Construction method of concrete arched door and window lintel

A construction method, round arch technology, applied in the construction field of concrete door and window lintels, can solve problems such as hidden dangers in construction quality, high construction difficulty, unsuitable for masonry on the upper part, etc., achieve excellent sealing performance, reduce formwork consumables, and quickly install and manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

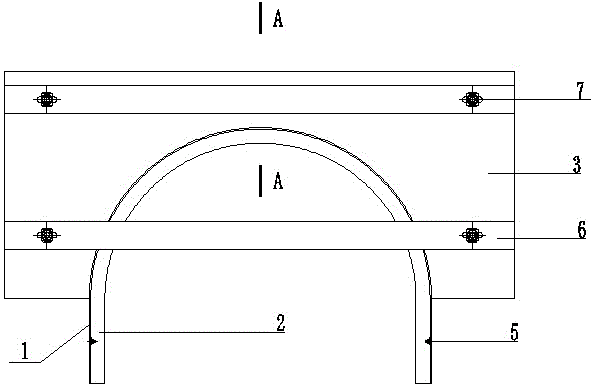

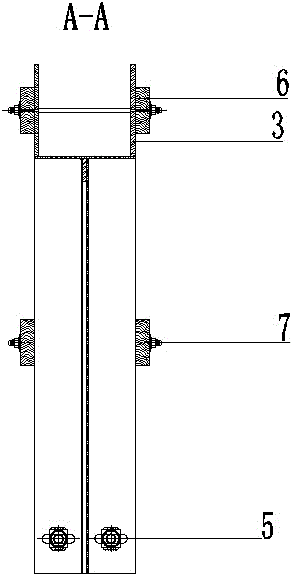

[0027] In a certain European-style construction project, 380 arched door and window heads are designed, all of which are semicircular. They are all constructed using this construction method of concrete arched door and window lintels. The construction steps are:

[0028] 1. Make a template:

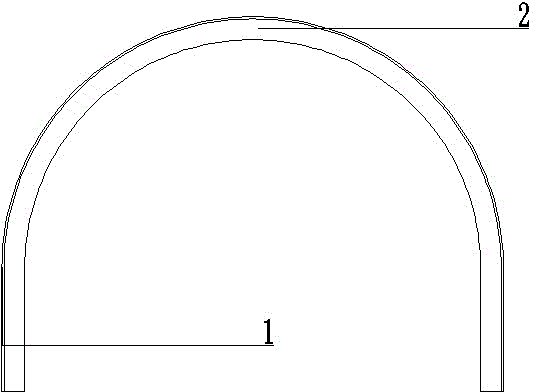

[0029] 1), making the bottom template:

[0030] This base formwork is made up of base plate 1 and stiffener plate 2, and the middle section of this base plate 1 is a semicircle section, promptly is semicircular shape, and the left and right end sections of this base plate 1 are the vertical sections that are symmetrically placed below, promptly take width and this circle The arched door and window head is designed as a long steel plate with the same width, and the middle section is bent into a semicircle with the same radius as the round arched door and window opening, and the left and right end sections are vertical sections that are placed symmetrically below. Both are 300mm, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com