Material carrying mechanical arm structure and moving type kitchen carrying robot with material carrying mechanical arm structure

A technology for handling robots and handling machinery, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as being unsuitable for large-scale handling in kitchens, not finding robots, and labor-intensive workers, saving labor and production costs, Reduced eccentric load, automation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the embodiments of the present invention.

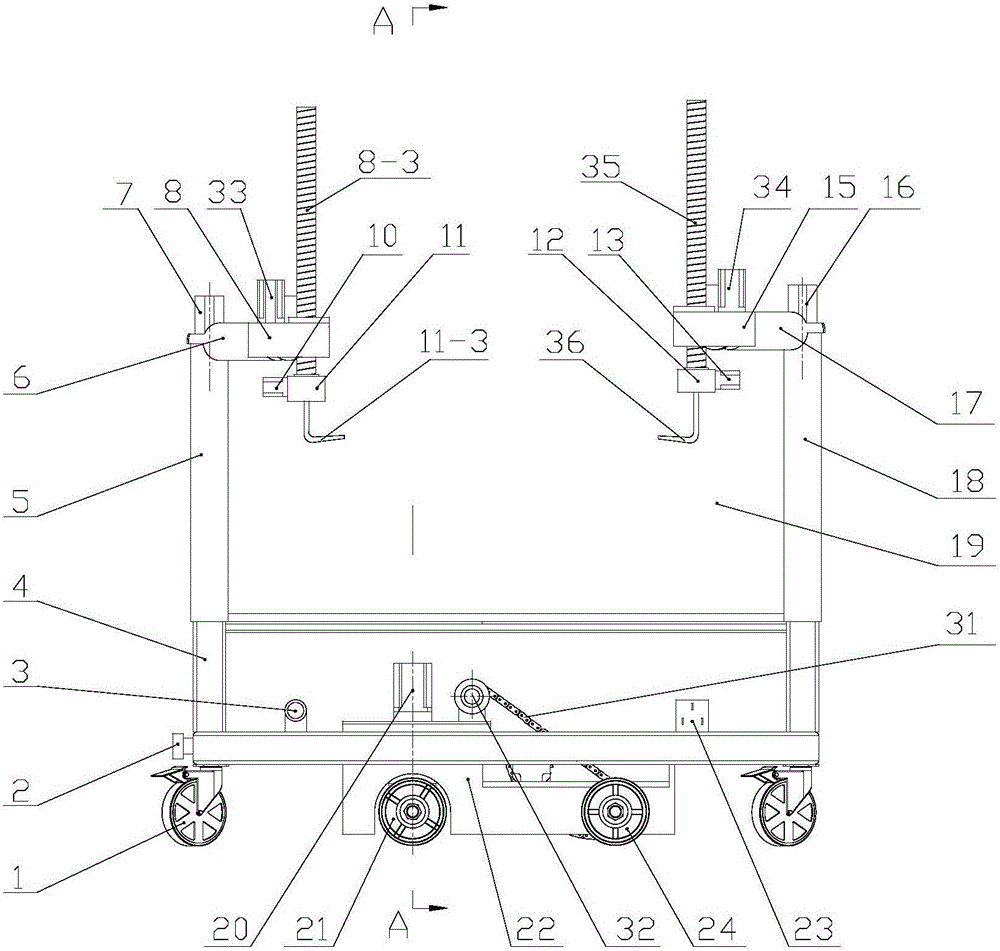

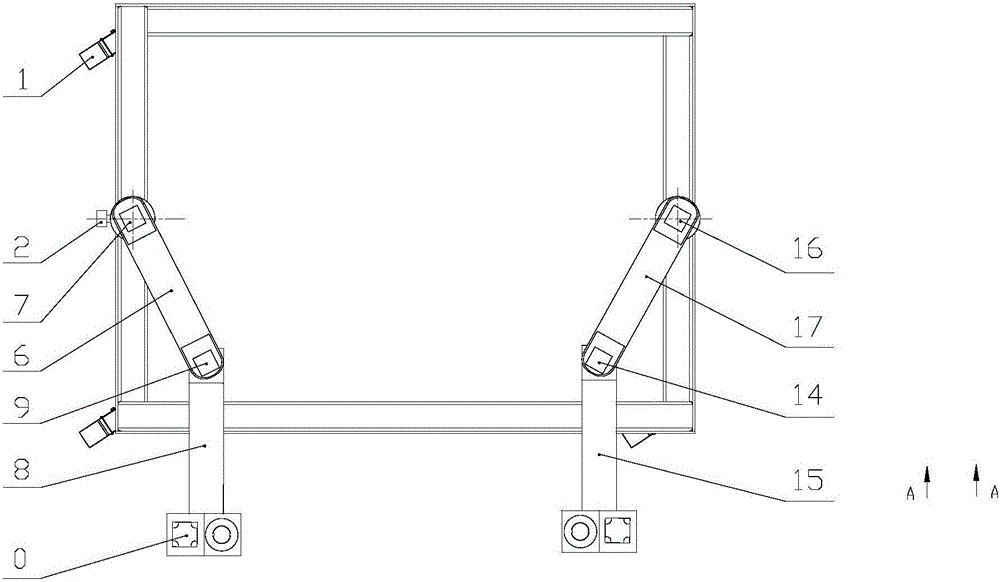

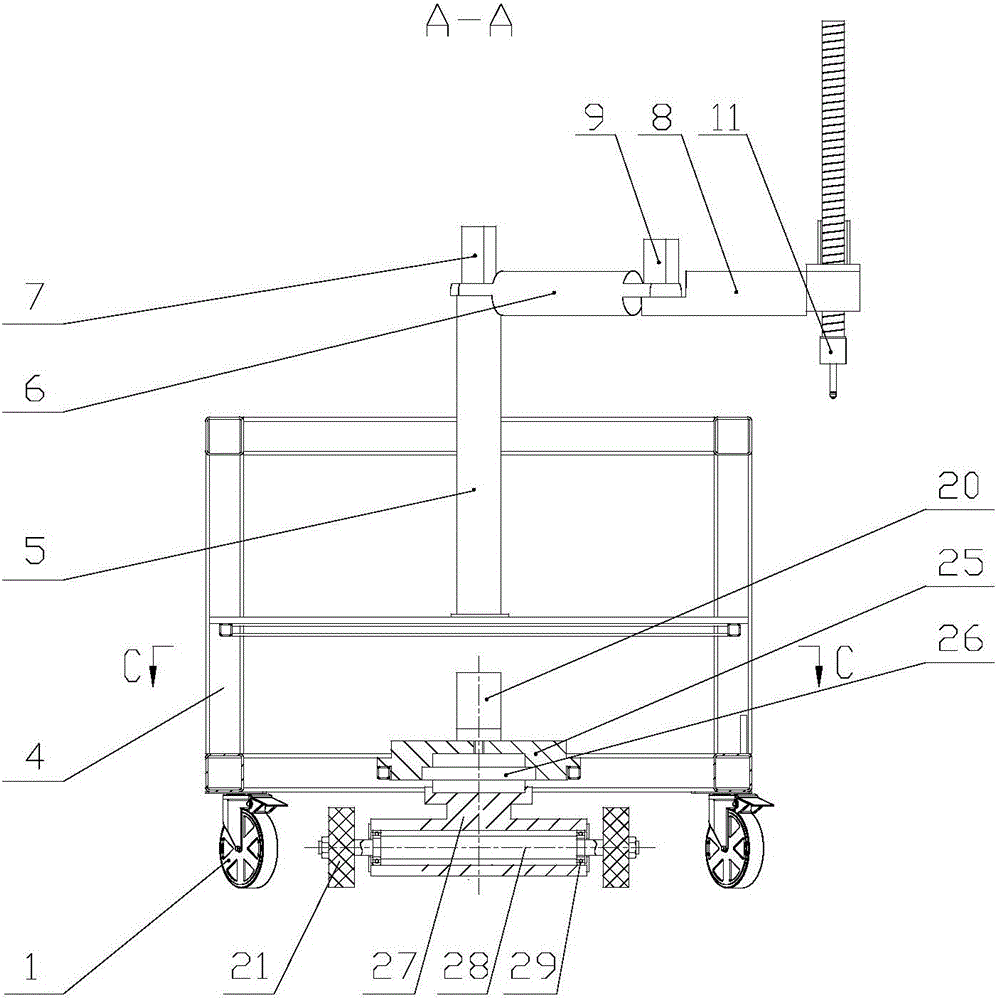

[0030] Such as Figure 1-5 As shown, a mobile kitchen handling robot includes a vehicle frame 4, a walking and material delivery system, a material handling mechanical arm structure, a barcode identification system, a road obstacle identification system and a robot control system.

[0031] ( 1 ) walking and material delivery system

[0032] Four corners of vehicle frame 4 bottoms are equipped with four universal wheels 1 respectively, are used to support whole mobile robot, and universal wheels 1 can rotate freely, to realize motions such as advancing, turning.

[0033]In the middle of the bottom of the vehicle frame 4, the inside of the four universal wheels 1 are fixed with a wheel drive system vehicle frame 22, and the upper left side of the wheel drive system vehicle frame 22 is fixed with a steering motor fixed disk 25. Steering motor 20 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com