Design software system for ceramic tile molds and design method of design software system

A mold design and software system technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve problems such as difficulty in updating, error-prone, and failure to realize full digitization and intelligence of ceramic tile molds, so as to simplify the mold modification process and improve The effect of design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

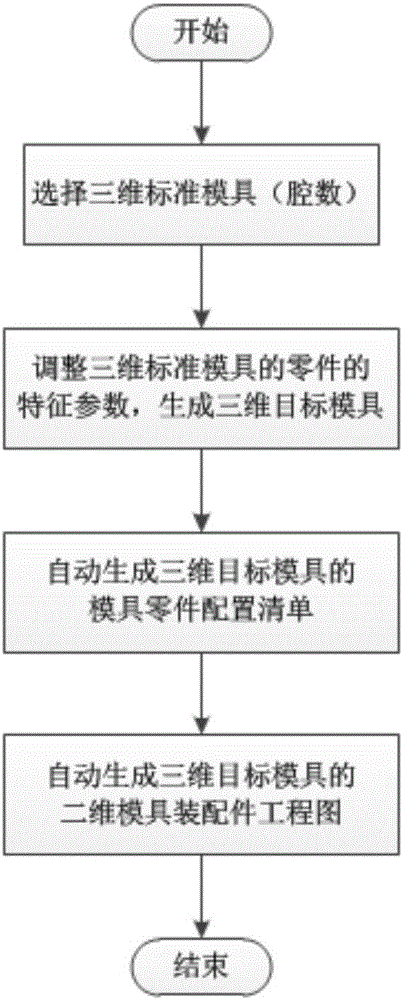

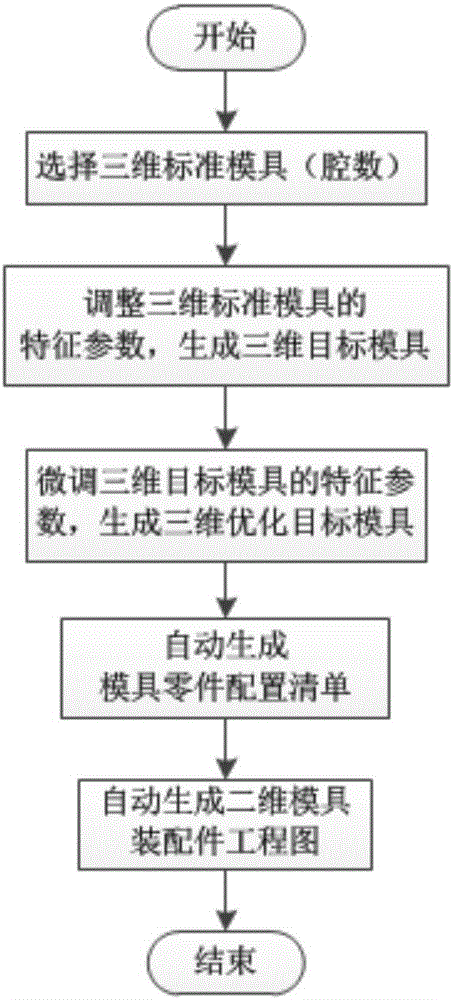

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

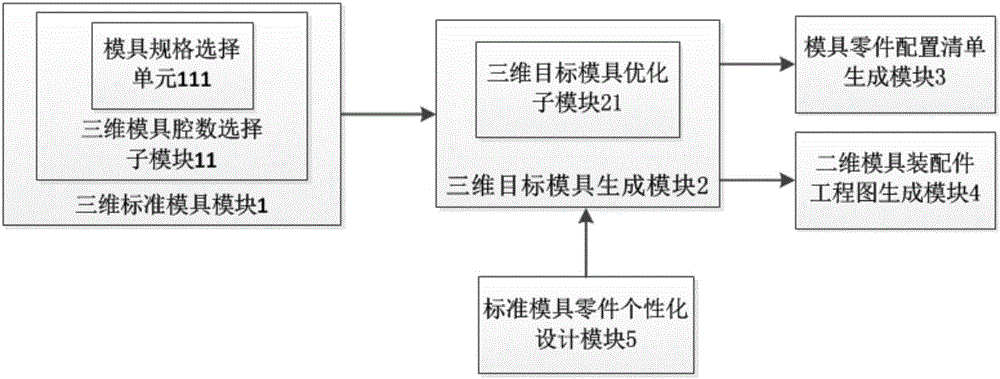

[0036] The ceramic tile mold design software system of the present embodiment, as figure 1 As shown, it includes a three-dimensional standard mold module 1, a three-dimensional target mold generation module 2, a mold part configuration list generation module 3 and a two-dimensional mold assembly engineering drawing generation module 4, and the output terminal of the three-dimensional standard mold module 1 is connected to the three-dimensional The input end of the target mold generation module 2 is electrically connected, the input end of the mold part configuration list generation module 3 and the input end of the two-dimensional mold assembly engineering drawing generation module 4 are all connected to the output end of the three-dimensional target mold generation module 2 electrical connection; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com