Patents

Literature

51results about How to "Optimizing the forming process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

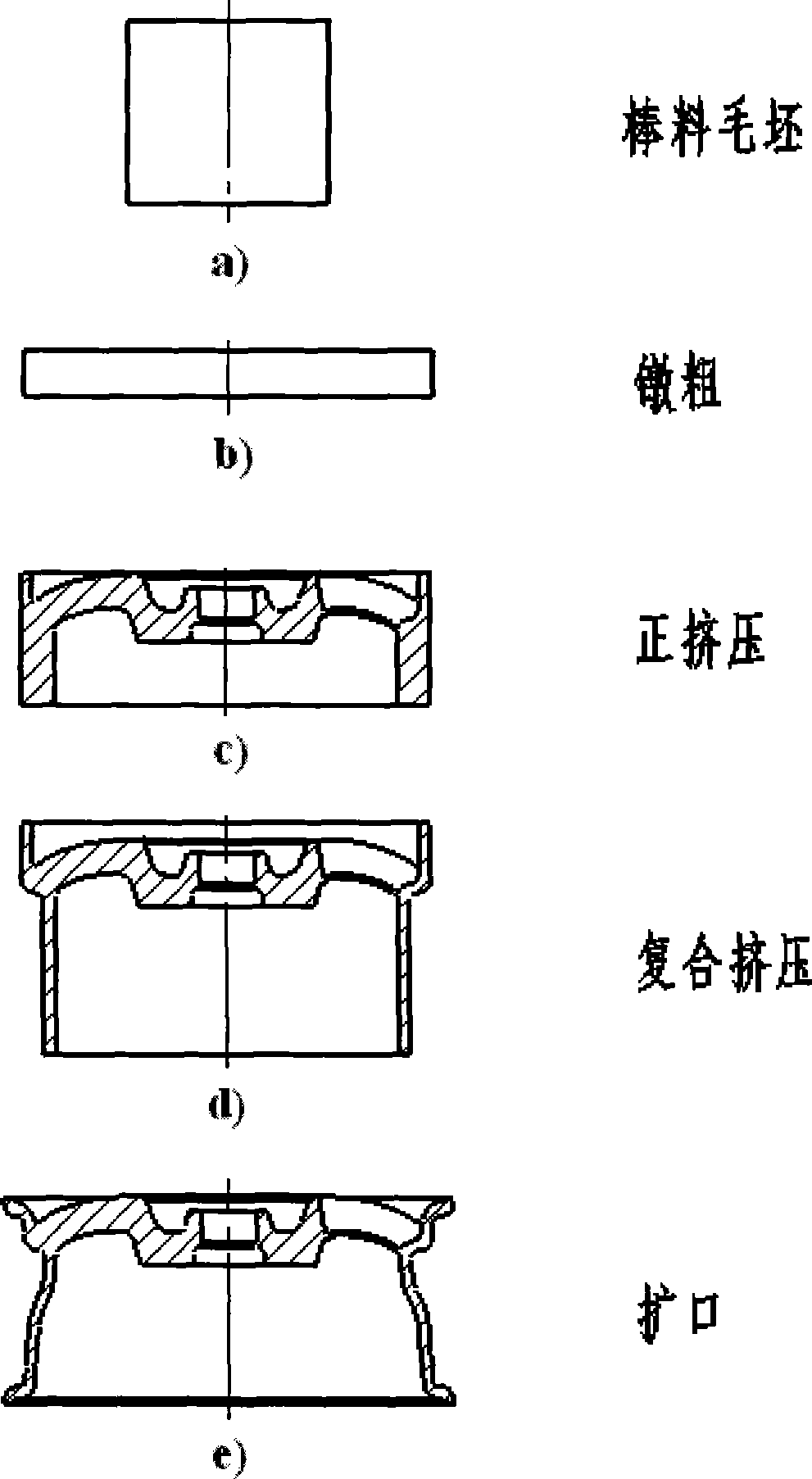

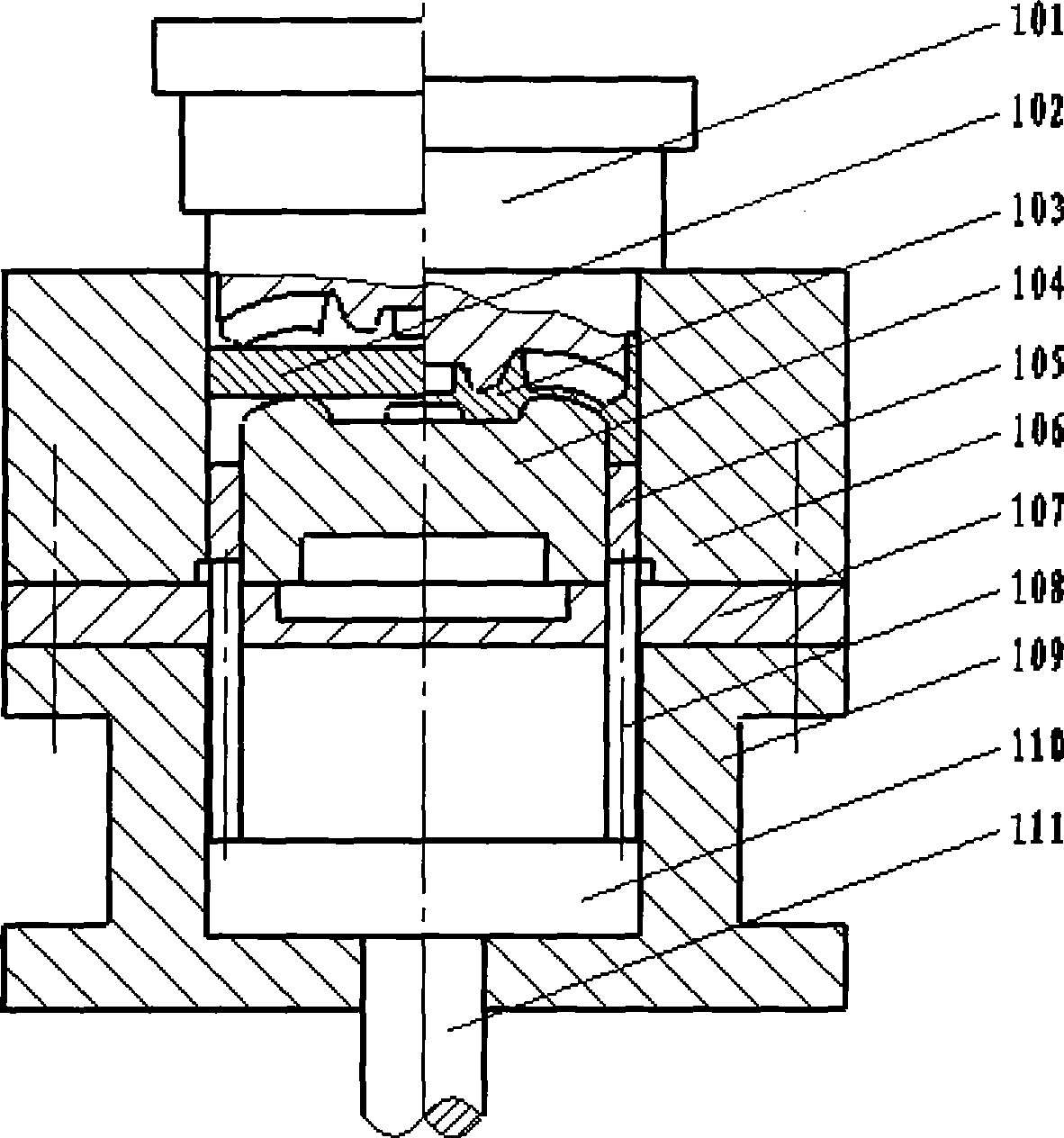

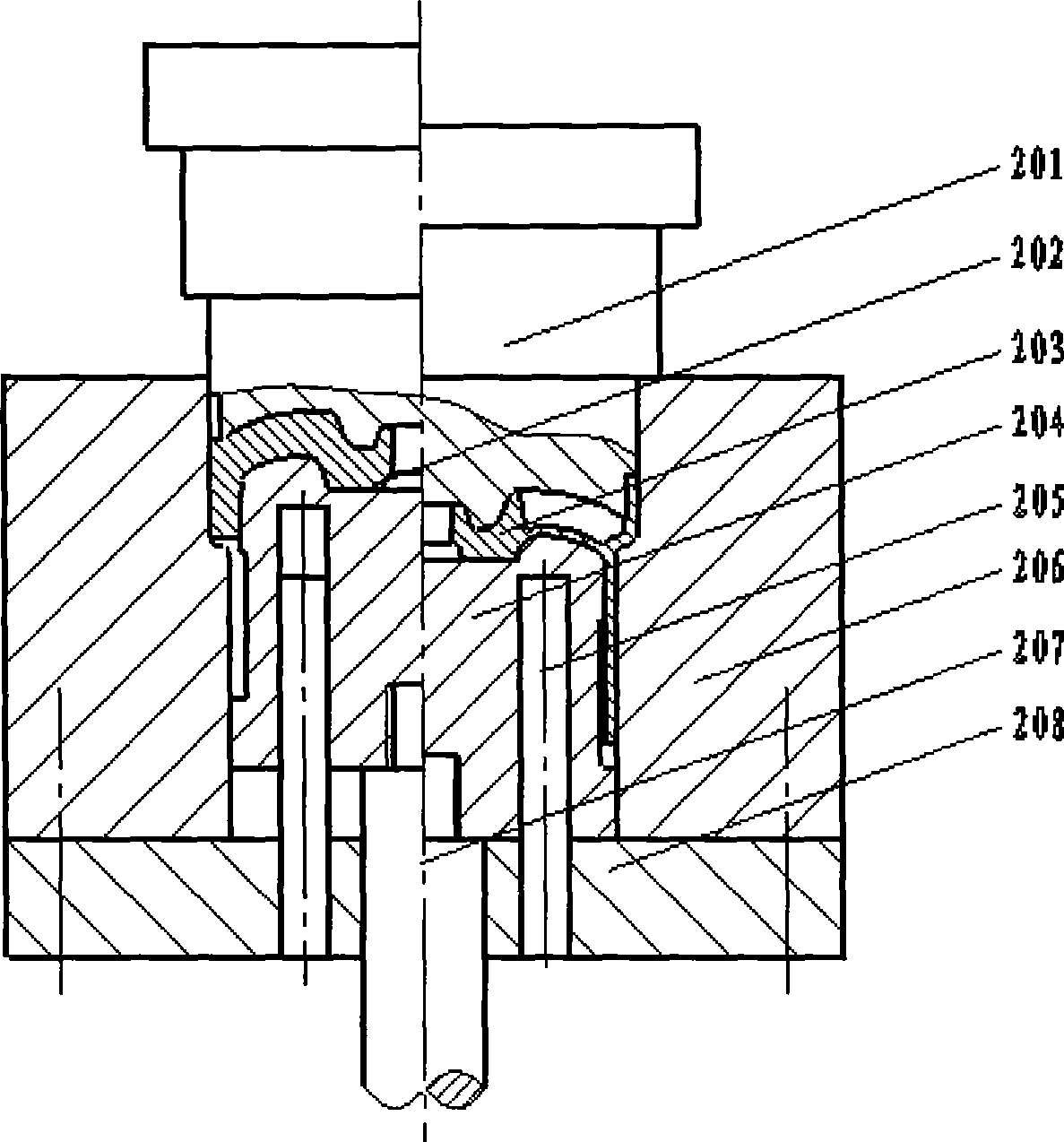

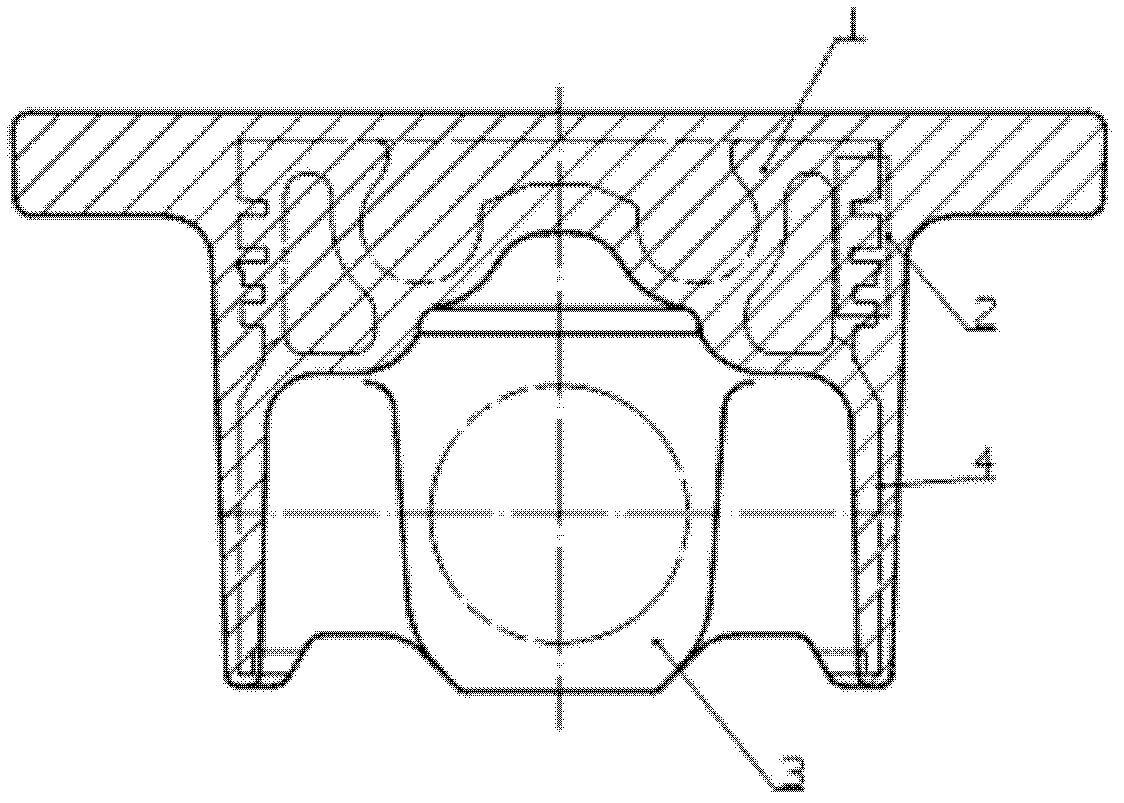

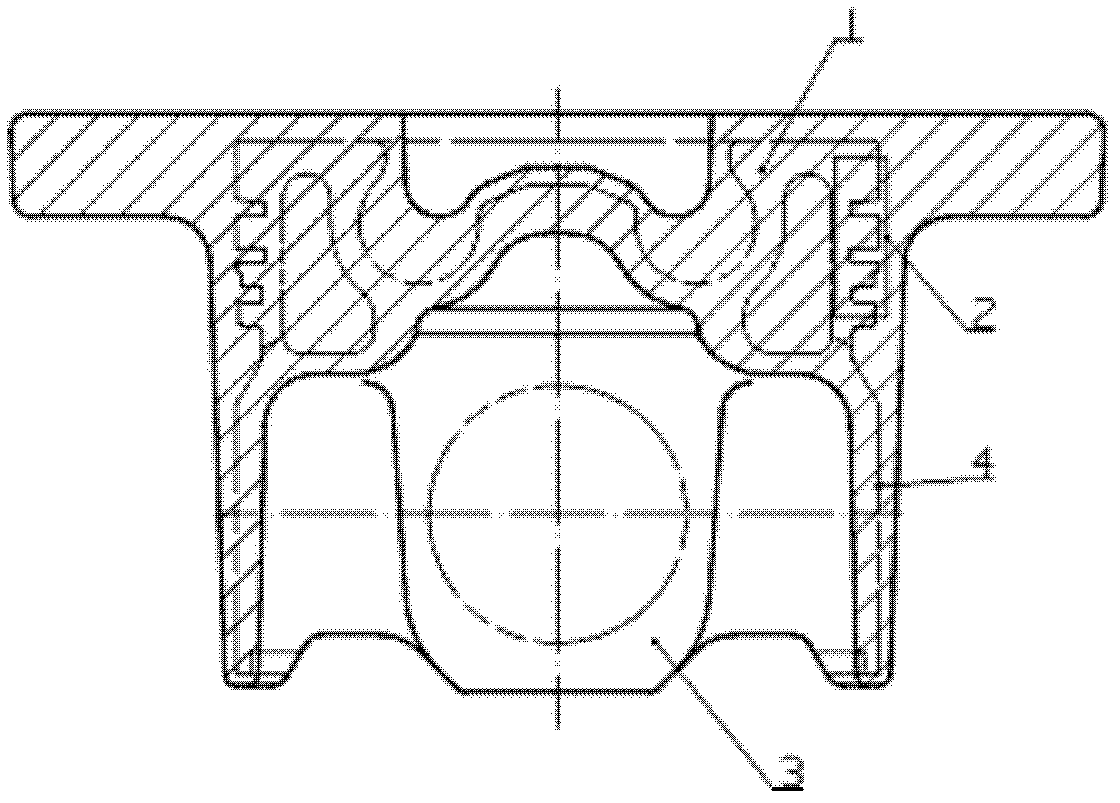

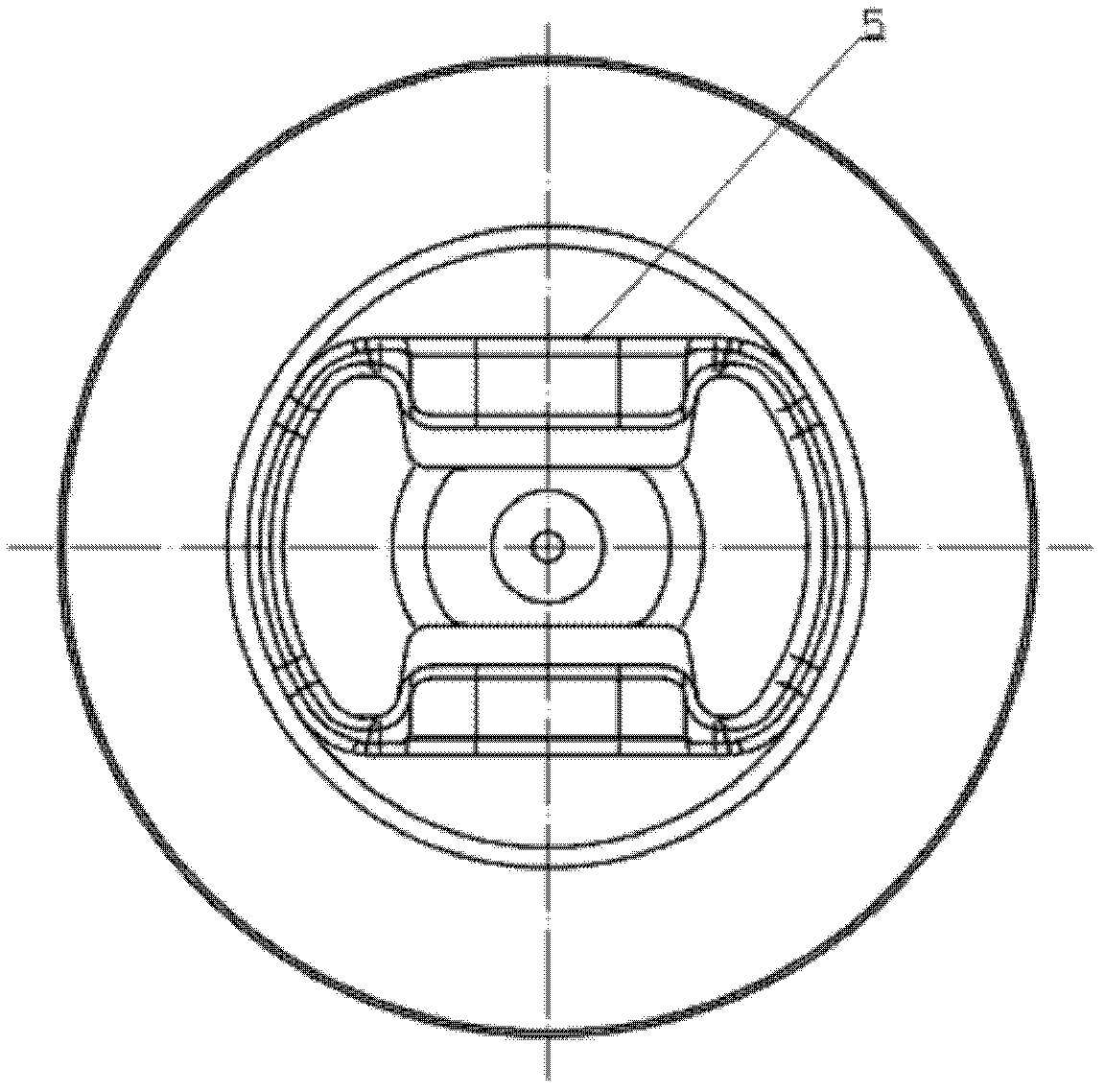

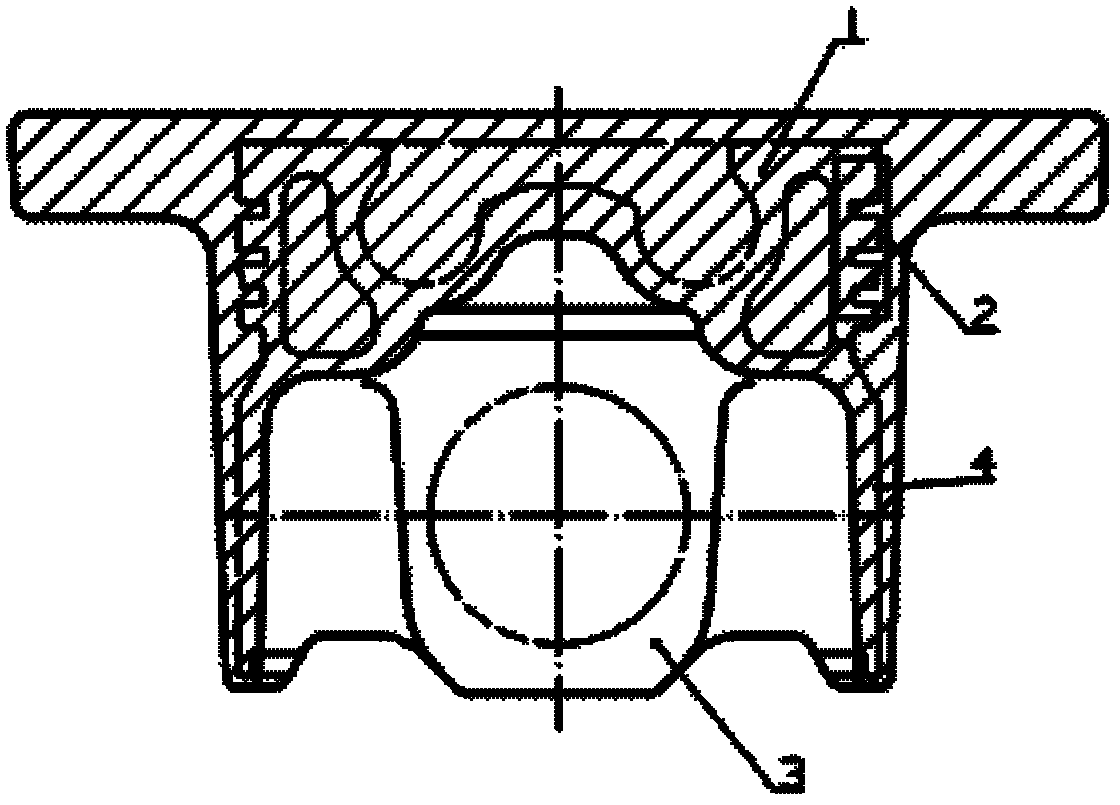

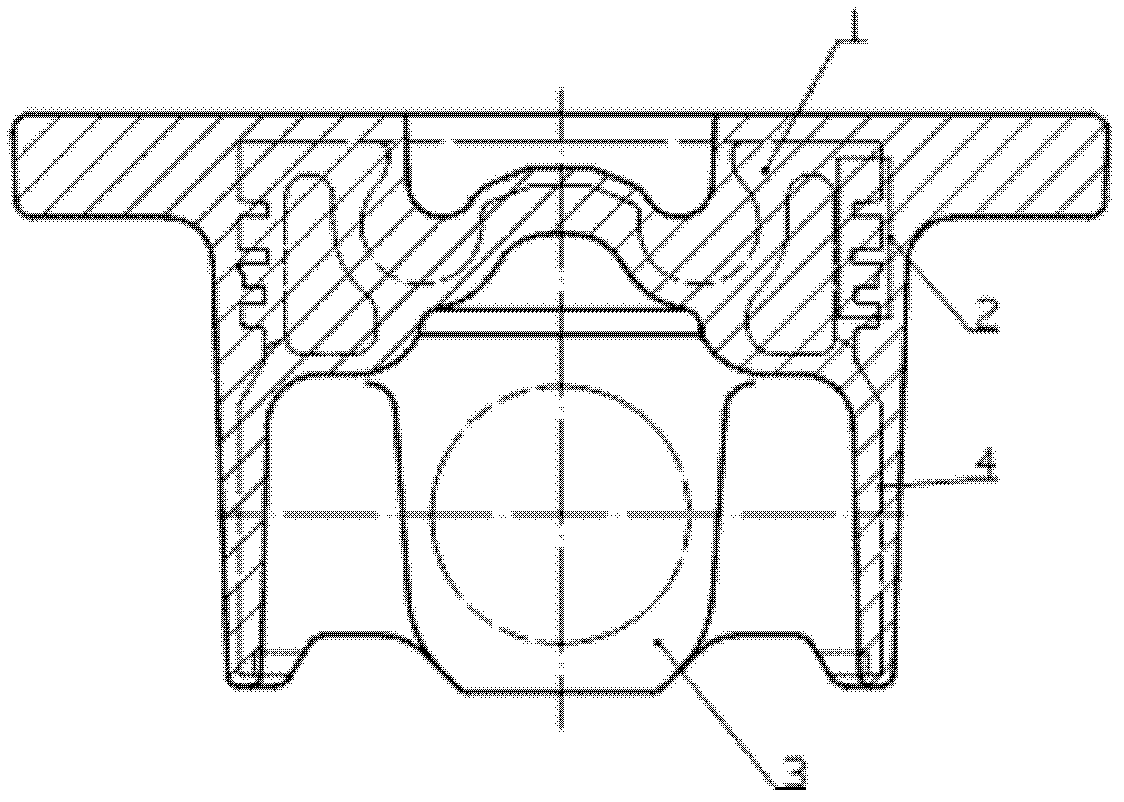

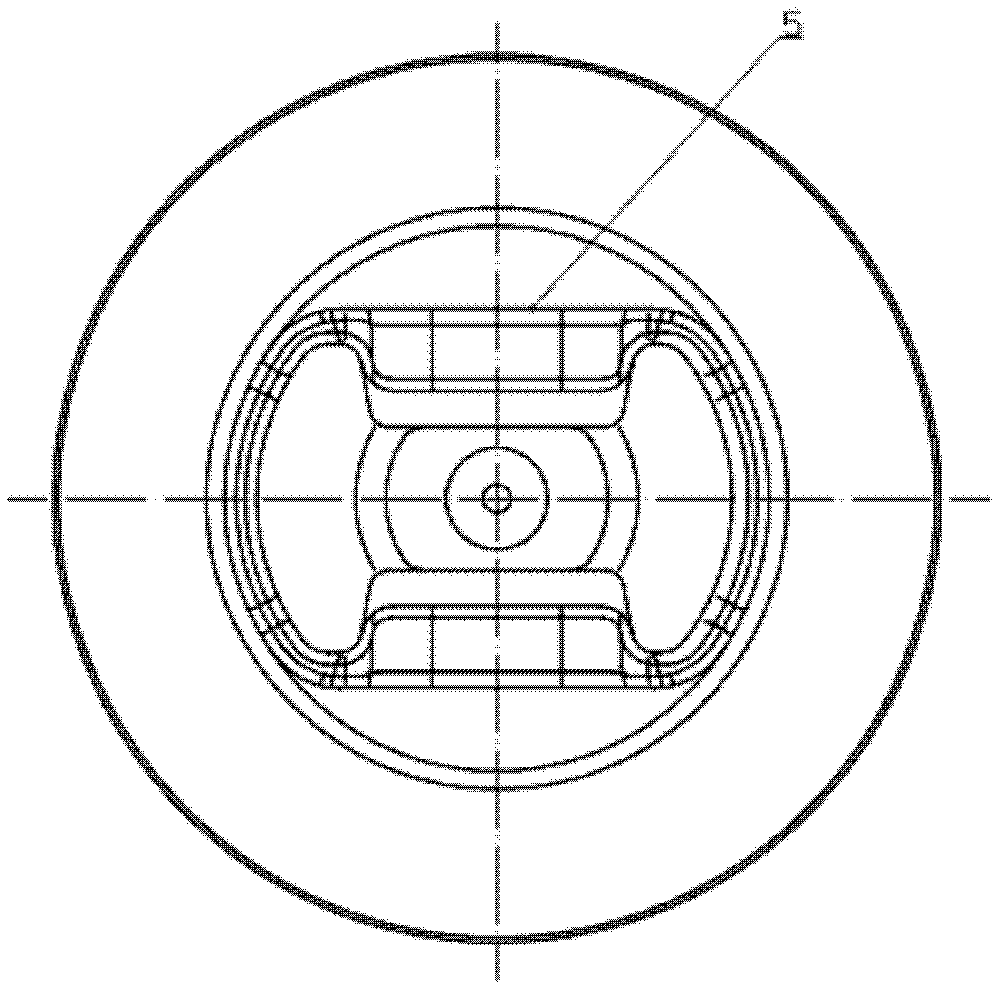

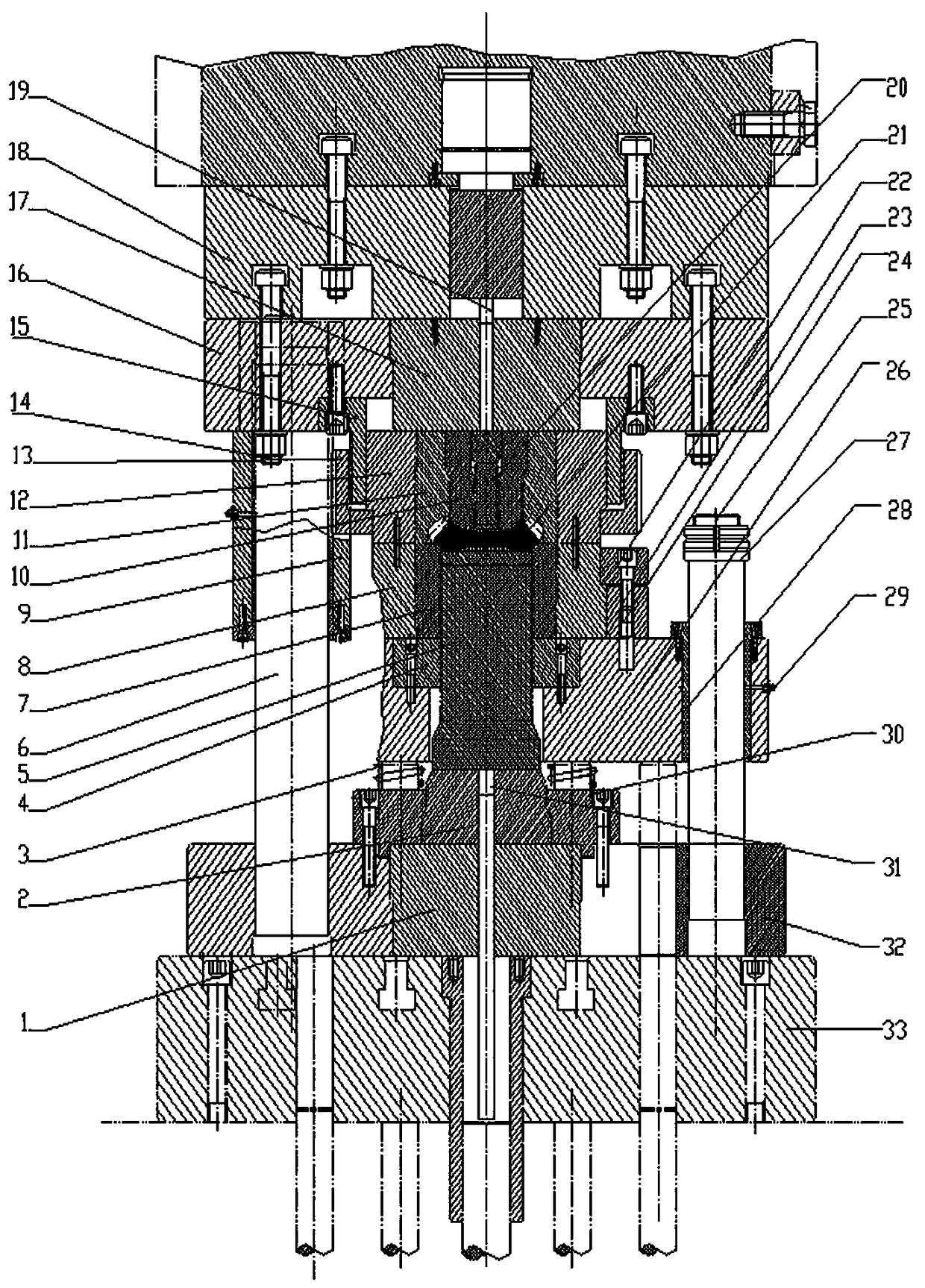

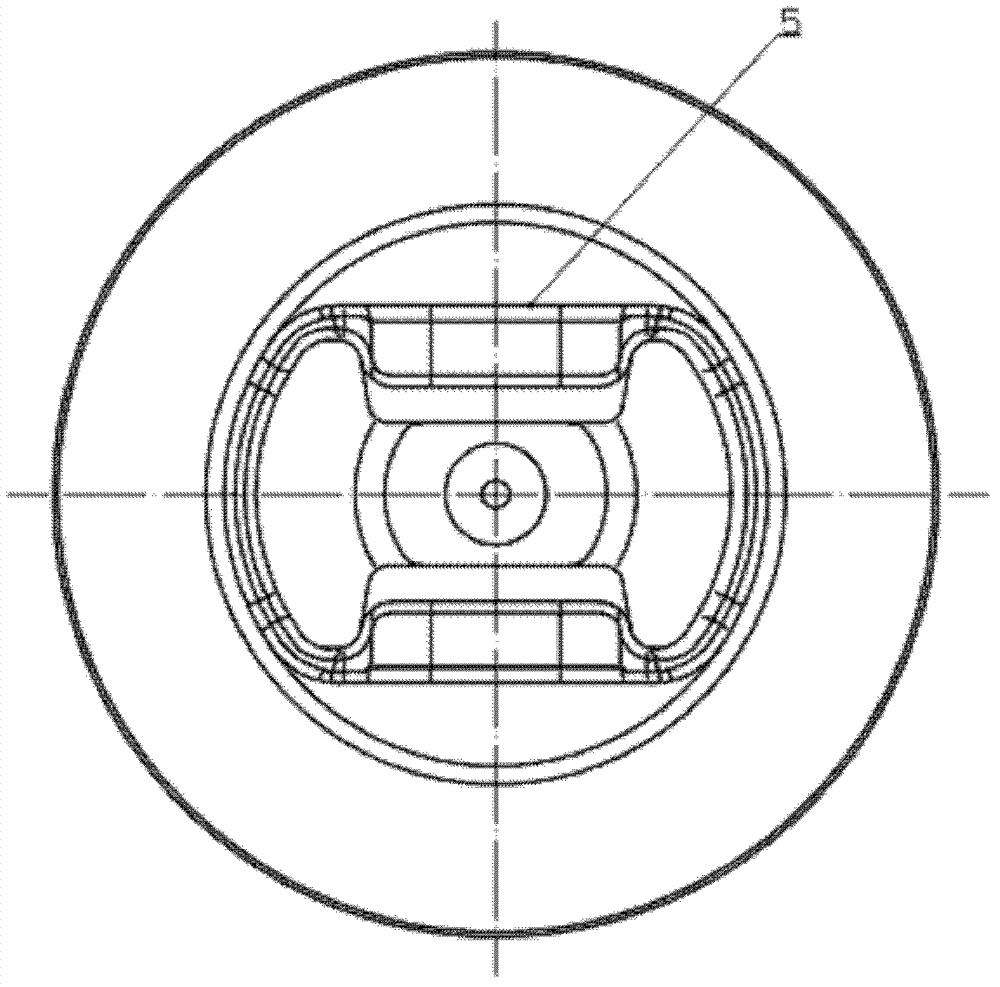

Press forming method of automobile hub and matched forming mold thereof

The invention relates to an extrusion forming method for a wheel hub of an automobile, and an extrusion piece for the wheel hub is formed by adopting work division procedures isothermally. The method comprises the following steps: a biscuit which has the same outside dimension as the outside dimension of the wheel hub to be formed is taken, and is subjected to processing and forming through forward extrusion, combined extrusion and a flaring procedure in sequence, wherein the forward extrusion forms a wheel arm and enables the rest metal to be gathered evenly in the peripheral positions of the wheel arm preliminarily; the combined extrusion pre-forms a barrel-shaped wheel rim and the upper and the lower wheel flanges of the wheel rim; and the flaring process enables the wheel rim to be formed. The invention further relates to three sets of moulds, which include a forward extrusion and forming mould, a combined extrusion and forming mould and a wheel rim flaring mould. The technical proposal of the invention can reduce the forming force, save the investment of the equipment and the mould, lower the production cost, and improve the quality of forming products.

Owner:HENAN UNIV OF SCI & TECH

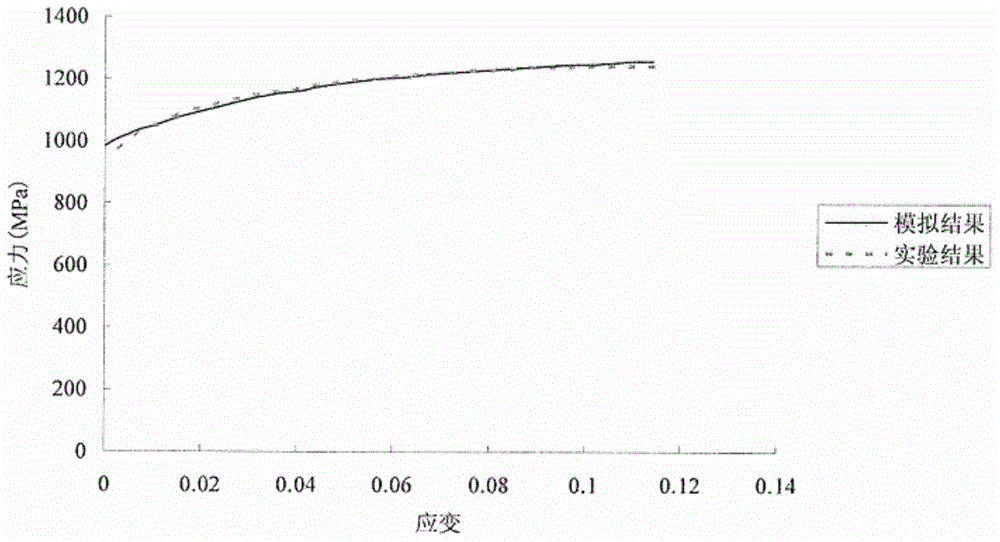

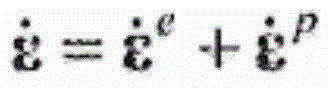

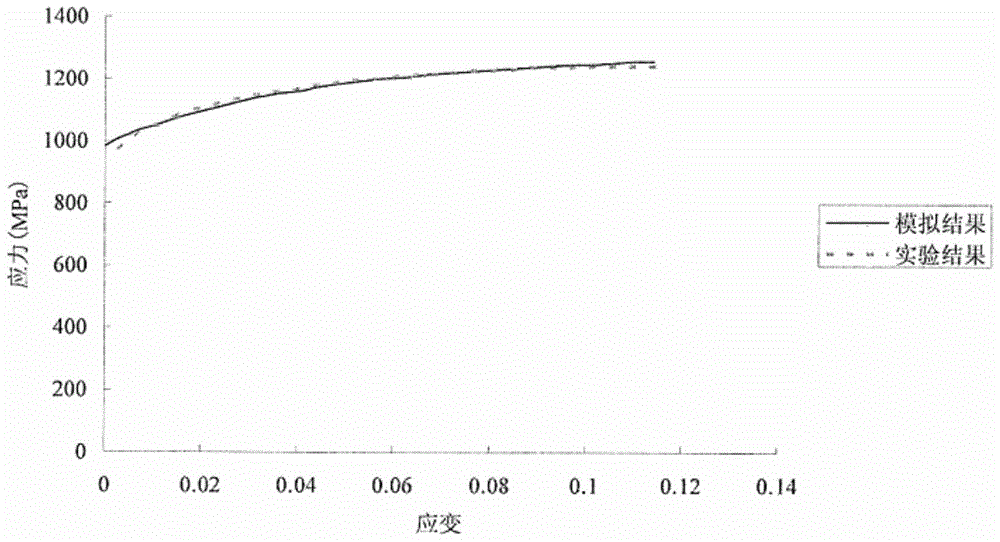

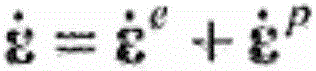

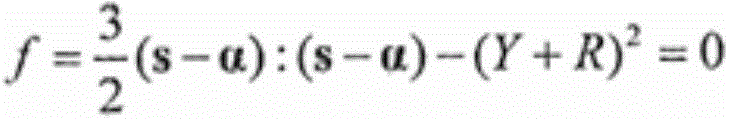

Establishing method of constructive model for rolling simulation of GH4169 materials

ActiveCN103605830ATruly reflect the change of flow stressHigh precisionSpecial data processing applicationsConstitutive equationSimulation software

The invention discloses an establishing method of a constructive model for rolling simulation of Gh4169 materials. The method comprises the following steps of 1) GH4169 alloy monotonic tensile test; 2) GH4169 alloy low-cycle strain control symmetric loading test; 3) constructive model parameter identification including selecting a Yoshida-Uemori model and obtaining constructive model parameters through software computation; 4) model verification including after finishing secondary development of a material constructive model, verifying the material constructive model through a cuboid forging process. The establishing method of the constructive model for rolling simulation of the GH4169 materials has the advantages that the constructive model established through the method can accurately represent the stress-strain of deformed GH 4169 materials and really reflect the flow stress change of metal. The method can provide accurate material models for numerical simulation software, improve the accuracy of simulation results and have significance to material deformation characteristic analysis and forming process optimization.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

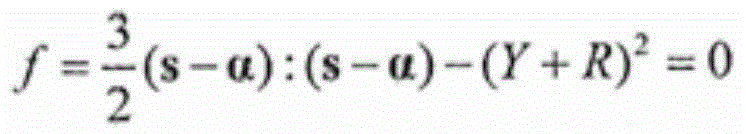

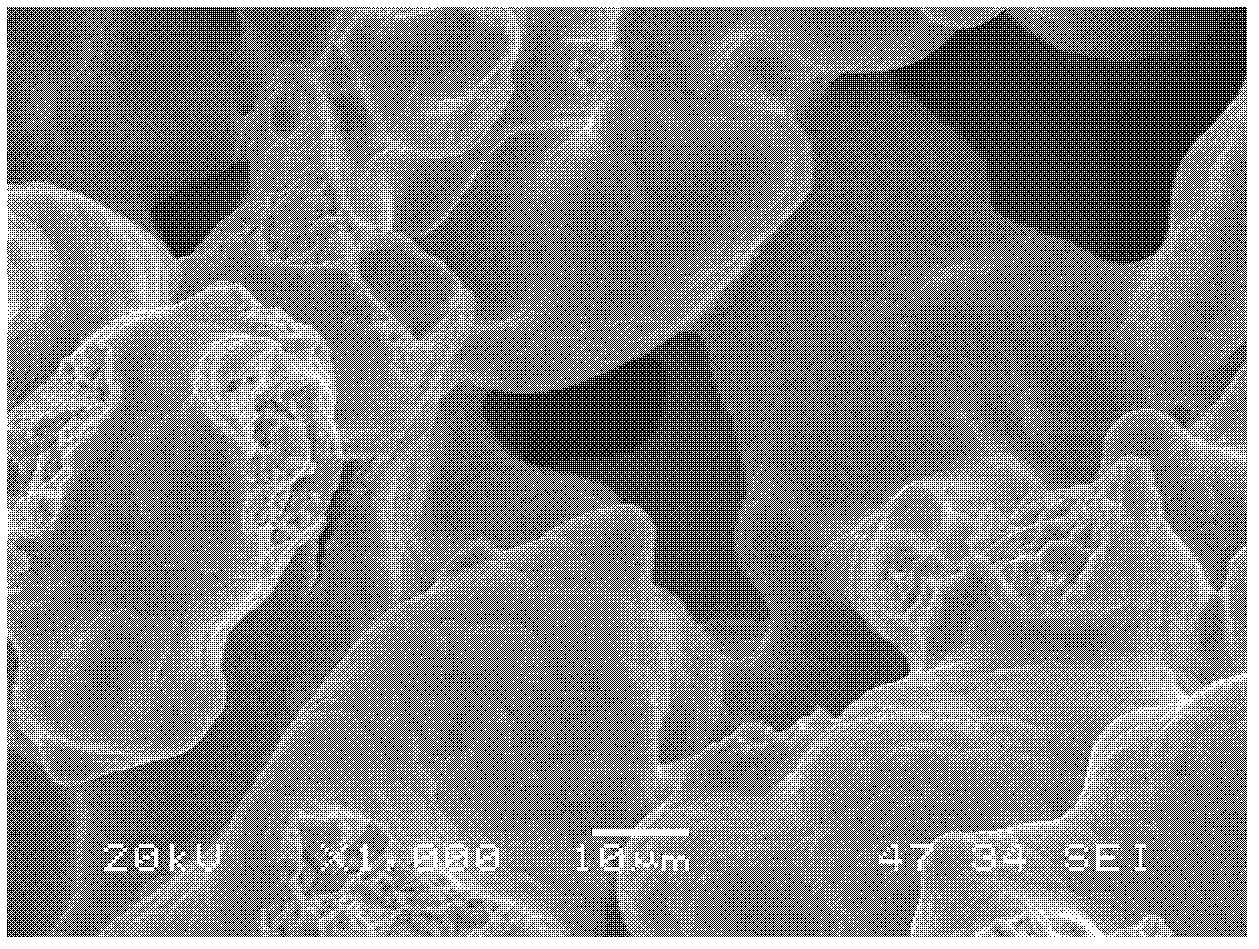

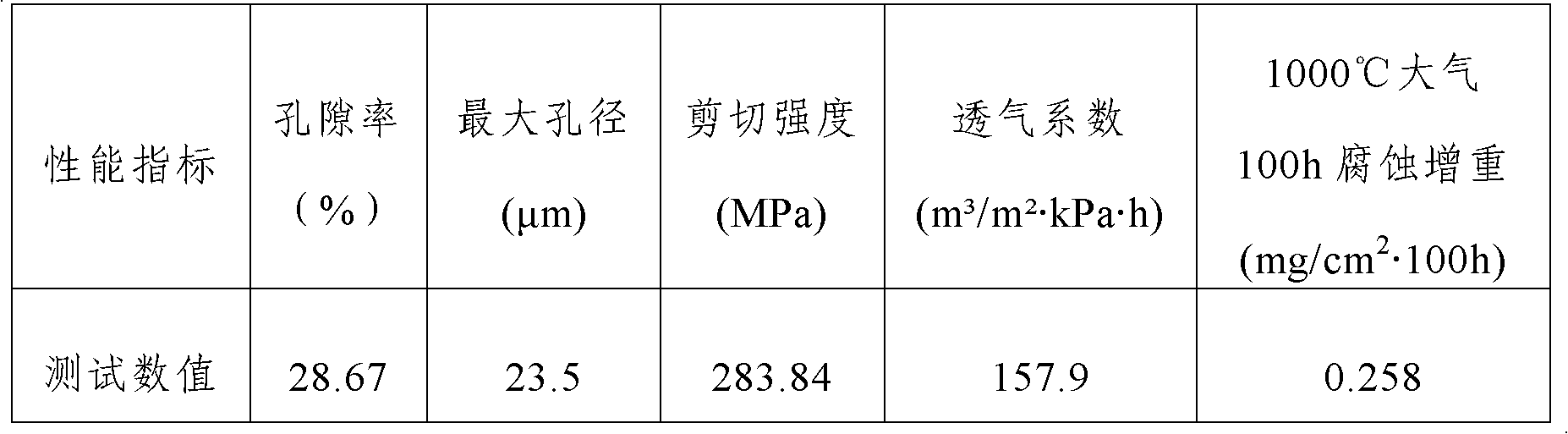

Porous material for purifying high-temperature gas and preparation method thereof

The invention discloses a porous material for purifying high-temperature gas, which is prepared from the following components in percentage by mass: 10-20% of Cr, 5-12% of Al, 1-3% of Fe, 0-0.1% of Y and the balance of Ni and inevitable impurities. The invention also discloses a preparation method of the porous material. Since the principal elements of the porous material are high-temperature alloy principal elements Ni and Cr, the porous material has the advantages of high strength, good toughness and good weldability in the high-temperature alloy, and the maximum application temperature is up to 800 DEG C; and since high-content Al is added, a compact and stable aluminum oxide film is formed on the surface of the pore walls of the porous material in the application process, thereby ensuring the excellent corrosion resistance under the conditions of high temperature and complex atmosphere. The powder classification and pressing technique ensures the uniformity of the porous material;and by adopting the vacuum sintering technique, the porous material has favorable comprehensive properties in the aspects of strength, toughness and filtering quality.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

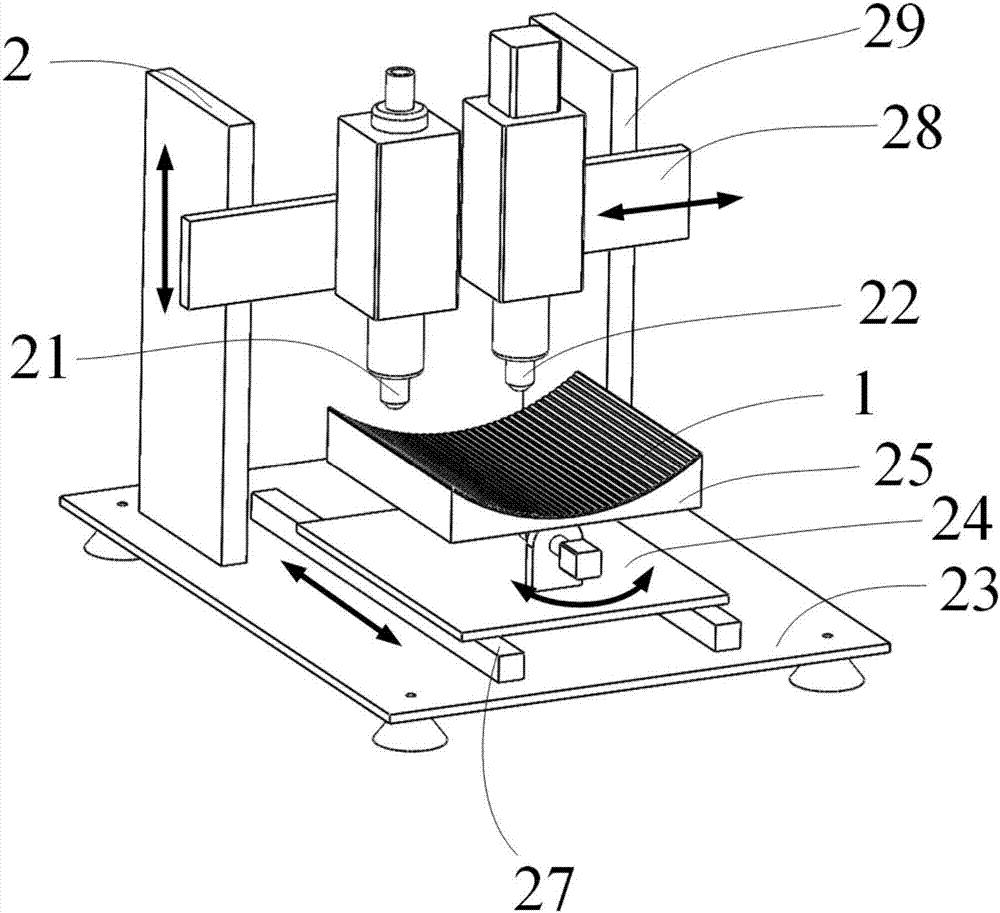

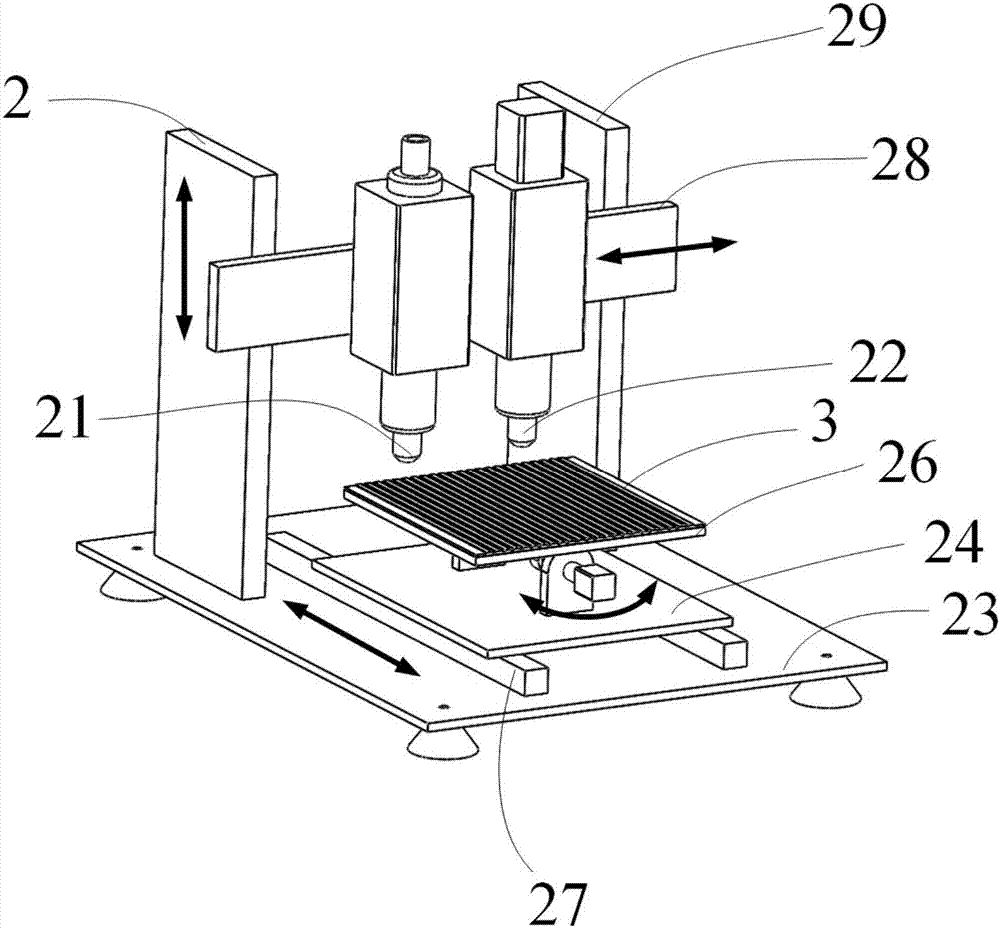

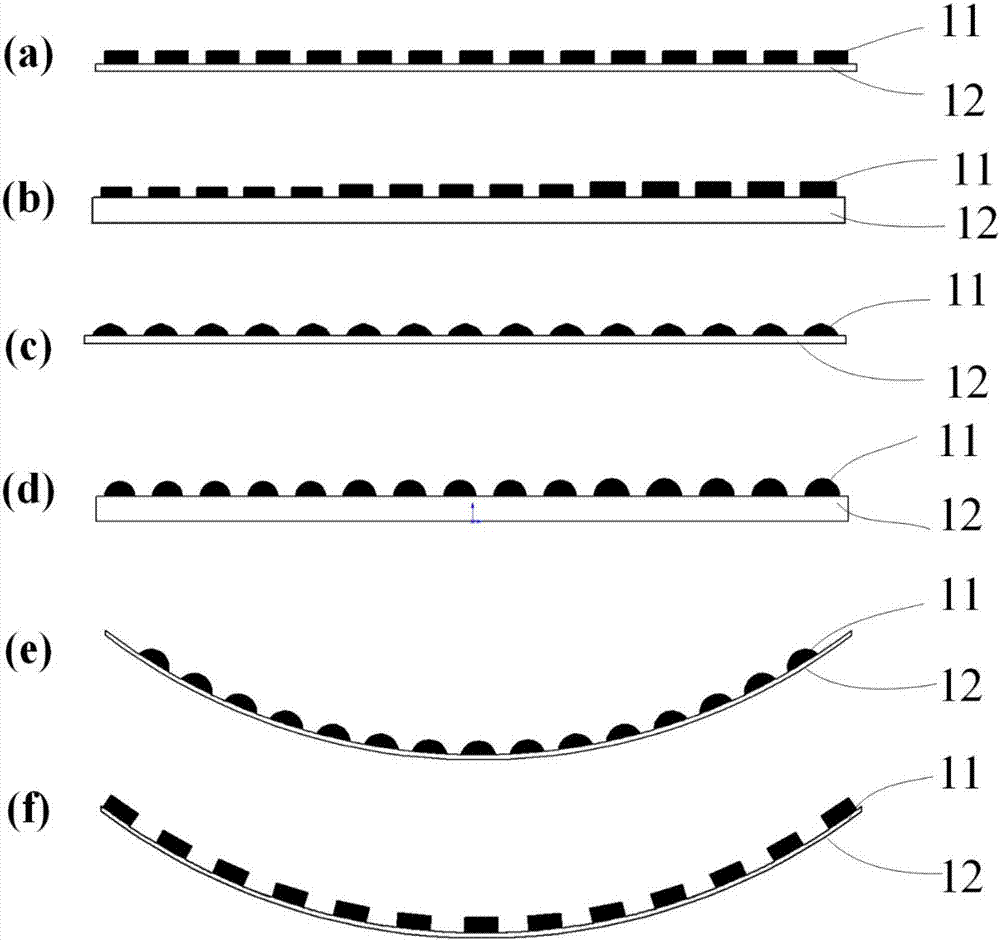

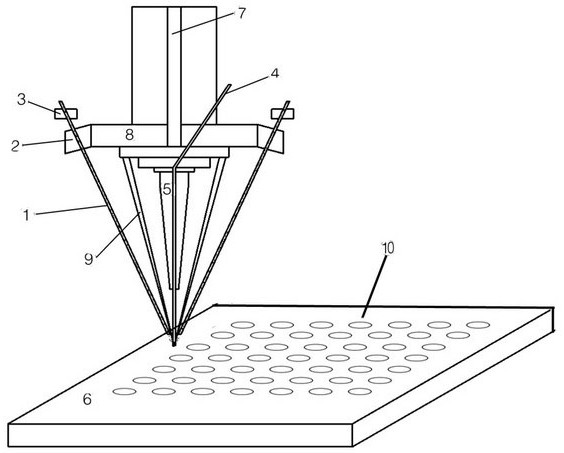

Device and method for 3D printing of size-variable three-dimensional optical gratings

InactiveCN106926593AEnsure consistencyMake sure you are always coplanarPower drive mechanismsOther printing apparatusGratingEngineering

The invention discloses a device and a method for 3D printing of size-variable three-dimensional optical gratings. The device comprises a first spraying nozzle, a second spraying nozzle, a base plate, a Y-directional sliding plate, a base plate, Y-directional guide rails, an X-directional transverse beam, Z-direction stand columns and a control module; the two Y-directional guide rails are symmetrically installed on the base plate in parallel, and the Y-directional sliding plate is installed on the guide rails in a manner of being capable of sliding in the Y-axis direction; the two Z-direction stand columns are symmetrically installed at one end of the base plate in parallel, and the X-directional transverse beam is installed on the Z-direction stand columns in the manner of being capable of sliding in the Z-axis direction; the first spraying nozzle and the second spraying nozzle are installed on the X-directional transverse beam in the manner of being capable of sliding in the X-axis direction; the base plate is rotationally installed on the Y-directional sliding plate; and the control module is used for controlling the first spraying nozzle, the second spraying nozzle, the X-directional transverse beam, the Y-directional sliding plate and the base plate to move. By means of the device and the method, the preparing time of the three-dimensional optical gratings can be greatly shortened, the multiple optical gratings in different sizes can be molded at a time, the requirement of multiple and different applications can be met on both the plane and the curve face, and cost is greatly saved.

Owner:WUHAN UNIV

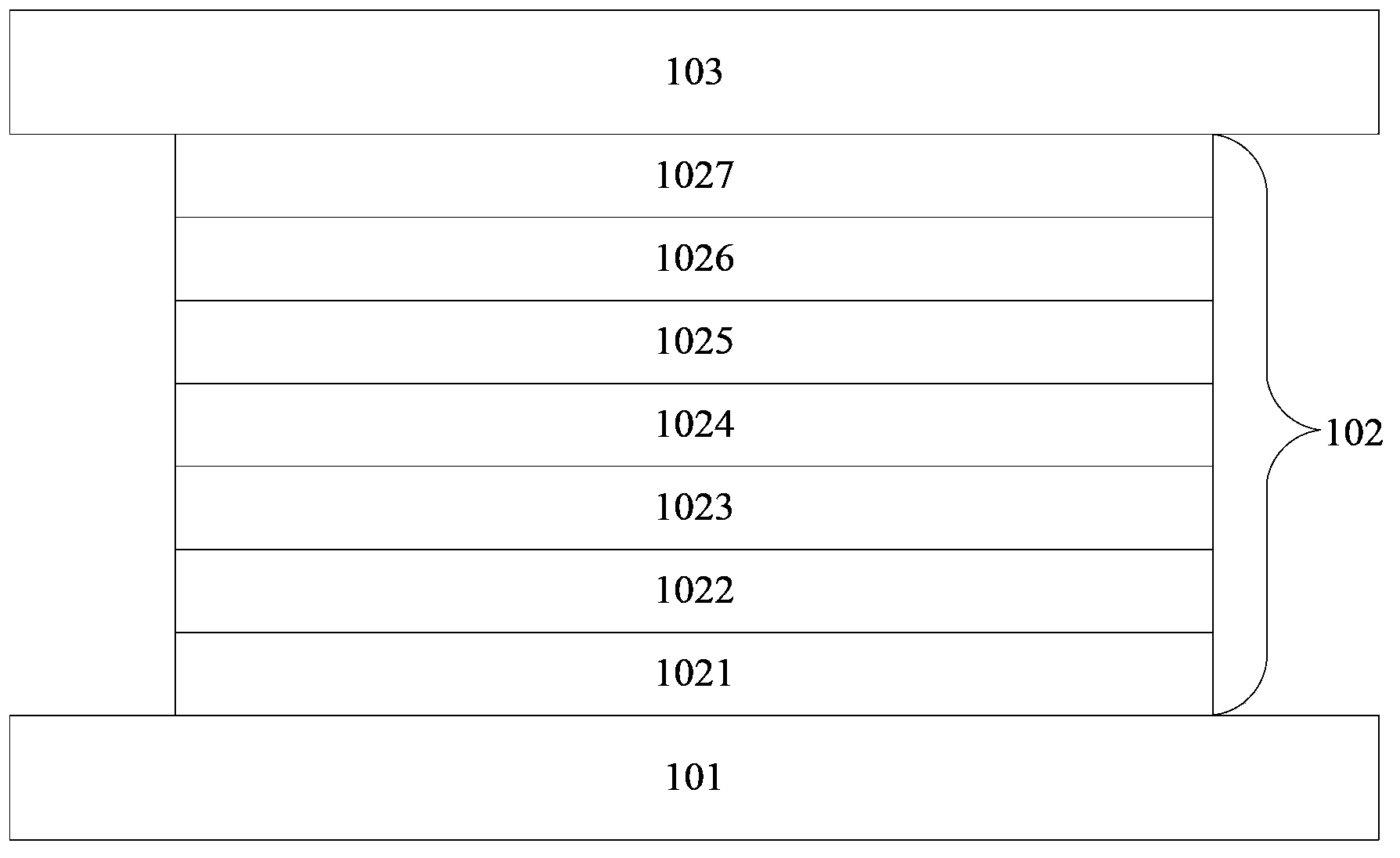

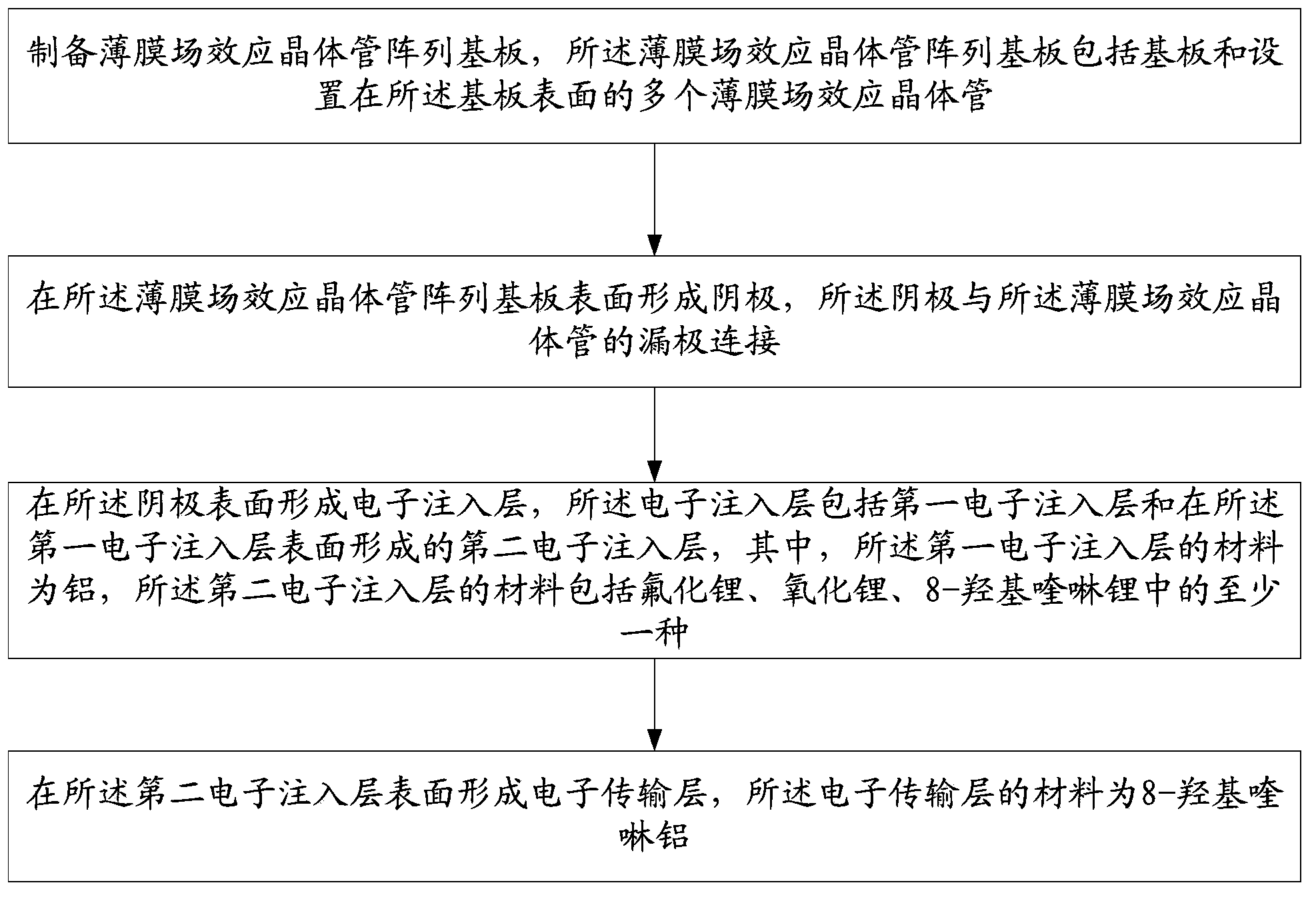

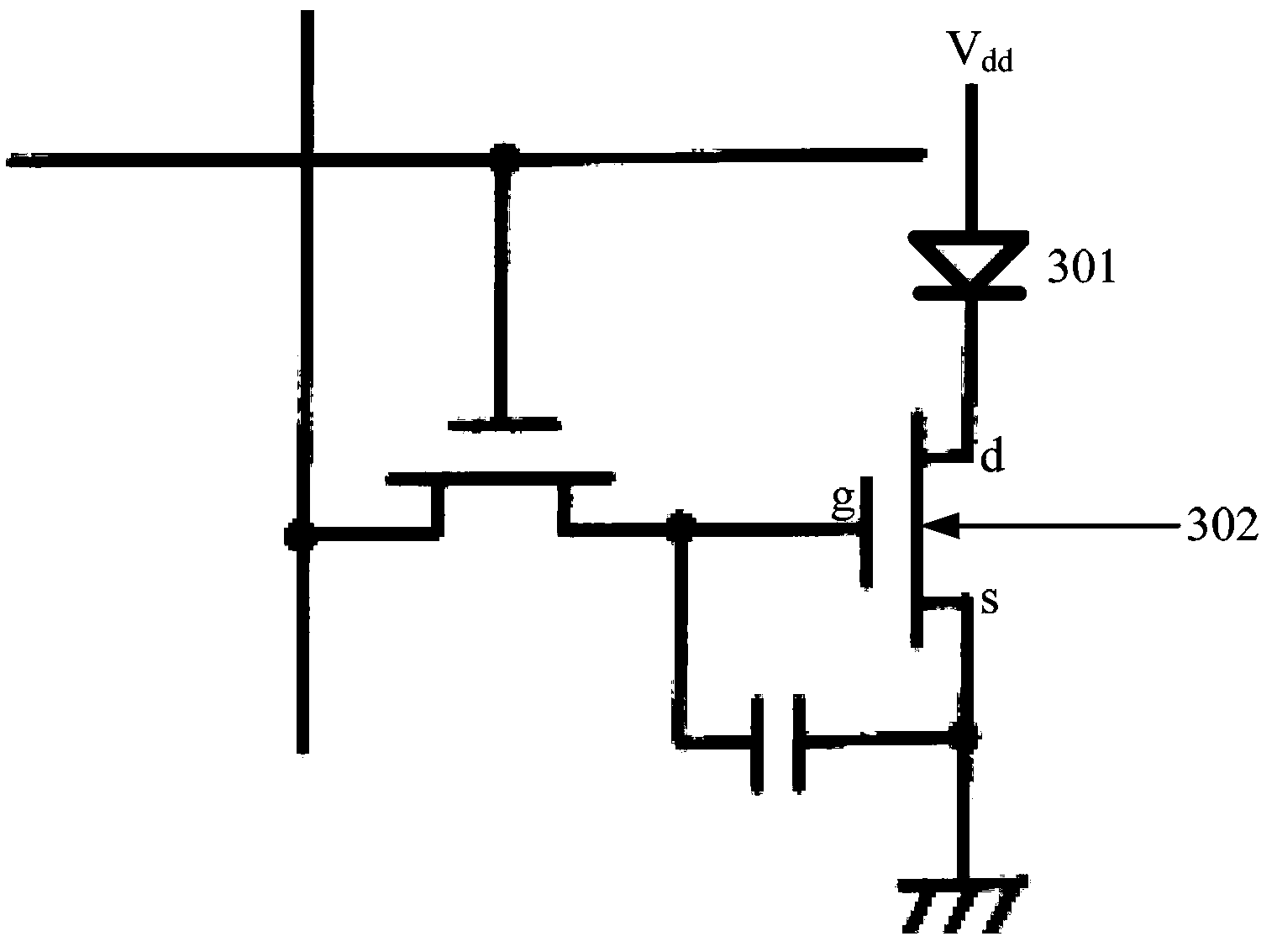

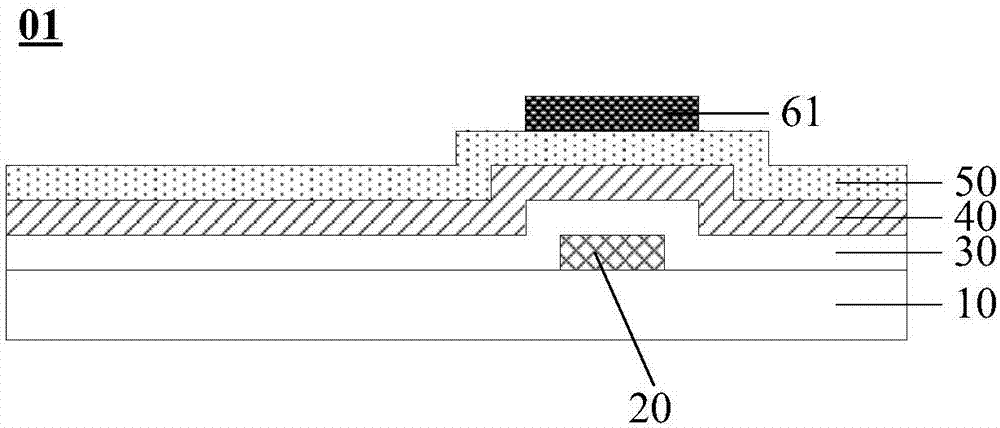

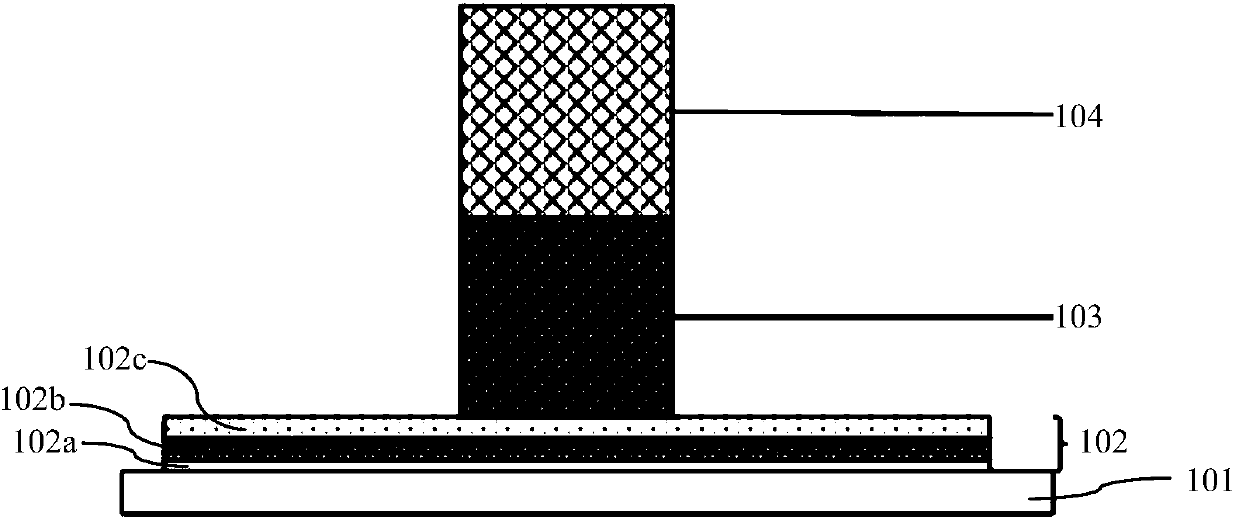

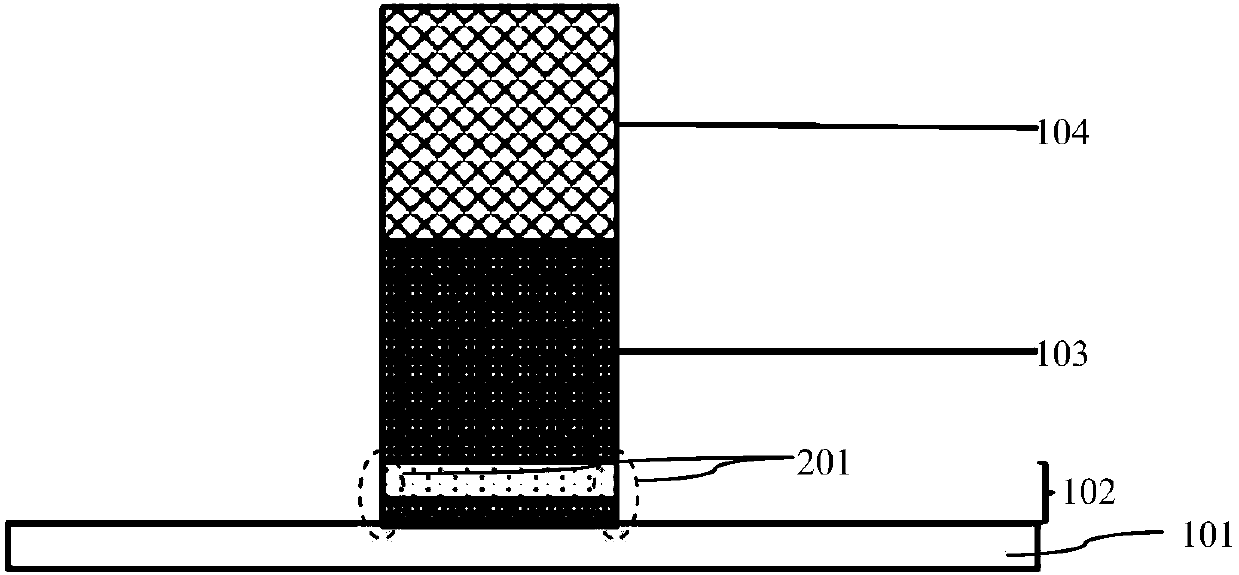

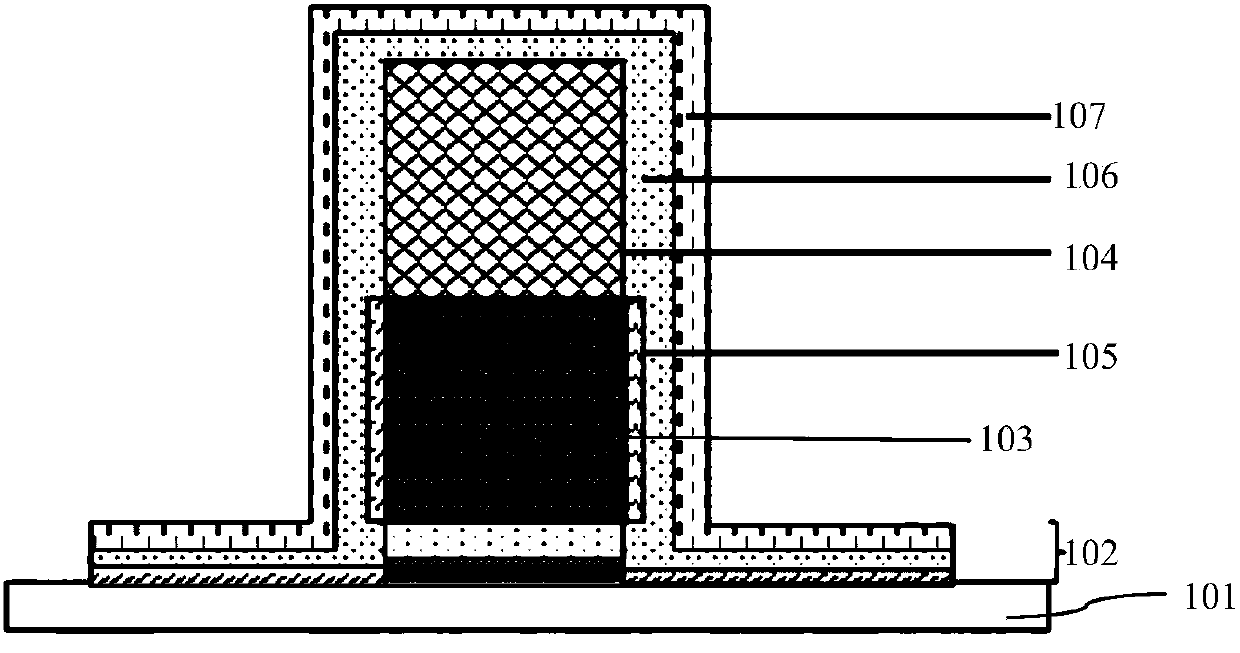

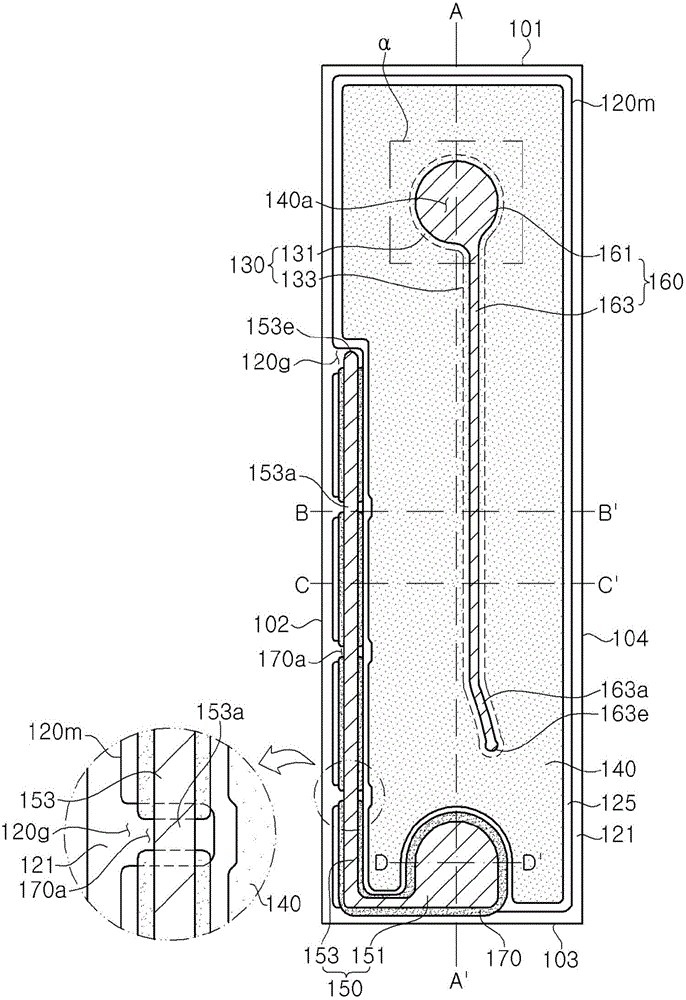

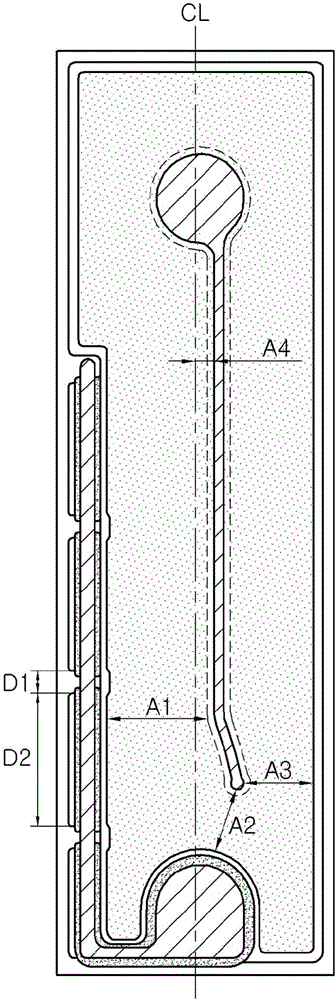

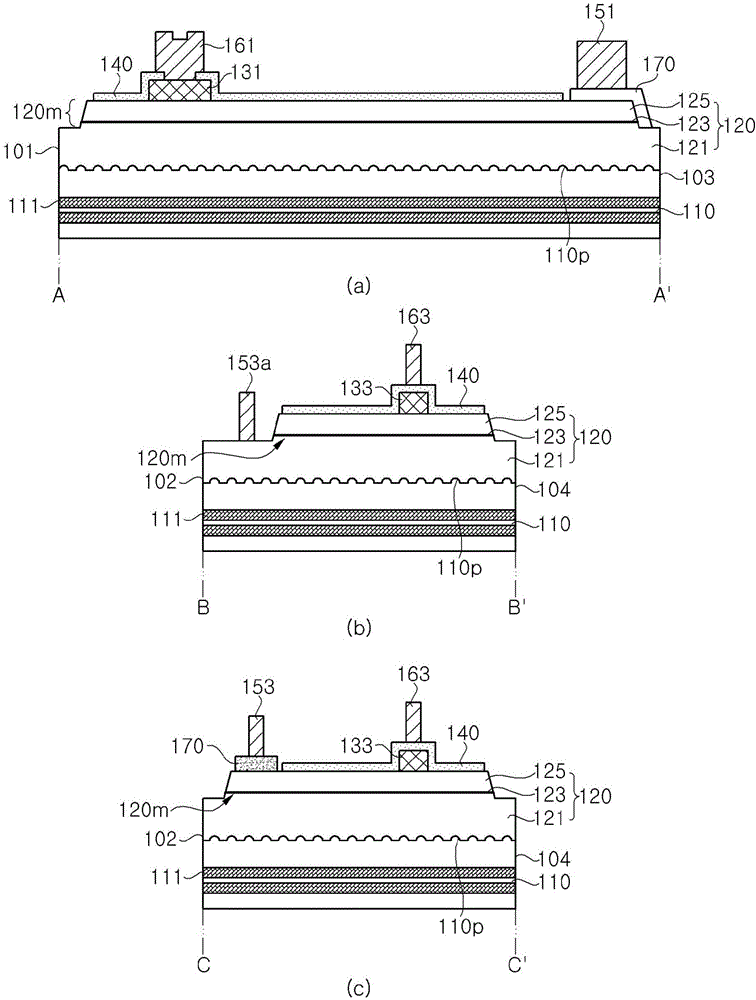

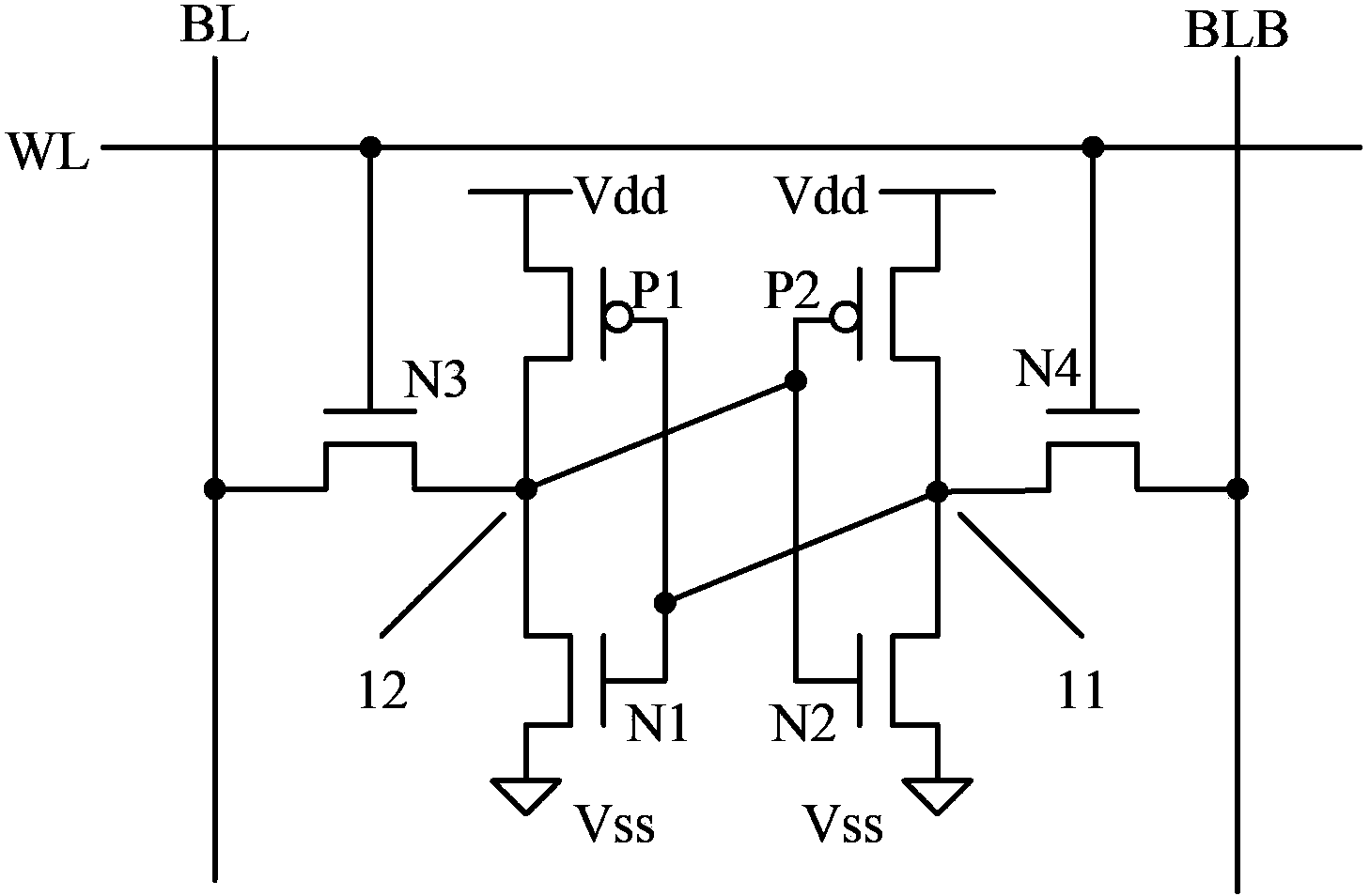

AMOLED (active matrix organic light emitting diode) and manufacturing method thereof

ActiveCN103400943AOptimizing the forming processImprove injection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingBand bendingElectron injection

The invention provides an AMOLED (active matrix organic light emitting diode) and a manufacturing method of the AMOLED. The manufacturing method comprises the following steps of manufacturing a TFT (thin film transistor) array substrate; forming a cathode on the surface of the FTF array substrate; forming an electron injection layer on the surface of the cathode, wherein the electron injection layer comprises a first electron injection layer and a second electron injection layer formed on the surface of the first electron injection layer, the first electron injection layer is made of aluminum, and the second electron injection layer is made from at least one of LiF, Li2O and Liq; and forming an electronic transfer layer on the surface of the second electron injection layer, wherein the electronic transfer layer is made from 8-hydroxyquinoline. According to the AMOLED and the manufacturing method of the AMOLED, which are disclosed by the invention, the material of the electron injection layer is resolved under the coexistence of Al and Alq3 to generate Li<+>Alq3<-> to modify an interface between the Al and the Alq3 to cause band bending of the Alq3, so that electrons in the cathode can more easily be injected into the electronic transfer layer; and therefore, the electron injection efficiency is improved, and the light emitting efficiency of the AMOLED is improved.

Owner:TRULY SEMICON

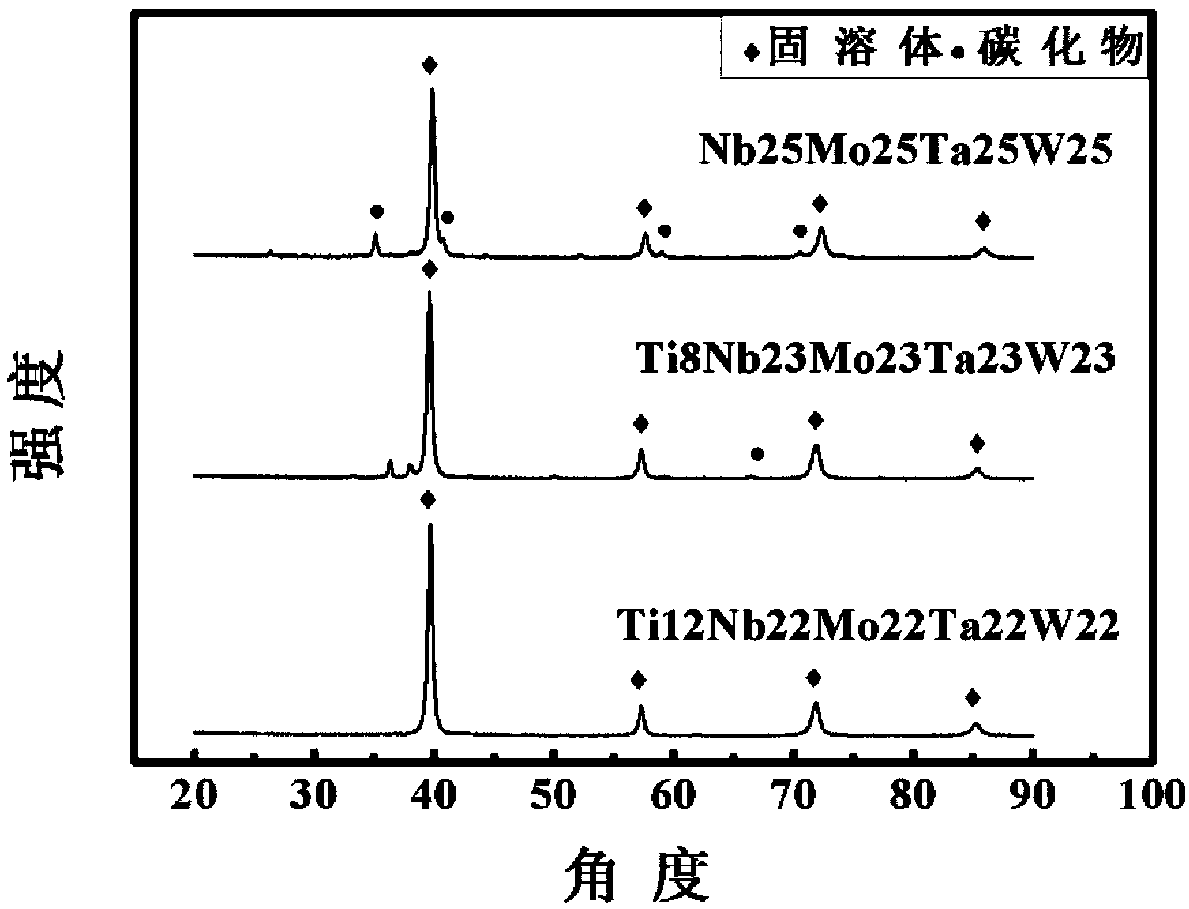

High-melting-point high-entropy alloy NbMoTaWVTi and preparation method thereof

ActiveCN105950944AUniform composition and nearly full densityOptimizing the forming processElectric arc furnaceHigh entropy alloys

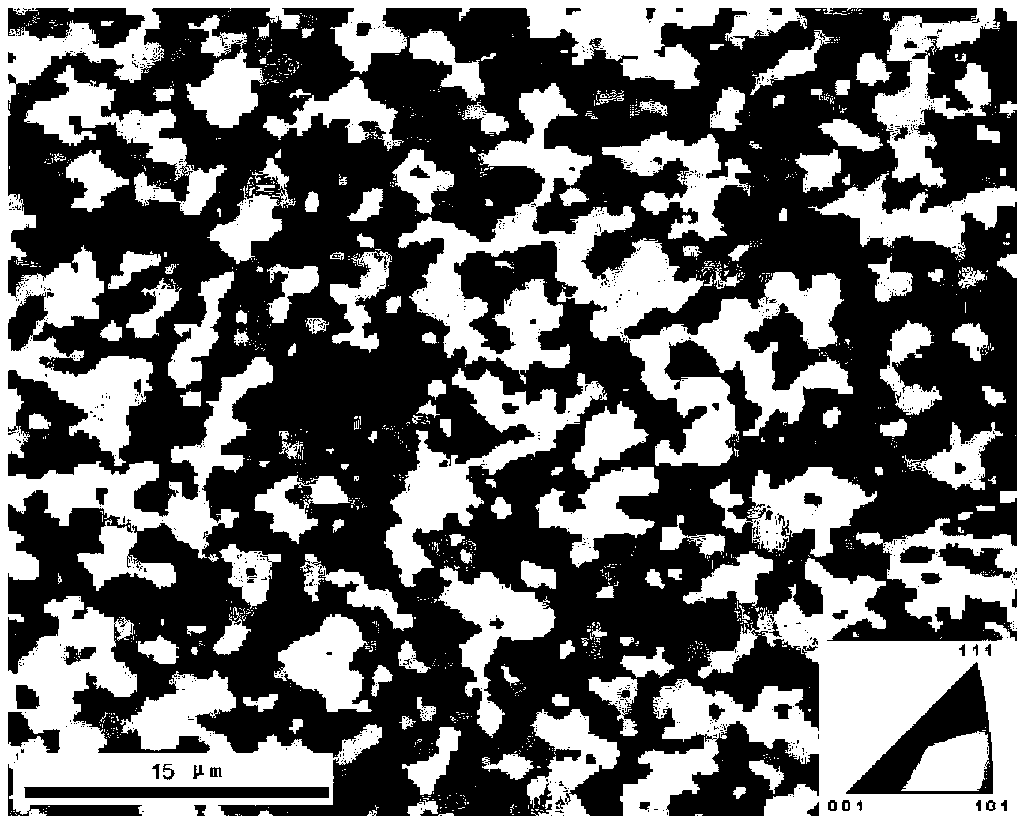

The invention belongs to the technical field of high-entropy alloys and discloses a high-melting-point high-entropy alloy NbMoTaWVTi and a preparation method of the high-melting-point high-entropy alloy NbMoTaWVTi. According to the method, a forming method that a mechanical alloying technology and a spark plasma sintering technology are combined is adopted. Compared with a traditional vacuum arc furnace casting method, by the adoption of the preparation method, operation is easier and more convenient, the temperature required in forming is lowered greatly, sintering time is short, a block material which is uniform in composition and near-total dense can be obtained through one-time sintering, and near-net forming is achieved; and the microscopic structure of the obtained alloy is characterized in that granular second phases are diffused and distributed in an isometric crystal matrix. By the adoption of the preparation method, the prepared alloy is uniform in structure and tiny in grain size and has higher strength and plasticity, and the optimum mechanical performance meets the conditions that compression yield strength is 2,709.2 MPa, the maximum compressive strength is 3,114.9 MPa, and the plasticity dependent variable generated in fracture is 7.5%.

Owner:SOUTH CHINA UNIV OF TECH

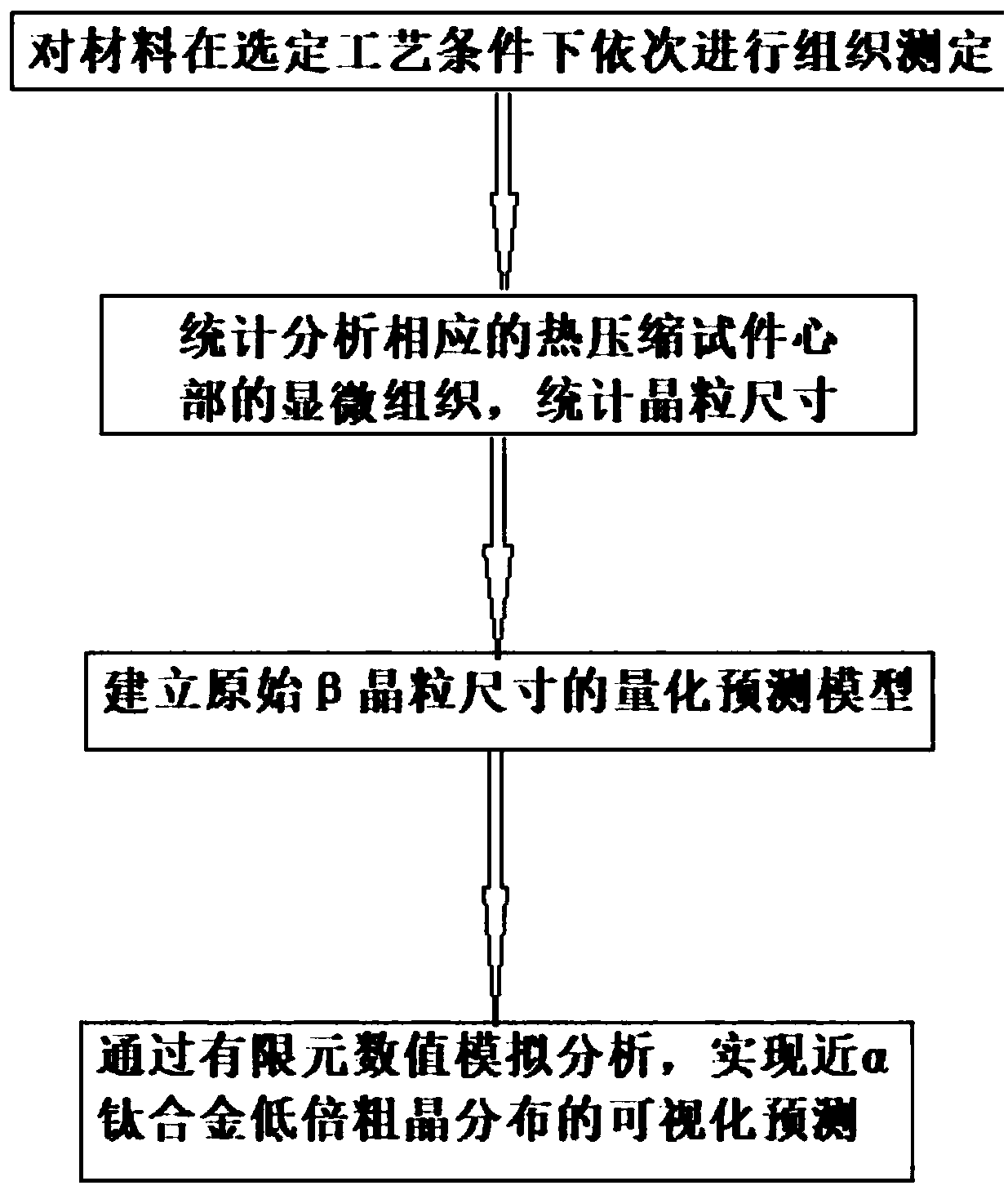

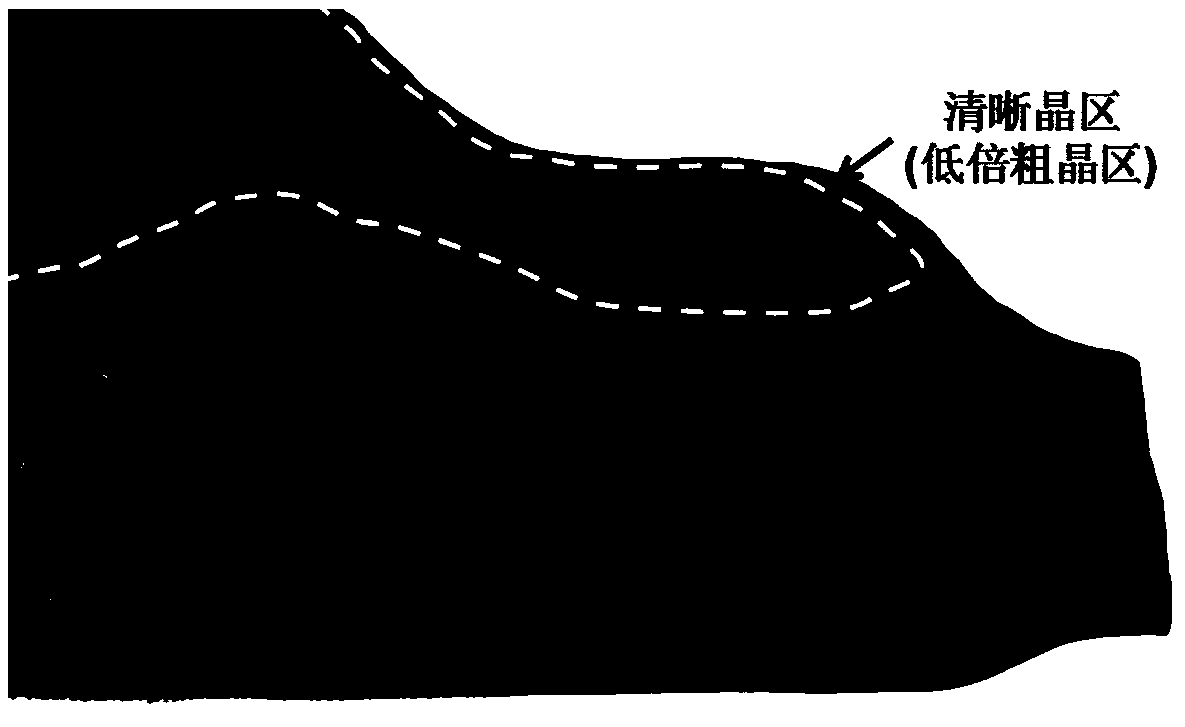

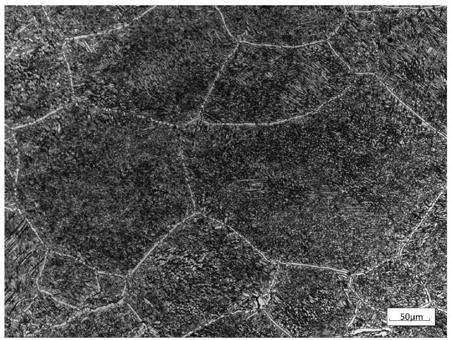

A prediction method of near alpha alpha titanium alloy low-power coarse grain structure distribution

ActiveCN109446728ASolve uncontrollable problemsPredictive distributionDesign optimisation/simulationSpecial data processing applicationsPredictive methodsStatistical analysis

The invention relates to a prediction method of near alpha titanium alloy low-power coarse grain structure distribution. The prediction method comprises the following steps of S1 determining the structure of a material under a selected process condition; S2 carrying out statistical analysis on the microscopic structure of the core of the thermal compression test piece under the corresponding process, and carrying out statistical analysis on the grain size; S3 establishing a quantitative prediction model of the original grain size; and S4 on the basis of microscopic structure critical conditionD beta>=D0 formed by the low-power coarse crystals, realizing the visual prediction of near alpha-titanium alloy low-power coarse crystal distribution through secondary development and numerical simulation analysis of finite element software. The prediction method for the macroscopic structure distribution of the near alpha-titanium alloy can effectively reveal the microscopic structure change ofthe near alpha-titanium alloy forge piece after forging heat treatment, and particularly realizes visual prediction of the original grain coarsening and the macroscopic structure distribution causedby the original grain coarsening. The forming process is optimized, the low-power coarse grain area is reduced, and the prediction result is accurate.

Owner:YANSHAN UNIV

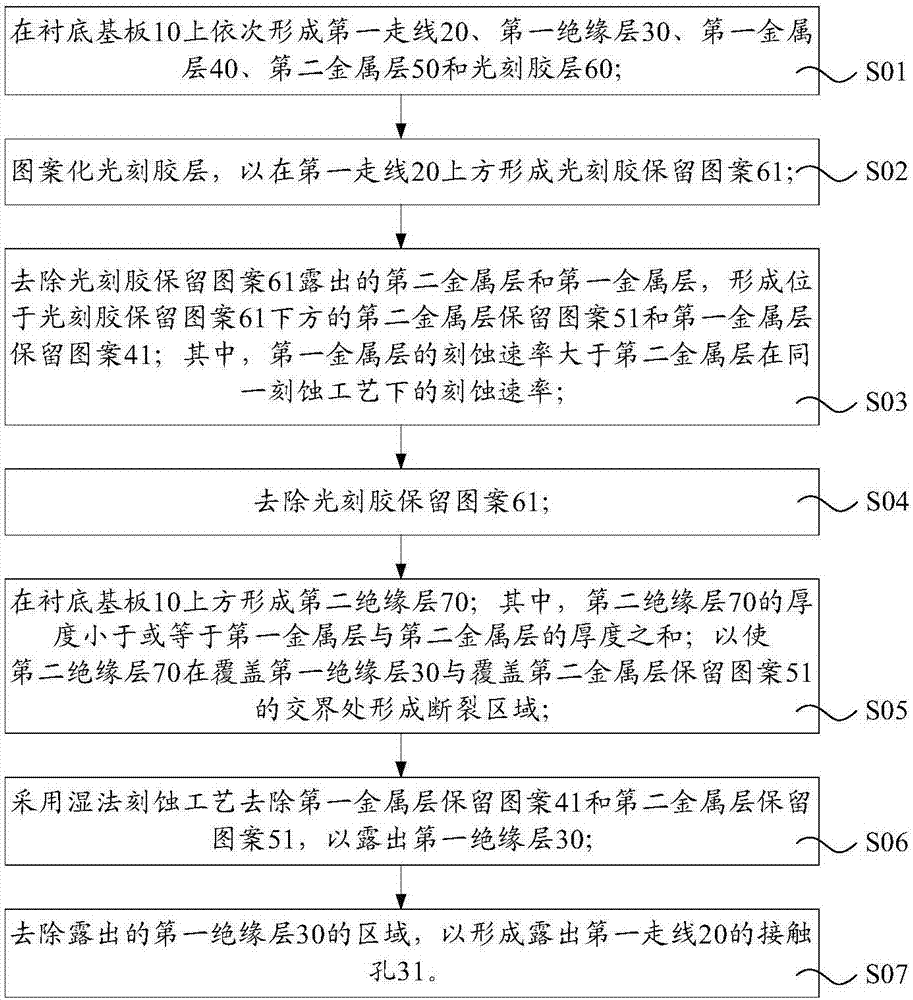

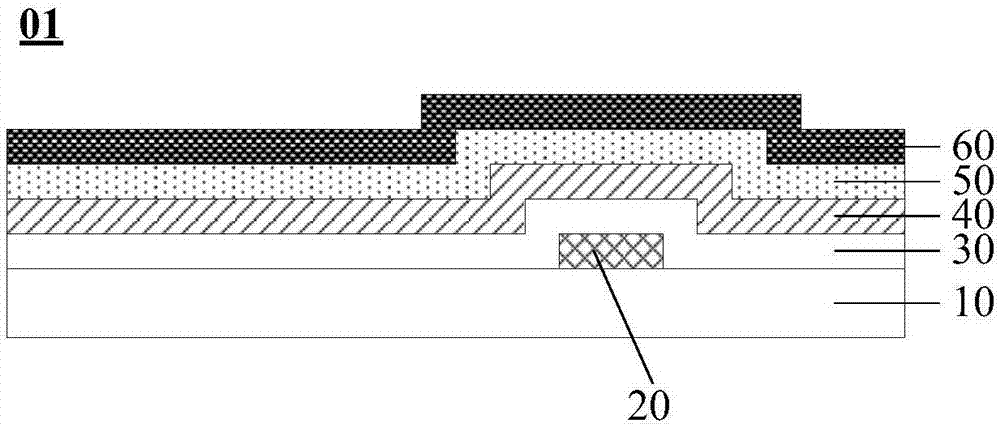

Preparation method of display substrate, array substrate and display apparatus

ActiveCN106898578AExtended processing timeShorten maintenance cycleSolid-state devicesSemiconductor/solid-state device manufacturingPhotoresistMetal

The embodiment of the invention provides a preparation method of a display substrate, an array substrate and a display apparatus, and relates to the technical field of display, solving the problem that a traditional contact hole process can cause solidification of photoresist, particle residue; the process time is prolonged; and the equipment maintenance period is shortened. The preparation method of a display substrate includes the steps: forming first wiring, a first insulating layer, first and second metal layers, and a photoresist layer; forming a photoresist reservation pattern above the first wiring; forming second and first metal layer reservation patterns below the photoresist reservation pattern, wherein the etching rate of the first metal layer is greater than the etching rate of the second metal layer; removing the photoresist reservation pattern; forming a second insulating layer, wherein the thickness of the second insulating layer is equal to the sum of the thickness of the first and second metal layers; and the second insulating layer is provided with a fracture area at the juncture covering the first insulating layer and the second metal level reservation pattern; utilizing a wet etching process to remove the first and second metal level reservation patterns to expose the first insulating layer; and forming a contact hole exposing the first wiring.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

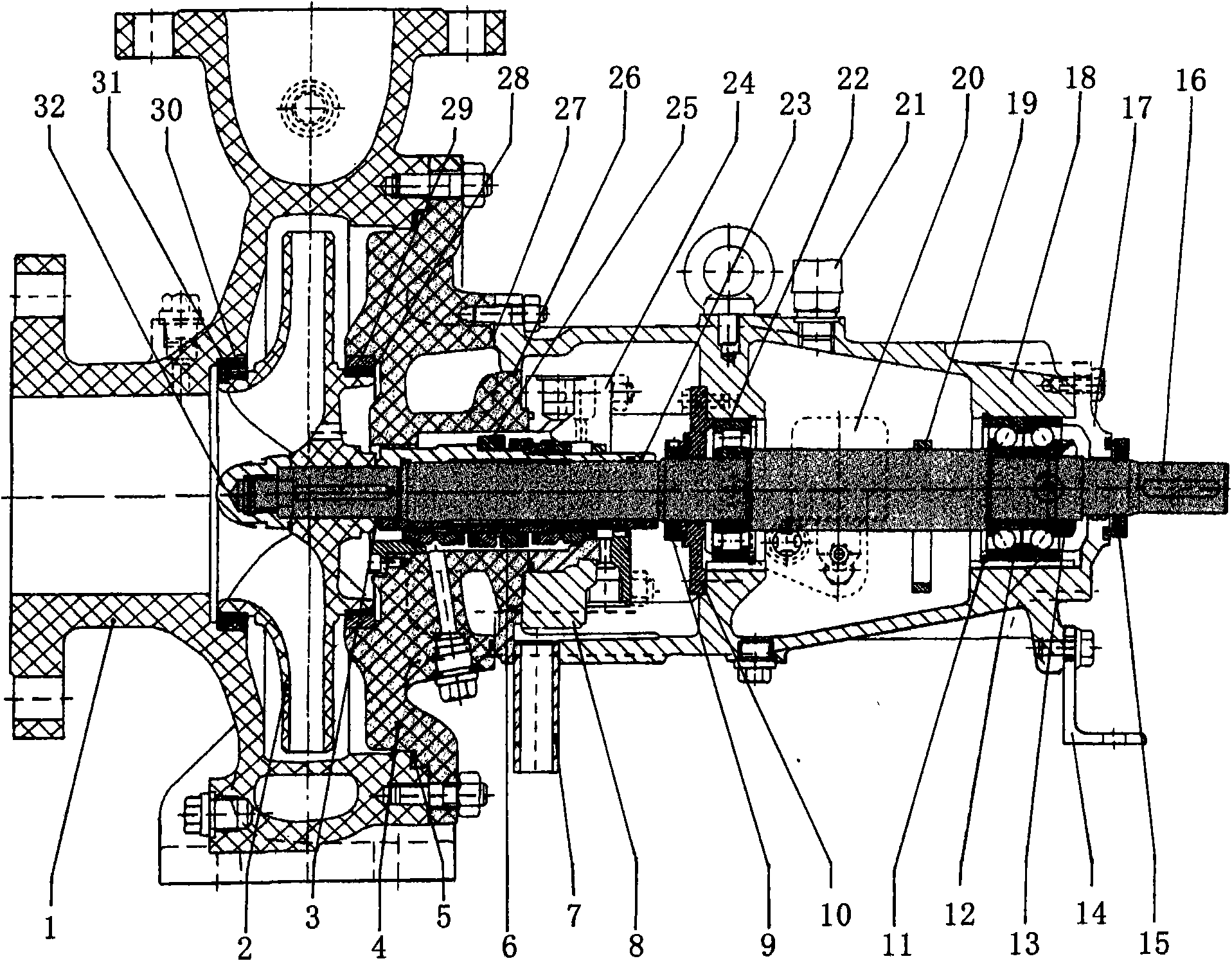

Corrosion-resistant pump made from carbon/carbon composite materials

ActiveCN101603539AEasy to processOptimizing the forming processSpecific fluid pumpsPump componentsImpellerCarbon composites

The invention relates to a corrosion-resistant pump made from carbon / carbon composite materials, comprising components, such as a motor, a transmission shaft, a pump bracket, a press cover, a pump body, a pump cover, an impeller, a mechanical sealer, and the like which are connected by utilizing a shaft coupling. The corrosion-resistant pump made from carbon / carbon composite materials is characterized in that carbon fibers are shortly cut into short cut wires of 0.5mm-5mm or the carbon fibers are ground into powder of 200-400 meshes, then the short cut wires or the powder is mixed with an adhesive to manufacture special mixed particles, then the mixed particles are doped with a parting agent, and the mixture is put into a mould, is heated, is molded, enters a carbonization furnace, is kept under a state without oxygen, is sintered, is finely processed and then is assembled with other components to obtain a product; the product can reach the tensile strength of 30.67MPa, the bending strength of 55.4MPa, the heat conductivity coefficient of 110kilocalorie / meter.hour.DEG C and the service life of 36 months; and under the condition of 300 DEG C, various fluid media with strong corrosiveness can be stably and continuously conveyed for a long time.

Owner:大连富鼎碳素装备有限公司

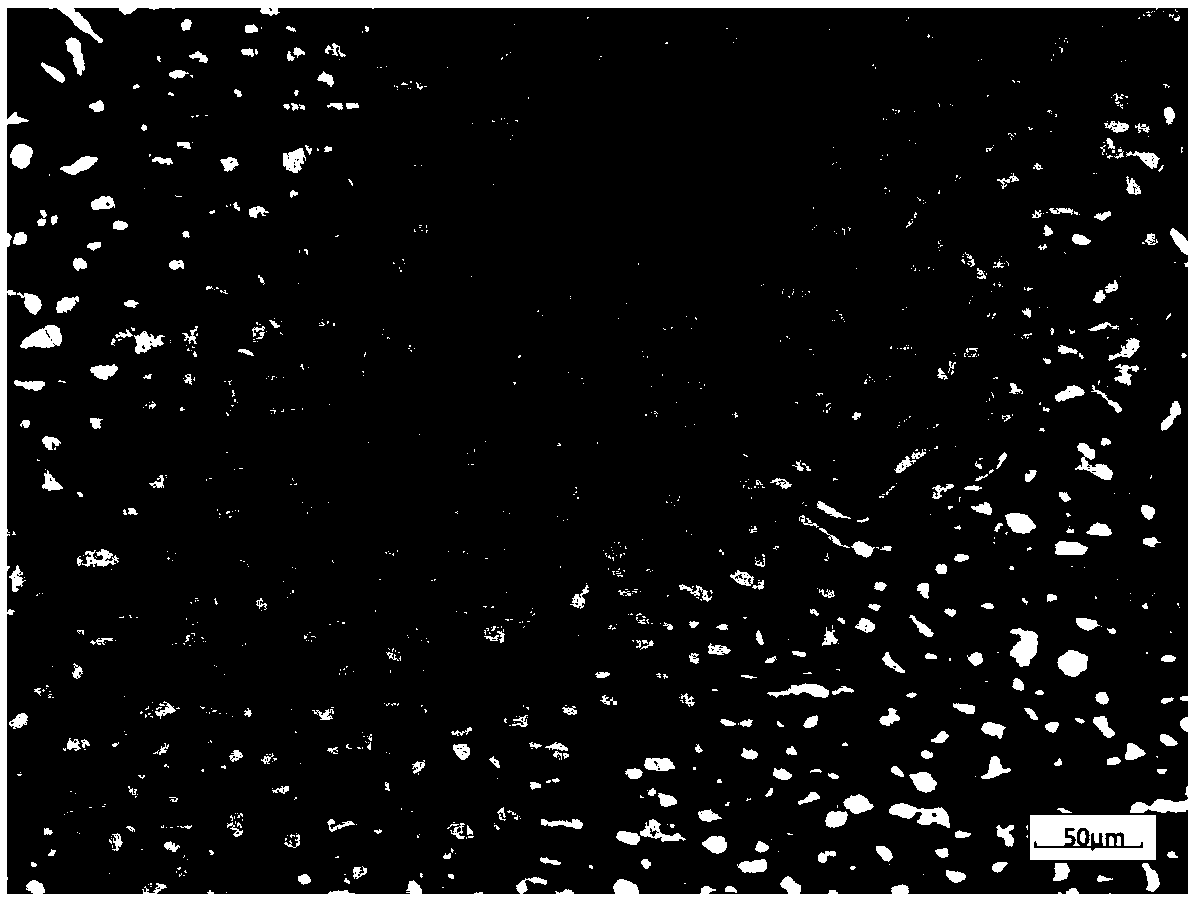

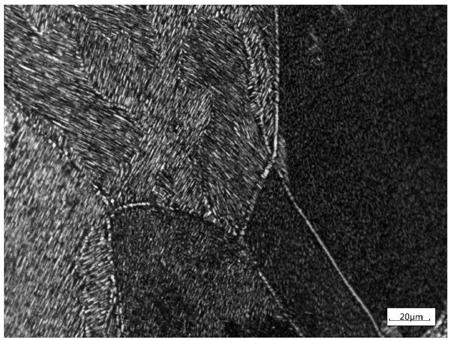

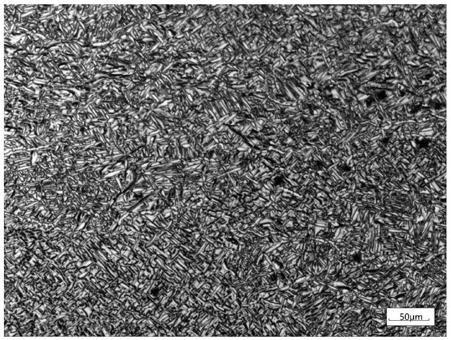

Prediction method for titanium alloy die forging part basket-weave microstructure distribution

ActiveCN108977741AIncrease production costOptimizing the forming processDesign optimisation/simulationSpecial data processing applicationsThermal compressionFinite element software

The invention provides a prediction method for titanium alloy die forging part basket-weave microstructure distribution. The prediction method comprises the following steps: S1, performing tissue teston a material under different deformation conditions; S2, obtaining rheological curve through thermal compression deformation experiments under different deformation parameters, obtaining a constitutive model capable of predicting titanium alloy deformation resistance through numerical analysis and simultaneously analyzing effects of deformation parameters on a microstructure evolvement rule; S3,establishing critical criterion; S4, establishing a visual prediction model of die forging part basket-weave microstructure distribution through finite element software secondary development based onthe critical technological conditions of basket-weave microstructure formation and comparing, analyzing and verifying the visual prediction model with actual results. The established prediction method for titanium alloy die forging part basket-weave microstructure distribution disclosed by the invention disclosed by the invention can effectively reveal microstructure change of titanium alloy after forged hardening and can predict basket-weave tissue distribution in forged pieces under the certain conditions.

Owner:YANSHAN UNIV +1

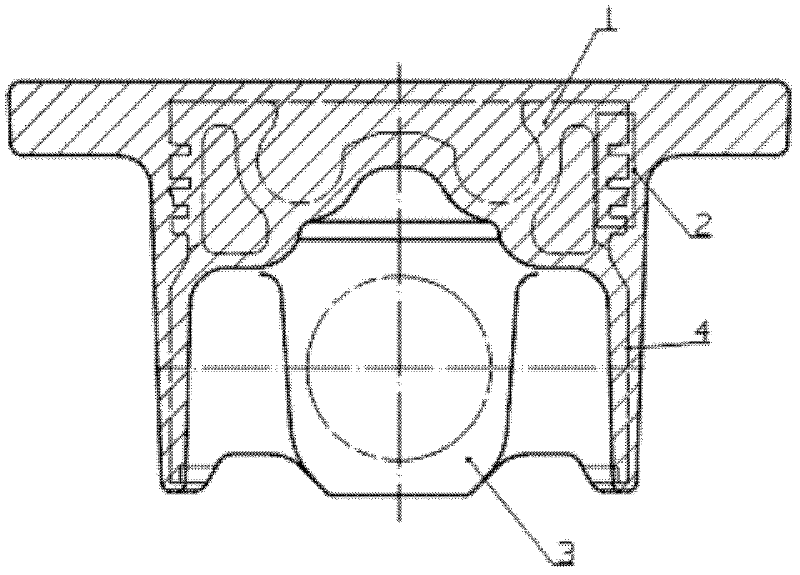

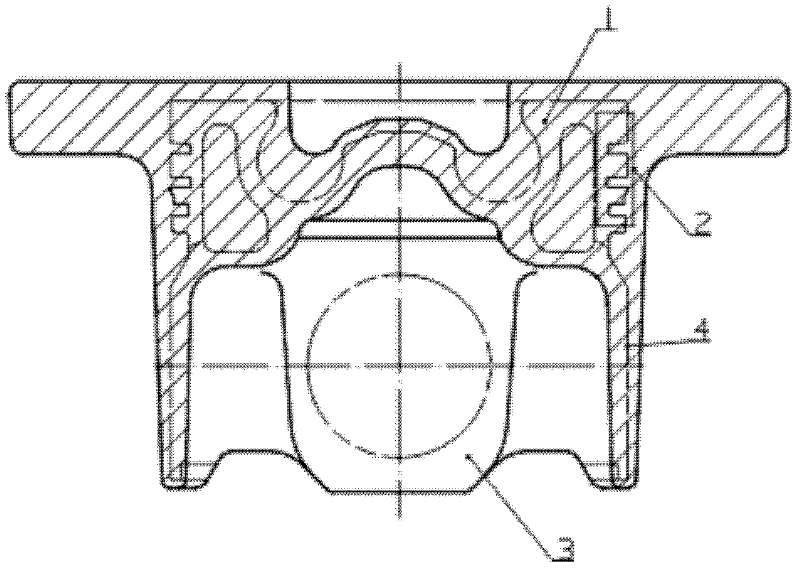

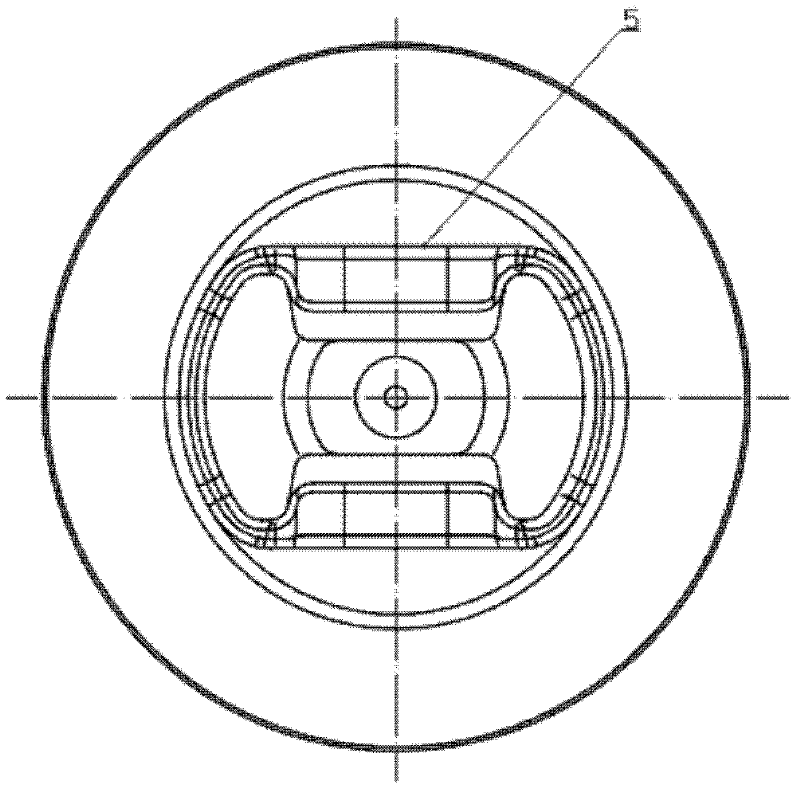

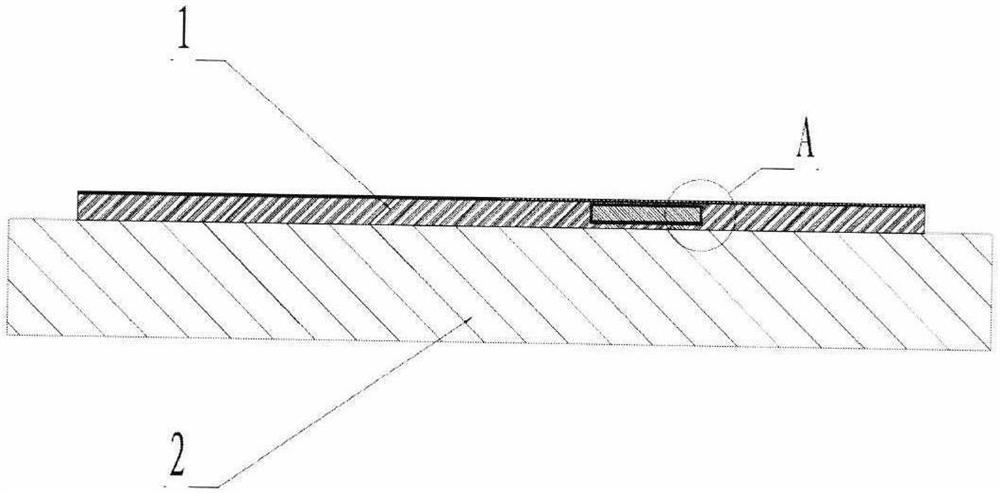

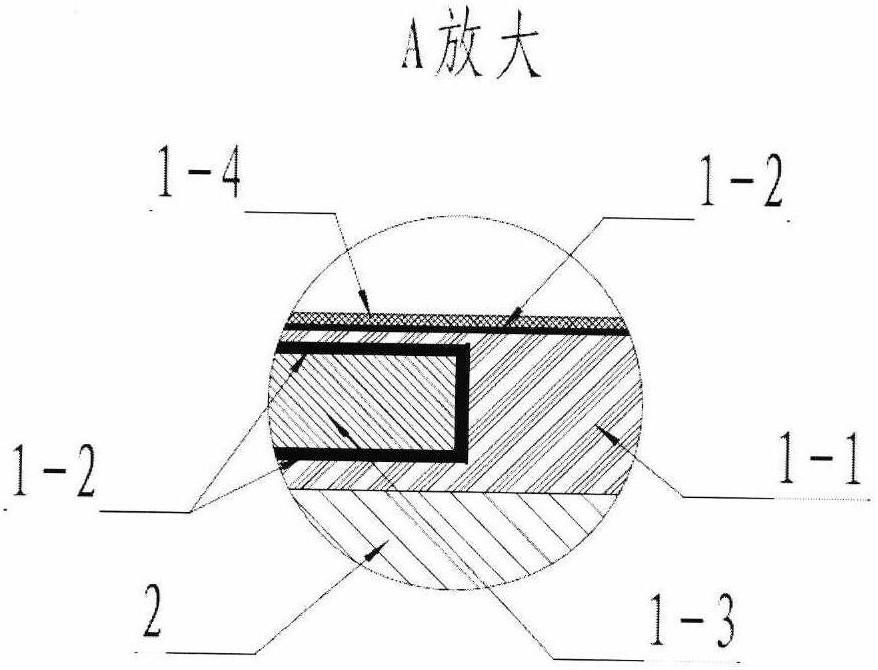

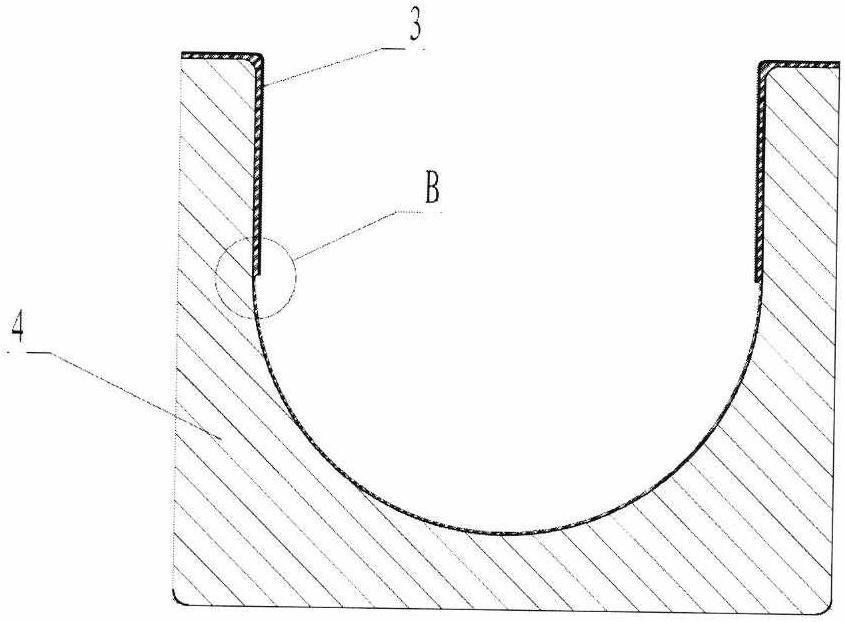

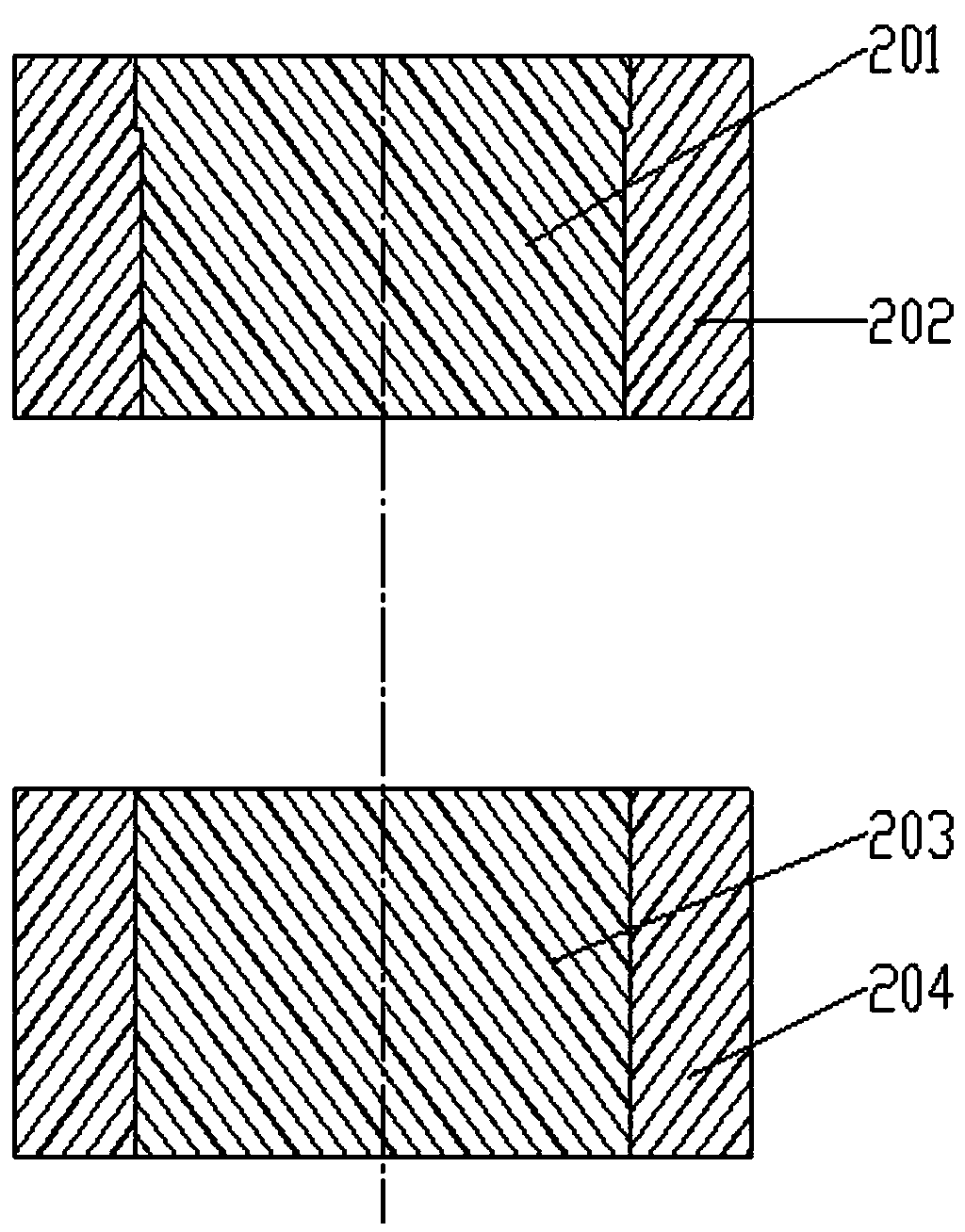

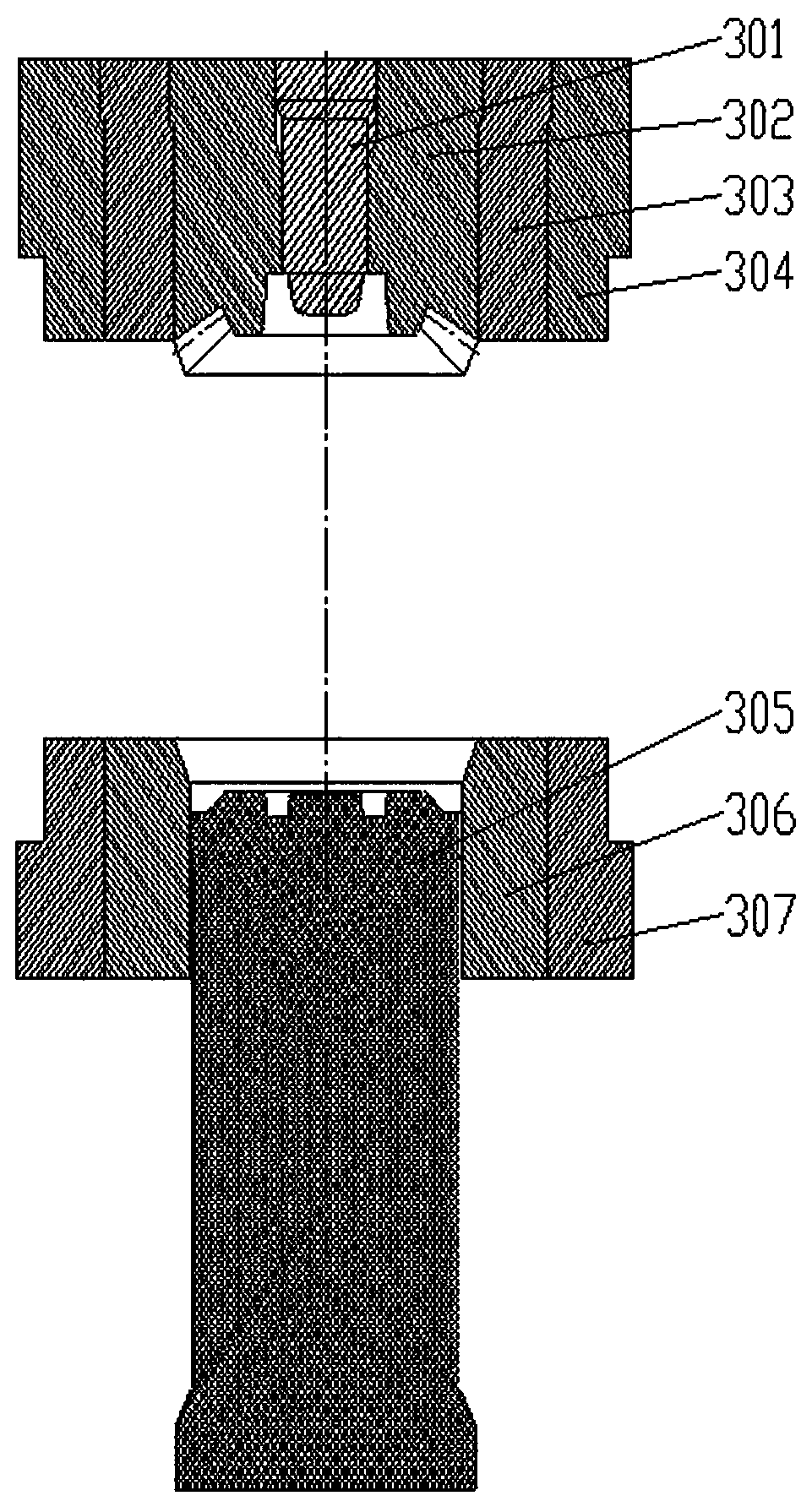

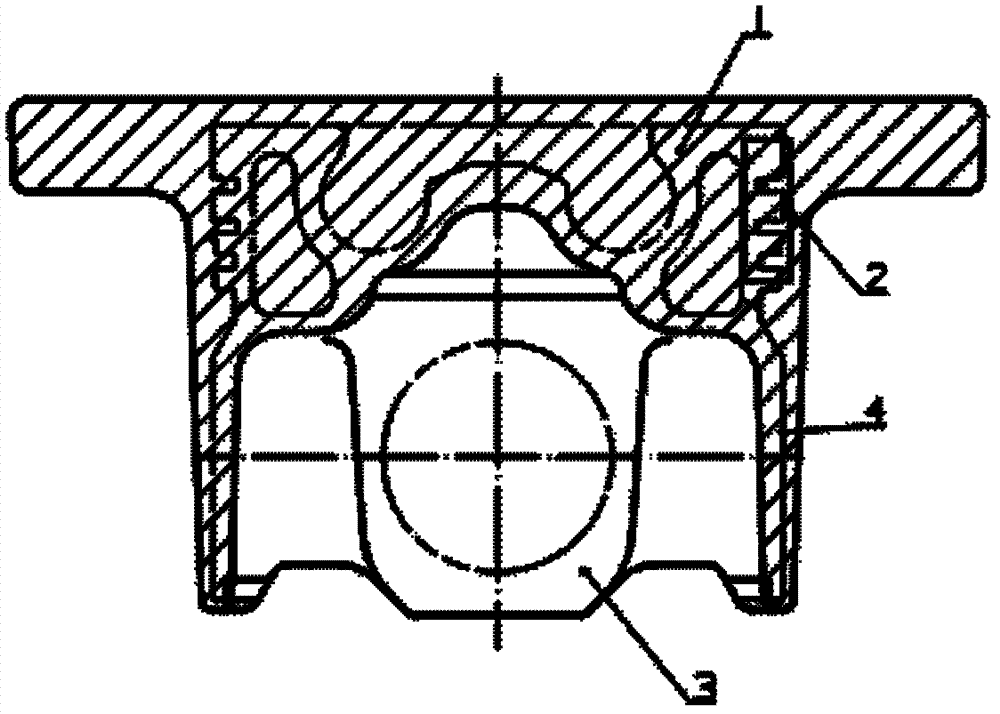

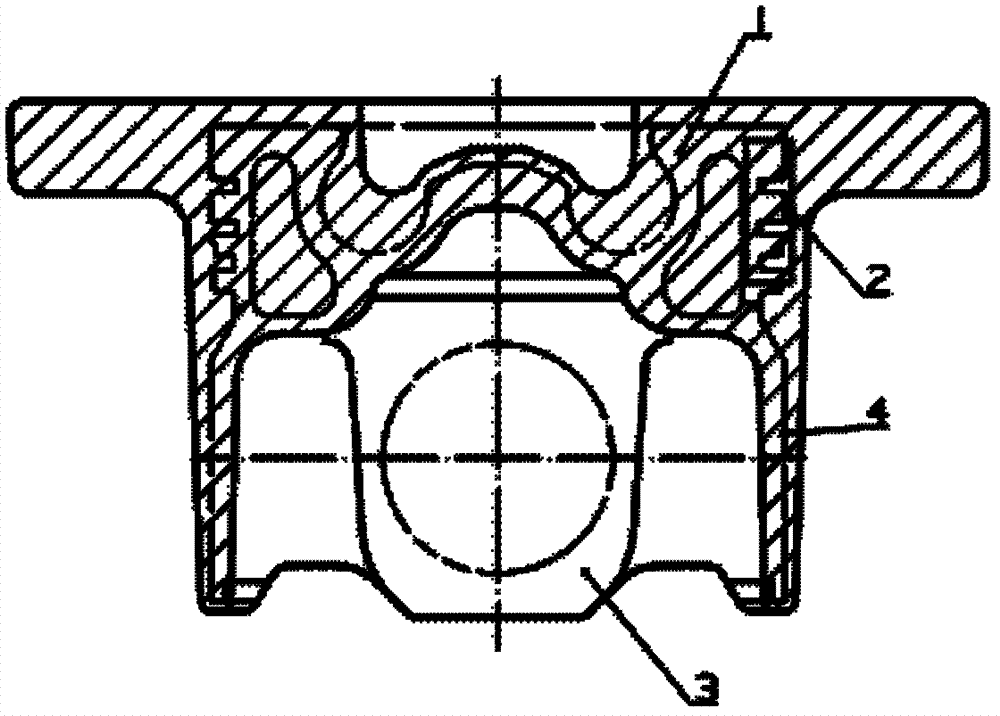

Technology for manufacturing hotly-spun pressed forged steel single-piece piston with inner cooling oil cavity

The invention discloses a technology for manufacturing a hotly-spun pressed forged steel single-piece piston with an inner cooling oil cavity, which comprises the following steps of: forging piston blanks; mechanically processing the piston blanks to obtain the piston as a semi-finished product with an inside part of the inner cooling oil cavity and a covering part for blocking the inner cooling oil cavity, heating the covering part and downwardly spinning the covering part of the inner cooling oil cavity in the piston by the hot spinning technology to contact the inside part of the inner cooling oil cavity to form a complete inner cooling oil cavity; and not processing gaps of the inside part and the covering part of the inner cooling oil cavity, remaining the gaps or simply sealing by the general welding technology, such as argon arc welding and the like, and precisely processing into the piston as a finished product. The hotly-spun pressed forged steel single-piece piston with the inner cooling oil cavity manufactured by the technology disclosed by the invention is simple in structure, relatively easy and convenient to manufacture, high in production efficiency and low in manufacturing cost, and can meet the requirements of an engine on high power, high strength, and low emission, and the like.

Owner:BINZHOU BOHAI PISTON CO LTD

Manufacturing process of solid cold-spun forged steel piston with internal cooling oil chamber

The invention discloses a manufacturing process of a solid cold-spun forged steel piston with an internal cooling oil chamber. The manufacturing process comprises the following steps: performing solid forging to obtain a piston blank; machining a semi-finished piston product with an inside part of the internal cooling oil chamber and a shielding part for blocking off the internal cooling oil chamber; then heating the shielding part, and spinning downwards the shielding part of the internal cooling oil chamber of the piston by adopting the hot spinning process so that the shielding part contacts with the inside part of the internal cooling oil chamber so as to form the complete internal cooling oil chamber; and reserving the gap between the inside part and the shielding part of the internal cooling oil chamber and the shielding part without disposal or simply closing the gap by argon-arc welding and other common welding processes, and then performing precision machining to finally obtain the finished piston. The manufacturing process has the advantages of simple structure, more simple and convenient manufacturing procedures, high production efficiency, low manufacturing cost and the like, and can meet the requirements of an engine on high power, high strength and low emission.

Owner:BINZHOU BOHAI PISTON CO LTD

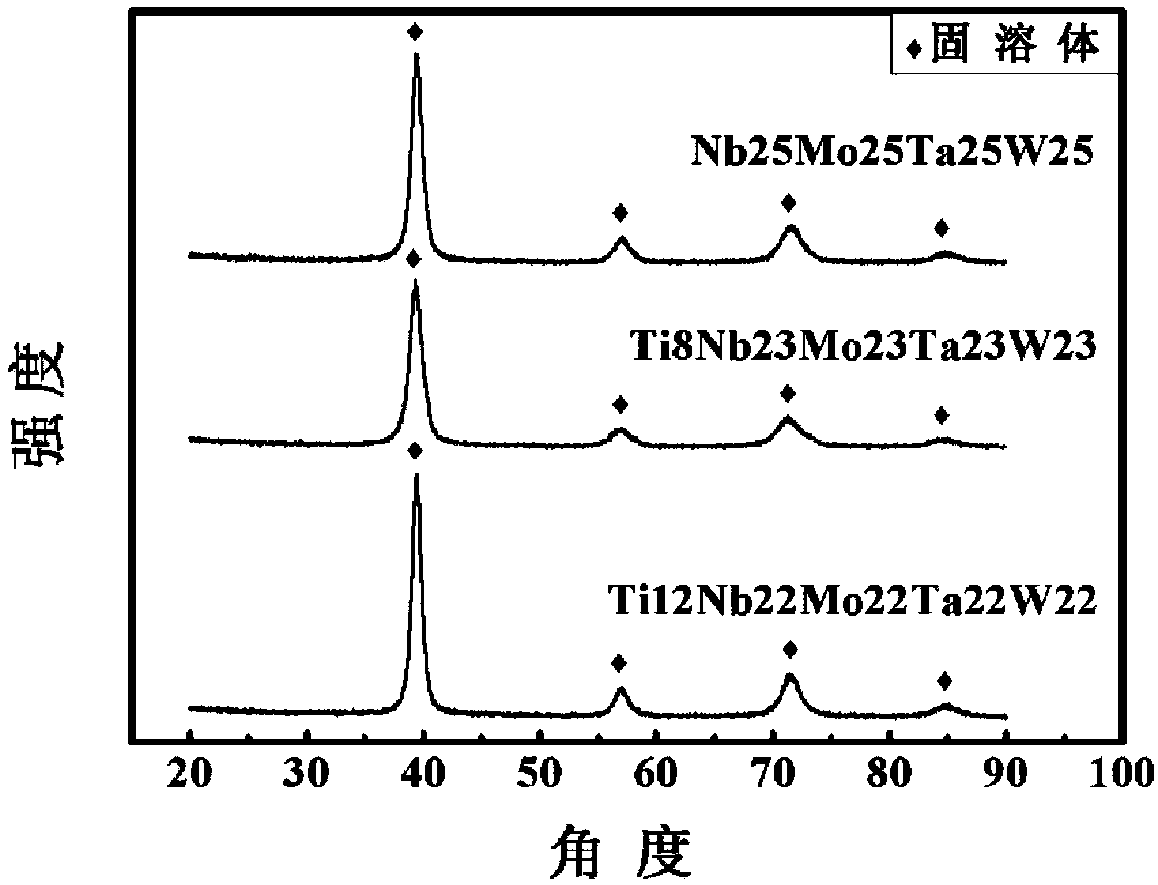

Multi-principal-component high-temperature alloy and preparation method thereof

The invention discloses a multi-principal-component high-temperature alloy and a preparation method thereof. The preparation method adopts a forming technique combining mechanical alloying with discharge plasma sintering, an element Ti is added on the basis of four elements of Nb, Mo, Ta and W with high melting points, alloying is achieved when the elements are in solid states, the melting and solidifying processes are not required, a blocky material with the high performance can be obtained through only one-time solid phase sintering, and the problem that a smelting method is high in smeltingtemperature is solved, so that the machining temperature is reduced substantially, and a technology is simplified; and the defect that a NbMoTaW multi-principal-component high-temperature alloy system is low in room-temperature plasticity is overcome. The preparation method has the advantages of low preparation temperature, high efficiency, less energy consumption and the like; a prepared alloy matrix is of a single-phase body-centered cubic structure, uniform in structure and small in crystal grain, has relatively high strength and plasticity, and is obvious in fine grain strengthening and carbide dispersion strengthening effects.

Owner:SOUTHEAST UNIV

Manufacturing method of aramid fiber composite spaceborne helical antenna

ActiveCN111903223BLow densityMake up for the lack of weightAntenna adaptation in movable bodiesRadiating elements structural formsSatellite dataGlass fiber

The invention discloses a manufacturing method of an aramid fiber composite material space-borne helical antenna, which relates to a manufacturing technology of a space-borne helical antenna in the field of aerospace communication. The present invention adopts Kevlar fiber composite material with low density and good dielectric properties, adhesive film layer, and metal mesh layer to make reflective plate, radome and support body, so that the antenna has high reliability and minimizes the weight of the antenna. The transmitted electromagnetic wave and reflected electromagnetic wave part are processed into a whole, which can transmit electromagnetic wave and reflect electromagnetic wave at the same time, and meet the electrical performance requirements. The aramid fiber composite material space-borne helical antenna is manufactured by vacuum, heating, and pressure curing molding processes. The invention also has the advantages of simple structure and simple and easy-to-operate forming process, which makes up for the shortcomings of the traditional space-borne glass fiber reinforced plastic and aluminum alloy combined helical antenna with large weight and poor dielectric performance, and reduces the weight by 20% to 40%. It is especially suitable for the manufacture of various antennas such as inter-satellite data transmission.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Technology for manufacturing hotly-spun pressed forged steel single-piece piston with inner cooling oil cavity

The invention discloses a technology for manufacturing a hotly-spun pressed forged steel single-piece piston with an inner cooling oil cavity, which comprises the following steps of: forging piston blanks; mechanically processing the piston blanks to obtain the piston as a semi-finished product with an inside part of the inner cooling oil cavity and a covering part for blocking the inner cooling oil cavity, heating the covering part and downwardly spinning the covering part of the inner cooling oil cavity in the piston by the hot spinning technology to contact the inside part of the inner cooling oil cavity to form a complete inner cooling oil cavity; and not processing gaps of the inside part and the covering part of the inner cooling oil cavity, remaining the gaps or simply sealing by the general welding technology, such as argon arc welding and the like, and precisely processing into the piston as a finished product. The hotly-spun pressed forged steel single-piece piston with the inner cooling oil cavity manufactured by the technology disclosed by the invention is simple in structure, relatively easy and convenient to manufacture, high in production efficiency and low in manufacturing cost, and can meet the requirements of an engine on high power, high strength, and low emission, and the like.

Owner:BINZHOU BOHAI PISTON CO LTD

Precision forging forming technology of large-specification straight-tooth bevel gear

InactiveCN108607946AOptimizing the forming processForging/hammering/pressing machinesWheelsGear wheelBevel gear

The invention discloses a precision forging forming technology of a large-specification straight-tooth bevel gear. The technology comprises the following steps that (1), a machining raw material is heated to 850 DEG C in an electric furnace; (2), a flat-mold mold is placed on the precision forging forming equipment, the tonnage of the forging machine is adjusted according to the size of the required straight-tooth bevel gear to carrying out upsetting on the material to reach the required thickness; (3), and an upper mold and a lower mold are heated to 350 DEG C under the mold opening state ofthe forging machine. According to the technology, the forming technology is suitable for machining the large-specification straight-tooth bevel gear, forming resistance is different when the gear is formed in different stages, so that the forming process is divided into warm forging forming and cold forging forming on the basis of original primary forming in the forming process; due to the fact that the changing of the forming resistance of the warm forging process in different stages is relatively large, the warm forging process is divided into three times in order to protect the mold, afterthe machining technology is improved, a set of mold is changed into four sets of molds by improving the mold, after the mold is improved, the forming equipment is improved according to the movement conditions of different parts of the mould during machining.

Owner:ZHANGJIAGANG INST OF IND TECH SOOCHOW UNIV +1

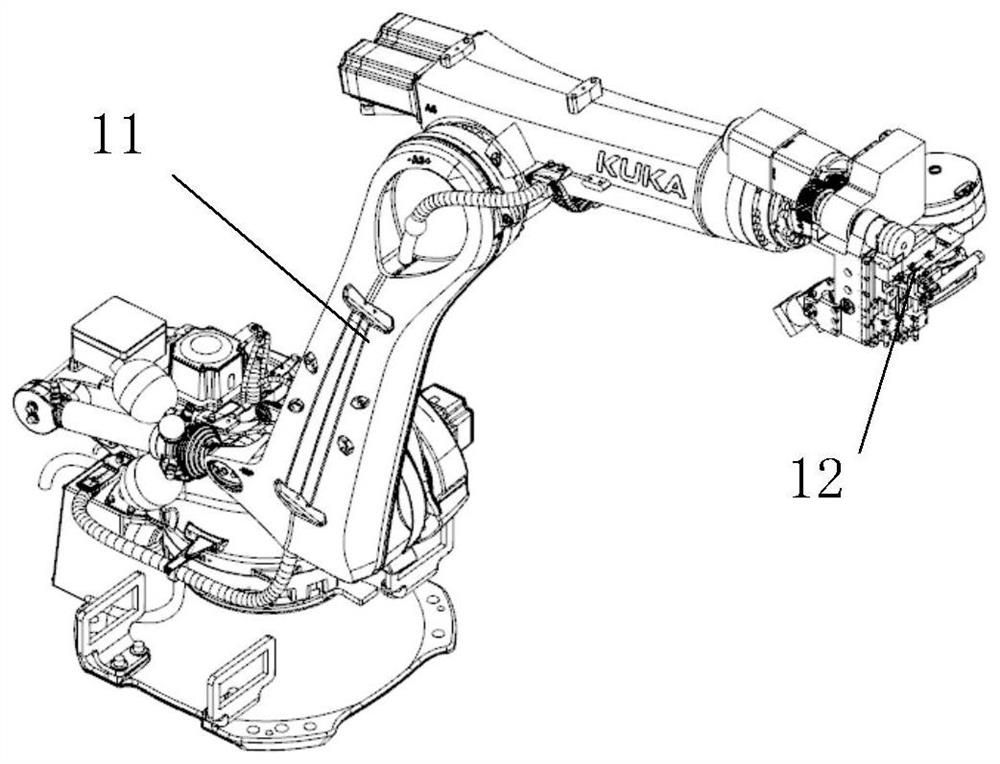

Pipe fitting forming machining method and device for pre-welded bifurcated branch pipes

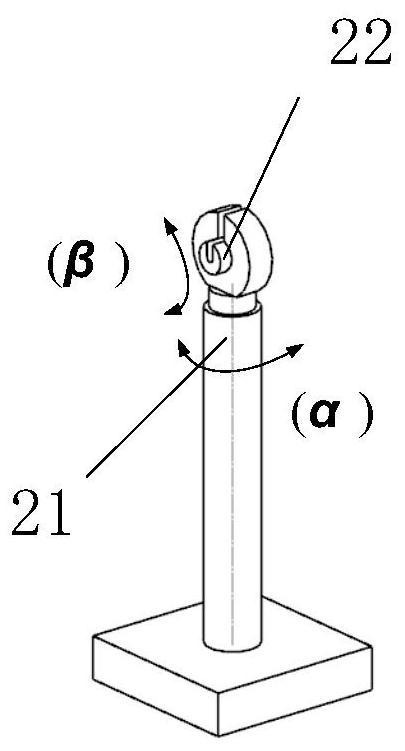

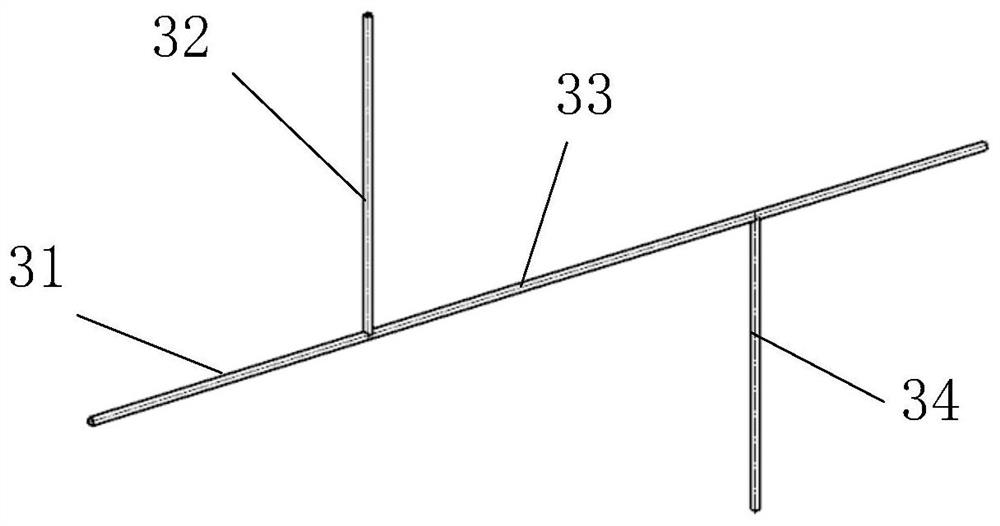

ActiveCN113020354ASolving Bending and Forming ChallengesReduce complexityMetal-working feeding devicesPositioning devicesRotational axisPipe fitting

The invention discloses a pipe fitting forming machining method and device for pre-welded bifurcated branch pipes. The pipe fitting forming machining device comprises a pipe bending robot and a clamping rotating device. A tail end bending forming device is used for conducting bending forming on pipe blanks according to a system instruction, the clamping rotating device comprises a clamping device, a first rotating shaft and a second rotating shaft, the clamping device is installed on the second rotating shaft, and the second rotating shaft can drive the clamping device to rotate around the horizontal axis; and the first rotating shaft can drive the second rotating shaft and the clamping device to rotate around the vertical axis together, the clamping device is used for clamping a main pipe of the pipe blanks, and the first rotating shaft and the second rotating shaft are matched with the pipe bending robot to adjust the positions and postures of the pipe blanks and rotate in a linkage mode. The problem of integral bending forming of a component with a plurality of forked branch pipes is solved; and economical benefits are obvious, efficiency is high, and intelligent bending forming is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

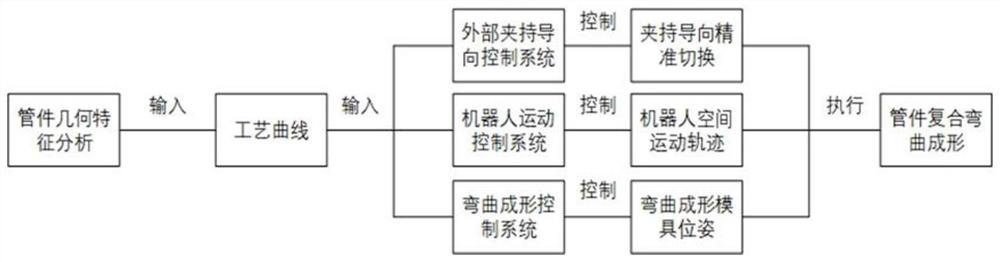

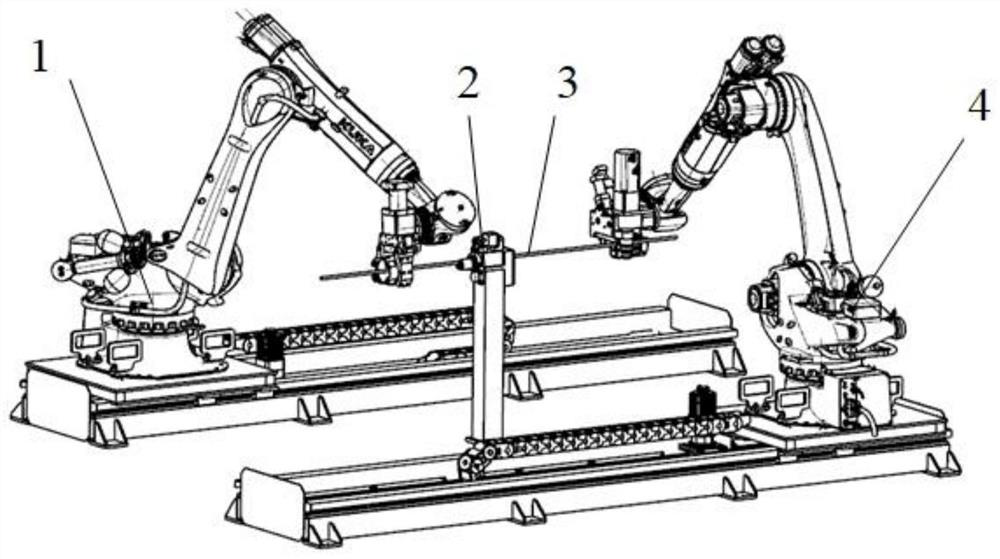

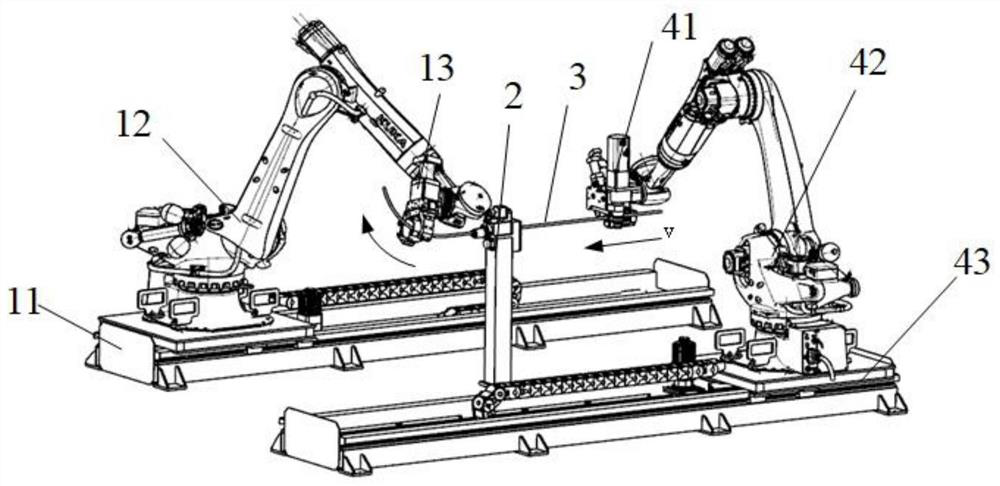

Parallel rail type intelligent robot composite bending forming machining method and device

The invention discloses a parallel rail type intelligent robot composite bending forming machining method and device. The device comprises two industrial robots, a free bending forming device, a bending forming device, an external clamping guiding device and two ground rails. The free bending forming device and the bending forming device are mounted at the tail ends of the two industrial robots respectively, the industrial robots are mounted on the ground rails, and the two industrial robots are arranged in parallel and can horizontally move along the ground rails respectively. The external clamping guiding device is located between the two industrial robots. By adopting the two industrial robots with the ground rails, the free bending forming system and the bending forming system are mounted at the tail ends of the robots respectively, so that in a bending forming process of a complex space component, a continuous variable curvature radius characteristic can be formed, a small bending radius characteristic can also be formed, and even a bending-torsion composite characteristic can be formed. Frequent die replacement in a single forming mode is avoided, and multi-bending-mode composite integrated short-process forming of a multi-feature complex space pipe fitting is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A Method for Establishing Constitutive Model for Rolling Simulation of gh4169 Material

ActiveCN103605830BTruly reflect the change of flow stressHigh precisionSpecial data processing applicationsFlow stressProcess optimization

The invention discloses an establishing method of a constructive model for rolling simulation of Gh4169 materials. The method comprises the following steps of 1) GH4169 alloy monotonic tensile test; 2) GH4169 alloy low-cycle strain control symmetric loading test; 3) constructive model parameter identification including selecting a Yoshida-Uemori model and obtaining constructive model parameters through software computation; 4) model verification including after finishing secondary development of a material constructive model, verifying the material constructive model through a cuboid forging process. The establishing method of the constructive model for rolling simulation of the GH4169 materials has the advantages that the constructive model established through the method can accurately represent the stress-strain of deformed GH 4169 materials and really reflect the flow stress change of metal. The method can provide accurate material models for numerical simulation software, improve the accuracy of simulation results and have significance to material deformation characteristic analysis and forming process optimization.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

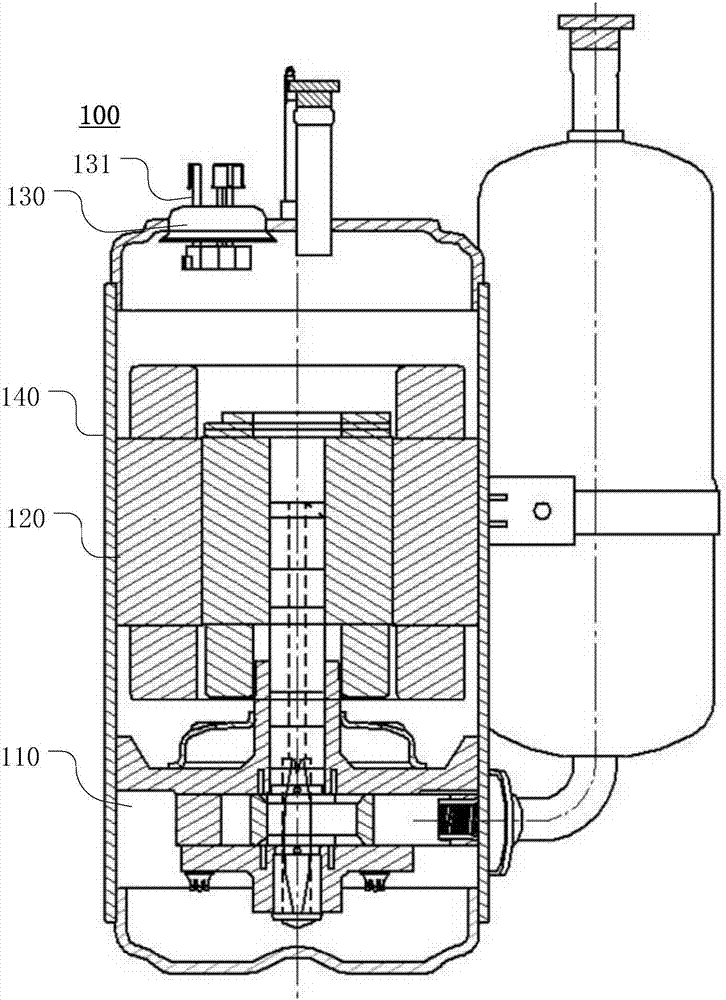

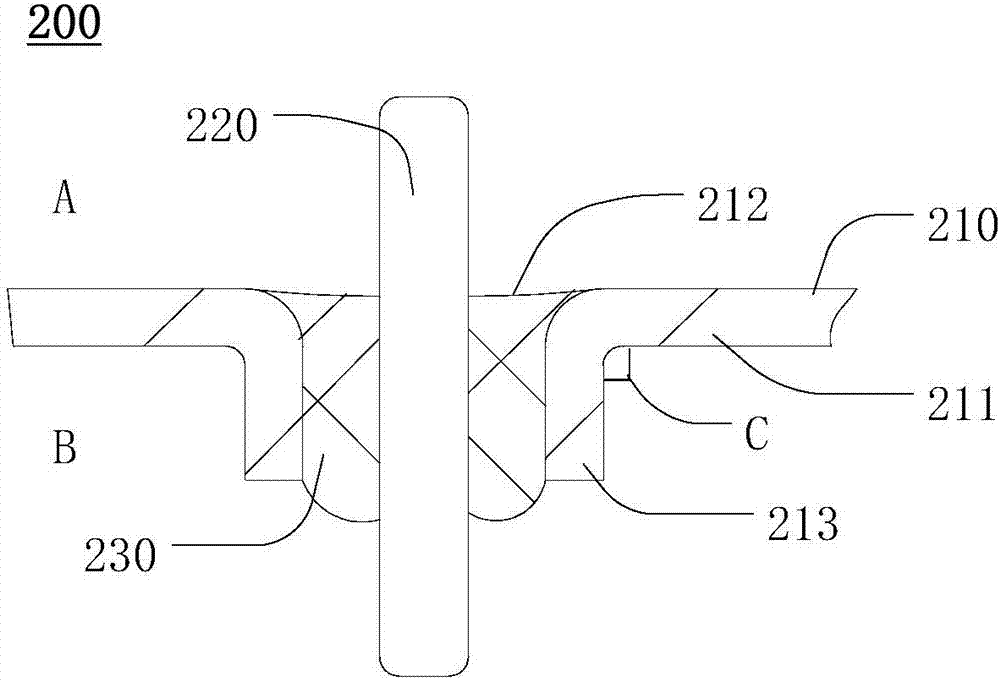

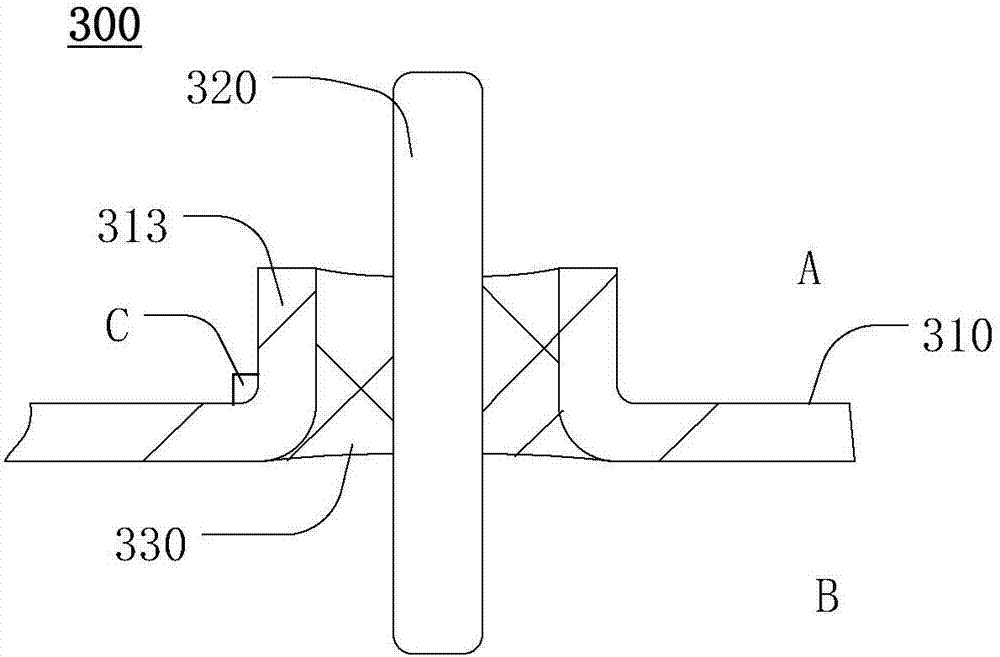

Compressor and wiring mechanism thereof

InactiveCN107345520AImprove reliabilityReduce defective rateRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsEngineering

The invention provides a compressor and a wiring mechanism thereof. The wiring mechanism comprises a shell, at least one pin and an adhesive part; the shell comprises a body, at least one through hole is arranged on the body, and a convex part is arranged on the body and is positioned at the edge of the through hole; at least one pin penetrates through the through hole; and the adhesive part is located between the pin and the body of the shell and fills the through hole. According to the compressor and the wiring mechanism thereof, the defect rate caused by glass breakage of the wiring mechanism can be reduced, the reliability of the compressor is improved, and the internal space of the compressor is saved.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

Manufacturing method of SONOS memory grid electrode structure

InactiveCN107833890ASave etching process stepsReduce process costSolid-state devicesSemiconductor devicesOxideEngineering

The invention discloses a manufacturing method of an SONOS memory grid electrode structure. The method comprises steps of step 1, successively forming an ONO layer, a polysilicon gate and a top oxidelayer; step 2, carrying out photoetching to define forming regions of the grid electrode structure and successively etching the top oxide layer and the polysilicon gate; step 3, successively depositing a first side wall oxide layer and a second side wall nitration layer; and step 4, using the comprehensive etching technique to successively etch the second side wall nitration layer, the first sidewall oxide layer and the ONO layer, and carrying out auto-collimation on the formed side wall structures, and the ONO layers at the bottoms of the polysilicon gate and the side wall structures. According to the invention, the reliability of the device can be improved and technique cost can be reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

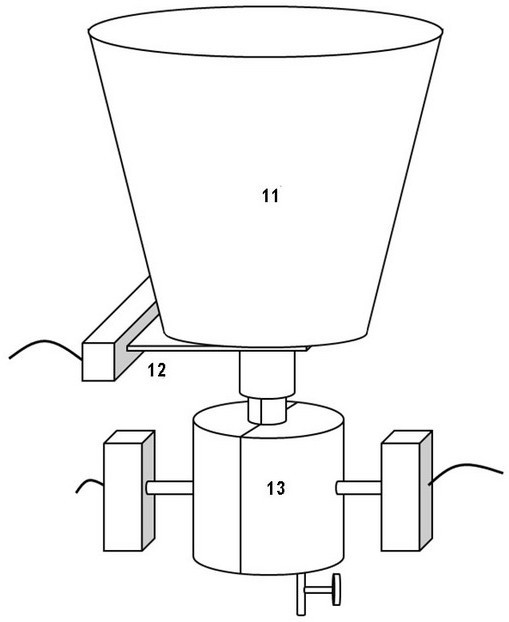

High-throughput preparation method of high-temperature titanium alloy material based on laser in-situ metallurgy

ActiveCN113664219AEnsure consistencyEasy to screen for optimal designAdditive manufacturing apparatusIncreasing energy efficiencyErbium lasersMetallurgy

The invention provides a high-throughput preparation method of a high-temperature titanium alloy material based on laser in-situ metallurgy. The method comprises the following steps: 1) taking a titanium alloy as a basic component, doping rare earth and / or a high-melting-point element, and designing a novel high-temperature titanium alloy with various component proportions at one time; (2) symmetrically arranging a plurality of lateral powder feeding heads and a plurality of independent powder flow monitoring modules in one-to-one correspondence with the lateral powder feeding heads on the periphery of an output mirror of a coaxial wire feeding laser machining head for wire feeding and powder feeding; (3) carrying out wire feeding and powder feeding according to the configured wire feeding speed and powder feeding speed, simultaneously starting a laser device, enabling high-energy ring laser beams to fuse the wires and the powder in situ according to at least one set of preset technological parameters, and carrying out high-throughput forming to obtain massive cast ingots of the novel high-temperature titanium alloy with the different component proportions; and (4) carrying out high-temperature compression test on the cast ingots of the high-temperature titanium alloy to determine the compressive strength, and optimally designing the components of the high-temperature titanium alloy according to the compressive strength.

Owner:北京煜鼎增材制造研究院有限公司

Light emitting element

ActiveCN106663722AOptimizing the forming processSimple packaging processSolid-state devicesSemiconductor devicesInsulation layerEngineering

Disclosed is a light emitting element. The light emitting element comprises: a first conductive type semiconductor layer; a mesa that includes an active layer and a second conductive type semiconductor layer; a current blocking layer; a transparent electrode at least partially covering the current blocking layer; a first electrode that includes a first electrode pad and a first electrode extension; a second electrode that includes a second electrode pad and a second electrode extension; and an insulation layer partially located on the lower portion of the first electrode, wherein the mesa includes at least one groove formed on a side thereof, the first conductive type semiconductor layer is partially exposed through the groove, the insulation layer includes an opening through which the exposed first conductive type semiconductor layer is at least partially exposed, the first electrode extension includes one or more extension contact portions that are brought into contact with the first conductive type semiconductor layer through an opening, and the second electrode extension includes an end that has a width different from the average width of the second electrode extension.

Owner:SEOUL VIOSYS CO LTD

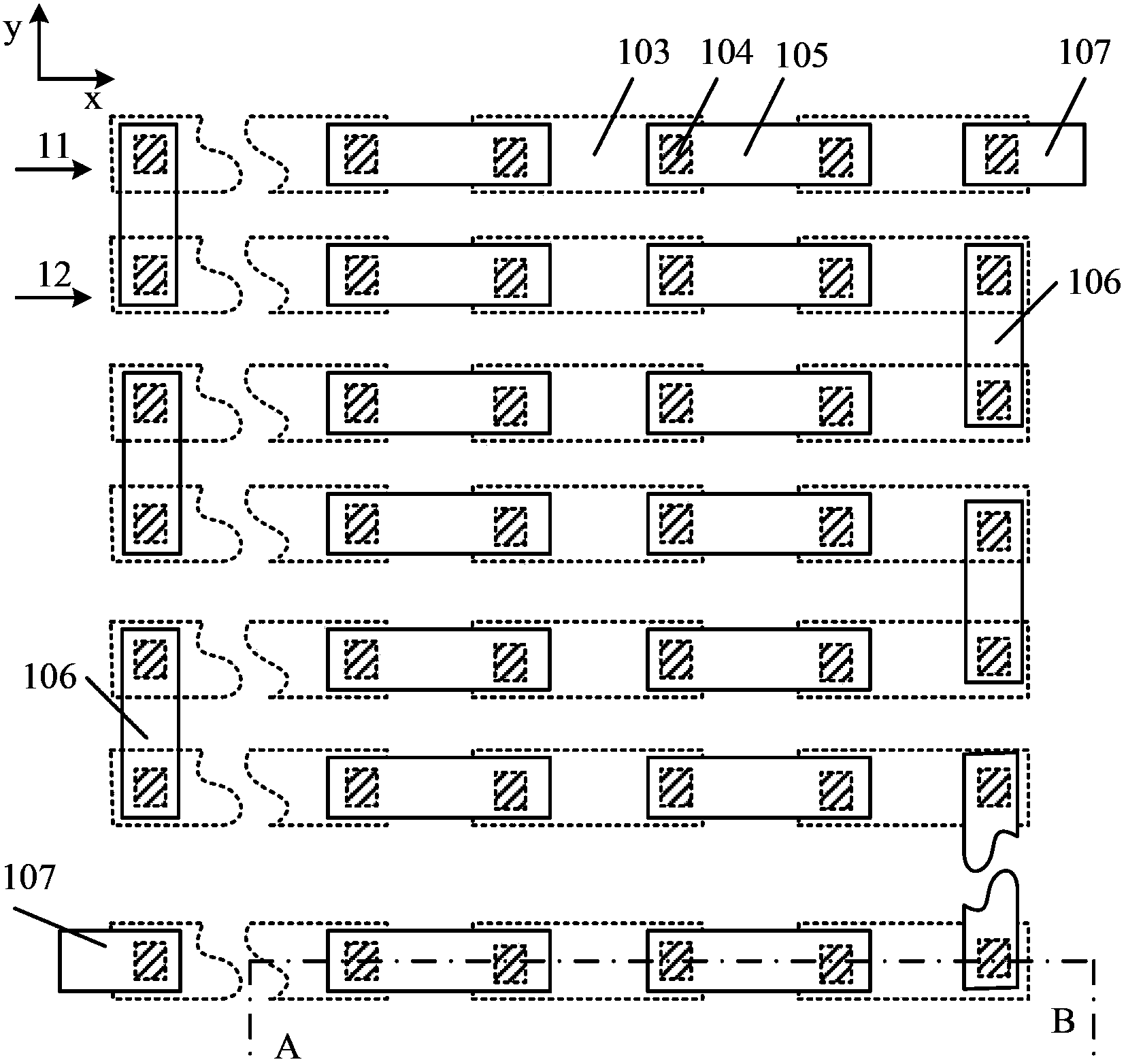

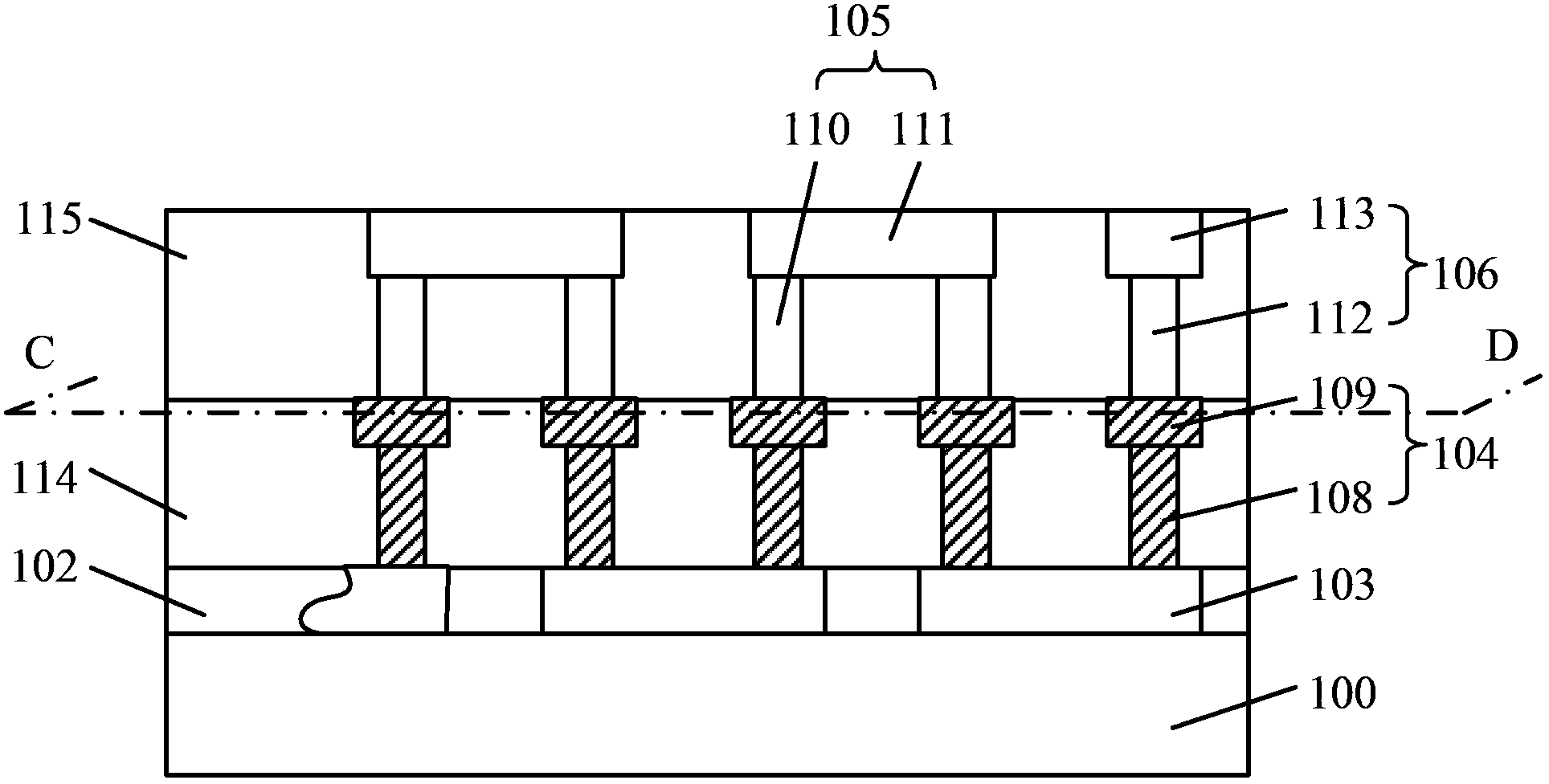

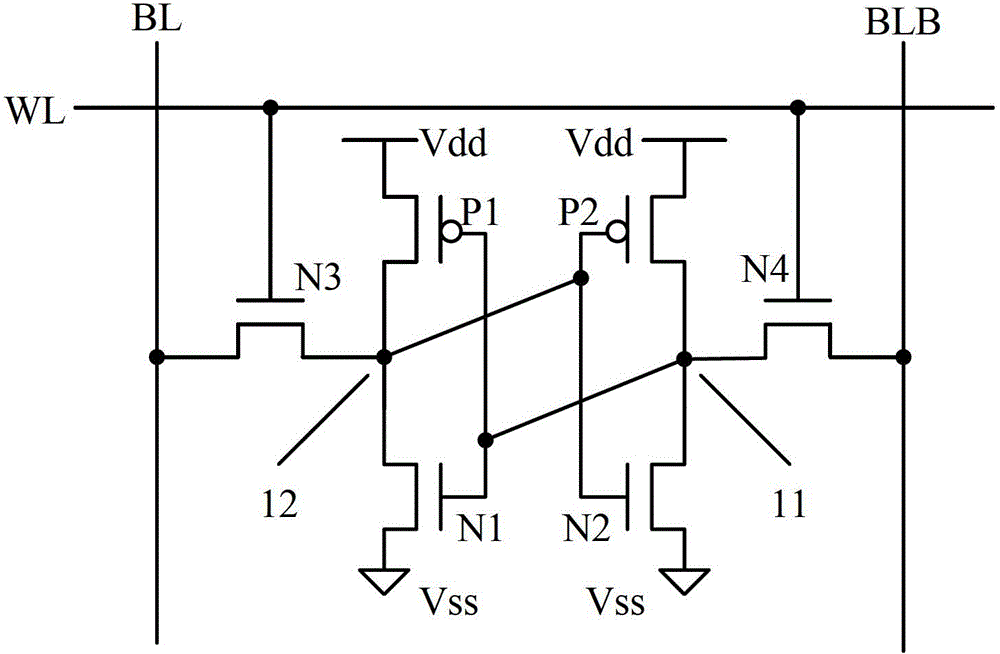

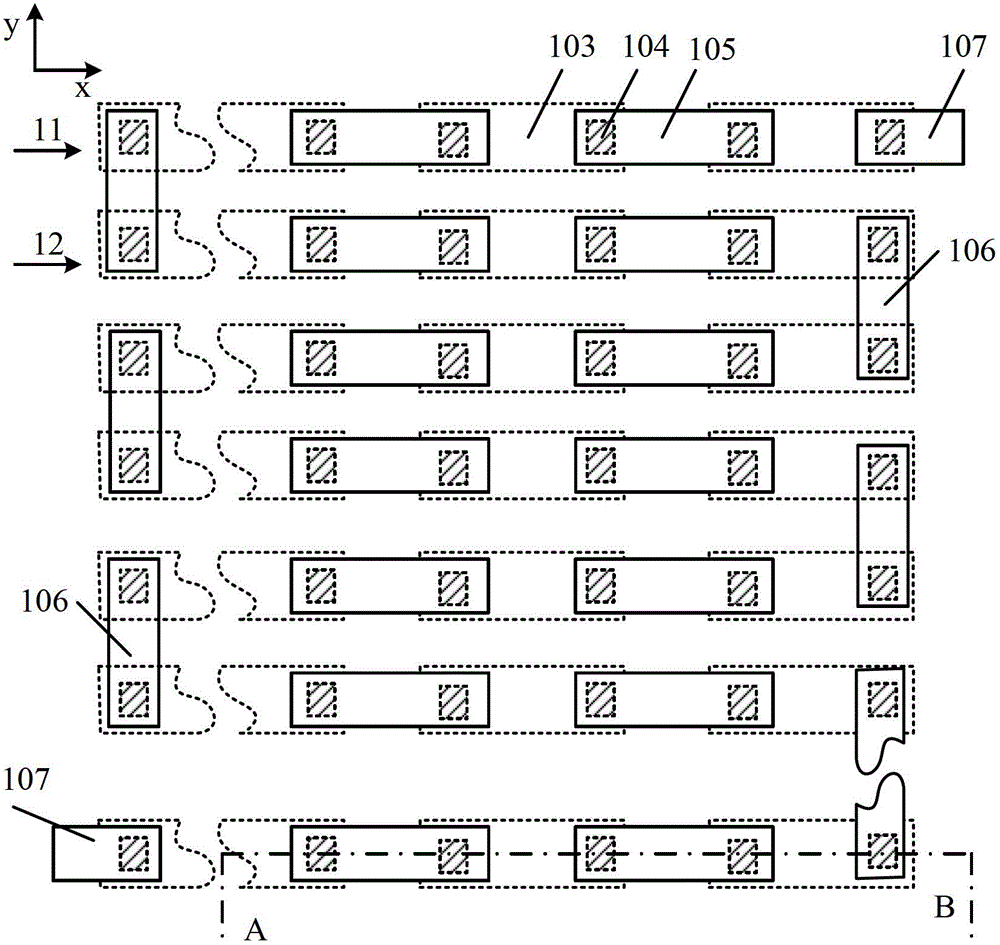

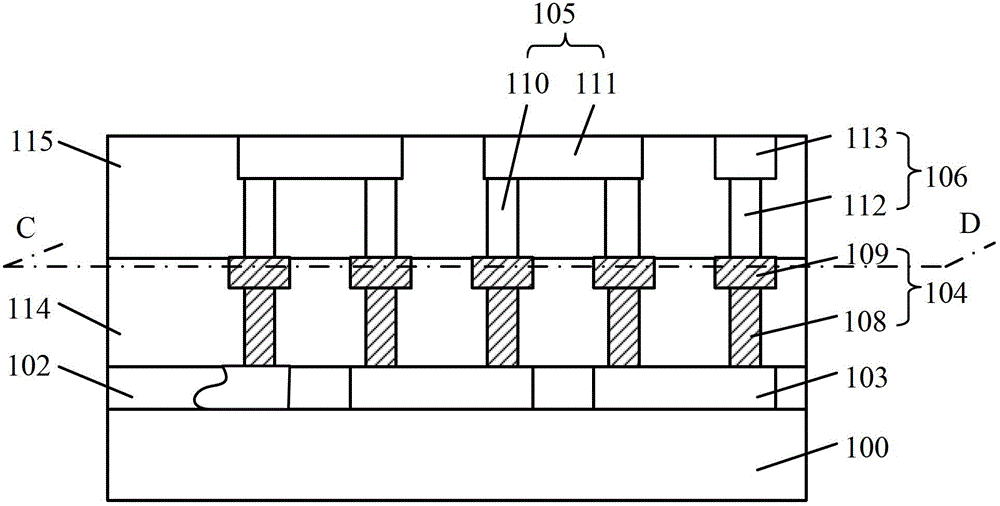

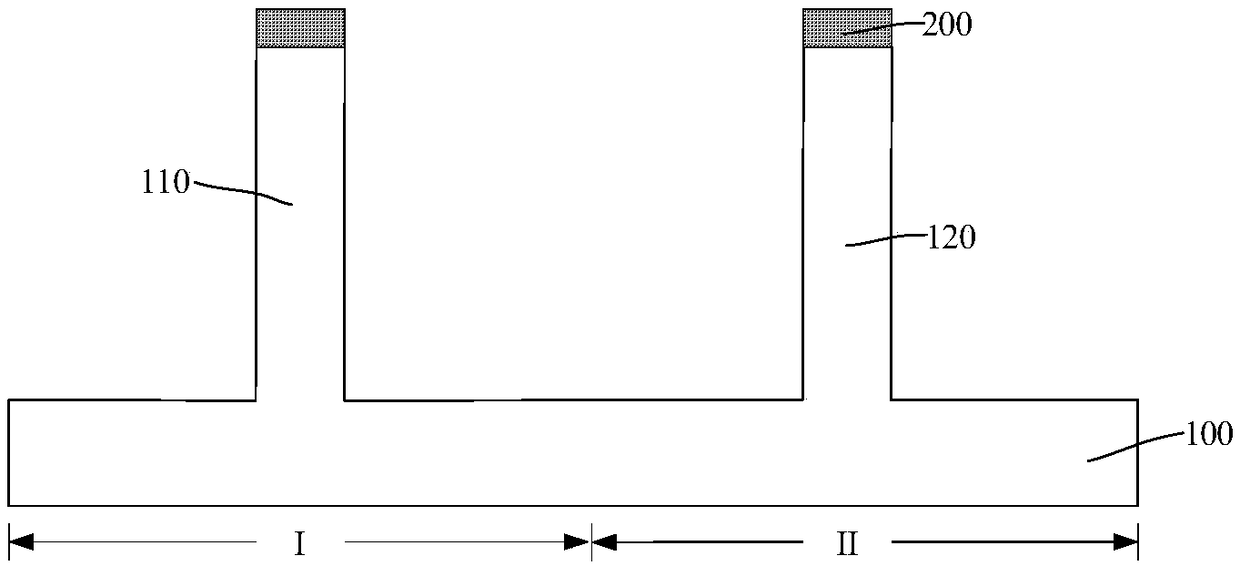

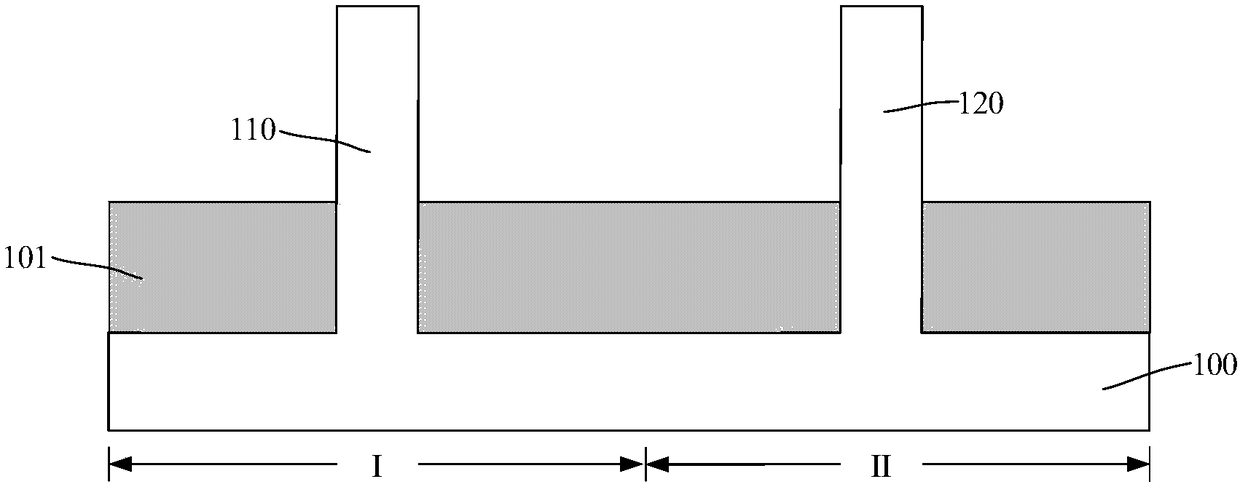

Semiconductor test structure and test method thereof

ActiveCN103839922ASave spaceHigh precisionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectrical resistance and conductanceTest efficiency

The invention discloses a semiconductor test structure and a test method of the semiconductor test structure. The semiconductor test structure is formed in the mode that a plurality of dually-embedded structures which are distributed in rows and columns form a plurality of sub test chains connected in series, the head ends of the sub test chains are connected with one another, the tail ends of the sub test chains are connected with one another, and therefore the sub test chains are connected in series to form the semiconductor test structure. According to the semiconductor test structure and the test method of the semiconductor test structure, space is saved; by means of testing the resistance of the semiconductor test structure, whether the dually-embedded structures have defects is judged; the test method is simple, and test efficiency is high.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Semiconductor test structure and its test method, detection method

ActiveCN103839922BSave spaceOptimizing the forming processSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsTest efficiencyTest series

Owner:SEMICON MFG INT (SHANGHAI) CORP

Manufacturing process of solid cold-spun forged steel piston with internal cooling oil chamber

The invention discloses a manufacturing process of a solid cold-spun forged steel piston with an internal cooling oil chamber. The manufacturing process comprises the following steps: performing solid forging to obtain a piston blank; machining a semi-finished piston product with an inside part of the internal cooling oil chamber and a shielding part for blocking off the internal cooling oil chamber; then heating the shielding part, and spinning downwards the shielding part of the internal cooling oil chamber of the piston by adopting the hot spinning process so that the shielding part contacts with the inside part of the internal cooling oil chamber so as to form the complete internal cooling oil chamber; and reserving the gap between the inside part and the shielding part of the internal cooling oil chamber and the shielding part without disposal or simply closing the gap by argon-arc welding and other common welding processes, and then performing precision machining to finally obtain the finished piston. The manufacturing process has the advantages of simple structure, more simple and convenient manufacturing procedures, high production efficiency, low manufacturing cost and the like, and can meet the requirements of an engine on high power, high strength and low emission.

Owner:BINZHOU BOHAI PISTON CO LTD

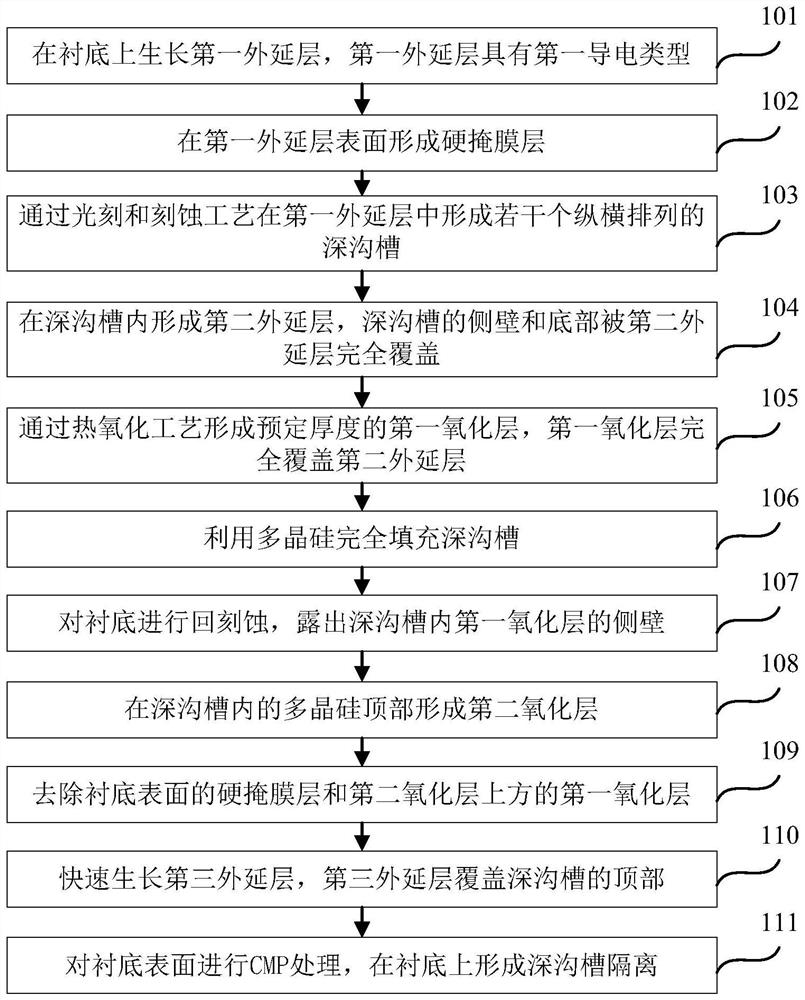

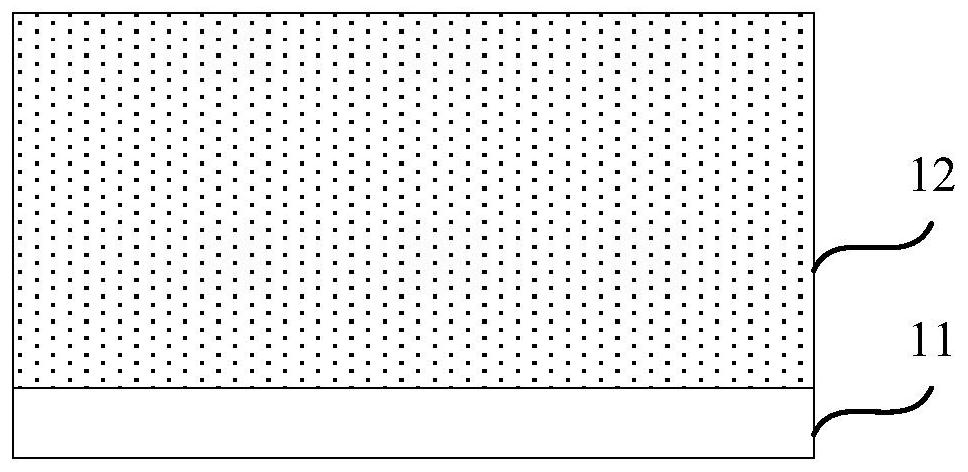

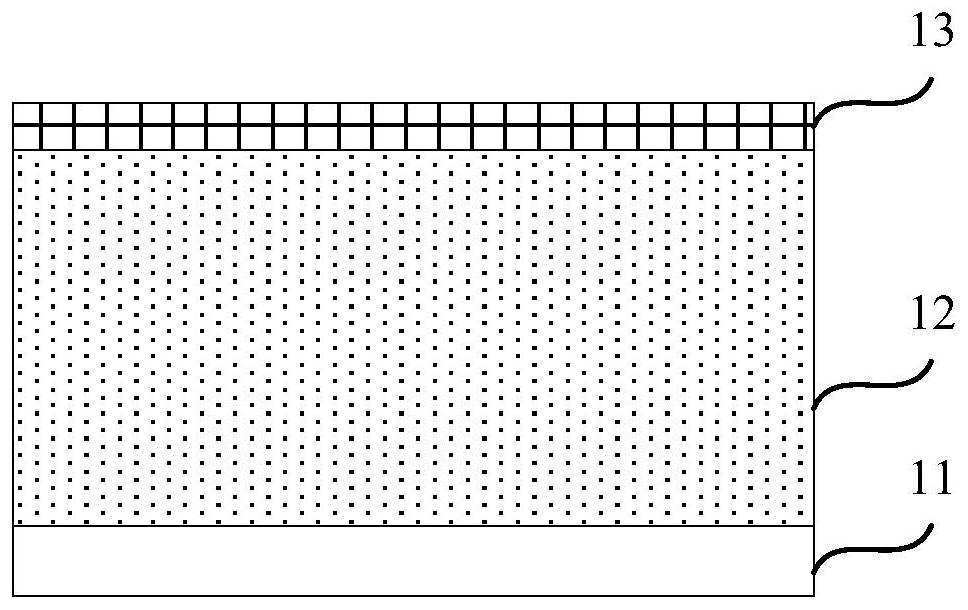

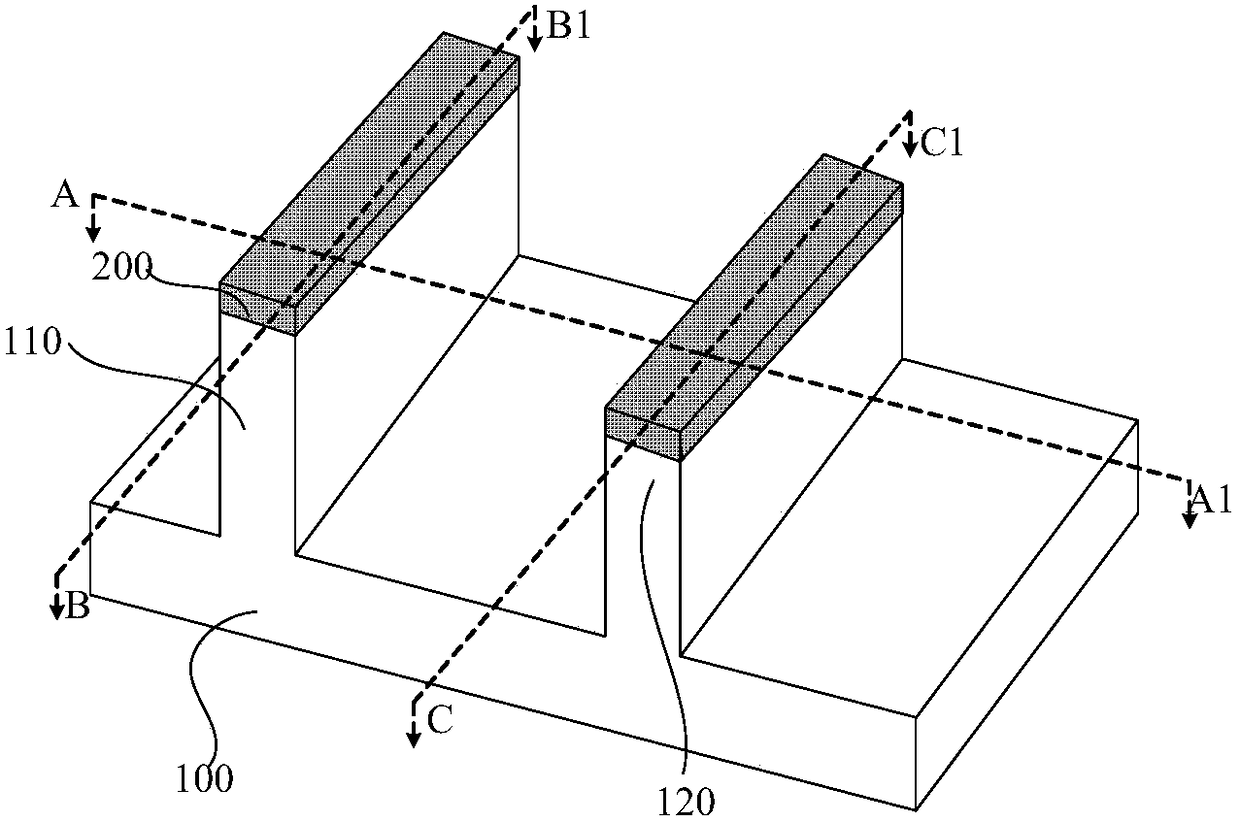

Deep trench isolation forming method of CIS device, and semiconductor device structure

ActiveCN112928058AOptimizing the forming processImproving the performance of CIS devicesSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsEngineering

The invention discloses a deep trench isolation forming method of a CIS device, and a semiconductor device structure, and relates to the field of semiconductor manufacturing. The method comprises the following steps: growing a first epitaxial layer on a substrate; forming a hard mask layer; forming a plurality of deep grooves which are arranged vertically and horizontally in the first epitaxial layer; forming a second epitaxial layer in the deep trench; forming a first oxide layer on the surface of the second epitaxial layer in the deep trench; fully filling the deep trench with polycrystalline silicon; performing back etching on the substrate to expose the side wall of the first oxide layer in the deep trench; forming a second oxide layer on the top of the polycrystalline silicon; removing the first oxide layer above the hard mask layer and the second oxide layer; rapidly growing a third epitaxial layer; and performing CMP processing on the surface of the substrate, and forming deep trench isolation on the substrate. The problem that when deep trench isolation of a CIS device is formed in an epitaxial growth mode, the top of a deep trench crossing area is prone to having a sealing defect is solved. The formation process of the deep trench isolation is optimized, and the device performance is improved.

Owner:HUA HONG SEMICON WUXI LTD +1

Semiconductor structure and formation method thereof

ActiveCN108630683AImprove electrical performanceIncrease drive currentTransistorSolid-state devicesSchottky barrierSemiconductor structure

A semiconductor structure and a formation method thereof are disclosed. The method comprises the following steps of providing a substrate including an NMOS area; forming a gate structure on the substrate; forming an N-region groove in the substrate of the two sides of the gate structure; forming an N-region doped epitaxial layer in an N-region groove, wherein the N-region doped epitaxial layer isthe laminated structure of a first N-type doped epitaxial layer and a second N-type doped epitaxial layer, the first N-type doped epitaxial layer is a first epitaxial layer doped with N-type ions, thesecond N-type doped epitaxial layer is a second epitaxial layer doped with the N-type ions, and the forbidden band width of the second epitaxial layer is smaller than the forbidden band width of thefirst epitaxial layer; forming an interlayer dielectric layer on the N-region doped epitaxial layer; forming a first contact opening which is exposed out of the N-region doped epitaxial layer in the interlayer dielectric layer; and forming a first contact hole plug in the first contact opening. In the invention, through the second epitaxial layer doped with the N-type ions, a Schottky barrier height is reduced, the N-type ion concentration of the N-region doped epitaxial layer is increased and a contact resistance is reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

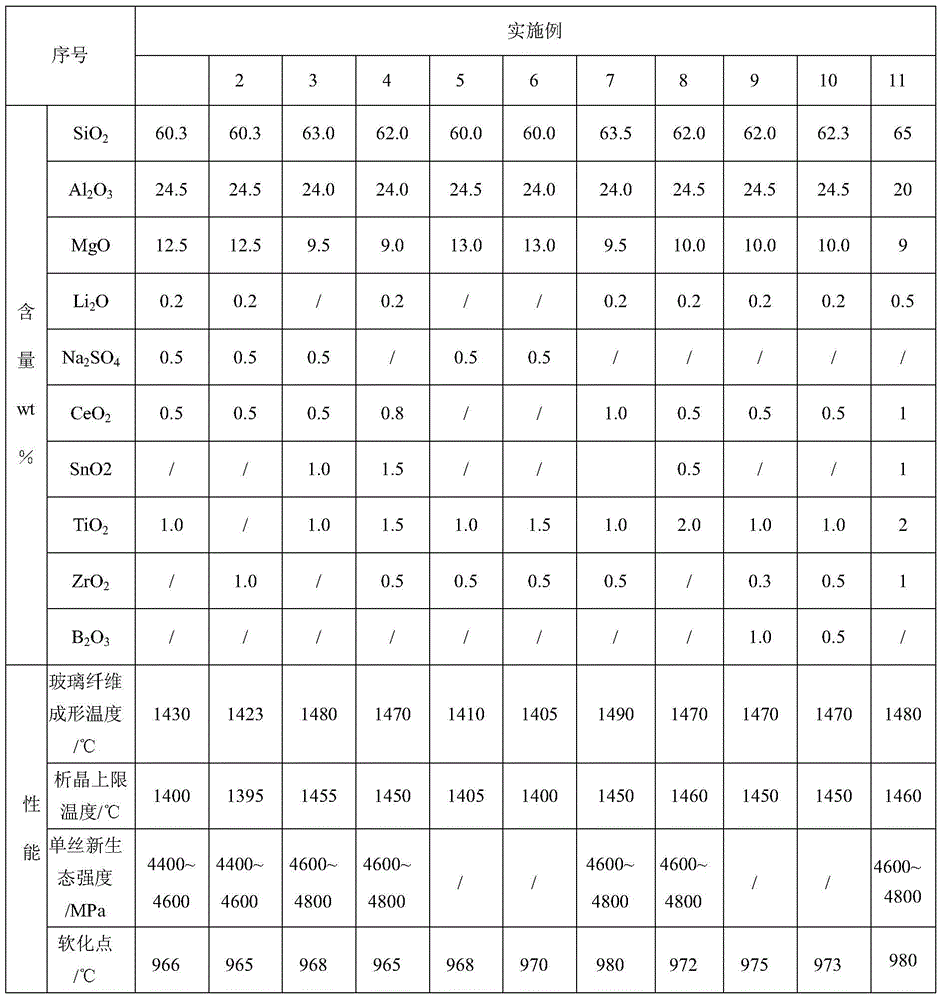

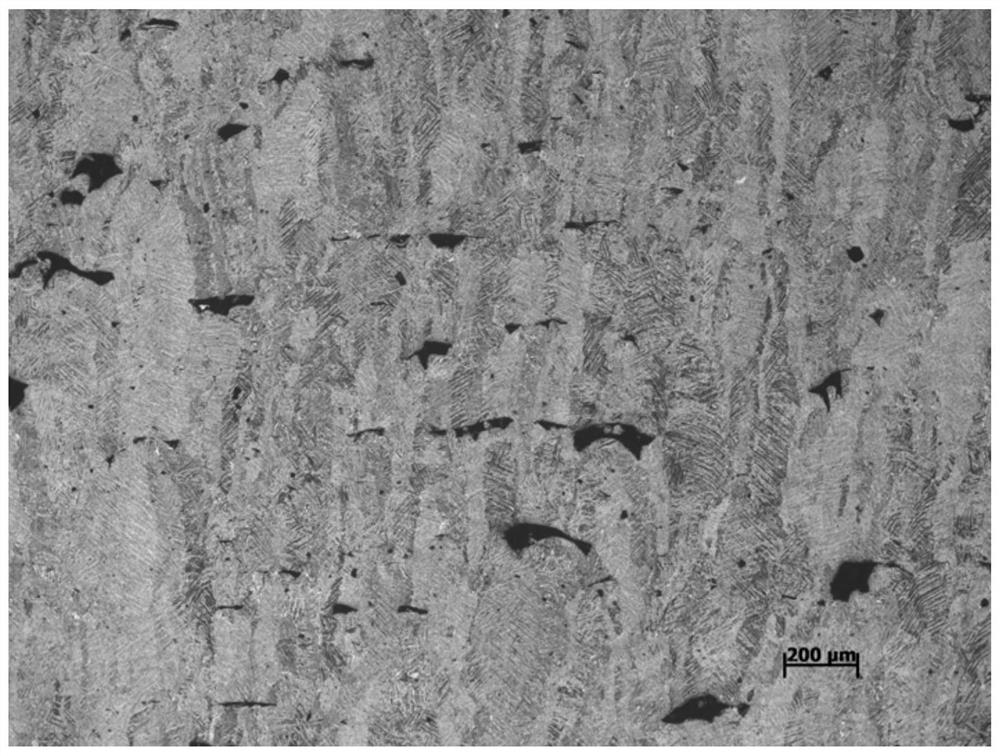

A high-performance glass fiber

ActiveCN104478223BImprove forming process performanceAdapt to serial productionGlass fiberUltimate tensile strength

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

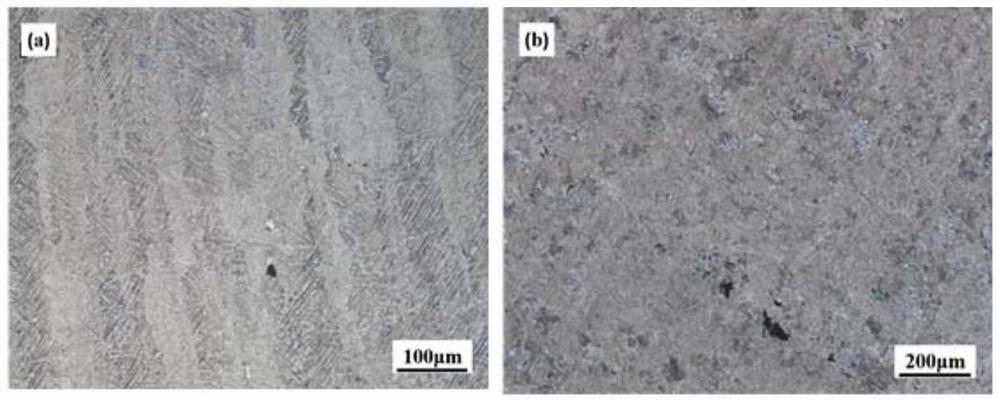

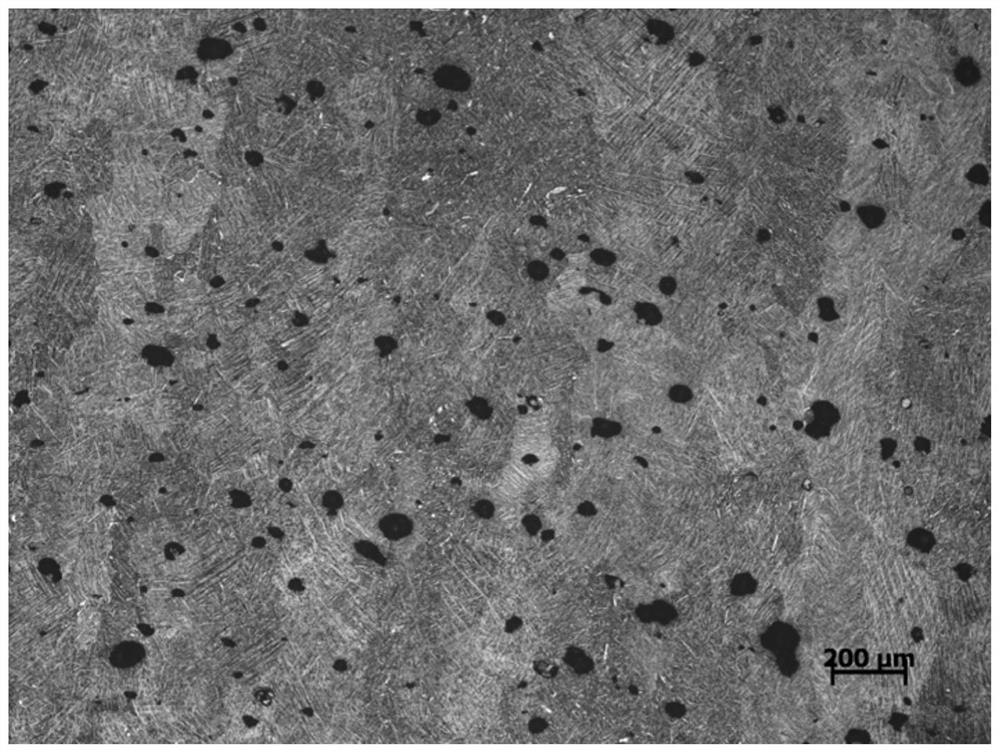

Method of regulating and controlling laser selective melting formed titanium alloy process based on flaw form

InactiveCN112548119AReduce energy densityIncrease laser powerAdditive manufacturing apparatusMetallurgyTitanium alloy

The invention relates to the technical field of titanium alloy materials, in particular to a method of regulating and controlling a laser selective melting formed titanium alloy process based on a flaw form. The method comprises the following steps of: first, detecting a microscopic structure of a laser selective melting formed titanium alloy; analyzing and determining a flaw type in the titaniumalloy; and optimizing forming process parameters according to the flaw type. The optimization is specifically as follows: if a flaw is in an irregular shape, it shows that the energy density is low, and adjustment can be carried out by improving the laser power or reducing the scanning speed; and if the flaw is in a regular shape, it shows that the energy density is too high, and adjustment can becarried out by reducing the laser power or improving the scanning speed. By adopting the method, quick responding adjustment on the forming process parameters can be carried out based on demands on surface quality, forming efficiency of a formed member and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com