Off-site assembled container manufacturing method, bag-type pressure drain tank and liquid level controller

A liquid level controller and container manufacturing technology, which is applied in the direction of liquid level control, containers, large containers, etc., can solve the problems of increased cost, production and installation time, difficulties, increased production equipment, plant investment and management costs, etc., to achieve Less area required for workshops and storage, lower storage and transportation costs, lower investment and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

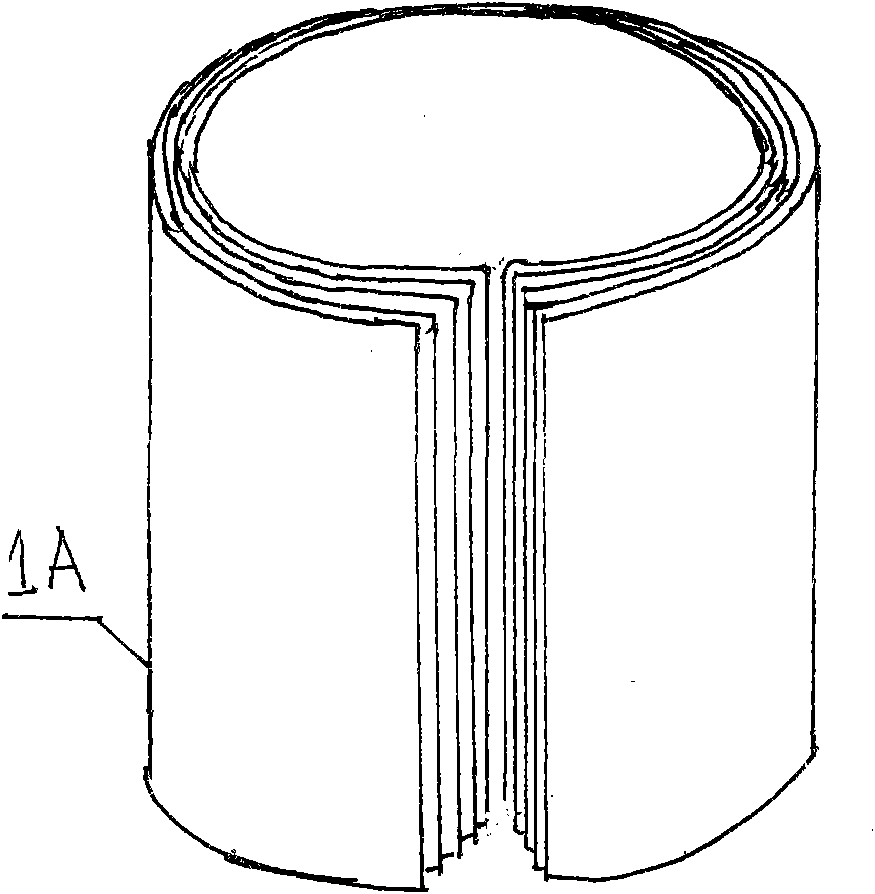

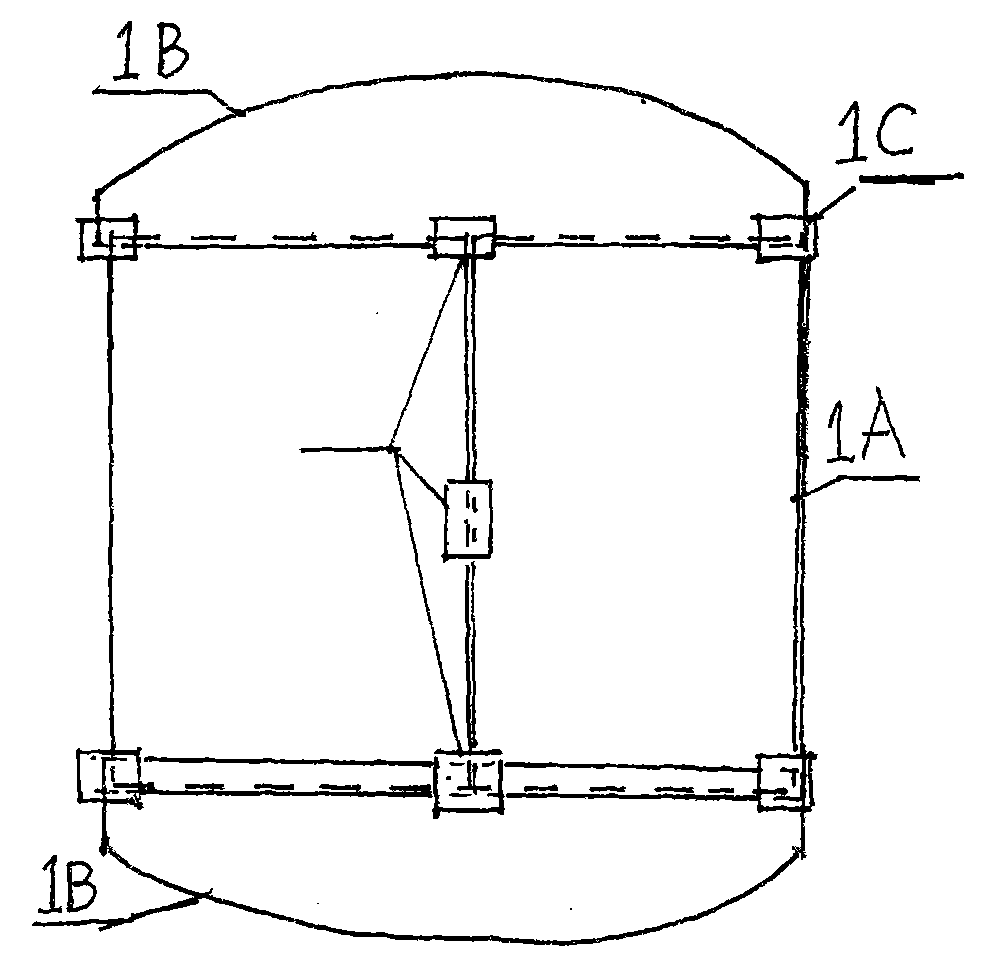

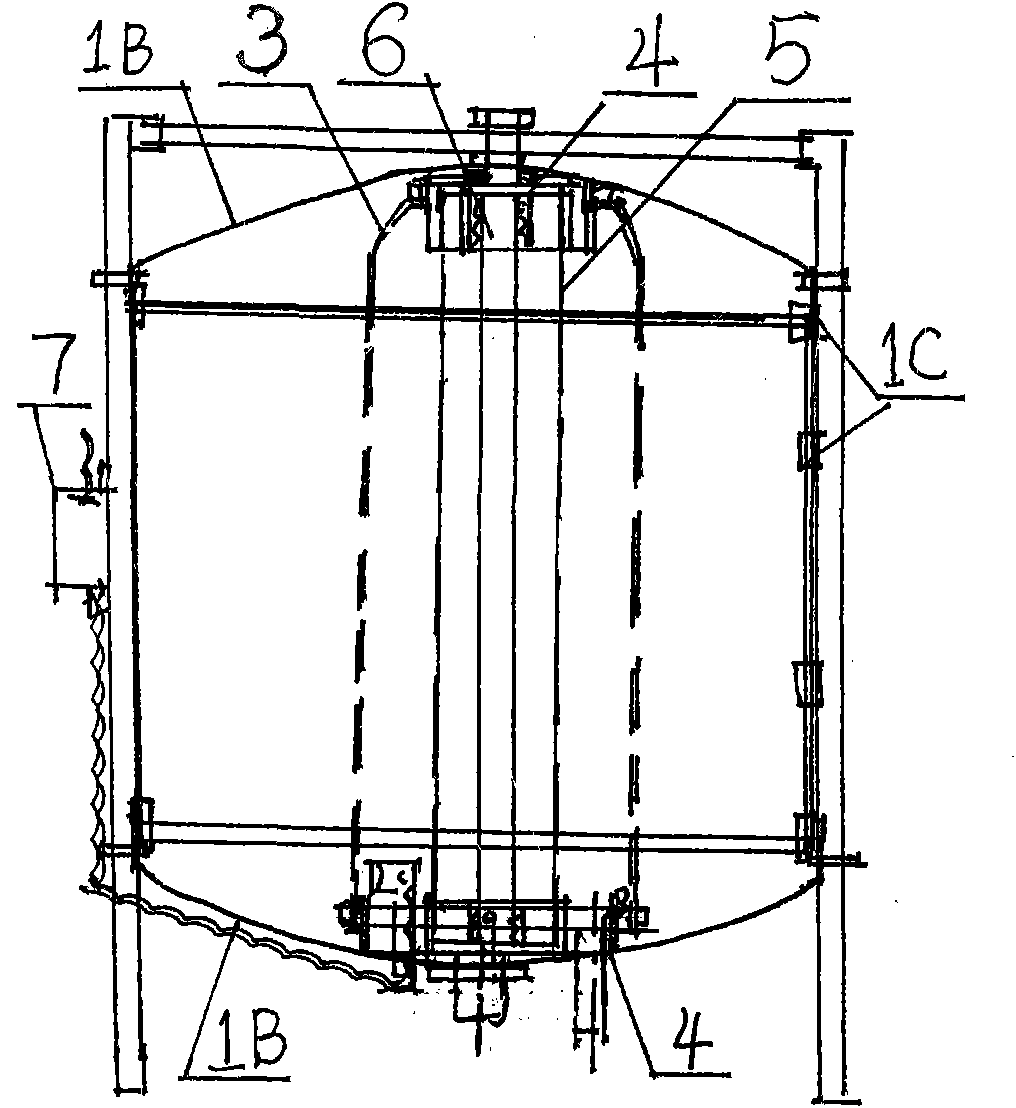

[0012]This application is a plurality of inventions under one general idea, and they have the same associated specific technical features. That is, the manufacturing method of the container that can be assembled in different places is mainly used for manufacturing the bladder type pressure drainage tank, and is also suitable for manufacturing various containers of other purposes and types. And the water tank body of this bladder pressure drainage tank mainly adopts the manufacturing method of the container that can be assembled in different places to make, and also can adopt other method forms to make. Similarly, the liquid level controller is mainly used for the liquid level control of the capsule type pressure drainage tank, and can also be used for the liquid level control of other types of containers. That is to say, the liquid level control of the bladder pressure drainage tank mainly adopts the liquid level controller, and other forms of liquid level controllers can also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com