Plastering-free building wall construction technology

A construction technique and a plaster-free technology, which is applied to building structures, buildings, building components, etc., can solve the problems of large deviations in verticality and flatness of walls, inability to achieve quasi-clear water without plastering, and insufficient protection of finished walls. problems such as slurry, to achieve the effect of low cost, superior wall quality, and saving formwork materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

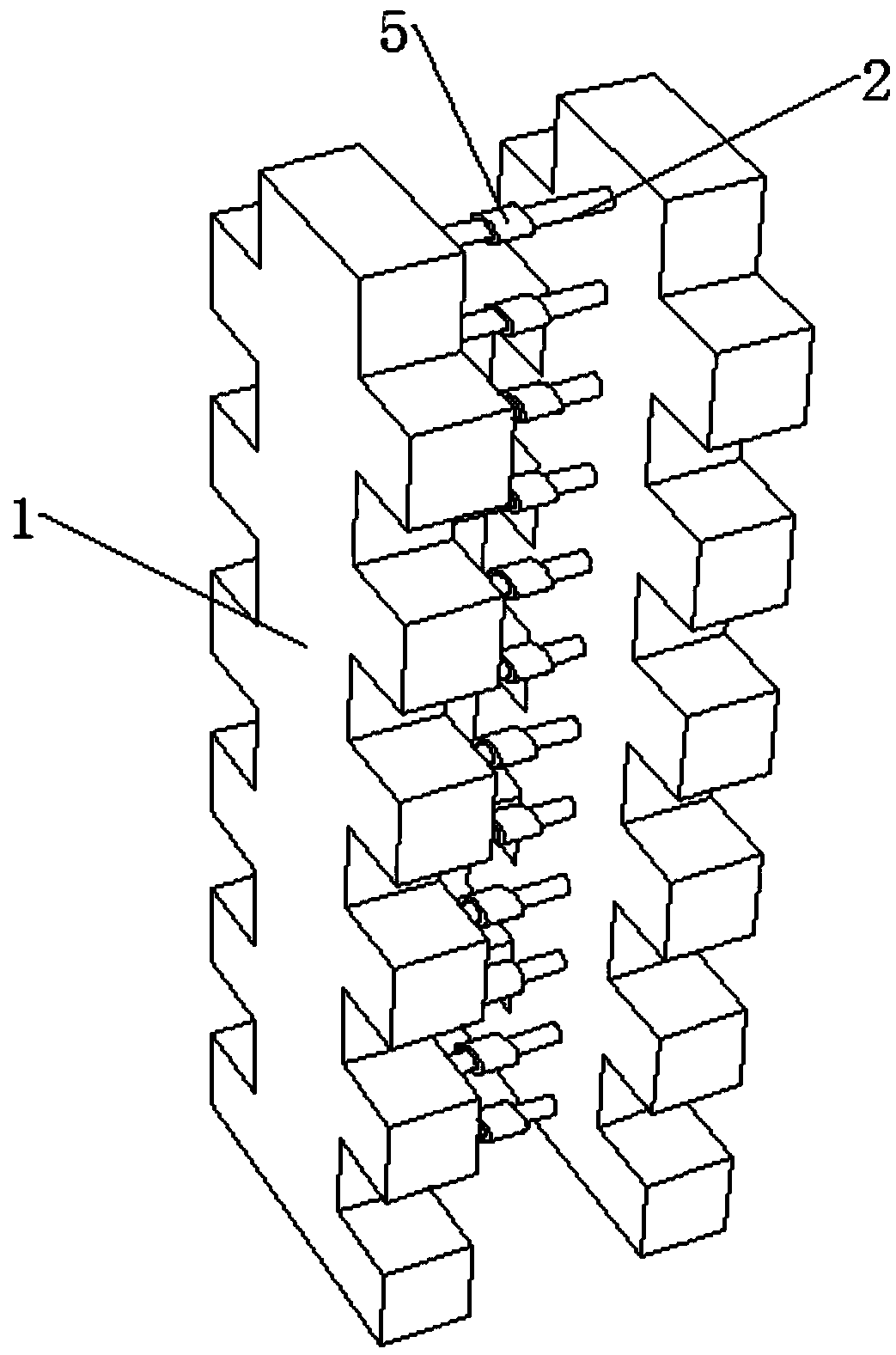

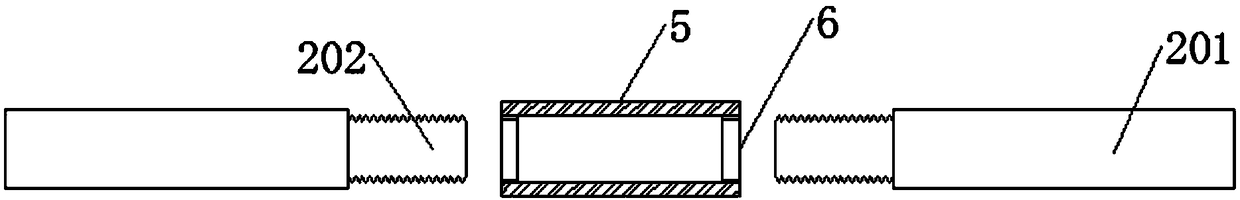

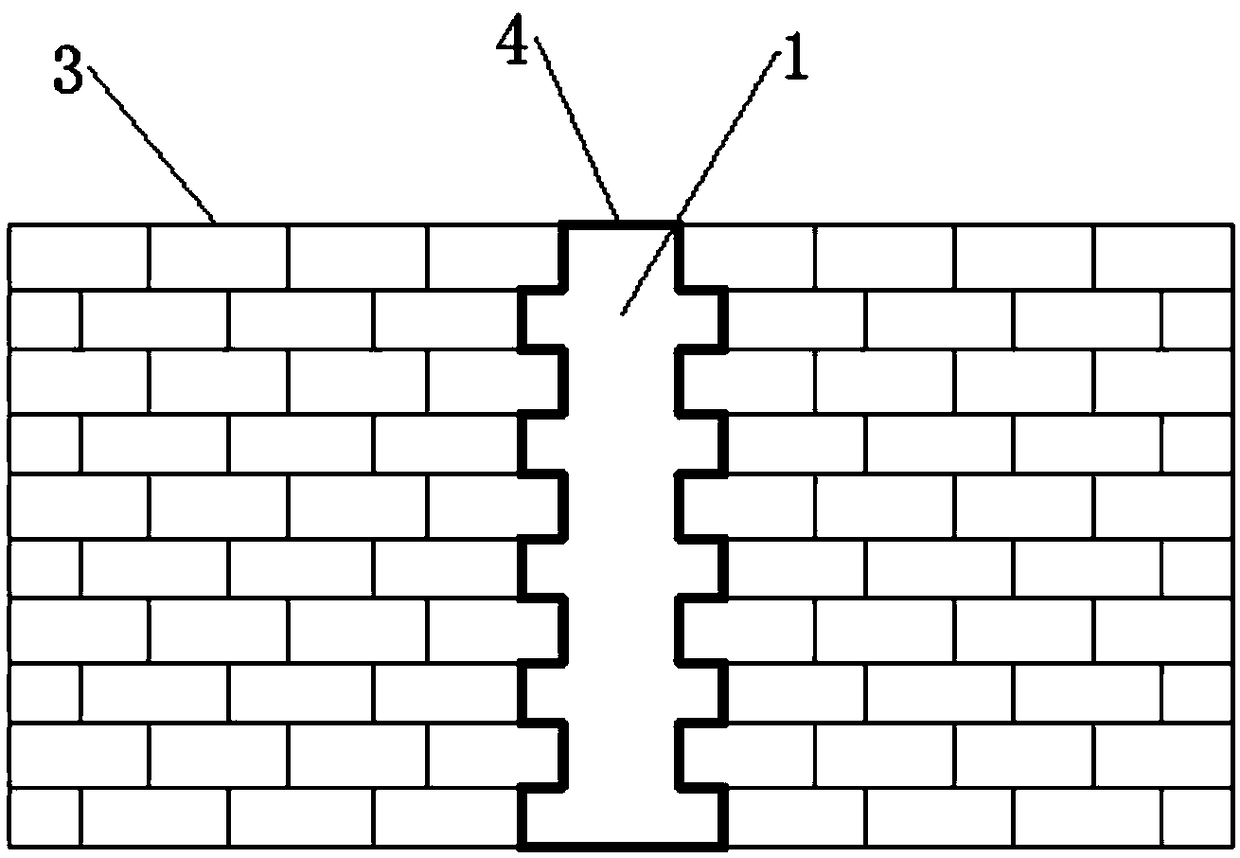

[0047] see Figure 1-6 , the building wall plaster-free construction process, the specific steps are as follows:

[0048] a. Clean the base, remove the remaining mortar and sundries in the masonry parts, and clean up the parts protruding from the masonry surface, exposed steel bars and lead wires;

[0049] b. Positioning and setting out, the measuring and setting out should be matched with the measuring network of the main structure, and the baseline of the main structure shall prevail, and the plane reference line and the elevation reference line of the outer wall shall be pulled out;

[0050] c. Structural column formwork, planting bars, and binding, using a pair of structural column prefabricated formwork 1 as a template;

[0051] d. Polymer mortar mixing and masonry, using blocks to build the infill wall masonry 3, and the connection between the infill wall masonry 3 and the structural column should be made of horse teeth;

[0052] e. After the strength of the filling wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com