Patents

Literature

42results about How to "Not easy to leak slurry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

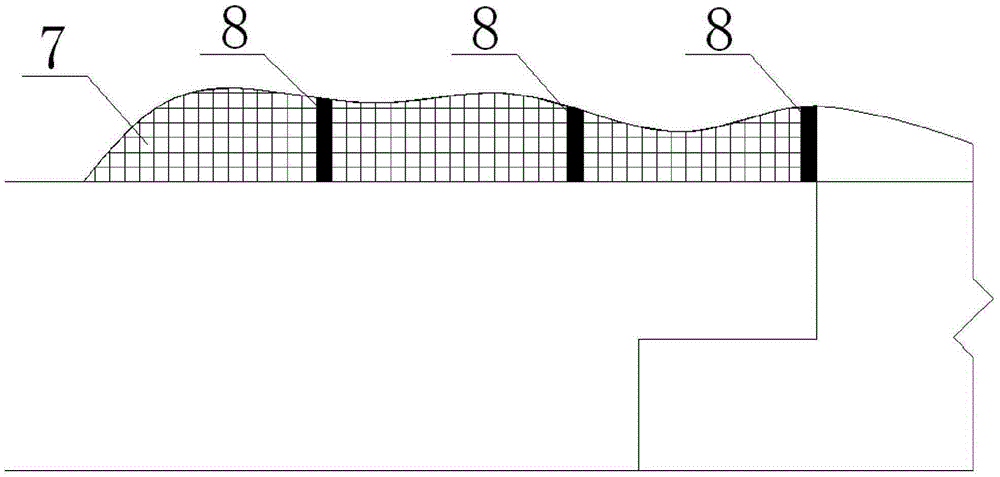

Construction method for pouring airtight partition wall between recovered roadway and reserved roadway

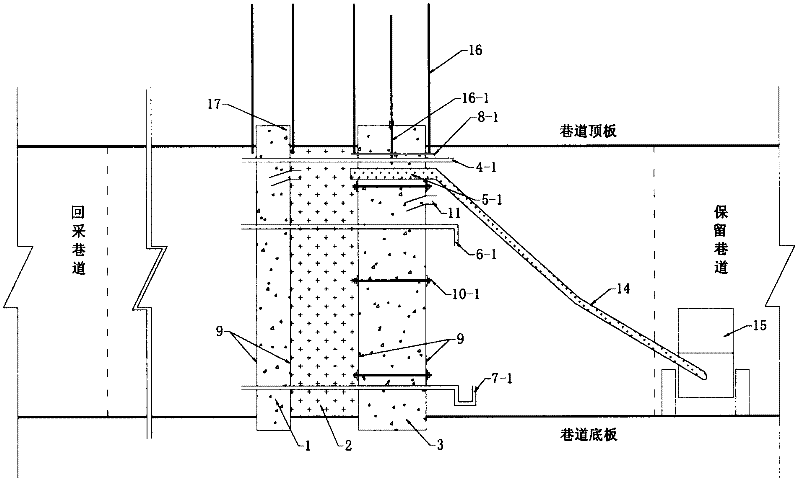

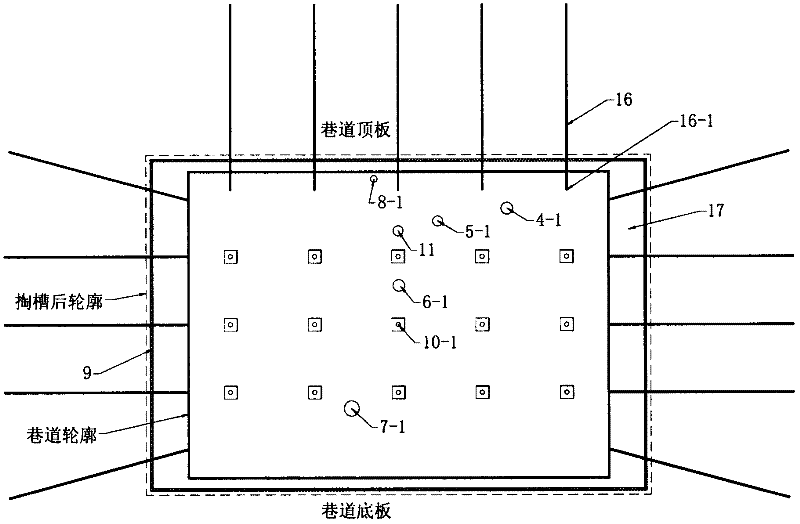

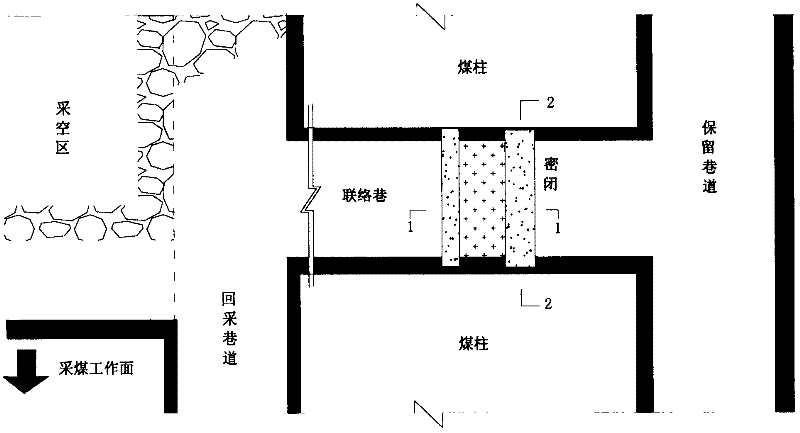

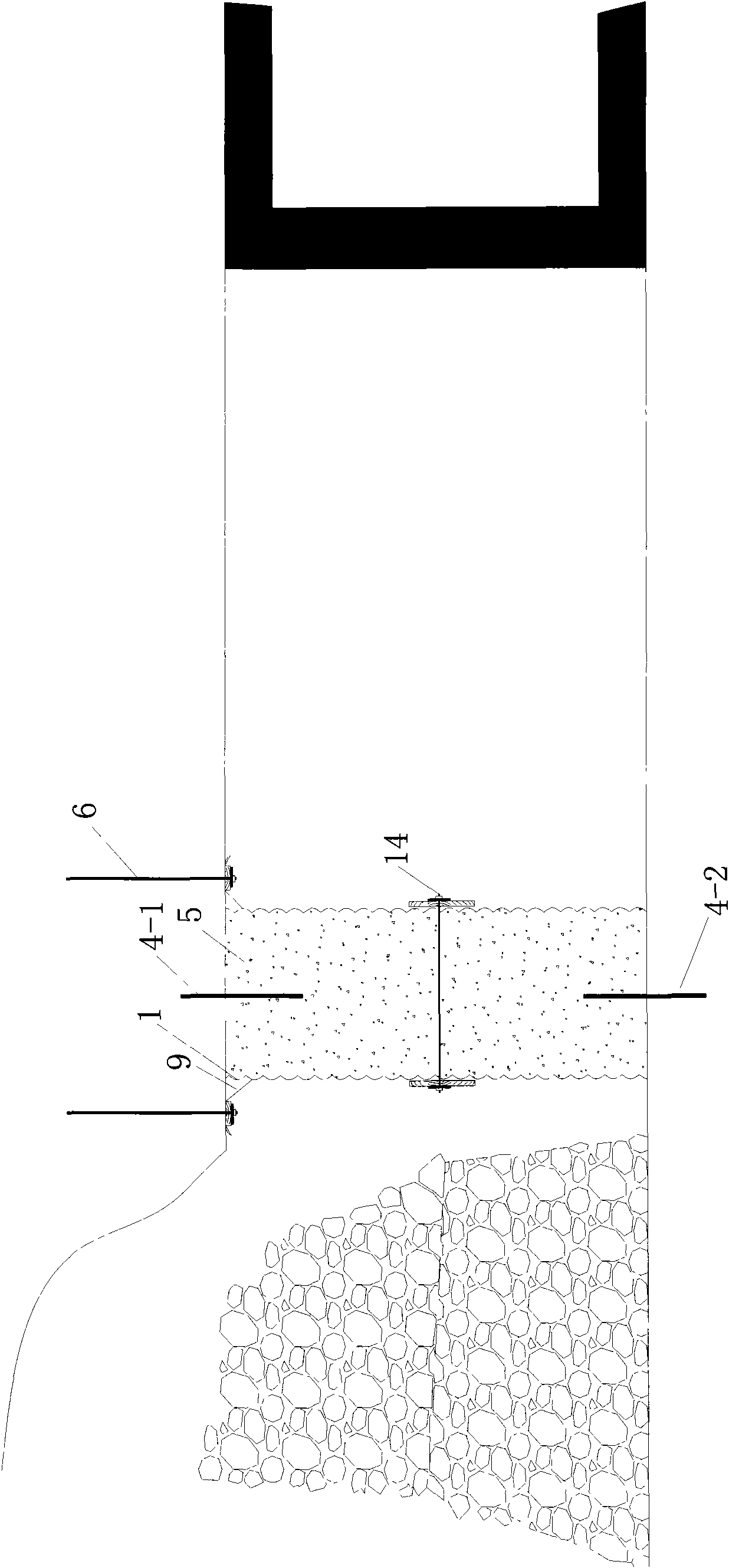

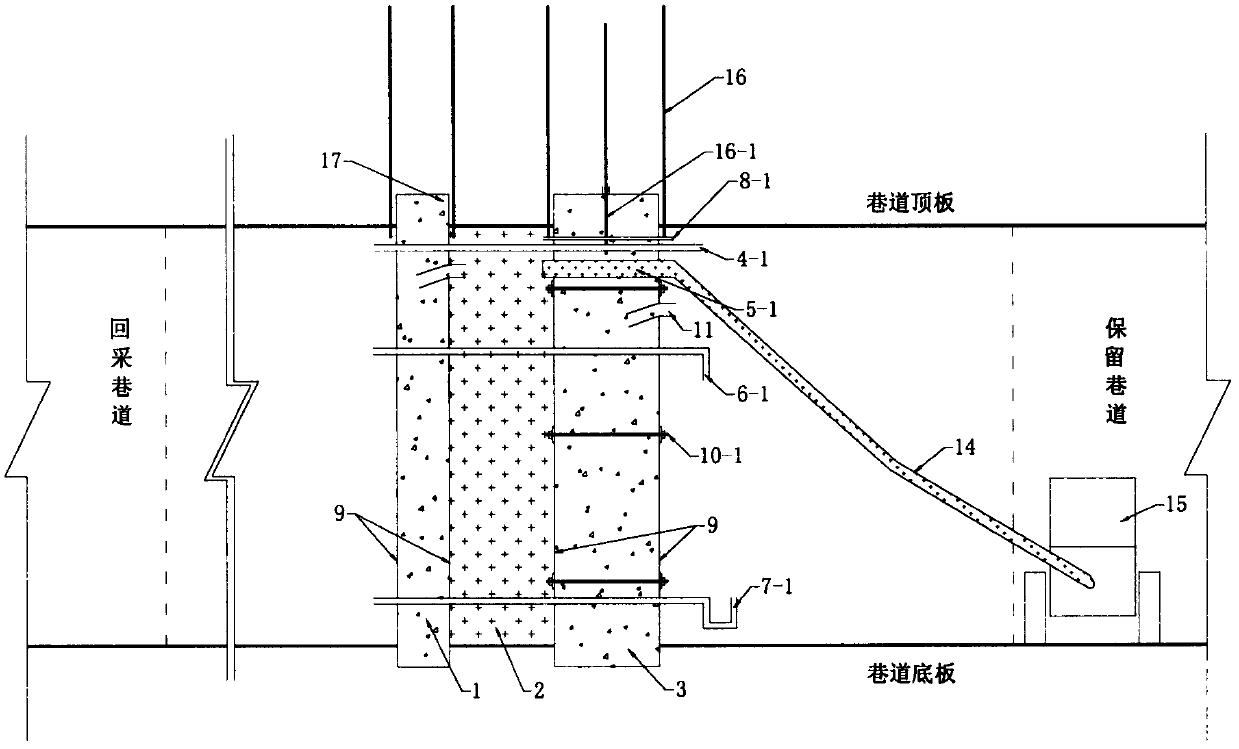

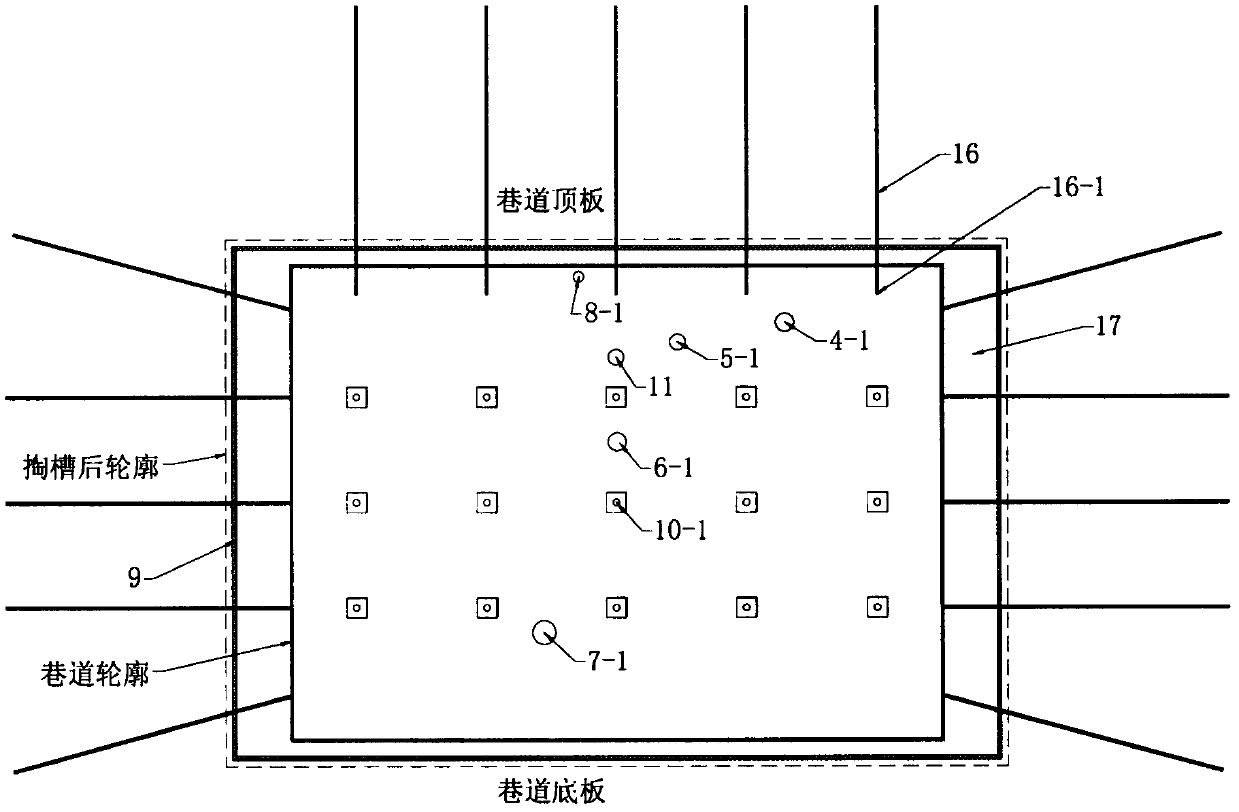

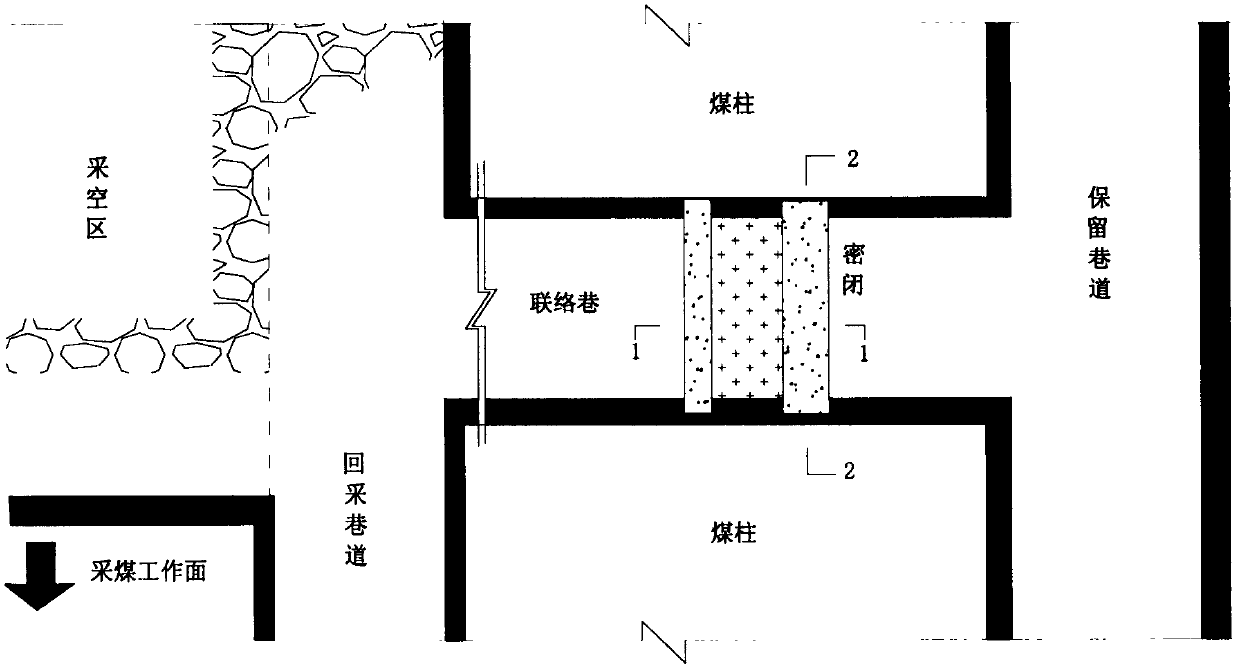

The invention discloses a construction method for pouring an airtight partition wall between a recovered roadway and a reserved roadway. The airtight partition wall is formed by an inner concrete single wall, an outer concrete single wall and a middle loess concrete wall; and the airtight structure is provided with three layers of walls: the inner side and the outer side are respectively provided with the airtight single wall which is formed in a way that a concrete pump pours concrete into a fiber flexible template, and the loess concrete wall filled by loess-based materials is arranged between the two single walls. The flexible templates are made in advance according to design requirements; a slot is drilled on a preset airtight surrounding rock connecting the roadways; anchor rods are constructed in the slot; after the flexible templates are hung onto the slot through a single hydraulic prop or the anchor rods, the concrete is successively poured into the inner side flexible template and the outer side flexible template by a concrete conveying pipe and a pouring opening through the concrete pump to form the inner single wall and the outer single wall; and after the inner single wall and the outer single wall are poured completely, the loess is poured between the inner single wall and the outer single wall to form the concrete airtight wall. The structure is safe and reliable, the construction cost is low, the construction speed is fast, the labor intensity is low, and the requirements of mine production with high production and high efficiency are met.

Owner:XIAN UNIV OF SCI & TECH +1

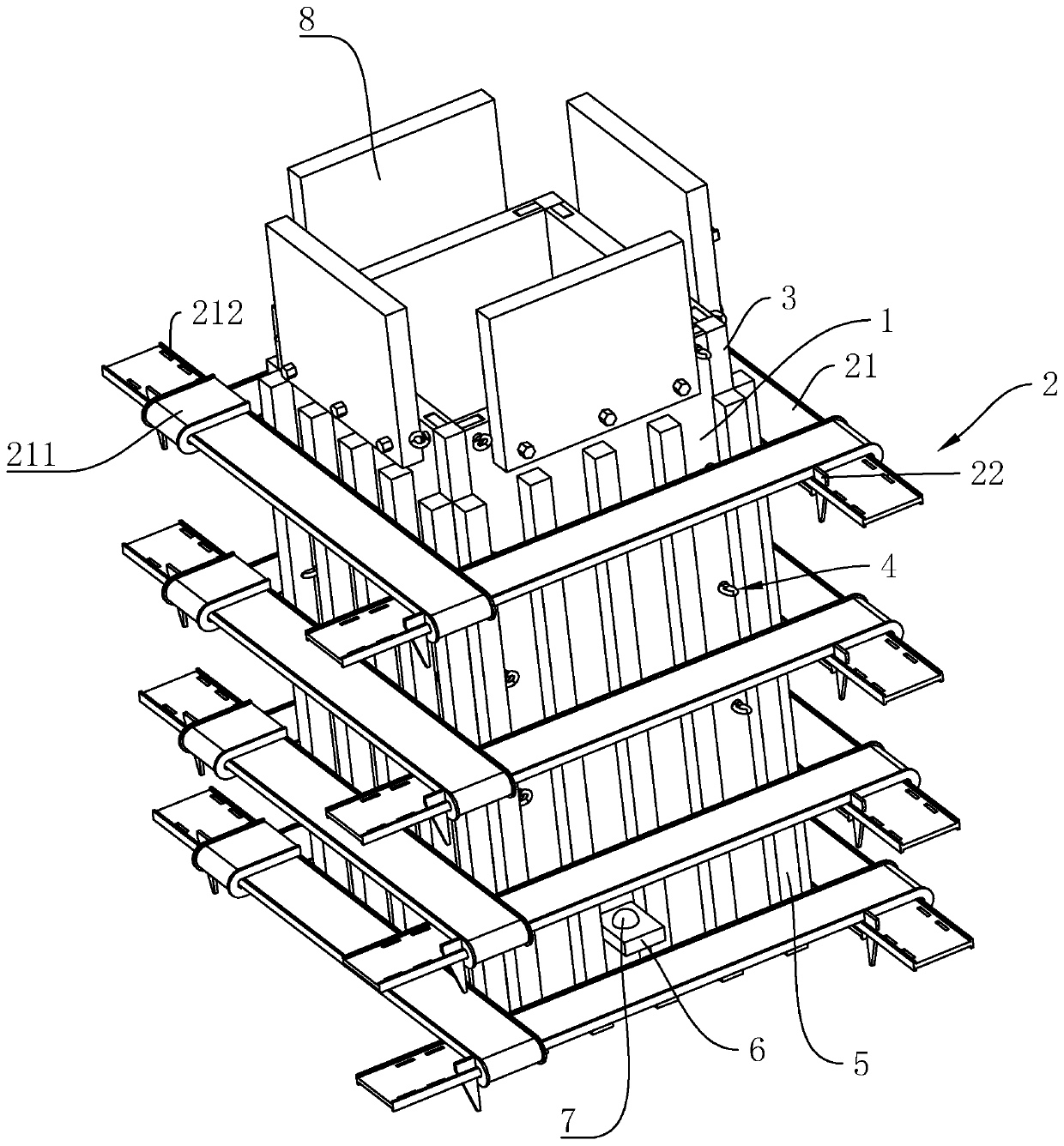

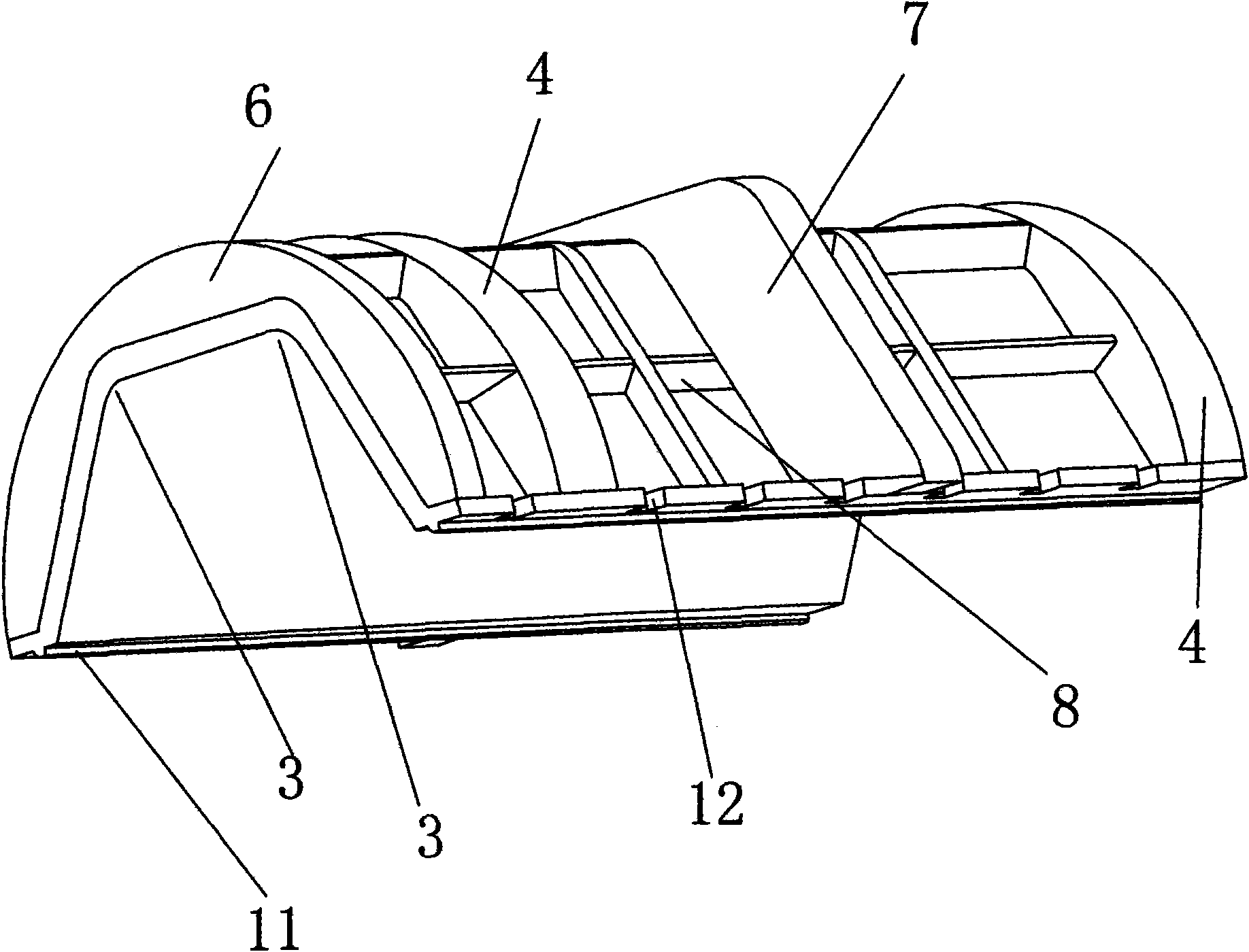

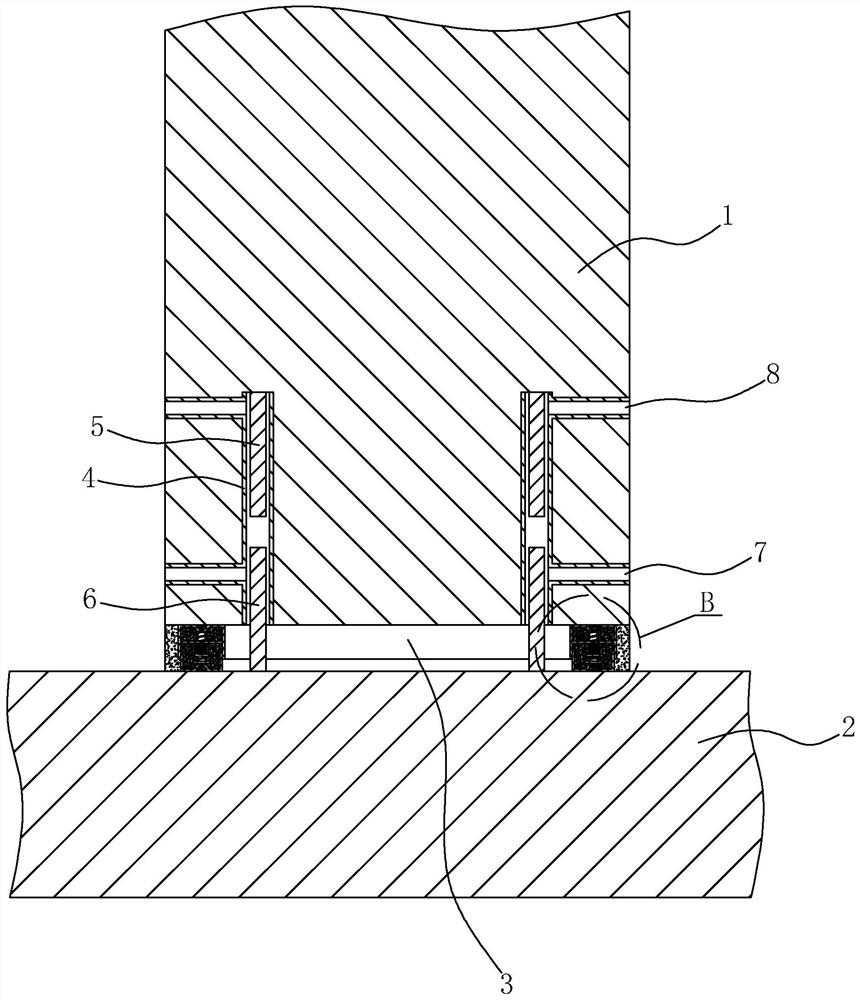

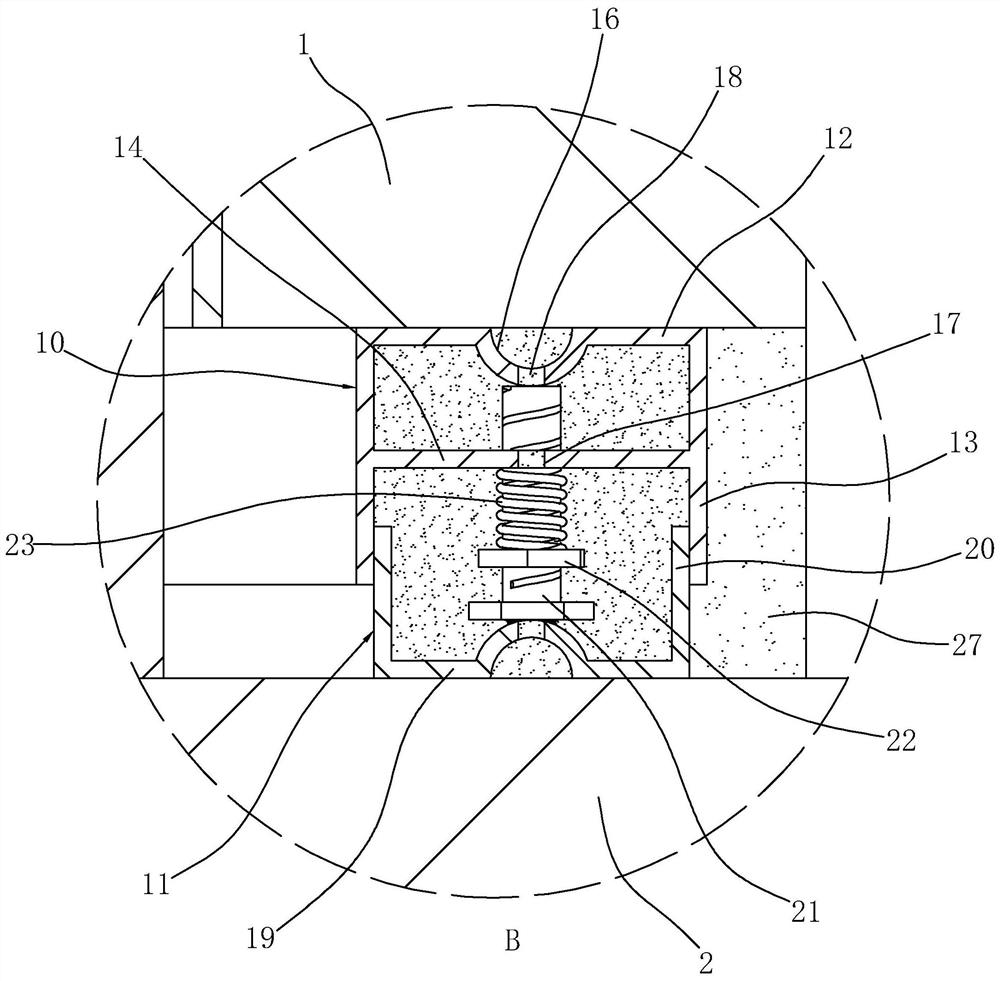

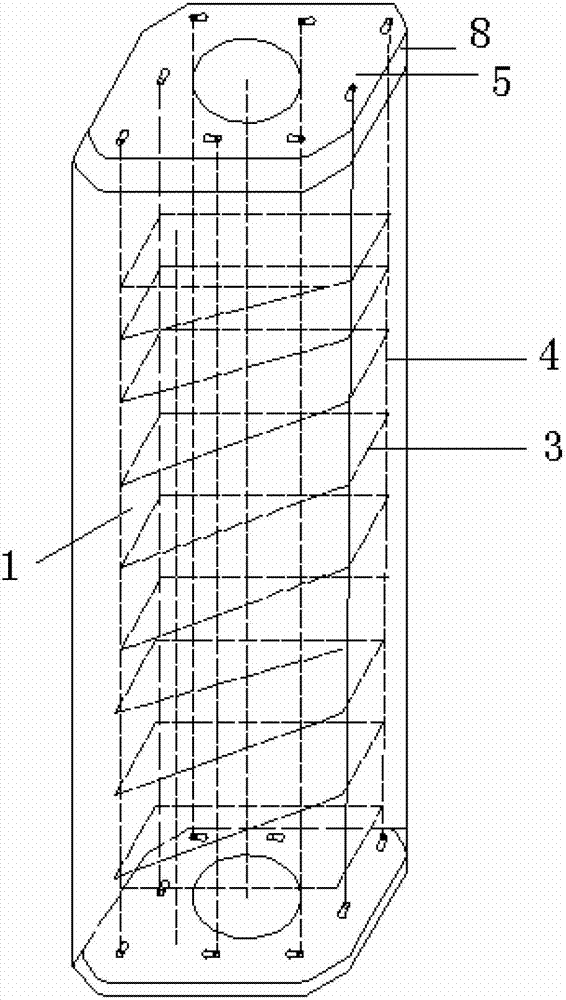

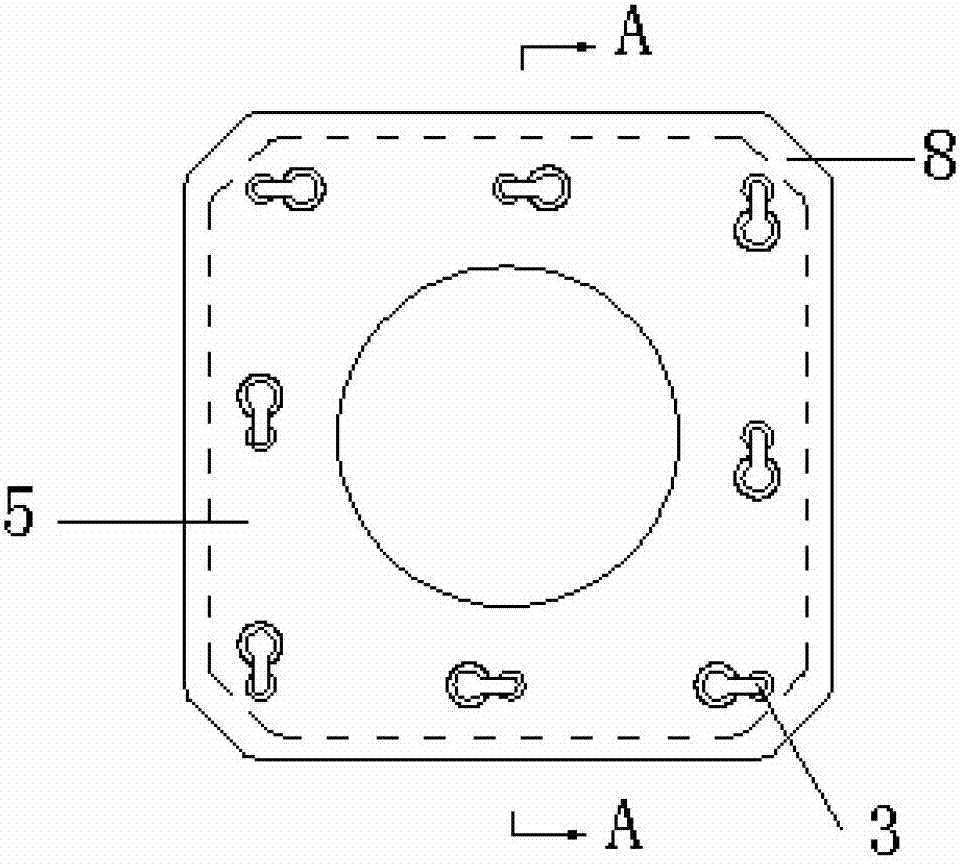

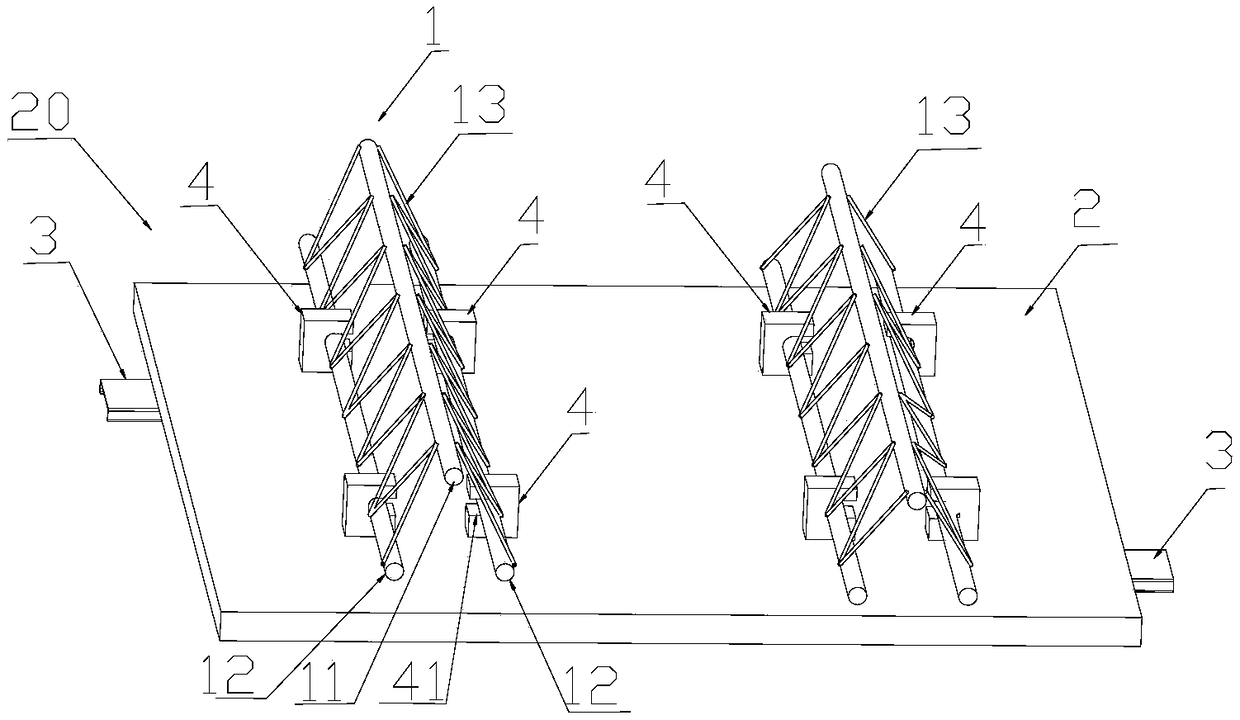

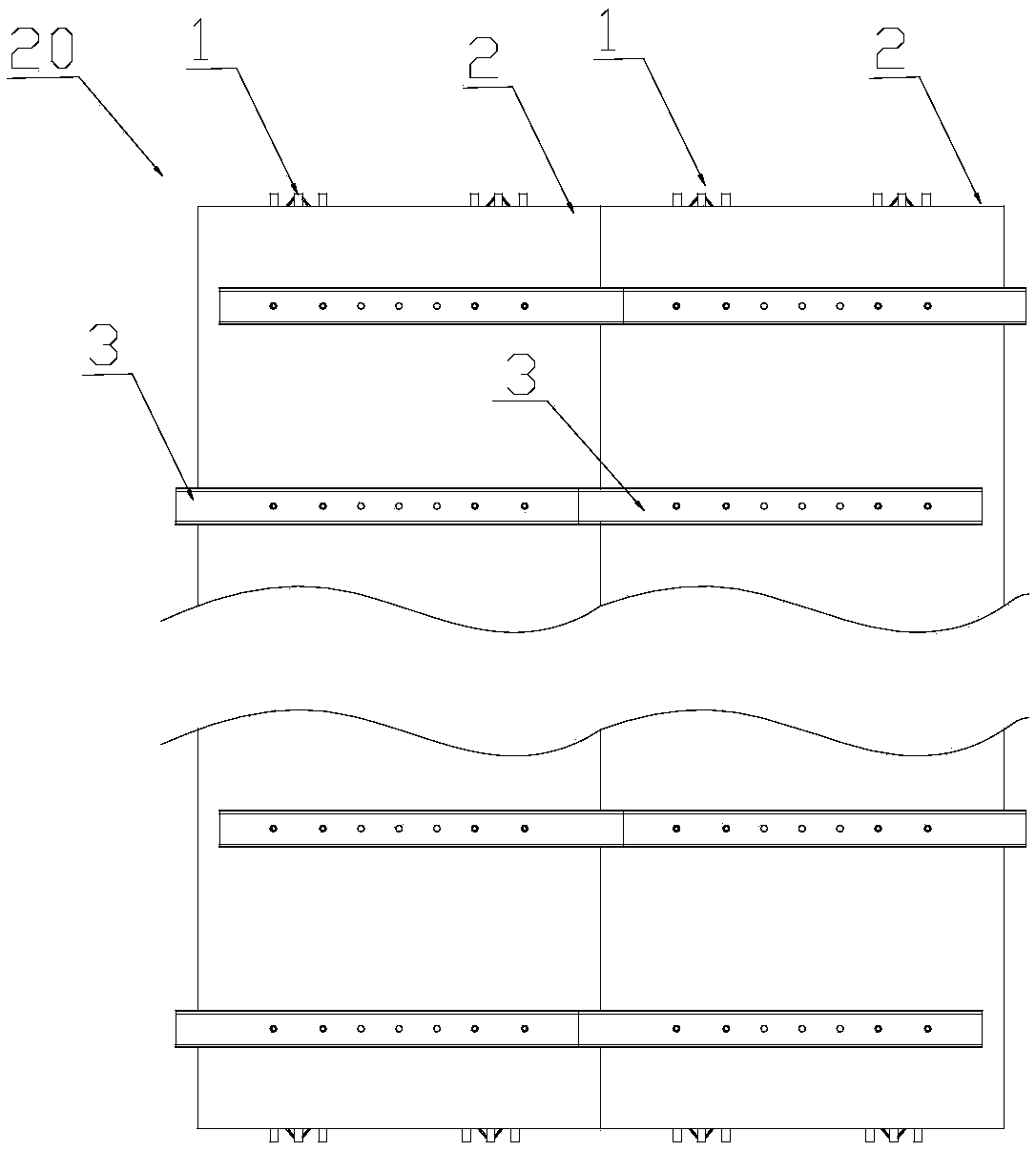

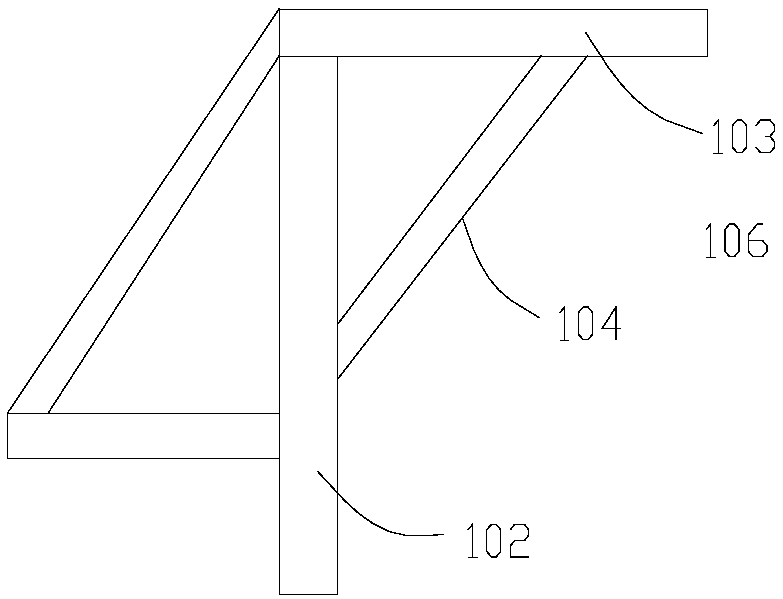

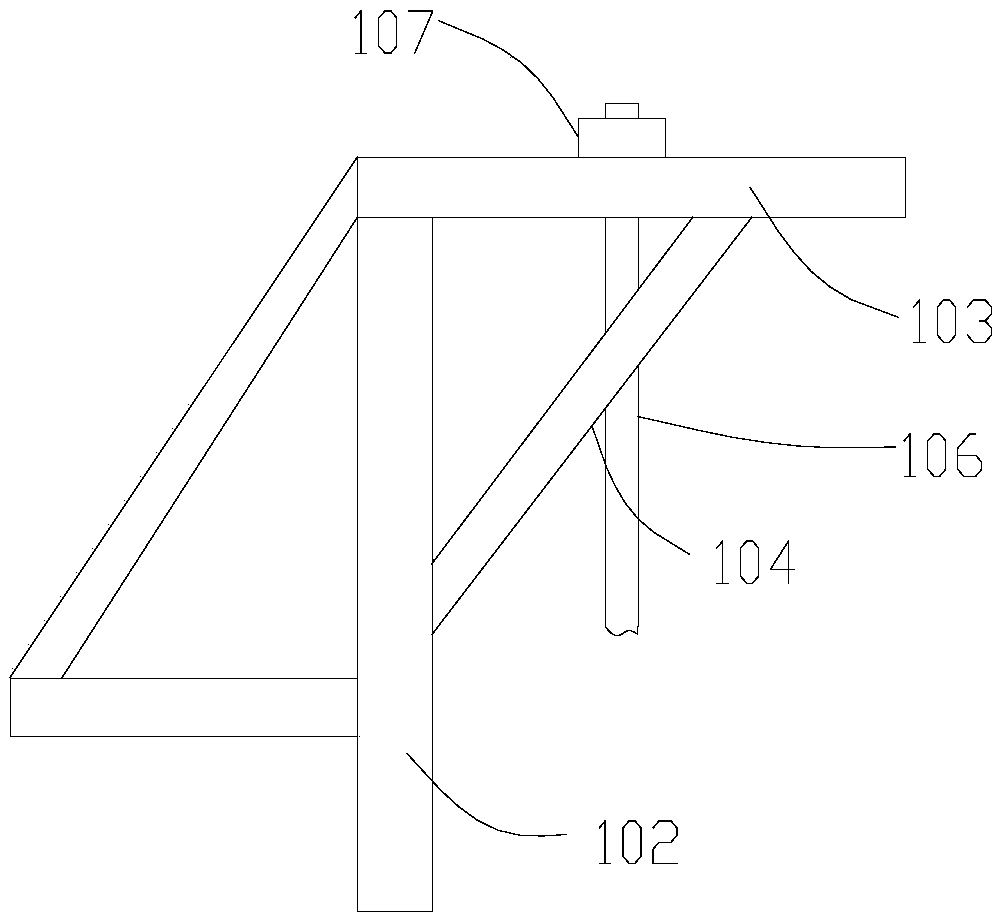

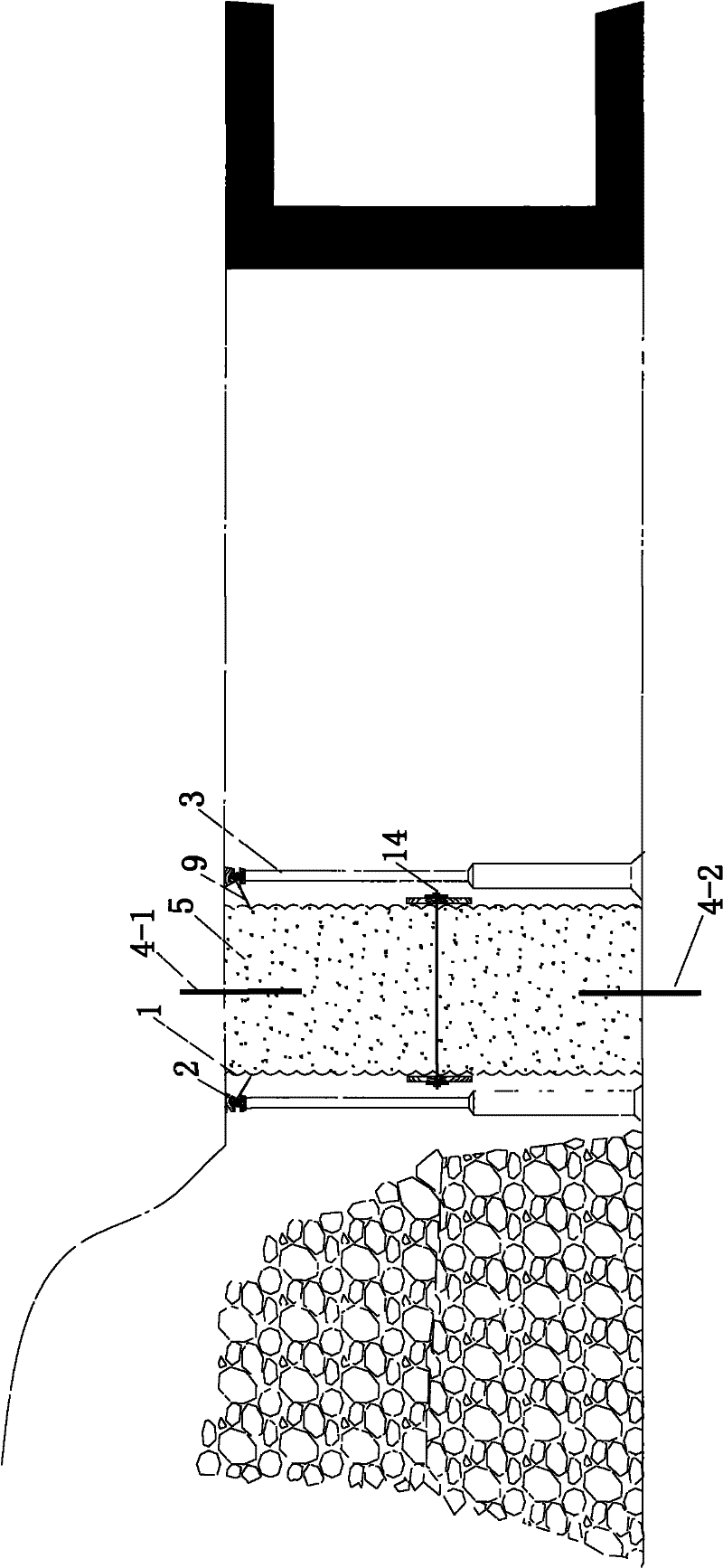

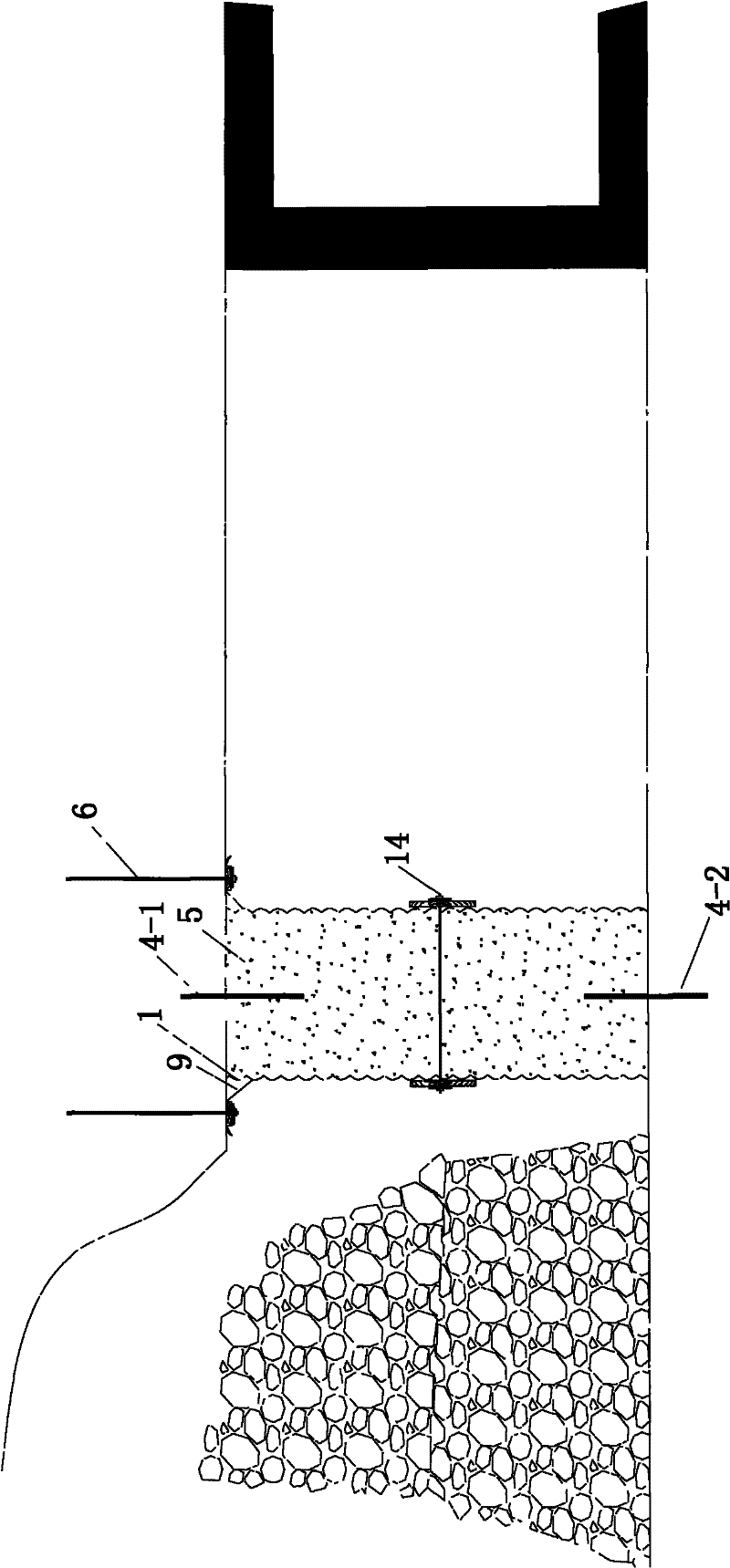

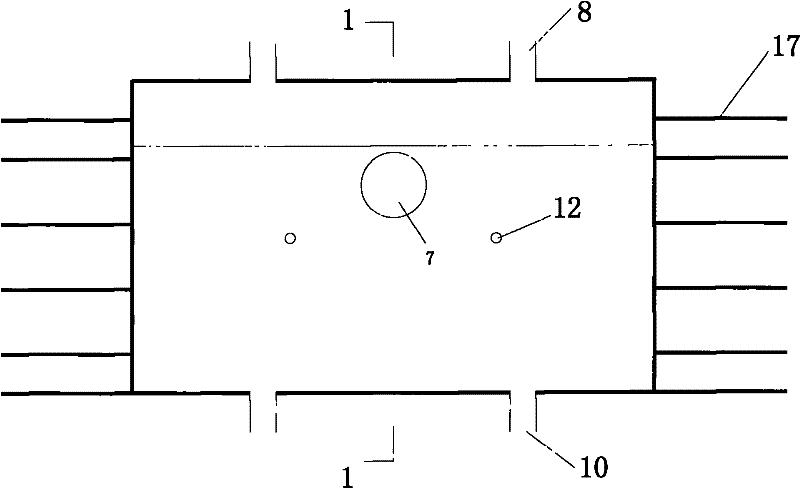

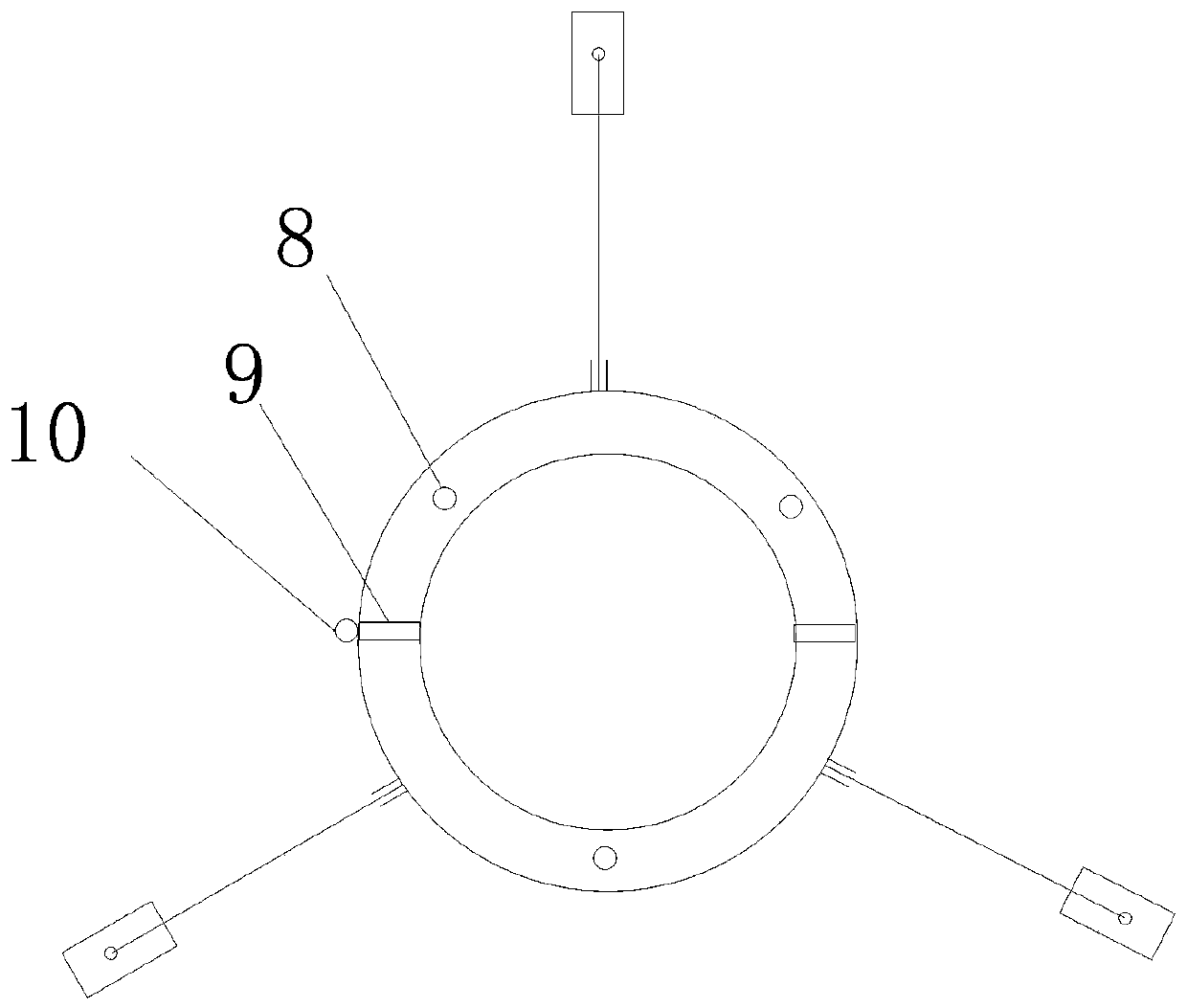

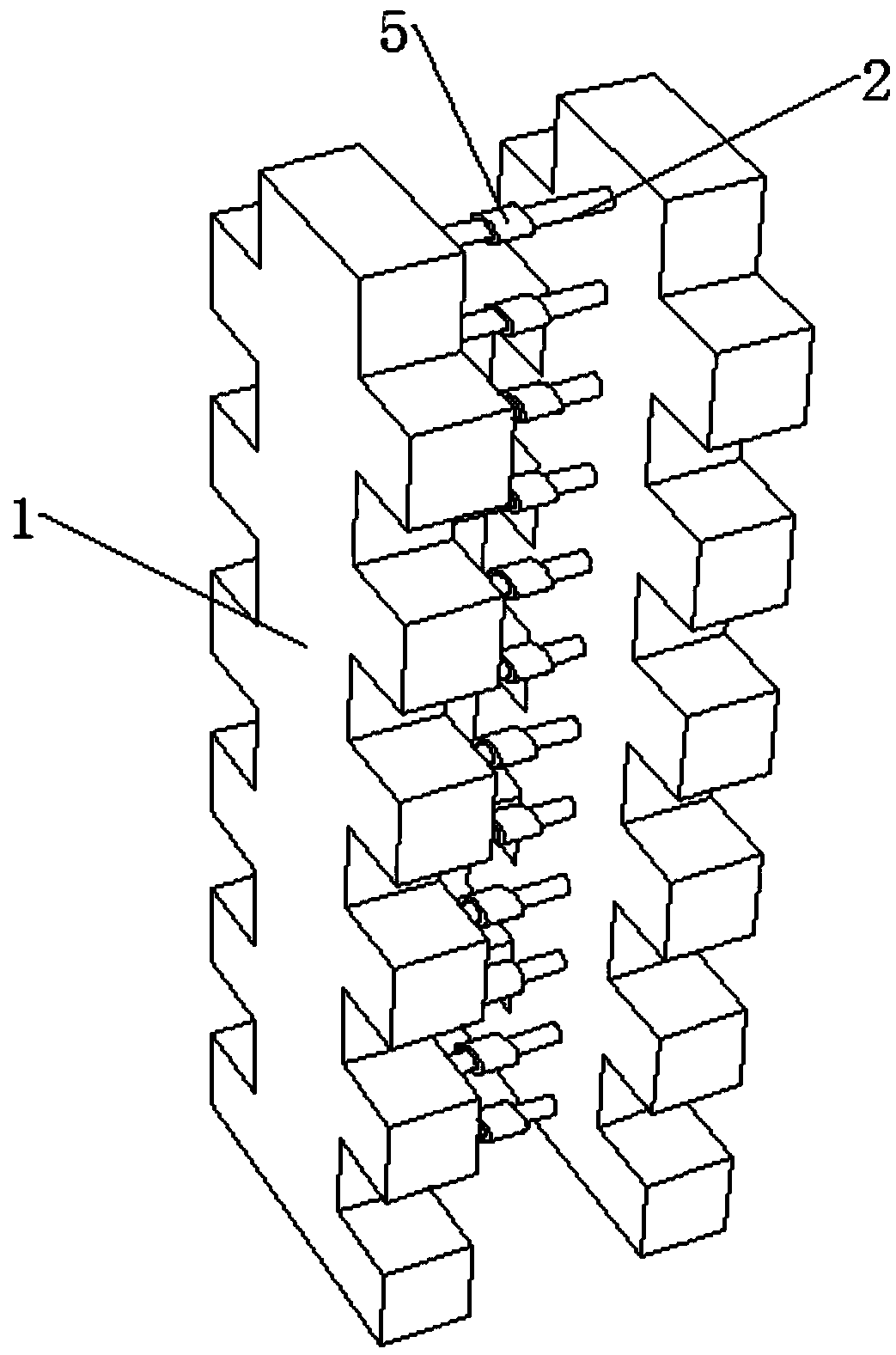

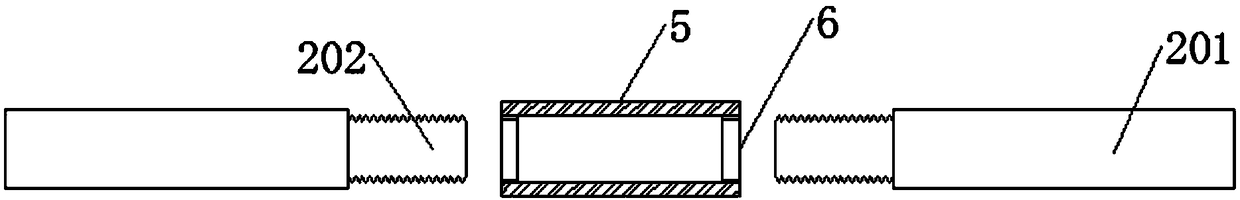

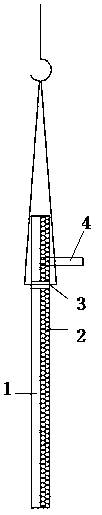

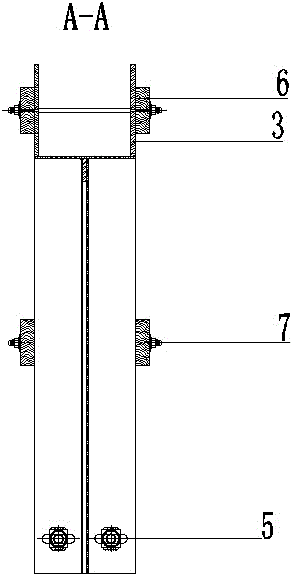

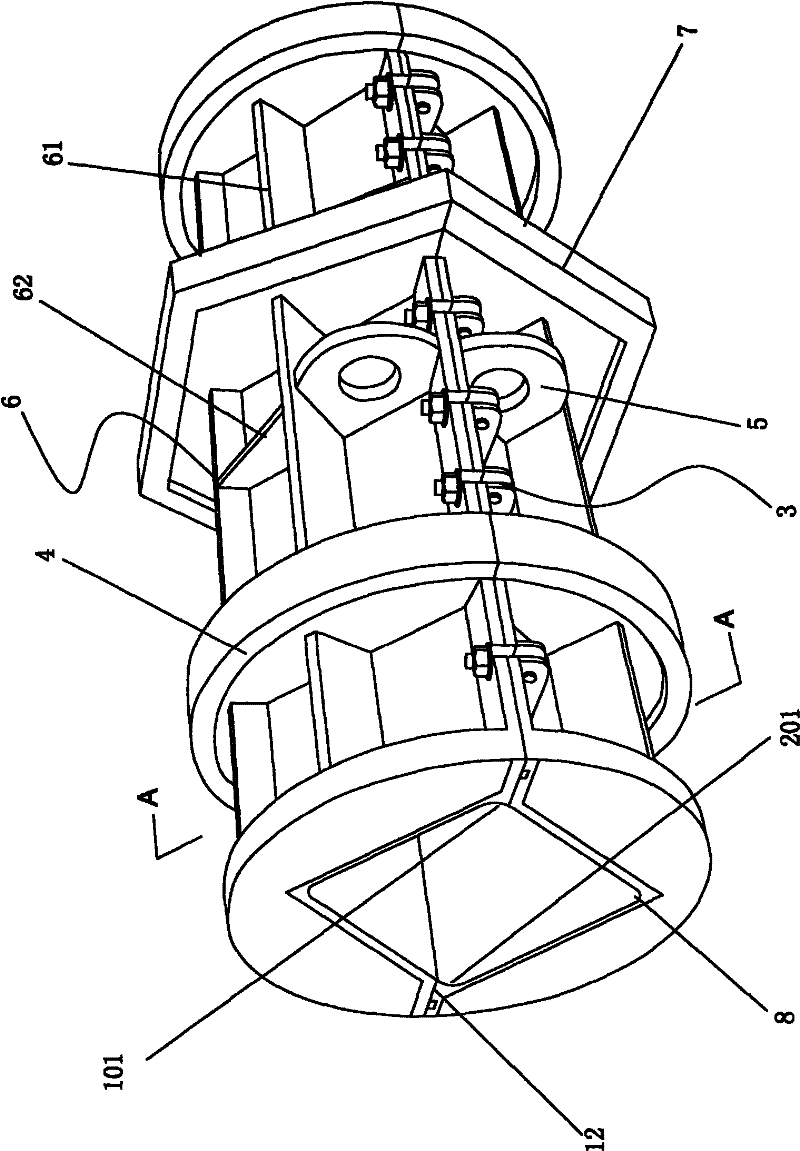

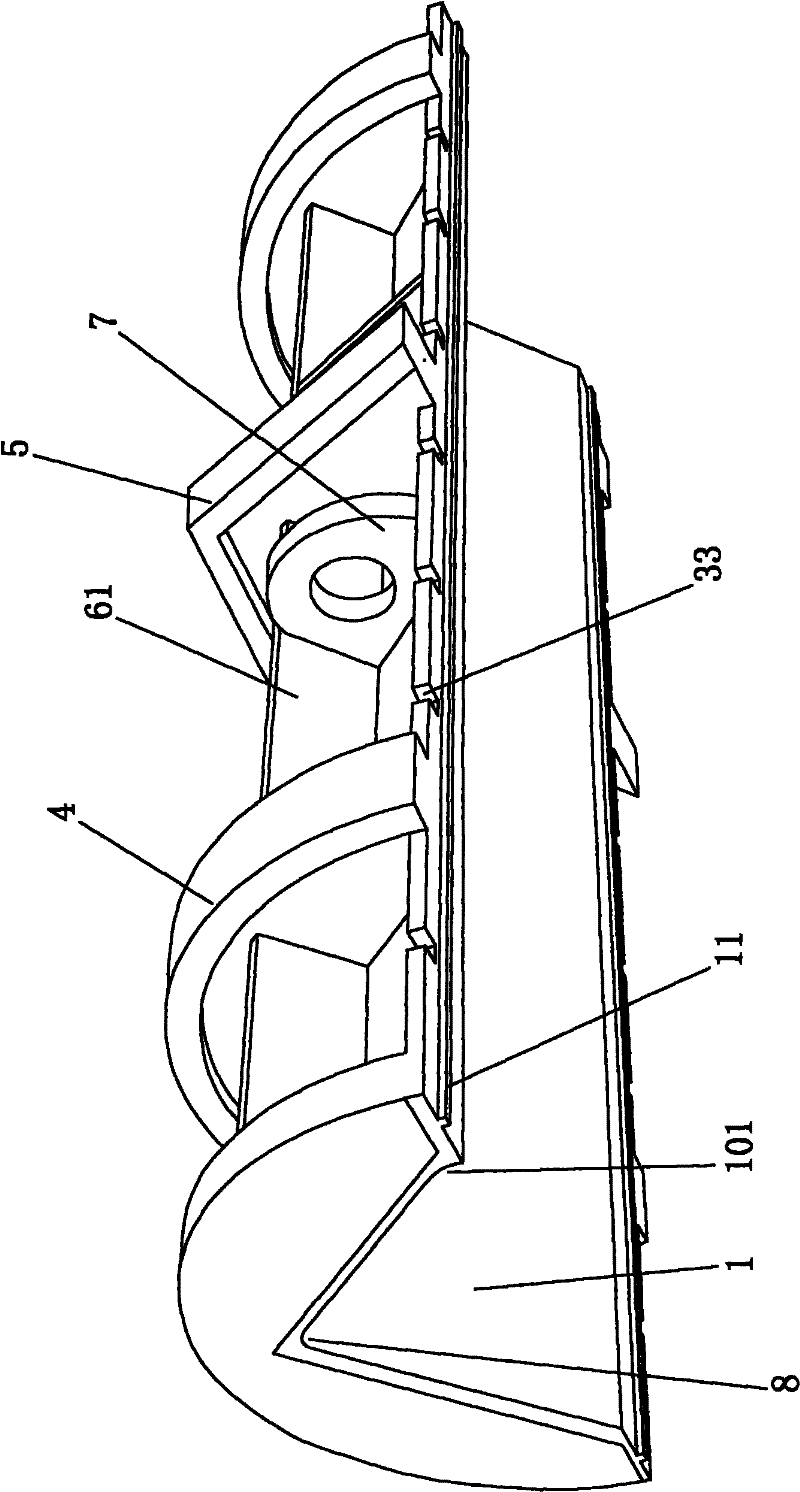

Device and method for casting concrete continuous walls along gob-side entry retaining by mining working face

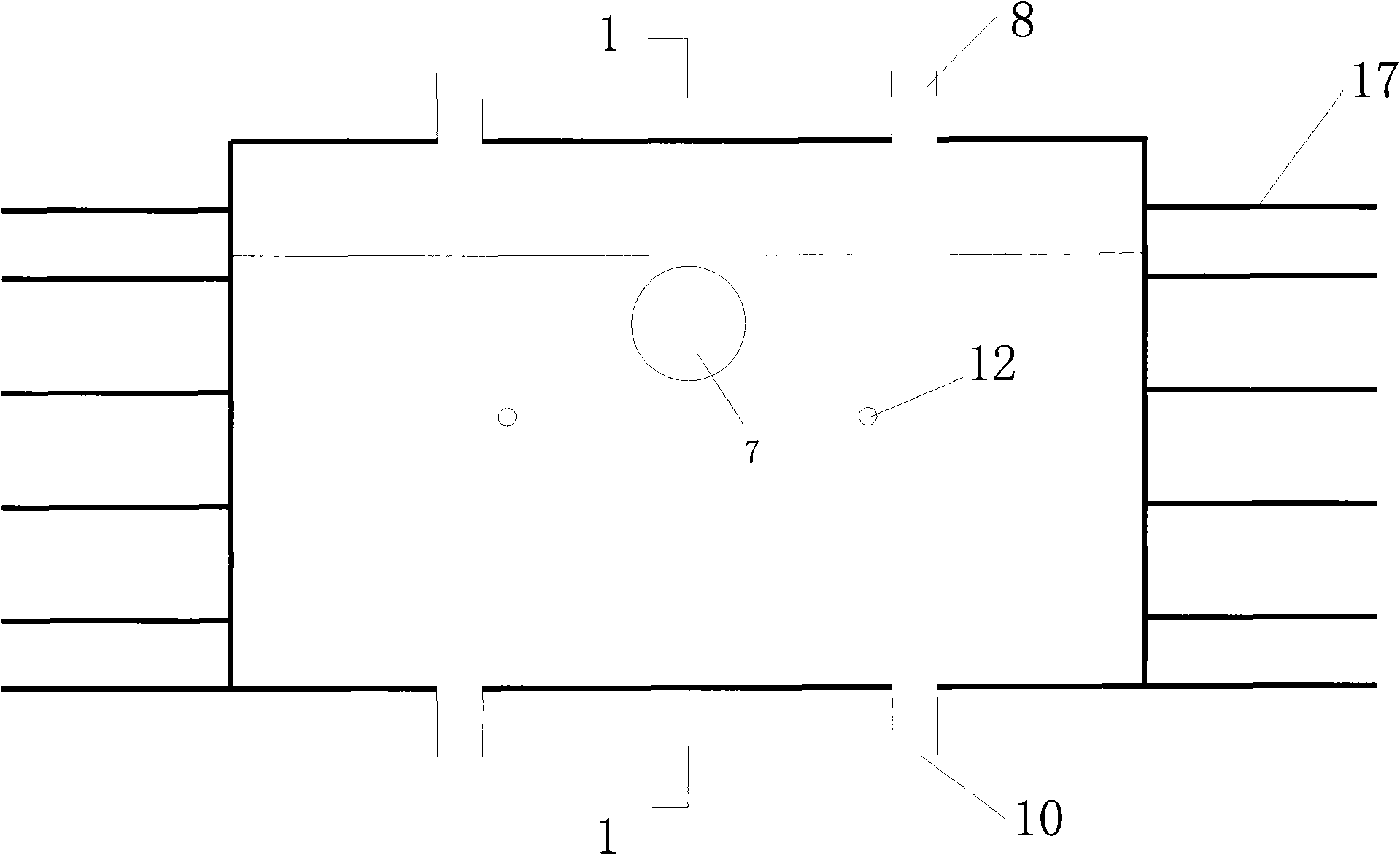

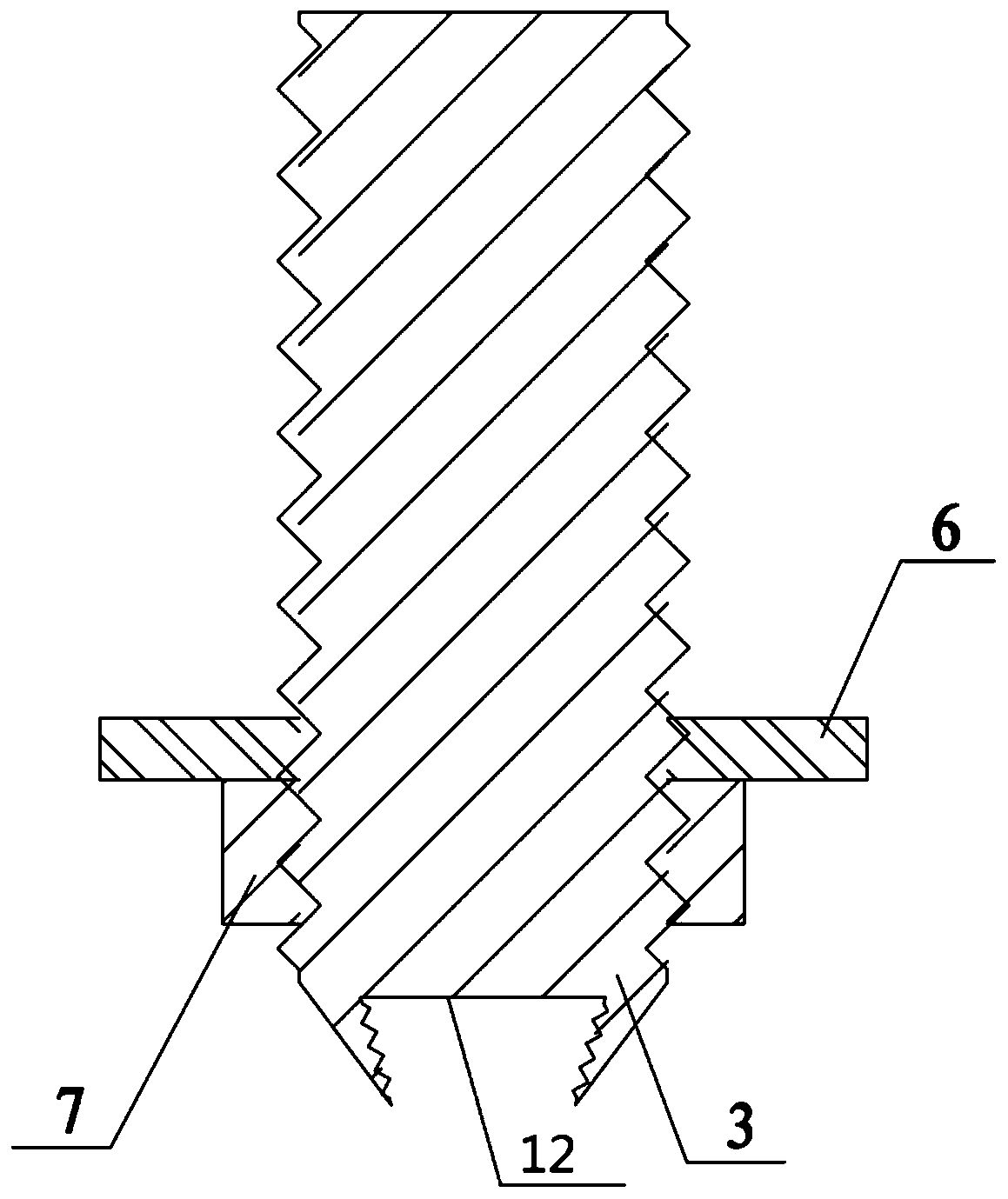

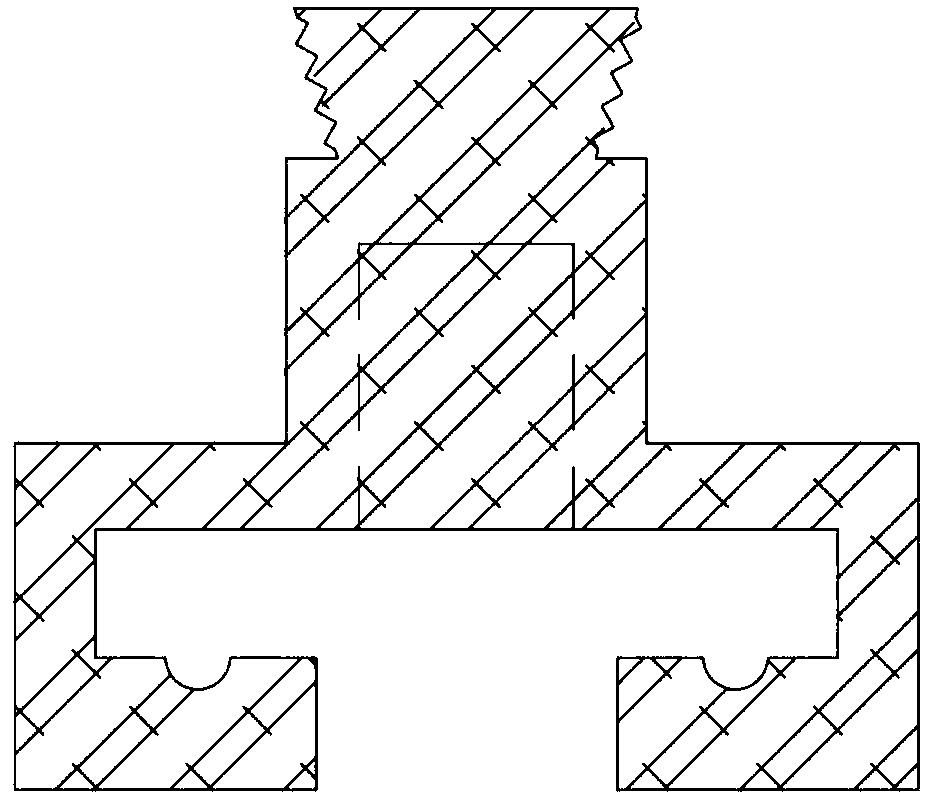

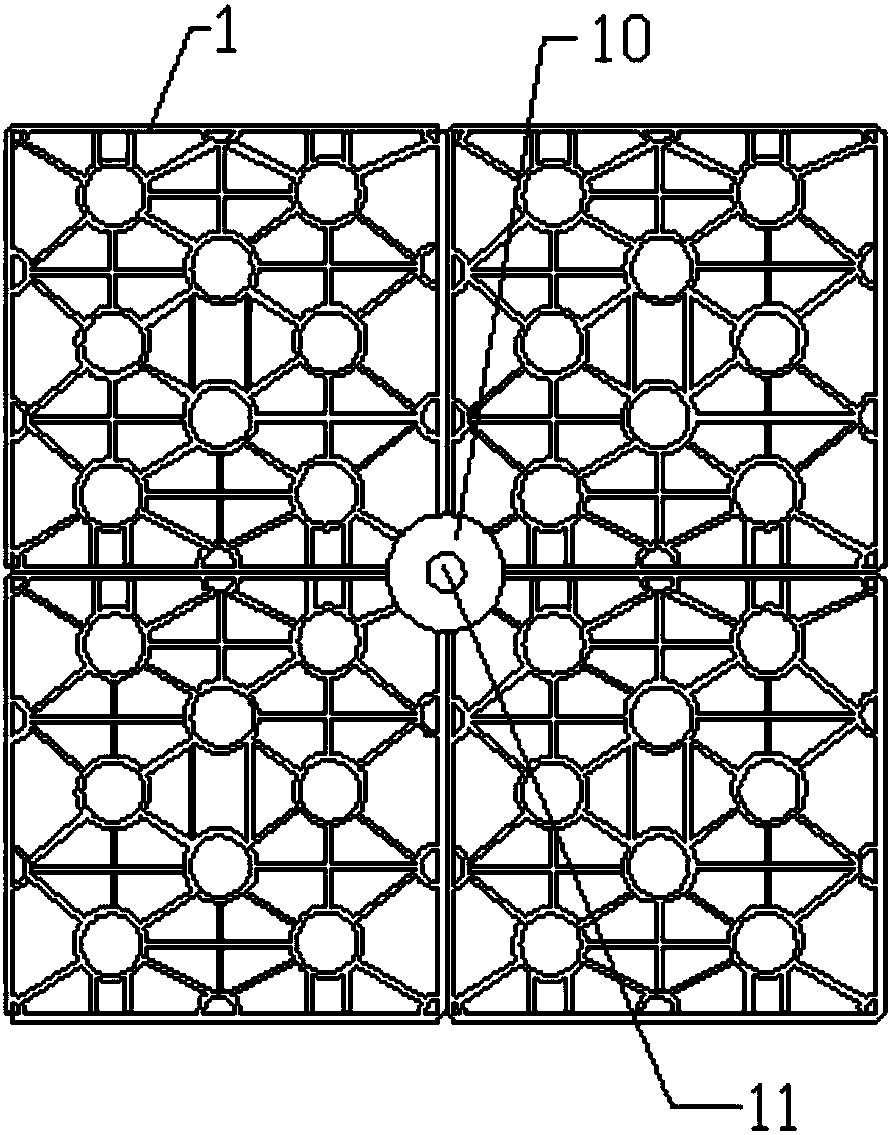

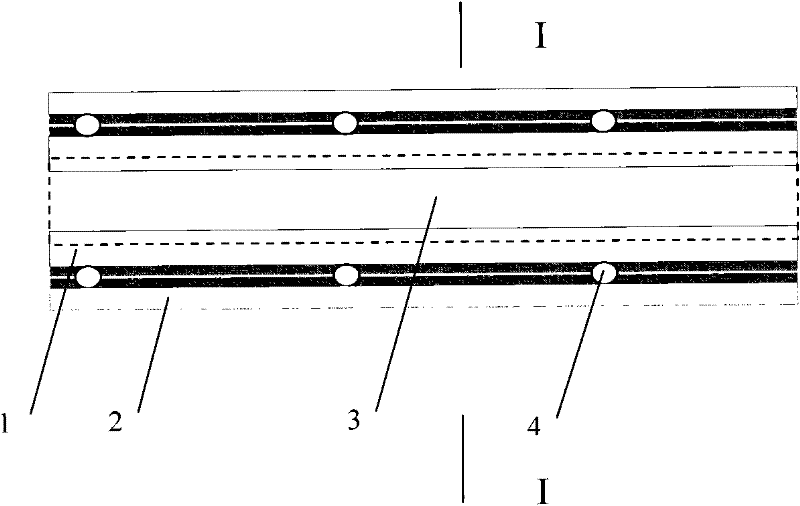

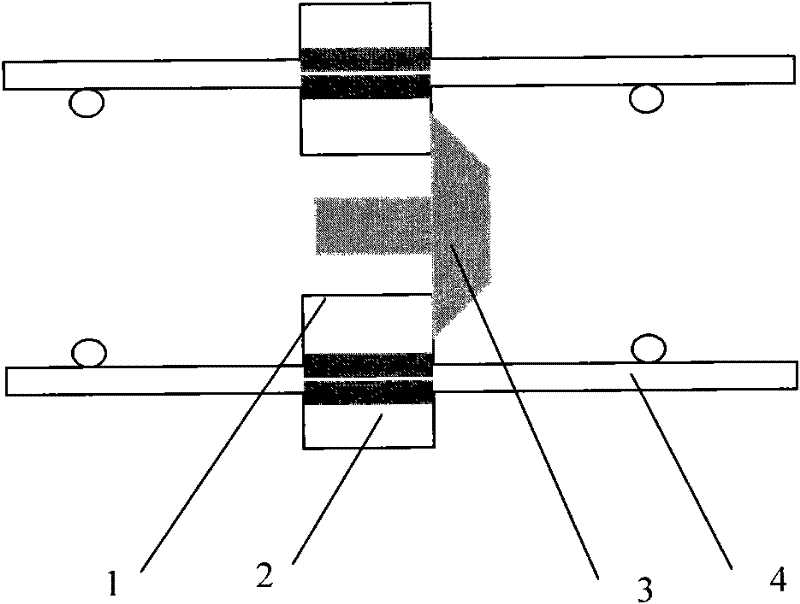

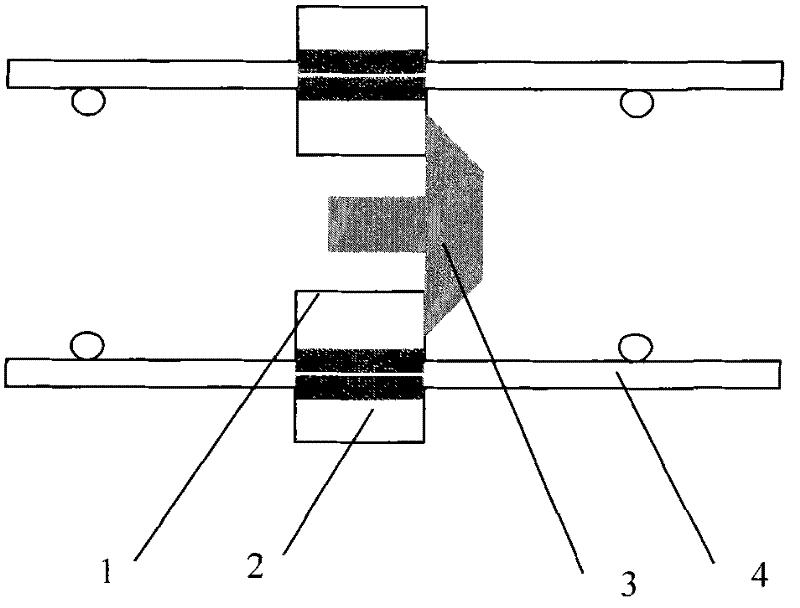

ActiveCN101649744AGood top connection effectFilled tightlyUnderground chambersTunnel liningFiberSteel bar

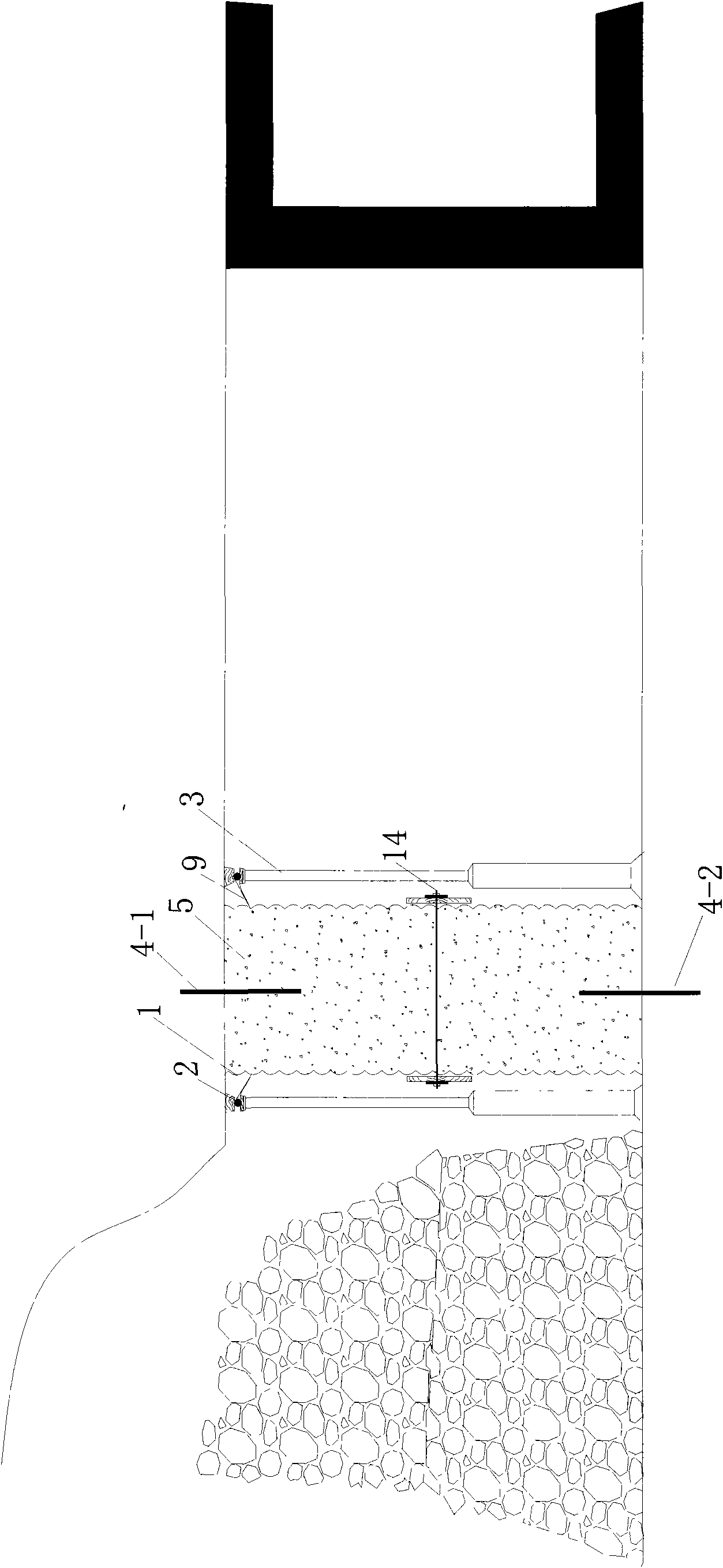

The invention discloses a device and a method for casting concrete continuous walls along gob-side entry retaining by a mining working face. A fiber flexible template is in cuboid shape or in cubicalshape, which is formed by a main body template and a top joint template and is connected with a flange, a casting opening, a reinforcing steel bar implanting opening, a spacing hole and a tiepiece. The method comprises the following steps: the fiber flexible template is manufactured in advance; the flexible template is hung over on a top plate of a coal seam through an individual hydraulic prop oran anchor rod by the flange; the exposure end of the implanted reinforcing steel bar is inserted in the flexible template through the reinforcing steel bar implanting opening; a leading screw penetrates into the spacing hole and two ends thereof are fixed by tray nuts; the casting opening is inserted with a concrete conveying pipe and is bonded; concrete is poured into the flexible template through the conveying pipe by a concrete pump; and finally the concrete continuous walls are formed. The invention has simple structure, high-speed construction, high work efficiency, good impermeability,uneasily slurry leaking property, densely filled concrete and good top joint effect, can carry out mechanized operation, adapts to the change of gradient of the roof and floor, and can be widely usedin the following industries, such as coal mine, metallurgical mine, water conservancy, underground construction and national defense and the like.

Owner:SHAANXI PIONEERING ARCHITECTURAL TECH

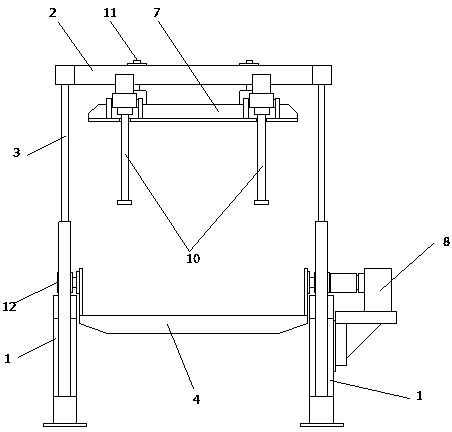

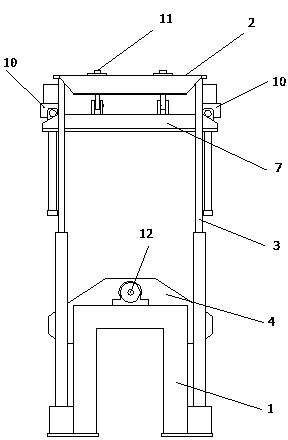

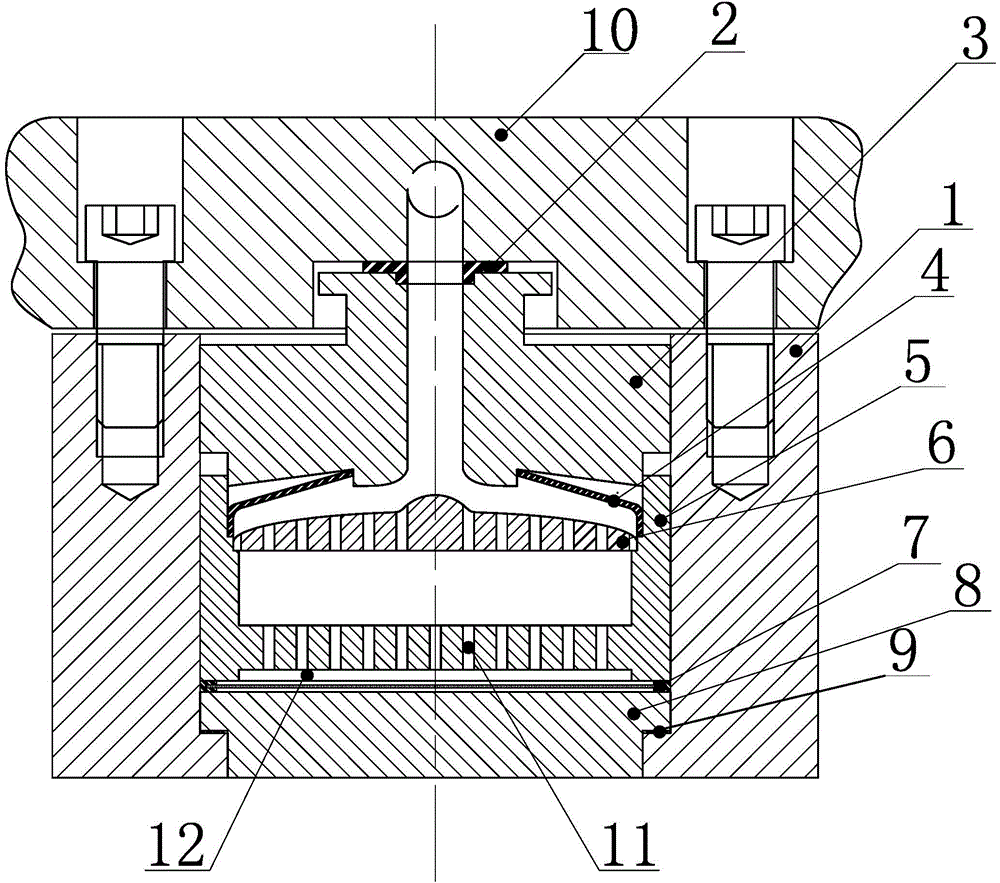

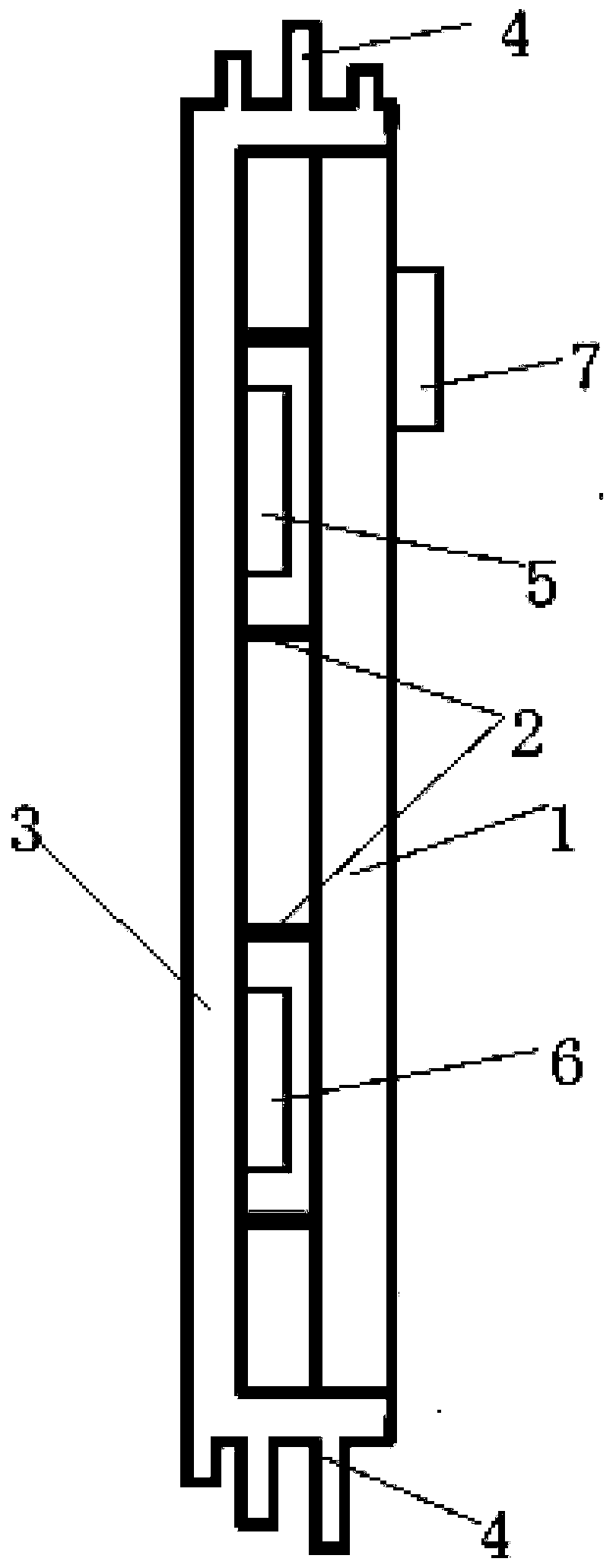

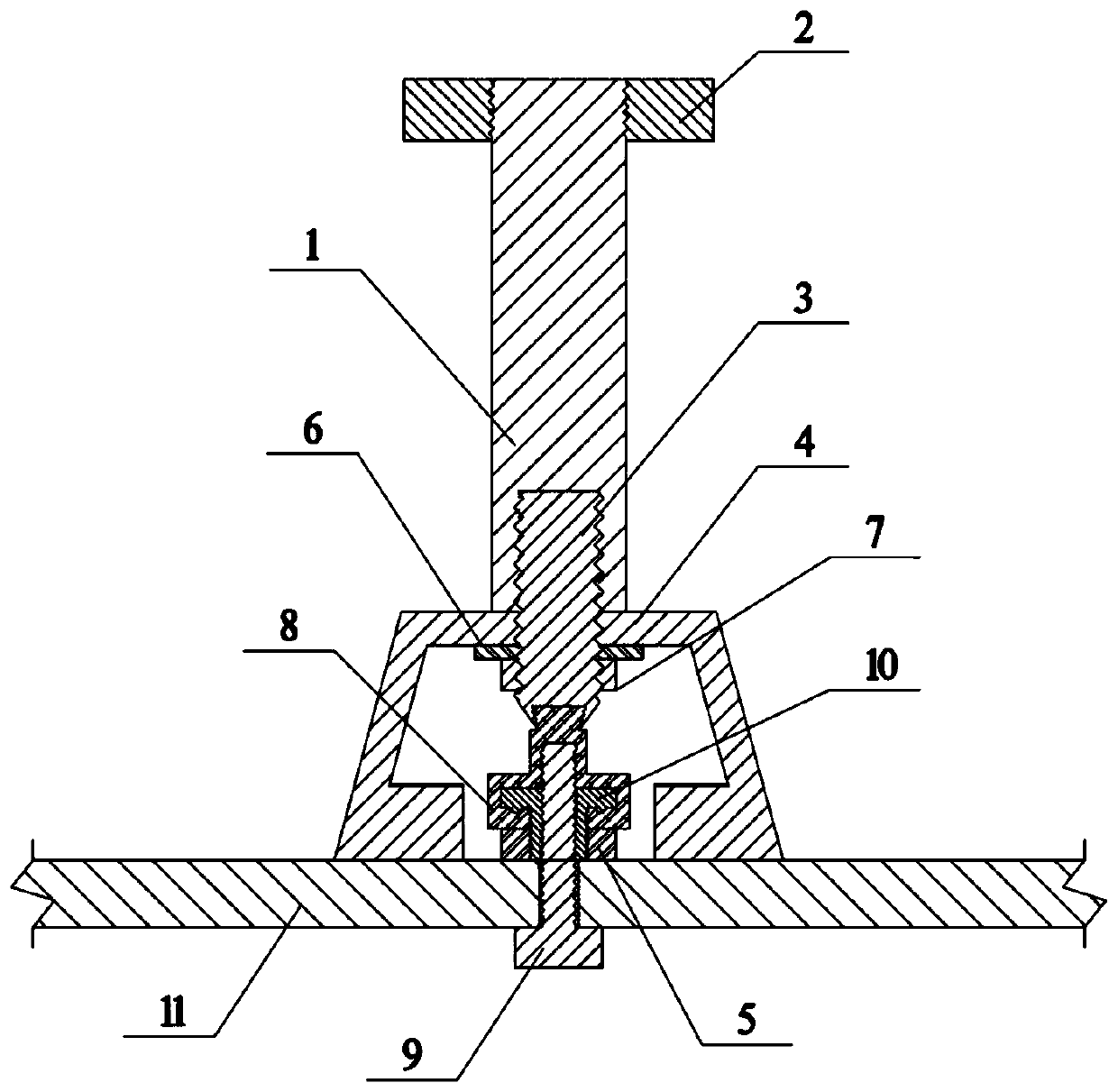

Individual type high-pressure grouting forming machine

InactiveCN103831887AReduce difficultyVariable groutingAuxillary shaping apparatusMolding machineEngineering

The invention relates to a grouting forming device in ceramic production, in particular to an individual type high-pressure grouting forming machine. The individual type high-pressure grouting forming machine comprises a support, a transverse beam frame, a base and an upper die frame, wherein the support is provided with a vertical guide column, and the transverse beam frame is driven by a lifting device to conduct vertical movement on the support by being guided by the guide column; the upper die frame is arranged on the transverse beam frame through a pothook; the base is arranged on the support through a turning bearing, and the base can turn on the support by being driven by a turning power device; the upper die frame and the base are provided with a clamping device, an upper mould is arranged in the upper die frame when a lower mould is placed in the base, the upper die frame moves downwards along the guide column along with the transverse beam frame and is combined to the base, and the upper die frame and the base are clamped by the clamping device to form a whole. The individual type high-pressure grouting forming device can be suitable for a plurality of types of products, blank releasing and taking are automated, and dangerous and high-strength manual work is replaced.

Owner:唐山森兰瓷科技有限公司

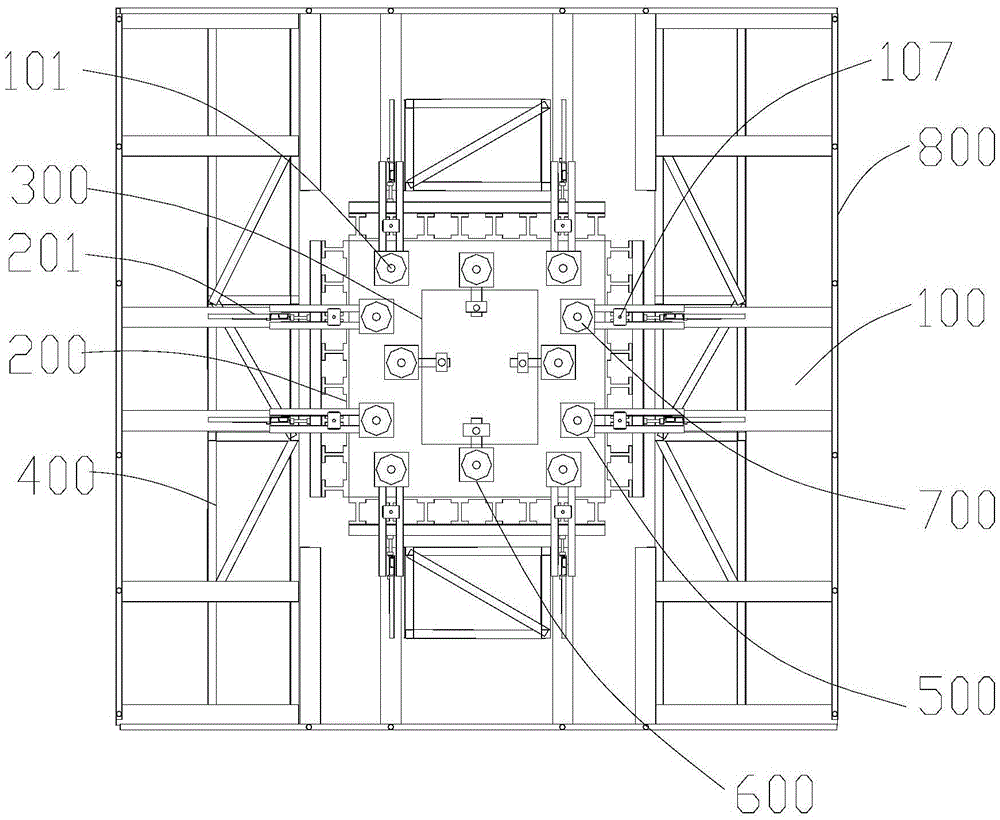

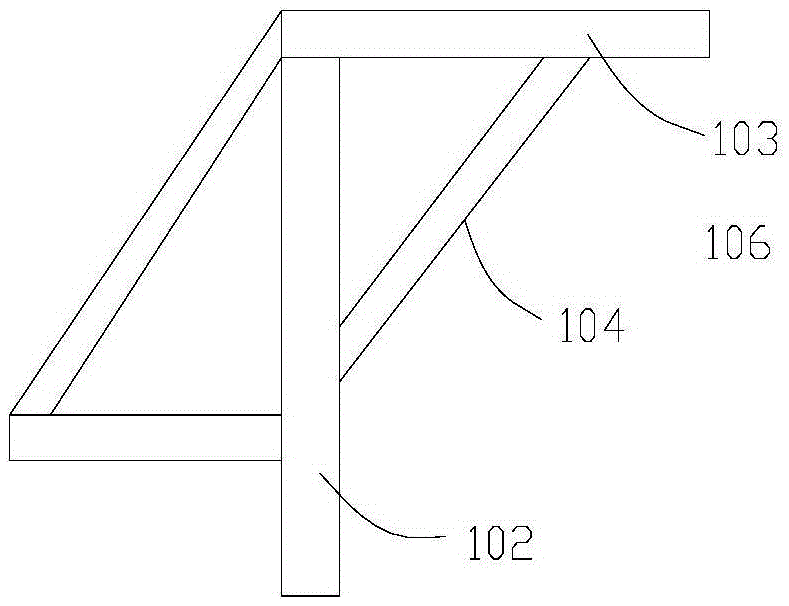

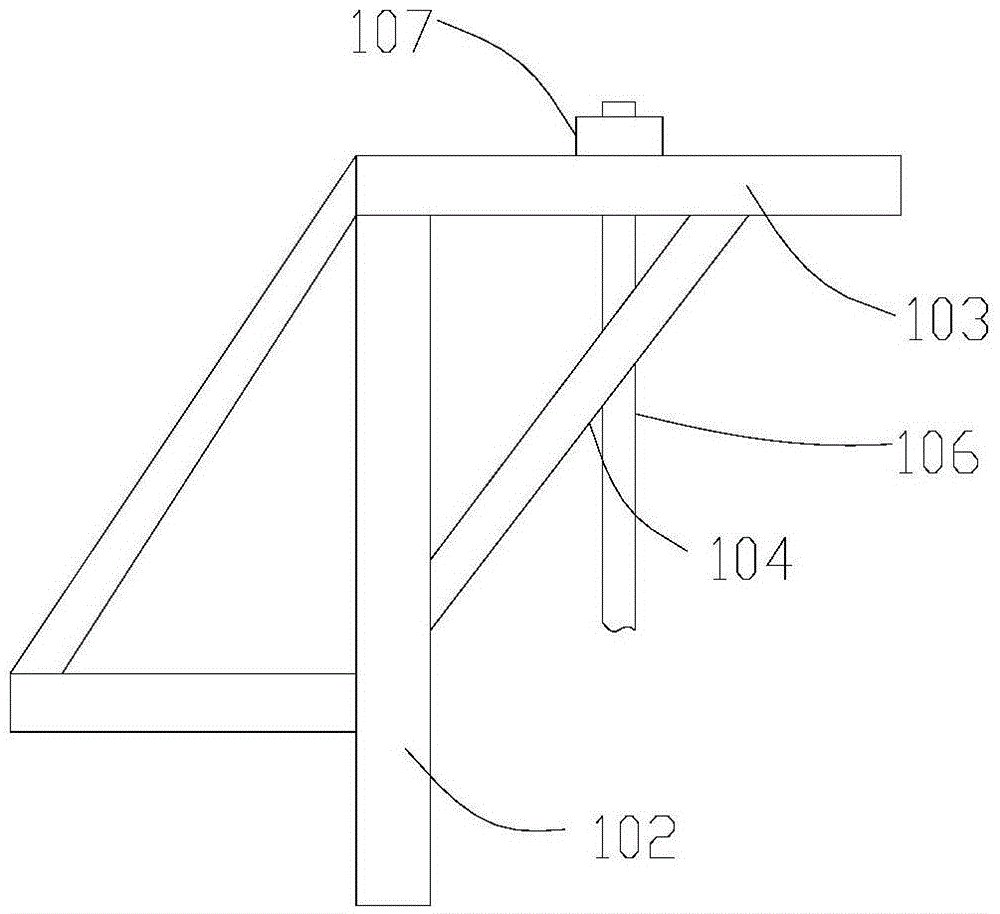

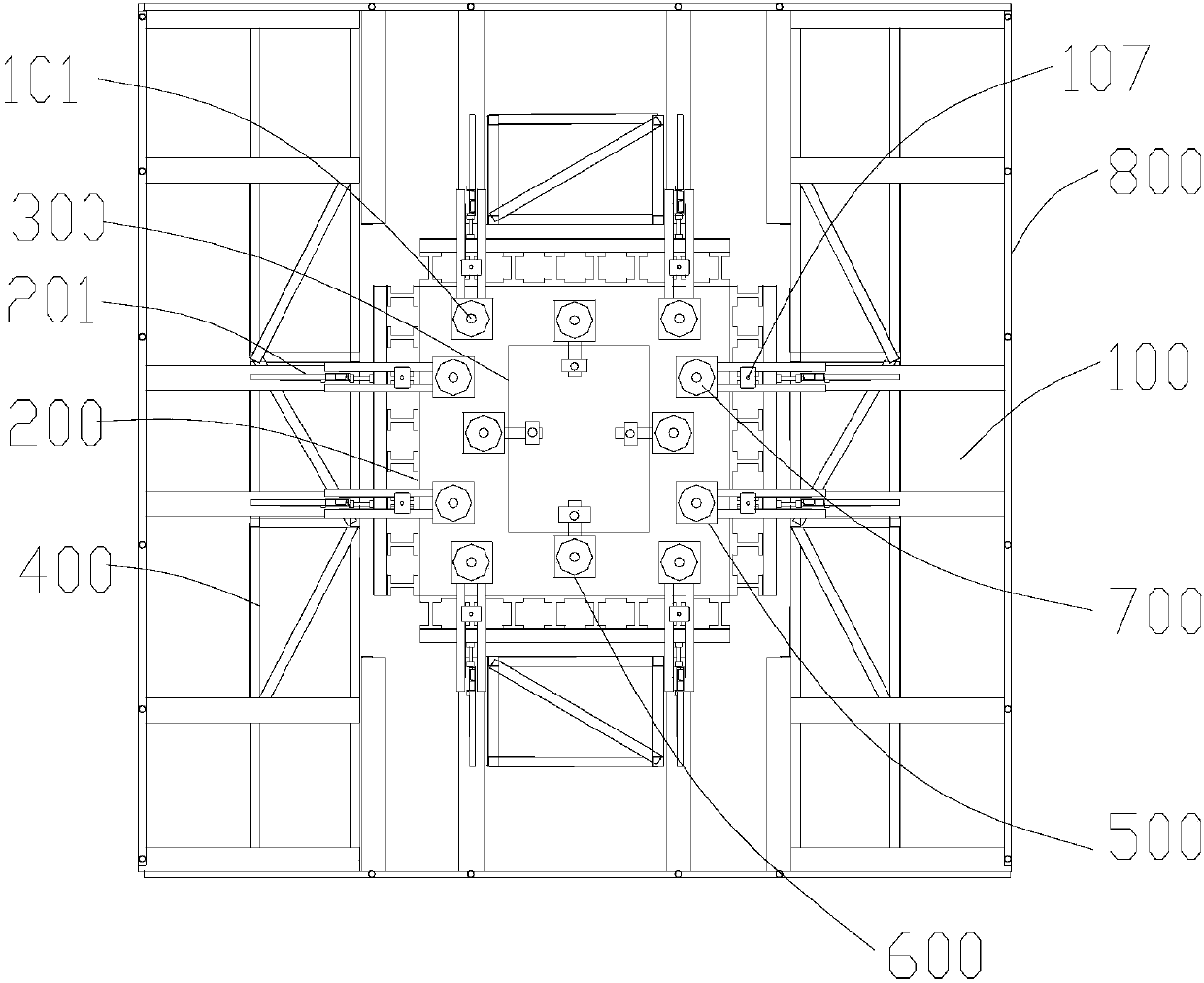

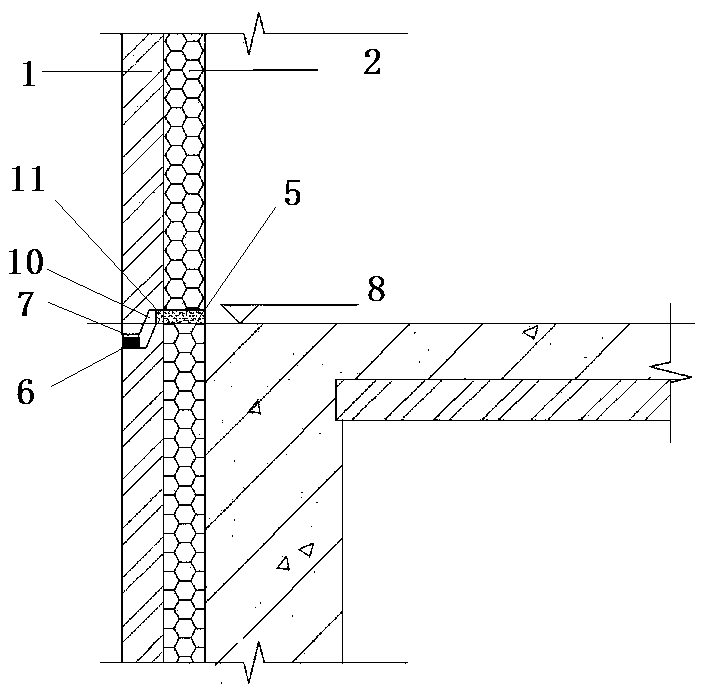

High concrete pier construction formwork device

ActiveCN105544397ASimple structureCompact structureBridge structural detailsBridge erection/assemblySupporting systemSupport system

The invention provides a high concrete pier construction formwork device and belongs to the technical field of building equipment. The high concrete pier construction formwork device comprises a formwork system, a supporting system, a hydraulic lifting system and an operation platform. The formwork system comprises an inner formwork and an outer formwork. The supporting system comprises an enclosing truss, multiple outer lifting frames and multiple inner lifting frames, wherein the enclosing truss is arranged on the outer side of the outer formwork, and the distance between the enclosing truss and the outer formwork ranges from 300 mm to 500 mm; and the outer lifting frames are fixedly connected with the enclosing truss, the outer formwork is installed on the outer lifting frames, and the inner formwork is installed on the inner lifting frames. The hydraulic lifting system is used for driving the inner lifting frames and the outer lifting frames to move in a reciprocating manner, so that the enclosing truss, the outer formwork and the inner formwork move synchronously. The operation platform is located in a cavity defined by the inner formwork and on the enclosing truss. The formwork device is compact in whole structure, the structure is firm and reliable, and in the lifting process, the stress of the formworks is more even, and the formworks are lifted more conveniently and rapidly.

Owner:THE THIRD ENG CO LTD OF THE HIGHWAY ENG BUREAU OF CCCC

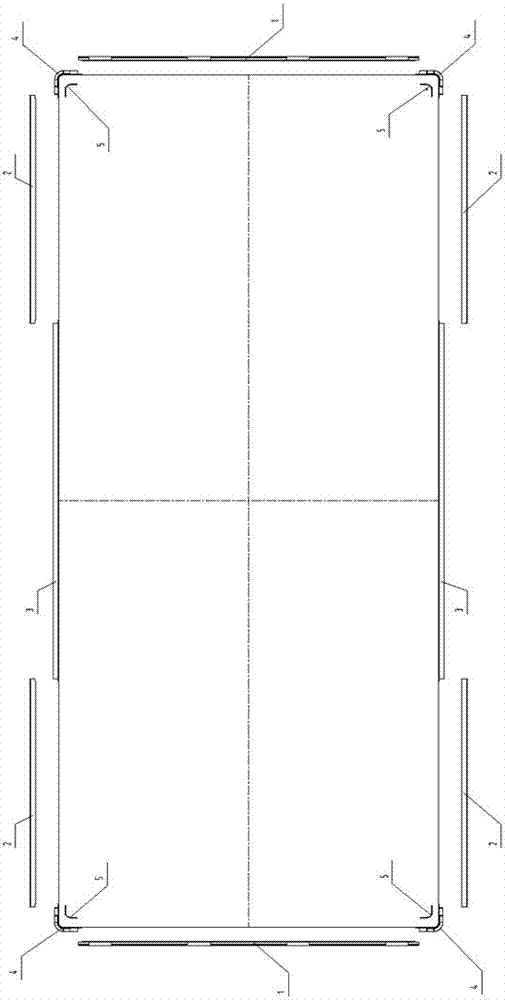

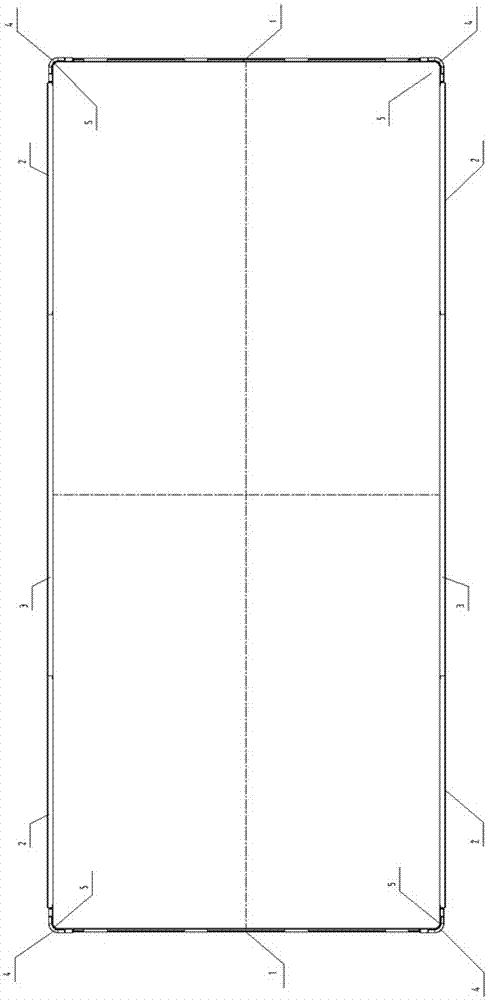

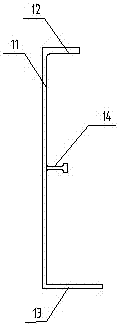

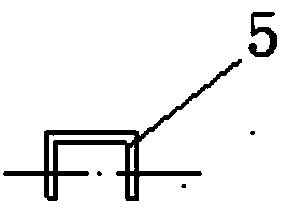

Upright post formwork

InactiveCN110242041AImprove connection strengthNot easy to leak slurryForms/shuttering/falseworksSquare cross sectionEngineering

Owner:北京碧鑫水务有限公司

Spinning device for dry-jetting and wet-spinning method

InactiveCN104153008AReduce processing costsFit closelySpinnerette packsSpinning head liquid feederFiberSlurry

A spinning device for a dry-jetting and wet-spinning method comprises a base, wherein a sand cavity is formed in the base, a distributing plate, a partition plate, a multi-layer filter screen and a spinneret plate are sequentially arranged in the sand cavity from top to bottom. A gland moving in the axial direction is installed in the base, arranged above the sand cavity and provided with a size flow channel, an inlet of the size flow channel is communicated with a size outlet of a spinning box, and an outlet of the size flow channel is communicated with the sand cavity; the distributing plate is arranged at the downstream position of the outlet of the size flow channel, and a plurality of flow guide holes are evenly distributed in the distributing plate; flow guiding holes are evenly distributed in the partition plate, and the portion, between the partition plate and the distributing plate, of the sand cavity is filled with filter sand; a certain gap is formed between the multi-layer filter screen and the partition plate to form a pressure stabilizing chamber; the spinneret plate makes close contact with the lower surface of the multi-layer filter screen. The spinning device is good in sealing effect, not prone to leaking size, the size flows without dead angles, and therefore the performance of fibers is ensured.

Owner:SHANDONG YINGLI IND

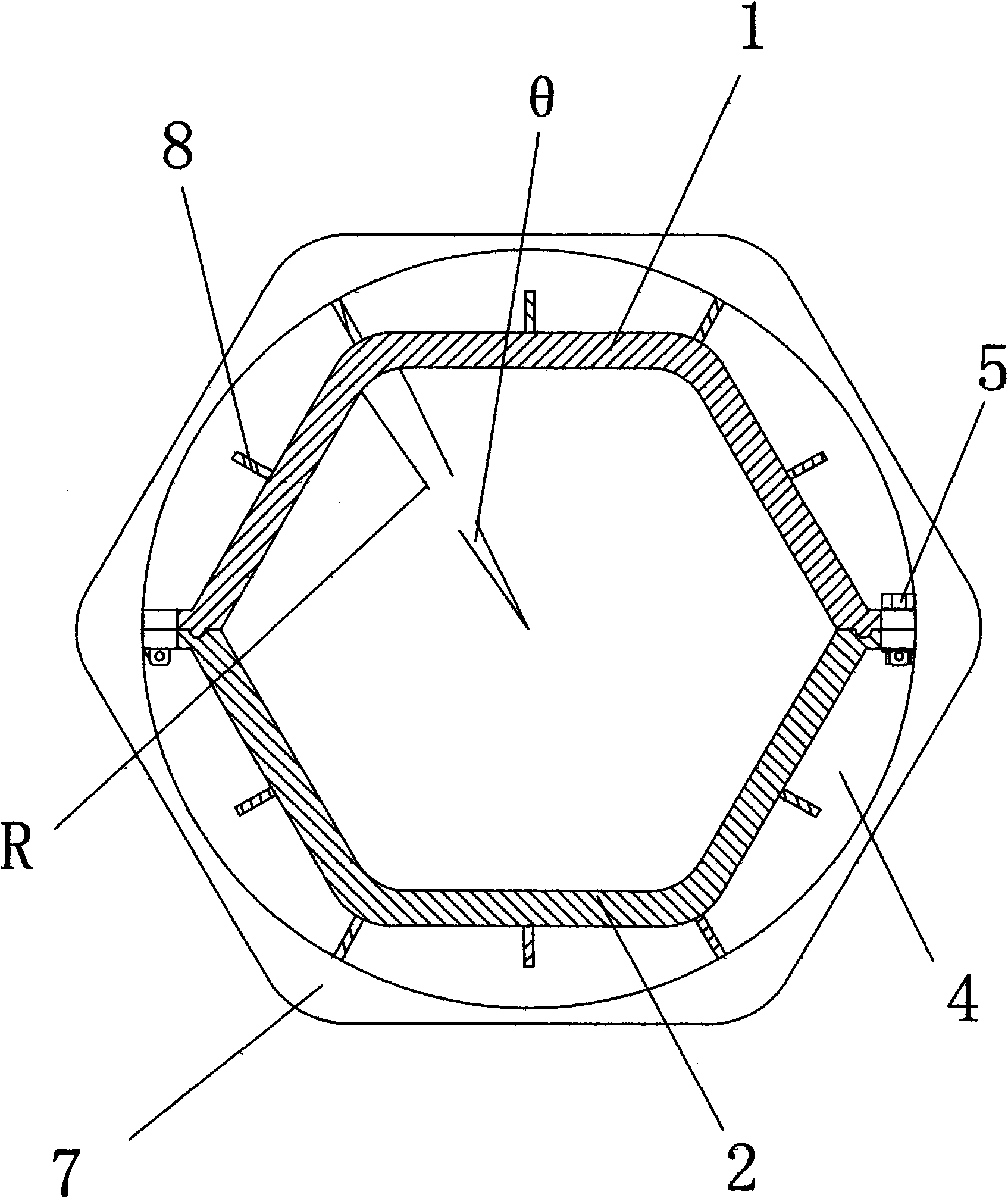

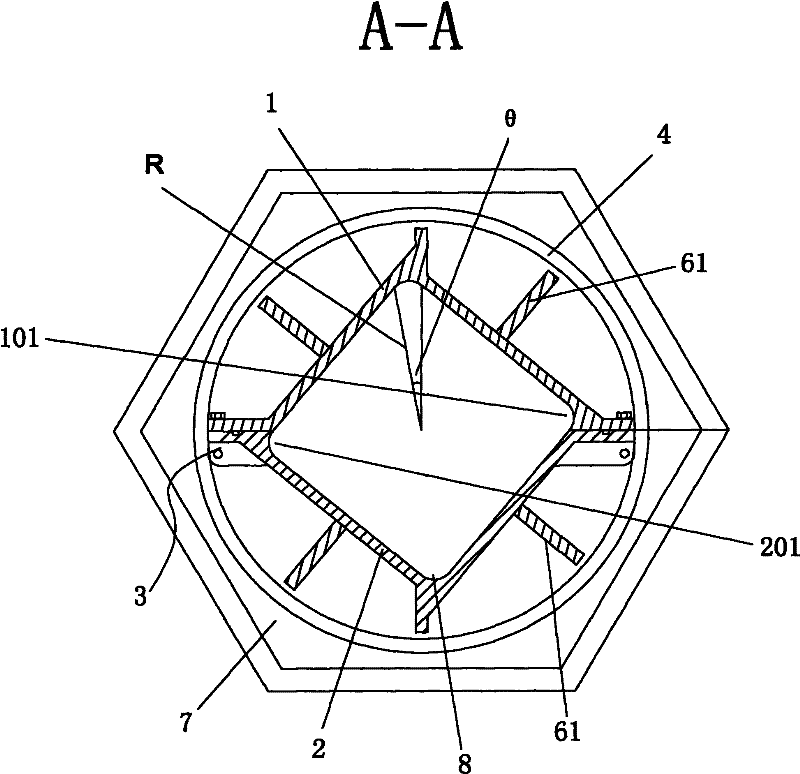

Centrifugal moulding mould used for manufacturing concrete hexagonal piles

The invention discloses a centrifugal moulding mould used for manufacturing concrete hexagonal piles, which comprises an upper mould body and a lower mould body and is characterized in that: after the upper mould body and the lower mould body are closed, the cross section of an inner cavity is hexagonal; the upper mould body and the lower mould body are provided with a plurality of running wheels which make the mould rotated on a centrifugal machine; and the upper mould body and the lower mould body are fixedly connected through screws. The invention aims to overcome the defects of the prior art and provide a centrifugal moulding mould having a simple structure and used for manufacturing concrete hexagonal piles which have the performance such as bending resistance, shear resistance, high bearing capacity and withdrawal resistance much higher than that of tubular piles, square piles and hollow square piles.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

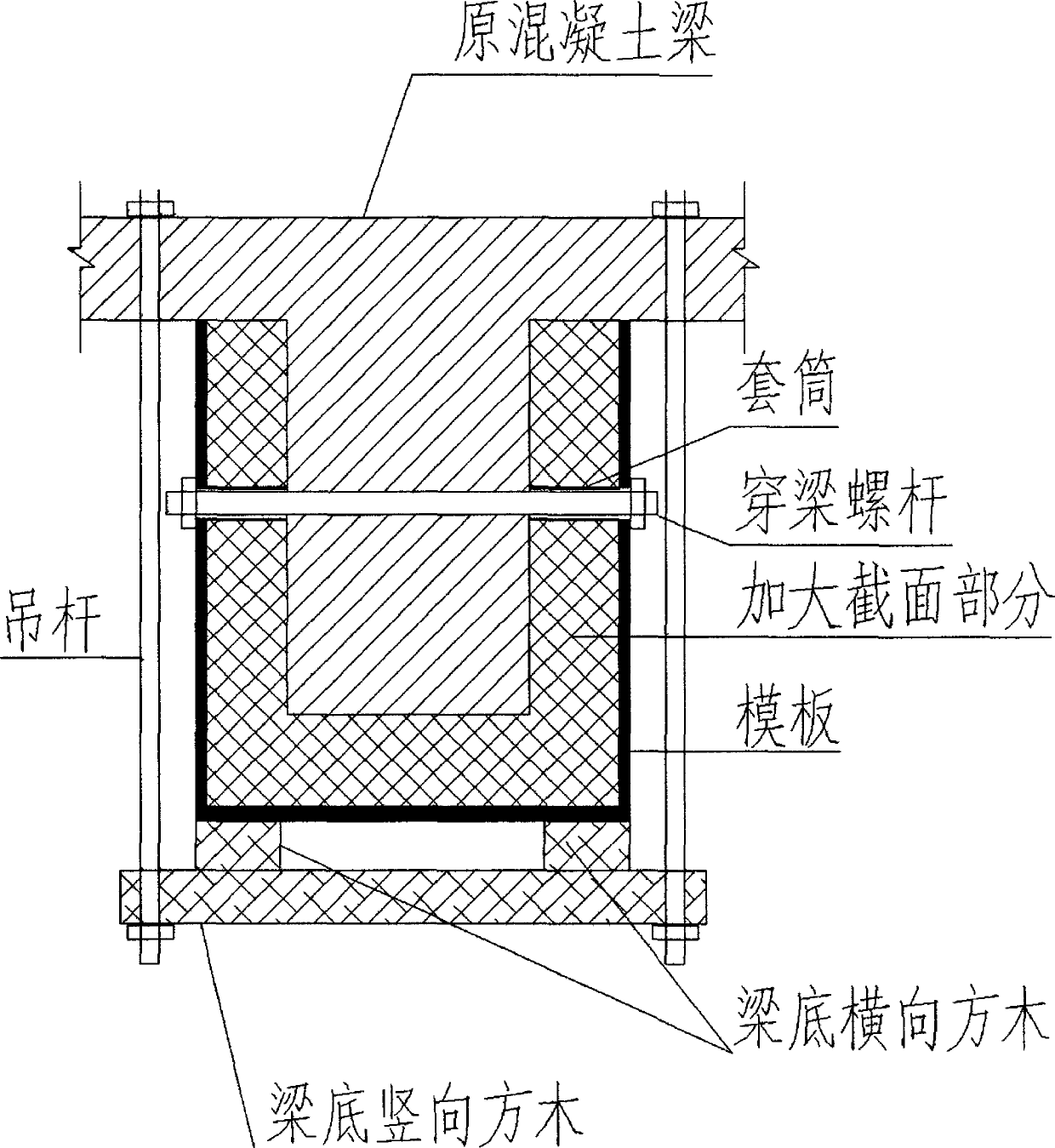

Suspension mold for enlarging and reinforcing concrete beam and construction method of suspension mold

InactiveCN103556820AAvoid truncationNot easy to leak slurryBuilding repairsAuxillary members of forms/shuttering/falseworksConcrete beamsBuilding construction

Owner:HANGZHOU GULI CONSTR ENG

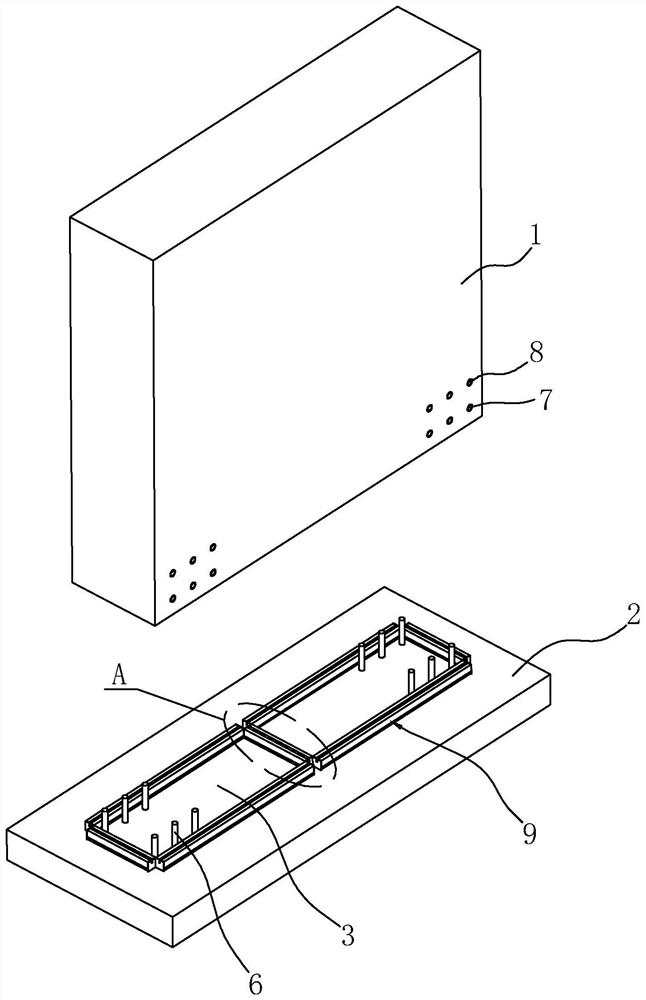

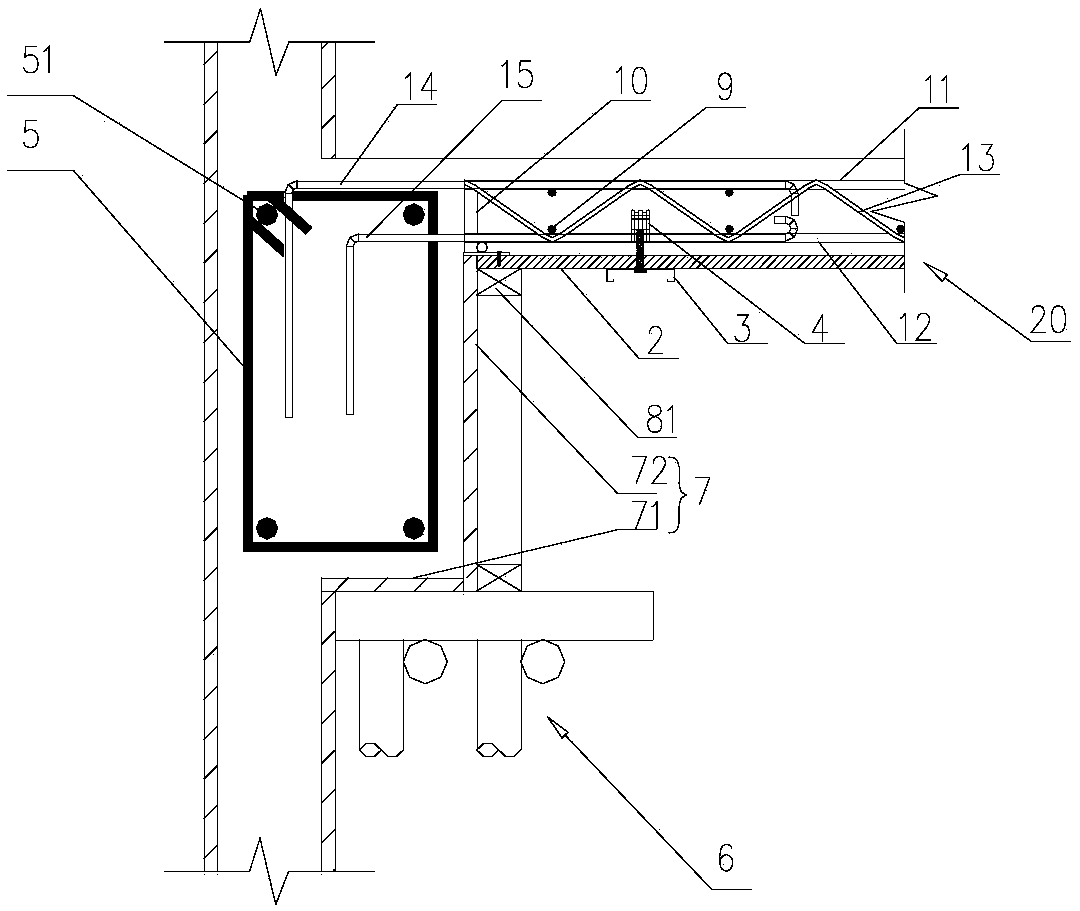

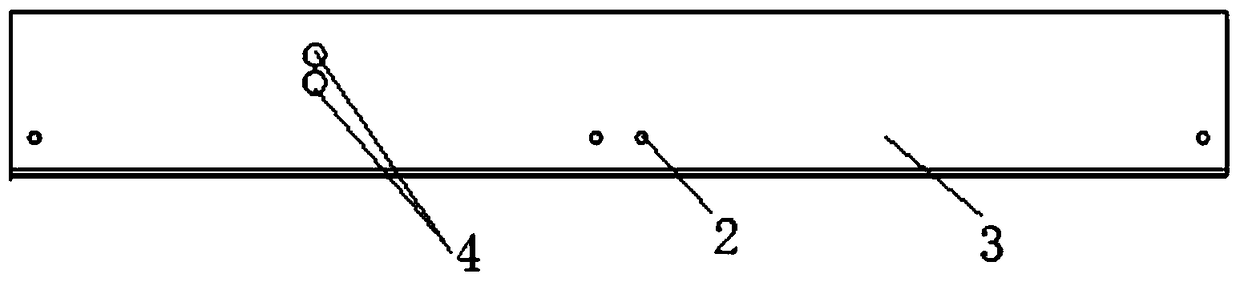

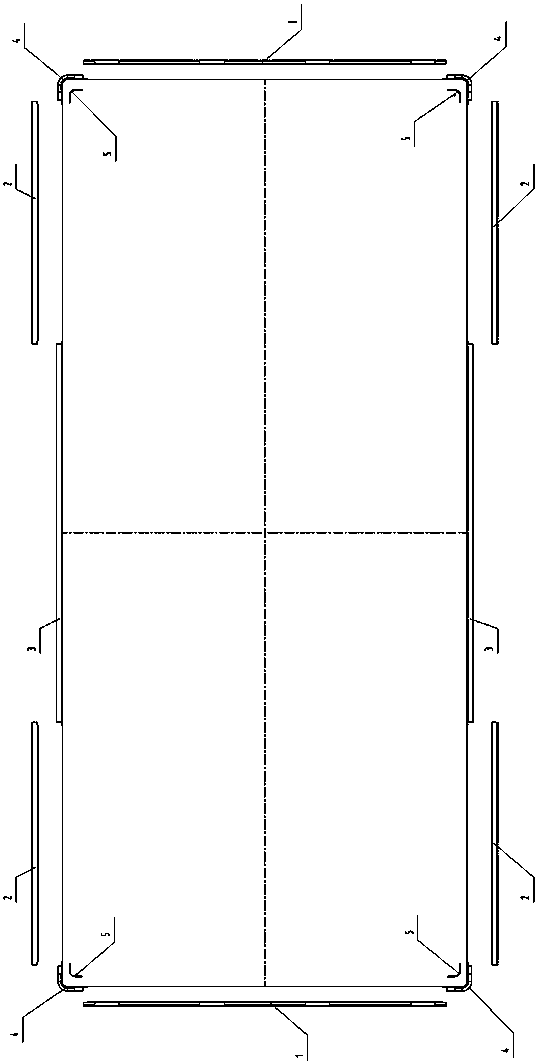

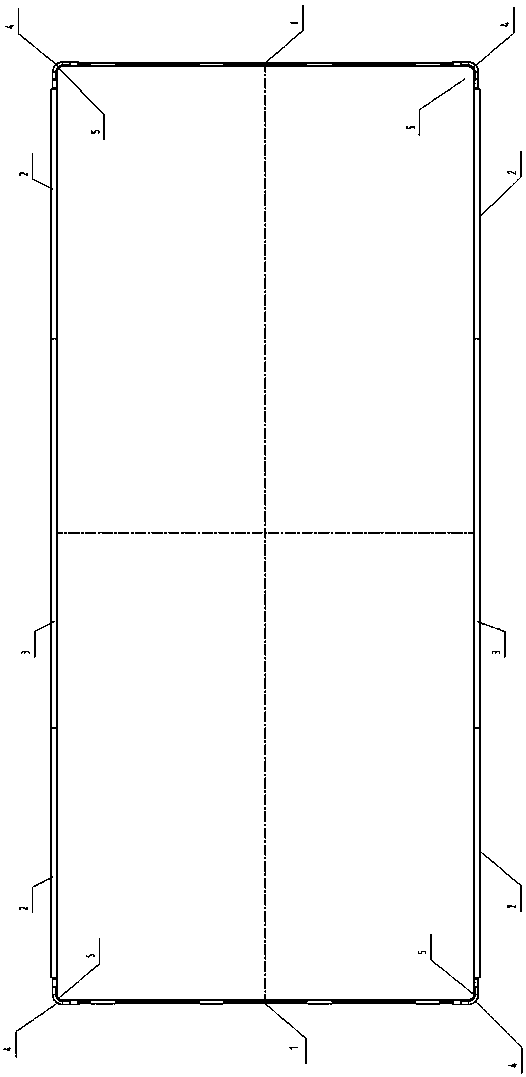

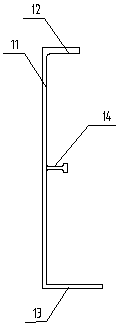

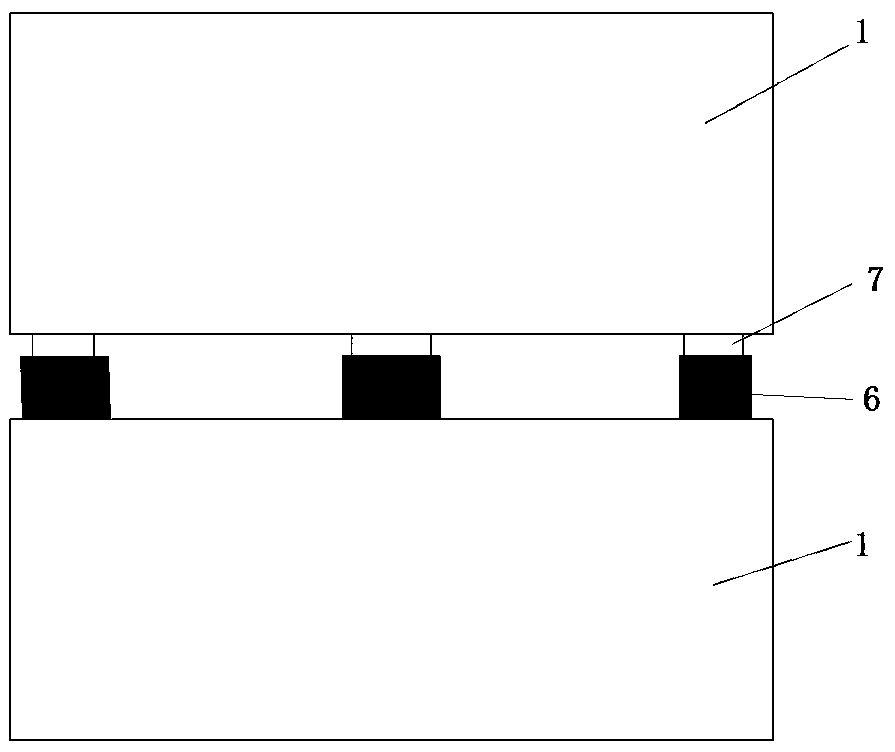

Fabricated building bin sealing structure and construction method

ActiveCN112593640AImprove sealingNot easy to leak slurryBuilding insulationsCement slurryMechanical engineering

The invention relates to a fabricated building bin sealing structure and a construction method. The bin sealing structure comprises a first prefabricated part, a second prefabricated part and a connecting rod, wherein the connecting rod comprises an upper rod piece and a lower rod piece, the upper rod piece comprises a top plate and two upper side plates perpendicularly connected to the top plate,and a transverse partition plate parallel to the top plate is connected between the middles of the two upper side plates; circulating holes are uniformly distributed in the transverse partition platein the length direction; the lower rod piece comprises a bottom plate and two lower side plates perpendicularly connected to the bottom plate, and the two lower side plates are oppositely arranged; the two lower side plates are positioned between the two upper side plates; screw rods are fixedly connected to the positions, close to the two ends, of the inner wall of the bottom plate, through holes are formed in the positions, corresponding to the screw rods, of the transverse partition plate, and nuts are in threaded connection with the screw rods and are abutted against the transverse partition plate; the top plate is tightly attached to the first prefabricated part, and the bottom plate is tightly attached to the second prefabricated part; and a grouting hole and a slurry outlet are formed in the connecting rod, and cement slurry is poured into the connecting rod. The fabricated building bin sealing structure can solve the problem of slurry leakage of an existing bin sealing mode effectively.

Owner:中核华辰工程管理有限公司

Self-compacting concrete aluminum alloy edge-sealing formwork for ballastless track

ActiveCN106948229AUnbroken strengthImprove bearing capacityBallastwayRailway track constructionCorner angleEdge banding

The invention relates to a self-compacting concrete aluminum alloy edge-sealing formwork for a ballastless track. The self-compacting concrete aluminum alloy edge-sealing formwork for the ballastless track comprises two end molds, four standard side molds, two adjusting side blocks, four corner formworks, and four inserting boards, which are symmetrically assembled into the quadrilateral self-compacting edge-sealing formwork, wherein the end mold comprises a panel and upper and lower frame plates, a reinforcing rib is arranged in the middle part of the panel to form a groove shape, and the end mold is integrally molded by extrusion once through an aluminum profile extrusion device; the standard side molds and the adjusting side molds are made of square tube aluminum profiles, and are molded by extrusion once through the extrusion equipment, the corner formworks and the inserting boards are made of arc-shaped aluminum profiles, and are molded by extrusion once through extrusion equipment. The self-compacting concrete aluminum alloy edge-sealing formwork for the ballastless track provided by the invention solves the problems of slow turnover of the formwork, fewer use times, easy deformation, easy rusting, formwork swelling and mortar leakage of self-compacting concrete, poor exhaust effect, uneasy installation, great waste of human resources and the like under construction.

Owner:湖南天象建筑科技有限公司

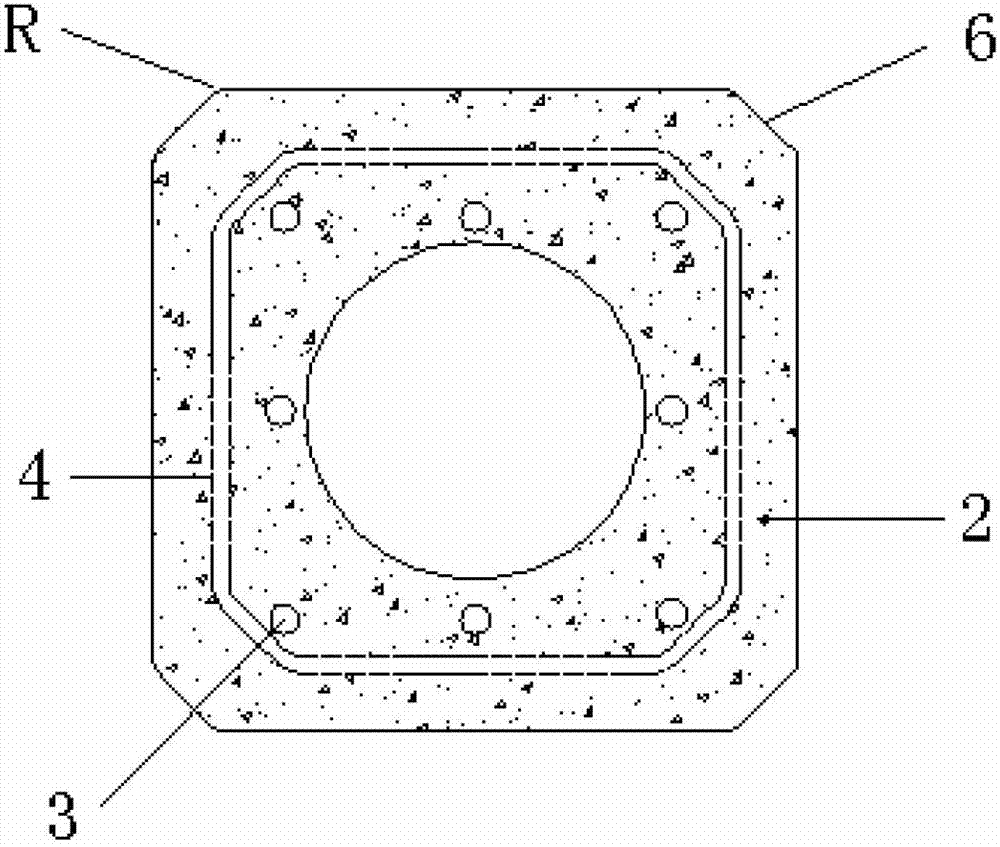

Octagonal concrete centrifugal pile and forming mould thereof

InactiveCN102808404AImprove molding qualityGuarantee molding qualityMouldsBulkheads/pilesStress reliefEnergy analysis

The invention provides an octagonal concrete centrifugal pile and a forming mould thereof. A pile body adopts a hollow structure, and the outer profile of the cross section of the pile body is in an octagonal shape. The edges of the octagonal shape have different length, the short edges are respectively 40 mm, 45 mm, 50 mm and 55 mm in length according to different pile shapes, and all the corners of the edges are in a stress relief arc shape; and the arc radii are the same and are respectively 18 mm, 22 mm, 24 mm and 26 mm according to the different pile shapes. The octagonal concrete centrifugal pile has the benefits as follows: the material is saved, the self weight is light, the pile is not easy to damage, the pile body is good in ductility, the pile forming quality is improved by 20%, the bending and shearing resistance is improved by 30%, the production process is easier to control and the mould is easier to make. Poor durability of pile body concrete due to pile material damage in the transportation and construction processes can be avoided. The bearing capacity provided by a single pile is 30% higher than that provided by the general process, the economic property is good, and the cost is saved by about 25%. The pile body of the forming mould is easy to de-mould, and the effects of energy saving and emission reduction can be achieved.

Owner:TIANJIN JIANCHENGJIYE GRP

End supporting joint structure and construction method of detachable steel bar truss plate

PendingCN108625488ASimple stitchingEasy to dismantleFloorsForms/shuttering/falseworksSlurrySurface level

The invention relates to the field of concrete structure building construction, in particular to an end supporting joint structure of a detachable steel bar truss plate. The end supporting joint structure comprises the steel bar truss plate, a frame structure and a first supporting piece. The steel bar truss plate comprises a floor bearing plate and a steel bar truss detachably connected to one side of the floor bearing plate. A frame formwork is arranged on the outer side of the frame structure and comprises a side formwork, the floor bearing plate is arranged on one side of the side formwork, and the upper end of the side formwork and the upper surface of the floor bearing plate are equivalent in height. The first supporting piece is provided with the end for supporting the steel bar truss plate. The ends of the side formwork and the floor bearing plate mutually abut or are arranged in a clearance mode, thus splicing and dismantling of the side formwork and the floor bearing plate are easy and easy to operate, slurry is not prone to leaking, the formed floor face and the beam face or a wall face are good in transition, the pour-formed floor face is good in integrity, shock and impact resistance and waterproofness, and the floor face is level and can be directly whitewashed, assembled and disassembled.

Owner:ZHE JIANG ZHONGYI BUILDING MATERIALS TECH CO LTD

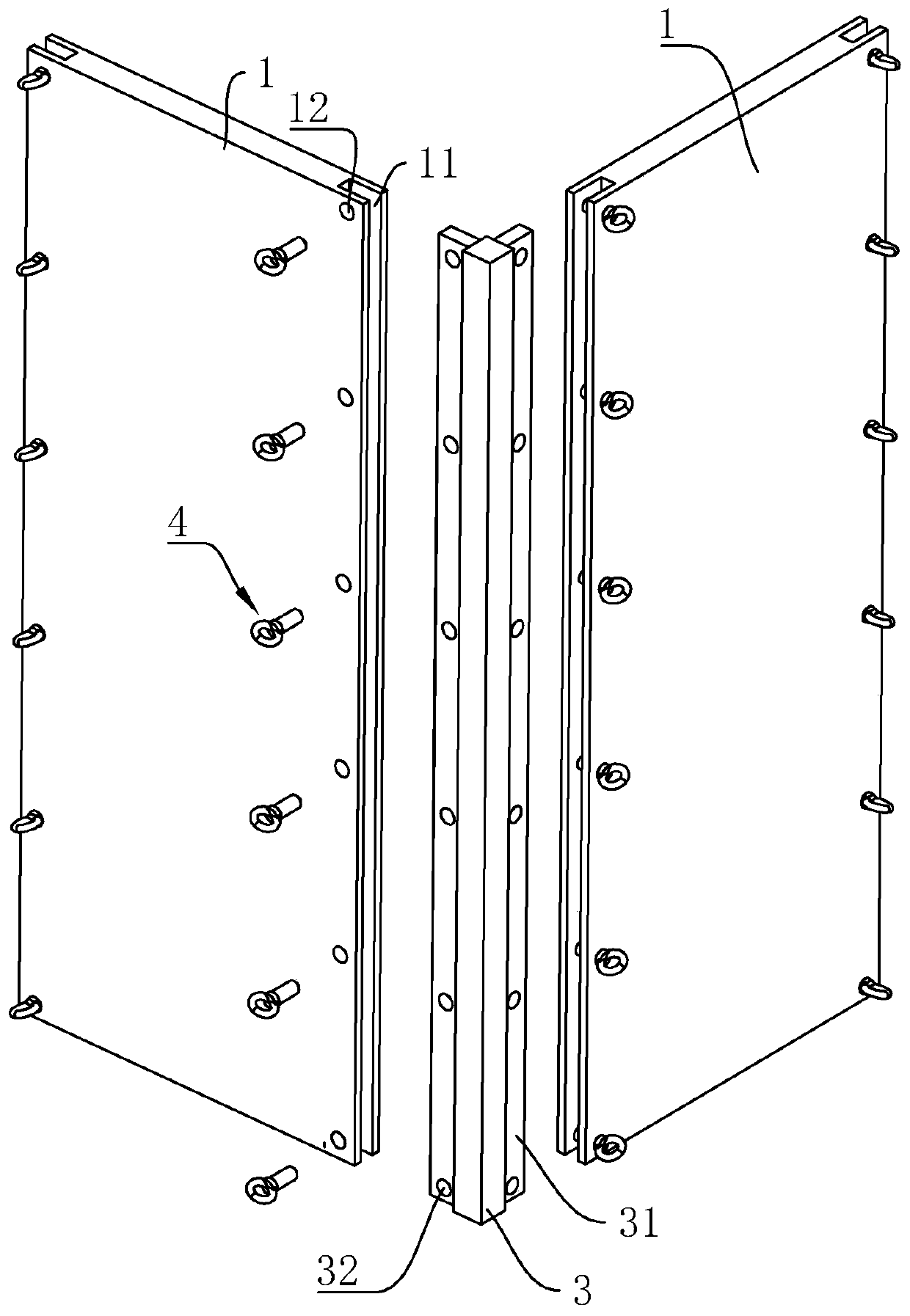

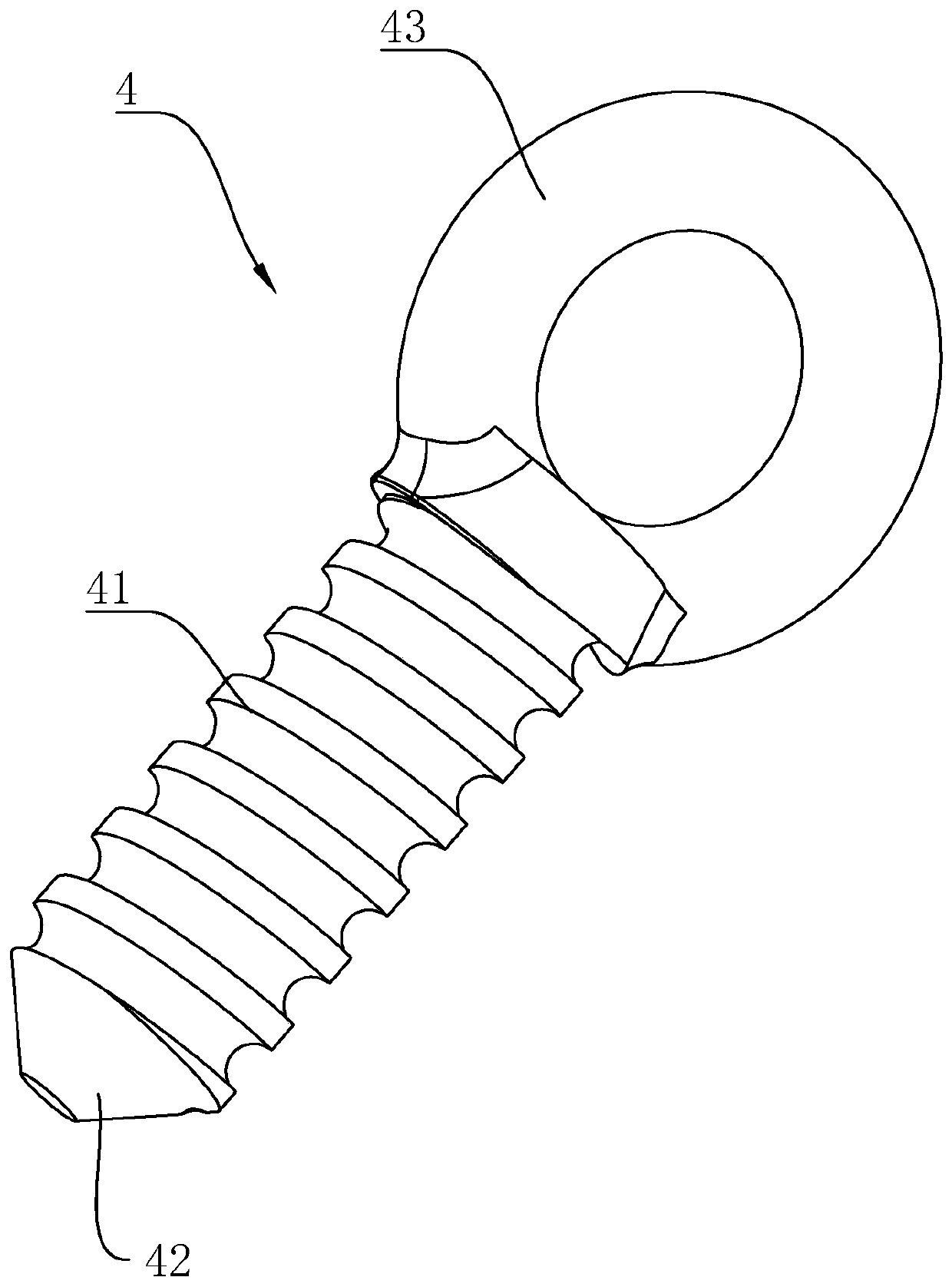

A construction formwork for gypsum cast-in-place wall and its construction method

InactiveCN105113783BRealize step-by-step constructionGuarantee the construction qualityForms/shuttering/falseworksPlasterworkArchitectural engineering

The invention relates to a construction formwork of a gypsum cast-in-place wall and a construction method of the construction formwork. The construction formwork comprises main-face formworks, side-face formworks, a bottom-face formwork, clamping dies, bolts and inner limiting sleeves, the main-face formworks are used for pouring a gypsum base wall material, the side-face formworks close the main-face formworks during pouring, the bottom-face formwork is used for pouring a waterproof cushion layer material, the clamping dies limit the main-face formworks during pouring, the inner limiting sleeves sleeve the bolts and play a role in limiting during pouring, height of the bottom-face formwork is adapted to that of a waterproof cushion layer, heights of the main-face formworks and the side-face formworks are adapted to that of the wall, and bolt holes used for connecting and positioning are formed in each of the main-face formworks, the bottom-face formwork and the side-face formworks. The construction formwork is supportive of construction of a waterproof layer and gypsum pouring construction sequentially, and gypsum pouring can be completed at one time, so that the construction formwork is high in construction efficiency and less prone to mortar leakage; waterproof protection of the bottom of the gypsum wall is realized.

Owner:WUHAN UNIV OF TECH

Plasticizing bubble mixed light soil

The invention discloses plasticizing bubble mixed light soil, which comprises the following main components: cement, a proper amount of water, a proper amount of bubble and plasticizing agent solution, wherein the plasticizing agent solution accounts for 3 to 6 weight percent of the light soil. The plasticizing agent solution is added into the common bubble mixed light soil to make the bubble mixed light soil quickly solidified and reduce the fluidity, and the plasticizing agent solution also has the flocculation function, so the bubble mixed light soil is difficult to disperse underwater; and the plasticizing bubble mixed light soil has the advantages of low fluidity, difficult leakage in the casting process and no dispersion in water, and is suitable for filling holes.

Owner:GUANGDONG GUANSHENG CIVIL ENG TECH

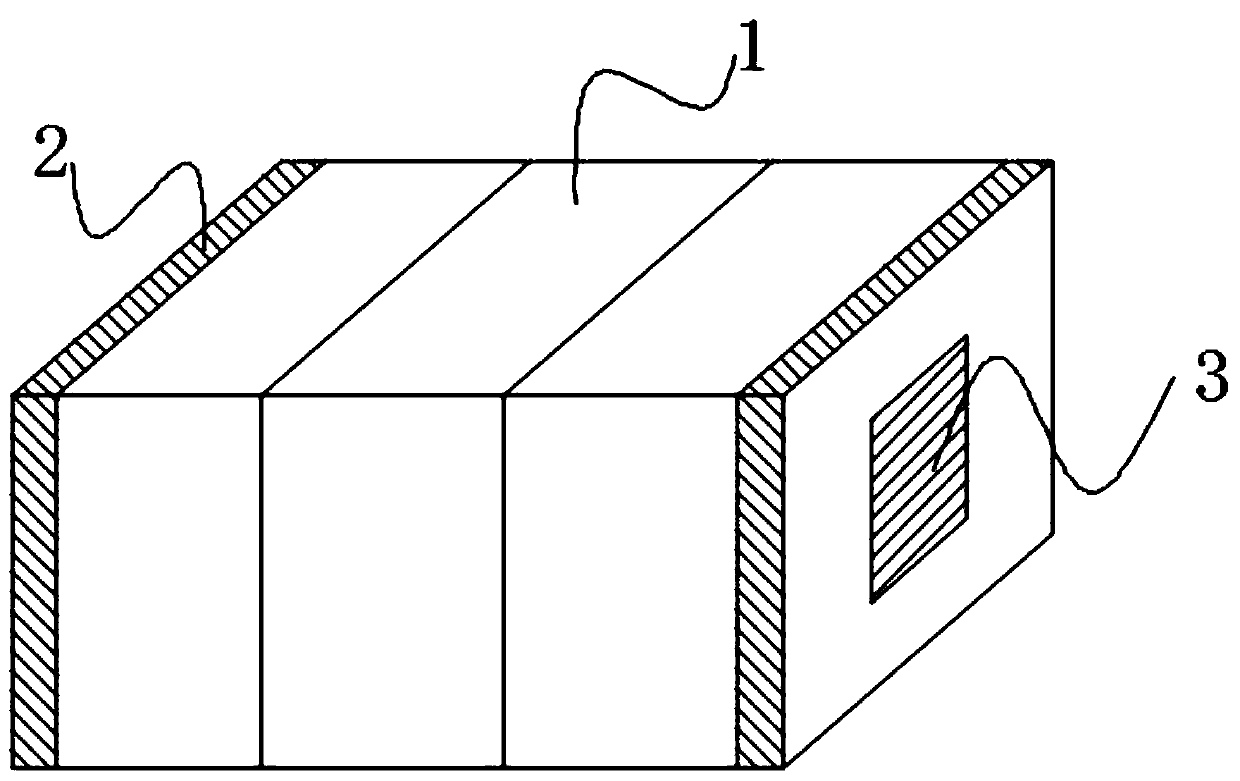

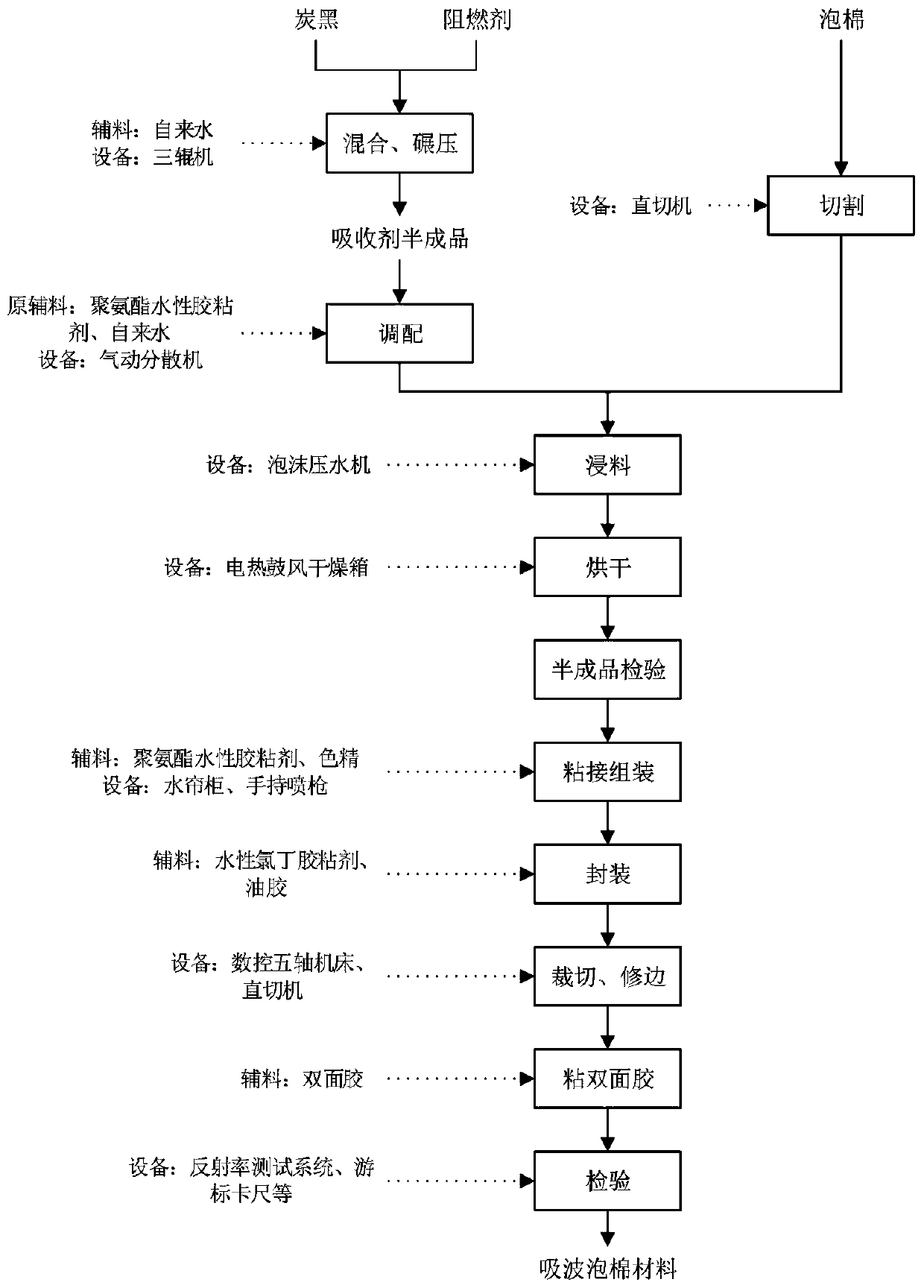

Wave-absorbing foam material and preparation process thereof

InactiveCN110126375AImprove absorption rateHigh strengthSynthetic resin layered productsLaminationMicrowaveSlurry

The invention discloses wave-absorbing foam which comprises a plurality of layers of flame-retardant foam bodies which are sequentially bonded and are soaked with absorbents. A layer of TPU film is adhered to each of the two flame-retardant foams on the outermost layer; and a double faced adhesive tape is adhered to one layer of TPU thin film. The invention also discloses a preparation process ofthe wave-absorbing foam, including: firstly preparing the absorbent, and soaking the flame-retardant foam in the absorbent; controlling the drying temperature to be 60-80 DEG C, drying the material for 1.5-2.0 hours to obtain the semi-finished product, sequentially bonding and assembling a plurality of flame-retardant foams with different absorbent contents after the semi-finished product is inspected to be qualified to obtain a plurality of layers of foams; then bonding a TPU film with the assembled multiple layers of foams, cutting and trimming the assembled foams, and finally inspecting thefinished product. The wave-absorbing foam is high in microwave absorption rate, high in strength and not prone to damage in the using process, slurry leakage is not likely to happen in the machiningprocess of the microwave-absorbing foam, and the rate of finished products is high.

Owner:成都雷隐科技有限公司

Concrete high pier construction formwork device

PendingCN108049316ASimple structureCompact structureBridge erection/assemblyBridge materialsSupporting systemArchitectural engineering

The invention provides a concrete high pier construction formwork device, and belongs to the technical field of building equipment. The concrete high pier construction formwork device comprises a formwork system, a supporting system, a hydraulic lifting system and an operation platform; the formwork system comprises an inner template and an outer template; the supporting system comprises an enclosure truss, a plurality of outer lifting frames and a plurality of inner lifting frames; the enclosure truss is arranged outside the outer template; a distance between the enclosure truss and the outertemplate is 220mm to 280mm; the plurality of outer lifting frames are all fixedly connected with the enclosure truss, the outer template is mounted on the outer lifting frames, and the inner templateis mounted on the inner lifting frames; the hydraulic lifting system is used for driving the inner lifting frames and the outer lifting frames to reciprocate so as to enable the enclosure truss, theouter template and the inner template to synchronously move; the operation platform is positioned in a cavity formed by the surrounding of the inner template and positioned on the enclosure truss. Theformwork device is compact in integral structure and firm and reliable in structure; in the lifting process, a formwork is more uniform in stress and more convenient and rapid to lift.

Owner:THE THIRD ENG CO LTD OF THE HIGHWAY ENG BUREAU OF CCCC

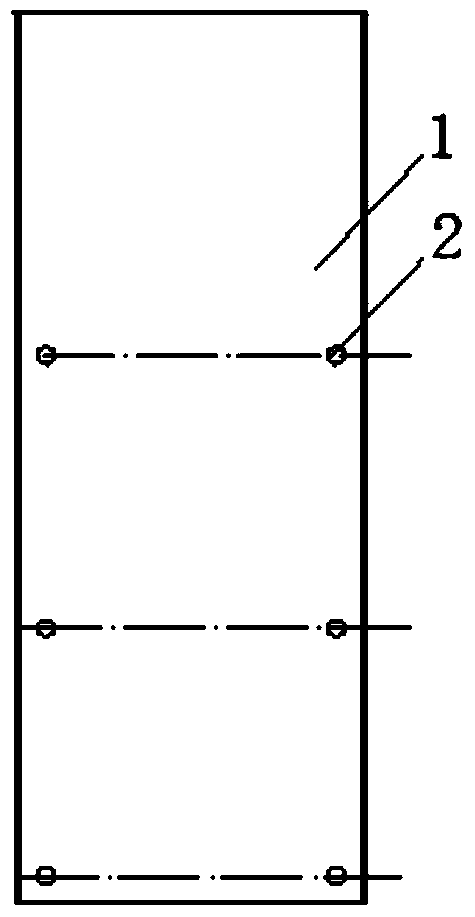

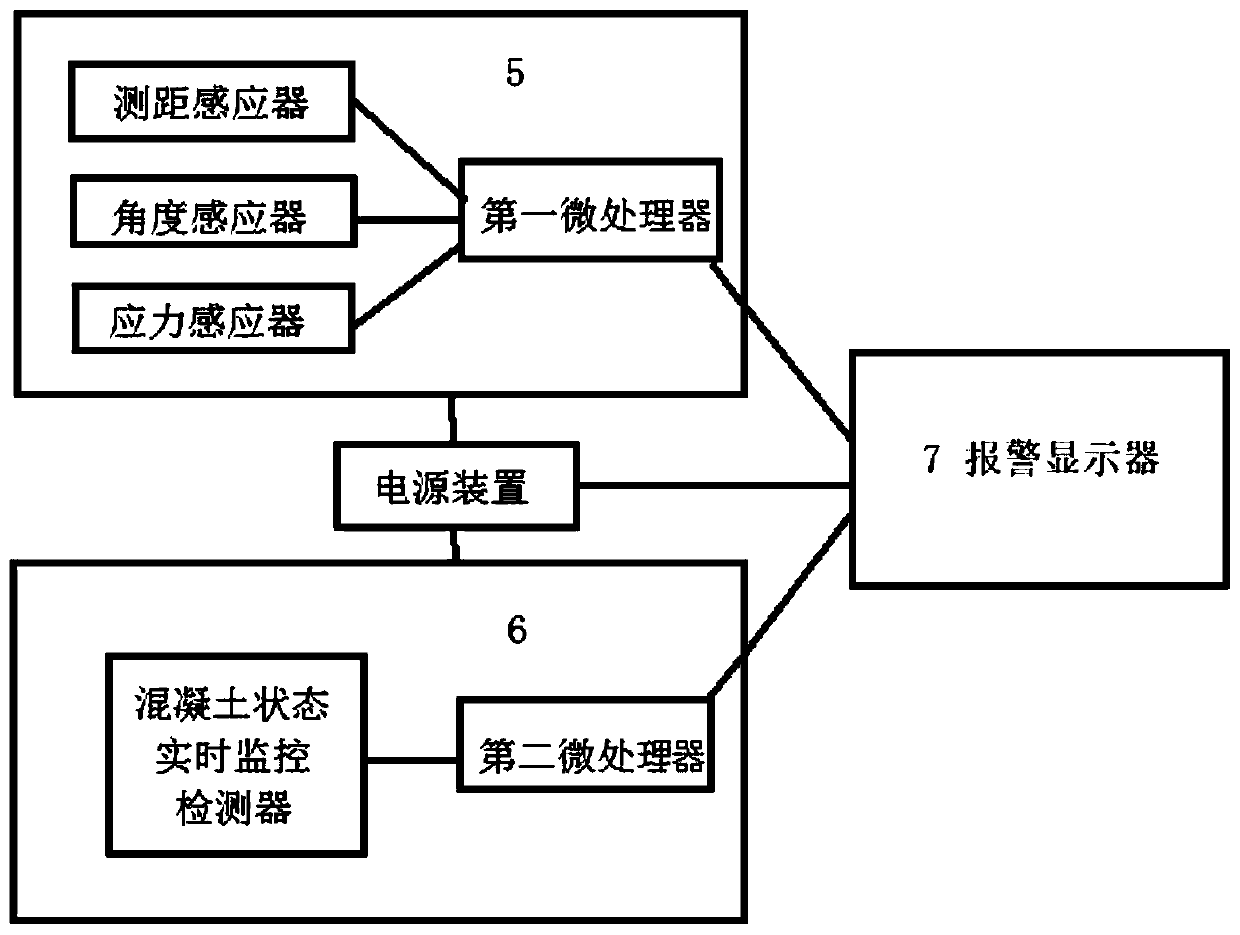

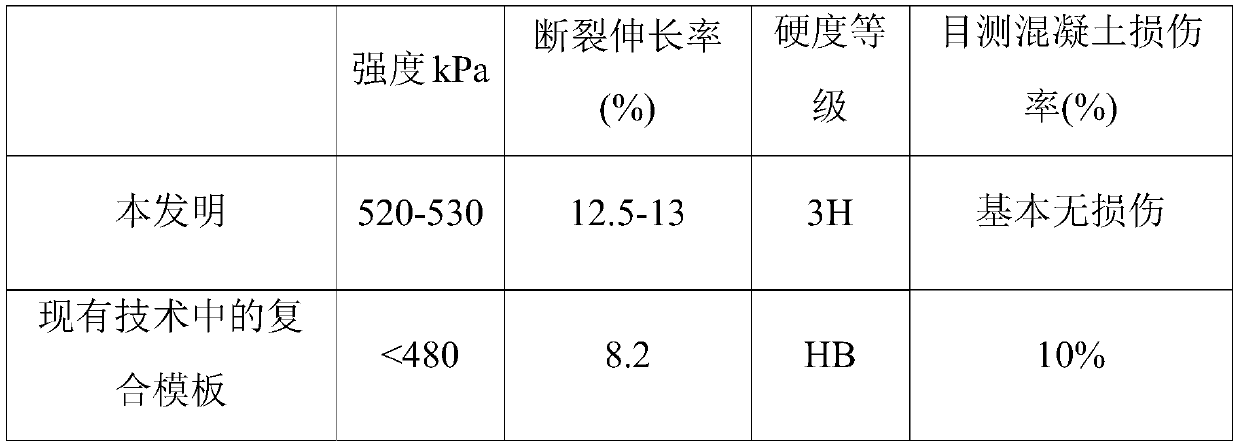

Composite formwork for building and manufacturing method thereof

InactiveCN111572143AEasy to assembleEasy to demouldProgramme controlMeasurement devicesConvex structureArchitectural engineering

The invention discloses a composite formwork for a building and a manufacturing method thereof. The composite formwork sequentially comprises a reinforcing structure layer (1), a grid supporting layer(2) and an inner structure layer (3) from outside to inside. The inner structure layer (3) seals the reinforcing structure layer (1) and the grid supporting layer (2) on the left side and the right side of the composite formwork for the building, and a plurality of concave-convex structures (4) capable of being spliced with one another are formed on the sealed parts on the left side and the rightside respectively. The manufacturing method comprises the following steps: 1) preparing the reinforcing structure layer (1); 2) preparing the grid supporting layer (2); 3) compounding the reinforcingstructure layer (1) and the grid supporting layer (2); and 4) preparing the inner structure layer (3). According to the formwork, the problems that in the concrete pouring process, defects are proneto occurring due to the fact that local vibration is not tight and filler is not compact are solved, the disclosed formwork is light in weight and high in strength, the service lifetime is prolonged,no release agent is used so that environmental pollution is avoided, and the manufacturing method is simple in process and low in energy consumption.

Owner:北京启顺京腾科技有限责任公司

Device and method for pouring concrete continuous wall along gob-side entry in mining face

ActiveCN101649744BGood top connection effectFilled tightlyUnderground chambersTunnel liningInjection portRock bolt

The invention discloses a device and a method for pouring a concrete continuous wall along a gob-side entry in a mining working face. The shape of the fiber flexible formwork is a cuboid or a cube, and it is composed of a main formwork and a roof formwork. The fiber flexible formwork is connected with flanges, pouring ports, planting ribs, limit holes, and tie bars. The fiber flexible formwork is prefabricated, and the flange hangs the flexible formwork on the coal seam roof through a single hydraulic prop or anchor rod. The ends are fixed with pallet nuts, the concrete delivery pipe is inserted into the filling port and tied, and the concrete pump is used to inject concrete into the flexible formwork through the delivery pipe to form a concrete continuous wall. The structure is simple, the construction speed is fast, the labor efficiency is high, the airtightness is good, the grout is not easy to leak, the concrete filling is dense, the roofing effect is good, the mechanized operation, adapt to the change of the slope of the roof and the floor, widely used in coal mines, metallurgical mines, water conservancy, underground construction , defense and other industries.

Owner:SHAANXI PIONEERING ARCHITECTURAL TECH

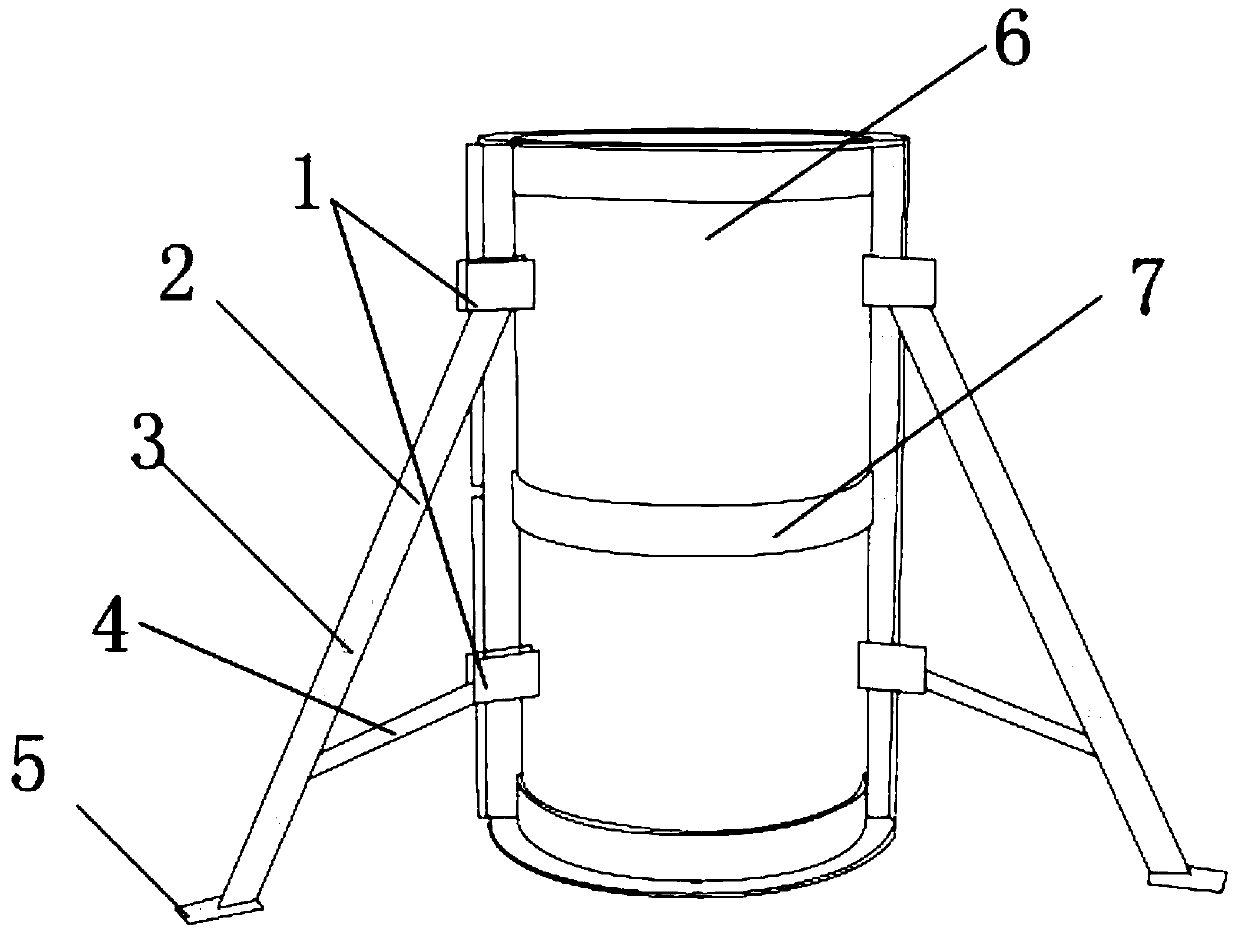

Pile foundation construction formwork tool

The invention relates to a pile foundation construction formwork tool. The pile foundation construction formwork tool comprises a formwork body. The formwork body is a cylindrical mold steel formwork.Three sets of movable connection holes are formed in the side walls of the formwork body. Each set of movable connection holes comprises an upper movable connection hole body and a lower movable connection hole body, wherein the upper movable connection hole bodies are connected with upper diagonal braces, the lower movable connection hole bodies are connected with lower diagonal braces, the other ends of the upper diagonal braces are fixed to the ground by fixing gaskets, and the other ends of the lower diagonal braces are connected to upper diagonal braces. The steel mold formwork is high in rigidity, mold bursting and slurry leaking are not prone to being generated, and good in stability, and can be reused, the surface is easy to clean, and the use costs of molds are reduced.

Owner:中国电建集团贵州工程有限公司

Tunnel embedded groove mold locking device

InactiveCN111331711AReduce damageNot easy to leak slurryDischarging arrangementMould fastening meansSteel platesRock bolt

The invention discloses a tunnel embedded groove mold locking device, and relates to the field of engineering construction. The device comprises an embedded anchor rod, a locking screw rod, a groove channel, a clamp-shaped plastic part, a T-shaped connecting piece, a fastening steel plate and a bolt. The device is used in the field of installation and fixation of a large number of equipment pipelines of contact networks, evacuation platforms and the like in subway tunnels. Compared with an existing embedded groove, the embedded groove can be accurately locked with a mold, the integrity of themain body structure is guaranteed, demoulding is easy, and the tunnel space is saved.

Owner:JIANGSU UNIV

All-plastic building formwork

InactiveCN108035536AGuaranteed flatnessGuaranteed temperatureForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksIndustrial engineeringBuilding construction

The invention discloses an all-plastic building formwork which is simple in structure, low in construction cost and high in practicability. The all-plastic building formwork comprises a surrounding plate. A semi-arc-shaped supporting plate is arranged on one side of the surrounding plate. A supporting strip is arranged on one side of the semi-arc-shaped supporting plate. An adjusting hole is formed in one side of the supporting strip. A circular supporting plate is arranged on one side of the adjusting hole. A fixing protruding strip is arranged on one side of the circular supporting plate. Abase is arranged on one side of the fixing protruding strip. A small arc-shaped plate is arranged on one side of the base. By means of the all-plastic building formwork, through the tight combinationof concave-convex grooves, the flatness of a wall body is ensured, the wall body can be prevented from mortar leakage and is not prone to deformation, lots of cost is saved, and the formwork is suitable for use and popularization.

Owner:山东盛祥生态环保科技有限公司

Supporting method of side template at later casting zone of floor part

InactiveCN102345387AReduce workloadLow costForms/shuttering/falseworksBuilding material handlingFloor slabSoft materials

The invention relates to a building construction method, and in particular relates to a supporting method of a side template at a later casting zone of a floor part. Upper-row and lower-row steel bars of a floor are respectively clamped and fixed by using two compound strips (one side is made of soft materials and the other side is made of hard materials) from the upper surface and the lower surface, a blocking strip is centrally placed between the upper-row steel bars and the lower-row steel bars to block the gap between the two compound strips, and the blocking strip is well fixed, and then the die supporting procedure is finished; and after the concrete is cast and initially set, the blocking strip and the compound strips are loosened and taken down, and then the die removing procedure is finished. According to the supporting method provided by the invention, the compound strips and a blocking plate produced in a standard manner are used, so that the work quantity of workers on site can be reduced, the erection and disassembly construction is simple, convenient and fast, the appearance of the concrete section is good, the slurry leakage is not easy, and the picking and chiseling at a later period are reduced; and since the compound strips and the blocking plate can be used periodically for multiple times, the cost can be reduced and a great amount of labor and the consumption of the template can be saved.

Owner:李国庆

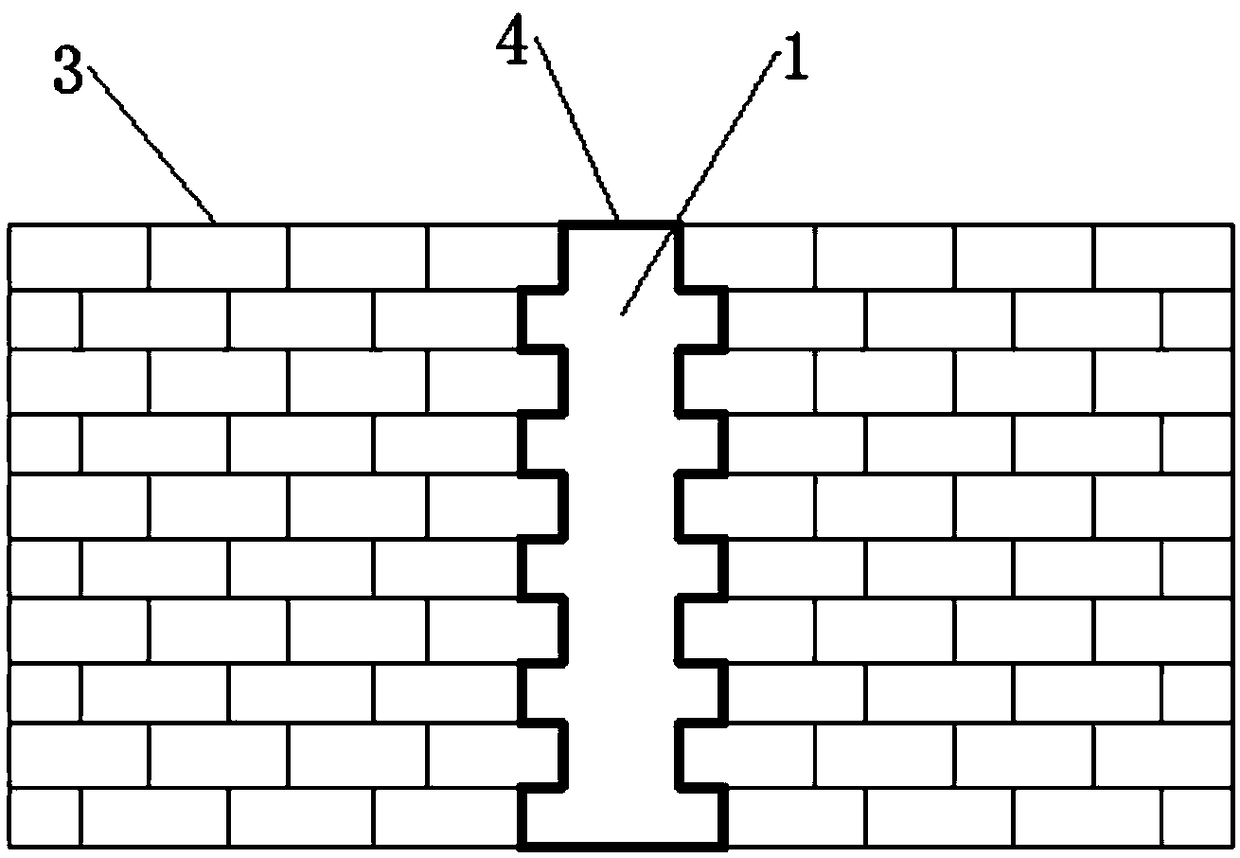

Plastering-free building wall construction technology

InactiveCN109184103ASave materialAvoid run-of-the-millCovering/liningsWallsPrecast concretePrefabrication

The invention discloses a plastering-free building wall construction technology, which belongs to the technical field of building construction. The plastering-free building wall construction technology includes the following steps: (1) base course cleaning: the residual mortar and sundries in the masonry part are cleared, and the parts protruding from the masonry surface and the exposed steel barheads and lead wire ends are cleared; (2) positioning and setting-out: measurement setting-out should be matched with the measurement net of the main structure, and the plane and elevation baselines of the external wall are turned out based on the baseline of the main structure; (3) constructional column form erecting, steel bar planting and binding: a pair of constructional column prefabricated templates is used as templates; and (4) polymer mortar mixing and group laying: building blocks are laid on an infilled masonry wall, and the joints of the infilled masonry wall and the constructionalcolumns are built into serrated racking structures. The prefabrication of combined fabricated buildings can be realized. Form erecting is carried out by using prefabricated concrete slabs instead of the traditional wooden formwork, and the building wall is not easy to crack and hollow. Compared with the traditional plastering technology, the quality of the wall has significant advantages.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

A self-compacting concrete aluminum alloy edge-sealing formwork for ballastless track

ActiveCN106948229BUnbroken strengthImprove bearing capacityBallastwayRailway track constructionMaterials scienceAluminium alloy

The invention relates to a self-compacting concrete aluminum alloy edge-sealing formwork for a ballastless track. The self-compacting concrete aluminum alloy edge-sealing formwork for the ballastless track comprises two end molds, four standard side molds, two adjusting side blocks, four corner formworks, and four inserting boards, which are symmetrically assembled into the quadrilateral self-compacting edge-sealing formwork, wherein the end mold comprises a panel and upper and lower frame plates, a reinforcing rib is arranged in the middle part of the panel to form a groove shape, and the end mold is integrally molded by extrusion once through an aluminum profile extrusion device; the standard side molds and the adjusting side molds are made of square tube aluminum profiles, and are molded by extrusion once through the extrusion equipment, the corner formworks and the inserting boards are made of arc-shaped aluminum profiles, and are molded by extrusion once through extrusion equipment. The self-compacting concrete aluminum alloy edge-sealing formwork for the ballastless track provided by the invention solves the problems of slow turnover of the formwork, fewer use times, easy deformation, easy rusting, formwork swelling and mortar leakage of self-compacting concrete, poor exhaust effect, uneasy installation, great waste of human resources and the like under construction.

Owner:湖南天象建筑科技有限公司

Construction method of PCF board for fabricated building

InactiveCN111119495AImprove securityResolve collisionHeat proofingBuilding material handlingArchitectural engineeringStructural engineering

The invention discloses a construction method of a PCF board for a fabricated building. The construction method comprises the following steps that in the production of the PCF board, a penetrating hole is reserved as a hoisting hole for hoisting, base course cleaning, laying off and elevation adjusting are conducted, a vertical connecting plate is fixed, a bed mortar is laid at the bottom of an insulation board of the PCF board, the bed mortar extends out of the insulation board, and the height of the bed mortar is higher than the elevation; the PCF board is vertically hoisted by using the hoisting hole; and after the PCF board is fixed by an inclined support, the perpendicularity of a PCF board component is accurately corrected and adjusted, then the connection is conducted firmly, and unhooking is conducted after rechecking the sideline, perpendicularity, flatness and top elevation of the PCF board. According to the construction method, the PCF board can be vertically hoisted duringhoisting, the problem of collision with an external frame during the previous inclined hoisting is solved, the safety during hoisting is greatly improved, and the efficiency is greatly improved compared with the inclined hoisting; and the problems of rectification of defects in the later decoration of an external wall and an internal wall and the like caused by the insufficient installation accuracy of the PCF board component are solved, and the benefit is improved.

Owner:BUILDING & MOUNTING ENG CO LTD NO 12 BUREAU MINIST OF RAILWAYS +1

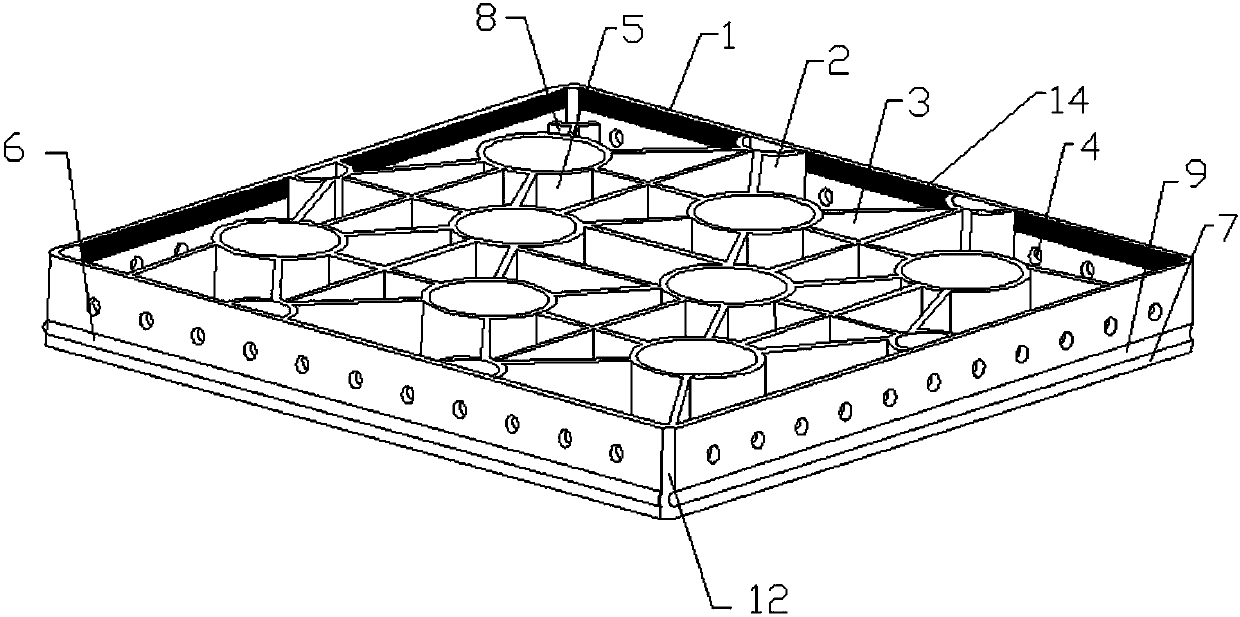

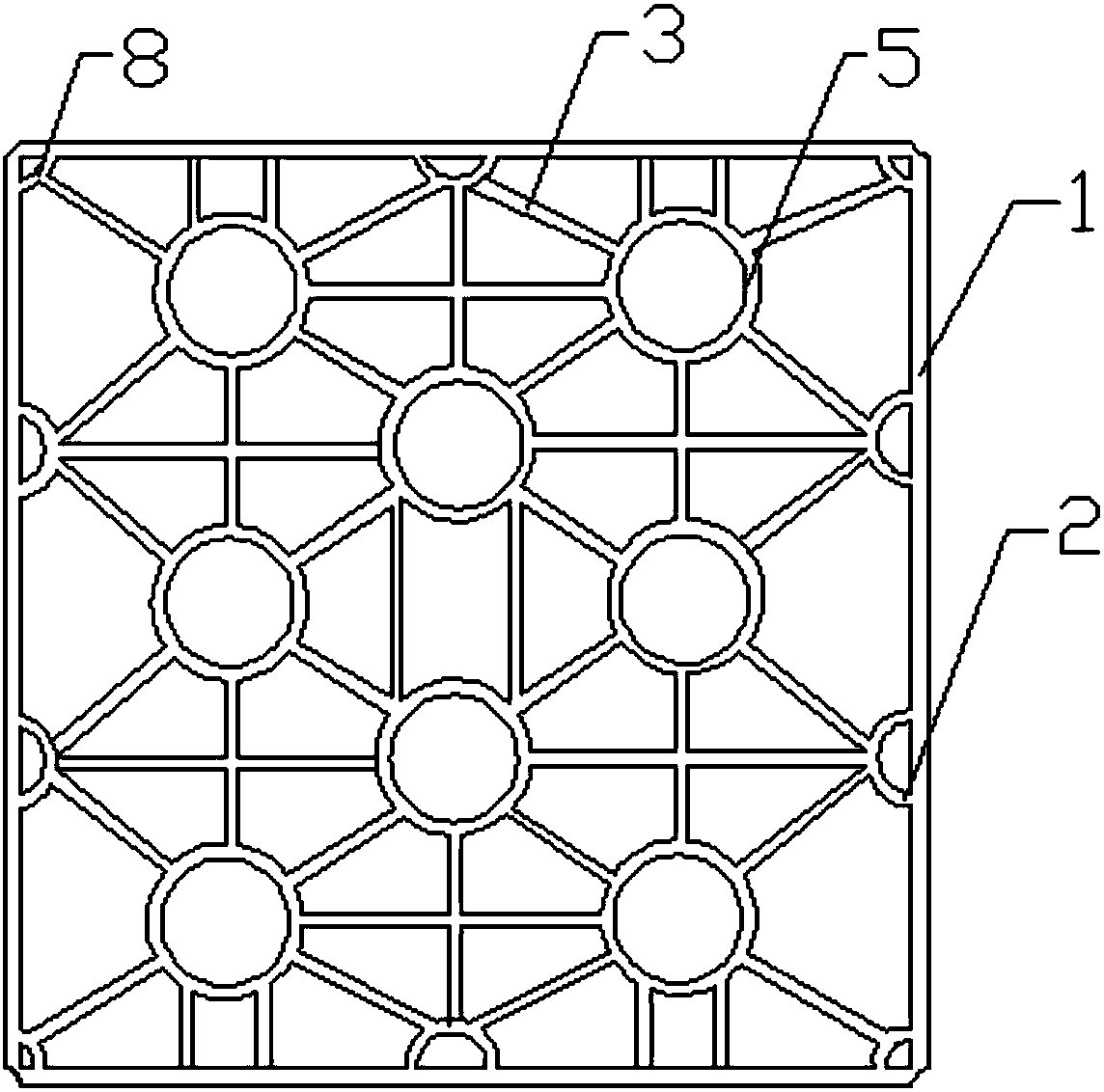

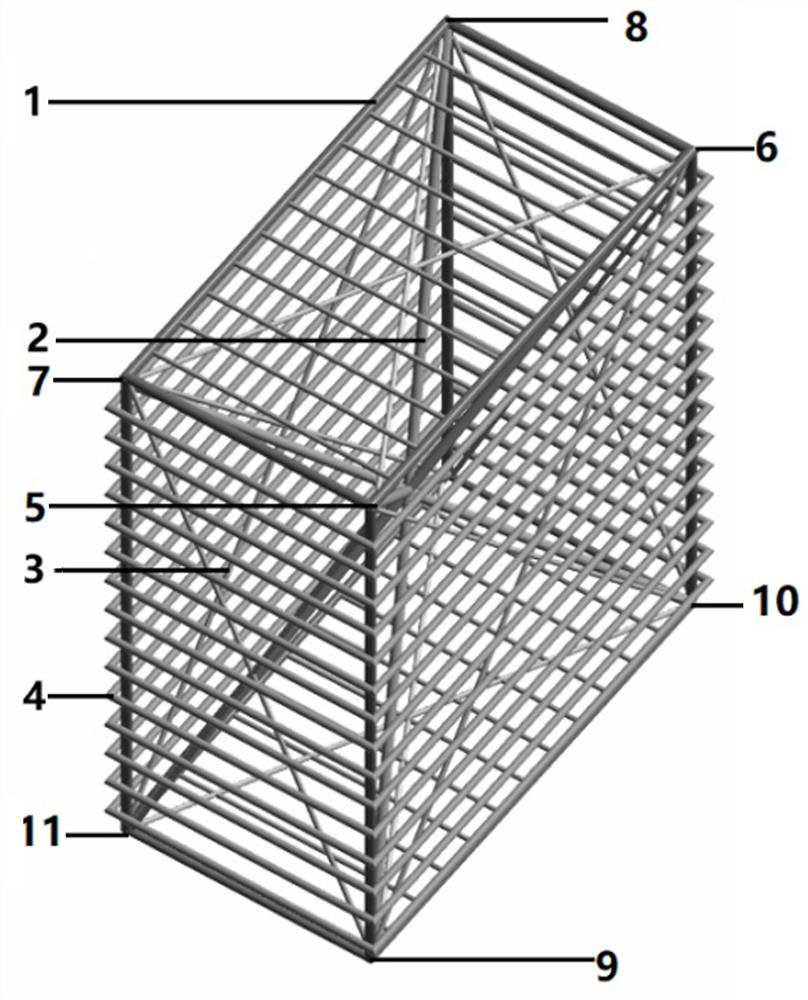

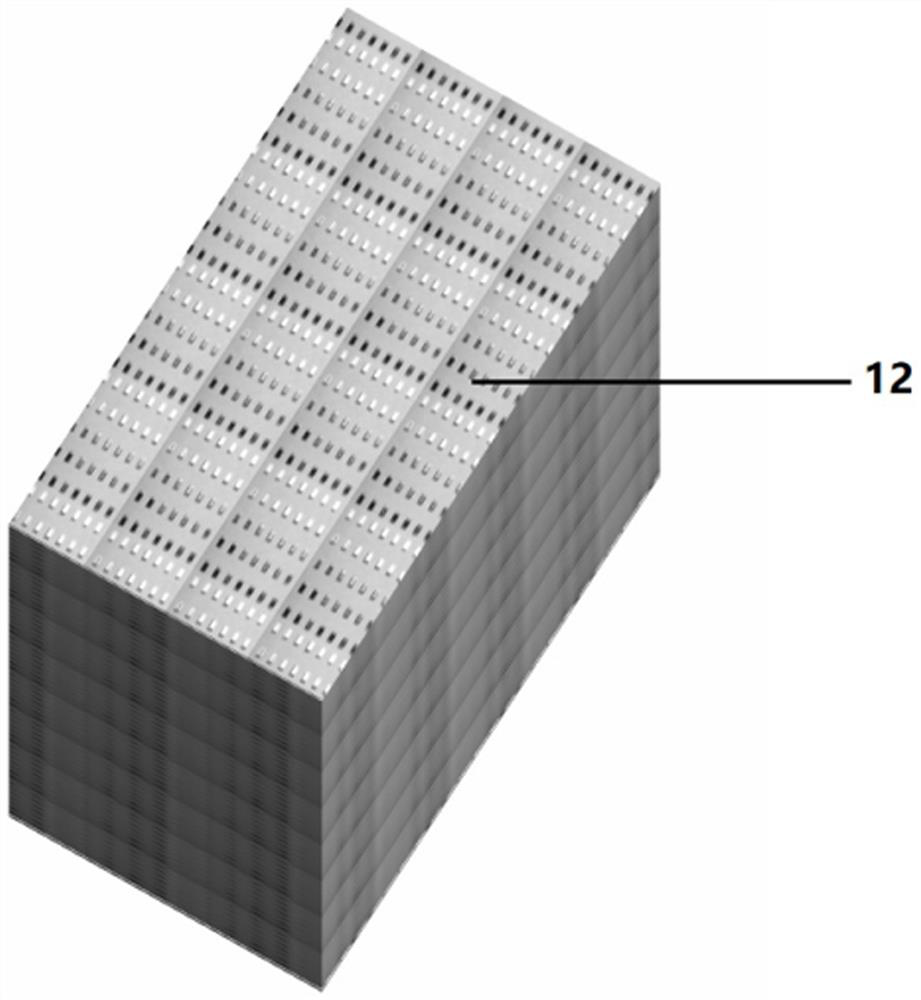

Hollow box device for ultra-thick hollow floor and manufacturing method thereof

The invention discloses a hollow box device for an ultra-thick hollow floor and a manufacturing method thereof. The hollow box device comprises a cuboid framework and a closing plate for blocking theouter surface of the framework. The framework comprises edge ribs located on the edges of the framework, vertex angles connected with the adjacent edge ribs, a first reinforcing rib mechanism locatedin the framework and used for connecting the two vertex angles, and a second reinforcing rib mechanism located on the side face of the framework and used for connecting the two adjacent edge ribs. Thehollow box device is simple in structure, the cuboid framework is arranged, the structure is firm, and the deformation resistance is high; the outer surface of the framework is blocked through the closing plate, slurry leakage is not easy to occur, and buoyancy is low; the framework can be manufactured through on-site waste, and the project cost is saved; and factory prefabrication does not needto be conducted in advance, the manufacturing is flexible, and the efficiency is high.

Owner:宝冶(郑州)建筑工程有限公司

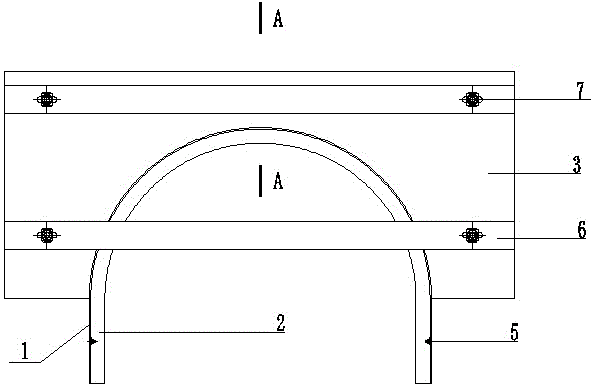

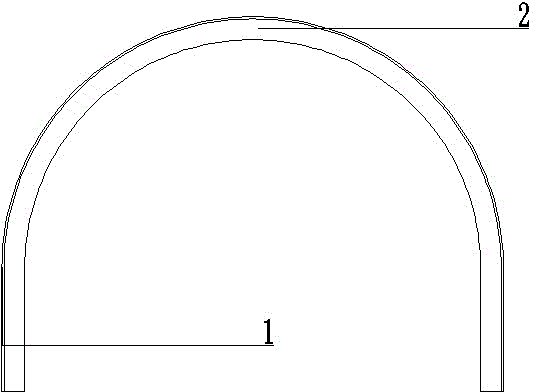

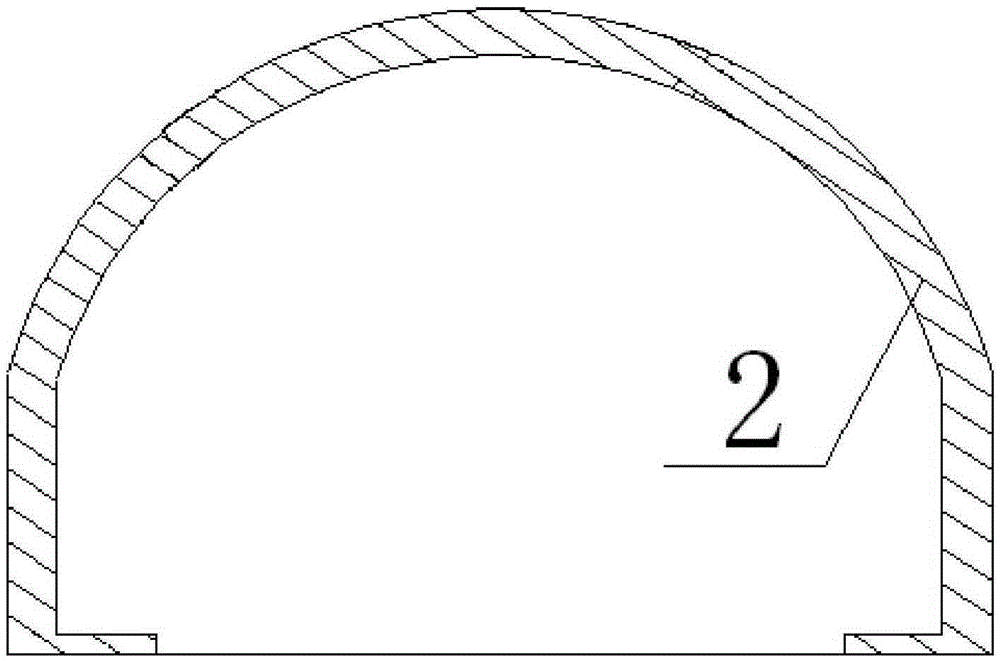

Construction method of concrete arched door and window lintel

ActiveCN102852329BLess consumablesSimple structureForms/shuttering/falseworksBuilding material handlingWood plankLintel

The invention relates to a construction method of a concrete arched door and window lintel, and belongs to a civil engineering building construction method, which comprises the following construction steps of: production of templates: 1) production of a bottom template: the bottom template consists of a bottom board and a reinforcing rib board, the middle section of the bottom board is a semi-circular section, the left and right sections of the bottom board are symmetrically downward vertical sections, and the middle of the bottom surface of the bottom board is welded with the reinforcing rib board; and 2) production of side templates: the center of a long bottom side of a rectangular wood board is used as a center of a circle, and the radius of the middle section of the bottom template is used as a radius to be cut into a semi-circular opening; and installation of templates: 1) installation of the bottom template: the left and right vertical sections of the bottom board are correspondingly and fixedly arranged on the wall at the left and right ends of the concrete arched door and window lintel by expansion bolts in accordance with the alignment position, and then a reinforcement cage is placed; 2) installation of side templates: the two side templates and the front and back sides of the bottom template are correspondingly matched, long baseplates are arranged, and split bolts are used to fix the front and back side templates; and pouring of lintel. The lintel is simple and practical, and has an excellent sealing performance.

Owner:CHINA MCC17 GRP

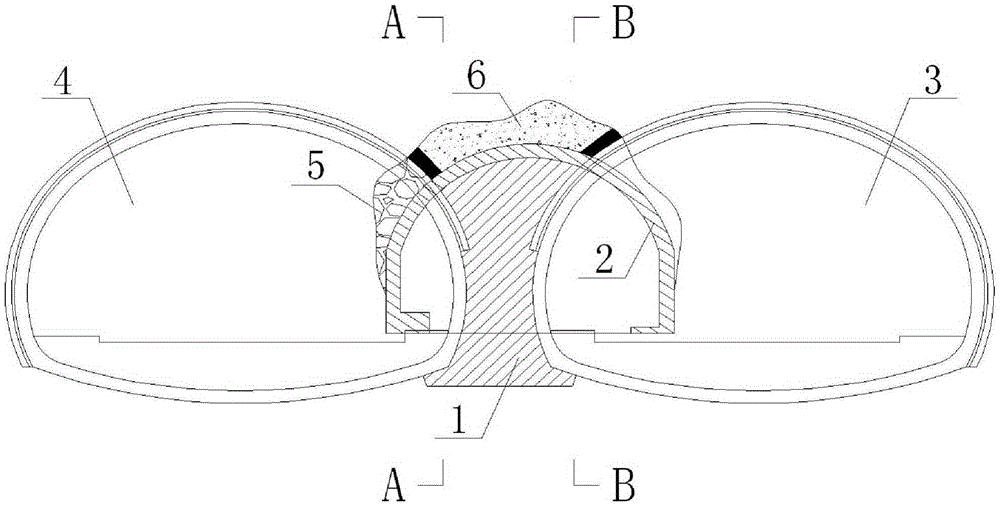

Construction method of backfilling the original lining cavity at the top of the middle partition wall when the single-cavity tunnel is changed to multiple arches

InactiveCN103953366BAvoid deformationEnsure construction safetyUnderground chambersTunnel liningShotcreteSlag

The invention discloses a middle separation wall top original lining cavity backfilling construction method when a single-hole tunnel is changed into multiple arches. The method sequentially comprises the following steps that a, a middle separation wall is cast; b, an anterior hole is constructed; c, hole slag dug from the anterior hole is used for filling back a cavity arranged at one side of a posterior hole to the digging outline part of the posterior hole; d, a steel bar net is paved on the top of the backfilled hole slag, and then, concrete is sprayed on the surface of the steel bar net; e, an end template is arranged along a tunnel longitudinal frame, in addition, the end template, the surrounding rock and the original lining are fixedly built through lining by using anchor bolts; f, a side template is erected at the digging outline part of the anterior hole; g, concrete is filled and is compactly vibrated and smashed; h, the posterior hole is constructed; i, the original lining of the existing tunnel in the anterior hole and the posterior hole is dismounted. The construction method has the advantages that the original tunnel top cavity backfilling problem is effectively solved, so the pressure of the surrounding rock is uniformly transmitted onto a support protection structure, the stress uniformity and the structure completeness of the lining can be ensured, and the loading capability and the durability are improved.

Owner:CHANGAN UNIV +1

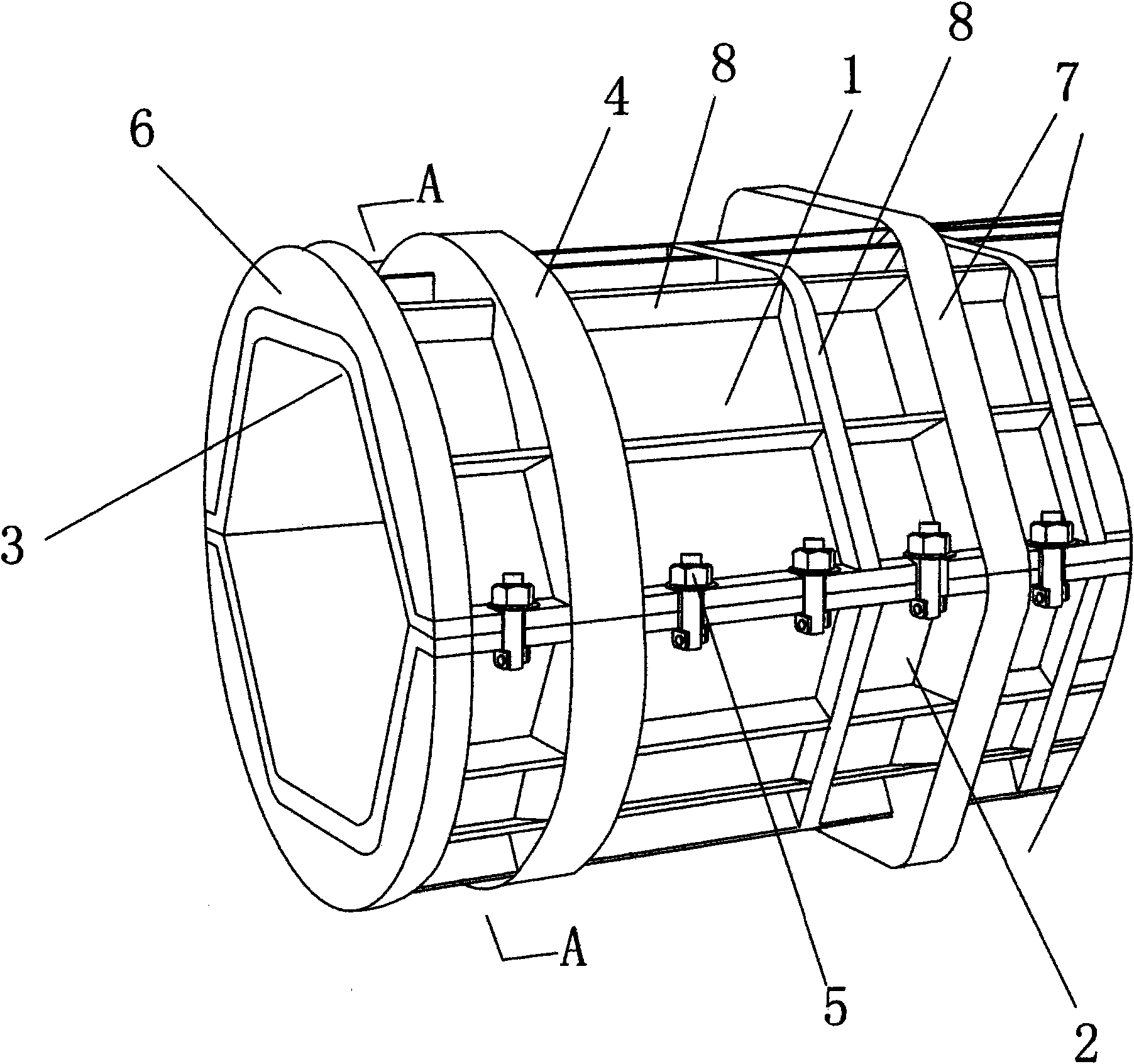

Concrete hollow square pile centrifugal casting mold

ActiveCN101934554BGuaranteed compactnessUniform centrifugal force distributionMouldsCasting moldMaterials science

The invention discloses a concrete hollow square pile centrifugal casting mold, which comprises an upper mold body and a lower mold body. An upper stress-relieved arc is arranged on the inner side of one side of the upper mold body; the inner side of the other side of the upper mold body is a straight side; a lower stress-relieved arc is arranged on the inner side of one side of the lower mold body opposite to the upper stress-relieved arc; and the inner side of the other side of the lower mold body is a straight side. The upper mold body and the lower mold body are closed to be fixedly connected through a locking assembly; a joint of the upper mold body and the lower mold body is formed outside the upper stress-relieved arc and the lower stress-relieved arc; the cross section of a cavityformed by closing the upper mold body and the lower mold body is quadrangular; a plurality of running wheels which make the mold rotate on a centrifugal machine are arranged on the upper mold body and the lower mold body; and a crane hanger for hoisting and a fixing device for preventing the mold from rolling in the process of removing the mold are arranged on the upper mold body and the lower mold body.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

Construction method for pouring airtight partition wall between recovered roadway and reserved roadway

ActiveCN102337906BNo vibrationFast constructionMining devicesUnderground chambersFiberUltimate tensile strength

The invention discloses a construction method for pouring an airtight partition wall between a recovered roadway and a reserved roadway. The airtight partition wall is formed by an inner concrete single wall, an outer concrete single wall and a middle loess concrete wall; and the airtight structure is provided with three layers of walls: the inner side and the outer side are respectively provided with the airtight single wall which is formed in a way that a concrete pump pours concrete into a fiber flexible template, and the loess concrete wall filled by loess-based materials is arranged between the two single walls. The flexible templates are made in advance according to design requirements; a slot is drilled on a preset airtight surrounding rock connecting the roadways; anchor rods are constructed in the slot; after the flexible templates are hung onto the slot through a single hydraulic prop or the anchor rods, the concrete is successively poured into the inner side flexible template and the outer side flexible template by a concrete conveying pipe and a pouring opening through the concrete pump to form the inner single wall and the outer single wall; and after the inner single wall and the outer single wall are poured completely, the loess is poured between the inner single wall and the outer single wall to form the concrete airtight wall. The structure is safe and reliable, the construction cost is low, the construction speed is fast, the labor intensity is low, and the requirements of mine production with high production and high efficiency are met.

Owner:XIAN UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com