Flexible multipoint supported system in use for digital controlled machining laminae

A flexible support, multi-point support technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficult automatic adjustment and poor rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

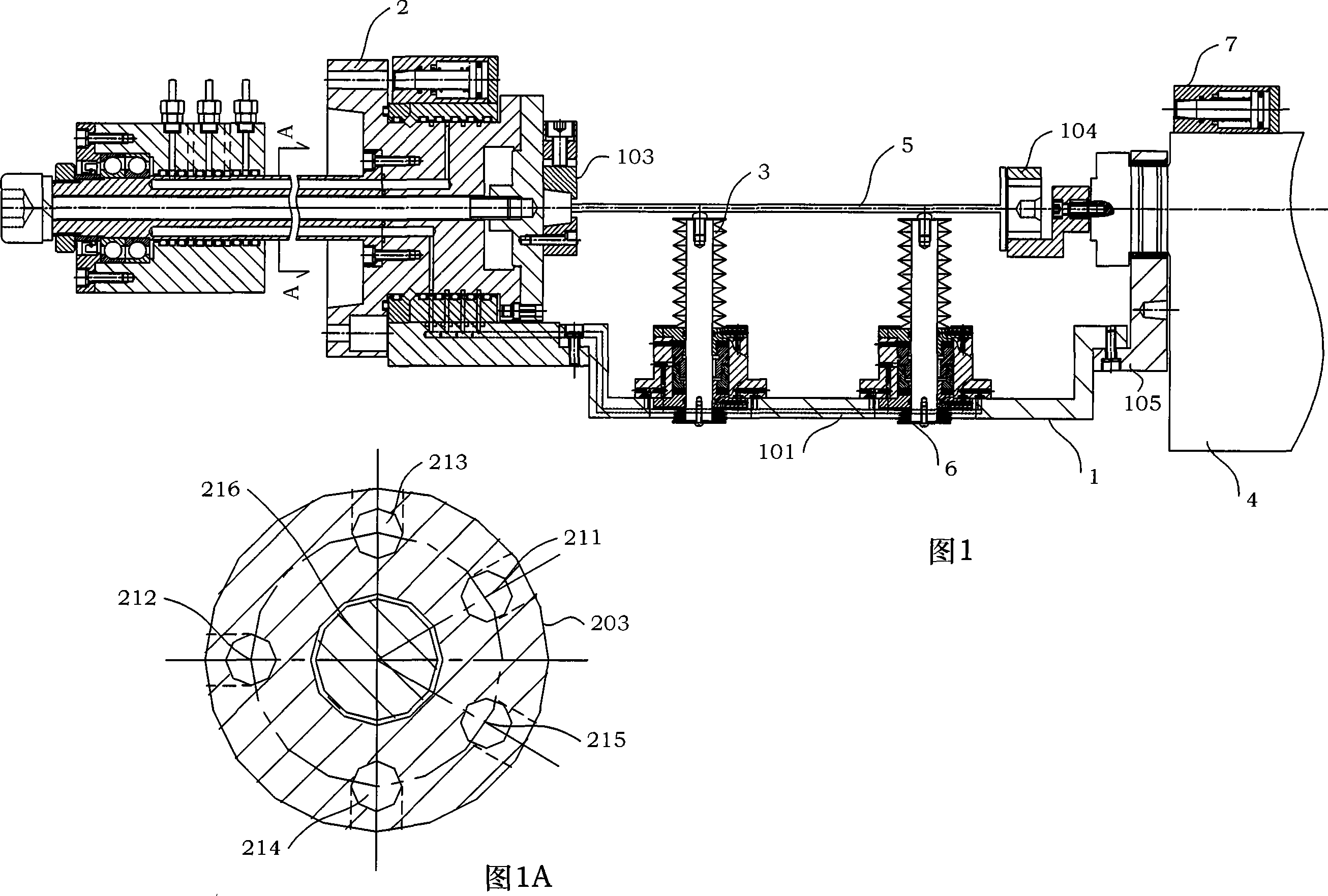

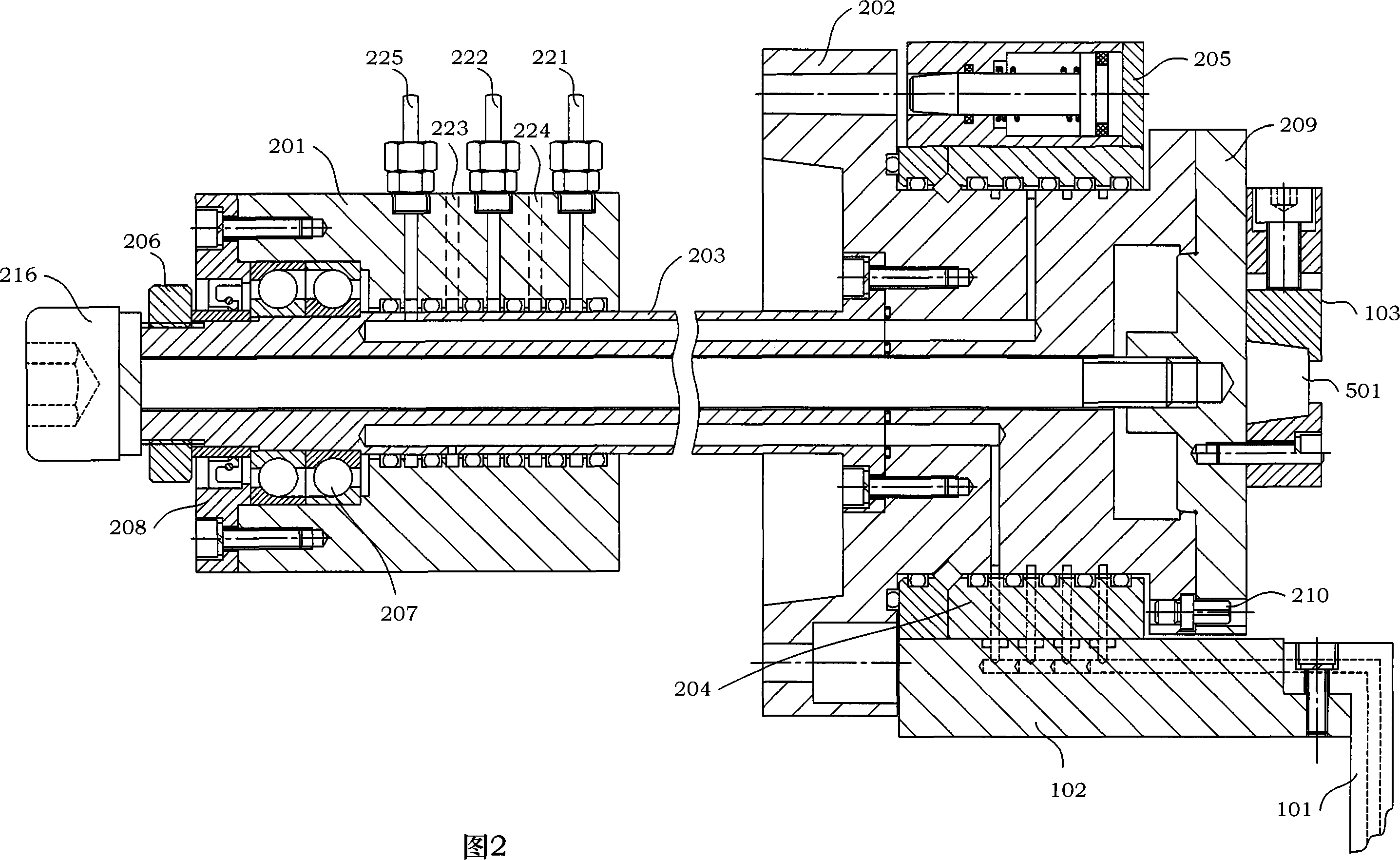

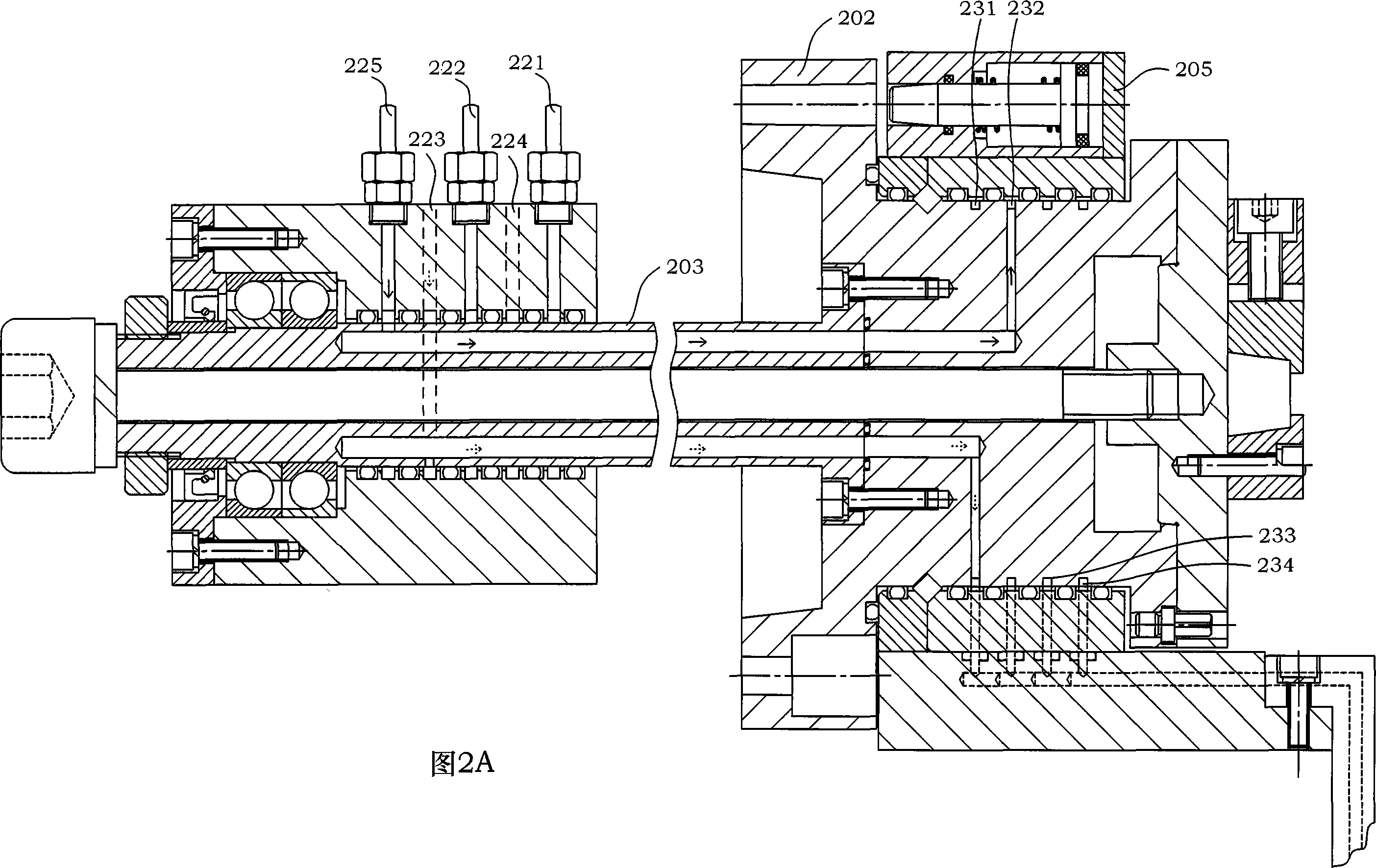

[0014] The present invention is a flexible multi-point support device for CNC machining of blades, which consists of a cradle assembly 1, a working fluid supply assembly 2, an A flexible support assembly 3, and a B flexible support assembly 6, as shown in Fig. 1 and Fig. 2 . The cradle assembly 1 includes a cradle left support 102, a cradle right support 105, and a cradle 101, and the cradle left support 102 is connected to the oil distribution seat 204 with a cross bearing, and the cradle right Bearing 105 is connected on the machine tool tailstock 4 with the cylindrical auxiliary support structure, and the two ends of cradle 101 are connected on the cradle left bearing 102, the cradle right bearing 105. The working fluid supply assembly 2 includes an oil inlet distributor 201, an oil outlet distributor 202 and a composite pipeline 203, which function to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com