Individual type high-pressure grouting forming machine

A high-pressure grouting and molding machine technology, used in ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of easy slurry leakage, surface caving, cracking, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in detail below in conjunction with the accompanying drawings and embodiments, the purpose is only to better understand the content of the present invention.

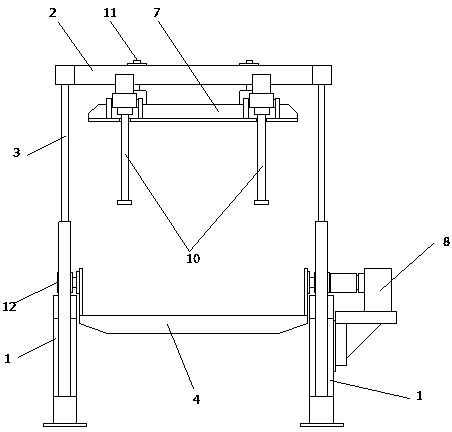

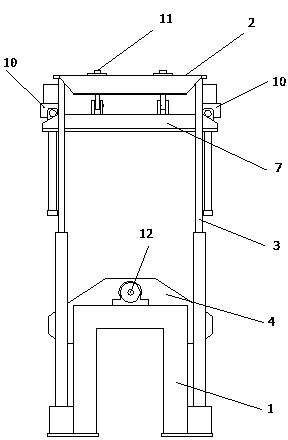

[0013] Such as figure 1 with figure 2 As shown, the monolithic high-pressure grouting molding machine described in this embodiment includes a bracket 1, a beam frame 2, a base 4 and an upper mold frame 7, and the bracket 1 has a vertical guide column 3, and the beam frame 2 Driven by the lifting device, it moves vertically on the bracket 1 through the guiding action of the guide column 3; the upper mold frame 7 is installed on the beam frame 2 through the hook 11; the base 4 is installed on the bracket 1 through the flip bearing 12 Above, driven by the overturning power device 8, the base 4 can be turned over on the support 1; the upper mold frame 7 and the base 4 have a clamping device 10, the lower mold is placed in the base 4, and the upper mold is installed on the upper mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com