Press forming method of automobile hub and matched forming mold thereof

An automobile wheel hub and extrusion forming technology, which is applied in the direction of metal extrusion dies, etc., can solve the problems of complex process, reduce forming force, and high cost, and achieve the effects of simplifying process, reducing deformation resistance, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

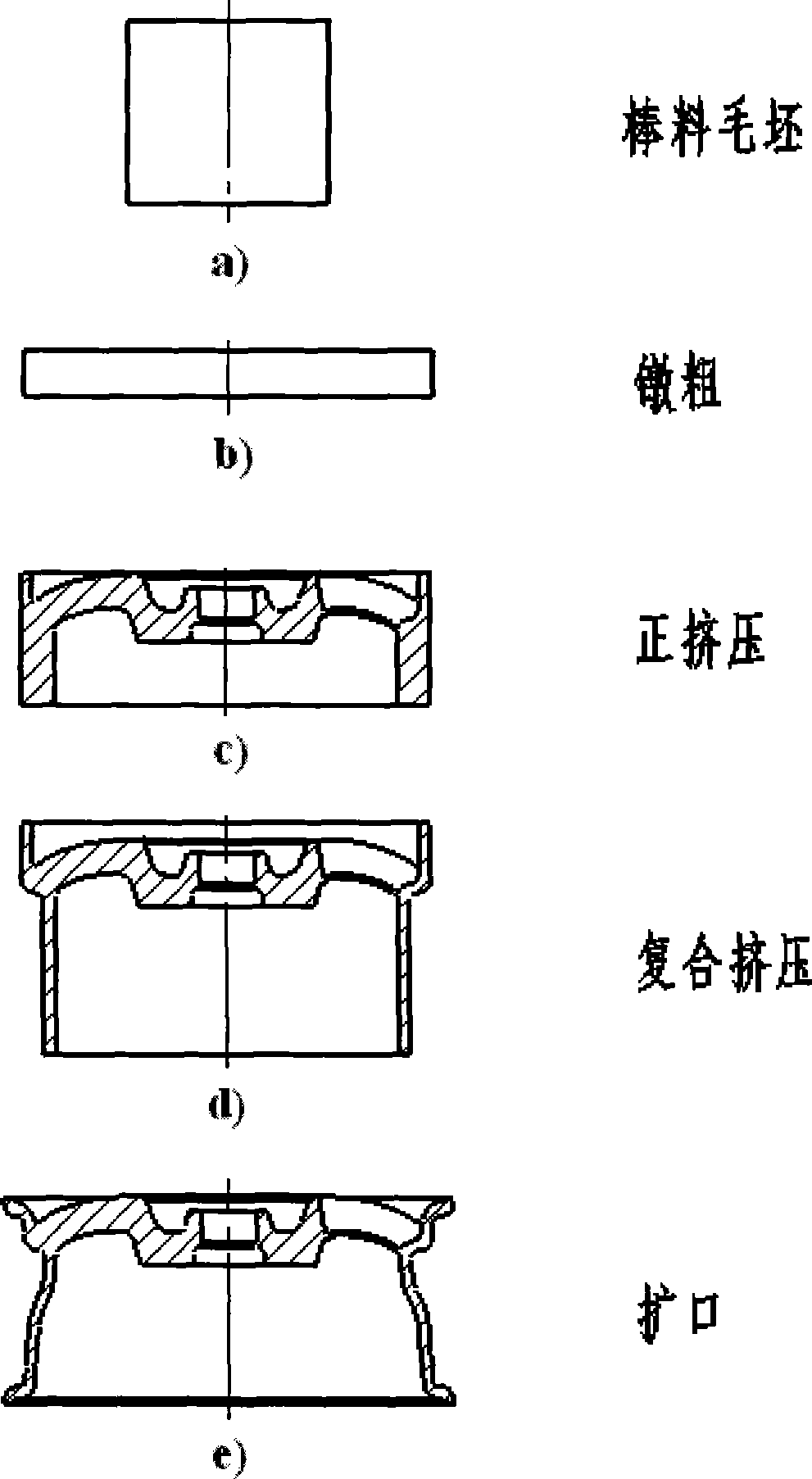

[0066] The forming method of the hot solid extruded magnesium alloy wheel hub of the present embodiment is completed by the following steps:

[0067] 1. The hub material is made of cast or rolled magnesium alloy bar, models such as AZ31B, AZ61A, AZ80A, AZ91D, MB2, MB3, MB5, MB6, MB7, MB8, MB11, MB14, MB15, ZM1, ZM5, ZM10, etc. Changing temperature conditions can also be used in the forming of aluminum alloy wheels.

[0068] 2. Use a sawing machine to cut the material according to the required size.

[0069] 3. Heating the billet in step 2, the heating temperature range is 250-420°C;

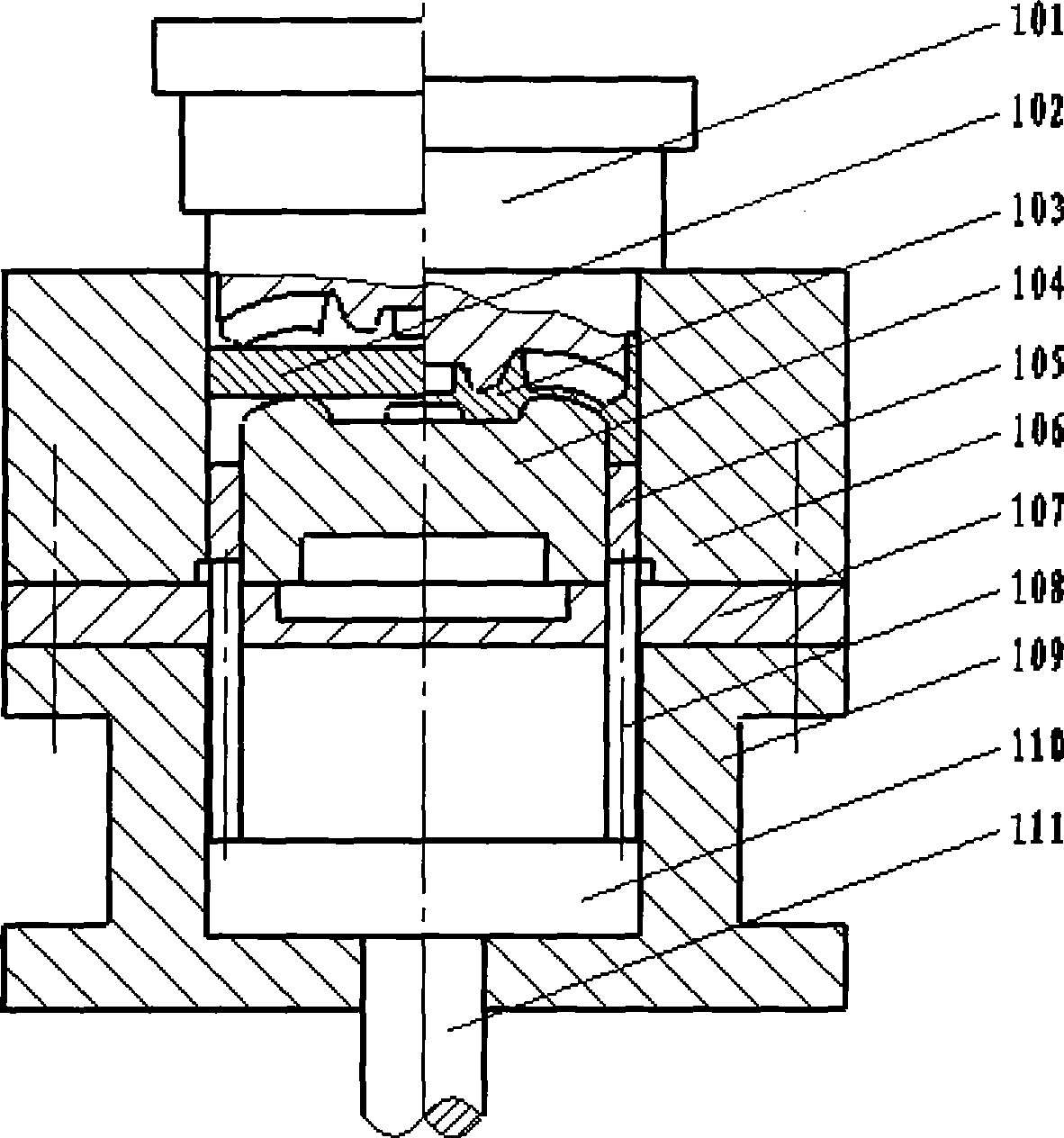

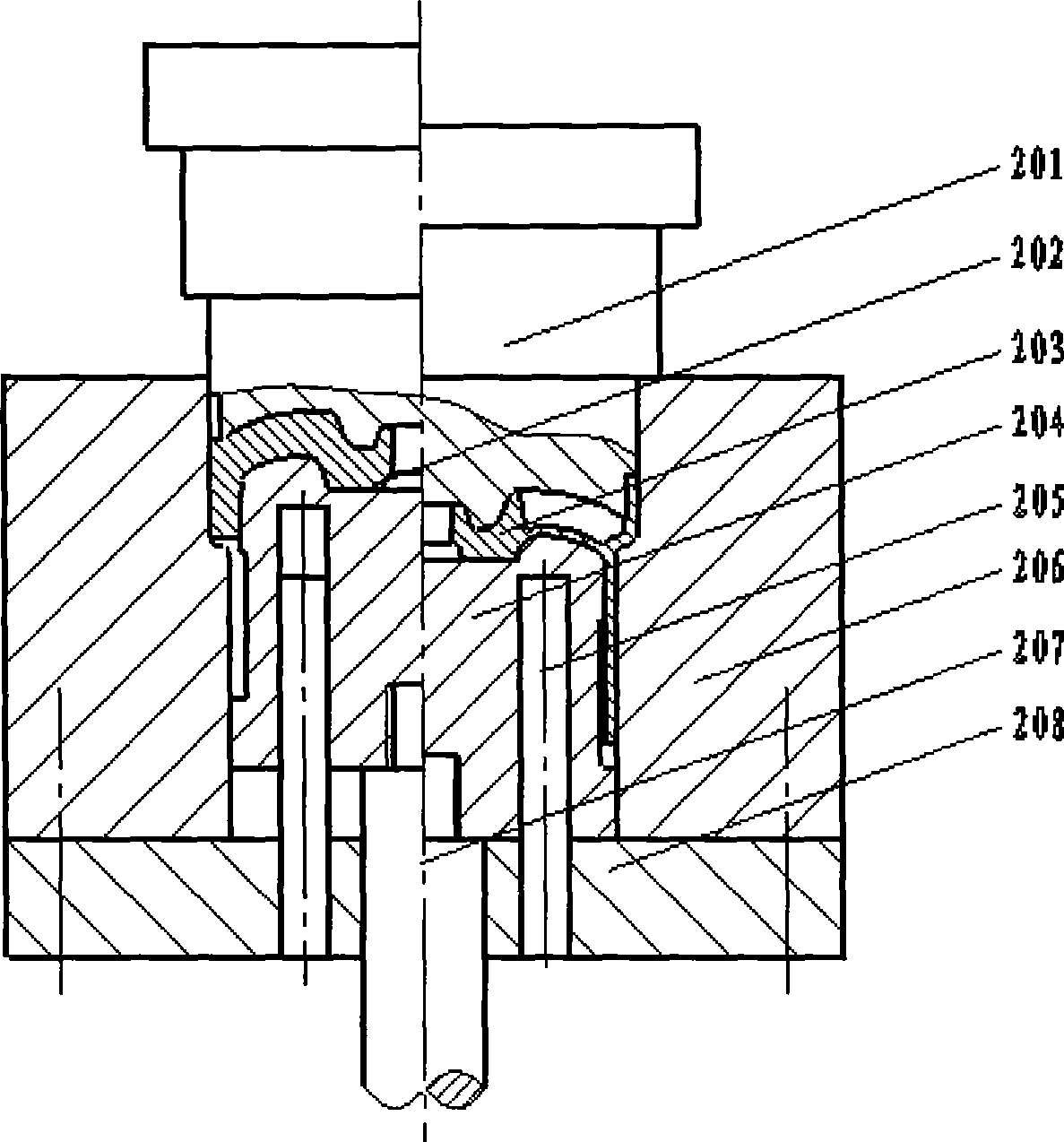

[0070] 4. Heat each mold as required. In order to realize isothermal extrusion forming, the heating temperature of the forward extrusion mold and the compound extrusion mold are consistent with the molding temperature, and the temperature of the rim flaring mold is about 250°C.

[0071] 5. Upsetting the heated blank in step 3 to the required size.

[0072] 6. Preheat the upsetting blank in ste...

Embodiment 2

[0079] The difference between this embodiment and Example 1 is that the blanks that have been upset, coated with lubricant and heated to the forming temperature are put into three sets of molds and formed sequentially, which can avoid repeated heating, save energy, realize continuous production, and improve Productivity.

Embodiment 3

[0081]The difference between this embodiment and Example 1 is: change the mold used in step 9 into a mold without die constraints ( Image 6 ), the structure of the flaring die is simplified, the cost is reduced, and the operation is convenient, which is suitable for the flaring process when the transition in the middle of the rim is relatively smooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com