Patents

Literature

203results about How to "Little room for movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

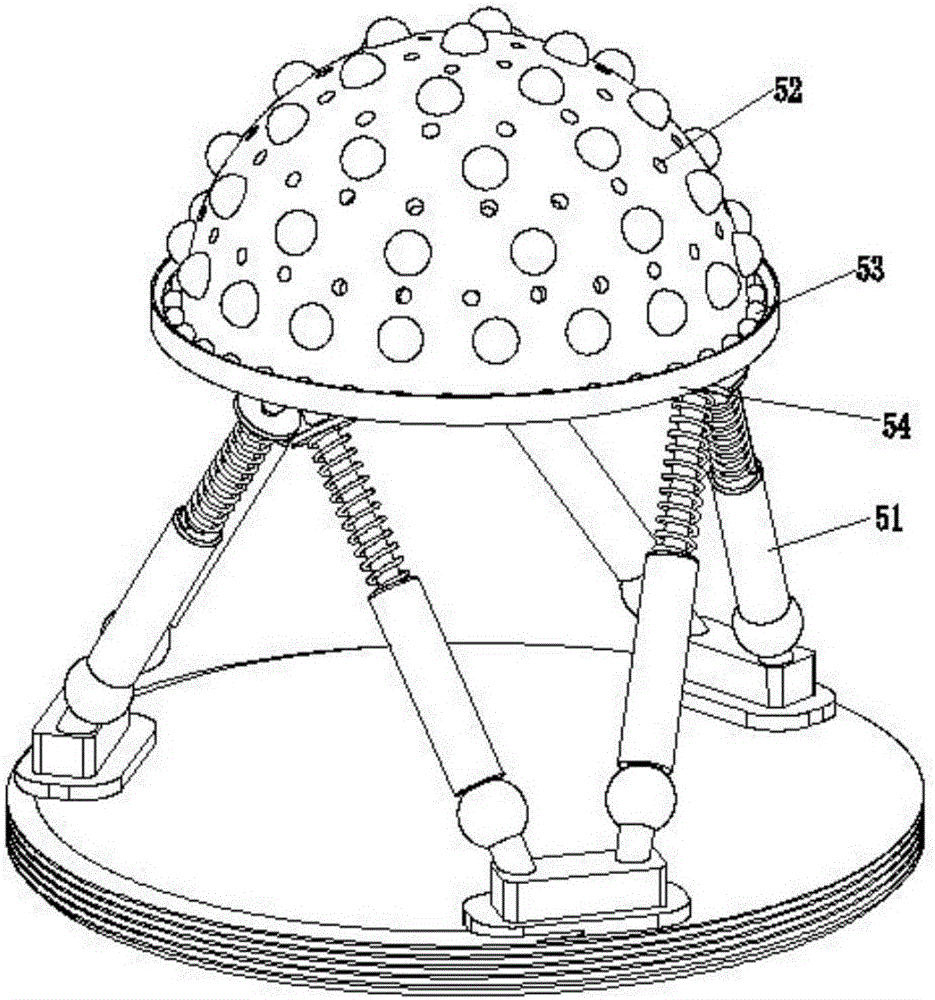

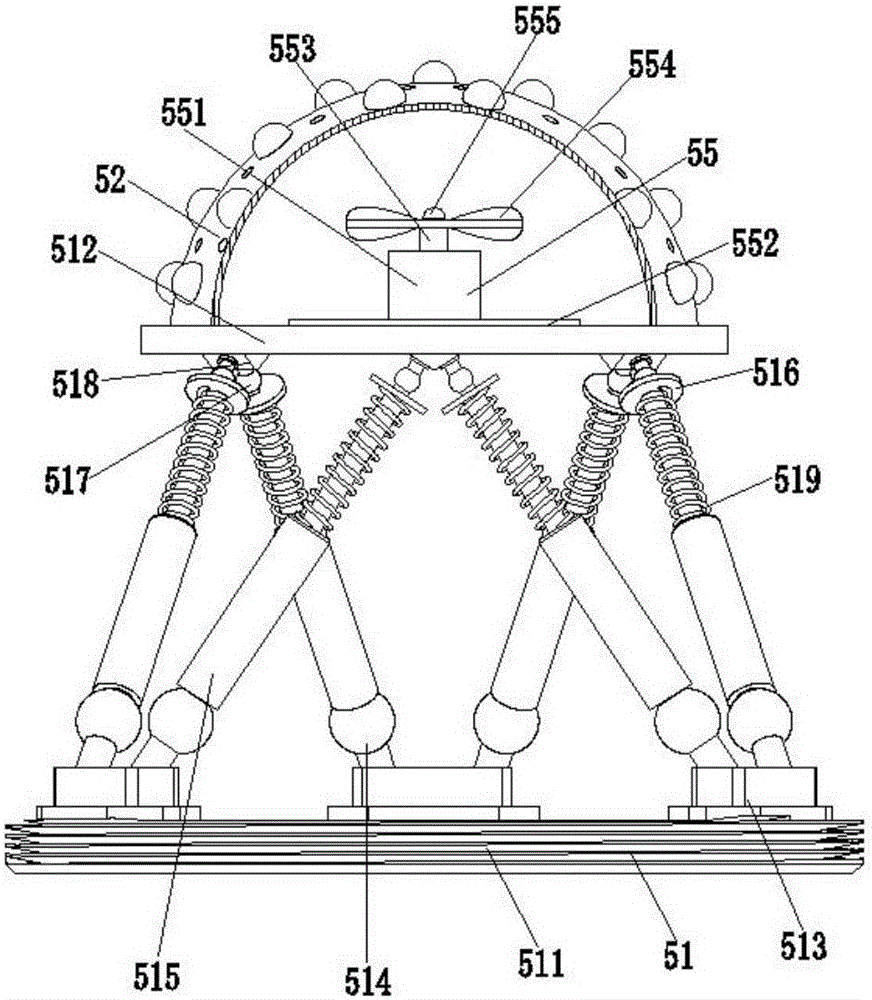

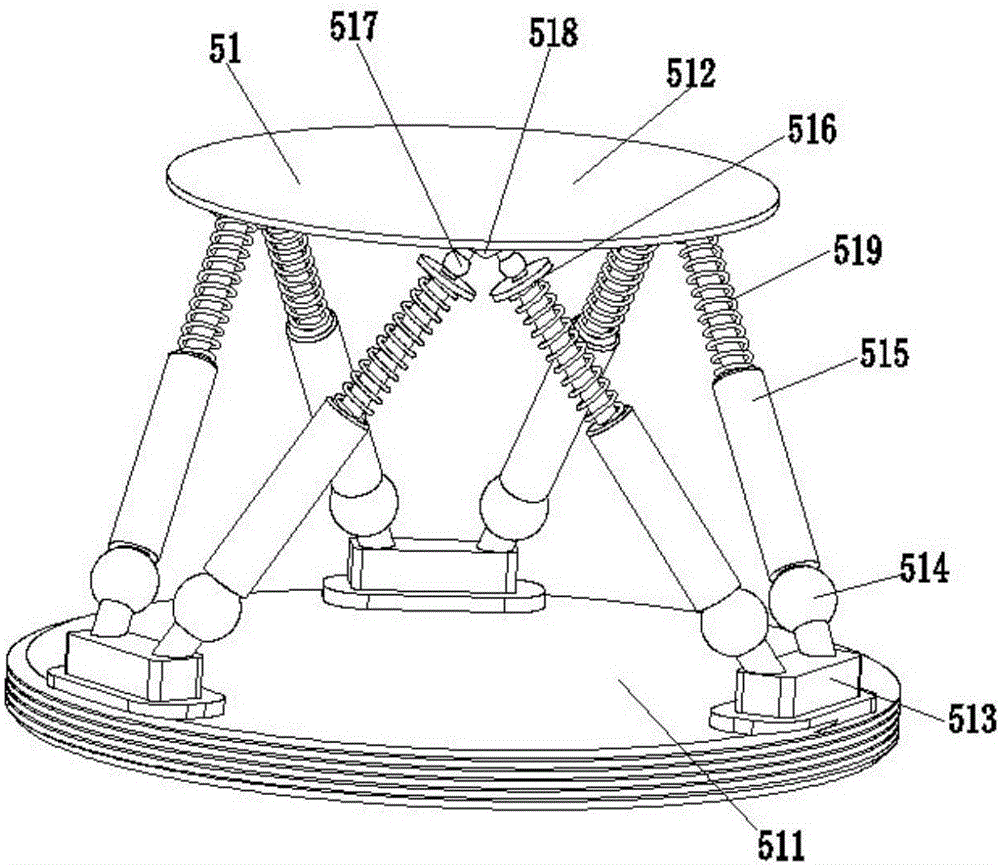

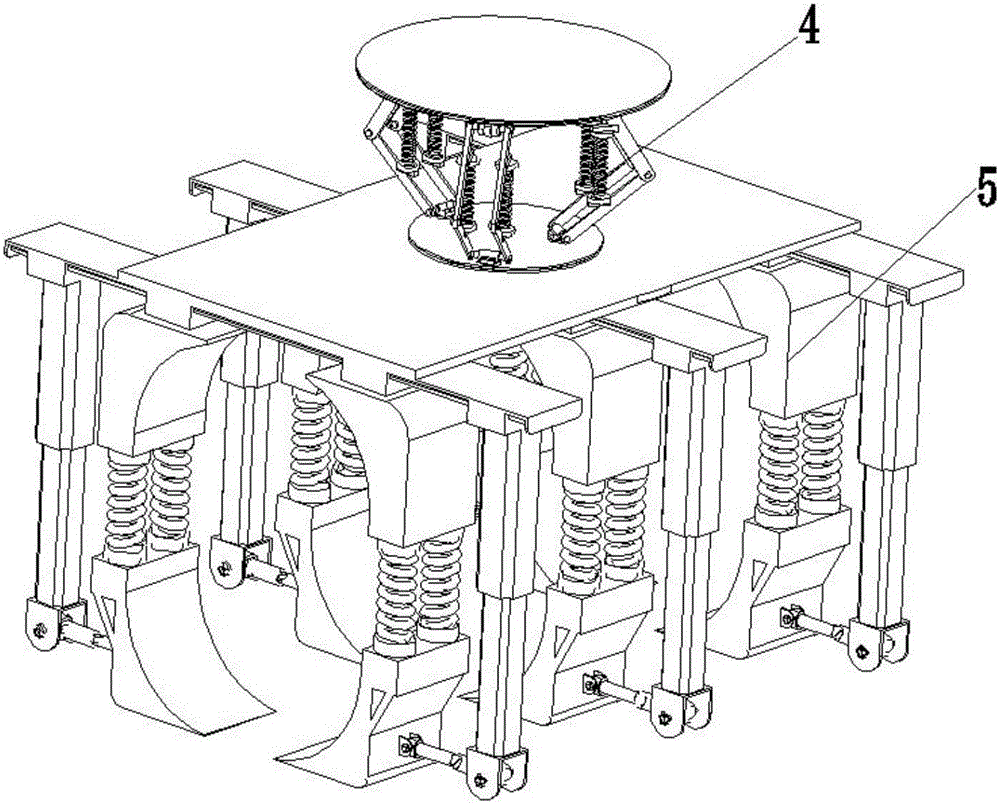

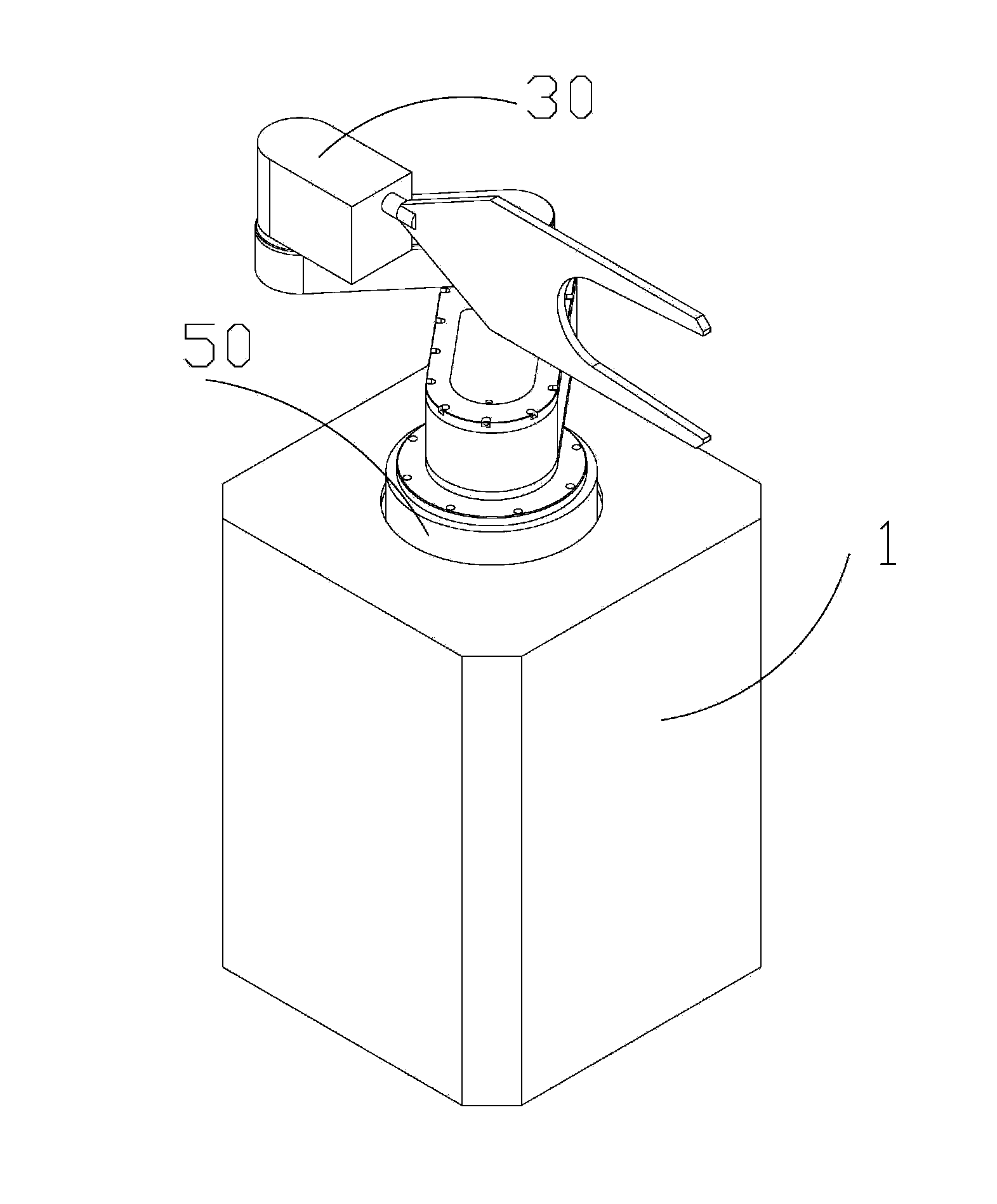

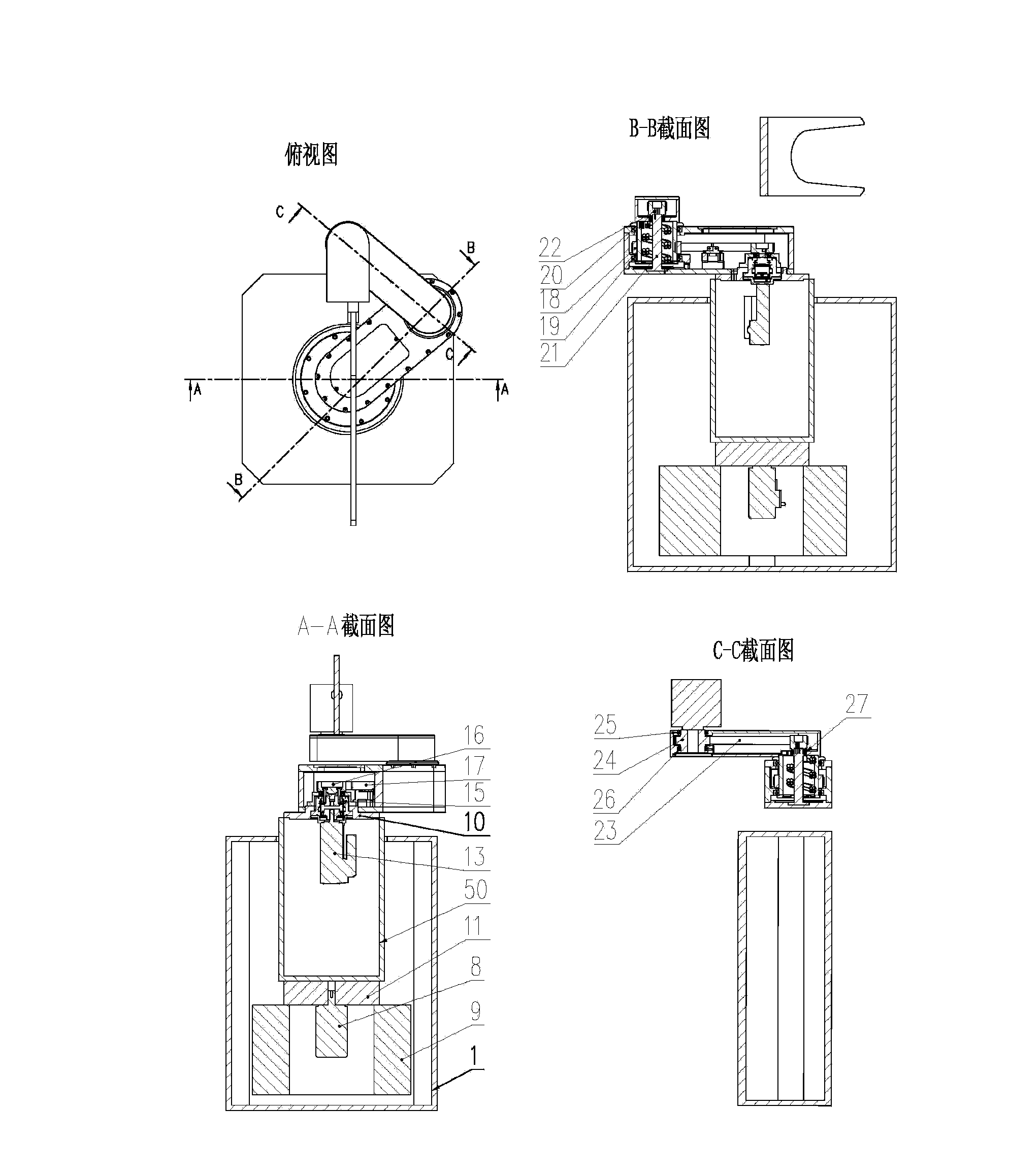

Intelligent armpit massage device based on Stewart parallel mechanisms

ActiveCN105796296AGood for physical and mental healthGood health effectProgramme-controlled manipulatorVibration massageMassageDegrees of freedom

The invention relates to an intelligent armpit massage device based on Stewart parallel mechanisms, which comprises the Stewart parallel mechanisms, a massage outer cover, advance balls, a check ring and an air supply device. The massage outer cover is positioned right above the Stewart parallel mechanisms; vibrating massage heads and air holes are respectively and uniformly formed on the outer surface of the massage outer cover; the vibrating massage heads and the air holes are arranged in a pairwise staggered manner; the check ring is positioned outside the message outer cover, and the check ring is fixed with the Stewart parallel mechanisms; the advance balls are uniformly mounted between the check ring and the massage outer cover. The intelligent armpit massage device disclosed by the invention can be used for carrying out manipulation massaging and air-cooling sweat dissipation on the armpit of a human body, is obvious in massaging effect and high in massage comfort, and takes a good health care effect on the armpit of the human body; the intelligent armpit massage device adopts the 6-SPS Stewart parallel mechanisms, has high bearing capacity and high micromotion accuracy, can take the 3-DOF translational and 3-DOF rotational move in six DOF (Degree of Freedom) directions in total in the space, has a large contact area with the armpit of the human body, and has a good massaging effect.

Owner:邳州市鑫盛创业投资有限公司

Full-automatic hydraulic and hydroelectric engineering drain pipe clamping integrated machine

InactiveCN105887777AHigh degree of automationImprove work efficiencyWater-power plantsHydro energy generationHydropowerAutomation

The invention relates to a full-automatic hydraulic and hydroelectric engineering drain pipe clamping integrated machine. The full-automatic hydraulic and hydroelectric engineering drain pipe clamping integrated machine comprises a walking device, an adjustable support, a rotation device, a delta parallel mechanism and a clamping device. The adjustable support is located above the rear portion of the walking device. The rotation device is located at the position of the front end of the adjustable support. The rotation device is fixedly connected with the adjustable support. The delta parallel mechanism is located between the rotation device and the clamping device. The upper end of the delta parallel mechanism is connected with the rotation device. The lower end of the delta parallel mechanism is connected with the clamping device. By means of the full-automatic hydraulic and hydroelectric engineering drain pipe clamping integrated machine, a series of operation such as grabbing, carrying and stacking of water conservancy and hydropower pipelines can be achieved, the automation degree is high, movement is steady and flexible, the operation efficiency is high, and the problems that the manual carrying operation is high in cost, low in efficiency, large in dangerousness and the like are solved.

Owner:陈薇

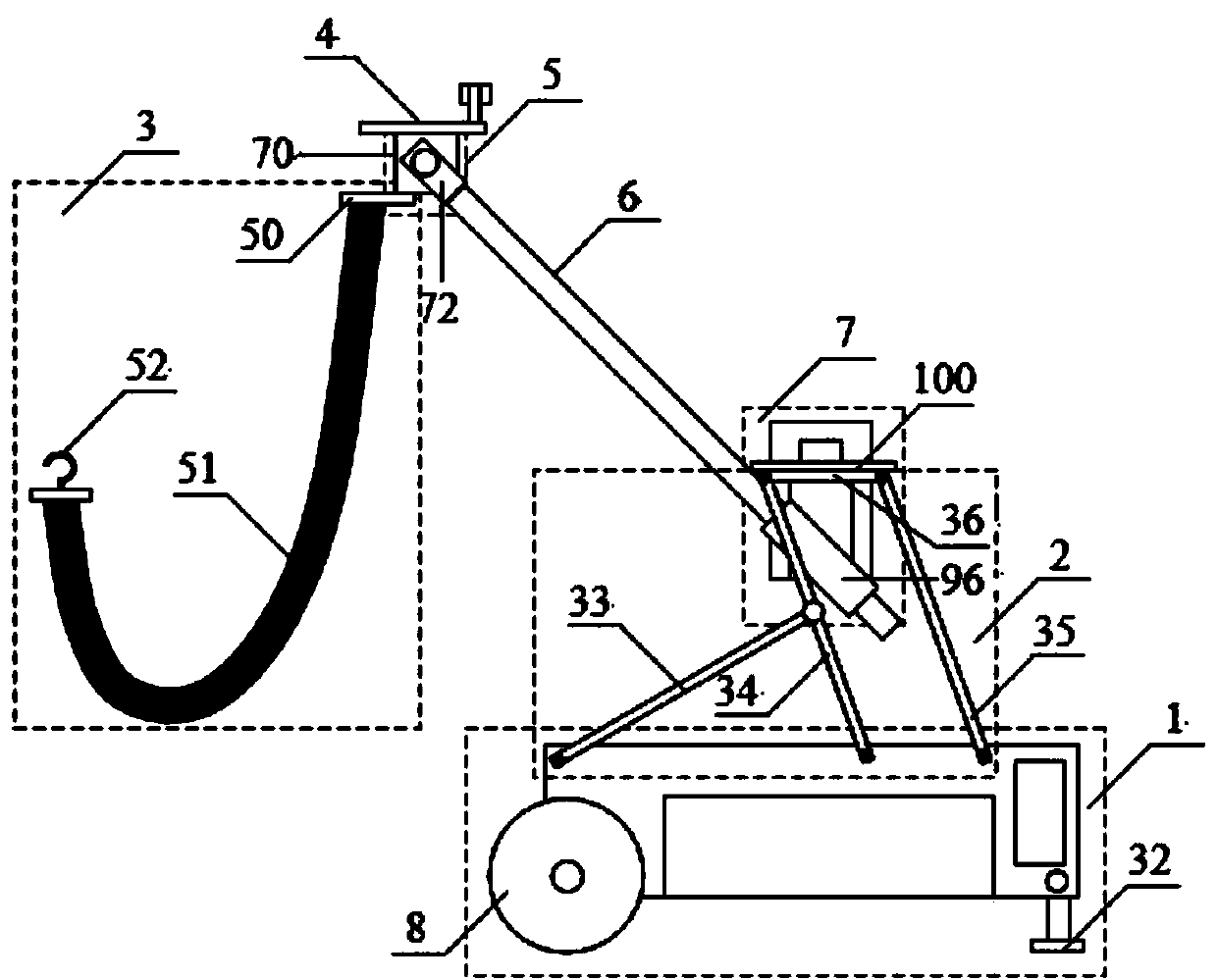

Agricultural high fruit picking device

The invention discloses an agricultural high fruit picking device comprising a two wheel trolley. A lifting mechanism is movably connected to the upper portion of the two wheel trolley and is movably connected to a console; the console is movably connected to one end of a telescopic arm, the other end of the telescopic arm is movably connected to a balance mechanism, the top of the balance mechanism is connected to a shearing arm, and the bottom of the balance mechanism is connected to an accommodating bag. According to the device, the two wheel trolley replaces of a power transport vehicle to be adaptive to poor driving condition of an orchard; the telescopic arm replaces of a mechanical arm with multiple freedom degrees, weight is decreased, structure and control of the arm are simplified, and the moving space of the arm is saved; the suspended soft bag replaces of a fixed fruit conveying channel, the fruit conveying distance is shortened, and fruit damage is reduced; the device is more adaptive to the application for the orchard.

Owner:XI'AN POLYTECHNIC UNIVERSITY

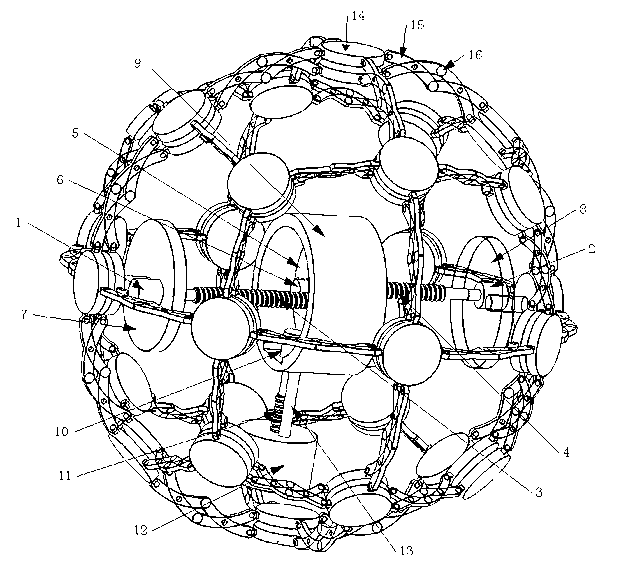

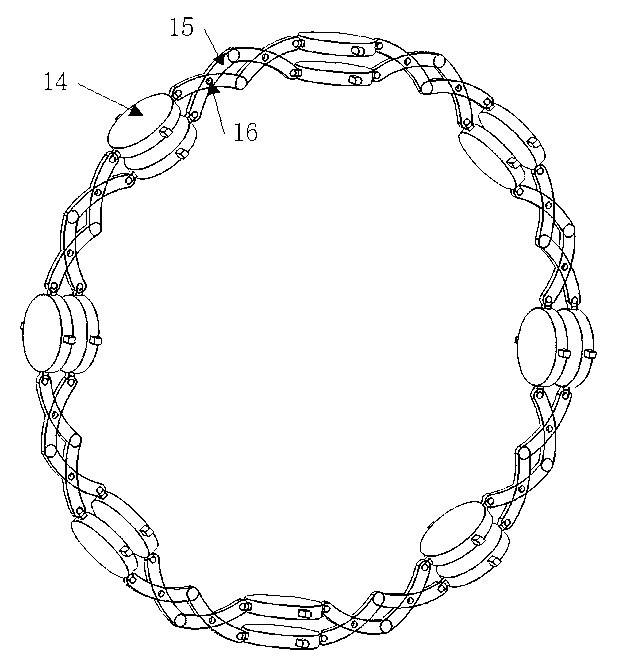

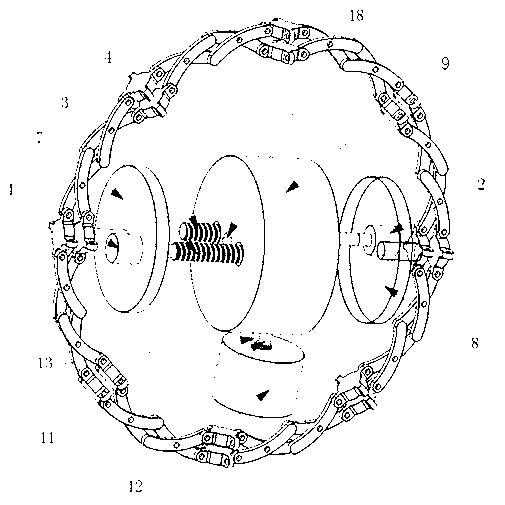

Extensible spherical robot mechanism

The invention discloses an extensible spherical robot mechanism comprising an outer spherical frame, a sphere extension mechanism and a rolling mechanism. Connecting blocks and connecting rods are connected through hinges to form the outer spherical frame so as to form a parallelogram mechanism composed of three mutually perpendicular round frames as main frames and six square frames; the sphere extension mechanism comprises a left fixed plate and a right fixed plate which are fixed on the connecting blocks; the sphere extension mechanism is connected with the rolling mechanism through a center shaft. The extensible spherical robot mechanism can work in more complicated environments, when movement spaces are broad, the size of the extensible spherical robot mechanism can be enlarged, the large extensible spherical robot mechanism is high in speed and good in mobility performance, and when in narrow spaces, the extensible spherical robot mechanism can be downsized so as to pass the narrow spaces.

Owner:SHANGHAI UNIV

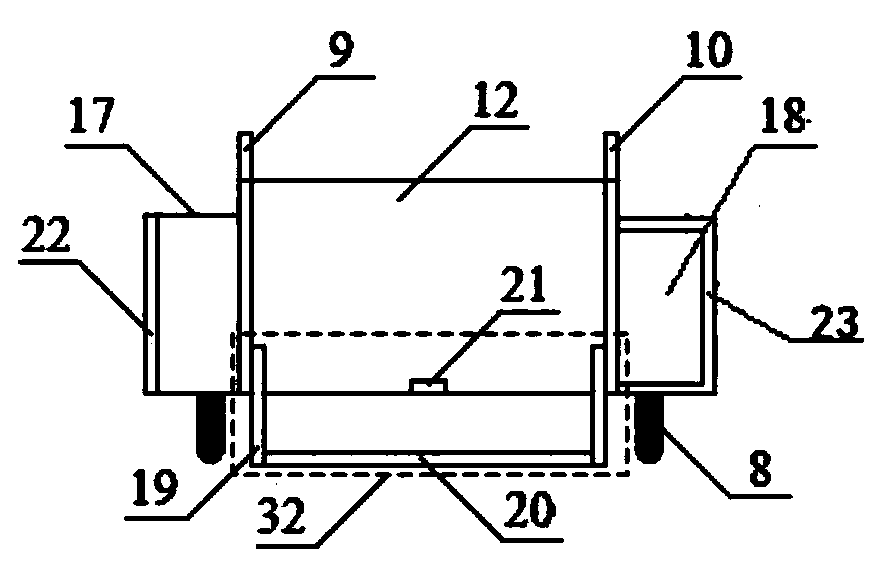

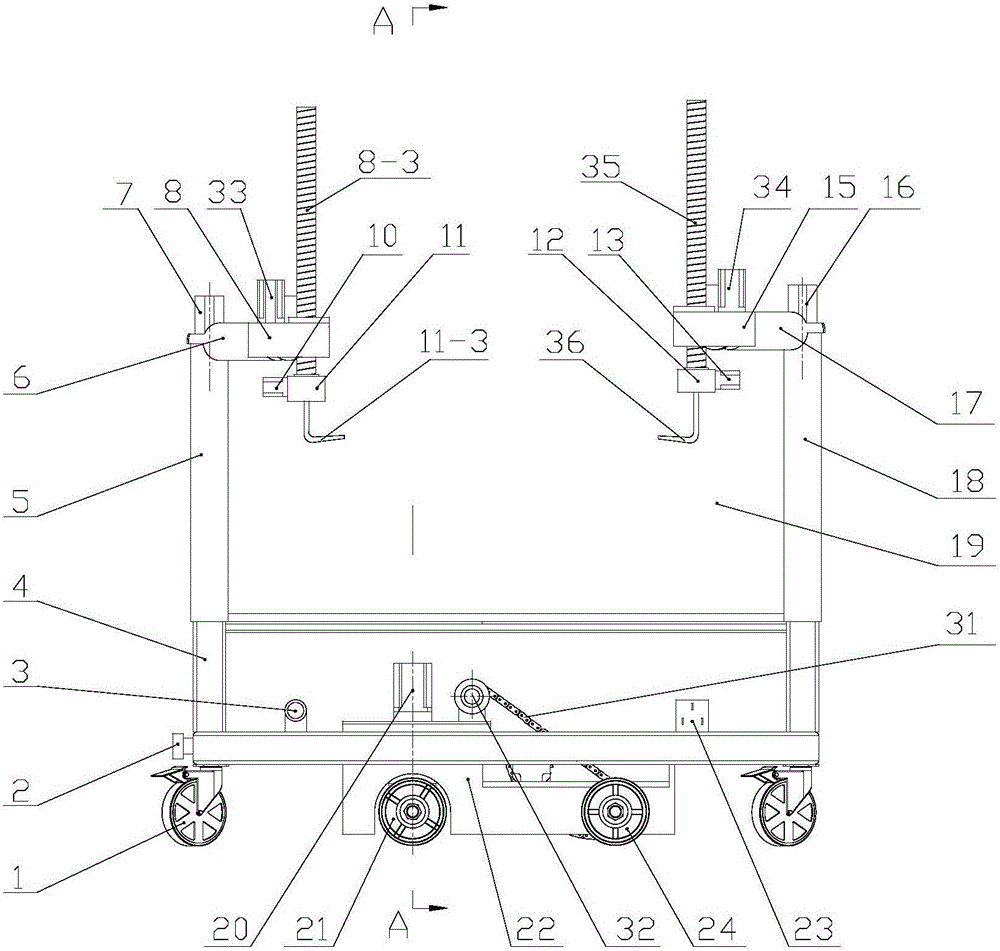

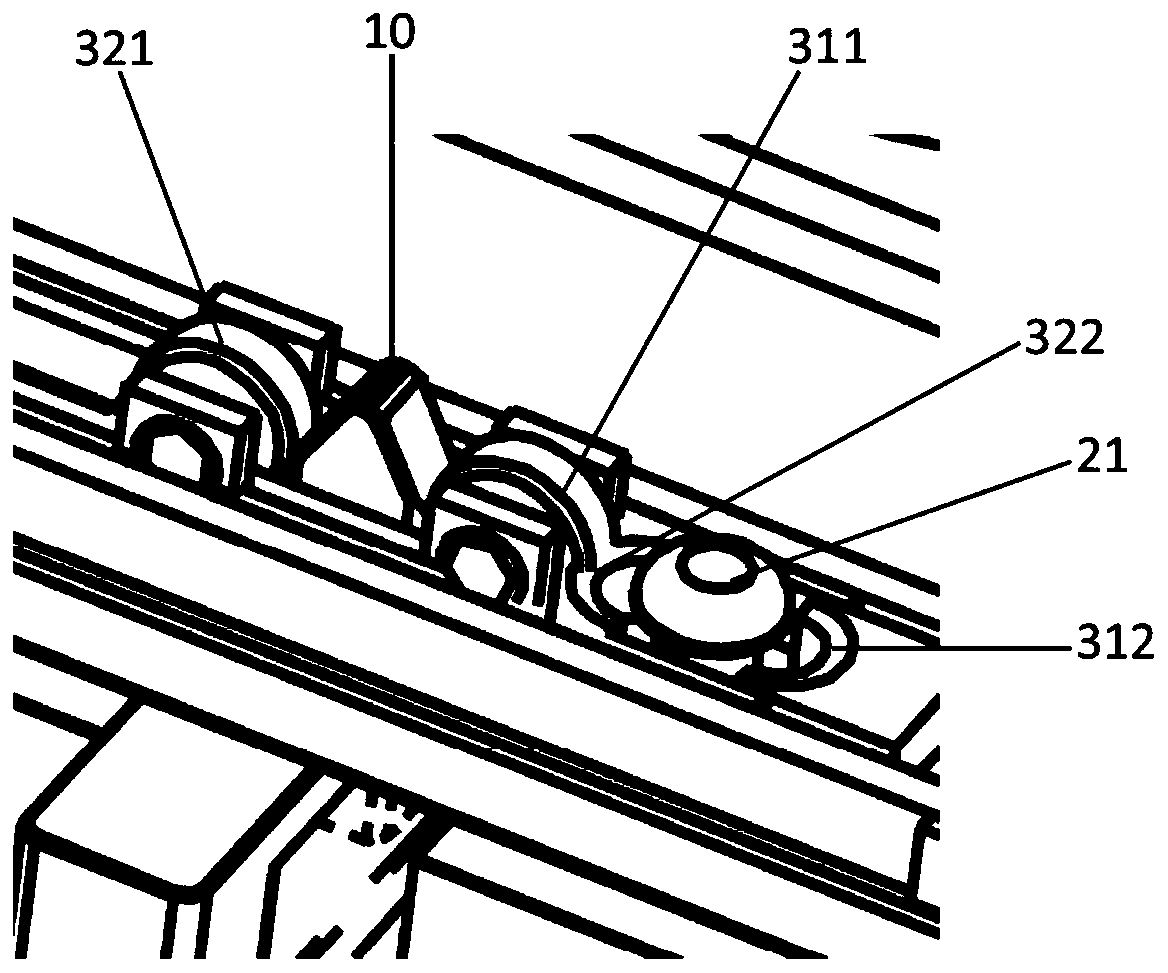

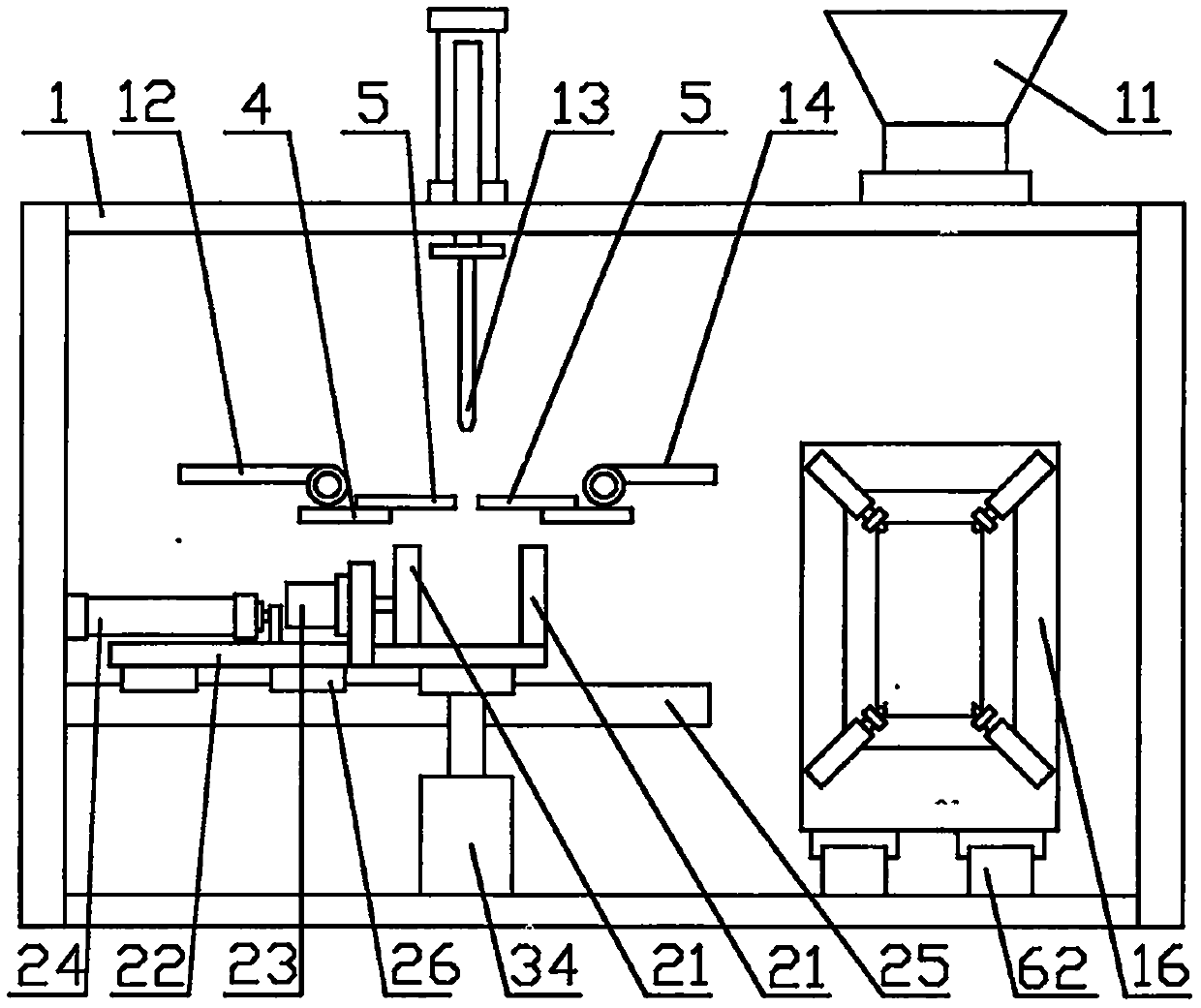

Double-station grabbing mechanism

InactiveCN106586532ALittle room for movementAvoid the risk of interferenceConveyor partsEngineeringProduct Part

A double-station grabbing mechanism comprises two grabbing mechanism bodies slidably mounted on a rack. Three stations are arranged below the two grabbing mechanism bodies. The two grabbing mechanism bodies are fixedly connected through a connecting rod. The three stations are arranged linearly. The distance between every two adjacent stations is equal to the distance between the two grabbing mechanism bodies. The two grabbing mechanism bodies move synchronously left and right in the transverse direction. The left grabbing mechanism body conveys products in the left station to the middle station firstly, the right grabbing mechanism body conveys products in the right station to the middle station for assembling the products and the products conveyed by the left grabbing mechanism body. According to the scheme, coordinative carrying of the products on the grabbing mechanism bodies on the two sides can be achieved just through one set of air cylinders, the movement space of a product part transmission mechanism is reduced, and the production cost is lowered.

Owner:BOZHON PRECISION IND TECH CO LTD

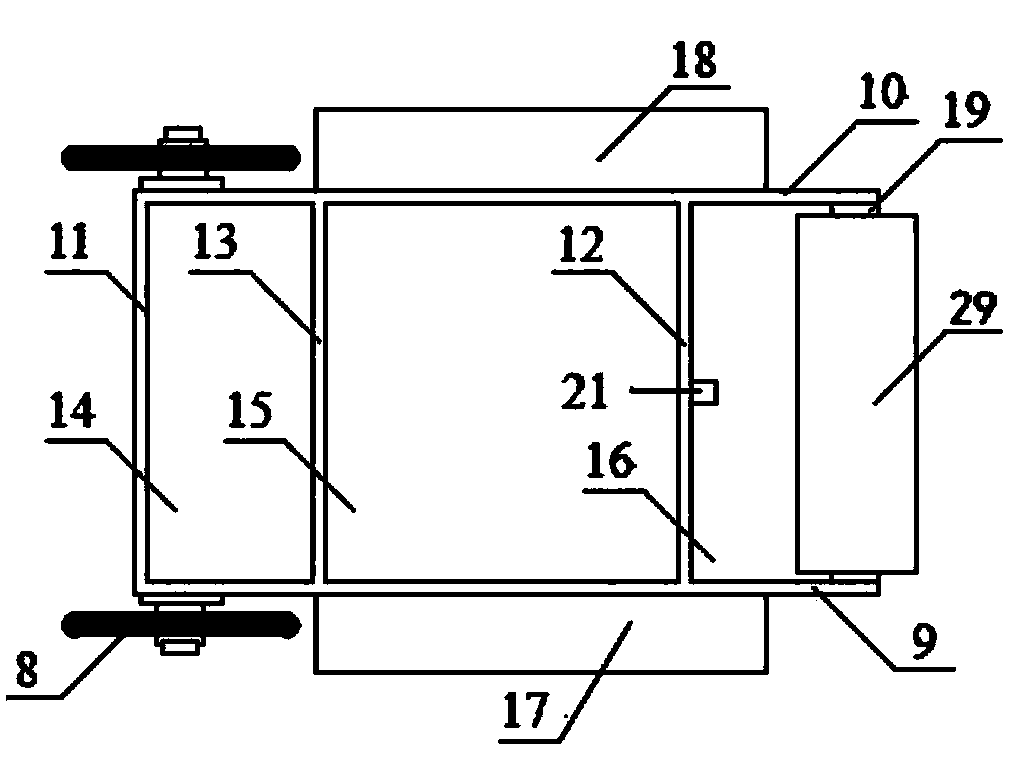

Material carrying mechanical arm structure and moving type kitchen carrying robot with material carrying mechanical arm structure

InactiveCN105881522AAchieve freedom of movementLittle room for movementProgramme-controlled manipulatorConveyor partsControl engineeringElectric machinery

The invention discloses a material carrying mechanical arm structure which comprises two mechanical arms which are symmetric left and right. Each mechanical arm comprises a large arm, a large arm motor, a small arm, a small arm motor, a lifting arm, a vertically-moving motor and a clamping device. The two clamping devices are horizontally opposite to each other left and right so as to be matched to clamp materials. The material carrying mechanical arm structure can carry different materials different in size and height and is particularly suitable for carrying materials such vegetables, flour and semi-finished products in kitchens of large canteens, hotels and restaurants. The invention further discloses a moving type kitchen carrying robot with the mechanical arm structure. The moving type kitchen carrying robot can walk and turn automatically, automatically recognize the position information of the materials, automatically avoid obstacles and automatically load and unload the materials, the materials cannot be carried manually, equipment does not need to be controlled manually, the automation degree and the production efficiency are high, the labor force and production cost are saved, and control is simple and reliable.

Owner:UNIV OF JINAN +1

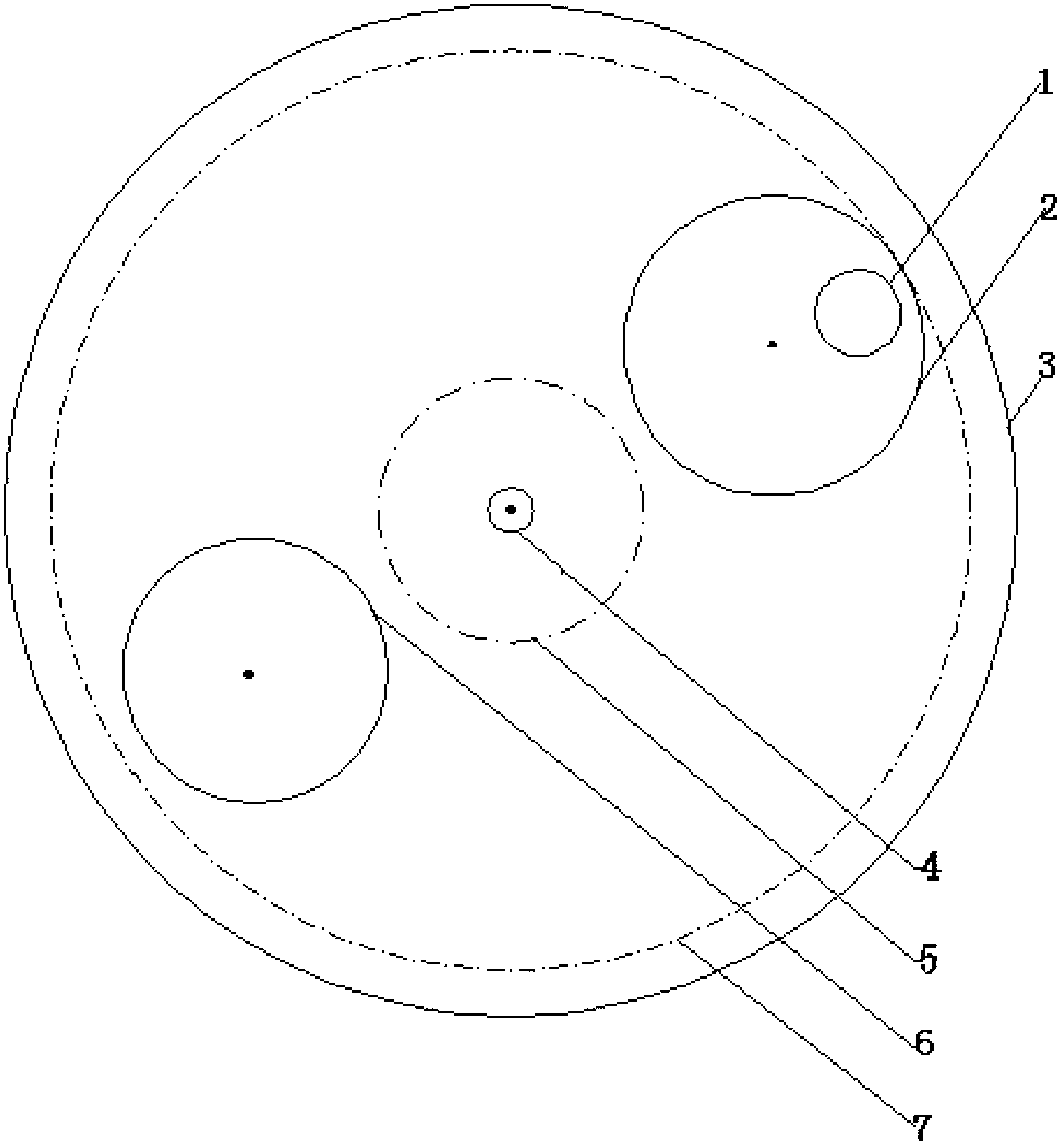

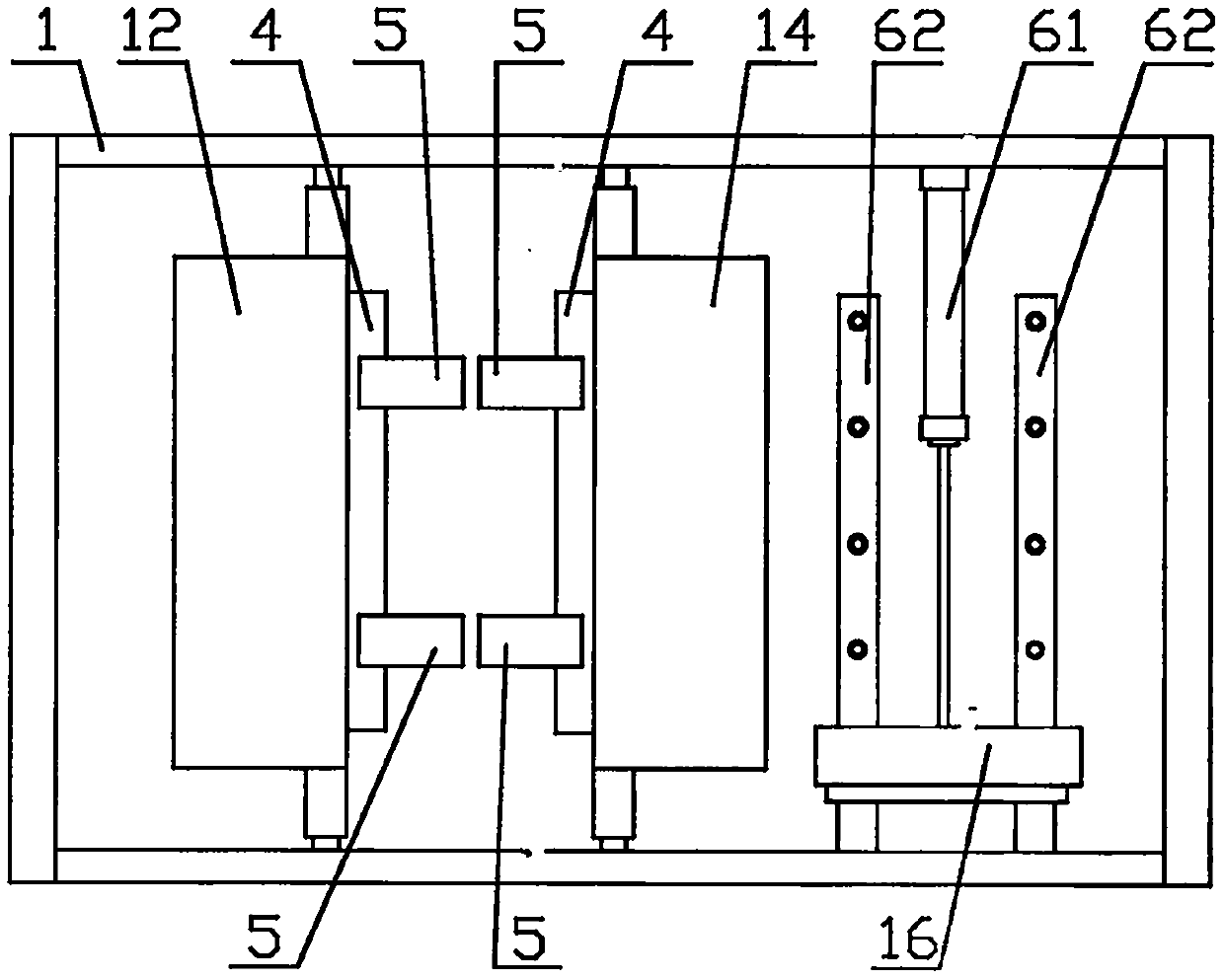

Multi-cock system for accelerator to drive subcritical reactor to refuel

InactiveCN102708936ALittle room for movementEasy to separateNuclear energy generationReactor fuel elementsNuclear engineeringBeam tube

A multi-cock system for an accelerator to drive a subcritical reactor to refuel comprises a large cock, a first small cock, a second small cock, a control deflection barrel and a refueling machine, wherein the large cock is installed on a reactor top cover to be concentric with the reactor top cover, the first small cock and the second small cock are installed on the large cock and are eccentric to the large cock, the refueling machine is installed on the first small cock and is eccentric to the first small cock, the control deflection barrel is connected onto the second small cock, the control deflection barrel is a cylindrical mechanism carrying a control bar system, and the control deflection barrel is provided with a curved through groove from the axis to the outside and from top to bottom, which is used for detaching an accelerator proton beam tube. When the reactor runs, the control deflection barrel is positioned right above a reactor core. Fusible alloy at the sealed position of the cock is molten in refueling operation, the second small cock firstly translates the control deflection barrel to the position which is away from the reactor core so as to reserve a space for the refueling operation, and then a crankshaft connecting rod mechanism consisting of the large cock, the first small cock and the refueling machine can align the refueling machine to any refueling position on the reactor core through the reciprocating movement. Due to the adoption of the multi-cock system, the refueling circulation of an accelerator drive system (ADS) reactor can be well completed, and the normal work of other systems of the ADS is not influenced.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Breaking and cleaning machine for plastic bags

ActiveCN106827293AImprove processing qualityReduce volumePlastic recyclingCleaning using liquidsElastic compressionSlurry

The invention relates to the technical field of plastic bag processing equipment and discloses a breaking and cleaning machine for plastic bags. The breaking and cleaning machine comprises a rack. A material sorting chamber, an extrusion chamber, a breaking chamber and a precipitating chamber are sequentially arranged on the rack from top to bottom. A breaking tool is arranged in the breaking chamber. A first cylinder and a pressing mechanism are arranged on the rack. The pressing mechanism comprises a second cylinder and a pressing cap. A sliding rail is arranged in the pressing cap. A pressing plate is arranged below the pressing cap and fixedly connected to the lower end of the second cylinder. An elastic compression cylinder is arranged in the material sorting chamber. A filling cavity is formed between the compression cylinder and the material sorting chamber. A feeding opening is formed in the filling cavity. The bottom wall of the material sorting chamber comprises a left bottom plate and a right bottom plate which are slidably connected with each other. A vertical inserting rod is arranged on the left bottom plate. The lower end of the inserting rod extends into the extrusion chamber. A partition layer is arranged in the extrusion chamber. Starch slurry is arranged in the partition layer. Leakage holes are formed in the partition layer. Paired rollers are arranged on the outer side of the face, with the leakage holes, of the partition layer and are each provided with a freezing pipe spirally wound. The lower ends of the paired rollers both incline towards the axis of the extrusion chamber. By means of the breaking and cleaning machine, the plastic bags can be strongly broken.

Owner:重庆鑫斗包装材料有限公司

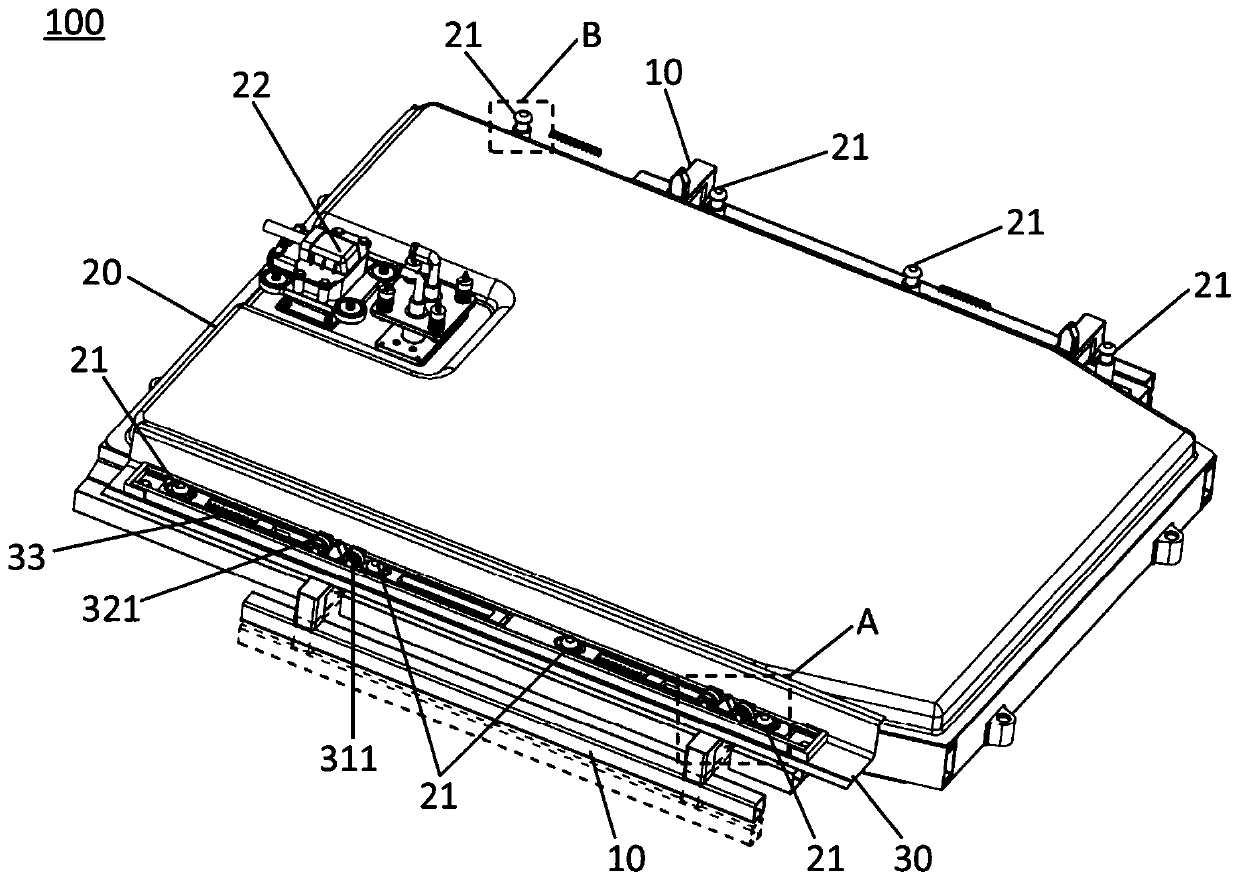

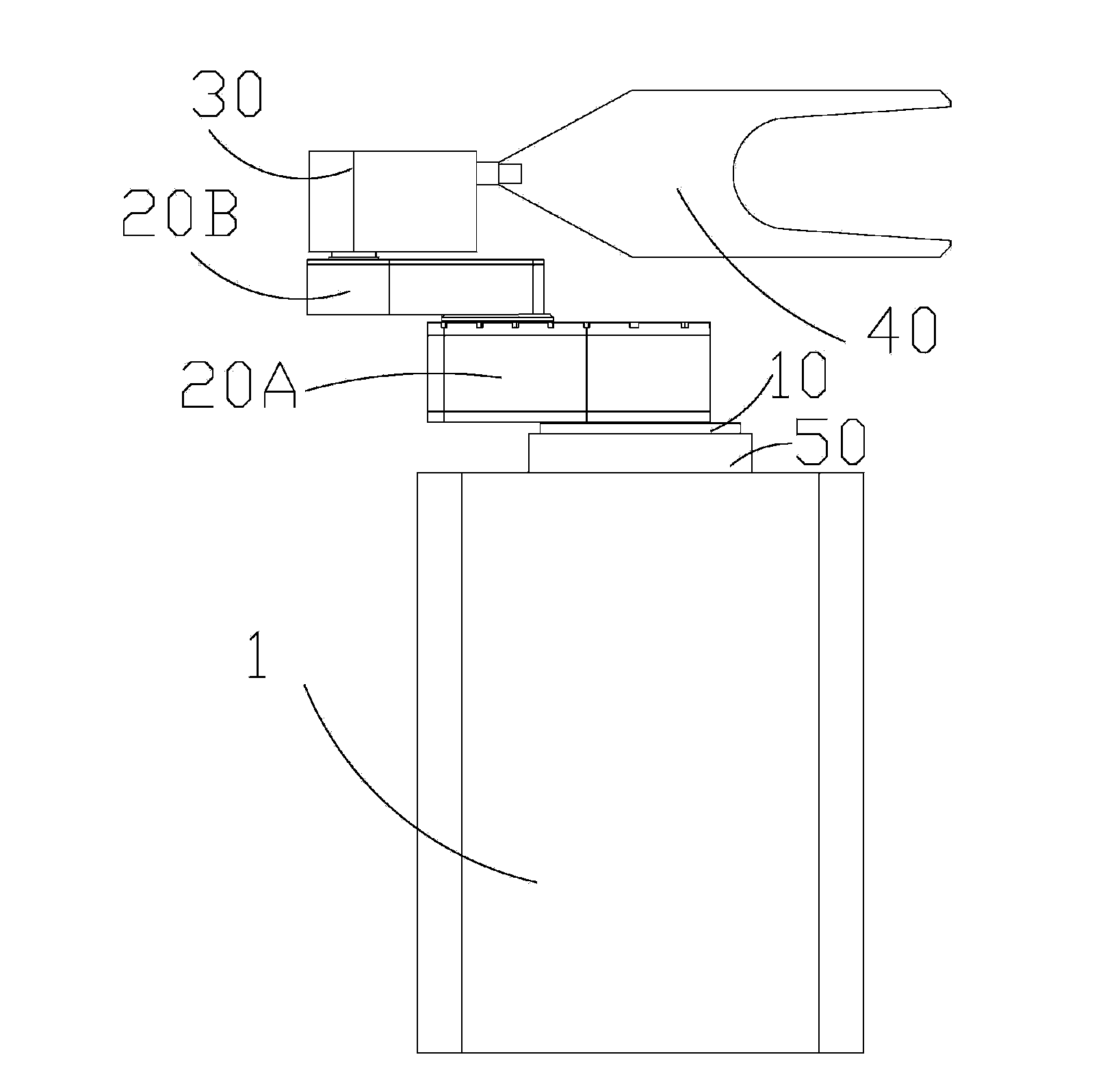

Battery locking device, electricity exchange system and electricity exchange method for vehicle

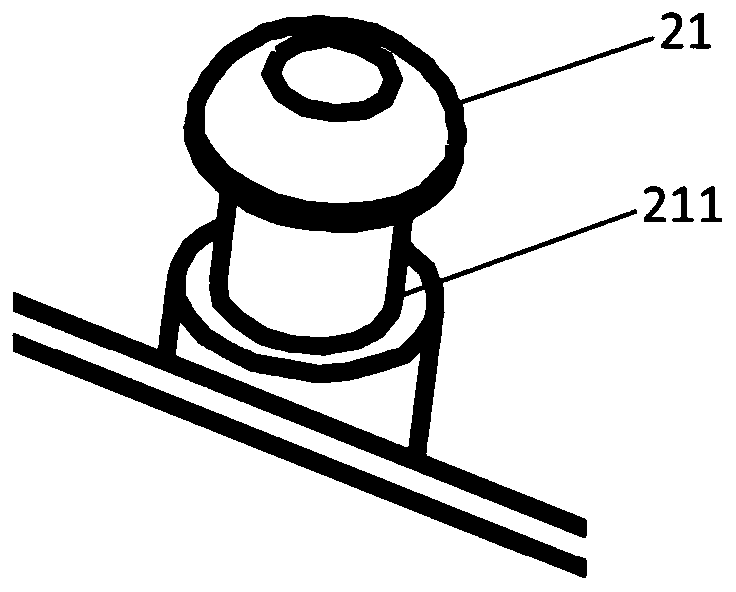

ActiveCN110015122AImprove replacement efficiencySimple actionCharging stationsElectric propulsion mountingElectricityElectrical battery

The invention provides a battery locking device, an electricity exchange system and an electricity exchange method for a vehicle, and belongs to the field of vehicles. The battery locking device includes a lifting mechanism, a plurality of locking rods, a locking structure, and a spring, wherein the lifting mechanism can stretch out and draw back in the vertical direction, the locking rods are protruded from a battery pack in the vertical direction of the vehicle, the locking structure is fixed to a vehicle body and comprises a first movable block, and a second movable block, wherein the firstmovable block can move in the horizontal direction and is provided with a first contact block and first clamping connection surfaces with the same number of the locking rods, and the second movable block can move in the horizontal direction and is provided with a second contact block and a plurality of second clamping connection surfaces. When the battery locking device is in the locking state, the locking rods are clamped tightly by the first clamping connection surfaces and the second clamping connection surfaces, when the battery locking device is in the loosen state, the lifting mechanismextends between the first contact block and the second contact block to push the first movable block and the second movable block to move towards each other, and thus each pair of the first clampingconnection surfaces and the second clamping connection surfaces move back to release the locking rods. The battery locking device can effectively improve the electricity exchange efficiency of the battery locking device.

Owner:ZHEJIANG JIZHI NEW ENERGY AUTOMOBILE TECH CO LTD +1

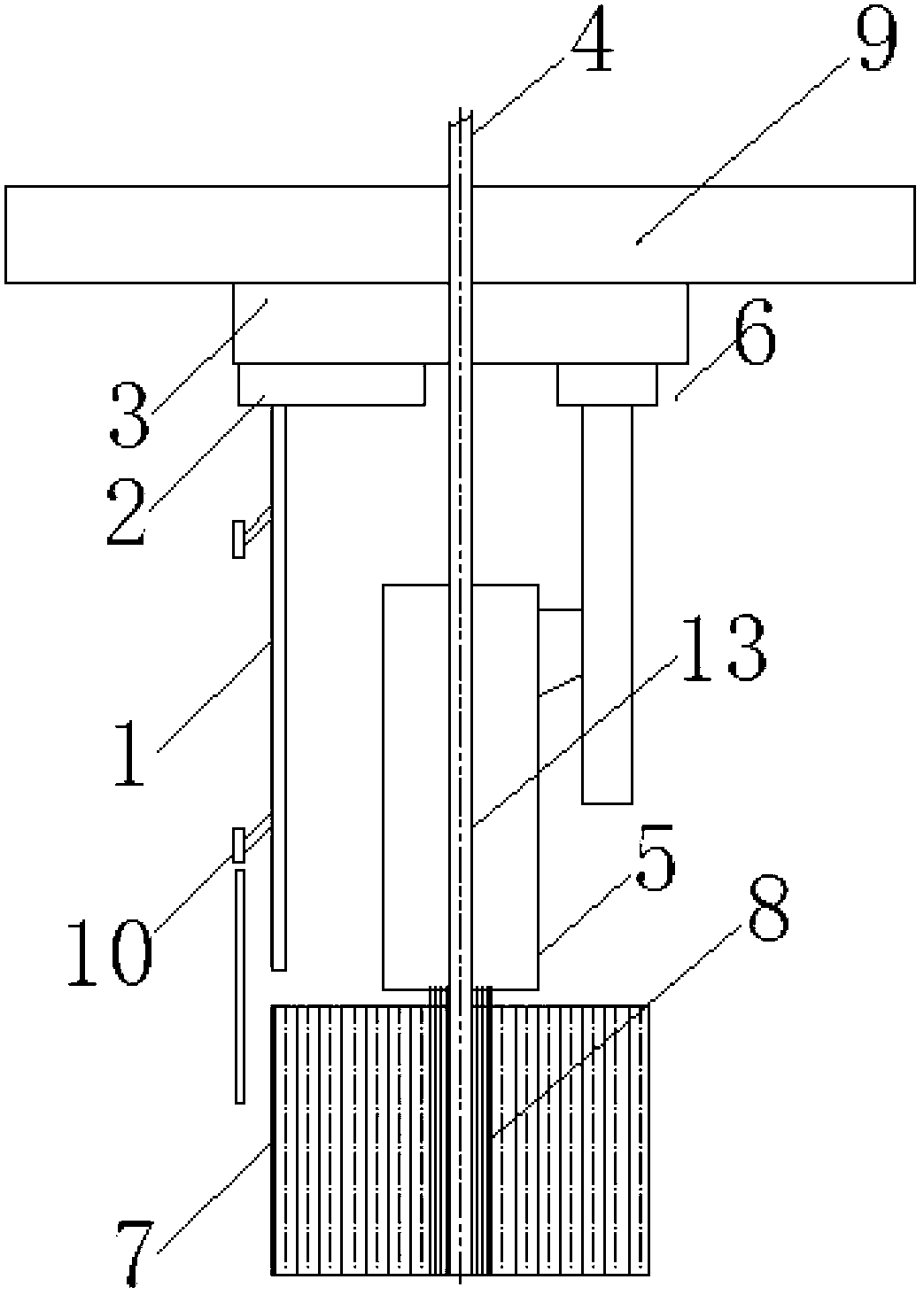

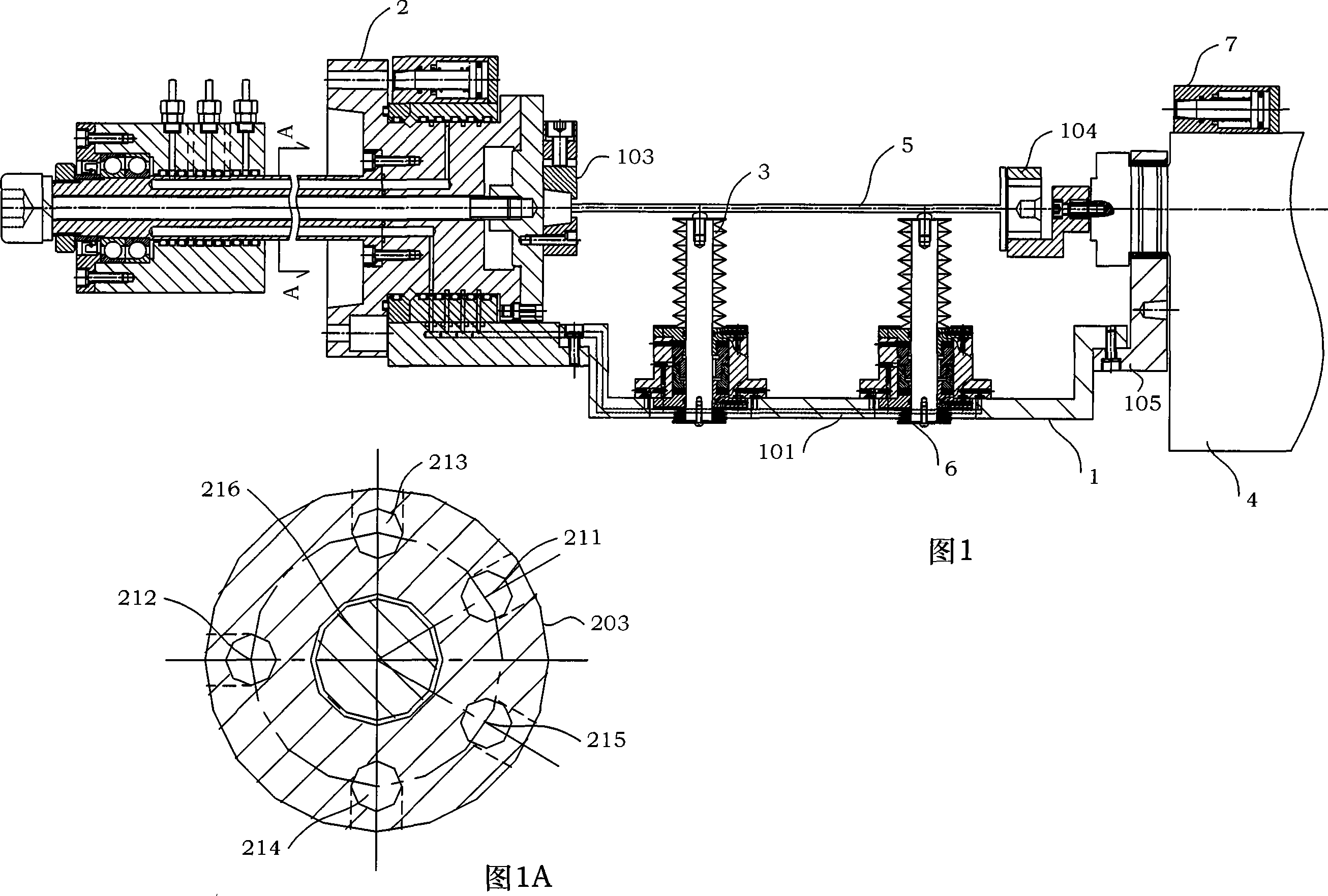

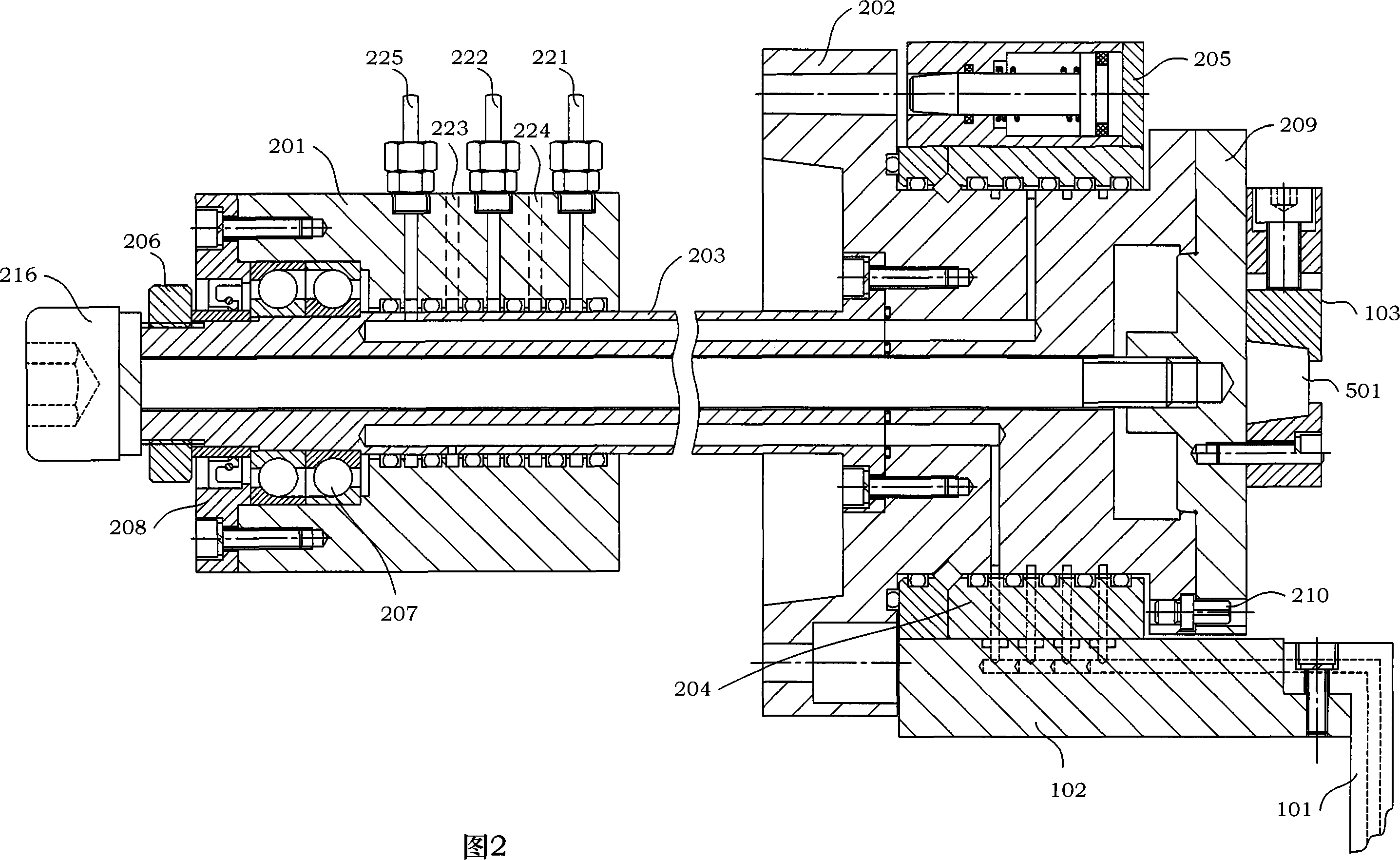

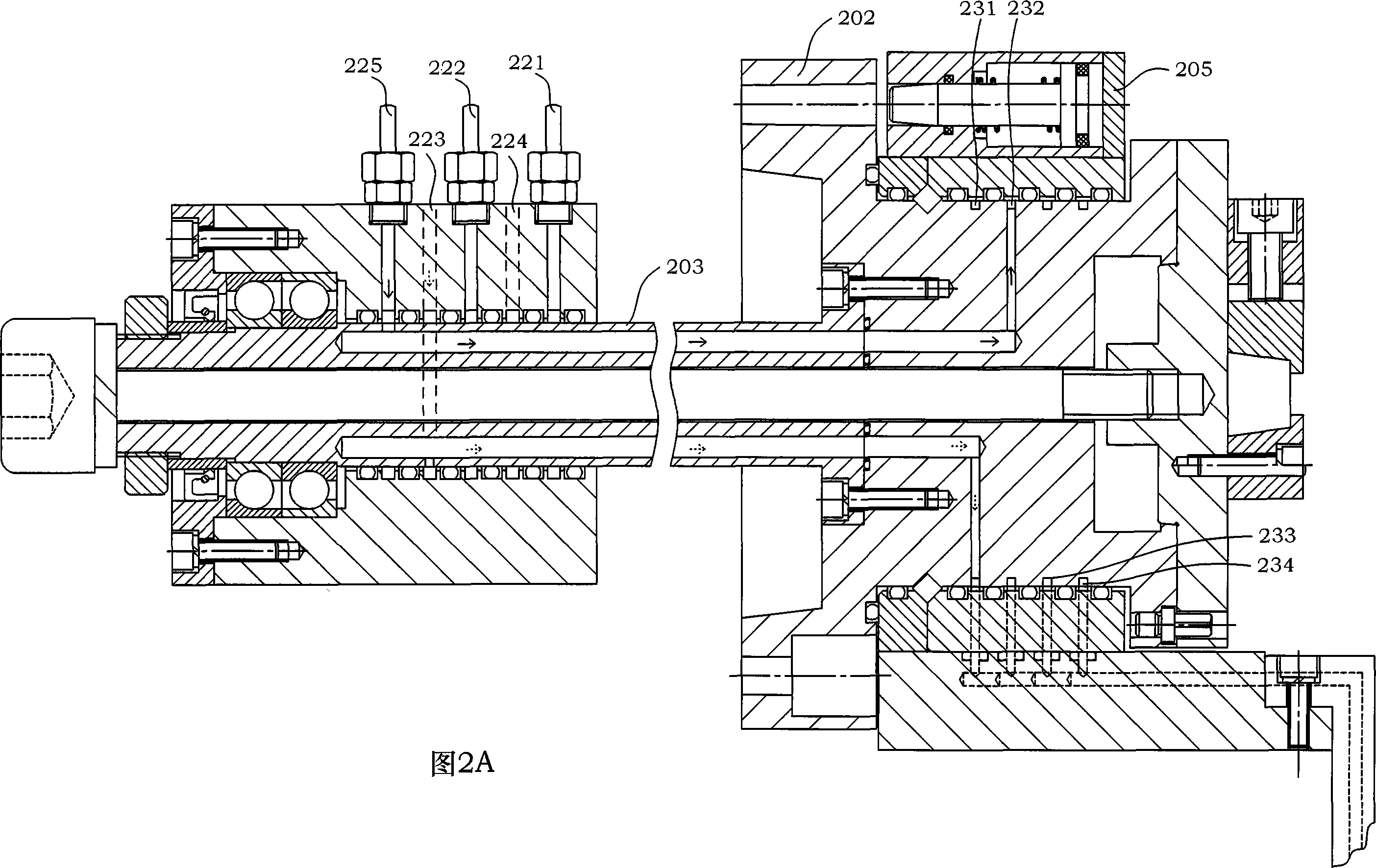

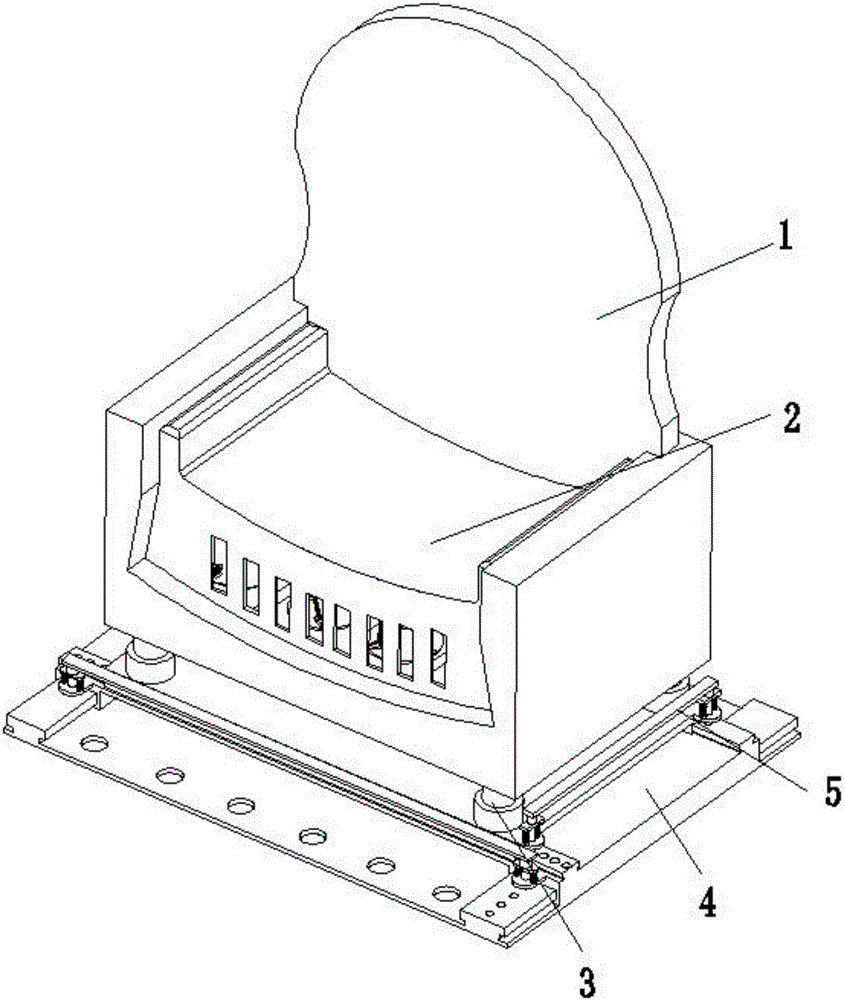

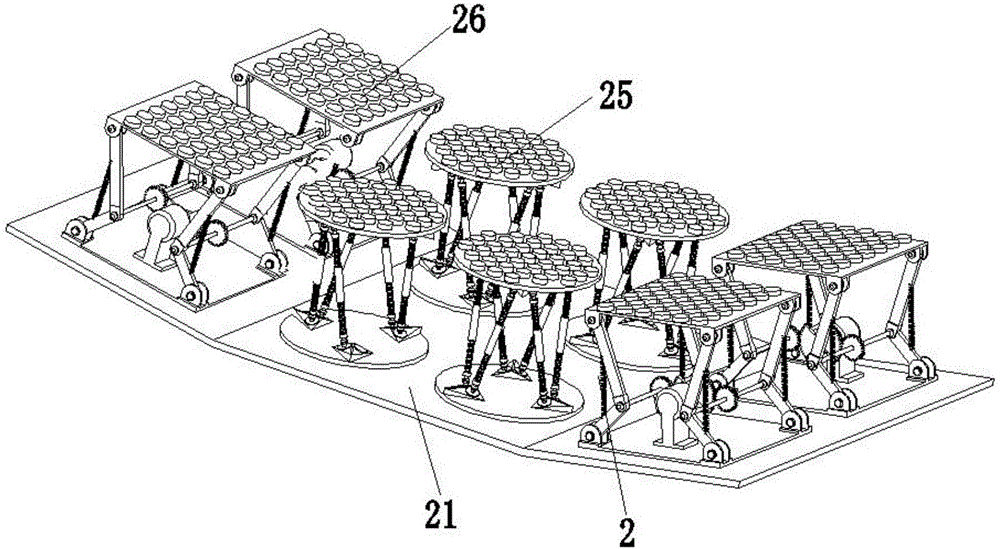

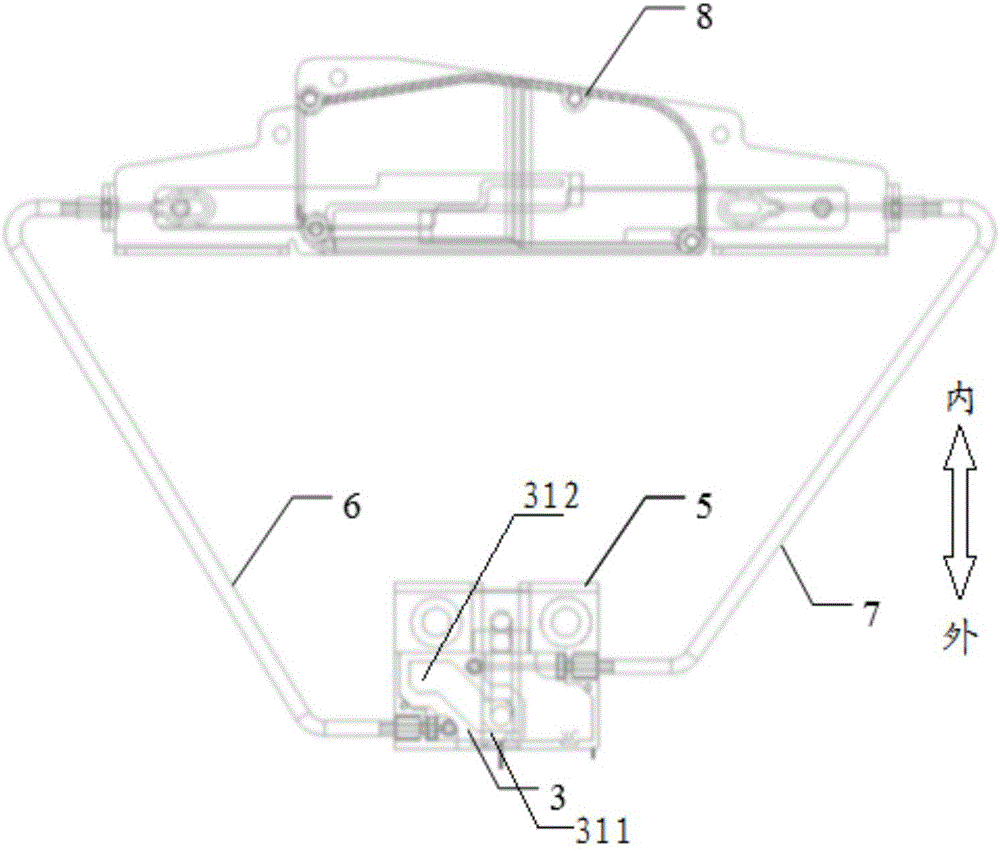

Flexible multipoint supported system in use for digital controlled machining laminae

InactiveCN101092020AAvoid interferenceSimple structurePositioning apparatusMetal-working holdersSupporting systemWorking fluid

The invention discloses a flexible multipoint supporting device for vane digital control machining. It is made up of cradle assembly, work flow feeding assembly, A flexible supporting component, and B flexible supporting component. The device realizes fixation for cradle assembly through cone pin controlled by A oil cylinder fixed on oil outlet distribution base and B oil cylinder fixed on machine tool tail base. The first machining location is used to realize synchronously turning action for cradle assembly and vane. And the second machining location is used to realize surface changing supporting for vane. The invention is mainly used to improve technical system rigidity and automation degree and machining accuracy. The flexible supporting structure also could be used as rapid and low cost assistant supporting for other weak rigidity machining.

Owner:BEIHANG UNIV

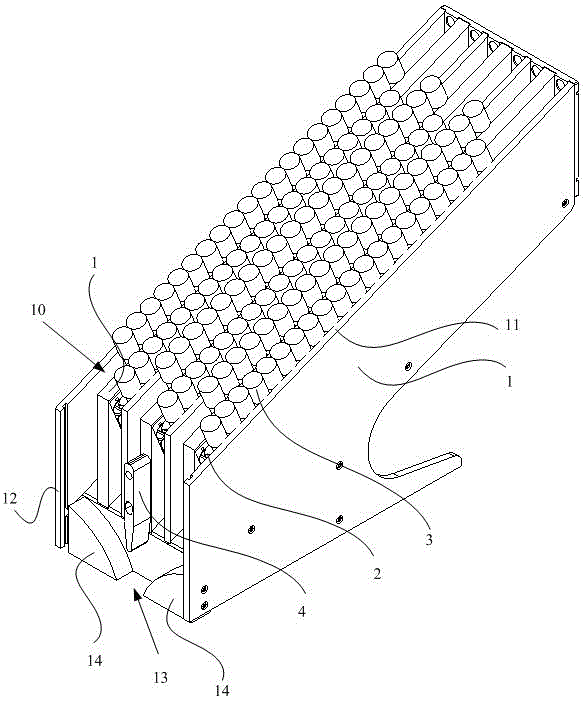

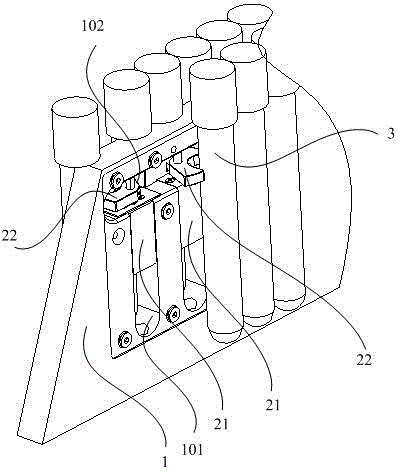

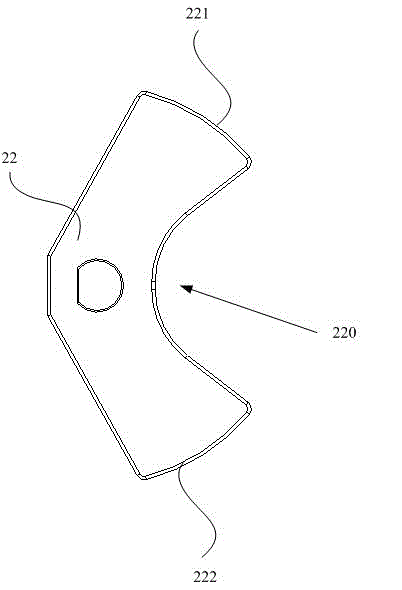

Test tube conveying mechanism and test tube label sticking equipment

ActiveCN104943926AImprove reliabilityImprove operating precisionConveyor partsLabelling machinesEngineeringTest tube

The invention discloses a test tube conveying mechanism and test tube label sticking equipment. The test tube conveying mechanism comprises multiple sheets of carrier plates and multiple test tube outputting components. A conveying guide groove is formed between each two sheets of the carrier plates. Inclined guide faces are formed in the conveying plats. A test tube outputting component is arranged at an outlet of each conveying guide groove. Each test tube outputting component comprises a motor and a swing arm. The swing arms are provided with rotating shafts. The motors are in transmission connection with the rotating shafts. A groove-shaped space used for containing a single test tube is formed between the two end portions of each swing arm. The test tube conveying mechanism and the test tube label sticking equipment have the advantages that minimizing type design of the test tube conveying mechanism is achieved, and the reliability and operating accuracy of the test tube conveying mechanism are improved.

Owner:青岛华诺医学科技有限公司

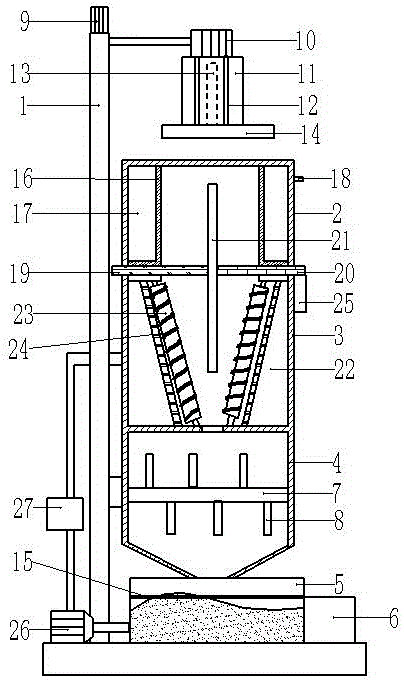

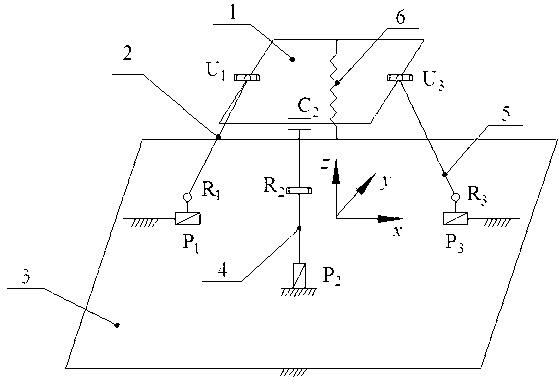

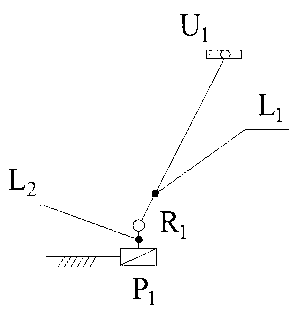

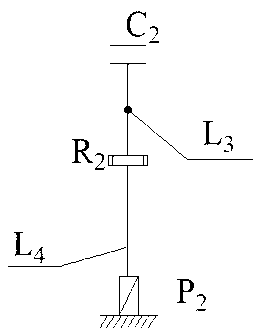

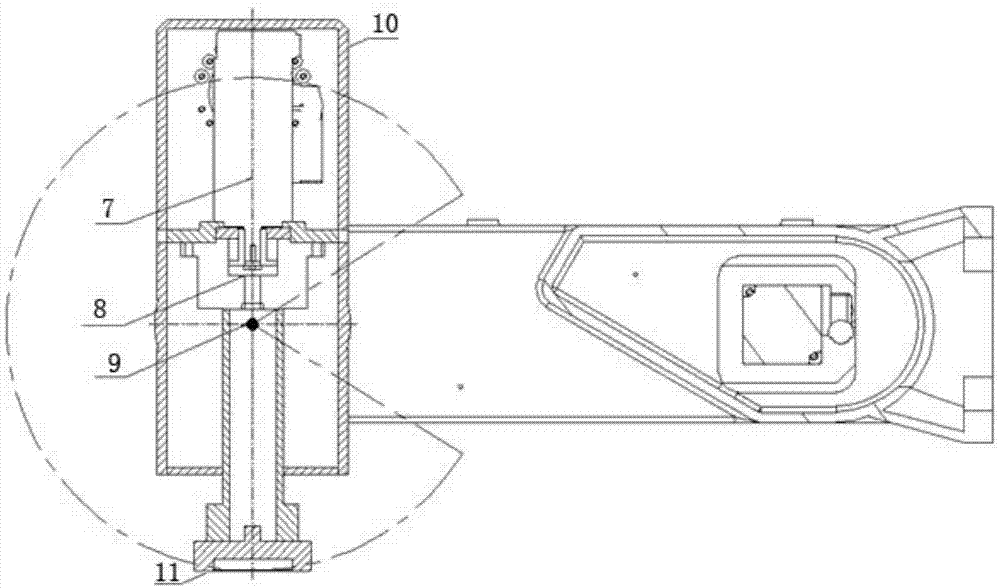

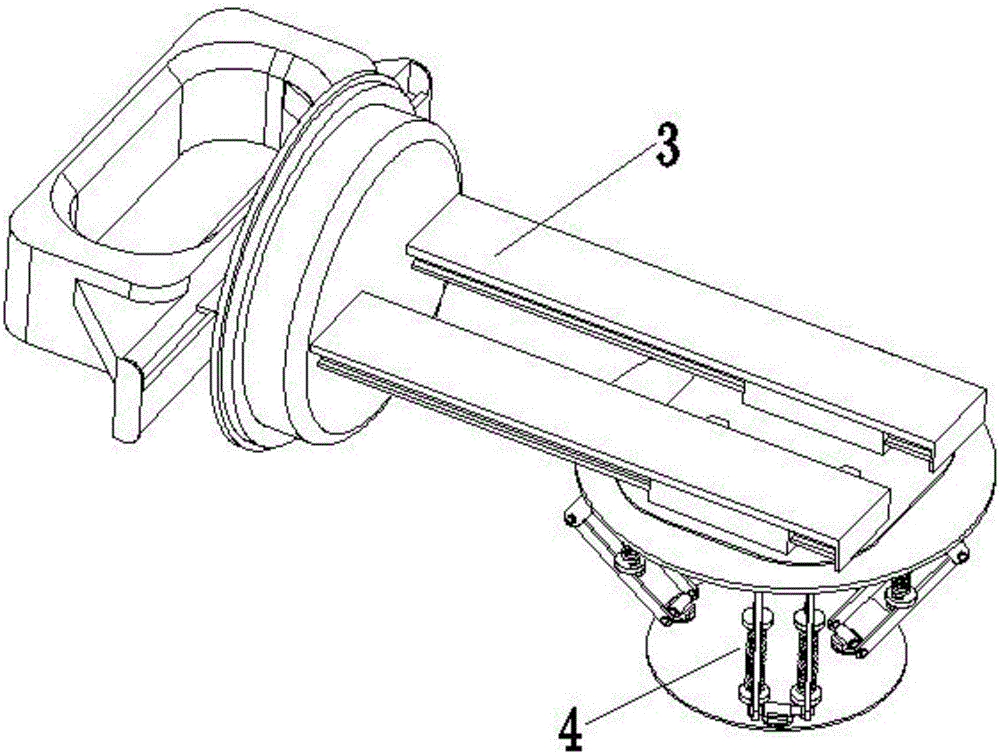

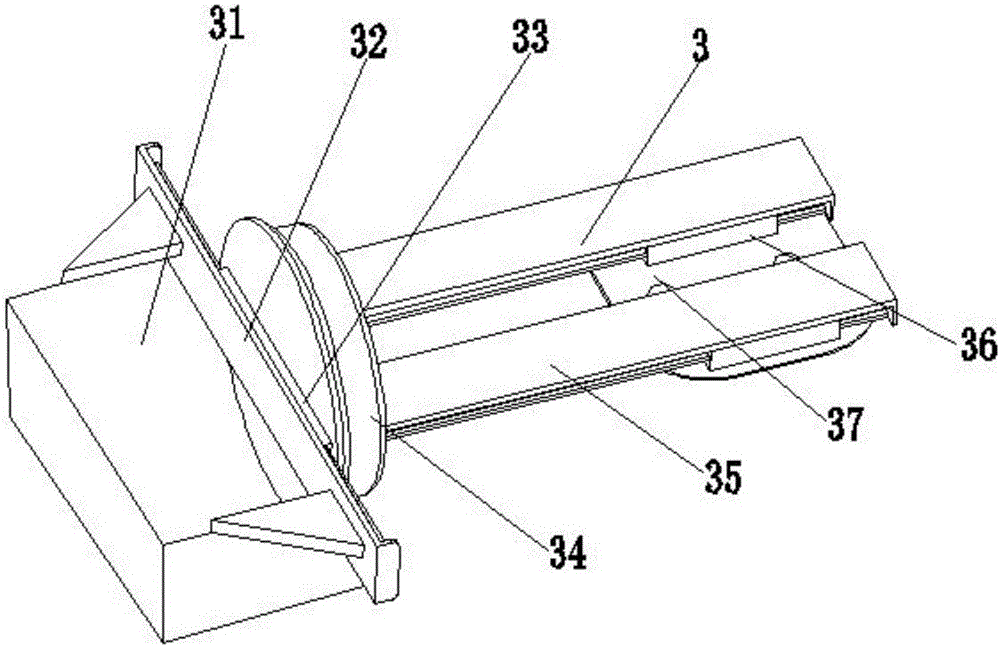

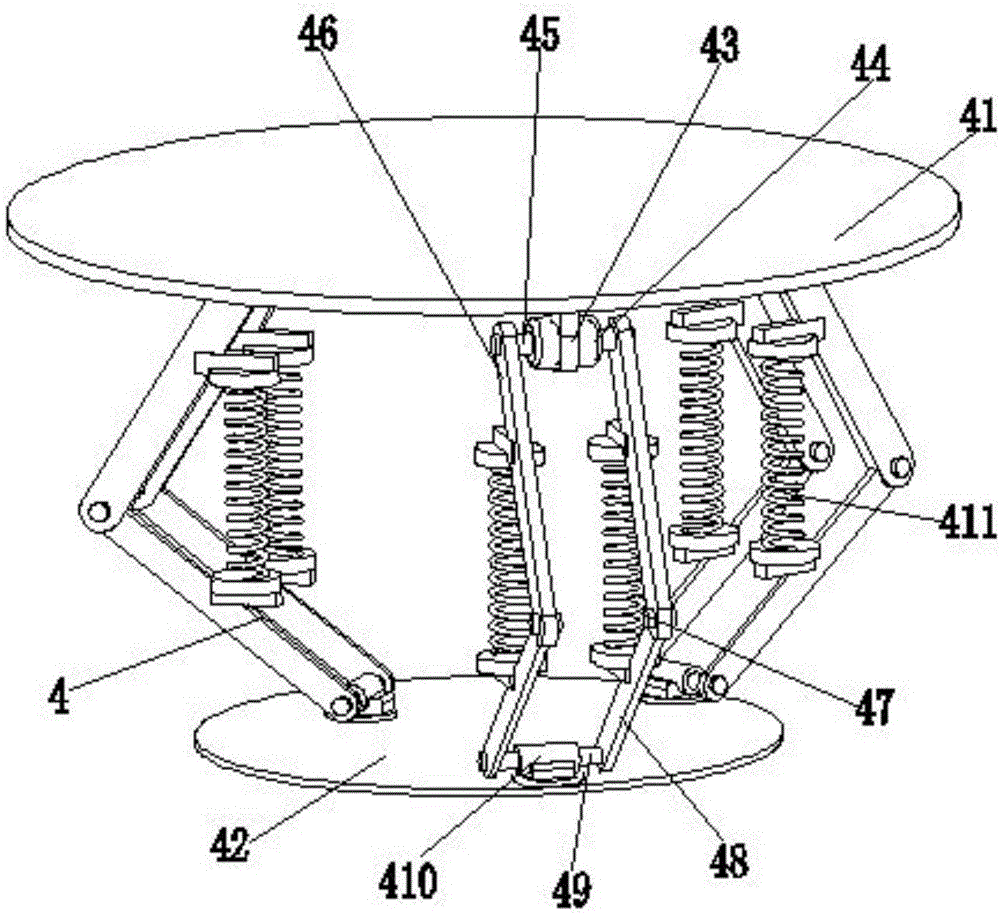

Three-degree-of-freedom parallel material vibration sorting platform

ActiveCN103286078AImprove sorting efficiencyRealize multi-dimensional vibration sortingSortingProcess engineeringKinematic chain

The invention discloses a three-degree-of-freedom parallel material vibration sorting platform and relates to material vibration sorting machinery. The three-degree-of-freedom parallel material vibration sorting platform consists of a movable platform, a fixed platform, a first kinematic chain, a second kinematic chain, a third kinematic chain and an extension spring. The vibration mechanism consists of two PRU kinematic chains and a PRC kinematic chain, and translation of the platform along the X-axis and Z-axis directions and rotation of the platform along the X-axis direction can be realized. According to the traditional vibration sorting platform, one-dimensional material vibration can be realized only, and multi-dimensional vibration cannot be finished. Therefore, the shape and the size of the sorted materials are greatly limited, so that the product does not have the universality. The material vibration sorting platform has the advantages of high decoupling performance, fast dynamic response, convenience in control, simple structure and the like, can meet the multi-dimensional vibration sorting requirements of different materials and is high in universality.

Owner:JIANGSU UNIV

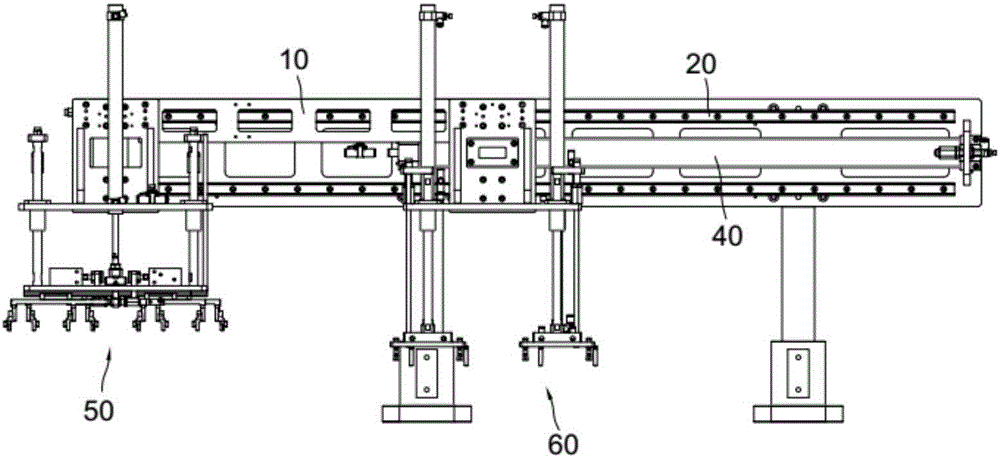

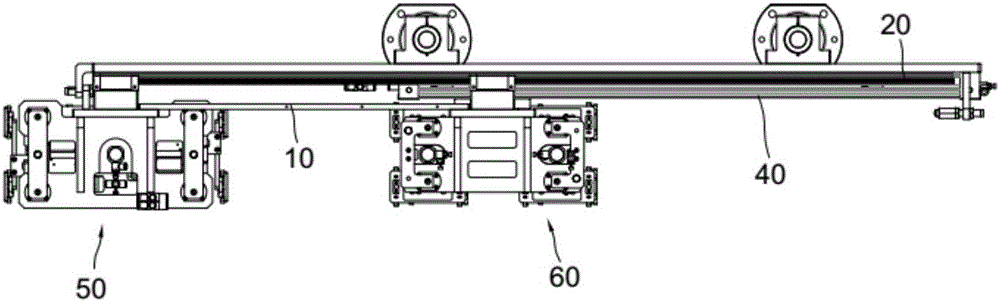

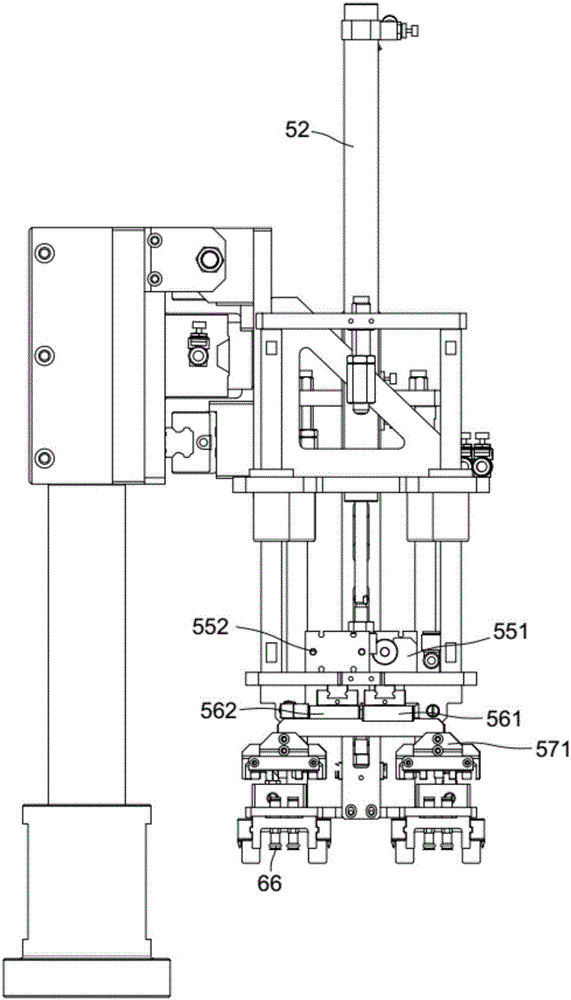

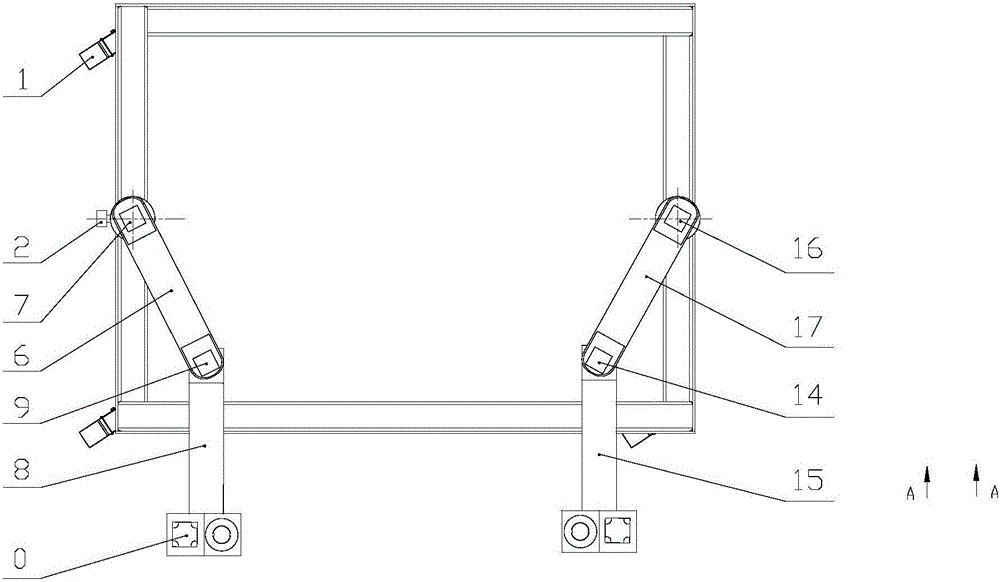

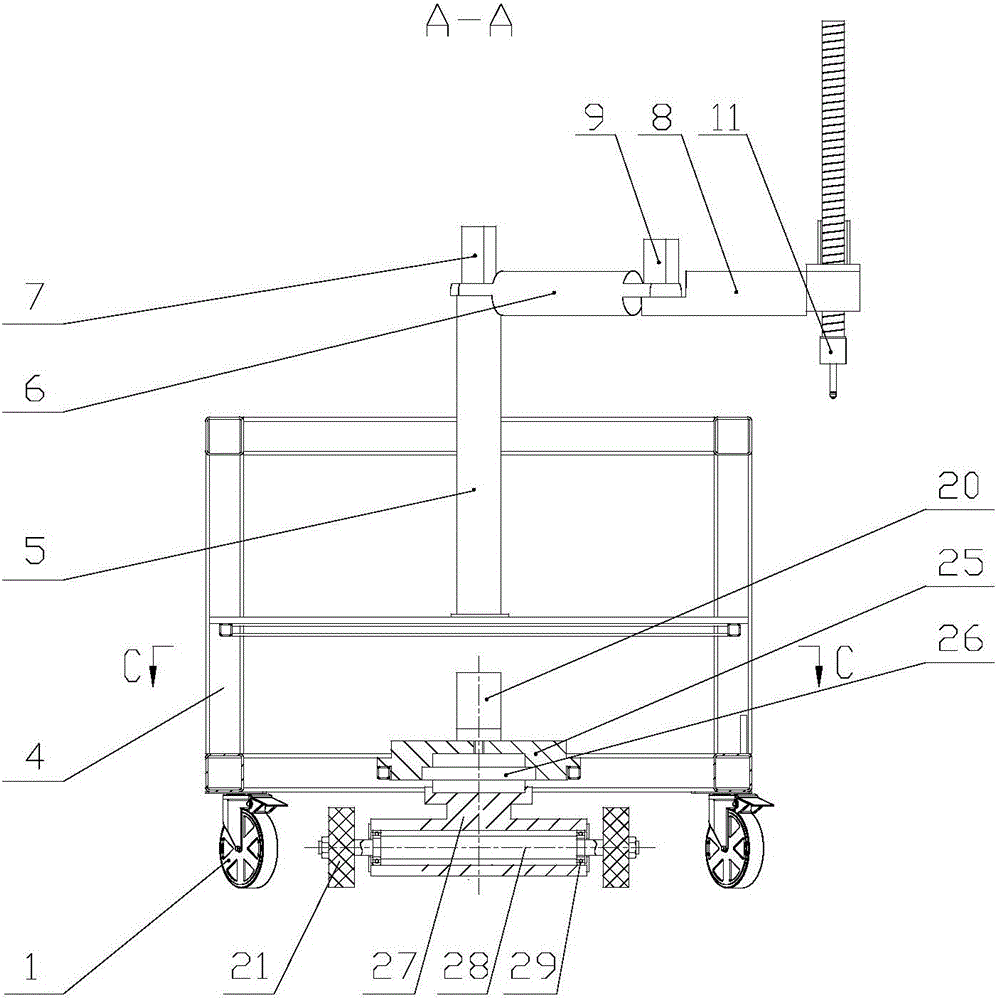

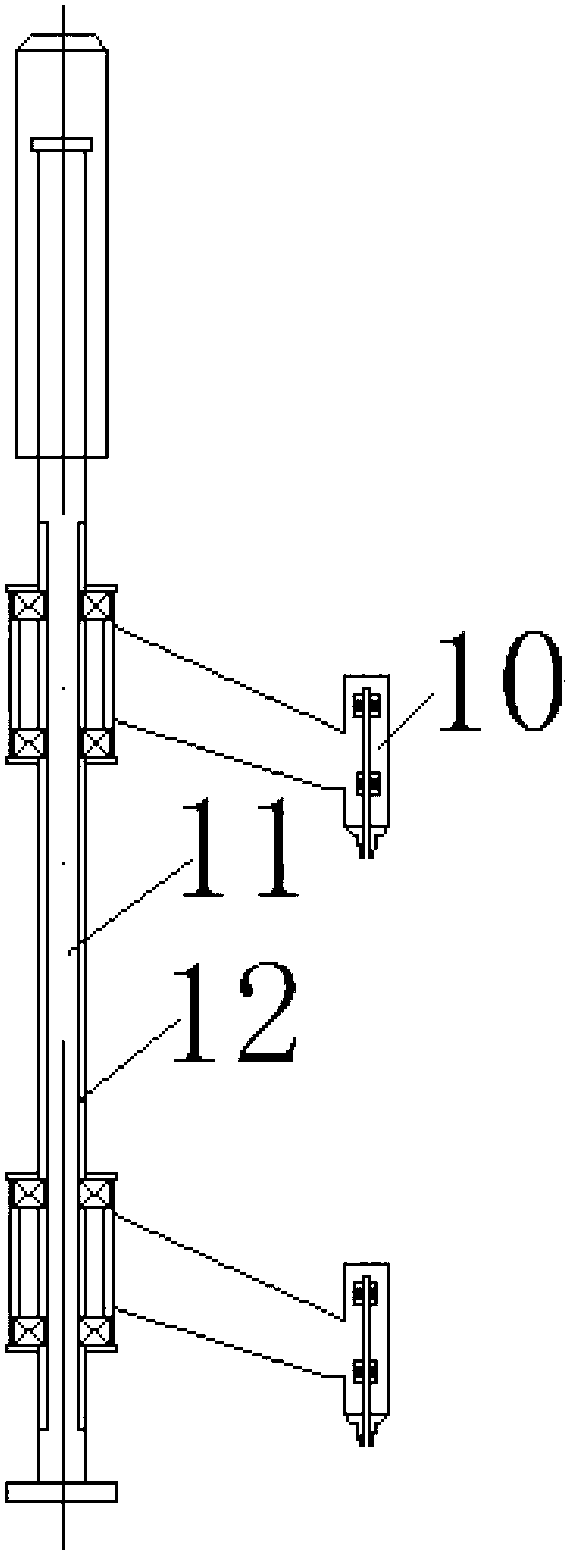

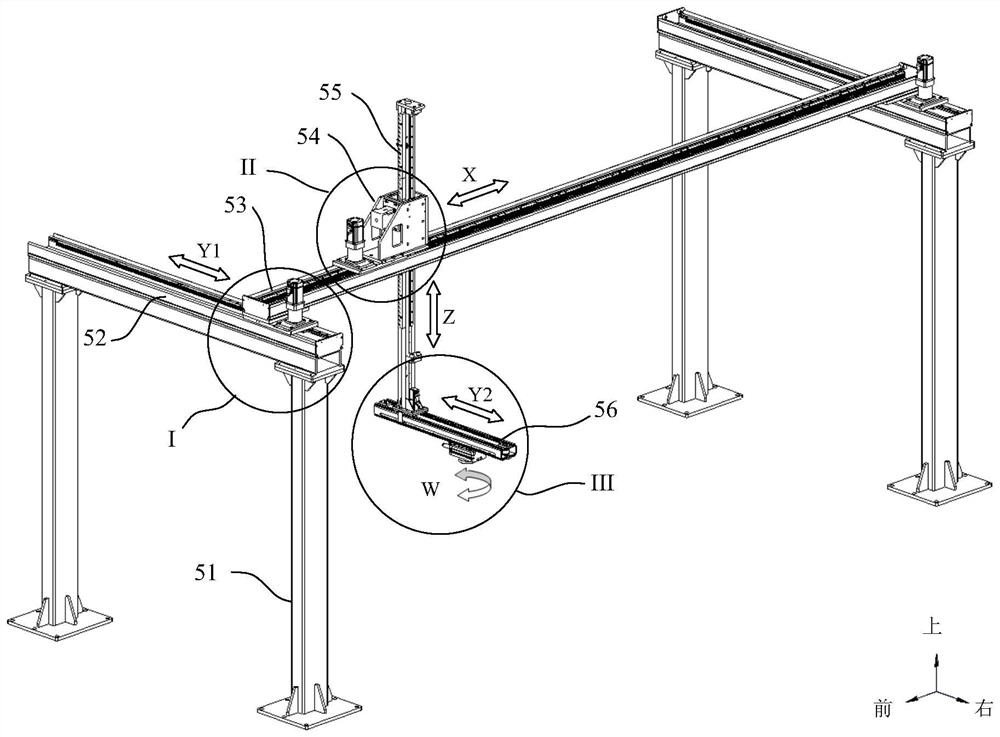

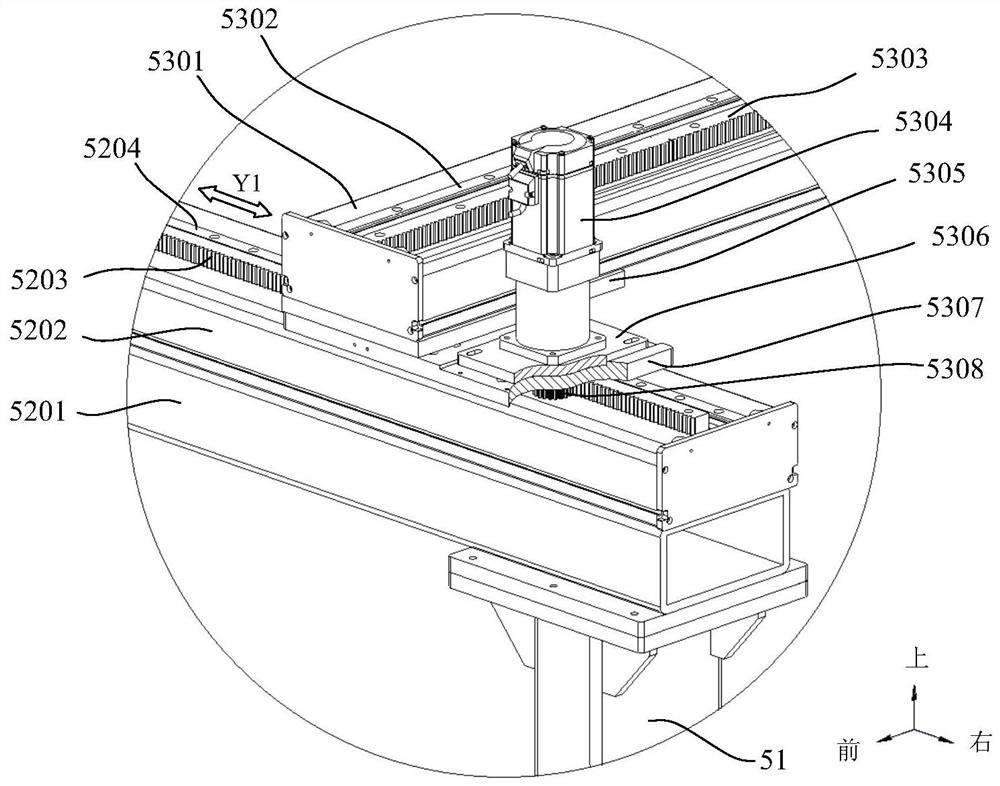

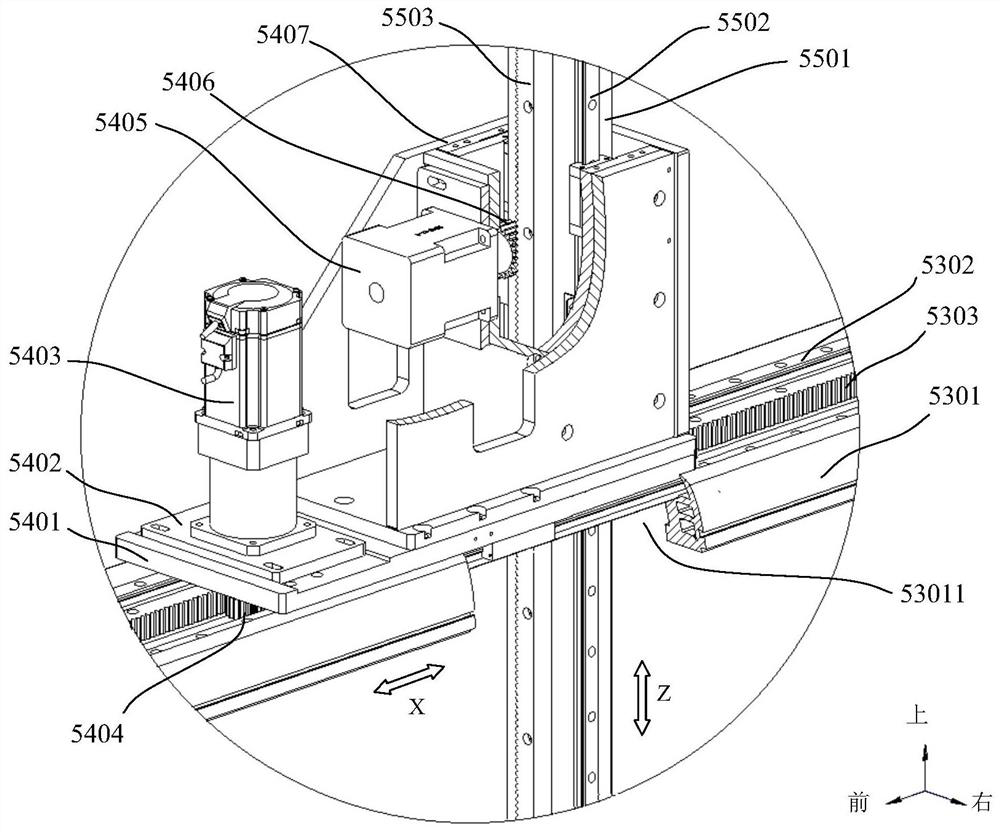

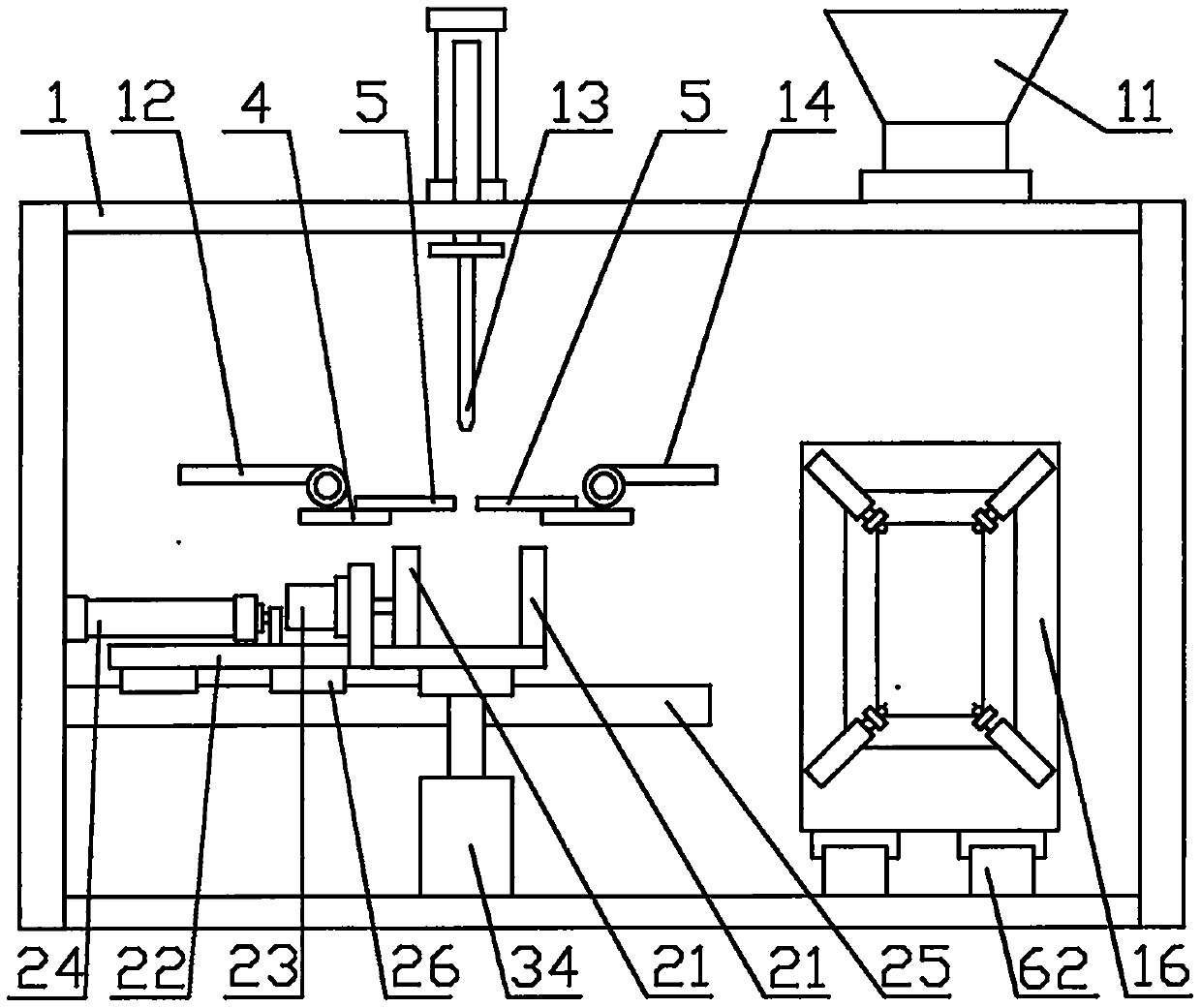

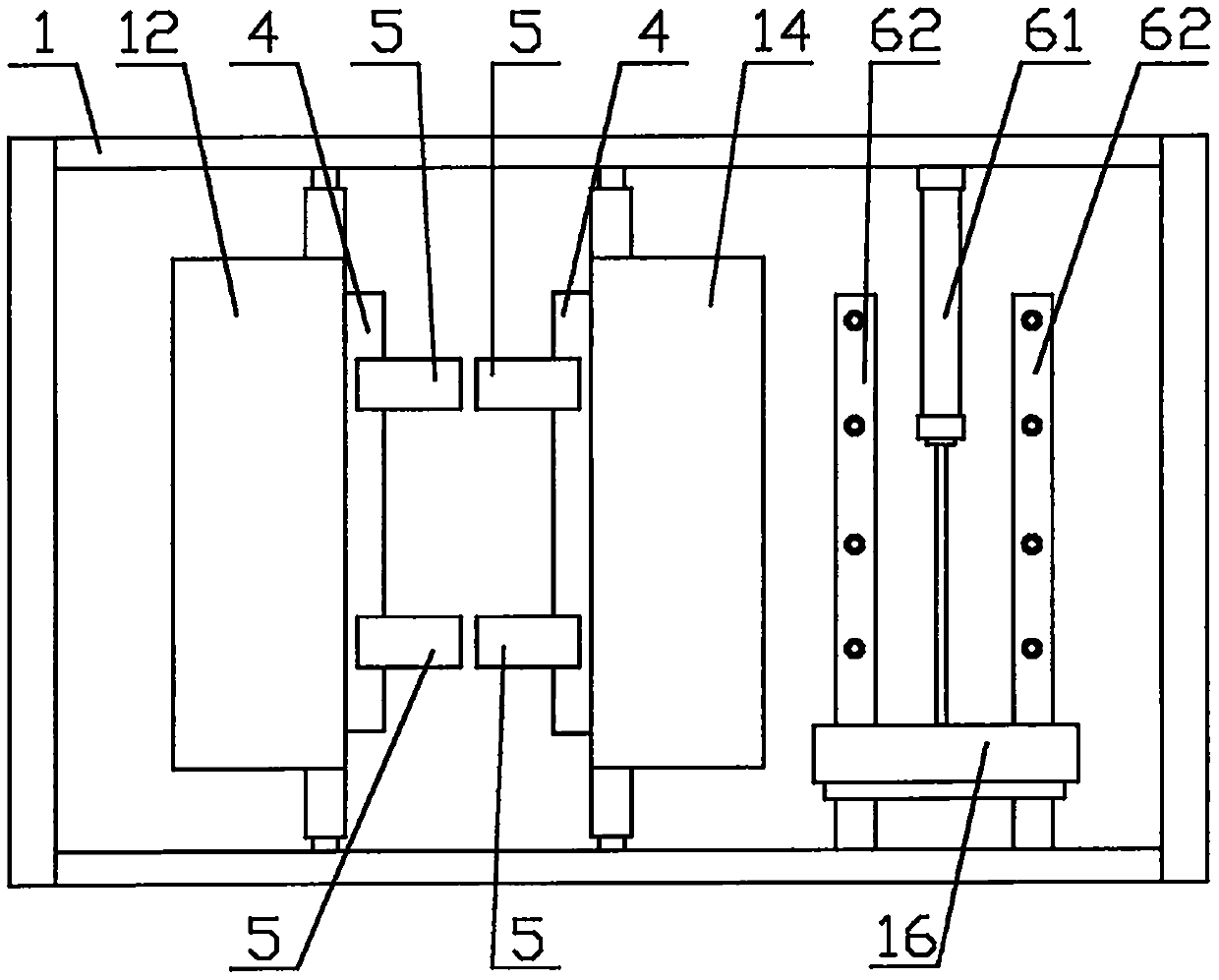

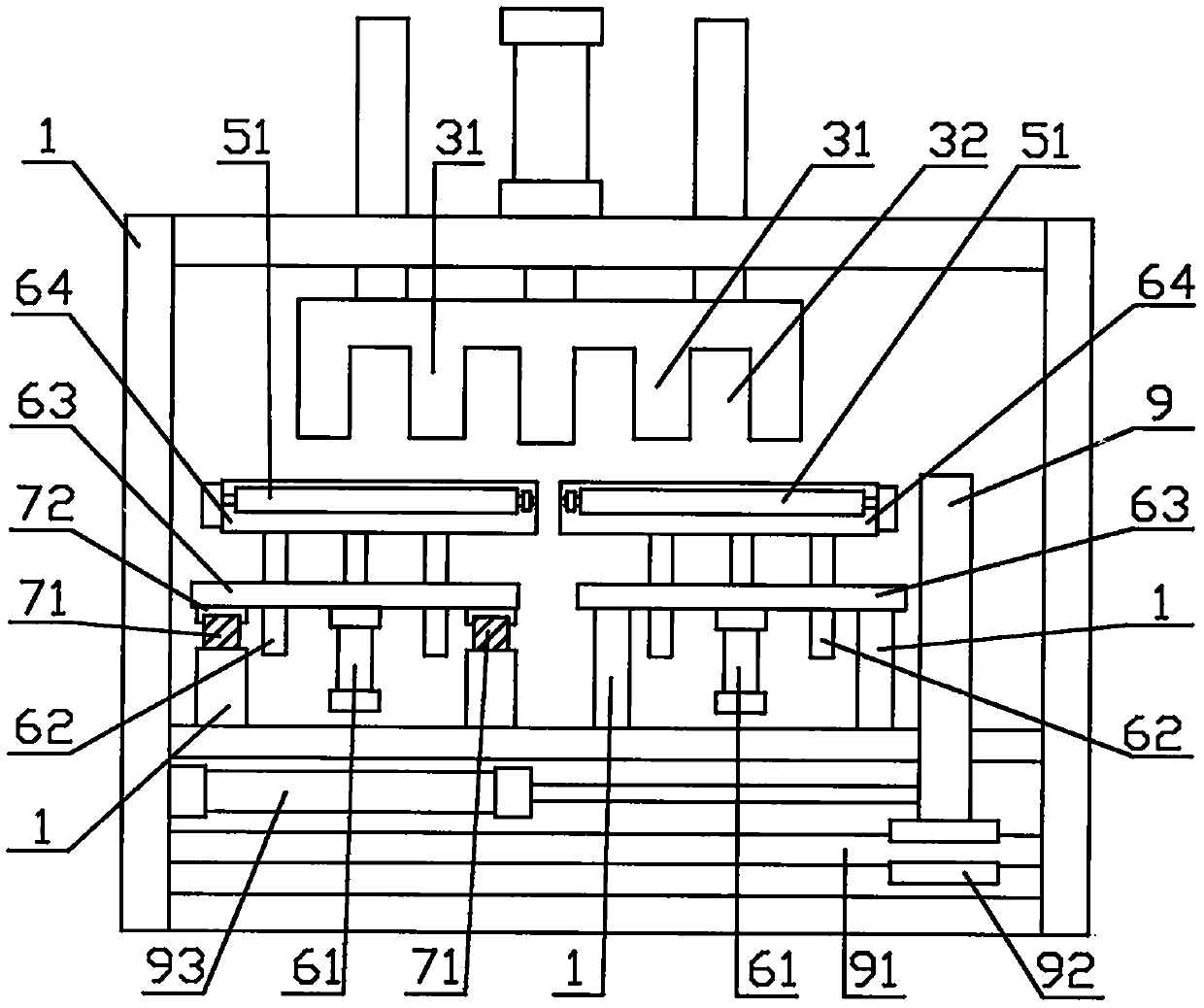

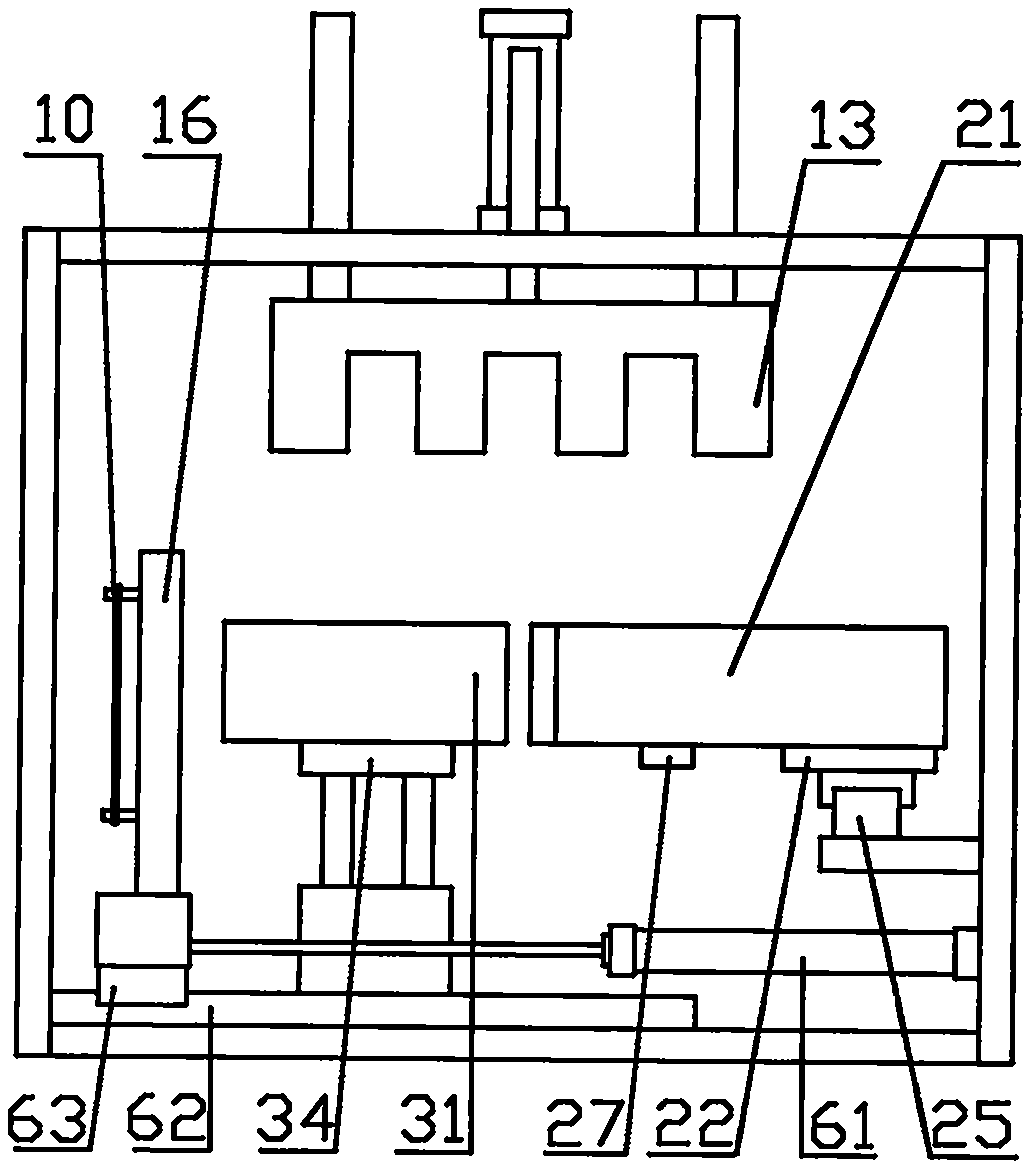

Double-transverse-moving truss manipulator for drum brake pad hot press molding production line

InactiveCN112045666AFulfill exercise requirementsMove fastProgramme-controlled manipulatorRobot handEngineering

The invention discloses a double-transverse-moving truss manipulator for a drum brake pad hot press molding production line. The double-transverse-moving truss manipulator comprises two Y1-axis fixedbeam assemblies, an X-axis movable beam assembly which is supported by the Y1-axis fixed beam assemblies and can axially move along the Y1-axis fixed beam assemblies, an Z-axis base assembly, an Z-axis mechanical arm assembly and an Y2-axis movable beam assembly which can axially move along the X-axis movable beam assembly, wherein the Z-axis mechanical arm assembly penetrates the Z-axis base assembly and can move in the Z-axis base assembly, and meanwhile the Z-axis mechanical arm assembly is driven by the Z-axis base assembly to move axially along the X-axis movable beam assembly, the Y2-axis movable beam assembly is arranged at the lower end of the Z-axis mechanical arm assembly, and the Y2-axis movable beam assembly can move relative to the Z-axis mechanical arm assembly. The truss manipulator is responsible for operations of feeding, release agent spraying, filler scraping, finished product taking out, partition plate filling and the like of each hot press in a production processof a drum brake pad, so that a movement speed is increased, the operation time is shortened, the movement space can be shortened, and interference is avoided.

Owner:HUBEI UNIV OF ARTS & SCI

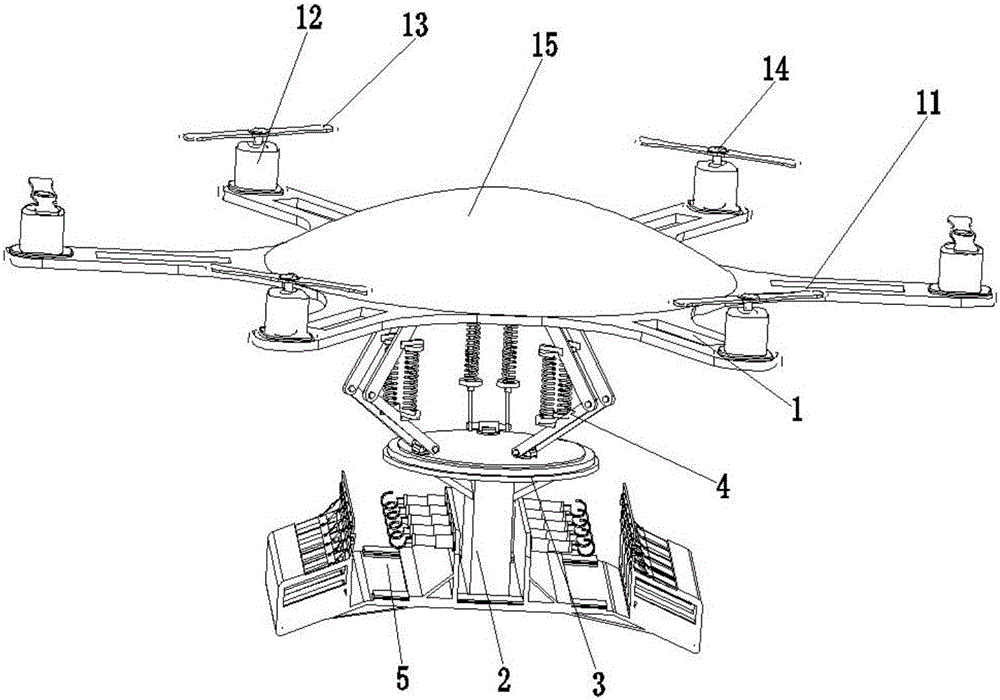

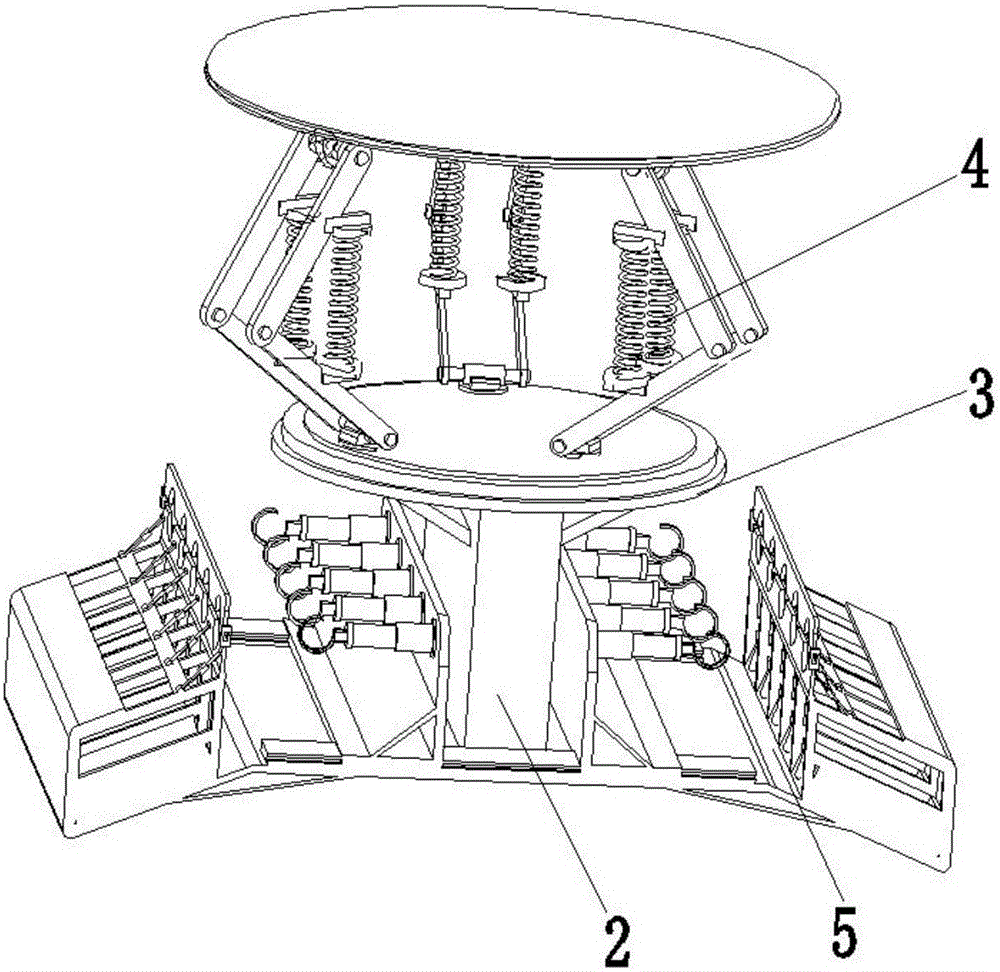

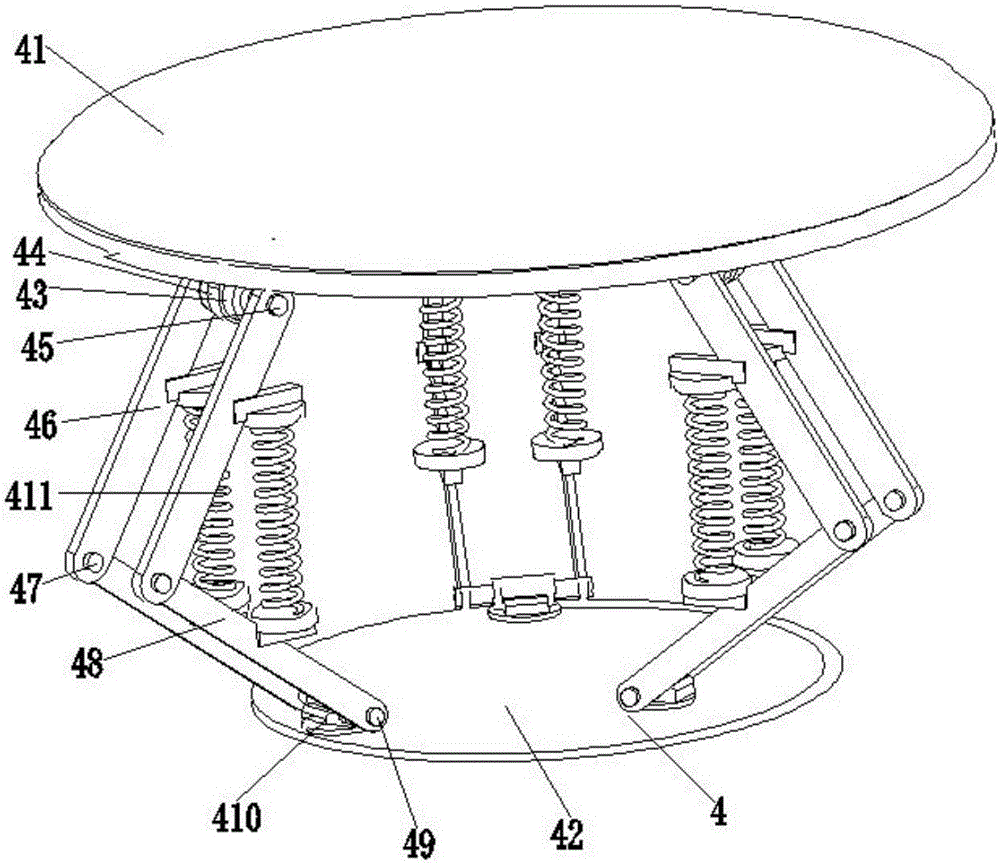

Fire rescue hexrcopter for aerial electric power line

ActiveCN106114834ASolve the problem of high risk of artificial fire extinguishingHigh degree of automationProgramme-controlled manipulatorFire rescueFire protectionEngineering

The invention relates to a fire rescue hexrcopter for an aerial electric power line. The fire rescue hexrcopter for the aerial electric power line comprises an unmanned aerial vehicle body, supporting posts, a connecting disc, a delta parallel mechanism and a fire extinguishing device. The number of the supporting posts is four, the supporting posts are located at four vertices of the fire extinguishing device correspondingly, the bottom ends of the supporting posts are connected with the fire extinguishing device, and the top ends of the supporting posts are connected with the connecting disc. The delta parallel mechanism is located between the connecting disc and the unmanned aerial vehicle body, the lower end of the delta parallel mechanism is connected with the upper end face of the connecting disc, and the upper end of the delta parallel mechanism is connected with the unmanned aerial vehicle body. The fire rescue hexrcopter for the aerial electric power line can be used for carrying out high-altitude fire protection and fire extinguishing operation when the aerial electric power line is on fire, and is high in automation degree, steady and flexible in flying during fire extinguishing, wide in fire extinguishing spraying range, high in fire extinguishing efficiency and high in safety, and the problem that the dangerousness of manual fire protection and fire extinguishing for the aerial electric power line is high is solved.

Owner:嘉兴云泽科技有限公司

Plastic bag folding and rubber band binding all-in-one machine

The invention discloses a plastic bag folding and rubber band binding all-in-one machine. The machine comprises a machine frame, a vibration disc device, a rubber band expanding device, a handle folding device, a tail folding device and a plate inserting device, and is characterized in that a bag supporting device, a bag clamping device and a bag conveying movement device are further arranged at the corresponding positions of the inserting plate; the machine further comprises a bundling movement device and a suspension outer bag clamping mechanism, the bag supporting device and the bag clamping device are used for folding a plastic bag from the middle position and clamping and shaping the plastic bag, then the bag clamping device or a bag clamping mechanical arm clamps one side of the plastic bag, and the other side of the plastic bag is inserted into the rubber band expanding device to be bundled. The machine has the advantages that operation from folding to bundling is carried out almost in a clamping plate mechanism of the bag clamping device, so that folding and bundling are integrated without mechanical arm changing, the folding and bundling work is stable and reliable, and the structure is simple and compact.

Owner:王秀来

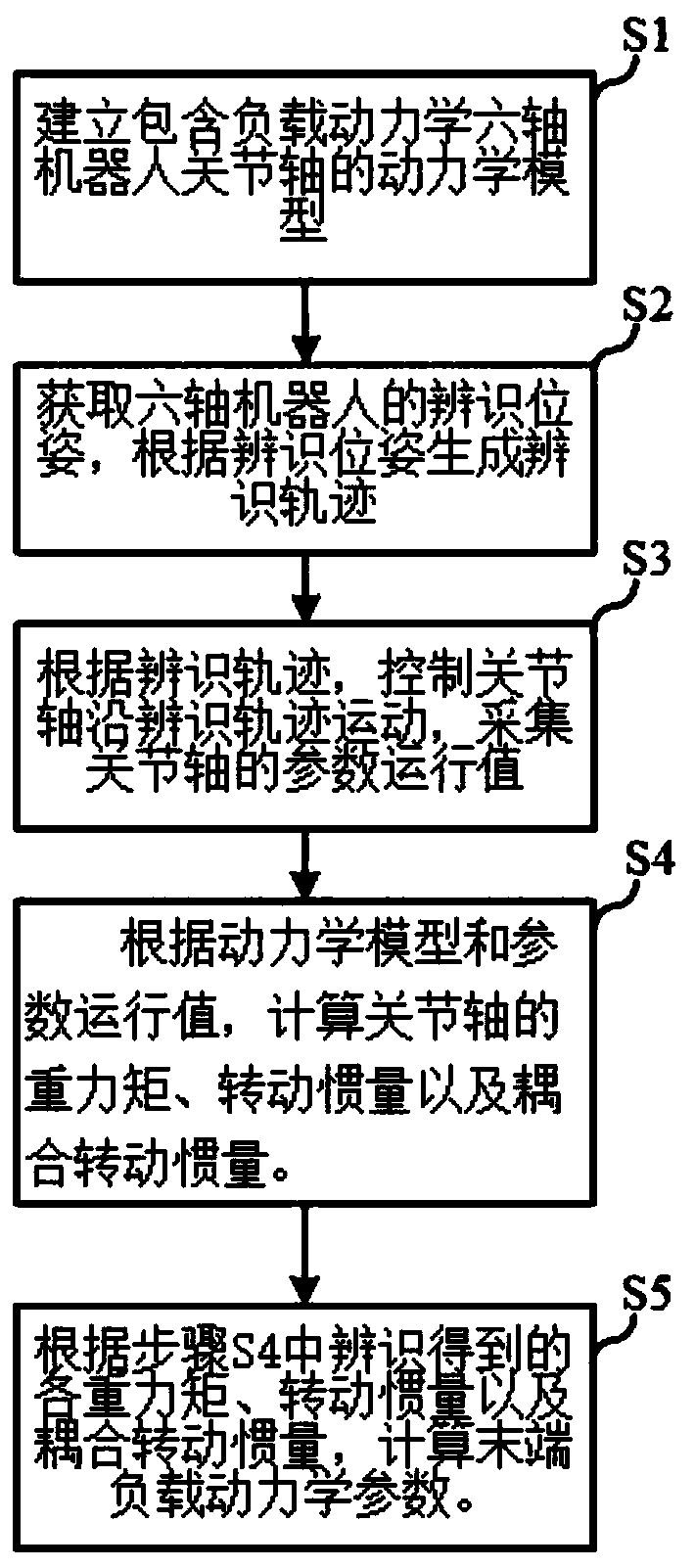

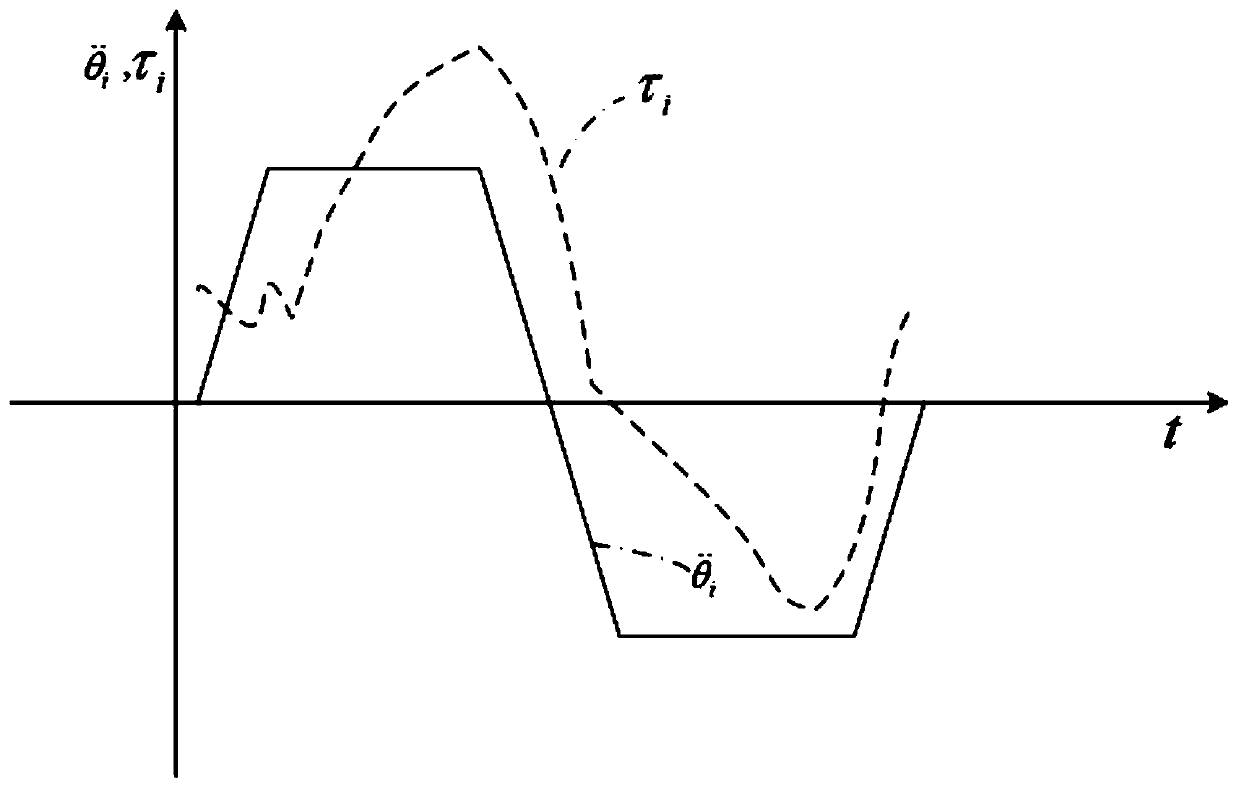

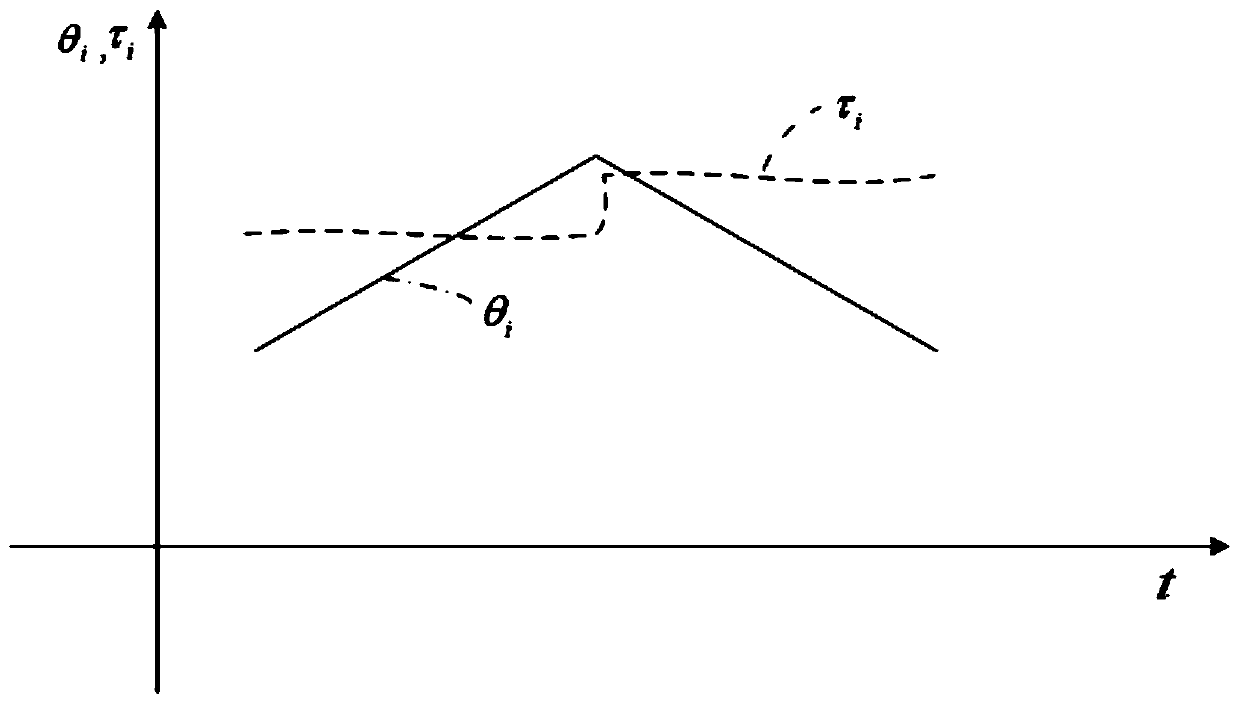

Six-axis robot tail end load identification method and module

ActiveCN111037567AReduced precision requirementsLittle room for movementProgramme-controlled manipulatorMoment of inertiaRobot control

The embodiment of the invention relates to the technical field of robot control and discloses a six-axis robot tail end load identification method and module. The method comprises steps of establishing a kinetic model of a joint axis; obtaining an initial pose of the six-axis robot, and generating an identification track according to the initial pose; according to the identification track, controlling a joint shaft move along the identification track, and acquiring parameter operation values of the joint shaft; according to a kinetic model and a parameter operation value, calculating gravitational moment, rotational inertia and coupling rotational inertia of the joint shaft; and according to the gravitational moment, the rotational inertia and the coupling rotational inertia, calculating terminal load kinetic parameters. The invention further provides a six-axis robot tail end load identification module. Compared with the prior art, the six-axis robot tail end load identification module has the advantages that the required space is small in the six-axis robot tail end load identification process, the requirements for the six-axis robot body kinetic parameters are extremely low, andtail end load kinetic parameter identification precision is high.

Owner:上海新时达机器人有限公司

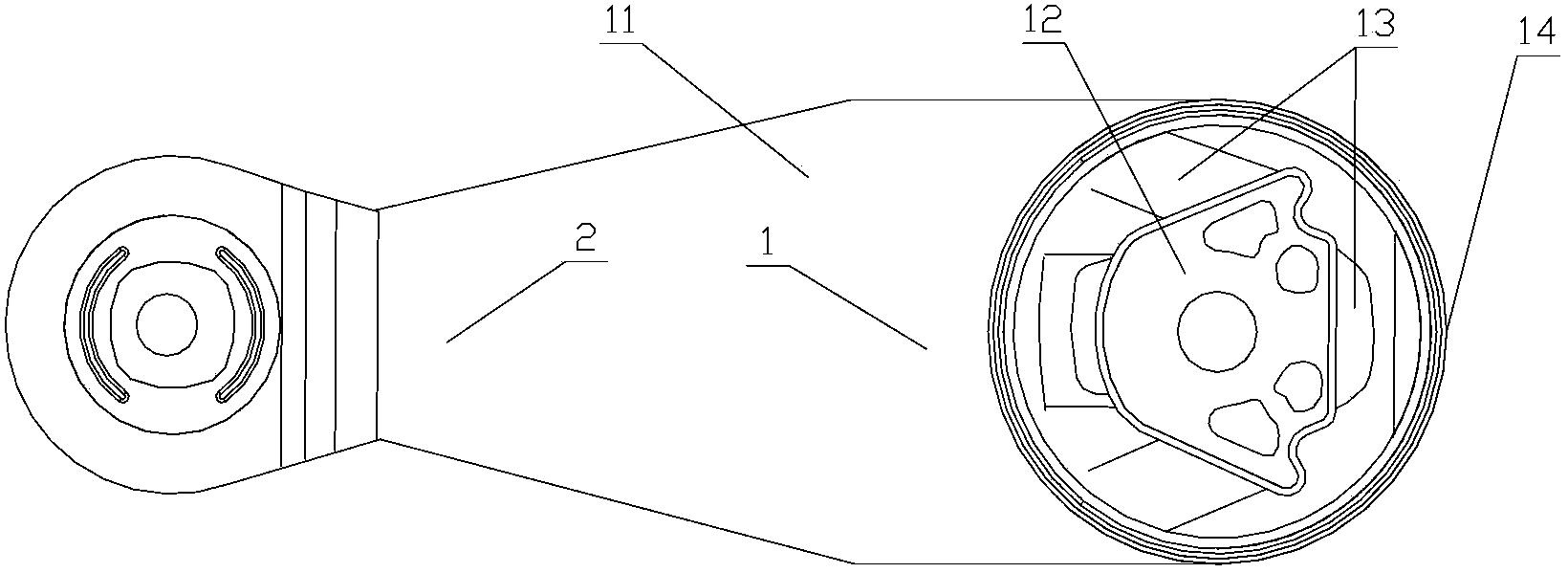

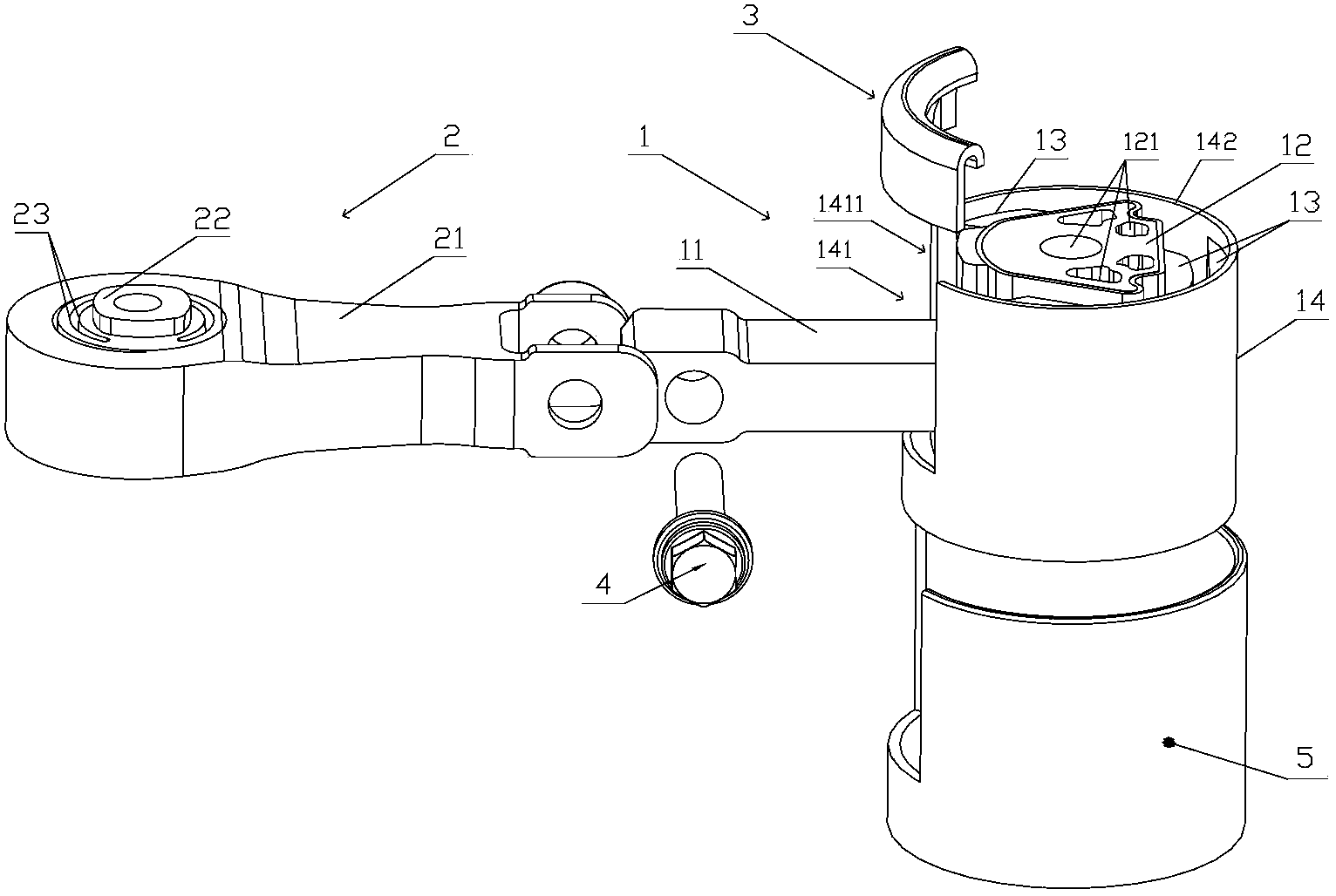

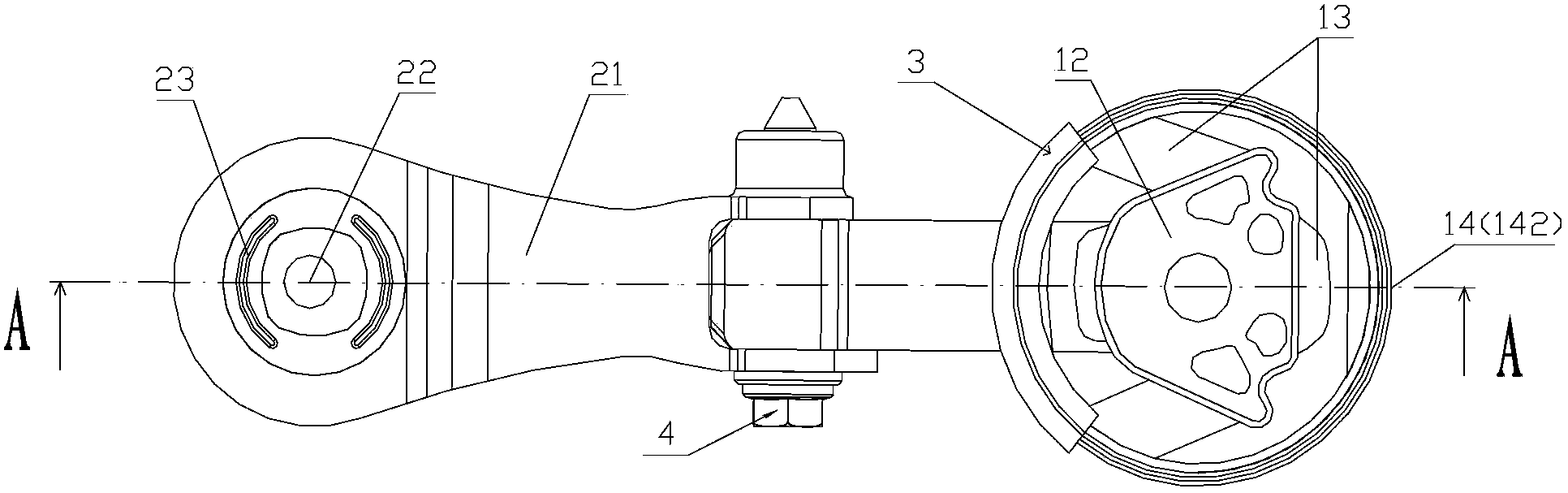

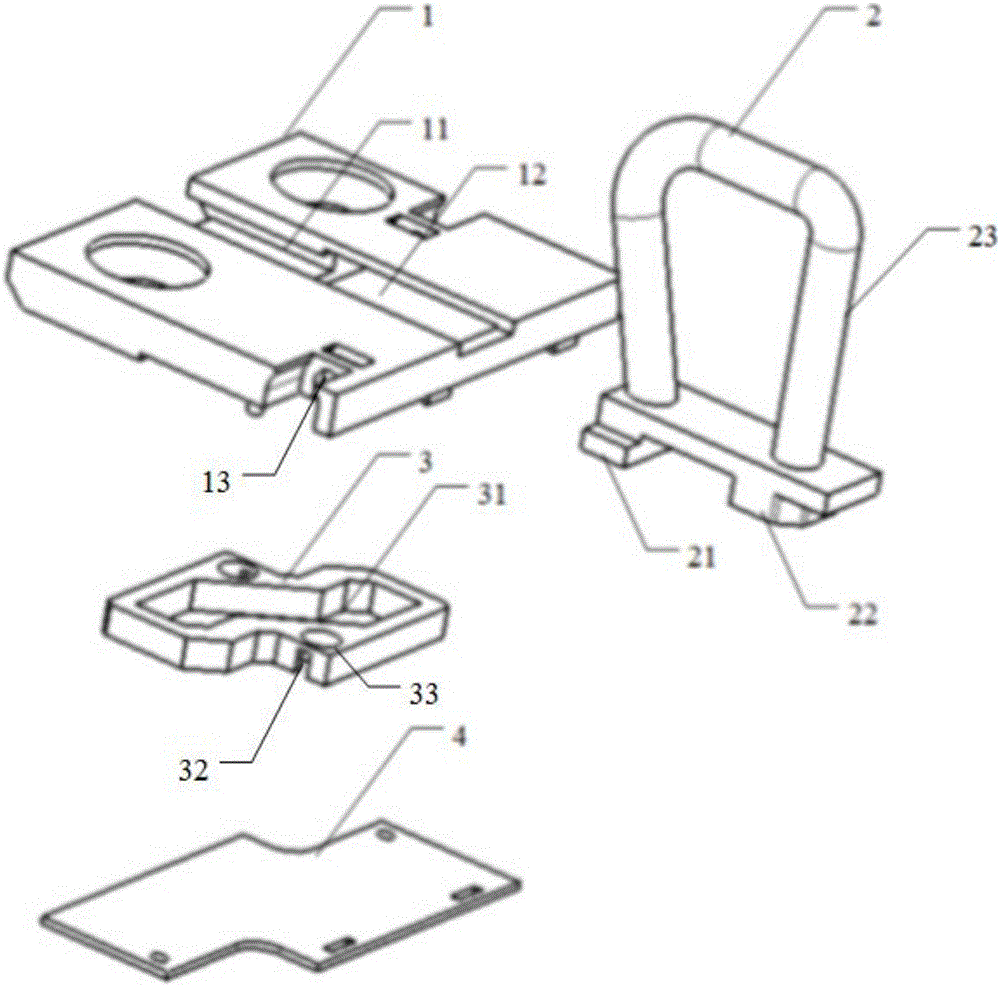

Power assembly suspended torsion bar and mounting structure thereof

ActiveCN103538458AImprove protectionEasy to install and disassembleJet propulsion mountingInternal combustion mountingEngineeringPowertrain

The invention discloses a power assembly suspended torsion bar. The power assembly suspended torsion bar comprises a first part (1) and a second part (2) used for being connected with a power assembly. The first part (1) is detachably connected with the second part (2). The first part (1) comprises a first connection arm (11), a first inner core body (12), an outer sleeve (14) and a first damping piece (13) arranged between the first inner core body (12) and the outer sleeve (14). An inserting opening (141) is formed in the peripheral wall of the outer sleeve (14), and the first connection arm (11) extends into the outer sleeve (14) from the inserting opening (141) and is fixedly connected with the first inner core body (12) in the outer sleeve (14) or integrated with the first inner core body (12) in the outer sleeve (14). The power assembly suspended torsion bar is of a split structure so as to be conveniently mounted and dismounted or maintained, and is small in size, and low in weight, and after the power assembly suspended torsion bar is mounted, the mounting space can be reduced.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

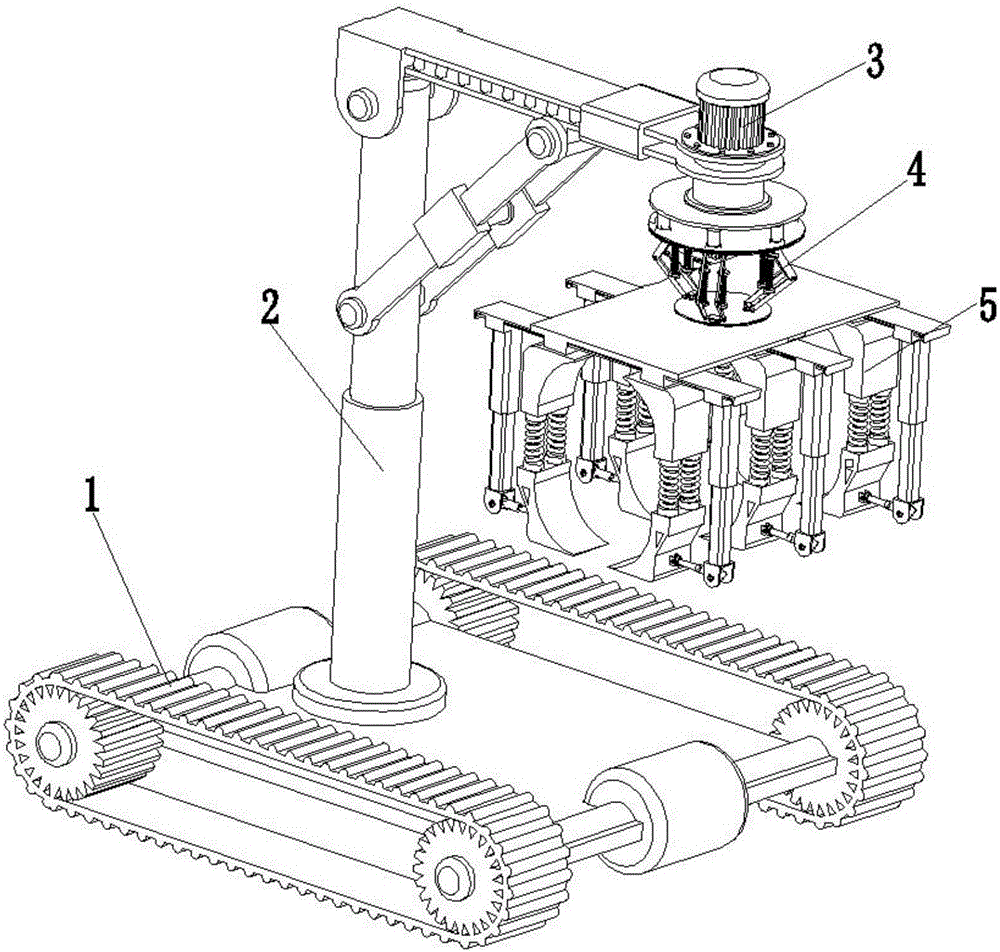

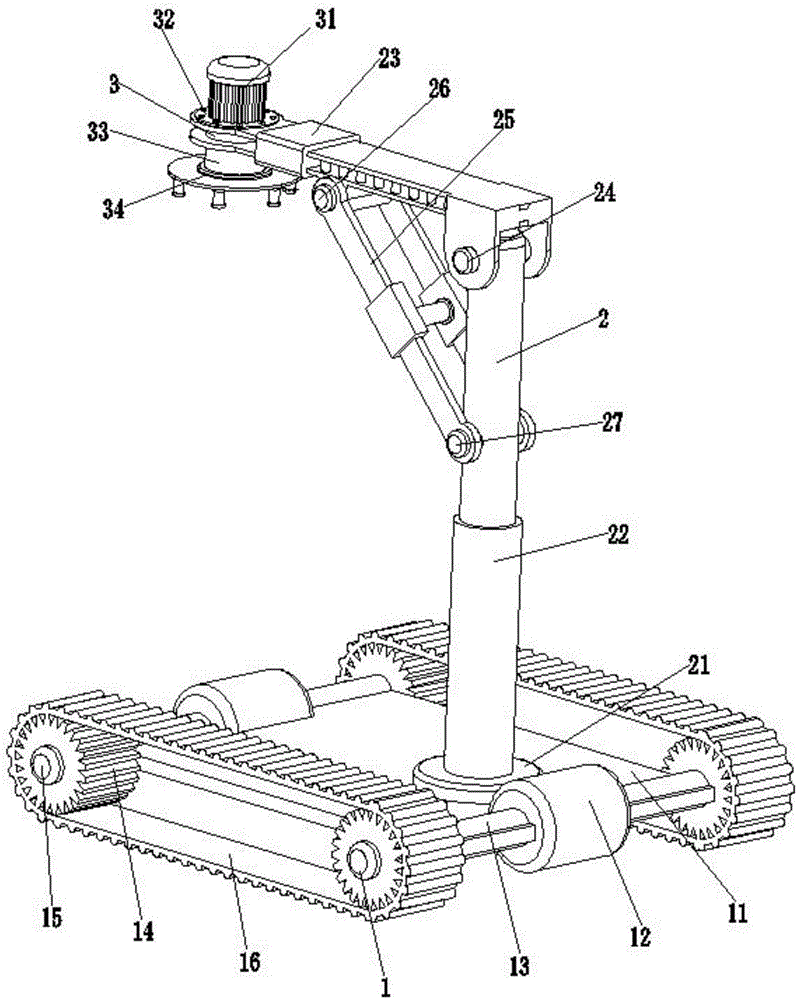

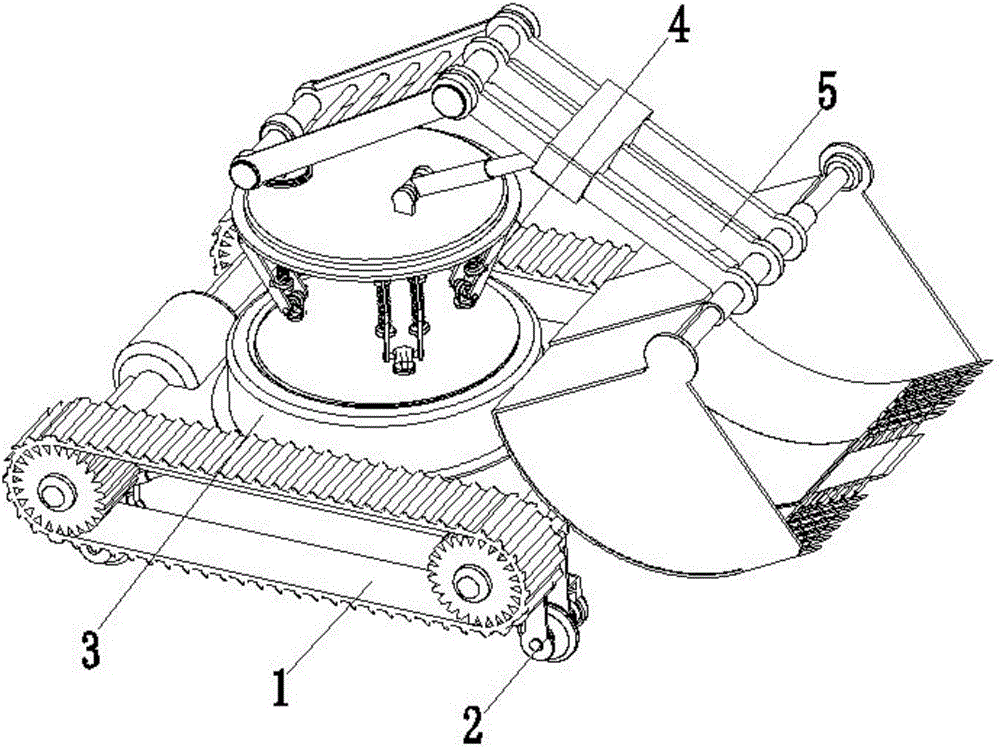

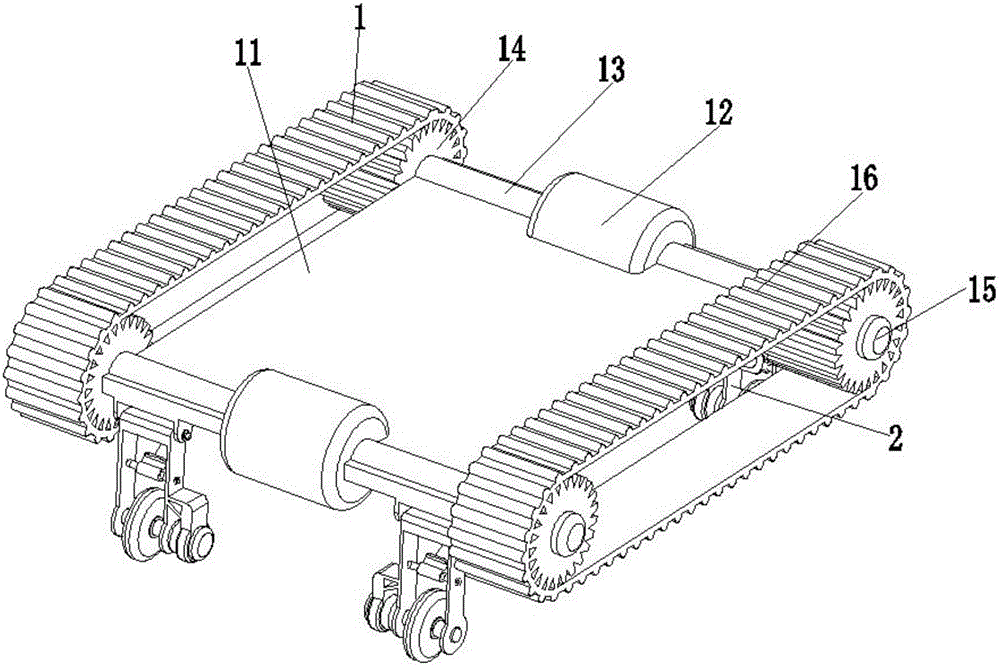

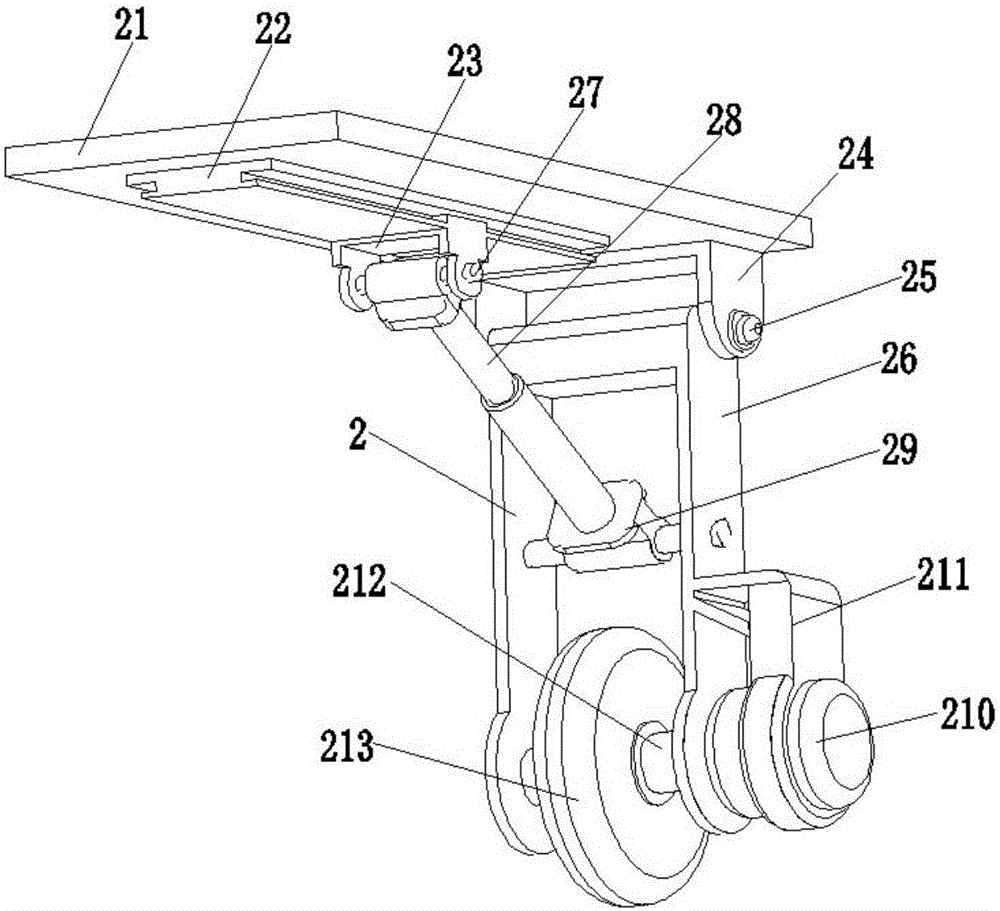

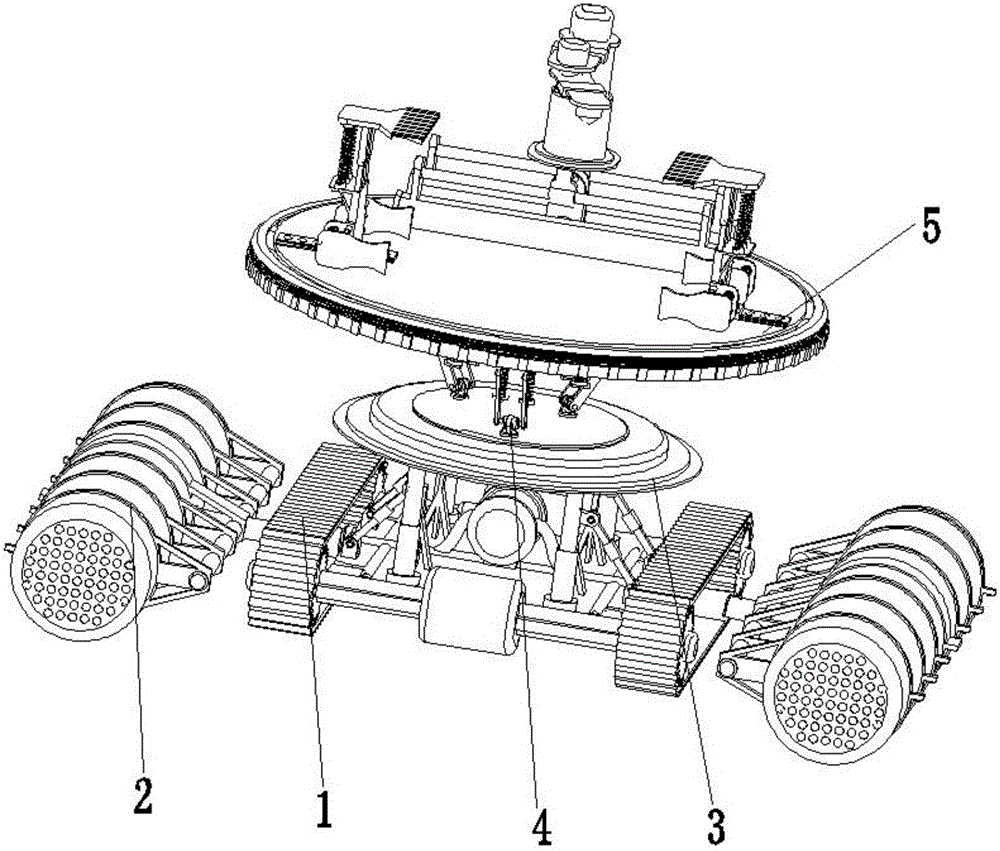

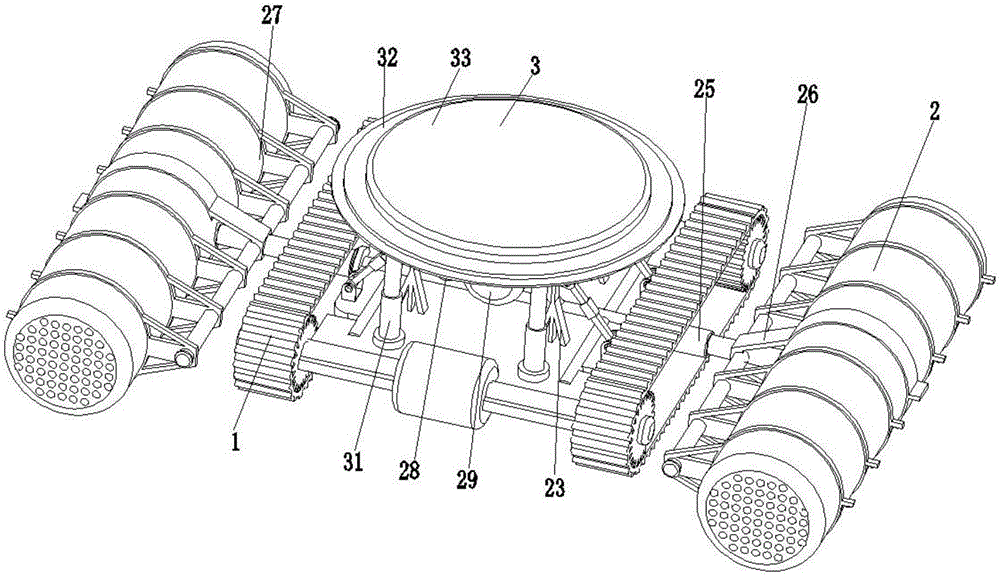

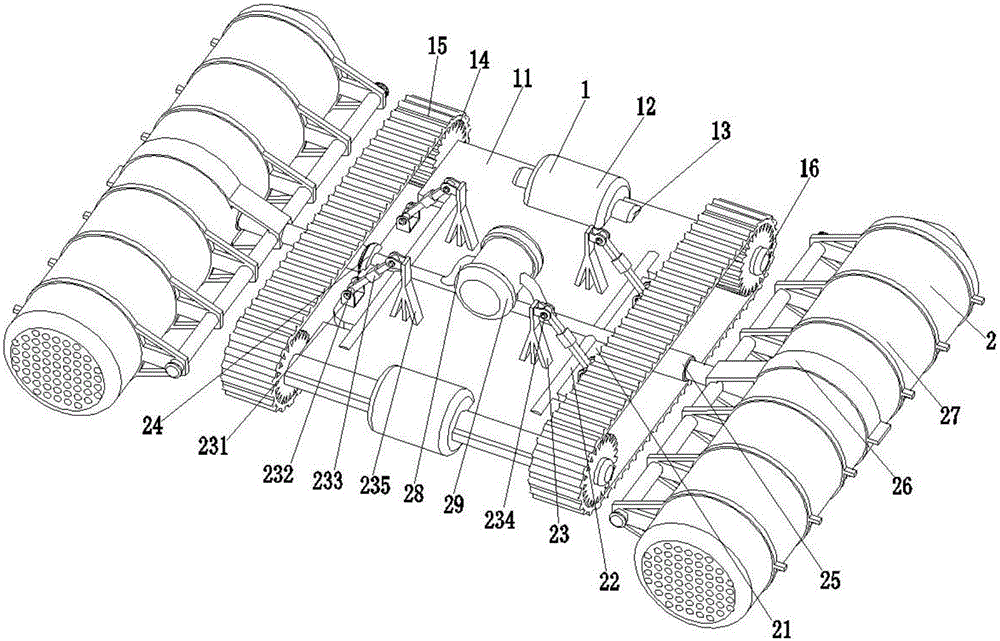

Urban municipal sidewalk ditch maintenance operation robot

ActiveCN106149860AFreedom to adjust flexiblyHigh degree of intelligenceSewer systemsEndless track vehiclesEngineeringWorkload

The invention relates to an urban municipal sidewalk ditch maintenance operation robot. The urban municipal sidewalk ditch maintenance operation robot comprises crawler walking devices, wheel type walking devices, an electric rotating table, a delta parallel mechanism and a cleaning device. The number of the wheel type walking devices is four and the wheel type walking devices are symmetrically arranged on the left sides and the right sides of the crawler walking devices respectively. The electric rotating table is located in the centers of the upper ends of the crawler walking devices and fixedly connected with the crawler walking devices. The delta parallel mechanism is located between the electric rotating table and the cleaning device, the lower end of the delta parallel mechanism is connected with the electric rotating table, and the upper end of the delta parallel mechanism is connected with the cleaning device. The urban municipal sidewalk ditch maintenance operation robot can carry out cleaning, dredging and maintaining operation on urban municipal sidewalk ditches, is flexible in degree-of-freedom adjustment and high in intelligent degree and cleaning and dredging efficiency, and solves the problems that existing manual cleaning and dredging are large in workload, low in efficiency, high in cost and the like.

Owner:江苏大道生物环境科技有限公司

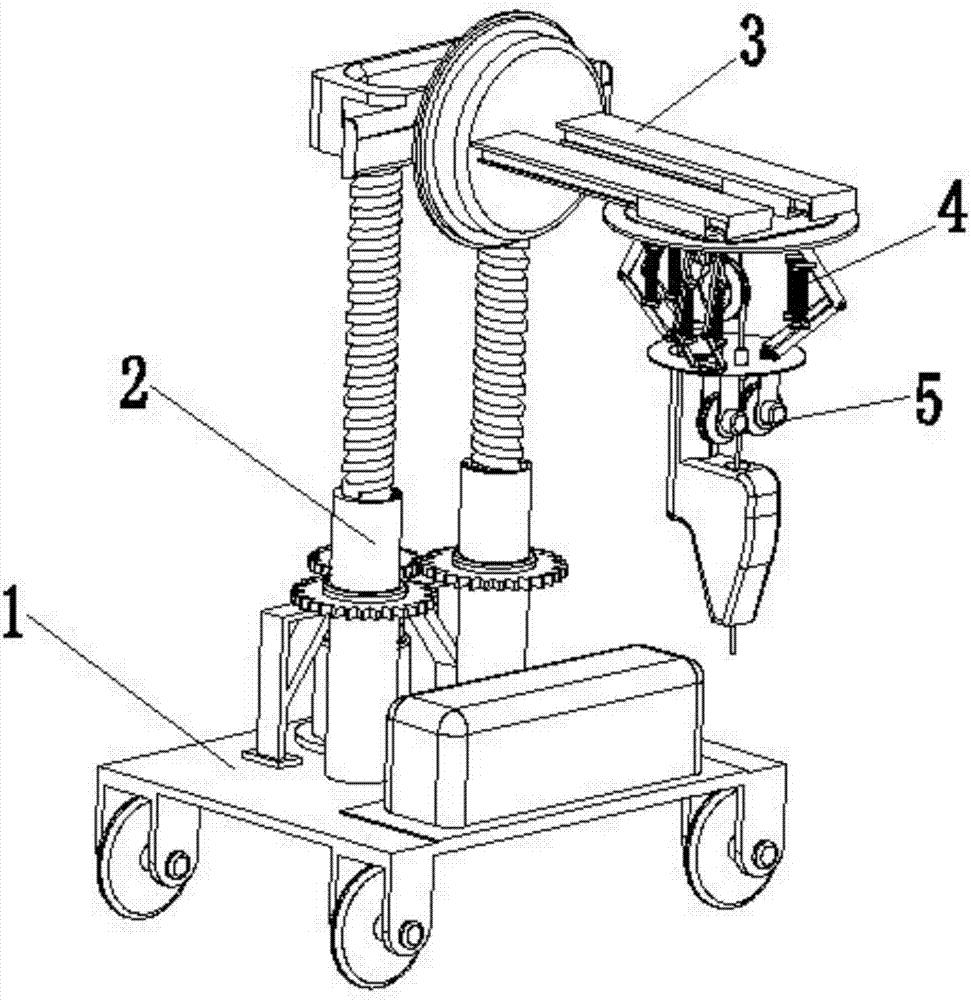

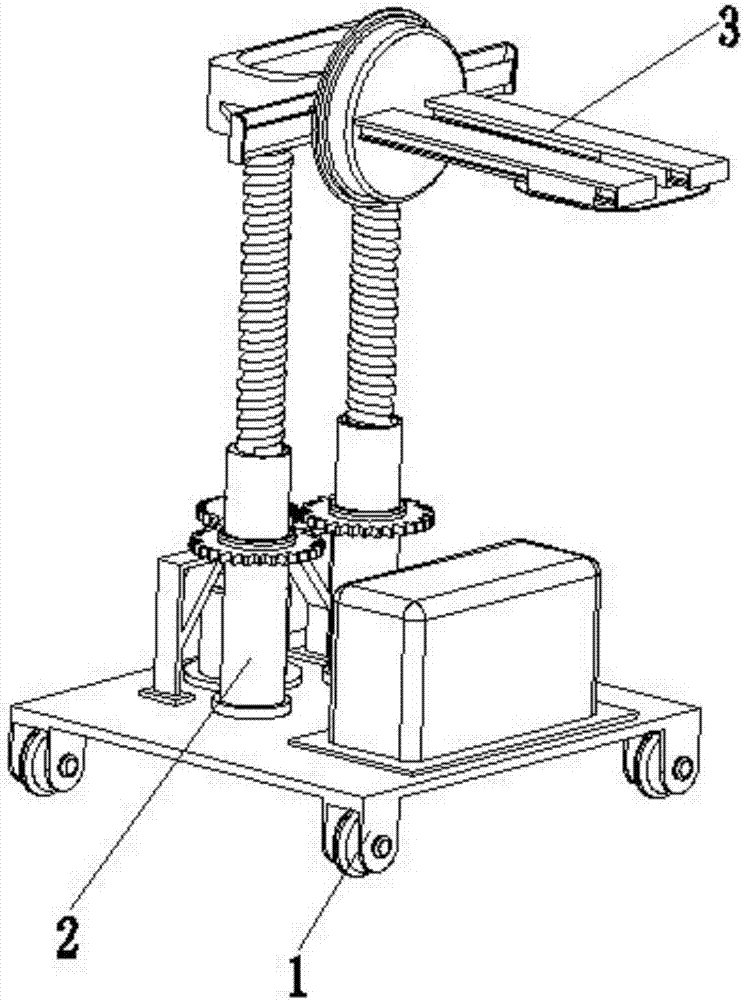

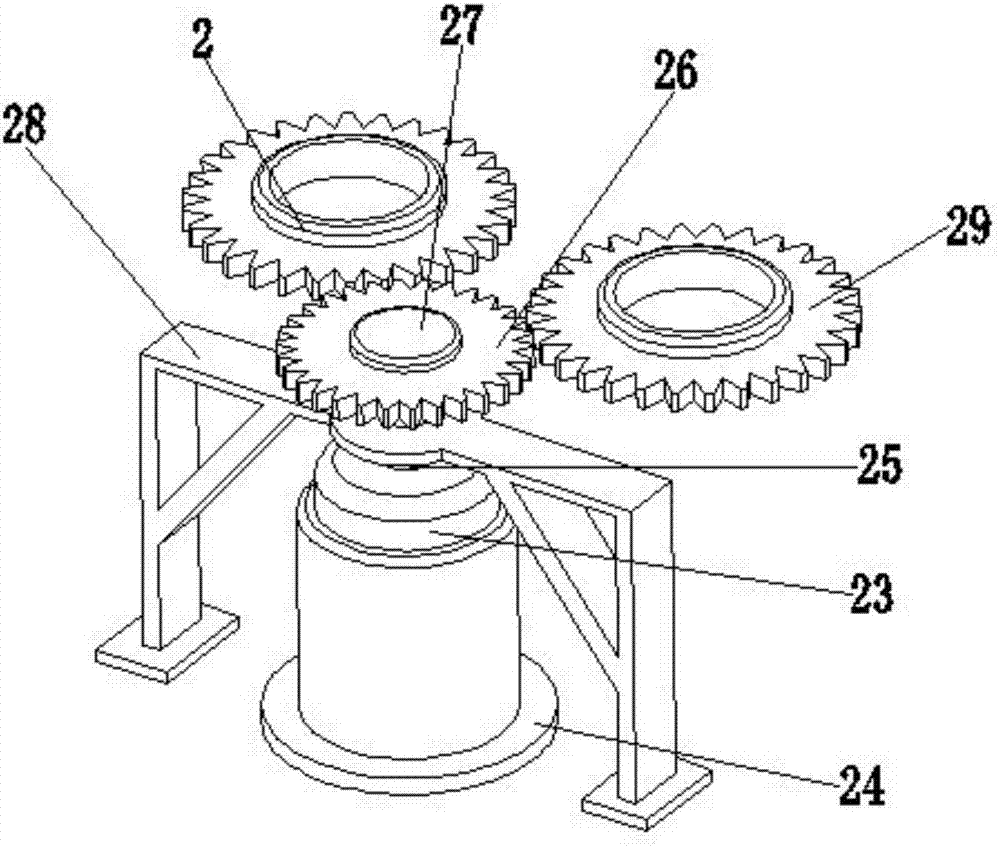

An all-round industrial automation welding robot

ActiveCN105798497BAdjustable positionFlexible movementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAutomation

The invention relates to a comprehensive industrial automation welding robot. The comprehensive industrial automation welding robot comprises a moving base, a lifting device, a rotary drive device, a delta parallel mechanism and a welding execution device. A square fixed platform is arranged at the upper end of the moving base, and one-way walking wheels are symmetrically arranged on the four top corners of the bottom face of the square fixed platform correspondingly; and a welding machine is arranged on the front side of the upper end of the moving base, the lifting device is located at the rear side end of the moving base, the rotary drive device is located over the lifting device, the delta parallel mechanism is located below the front end of the rotary drive device, the welding execution device is located under the delta parallel mechanism, and the welding execution device is fixedly connected with the delta parallel mechanism. Full-automatic intelligent welding work can be achieved, during welding, the whole position is adjustable, the local position is flexible in motion, stability is high, meanwhile the function that welding wire feeding is achieved while welding is carried out is achieved, the welding efficiency is high, and the welding quality is good.

Owner:黑龙江严格数字矿山科技集团有限公司

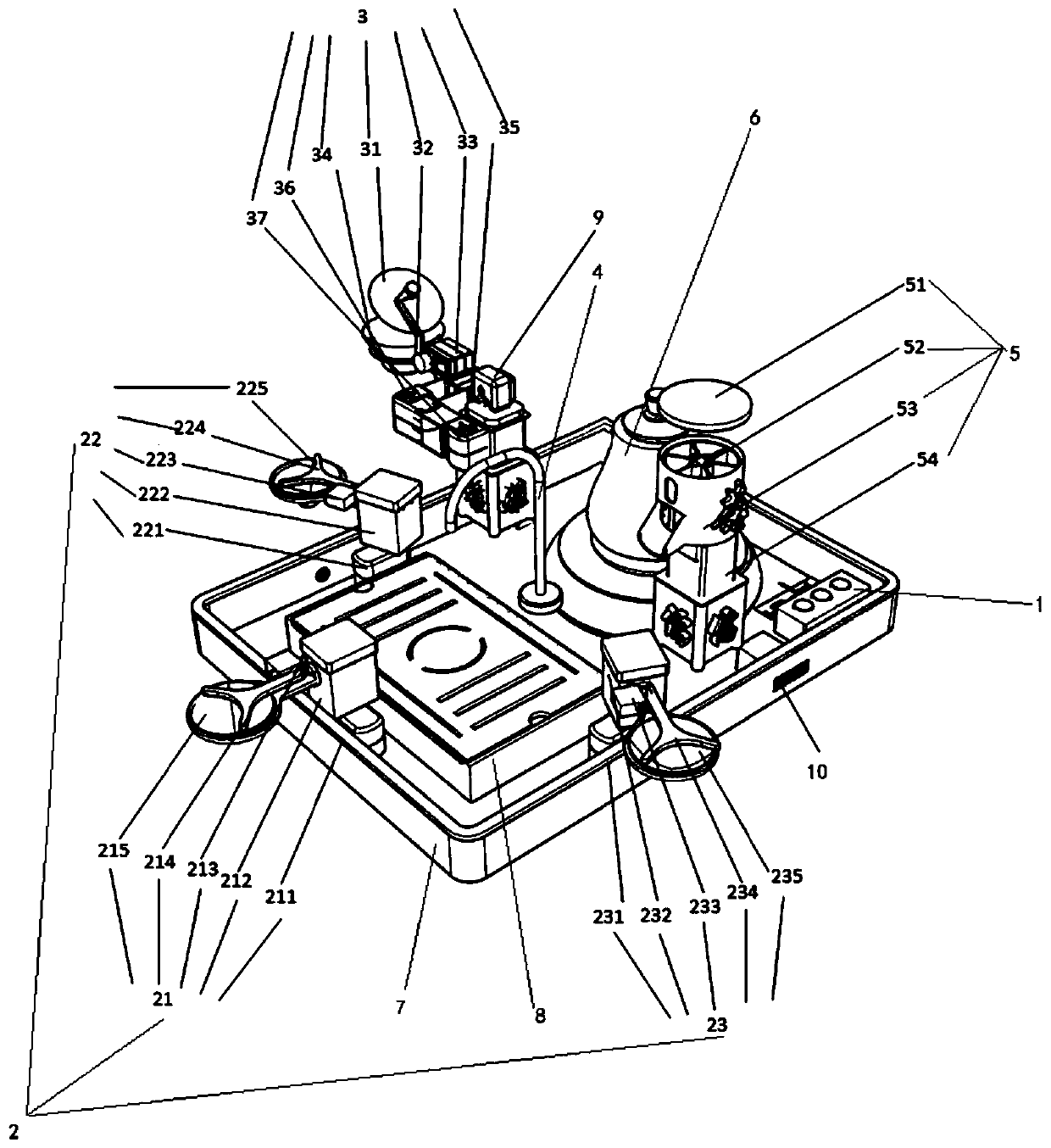

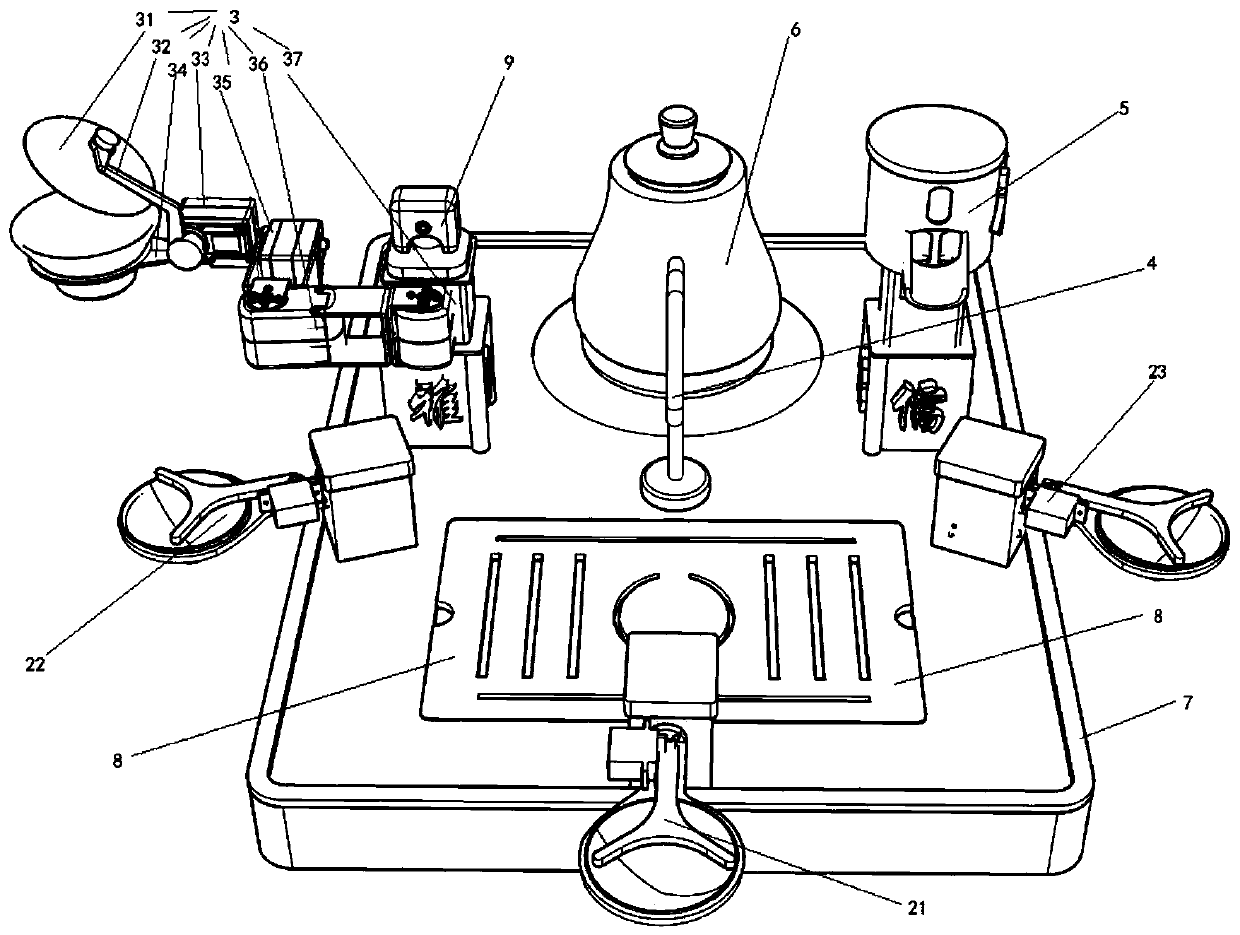

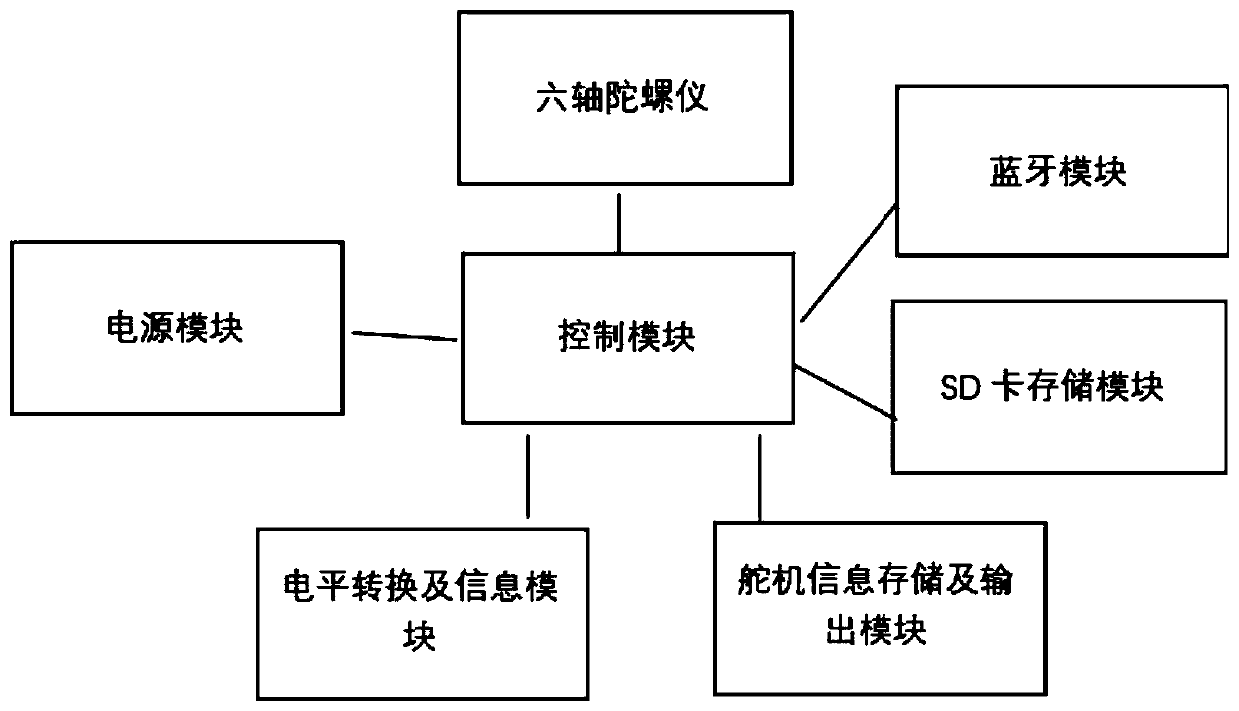

Full-automatic intelligent robot and control method thereof

InactiveCN110076794ALittle room for movementImprove experienceManipulatorAgricultural engineeringFuture of robotics

The invention belongs to the technical field of robots, and particularly relates to a full-automatic intelligent tea robot. The full-automatic intelligent tea robot comprises a master control box, a tea cup rotating mechanism, a tea pouring mechanical arm, a water feeding device, a tea canister storage device and a base; the master control box is arranged on the bottom of the base, a control key is arranged on the master control box, a master control board is arranged in the master control box, a control unit, a voice unit and a vision unit are integrated on the master control board, the tea cup rotating mechanism is arranged on the base and is located on the front side of the water feeding device, the tea cup rotating mechanism comprises multiple tea cup rotating frames, the tea cup rotating frames can coaxially rotate, and the tea pouring mechanical arm and the tea canister storage device are arranged on the left side and the right side of the water feeding device correspondingly. The invention further relates to a control method of the full-automatic intelligent tea robot. The robot is designated to sequentially finish bowl washing, tea washing, cup washing, tea making, tea pouring, and tea giving actions.

Owner:西安缔造者机器人有限责任公司

Clamping head for full-automatic hydroelectric engineering drain pipe

InactiveCN105905594AHigh degree of automationImprove work efficiencyConveyorsConveyor partsManual handlingSix degrees of freedom

The invention relates to a clamping head for a full-automatic hydroelectric engineering drain pipe. The clamping head comprises a delta parallel mechanism and a clamping device, wherein the delta parallel mechanism is positioned just above the clamping device, and the lower end of the delta parallel mechanism is connected with the clamping device. According to the clamping head, a series of operations of grabbing, handling and stacking water and hydroelectric pipelines can be realized, the clamping head has the advantages of high degree of automation, stability and flexibility in movement and high operating efficiency, and the problems of high operating cost, low efficiency, large danger and the like of manual handling are solved; the delta parallel mechanism of the clamping head can move in space in six degrees-of-freedom directions including three translations and three rotations, the movement space is small, the movement speed is high, and the movement flexibility is good; according to the clamping head, the whole clamping device is driven to flexibly and slightly move in space by the delta parallel mechanism, and the delta parallel mechanism is mainly used for adjusting the local small size when the clamping head is used for handling and stacking the water and hydroelectric pipelines.

Owner:陈薇

Intelligent robot for multi-degree-of-freedom overwater shooting operation

ActiveCN106004282AEasy to fixHigh degree of intelligenceAmphibious vehiclesProgramme-controlled manipulatorMulti degree of freedomEngineering

The invention relates to an intelligent robot for multi-degree-of-freedom overwater shooting operation. The intelligent robot comprises a land walking device, a water surface walking device, a lifting device, a delta parallel mechanism and a shooting device, wherein the water surface walking device is connected with the land walking device, the lifting device is located right above the land walking device, the lower end of the lifting device is connected with the upper end of the land walking device, the delta parallel mechanism is located between the lifting device and the shooting device, the lower end of the delta parallel mechanism is connected with the lifting device, and the upper end of the delta parallel mechanism is connected with the shooting device. The intelligent robot has the functions of land walking, water surface walking, azimuth angle adjustment, camera fixation and shooting operation and is high in intelligent degree, convenient and flexible in azimuth angle adjustment, convenient and stable in camera fixation and high in shooting speed and quality, and the problems that the monitoring difficulty is high, shooting is very dangerous, the shooting quality is poor and the like during existing manual shooting by a ship are solved.

Owner:宿迁中略科技咨询有限公司

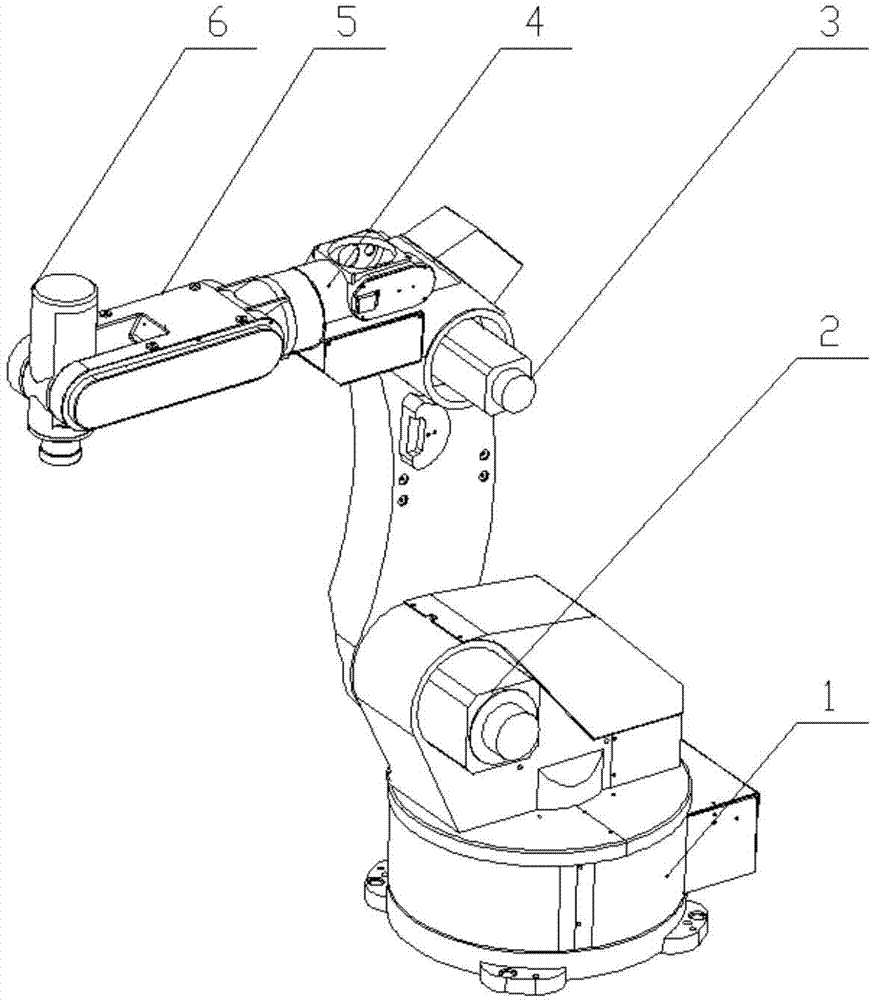

Robot front-end arm based on rear-mounted wrist point motor

ActiveCN104493820AIncrease flexibilityImprove stabilityProgramme-controlled manipulatorArmsInstabilityElectric machinery

The invention provides a robot front-end arm based on a rear-mounted wrist point motor. A robot terminal executor is arranged at the forefront of the front-end arm; the front-end arm comprises a speed reducer and a motor; the speed reducer and the motor are coaxial; the axis of the speed reducer and the axis of the motor pass through a wrist point of the front-end arm; the speed reducer is arranged at the rear of the wrist point; the motor is arranged at the rear of the speed reducer; and the motor is connected with the speed reducer through a motor shaft. The driving motor of the front-end arm is placed at the rear end of the wrist point of a wrist of the front-end arm, the center of gravity moves backwards, the stability of a whole structure of a robot is improved, and the problem of instability due to over-large inertia and over-large overshooting in a moving process is solved, and the robot is lightweight in structure and is intelligent.

Owner:NANJING PANDA ELECTRONICS +2

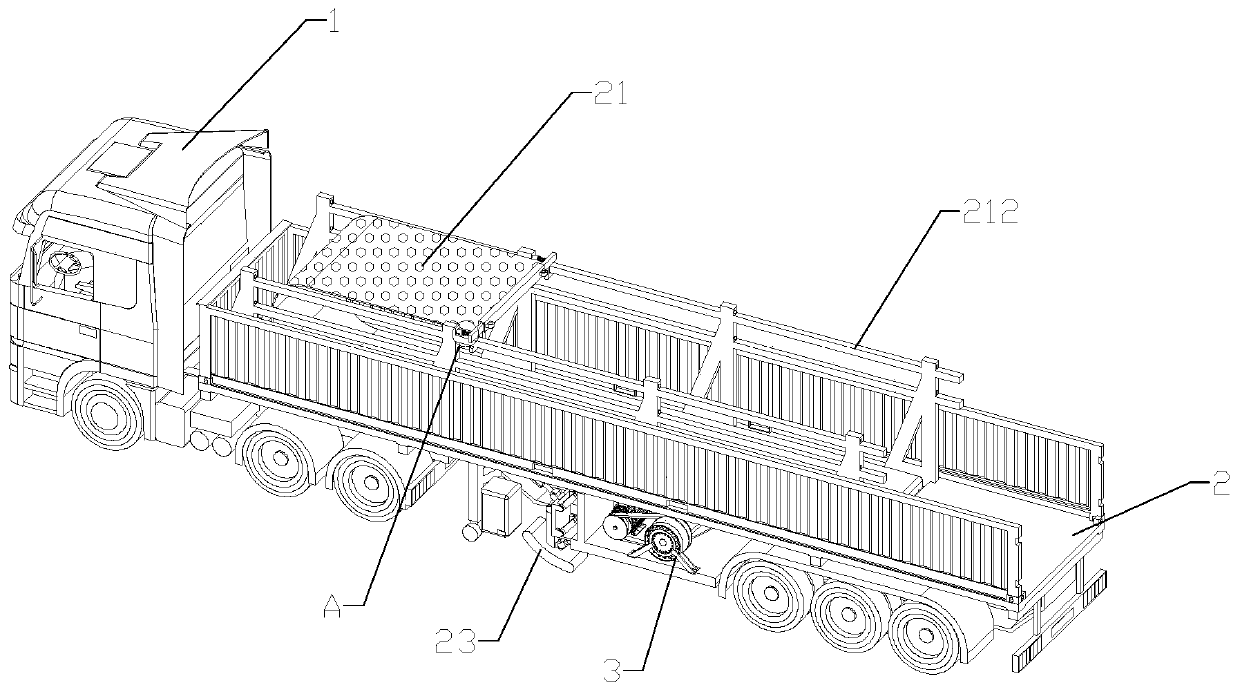

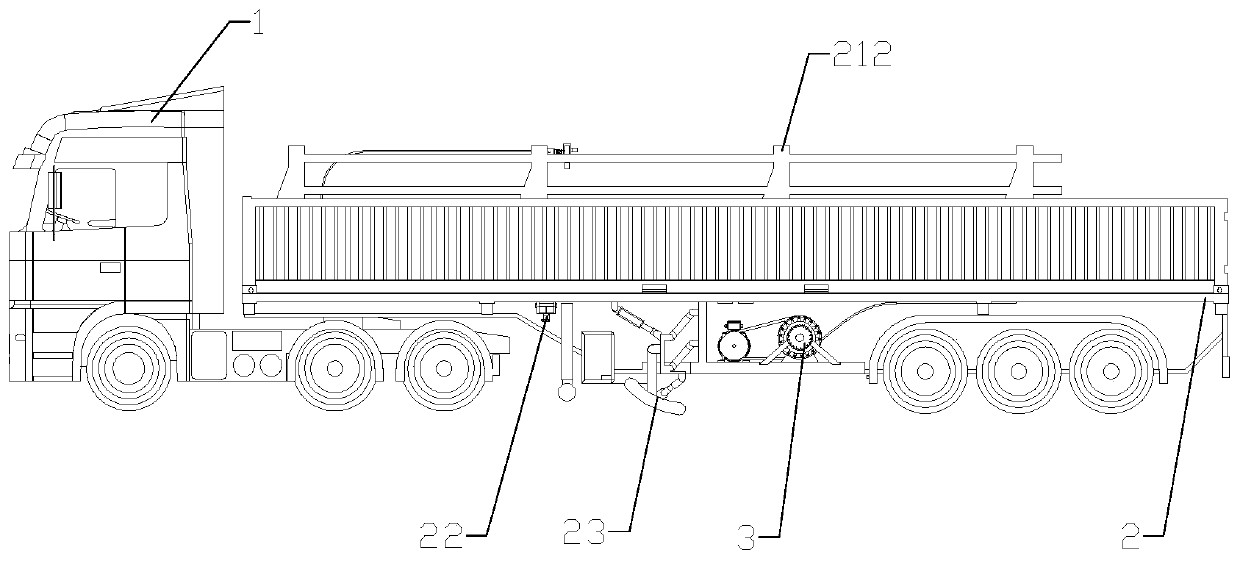

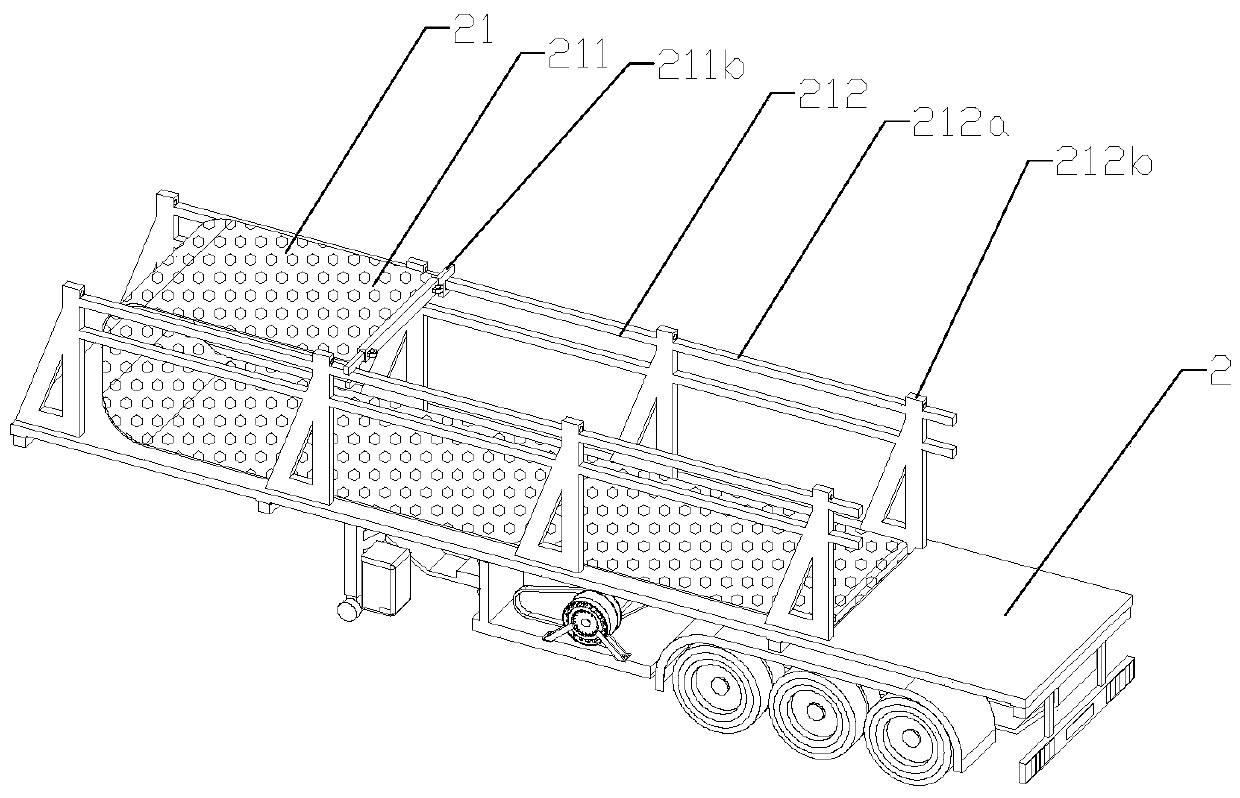

Semi-trailer truck with inertia forward impact protection function

ActiveCN110834578APrevent forward rushDecrease the coasting distanceBraking element arrangementsTractor-trailer combinationsElectric machineryStructural engineering

The invention discloses a semi-trailer truck with an inertia forward impact protection function. The semi-trailer truck comprises a tractor unit and a semi-trailer, wherein a braking sensing device isarranged in a cab of the tractor unit; the braking sensing device comprises a pedal and a sensor arranged on one side of the pedal; the semi-trailer is provided with an isolation and blocking device,an automatic locking device and a braking assisting device; the isolation and blocking device comprises an isolation and blocking net, fixing frames, a drum and drum driving motors; the fixing framesare arranged side by side on the left and right sides of the semi-trailer; the fixing frames comprise horizontal rods and a plurality of vertical rods; the front end of the isolation and blocking netis locked at the upper ends of the rear sides of intersections of the corresponding horizontal rods and the corresponding vertical rods through a telescopic rod; the lower end of the isolation and blocking net runs through the semi-trailer to be connected to the drum; output shafts of the driving motors are connected to a drum shaft through belts and belt pulleys; and the positions of two ends ofthe drum shaft are limited by position-limiting mechanisms. The semi-trailer truck with the inertia forward impact protection function has the characteristics of freight isolation and blocking, automatic locking, and braking assisting of the semi-trailer truck.

Owner:梁山运通机械制造有限公司

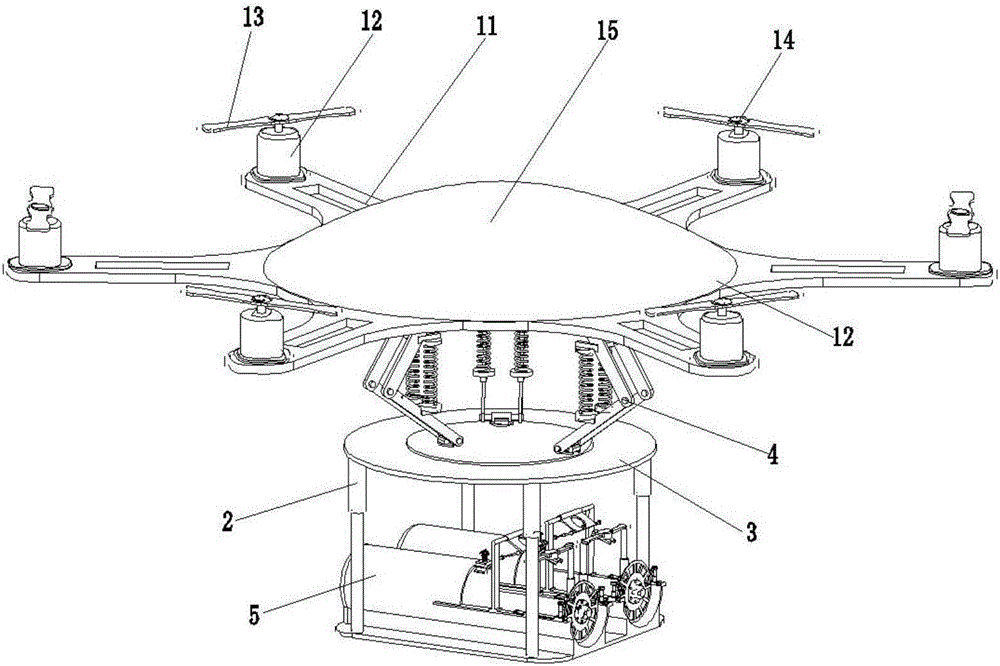

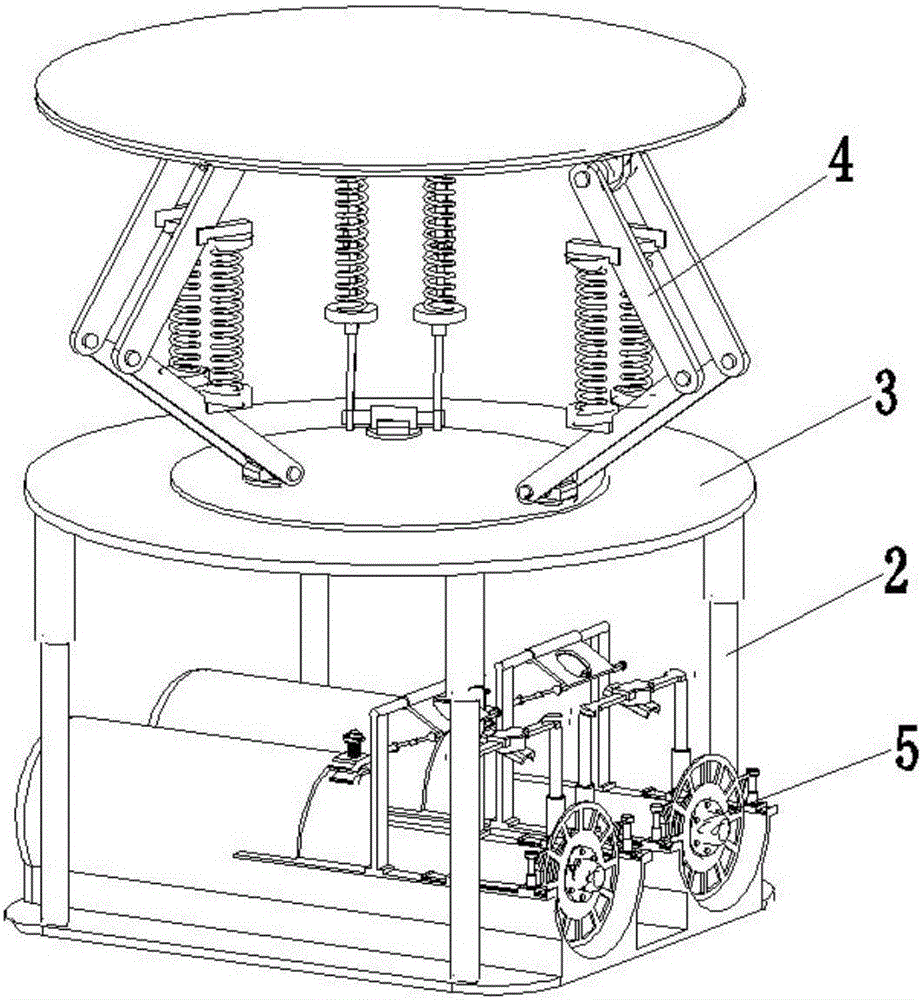

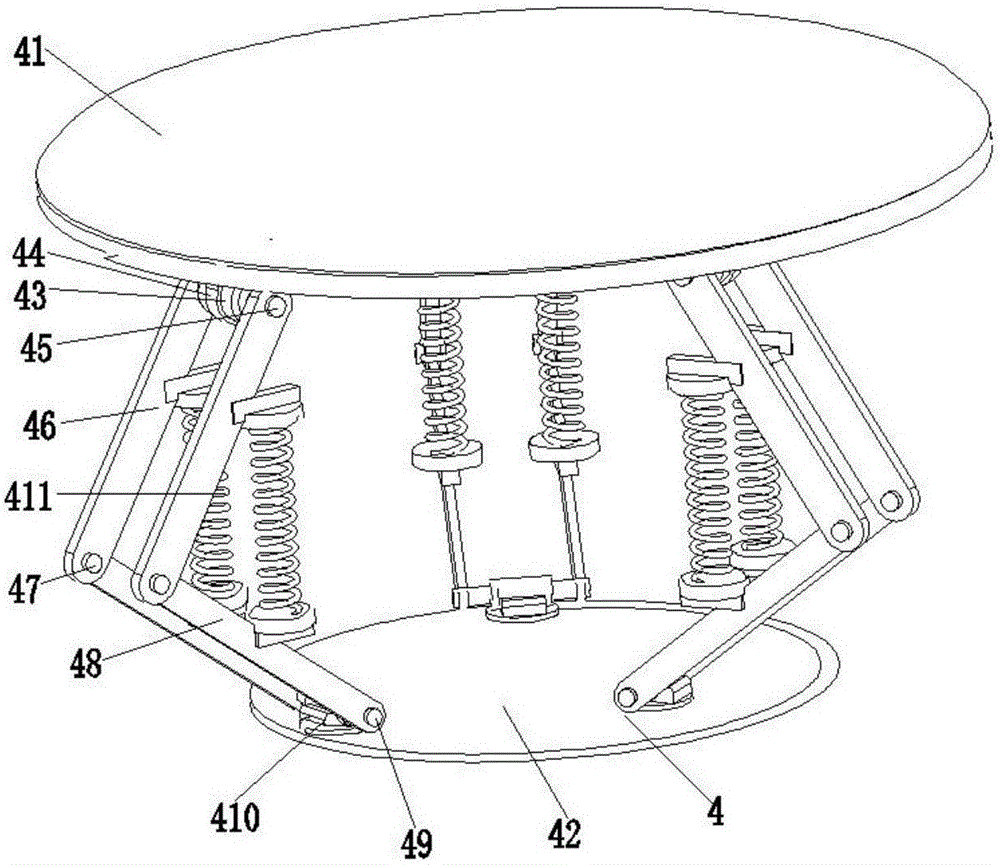

Fire extinguishing six-rotor unmanned aerial vehicle for electric power overhead electric wires and cables

ActiveCN106005418ARealize the adjustable angle functionWide range of fire extinguishing jetsAircraft componentsLaunching weaponsElectric power systemFire - disasters

The invention relates to a fire extinguishing six-rotor unmanned aerial vehicle for electric power overhead electric wires and cables. The fire extinguishing six-rotor unmanned aerial vehicle comprises an unmanned aerial vehicle body, a support table, an electric rotating table, a delta parallel mechanism and a fire extinguishing device. The support table is located in the center of the upper end of the fire extinguishing device and is of a Y-shaped structure, the lower end of the support table is fixedly connected with the fire extinguishing device, the upper end of the support table is connected with the lower end face of the electric rotating table, the delta parallel mechanism is located between the electric rotating table and the unmanned aerial vehicle body, the lower end of the delta parallel mechanism is connected with the upper end face of the electric rotating table, and the upper end of the delta parallel mechanism is connected with the unmanned aerial vehicle body. The fire extinguishing six-rotor unmanned aerial vehicle is capable of carrying out overhead fire extinguishing work on overhead electric wires and cables when a fire disaster occurs, is high in automation degree, stable and flexible in flying in the fire extinguishing process, large in fire extinguishing jetting range and high in fire extinguishing efficiency and safety, and solves the problem that high dangerousness exists in manual fire extinguishing for overhead electric wires and cables.

Owner:南通亿思特机器人科技有限公司

Movement adjusting device for all-directional industrial automatic welding robot

ActiveCN105921917AImprove welding qualityImprove welding efficiencyProgramme-controlled manipulatorWelding/cutting auxillary devicesVertical planeThree degrees of freedom

The invention relates to a movement adjusting device for an all-directional industrial automatic welding robot. The device comprises a rotary driving device and a delta parallel mechanism; the delta parallel mechanism is positioned below the front end of the rotary driving device; and the rotary driving device is fixedly connected with the delta parallel mechanism. The device provides the supporting and position adjusting effects to the welding robot, is high in bearing capacity, excellent in adjustability, high in movement flexibility, adjustable in whole position, flexible in local position movement and high in stability, and indirectly improves the welding quality and efficiency of the welding robot; the rotary driving device can realize left-right movement and front-back movement on the horizontal plane and rotating movement on the vertical plane, namely three-degree-of-freedom movement of one rotation and two translation in space; and the rotary driving device can guarantee adjustment of whole large size and large direction of the welding robot in welding, so that the welding performance of the welding robot is improved.

Owner:新沂市鹏立机械有限公司

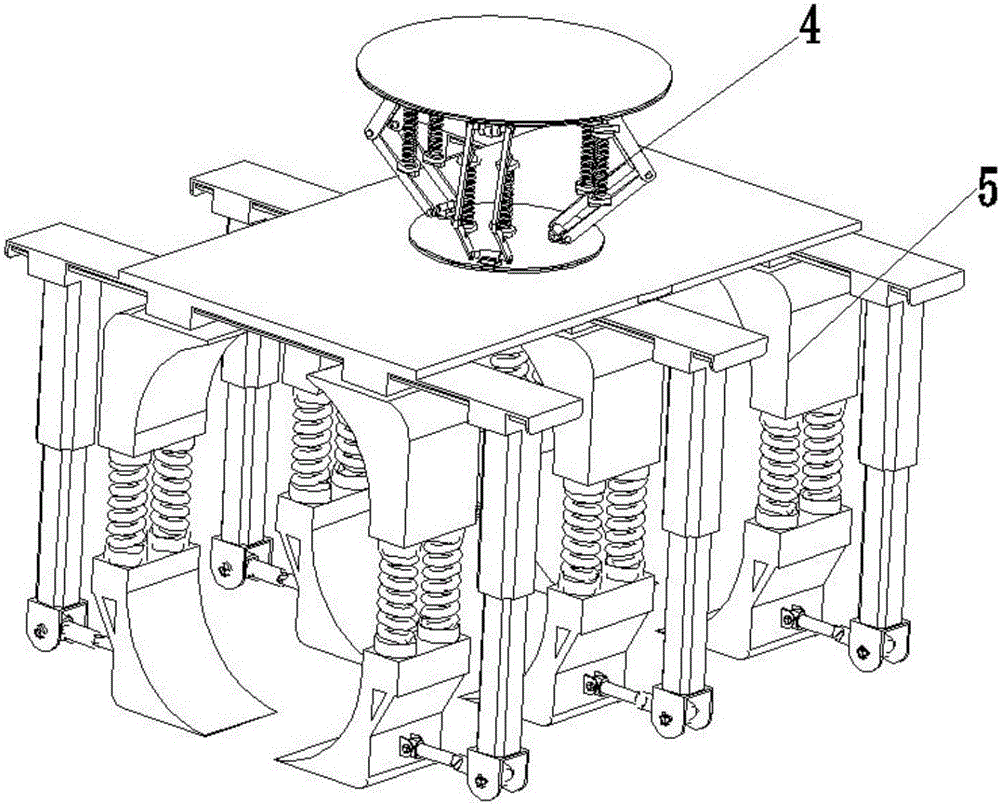

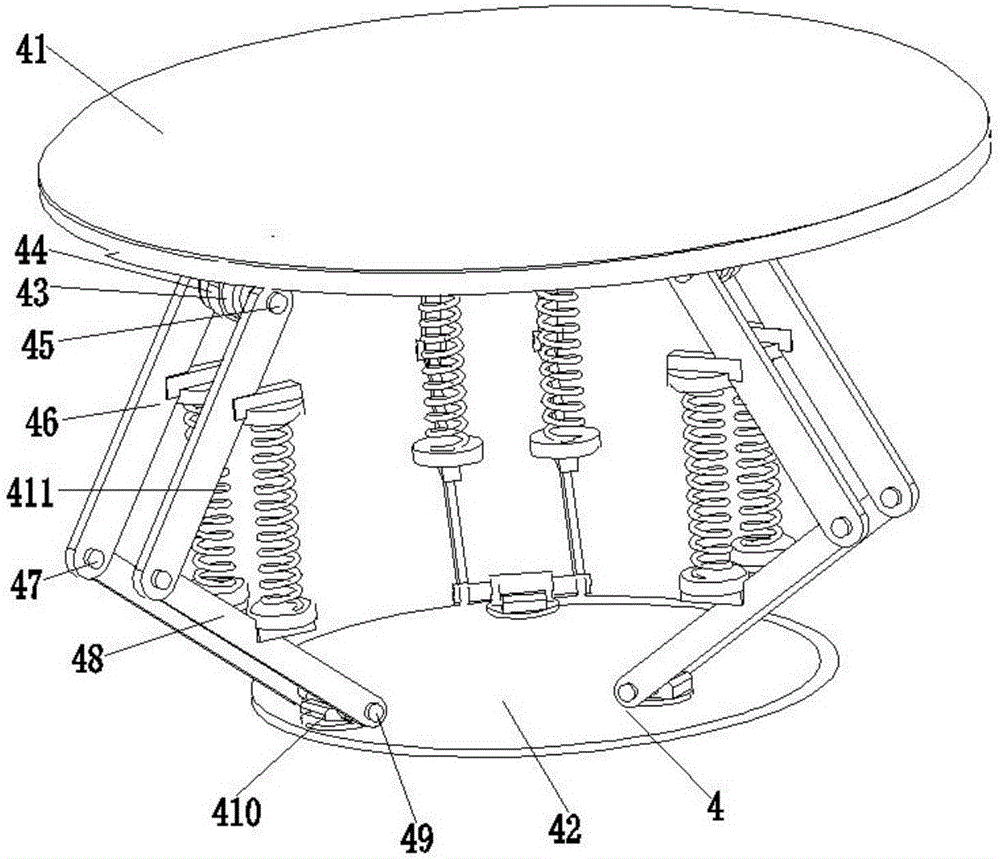

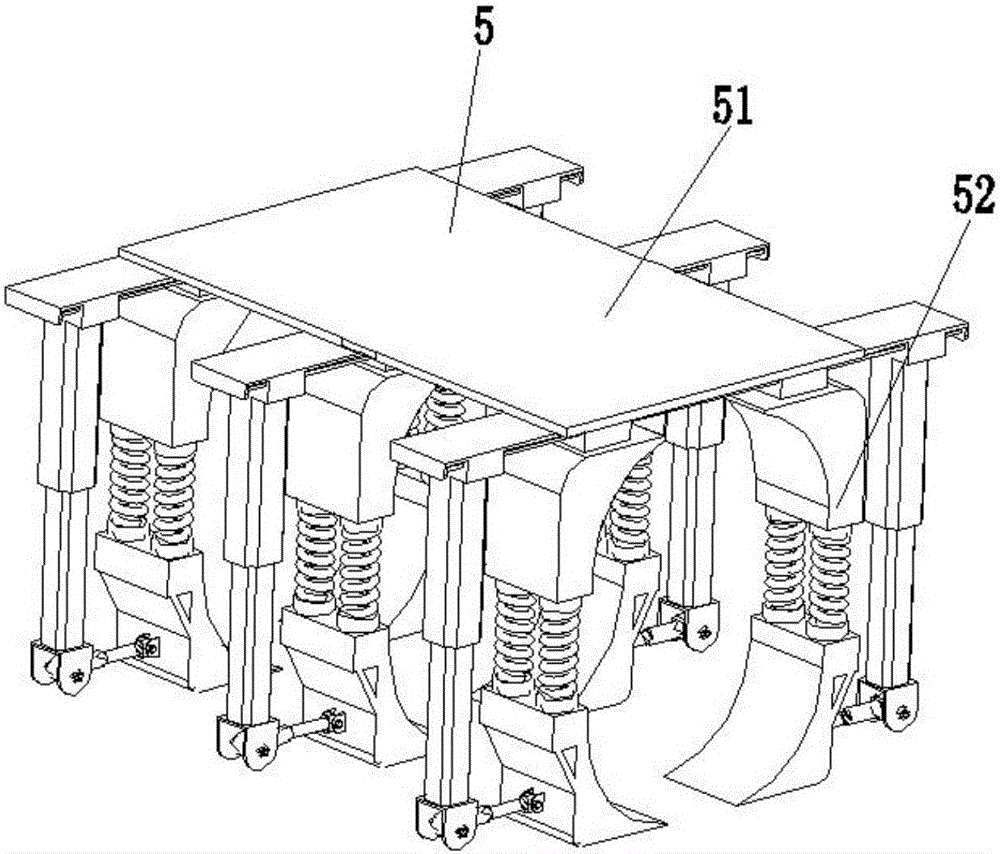

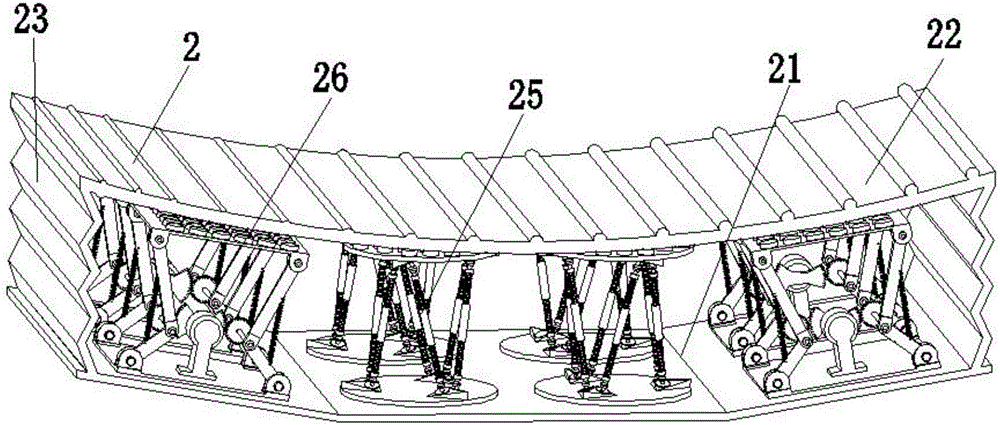

Redundancy double-parallel mechanism intelligent car seat with buttock massage function

The invention relates to a redundancy double-parallel mechanism intelligent car seat with a buttock massage function. The car seat comprises a seat body, a massage device, lifting support columns, a moving adjustment device and limiting devices. The massage device is located in a concave installing groove formed in the middle of a riding part of the seat body. The lower ends of the lifting support columns are fixed to the upper portion of the moving adjustment device. The limiting devices are installed on the front side and the right side end of the moving adjustment device. The overall height of the car seat can be adjusted, and use by drivers of different heights is facilitated; the whole car seat can move horizontally front and back and left and right, so that the specific position of the car seat in the using process is adjusted; the whole car seat can contract and massage the buttocks of a person, and is good in softness and small in occupied space; and massaging force generated in the massaging process is different according to different positions of the buttocks of the person, the massaging contact face is complete, the massaging effect is remarkable, and the comfort of buttock massaging is improved.

Owner:安徽信和汽车股份有限公司

Automatic folding and rubber band bundling all-in-one machine for plastic bag

InactiveCN109878792AUnified width specificationOmitting componentsPaper article packagingBundling machine detailsRelative motionEngineering

The invention discloses an automatic folding and rubber band bundling all-in-one machine for a plastic bag. The automatic folding and rubber band bundling all-in-one machine for the plastic bag comprises a rack, a vibrating disc device, a rubber band opening device, a lifting handle folding device, a tail folding device and an inserting plate device. The automatic folding and rubber band bundlingall-in-one machine for the plastic bag is characterized in that the automatic folding and rubber band bundling all-in-one machine for the plastic bag further comprises a retreating clamping plate device and a conveying clamping plate device, the retreating clamping plate device and the conveying clamping plate device are used for oppositely folding and clamping one side of the plastic bag, the retreating clamping plate device loosens the plastic bag and retreats after the plastic bag is finalized, then one side of the plastic bag is clamped by the conveying clamping plate device, and the otherside of the plastic bag is inserted into the rubber band opening device to be bundled through relative motion of the inserting device. The automatic folding and rubber band bundling all-in-one machine for the plastic bag has the advantages that the processes from folding to bundling are almost conducted in the conveying clamping plate device and a clamping plate mechanism, integration of foldingand bundling is achieved on the condition that hand changing is not needed, therefore, the folding and bundling work is stable and reliable, and the structure is simple and compact.

Owner:王秀来

Electric suction lock and tensioning transmission mechanism of tail end of automotive stern door

InactiveCN106150232ALittle room for movementSimple structureElectrical locking actuatorsReciprocating motionEngineering

The invention aims to solve the technical problem of providing an electric suction lock which is simple in structure and small in motion space. According to the technical scheme, the electric suction lock comprises a door lock main body, a sliding block, a bottom plate and a sliding pulling lug, wherein the door lock main body and the bottom plate define a hollow cavity; an empty groove communicating with the hollow cavity is formed in the door lock main body; the sliding block is positioned in the hollow cavity and passes through the empty groove in a reciprocating manner; a taper groove is formed in the sliding block; the sliding pulling lug comprises a first end; the first end is embedded in the taper groove through the empty groove; and when the sliding block does reciprocating motion in the hollow cavity, the first end moves in a reciprocating manner, and the movement locus of the sliding pulling lug does not coincide with that of the sliding block. The embodiment of the invention further provides a tensioning transmission mechanism of the tail end of an automotive stern door.

Owner:WINBO DONGJIAN AUTOMOTIVE TECHNOLOGY CO LTD

Single-arm manipulator

ActiveCN103802089AIncrease load capacityLittle room for movementProgramme-controlled manipulatorCoupled motionEngineering

The invention provides a single-arm manipulator. The manipulator comprises a column, a waist seat, a connecting fitting, a first arm, a second arm, an end member, a clamping claw, a first motor and a second motor, wherein the first arm and the second arm comprise butt ends and thin ends; the cylindrical connecting fitting is located in the column; the waist seat is in the shape of a flat plate, and the bottom of the waist seat is fixedly connected with the connecting fitting; the butt end of the first arm is fixedly connected with the waist seat, the thin end of the first arm is movably connected with the butt end of the second arm, and the thin end of the second arm is movably connected with the end member; the clamping claw which is roughly in a Y-shape is movably connected with the end member; the first motor and the second motor are in coupling motion to drive the first arm and the second arm in common and control the end member to perform rectilinear motion. The single-arm manipulator of the invention is small in occupied space and high in space utilization rate.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com