A high-performance glass fiber

A glass fiber, high-performance technology, applied in the field of composite materials, to achieve the effect of light weight, improved forming process, and increased forming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

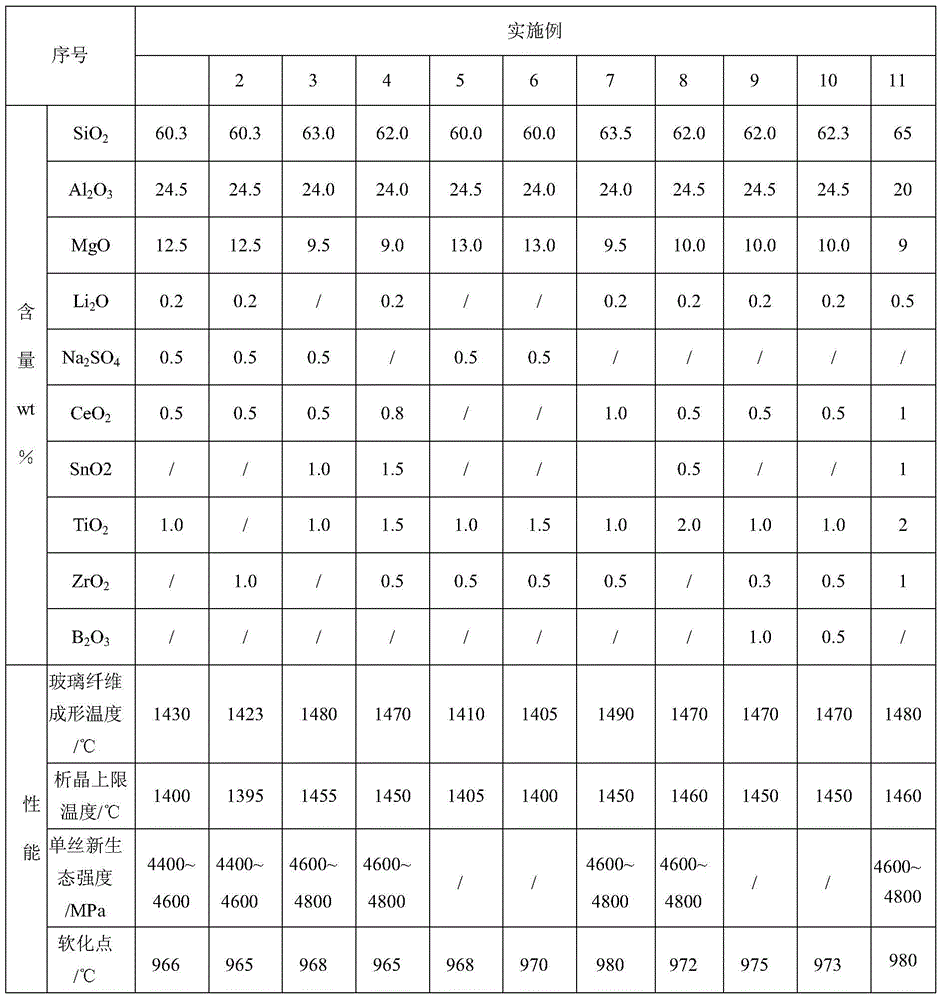

[0032] Embodiments of the present invention are shown in the following table:

[0033]

[0034] Calculate the required amount of various raw materials according to the chemical composition of the formulas listed in the above table, and mix them evenly to make batches after accurate weighing, mix them by air force and transport them to the feeding port of the kiln, and use an automatic feeding machine to feed them. At about 1620°C, a clarified and homogenized molten glass is obtained by melting in a furnace combined with electric melting or thermal power. The melted glass liquid can be prepared into glass balls (or use a one-step kiln for direct yarn production), and then the melted glass balls can be remelted at 1560°C in a platinum-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com