Wave-absorbing foam material and preparation process thereof

A preparation process and foam technology, applied in the field of wave-absorbing materials, can solve problems such as cost increase, absorbent waste, and easy damage, and achieve the effects of high absorption rate, low slurry leakage, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

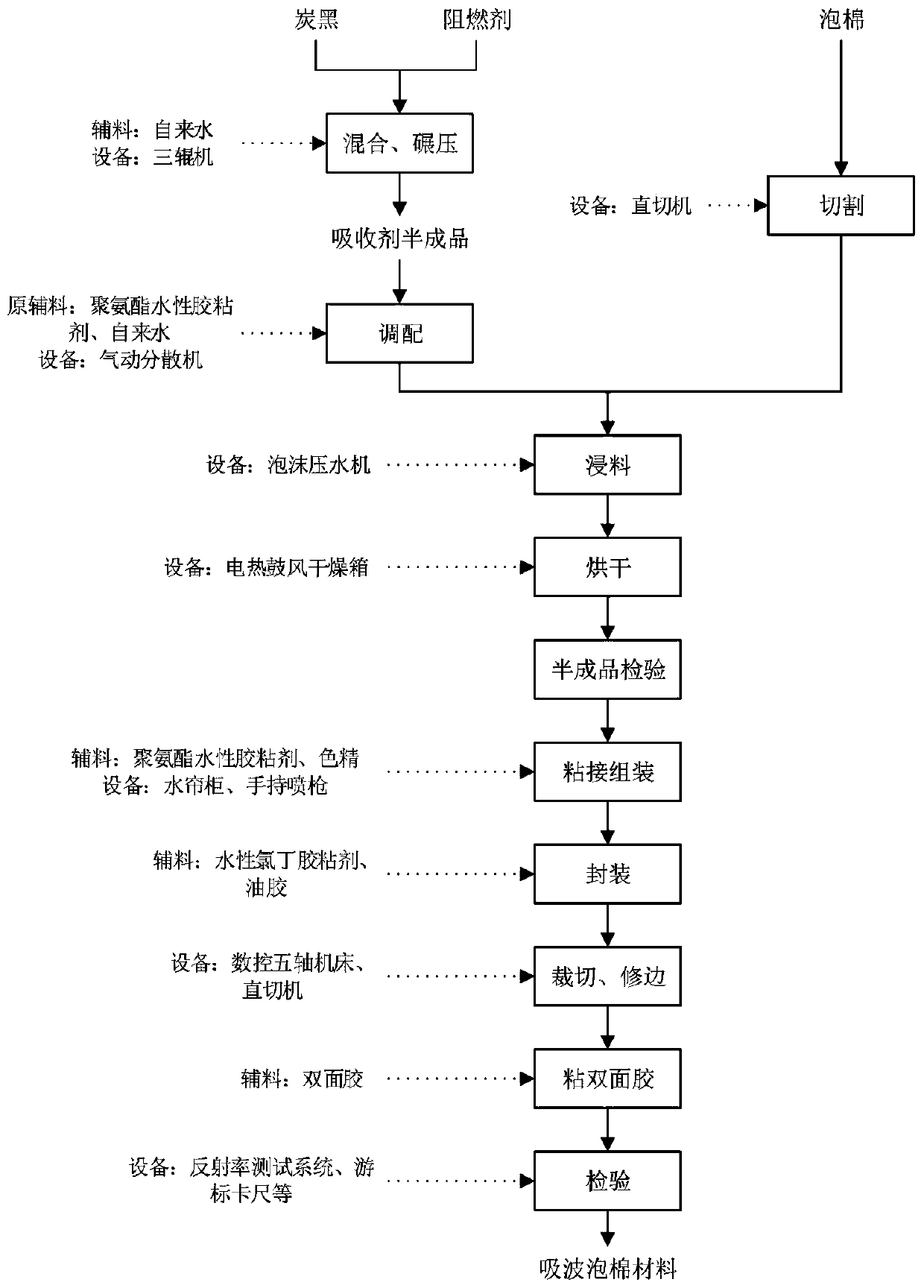

Method used

Image

Examples

Embodiment 1

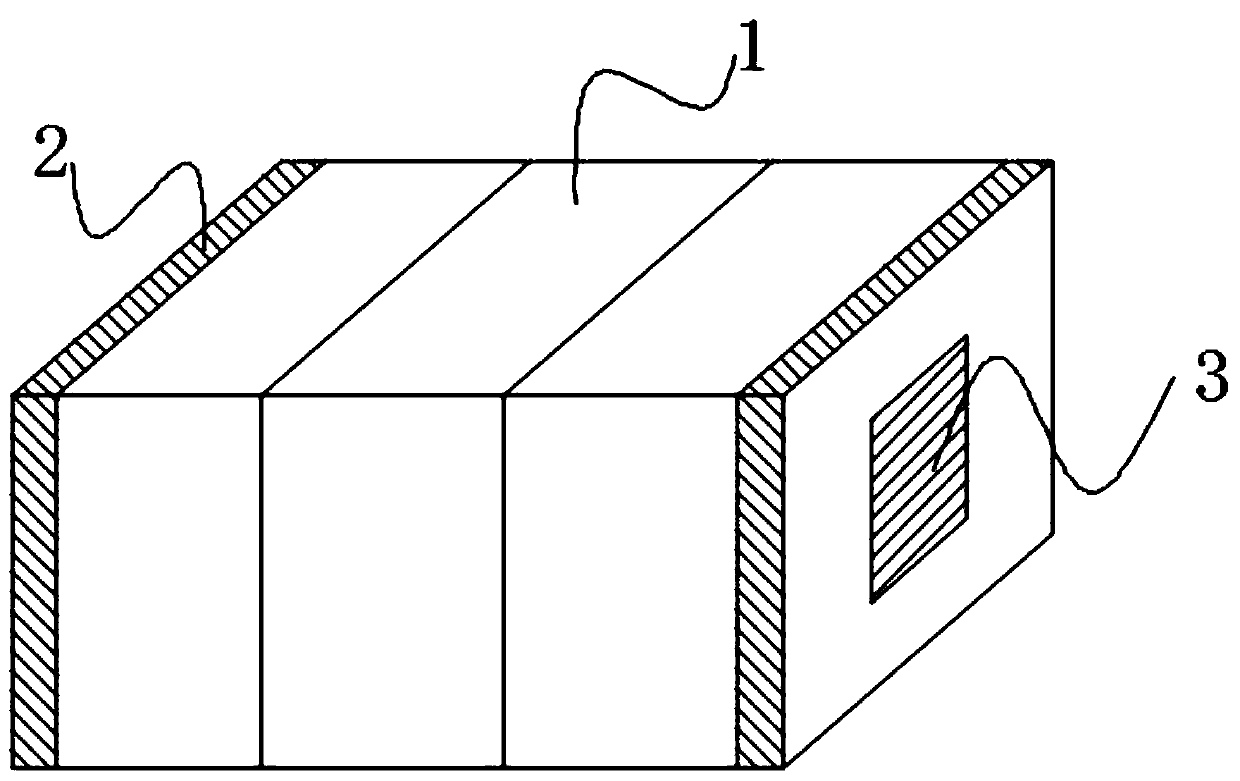

[0034] Such as figure 1 As shown, a wave-absorbing foam material includes three layers of flame-retardant foam 1 that are sequentially bonded by water-based neoprene adhesive and soaked with absorbent. A layer of TPU film 2 is adhered, and a double-sided adhesive tape 3 is adhered to the TPU film 2 on the right side.

[0035] Among them, the absorbent includes the following raw materials in parts by weight: 50 parts of carbon black, 10 parts of flame retardant, 20 parts of polyurethane water-based adhesive, 30 parts of graphene, 1.5 parts of antirust agent, 1.5 parts of antifungal agent, 1.5 parts of light stabilizer 1.5 parts of thickener, 1.5 parts of curing agent, 1.5 parts of antioxidant, 100 parts of water.

[0036] In this embodiment, the absorbing foam has a reflectivity Rw of -17dB to -25dB at the center frequency and normal incidence. The relative bandwidth of the vertical incidence reflectivity Rw can reach -13dB, -10dB is 24% and 35%, respectively, the internal pe...

Embodiment 2

[0038] In this embodiment, on the basis of Example 1, the absorbent includes the following raw materials in parts by weight: 80 parts of carbon black, 40 parts of flame retardant, 50 parts of polyurethane water-based adhesive, 40 parts of graphene, 2 parts of antirust agent, 2 parts of mold agent, 2 parts of light stabilizer, 2 parts of thickener, 2 parts of curing agent, 2 parts of antioxidant, 200 parts of water.

[0039] In this embodiment, the absorbing foam has a reflectivity Rw of -12dB to -20dB at the center frequency and normal incidence. The relative bandwidth of the vertical incidence reflectivity Rw can reach -13dB, -10dB is 19% and 28% respectively, the internal performance changes little when the incident angle is 30°, the vertical polarization is about -12dB when the incident angle is 45°, the incident angle At 60°, the vertical polarization is about -10dB, and the horizontal polarization is about -15dB.

Embodiment 3

[0041] In this embodiment, on the basis of Example 1, the absorbent includes the following raw materials in parts by weight: 60 parts of carbon black, 30 parts of flame retardant, 30 parts of polyurethane water-based adhesive, 25 parts of graphene, 1 part of antirust agent, 1 part of mold agent, 1 part of light stabilizer, 1 part of thickener, 1 part of curing agent, 1 part of antioxidant, 150 parts of water.

[0042] In this embodiment, the absorbing foam has a reflectivity Rw of -9dB--19dB at the center frequency and normal incidence. The relative bandwidth of the vertical incidence reflectivity Rw can reach -13dB, -10dB is 15% and 31%, respectively, the internal performance changes little when the incident angle is 30°, the vertical polarization is about -10dB when the incident angle is 45°, the incident angle At 60°, the vertical polarization is about -8dB, and the horizontal polarization is about -16dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| normal incidence reflectivity | aaaaa | aaaaa |

| normal incidence reflectivity | aaaaa | aaaaa |

| normal incidence reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com