Suspension mold for enlarging and reinforcing concrete beam and construction method of suspension mold

A technology of concrete beams and construction methods, which is applied to the preparation of building components on site, the connectors of formwork/formwork/work frame, and building maintenance, etc., which can solve the problems of waste, complicated operation, and low construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

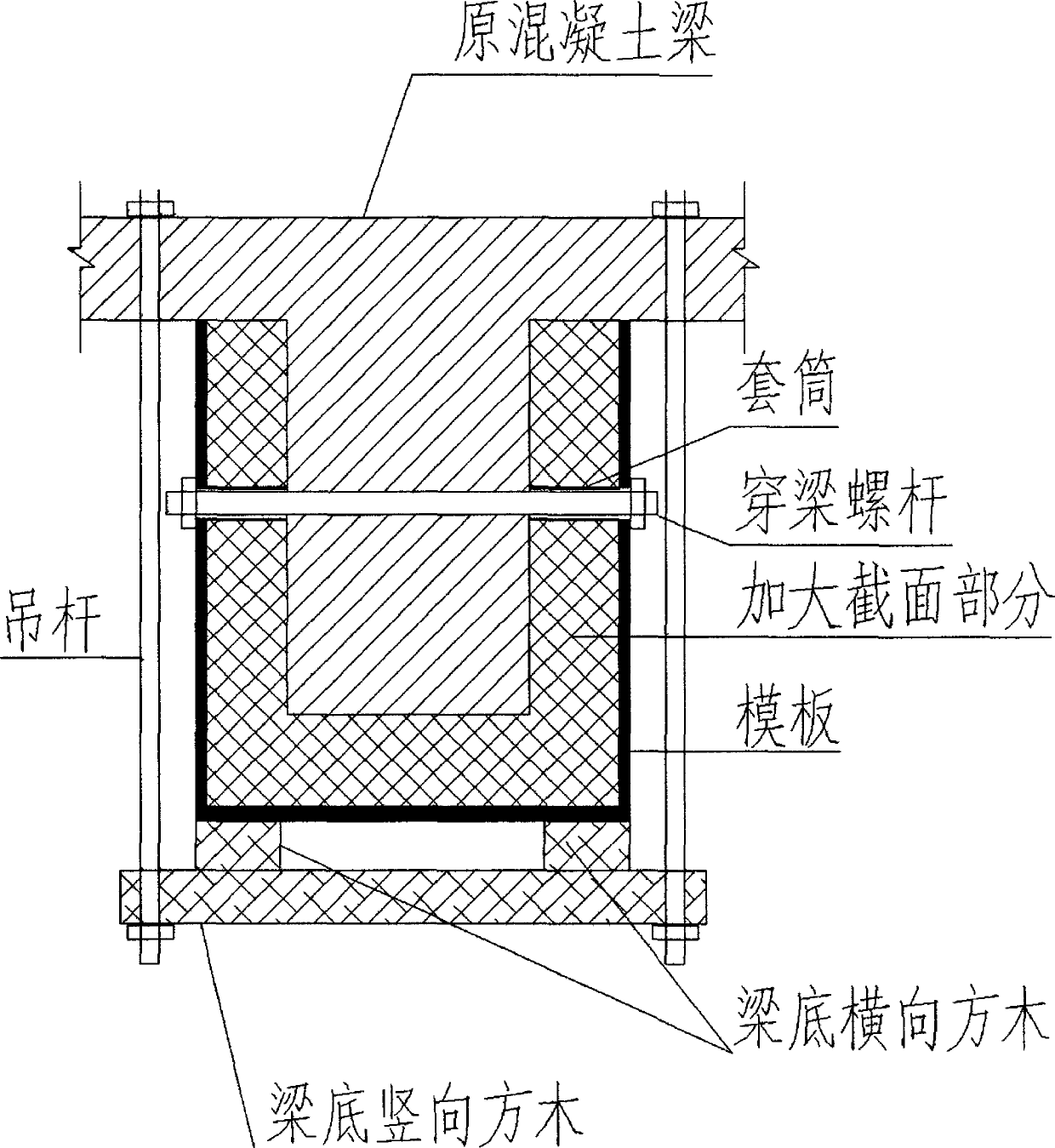

[0016] Such as figure 1 As shown, a kind of hanger formwork that a kind of concrete beam is used when increasing reinforcement, comprises concrete beam 1 and the floor slab 2 on concrete beam 1, is respectively provided with a suspender 3 on both sides of described concrete beam 1, these two One end of the boom 3 passes through the floor 2 and is fixed, and the other end is fixedly connected with a vertical square log 4, and the vertical square log 4 is provided with two horizontal square logs 5 on the left and right. A template 6 is provided, and the template 6 forms a closed grouting space 7 with the concrete beam 1, and the closed grouting space 7 is used for strengthening the concrete beam 1; a grouting hole 8 is also provided on the floor 2, and the grouting hole 8 Connected with the closed grouting space 7, concrete can be poured into the closed grouting space 7 from the grouting hole 8; the concrete beam 1 is also pierced with a beam-piercing screw 9, and the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com