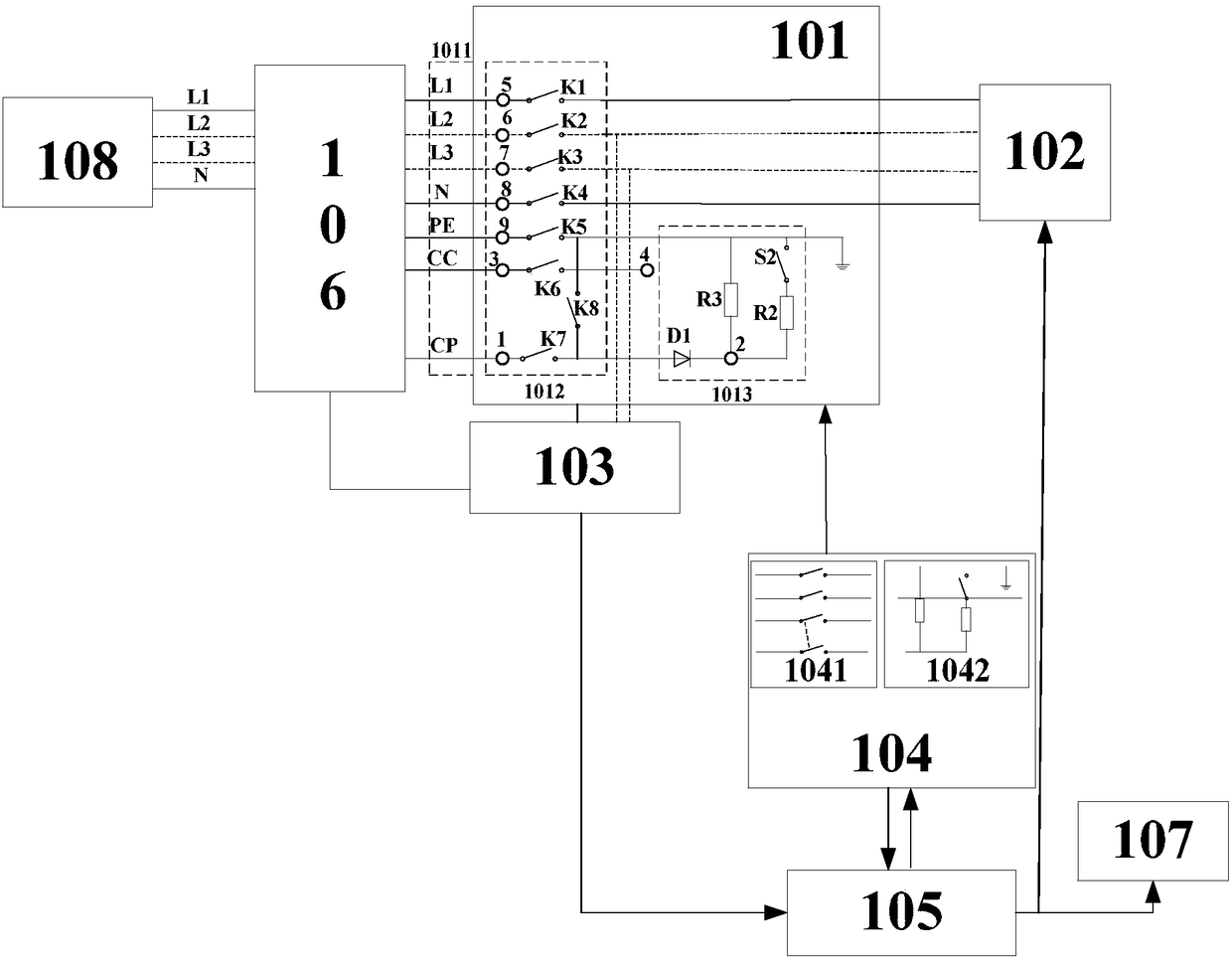

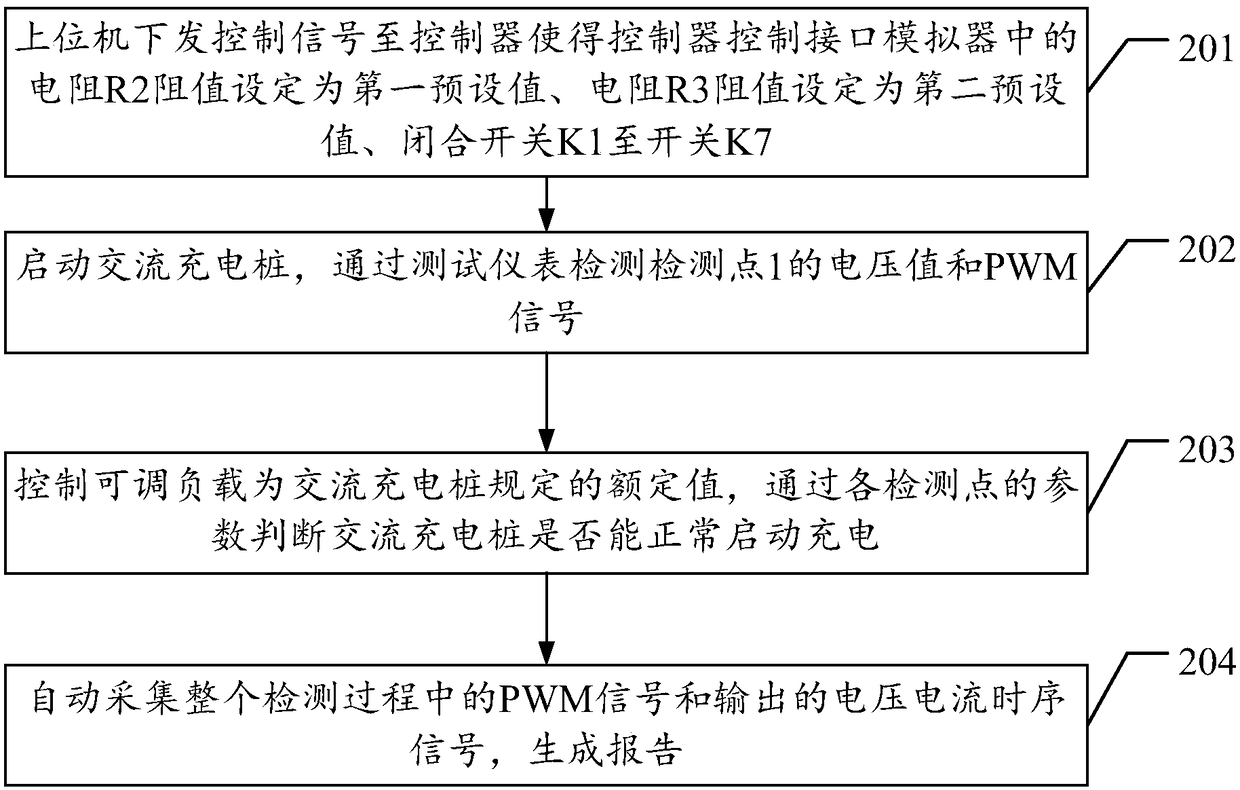

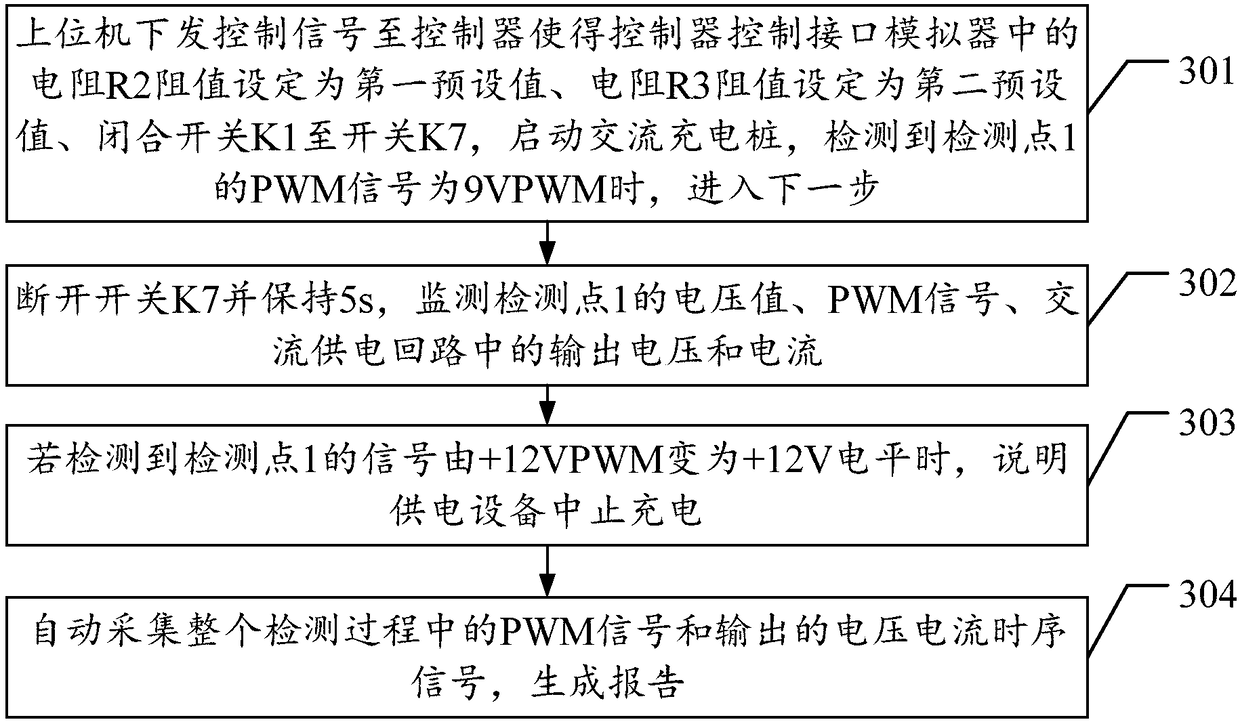

AC charging pile interoperability detection system and method

InactiveCN108181530AEasy to detectThe detection is convenient and fast according to the software set in the host computerPower supply testingElectrical resistance and conductanceEngineering

The invention provides an AC charging pile interoperability detection system and method. The system comprises an interface simulator, an adjustable load, a test instrument, a controller and an upper computer. The interface simulator is connected with an AC charging pile required to be detected. The test instrument is connected with the AC charging pile and the interface simulator. The adjustable load is connected with the interface simulator. The controller is connected with the interface simulator and used for controlling switch closing or separating of the interface simulator and adjusting the size of resistance. The test instrument, the adjustable load and the controller are connected with the upper computer. The switch and the size of the resistance can be automatically adjusted to control guide circuit parameters by controlling closing or separating of the circuit controller parameter adjustment switch of the interface simulator and adjusting the size of the resistance without manual adjustment, and the AC charging pile can be conveniently and rapidly detected according to the software set in the upper computer so that the technical problem of lack of the convenient detectionequipment and method for automatic and rapid detection of the AC charging pile at present can be solved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

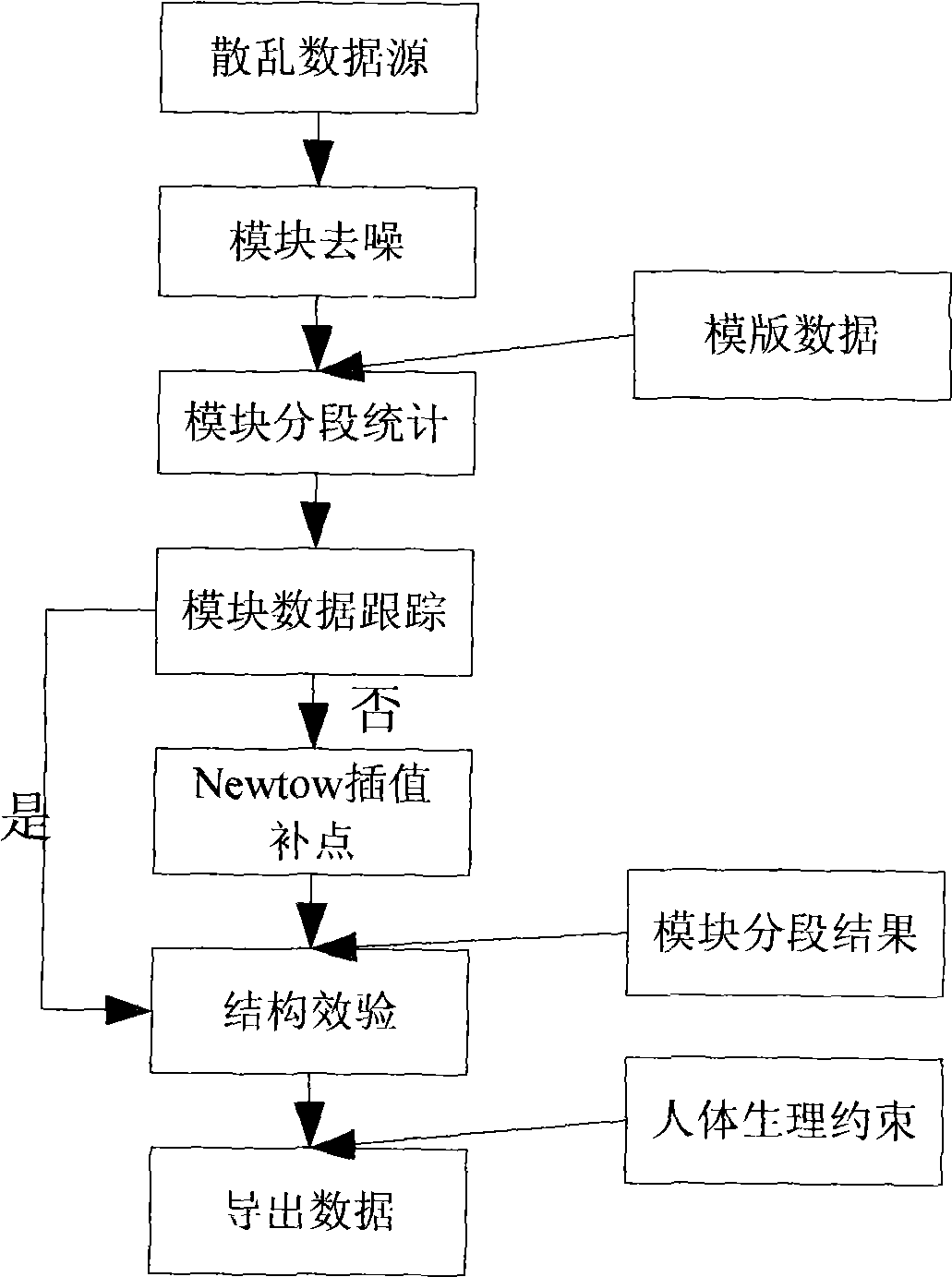

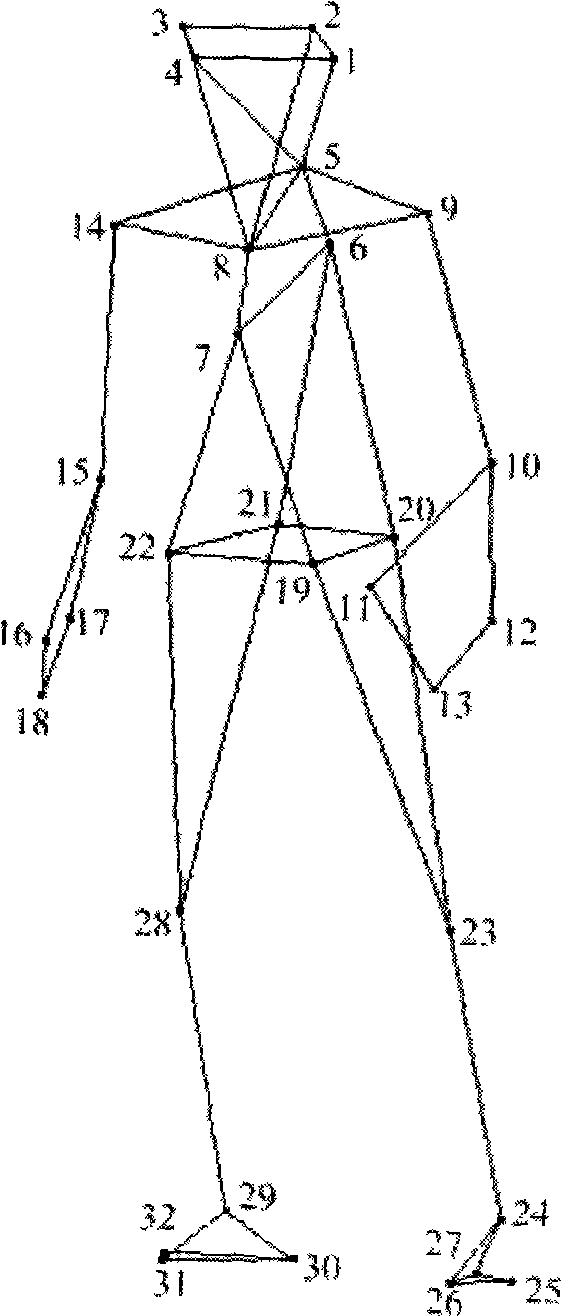

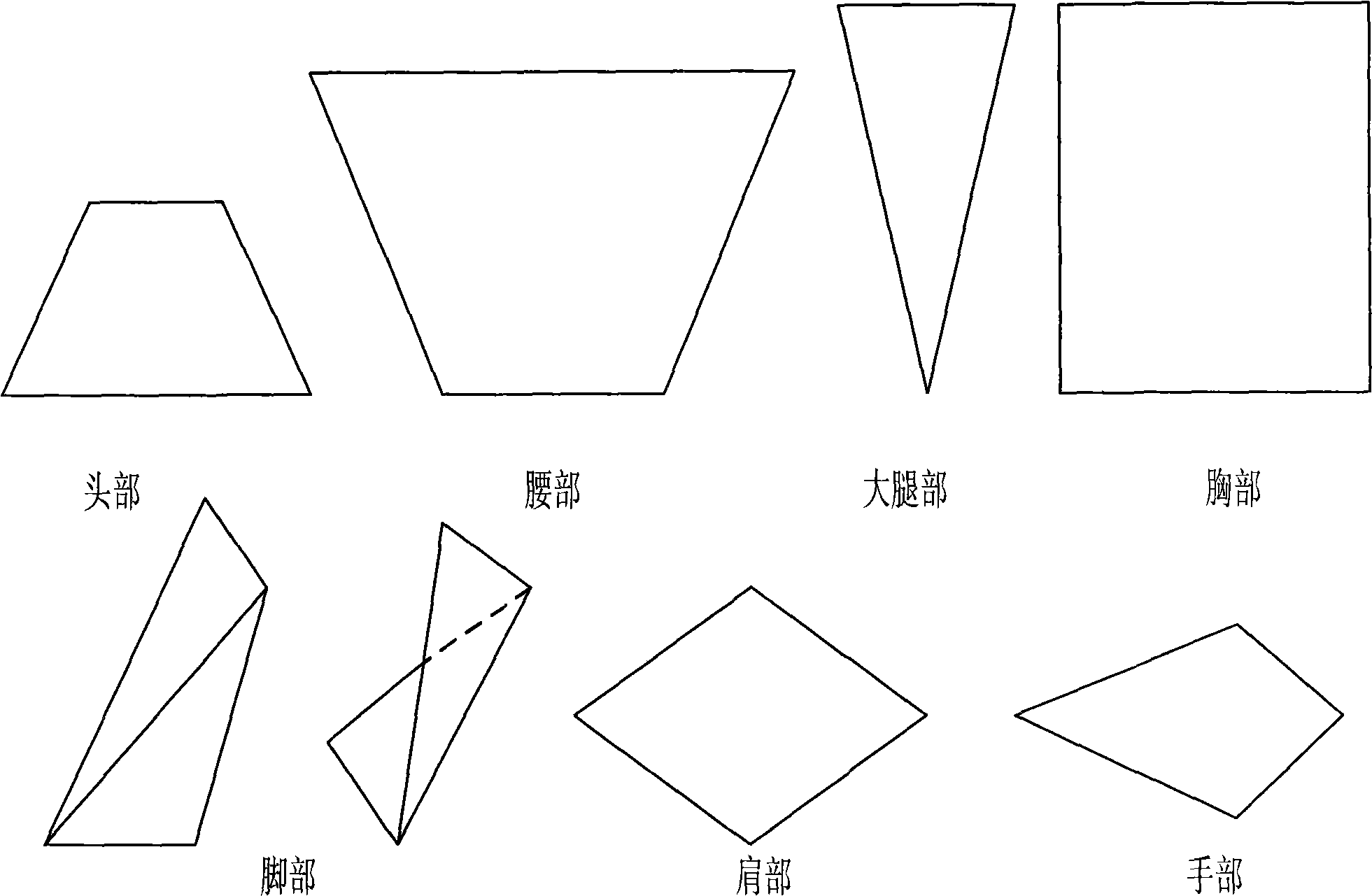

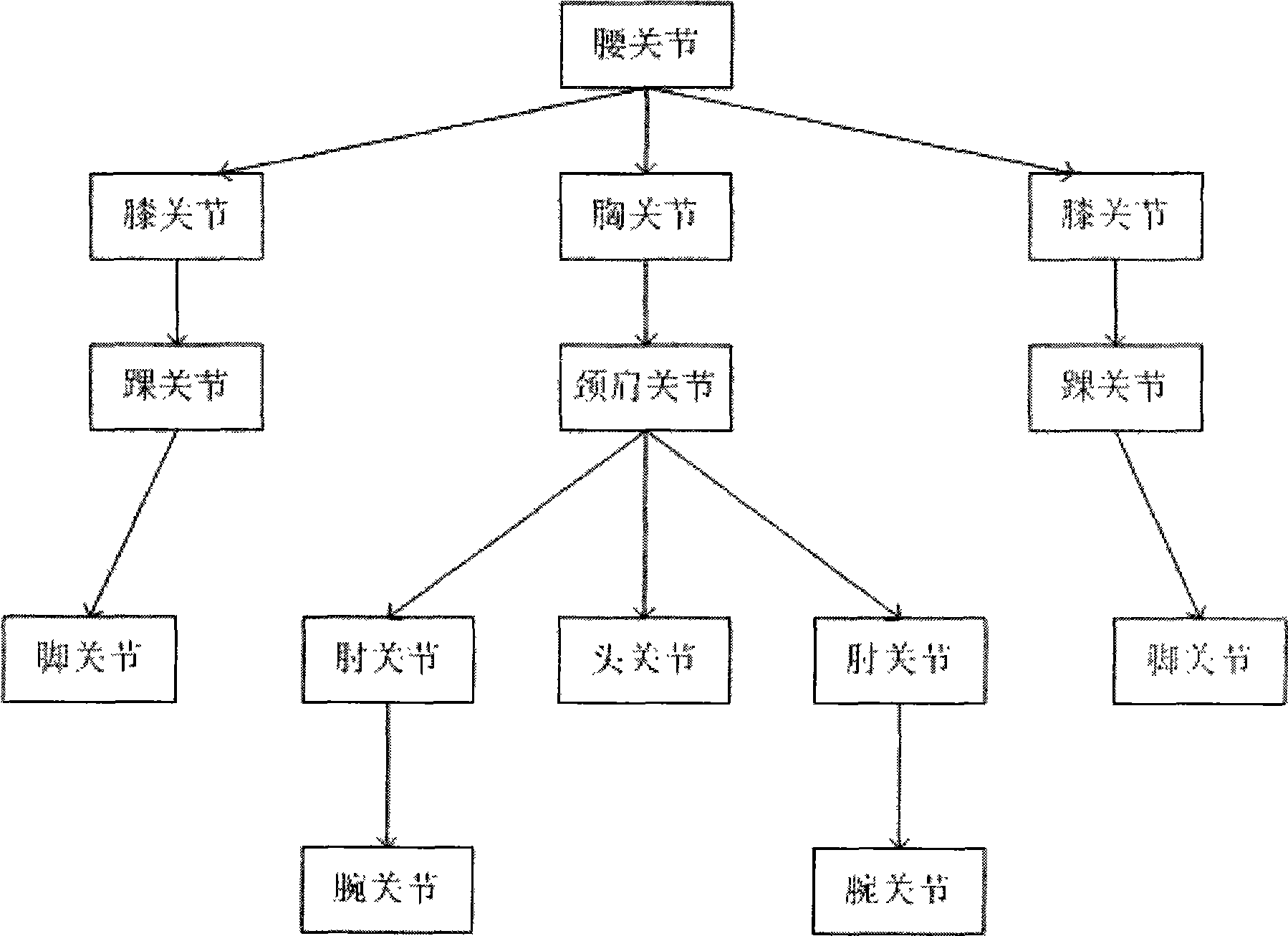

Optical motion capture data processing method based on module piecewise linear model

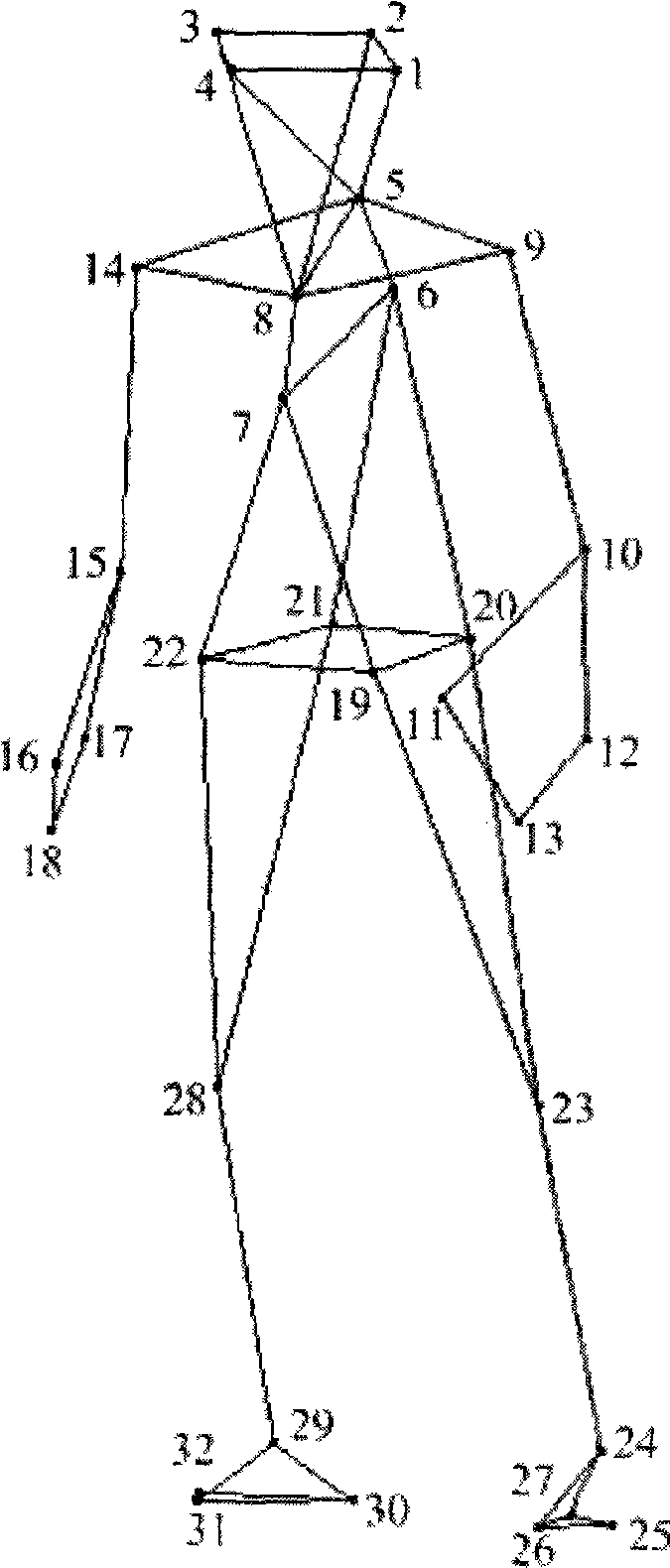

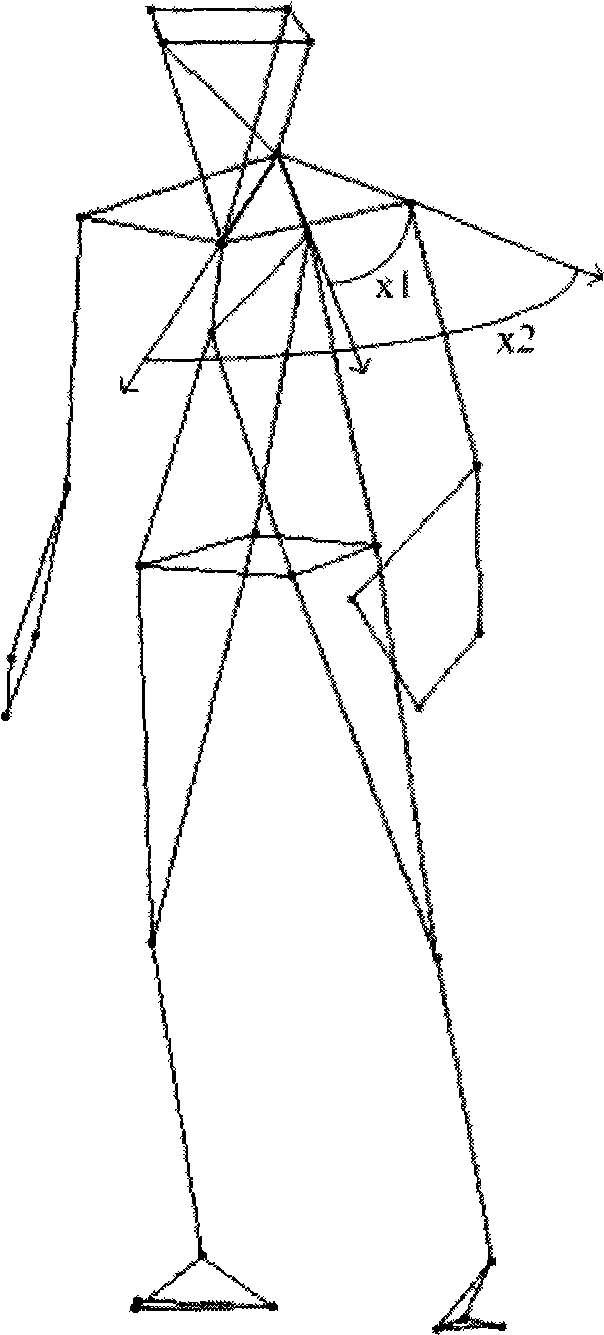

ActiveCN101533528AAchieve automatic processingReduce matching error3D modellingPattern recognitionHuman motion

The invention discloses an optical motion capture data processing method based on a module piecewise linear model. Based on overall information of optical human motion capture scattered data, a data processing algorithm based on the module piecewise linear model is provided. By using the module piecewise linear model to generalize the change characteristics of different modules, the method determines a matching priority and an intra-segment fitting function of module data, effectively performs overall layered prediction and tracking for each three-dimensional motion data module, performs de-noising processing for the noise data based on the module, and provides an interpolation fitting algorithm for the missing motion data based on segmenting Newton to perform reasonable supply. The optimized method does not need manual intervention during processing, and can meet real-time requirement.

Owner:DALIAN UNIV

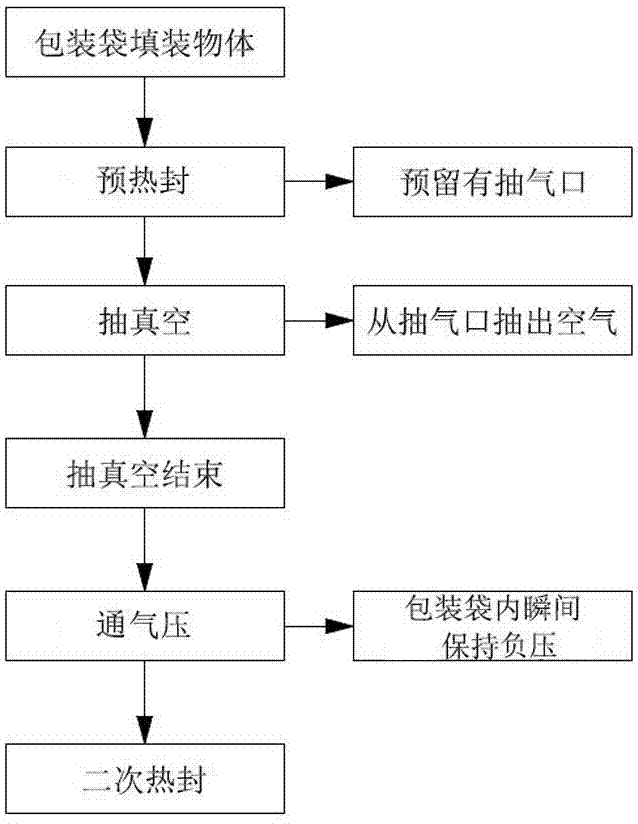

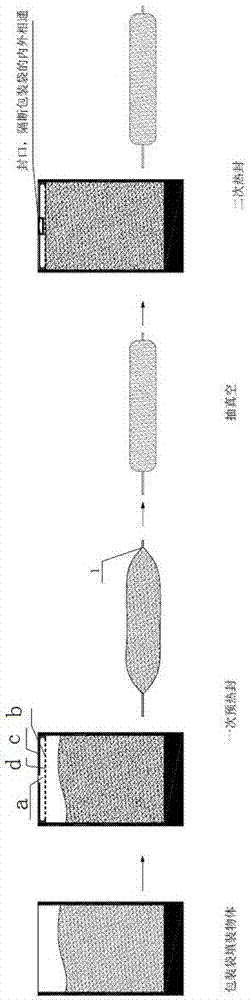

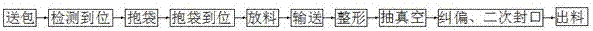

Vacuum packing method, vacuum packing treatment device and treatment method of vacuum packing treatment device

ActiveCN107878846AImprove stabilityIncrease success ratePackaging under vacuum/special atmosphereWrapper twisting/gatheringEngineeringWaiting time

The invention relates to a vacuum packing method, a vacuum packing treatment device and a treatment method of the vacuum packing treatment device. The vacuum packing treatment device comprises a shaping mechanism for a shaping station and a vacuumizing mechanism for a vacuumizing station, and the shaping mechanism comprises a shaping mechanism lifting air cylinder, a shaping mechanism mounting plate, an upper shaping plate connecting plate and a shaping plate. The shaping mechanism lifting air cylinder is mounted on the shaping mechanism mounting plate, the movable end of the shaping mechanismlifting air cylinder is hinged to the upper shaping plate connecting plate, and a balancing guiding shaft is arranged between the shaping mechanism mounting plate and the upper shaping plate connecting plate. The upper shaping plate connecting plate is connected with the shaping plate through an elastic cushion block, and a vibrating air cylinder is arranged on the shaping plate. According to thevacuum packing method, the vacuum packing treatment device and the treatment method of the vacuum packing treatment device, secondary hot sealing and vacuum packing are ingeniously combined, the stability is improved, the success rate is increased, and the traditional waiting time is shortened; and the shaping mechanism and the vacuumizing mechanism can be separately arranged so as to improve thepacking efficiency, flatness and beauty, and the structure is stable and reliable.

Owner:ZHANGZHOU JIALONG TECH INC

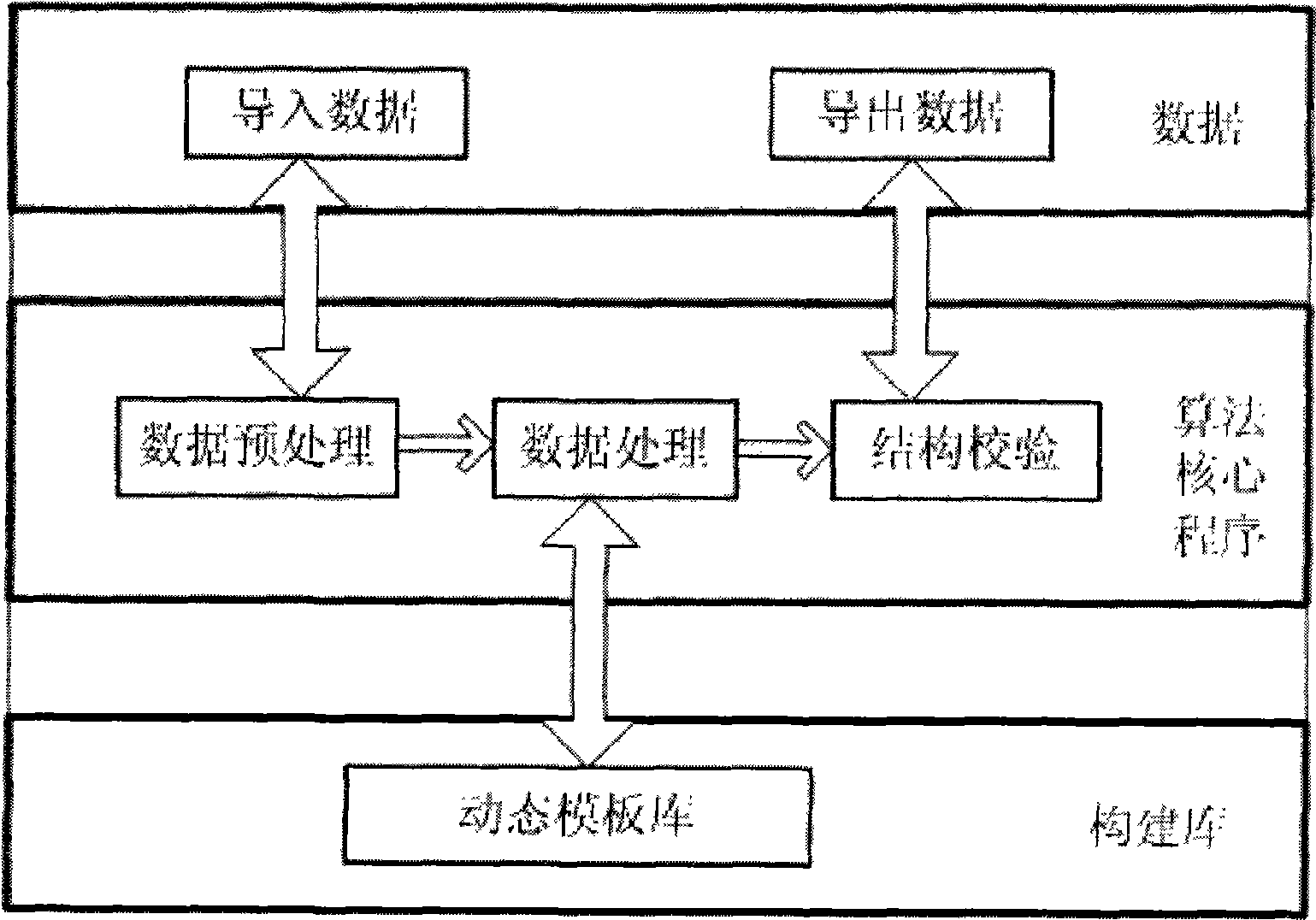

Optical motion capture data processing method based on dynamic template

ActiveCN101533526AAchieve automatic processingEliminate errors3D modellingMotion captureComputer science

The invention discloses an optical motion capture data processing method based on a dynamic template. By establishing a motion characteristic database, an improved optical motion capture data processing method based on a rigid body is provided; and the method stresses on solving the problem that the rigid body structure is damaged during motion, and establishes a dynamic matched template through the motion characteristic database so as to effectively solve the problems of mismatching and error accumulation because the prior rigid body matching only uses a unique match template. By using the information retrieval of the motion characteristic database, the method automatically adjusts length error parameters of each rigid body during tracking and matching, and automatically finishes without manual intervention during processing; and single-frame data processing time consumption meets the real-time requirement of motion capture.

Owner:DALIAN UNIV

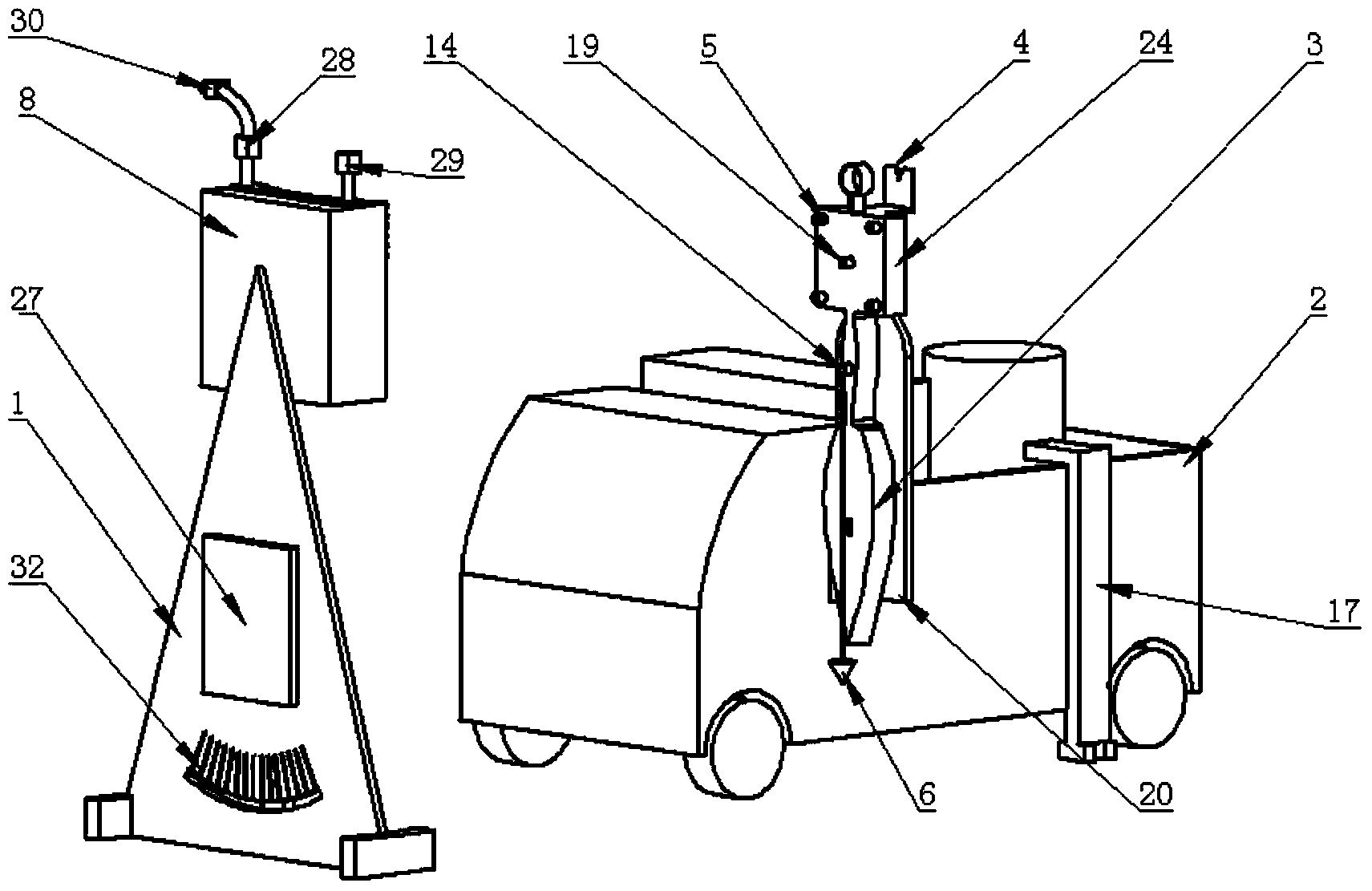

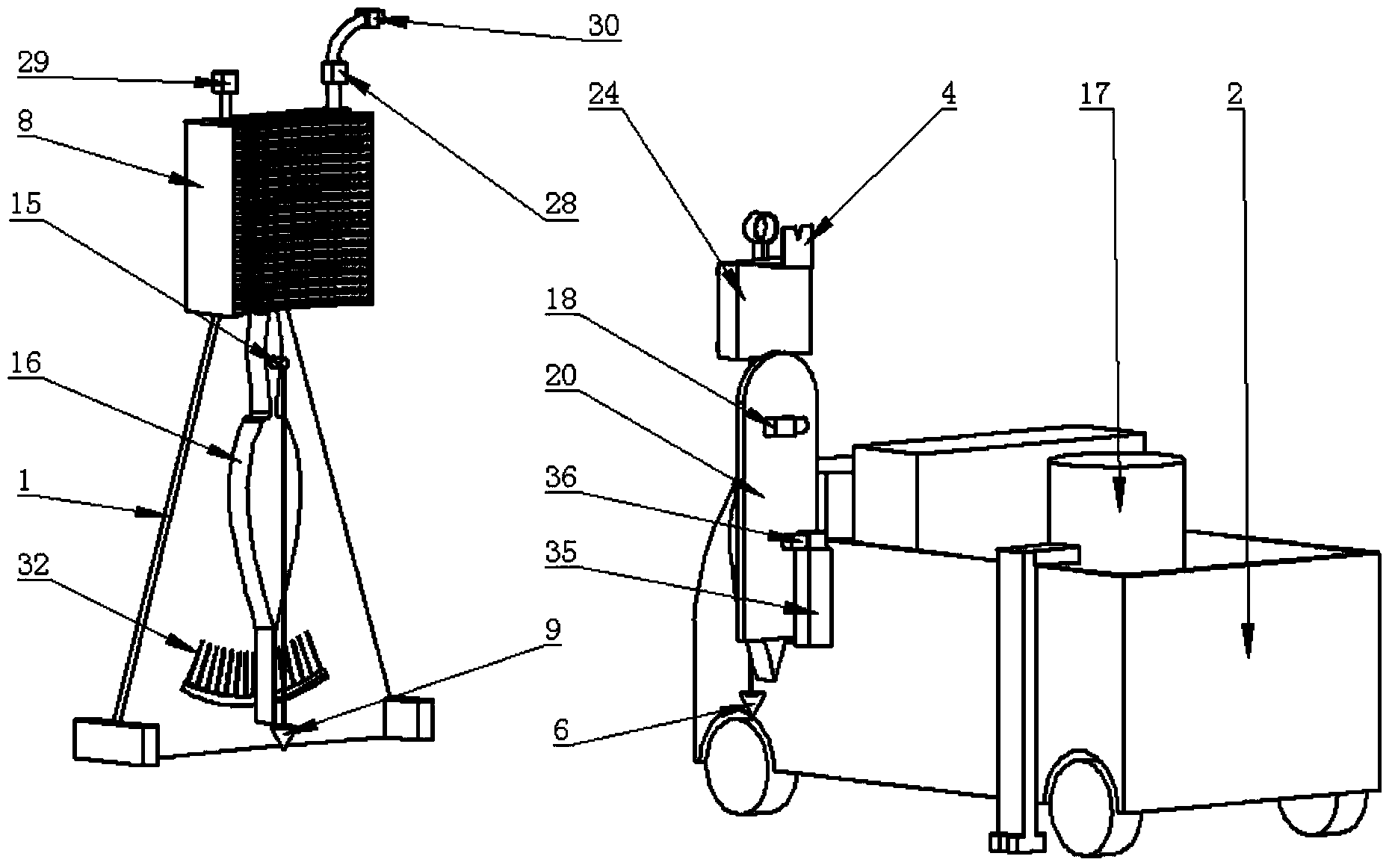

Intelligent marking-out system for traffic marker line

InactiveCN103452034AAvoid interferenceAvoid exposureRoads maintainencePosition/course control in two dimensionsLaser transmitterIn vehicle

The invention relates to the technical field of traffic construction equipment and particularly relates to a marking-out system. An intelligent marking-out system for a traffic marker line comprises a movable vehicle body, wherein a marking-out device is placed on the movable vehicle body; the intelligent marking-out system further comprises a reference bracket; the reference bracket is provided with a guide frame and an auxiliary control module; a photosensitive element array is arranged on the surface of the guide frame; the movable vehicle body is provided with a vehicle-mounted bracket; the vehicle-mounted bracket is provided with a main laser transmitting device and a main control module; a transmitting end of the main laser transmitting device is arranged towards a receiving end of the photosensitive element array. A direction adjusting mechanism is arranged on the movable vehicle body. The main control module is connected with a control end of the main laser transmitting device and the direction adjusting mechanism respectively. The auxiliary control module is connected with a signal output end of a photosensitive element. The main control module is in signal connection with the auxiliary control module. With the adoption of the technical scheme, the function of automatically adjusting the direction is realized in the marking-out process; manual adjustment is not needed and the whole marking-out process is simple and convenient; the marking-out precision is high.

Owner:SHANDONG UNIV OF TECH

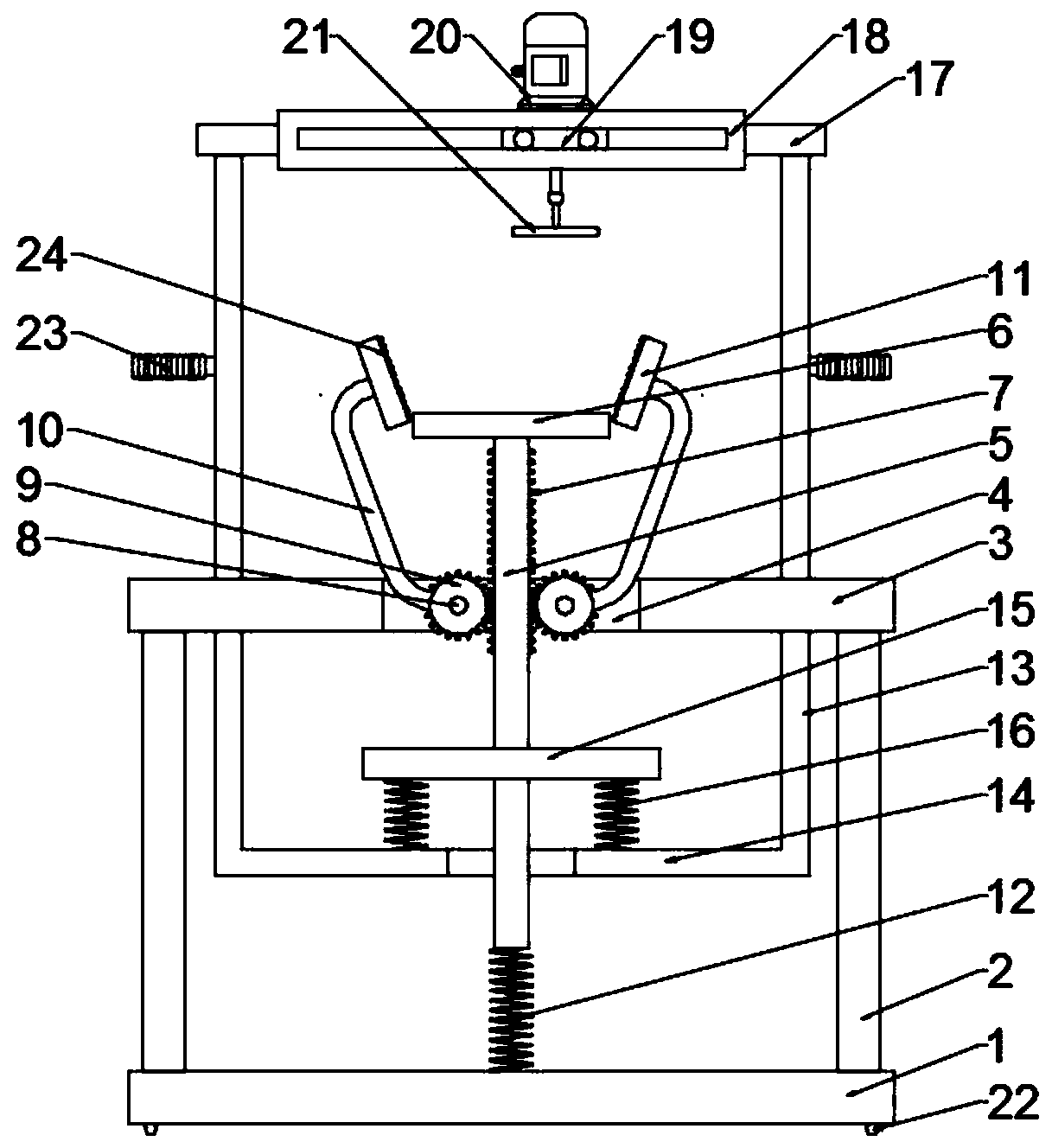

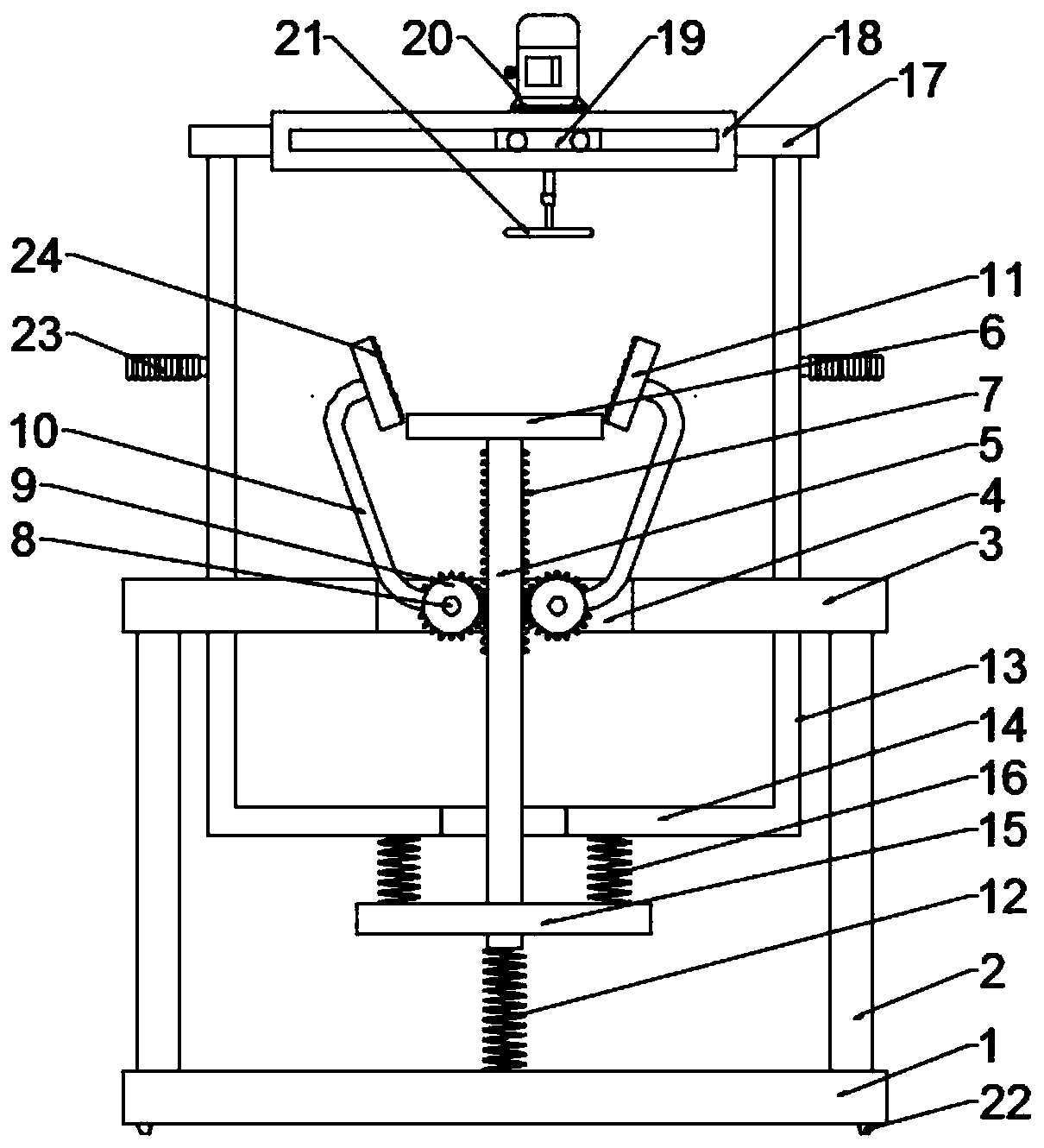

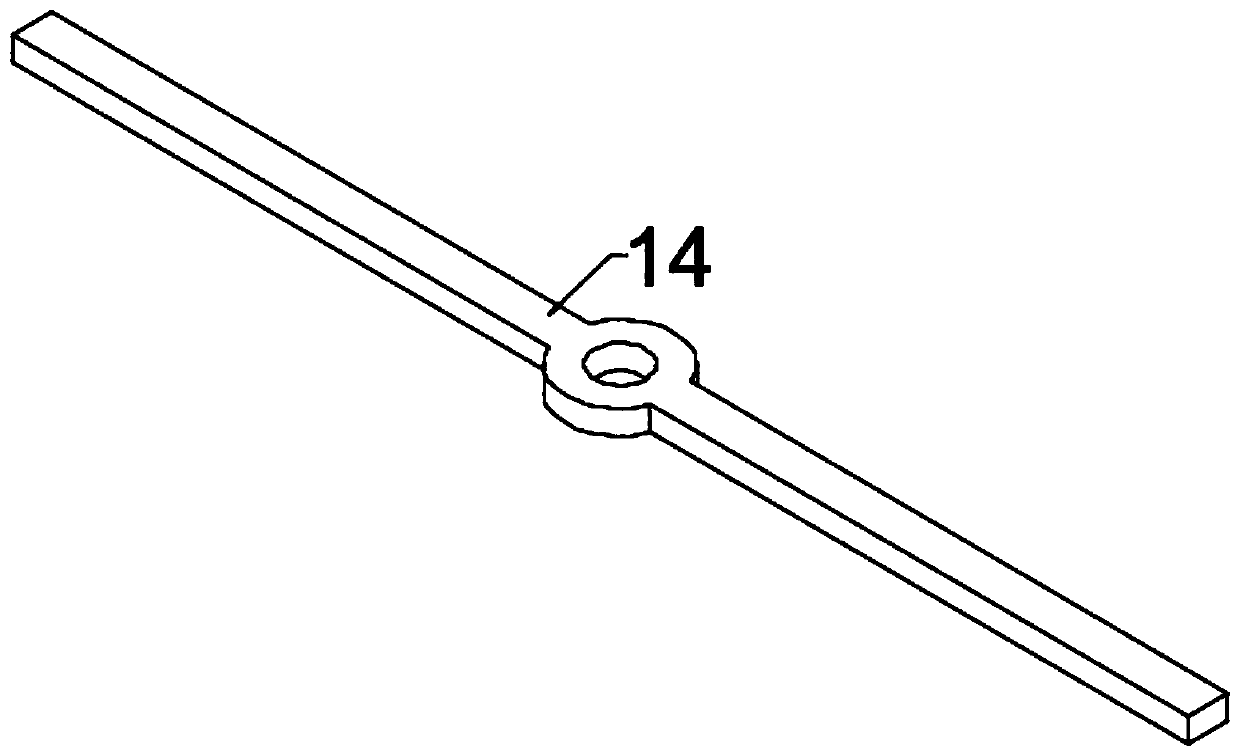

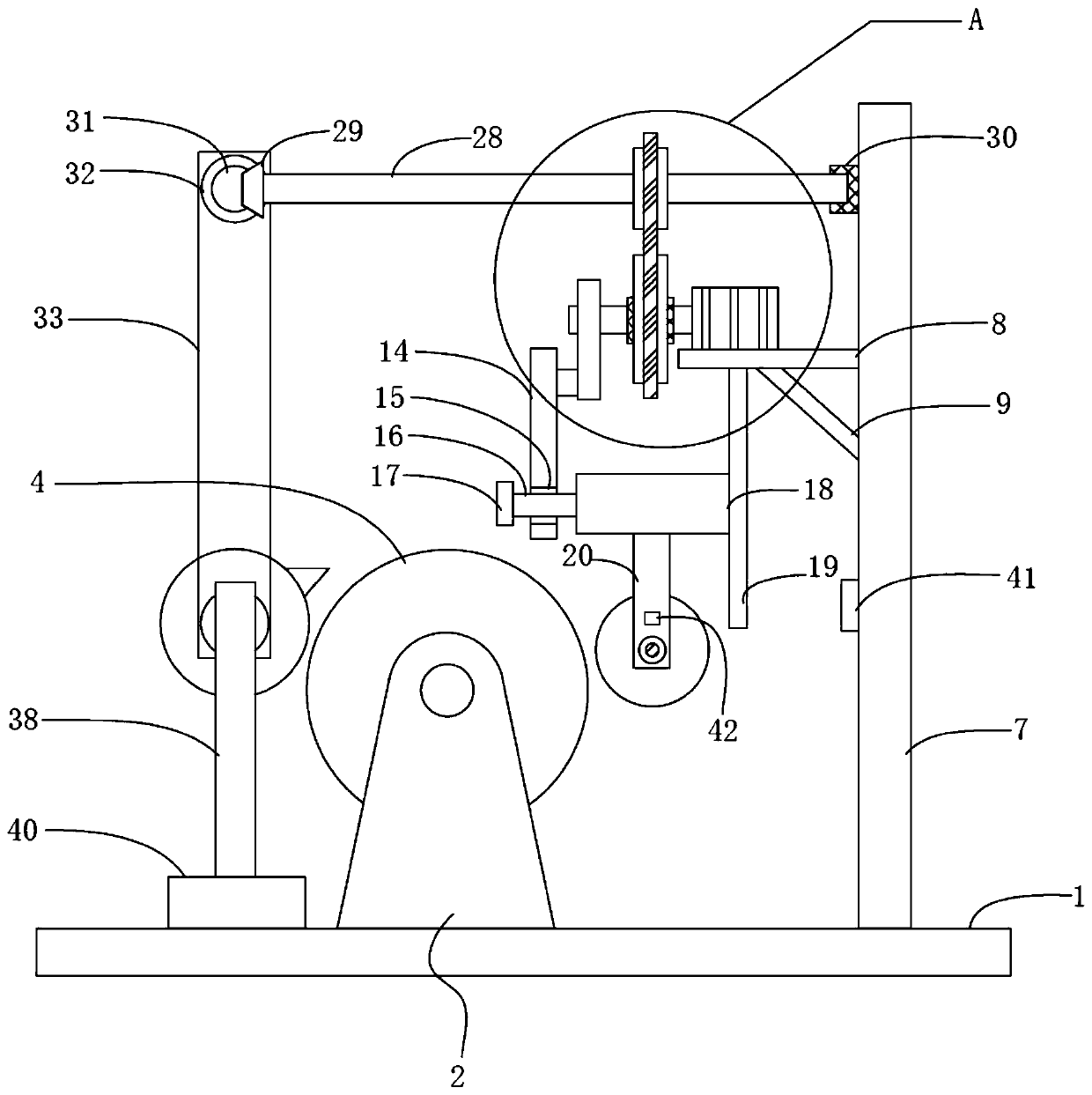

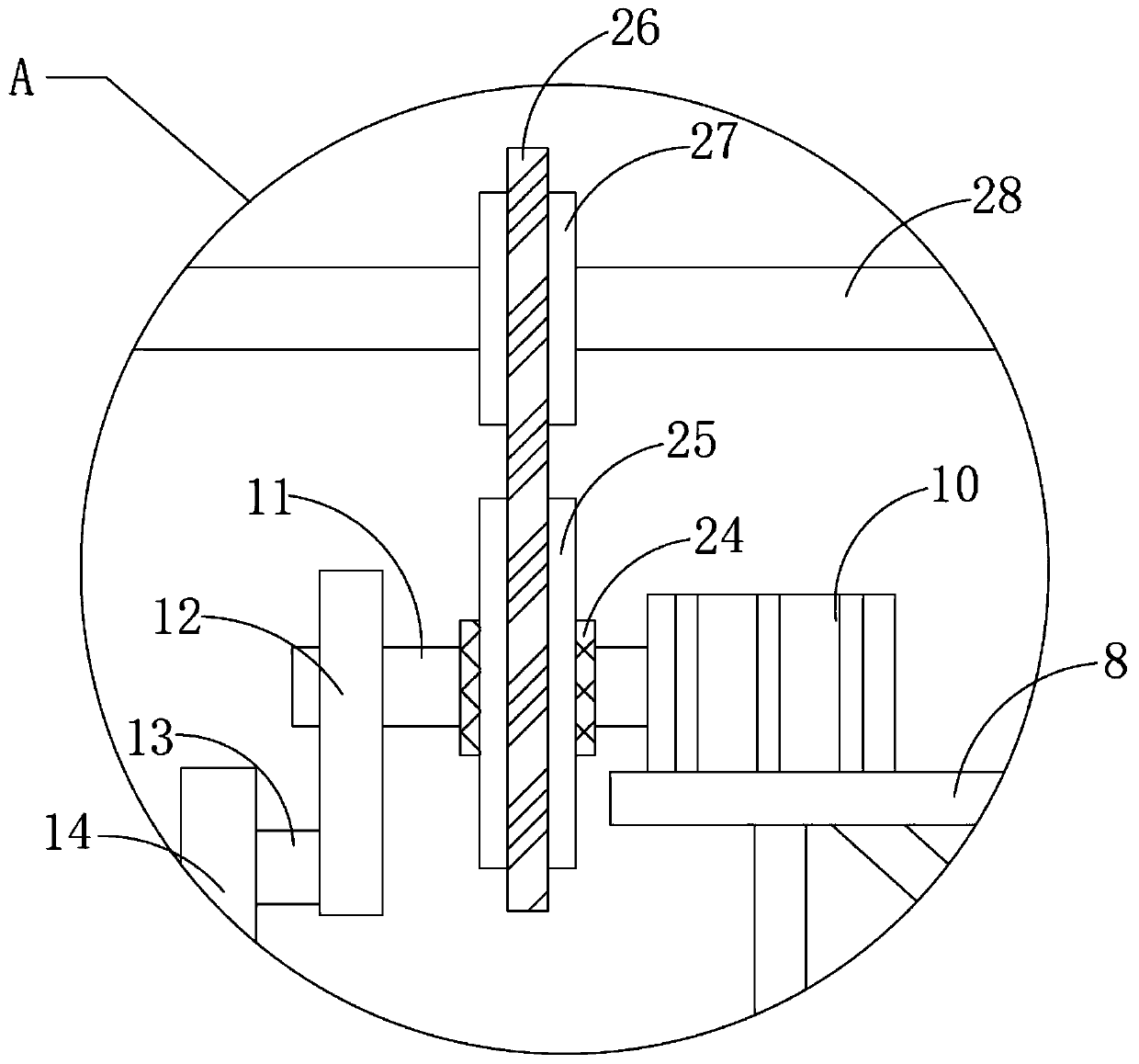

Polishing device for mold machining

The invention discloses a polishing device for mold machining and relates to a polishing device. The polishing device comprises a fixed bottom plate; supporting stand columns are fixedly connected tothe upper portion of the fixed bottom plate in a bilateral symmetry mode. An upper table board is fixedly connected above the supporting stand columns; a through groove is formed in the middle of theupper table board; longitudinal sliding rods are slidably connected to the inner sides of the through grooves; a supporting bottom plate is fixedly connected to the top of the longitudinal sliding rod, transmission teeth are fixedly connected to the two sides of the longitudinal sliding rod, two fixing shafts located in the through grooves are fixedly connected to the upper table top in a bilateral symmetry mode, driven gears are rotationally connected to the outer sides of the fixing shafts and engaged with the transmission teeth, and connecting swing rods are fixedly connected to the outer sides of the driven gears. The polishing device is simple in structure and convenient to use, a grinding tool needing to be ground is directly placed above the supporting bottom plate of the device inthe using process, then the motor is driven downwards to move downwards, grinding can be achieved, the device can automatically position and clamp the mold, manual adjustment is not needed, and therefore the grinding efficiency is effectively improved.

Owner:HUANGHUA RONGTAI MOLD

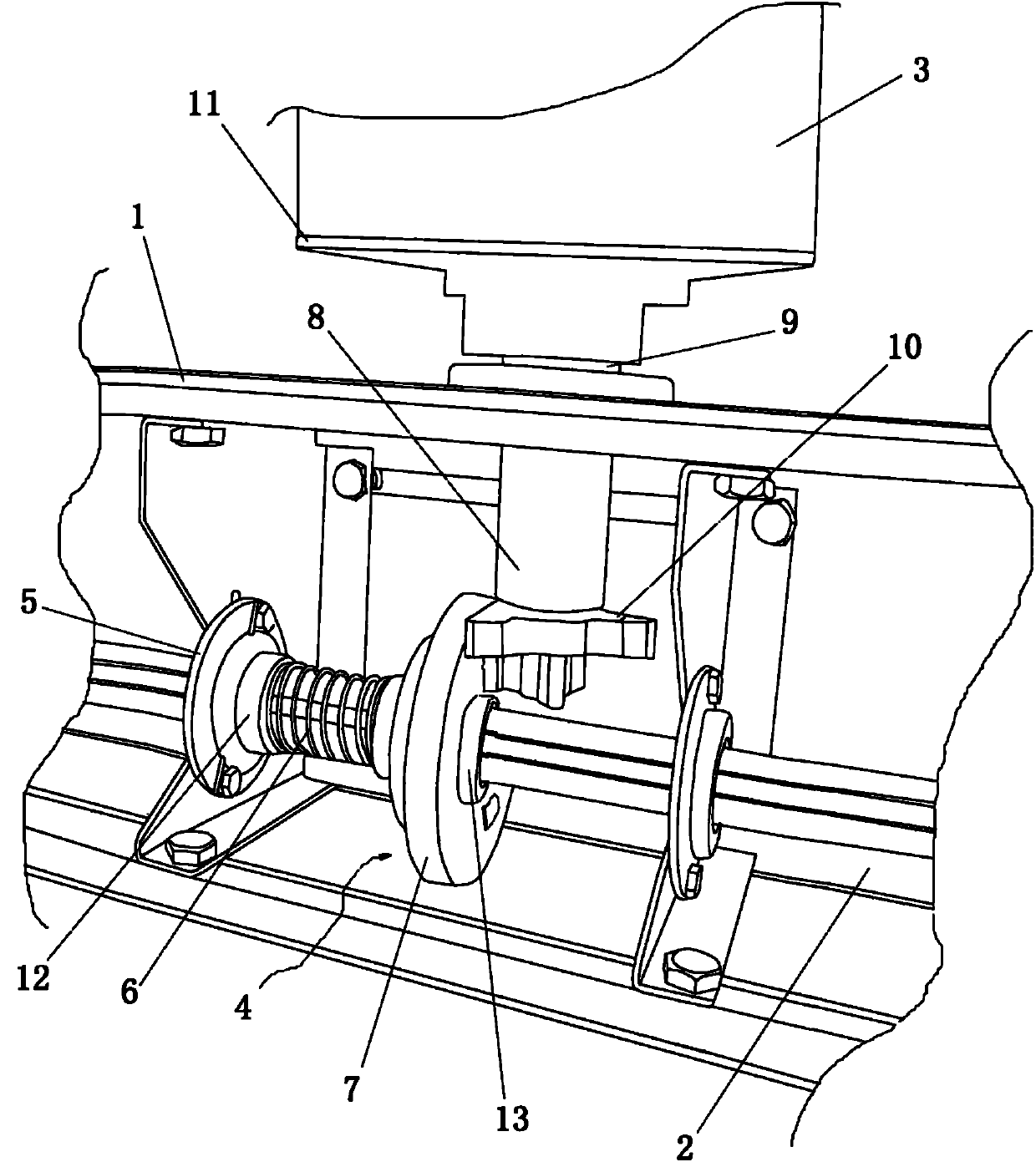

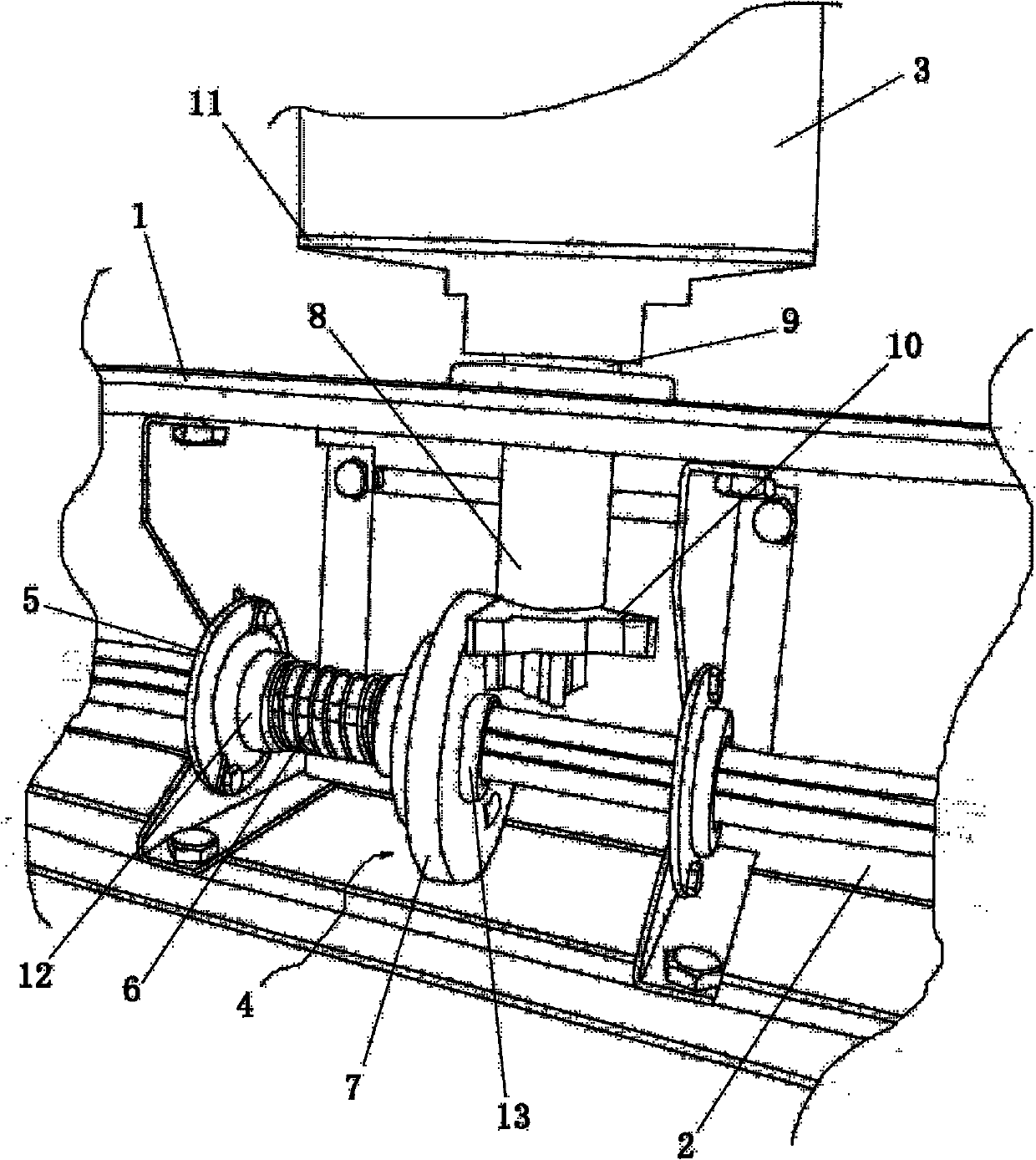

Turnover type billboard transmission mechanism

The invention discloses a turnover type billboard transmission mechanism, which comprises a shell and a transmission main shaft which is transversely arranged in the shell, wherein a plurality of transmission devices for driving a billboard triangular prism to turn over are arranged in the shell at intervals; each transmission device consists of a compression spring seat, a compression spring, a cam, a fixed seat, a transmission rod, a small triangular transmission plate and a large triangular connecting plate; the compression spring seat, the compression spring and the cam are sleeved on the transmission main shaft; the fixed seat is arranged on the shell; the transmission rod is arranged in the fixed seat; the small triangular transmission plate is arranged at the lower end of the transmission rod; the large triangular connecting plate is arranged at the upper end of the transmission rod; the small triangular transmission plate is in transmission connection with the cam; the large triangular connecting plate is fixedly connected with the lower end of the billboard triangular prism; and one end of the compression spring is in elastic contact with the cam, and the other end of the compression spring is in elastic contact with the compression spring seat. The cam can be automatically withdrawn and restored; wear of the transmission mechanism is effectively reduced; load of a motor is reduced; rupture of the lower end of the fixed seat and the transmission main shaft can be avoided; assembly and maintenance are facilitated; and billboard running efficiency can be effectively increased.

Owner:东莞市兴煌电子科技有限公司

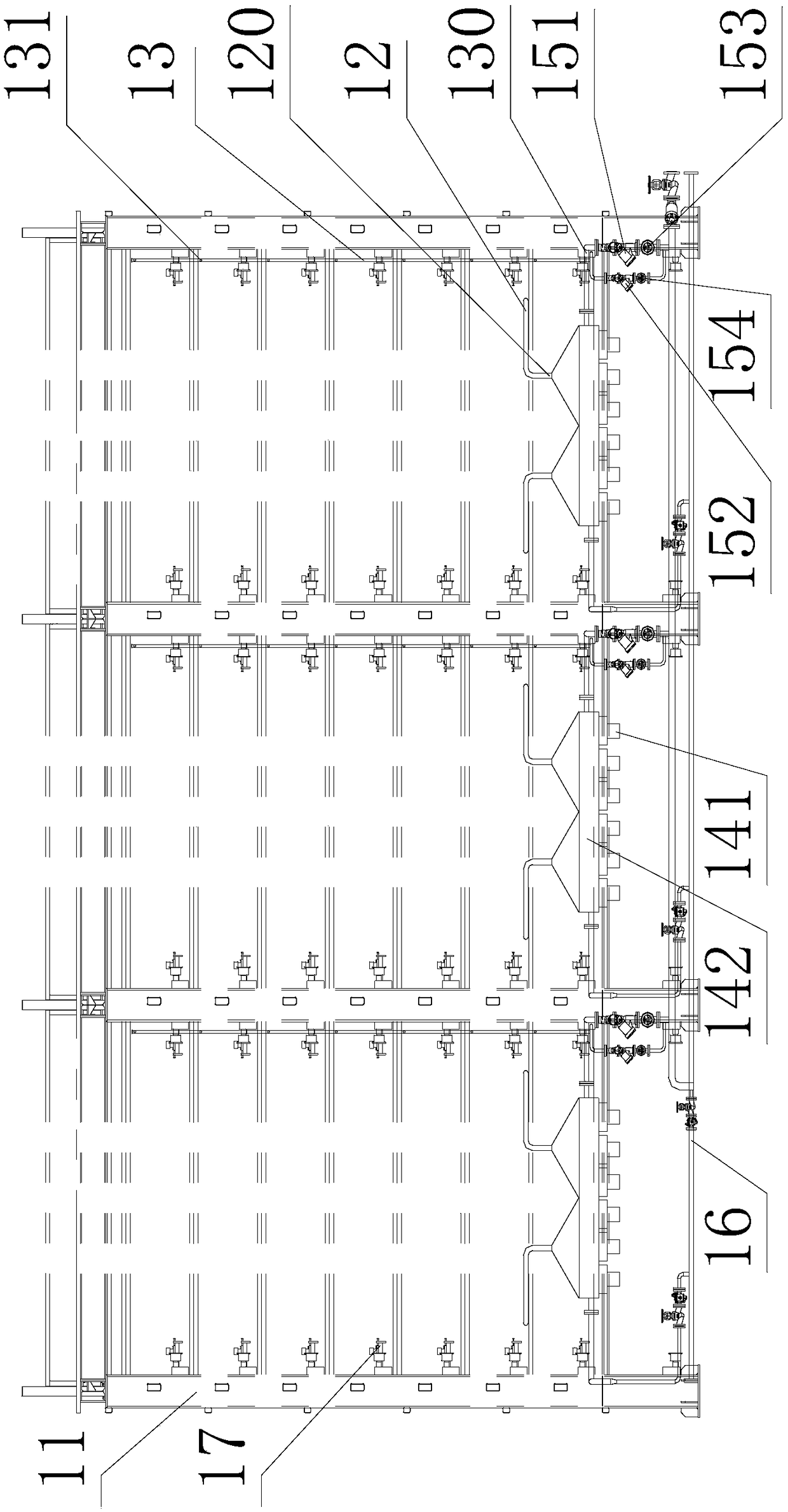

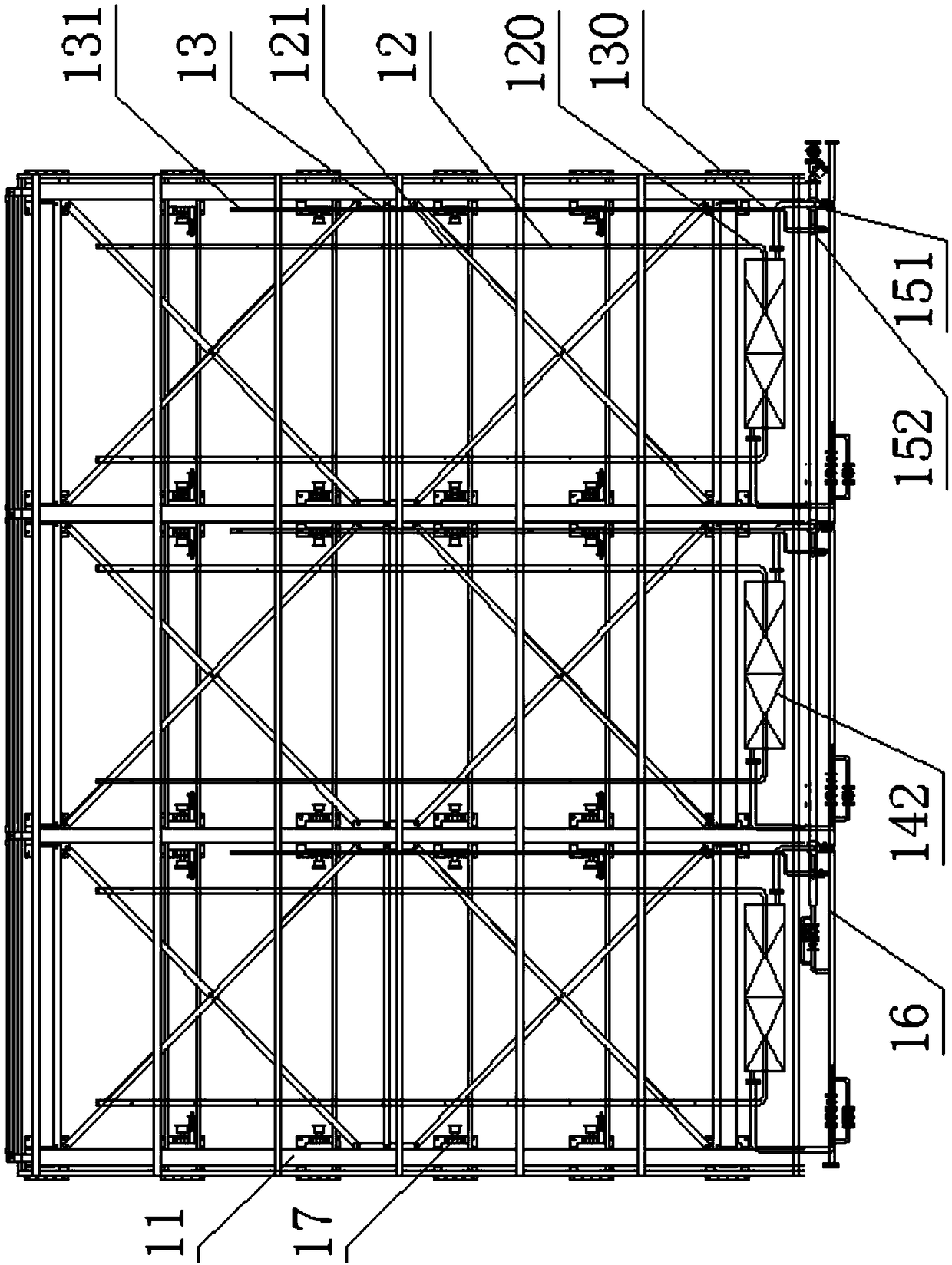

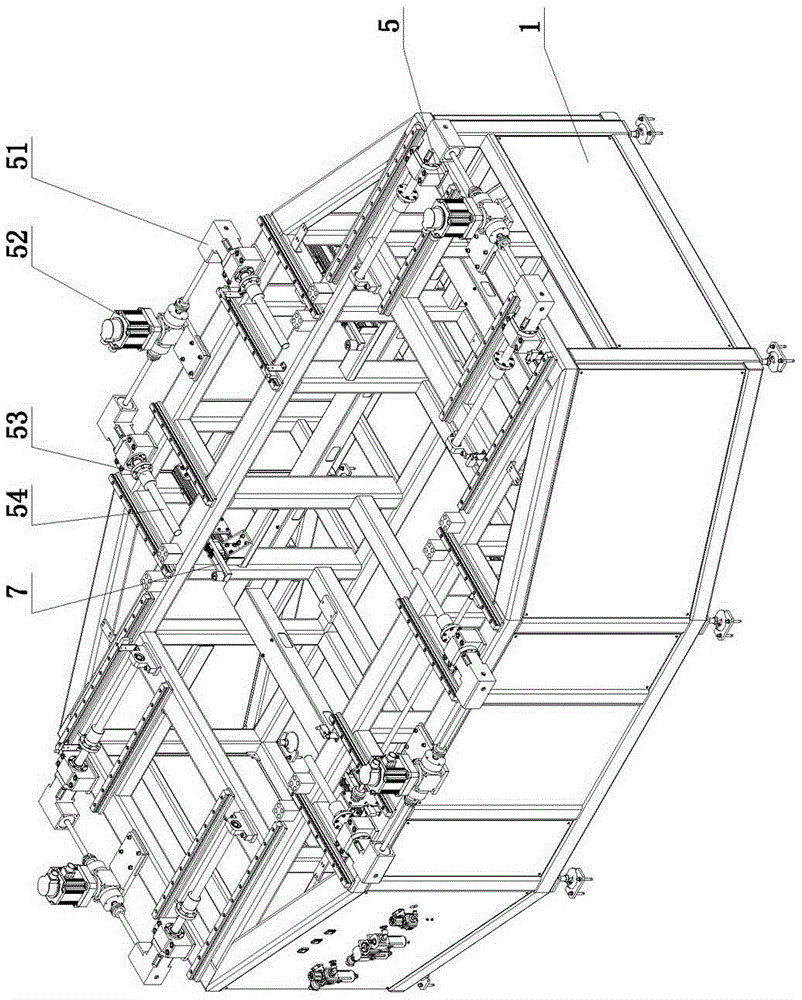

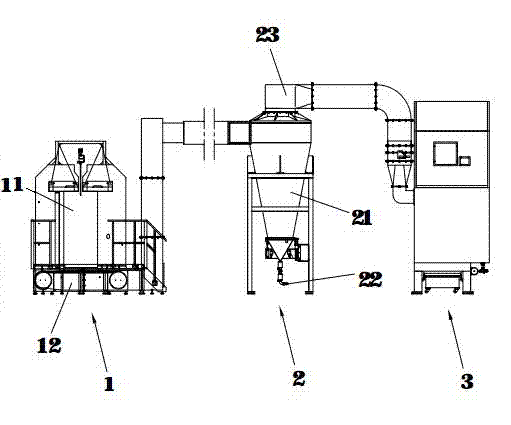

Curing kiln

InactiveCN109176855AImprove maintenance effectEasy to operateCeramic shaping apparatusKilnElectrical and Electronics engineering

The invention discloses a curing kiln. The curing kiln comprises a curling chamber. Supports for containing to-be-cured products, heating pipelines and humidifying pipelines are arranged in the curingchamber. At least two layers of supports are arranged in the height direction, at least two rows of supports are arranged in the width direction, and the adjacent layers or the adjacent rows communicate in space. At least one heating pipeline is arranged in each row of the supports, the heating pipelines are horizontally arranged, and the lengths of the heating pipelines penetrate through the whole length of each row. At least one humidifying pipeline is arranged in each row of the supports, the humidifying pipelines are vertically arranged, and the heights of the humidifying pipelines penetrate through the whole height of each row. The curing kiln is good in curing effect and convenient to operate.

Owner:长沙英平机械制造有限责任公司

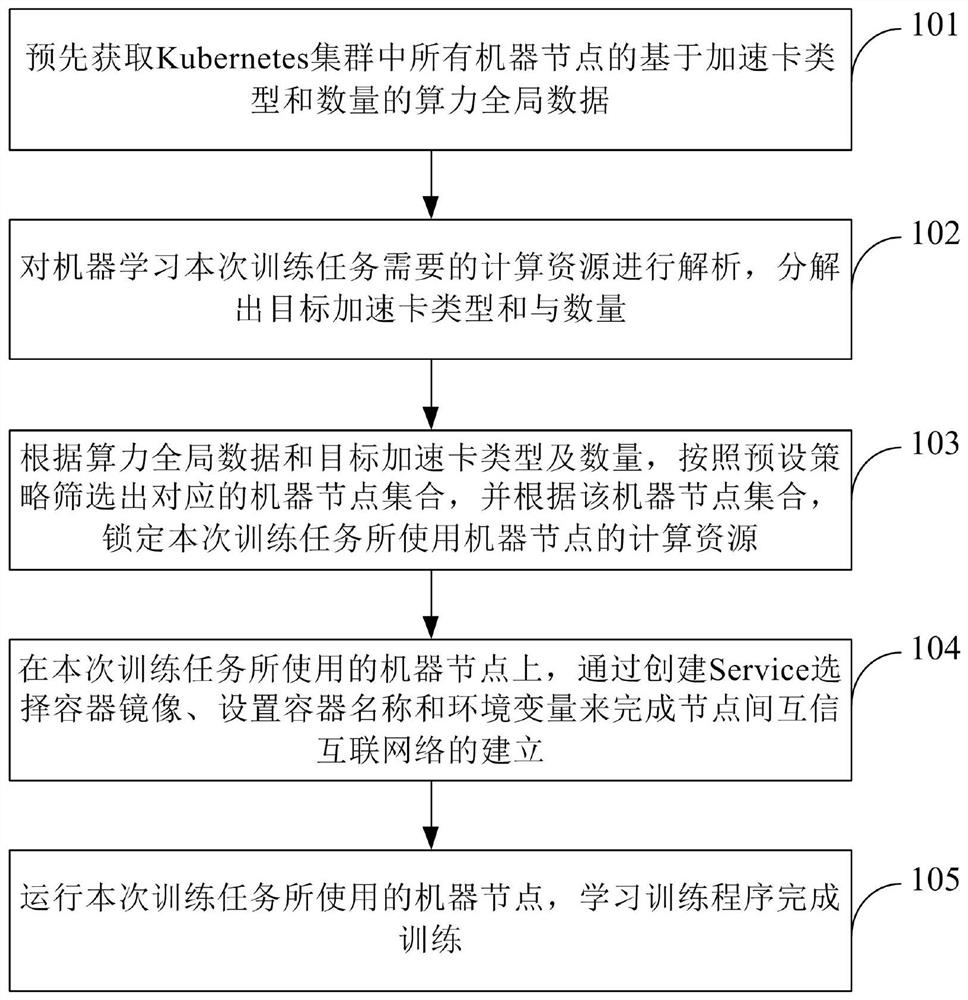

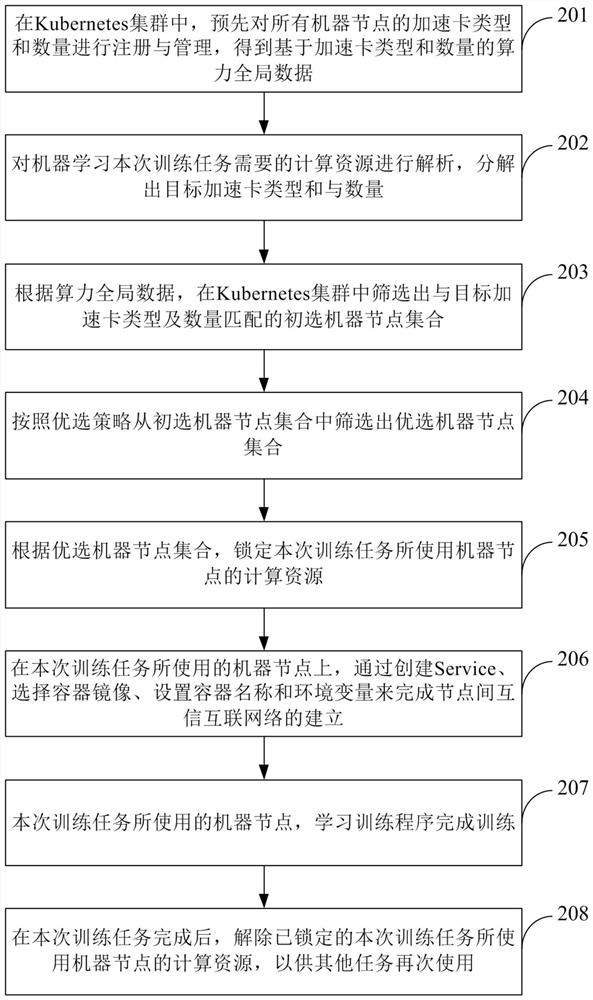

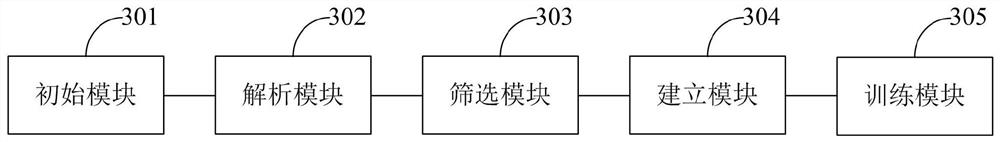

Computing power scheduling method and device based on Kubernetes

PendingCN112241321ARealize intelligent distributionIncrease automation and efficiencyResource allocationMachine learningNetwork onComputational resource

The invention discloses a computing power scheduling method and device based on Kubernetes, and relates to the field of artificial intelligence. The method comprises the following steps: analyzing computing resources required by a machine learning current training task to decompose the type and quantity of a target accelerator card, screening out a corresponding machine node set according to a preset strategy in combination with computing power global data of all machine nodes in a Kubernetes cluster, and locking the computing resources of the machine nodes used by the current training task according to the corresponding machine node set, and establishing an inter-node mutual trust interconnection network on the machine nodes used by the training task, running the machine nodes used by thetraining task, and learning a training program to complete training. The device comprises an initial module, an analysis module, a screening module, an establishment module and a training module. According to the invention, intelligent distribution of resources is achieved, manual adjustment is not needed, and the efficiency is greatly improved.

Owner:BEIJING YINGPU TECH CO LTD

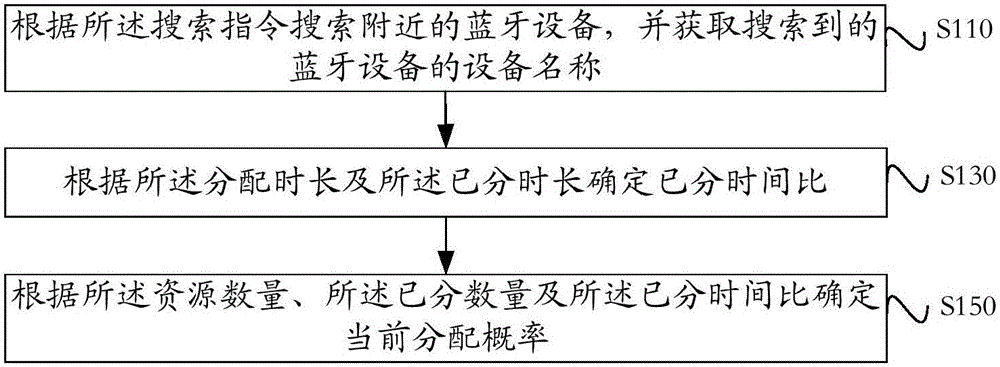

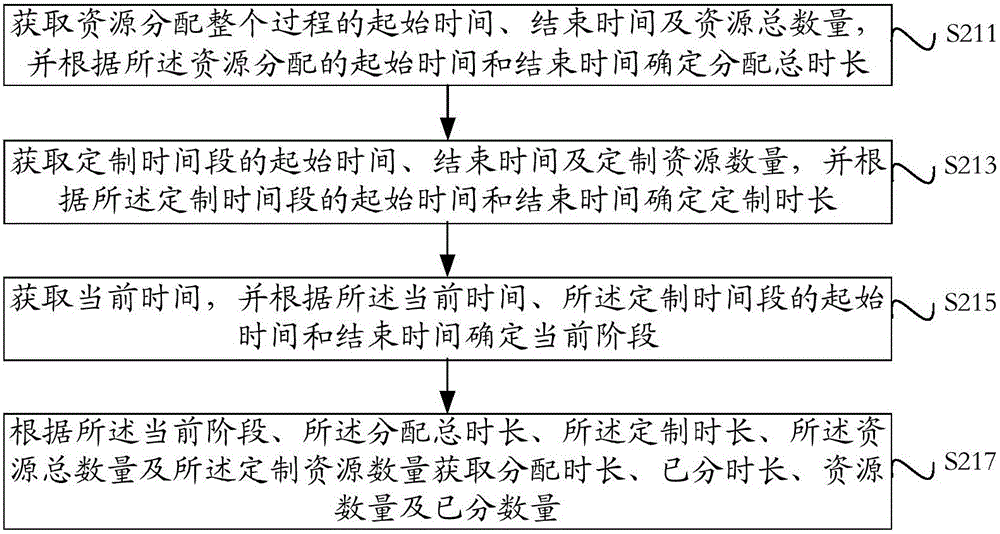

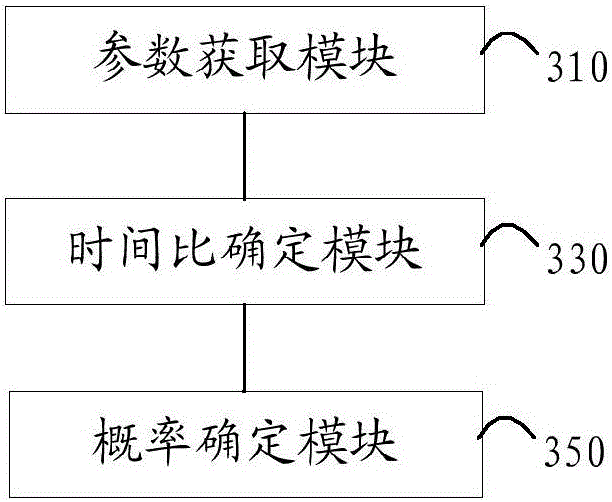

Probability adjusting method and probability adjusting device for resource allocation

InactiveCN105894338ATo achieve the purpose of adaptive adjustmentNo manual adjustmentDiscounts/incentivesMarket data gatheringTime ratioSelf adaptive

The invention provides a probability adjusting method for resource allocation. The probability adjusting method comprises the following steps of acquiring allocation duration and allocated duration of resource allocation, and acquiring the resource quantity and the allocated quantity of the resource allocation; determining the allocated time ratio according to the allocation duration and the allocated duration; determining the current allocation probability according to the resource quantity, the allocated quantity and the allocated time ratio, wherein the current allocation probability is allocation probability for allocating resources at current, and the resources are awards or rewards; as the allocated duration and the allocated quantity change along with the operation time of the resource allocation, the current allocation probability obtained by using the probability adjusting method for the resource allocation is accordingly changed. Therefore, the aim of self-adaptive adjustment can be achieved by using the probability adjusting method for the resource allocation. Meanwhile, according to the probability adjusting method for the resource allocation, no manual adjustment is needed, and human interference is reduced, so that the justice and equity of activities are guaranteed; in addition, the phenomenon that the probability of resource allocation is adjusted by artificially monitoring the resource allocation conditions in real is avoided, so that labor force is greatly saved.

Owner:ZHUHAI POWER SUPPLY BUREAU GUANGDONG POWER GIRD CO

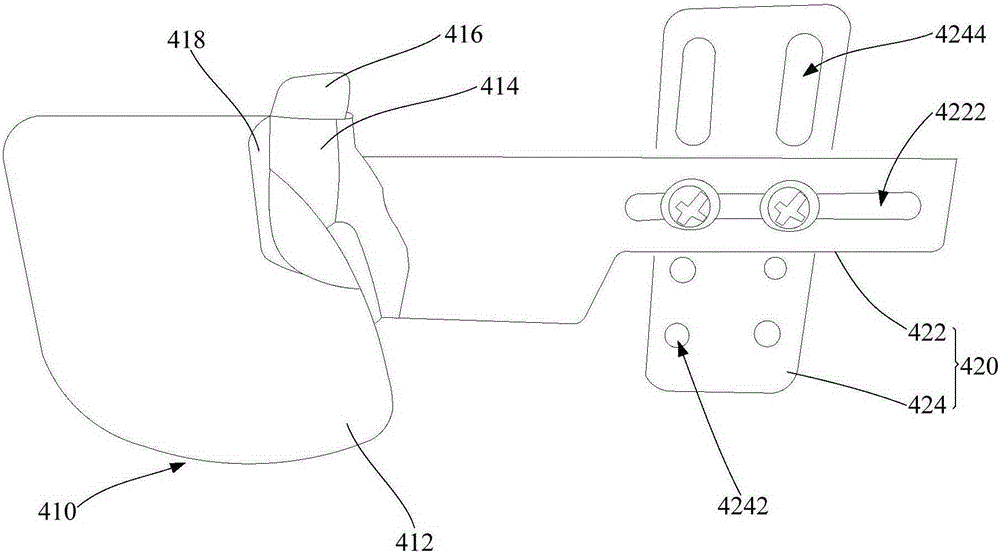

Novel lower-bodywork repair welding, positioning and locking device

InactiveCN103464945AReduce labor intensityNo manual adjustmentWelding/cutting auxillary devicesAuxillary welding devicesIn vehiclePosition sensor

The invention discloses a novel lower-bodywork repair welding, positioning and locking device and belongs to the field of welding fixtures. The novel lower-bodywork repair welding, positioning and locking device comprises a base, a support, a locking block, a pressing piece, a rocker arm, a rocker arm bracket, a cylinder guide rod, a cylinder mounting bracket and an air cylinder. The rocker arm is of a J structure like a sickle, and a part at the front end thereof is fixedly connected with the pressing piece. The rocker arm is hinged to the support through a connecting plate, the upper end of the connecting plate is fixedly connected with the rocker arm, and the lower end thereof is hinged to the support. An H-shaped buffer plate is arranged on the left side of the connecting plate. A tail end of the rocker arm is connected with the cylinder guide rod through the Y-shaped connecting rod, the upper end of the Y-shaped connecting rod is hinged to the rocker arm, and the lower end thereof is fixedly connected with the cylinder guide rod. The locking block is of a U structure, and one side of the locking block is provided with a position sensor. By the arrangement, welding precision is improved, and labor intensity of workers is greatly lowered. The novel lower-bodywork repair welding, positioning and locking device is reasonable in structural design, convenient and easy to operate, low in manufacturing cost and applicable to lower-bodyworks different in vehicle types.

Owner:WUXI YICHEN MOLD TECH

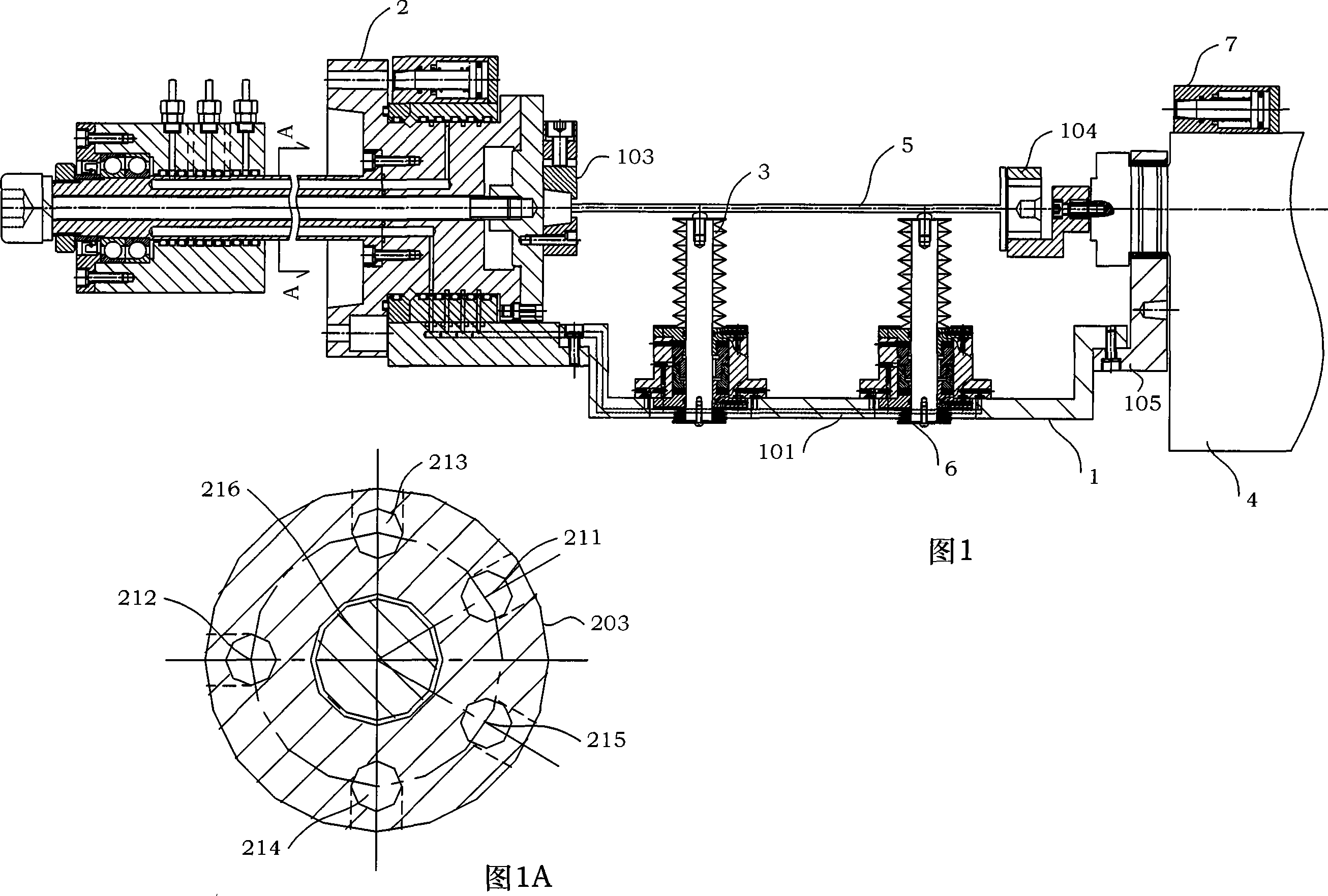

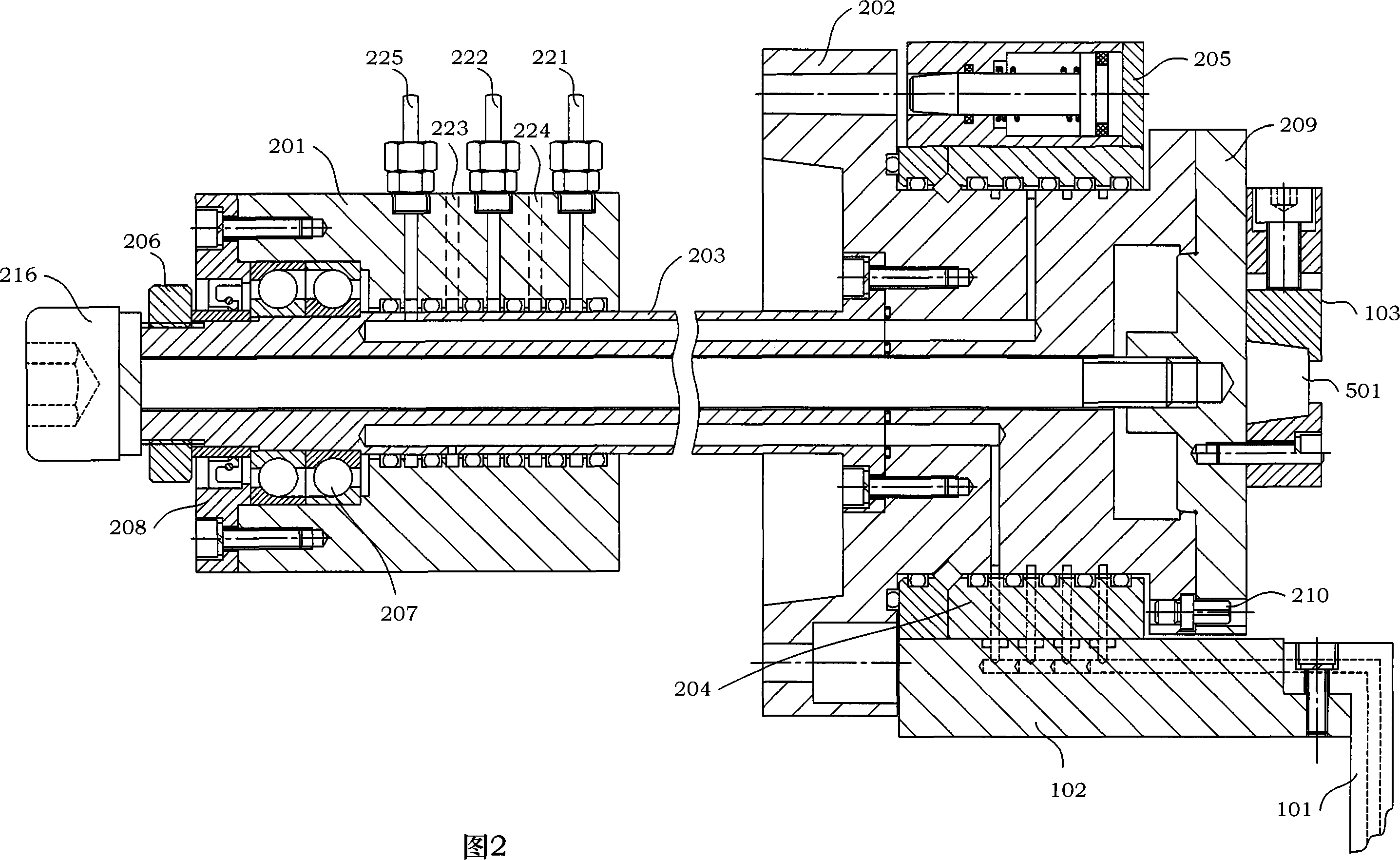

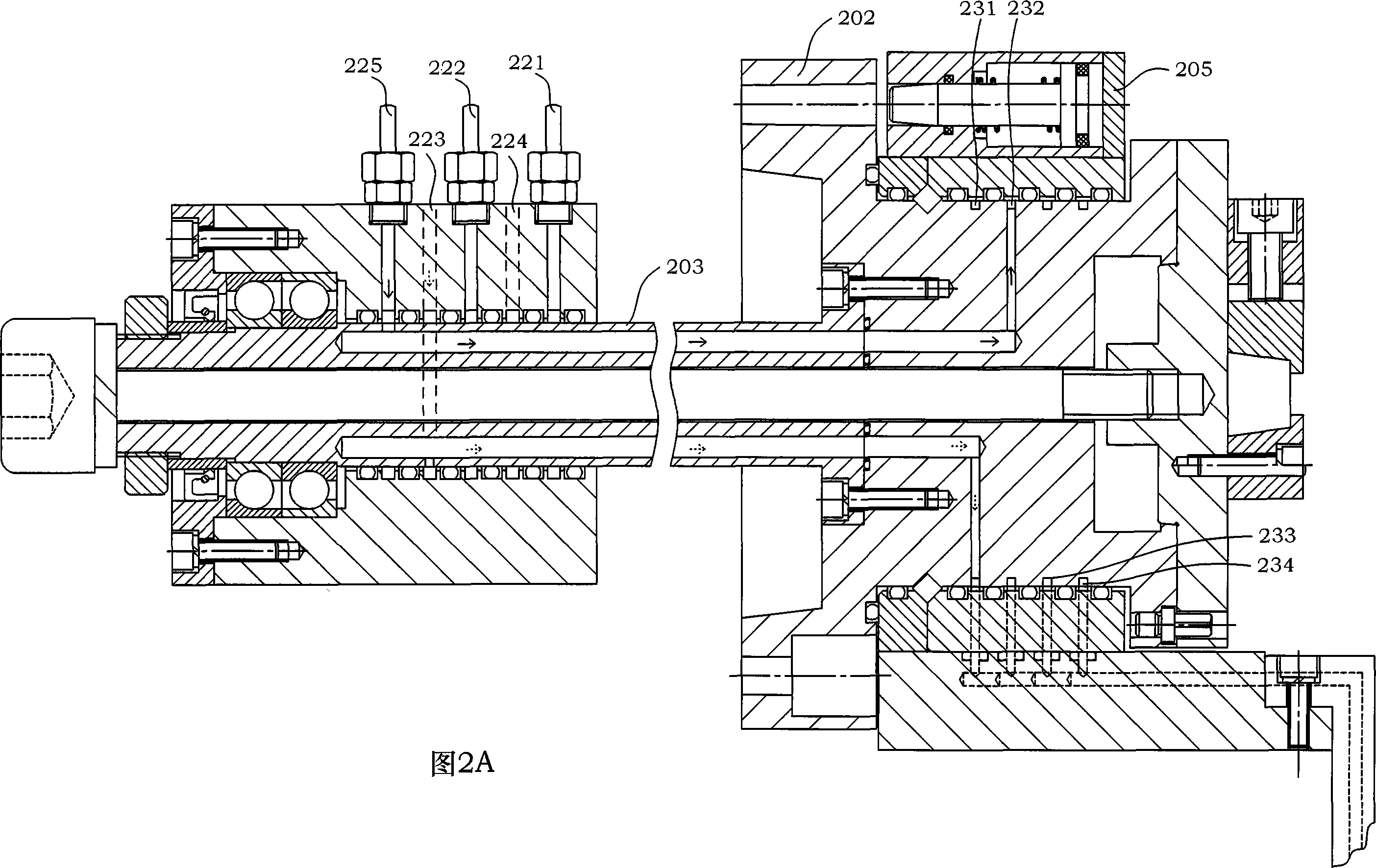

Flexible multipoint supported system in use for digital controlled machining laminae

InactiveCN101092020AAvoid interferenceSimple structurePositioning apparatusMetal-working holdersSupporting systemWorking fluid

The invention discloses a flexible multipoint supporting device for vane digital control machining. It is made up of cradle assembly, work flow feeding assembly, A flexible supporting component, and B flexible supporting component. The device realizes fixation for cradle assembly through cone pin controlled by A oil cylinder fixed on oil outlet distribution base and B oil cylinder fixed on machine tool tail base. The first machining location is used to realize synchronously turning action for cradle assembly and vane. And the second machining location is used to realize surface changing supporting for vane. The invention is mainly used to improve technical system rigidity and automation degree and machining accuracy. The flexible supporting structure also could be used as rapid and low cost assistant supporting for other weak rigidity machining.

Owner:BEIHANG UNIV

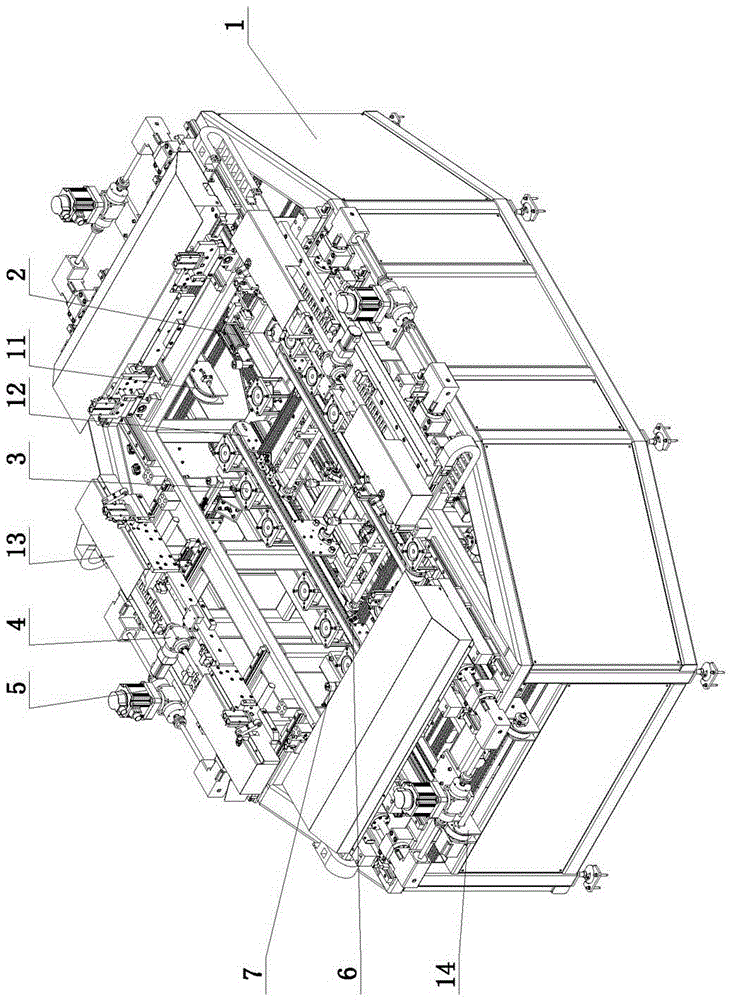

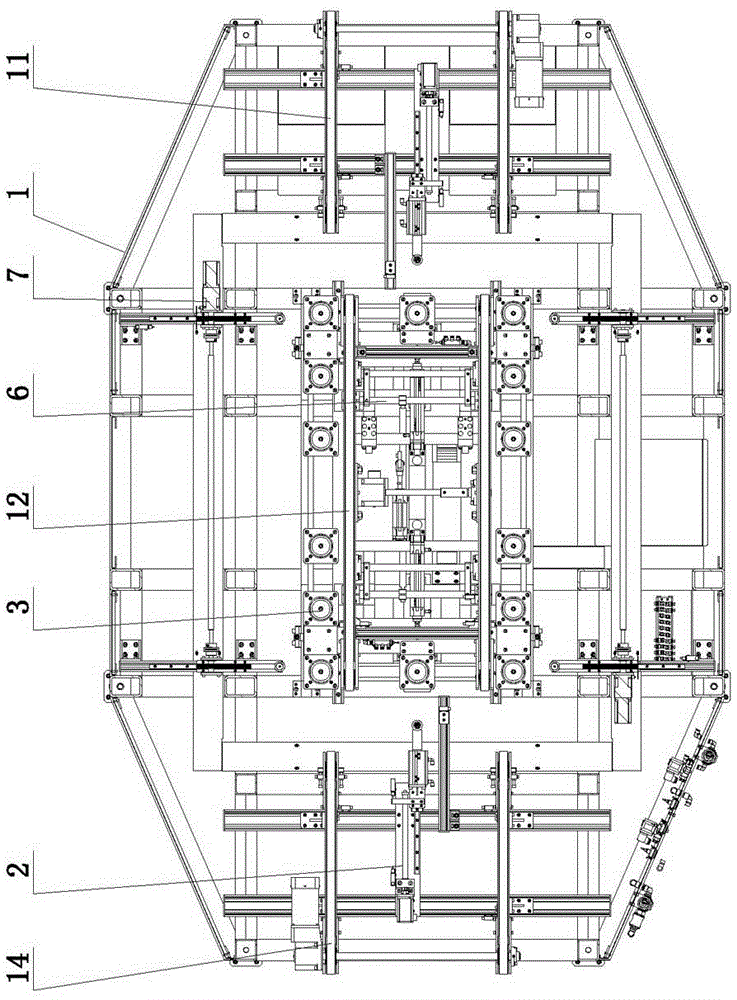

High efficiency full-automatic framing machine for solar cell module

ActiveCN106298608AEasy to adjustAvoid visual differencesFinal product manufactureSemiconductor/solid-state device manufacturingSolar cellAutomation

The invention provides a high efficiency full-automatic framing machine for a solar cell module, which belongs to the technical field of automatic production devices. The invention particularly relates to the high efficiency full-automatic framing machine in a solar cell module packaging device. The high efficiency full-automatic framing machine for the solar cell module has the advantages of high automation degree, good product uniformity and high production efficiency. The high efficiency full-automatic framing machine is characterized in that a feeding conveying device and a discharging conveying device are respectively arranged on two ends of the machine body; an intermediate conveying device is arranged at the middle part of the machine body through a lifting device; a component positioning device is arranged at a position corresponding to the intermediate conveying device in the machine body; and frame bonding devices are arranged on four sides of the component positioning device.

Owner:YINGKOU JINCHEN MACHINERY

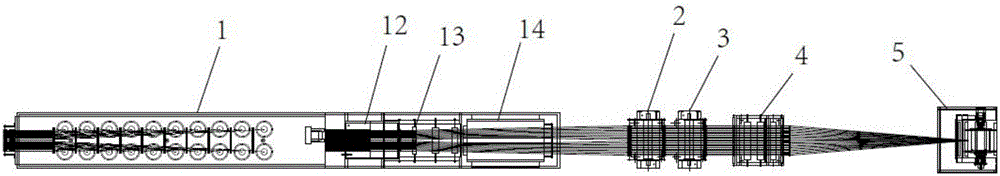

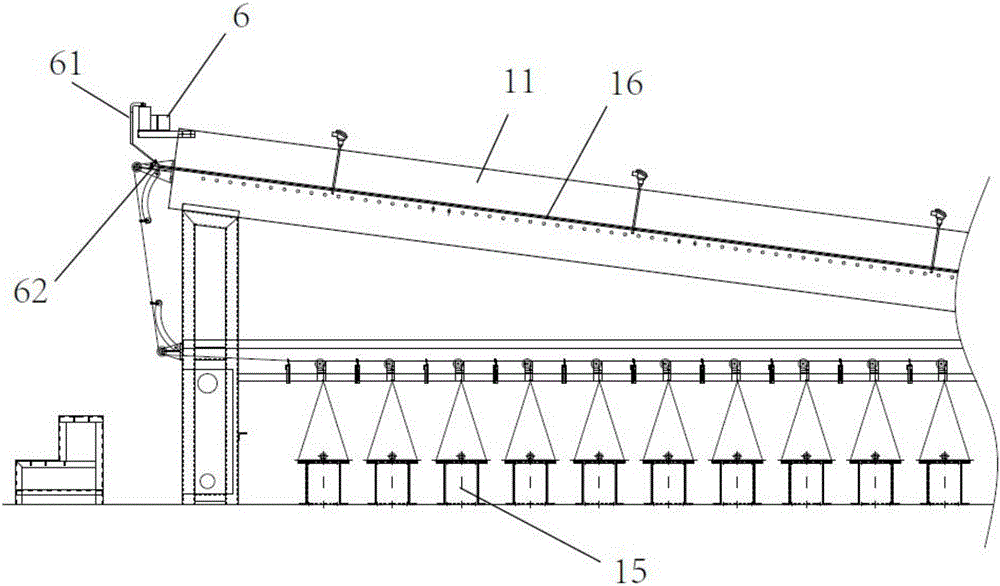

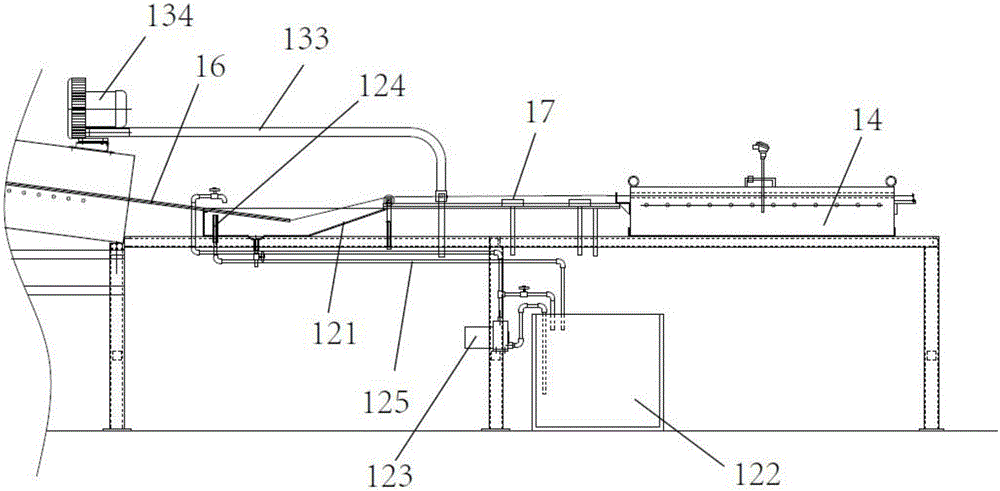

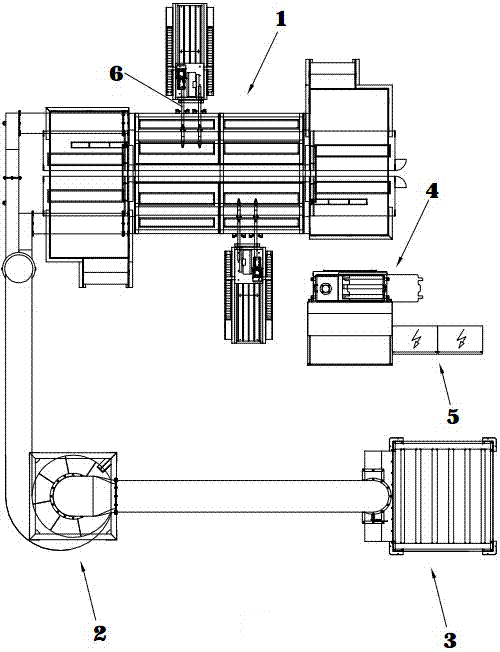

Multi-start annealing and doubling take-up machine

ActiveCN105913970AImprove work efficiencyAdjustable tensionFilament handlingFunction indicatorsComputer moduleMaterials science

The invention discloses a multi-start annealing and doubling take-up machine comprising an annealing machine, an active leading machine, a passive leading machine, a wire break shutdown test stand, and multiple take-up machines, which are arranged in sequence along the wire outgoing direction. The annealing machine comprises an annealing furnace, a cooling device, a blow-drying device and a baking box, which are arranged in sequence. The annealing furnace is arranged obliquely, and a pay-off device is arranged below the annealing furnace. The active leading machine draws wires processed by the annealing machine and sends the wires to the passive leading machine, and the passive leading machine sends the wires to the take-up machines. The wire break shutdown test stand is used for testing whether the wires are broken between the passive leading machine and the take-up machines. A branching module is arranged on the take-up machines. The multi-start annealing and doubling take-up machine is high in efficiency, simple to operate, and safe and reliable. The existing equipment is fully utilized to reduce equipment investment.

Owner:KUNSHAN FUCHUAN ELECTRICAL MACHINERY TECH

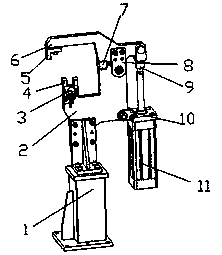

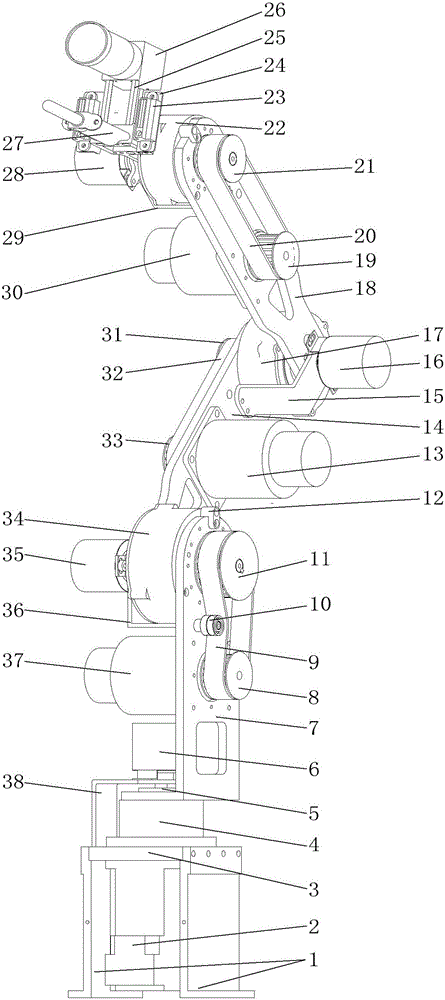

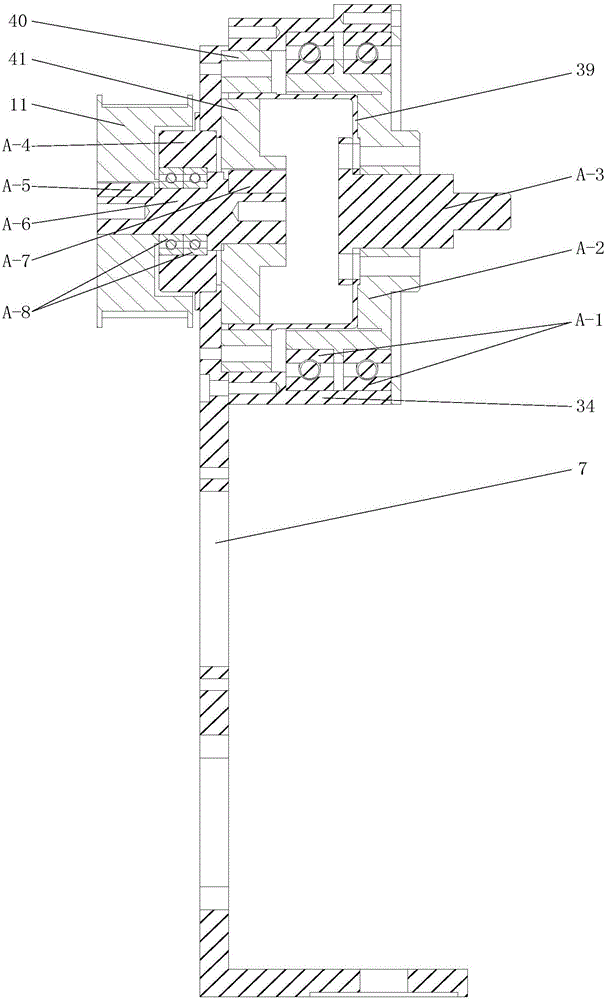

Intelligent mechanical arm with automatic button pressing function

InactiveCN105818134ASimple structureEmbody intelligenceProgramme-controlled manipulatorArmsComputer moduleReducer

The invention discloses an intelligent mechanical arm with an automatic button pressing function. The intelligent mechanical arm with the automatic button pressing function has four degrees of freedom. Each degree of freedom is controlled by a driving module composed of a servo motor and a harmonic reducer. Four encoders are arranged and can be used for detecting the movement angles of the four degrees of freedom each time. An industrial video camera is arranged and used for automatically searching for and recognizing a target button. The intelligent mechanical arm with the automatic button pressing function is provided with two infrared distance measuring sensors, and the two infrared distance measuring sensors are used for detecting the distance between the video camera and the target button, so that the effect that a clear picture is shot by the video camera is guaranteed, and accordingly the clear picture is recognized. According to the intelligent mechanical arm with the automatic button pressing function, the target button can be automatically found out and recognized from a plurality of buttons after a task instruction is received, the button is accurately pressed for completing a work task, the pose of the intelligent mechanical arm in the space coordinate system is detected automatically every time after the movement, the next instruction can be received for completing a task without manual adjustment, and the intelligent mechanical arm has the continuous working capacity and extremely high commercial value.

Owner:NANJING UNIV OF SCI & TECH

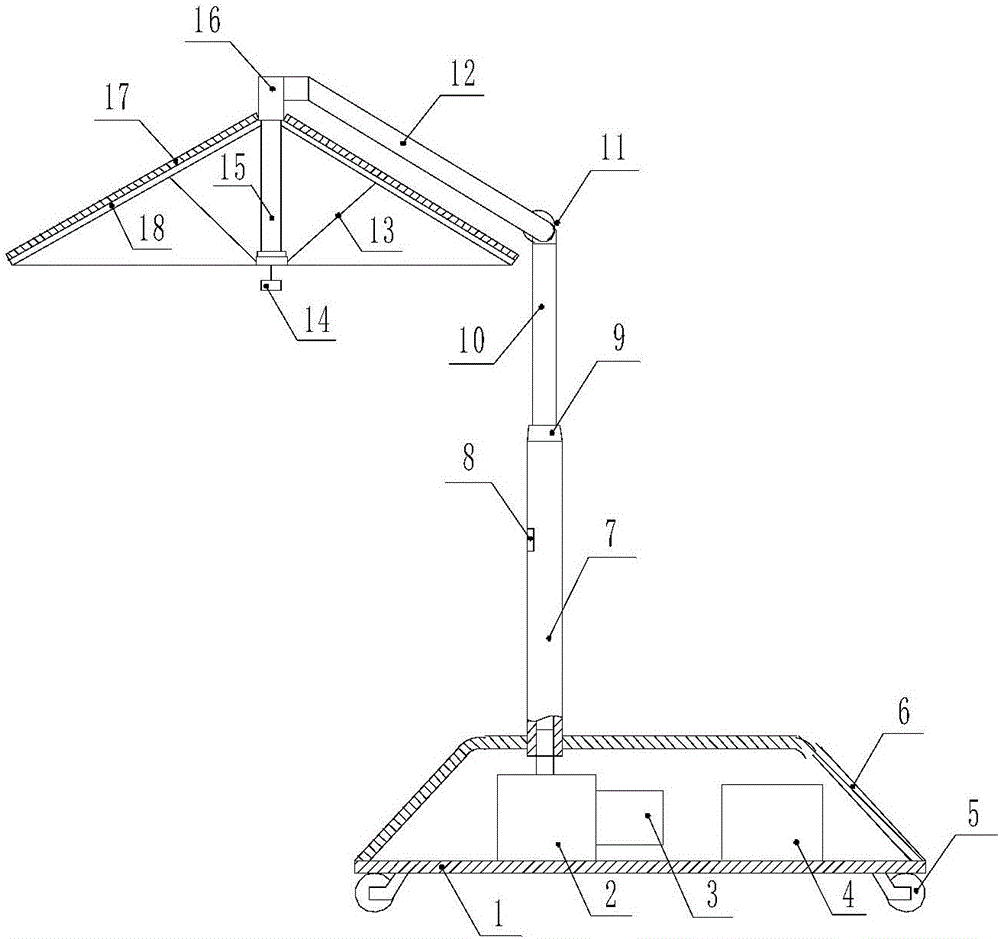

Sunflower-function type sun-shading umbrella for outdoor exercise

InactiveCN105852345ARealize emergency chargingImprove power generation efficiencyWalking sticksBatteries circuit arrangementsPolyesterIndium

The invention discloses a sunflower functional sunshade umbrella for outdoor sports. The main content is: the base plate is installed on the bottom surface of the base, the first motor is installed on the reducer, the reducer and the storage battery are installed on the base plate, and the bottom of the base plate Rollers are installed, the lower end of the fixed umbrella pole is connected to the output shaft of the reducer, the sliding umbrella pole is installed on the fixed umbrella pole by adjusting the locking cover, the second motor is installed on the top of the sliding umbrella pole, and the right end of the support pole is installed on the second motor. On the output shaft, the upper end of the umbrella tip is installed on the left end of the support pole, the top of the umbrella pole is installed on the bottom of the umbrella tip, the umbrella rib is installed on the umbrella pole through the constricting ring, the umbrella surface of indium gallium selenide film is installed on the umbrella rib, and the transparent polyester The film is installed on the surface of the indium gallium selenium film umbrella, the fan is installed at the bottom of the umbrella pole, and the USB module is installed on the fixed umbrella pole. The invention can not only be applied to people going out to camp, but also can be placed on the road for pedestrians to charge temporarily, and is especially suitable for use in field work.

Owner:JIANGSU MARITIME INST

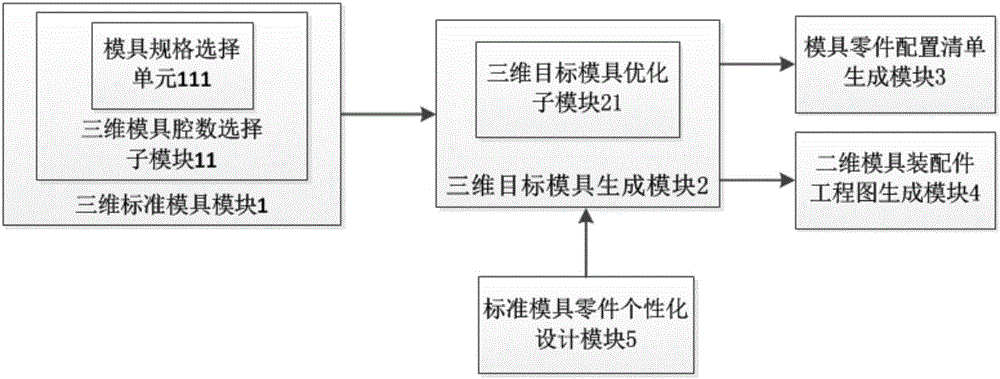

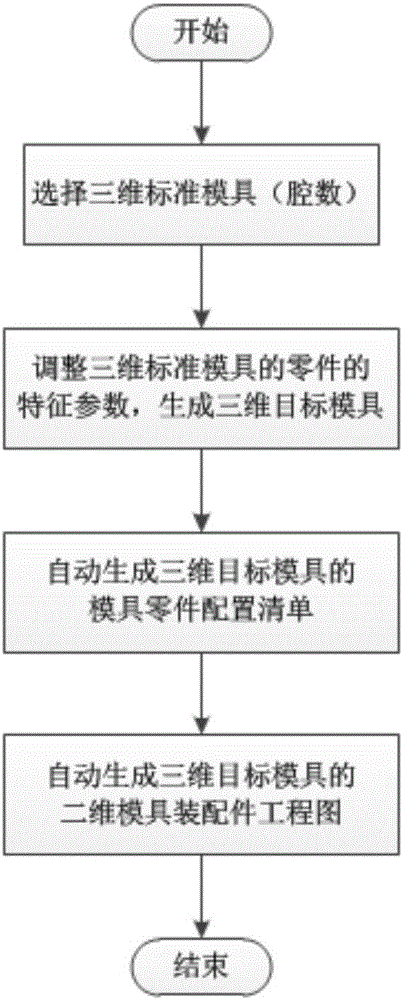

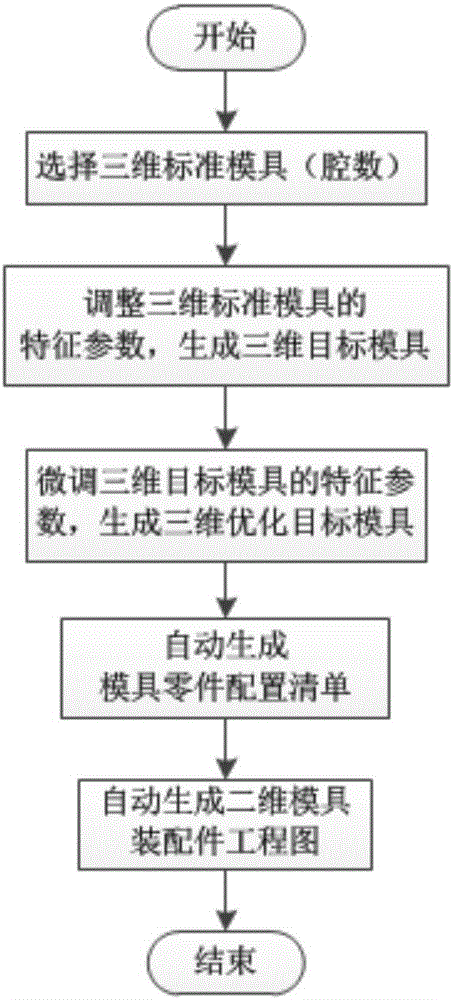

Design software system for ceramic tile molds and design method of design software system

ActiveCN106295032AImprove design efficiencyAchieve linear continuous changeGeometric CADSpecial data processing applicationsPersonalizationThree Dimensional Size

The invention discloses a design software system for ceramic tile molds and a design method of the design software system. The design method comprises the following steps: (1) classifying the similarity and characters of the tile molds according to the production standards of the tiles and the design technical specifications of the molds, and finding out logical laws; (2) establishing a three-dimensional standard mold model set and a mathematic model f(x) function relationship set corresponding to the three-dimensional standard mold model set by virtue of a CATIA design system, wherein other parts automatically generate corresponding and matched three-dimensional size structures and features according to a topological relation when coordinate parameters of a certain part structure are changed; and (3) establishing two-dimensional engineering drawings of all parts, wherein relevant sizes of the parts on the two-dimensional engineering drawings are automatically changed along the change of the parameters of three-dimensional mold parts. According to the design software system, the parts of the molds can be further individually designed and can be locally designed or corrected; and the design efficiency and precision are substantially improved, and the intelligence of the design technique of the ceramic tile molds is realized.

Owner:佛山市石湾陶瓷工业研究所有限公司

Gear impact fatigue detection device

InactiveCN110319994AAvoid damageNo manual adjustmentMachine part testingShock testingDrive motorEngineering

The invention discloses a gear impact fatigue detection device. The gear impact fatigue detection device comprises a workbench, two groups of mounting brackets are fixedly arranged on the workbench, and a driving threaded rod is movably provided with a test gear; an output end of a driving motor is fixedly provided with a rotating shaft, a first connecting rod is fixedly arranged on the rotating shaft through penetration; one end of a connection shaft, far away from a stop dog, is fixed on an impact block; and the impact gear is fixedly arranged at a center of an extension plate; an external side of the rotating shaft is provided with a ring bearing, the ring bearing is movably arranged at the center of a driving gear, and adjusting nuts is arranged at two sides for adjusting a single-tooth gear. The invention provides the gear impact fatigue detection device, in usage, test gear position of he test gear can be automatically and intermittently adjusted, impact times can be counted accurately, reciprocating operation impact of the impact gear can be realized through structures, a motor is free from working intermittently, and thus, the motor is protected effectively, so the gear impact fatigue detection device is very worth being generalized.

Owner:BENGBU COLLEGE

Temperature control method and device of air conditioner

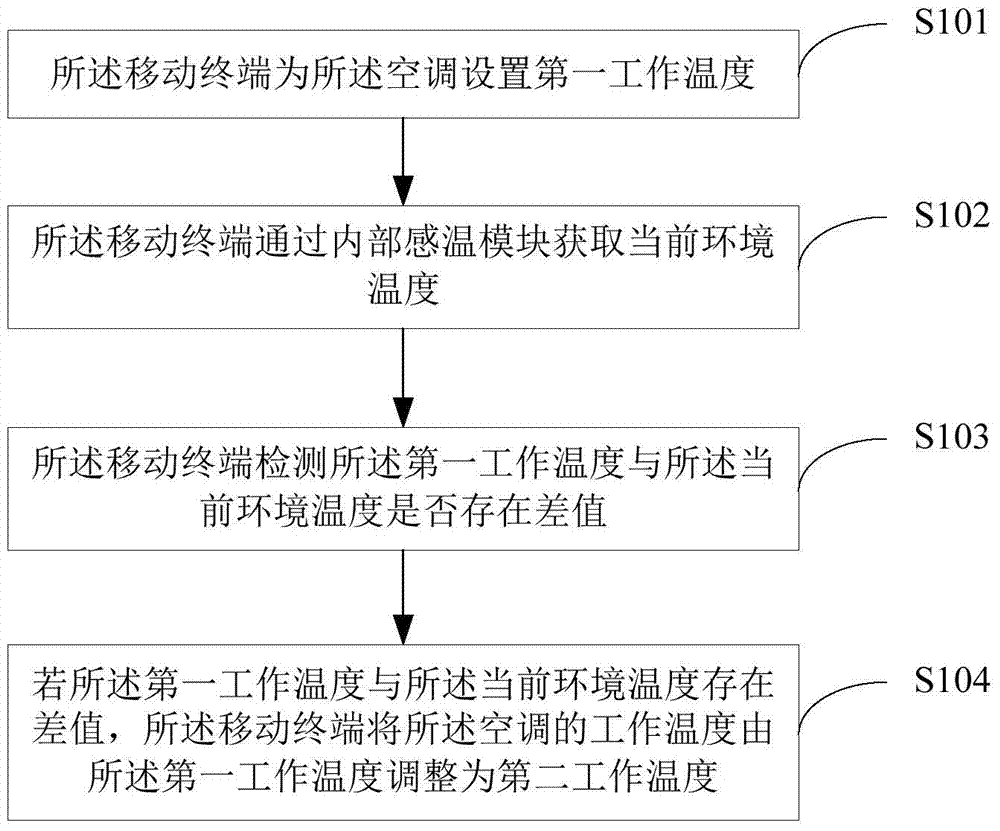

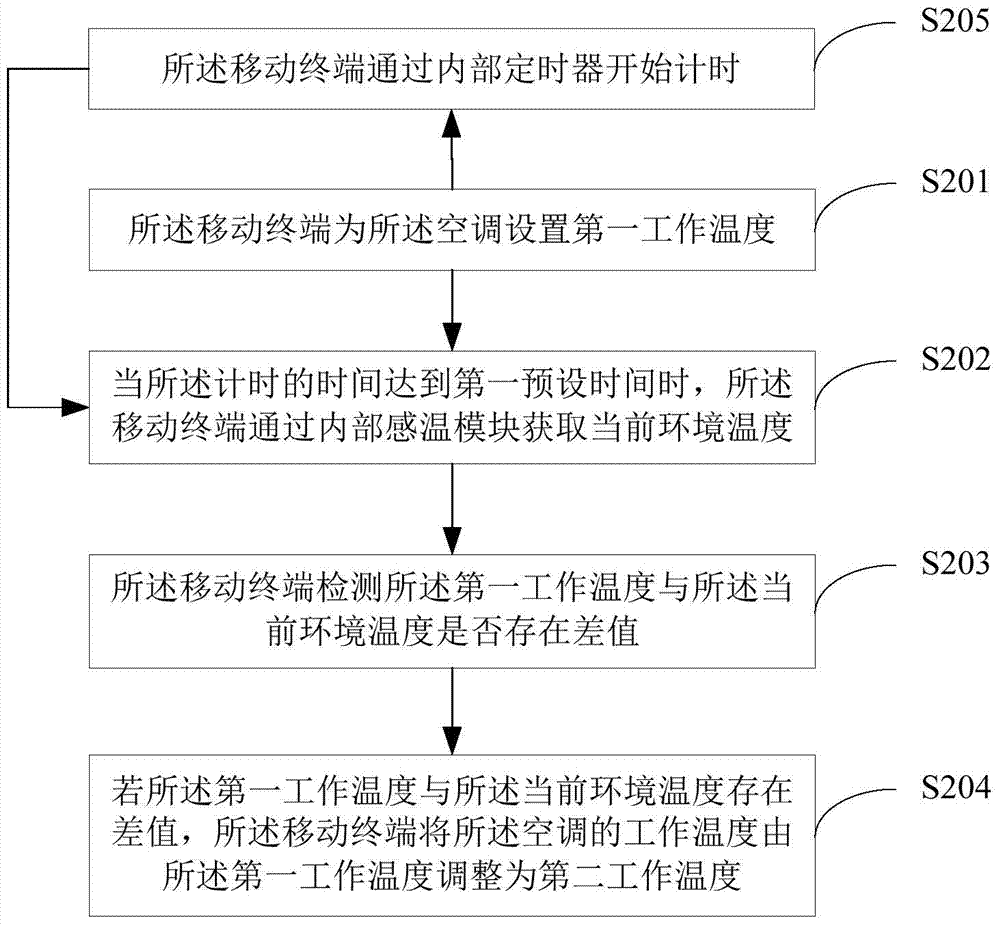

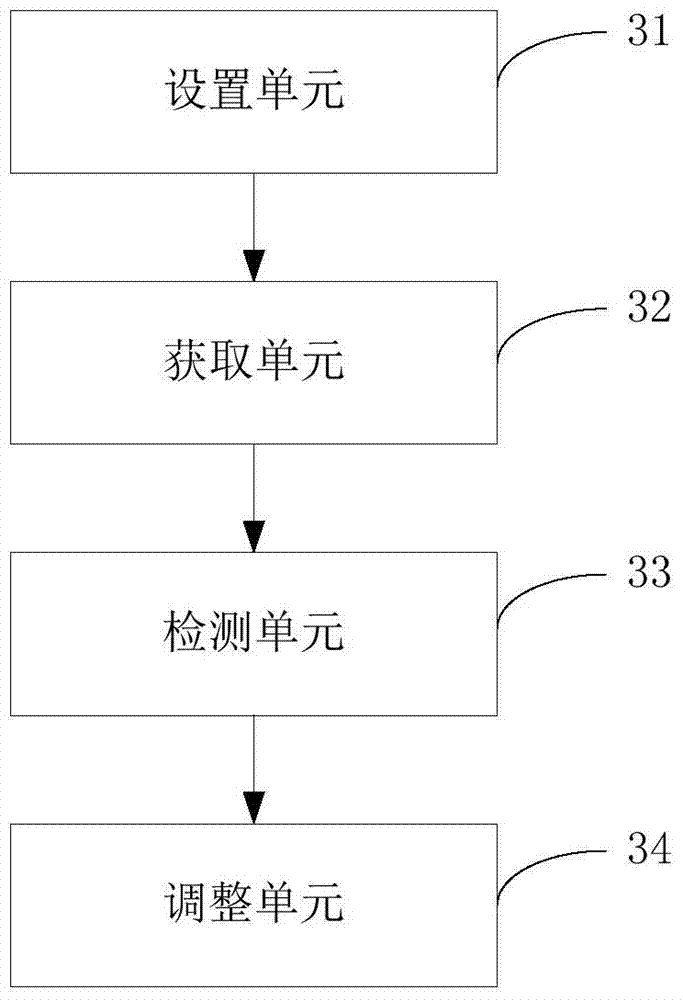

InactiveCN104848488AImprove control efficiencyNo manual adjustmentMechanical apparatusSpace heating and ventilation safety systemsTemperature controlEngineering

The invention relates to the technical field of control and provides a temperature control method and device of an air conditioner. The air conditioner is controlled remotely through a mobile terminal. The method includes: the mobile terminal sets a first working temperature for the air conditioner, obtains the current ambient temperature through an internal temperature-sensing module, and detects whether a differential value exists between the first working temperature and the current ambient temperature, if the differential value exists between the first working temperature and the current ambient temperature, the mobile terminal adjusts the working temperature of the air conditioner to a second working temperature from the first working temperature. The actual temperature near the human body is detected through the mobile terminal, and the intelligent temperature control adjustment is conducted on the air conditioner by taking the actual temperature as the basis. Therefore, the working temperature set by the air conditioner can be automatically consistent with the temperature felt by a user actually, manual adjustment is not needed, and the control efficiency of the air conditioner can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

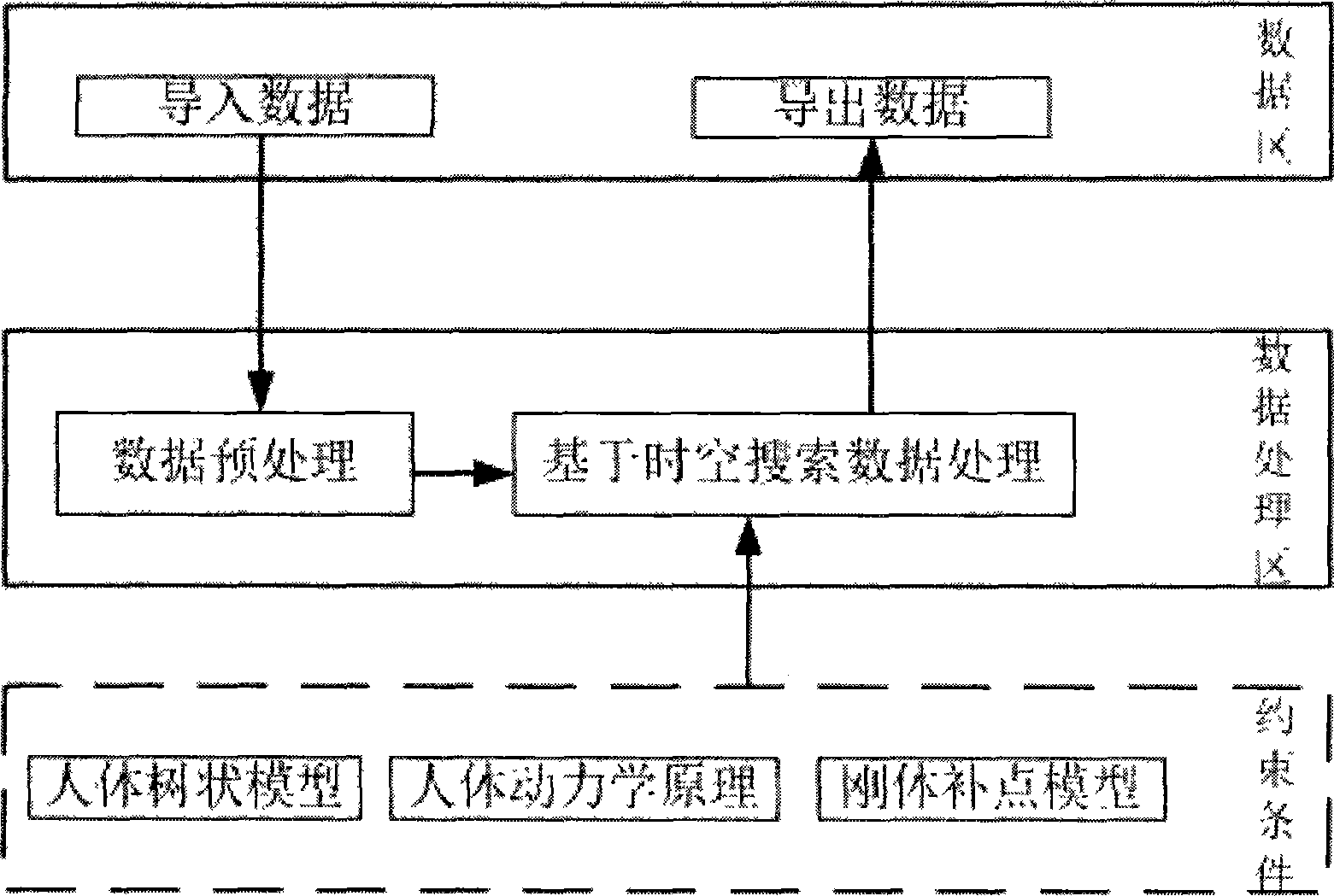

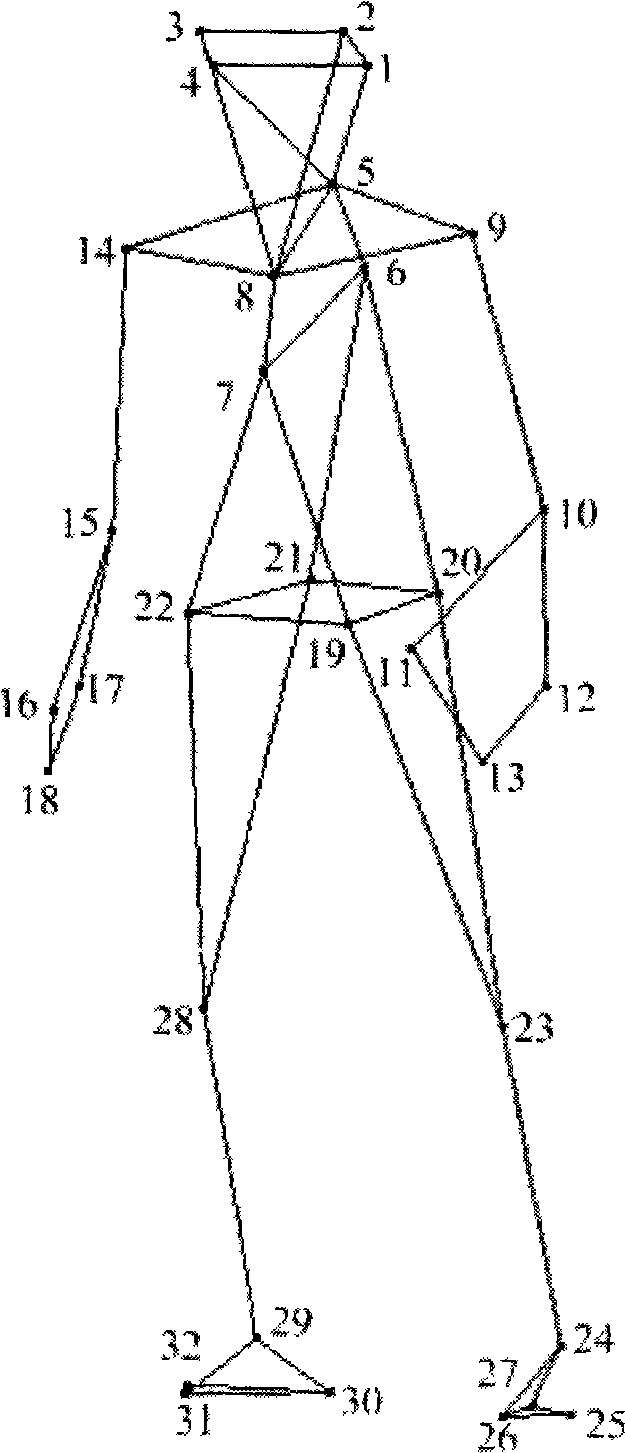

Optical motion capture data processing method based on space-time search data processing

ActiveCN101533527AReasonable useSolve the mismatch phenomenon3D modellingData acquisitionHuman motion

The invention discloses an optical motion capture data processing method based on space-time search data processing. Based on space-time information of optical human motion capture scattered data, space-time search data processing algorithm is provided. Because the optical motion data acquisition frequency is high, a front frame and a back frame of motion data form a smooth linear relation on a time shaft, and the data of each frame follow a definite topological relation on a space position due to the restraint of a human skeleton relation. The space-time search data processing algorithm reasonably utilizes the linear relation on the motion data time shaft and the topological relation on the space position as restraint conditions, effectively predicts and tracks the three-dimensional motion data, and removes noise in the noise data; and a point supplementing algorithm based on the rigid body is provided for the missing motion data so as to perform reasonable supplement. The method has the advantages that the manual intervention is not needed during processing, the real-time requirement can be met, and the matching efficiency is improved.

Owner:DALIAN UNIVERSITY

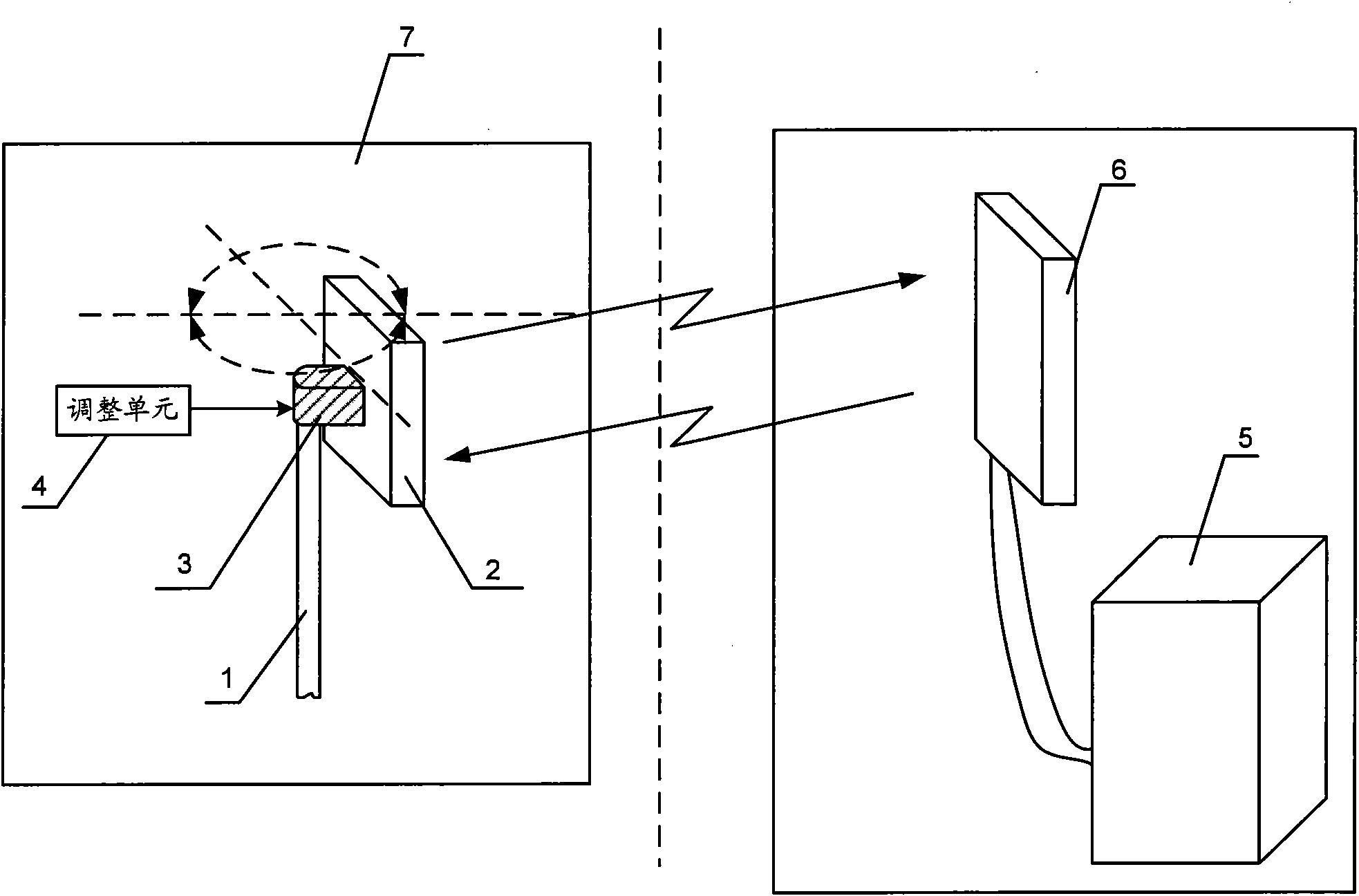

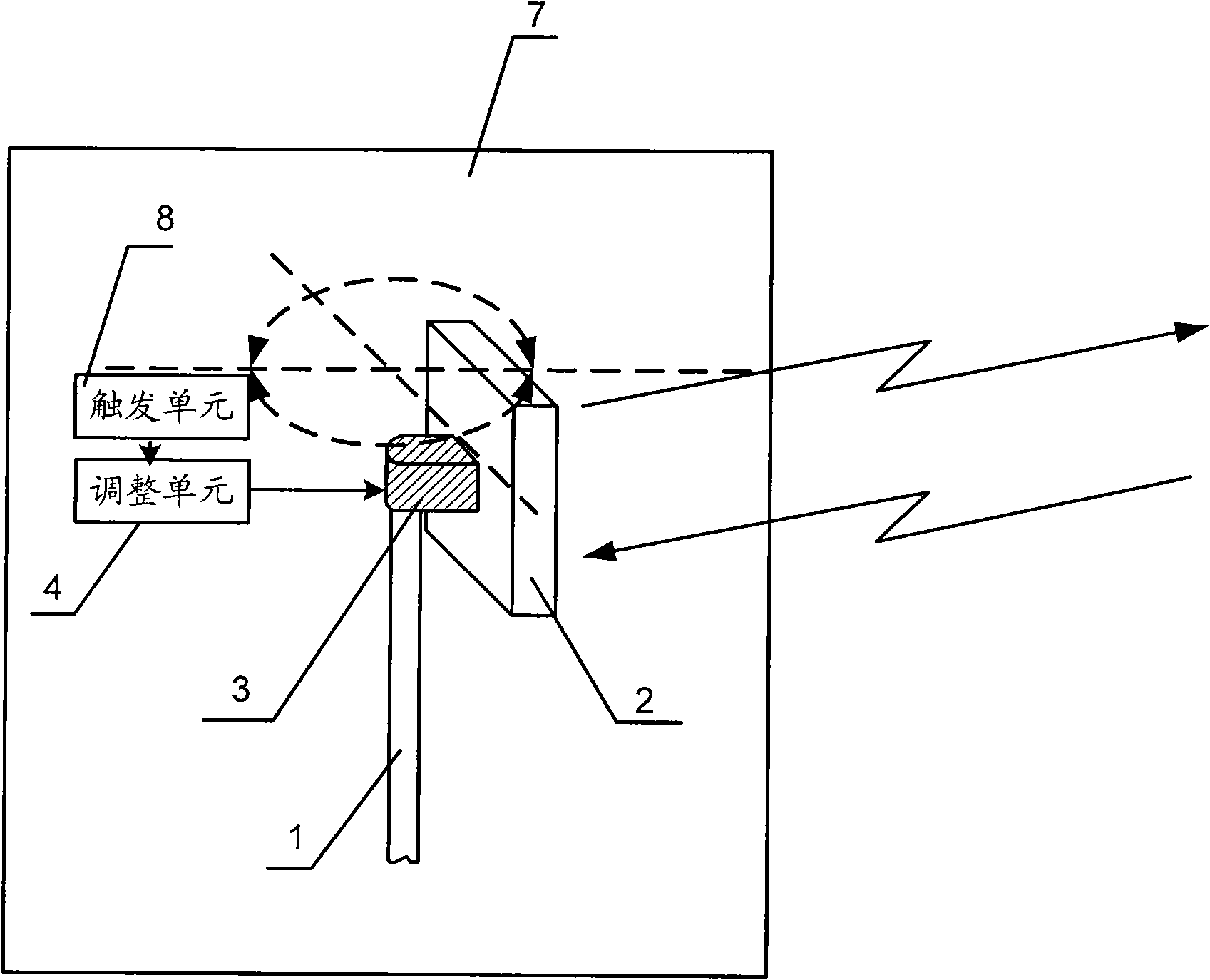

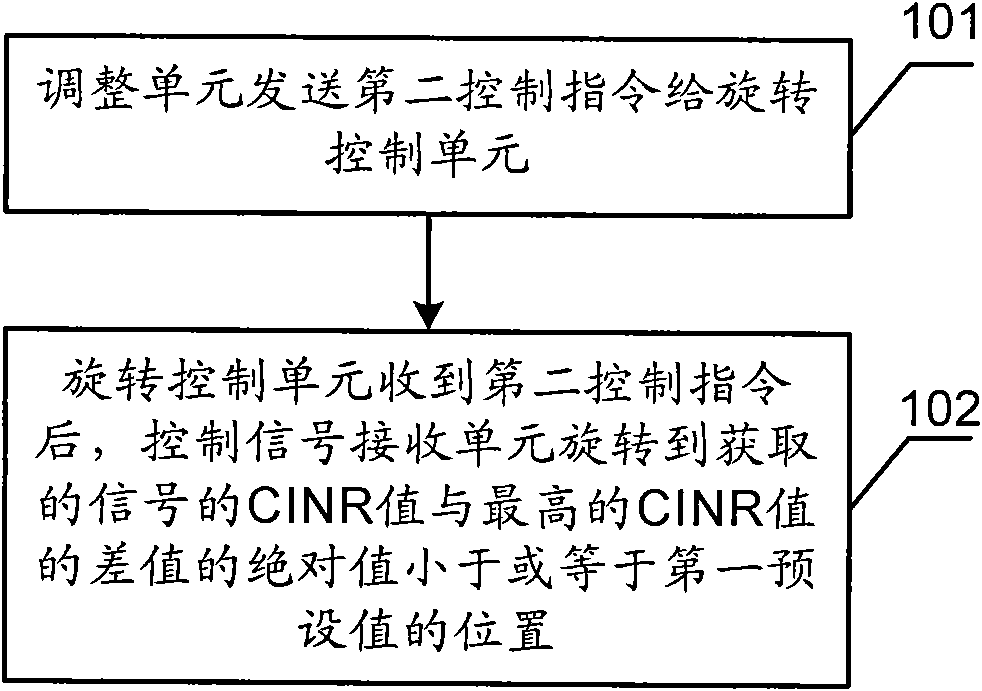

Directional antenna and automatic adjustment method thereof

The invention provides a directional antenna and the automatic adjustment method thereof. The directional antenna comprises an adjustment unit, a rotation control unit and a signal receiving unit, wherein the signal receiving unit is connected with the rotation control unit and is used for receiving signals and acquiring CINR (carrier to interference plus noise ratio) values of the signals; the adjustment unit is connected with the rotation control unit and is used for transmitting a second control instruction to the rotation control unit; and the rotation control unit is connected with the adjustment unit and the signal receiving unit, and is used for controlling the signal receiving unit to rotate to a position where the absolute value of the difference between the acquired CINR value of the signal and the highest CINR value is smaller than or equal to a first preset value after receiving the second control instruction transmitted by the adjustment unit. In the embodiment of the invention, the automatic adjustment of the directional antenna is achieved, which overcomes the inconvenience in manual adjustment.

Owner:HUAWEI TECH CO LTD

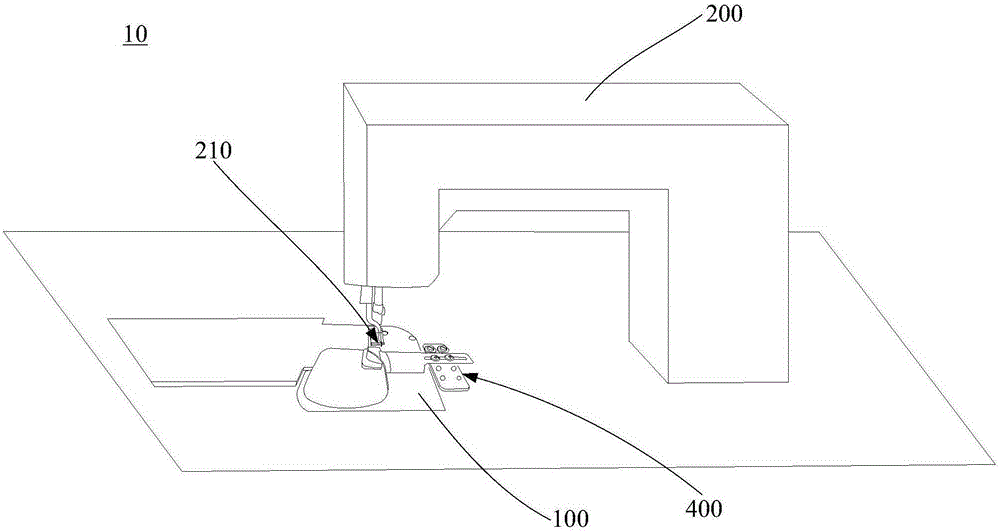

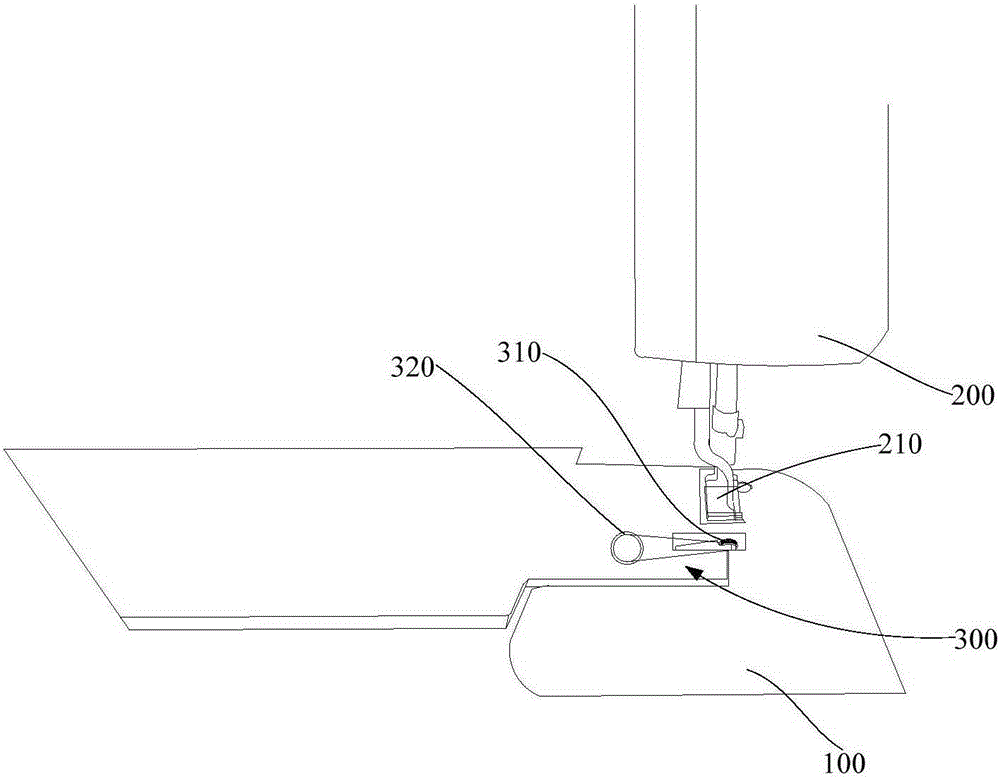

Sewing system and cloth guide mechanism thereof

The invention relates to a sewing system and a cloth guide mechanism thereof. A cloth guide board of the cloth guide mechanism comprises a feeding portion used for feeding objects to be sewn and a folding portion connected to the feeding portion and used for rolling and folding the objects to be sewn. The feeding portion is provided with a roller opening under the folding portion, a head roller on a sewing machine platform can come out the surface of the feeding portion from the roller opening to contact with the objects to be sewn and drive the objects to be sewn to move to the folding portion. The feeding portion is provided with the rolling opening, the head roller on the sewing machine platform can be directly used, so the head roller can drive the objects to be sewn to move to the folding portion, displacement of the objects to be sewn at the tail end of a conveying line can be avoided, the objects to be sewn can be accurately folded at the tail end without manual adjustment, and the efficiency is high.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

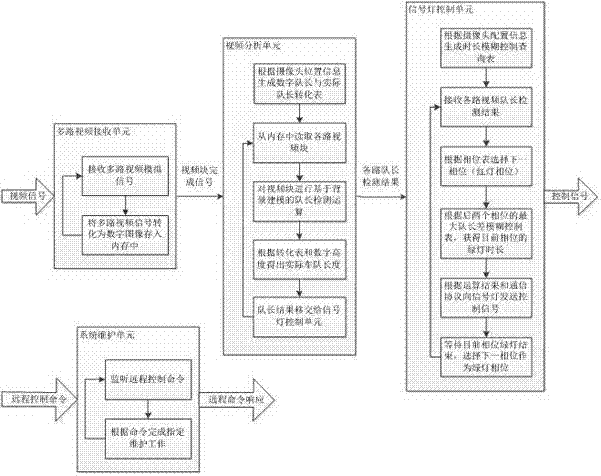

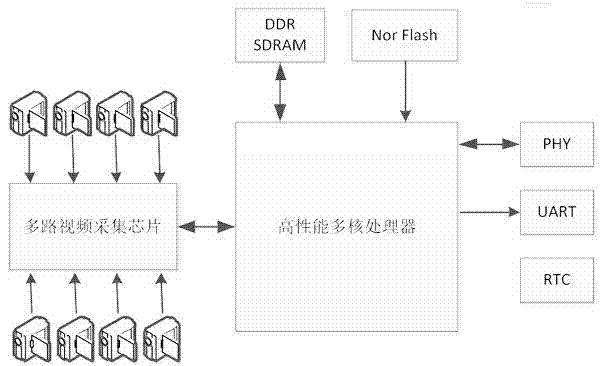

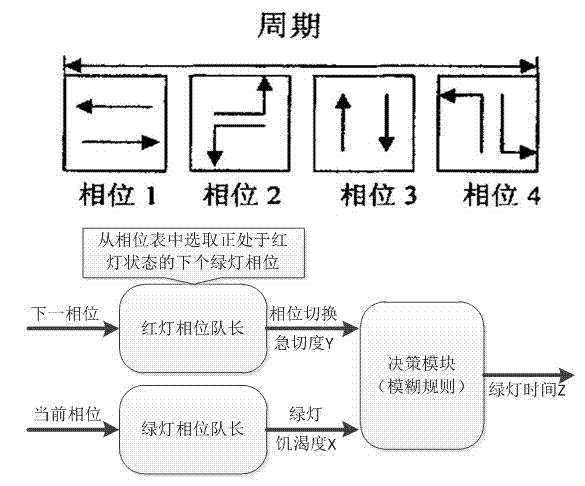

Intelligent traffic light controller based on video vehicle queue length detection and control method thereof

InactiveCN103247181AImprove traffic efficiencyReduce congestionControlling traffic signalsTraffic signalAutomatic control

The invention discloses an intelligent traffic light controller based on video vehicle queue length detection and a control method thereof, and provides a traffic light controller and method which are low in cost and can adjust traffic light time intervals automatically in various types of road junctions according to vehicle queue waiting condition on the road surface. Besides, road waiting vehicle queue length detection is performed by virtue of existing road cameras and a video analysis technology, and the traffic light time intervals are adjusted dynamically according to detection results of multiple waiting lanes. During construction, all that is needed is to mount a small-size control box on each road junction, the mounting cost is reduced greatly, and the construction scale is reduced; the controller and the method have wider application; and the duration of the traffic lights can be automatically controlled according to the vehicle queue length of each waiting lane in real time, manual adjustment is not needed, the road passage efficiency can be improved effectively, the traffic jam condition of crossroads can be relieved, and the normal passage of vehicles and pedestrians is guaranteed.

Owner:TONGJI UNIV

Powder feeding center of spraying equipment

InactiveCN102921614AEasy to measureEasy to measure depthLiquid surface applicatorsCoatingsColor changesMaterials science

The invention discloses a powder feeding center of spraying equipment, which comprises a powder recovery opening, a powder pump, a power recovery pipe, a powder feeding pipe, a reverse suction pump and a powder container, wherein the powder pump is communicated with the powder recovery opening and is used for feeding coating entering the powder recovery opening into the power recovery pipe; the powder feeding pipe is communicated with a spray gun; the powder recovery pipe and the powder feeding pipe are connected with the reverse suction pump and communicated with the powder container; and the reverse suction pump is used for sucking in airflow to suck powder in the powder recovery pipe and the powder feeding pipe into the powder container when color change is needed. The structure of the powder feeding center is optimized, a sensor is arranged to facilitate material depth measurement, a slidable bracket is arranged to enable the powder recovery pipe and the powder feeding pipe to suck in powder in real time, no manual adjustment is needed, and the work efficiency is improved.

Owner:ZHEJIANG MINGQUAN INDAL COATING

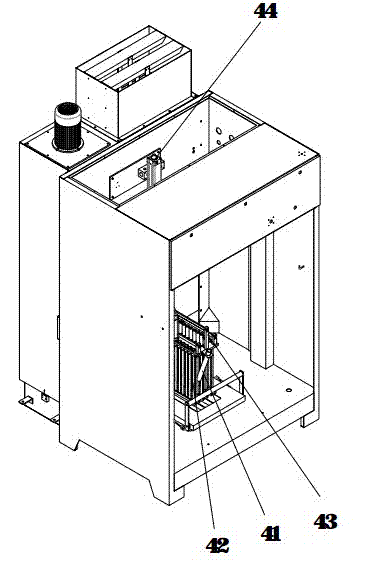

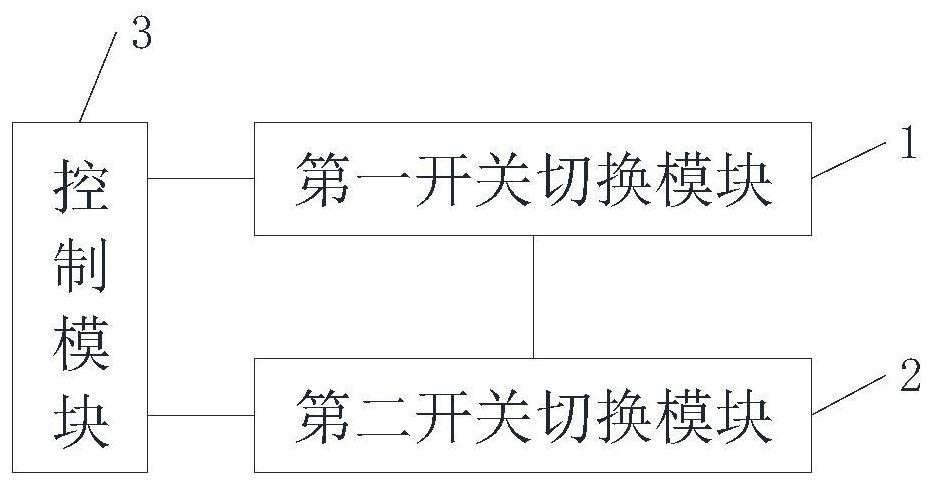

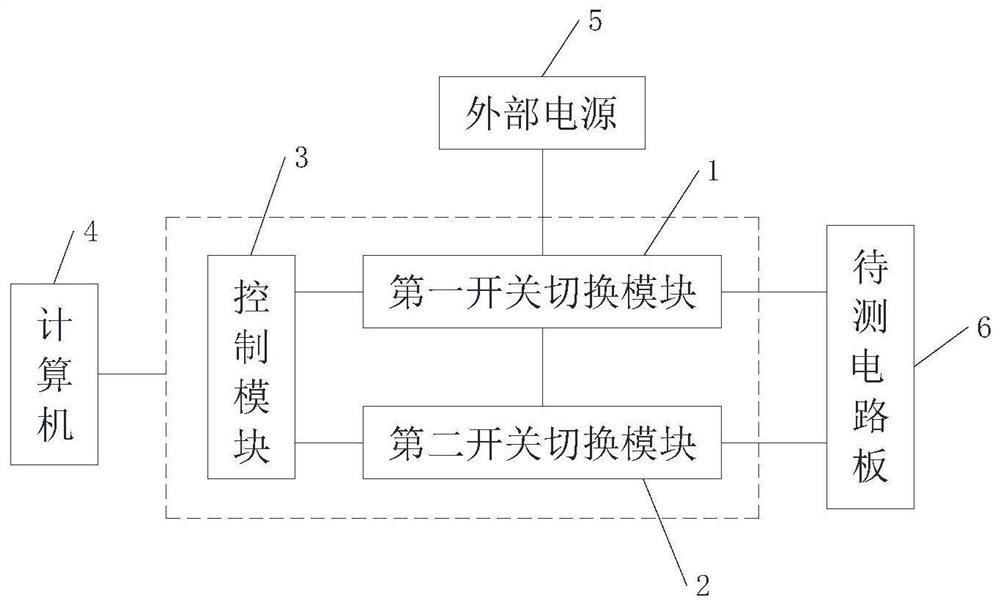

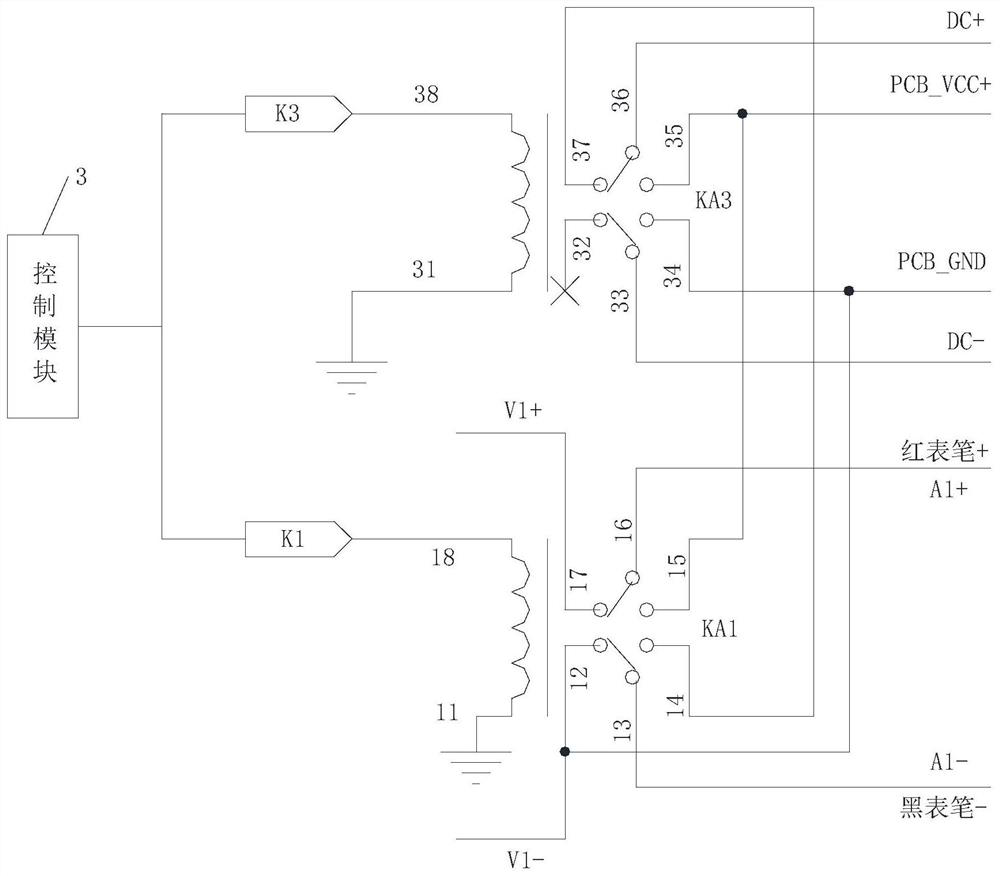

Automatic test circuit, automatic test instrument and automatic test system

ActiveCN112114244ANo manual adjustmentImprove test efficiencyPrinted circuit testingMeasurement instrument housingTest efficiencyControl engineering

The invention discloses an automatic test circuit, an automatic test instrument and an automatic test system. The automatic test circuit comprises a first switch switching module, a second switch switching module, and a control module which is connected with the first switch switching module and the second switch switching module, wherein the first switch switching module is provided with a powerinterface used for connection of positive and negative electrodes of an external power supply and a circuit board interface used for connection of positive and negative electrodes of a to-be-tested circuit board; the second switch switching module is connected with the first switch switching module, and the second switch switching module is provided with a meter pen interface used for connection of the positive electrode and the negative electrode of a meter pen and at least one group of voltage test interfaces used for connection of at least one group of voltage test points located on the to-be-tested circuit board; and the control module is used for controlling the on-off state of the first switch switching module and / or the second switch switching module. The dynamic test circuit disclosed by the invention can solve the problems that an existing digital universal meter is inconvenient to use and low in test efficiency.

Owner:SHENZHEN TOP TEK ELECTRONICS CO LTD

Numerical control complete-set pipe making machine

ActiveCN107470486AGuaranteed straightnessNo horizontalMetal-working feeding devicesPositioning devicesNumerical controlEngineering

The invention provides a numerical control complete-set pipe making machine. The numerical control complete-set pipe making machine comprises a pipe making machine body, a cutting machine, a feeding frame and a deviation rectifying device. The pipe making machine body and a cutting machine body are connected through the feeding frame, and the deviation rectifying device is installed on the feeding frame. The numerical control complete-set pipe making machine is characterized in that the deviation rectifying device comprises a clamping connection device, a vertical deviation rectifying device and a transverse deviation rectifying device. The clamping connection device sleeves a metal pipe, the bottom of the clamping connection device is arranged above the vertical deviation rectifying device, and the transverse deviation rectifying device is installed below the vertical deviation rectifying device. The numerical control complete-set pipe making machine has the advantages that due to the fact that the deviation rectifying device is additionally arranged in the numerical control complete-set pipe making machine, the straightness of the large-span metal pipe is guaranteed, and the transverse or vertical deviation and the rotation angle of the metal pipe cannot be caused in the conveying process.

Owner:JIANGSU ZHONGHAI HEAVY MACHINE TOOL

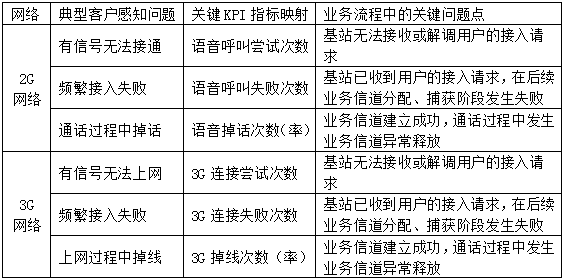

Mobile communication network user perception initiative optimized analysis method based on abnormal cell

InactiveCN105517021AAdapt to needsNo manual adjustmentWireless communicationAbnormal cellUser perception

The invention provides a mobile communication network user perception initiative optimized analysis method based on an abnormal cell. Intensive and automatic monitoring of wireless network performance is achieved from the micro level, an innovative two-queue and three-threshold analysis rule is utilized for automatically outputting carrier fan-class issue lists, automatically sending orders and achieving automatic verification, the problem is found before a user, the problem solving type passive optimization is changed into prevention type initiative optimization, and wireless network optimization converts from network index attention to user perception attention through monitoring of key KPI indexes sensitive to user perception.

Owner:ANHUI TELECOMM ENG

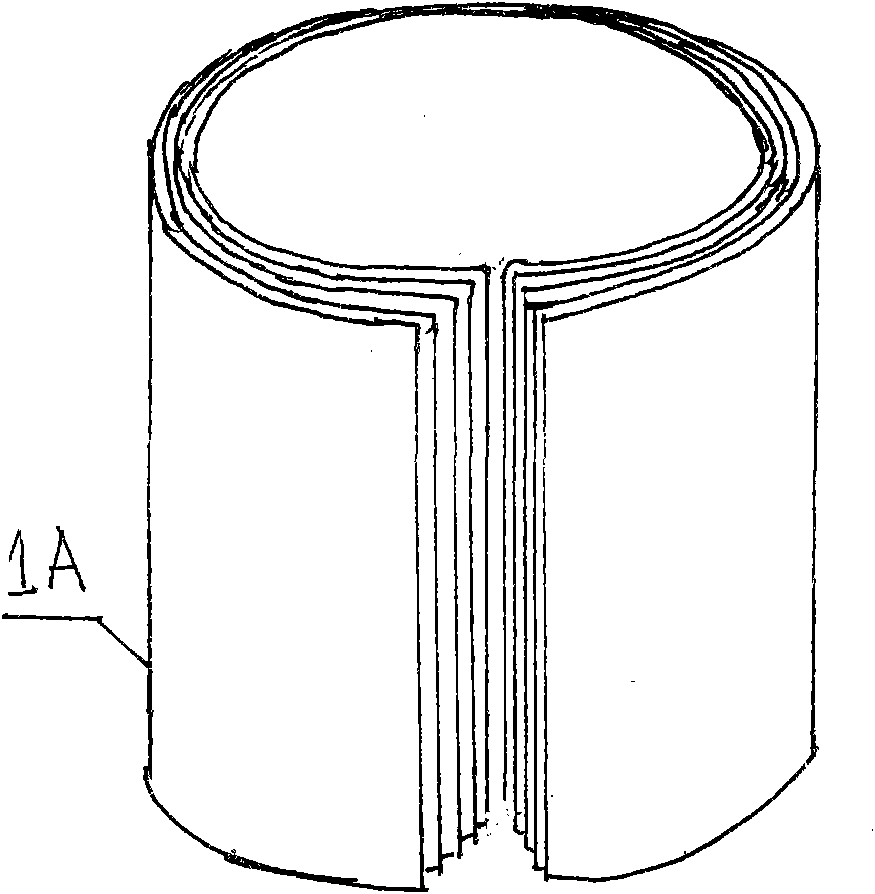

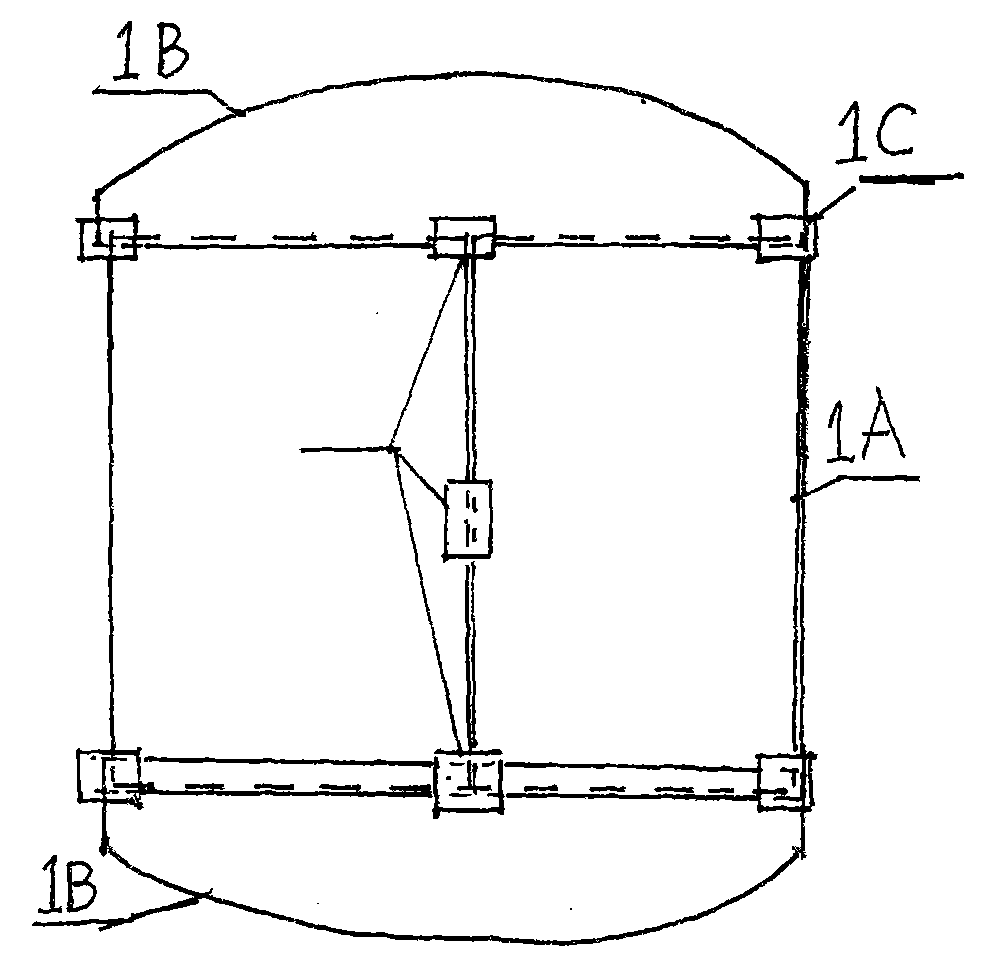

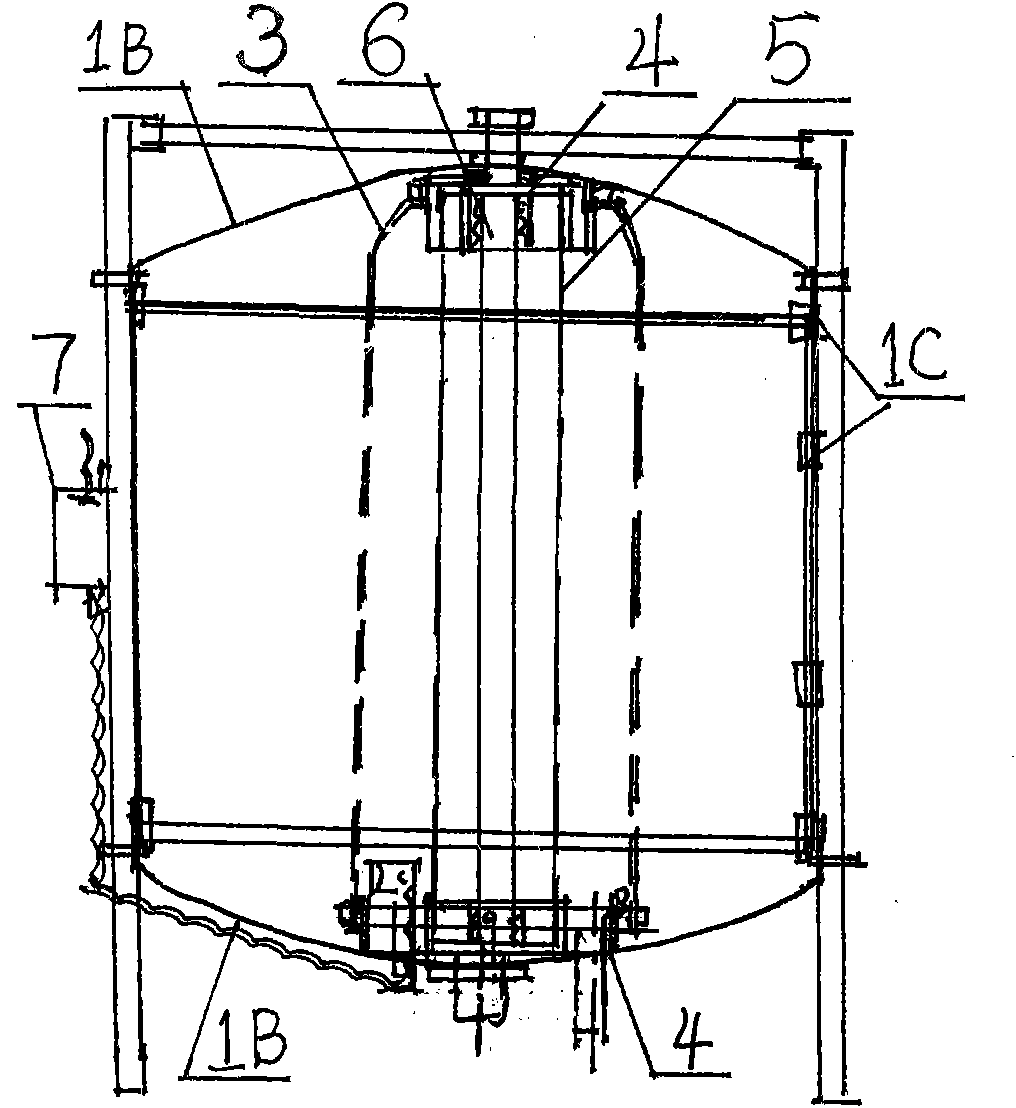

Off-site assembled container manufacturing method, bag-type pressure drain tank and liquid level controller

InactiveCN102001494AReduce areaSimple production equipmentFluid heatersMechanical apparatusWater qualityEngineering

The invention discloses an off-site assembled container manufacturing method, a bag-type pressure drain tank and a liquid level controller. The method for manufacturing the container and the water tank body comprises the following steps of: manufacturing middle containments at least annularly provided with an open edge and corresponding end covers on a production workshop according to the requirement respectively, and overlapping a plurality of middle containments and end covers inside and outside, or packing and storing the middle containments and the end covers; after being transferred to each use destination, connecting the open edge ends and the ends of the middle containments and the end covers or connecting through connecting members to form a container body by assembly; and arranging a fluid storage elastic bag or / and a bag joint, a filter element and / or an inner supporting frame and the liquid level controller consisting of a power supply master controller and a secondary controller connected by a power supply connecting wire on the corresponding positions. The method solves the problems of large storage space occupied by the container body, high cost and the like in the conventional one-time forming production method. The invention provides the bag-type pressure drain tank with strong non-bearing pressure drainage capability, low cost and cleaner water and the liquid level controller with low cost, more reliable and safer performance and the like.

Owner:陈广丰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com