Precision forging forming technology of large-specification straight-tooth bevel gear

A forming process, straight tooth bevel technology, applied in the direction of wheels, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency, flash, mold wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

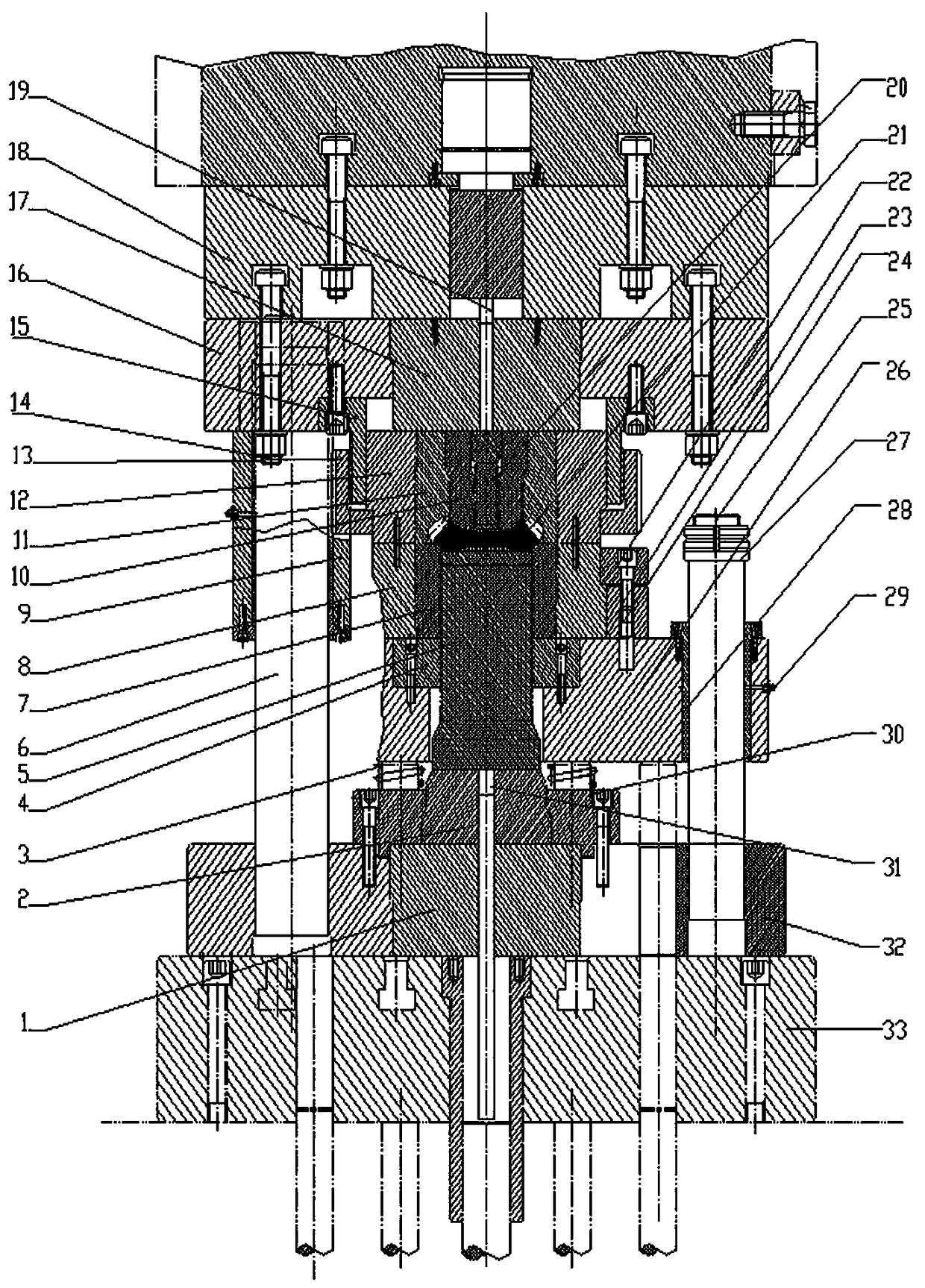

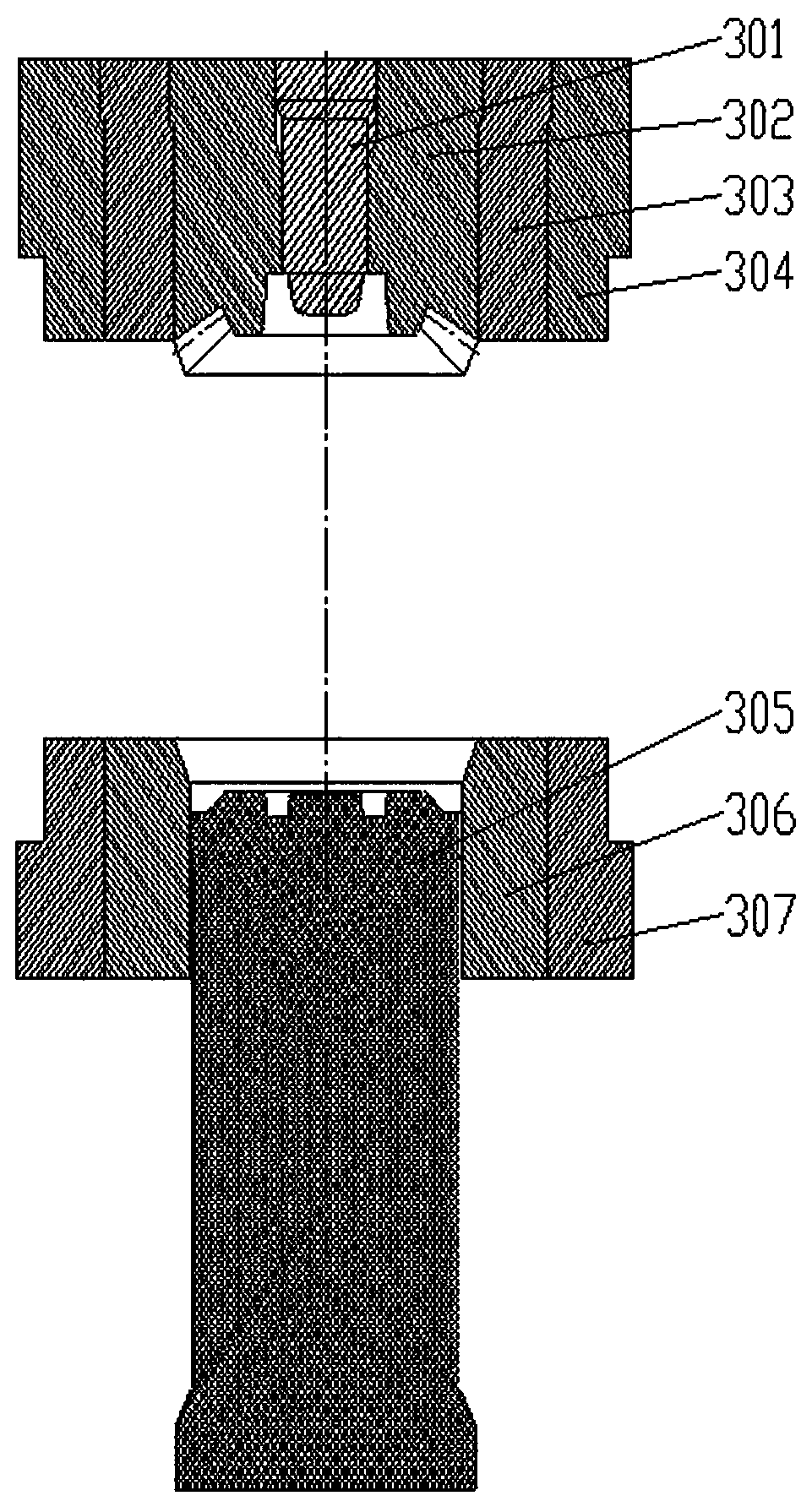

[0063] Example 1: A precision forging forming process for large-scale straight bevel gears, using a flat die to upset the raw material; using a warm forging forming die to process the tooth profile; using a warm forging shaping die to correct the tooth profile; using a cold forging finishing die Deflashing, finishing tooth shape,

[0064] Specifically include the following steps:

[0065] (1) Heating the processed raw materials to 850°C in an electric furnace;

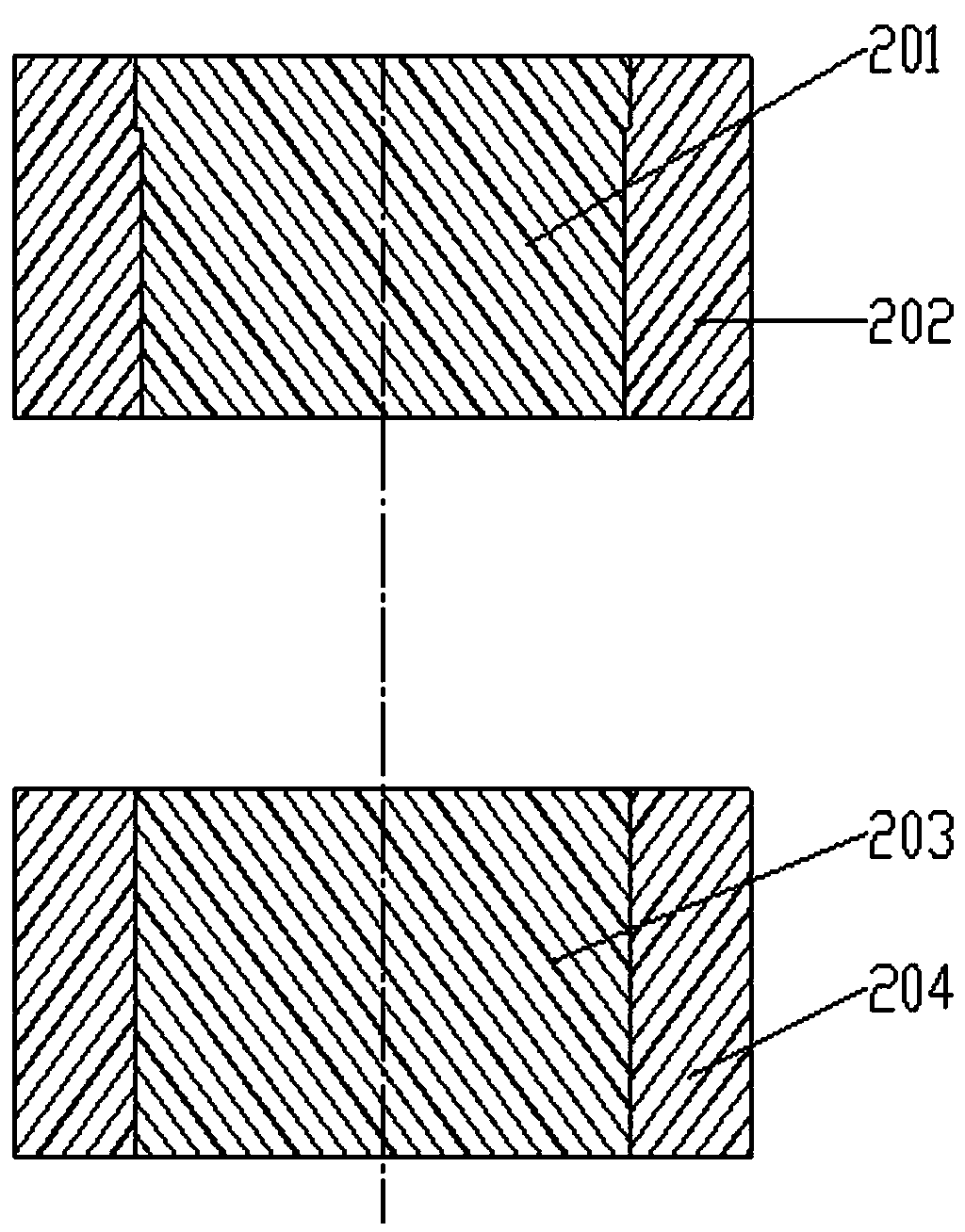

[0066] (2) Place the flat die on the precision forging forming equipment, adjust the tonnage of the forging press according to the required straight bevel gear size, and upset the raw material on the flat die to the required thickness;

[0067] (3) When the forging press is opened, heat the upper and lower molds to 350°C;

[0068] (4) Place the warm forging forming die on the precision forging forming equipment, and the warm forging forming punch moves down. When the warm forging forming punch and warm forging formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com