Composite formwork for building and manufacturing method thereof

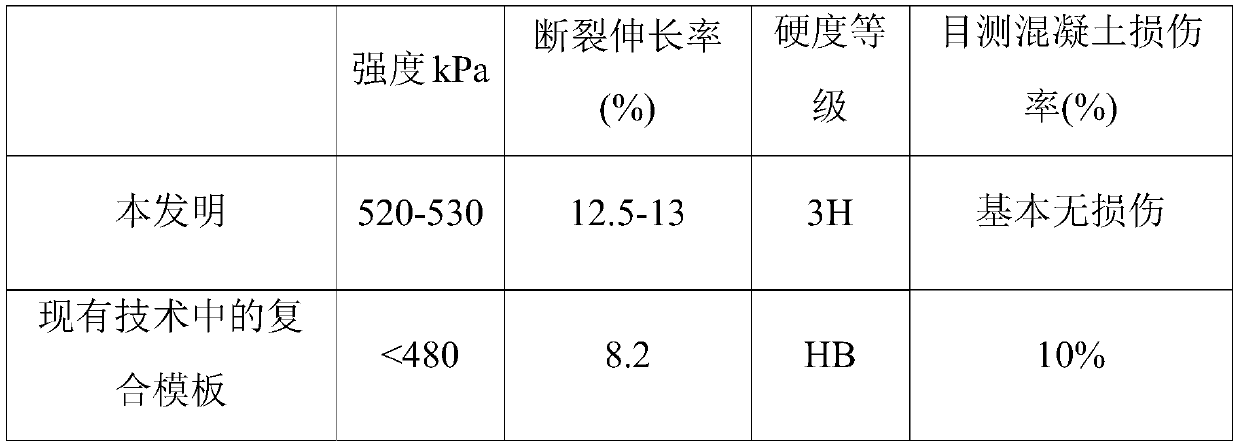

A composite formwork and construction technology, which is applied in building construction, on-site preparation of building components, construction, etc., can solve the problems of lax local vibration and unrealistic filling, etc., and achieves extended service life, easy disassembly, and easy The effect of demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

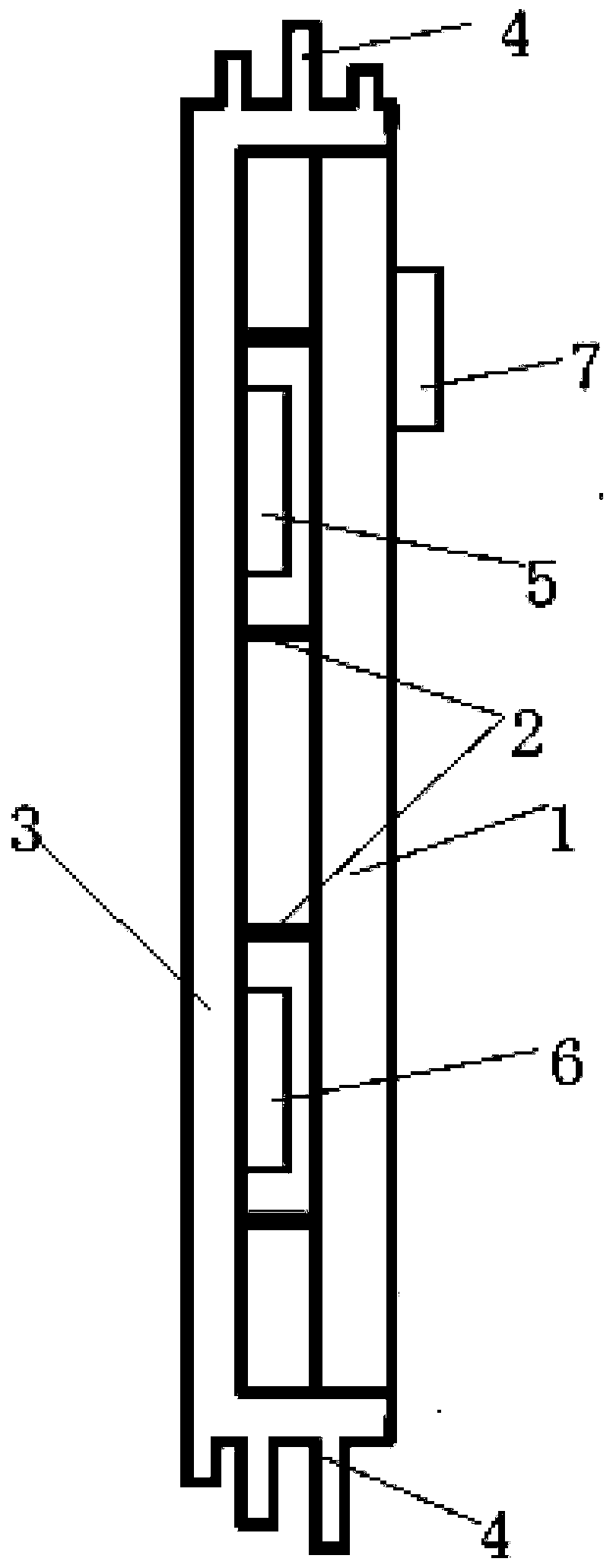

[0037] see Figure 1-2 , a kind of composite formwork for building, which includes a reinforced structure layer 1, a grid support layer 2 and an inner structure layer 3 from the outside to the inside; the inner structure layer 3 closes the reinforced structure layer 1 on the left and right sides of the composite formwork for building and the grid support layer 2, and the closed parts on the left and right sides each form a plurality of concave-convex structures 4 that can be spliced with each other, so that the adjacent building composite templates can be assembled tightly;

[0038] The reinforced structure layer 1 includes the following components in parts by weight: polyphenylene sulfide resin 50, glass fiber 50, polyvinyl chloride resin 30, bakelite powder 30, fly ash 20, potassium titanate whiskers 15, octadecanoic acid Zinc 10, Triphenyl Phosphate 12, Vinyl Triethoxysilane 3, Maleic Anhydride Grafted Polypropylene 6, Methylene Dichloride 2, Vinyl Ethyl Formate 5, Tricre...

Embodiment 2

[0047] A method for manufacturing composite formwork for construction, comprising the following steps:

[0048] 1) Prepare the reinforcement structure layer 1; use vinyltriethoxysilane to soak the fly ash and glass fiber at 22-25°C for 2-2.5h, and then dry at 115-120°C; Add potassium titanate whiskers, zinc octadecanoate and triphenyl phosphate and stir for 40-50 minutes; then add polyphenylene sulfide resin, polyvinyl chloride resin, bakelite powder, maleic anhydride grafted polypropylene, formaldehyde Mix pyridene chloride, ethyl vinylformate and tricresyl phosphate, heat to 92-96°C, keep warm for 15-20min, finally add the remaining components, heat up to 125-130°C, and knead for 15-20min; The refined product is sent to a twin-screw extruder for extrusion and cooling, and the extruded profile is cooled and qualitative, and then added to a cut-to-length cutting machine for cutting to obtain a reinforced structure layer 1;

[0049] 2) Prepare the grid support layer 2; in the ...

Embodiment 3

[0055] see Figure 1-2 , a kind of composite formwork for building, which includes a reinforced structure layer 1, a grid support layer 2 and an inner structure layer 3 from the outside to the inside; the inner structure layer 3 closes the reinforced structure layer 1 on the left and right sides of the composite formwork for building and the grid support layer 2, and the closed parts on the left and right sides each form a plurality of concave-convex structures 4 that can be spliced with each other, so that the adjacent building composite templates can be assembled tightly;

[0056] The reinforced structure layer 1 includes the following components in parts by weight: polyphenylene sulfide resin 60, glass fiber 45, polyvinyl chloride resin 40, bakelite powder 25, fly ash 28, potassium titanate whisker 10, octadecanoic acid Zinc 15, Triphenyl Phosphate 10, Vinyl Triethoxysilane 5, Maleic Anhydride Grafted Polypropylene 4, Methylene Dichloride 5, Vinyl Ethyl Formate 4, Tricres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com