Patents

Literature

148results about How to "Uniform and reasonable force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

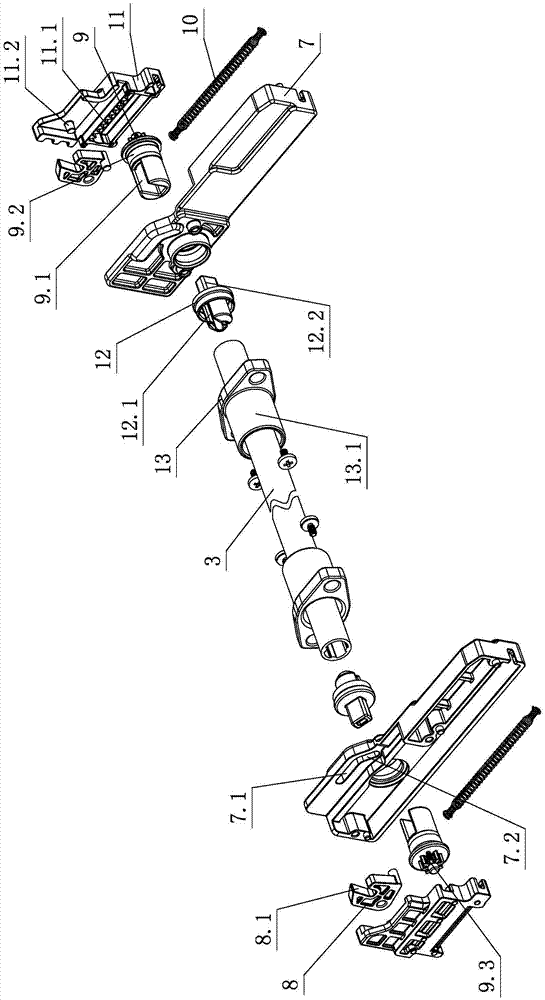

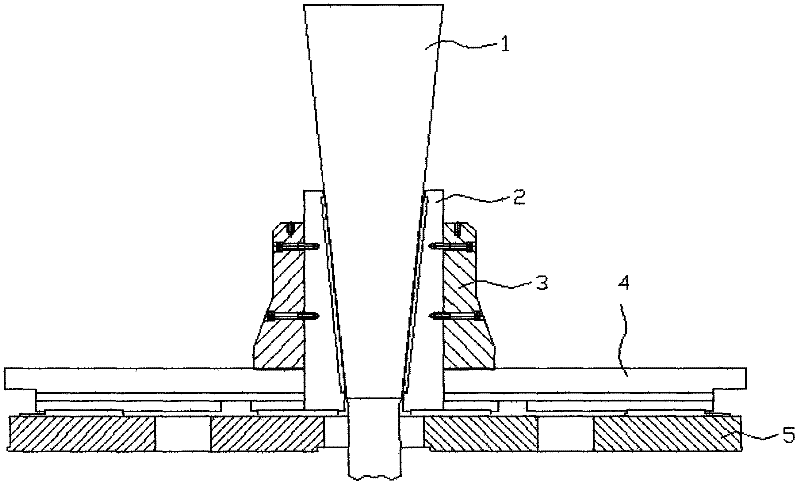

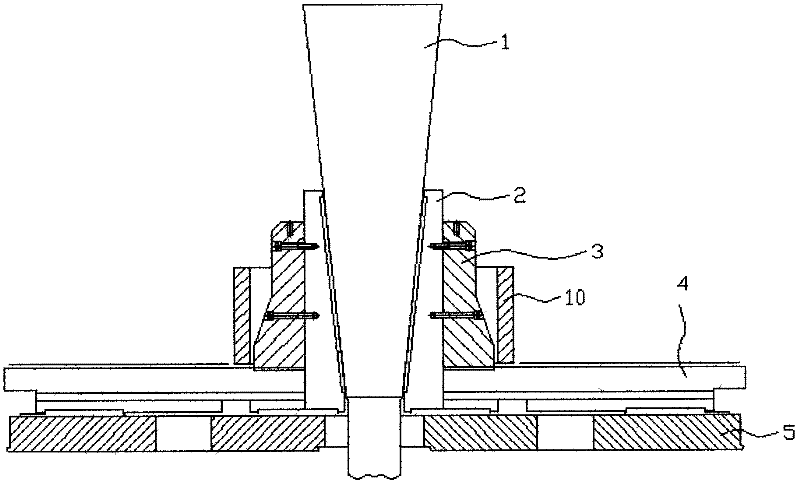

Straight pipe end clamping device of pipe expanding machine

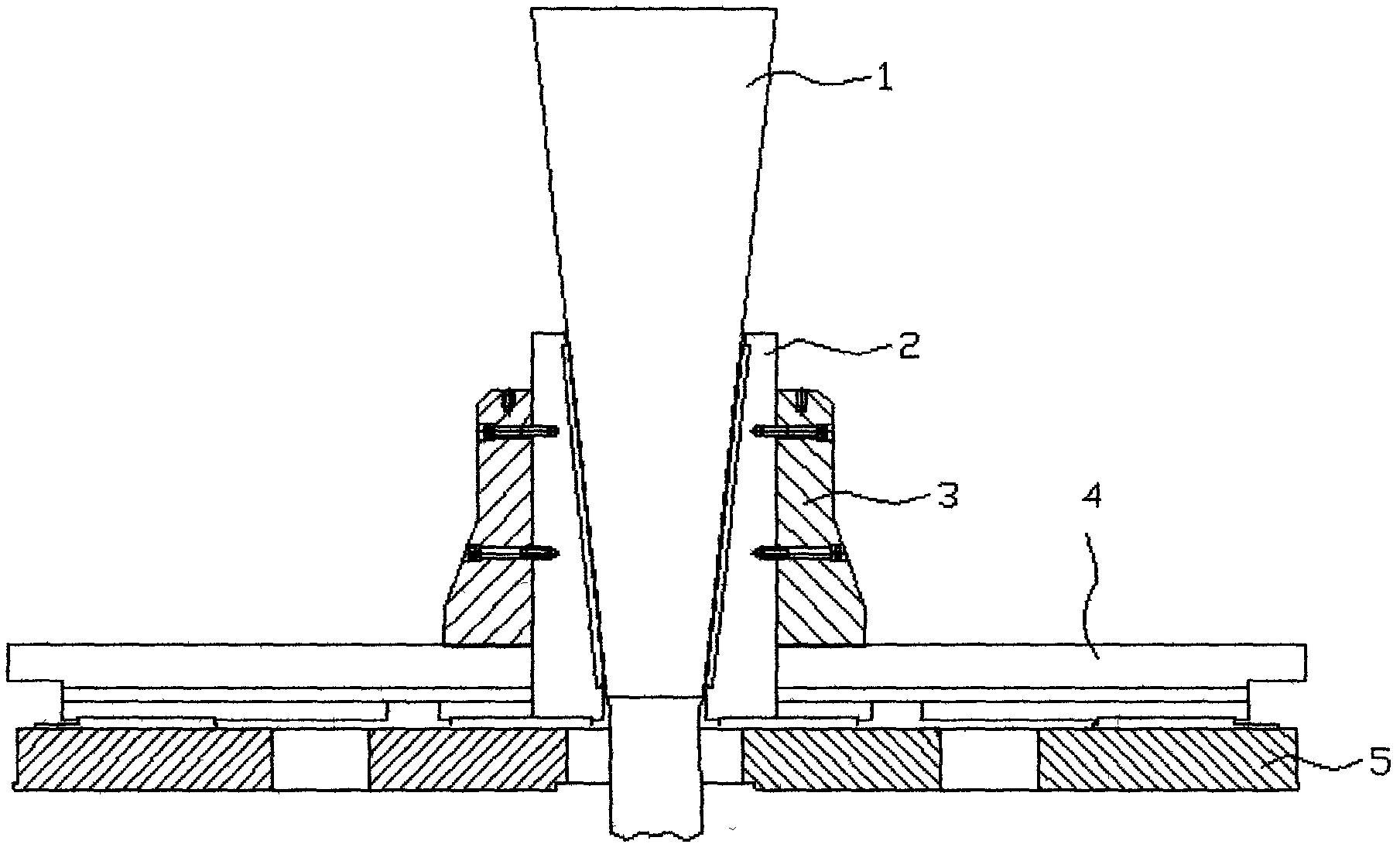

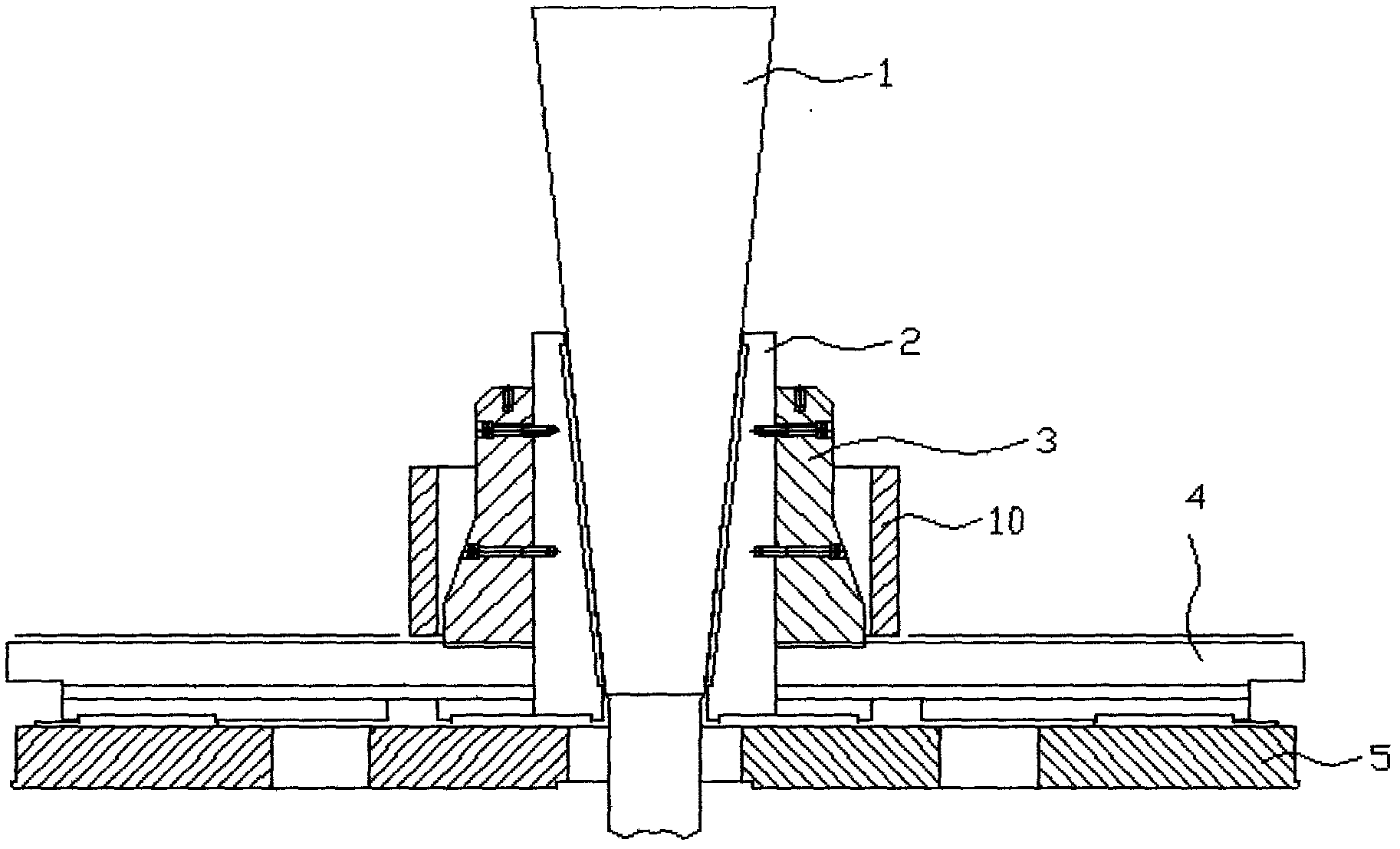

The invention relates to a straight pipe end clamping device of a pipe expanding machine. The clamping device comprises a clamping jaw mounting plate and a clamping sleeve mounting plate, wherein the clamping jaw mounting plate and the clamping sleeve mounting plate are arranged on a stripping seat, clamping jaws are arranged on the clamping jaw mounting plate, the back part of the largest conical surface of the head of each clamping jaw is provided with a section of cylindrical surface, the head of each clamping jaw is provided with a plurality of slots in the axial direction, a clamping sleeve is sheathed outside the clamping jaws and is arranged on the clamping sleeve mounting plate, the clamping sleeve mounting plate is driven by a driving mechanism to do vertical reciprocating movement, and then the clamping sleeve looses and closes the slots of the heads of the clamping jaws. When the heads of the clamping jaws are clamped, the inner cylindrical surface of the clamping sleeve is clamped with the sections of cylindrical surfaces of the heads of the clamping jaws, so the clamping is more reliable, the clamping process is more stable and is easier to control, and the clamping amount is controllable; and meanwhile, the position requirement is reduced when the clamping sleeve and the clamping jaws are clamped, the precision requirement on the driving mechanism of the clamping sleeve is also reduced, particularly under the condition of more clamping jaws, the original phenomenon of asynchronous clamping caused by nonuniform clamping points of each clamping jaw is avoided, and the uniformity of the clamping jaws during clamping is improved.

Owner:JDM JINGDA MASCH (NINGBO) CO LTD

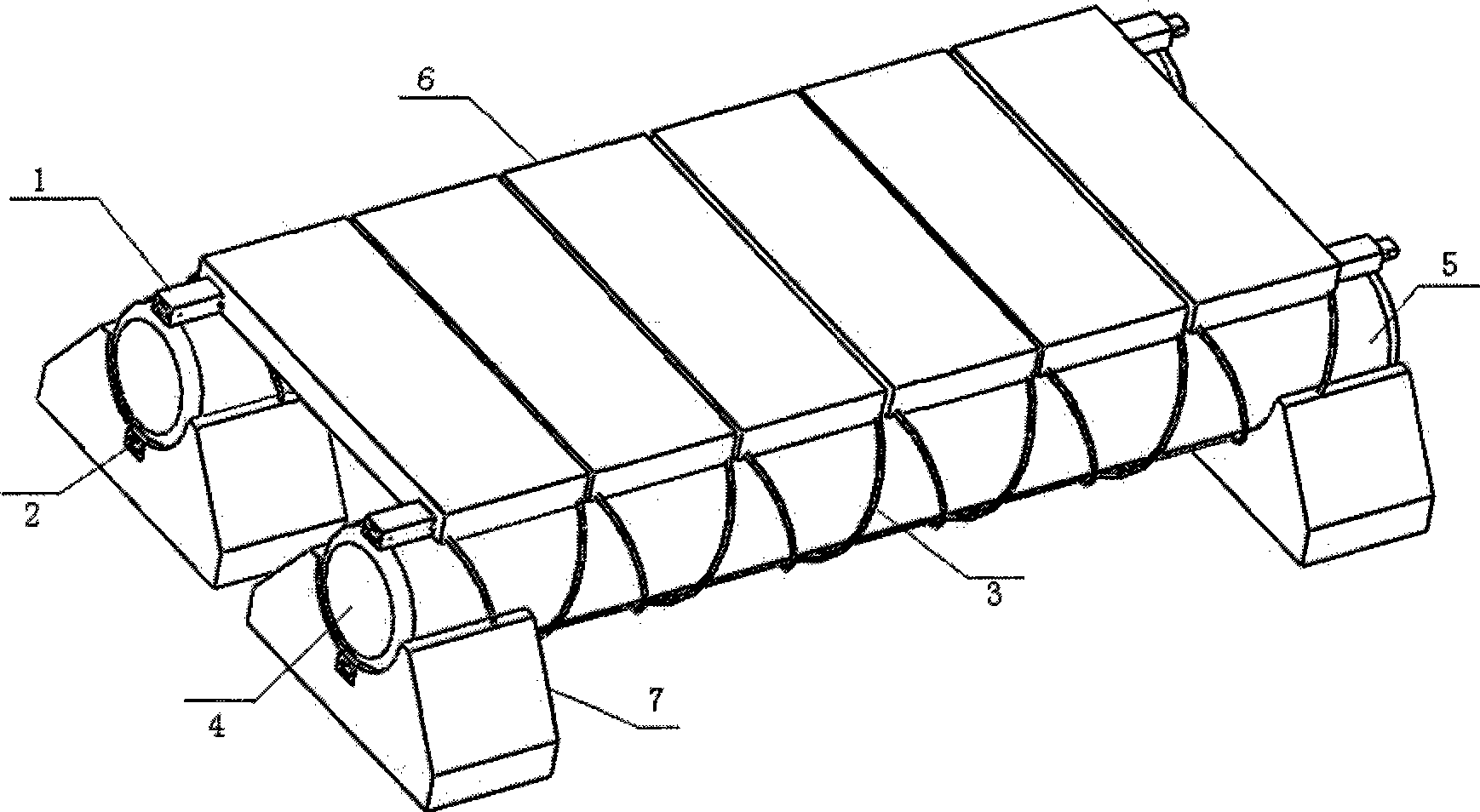

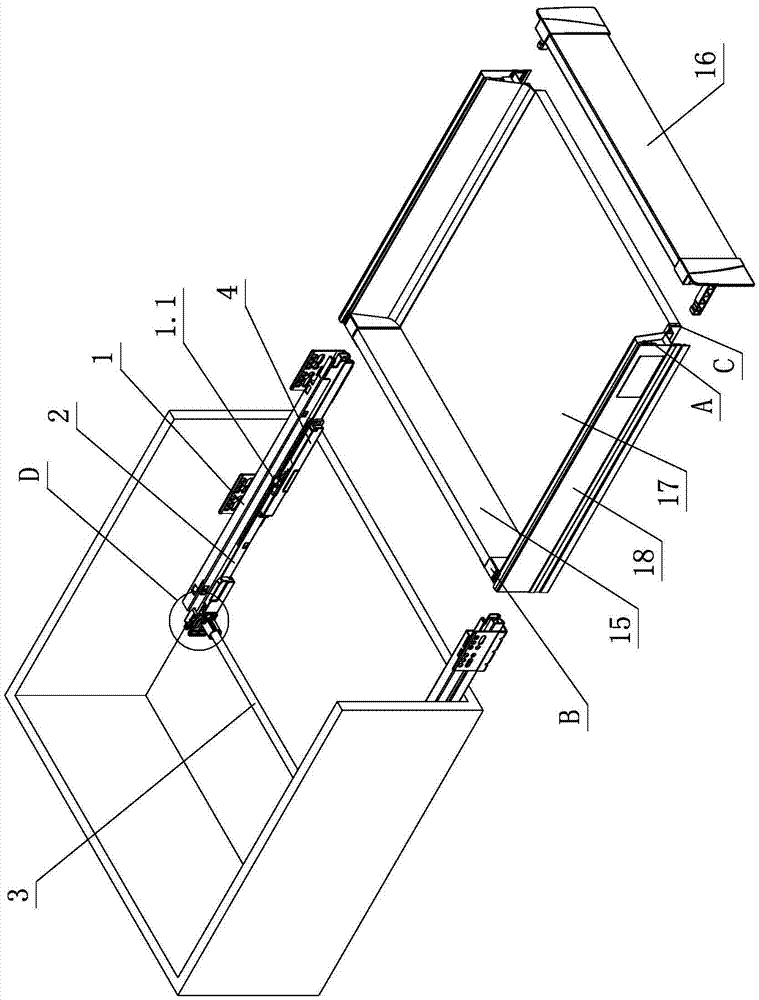

Expansion type cable-rod-film combined emergency bridge

The invention relates to a unfolding type cable-rod-film combined emergency bridge, which consists of a plurality of bridge units; each bridge unit consists of a cable-rod-film composite beam, a bridge faceplate and supports; the cable-rod-film composite beam is mounted in the groove of the supports; and the bridge faceplate is mounted on the cable-rod-film composite beam; the cable-rod-film composite beam consists of a top boom, a bottom boom, a low pressure inflated air bag and a stay cable; the top and the bottom boom are disposed on the upper and lower side of the beam; the low pressure inflated air bag is disposed in the middle of the beam; the stay cables are disposed on both sides of the beam; the bag is disposed on the bottom boom; the top boom is disposed on the bag; cross section of the top and the bottom boom and the low pressure inflated air bag is superposed with the vertical symmetrical axis; the cables are winded individually along both sides of the rod and passed through the node ring disposed on the rod side, and fixed by tightening the cables on both sides to connect the cable, the rod and the low pressure inflated air bag into one integral body. The novel emergency bridge achieves the advantages of extremely light weight, convenience for storing and carrying and rapid installation, and has high practical value and broad application prospect.

Owner:BEIHANG UNIV

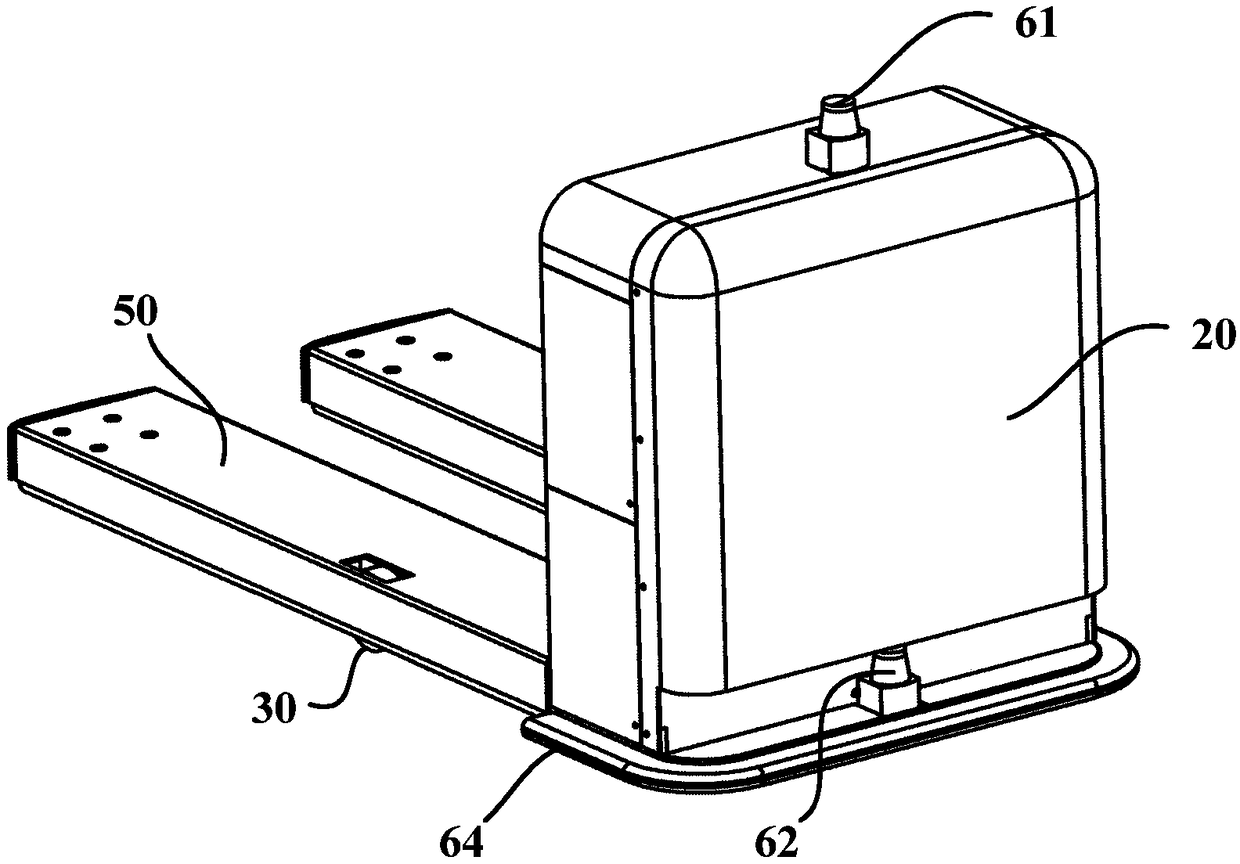

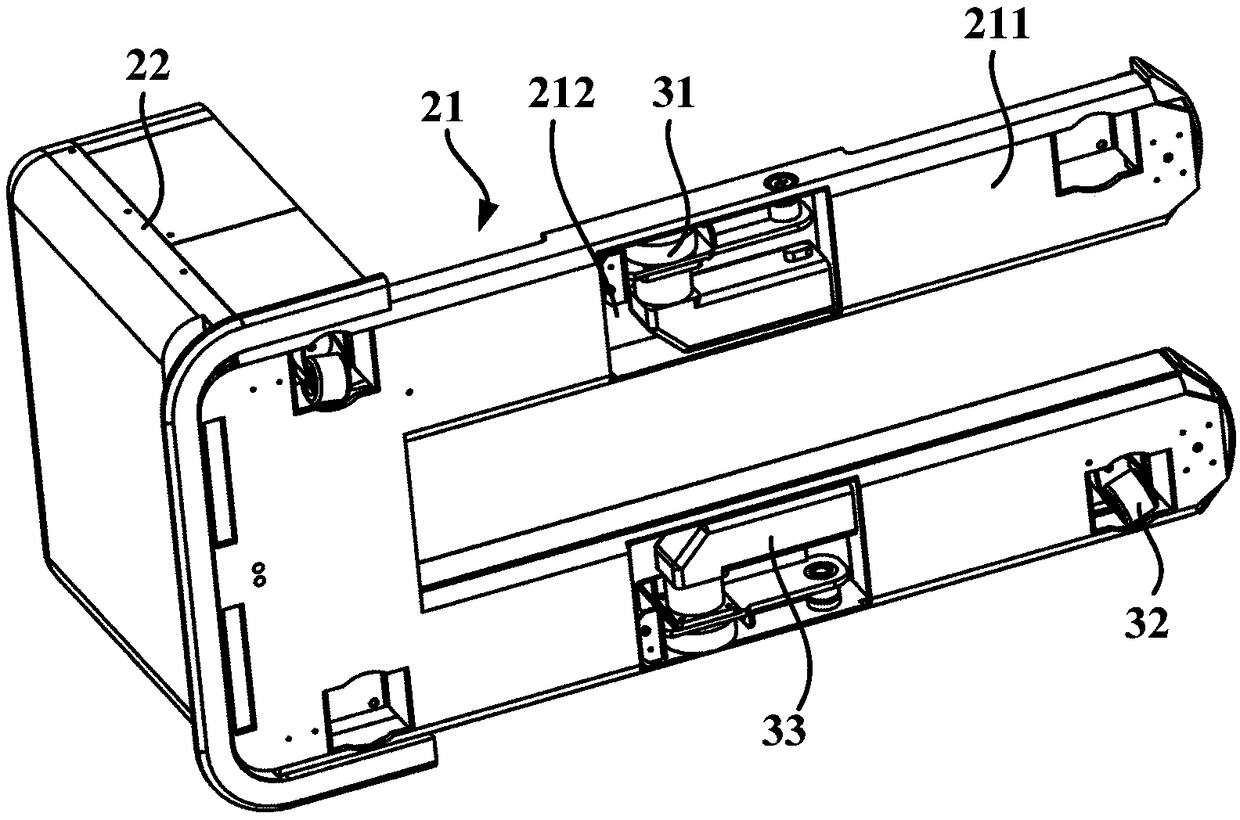

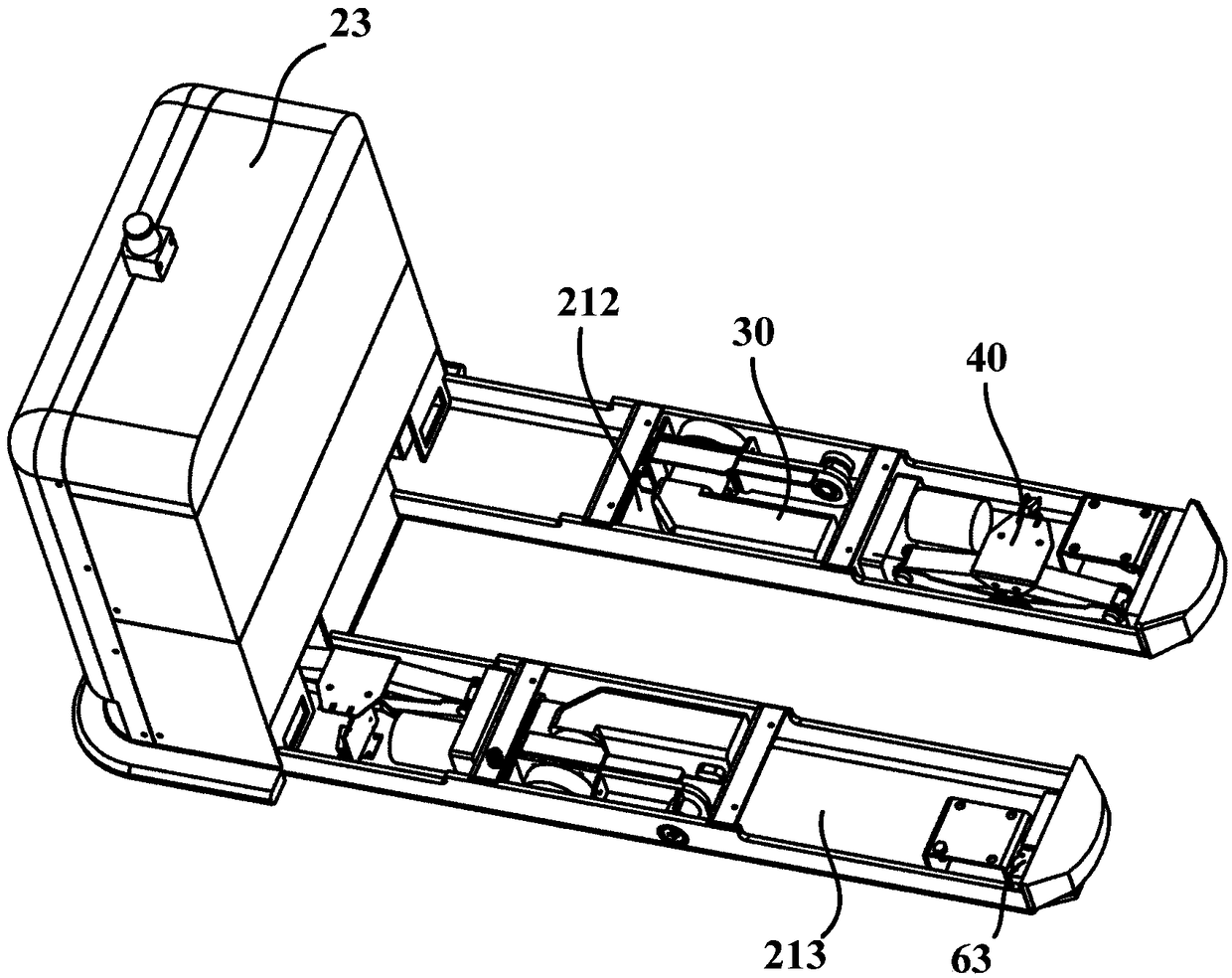

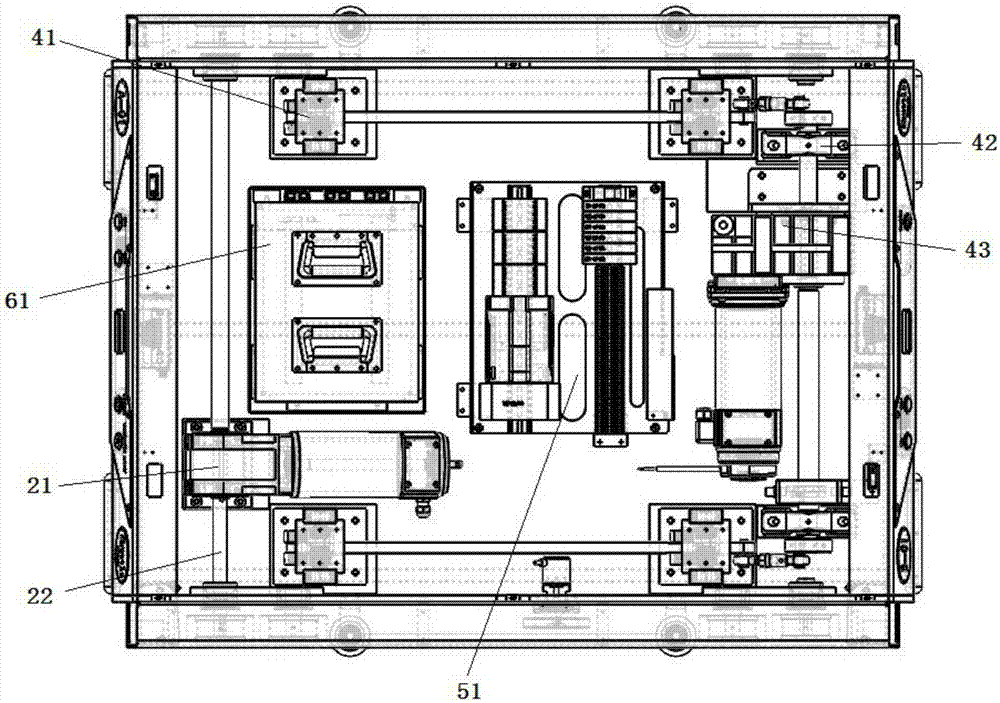

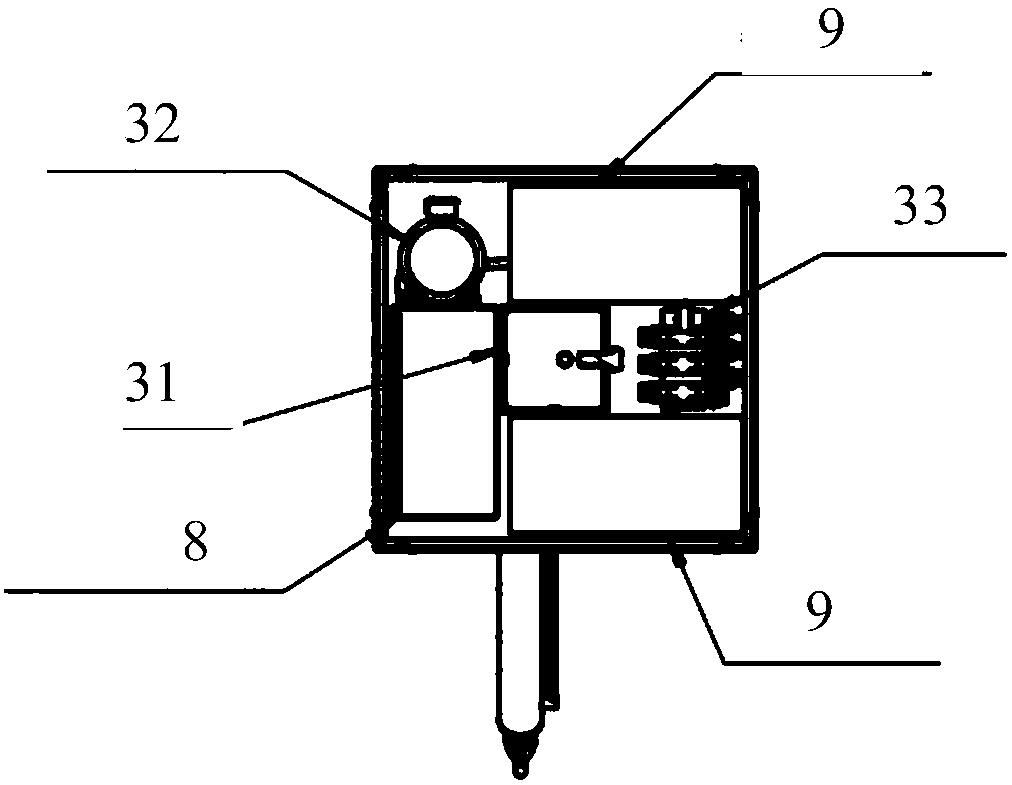

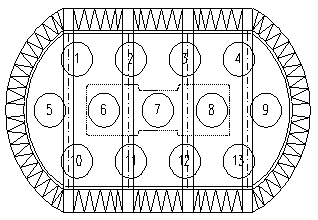

Multifunctional automatic guide transport vehicle

The invention relates to a multifunctional automatic guide transport vehicle. The multifunctional automatic guide transport vehicle comprises a vehicle body, a vehicle driving system, a multi-point jacking device, two supporting plates, a bus system and a safety guide device, wherein the vehicle body is provided with a chassis, and the chassis is provided with two fork foot base frames which are arranged in parallel; the vehicle driving system is provided with two driving wheels, a plurality of universal wheels and two first driving devices used for correspondingly driving the two driving wheels to rotate; the two driving wheels are arranged on the lower portions of the two sides of the middle of the chassis in the front-back direction correspondingly; the multi-point jacking device is provided with a plurality of lifting devices and second driving devices used for correspondingly driving the plurality of lifting devices to perform lifting motion; each supporting plate is provided withat least two lifting devices; the bus system synchronously controls the plurality of second driving devices; and the safety guide device is provided with a solid state laser radar, a laser obstacle avoidance sensor, a contact type sensor, a mechanical anti-collision strip arranged in the vehicle body, a sound-light alarm and an emergency stop button. According to the multifunctional automatic guide transport vehicle, the height of a cargo fork can be reduced to the largest extent, and turning can be realized at the minimum radius.

Owner:ZHEJIANG FIELD INTELLIGENT EQUIP CO LTD

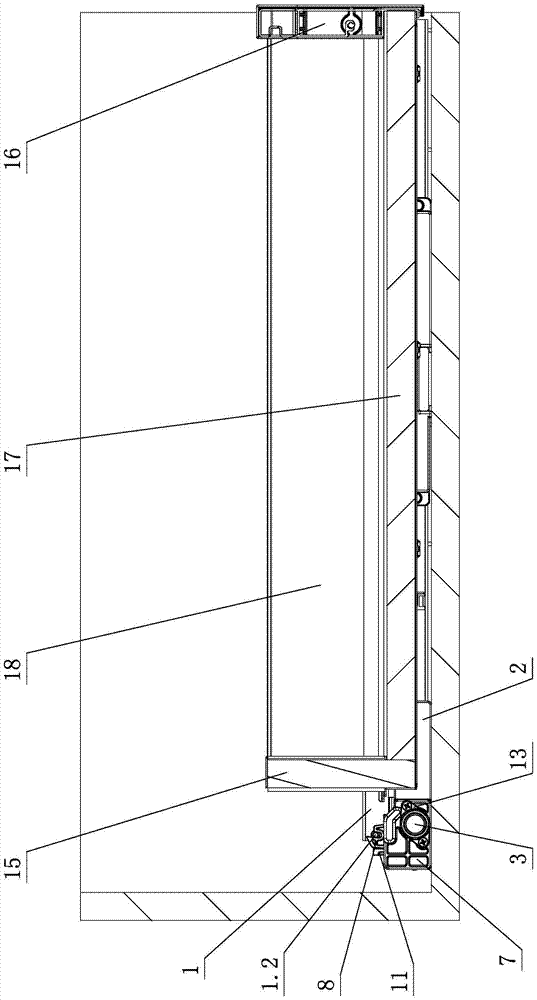

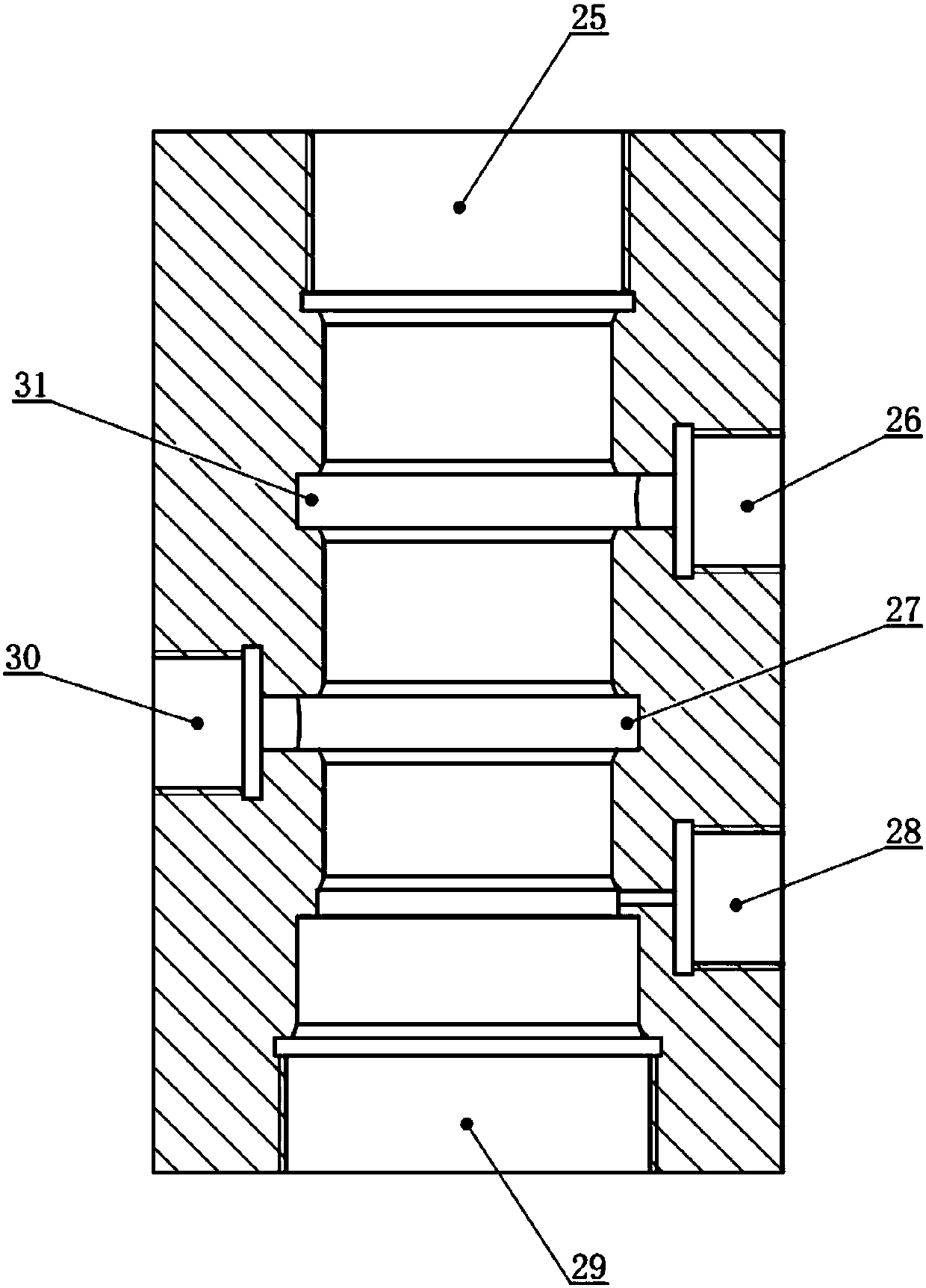

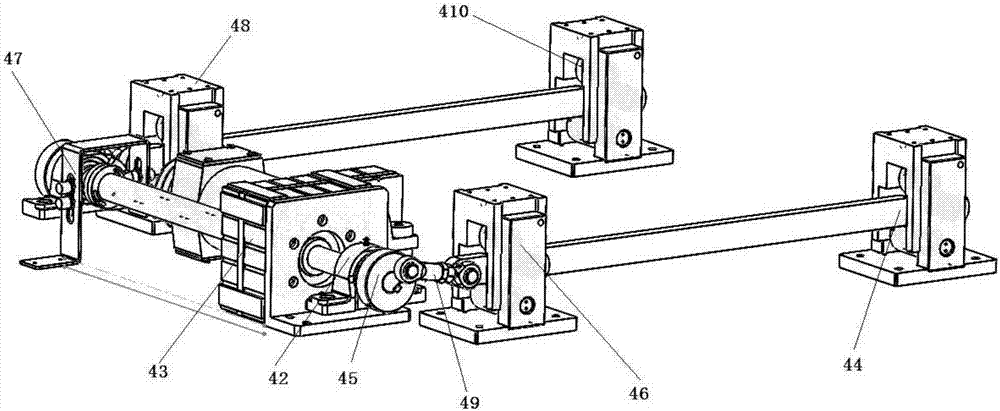

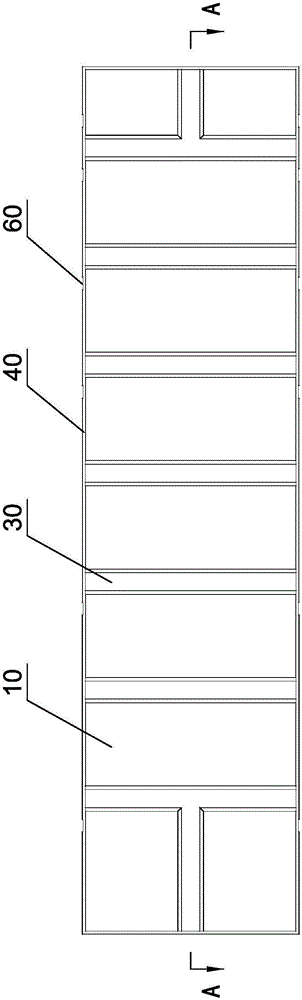

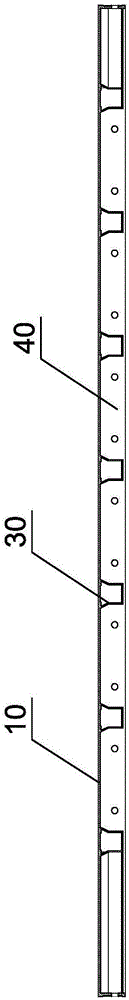

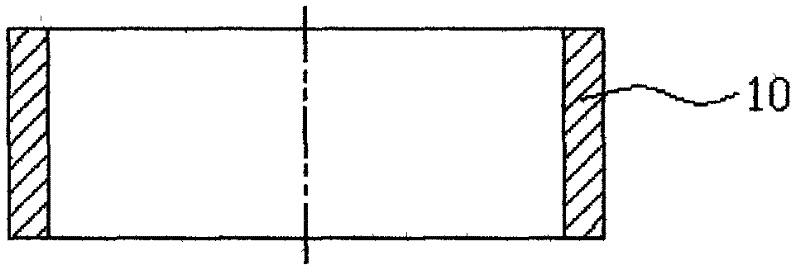

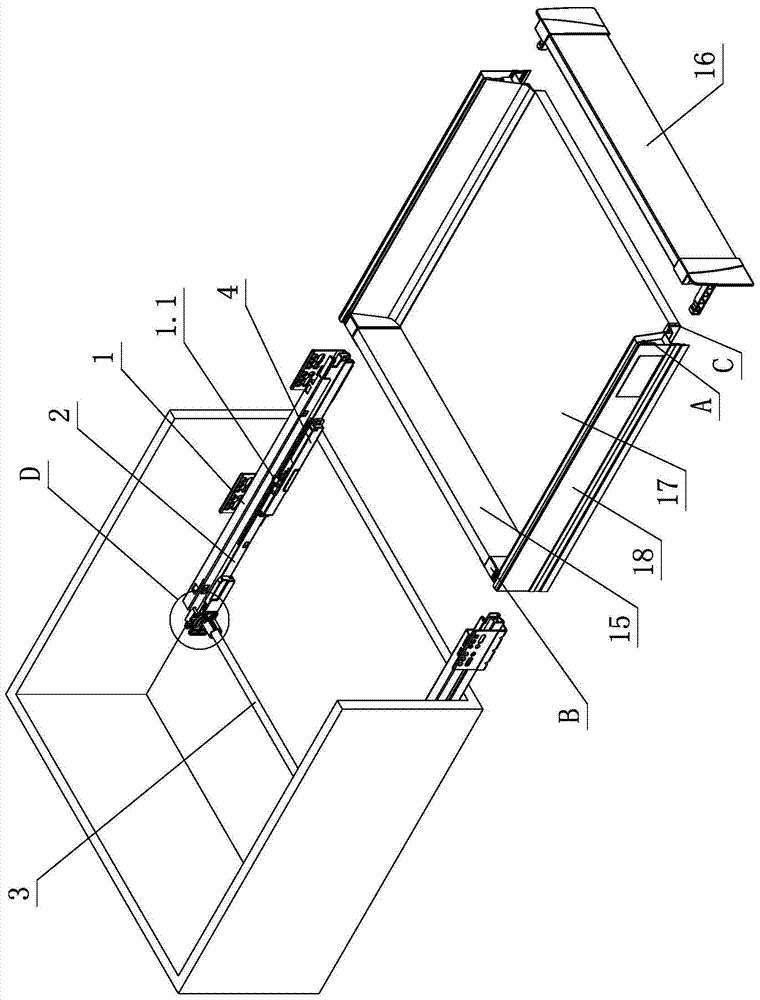

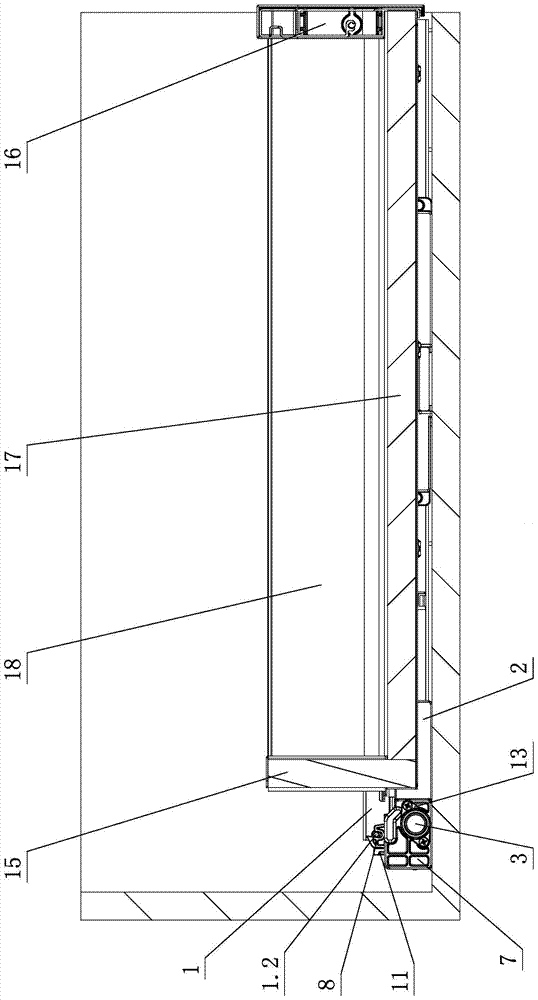

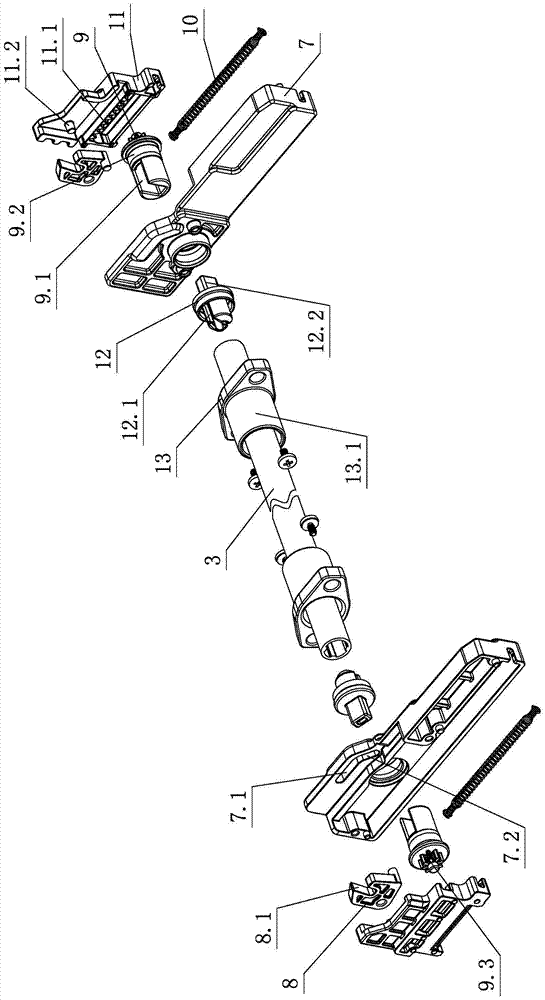

Synchronous deflection stabilizing mechanism of drawer slide rail

ActiveCN105433618AEasy to maintainImprove interior space and load capacityDrawersSurface plateClosed state

The invention provides a synchronous deflection stabilizing mechanism of a drawer slide rail. The synchronous deflection stabilizing mechanism comprises two sets of slide rail components arranged on left and right cabinet side boards, a drawer is arranged on the slide rail components and at least comprises a rear back plate and a front panel, the slide rail components comprise movable slide rails and fixed slide rails, the left and right movable or fixed slide rails are provided with pressing rebounding devices, the drawer is automatically opened at least in a closed state through the pressing rebounding devices, the inner sides of the left and right movable or fixed slide rails are provided with synchronous deflection devices, a synchronous rod is arranged between the left synchronous deflection device and the right synchronous deflection device which are in transmission connection with each other through the synchronous rod, the synchronous rod is arranged behind the rear back plate and the length of the synchronous rod is less than the width between the left and right movable or fixed slide rails; the left and right movable or fixed slide rails are provided with rebounding stirring parts and synchronous stirring parts at intervals, and the left and right movable slide rails are synchronously and / or simultaneously opened automatically, relative to the left and right fixed slide rails by respectively acting on the pressing rebounding devices and synchronous deflection devices through the rebounding stirring parts and the synchronous stirring parts at least in the closed state of the drawer.

Owner:伍志勇

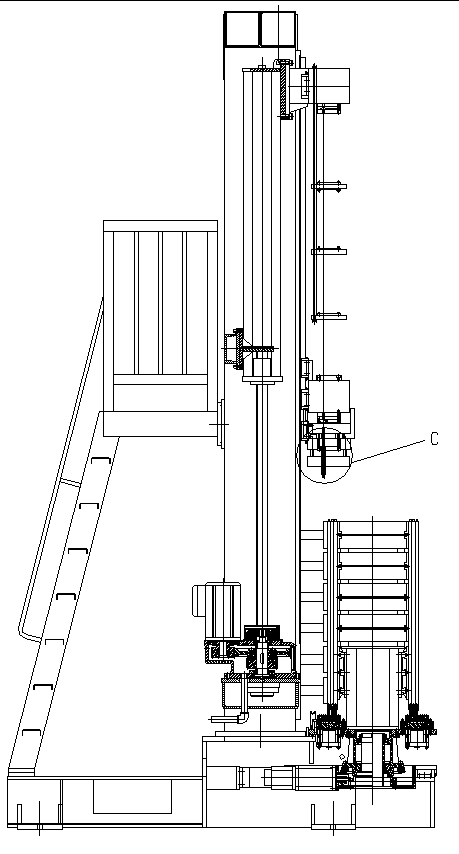

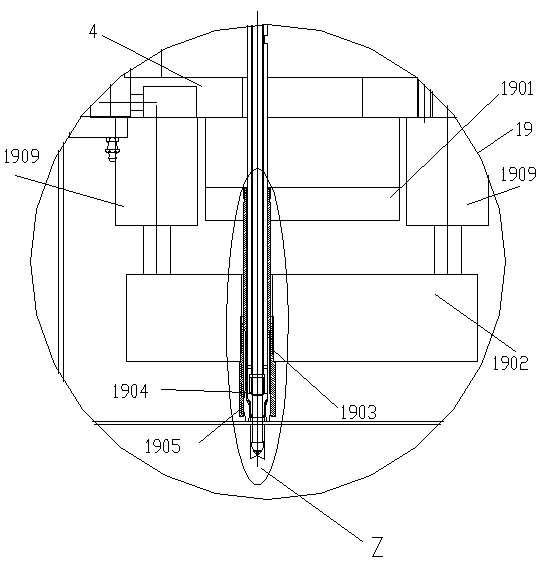

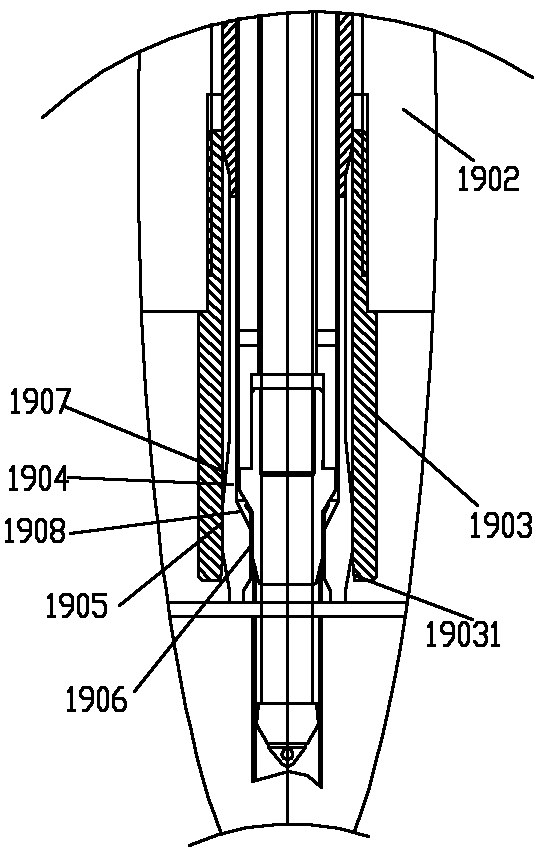

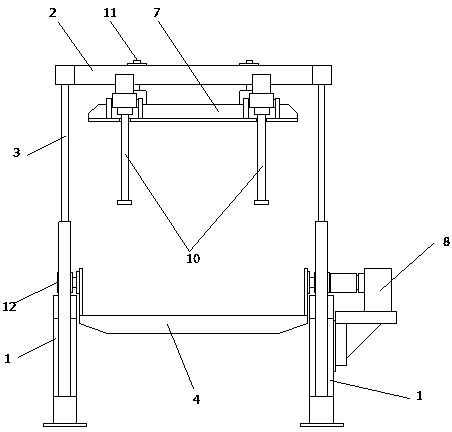

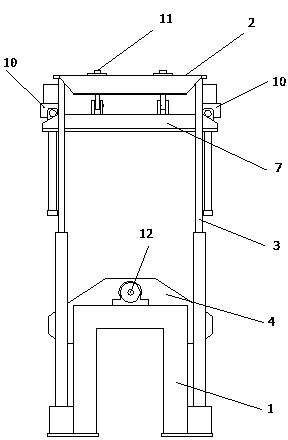

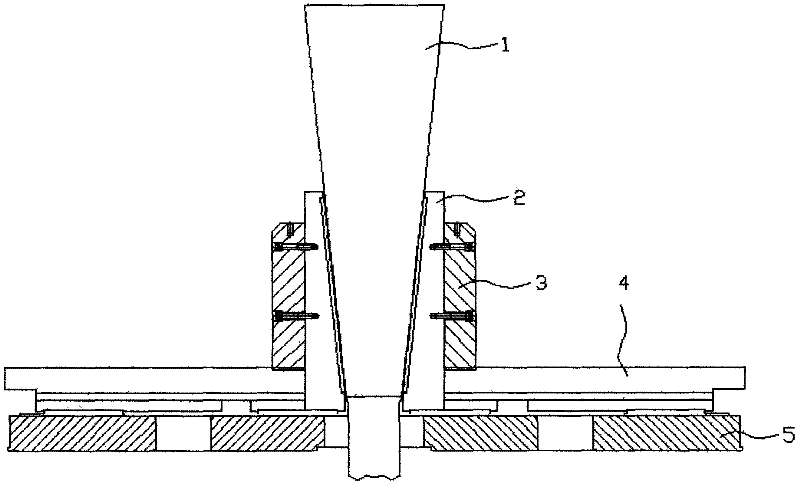

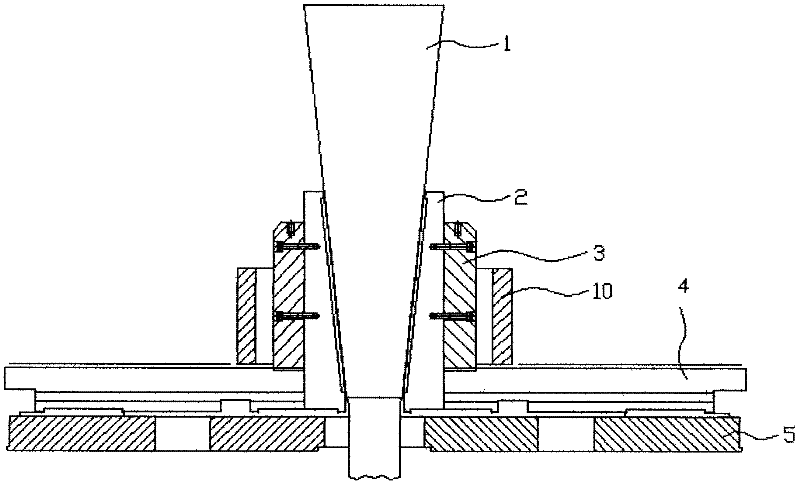

Individual type high-pressure grouting forming machine

InactiveCN103831887AReduce difficultyVariable groutingAuxillary shaping apparatusMolding machineEngineering

The invention relates to a grouting forming device in ceramic production, in particular to an individual type high-pressure grouting forming machine. The individual type high-pressure grouting forming machine comprises a support, a transverse beam frame, a base and an upper die frame, wherein the support is provided with a vertical guide column, and the transverse beam frame is driven by a lifting device to conduct vertical movement on the support by being guided by the guide column; the upper die frame is arranged on the transverse beam frame through a pothook; the base is arranged on the support through a turning bearing, and the base can turn on the support by being driven by a turning power device; the upper die frame and the base are provided with a clamping device, an upper mould is arranged in the upper die frame when a lower mould is placed in the base, the upper die frame moves downwards along the guide column along with the transverse beam frame and is combined to the base, and the upper die frame and the base are clamped by the clamping device to form a whole. The individual type high-pressure grouting forming device can be suitable for a plurality of types of products, blank releasing and taking are automated, and dangerous and high-strength manual work is replaced.

Owner:唐山森兰瓷科技有限公司

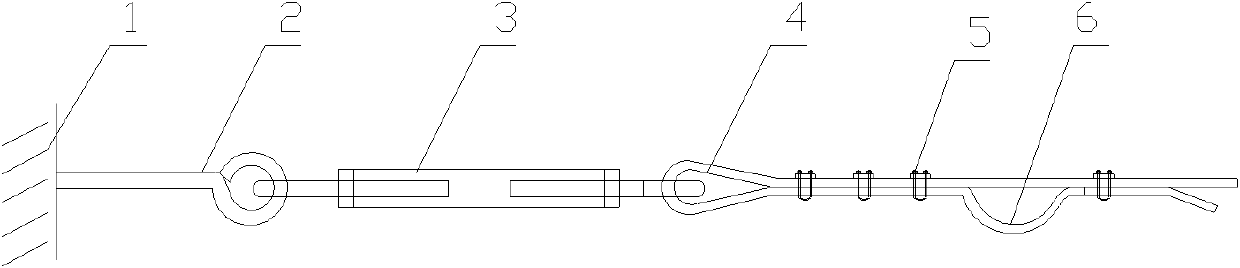

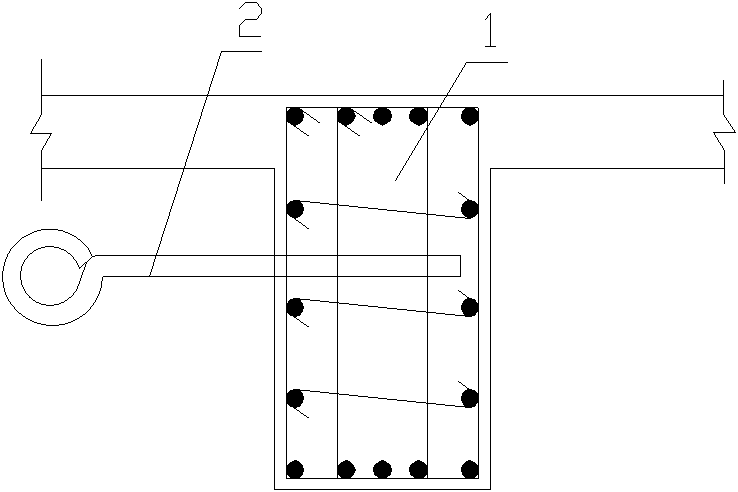

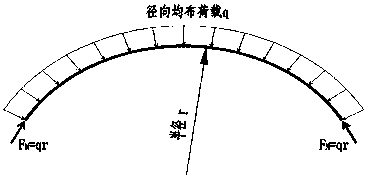

Flexible construction platform of suspension cable

ActiveCN102168483ALess consumablesShort build-up and disassembly cycleScaffold accessoriesBuilding support scaffoldsMaterial consumptionFloor slab

The invention discloses a flexible construction platform of a suspension cable, which comprises a transverse cable and a longitudinal cable arranged parallel to a horizontal plane, wherein the transverse cable and the longitudinal cable are vertically arranged in a net-shaped structure in a crossed way; two ends of the transverse cable and the longitudinal cable are fixed on a cross beam by anchor bolts; and a working surface is paved on the net-shaped structure. Front ends of the transverse cable and the longitudinal cable are in heart-shaped ring structures; and the heart-shaped rings are connected with the anchor bolts by using flower basket bolts. In the invention, a plane form obtained from transverse and longitudinal intersection of flexible steel wire ropes is selected; two ends ofthe transverse cable are fixed on a body structure girder by anchor devices; all loads on the platform are directly transmitted to the girder; and thus, the longitudinal cable is fixed on the girder or a shear wall. Adjustable devices (flower basket bolts) are arranged on cable ends to facilitate the adjustments of deflections of the cables. Therefore, the flexible construction platform of the suspension cable, disclosed by the invention, has the advantages of no limitation from floor slab load, less material consumption, short building and disassembling period, large span, light deadweight, uniform and reasonable stress and transmission, convenience for mounting and demounting and economic rationality.

Owner:浙江南湖建设有限公司

Thermal bulging process for special-shaped high-temperature-alloy rolled ring workpieces

The invention discloses a thermal bulging process for special-shaped high-temperature-alloy rolled ring workpieces, which includes steps of primary bulging; primary rotation; secondary rotation; secondary bulging and tertiary bulging. In the primary bulging, a special-shaped high-temperature-alloy rolled ring workpiece which is treated by thermal rolling is sleeved on the periphery of a preheated bulging block in a bulging machine, and the bulging block squeezes the ring workpiece axially along the inner circumference of the rolled ring workpiece after the bulging machine is started so that the primary bulging is completed, wherein the bulging temperature ranges from 820 DEG C to 860 DEG C, the bulging time ranges from 20s to 30s, the pressure holding time ranges from 10s to 11s, and the deflection ranges from 0.7% to 0.9%. The primary rotation is completed by rotating the rolled ring workpiece along the center axis by 45 degrees. The secondary bulging is completed by processes of the primary bulging, wherein the bulging temperature ranges from 790 DEG C to 830 DEG C, the bulging time ranges from 20s to 30s, the pressure holding time ranges from 16s to 18s, and the deflection ranges from 0.8% to 1 %. The second rotation is completed by rotating the ring workpiece again along the direction the same with that of the primary rotation. The tertiary bulging is completed by the processes of the primary bulging again, wherein the bulging temperature ranges from 760 DEG C to 800 DEG C, the bulging time ranges from 30s to 40s, the pressure holding time ranges from 25s to 28s, and the deflection ranges from 0.9% to 1.1%. The dimensional precision of the rolled ring workpiece can be 1%. to 2%. of the corresponding precision after the rolled ring workpiece is bulged, and the rolled ring workpiece is mainly used for the fields of space navigation and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

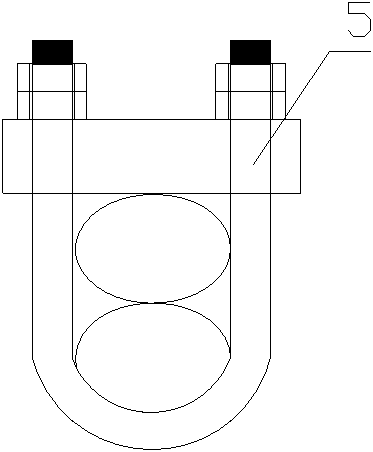

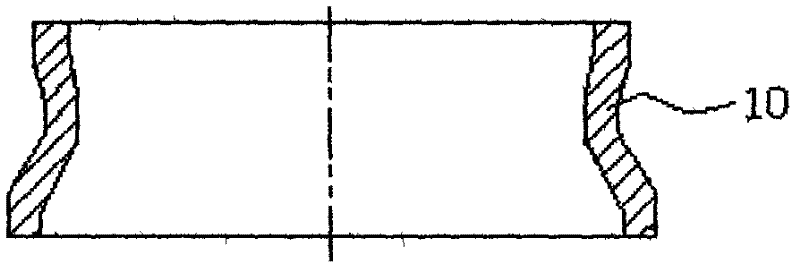

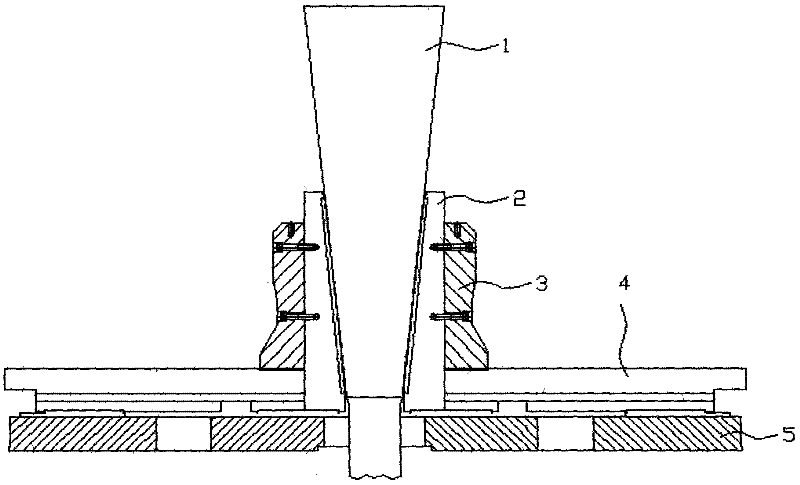

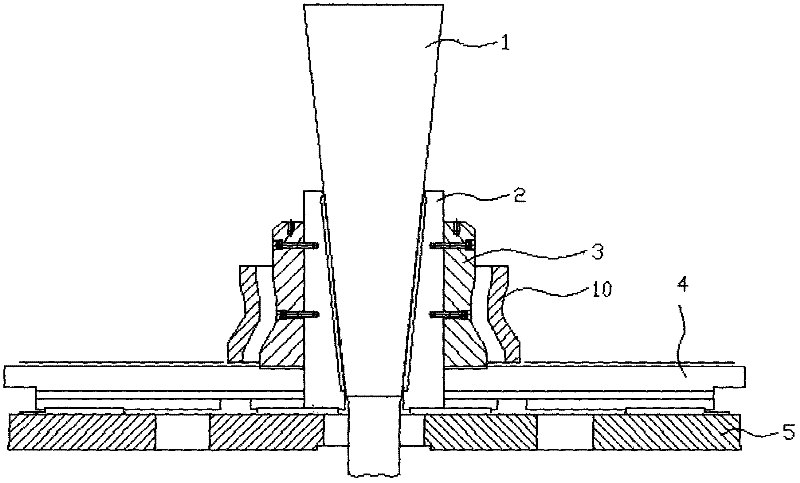

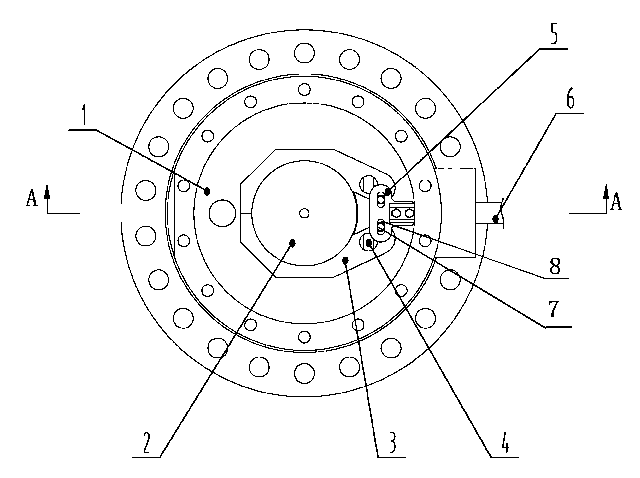

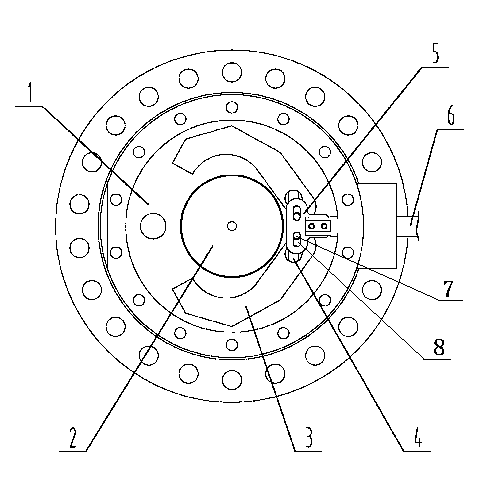

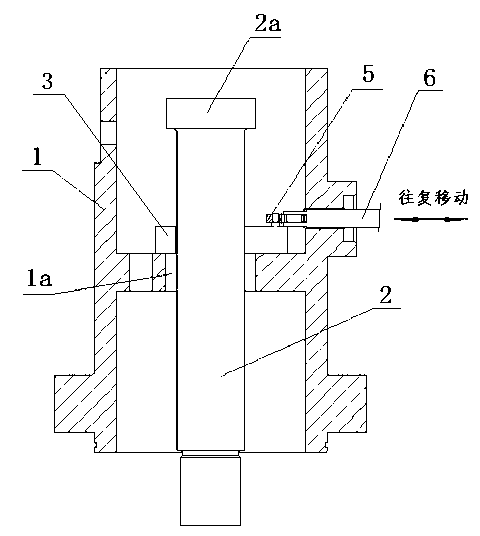

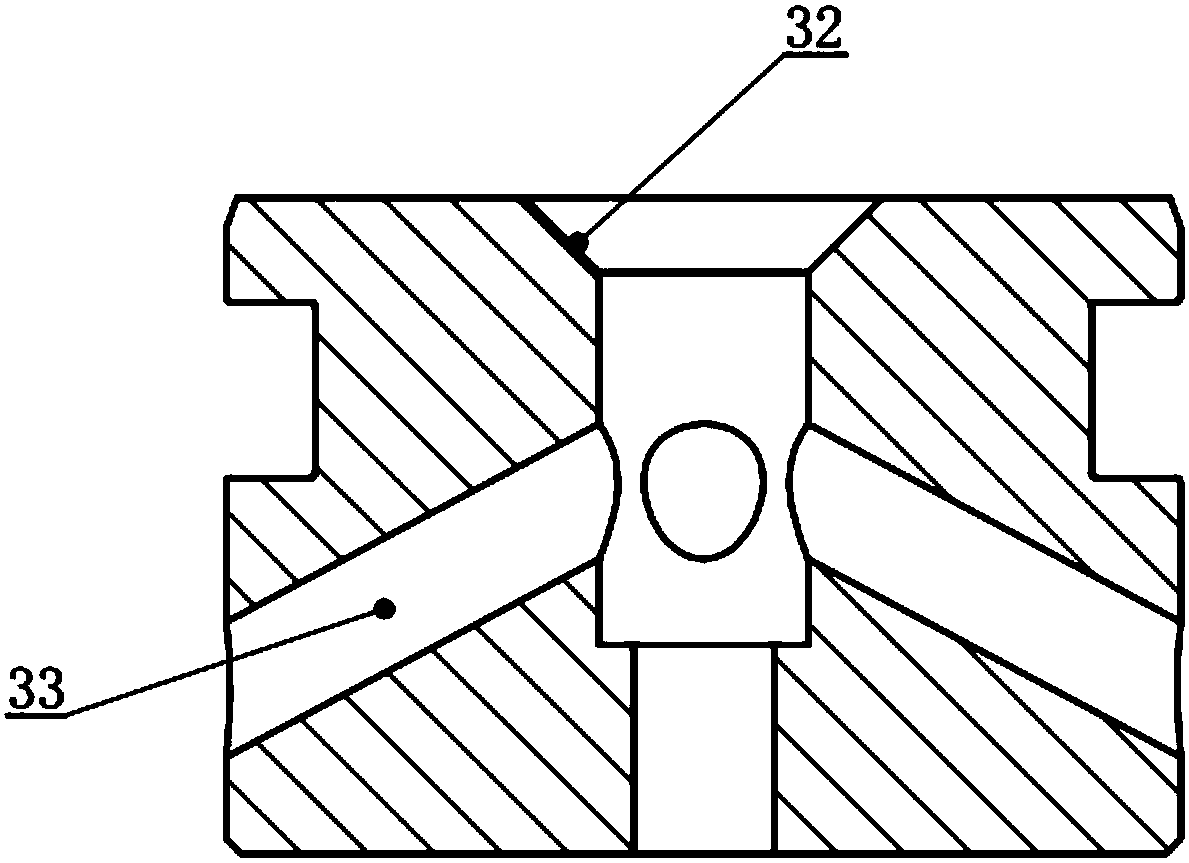

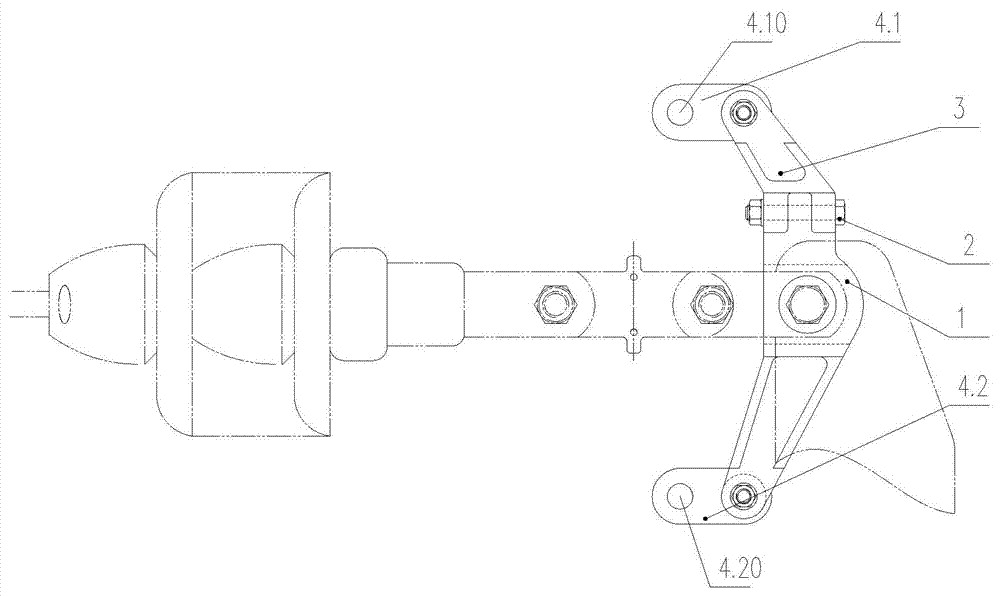

Oil cylinder locking device

ActiveCN102840191AOptionalUniform and reasonable forceFluid-pressure actuatorsEngineeringMechanical engineering

The invention discloses an oil cylinder locking device. In order to realize the safe and fast locking goal of an oil cylinder of a gate hydraulic hoist, the oil cylinder locking device comprises a locking seat, a locking post and a locking claw, wherein the locking seat is connected with a cylinder body, the locking post is arranged in the locking seat and is connected with a piston rod, the locking claw is arranged between the locking post and the locking seat and can limit the downward movement of the locking post, the locking claw is driven by a servo device to be locked or released, when the locking claw is released, the locking post can freely and vertically move relative to the locking seat, and when the locking claw is locked, a locking post head positioned at the upper part of the locking post is placed on the locking claw. The oil cylinder locking device has the advantages that the stress along main stress coupling elements (the locking post and the locking claw) is uniform and reasonable, a servo mechanism is compact, the servo stroke is short, the servo motive power source selectivity is high, and the locking problem of the oil cylinder of the Liyang tail water accident gate hydraulic hoist is solved.

Owner:POWERCHINA ZHONGNAN ENG

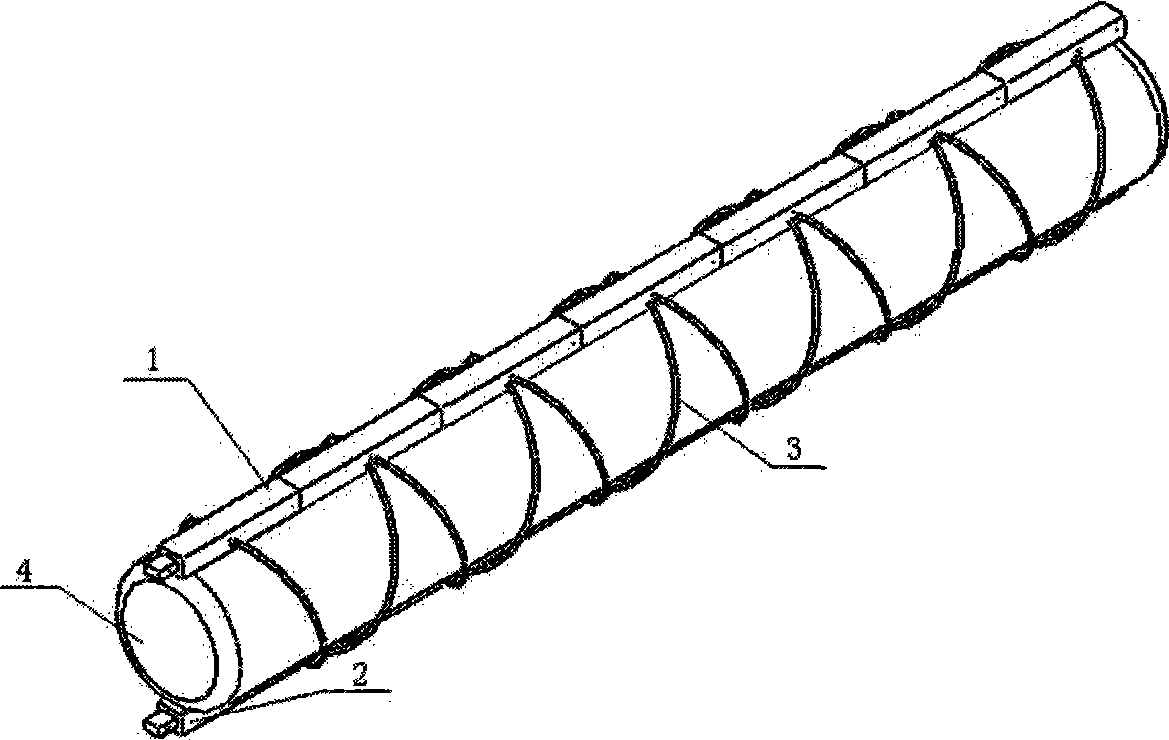

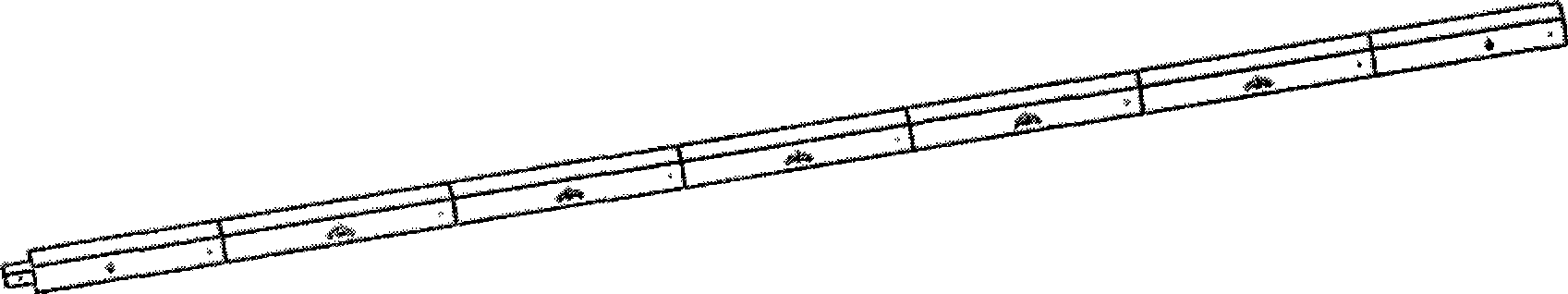

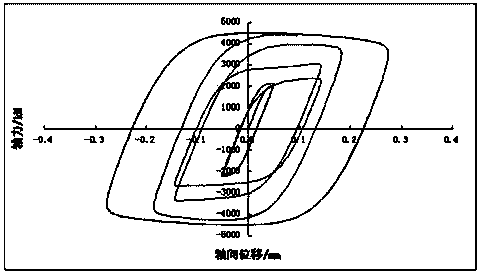

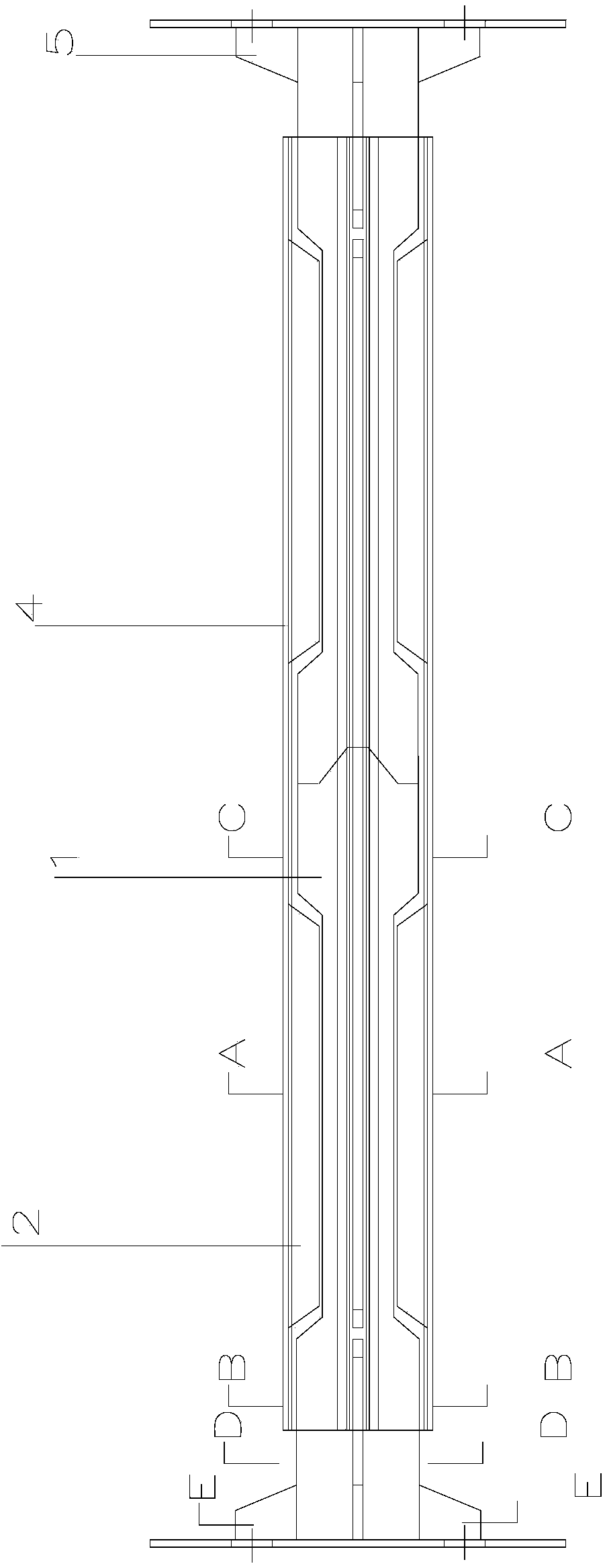

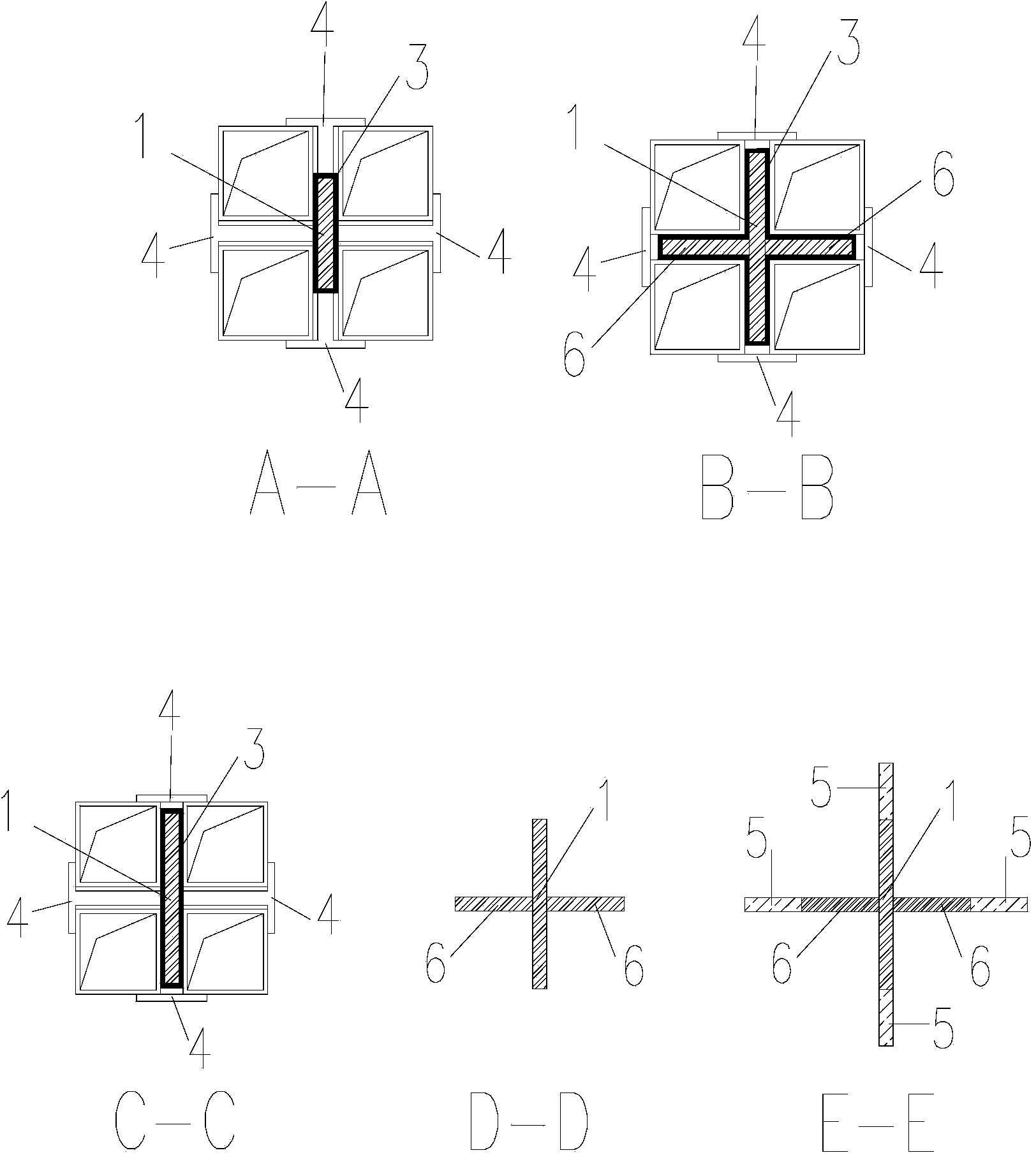

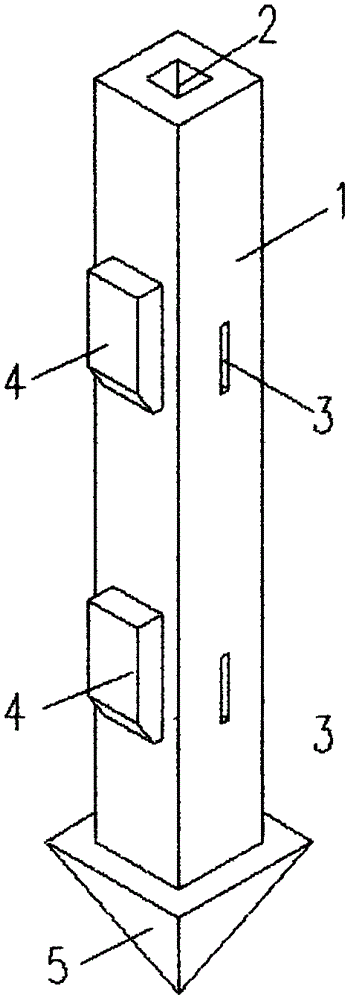

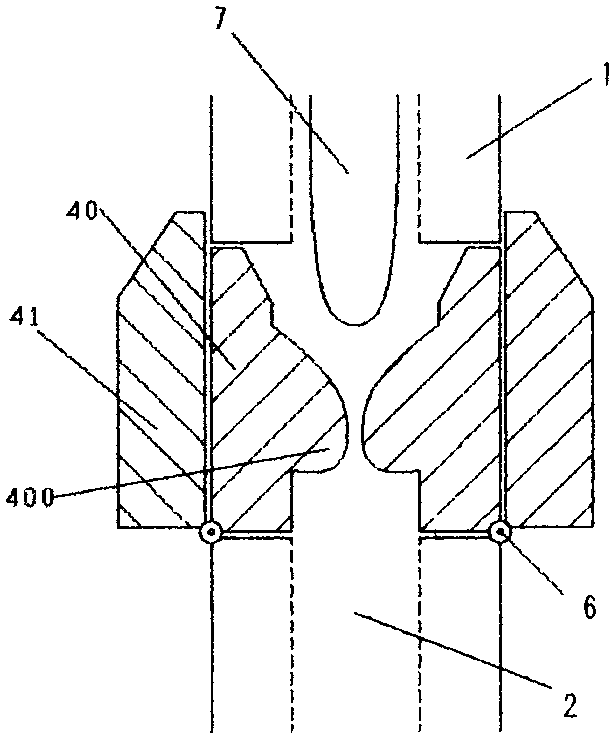

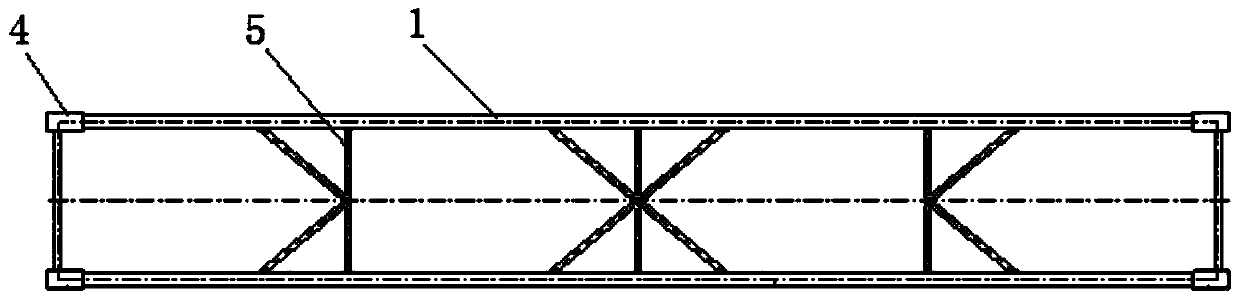

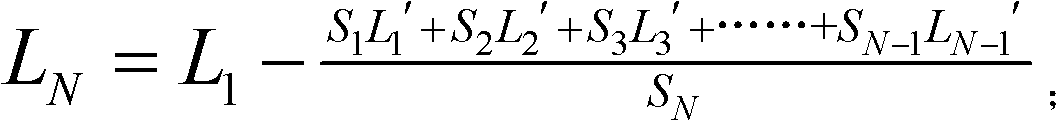

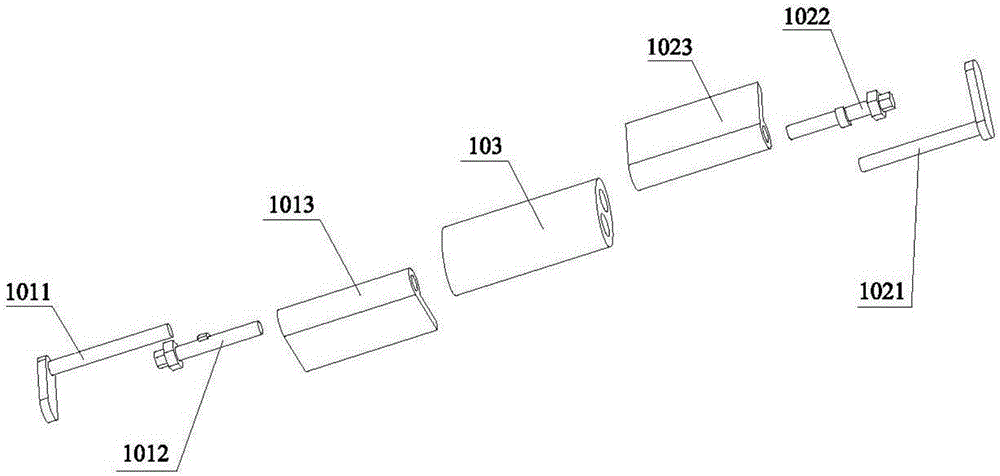

All-steel four-steel pipe multistage mountable overlong buckling-restrained brace

The invention discloses an all-steel four-steel pipe multistage mountable overlong buckling-restrained brace, and belongs to a novel energy dissipation and seismic mitigation component. On the basis of the traditional buckling-restrained brace, the steel core and the outer restraining component are manufactured and transported in stages and mounted at the construction site. By using the peripheral restraining mechanisms of four hollow steel pipes, the weight of the overlong buckling-restrained brace is effectively reduced so as to solve the difficulties that the general buckling-restrained braces are overlong to cause overlarge self-weight and the initial deflection cannot satisfy the existing requirements. The working section of the steel core is changed from one section to a plurality of sections, so that the stress of the steel core is more uniform and reasonable; the sections are connected to ensure that the length can be up to 30-50 meters; the all-steel four-steel pipe multistage mountable overlong buckling-restrained brace can be applied to the air cooling platform and special structures such as the large-scale industrial buildings and the like to improve the functionality of the buildings through increasing the structural rigidity, and can also be used for protecting the main structure under the design intensity, severe intensity and super-large earthquakes through self-buckling energy consumption.

Owner:BEIJING UNIV OF TECH

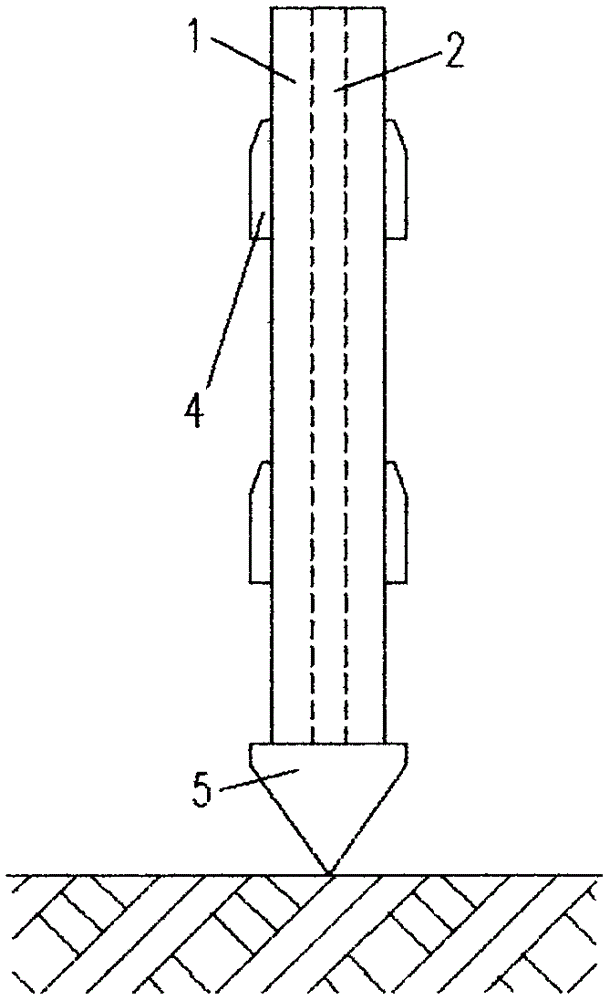

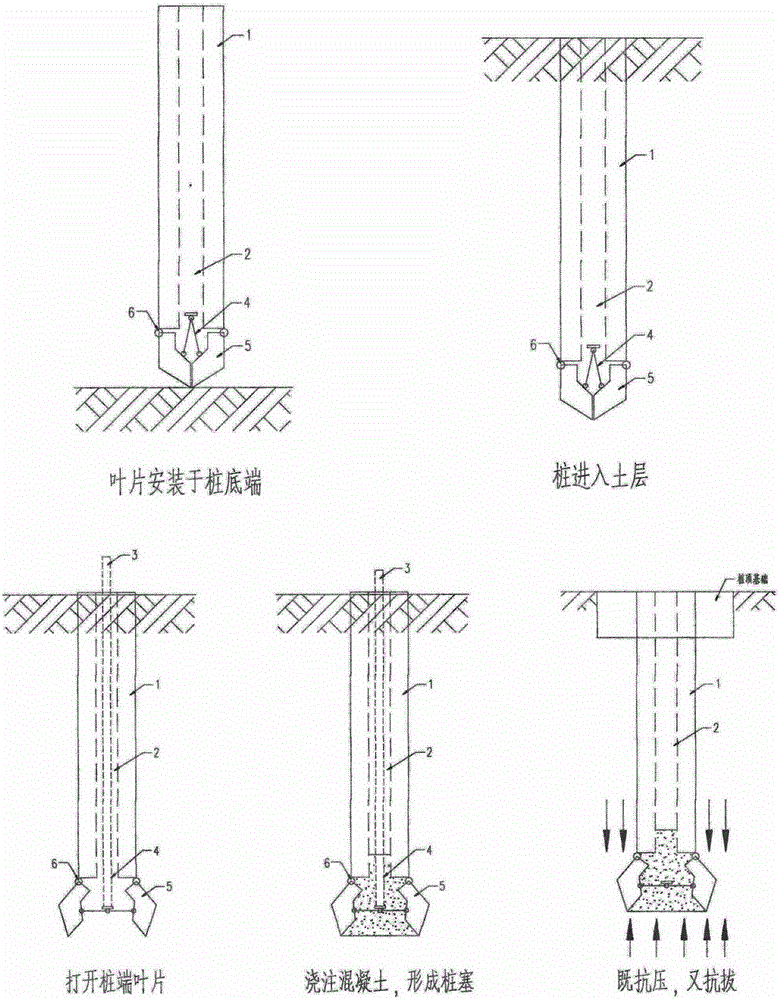

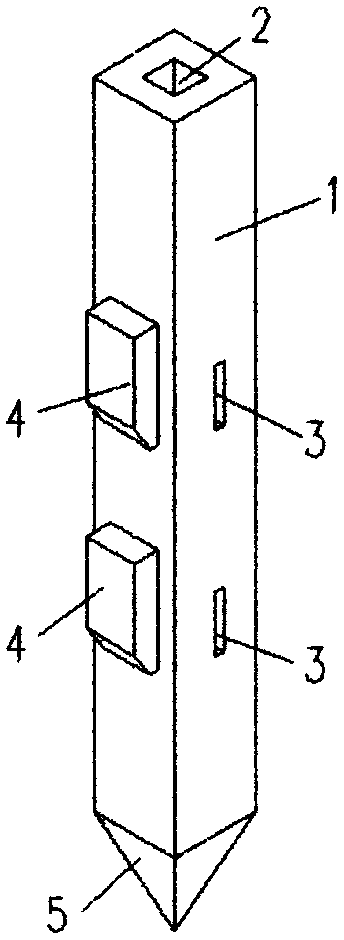

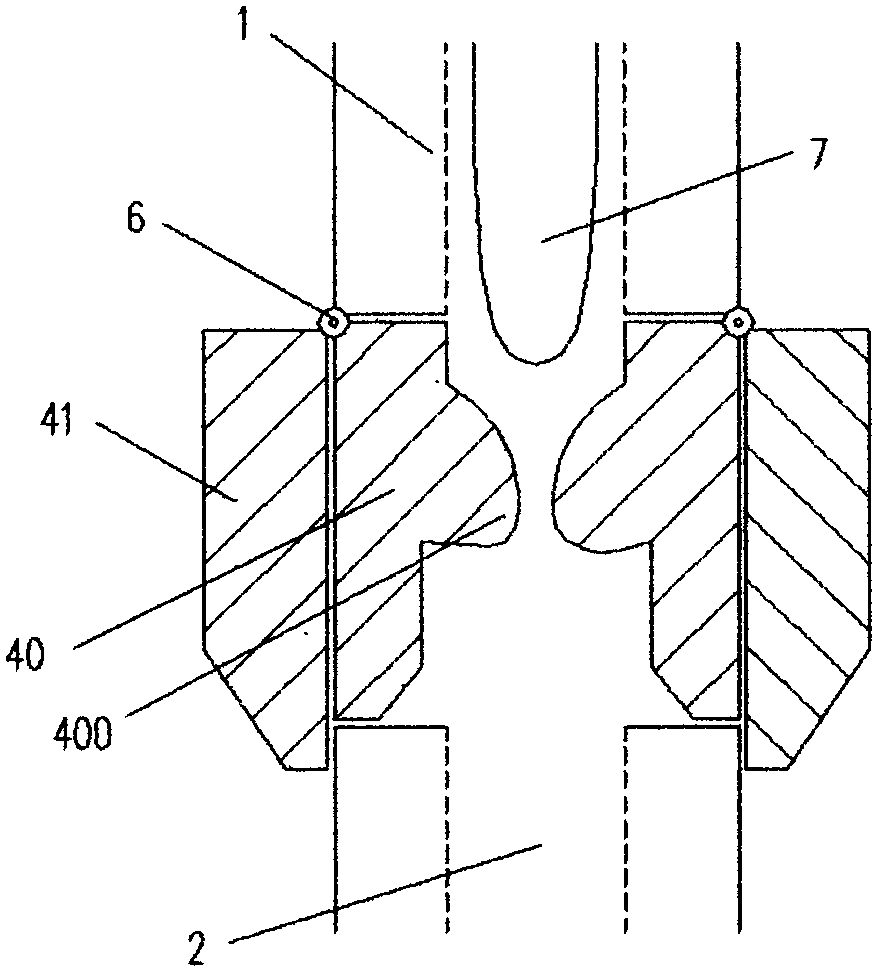

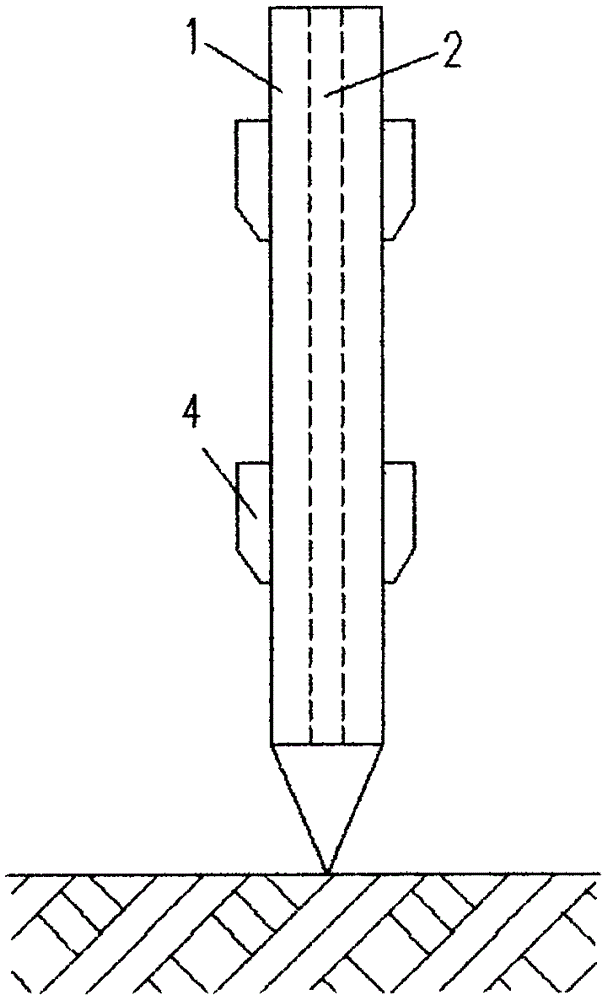

Uplift pile with unfolding barb and construction method thereof

InactiveCN105544525AImprove project qualityImprove securityBulkheads/pilesEngineeringBearing capacity

The invention discloses an uplift pile with an unfolding barb and a construction method thereof. The uplift pile comprises a precast tubular pile. The precast tubular pile comprises a maternal pile and a pile tip, wherein a pile body of the maternal pile extends from a pile tail to a cavity of the pile tip, one or more layers of vane pushing-away holes communicating with the cavity are formed in the pile wall of the maternal pile in the length direction of the pile body, the lower edges of the side, far away from the cavity, of the vane pushing-away holes are provided with vanes through rotary devices, the vanes can rotate away from the cavity around the rotary devices, and the cavity is provided with a force application part used for pushing the vanes away from the vane pushing-away holes. The construction method with the uplift pile with the unfolding barb is shown in the specification. Compared with a traditional precast pile, the unfolding vanes attached to the pile body work together with a soil body, so that the anti-floating design capacity of the uplift pile is greatly improved, the bearing capacity of the pile is improved by several times or even dozens of times, the number of piles and the length of the pile are greatly reduced, and the comprehensive benefits are quite remarkable.

Owner:陈明

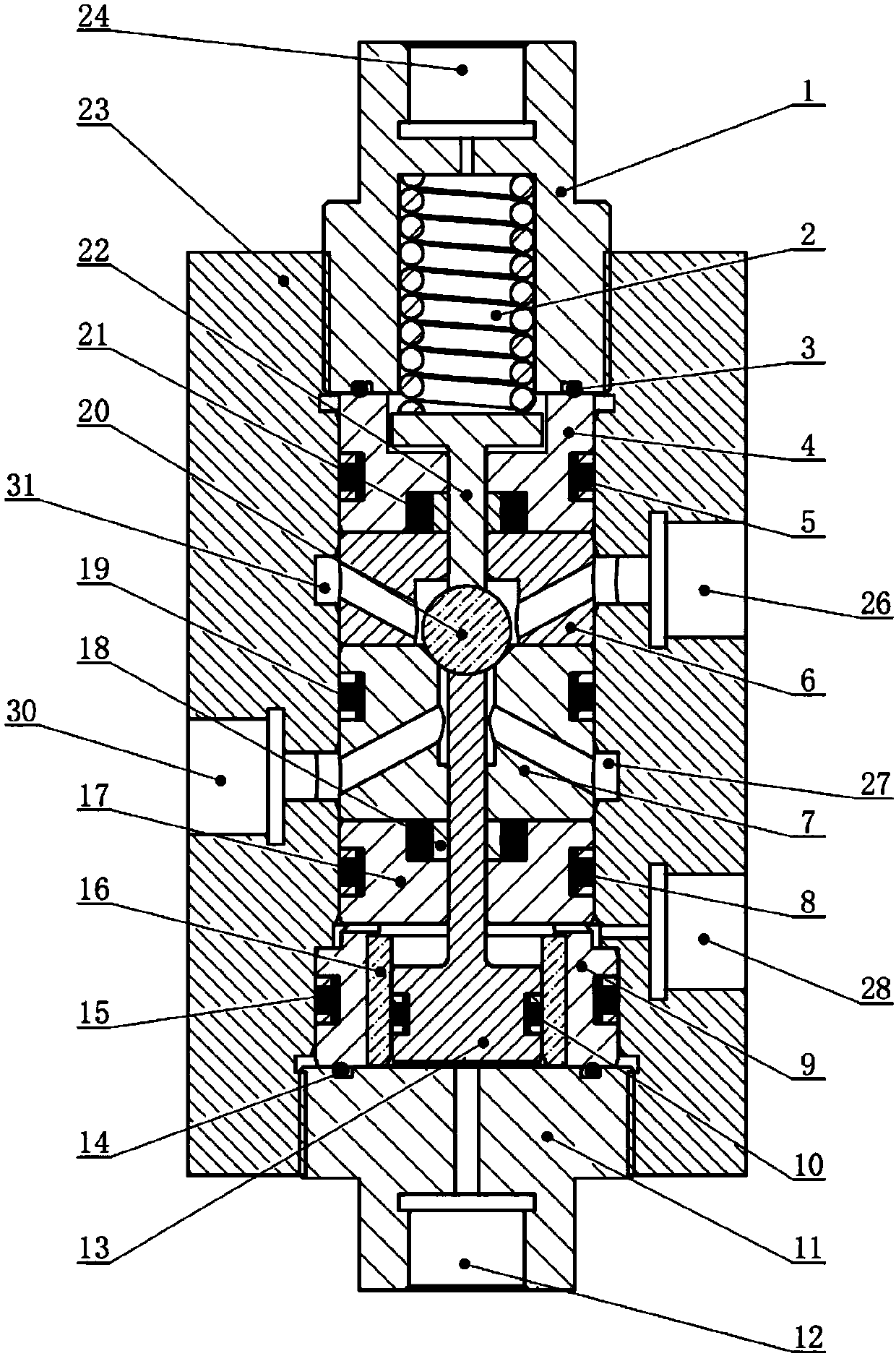

Deep sea automatic compensation type full deep sea hydraulic control stop valve

The invention belongs to the field of valves, and particularly discloses a deep sea automatic compensation type full deep seat hydraulic control stop valve. The deep sea automatic compensation type full deep sea hydraulic control stop valve comprises a valve body, a valve bush assembly and a valve core assembly. An inlet and an outlet are formed in the side face of the valve body, the valve bush assembly is mounted in the valve body in an embedded mode, and comprises a spring cap, a compression rod valve bush, a valve core cap, a valve seat, a compression sheet, a push rod valve bush substrateand a plug, the spring cap is connected with the upper end of the valve body, a compression rod balance port is formed in the spring cap, and a groove for mounting a spring is formed in the lower endof the spring cap. A valve port and a valve seat flow guide hole are formed in the valve seat, a valve core cap chamber and a valve core cap circulation hole are formed in the valve core cap, the plug is connected with the lower end of the valve body, and a control port is formed in the plug. The valve core assembly comprises a compression rod, a valve core and a push rod, the compression rod isinserted into the compression rod valve bush and the valve core cap sequentially, the valve core is arranged in a cavity formed between the valve core cap chamber and the valve port, the lower end ofthe push rod is mounted in the push rod valve bush substrate, and the upper end of the push rod is inserted into the compression sheet and the valve seat in sequence. The deep sea automatic compensation type full deep sea hydraulic control stop valve has the advantages of being stable in working property, good in airtightness, capable of achieving automatic compensation and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

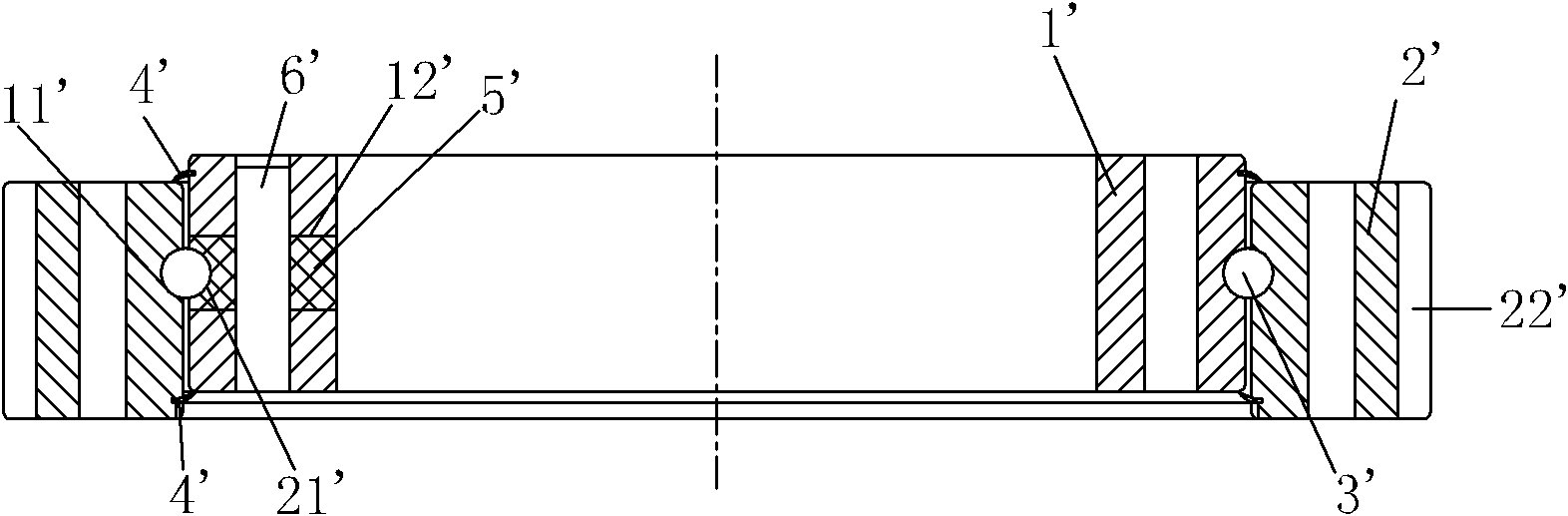

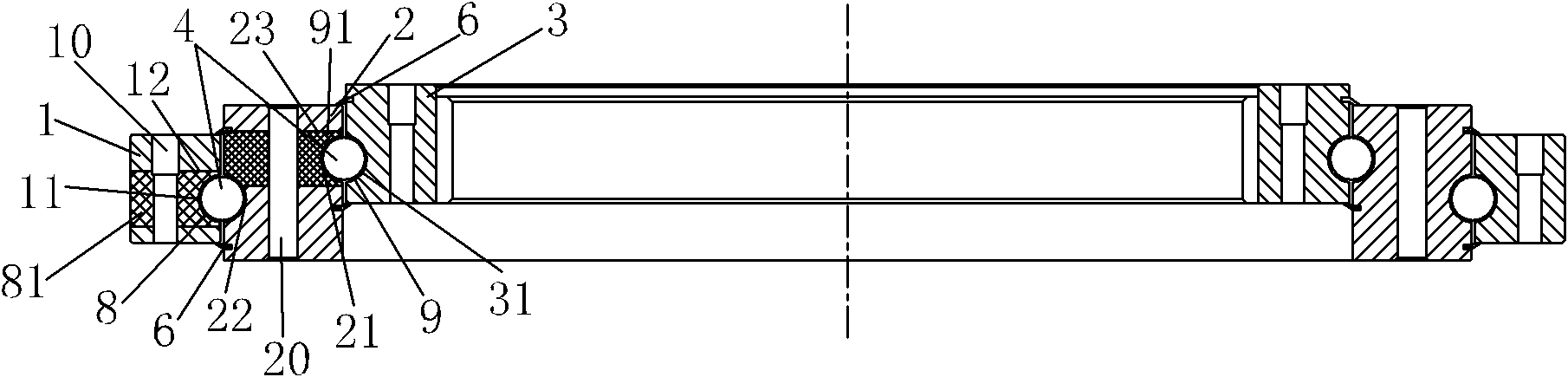

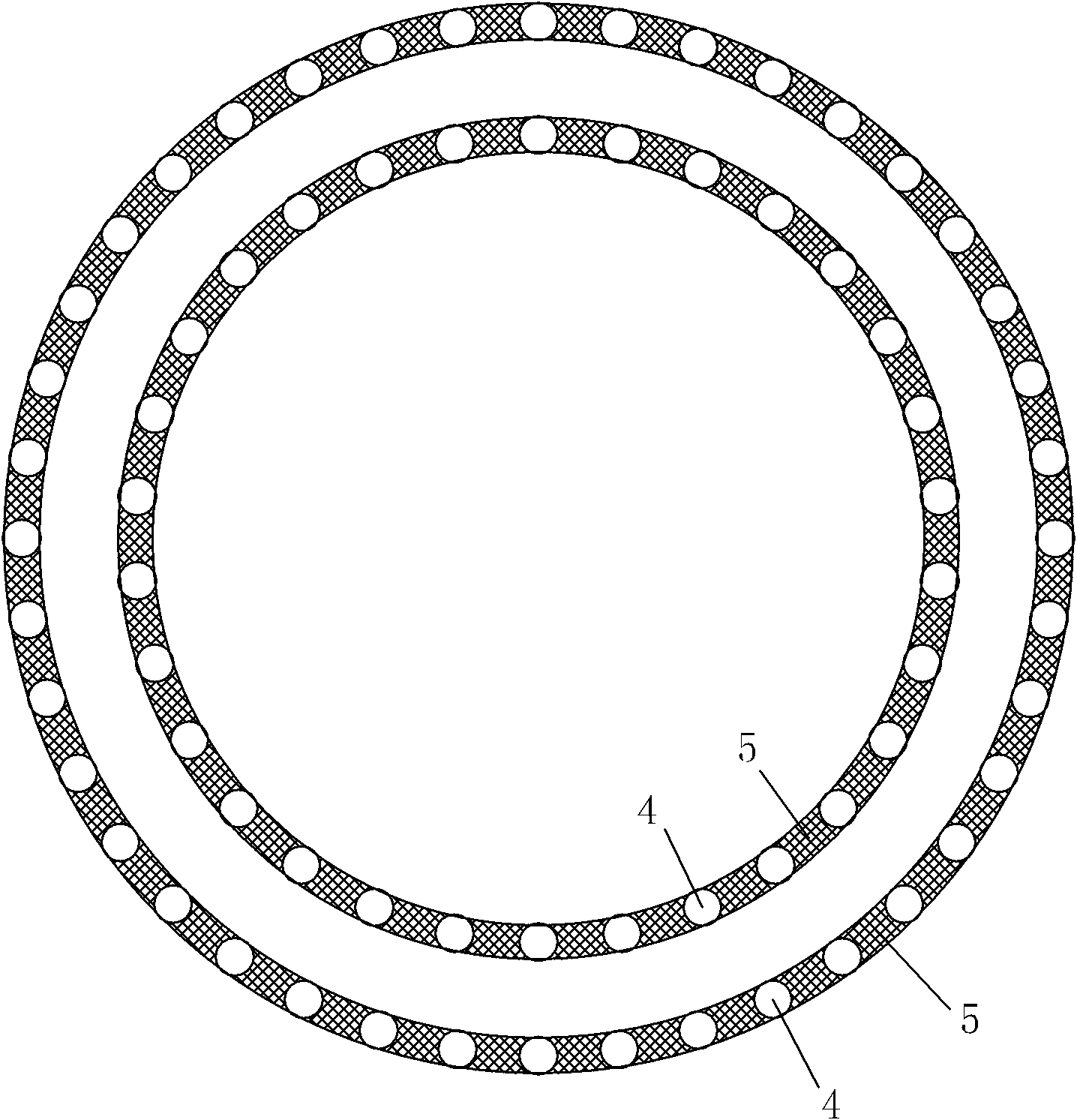

Three-circle double-raceway slewing bearing

InactiveCN102312919AStable forceUniform and reasonable forceRolling contact bearingsEngineeringSlewing bearing

The invention relates to a three-circle double-raceway slewing bearing and belongs to the technical field of slewing bearings. The three-circle double-raceway slewing bearing comprises an outer ring and an inner ring, wherein the inner wall of the outer ring and the outer wall of the inner ring are respectively provided with a first annular groove and a second annular groove; the three-circle double-raceway slewing bearing also comprises a central circle which is arranged between the outer ring and the inner ring; the inner and outer walls of the central circle are respectively provided with a third annular groove and a fourth annular groove which are symmetrically shaped and are corresponding to the second annular groove and the first annular groove; an external circular raceway is formed by the first annular groove and the fourth annular groove; an internal circular raceway is formed by the second annular groove and the third annular groove; the external circular raceway and the internal circular raceway are respectively provided with a plurality of rolling units; a spacing block is arranged between two adjacent rolling units; sealing rings are respectively arranged at the up and down joint of the outer ring and the central circle and the up and down joint of the central circle and the inner ring. The three-circle double-raceway slewing bearing provided by the invention is suitable for special main engine equipment for performing double rotation.

Owner:ANHUI ZONGCHEN SLEWING RING

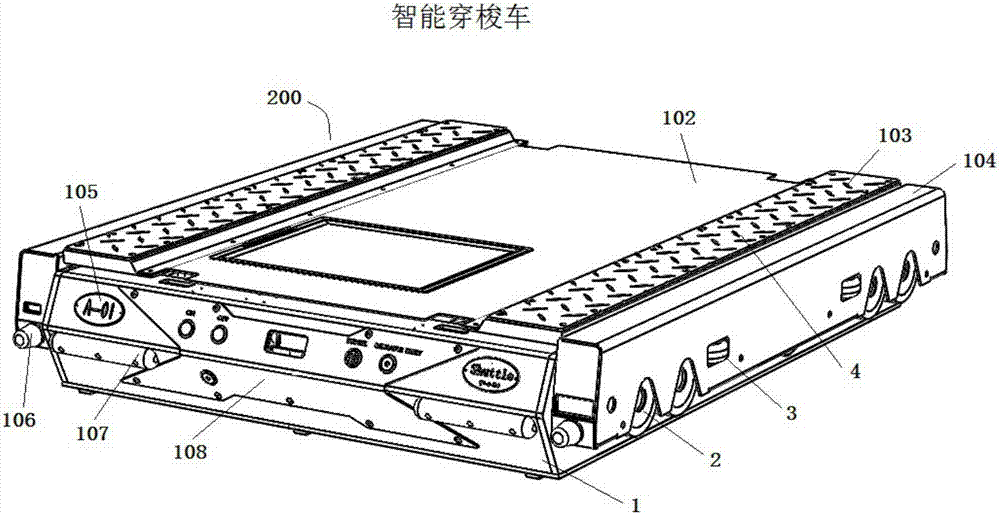

Shuttle vehicle

The invention discloses a shuttle vehicle. The shuttle vehicle comprises a vehicle frame and a travelling mechanism fixed to the vehicle frame and further comprises a lifting mechanism and a detecting device which are fixed to a rack. The travelling mechanism is driven by a motor to move, the lifting mechanism is driven by the motor to drive a connecting rod arranged on the rack to act to complete the lifting action, and after detecting signals of the detecting device fixed to a rack are processed, the travelling and lifting actions are controlled. Products can be stored and output in a semi-automatic mode, the inconvenience when a forklift drives into a passage to store and take goods in traditional storage is avoided, a large amount of site space and production cost are saved, and the production efficiency is improved.

Owner:南京冠帝仓储设备有限公司

Method for forming irregular ring piece by utilizing stainless-steel rectangular ring rolled piece through thermal bulging

ActiveCN102513457AHigh dimensional accuracyPrecise control of bulge sizeShaping toolsAbnormal shapedAerospace

The invention discloses a method for forming an irregular ring piece by utilizing a stainless-steel rectangular ring rolled piece through thermal bulging, comprising the following steps of: sleeving the heated stainless-steel rectangular ring rolled piece on the periphery of a pre-heated bulging blockin a bulging machine; starting the bulging machine so that the ring rolled piece is squeezed by the bulging block in a radial direction along the inner circumference surface of the ring rolled piece and becomes the irregular ring blank after being deformed for 11-13%, thus completing primary bulging; rotating the irregular ring blank for 45 degrees along an center axis, thus completing primary rotation; carrying out secondary bulging with the deformation amount of 1.8-2% and secondary rotation on the irregular ring blank according to the previous steps; carrying out tertiary bulging with the deformation amount of 1.4-1.6% and tertiary rotation on the irregular ring blank according to the previous steps; and carrying out quartus bulging with the deformation amount of 1.2-1.4% and quartus rotation on the irregular ring blank according to the previous steps, so as to obtain the irregular ring piece. The size precision of the irregular ring piece can reach 0.1-0.2% of the corresponding size. The irregular ring piece formed by using the method disclosed by the invention is mainly used for fields of aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

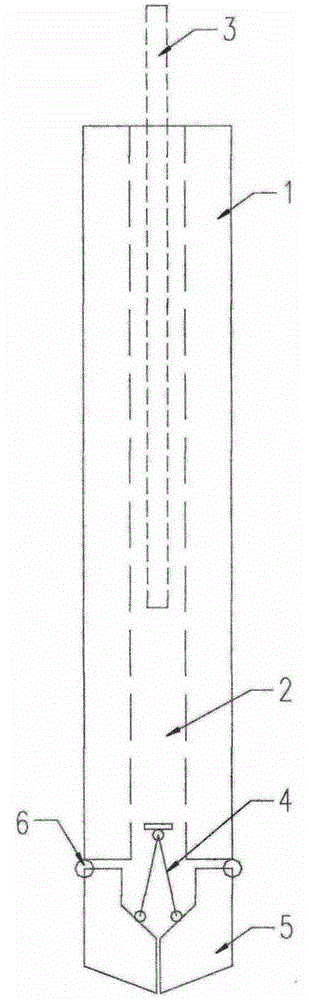

Bottom-expanded pipe pile with unfolded blades and pile driving method thereof

InactiveCN105386440AImprove bearing capacityImprove carrying capacityBulkheads/pilesBearing capacity

The invention discloses a bottom-expanded pipe pile with unfolded blades and a pile driving method thereof. The bottom-expanded pipe pile with the unfolded blades comprises a master pile, a cavity is reserved in the master pile, and the blades are arranged at the bottom end of the master pile and movably connected with the bottom of the master pile through connecting devices. A push-open device is also arranged on the bottom of the master pile and can fold and unfold the blades. In the pile driving process, the master pile is prefabricated firstly, then the blades are prefabricated and additionally arranged, the assembled blades are in a folded state before pile driving, the master pile is driven into a soil layer completely through hammering or static pressure, the blades are unfolded and concrete is poured. By means of the bottom-expanded pipe pile with the unfolded blades and the pile driving method thereof, the bearing capacity of the pile is enhanced by tens of times, meanwhile, the project quality is improved, and security is improved to a great extent.

Owner:陈明

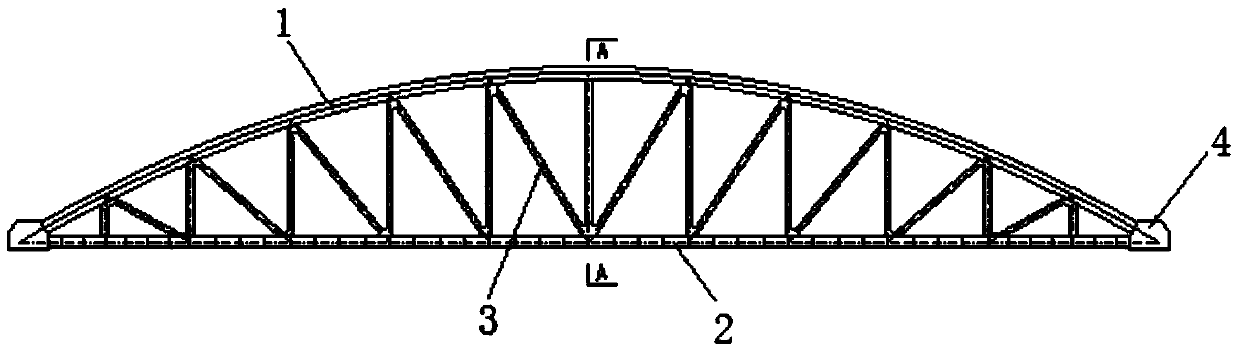

Steel tube truss arch bridge

InactiveCN103590321AUniform and reasonable forceReduce steel consumptionBridgesHollow coreSteel tube

The invention discloses a steel tube truss arch bridge which comprises two hollow round steel tube arch ribs, a hollow round steel tube straining beam and cross arms. The cross arms are connected between the two hollow round steel tube arch ribs in a welded mode, and a cross beam is welded onto the hollow round steel tube straining beam. The steel tube truss arch bridge further comprises an arch foot connecting device, rigid connection is formed between the two ends of each hollow round steel tube arch rib and the two ends of the hollow round steel tube straining beam through arch foot connecting plates, and truss type web members are connected between the abdomens of the hollow round steel tube arch ribs and the hollow round steel tube straining beam. According to the steel tube truss arch bridge, finished steel tubes manufactured in a factory are adopted, steel tube sections are welded at the construction site, the number of the sections is small, the welding quality is easy to guarantee, construction is convenient, and the construction period is short.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

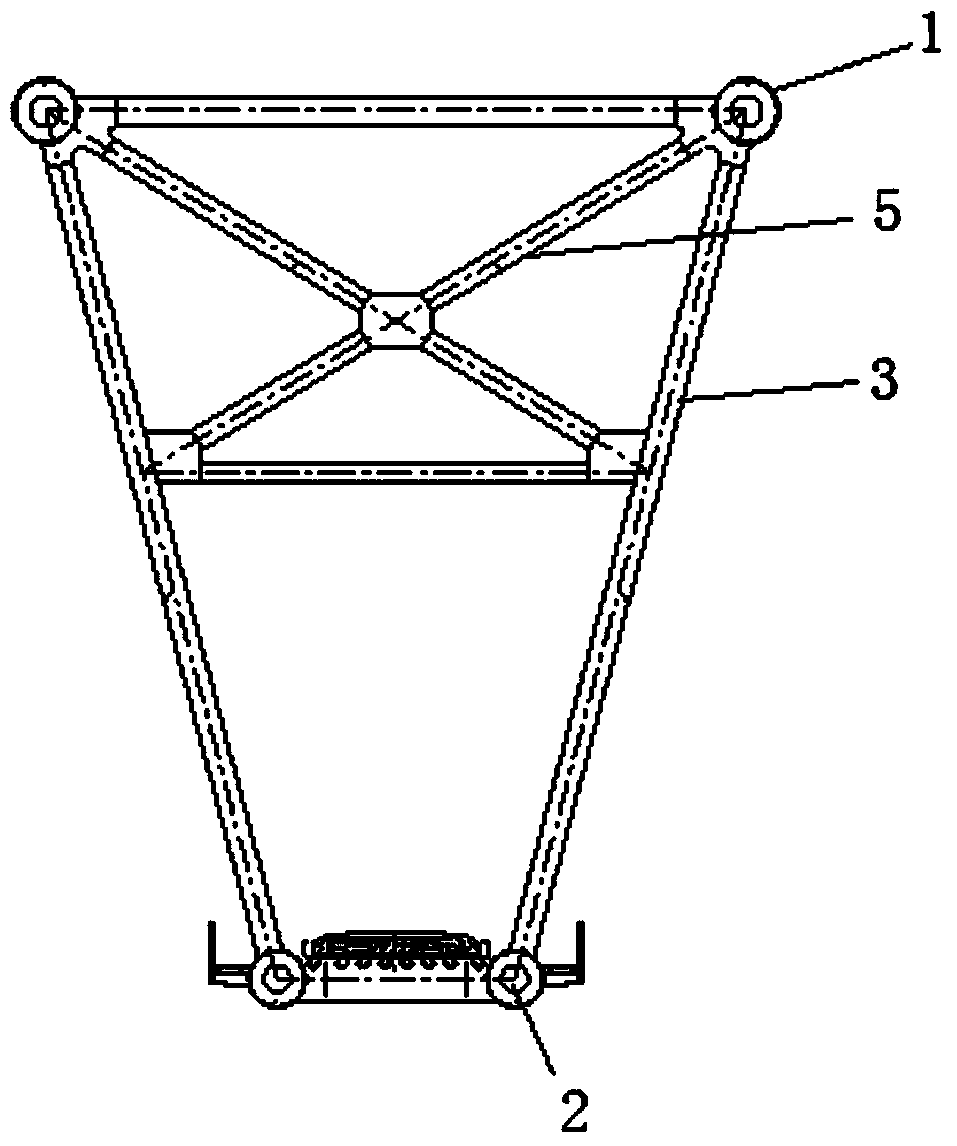

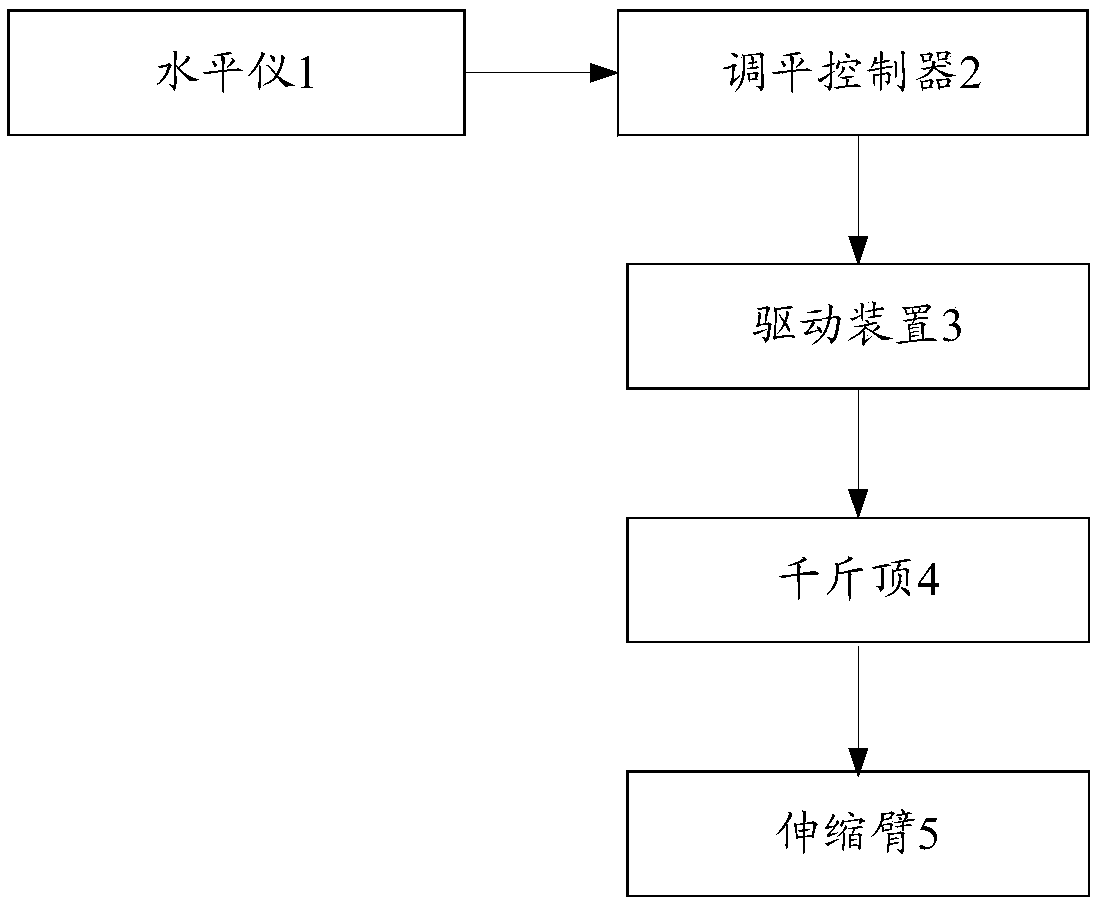

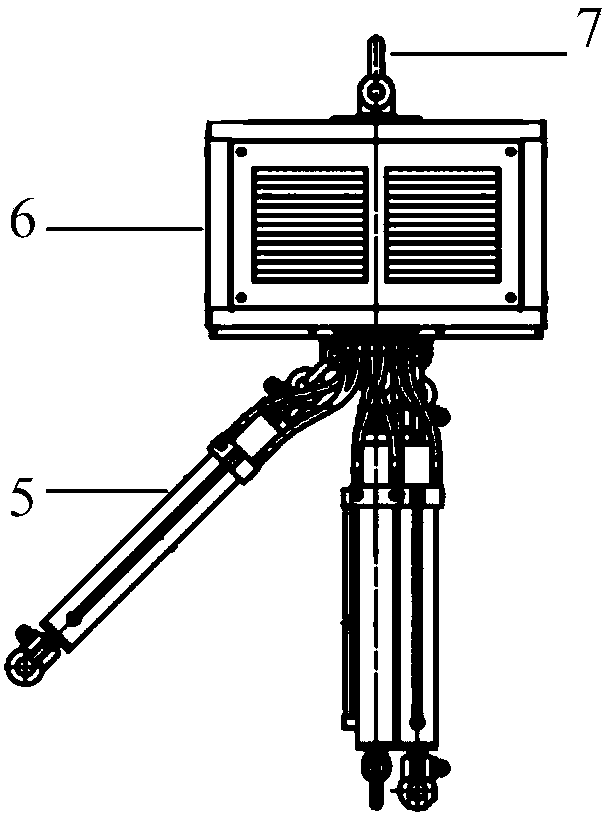

Automatic leveling device and method for prefabricated parts

PendingCN107585683AUniform and reasonable forceImprove construction efficiencyFluid-pressure actuator componentsLoad-engaging elementsEngineeringSelf adaptive

The invention provides an automatic leveling device and method for prefabricated parts. Original rough manual adjustment is changed into self-adaptive precise and automatic adjustment, the whole automatic leveling device for the prefabricated parts comprises a spirit level, a leveling controller, a drive device, a jack and telescopic booms, automatic horizontal position sensing and high-precisionself-adjustment after hoisting of vertical prefabricated parts are realized, horizontal position adjustment of the prefabricated parts such as the vertical prefabricated parts in the hoisting processis simplified greatly, automatic operation is realized, so that hoisting connection nodes, hangers and steel wire ropes in the hoisting process of the prefabricated parts such as the vertical prefabricated parts are stressed uniformly and reasonably, the prefabricated parts such as the vertical prefabricated parts can be in an ideal pose before reaching a designated position, and construction efficiency and quality of prefabricated buildings are improved.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD +1

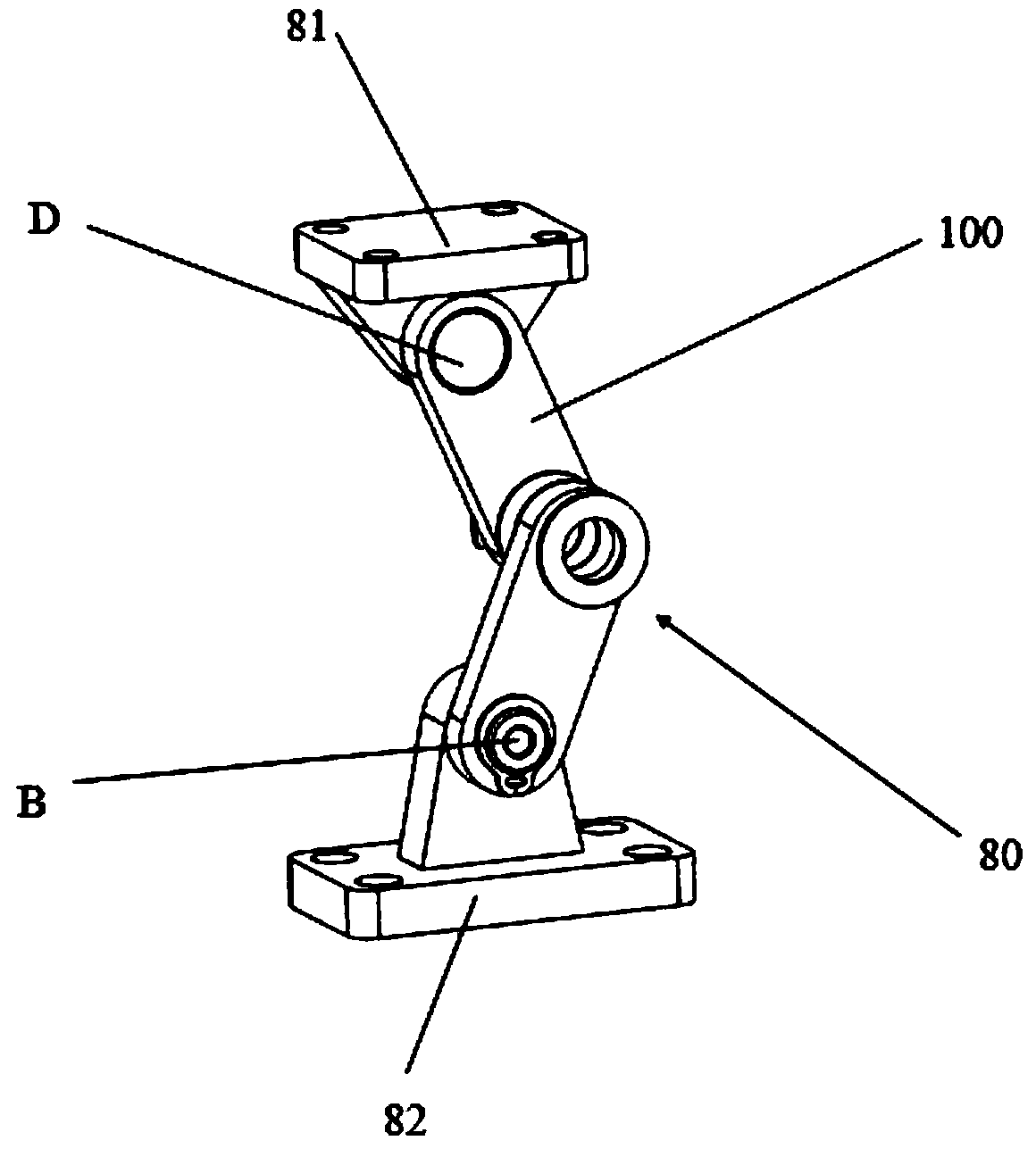

Trolley lifting mechanism used for carrying surgical tools

ActiveCN109573879ASmooth liftUniform and reasonable forceSurgical furnitureLifting framesEngineeringSupport plane

Owner:BEIJING SURGERII TECH CO LTD

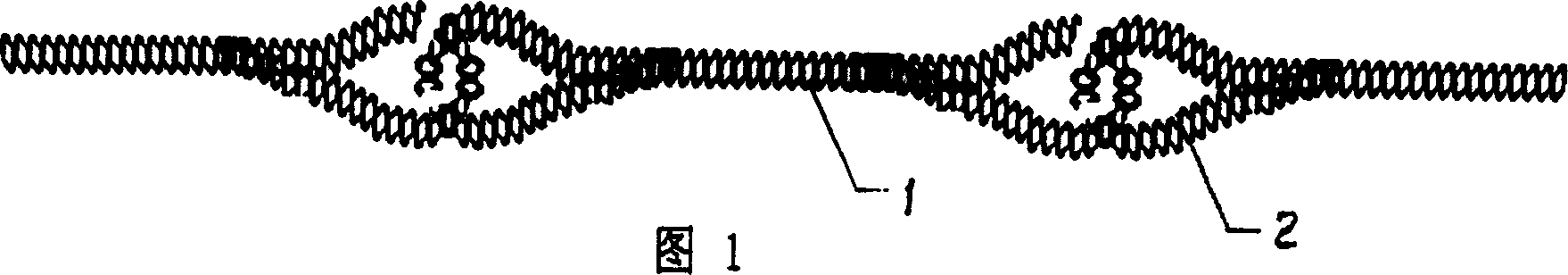

Netting method of superlarge mesh netsheet

The present invention relates to a method for tie-making net pieces with ultra-large meshes. Said invented technical scheme includes the following steps: decomposing mesh into mesh feet, making rope loop on two ends of every mesh foot respectively, according to twice mesh number of net piece series-connecting rope loops of mesh feet to form long rope, oppositely arranging the above-mentioned two long ropes, according to the defined mesh form using rope loops of added mesh feet to connect the correspondent mesh feet of the above-mentioned long rope respectively so as to obtain defined mash, repeatedly making the above-mentioned operation and can obtain the invented net piece.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

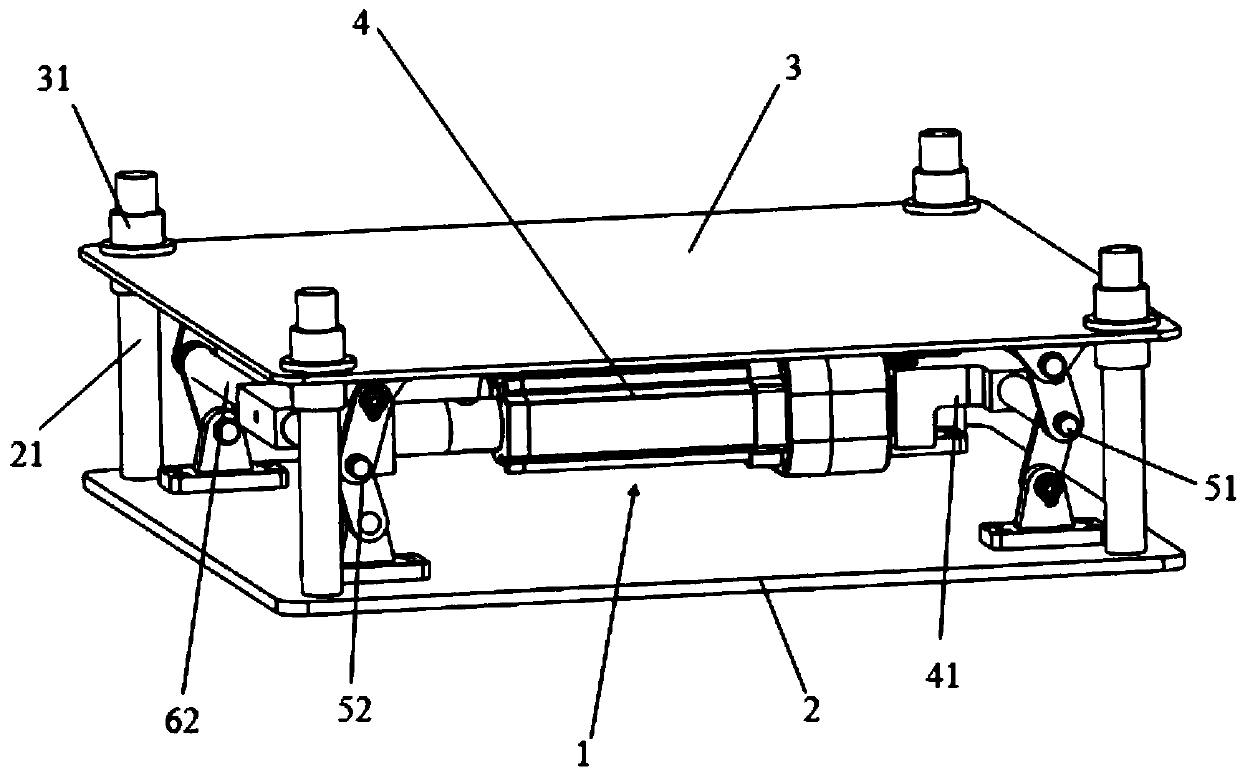

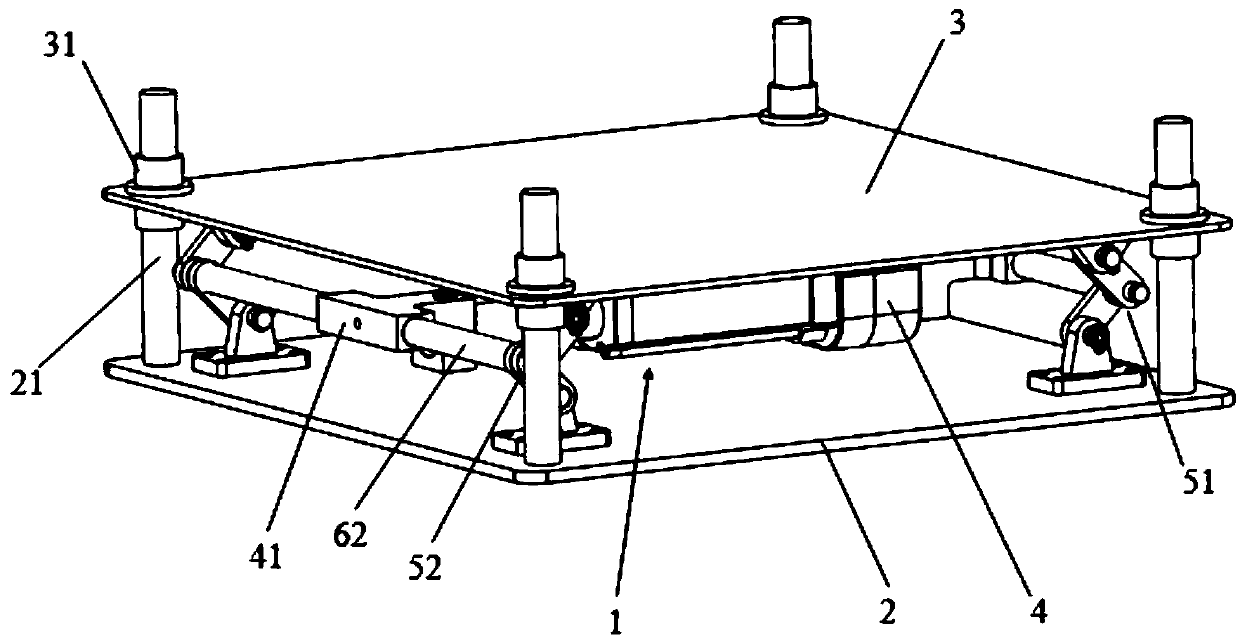

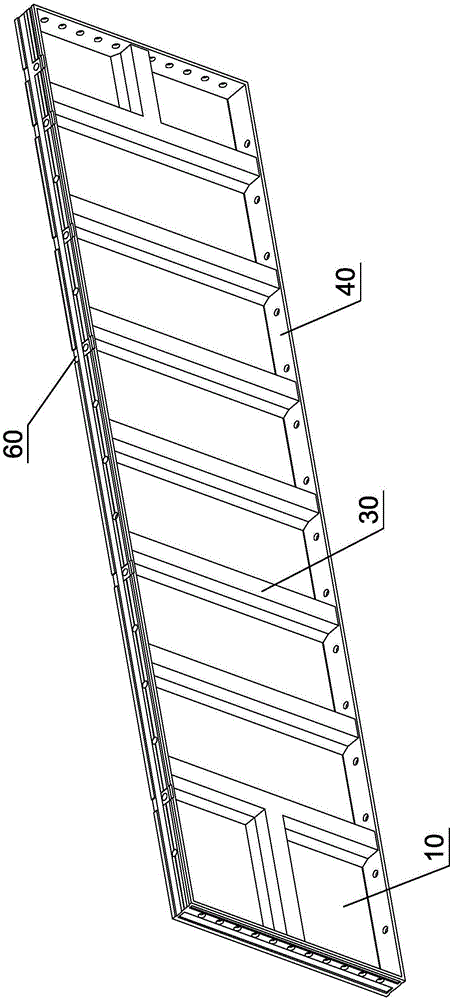

General template for pulling pieces and pulling rods and template system

ActiveCN106481064AUniform and reasonable forceCoordinated and minimal force deformationAuxillary members of forms/shuttering/falseworksForming/stuttering elementsClassical mechanicsEngineering

The invention discloses a general template for pulling pieces and pulling rods and a template system. The template system comprises the general template for the pulling pieces and the pulling rods, the pulling pieces (8), split bolt components (9) and back edge components (11), wherein the general template for the pulling pieces and the pulling rods comprises a panel (1), edge ribs (4), longitudinal reinforcing ribs (2) and horizontal reinforcing ribs (3); the bottom parts of the longitudinal reinforcing ribs (2) are fixedly connected with the panel (1); the bottom parts of the horizontal reinforcing ribs (3) are overlapped on the top parts of the longitudinal reinforcing ribs (2); pulling piece grooves (6) are arranged on the edge ribs (4); pulling rod holes (5) are arranged on the panel (1); bolt holes (7) are formed in the edge ribs (4); stress on the panel (1) is transferred to the horizontal reinforcing ribs (3) by the longitudinal reinforcing ribs (2), and then the stress is transferred to the longitudinally-arranged edge ribs (4) by the horizontal reinforcing ribs (3) so as to form a wholly-distributed two-way uniform-stressing system; the general template for the pulling pieces and the pulling rods is longitudinally arranged in a leaning manner and is fixedly connected; the pulling pieces (8) penetrate through the pulling piece grooves (6) to be oppositely pulled and fastened; the split bolt components (9) penetrate through the pulling rod holes (5) to be anchored on the back edge components (11) for oppositely pulling and fastening; and the unused pulling piece grooves (6) and the unused pulling holes (5) are sealed by adopting silica gel.

Owner:SHENZHEN RILI TECH CO LTD

Thermal bulging process for flash-welded stainless steel ring workpieces

The invention discloses a thermal bulging process for flash-welded stainless steel ring workpieces, which includes steps of primary bulging; primary rotation; secondary rotation; secondary bulging and tertiary bulging. In the primary bulging, a flash-welded stainless steel ring workpiece which is annealed is sleeved on the periphery of a preheated bulging block in a bulging machine after being heated, and the bulging block squeezes the ring workpiece axially along the inner circumference of the ring workpiece after the bulging machine is started so that the primary bulging is completed, wherein the bulging temperature ranges from 950 DEG C to 1040 DEG C, the bulging time ranges from 22s to 28s, the pressure holding time ranges from 18s to 20s, and the bulging deflection ranges from 0.12% to 0.15%. The primary rotation is completed by rotating the ring workpiece along the center axis by 45 degrees. The secondary bulging is completed by processes of the primary bulging, wherein the bulging temperature ranges from 920 DEG C to 1010 DEG C, the bulging time ranges from 20s to 25s, the pressure holding time ranges from 16s to 18s, and the deflection ranges from 0.08% to 0.09%. The second rotation is completed by rotating the ring workpiece again along the direction the same with that of the primary rotation. The tertiary bulging is completed by the processes of the primary bulging again, wherein the bulging temperature ranges from 890 DEG C to 980 DEG C, the bulging time ranges from 25s to 30s, the pressure holding time ranges from 21s to 23s, and the deflection ranges from 0.09% to 1%. The dimensional precision of the ring workpiece can be 1%. to 2%. of the corresponding precision after the ring workpiece is bulged, and the ring workpiece is mainly used for the field of space navigation.

Owner:GUIZHOU ANDA AVIATION FORGING

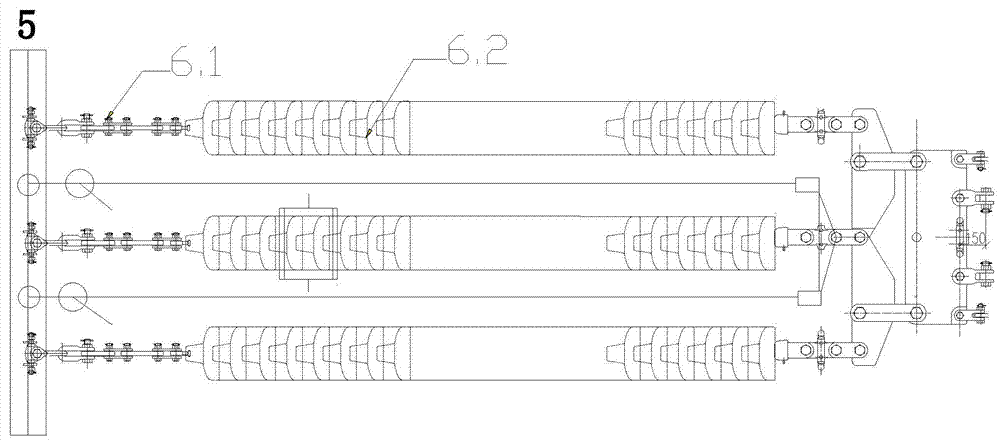

Construction technology for replacing monolithic 550kN glass insulators of strain towers of extra-high voltage direct-current transmission lines

ActiveCN104242153AImprove efficiencyImprove protectionApparatus for overhead lines/cablesEngineeringShackle

The invention provides a construction technology for replacing monolithic 550kn glass insulators of strain towers of extra-high voltage direct-current transmission lines. The construction technology includes the following steps: (1), lifting tool materials such as transmission ropes, yoke-plate strain clips, special strength bearing tools and shackles onto the towers; (2), installing main stress systems, and pre-tightening chain hoists after preparation of the systems; (3), fastening and mounting closed-type fasteners; (4), starting to tighten the main stress systems, tightening the closed-type fasteners and mounting new insulators; (5), completing operation after checkout. The construction technology can meet requirements on relative technical conditions of power-cut operation of the transmission lines of + / -800kv; the construction technology is applied together with the fasteners, double protection is realized, and thus, safety factor of field operation is improved; during overall replacement, protection measures for strain insulator strings are guaranteed; operation tools are portable, can be firmly mounted and conveniently demounted and has high safety; standardized operation instructions used for standardized field operation can be formed by the overall technology process.

Owner:STATE GRID CORP OF CHINA +2

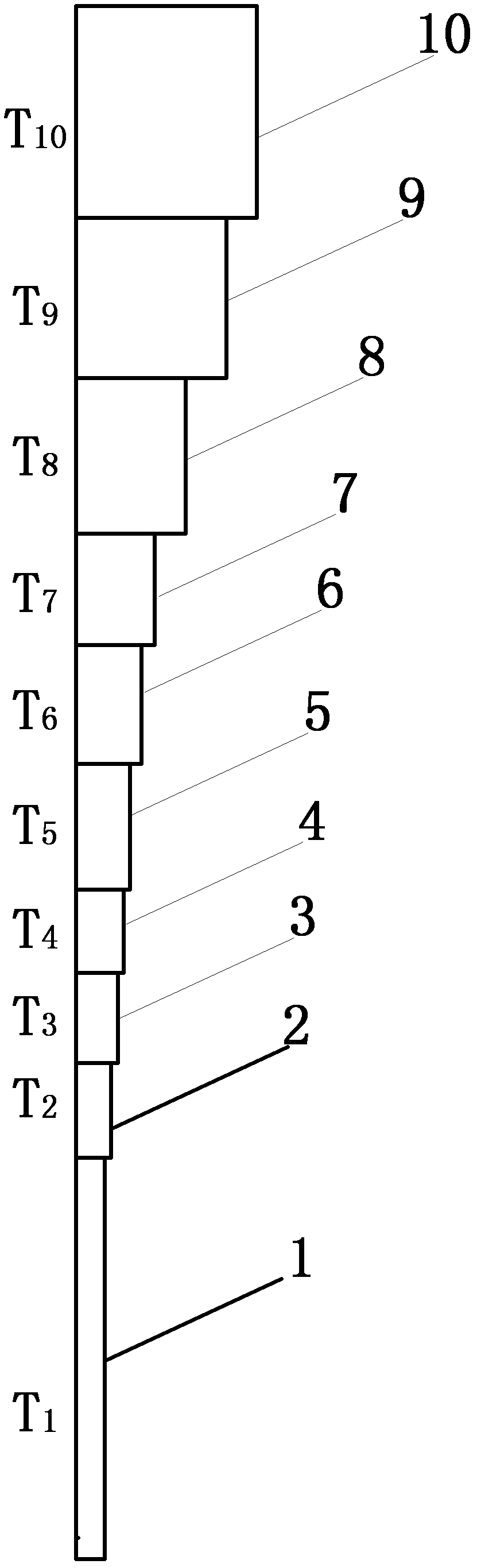

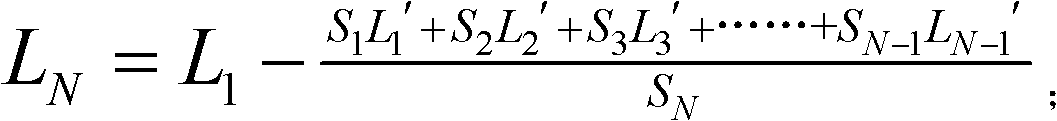

Method for designing mounted muffle for vertical bright annealing furnace

ActiveCN102433415ALight weightUniform and reasonable forceMuffle furnacesRetort furnacesUltimate tensile strengthMaterials science

The invention relates to a method for designing a mounted muffle for a vertical bright annealing furnace. The method is implemented as the following steps of: determining the thickness of the material of each section of a muffle based on the specifications of materials of sections of the muffle, wherein the thicknesses of the materials of sections of the muffle are thickened; in order to make each section as long as possible, calculating the theoretic maximal length of each section by leading the upper end stress of each section to be equal to allowable stress, on the premise that the material stress of each section of the muffle is within the allowable tensile strength range based on the thickness and specification of the material of each section of the muffle; by combining the thickness and maximal length specification of the material of each section of the muffle, dividing the maximal length specification of the material of each section of the muffle by the theoretic maximal length of each section to obtain the number of segments requiring to be welded, of the actual material of the muffle and the actual length of each section; and finally, performing an addition operation on the all actual lengths of sections to obtain the whole muffle length. The method in the invention can lower the self weight of the muffle and ensure uniform and reasonable stress of the whole muffle after being welded and spliced.

Owner:WISDRI WUHAN WIS IND FURNACE

Hinge

ActiveCN105041843AReduce the number of gapsAvoid missingCasings/cabinets/drawers detailsPivotal connectionsMachiningElectronic equipment

The invention discloses a hinge. The hinge comprises a first rotary piece, a second rotary piece and a protective piece. The first rotary piece comprises a first connecting piece, a first rotary shaft and a first shaft sleeve. The second rotary piece comprises a second connecting piece, a second rotary shaft and a second shaft sleeve. The hinge is formed by splicing the first rotary piece, the second rotary piece and the protective piece. The protective piece of the proper length can be adopted for reducing the number of gaps between the first rotary piece, the second rotary piece and the protective piece, the gaps even can be prevented from being generated, and the technical effect that liquid matter in electronic equipment can be effectively prevented from leaking is achieved. Due to the fact that the hinge special for the electronic equipment can be composed of components which are lower in machining difficulty and simple in splicing manner, the technical effects that the production cost is effectively reduced and production and machining efficiency is improved are achieved.

Owner:LENOVO (BEIJING) CO LTD

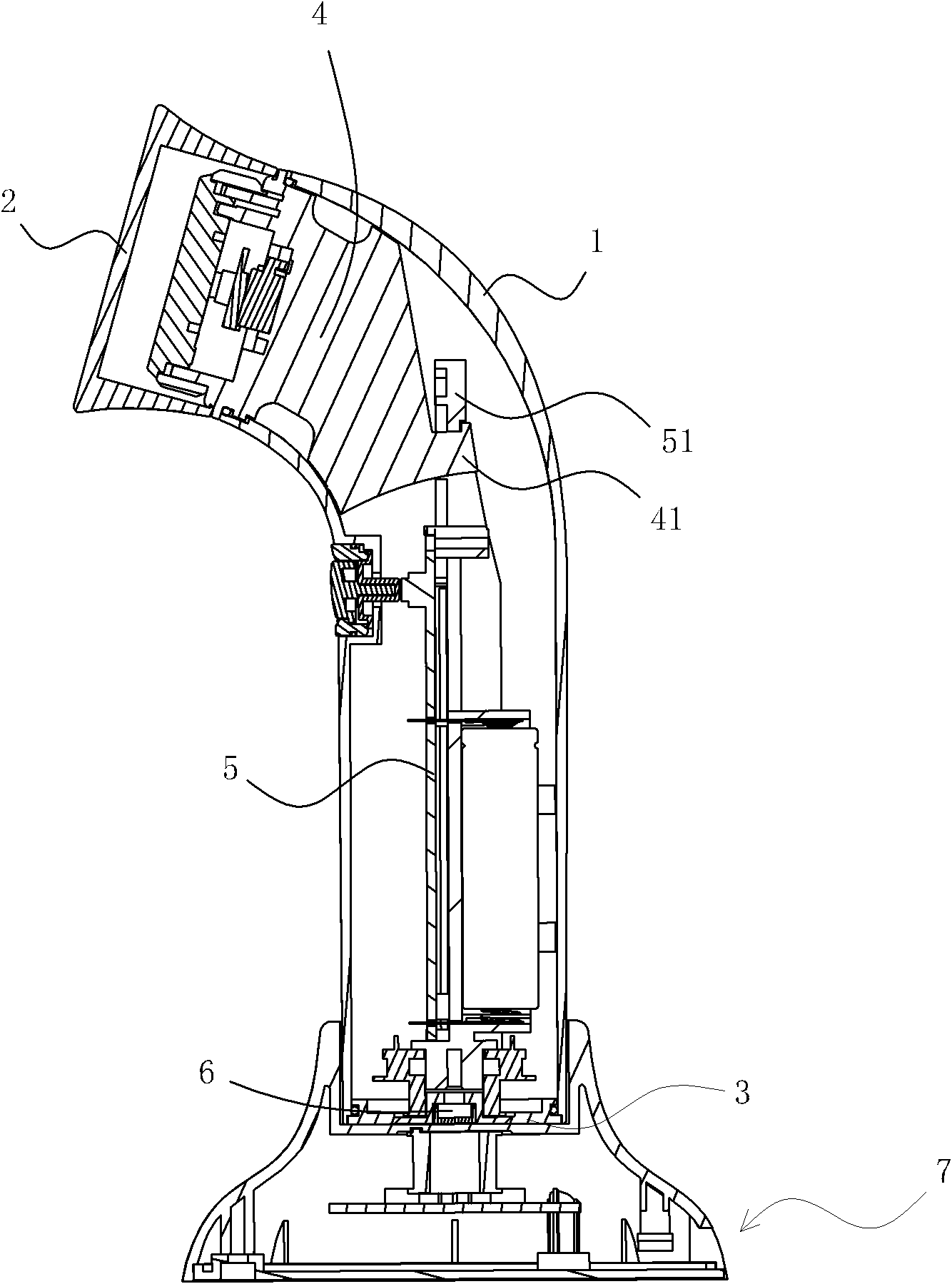

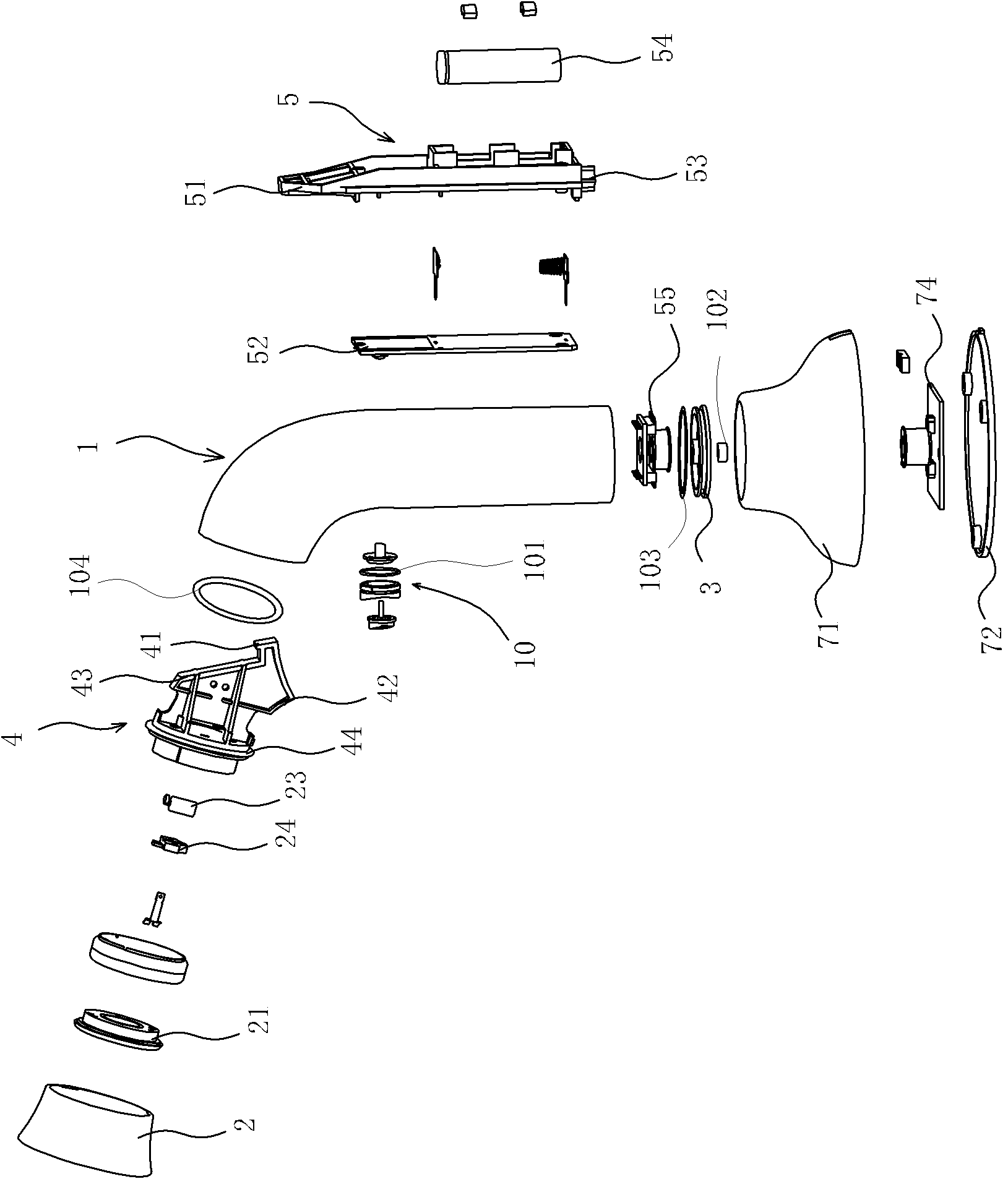

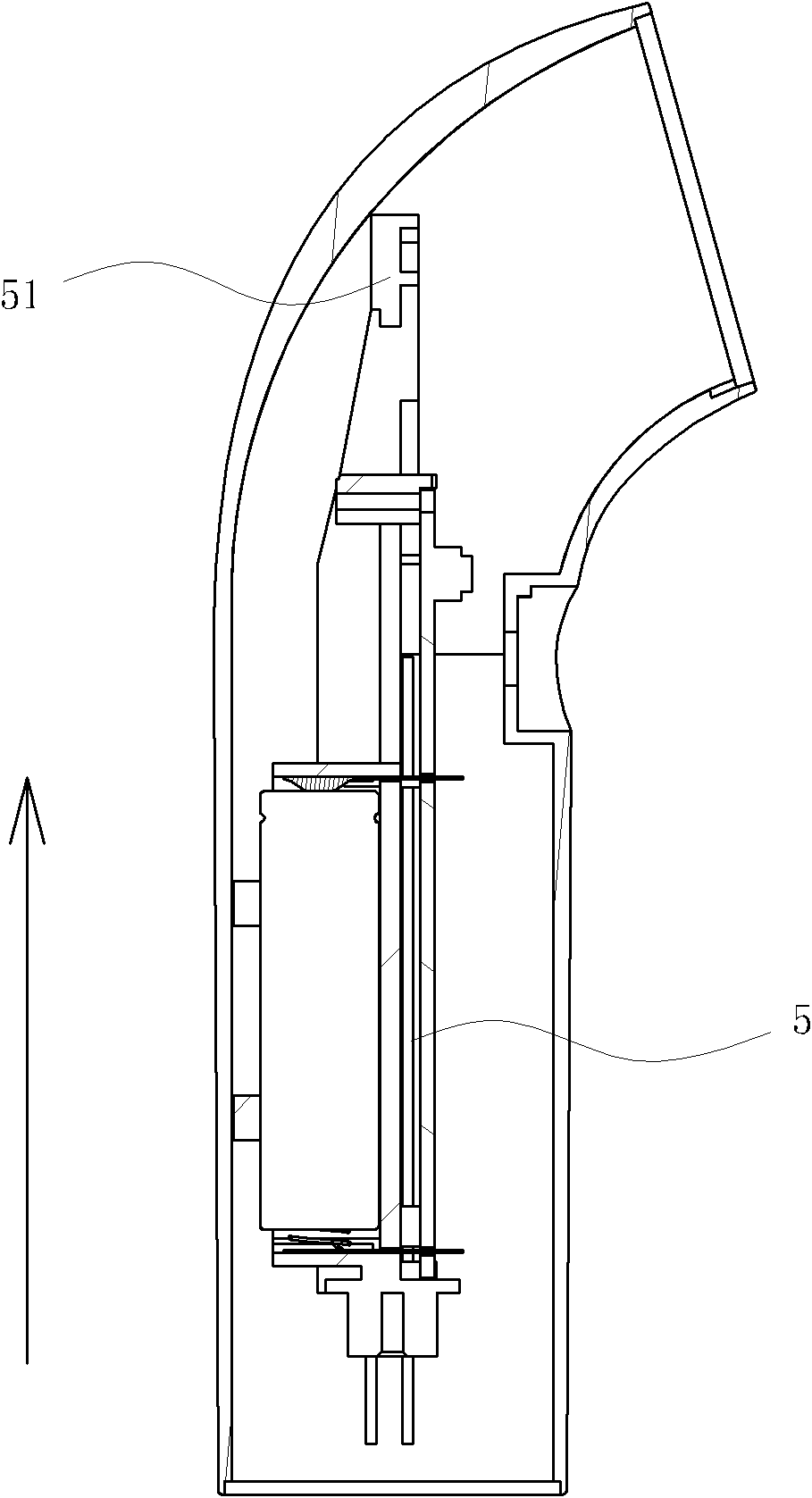

Ultrasonic beauty instrument

The invention discloses ultrasonic beauty instrument comprising a surface cover, a body, a shell of a bottom cover and an inner core component accommodated in the shell, wherein, the body comprises an elbow, and is divided into an upper section and a lower section by the elbow. The ultrasonic beauty instrument is characterized in that the body is an integral swan neck, the inner core component comprises an upper part positioned in the upper section of the body and a lower part positioned in the lower section of the body; the upper part includes a tabulate fixing frame which is fixedly connected to a motor and corresponding fixing accessories, and the end of the upper part has a hook; the lower part includes a tabulate fixing plate which is fixed with the circuit boards and the like, and the top of the lower part has a lantern ring; the lower section also comprises a guide slot which is parallel to the axis of the lower section, the lower part is in sliding fit with the guide slot; the hook crosses and hooks the lantern ring; a locking piece is arranged between the lower part and the bottom cover; and after the lower end of the lower part is fixed with the bottom cover by the locking piece, the upper part is tensioned and fixed by the lantern ring through the hook, thus the whole inner core component is fixed in the body properly. The ultrasonic beauty instrument has less fittings, less fixed parts and simple assembling procedures.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD +1

Process for forming special-shaped ring workpieces from aluminum alloy rectangular rolled ring workpieces by hot bulging

ActiveCN102500707AHigh dimensional accuracyPrecise control of bulge sizeShaping toolsMaterials scienceAerospace

The invention discloses a process for forming special-shaped ring workpieces from aluminum alloy rectangular rolled ring workpieces by hot bulging, which includes: sleeving a heated aluminum alloy rectangular rolled ring workpiece onto the periphery of a preheated bulging block in a bulging machine, squeezing the rolled ring part by the bulging block radially from the inner circumference surface of the rolled ring part after starting the bulging machine, completing the primary bulging after the rolled ring part is deformed by 10%-18% to form a special-shaped ring blank, completing the primary rotation by rotating the special-shaped ring blank around the center axis by 45 degrees; completing the secondary bulging by repeating the above steps to deform the specials-shaped ring blank by 1.3%-2% and completing the secondary rotation; completing the tertiary bulging with deformation of 1.3%-2% and completing the tertiary rotation; completing the fourth bulging with deformation of 0.8%-1%; and finally obtaining the special-shaped ring workpiece. The dimension precision of the special-shaped ring workpiece can be 1%.-2%. of the corresponding dimension, and is mainly used for making rotor parts such as cylindrical casings and the like in the aerospace field.

Owner:GUIZHOU ANDA AVIATION FORGING

Tubular pile with unfolding blades and construction method of tubular pile

The invention discloses a tubular pile with unfolding blades. The tubular pile comprises a prefabricated tubular pile, wherein the prefabricated tubular pile is pressed into a soil layer through hammering or static pressure and comprises a mother pile and a pile tip; a cavity extending from the pile tail to the pile tip is formed in the pile body of the mother pile; a layer or a plurality of layers of blade jacking holes communicated with the cavity are formed in the pile wall of the mother pile in the length direction of the pile body; blades which can rotate around rotating devices and rotate towards the direction far away from the cavity are arranged at the upper edge far away from the cavity of each blade jacking hole; and a force applying part used for jacking the blades out of the blade jacking holes is arranged in the cavity. The construction method of the prefabricated tubular pile can be referred in an instruction book; and compared with a conventional prefabricated pile, the pile body is provided with unfoldable blades, so that the end-bearing effect of the pile is greatly improved, the bearing capacity of the pile is increased by multiple times or even tens of times, the number of used piles and the pile length can be greatly reduced, and the comprehensive benefits are extremely remarkable.

Owner:陈明

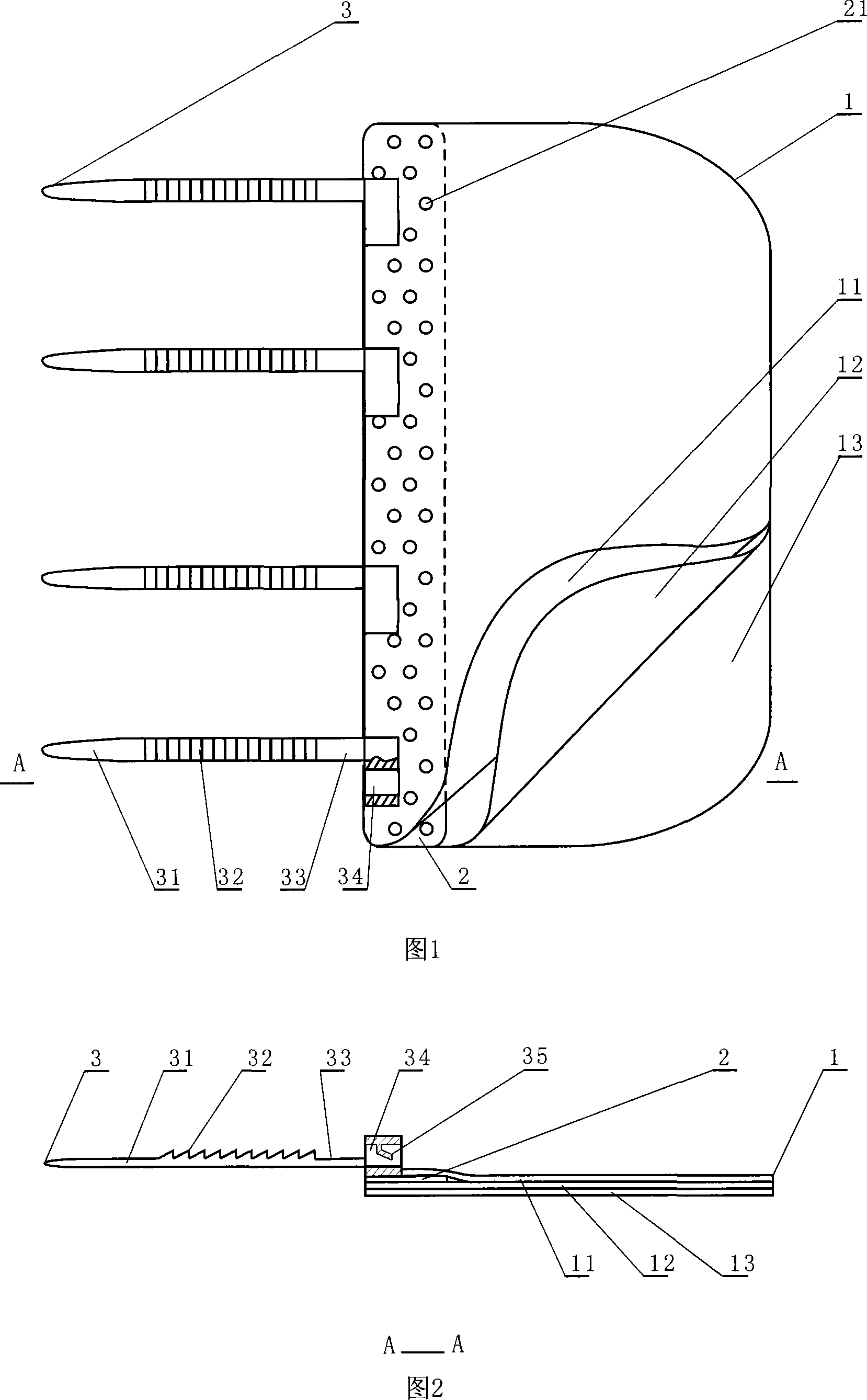

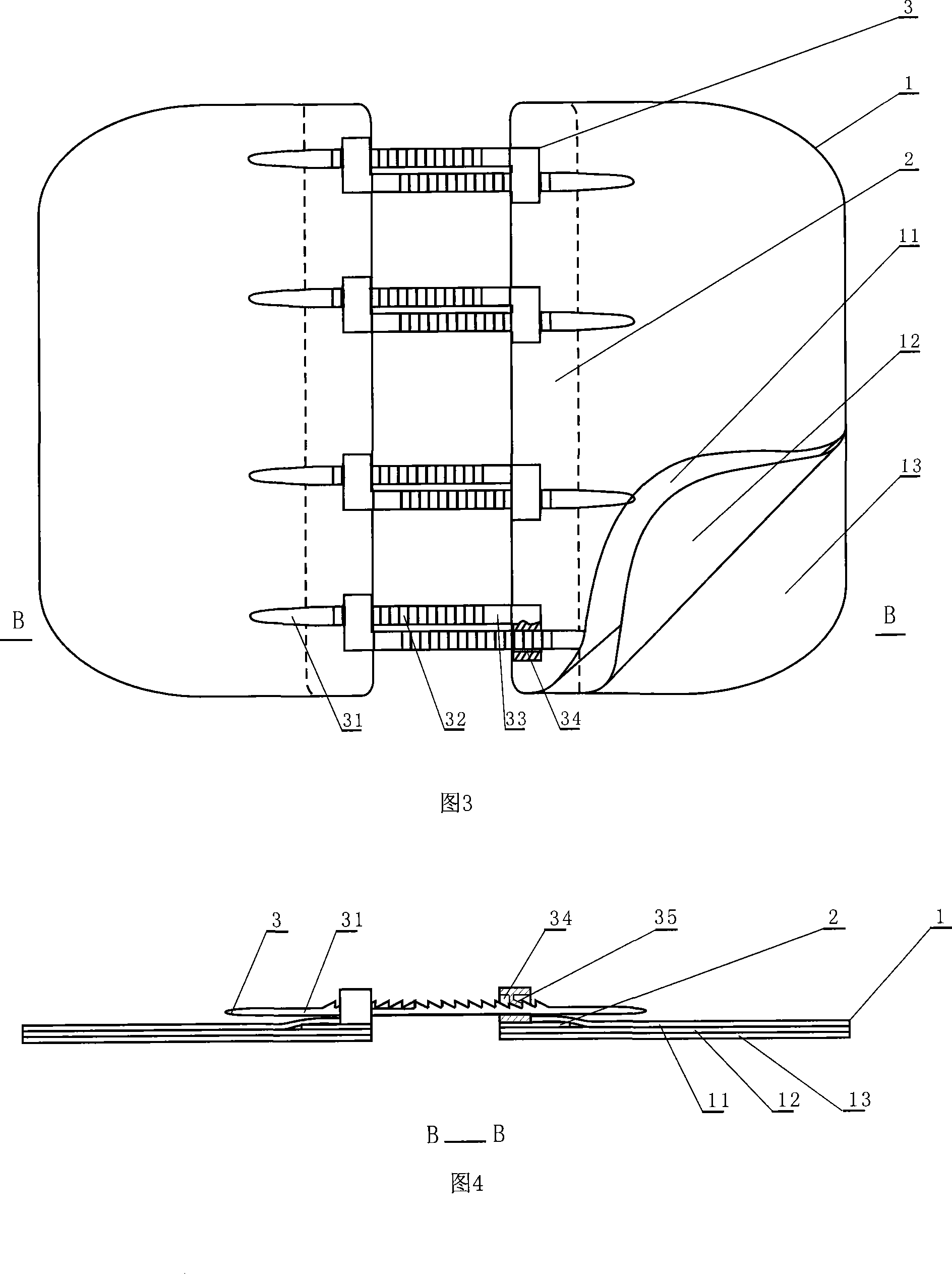

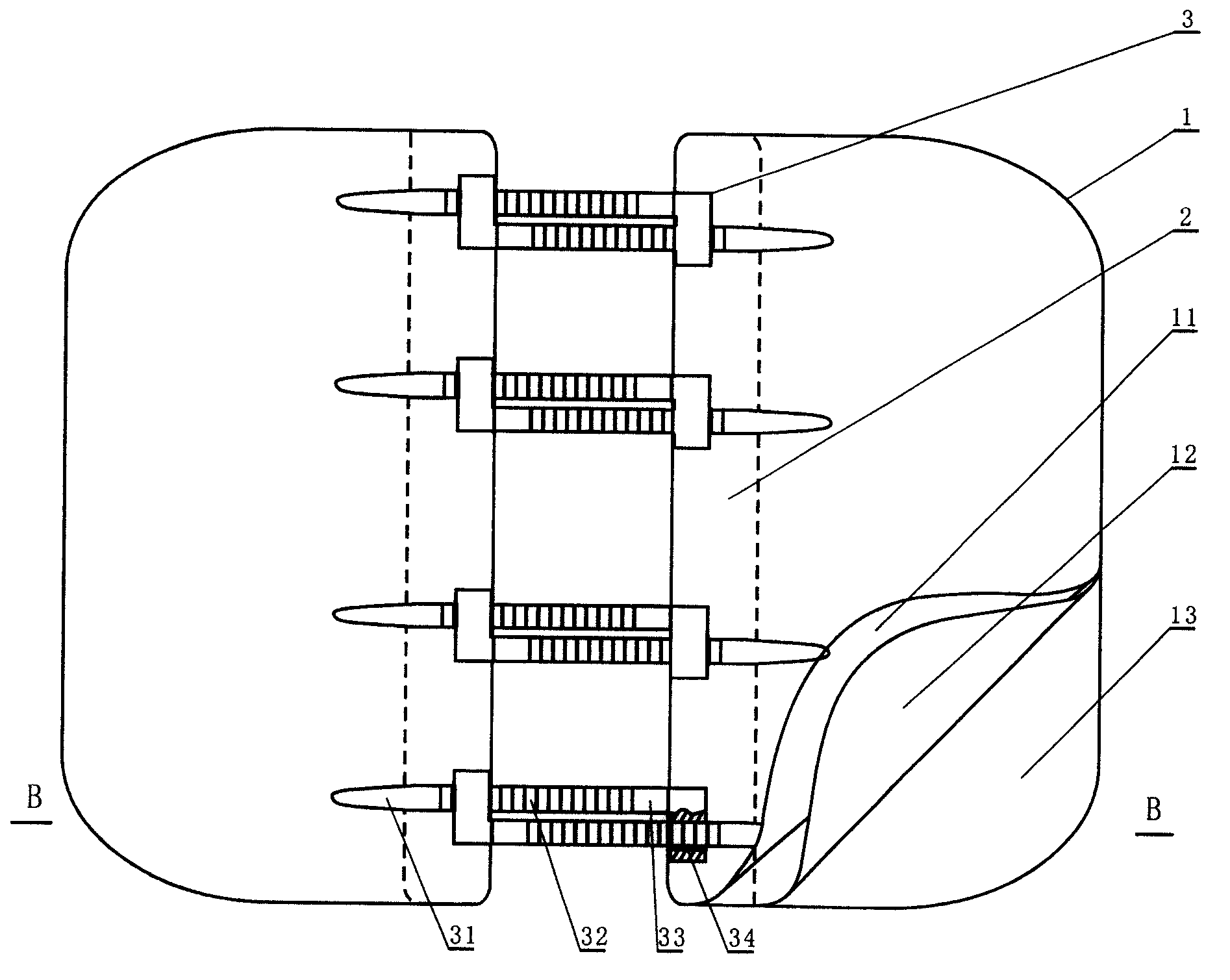

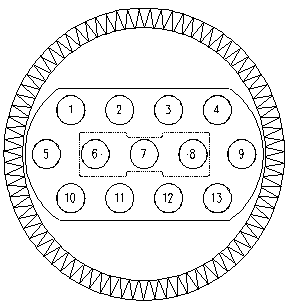

Skin wound stiching instrument and stiching method thereof

ActiveCN101229071BMake sure not to get all the wayImprove breathabilitySuture equipmentsSoft materialsEngineering

The invention discloses a skin wound suturing machine and a suturing method thereof. The suturing machine is formed by two substrates and each substrate of the suturing machine includes a rubberized fabric, a reinforcing rib and lock catches. The rubberized fabric is a ventilating soft material and the reinforcing rib is arranged along the length direction of the rubberized fabric. The rubberizedfabric comprises an upper rubberized fabric layer, a lower rubberized fabric layer and a protection layer. The reinforcing rib is arranged between the upper rubberized fabric layer and the lower rubberized fabric layer. The reinforcing rib is provided with a ventilating hole and a plurality of lock catches with same intervals. The lock catch is L-shaped and consists of a locking strip and a lock bracket. The locking strip is provided with a lock gear and a clearance area. The lock bracket is provided with a lock plunger. The two substrates of the invention are connected mutually by penetrating the lock bracket of each other through the locking strip of each own so as to apply a force at two sides of the wound by simultaneously drawing the corresponding locking strip at two sides of the wound when suturing. The invention rotates one of the two substrates by 180 degrees according to a clockwise or anticlockwise direction and the structures of the two substrates are completely consistentand only one substrate is needed manufacturing during production. The invention has the advantages of novel structure, simple operation, convenient use and low manufacture cost.

Owner:江苏泰应生物科技有限公司

8-shaped double-wall steel cofferdam and construction operation process

InactiveCN110485443AEasy to installIncrease vertical spacingFoundation engineeringDouble wallCofferdam

The invention discloses an 8-shaped double-wall steel cofferdam and a construction operation process. The cofferdam consists of an inner wall plate, an outer wall plate, compartment plates, a horizonal inclined support, an inner annular plate, an outer annular plate, vertical ribs, a vertical box, edge feet, a steel pipe inner support and bottom sealing concrete, wherein the inner wall plate, theouter wall plate and the vertical box form a main body of the 8-shaped double-wall steel cofferdam; the vertical ribs are respectively welded at the inner sides of the inner wall plate and the outer wall plate; in addition, the inner wall plate and the inner annular plate are welded into a whole; the outer wall plate and the outer annular plate are welded into a whole; the horizonal inclined support is welded between the inner annular plate and the outer annular plate; the inner wall plate and the outer wall plate are separated by a plurality of compartment plates; the edge feet are arranged at the bottoms of the inner wall plate and the outer wall plate; sandwich concrete is filled an inner cavity of the inner wall plate and the outer wall plate; and a water stop plate is arranged in a contact position of the bottom of the inner wall plate and the bottom sealing concrete. A series of problems of a common-use double-wall steel cofferdam during the construction process of a bearing table with great length-width ratio can be well solved; and the goals of safety, economical performance, cost reduction and efficiency improvement are achieved.

Owner:SICHUAN ROAD & BRIDGE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com