Patents

Literature

55results about How to "Reduce partial load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

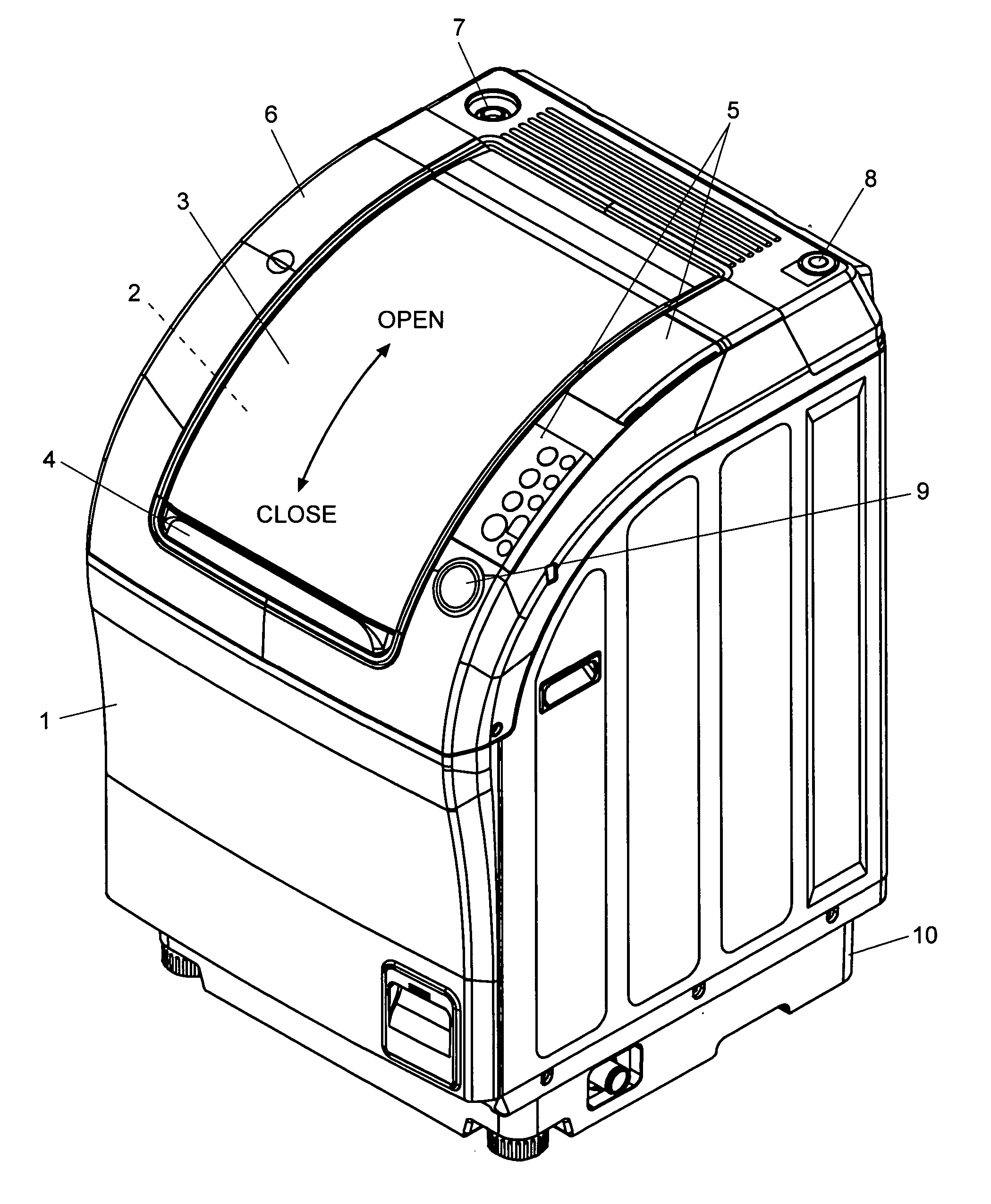

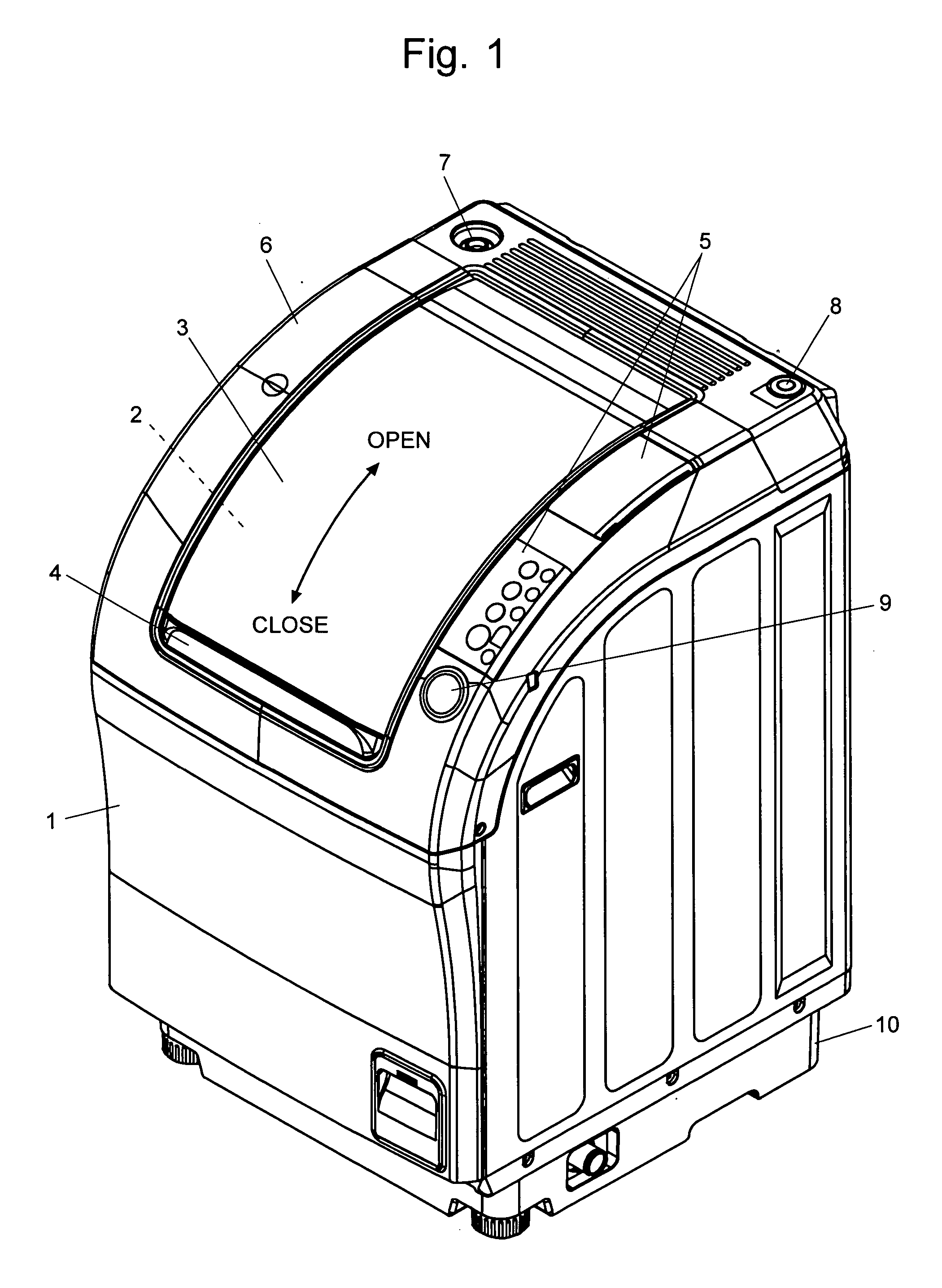

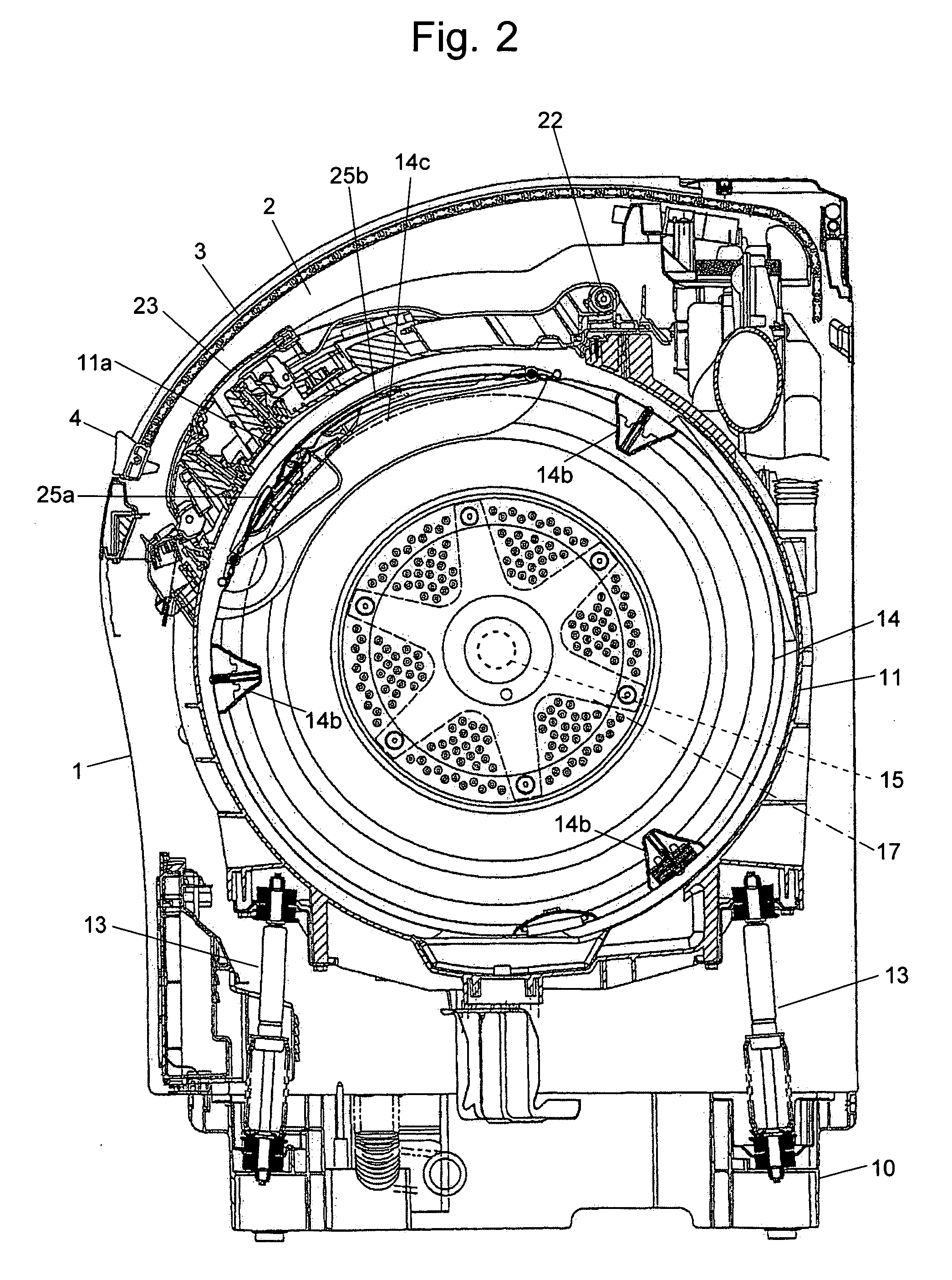

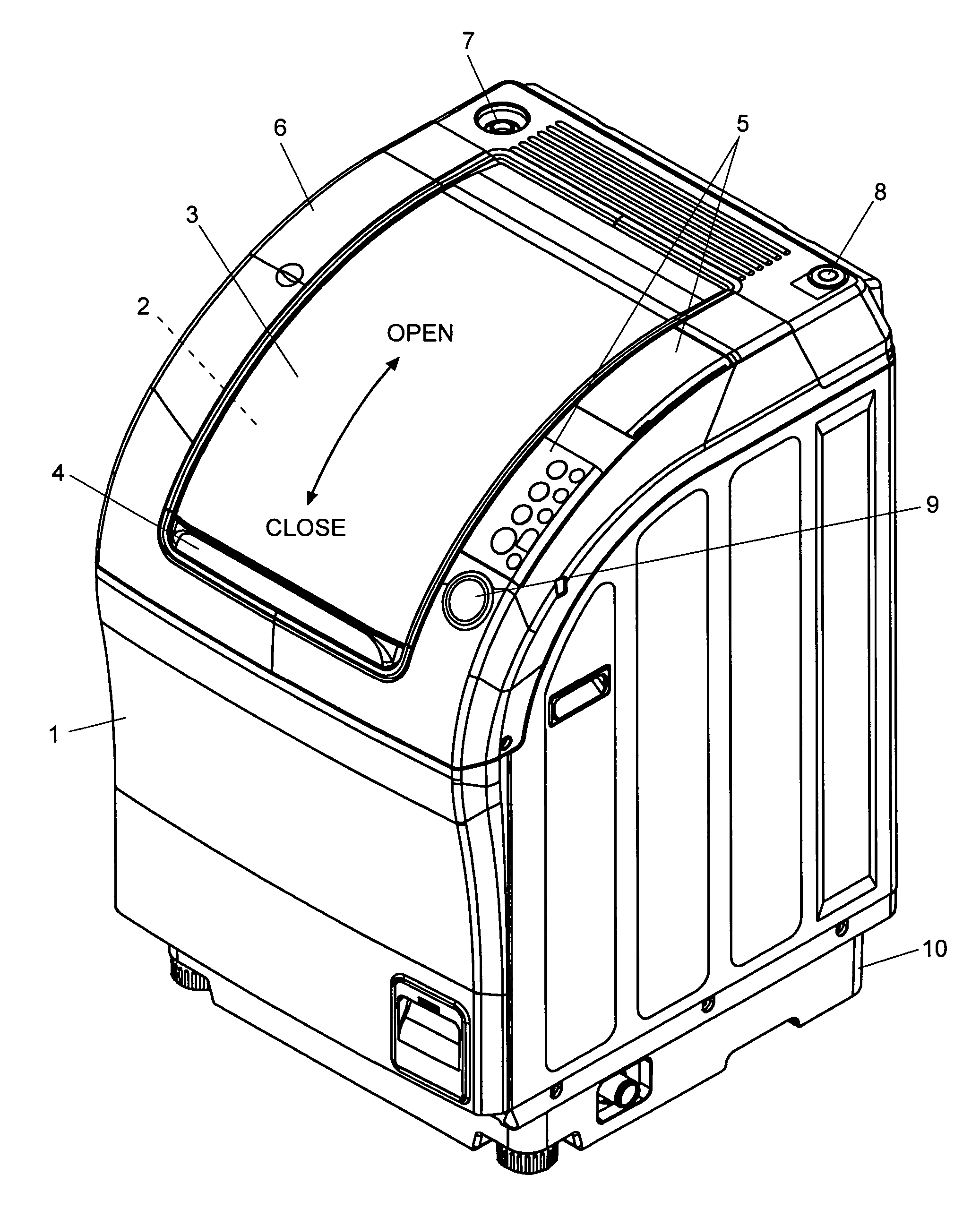

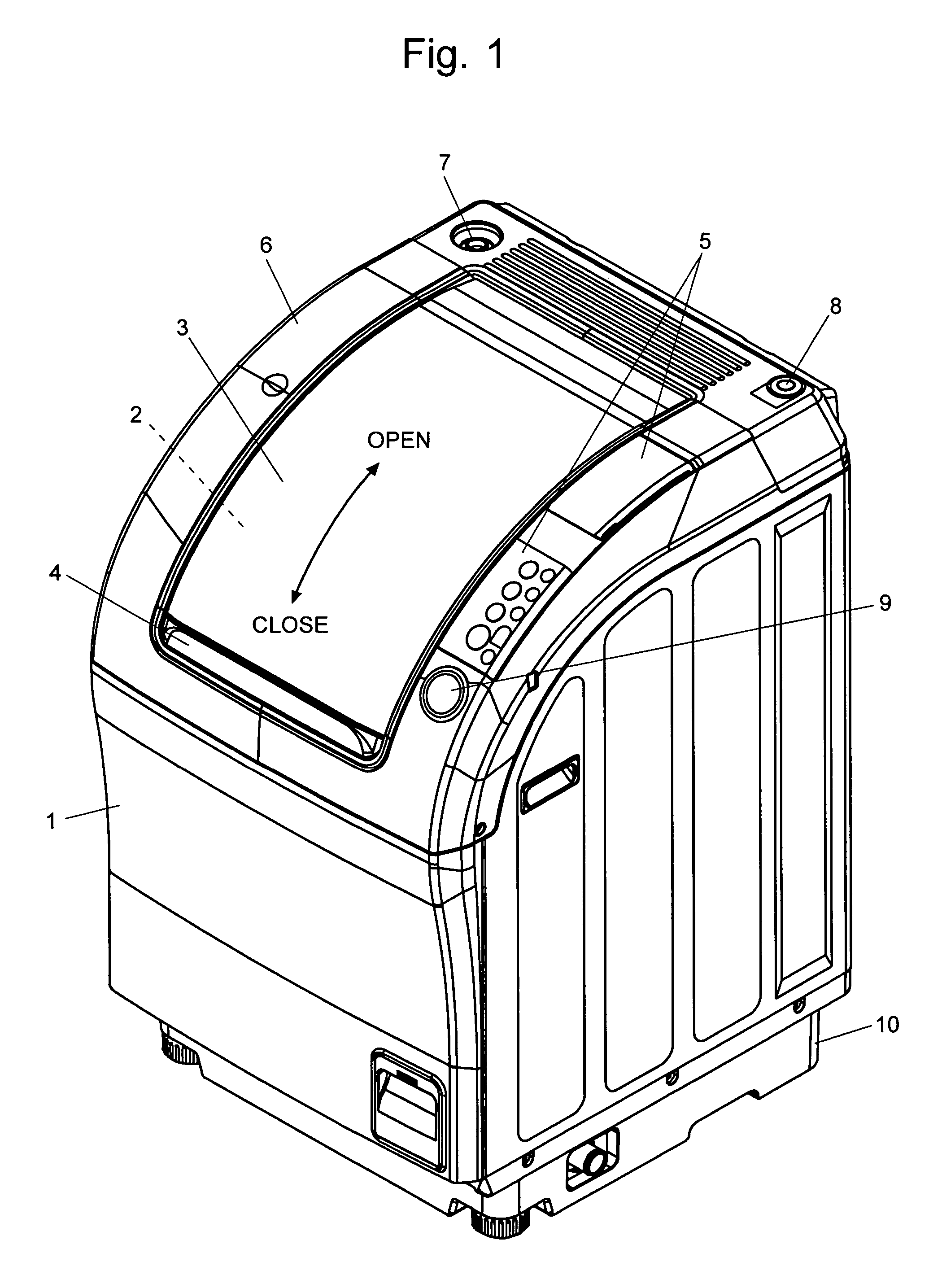

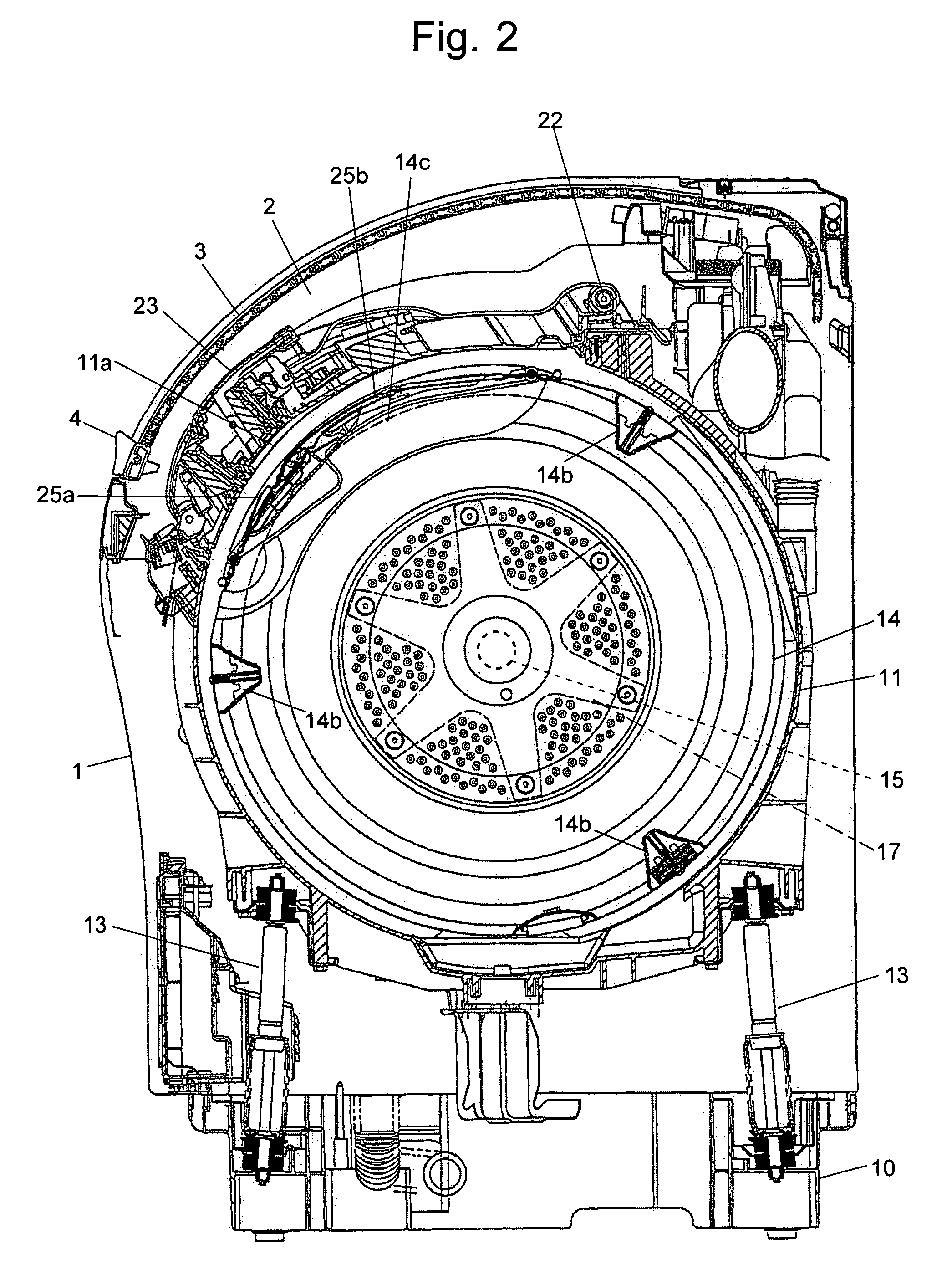

Drum type washing machine

ActiveUS20050268670A1Increase speedShort timeOther washing machinesControl devices for washing apparatusHigh probabilityStart up time

The present invention provides a drum type washing machine capable of adequately distributing the laundry articles along the inner circumferential wall of the drum at the start-up of the dehydrating operation with high probability, thereby reducing the start-up time of the dehydration. In an embodiment of the present invention, the drum is controlled to rotate at a constant speed 50 r.p.m. to agitate the laundry articles (Step S12), and the drum speed is almost continuously monitored. If the change in the speed does not exceed 1.5 r.p.m. for 0.5 second (Steps S13 through S16), the laundry articles are loosened and easy to distribute. Therefore, the drum speed is raised to 80 r.p.m. (Steps S17 and S18). If the eccentric load detected at this speed does not exceed a predetermined value (Steps S19 and S20), the laundry articles are adequately distributed along and pressed onto the inner circumferential wall of the drum. If a sudden change in the speed has been detected within a short period of time that is less than 36 milliseconds (Step S22), the laundry articles are tangled in a mass form. Therefore, the rotating direction of the drum is reversed, and the agitating direction is restarted in the opposite direction (Step S21).

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Drum type washing machine

ActiveUS7490490B2Increase probabilityReduce partial loadOther washing machinesControl devices for washing apparatusHigh probabilityStart up time

The present invention provides a drum type washing machine capable of adequately distributing the laundry articles along the inner circumferential wall of the drum at the start-up of the dehydrating operation with high probability, thereby reducing the start-up time of the dehydration. In an embodiment of the present invention, the drum is controlled to rotate at a constant speed 50 r.p.m. to agitate the laundry articles (Step S12), and the drum speed is almost continuously monitored. If the change in the speed does not exceed 1.5 r.p.m. for 0.5 second (Steps S13 through S16), the laundry articles are loosened and easy to distribute. Therefore, the drum speed is raised to 80 r.p.m. (Steps S17 and S18). If the eccentric load detected at this speed does not exceed a predetermined value (Steps S19 and S20), the laundry articles are adequately distributed along and pressed onto the inner circumferential wall of the drum. If a sudden change in the speed has been detected within a short period of time that is less than 36 milliseconds (Step S22), the laundry articles are tangled in a mass form. Therefore, the rotating direction of the drum is reversed, and the agitating direction is restarted in the opposite direction (Step S21).

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

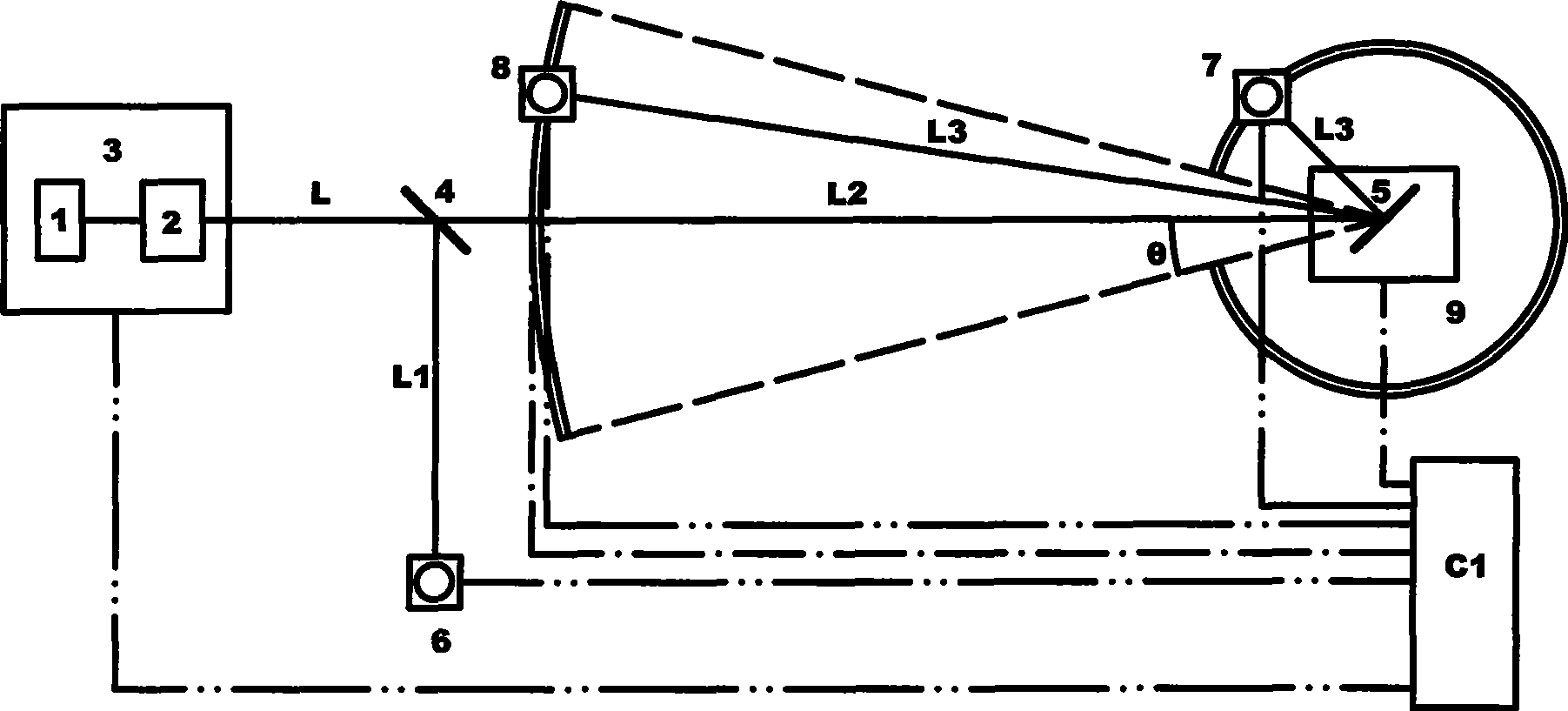

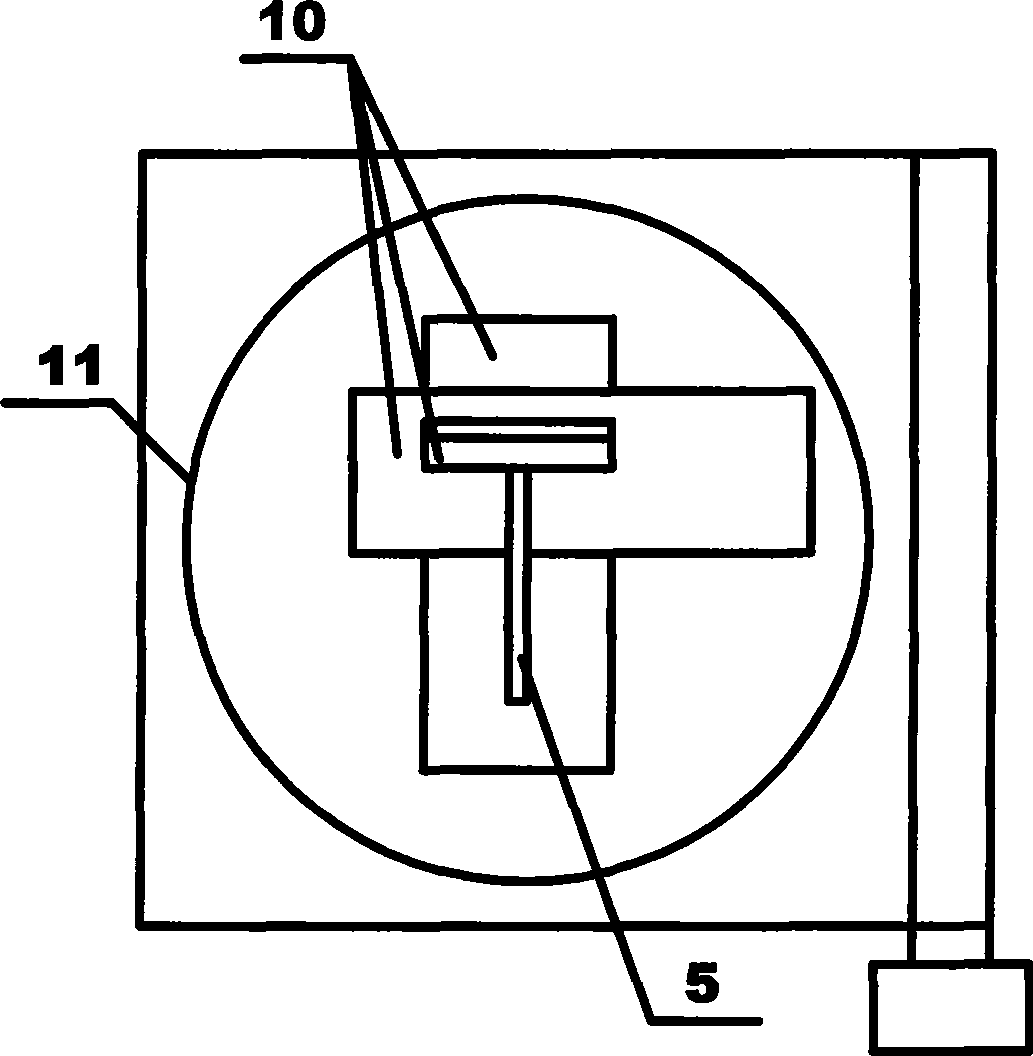

Measuring device and measuring method for diffraction efficiency of grating

InactiveCN101545826AReduce measurement blind spotsEqual propagation distanceTesting optical propertiesObservational errorBlind zone

The invention relates to a measuring device and a measuring method for the diffraction efficiency of a grating. The device comprises a monochromatic source, a beam splitter, a grating rotary table, detectors, a two-dimensional translation platform and a computer. The method is characterized in that: the second detector and the third detector are adopted to move on a small arc and a big arc respectively to detect the energy of a diffracted beam L3 of the grating to be tested; and the method realizes the aims of diminishing a measurement blind zone and reducing the requirement on the size of an optical platform. The double light path synchronous measurement is adopted to remove measurement errors caused by the instability of the light source.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

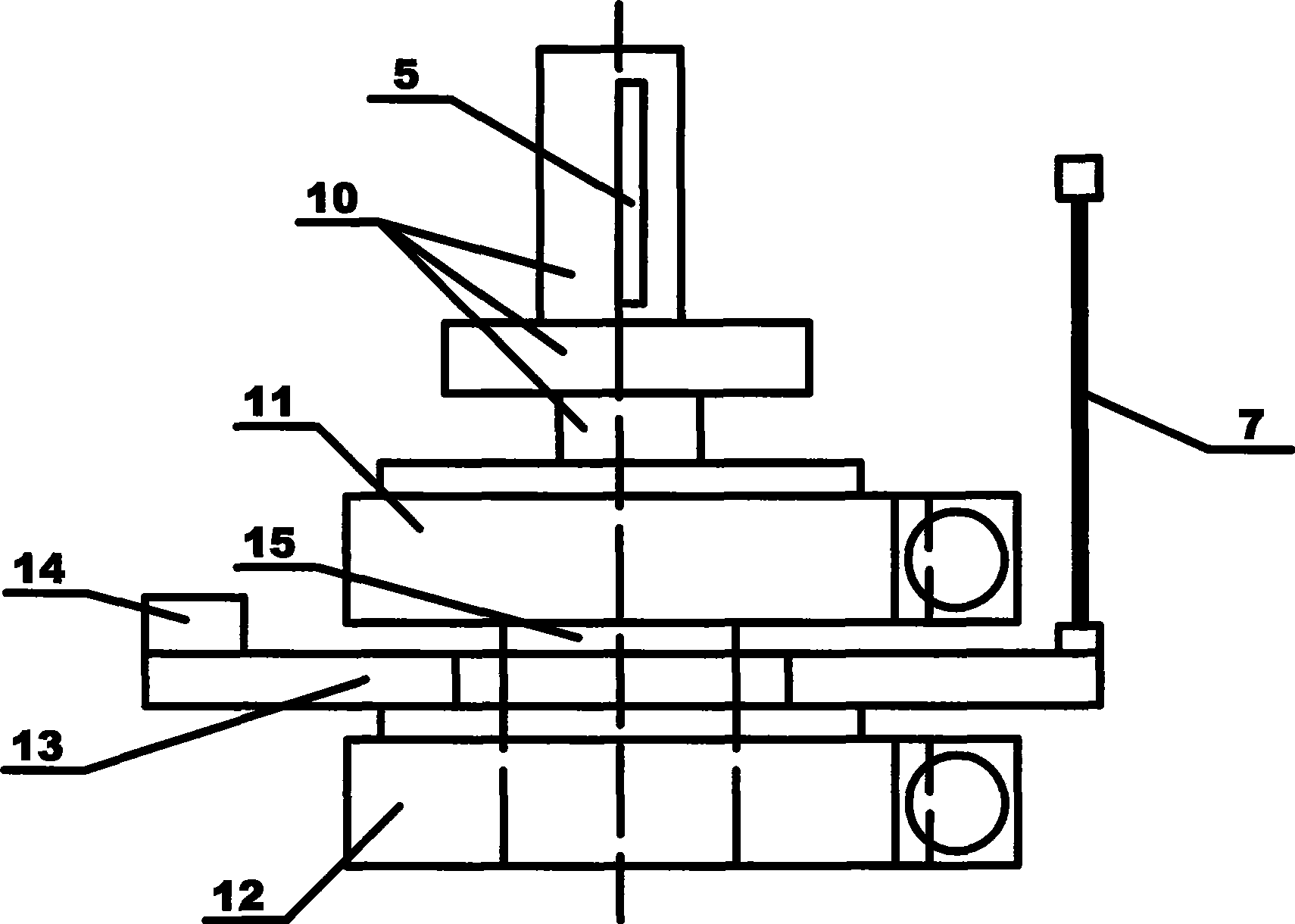

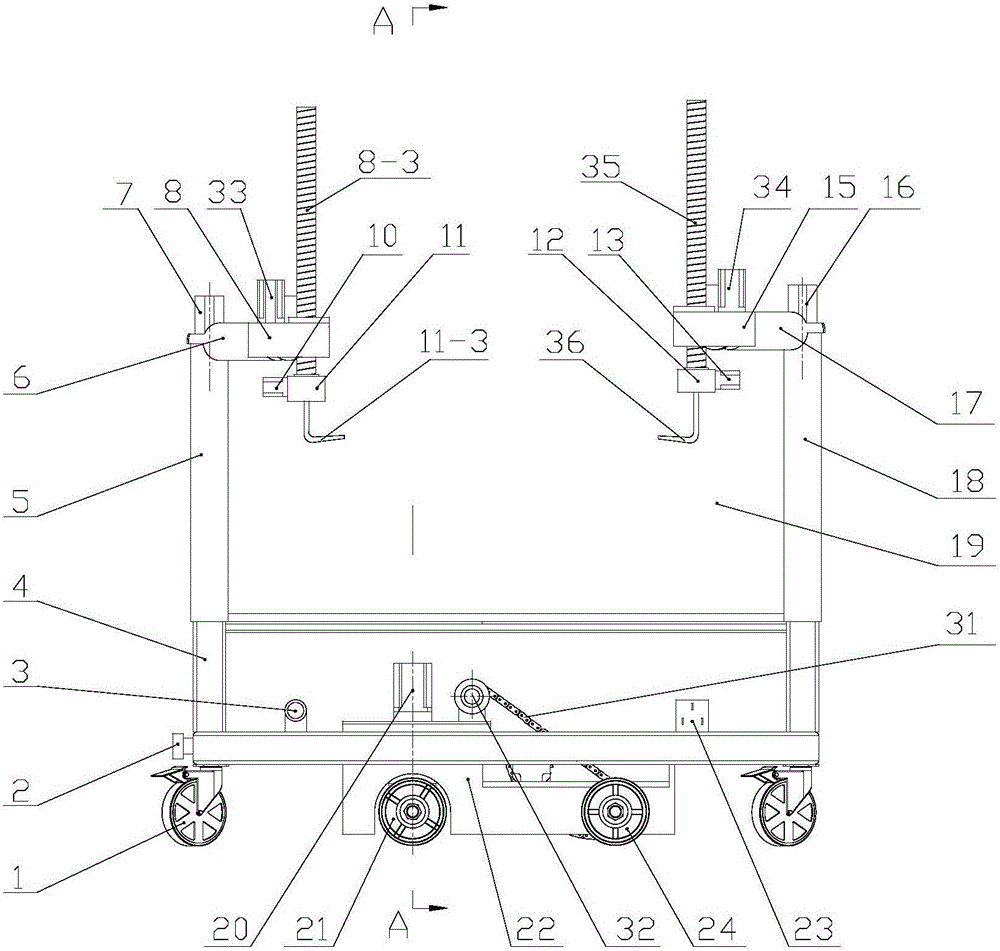

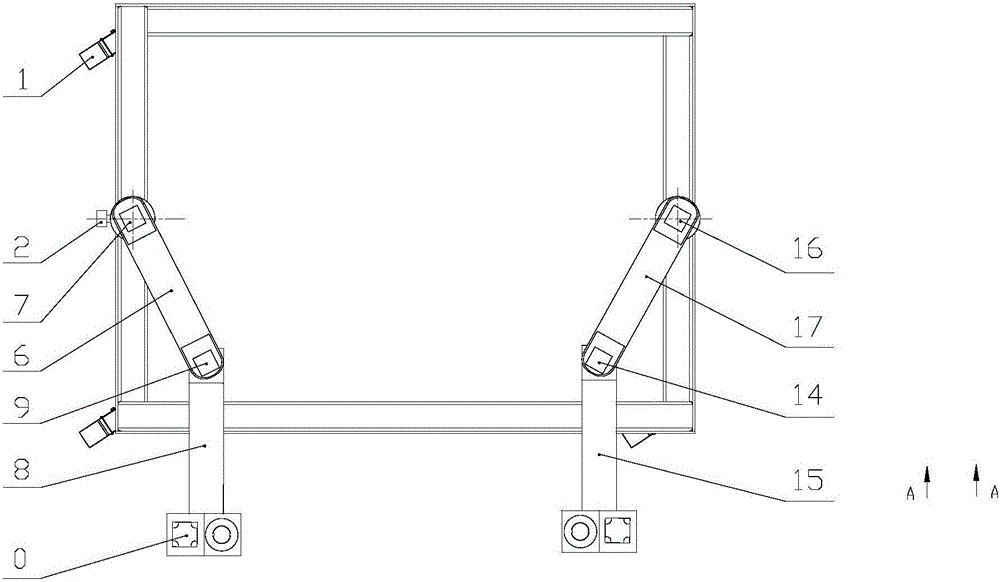

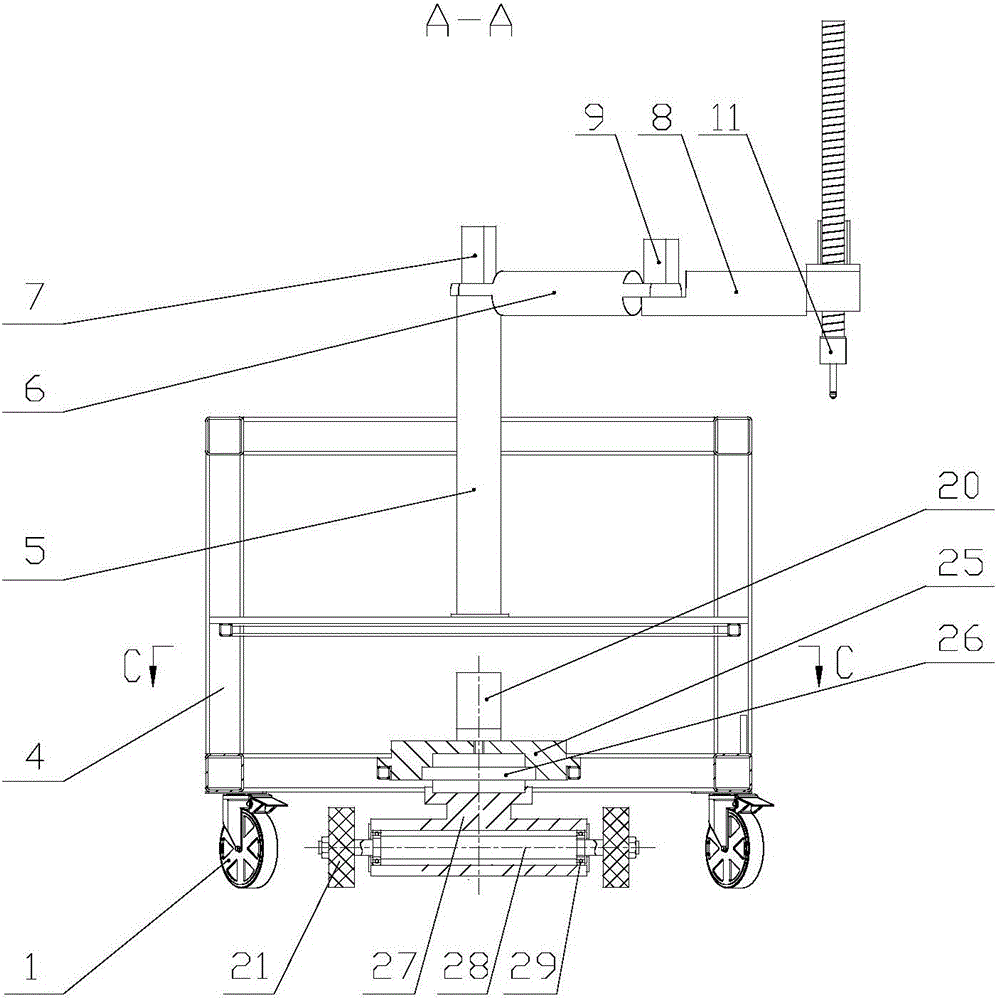

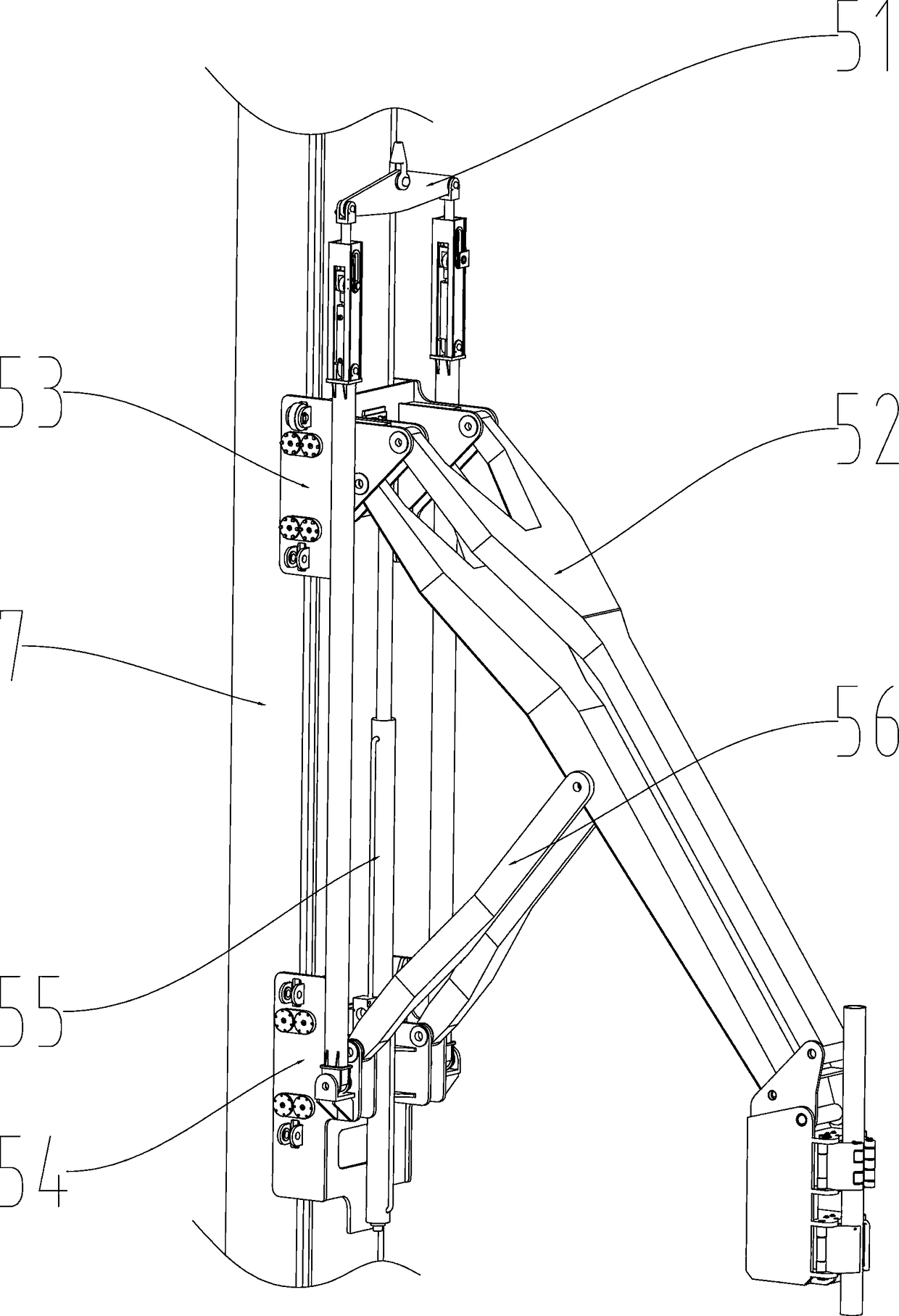

Material carrying mechanical arm structure and moving type kitchen carrying robot with material carrying mechanical arm structure

InactiveCN105881522AAchieve freedom of movementLittle room for movementProgramme-controlled manipulatorConveyor partsControl engineeringElectric machinery

The invention discloses a material carrying mechanical arm structure which comprises two mechanical arms which are symmetric left and right. Each mechanical arm comprises a large arm, a large arm motor, a small arm, a small arm motor, a lifting arm, a vertically-moving motor and a clamping device. The two clamping devices are horizontally opposite to each other left and right so as to be matched to clamp materials. The material carrying mechanical arm structure can carry different materials different in size and height and is particularly suitable for carrying materials such vegetables, flour and semi-finished products in kitchens of large canteens, hotels and restaurants. The invention further discloses a moving type kitchen carrying robot with the mechanical arm structure. The moving type kitchen carrying robot can walk and turn automatically, automatically recognize the position information of the materials, automatically avoid obstacles and automatically load and unload the materials, the materials cannot be carried manually, equipment does not need to be controlled manually, the automation degree and the production efficiency are high, the labor force and production cost are saved, and control is simple and reliable.

Owner:UNIV OF JINAN +1

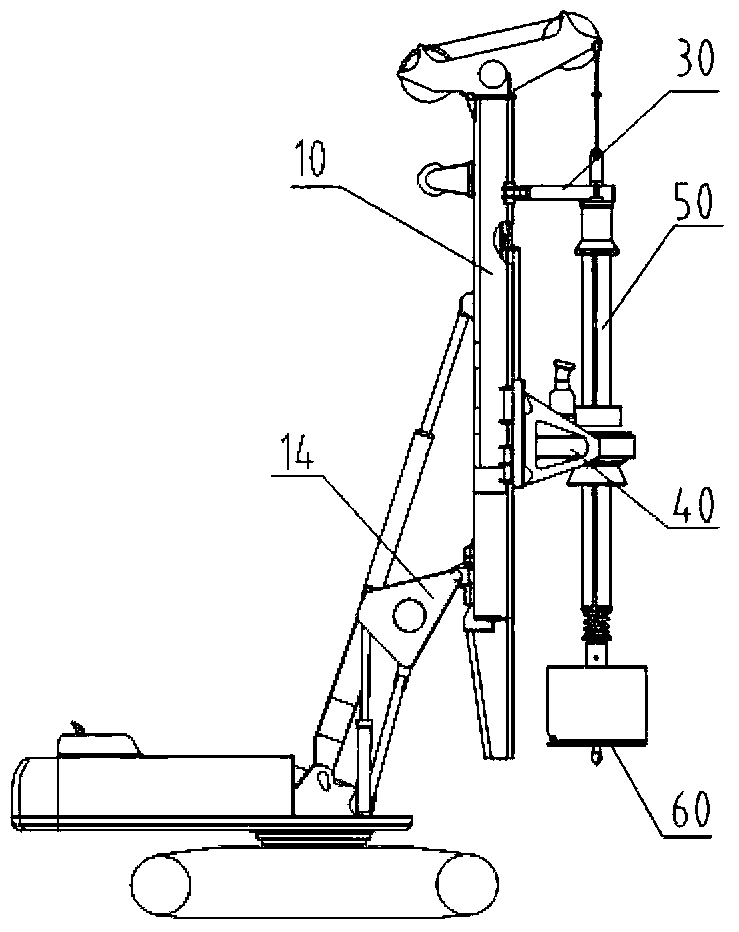

Pressurization control method and pressurization control system for rotary drilling rig

ActiveCN103437754AReduce vibration frequencyAvoid operational delaysAutomatic control for drillingDrill bitEquipment Safety

The invention discloses a pressurization control method and a pressurization control system for a rotary drilling rig. The pressurization control method for the rotary drilling rig includes the following steps that the pressure value of a rodless cavity of a left mast oil cylinder (11) and the pressure value of a rodless cavity of a right mast oil cylinder (16) are obtained respectively; a controller processes the pressure value of the rodless cavity of the left mast oil cylinder (11) and the pressure value of the rodless cavity of the right mast oil cylinder (16) to obtain the pressure difference value of the rodless cavity of the left mast oil cylinder (11) and the rodless cavity of the right mast oil cylinder (16); the pressure of a rodless cavity of a pressurization oil cylinder (20) is controlled according to the relationship of a preset pressure difference value and the pressure value of the rodless cavity of the pressurization oil cylinder (20). The pressurization control method for the rotary drilling rig can automatically adjust pressure applied to a power head by the pressurization oil cylinder, reduces the probability of drilling stem unbalance loading and mast unbalance loading caused when a drill bit impacts a load and a load is unbalance, lowers vibration frequency, and operating mechanism damage caused by factors such as human judging errors or operating delay and personal and equipment safety accidents caused due to the facts that damaged parts fall from a high altitude are avoided.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO +1

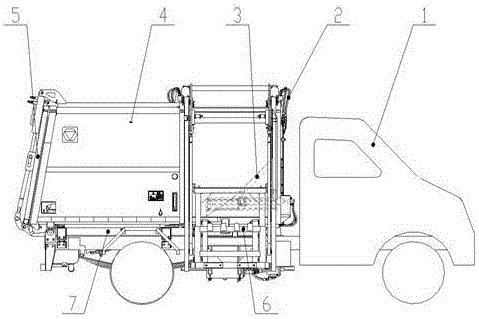

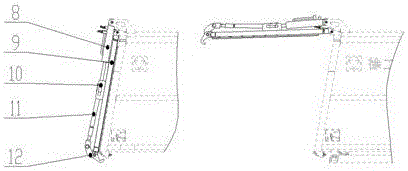

Side garbage collection device for compression type garbage vehicle

ActiveCN105905491AInhibit sheddingImprove reliabilityRefuse vehiclesRefuse collectionCompression device

The invention discloses a side garbage collection device for a compression type garbage vehicle. The side garbage collection device for the compression type garbage vehicle comprises a garbage collection device body (6) which is arranged on the side of a box body (4) and composed of a can turning oil cylinder (14), an upper cover plate (15), two pull rods (16), a cross beam (17), a can compression device I (18), a can hanging device (19) and a can compression device II (20). The can turning oil cylinder (14) drives the upper cover plate (15), the upper cover plate drives the pull rods (16), and then the pull rods (16) drive the can hanging device (19) hinged to the pull rods; and when the can hanging device (19) lifts up a garbage can, the can compression device I (18) ascends along with the pull rods (16) after compressing the garbage can, so that garbage can be dumped. By the adoption of the side garbage collection for the compression type garbage vehicle, the problem that a can compression device is stuck is solved effectively, meanwhile the situation that garbage is likely to be spilled out of the edge of a box body in the garbage dumping process is avoided effectively as well, meanwhile unbalance loading of a push plate is reduced, and the service life of the side garbage collection device is prolonged.

Owner:XUZHOU XUGONG ENVIRONMENTAL TECH CO LTD

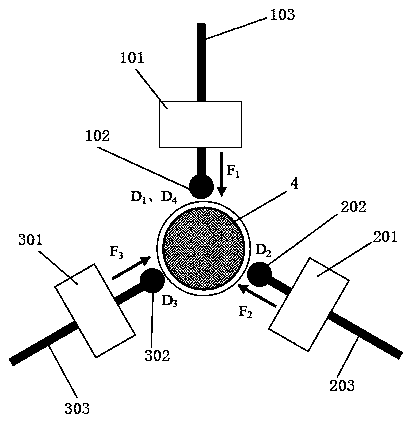

Precision control method for spinning machine

ActiveCN109213072AForce balanceReduce negative impactProgramme controlComputer controlHydraulic cylinderControl system

The invention discloses a precision control method for a spinning machine, which is controlled by two modes. One is that clearance deviation values of different positions are obtained by calculating through mathematical analysis; compensation is carried out through a horizontal ram position of a rotating wheel, and a clearance error is eliminated. The other one is that the clearance between the rotating wheel and a main shaft is dynamically adjusted by regularly monitoring the pressure of a horizontal ram hydraulic cylinder of the rotating wheel, and each rotating wheel is ensured to be stressed basically in balance, thereby meeting the stable processing requirement of a machine tool and reducing the negative impact of the equipment on the long part spinning process of the large spinning machine tool due to a component machining error, assembly and installation errors, and the like; at the same time, the control system can realize adaptive control, reduce equipment unbalance loading ofthe spinning process, avoid equipment vibration from generating, ensure the stability of the spinning process and ensure the spinning precision.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

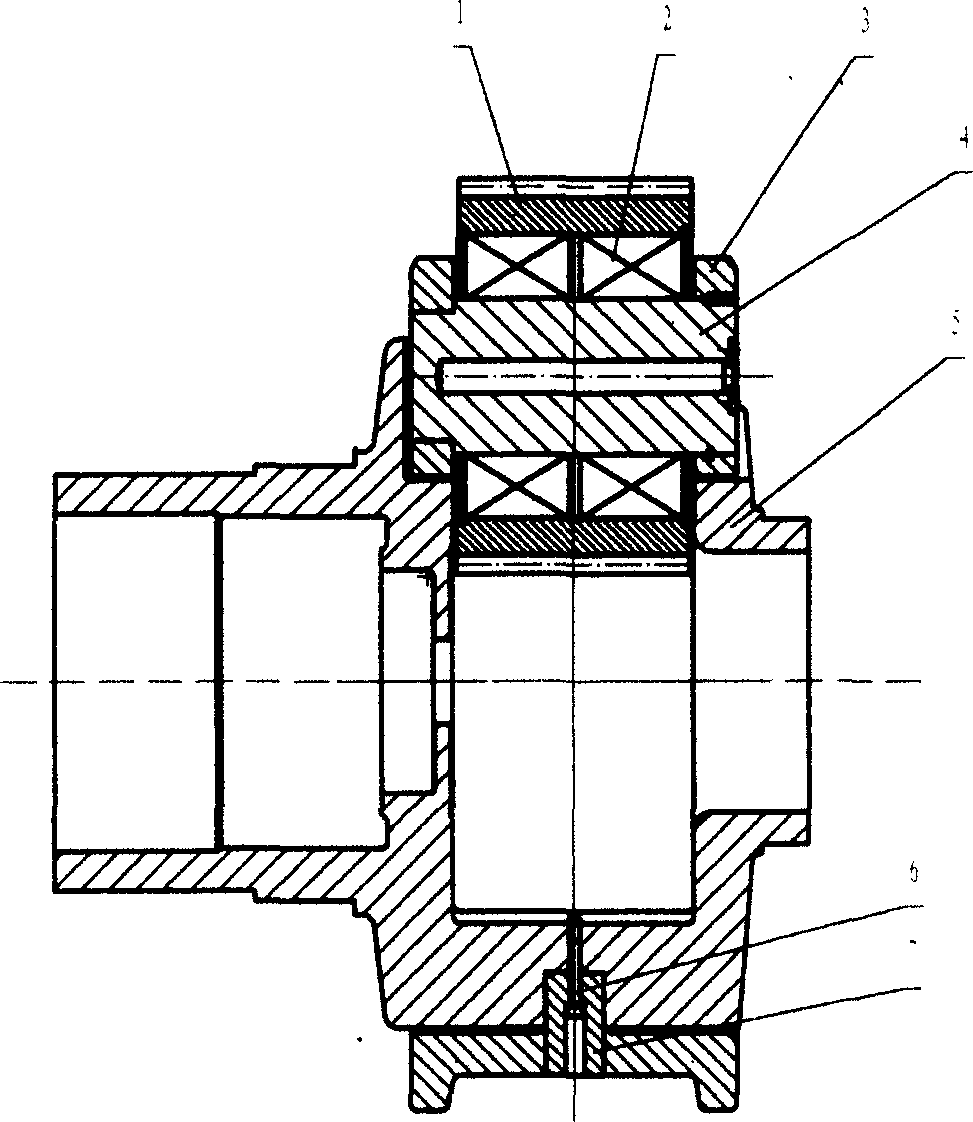

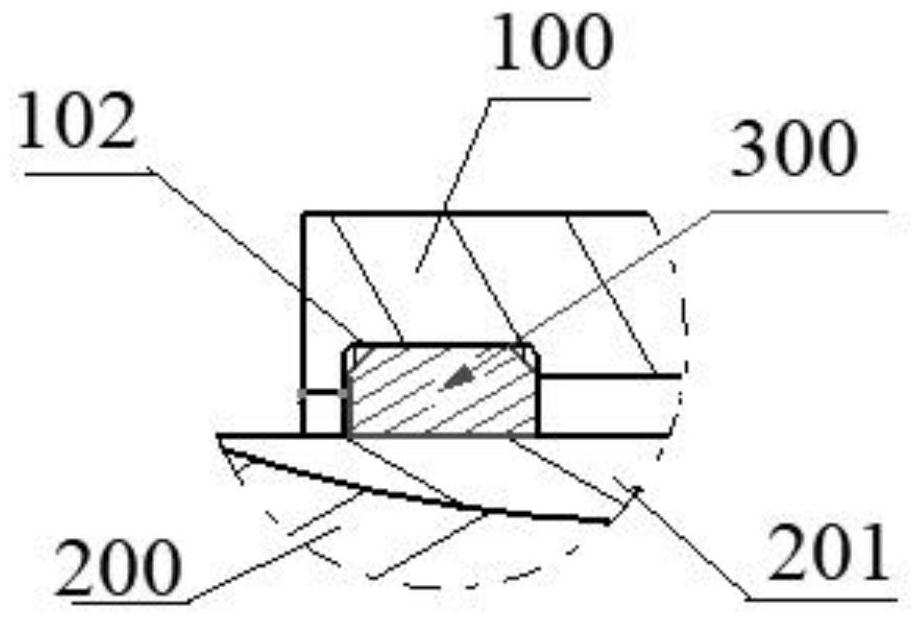

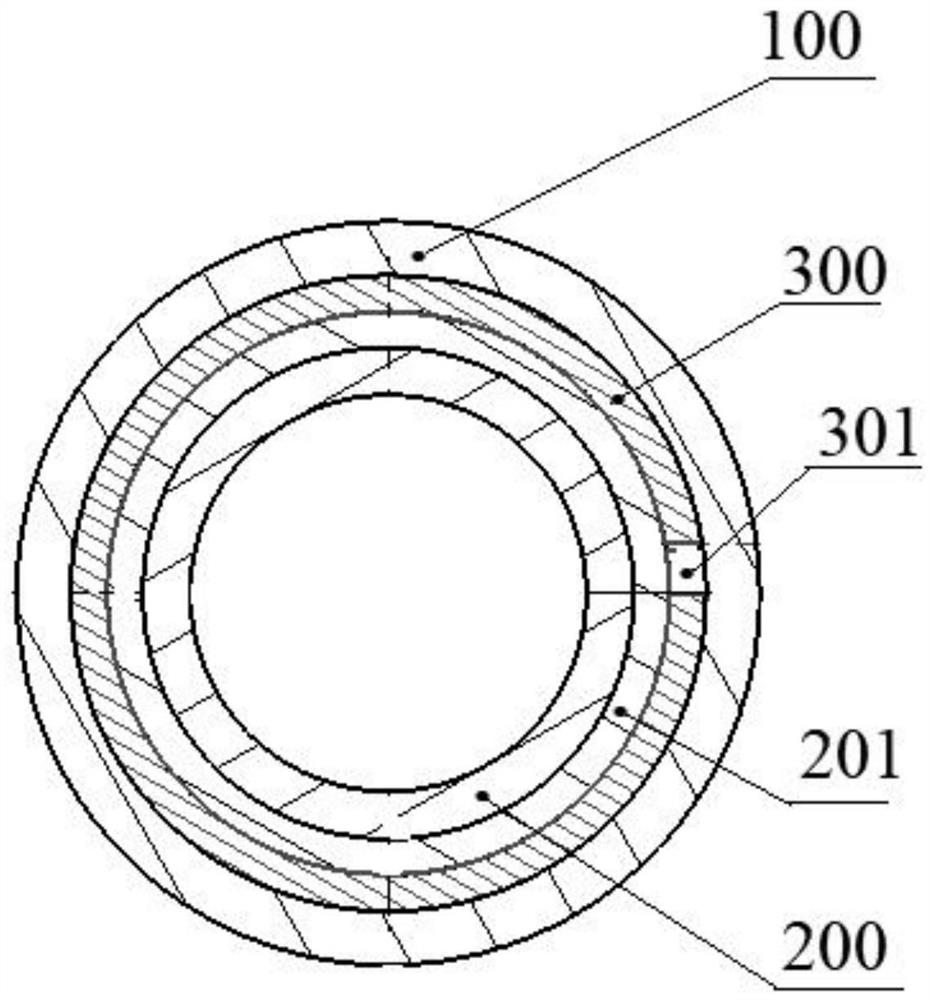

Assembly planetary carrier for wind power

InactiveCN1793701AReduce partial loadSame sizeEngine fuctionsWind motor supports/mountsElectricityVena contracta diameter

The invention discloses a combined planetary carrier for wind power generation, jacketing an inner planetary carrier having connection plates with an outer planetary carrier having orifice plates, where each connection plate can be provided with torque transmission connection piece only in the middle and has annular bonding surface able to tightly cooperate with the connection piece , the inner and outer planetary carriers are interconnected through connection pieces, and fastened through fastening pieces, and after assembled, the inner and outer planetary carriers contact only on the annular bonding surface and the other parts are suspended in the air. Because the torque acts on the middles of the connection plates, the axes of planetary and central gears are always parallel mutually, and it largely prolongs the service life of planetary bearing and assuring the reliability of planetary gearing. The invention is especially applied to the occasion of variable torque input.

Owner:德阳东汽表面工程技术有限公司

Elevator balance weight device

InactiveCN104891316AReduce partial loadReduce wearBuilding liftsMine liftsEngineeringElectric cables

The invention discloses an elevator balance weight device, which is mounted on a lift car (6) of an elevator, wherein a servo electric cable (8) is set at the other side provided with a counter weight (7) set on one side relative to two sides of the lift car (6); an elevator balance compensation chain (5) is connected between the lift car (6) and the counter weight (7); the elevator balance weight device comprises a balance weight (4); the balance weight is located on one side relative to the counter weight (7) on the lift car (6); the balance weight (4) can be movably set on the lift car (6) relatively far away from and next to the balance weight (7); and a driving device is mounted on the lift car for driving the balance weight to move along the direction of being far away from and next to the counter weight (7). According to the invention, real-time balance to the reduction and increase in weight of a balance compensation beam can be realized, so unbalance loading of the lift car can be effective; abrasion to a guide device is reduced; and the comfort of a passenger who is taking the elevator can be improved at the same time.

Owner:三六零安全科技股份有限公司

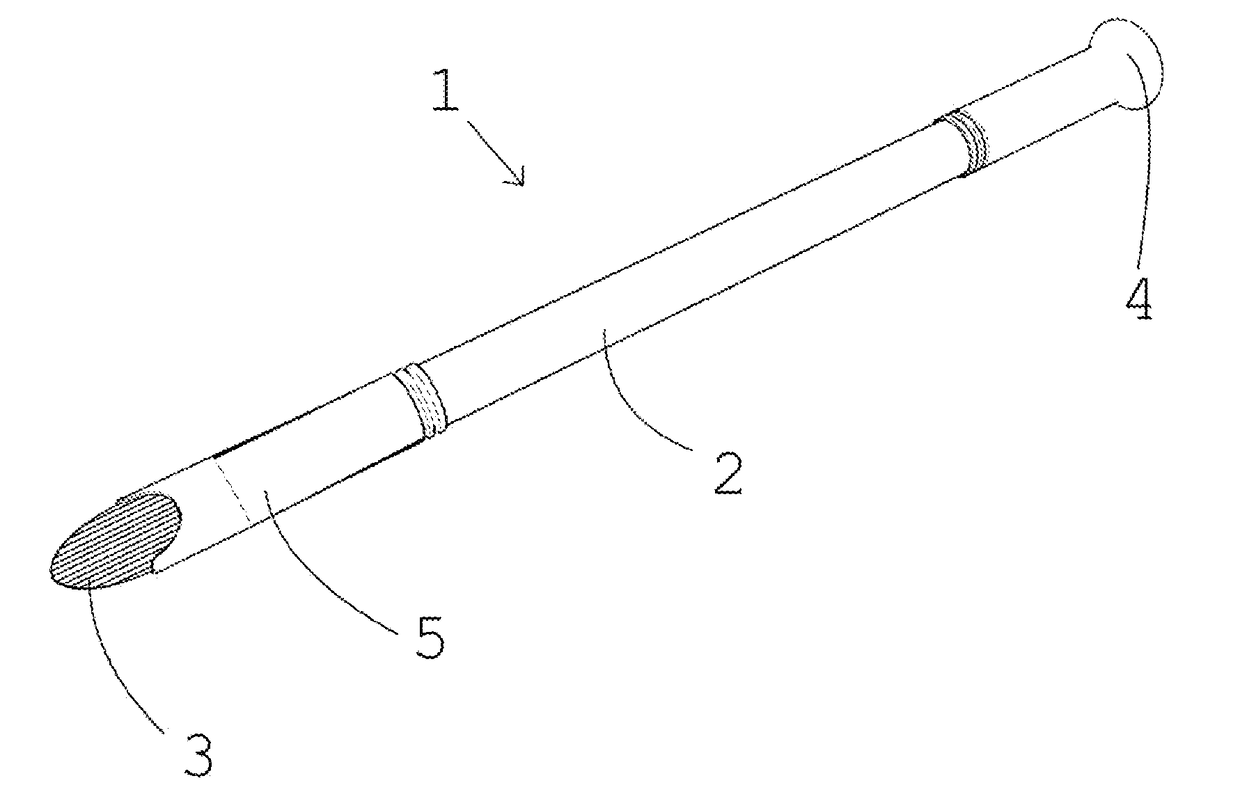

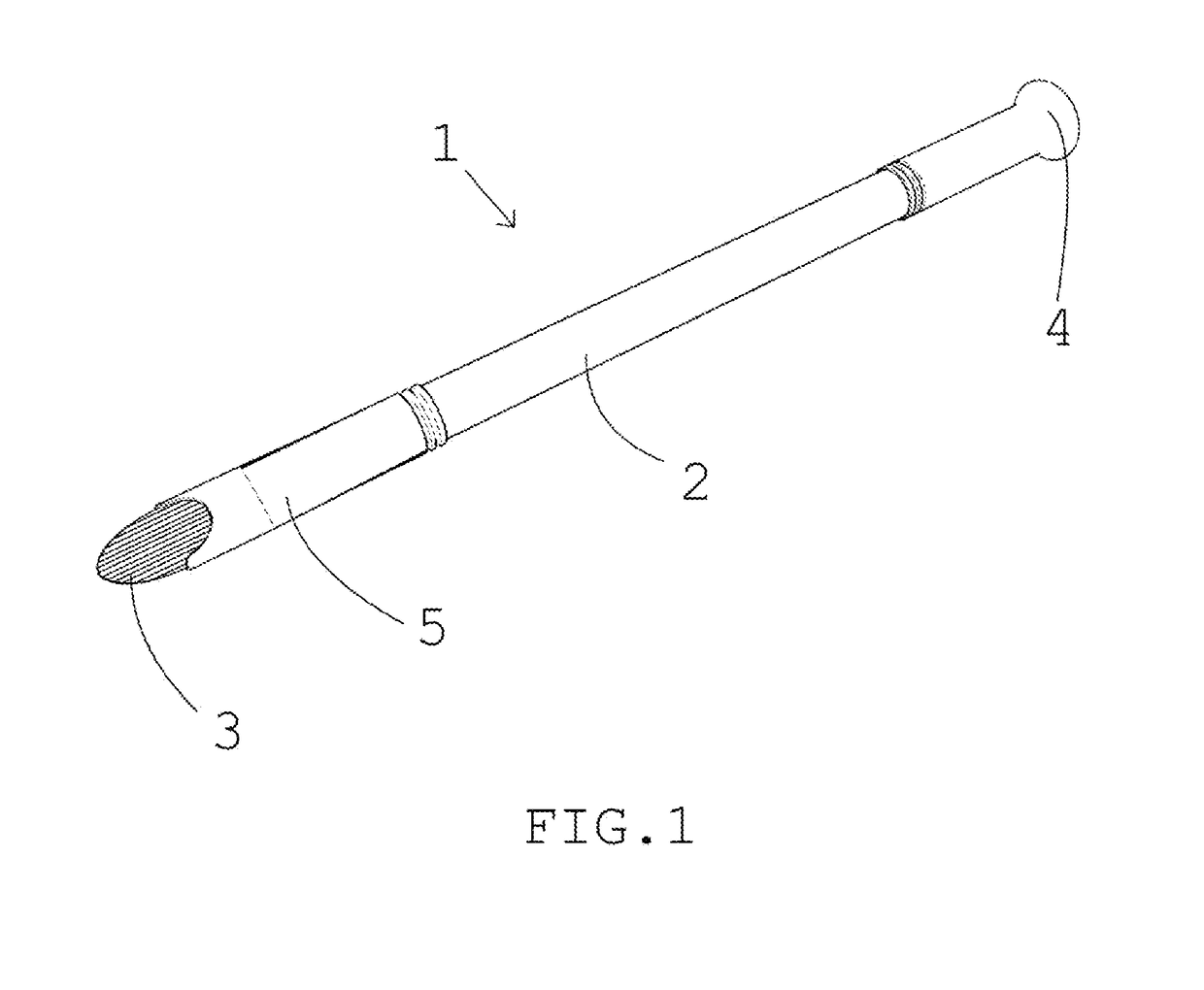

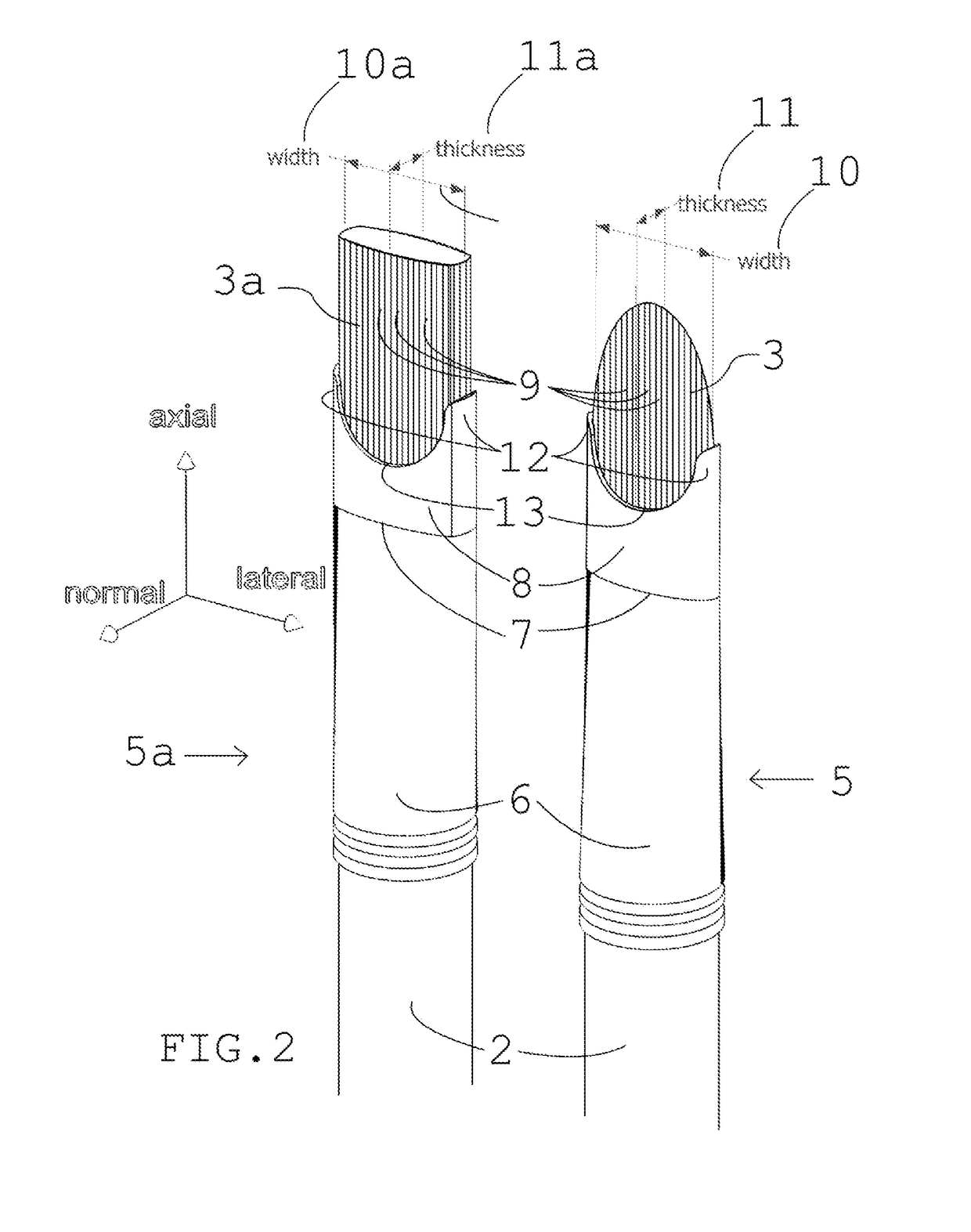

Lateral Support Brush

A paint brush comprises an elongate handle having a proximal end and a distal end, a tuft of bristles having properties according to at least two distinct directions, and a ferrule. The bristles are arranged substantially parallel to an axial direction and the cross section of the tuft of bristles is in a plane that has a width in a lateral direction. One end of the handle is operatively associated and is in substantially longitudinal alignment with the tuft and the ferrule is adapted to surroundingly encircle and connect said handle to said tuft of bristles so as to support the bristles against splaying in the lateral direction and limit deflection of the width.

Owner:SOLOFF BRANDON

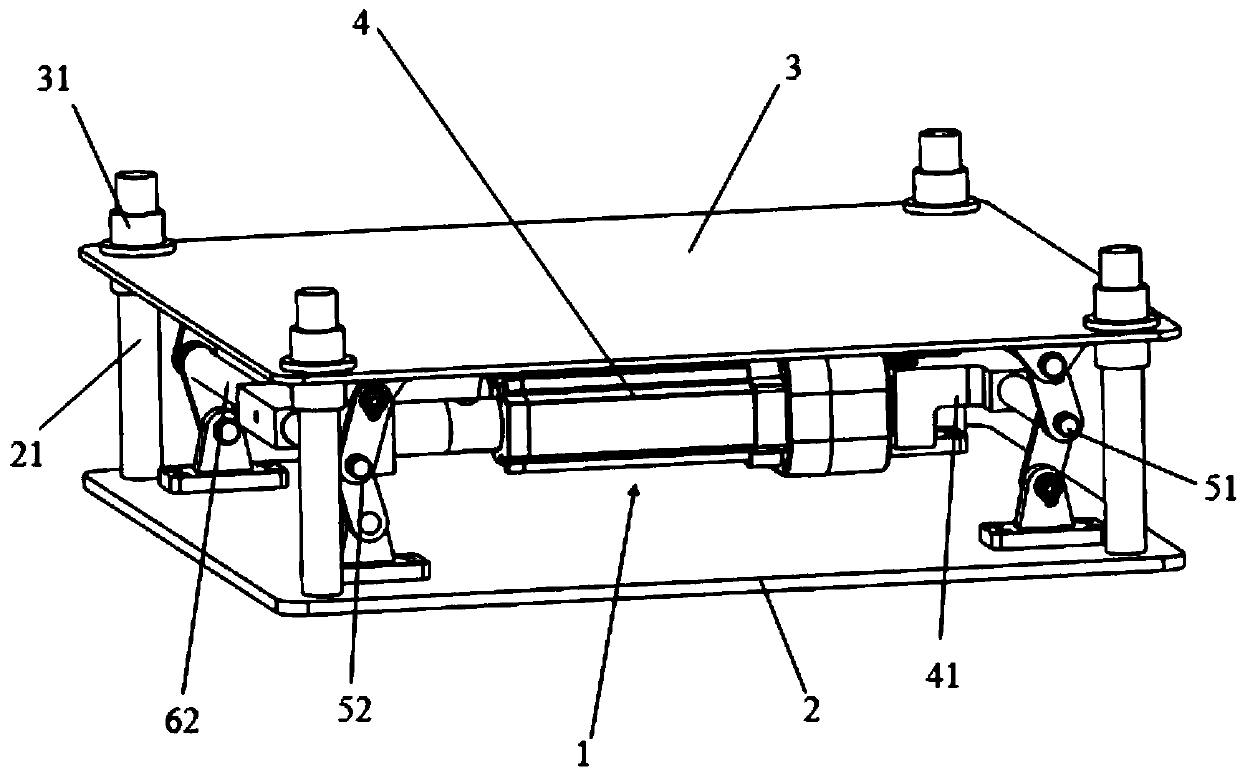

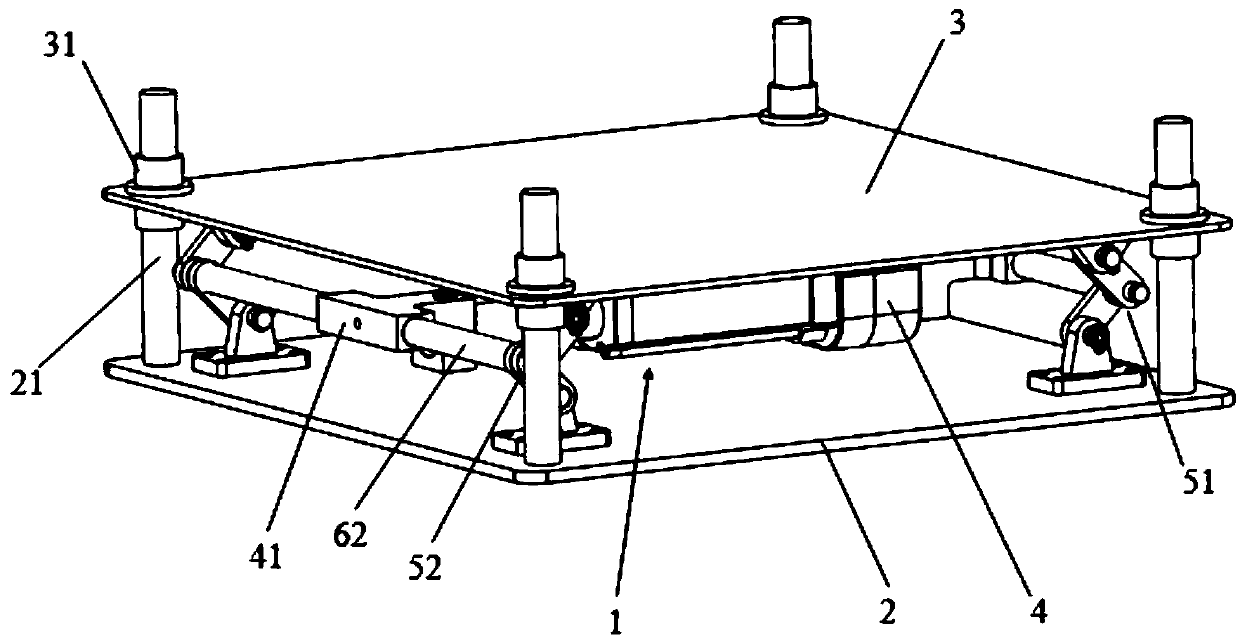

Trolley lifting mechanism used for carrying surgical tools

ActiveCN109573879ASmooth liftUniform and reasonable forceSurgical furnitureLifting framesEngineeringSupport plane

Owner:BEIJING SURGERII TECH CO LTD

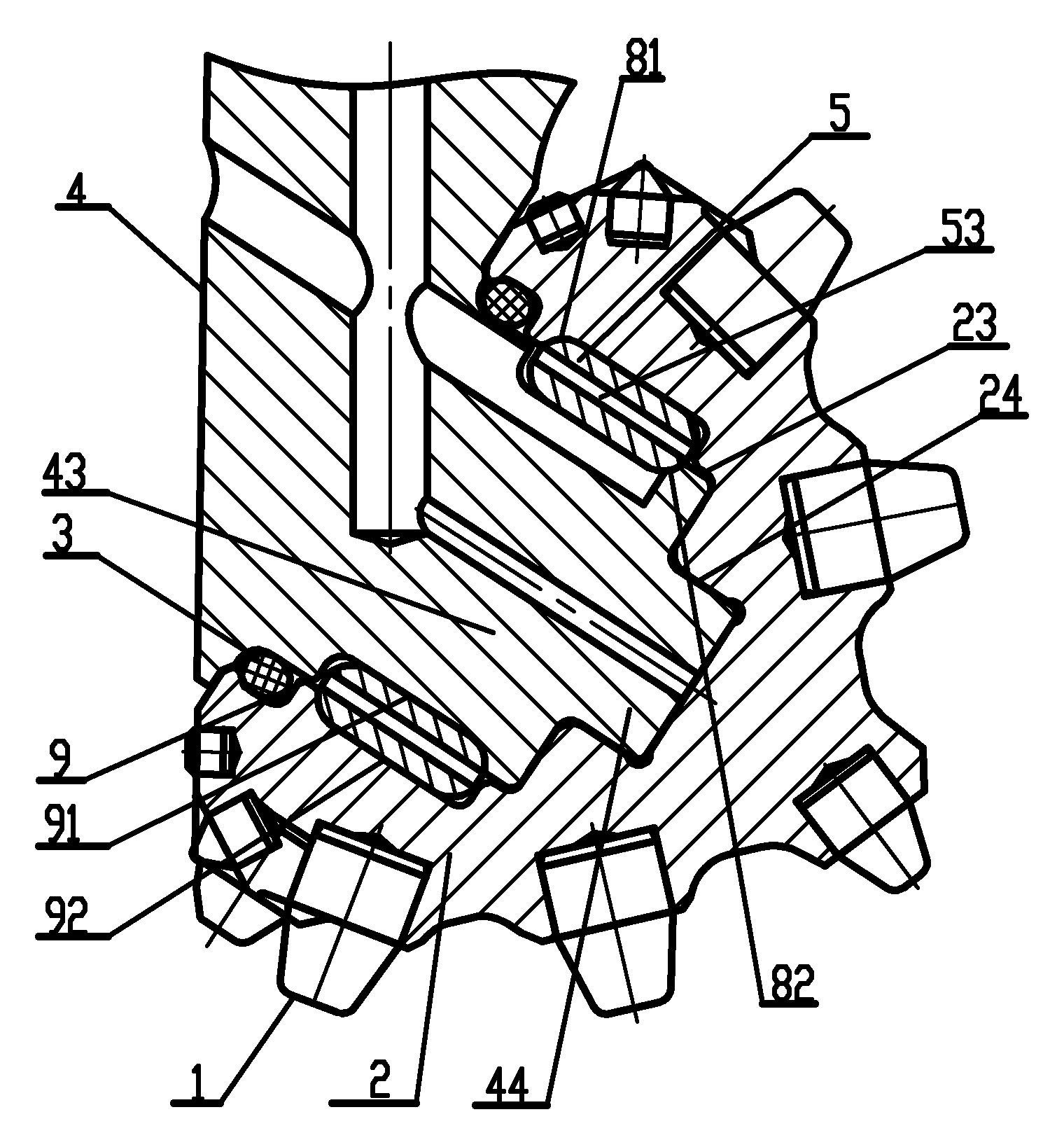

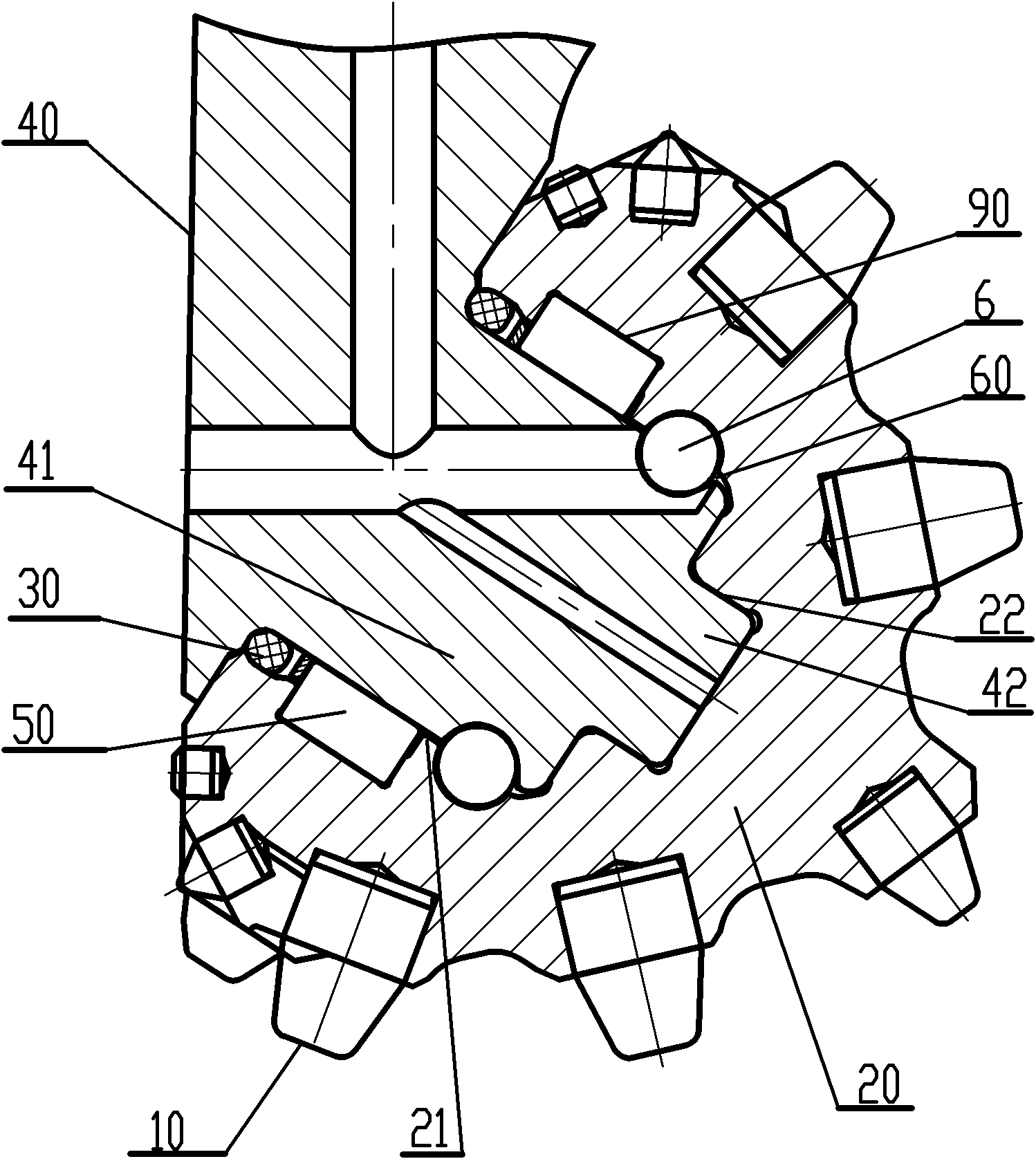

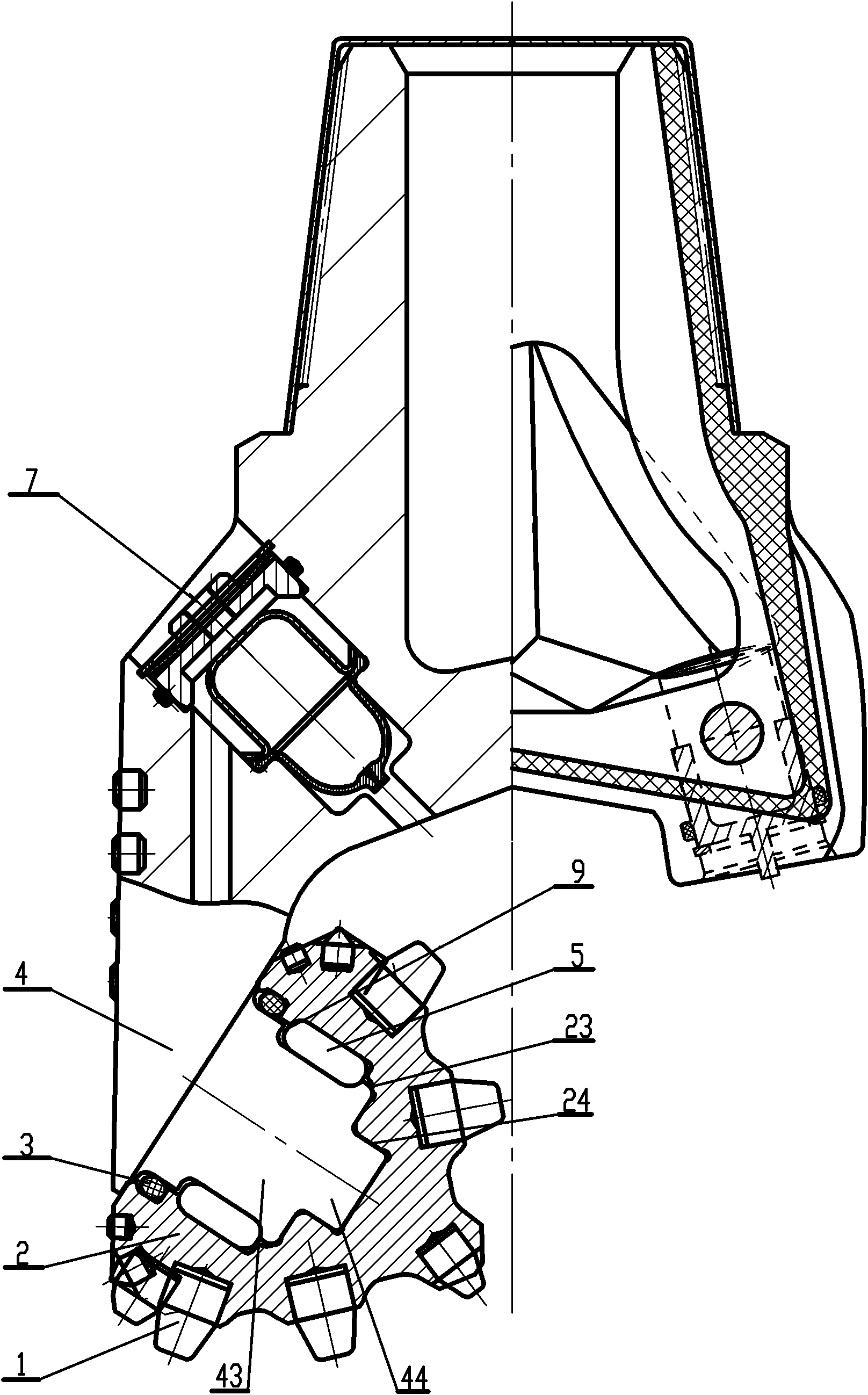

High pressure resistant and impact resistant roller bit with high rotating speed

InactiveCN101812970AAvoid weak spotsIncrease the bearing areaDrill bitsBearing componentsRolling resistanceEngineering

The invention relates to a high pressure resistant and impact resistant roller bit with high rotating speed, comprising a roller cone and a cone leg. The cone leg is provided with a big journal and a small journal, and the roller cone is correspondingly provided with a big axle hole and a small axle hole which are respectively sleeved on the big journal and the small journal of the cone leg and connected to the cone leg in rolling friction through a pin roller embedded into a ball track. The roller bit is characterized in that the periphery of an outer surface of the big journal is provided with a journal semi-ball track formed by a journal annular groove with a width extended nearby the end part of the big journal, the wall of the big axle hole and the journal semi-ball track are correspondingly provided with an axle hole semi-ball track formed by an axle hole annular groove, the ball track is formed by closing the journal semi-ball track and the axle hole semi-ball track, the pin roller is a cavity lengthening-type pin roller with an end face as a curved surface, and a generator of a cylindrical surface of the pin roller is a convex log curve or a camber line. The invention has the advantages of carrying more loads and improving the impact resistant toughness and is suitable for the high pressure deep drilling operation.

Owner:TIANJIN LILIN BIT

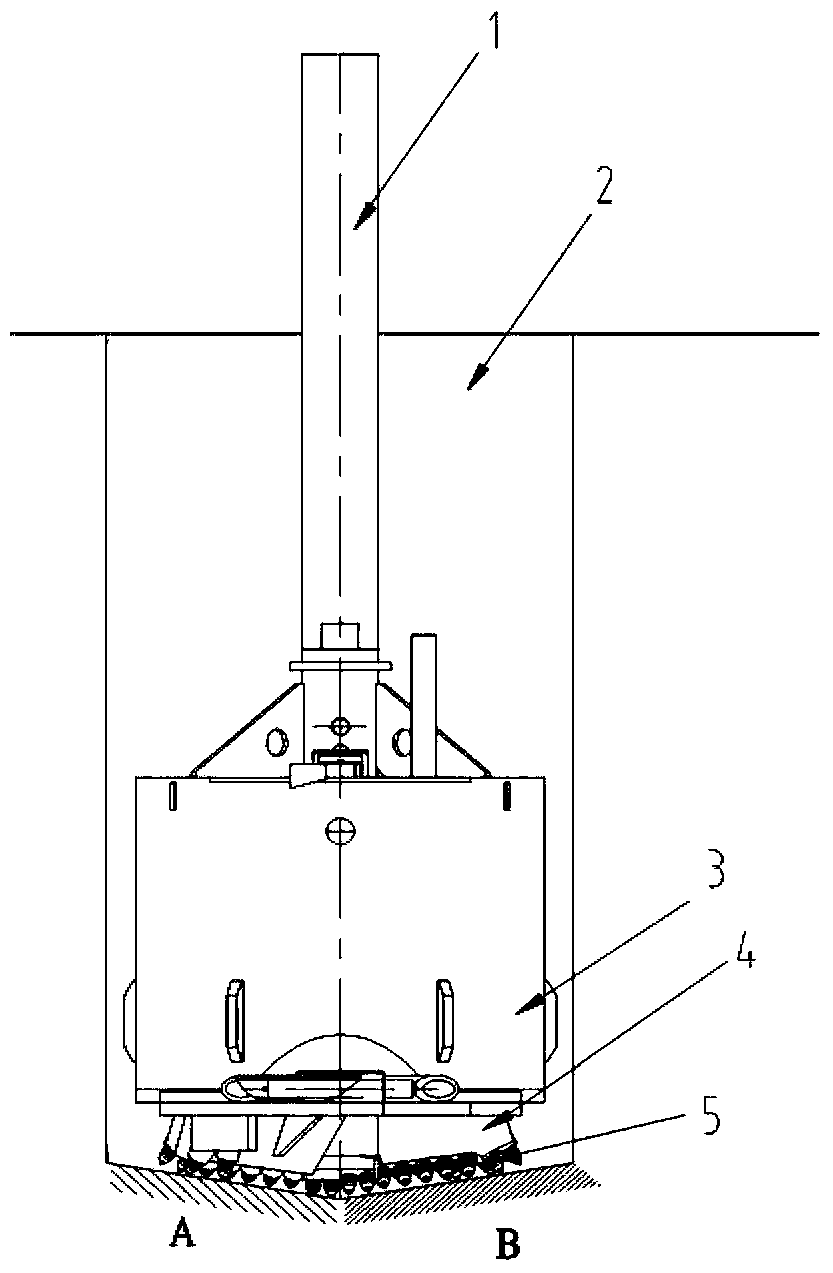

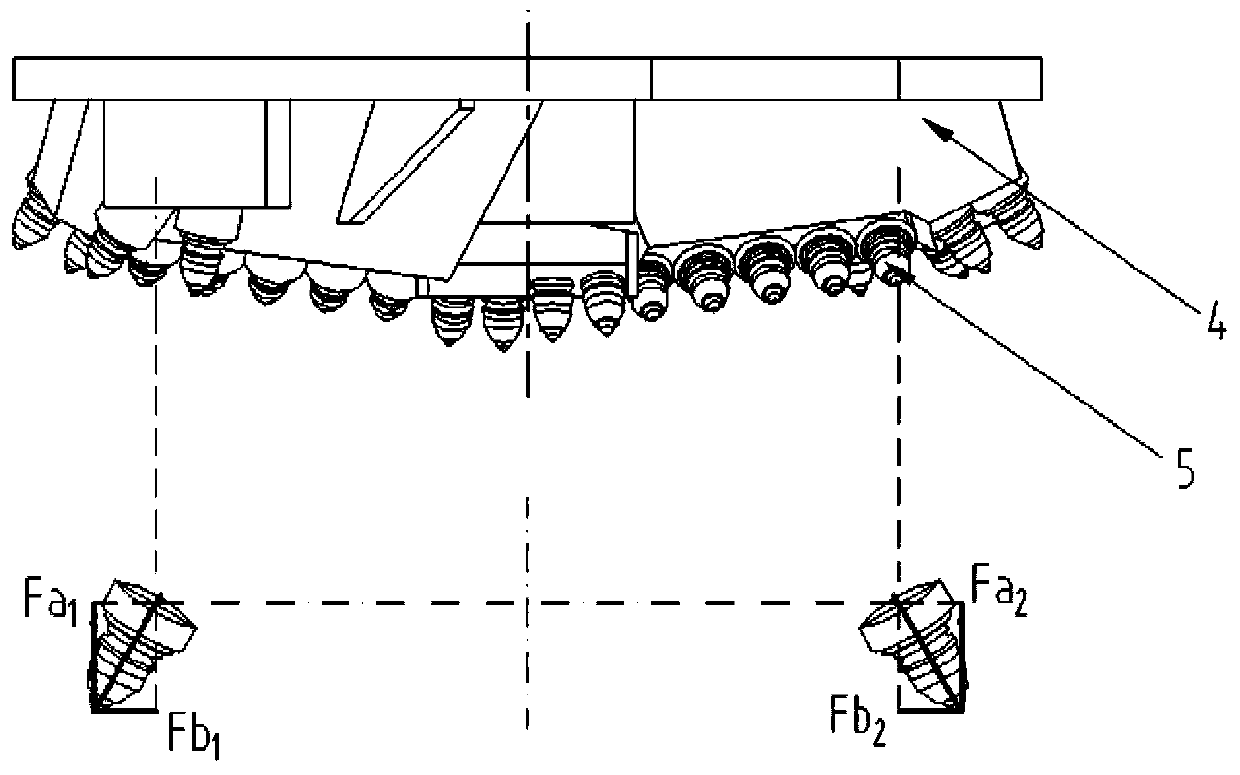

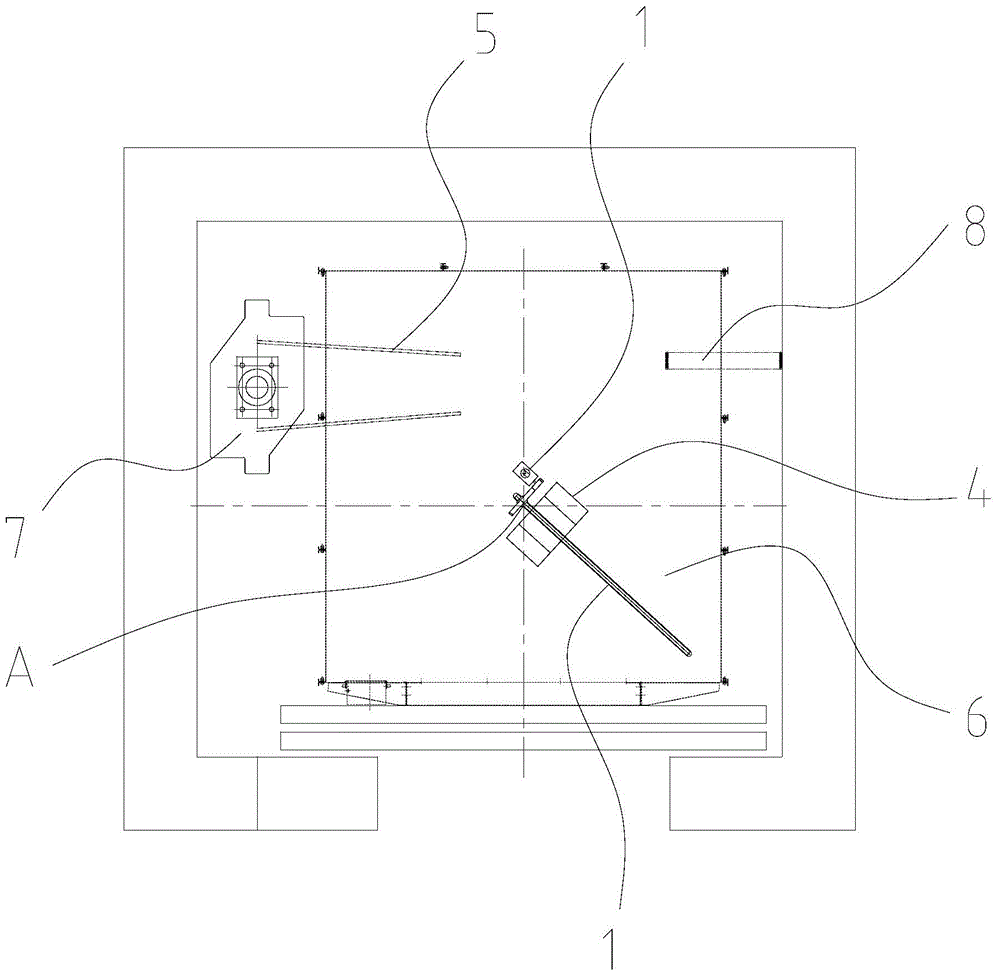

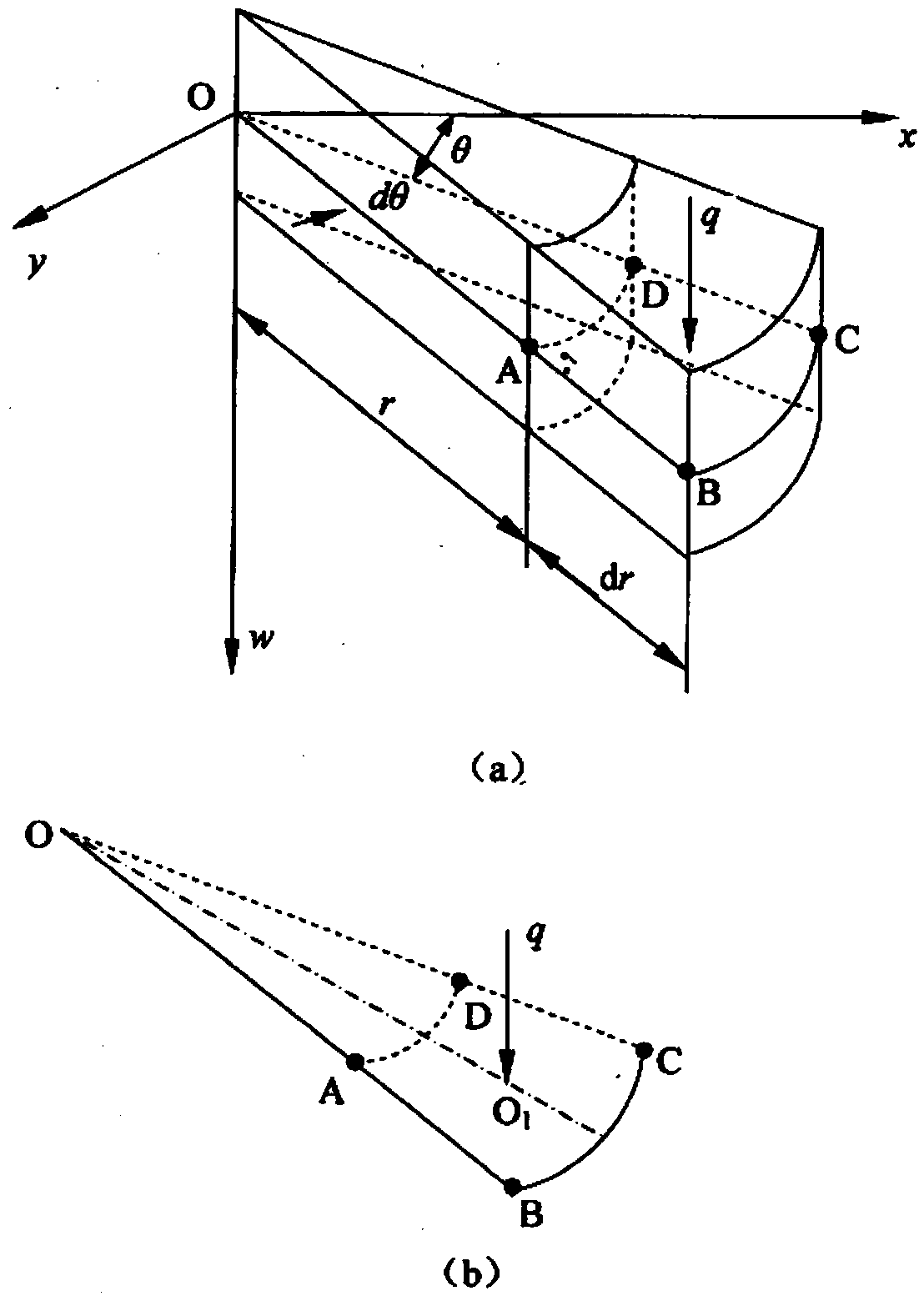

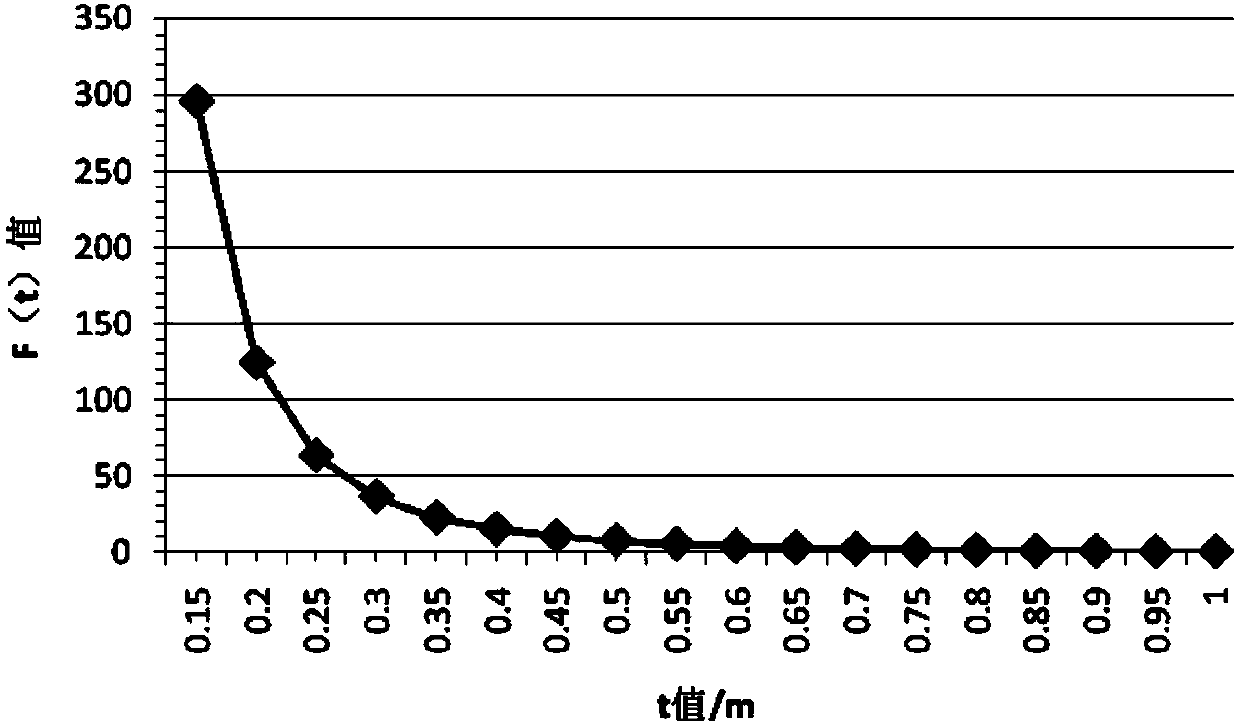

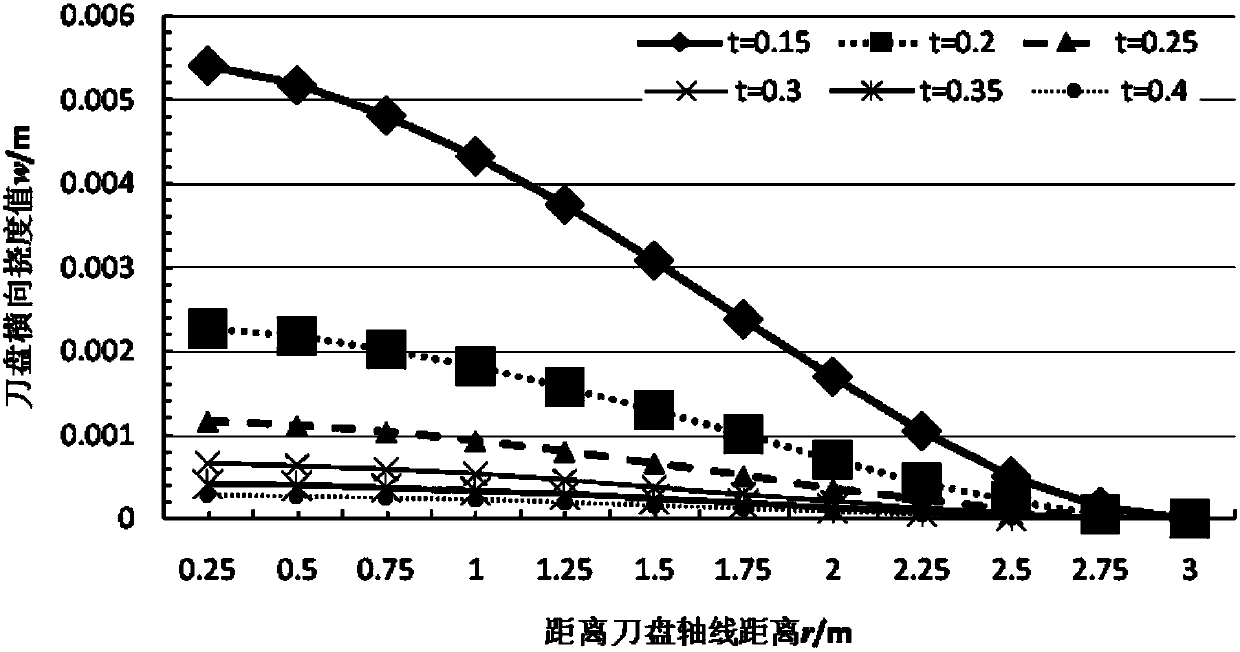

Method for determining cutter head thickness of full face tunnel boring machine

ActiveCN107729697AIncrease profitReduce unevennessGeometric CADSpecial data processing applicationsDesign technologyTunnel boring machine

The invention discloses a method for determining a cutter head thickness of a full face tunnel boring machine (TBM), belonging to the technical field of design of parts of a tunnel boring machine. According to the method for determining the cutter head thickness of the tunnel boring machine, the cutter head thickness is determined according to a theory of elastic mechanics by calculating deflection w(r, theta) of the TBM cutter head under the action of a transverse load q. Specifically, the bending deflection is only related to the cutter head radius and the cutter head thickness under the condition of TBM cutter head materials and a certain distributed load, while the cutter head radius is determined by a tunnel excavation radius. Therefore, the transverse bending deflection of the TBM cutter head is actually determined by the cutter head thickness. In order to enable the cutter head to be not subjected to the actions of transverse load and upsetting moment in the TBM tunneling process, disc cutters are symmetrically and uniformly arranged on the cutter head; and the bending deflection of the TBM cutter head is symmetrical around a cutter head axis under the load action of the disc cutters. According to the method disclosed by the invention, non-uniform deformation of the cutter head in the full face TBM construction process is reduced, the construction work cost is reduced, and the corresponding construction period is shortened.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

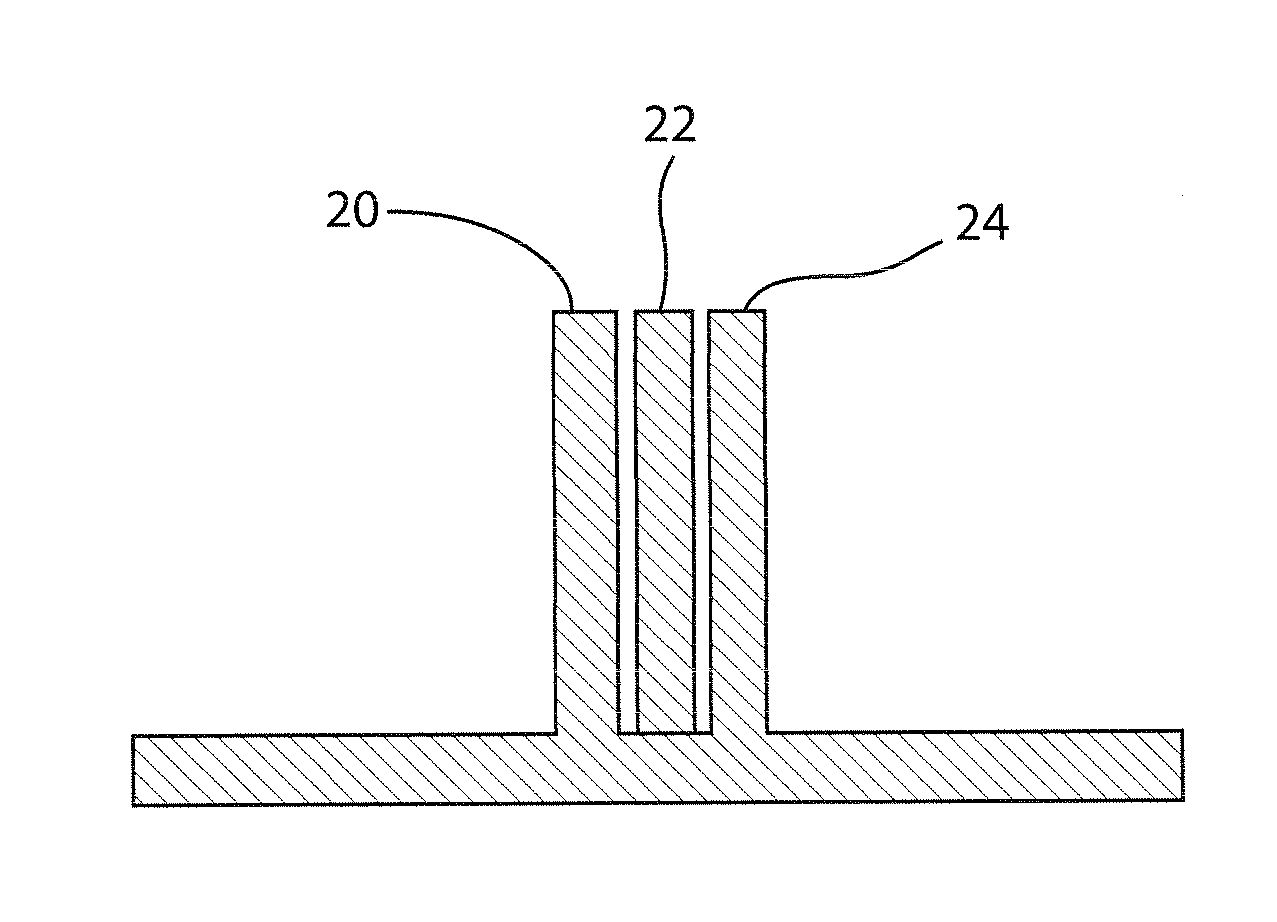

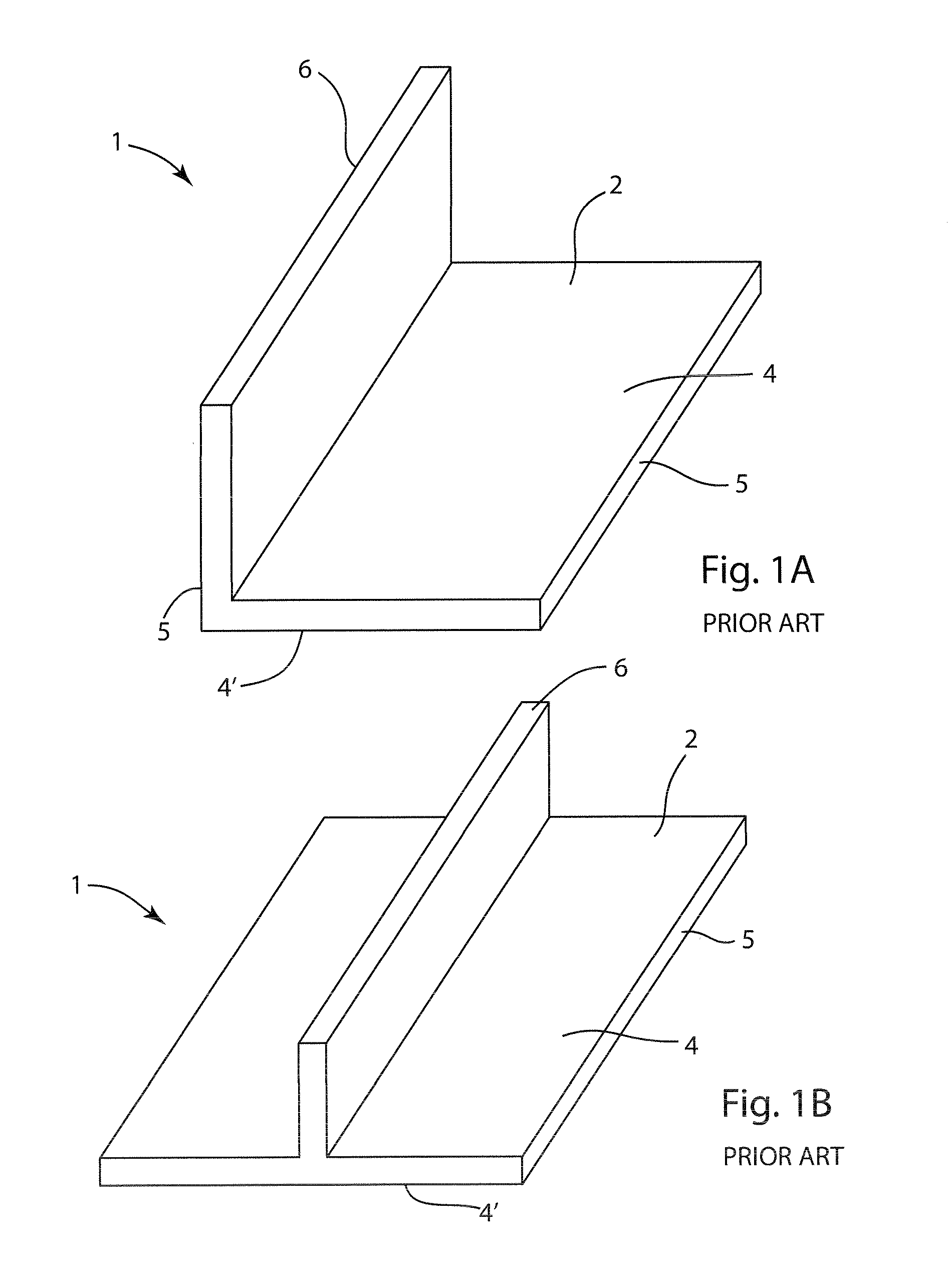

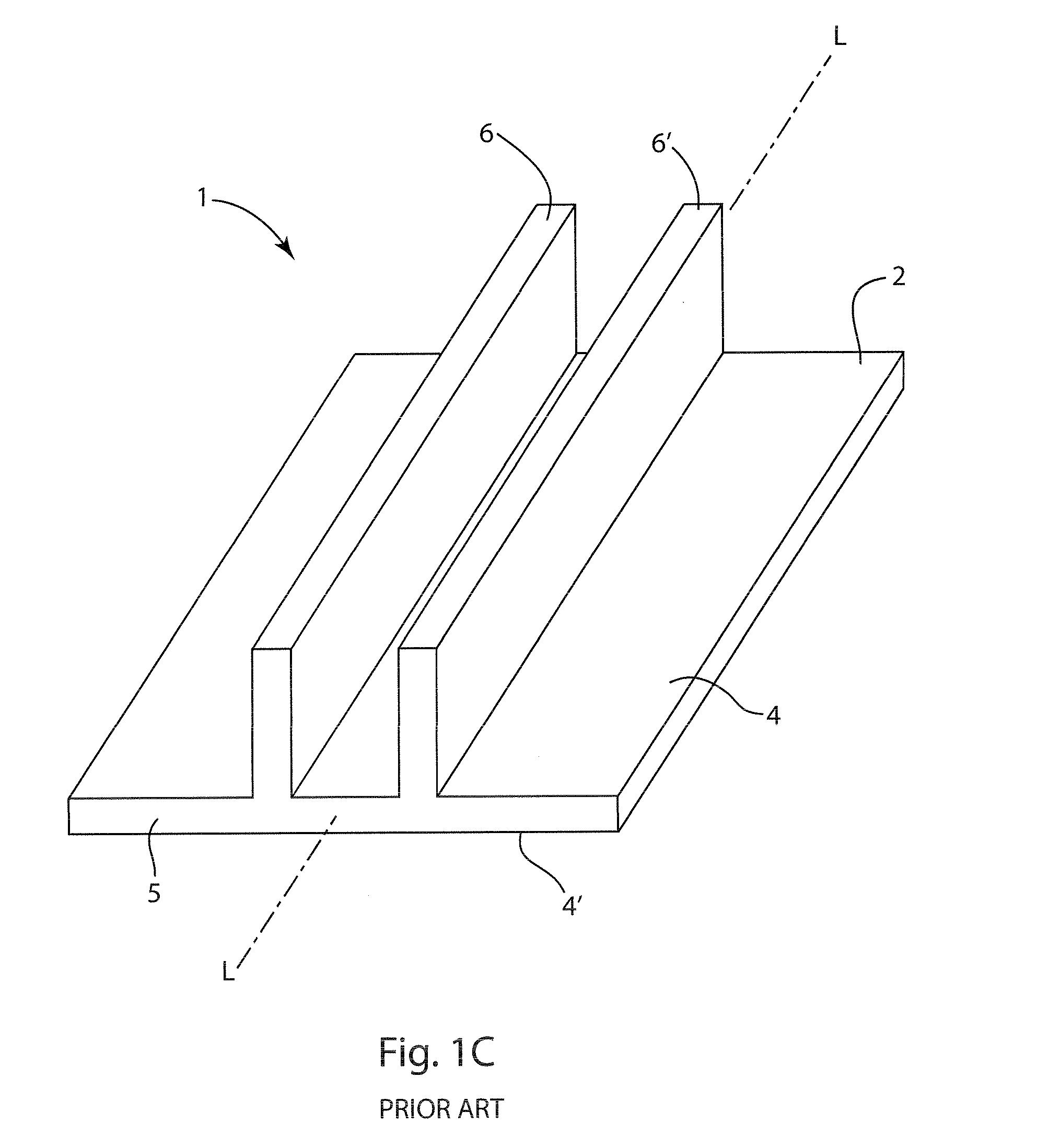

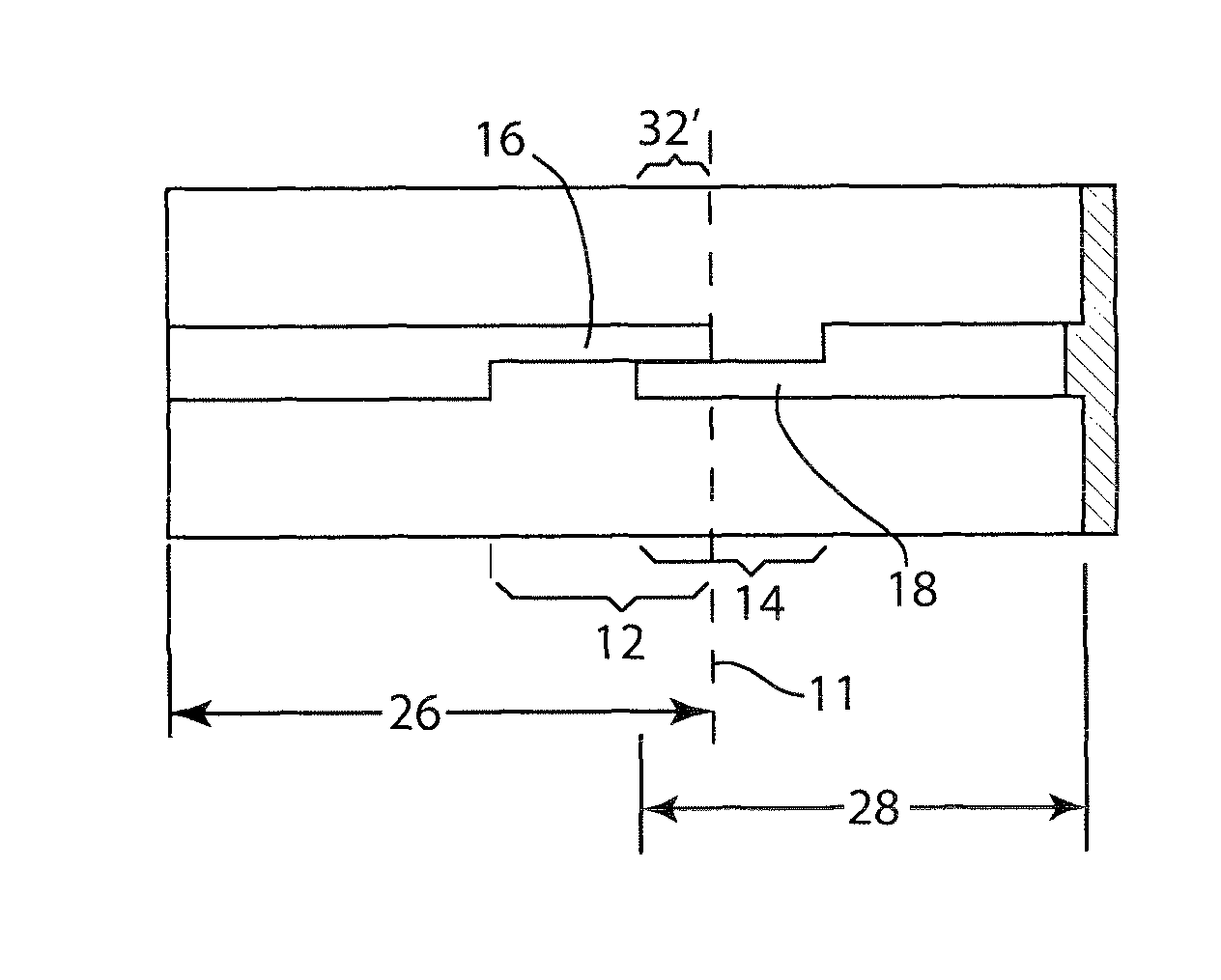

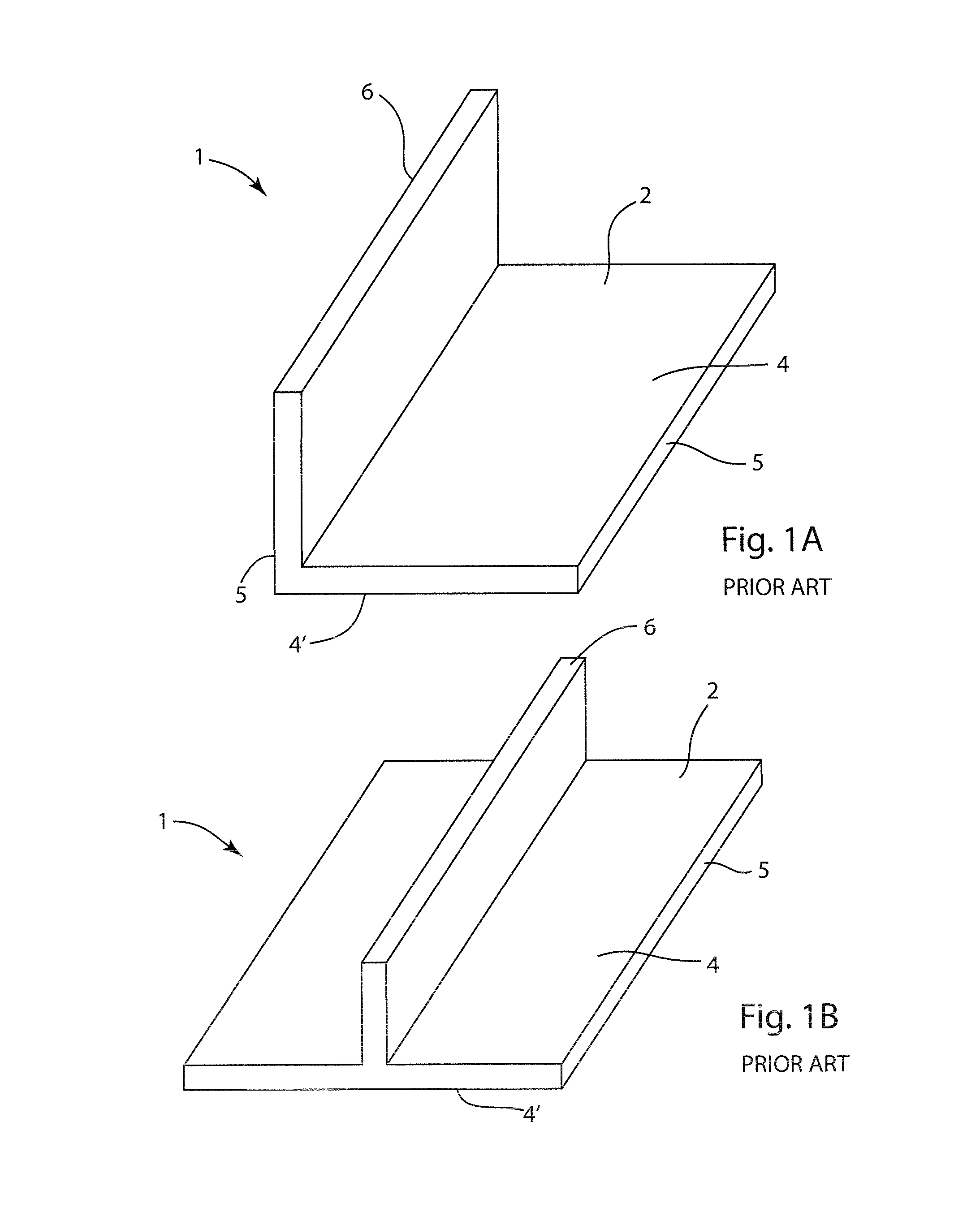

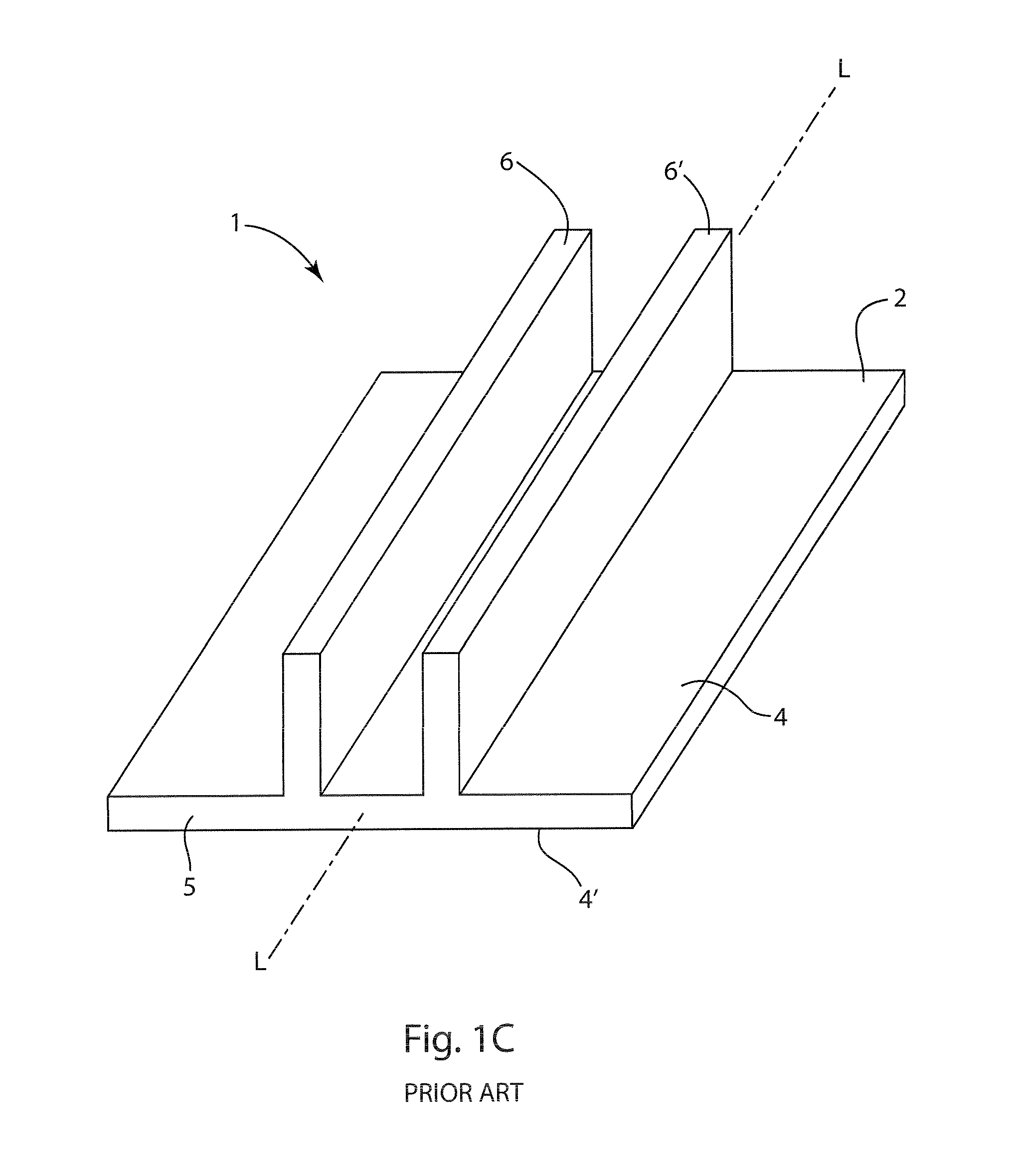

Three-dimensional woven corner fitting with lap joint preforms

ActiveUS20140178645A1Decrease overlap regionDesirable propertyLayered productsSevering textilesFiberLap joint

A three-dimensional corner lap joint preform and a method of forming a three-dimensional corner lap joint preform including a woven flange with one or more legs that extend from the flange. The legs may include one or more independently woven portions which allow formation of a corner without darting the leg or adding additional reinforcement. The independently woven portions may include warp fibers which are not woven into the preform. The unwoven area allows removal of a portion of the leg prior to formation of the corner, allowing the portions of the leg to overlap and form a lap joint.

Owner:ALBANY ENGINEERED COMPOSITES

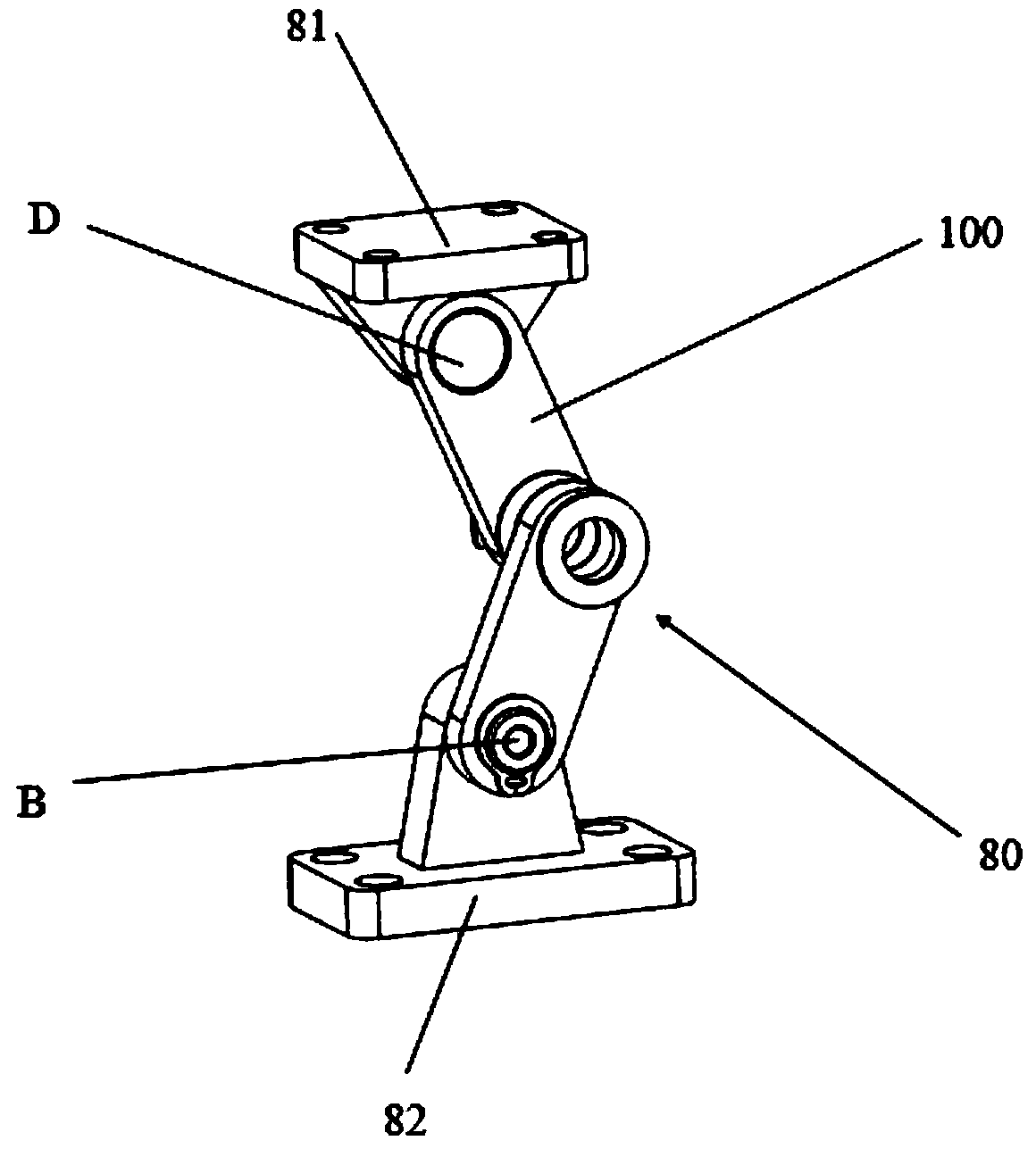

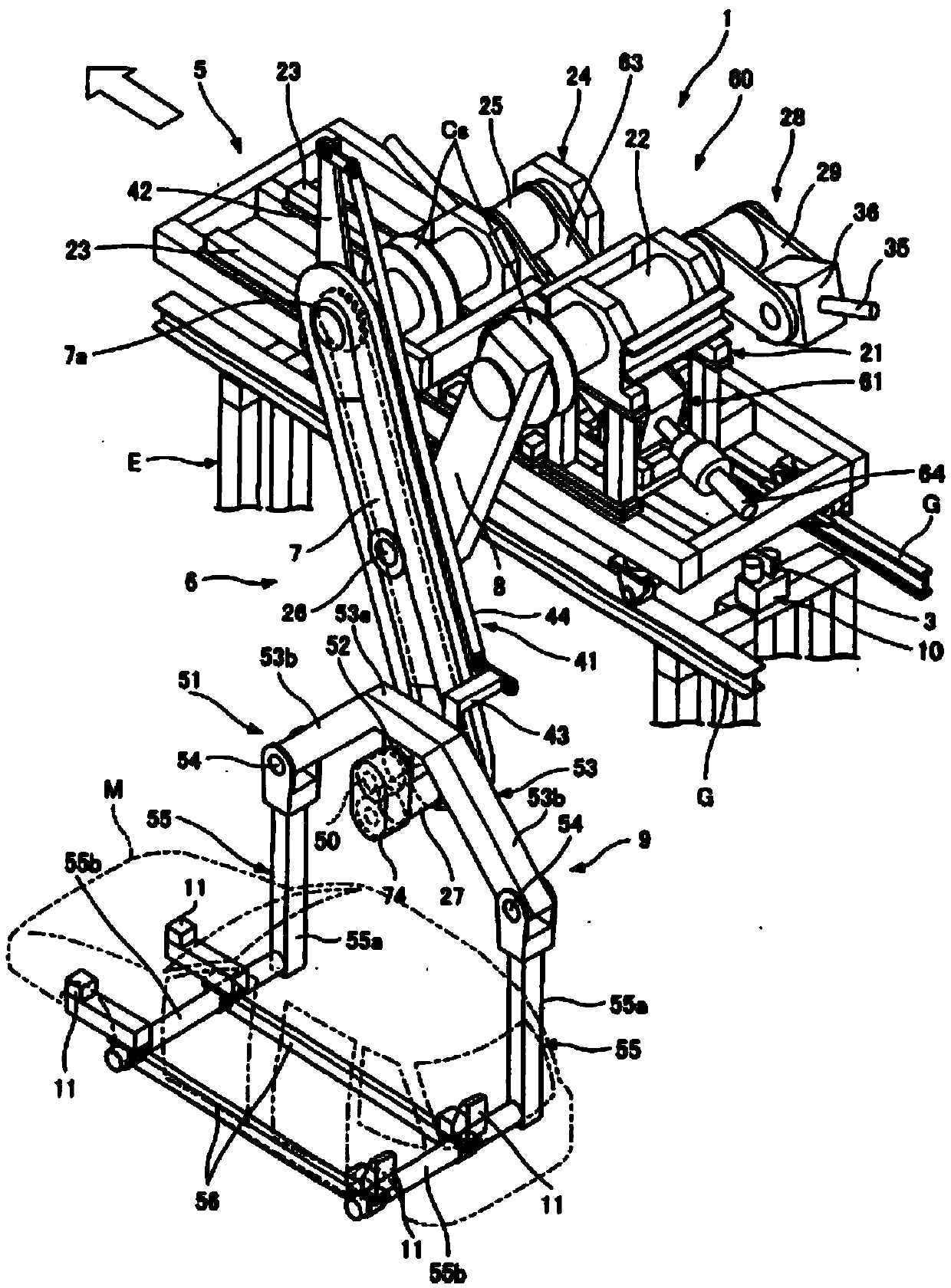

Carrying device

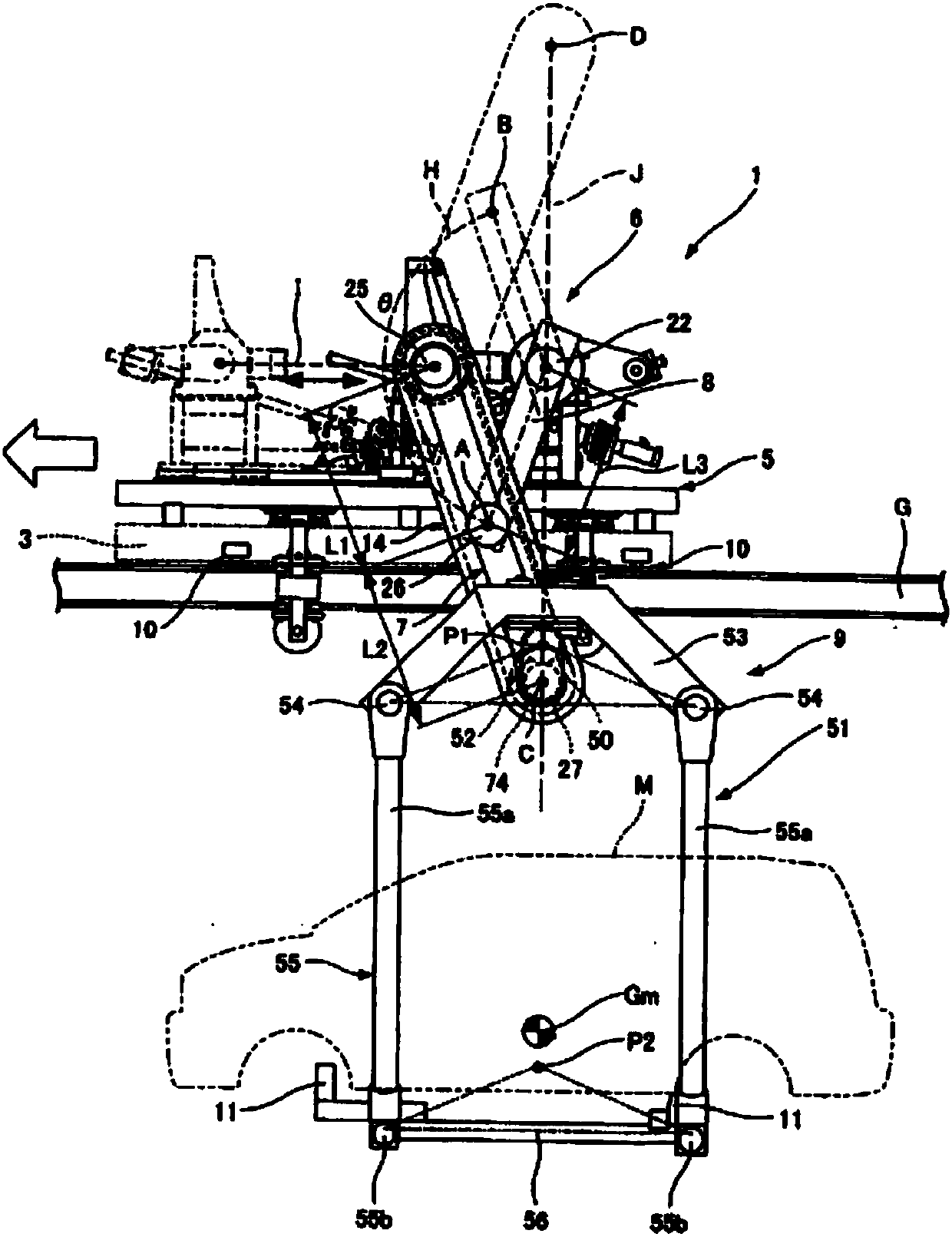

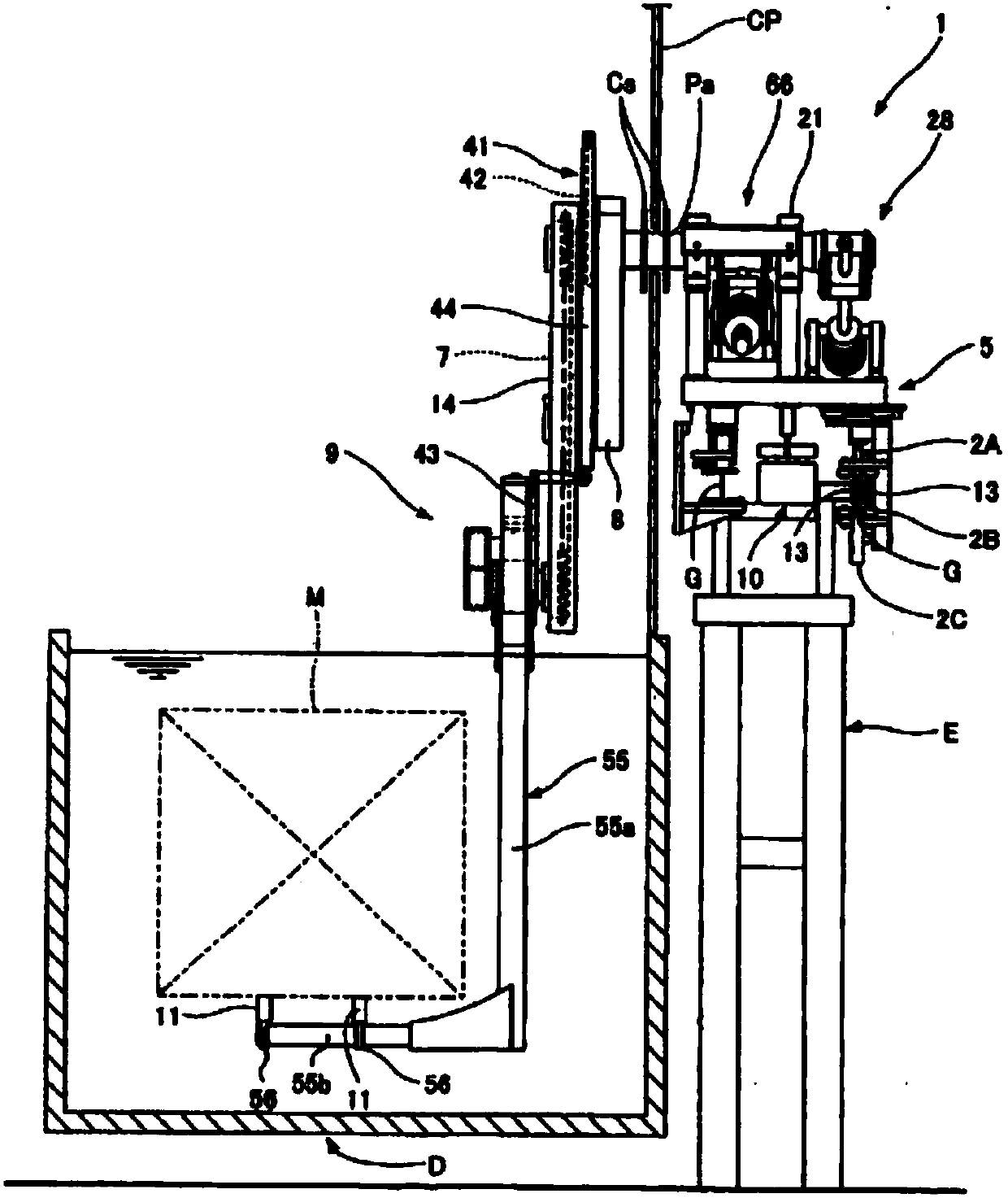

The purpose of the present invention is to provide a carrying device capable of lifting a vehicle body according to a trajectory closer to a vertical line. The carrying device is provided with a crankarm (7) and a rocker arm (8), a base end of the crank arm (7) is freely rotatably supported on a second support shaft (25) and a suspension supporting device (9) is freely rotatably supported on thefree end side; a base end of the rocker arm (8) is fixed on a first supporting shaft (22); the front end of the rocker arm (8) is connected with the middle position of the crank arm (7), so that a movable bearing seat (24) supporting the second support shaft (25) and a fixed bearing seat (21) supporting a first support shaft (21) can be freely close to each other and separated from each other. According to the carrying device, a free end support shaft (50) on the free end side of the crank arm (7) can be lifted and moved along a vertical trajectory J in a substantially perpendicular direction;the suspension part of a suspension supporting device (9) is parallel to a connecting rod mechanism (51), so that the free end support shaft (50) is separated from the line connecting suspension pins(54,54) at the two ends of an upper rack (53) and is arranged at the upper portion; and through the arrangement, a rotation center P2 of a connection frame (56) having a retainer (11) of a vehicle body M is enabled to be close to or consistent with the center of gravity Gm of the vehicle body M.

Owner:广东创机智能科技有限公司

Three-dimensional woven corner fitting with lap joint preforms

ActiveUS9290865B2Decrease overlap regionDesirable propertyWoven fabricsThin material handlingFiberLap joint

A three-dimensional corner lap joint preform and a method of forming a three-dimensional corner lap joint preform including a woven flange with one or more legs that extend from the flange. The legs may include one or more independently woven portions which allow formation of a corner without darting the leg or adding additional reinforcement. The independently woven portions may include warp fibers which are not woven into the preform. The unwoven area allows removal of a portion of the leg prior to formation of the corner, allowing the portions of the leg to overlap and form a lap joint.

Owner:ALBANY ENGINEERED COMPOSITES

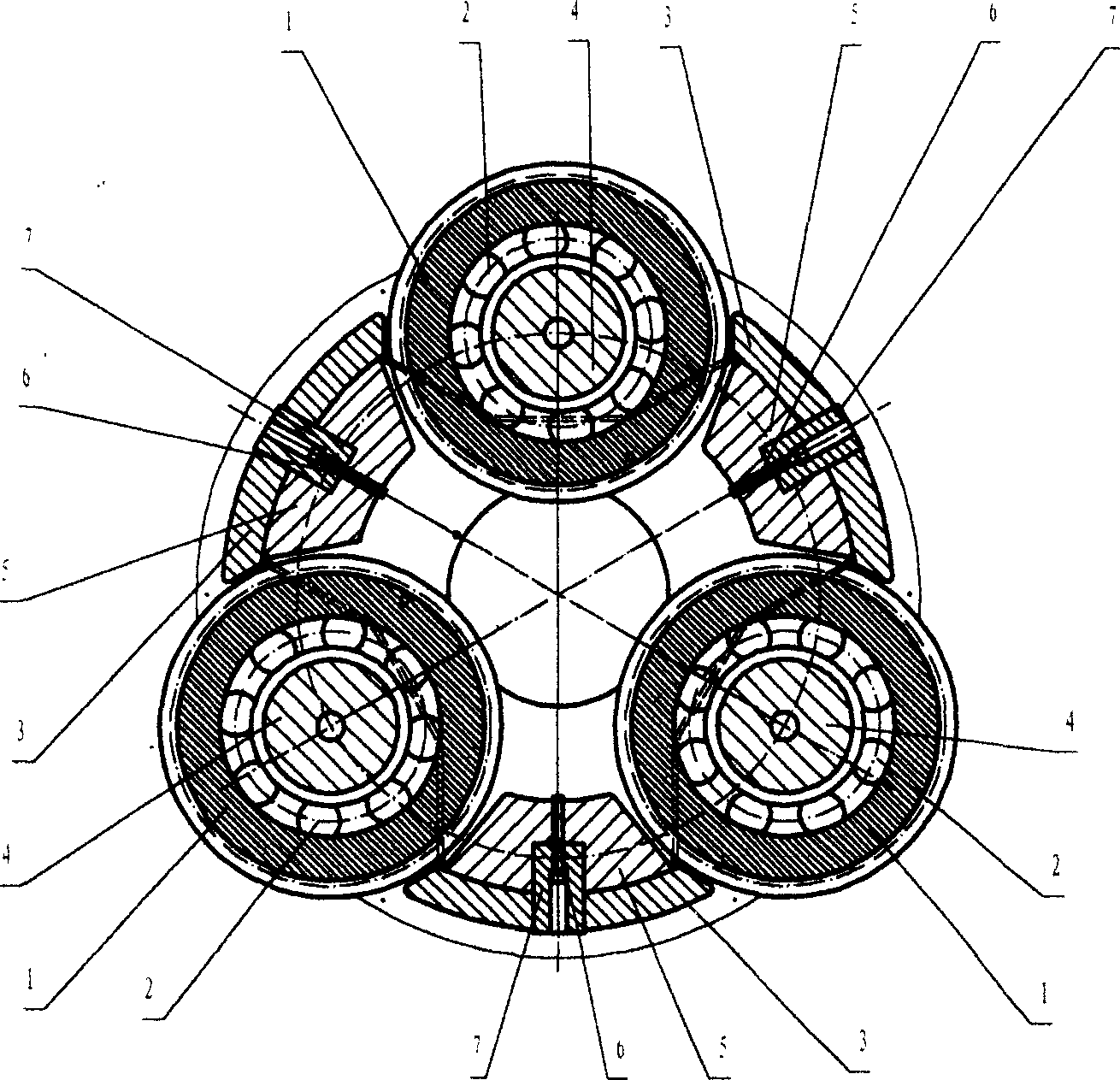

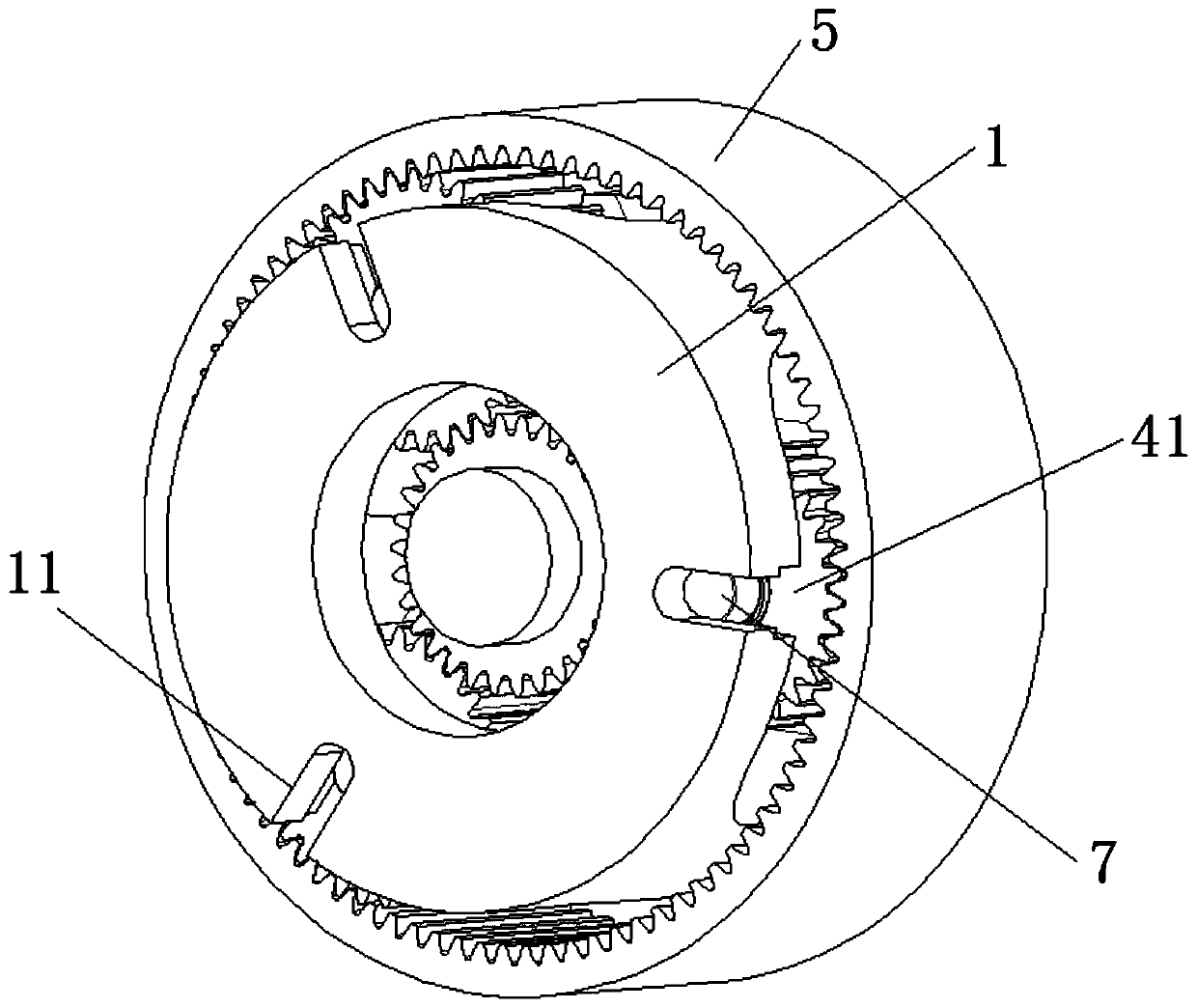

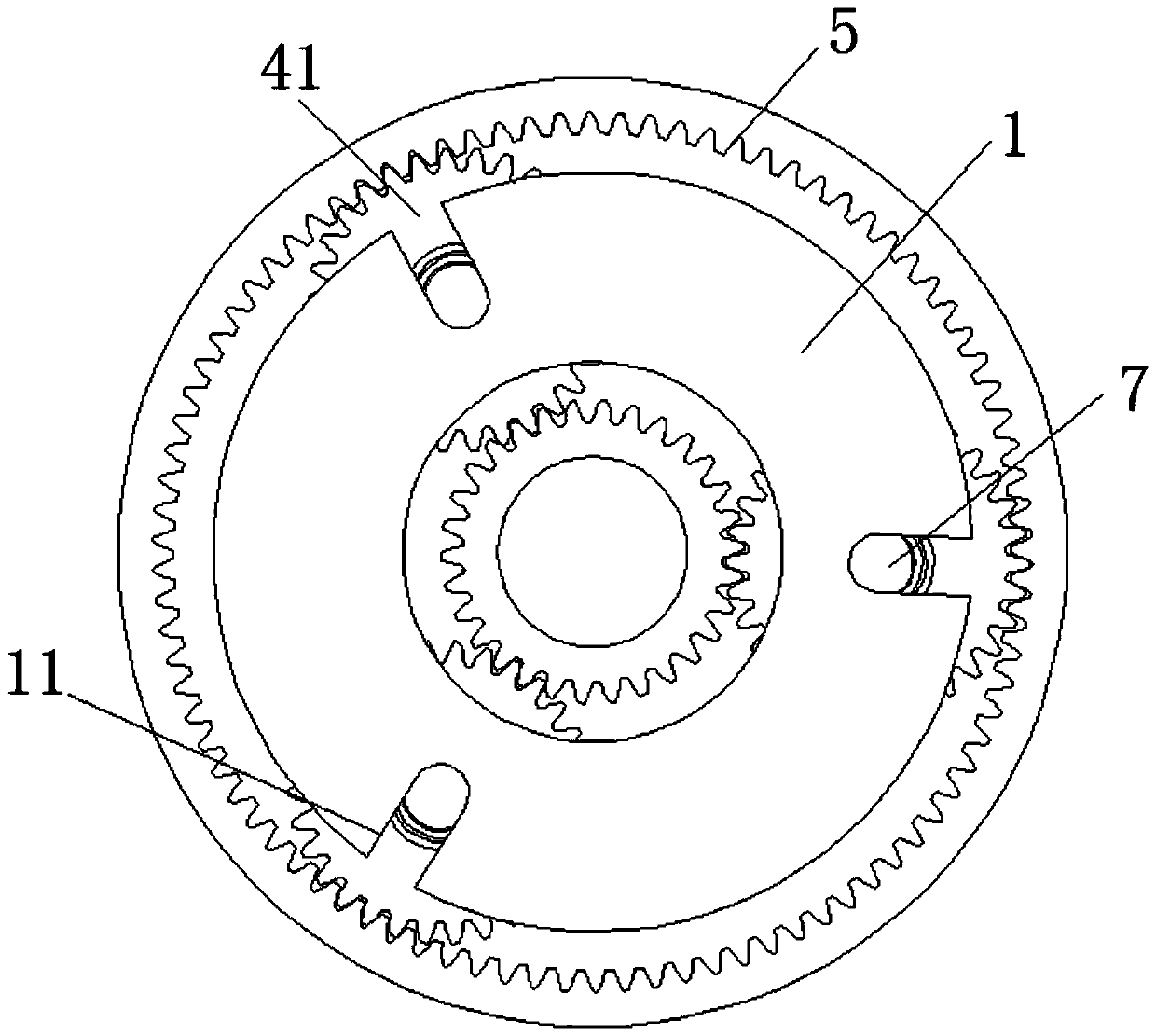

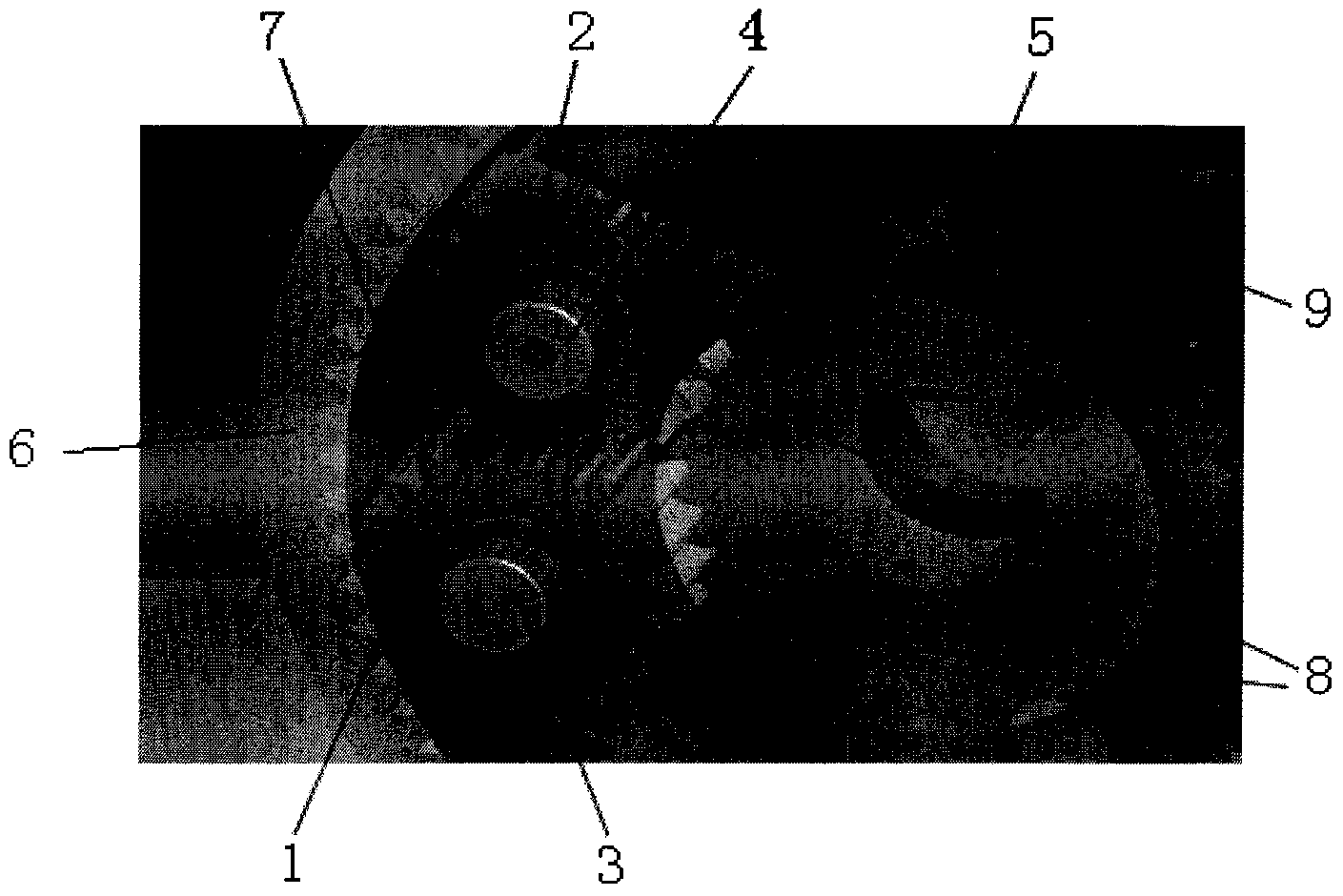

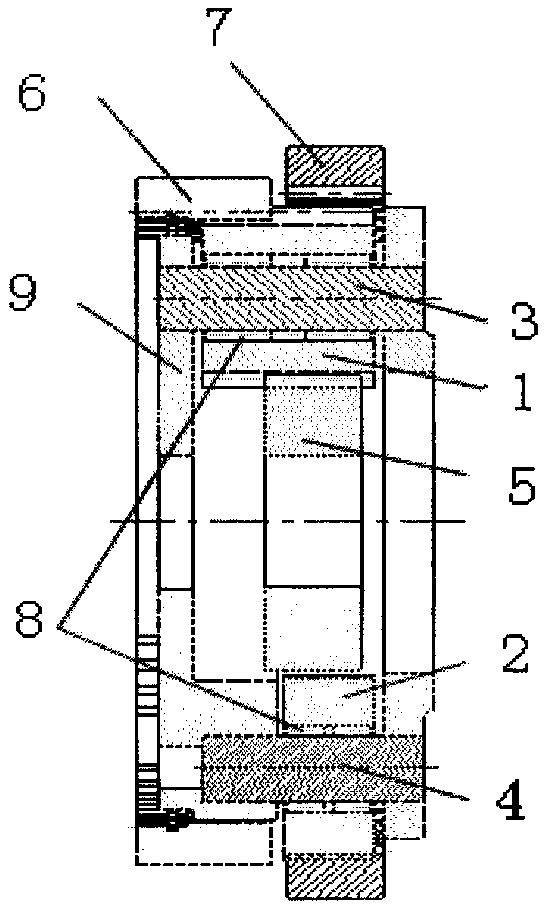

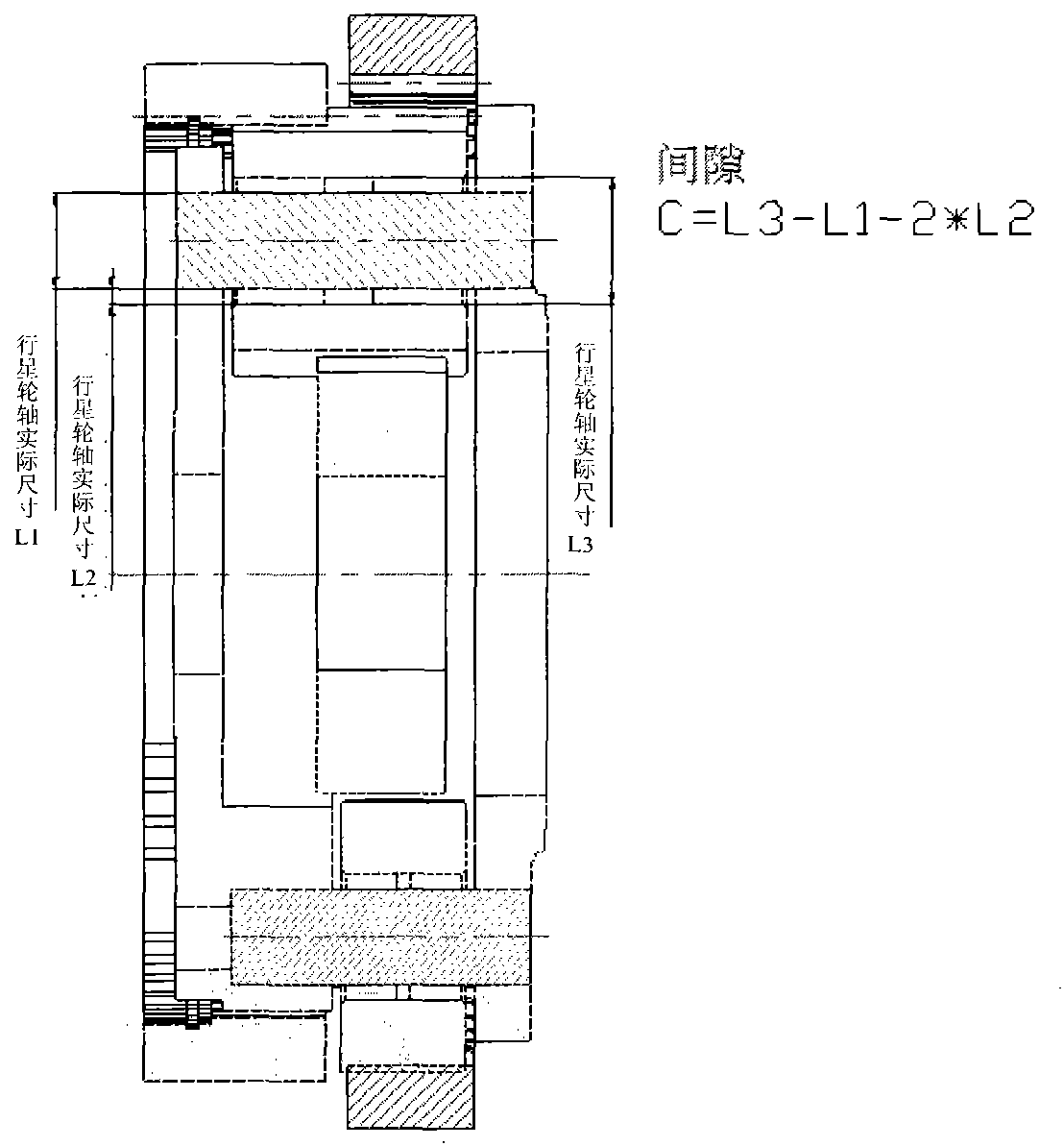

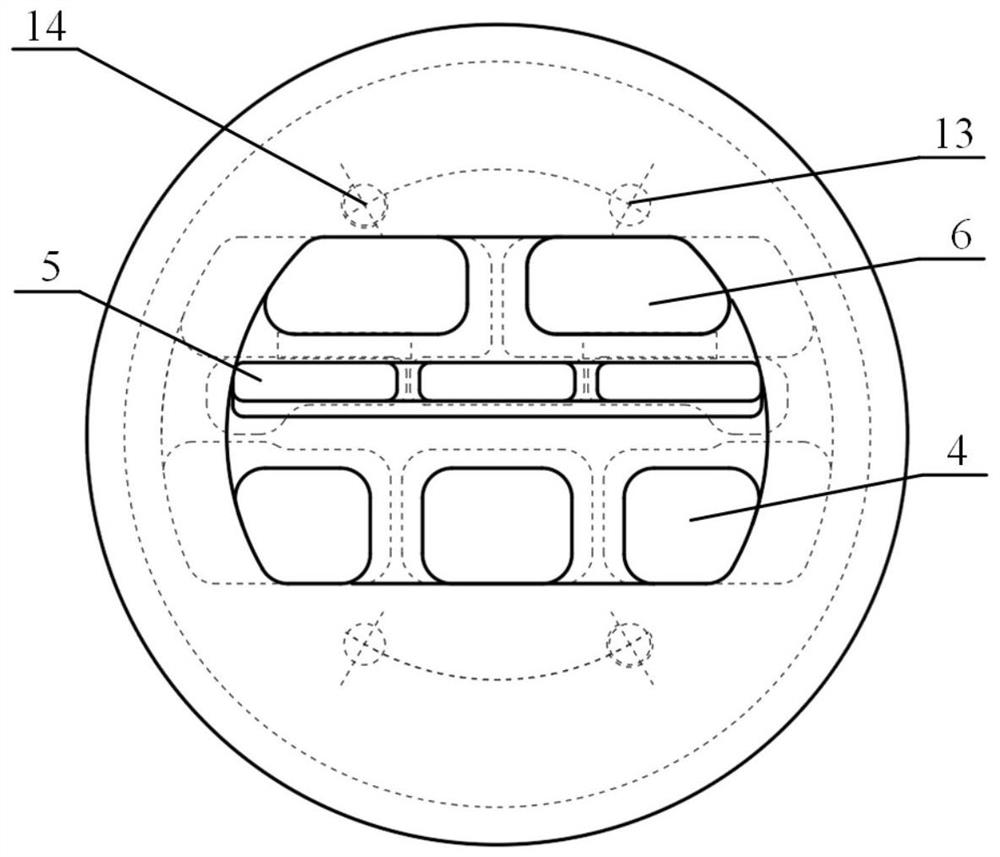

Floating planetary gear train structure for miniature precise planetary reducer

PendingCN110159710AUniform loadLimited axial movementGear vibration/noise dampingToothed gearingsLow speedReducer

The invention discloses a floating planetary gear train structure for a miniature precise planetary reducer. The floating planetary gear train structure comprises a planetary carrier, a high-speed sungear, a low-speed sun gear, a planetary gear set and an inner gear ring, wherein the high-speed sun gear is meshed with the planetary gear set, the inner gear ring is meshed with the planetary gear set, the planetary carrier is in a cage type structure, and the planetary gear set is arranged on the cage type planetary carrier in a floating mode to automatically adapt to the central distance and the matching clearance; the floating planetary gear train structure further comprises a gasket, and the two ends of the planetary gear set are correspondingly limited by the cage type planetary carrierand the gasket to limit the axial movement of the planetary gear set. The floating planetary gear train structure for the miniature precise planetary reducer is exquisite and compact in structure, aU-shaped stepped slot and an annular open slot are designed on the cage type planetary carrier, planetary gears are mounted on the U-shaped stepped slot in a rotating floating mode through pin shaftsand needle bearings so as to automatically adapt to the central distance and the matching clearance, so that the loads of all the planetary gears are uniform, the meshing transmission of the sun gear,the planetary gear and the inner gear ring is ensured, the operation is smooth, the noise and the temperature rise are reduced, the problems of blockage or unbalance are solved, and the reliability is high.

Owner:ZHEJIANG UNIV KUNSHAN INNOVATION INST

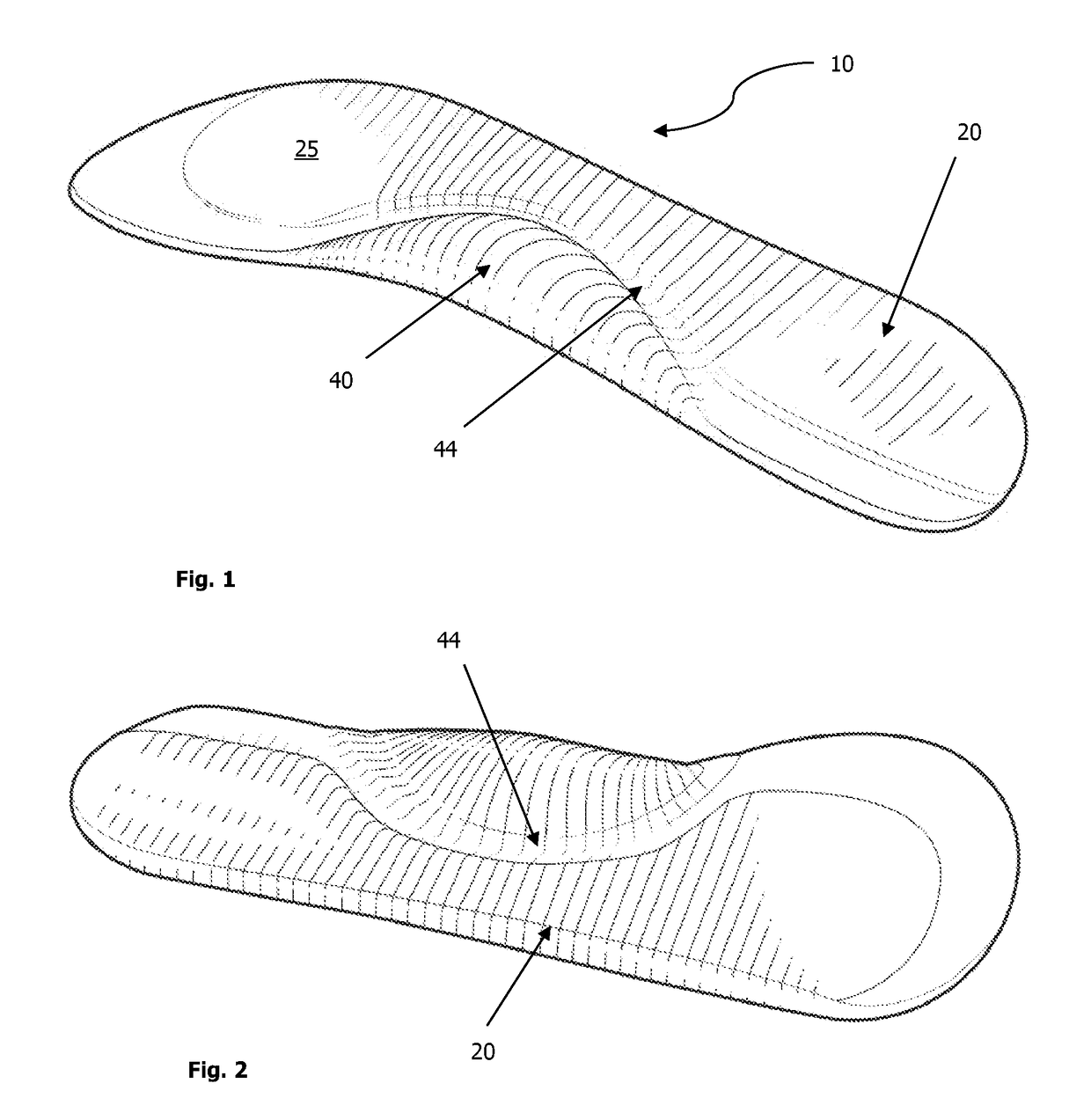

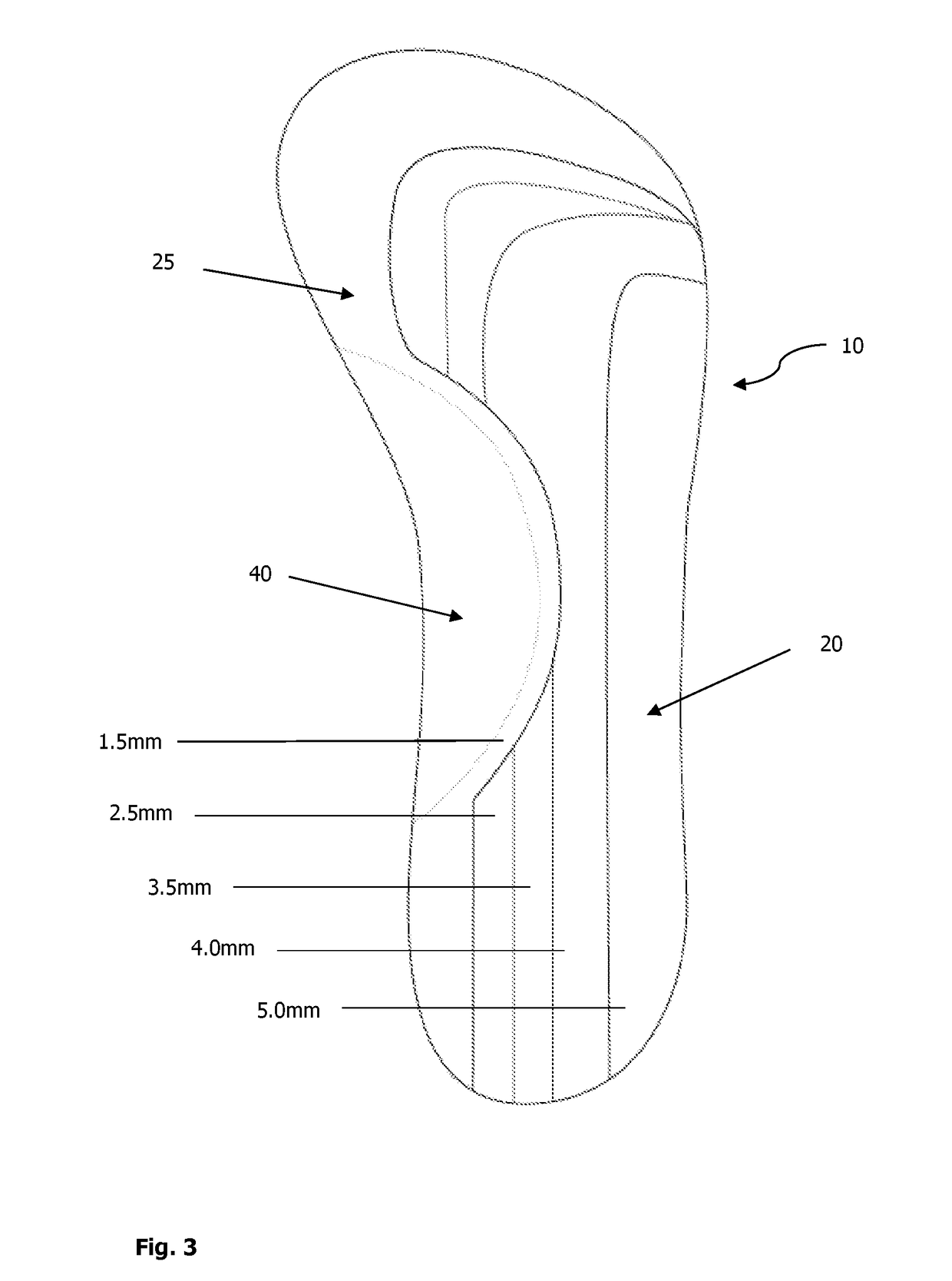

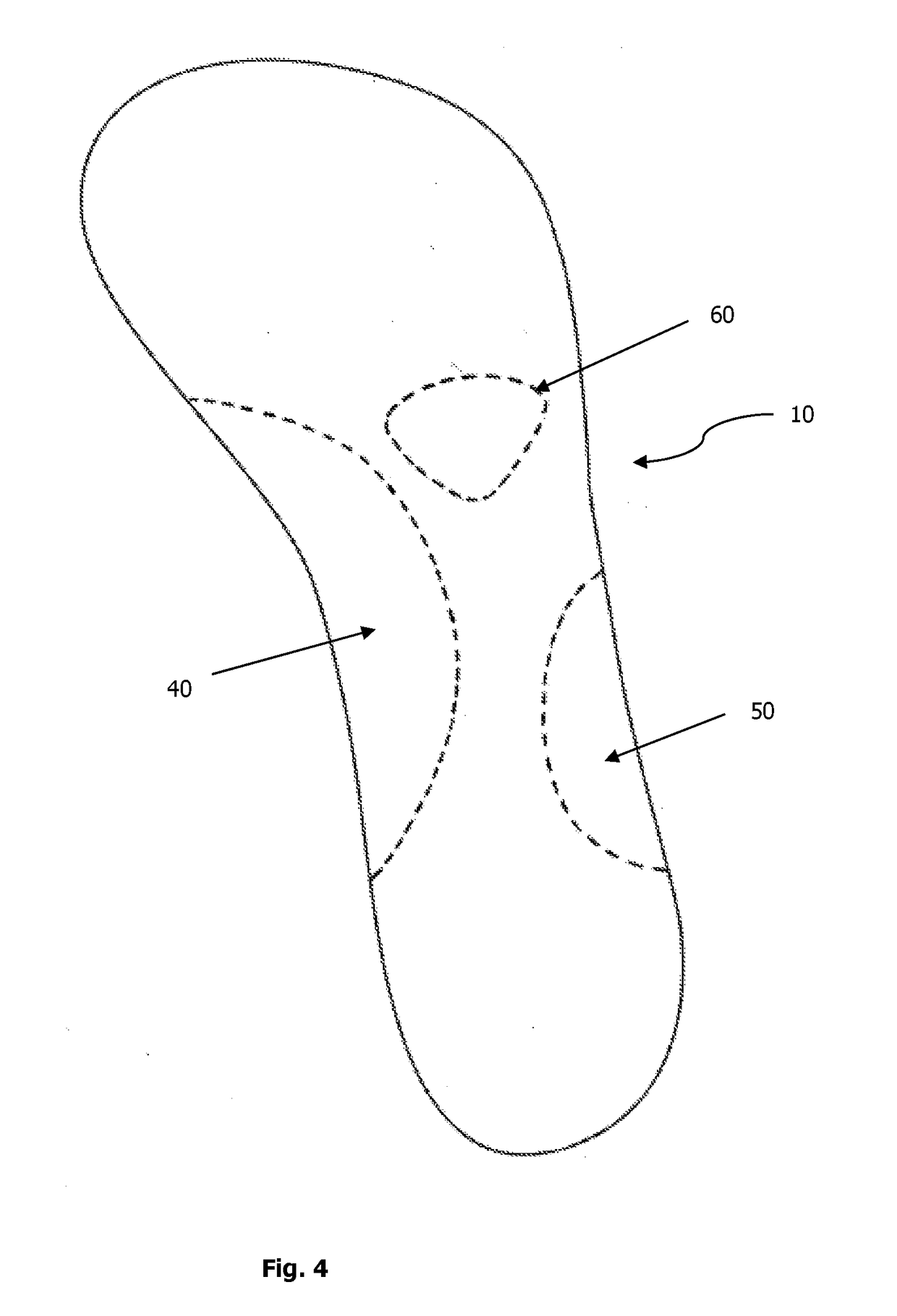

Orthotic device for shoes

An orthotic device (10) for use with heeled, dress, flat or sport shoes, the device (10) comprising a body (25), a medial arch support (40) defined by a projection extending upwardly away from the body (25); and a valgus wedge (20) defined by a projection located at a lateral rear foot portion and / or a lateral forefoot portion of the body (25), the valgus wedge (20) being adapted to evert the foot and concentrate the support of the device (10) laterally.

Owner:WAYFARER CO PTY LTD

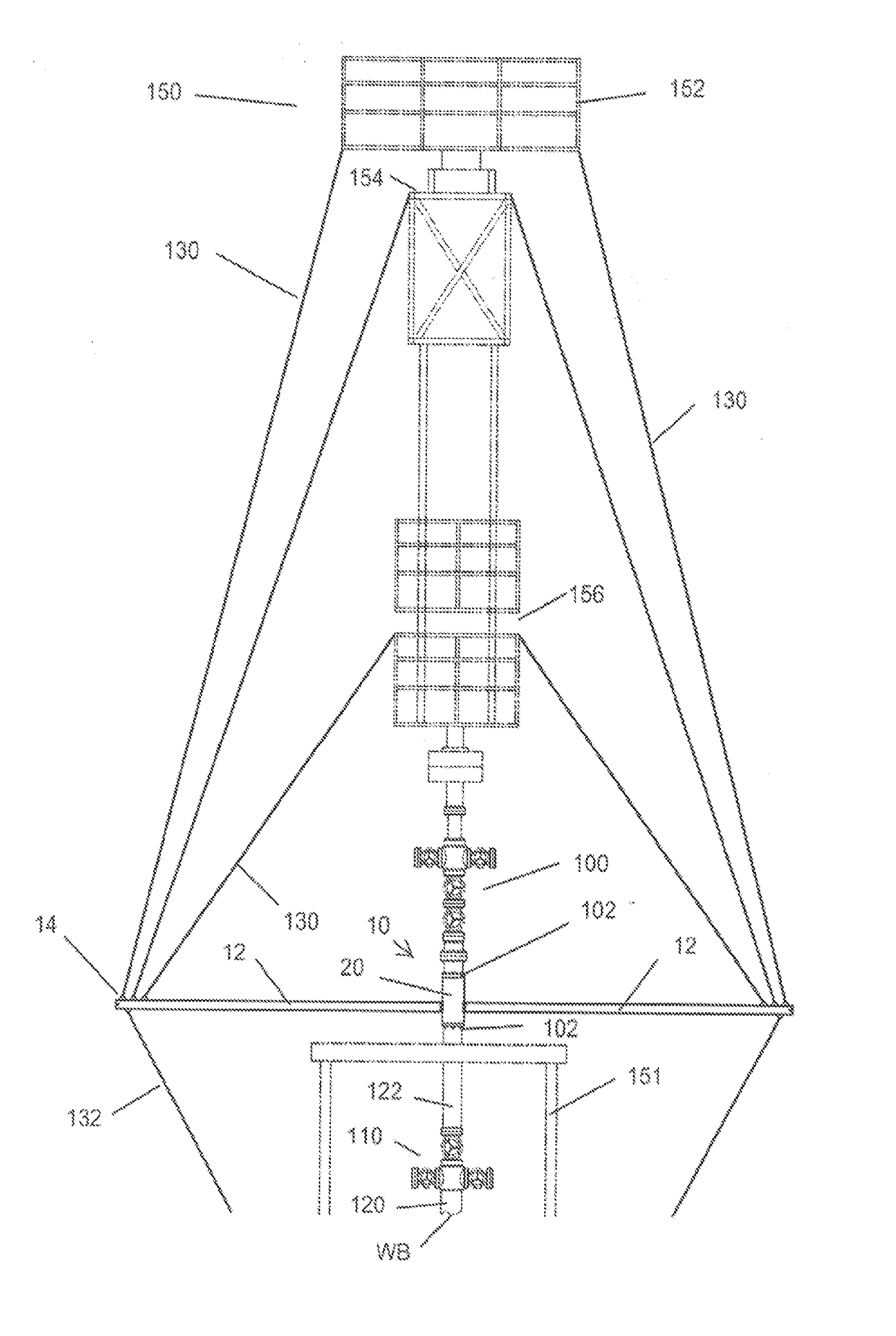

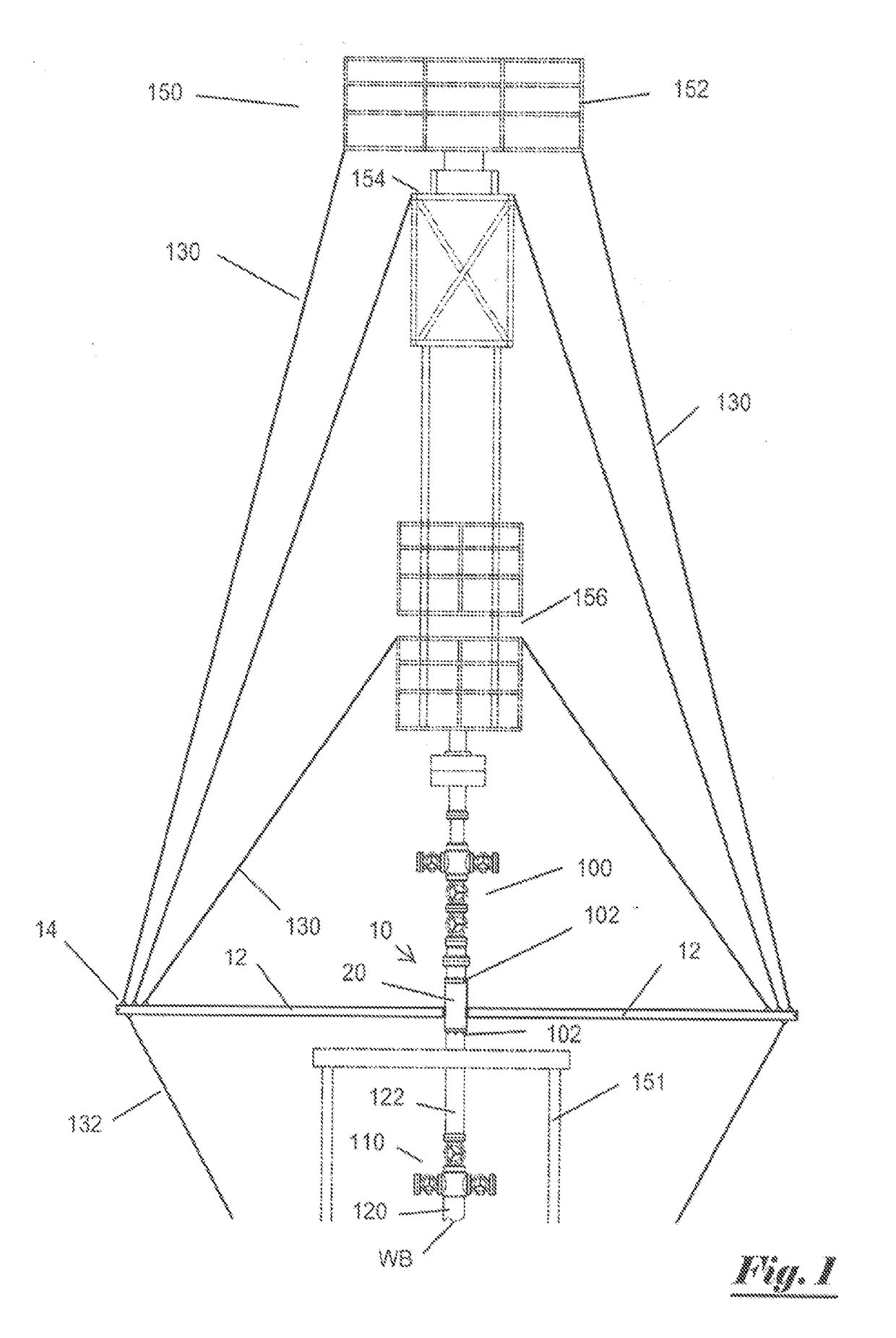

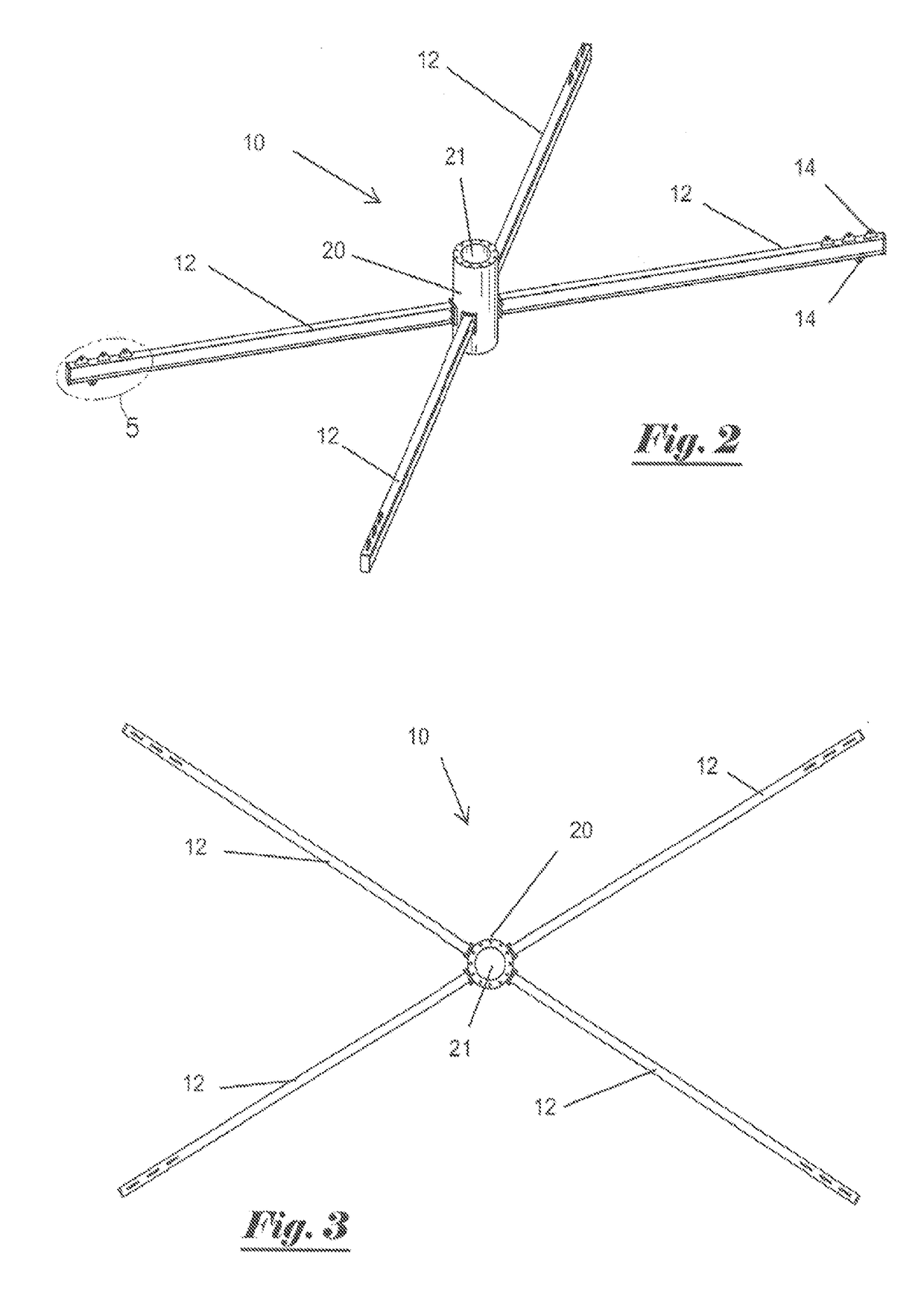

Anchor Spool

ActiveUS20180100378A1Easy to mergeReduce needDrilling rodsDerricks/mastsEngineeringMechanical engineering

A tubular anchor spool having a plurality of removably attached, radially extending, support beams removably attached to a BOP stack of a wellbore to provide a temporary support framework for workover equipment such as a snubbing unit. Guywires are attached to the support beams of the temporary framework for support of the workover equipment. The anchor spool is fabricated offsite and delivered to the well site for installation.

Owner:HARDY MARK JAMES

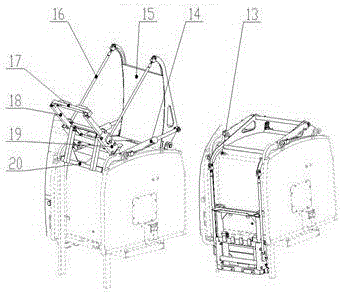

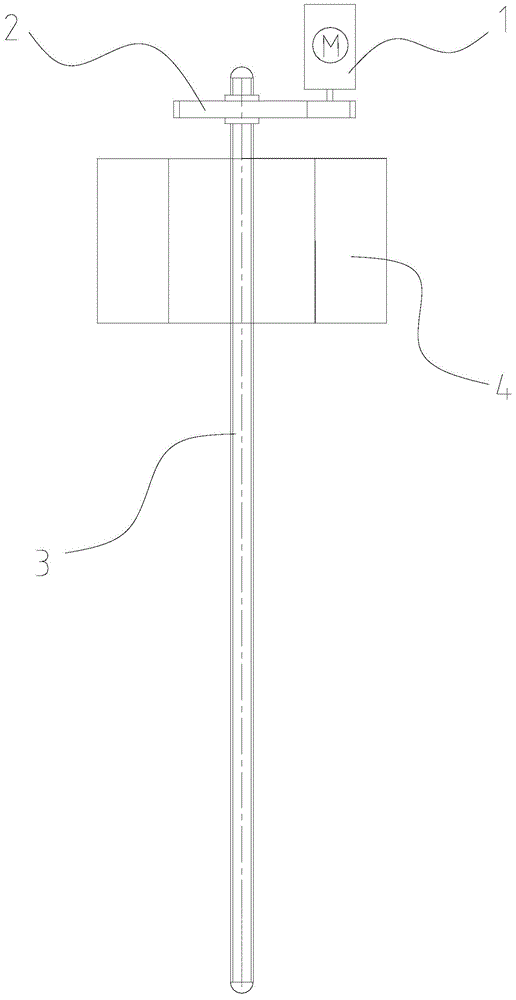

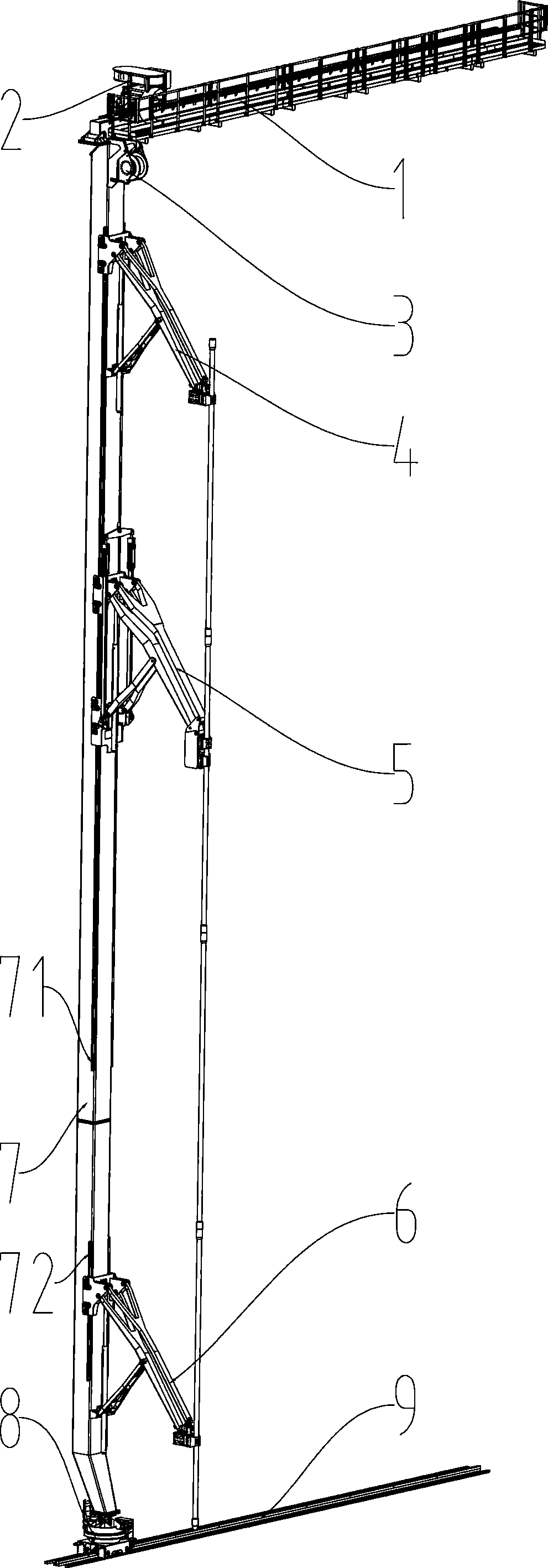

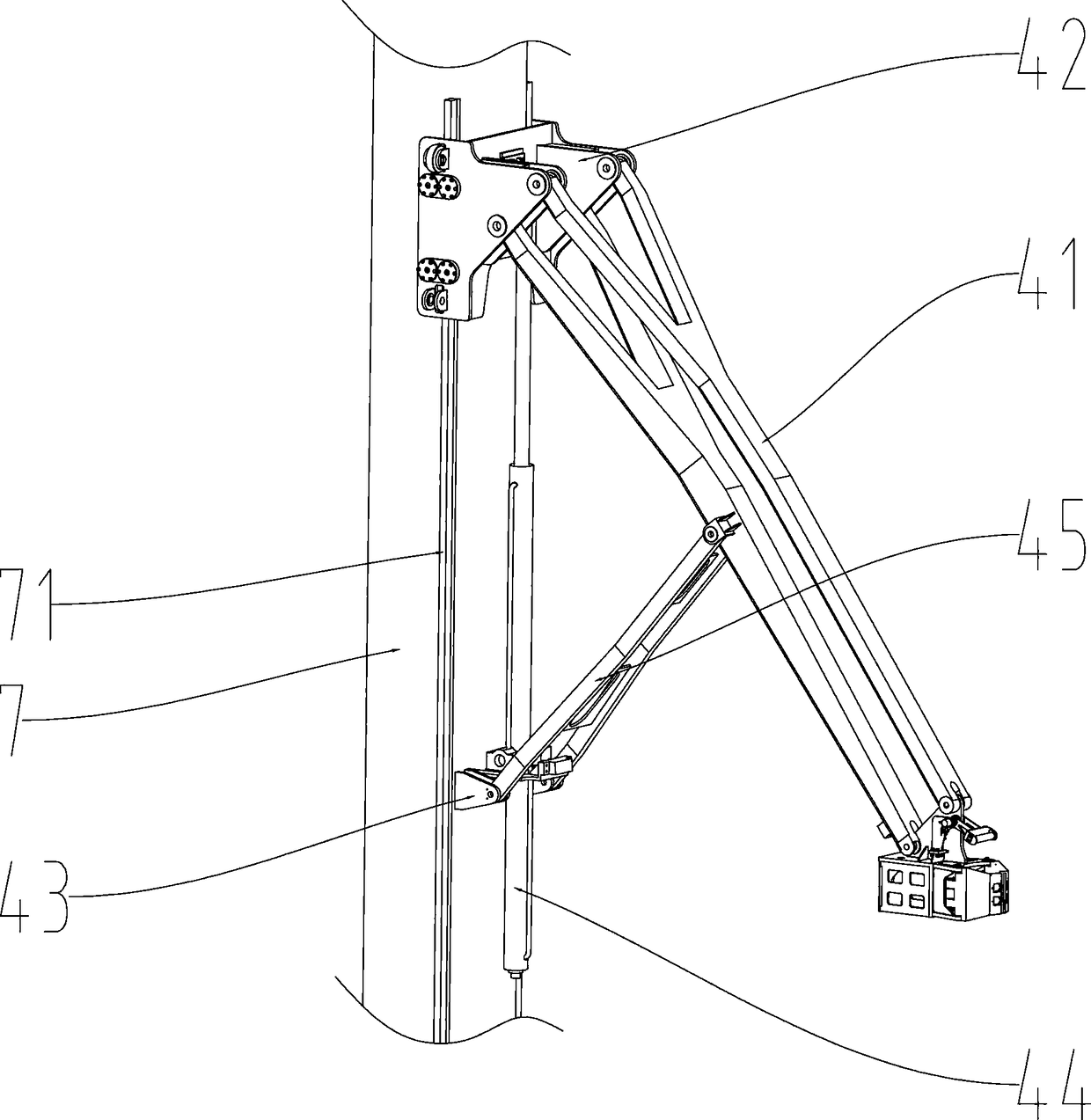

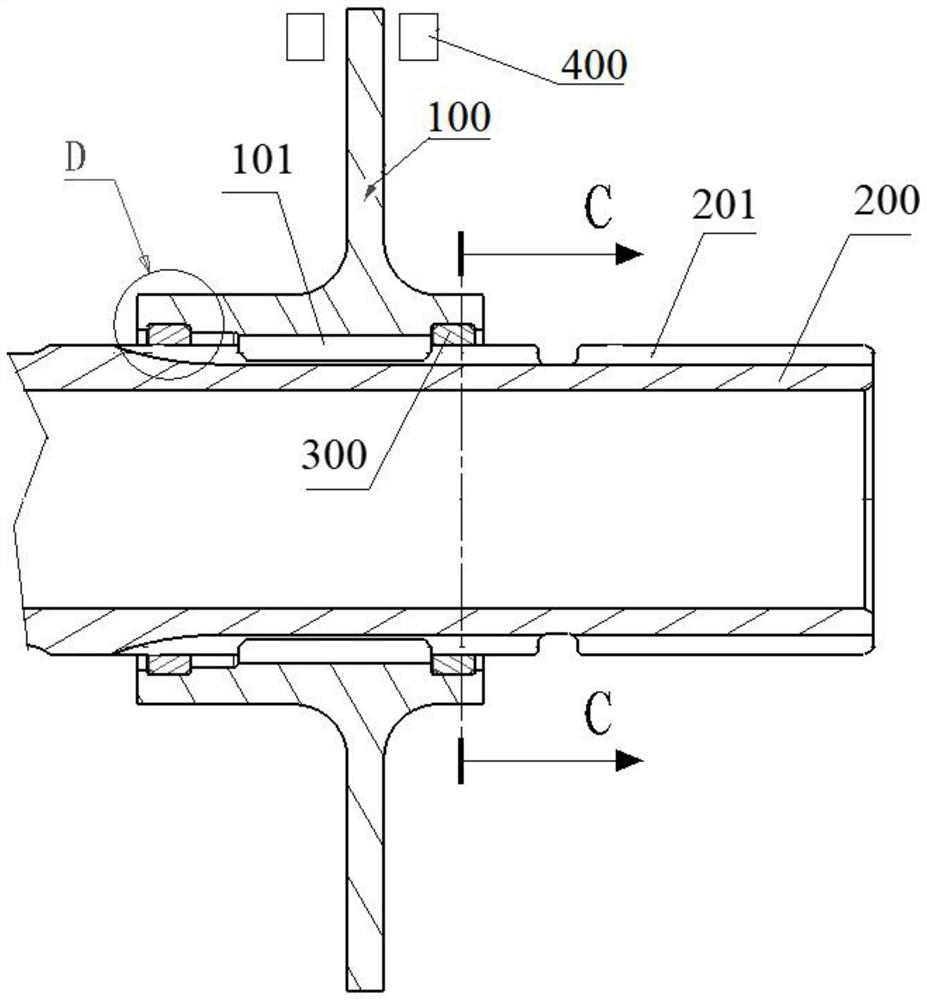

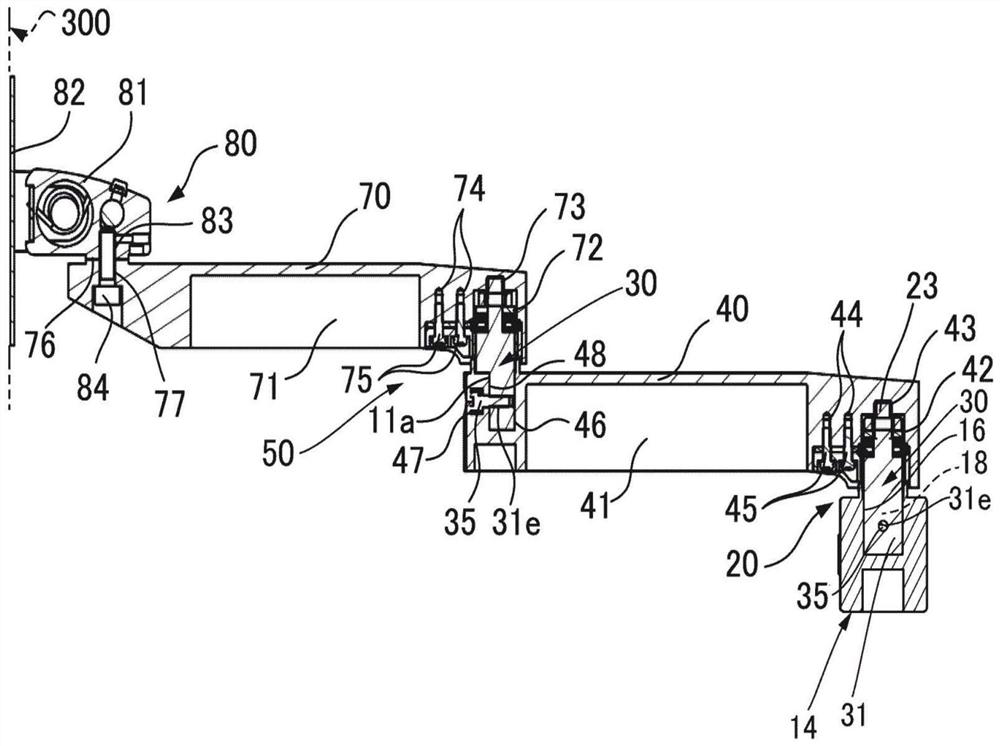

Pipe alignment machine

PendingCN109083605AReduce labor intensityEven by forceDrilling rodsDrilling casingsSynchronous controlEngineering

The invention relates to the field of ocean drilling engineering equipment, in particular to a pipe alignment machine for an ocean drilling platform. The pipe alignment machine can hoist, move and carry four three-joint units at the same time. The pipe alignment machine comprises an upper rail, an upper driving cart movably connected with the upper rail, a column movably connected with the bottomof the upper driving cart, a lower driving cart movably connected with the bottom of the column and a lower rail. The bottom of the upper driving cart is movably connected with the top of the column,the lower rail is movably connected with the lower driving cart, and the machine further comprises a lifting winch fixedly connected with the top of the column, an upper righting arm fixedly connectedwith the column, a lifting arm movably connected with the column and a lower righting arm fixedly connected with the column. The pipe alignment machine easily achieves synchronous control and achieves the aims that the labor intensity is reduced, the equipment stability is improved, the space is saved, the synchronous stability is improved, and the operation efficiency is improved.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

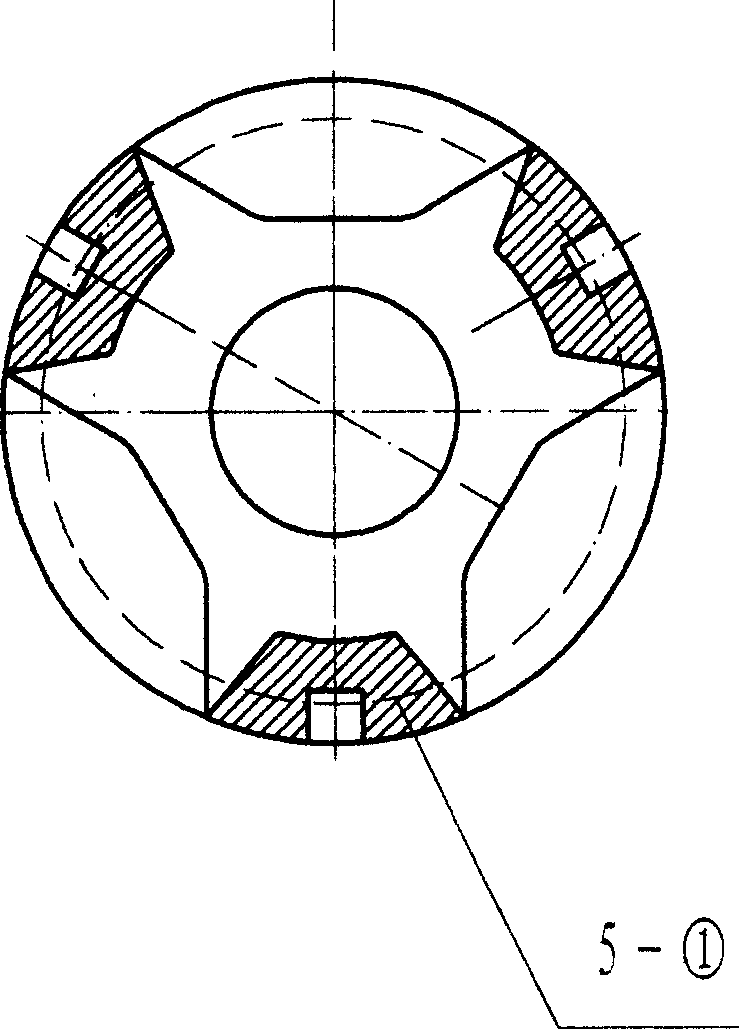

Composite planet row structure adapting to high-rotation-speed working condition

ActiveCN103527717AIncrease capacityReduce partial loadToothed gearingsGearing detailsNeedle roller bearingEngineering

The invention belongs to the technical field of mechanical transmission and particularly relates to a composite planet row structure adapting to a high-rotation-speed working condition. In order to prolong the service life of a composite planet row and meet the use requirements of the composite planet row, the composite planet row structure adapting to the high-rotation-speed working condition includes a planet carrier, planet wheel axles, planet wheels, a sun wheel, gear rings and needle bearings, wherein the planet wheel axles are installed on the planet carrier, and the planet wheels, the sun wheel, the gear rings and the needle bearings achieve transmitting revolving speed and torque. The planet wheels are composed of the planet wheel A and the planet wheel B; the planet wheel axles are composed of the planet wheel axle A and the planet wheel axle B; the gear rings are composed of the gear ring A and the gear ring B. In this way, unbalance loading of the two planet wheels is reduced through the composite planet row, loading of the needle bearings in the two planet wheels is equalized, the acting force exerted on needle bearing retainers due to torsion of all rollers is reduced, the friction force exerted on the rollers in the running process of the needle bearings is reduced, and the total capacity of roller pins of each planet wheel is increased.

Owner:CHINA NORTH VEHICLE RES INST

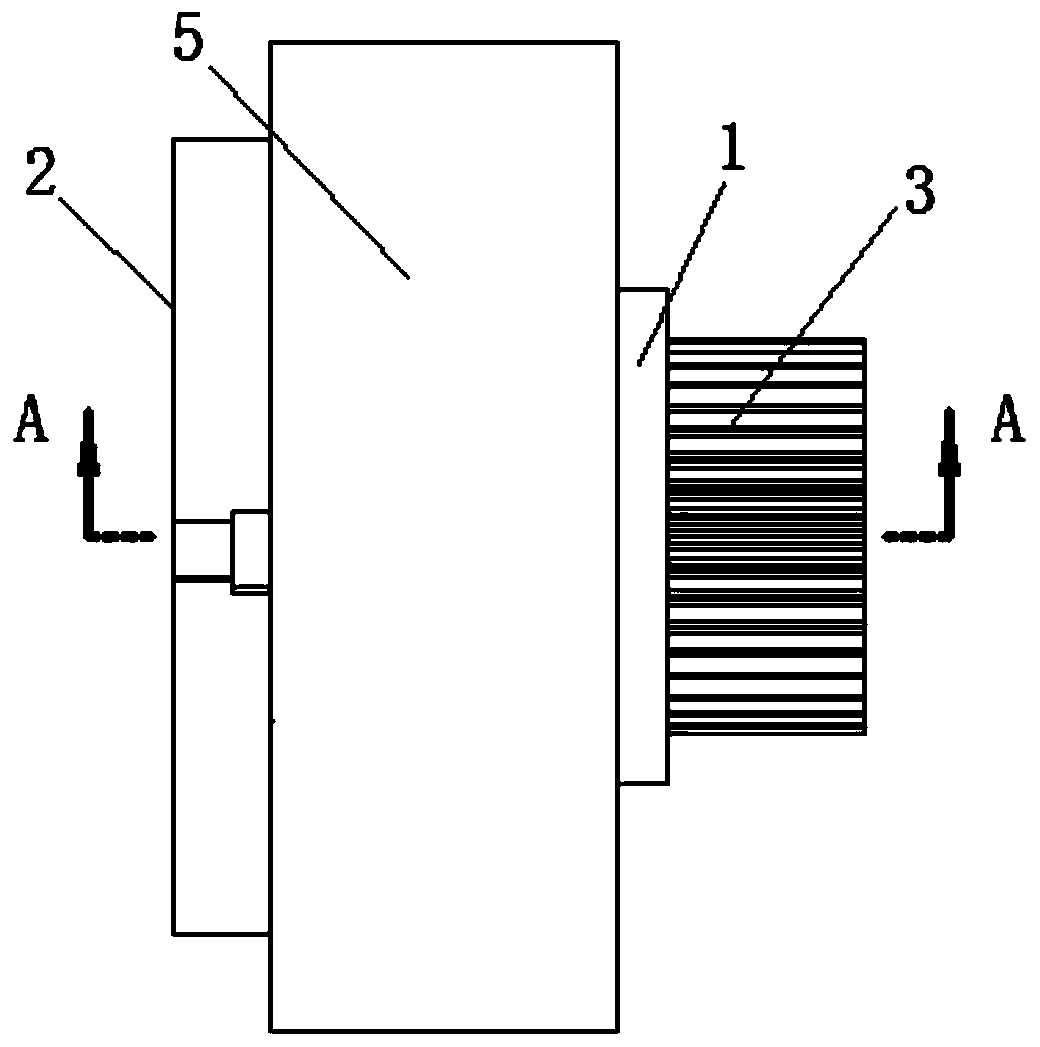

Profile forming device and method for heat dissipation element with micro-channel offset layout

ActiveCN114289537AReduced wear and unbalanced loadsHigh forming precisionExtrusion diesPhysicsExtrusion moulding

The invention provides a profile forming device and method for a heat dissipation element with micro-channels arranged in an offset mode, and relates to the field of profile extrusion forming, the profile forming device comprises a mold, flow dividing holes, a mold core and a forming cavity are arranged in the mold, the flow dividing holes are formed in the two sides of the mold core respectively, the sectional areas of the flow dividing holes in the two sides are different, and a mold core needle at one end of the mold core stretches into a working tape; a forming cavity is formed between the mold core needle and the working tape, and the distance between the mold core needle and the thick-wall side working tape is larger than that between the mold core needle and the thin-wall side working tape; the shunting hole in one side of the mold core is communicated with the thick-wall side of the forming cavity through the welding chamber, and the shunting hole in the other side of the mold core is communicated with the thin-wall side of the forming cavity through the welding chamber; in order to solve the problem that an existing profile for a heat dissipation element with a micro-channel arranged in an offset mode is difficult to form, the diverting holes arranged in the offset mode are formed to reasonably divert metal, so that the wall thickness distribution requirement of the profile with the micro-channel arranged in the offset mode is met, stress on the two sides of a die core is balanced, die abrasion and unbalance loading are reduced, the forming precision of the profile is improved, and the service life of a die is prolonged.

Owner:SHANDONG UNIV

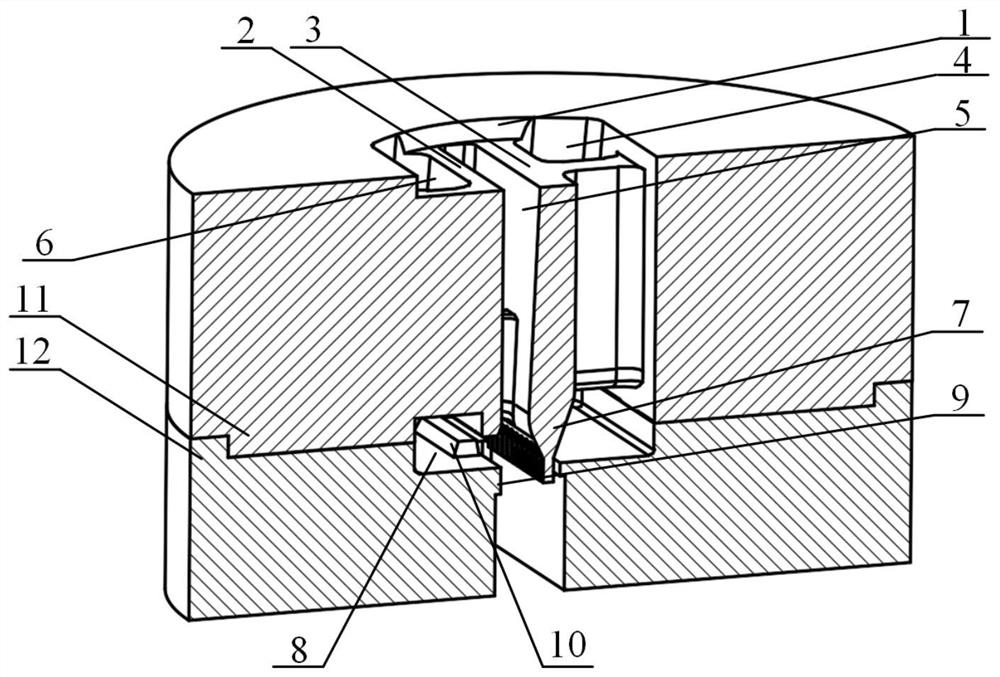

Brake device adopting anti-attrition mechanism of axial floating spline

The invention discloses a brake device adopting an anti-attrition mechanism of an axial floating spline, relates to the technical field of mechanical braking, and solves the problem that an inner spline of a brake disc of a helicopter is prone to abrasion due to the action of unbalance loading and an impact load. The anti-attrition mechanism comprises at least two installation grooves formed in an inner hole of the brake disc, and of an annular structure, and at least two supporting pieces matched with the installation grooves, the supporting pieces are embedded into the installation grooves, the supporting pieces protrude out of the installation grooves, the deflection amount of the spline is reduced by additionally arranging centering supports at the two ends of the spline, and therefore the unbalance loading is reduced, and the effect of reducing the abrasion is achieved, mainly, the supporting pieces and the installation groove structures of the supporting pieces are additionally arranged at the two ends of the spline in the brake disc; the supporting pieces are made of abrasion-resistant and corrosion-resistant high-density plastic, so that the problem that the spline of the brake disc is prone to abrasion is solved, and meanwhile, the weight is not increased; and the supporting pieces are provided with openings, so that installation is facilitated.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

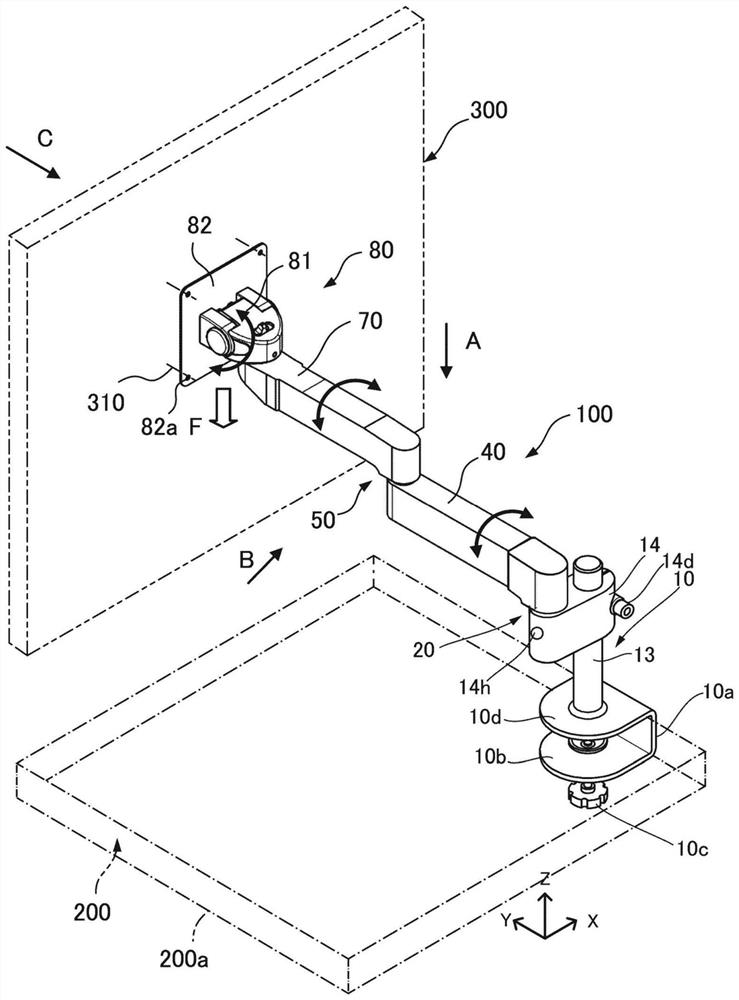

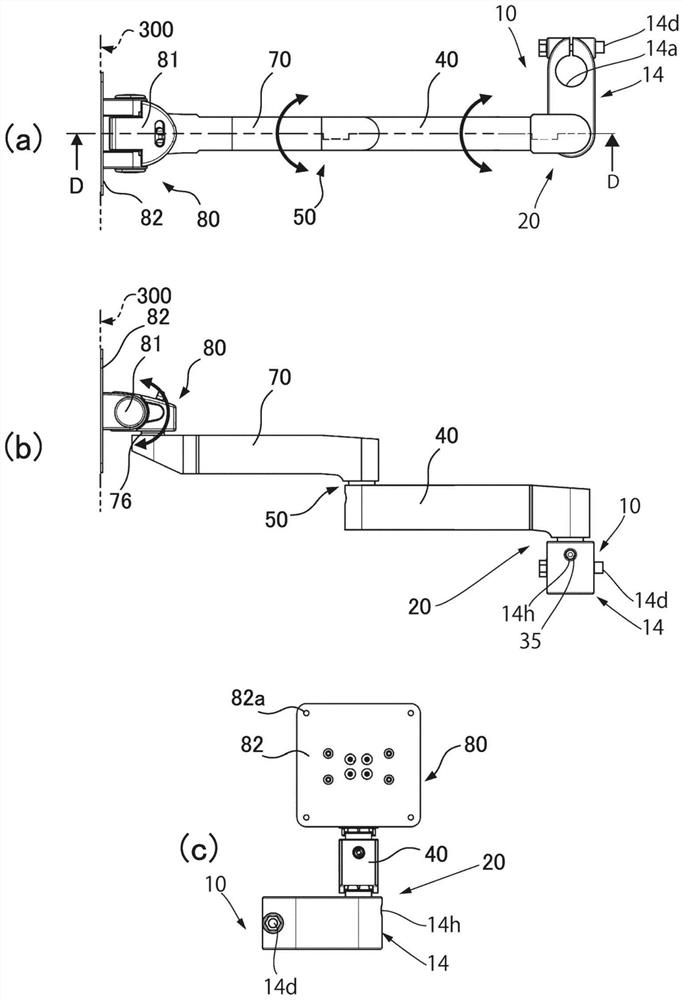

Supporting mechanism and supporting device having the same

The invention provides a supporting mechanism and a supporting device with the same. The supporting mechanism swings in the horizontal direction by mounting a support arm, the front end of which is mounted on various devices, to a mounting element by using a rotary torque hinge; in this way, unbalance loading generated on the friction torque generation means of the rotary torque hinge can be reduced. In order to achieve the purpose, the supporting mechanism uses a rotary torque hinge comprising a friction torque generation means; the friction torque generation means uses elastic members such as friction washers and spring washers; the upper part of a hinge shaft of the rotary torque hinge is pivoted to a mounting hole part arranged on the supporting arm; meanwhile, a bracket for supporting the supporting arm is arranged on the hinge shaft in a friction rotation mode by means of the friction torque generation means.

Owner:KEM HONGKONG

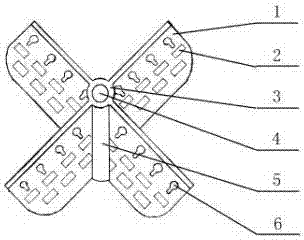

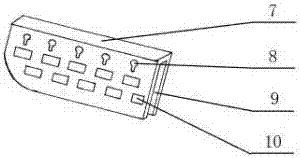

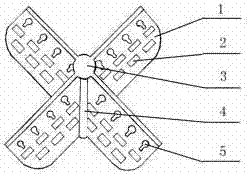

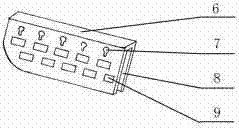

Anti-unbalance-load and anti-winding device for pulsator washing machine with different water leaf and barrel diameter

ActiveCN106968081AReduce tanglingAdjustable buoyancyOther washing machinesTextiles and paperConductor CoilMechanical engineering

The invention discloses an anti-unbalance-load and anti-winding device for a pulsator washing machine with a different water leaf and a barrel diameter, the bottom of a hollow separating piece fixing column is closed, and four space separating pieces are arranged on the hollow separating piece fixing column along the circumferential direction; the lower edges of the space separating pieces are of arc shapes which are matched with the round arc shape at the outer side of the bottom of a washing machine tub, and water guide holes are arranged in the space separating pieces; a grip is arranged on the upper end of the space separating piece fixing column, and a water injection port is arranged on the center of the grip and the water injection port is communicated with the inner cavity of the hollow space separating pieces, the water injection port is provided with a water injection closure stud. The anti-unbalance-load and anti-winding device for the pulsator washing machine with the different water leaf and the barrel diameter has the advantages of preventing the deformation or even damage caused by the excessive winding of clothes, and reducing the unbalance load of the pulsator washing machine during the dehydration rotation process, and being used on the diameter pulsator washing machine with different washing machine tub, and being capable of adjusting the buoyancy.

Owner:兰陵财金产业发展有限公司

Rotary shearing and impact linkage single pneumatic anchor bolt drill

InactiveCN107664014AIncrease the speed of excavationRelieve mining tensionBorehole drivesAnchoring boltsReciprocating motionReduction drive

The invention relates to a rotary shearing and impact linkage single pneumatic anchor bolt drill. The drill is composed of a pneumatic gear motor, an underdriving gear set, a main shaft, a buffer spring, a piston, an annular distributing valve, a muffler, a box body, an end cover and the like and is characterized in that a pneumatic impact device, a pneumatic motor gear and a secondary cylindricalgear reducer are arranged in a U shape in the same box body, which can reduce the size and weight of the box body; the rear section of the main shaft is processed to be a spline shaft conducting reciprocating movement in a spline housing, and the spline housing is installed in a reducer gear IV to transmit running torque to the main shaft; the front section of the main shaft is fixed through thebuffer spring and has the dumping function of a drill body, the piston impacts the main shaft, and the main shaft drives a drill pipe and a drill bit to impact and break a rock; the impact device is turned off when drilling is normally conducted, and the rock is broken only by using rotary shearing; when a hard rock is to be drilled, the impact device is turned on, rotary shearing and impact act jointly, and the hard rock can be drilled fast.

Owner:ANHUI UNIV OF SCI & TECH

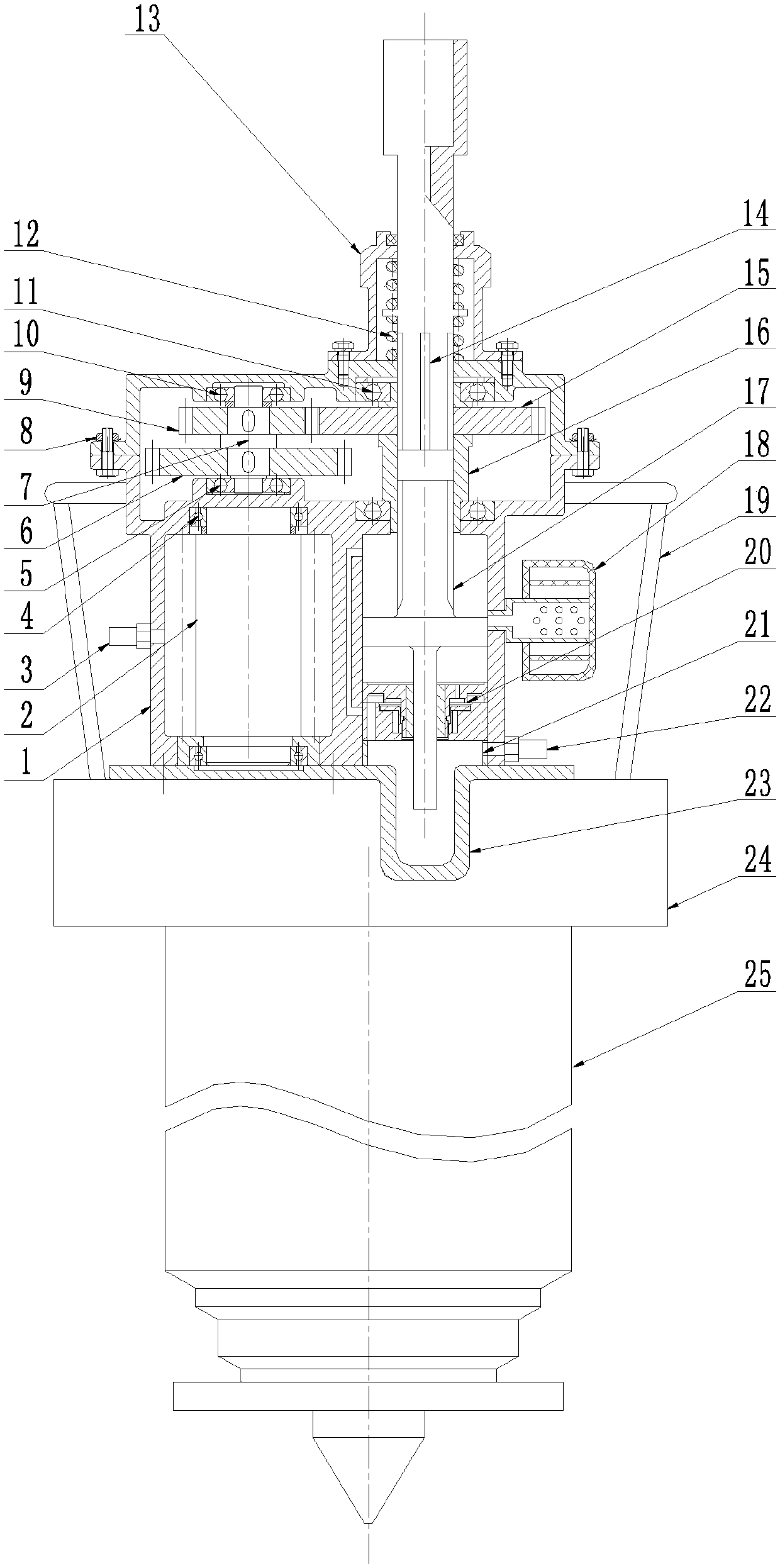

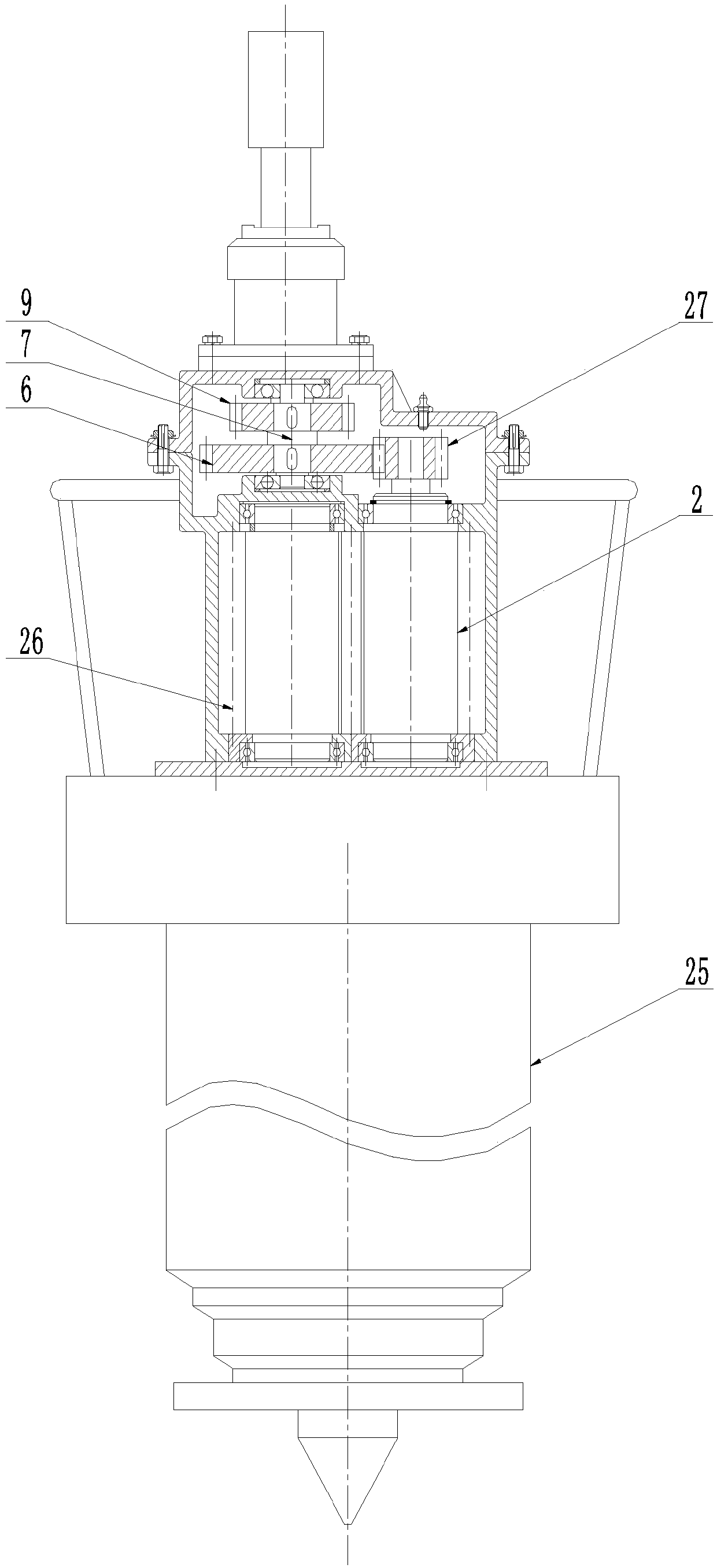

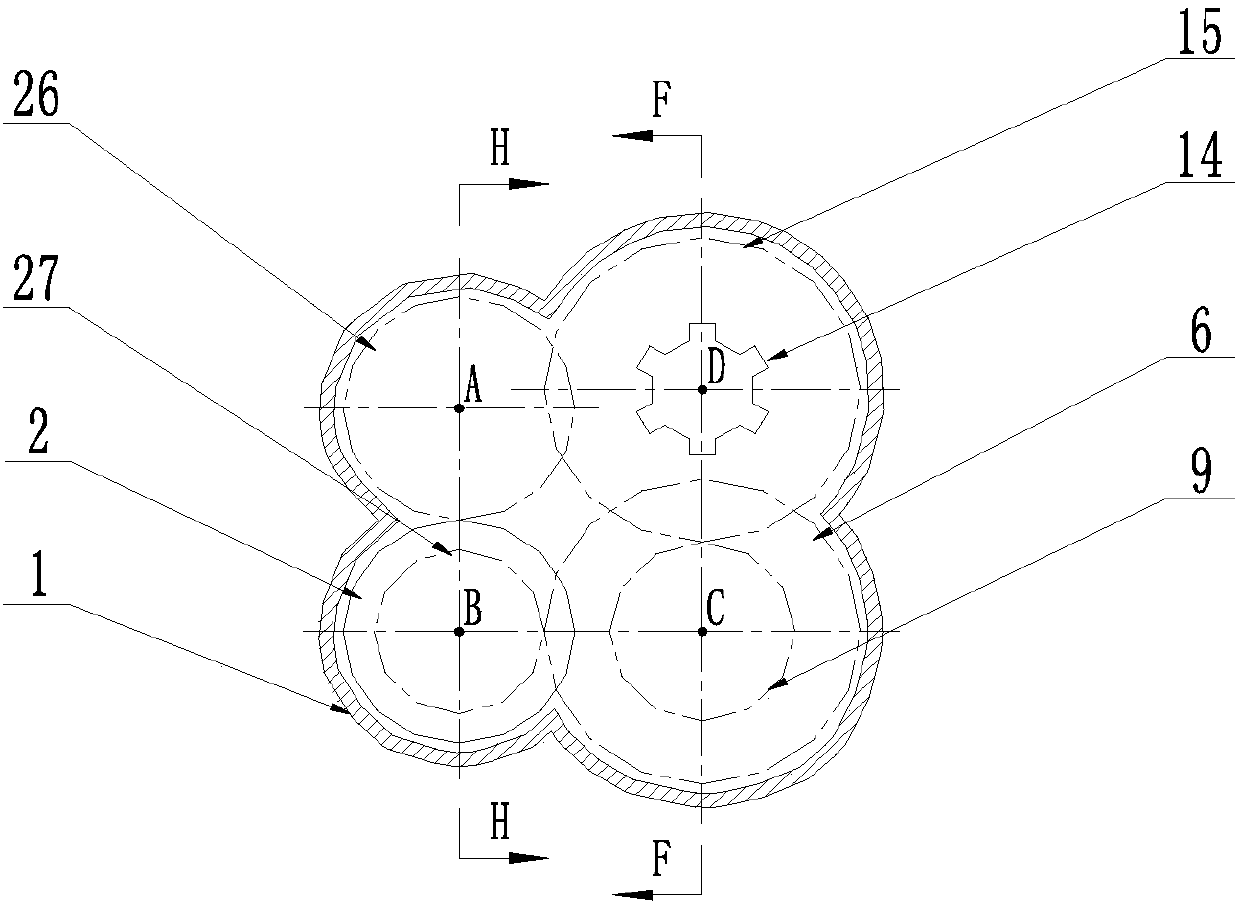

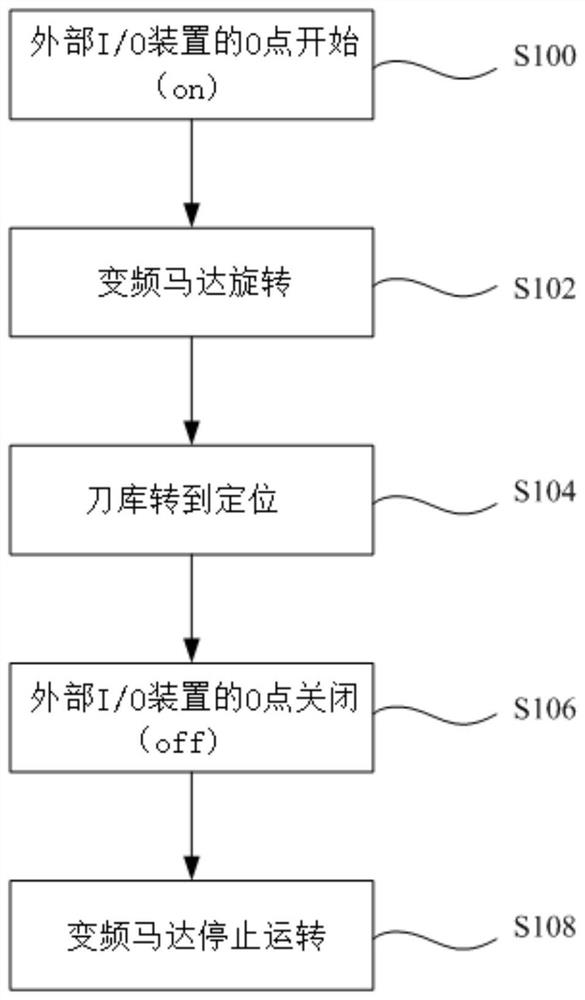

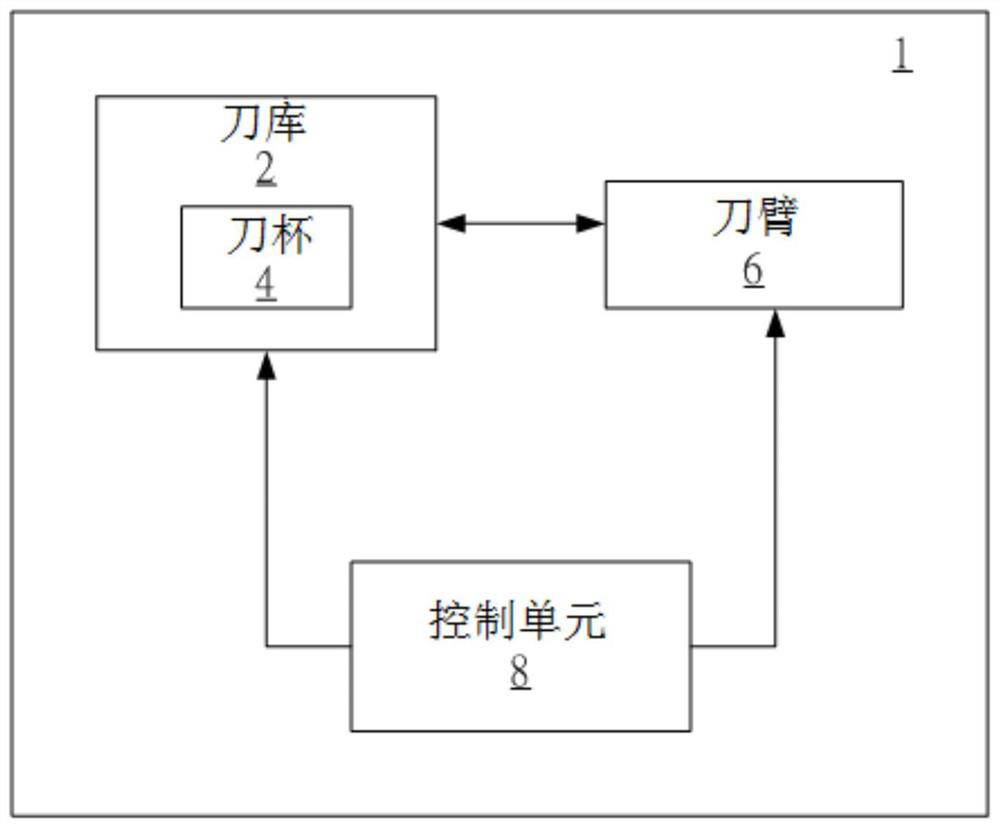

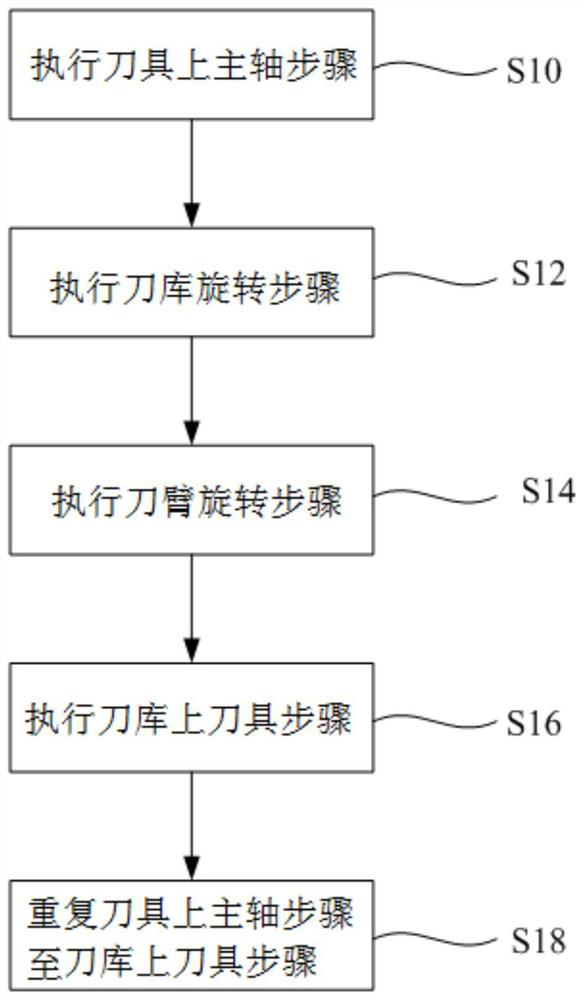

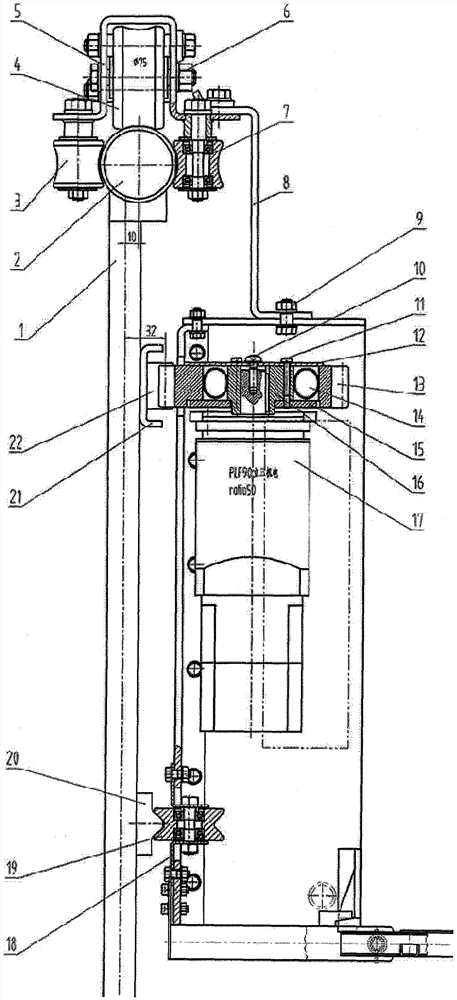

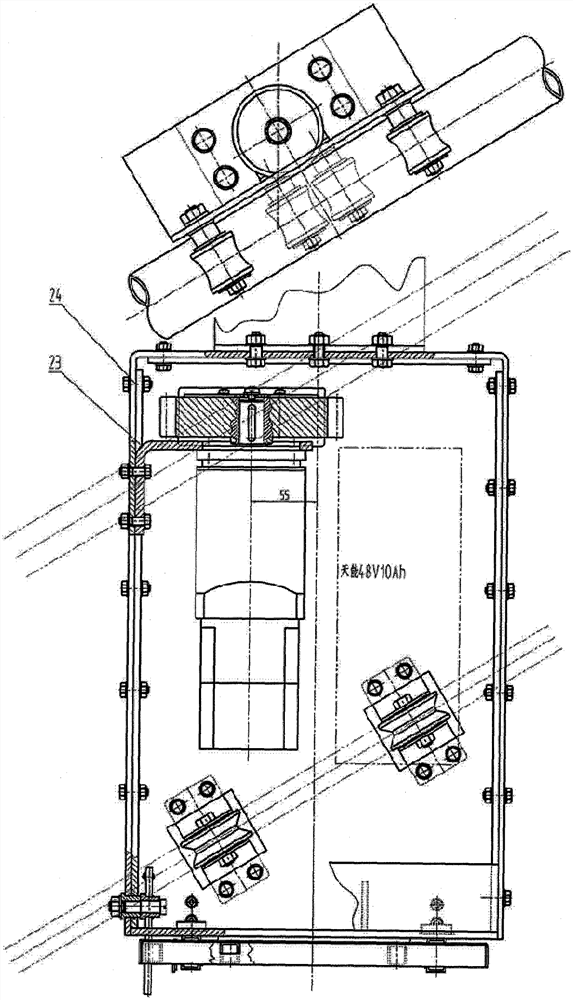

A tool magazine control system and its control method

ActiveCN111360572BReduce partial loadImprove tool change efficiencyLarge fixed membersPositioning apparatusControl systemIndustrial engineering

The invention discloses a tool magazine control system and a control method thereof, which includes: a tool magazine, the knife magazine has a plurality of knife cups, and each of the knife cups is used to accommodate a tool; a knife arm, the The knife arm is used to pick and place the tool from the tool magazine and replace the tool on the main shaft; the control unit is used to control the rotation of the tool magazine so that the knife cup corresponds to the knife arm, controlling the rotation of the knife arm to transfer the tool from the main shaft to be accommodated in the knife cup of the tool magazine or to be transferred from the knife cup of the tool magazine to a tool mounted on the main shaft superior. Adjust the tool magazine speed, tool arm speed and arrange the position of the tool in the tool magazine through the tool weight information to reduce the unbalanced load of the tool magazine, thereby improving the tool change efficiency of the tool magazine and the service life of the tool magazine. Accordingly, the workpiece has a good surface quality during the finishing process.

Owner:新代科技(苏州)有限公司

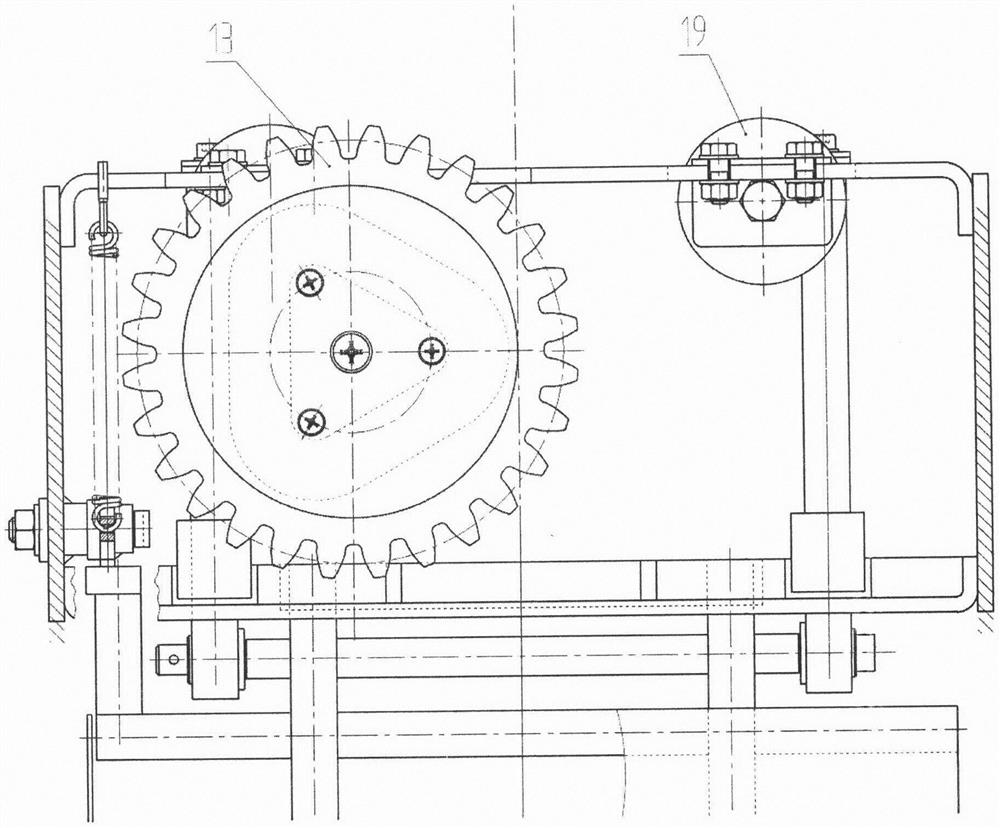

Flexible gear driven corridor elevator walking mechanism

PendingCN112645183ANormal traffic is not affectedSmall footprintPortable liftingBuilding liftsGear driveGear wheel

The invention relates to a flexible gear driven corridor elevator walking mechanism, and belongs to the technical field of general equipment of elevators. The flexible gear driven corridor elevator walking mechanism comprises a load bearing wheel assembly, a machine frame, a power assembly and a supporting wheel assembly, wherein the load bearing wheel assembly comprises a wheel frame, a load bearing wheel and guide wheels; the cross section of the wheel frame is like a door frame; the load bearing wheel is positioned in the middle of the wheel frame and is horizontally arranged; the guide wheels are positioned at two wings of the load bearing wheel and are vertically arranged; the load bearing wheel and the guide wheels form a structure like a Chinese character 'pin'; and a load bearing guide rail is encircled in the center. The machine frame is an elevator body framework and is mechanically connected with the load bearing wheel assembly through a hanging plate. The power assembly comprises a speed reducing motor and a gear; the gear and the speed reducing motor are flexibly connected, and are meshed with a rack on a corridor; and support wheels are positioned below the gear. The flexible gear driven corridor elevator walking mechanism has the main characteristics that the width of each of the guide rails and the rack protruding a guardrail does not exceed 5 cm, and the normal passage of the corridor is not influenced basically. In addition, the rack is positioned between the bearing guide rail and a supporting guide rail, and an unbalance-loading crawling phenomenon can be relieved.

Owner:NANJING INST OF TECH

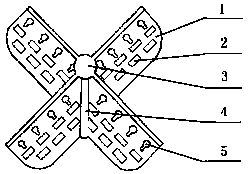

Application method of anti-eccentric load and anti-winding device for pulsator washing machines with different barrel diameters

ActiveCN107142680AEffective separationFlexible rotationOther washing machinesTextiles and paperEngineeringConductor Coil

The invention discloses an application method of an anti-eccentric load and anti-winding device for pulsator washing machines with different barrel diameters. A space separator fixing column is provided with four space separators along the circumferential direction; the lower edges of the space separators are in an arc form matched with the arc at the outer side of the bottom of a washing barrel; a water guide hole is formed in each space separator and is rectangular hole distributed in each space separator, so that a washing solution can flow in various separated spaces of the washing barrel; a grip is arranged at the upper end of each space separator; a movable separator sleeves each space separator; and a separator clamping groove located in the upper edge of each separator is arranged in each space separator and a clamping bolt is placed for fixing the position of each movable separator. According to the application method, deformation or even damage caused by excessive winding of clothing can be prevented, eccentric loads of the pulsator washing machines in the dehydration rotation process are reduced, and the application method can be especially applied to the pulsator washing machines with different washing barrel diameters.

Owner:蚌埠启邦科技信息咨询有限公司

How to use anti-eccentric load and anti-winding devices for pulsator washing machines with different barrel diameters

ActiveCN107142680BReduce tanglingDoes not interfere with washing effectOther washing machinesTextiles and paperWinding machineSpatial partition

The invention discloses a method for using an anti-eccentric load and anti-winding device for pulsator washing machines with different barrel diameters. Four space partitions are arranged on the space partition fixing column along the circumferential direction; the lower edge of the space partition is in the shape of The outer circular arc of the bottom of the washing tub matches the arc shape, and the water guide hole is arranged on the space separator, and the water guide hole is a rectangular hole distributed on the space separator, so that the washing liquid can flow in the separate spaces of the washing bucket; A handle is provided on the upper end of the space divider fixing column; a movable divider is set on each space divider; a divider slot on the upper edge of the divider is set on the space divider, and a clamping bolt is placed for fixing the movable divider s position. The invention can prevent deformation or even damage caused by the excessive winding of clothes, reduce the unbalanced load of the pulsator washing machine during dehydration and rotation, and can especially be used on pulsator washing machines with different diameters of washing buckets.

Owner:蚌埠启邦科技信息咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com