High concrete pier construction formwork device

A technology of high concrete pier and formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the existing technology, the sliding form construction technology is adopted, and the formwork device has a large one-time investment, which has certain restrictions on the facade shape of the structure. The structural design must also be coordinated according to the characteristics of the sliding form construction, and in the construction organization management, A scientific management system and a large number of professional teams are required, and the construction cost is high.

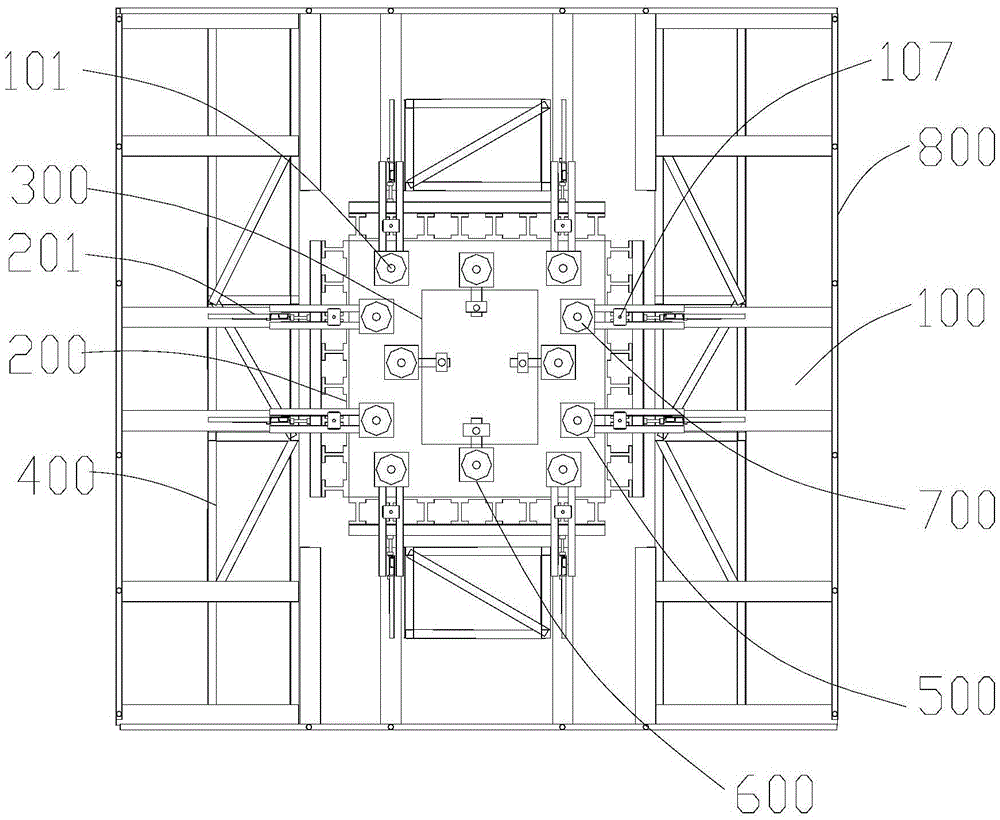

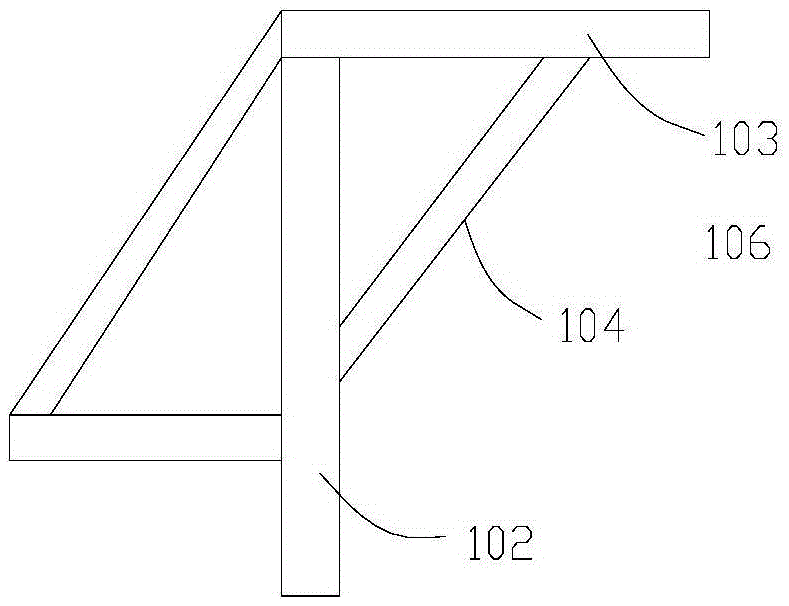

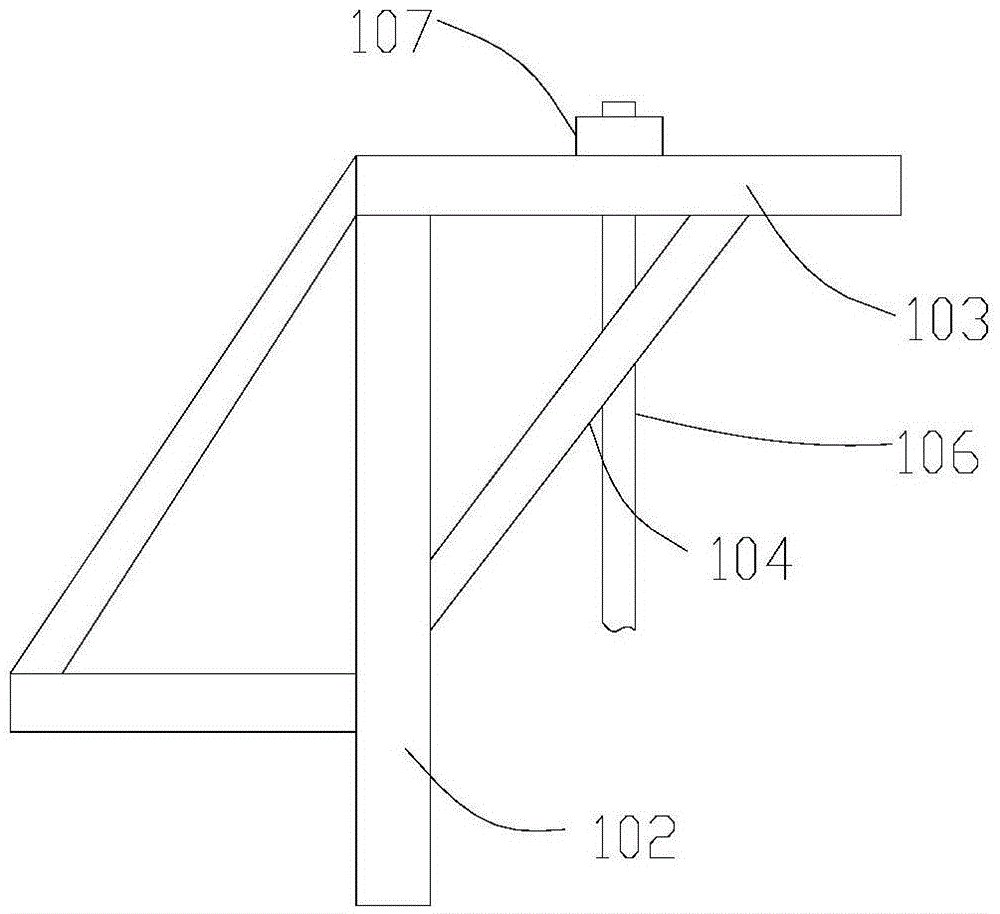

[0038] In view of this, the designer of the present invention designed a formwork device for high concrete pier construction. The formwork device has a simple and reasonable structure and low manufacturing cost. At the same time, the formwork device has a compact and firm structure. During the construction process, the climbing operation of the formwork system is flexible , The force balance of the whole device during the climbing process saves construction time.

[0039] In order to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com