Centrifugal moulding mould used for manufacturing concrete hexagonal piles

A centrifugal forming and hexagonal technology, applied in the direction of molds, etc., can solve the problems of poor shear resistance, unguaranteed durability, waste of national resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

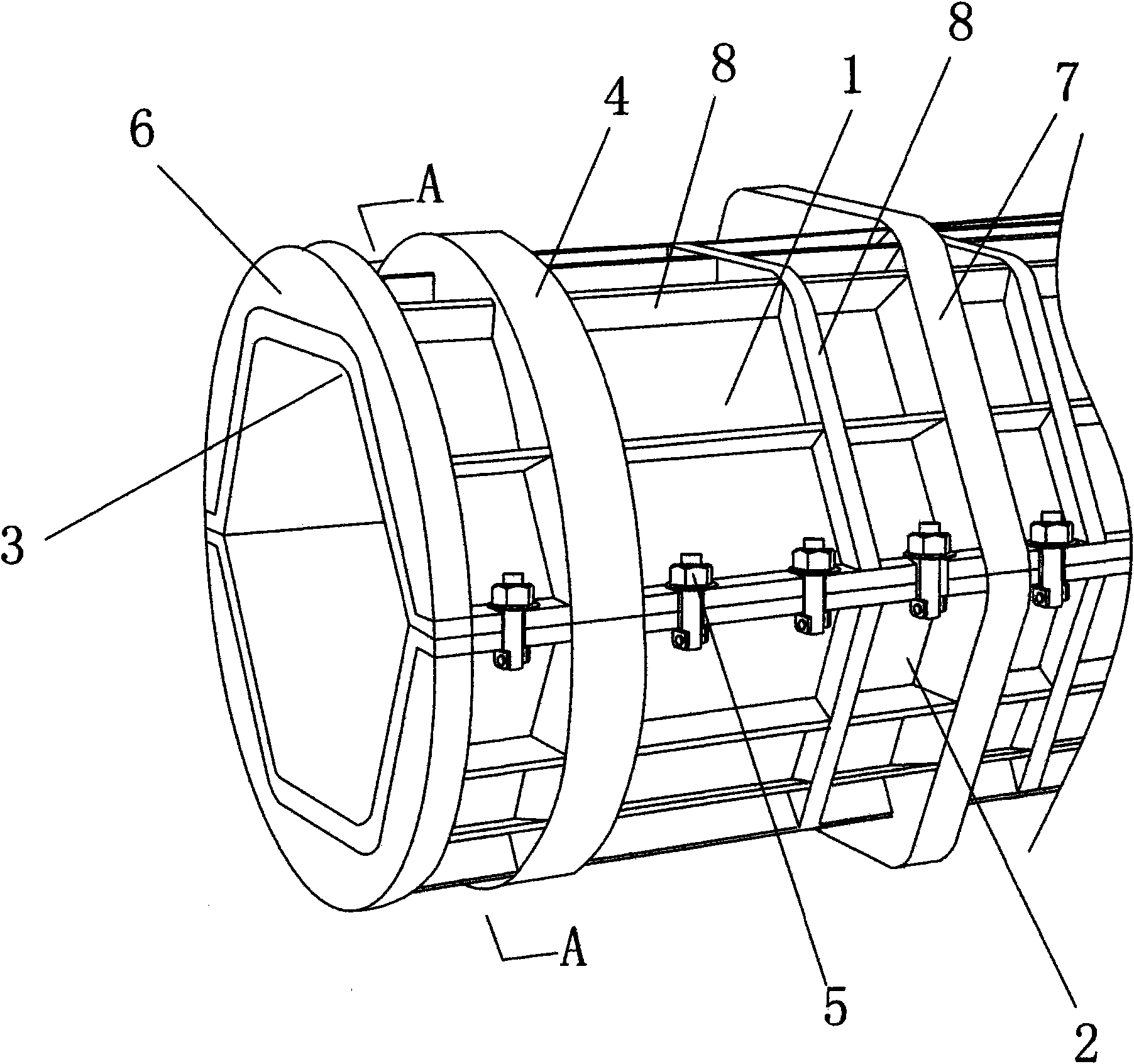

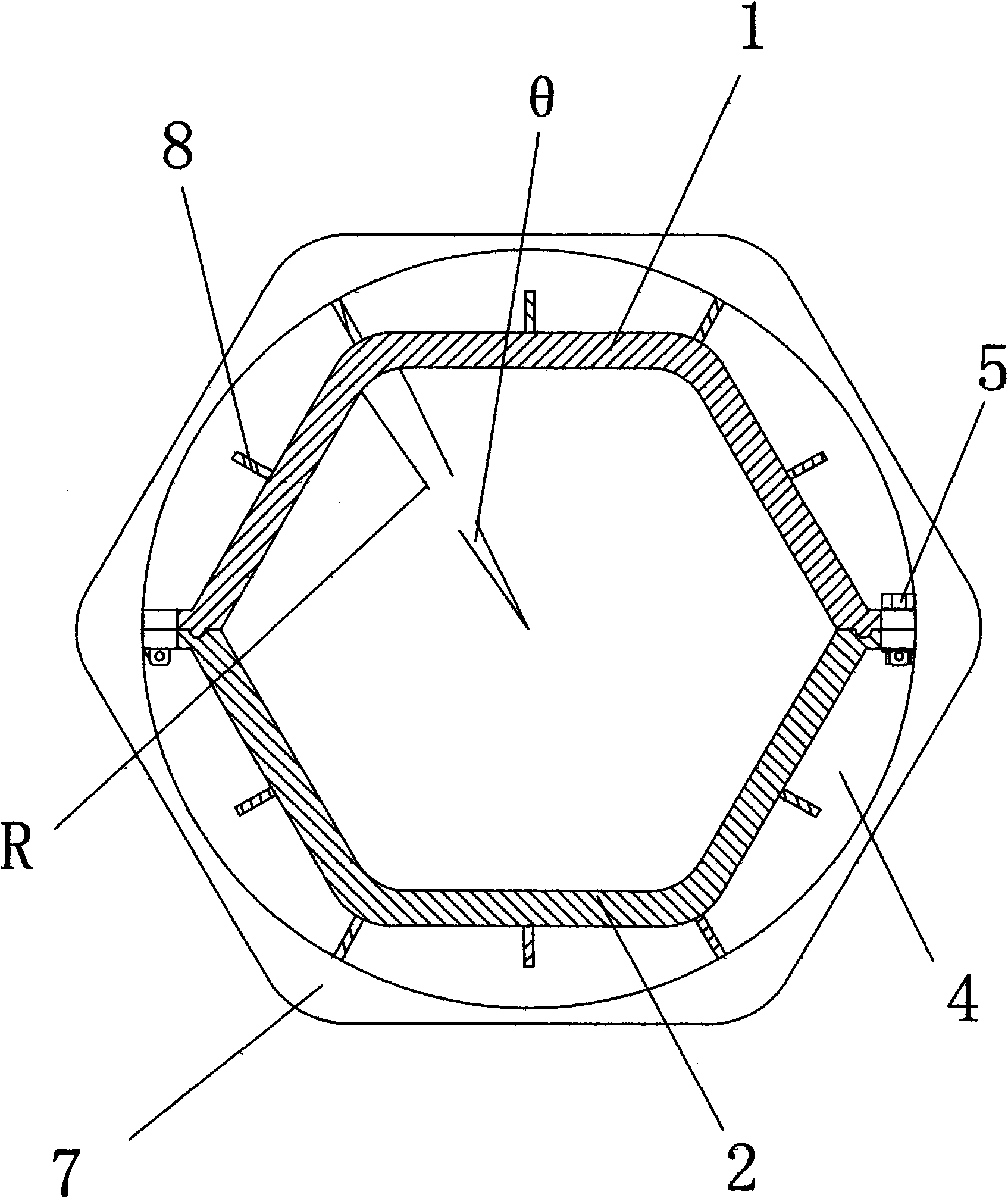

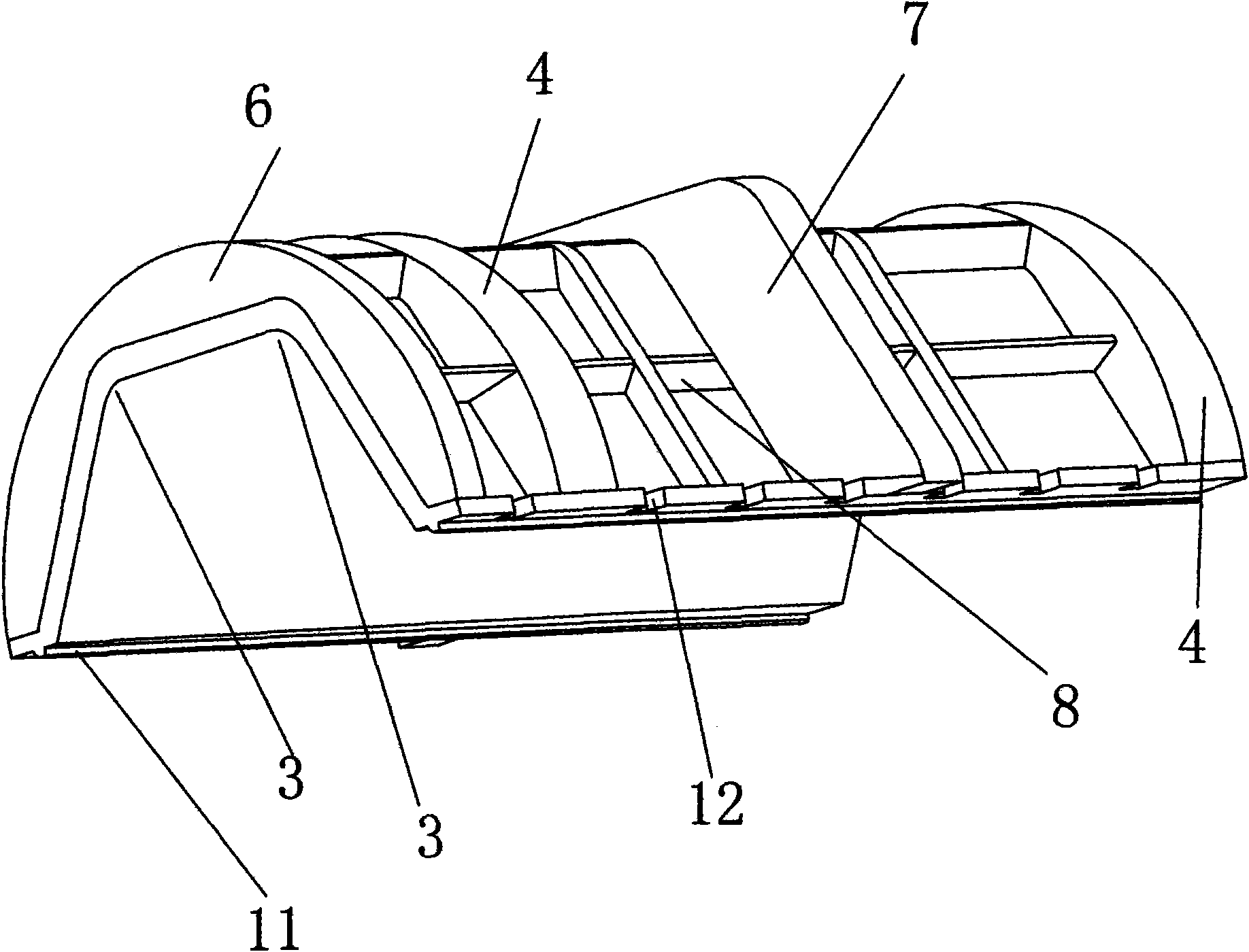

[0024] Such as Figures 1 to 4 Shown a kind of centrifugal molding mold that is used to make concrete hexagonal pile, comprises upper mold body 1 and lower mold body 2, after described upper mold body 1 and lower mold body 2 closed molds, its inner cavity cross section is Hexagonal, the bottom surface of the upper mold body 1 and the side pass through the arc 3, the arc angle θ is 30-120°, the arc radius R is 5-50mm, the lower mold body 2 The bottom surface and the side are transitioned through the arc 3, and the arc angle θ of the stress relief is 30-120°. The radius R of the arc is 5-50 mm. A plurality of running wheels 4 that make the mold rotate on the centrifuge, the distance between the two adjacent running wheels 4 is two meters, and the running wheels are added by analogy according to the length of the pipe mold; the upper mold b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com