An Angle Adjustable Dual Light Source Inkjet Printing Nozzle

A printing nozzle and inkjet technology, applied in the coating device, additive processing, etc., can solve the problems of insufficient light source adjustability, high cost of scanning galvanometer, uneven spot energy, etc., to improve the forming process performance , light weight, and the effect of improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

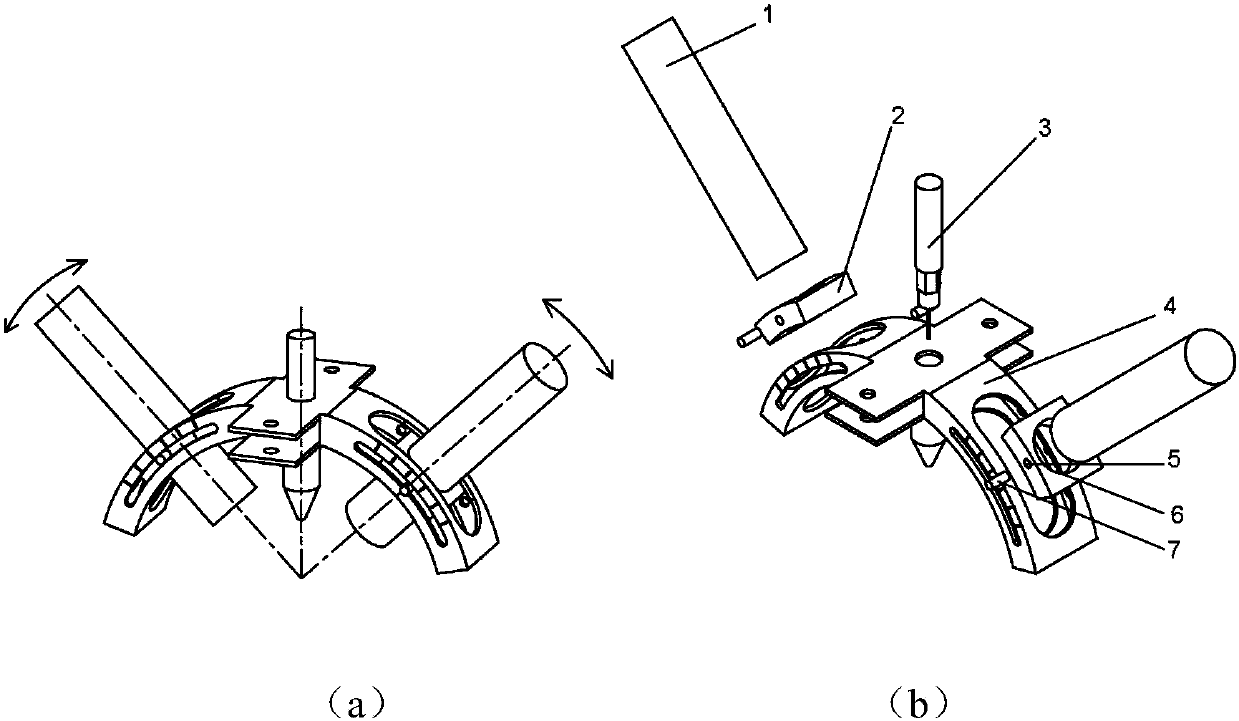

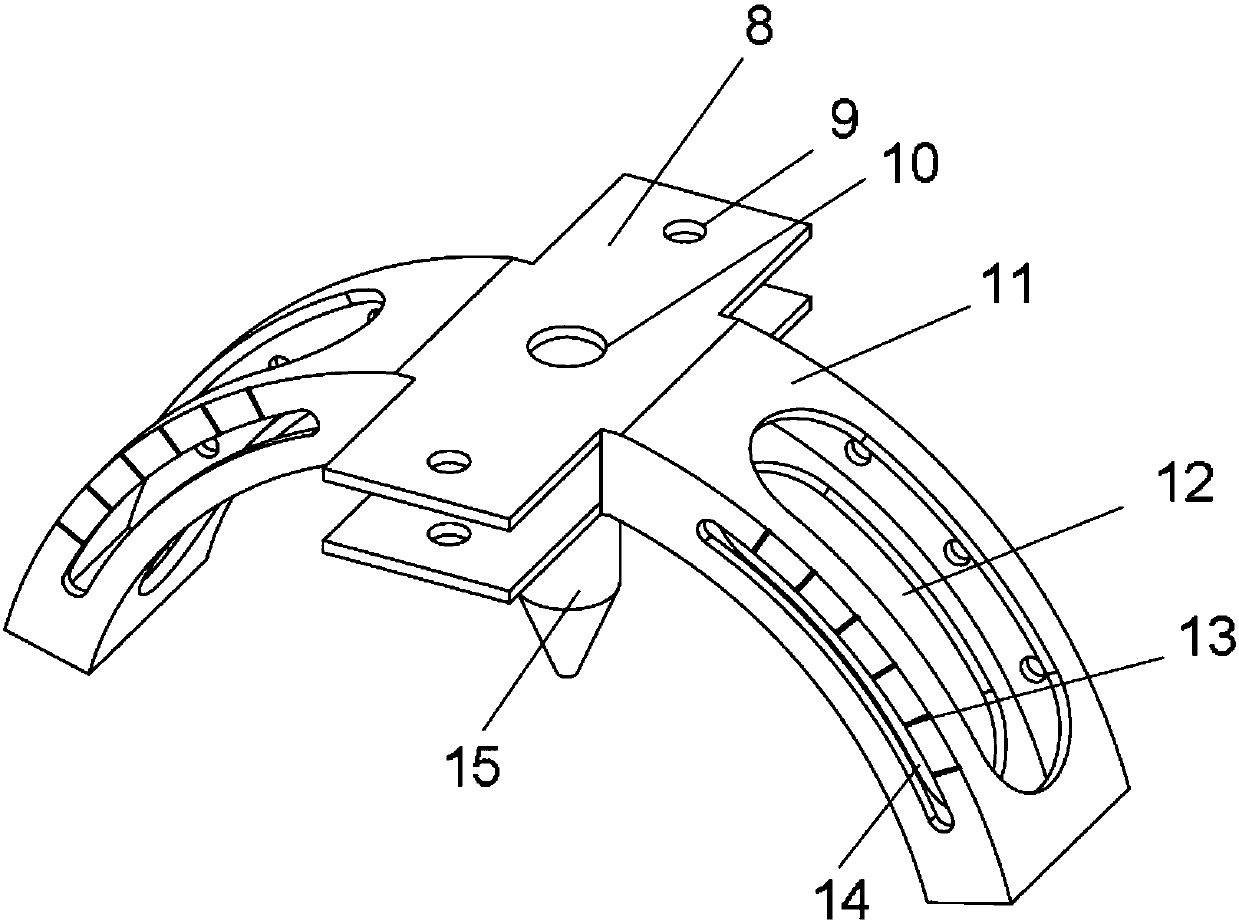

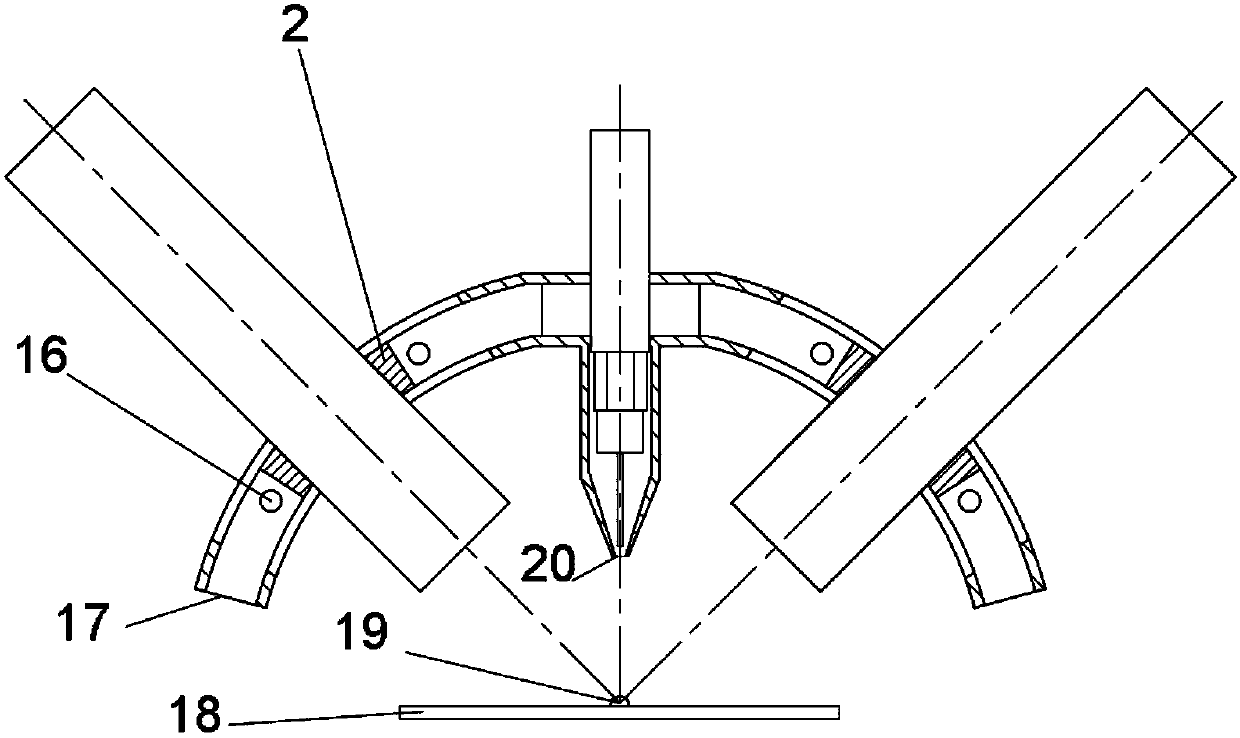

[0043]The angle-adjustable dual-light source inkjet printing nozzle is installed on the three-dimensional motion platform or the mechanical arm, which can realize the light-curing forming through the movement of the three-dimensional motion platform or the mechanical arm. The frequency of the inkjet nozzle and the switch of the light source are controlled by external signals. The light-curable material uses a light-curable PEGDA solution with a concentration of 10% (w / v)-50% (w / v), and the material is delivered to the inkjet nozzle through a hose under pressure. The light intensity of the two light sources is set to 2000mw / cm 2 , the illumination angle is 45°, the inkjet nozzle adopts a micro solenoid valve, the frequency is set to 5Hz, and the movement speed is 5mm / s. It can print a line-surface structure with uniform size, and the line width is about 1mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com