Patents

Literature

77results about How to "Guaranteed temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antiwear lubricating paint for engine piston ring

The antiwear lubricating paint for engine piston ring is one kind of dry film lubricant. The paint consists of compoiste adhesive, antiseptic additive, antiwear additive, surfactant and dispersing medium. It is painted to the surface of piston and high temperature cured to form firm, compact and dense solid film with excellent antiwear resistance, high impact resistance and good sealing performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

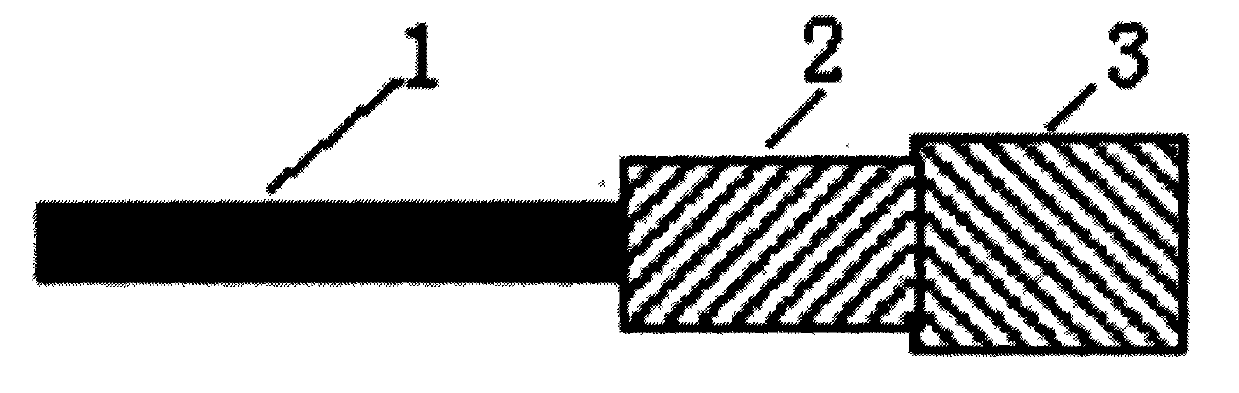

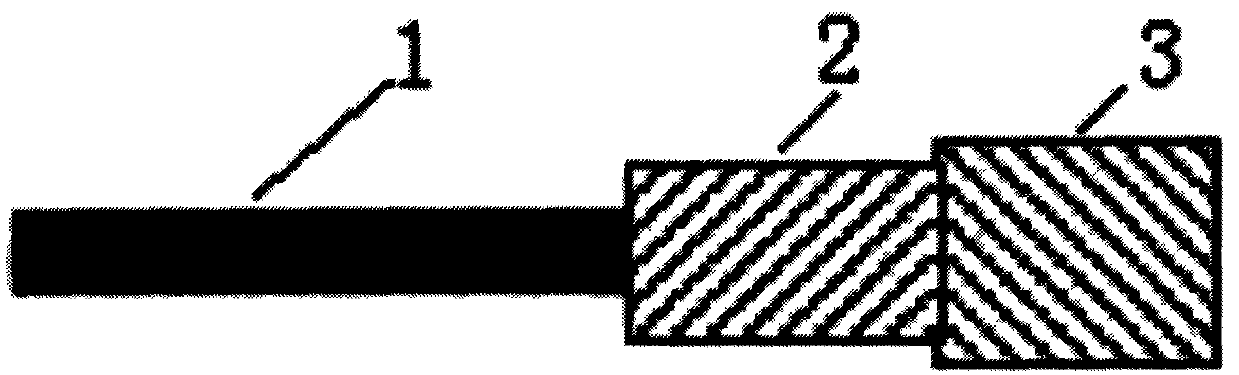

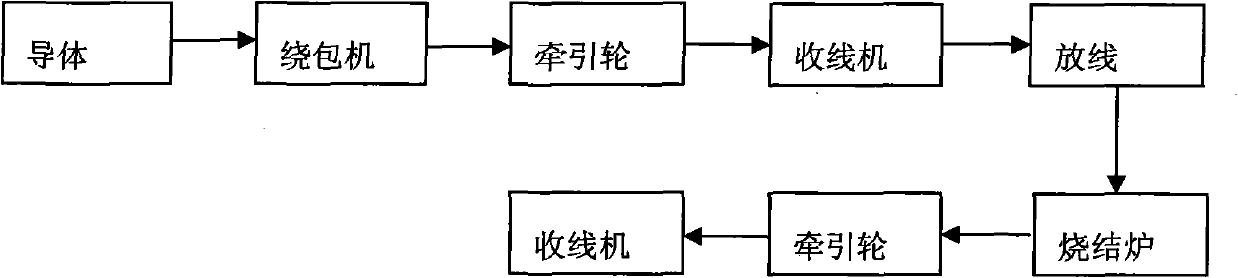

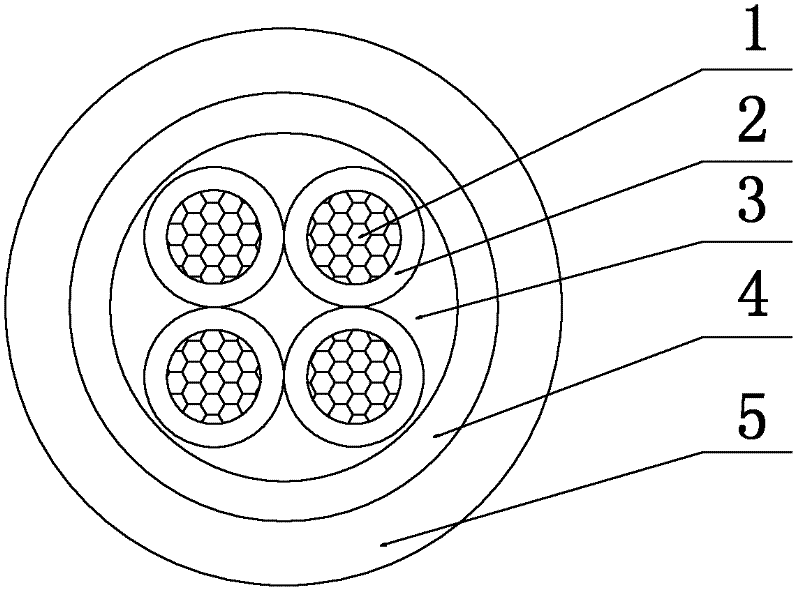

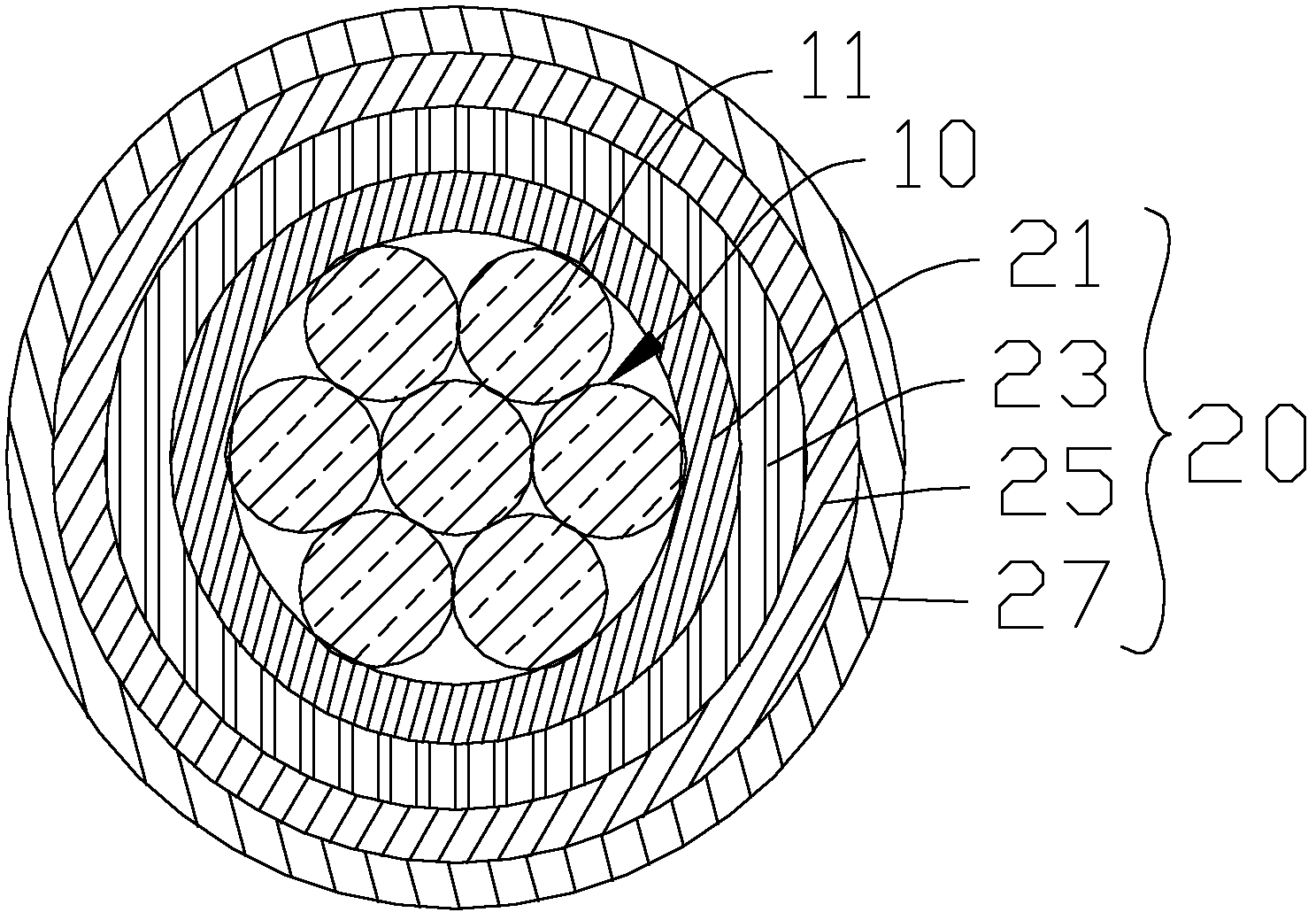

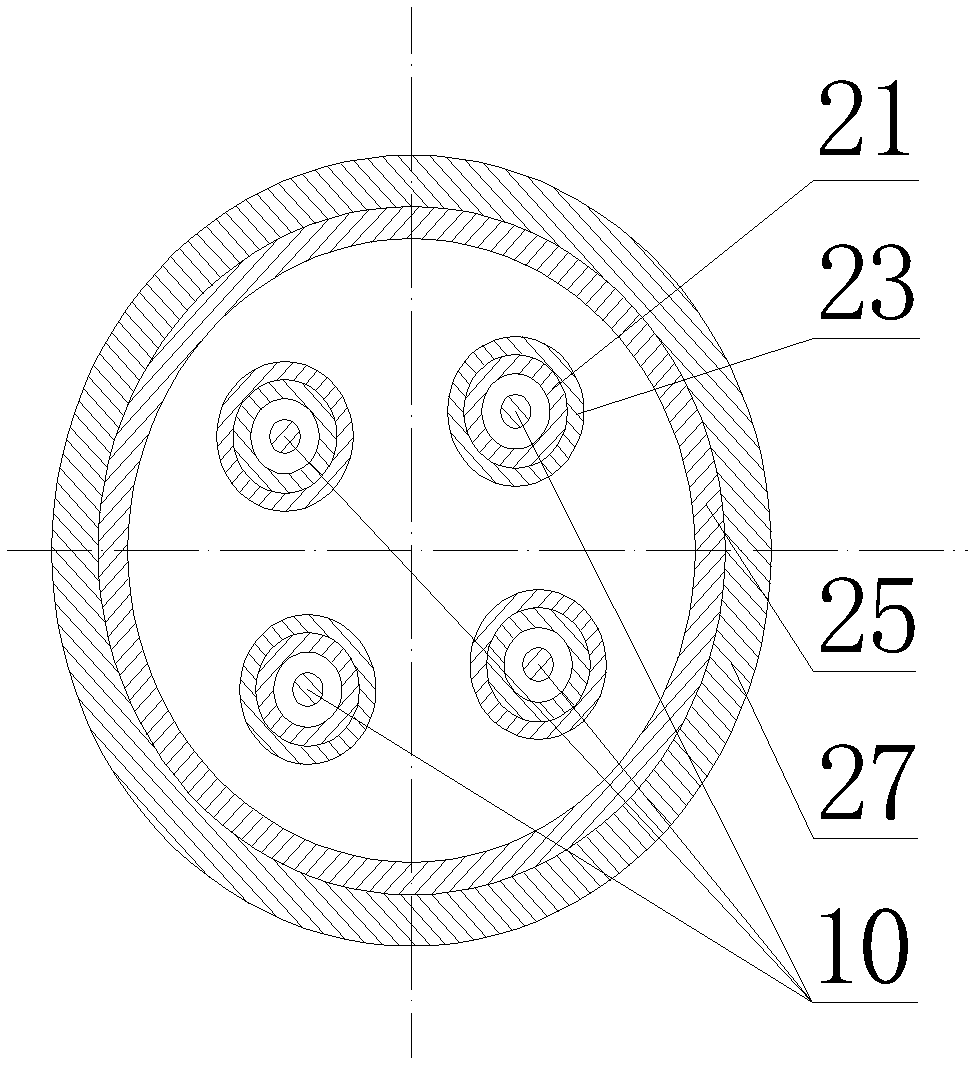

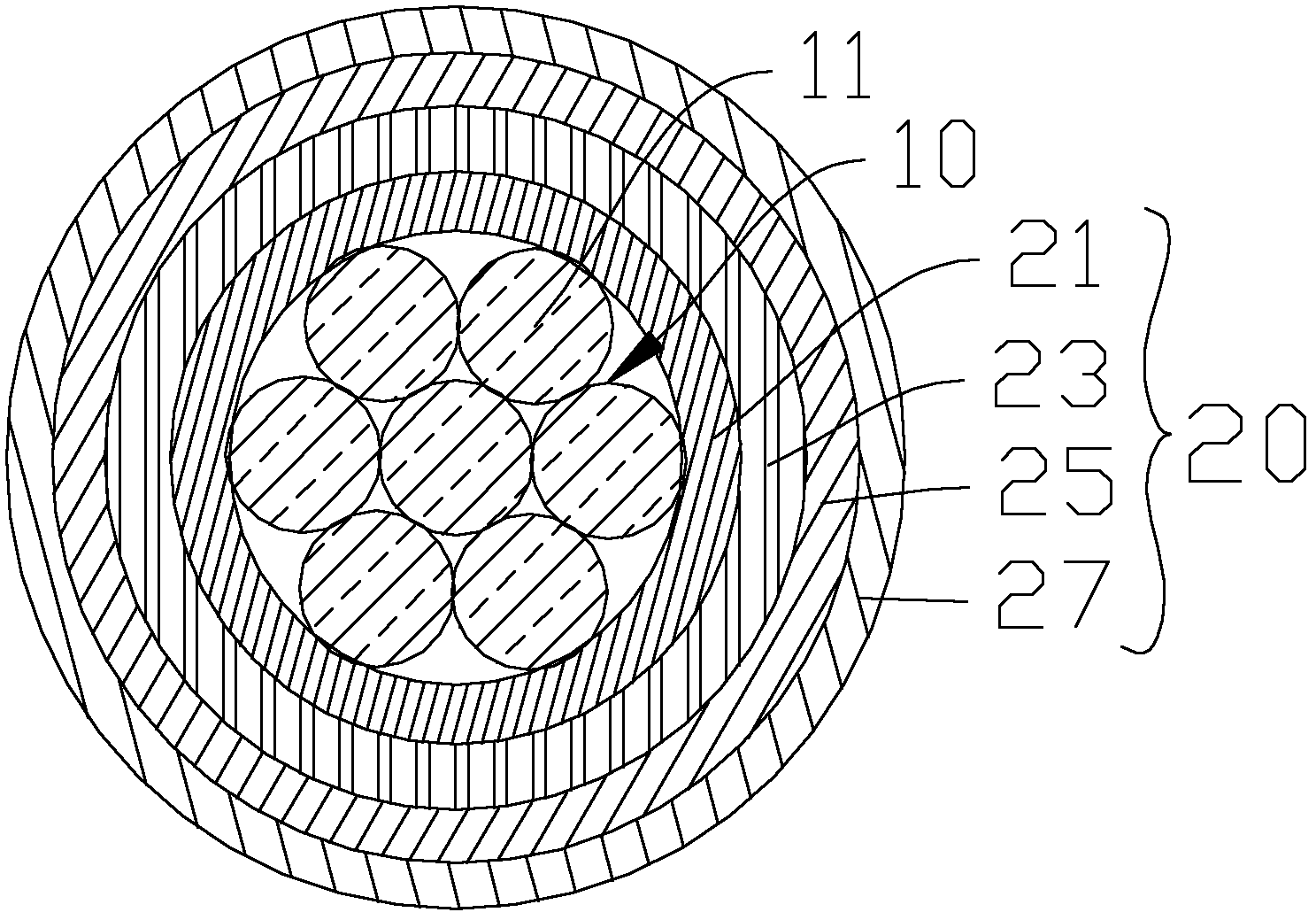

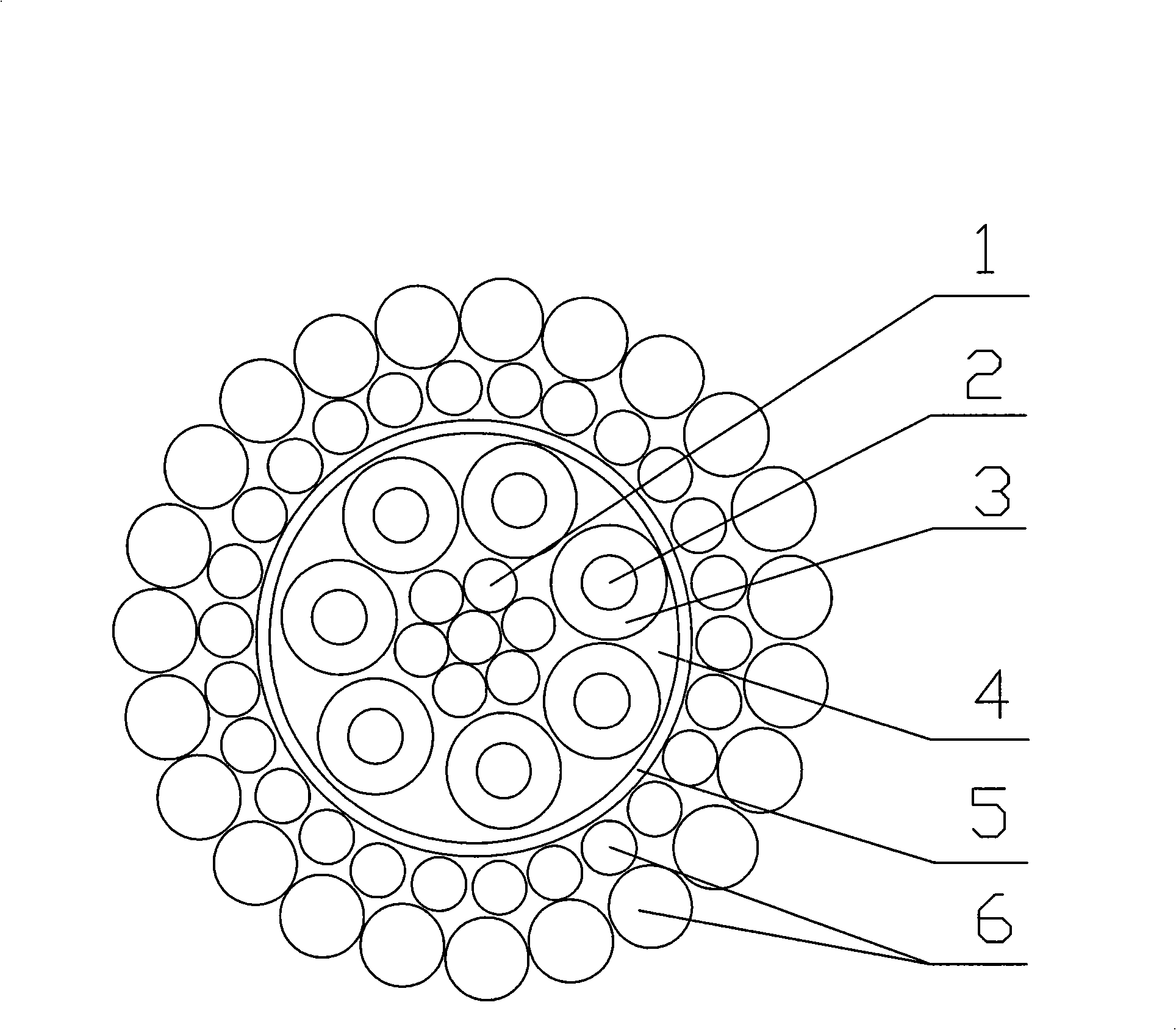

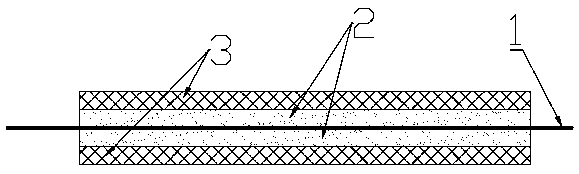

High-temperature resistant dual-layer insulating seamless lapped wire

InactiveCN101770831AGuaranteed temperature resistanceImprove job stabilityPlastic/resin/waxes insulatorsInsulated cablesCopper conductorAviation

The invention relates to the field of a wire and a cable, in particular to a high-temperature resistant thin insulating wire used for power and signal transmission in the field of aviation. The cross section of a high-temperature resistant dual-layer insulating seamless lapped wire respectively comprises a twisted copper conductor, an inner insulating layer of a lapped polyimide film and an outer insulating layer of a lapped Teflon film from inside to outside. Compared with the traditional insulating wire for aviation, the wire in the invention has the characteristics of high-temperature resistance, light weight and low cost.

Owner:SHANGHAI SPECIAL CABLE ELECTROTECHN

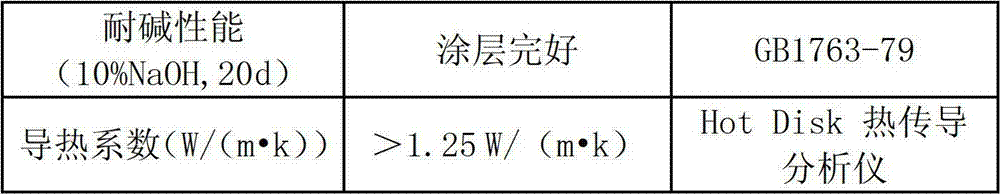

Anti-corrosion heat-conducting coating for heat exchanger and preparation method of coating

ActiveCN102964963AHigh thermal conductivityImprove heat transfer performanceAnti-corrosive paintsEpoxy resin coatingsChemistryTitanium dioxide

The invention discloses an anti-corrosion heat-conducting coating for a heat exchanger and a preparation method of the coating. The formula of the anti-corrosion heating conducting coating comprises the following raw materials by weight percent: 30%-40% of matrix resin, 40%-50% of filler, 0.5%-1% of auxiliaries and 15%-25% of diluting agent, wherein the matrix resin is a mixture of resin A and resin B, the resin A is a SH-023-7 type organic silicon modified epoxy resin product, the resin B is a 2130 type phenolic resin product, and the filler is a mixture of 40%-55% of aluminum nitride, 10%-15% of glass powder, 15%-25% of barium sulfate and 10%-15% of titanium dioxide. With the coating provided by the invention, better anti-corrosion performance and heat-conducting performance of the heat exchanger are realized; and in the filler range, the heat conductivity of the coating is maximally up to 3.912W / (m.k).

Owner:江苏四方威凯科技有限公司

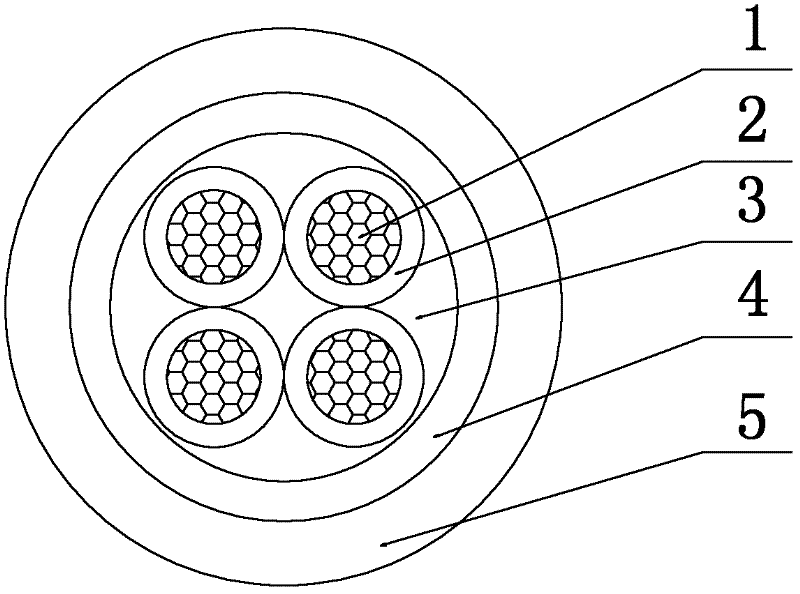

Silane halogen-free flame retardant cross-linking polyolefine cable and manufacturing method thereof

InactiveCN102509577AMeet performance requirementsGuaranteed temperature resistanceNon-insulated conductorsInsulated cablesCross-linkElectrical conductor

The invention relates to a silane halogen-free flame retardant cross-linking polyolefine cable. The cable is successively composed of a conductor, an insulating layer, a packing layer, a flame retardant oxygen barrier layer and an outer protective layer, and is characterized in that the insulating layer adopts a low-fume halogen-free flame retardant silane cross-linking polyolefine material, a halogen-free high flame retardant bag belt is wrapped outside a cable core so as to form the oxygen barrier layer, and the outer protective layer adopts a thermoplastic low-fume halogen-free flame retardant silane cross-linking polyolefine material; low-fume halogen-free flame retardant silane cross-linking polyolefine is prepared by a two-step method, namely adding a grafted silane copolymer into a catalysis master batch at the mass ratio of 95:5 and then extruding out by virtue of a common extruding machine with the phi of 90 / 25; and cross linkage is realized through any of the following methods: a, immerging in hot water at 90-90DEG C, and performing cross linkage for 2-4 hours; and b, exposing to low pressure steam humidity at 0.15bar, and performing cross linkage for 3-5 hours. The cable provided by the invention has the advantages of greatly improving the insulating property, and meeting the requirements of an environmentally-friendly cable.

Owner:南洋电缆集团有限公司

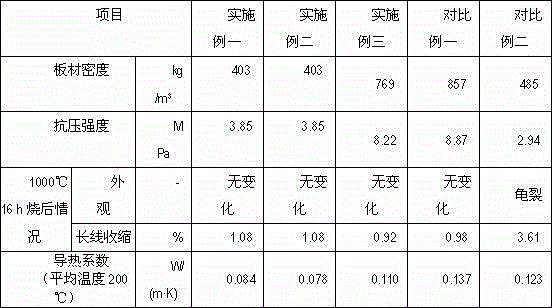

Method for manufacturing high-strength and energy-saving xonotlite heat-insulation product

InactiveCN103951363AHigh strengthLow densityWater-setting substance layered productHigh densityVolumetric Mass Density

The invention discloses a method for manufacturing a high-strength and energy-saving xonotlite heat-insulation product. On the basis of a high-density plate production process based on a static method, xonotlite slurry synthesized by using a dynamic hydrothermal method is added to reduce the density of a plate so as to obtain the high-strength and energy-saving xonotlite heat-insulation product with moderate density and relatively high strength. Meanwhile, a layer of aluminum foil is coated to ensure that the product has water resistance, the heat insulation effect of materials is enhanced, and the condition of the product is optimized.

Owner:莱州明发隔热材料有限公司

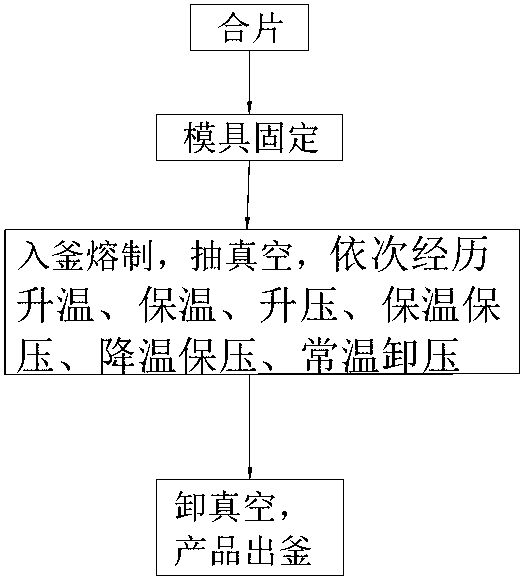

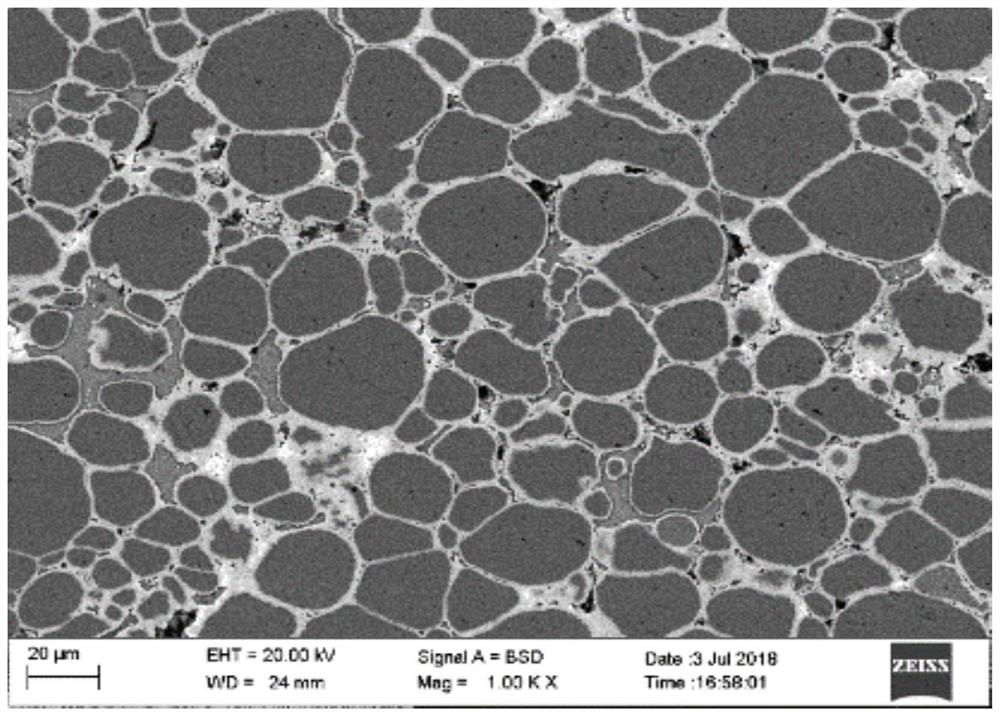

Polypropylene foam material with gradient pore structure and preparation method thereof

InactiveCN108164814AGuaranteed temperature resistanceGuaranteed mechanical propertiesPolymer sciencePolypropylene

The invention discloses a polypropylene foam material with a gradient pore structure and a preparation method thereof, belongs to the technical field of foam materials, and solves the problem to provide a preparation method of a foam material, which has the advantages of being simple in process, low in equipment requirement, and capable of realizing gradient change of foam pores in the foam material. According to the preparation method, polypropylenes with different melt strengths and a nucleating agent are firstly mixed; polypropylene resin particles having multi-layer distribution can be obtained by multi-layer co-extruding, drawing and pelletizing, or polypropylene resin particles having various components can be obtained by extrusion by an extruder, drawing and pelletizing, and a multi-layered polypropylene resin sheet can be obtained by mould pressing into sheets and superimposing and melting-molding; and finally the multi-layered particles or the multi-layered sheet are foamed toobtain the polypropylene foam material with the gradient pore structure. The polypropylene foam material has the characteristics of gradual change of the foam pore structure, the functionalization ofthe polypropylene foam material can be effectively achieved, the cost is reduced, and application methods of the material in the automotive, food, medical and other fields can be broadened.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

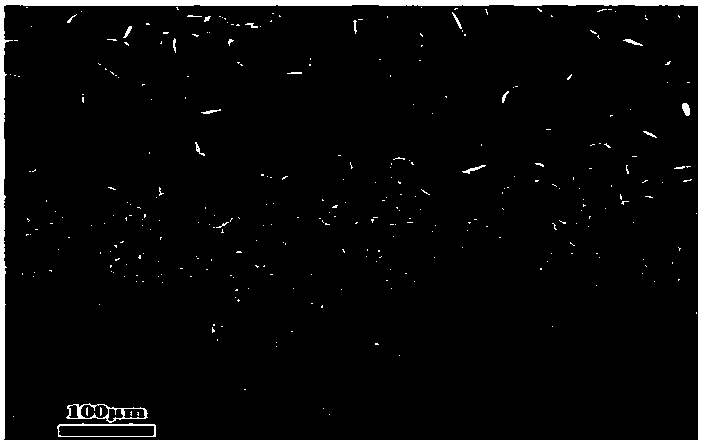

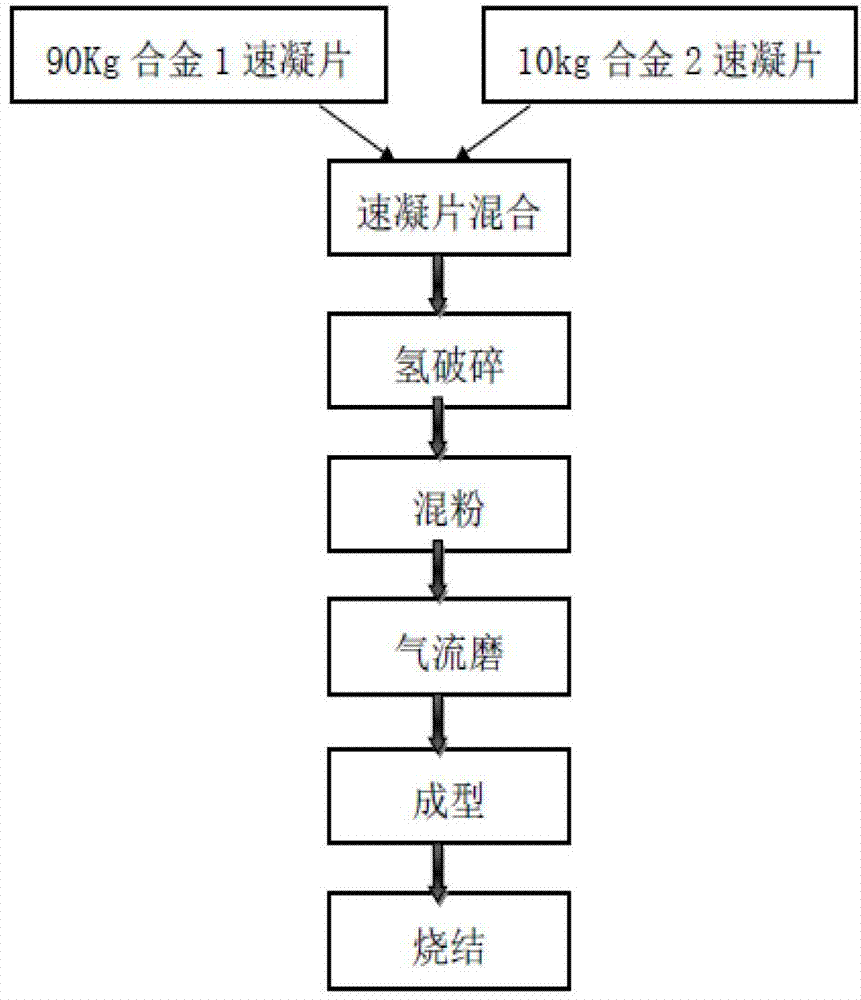

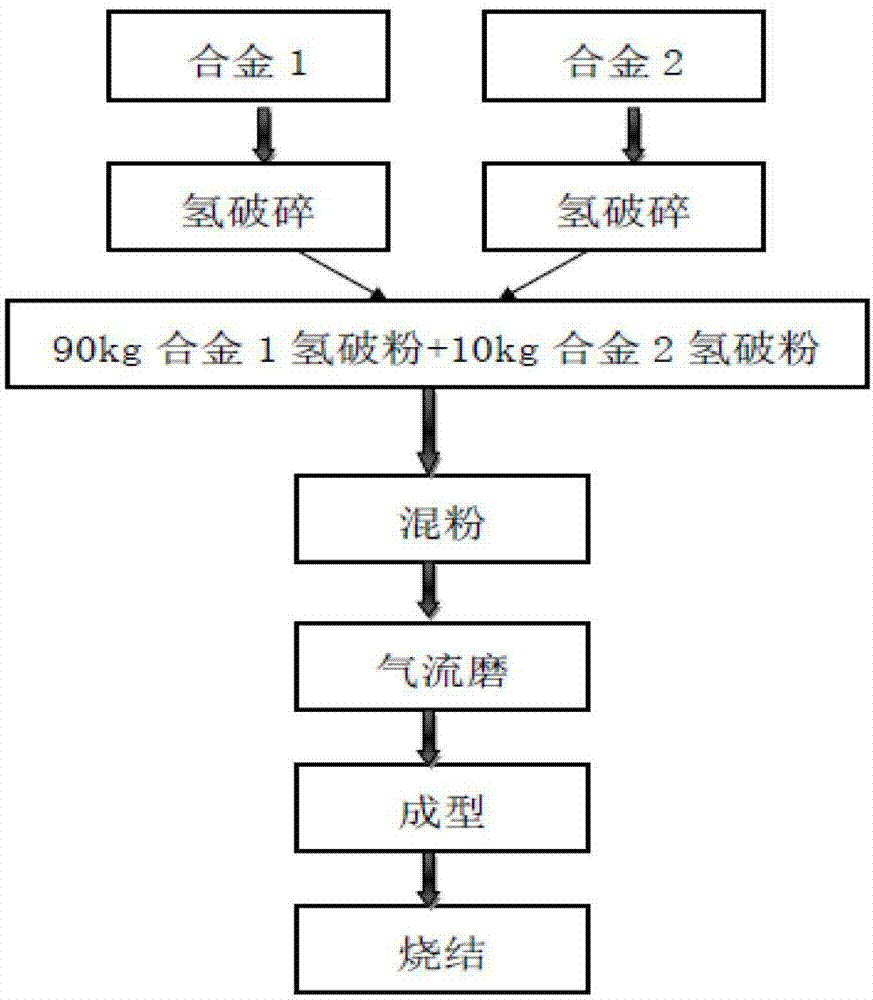

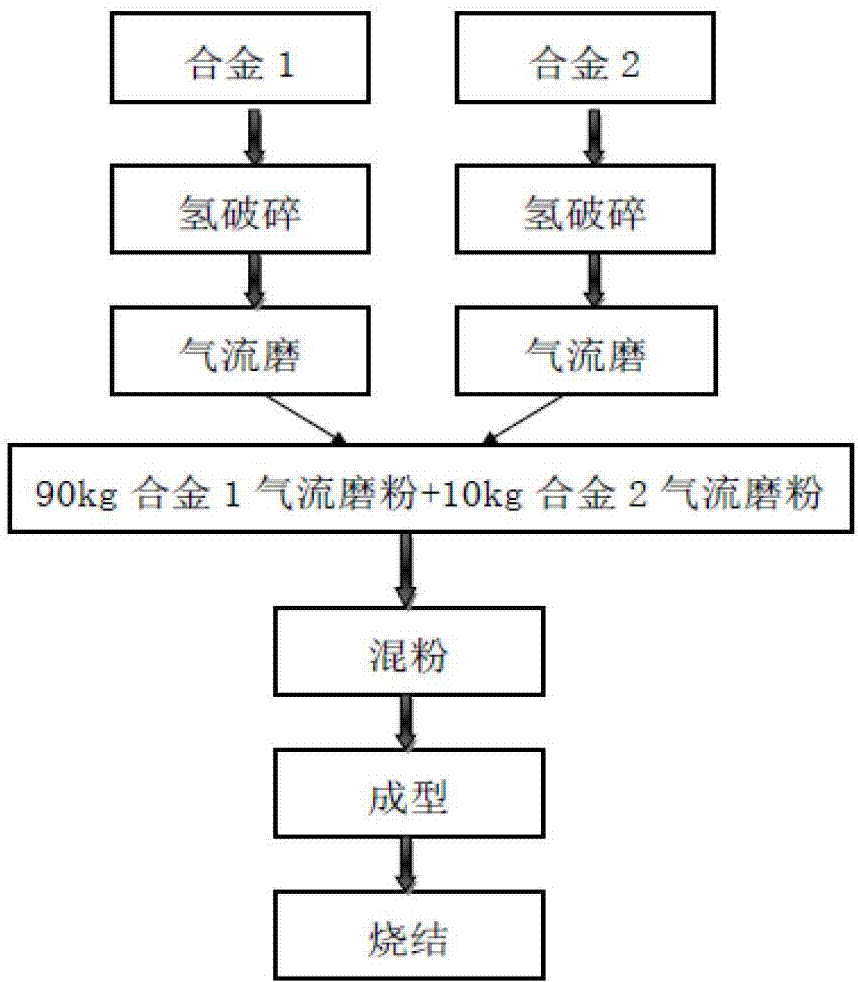

Powder for sintering rare-earth permanent magnet

ActiveCN103093911AEasy to wrapInhibition of grain growthPermanent magnetsInorganic material magnetismAdditive ingredientMetallurgy

The invention relates to powder for preparing and sintering a rare-earth permanent magnet. The powder is obtained by mixing two kinds of powder with different ingredients, different average particle sizes and different melting points. By that the powder is used for preparing and sintering the rare-earth permanent magnet, the temperature endurance of the magnet can be improved, production cost is reduced, and heavy rare earth resources are saved.

Owner:ORIENT MAGNET TECH OMT

Epoxy-modified sulfonic waterborne polyurethane emulsion and preparing method and application thereof

InactiveCN105131243AImprove hydrolysis resistanceImprove performancePolyurea/polyurethane coatingsEpoxyPolyurethane adhesive

The invention discloses an epoxy-modified sulfonic waterborne polyurethane emulsion and a preparing method and application thereof. The sulfonic waterborne polyurethane emulsion is prepared from, by weight, 70-80 parts of polyhydric alcohol, 10-15 parts of diisocyanate, 1-2 parts of small molecular alcohol chain extender, 0.01-0.05 part of organobismuth and / or organotin catalyst, 2.5-3.5 parts of hydrophilic chain extender and 5-15 parts of epoxy resin. The formula is simple, blending stability is high, the hydrolysis resistance of a waterborne polyurethane adhesive is improved, and the epoxy-modified sulfonic waterborne polyurethane emulsion can be used for preparing 3D furniture paint-free blister adhesives and has the advantages of low use temperature, high adhesion strength, high temperature resistance and the like.

Owner:重庆中科力泰高分子材料有限公司

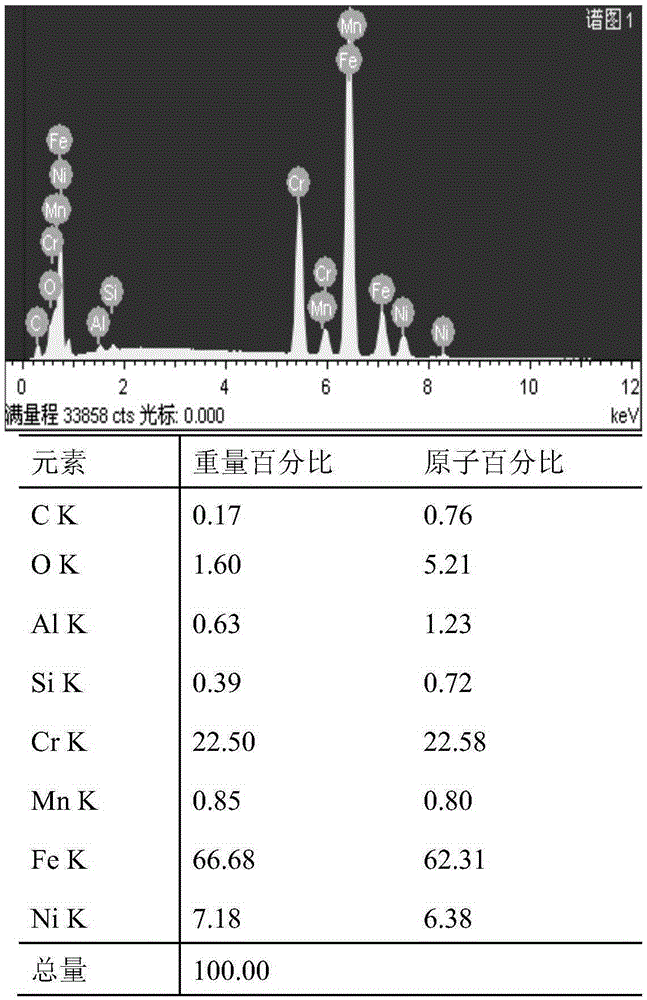

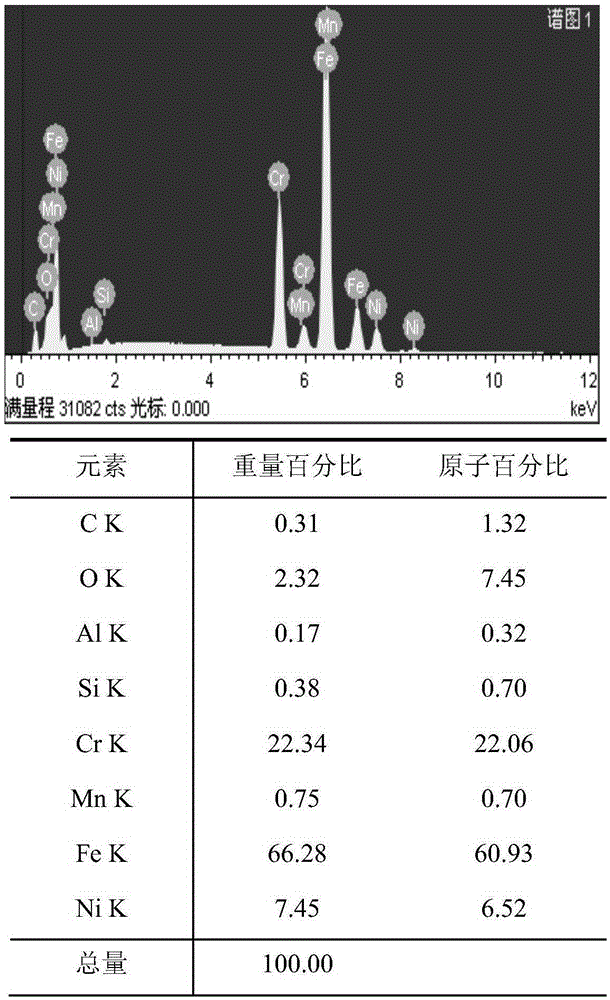

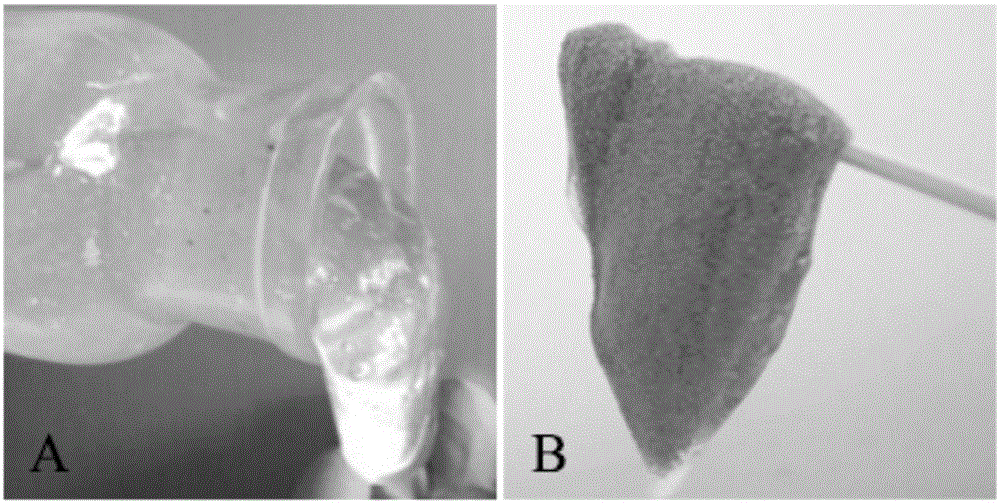

Solid phase micro-extraction fiber, and preparation method and use thereof

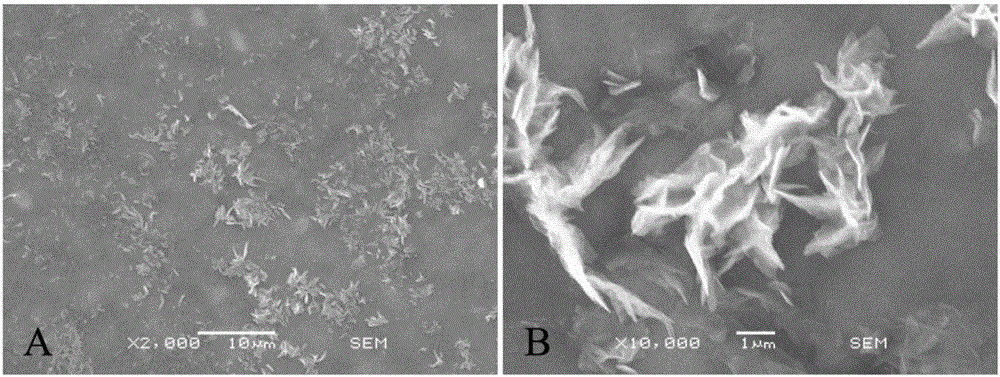

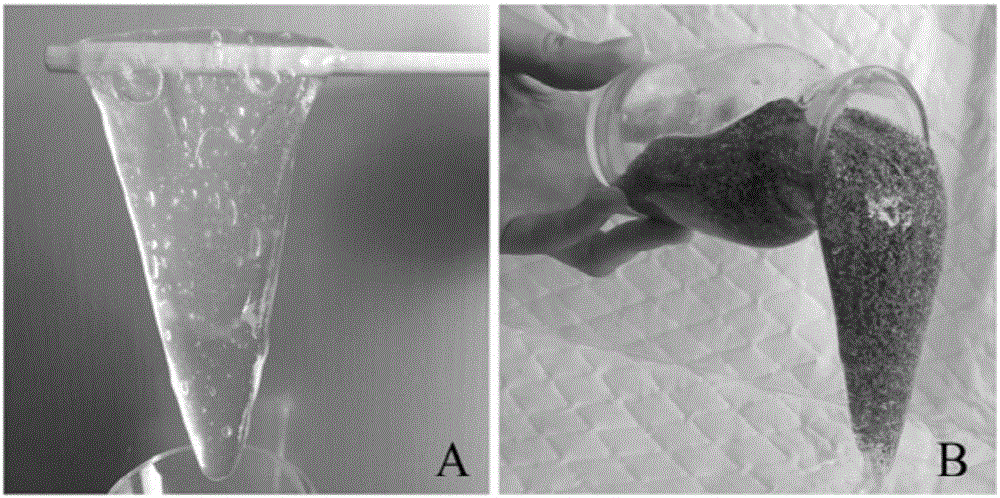

ActiveCN105268414AHigh porosityEasy extractionOther chemical processesSolid sorbent liquid separationFiberOrganic solvent

The invention discloses a solid phase micro-extraction fiber. The solid phase micro-extraction fiber comprises a stainless steel wire and a coating, and the oxygen atom percentage of elements on the surface of the stainless steel wire is not smaller than 30%. The invention also provides a preparation method of the solid phase micro-extraction fiber, and an application of the solid phase micro-extraction fiber in manufacturing of solid phase micro-extraction products. The solid phase micro-extraction fiber has the advantages of firm combination between the coating and the stainless steel wire, difficult shedding, long service life, good temperature resistance, good organic solvent resistance, good acid and alkali resistance, and also combines the respective advantages of solid phase micro-extraction fibers with fused quartz as a matrix material and solid phase micro-extraction fibers with stainless steel wires as a matrix material;, the solid phase micro-extraction fiber has better extraction performance and higher detection sensitivity than commercial extract fibers; and the fiber prepared in the invention has good reappearance and repeatability, and is very suitable for industrial practical application.

Owner:段忆翔 +1

Low-damage and ultralow-concentration guar gum fracturing fluid system, preparation method and application of guar gum fracturing fluid system

ActiveCN106085404AReduce concentrationReduced shear resistanceDrilling compositionCarrying capacityHeat resistance

The invention discloses a low-damage and ultralow-concentration guar gum fracturing fluid system, a preparation method and an application of the guar gum fracturing fluid system and belongs to the technical field of reservoir reforming for oil-gas field development. In order to solve the problems that the existing conventional fracturing fluid systems hardly give attention to the lowering of concentration of a thickener, the prolonging of crosslinking time, the improving of gel strength and gelout capability and being environmentally friendly, a SITAR-11 powerful delayed crosslinker is selected, so that formed gel is endowed with a relatively high delayed crosslinking effect while heat resistance, shearing resistance and solid carrying capacity for the formed gel are guaranteed, and the concentration of the thickener is greatly lowered; and on one hand, the reduction of cost and the increase of economic benefit are facilitated, and on the other hand, the amount of gelout residues is reduced after the concentration of the thickener is lowered. Further, FANTA-05 and FANTA-06fracturing gelout enzymes, which are thorough in gelout and controllable in gelout time, and a ZITHE-34 efficient discharge aiding agent are added in a matched manner, so that the fracturing fluid system, which has a delayed crosslinking effect, is high in heat resistance and salt tolerance, excellent in solid carrying behavior, controllable in gelout time and thorough in gelout and is green, environmentally friendly and efficient, can be formed.

Owner:CHINA PETROLEUM & CHEM CORP +1

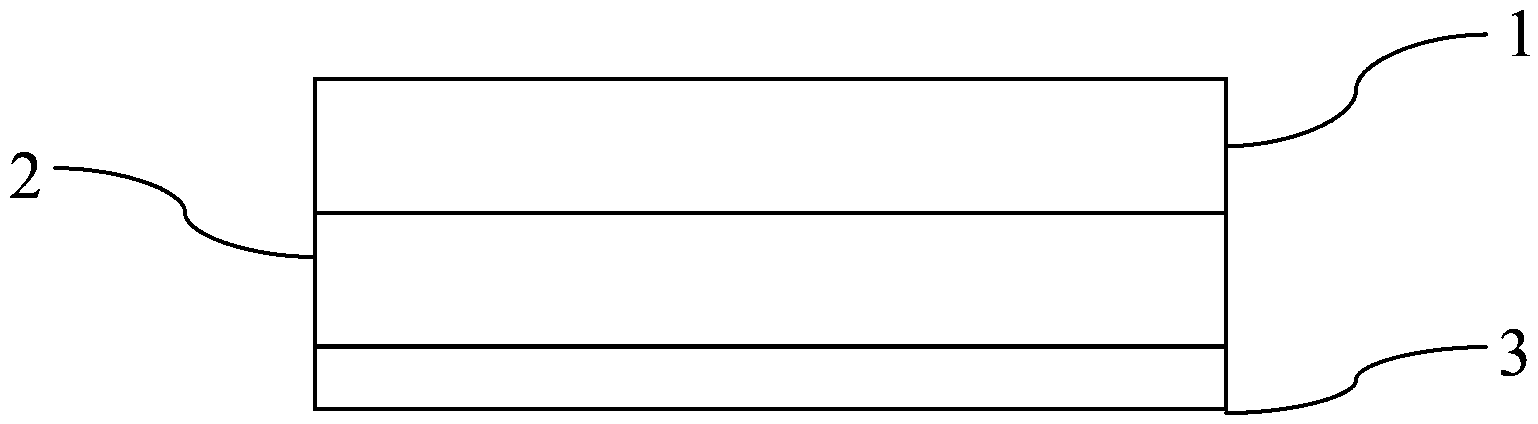

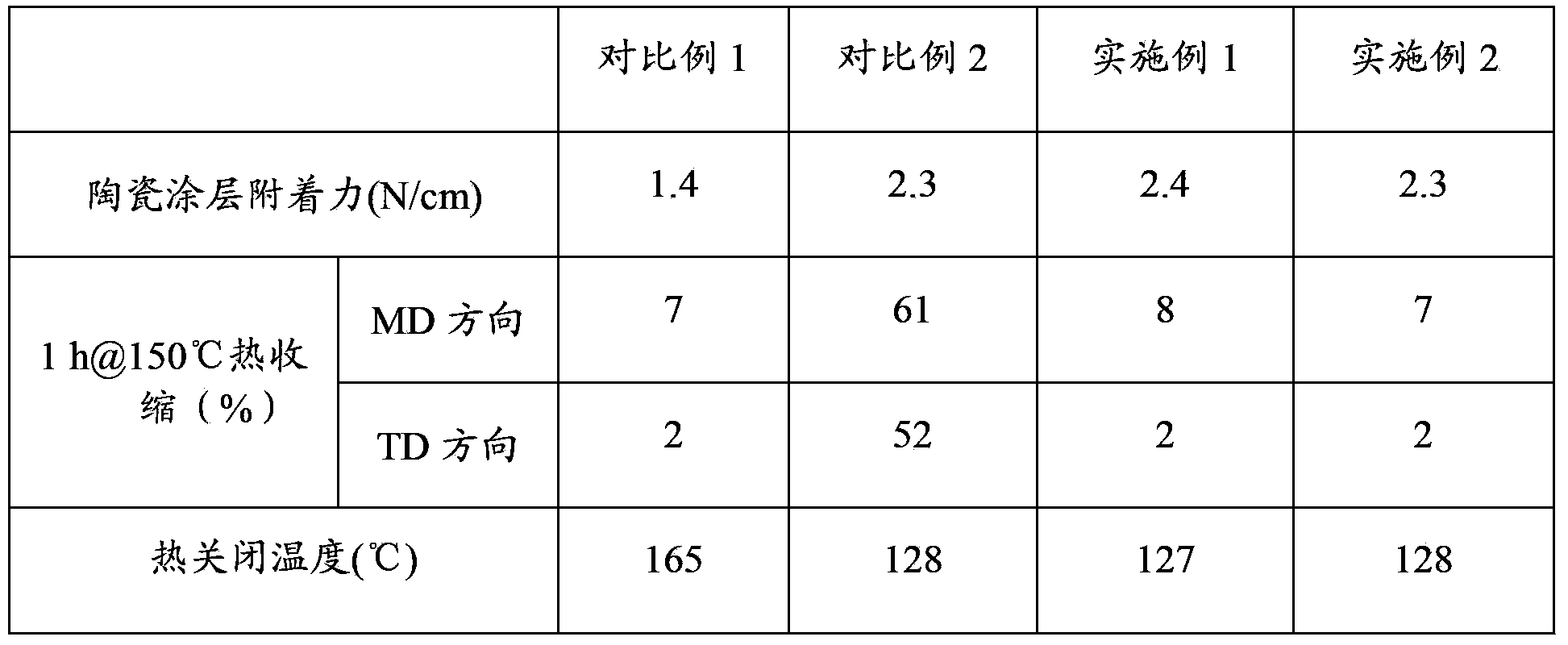

Three-layer membrane for lithium ion battery

InactiveCN103354279AGuaranteed Peel StrengthGuaranteed stabilityCell component detailsCeramic coatingHeat resistance

The application discloses a three-layer membrane for a lithium ion battery. The membrane is composed of 3 composite layers, wherein a second composite layer is interlaid between a first composite layer and a third composite layer; the first composite layer comprises at least a heat-resistance layer with a porous structure; the second composite layer comprises at least a closed layer with a porous structure; the third composite layer comprises at least a ceramic layer with a porous structure. According to the membrane, the ceramic layer is in direct contact with the closed layer with a good surface coating property, thereby ensuring the peel strength and stability of the membrane. The heat-resistance layer can be used for guaranteeing the temperature resistance and mechanical strength of the membrane. Compared with a single-layer PP microporous membrane and a composite membrane with a ceramic coating, the three-layer membrane has the advantage that the high stability and the high tearing strength are guaranteed as the coating is unlikely to fall off. Compared with a single-layer PE microporous membrane and a composite membrane with a ceramic coating, the three-layer membrane has the advantage of better high temperature resistance.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

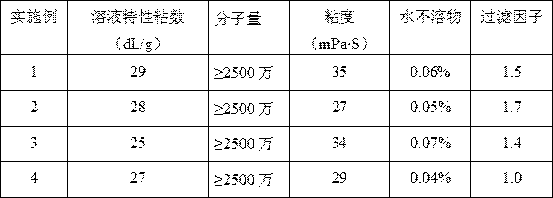

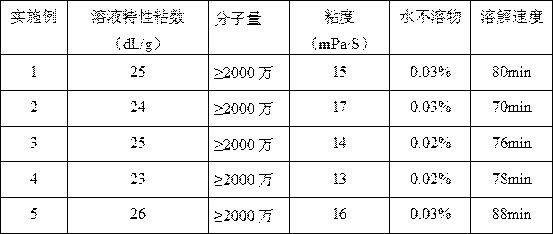

Novel heat-resistant salt-resistant polyacrylamide and synthesis method thereof

The invention provides novel heat-resistant salt-resistant polyacrylamide and a synthesis method thereof. Polyacrylamide structurally includes sulfonic acid radicals and pyrrolidone radicals, the salt-resistant performance of heat-resistant salt-resistant polyacrylamide reaches 20,000 degrees of mineralization, the total number of calcium and magnesium ions reaches 504 mg / L, and the temperature reaches 85 DEG C. The synthesis method includes the following steps of firstly, in a redox and azo compounding trigger system, refined acrylamide monomers (AM), functional monomers AMPS and vinylpyrrolidone react under the trigger temperature of -2-0 DEG C to obtain glue; secondly, pelleting, hydrolysis, drying, smashing and sieving are carried out. Under the ultralow temperature, the redox and azocompounding trigger system is adopted for polymerization, sulfonic acid radical strong water groups and pyrrolidone radicals are introduced into polyacrylamide, a self-made mixed stabilizer is added during hydrolysis, and not only is the salt-resistant capability of polyacrylamide improved, but also ultra-high molecular weight shear degradation and heat-resistant performance are ensured.

Owner:TIANJIN BO HONG CHEM +1

Auxiliary for reducing VOC (Volatile Organic Compound) of coating of transfer coating and preparation method thereof

ActiveCN104371410AMaintain printabilityMaintain peelabilityCellulose coatingsPolyester coatingsPolyesterResource saving

The invention relates to an auxiliary for reducing a VOC (Volatile Organic Compound) of a coating of a transfer coating and a preparation method thereof and belongs to the technical field of transfer coating auxiliaries. The auxiliary for reducing the VOC of the coating of the transfer coating comprises the following components in percentage by weight: 30-80% of a cosolvent and 20-70% of mixed polyesters. The auxiliary for reducing the VOC of the coating of the transfer coating provided by the invention can be used for maintaining the original performances of a transfer coating base material such as printability, strippability, solvent resistance, temperature tolerance, rub resistance and the like; the adjustment on the volatile speed of the whole solvent system of the coating can be assisted and the VOC content of the coating is effectively reduced; the use method of the auxiliary is convenient and is easy to operate, and auxiliary can be added either in a paint mixing stage or in coating synthesis and preparation; the auxiliary is easy to coat, rapid to dry and resource-saving, and energy resource waste caused by increasing the temperature to reduce the VOC content of the coating can be avoided.

Owner:YANTAI BOYUAN TECH MATERIALS

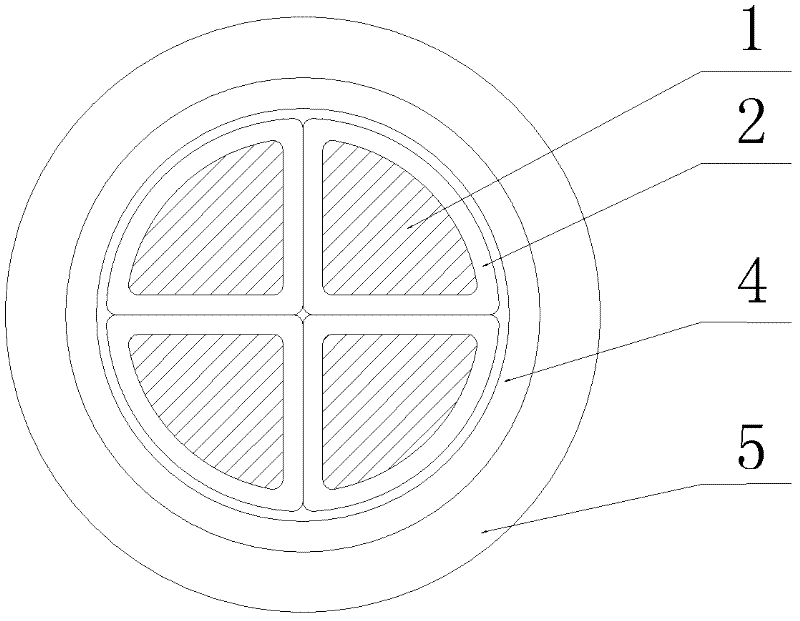

Cladding layer of lead and lead provided with same

InactiveCN102592725AGuaranteed temperature resistanceRealize no agingInsulated cablesInsulated conductorsFiberGlass fiber

The invention relates to a cladding layer of a lead, and a lead provided with the same. The cladding layer is clad on the circumference of a lead core of the lead, and comprises a first insulating layer wound on a conductor core, a second insulating layer wrapped on the first insulating layer, a shielding layer wrapped on the second insulating layer and a protective layer wrapped on the circumference of the shielding layer; the first insulating layer adopts a banded structure formed by mica; the second insulating layer is formed by weaving glass fibers; the shielding layer is formed by weaving nickel wires; and the protective layer is formed by weaving glass fibers. In the lead, the cladding layer is composed of the first insulating layer, the second insulating layer, the shielding layer and the protective layer, the first insulating layer is wound with a mica tape, the second insulating layer adopts the reticular glass fiber, the shielding layer adopts the netted nickel wires, and the protective layer adopts the reticular glass fiber, so that the temperature tolerance of the lead is effectively ensured, and the purpose of non-aging of the lead used in the high-temperature environment is further achieved.

Owner:CHINA HANGFA SOUTH IND CO LTD

High-temperature cable for high-strength bearing detection

InactiveCN101299353AThere will be no scrappingGuaranteed temperature resistancePlastic/resin/waxes insulatorsInsulated cablesWell loggingEngineering

A high strength bearing detection high temperature cable, belongs to the cable technical field, characterized by being provided with a 1+6 stranding reinforce steel core, a double layer reverse outward armour steel wire and a plurality of insulated cores evenly and closely wound aroud the 1+6 stranding reinforce steel core to compose the cable core. Stuffed inorganic ropes are provided in the cable core, and a special macromolecule material sheath is coated on the cable core; the double layer reverse outward armour steel wire is wrapped at the cirumferential of the sheath; the surface of the steel wire armour is coated with a layer of soft mask rust preventive oil. The invention ahs reasonable and simple structure, easy manufacture, good utilization qualities, strong cable bearing ability, good corrosion-resisting properties, safety and long service life. The cable is the ideal cable in the well logging, the perforation, the river, the gulf, the irrigation works and the exploration and the like.

Owner:BAOSHENG SCI & TECH INNOVATION

Instant polyacrylamide for offshore oil displacing and synthesis method thereof

InactiveCN109134752AHigh molecular weightImprove salt resistanceDrilling compositionFunctional monomerSynthesis methods

The invention provides instant polyacrylamide for offshore oil displacing, which comprises a sulfonic acid group, the salt resistance of the instant polyacrylamide for offshore oil displacing reaches326.3 million mineralization degrees, the total amount of calcium and magnesium ions reaches 885 mg / L, and temperature is 85 DEG C. The method comprises the following steps: 1, in a redox and azo compound initiation system, a refined acrylamide monomer AM and a functional monomer AMPS react at an initiation temperature of 2 DEG C to obtain colloid; 2, granulating, hydrolyzing, drying, crushing andsieving are carried out. According to the invention, the redox and azo compound initiation system are used for polymerization under the ultra-low temperature, a sulfonic acid group strong water groupis introduced into the polyacrylamide, and self-made mixed stabilizer is added at the same time of hydrolysis, so that the salt resistance of the polyacrylamide is improved, the ultrahigh molecular weight shear degradation and temperature resistance are ensured, the dissolving speed is improved, and the dissolving performance is improved.

Owner:TIANJIN BO HONG CHEM +1

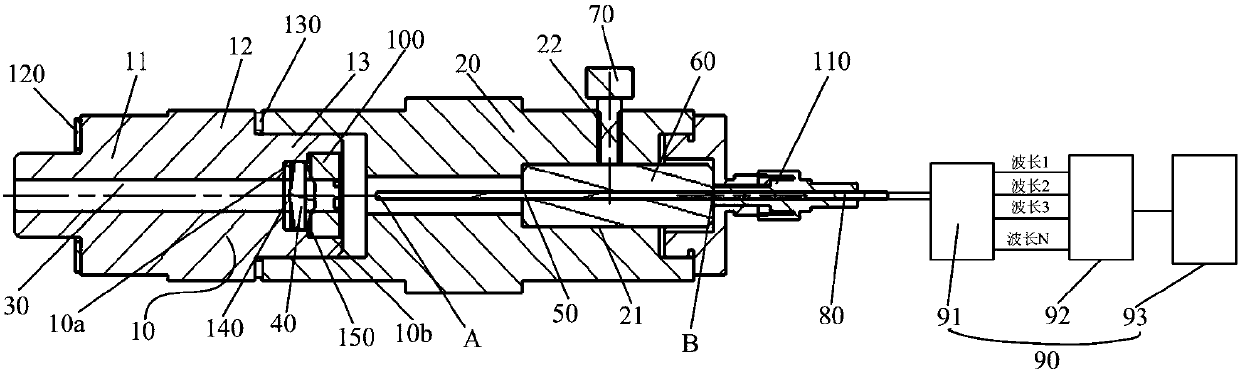

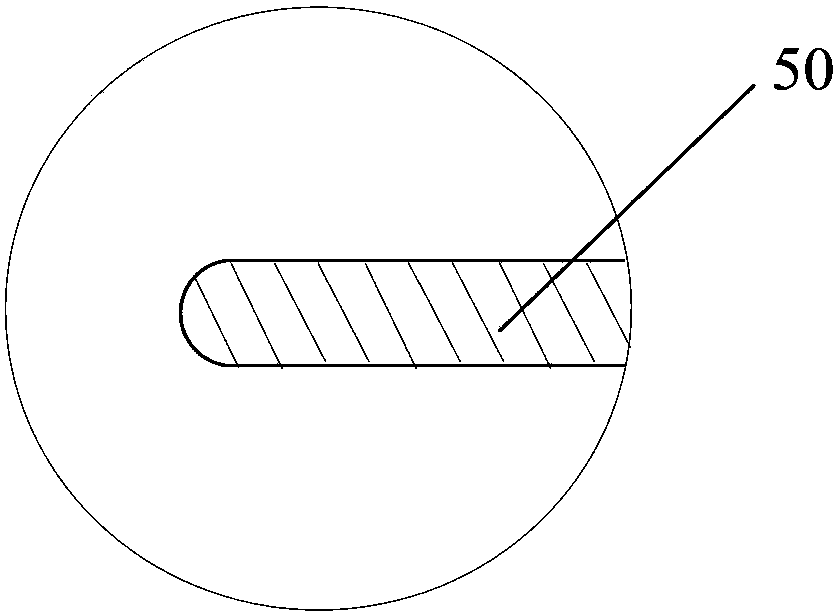

Temperature sensing device

InactiveCN109827675ARaise the upper limit of temperature measurementImprove coupling efficiencyThermometers using physical/chemical changesOptical radiationBlackbody cavity

The invention provides a temperature sensing device. The temperature sensing device comprises a sensing head base, a sensing head body part, a simulated blackbody cavity, a high-temperature optical system, a high-temperature-resistant optical fiber, an optical fiber fixing structure, a fixing jackscrew, a light transmission optical fiber and a signal processing system. The simulated blackbody cavity is arranged in the sensing head base; the high-temperature optical system is used for collecting an optical radiation signal emitted by the simulated blackbody cavity; the high-temperature-resistant optical fiber is used for receiving the optical radiation signal collected by the high-temperature optical system; the optical fiber fixing structure is used for fixing the high-temperature-resistant optical fiber; the fixing jackscrew is used for limiting movement of the optical fiber fixing structure in the axial direction of the sensing head body part; the light transmission optical fiber isconnected with the high-temperature-resistant optical fiber; and the signal processing system is used for converting the optical radiation signal outputted by the light transmission optical fiber intothe temperature of an object to be measured. According to the technical scheme, the technical problems that in the prior art, the temperature measuring range of a temperature sensing device is limited, and dynamic response, interference shielding, service life and severe environment adaptability are poor are solved.

Owner:BEIJING ZHENXING METROLOGY & TEST INST

Preparation method of high-weather-resistance fluorescent coloring particles

ActiveCN107163929AGuaranteed temperature resistanceGuaranteed solvent resistanceLuminescent compositionsWeather resistancePolymer science

The invention relates to a preparation method of fluorescent coloring particles, and aims to provide high-weather-resistance fluorescent coloring particles and a preparation method thereof. Compared with domestic and foreign products prepared by the prior art, the fluorescent coloring particles prepared by the method have high weather resistance, and can be taken as fluorescent pigments to be applied to the fields of plastics, plastic cement, coatings, ink and the like. According to the technical scheme, the preparation method of the high-weather-resistance fluorescent coloring particles comprises the following steps in sequence: (1) preparing high-weather-resistance nanoscale polyacrylic resin particles; (2) preparing a fluorescent coloring particle carrier resin prepolymer; (3) coloring and emulsifying the carrier resin; (4) curing fluorescent coloring resin particles.

Owner:ZHEJIANG JCOLOR TECH CO LTD

Thermal recovery compensation sealed pipe column

InactiveCN104295278AImprove wear resistanceGuaranteed temperature and corrosion resistanceFluid removalTemperature resistanceAustenitic stainless steel

Owner:CHINA PETROLEUM & CHEM CORP +1

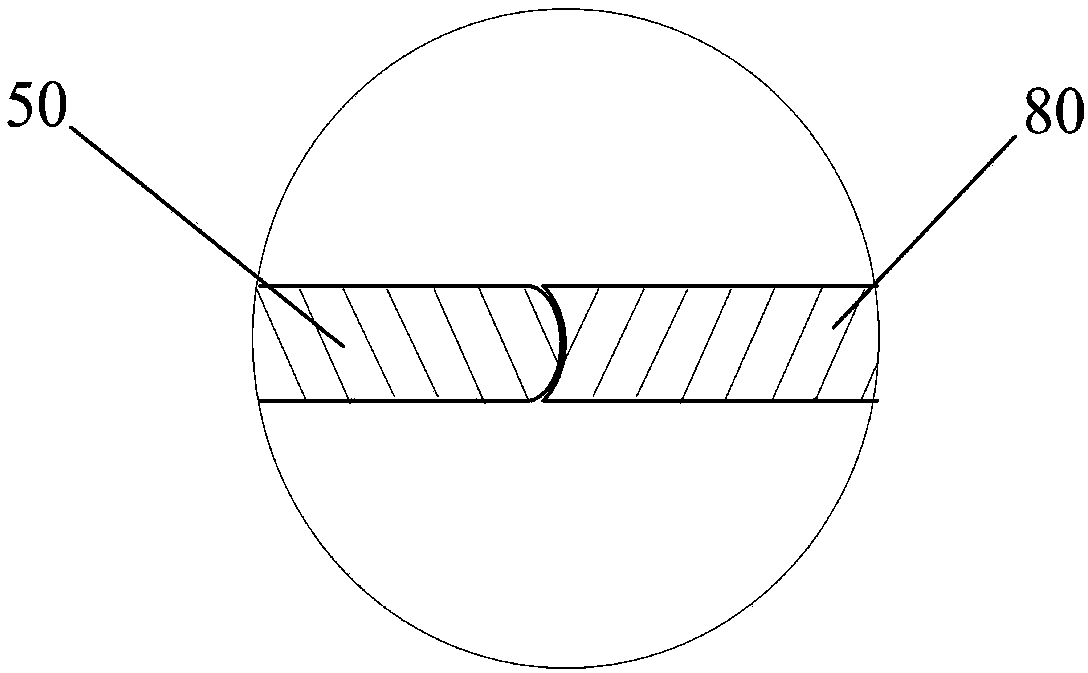

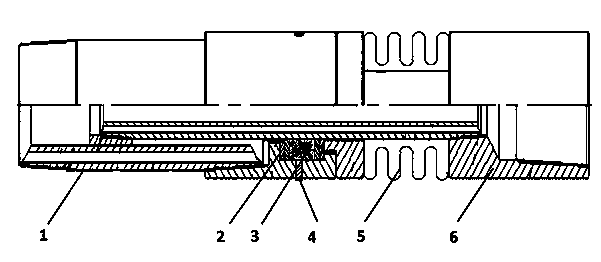

Laminated electromagnetic shielding glass utilizing TPU or SGP film and production technology thereof

InactiveCN109334137AImprove performanceImprove performance parametersSynthetic resin layered productsGlass/slag layered productsElectromagnetic shieldingEngineering

The invention discloses laminated electromagnetic shielding glass utilizing a TPU or SGP film and a production technology thereof, and relates to the technical field of shielding devices. The laminated electromagnetic shielding glass utilizing the TPU or SGP film comprises a shielding wire net and base materials which are clamped at two sides of the shielding wire net, wherein the base materials are connected to the shielding wire net through the film; and the film is the TPU or SGP film. The laminated electromagnetic shielding glass utilizing the TPU or SGP film has the advantages of being high in qualification rate, high in temperature resistance and high in impact resistance.

Owner:QINHUANGDAO BODUN ELECTRONICS

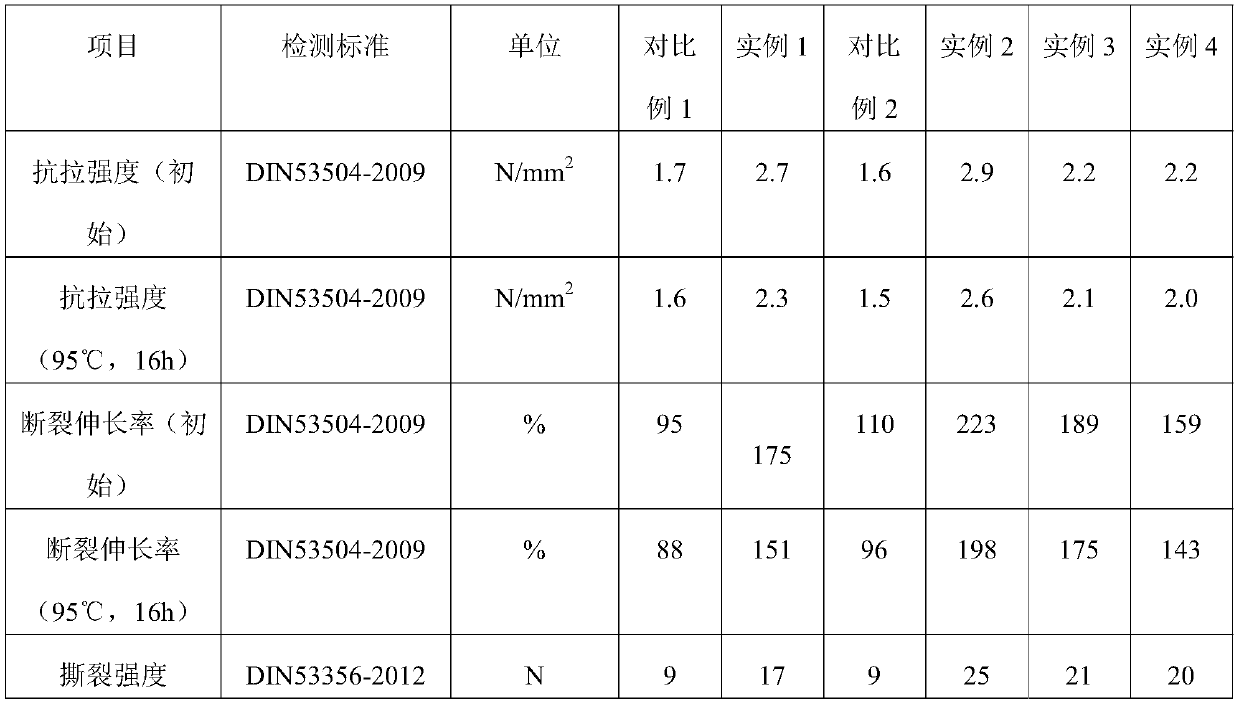

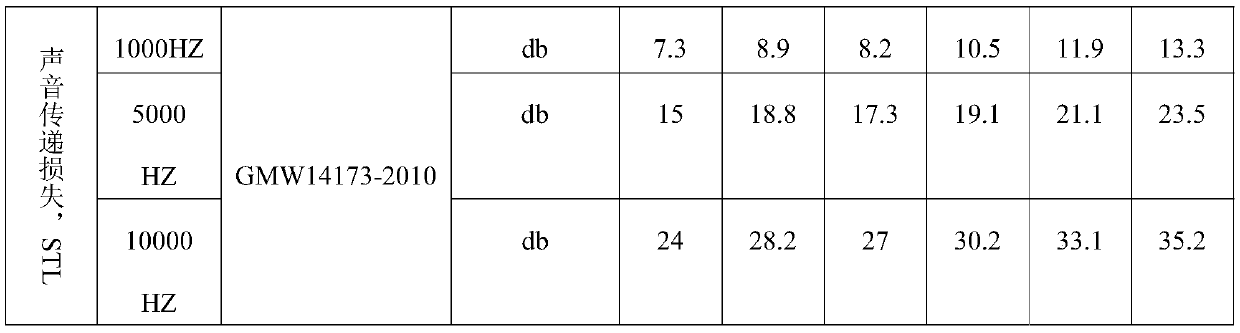

Automobile sound insulation pad skin and preparation thereof

The invention relates to an automobile sound insulation pad skin and preparation thereof. The automobile sound insulation pad skin comprises the following components by weight: 10-30 parts of a firstcomponent, 0-20 parts of a polyolefin plastic, 0-45 parts of inorganic filler, 30-85 parts of phosphorus iron powder, 0.5-2 parts of a processing aid, and 0.05-1.5 parts of a thermal oxygen stabilizer, wherein the first component is one of or a mixture of several of a polyolefin elastomer POE, a styrene block copolymer elastomer or an oil-filled product thereof, ethylene propylene rubber or an oil-filled product thereof, EVA, EMA, TPU or TPV. Compared with the prior art, according to the invention, phosphorus iron powder is introduced into the formula of the skin, while the specific gravity ofthe sound insulation pad skin is effectively increased, the mechanical properties and temperature resistance of the sound insulation pad skin are ensured, so that compared with conventional skin, thesound insulation amount of the finally prepared skin material can maximumly be reduced by about 5db or even higher under the conditions of a same thickness and a same filler adding amount.

Owner:SHANGHAI HUAGU VEHICLE IND CO LTD

Preparation method for polyamide imide foam

The invention discloses a preparation method for polyamide imide foam and belongs to the field of polymer synthesis methods. The preparation method comprises the following steps: adding diisocyanate,trimellitic anhydride, aromatic dianhydride and catalyst into a reaction kettle, heating the reaction kettle and then reacting while stirring at a constant temperature, thereby acquiring a prepolymer;pouring out the prepolymer, cooling down and utilizing a grinder to grind the cooled prepolymer into a foam precursor; spreading the foam precursor in a mould; foaming at high temperature to performclosed-loop curing, standing and naturally cooling to room temperature, and then de-molding, thereby acquiring the polyamide imide foam material. The polyamide imide foam material prepared according to the invention has the characteristics of high / low temperature resistance of polyimide, fire resistance and high strength of polyamide, and is low in cost. The foaming technology for generating CO2 from self-reaction without dissolvent reaction is capable of boosting the popularization and application of the polyamide imide foam in more fields.

Owner:溧阳华晶合成材料有限公司 +1

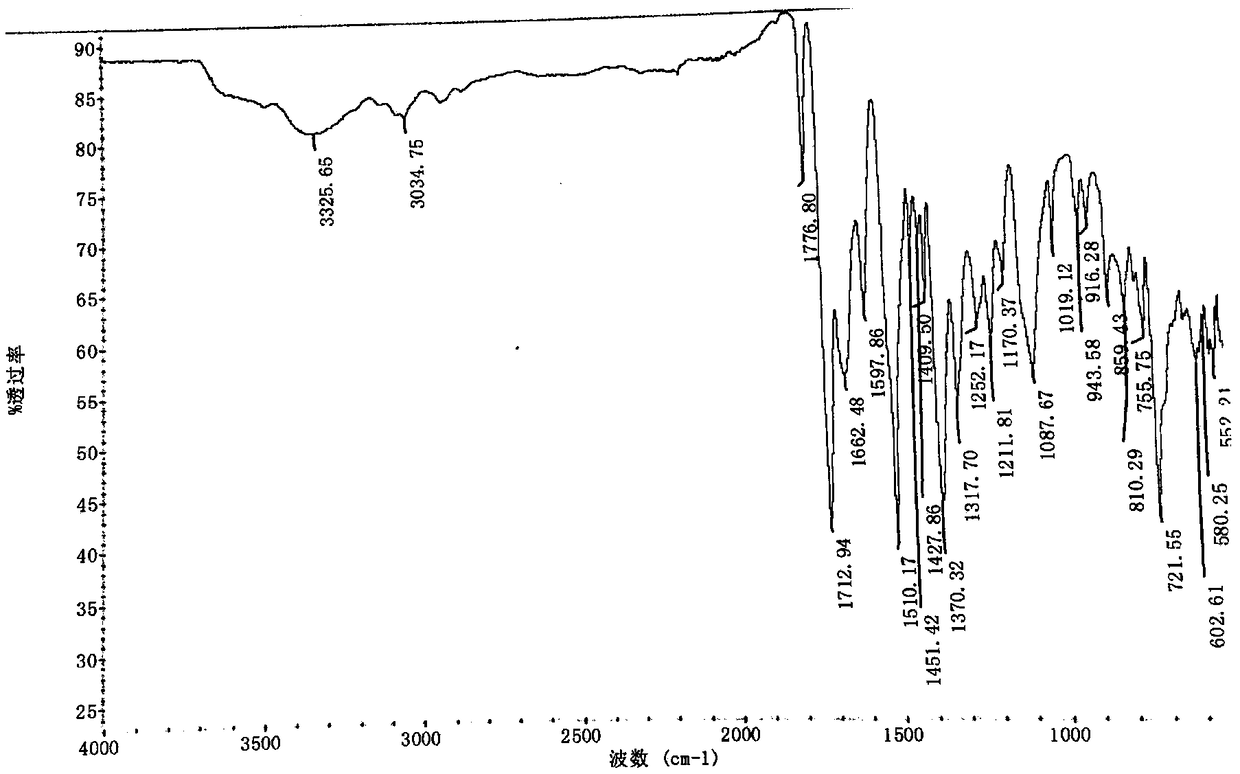

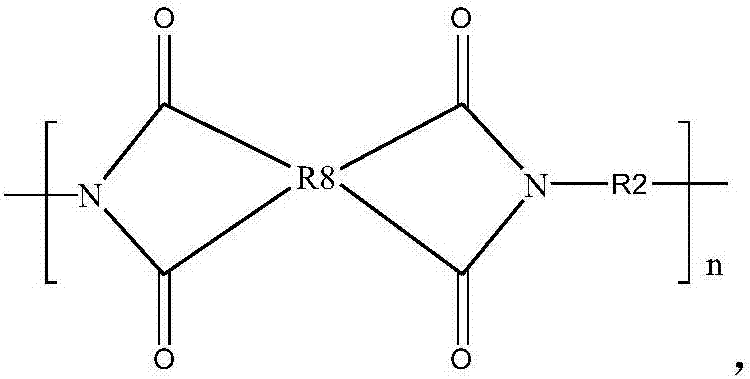

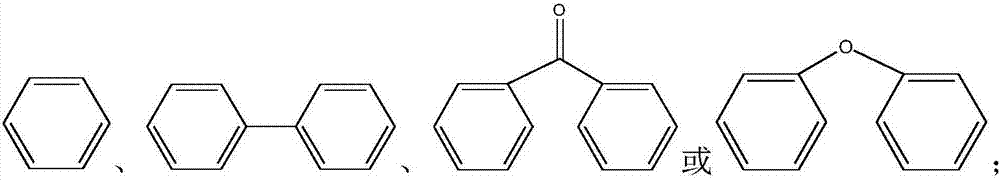

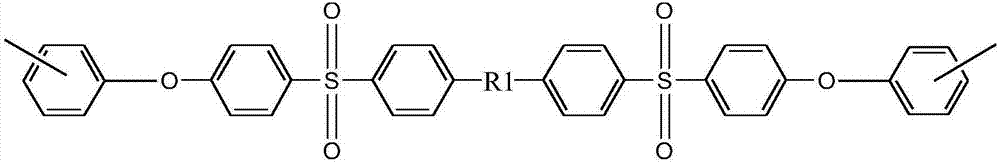

Polyimide resin and its preparation method

ActiveCN107417916AImprove liquidityGuaranteed temperature resistancePhosphorus organic compoundsStructural formulaStructural unit

The invention discloses a polyimide resin and its preparation method. The structural formula of the polyimide resin includes the following structure unit: the structure is as shown in the formula. A diamine monomer containing flexible chain section is autonomously compounded, and the flexible chain section is introduced to the polyimide resin; thus the resin mobility is improved; meanwhile, phosphorus element is introduced, and the temperature resistance of resin is kept; moreover, the flame retardance of resin is improved.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

RFID (radio frequency identification) electronic tag inlay

InactiveCN102880900AWith electrical propertiesSimple structureRecord carriers used with machinesEpoxyEngineering

An RFID (radio frequency identification) electronic tag inlay belongs to the technical field of electronic tags and comprises a chip and a PCB (printed circuit board) substrate hard antenna or a PI (polyimide) substrate flexible antenna, wherein the chip is connected and conducted with the PCB substrate hard antenna or the PI substrate flexible antenna through a metal wire; connecting points of the PCB substrate hard antenna or the PI substrate flexible antenna and the chip and the chip are coated with epoxy resin; the PCB substrate hard antenna or the PI substrate flexible antenna is provided with a via hole communicated with an external circuit with a larger size; and the chip is in the HF (high frequency) (13.56 MHz) band and UHF (ultra high frequency) (860-960 MHz) band. The RFID electronic tag inlay has a reasonable and simple structure and is easy to manufacture. The RFID electronic tag inlay adopts the PCB substrate hard antenna or the PI substrate flexible antenna as the substrate, the chip is connected and conducted with the antenna through the metal wire, and the chip is coated with the epoxy resin, so that the inlay has electrical property and can be connected with the circuit with larger size to improve the property thereof.

Owner:JIANGSU FUNA ELECTRONICS SCI & TECH +1

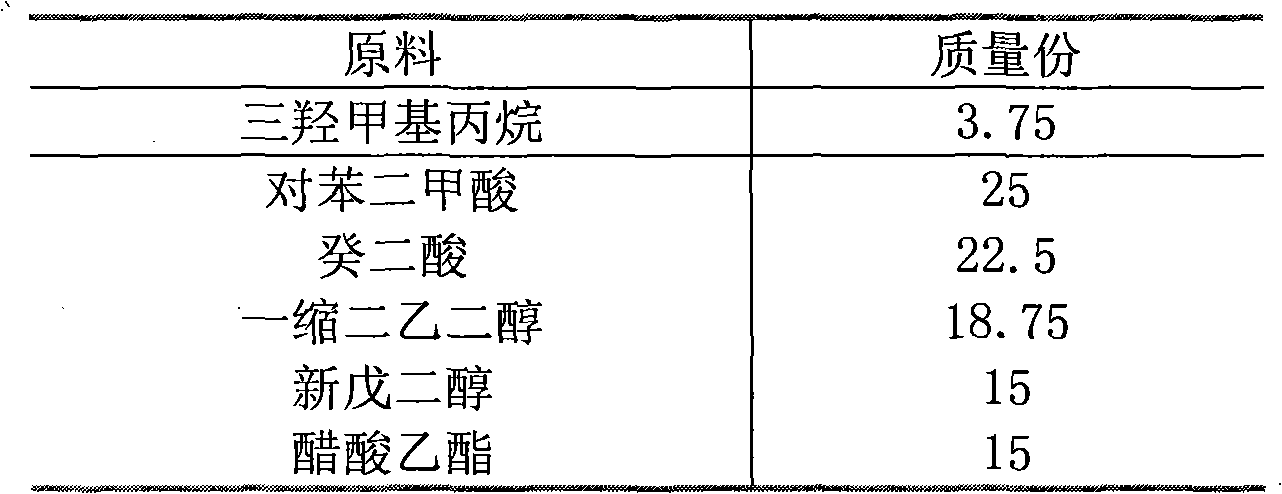

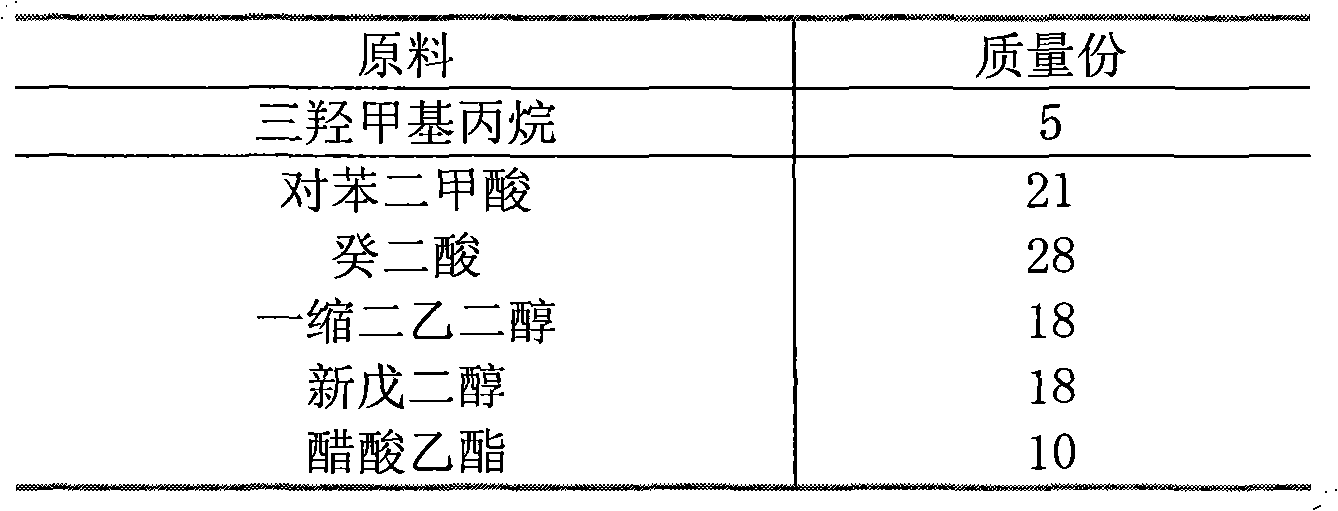

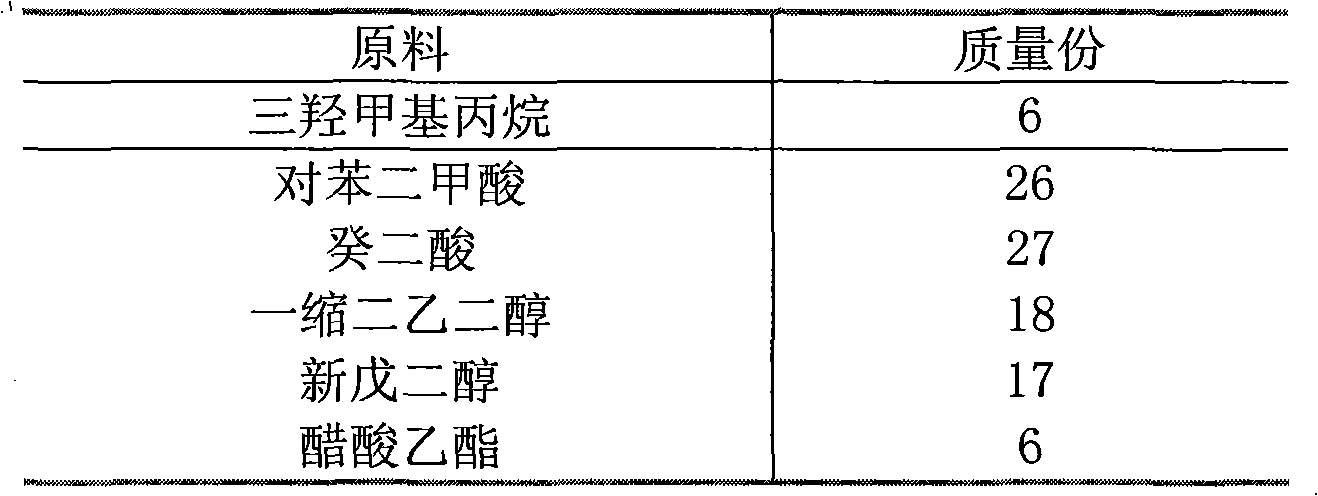

Method for preparing temperature-resistant type compound bonding agent

ActiveCN101805579AMeet the temperature resistance performance requirementsHigh solid contentAdhesivesEnd-groupDissolution

The invention discloses a method for preparing a temperature-resistant type compound bonding agent. The method comprises: a, esterifying reaction, namely adding trimethylolpropane, terephthalic acid, decanedioic acid, diglycol and neopentylene glycol into a polyester synthesis kettle, heating the mixture, and realizing complete esterificaiton after the reaction; b, polycondensation reaction, namely creating a low vacuum of -0.04 to -0.02MPa by pumping in the polyester synthesis kettle by pumping after the esterifying reaction is completed first, then creating a high vacuum of -0.09 to -0.05MPa by pumping in the polyester synthesis kettle with the temperature of the kettle kept between 245 and 255 DEG C during the high-vacuum pumping, and finally creating a volume of-0.094MPa by long-term pumping in the kettle, and after the long-vacuum pumping, completing the polycondensation reaction to obtain polyester polyhydric alcohol; and c, dissolution, namely cooling the prepared polyester polyhydric alcohol, adding acetic ether, and uniformly stirring the mixture to obtain the compound bonding agent. In the method, micromolecular tri-functionality polyhydric alcohol is added in the synthetic process of the polyester polyhydric alcohol, so that the prepared polyester polyhydric alcohol has more than two active end groups, and after the polyester polyhydric alcohol is cured by using a conventional multi-functionality curing agent, the crosslinking density is bigger and the temperature resistance is guaranteed.

Owner:NANTONG GAOMENG NEW MATERIAL

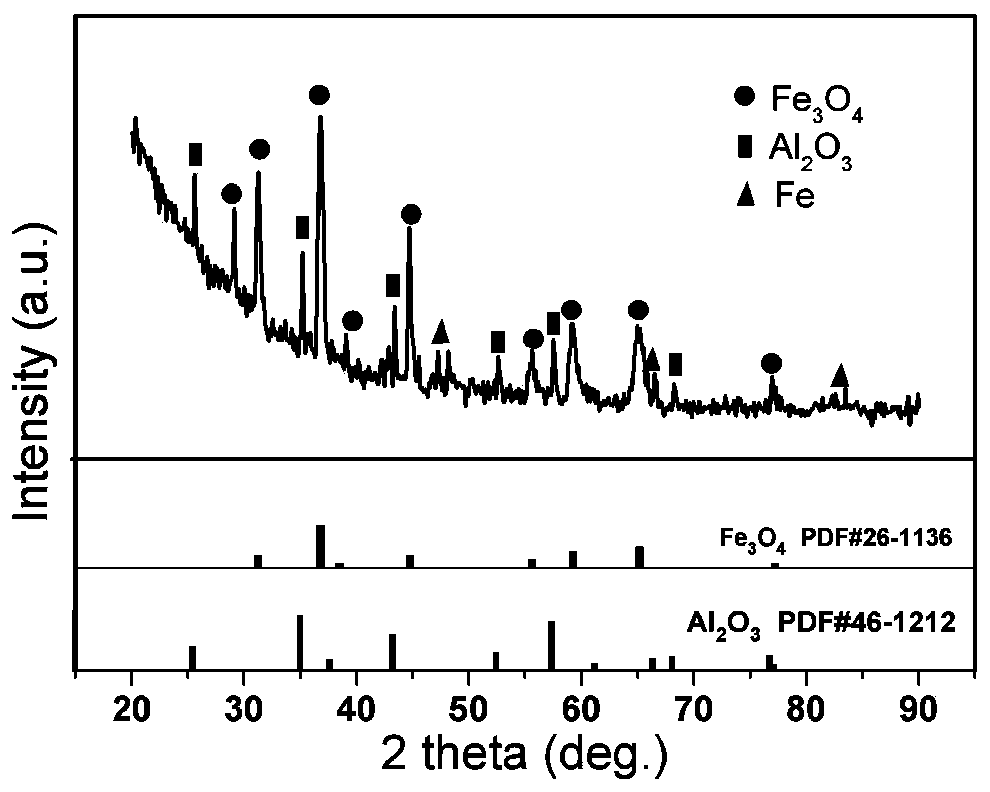

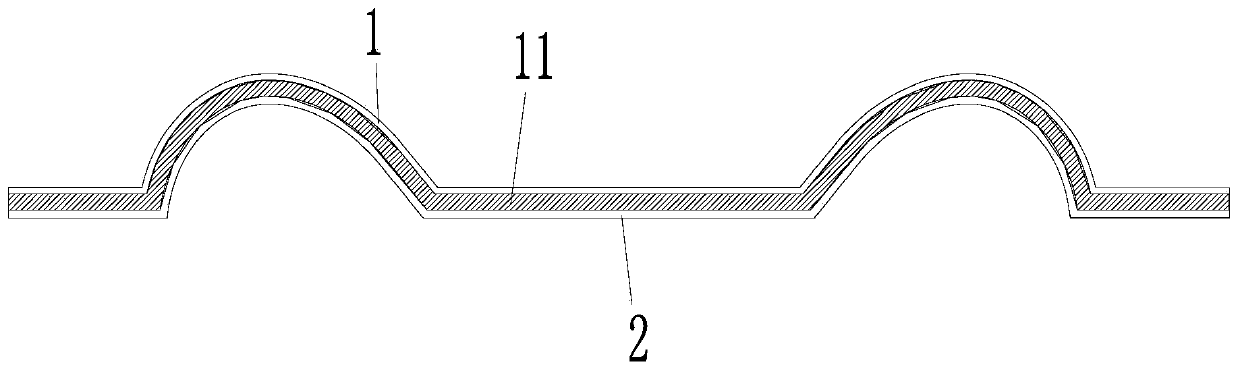

Preparation method for ferrite/reductive metal composite particles and method for preparing high-temperature invisible coating layers based on laser 3D printing

ActiveCN110405196ASimple processMeet the requirements of high temperature stealthAdditive manufacturing apparatusTransportation and packagingFerrite powderTemperature wave

The invention discloses a preparation method for ferrite / reductive metal composite particles and a method for preparing high-temperature invisible coating layers based on laser 3D printing, belongs tothe technical field of wave absorption coating layer preparation, and solves the problems of insufficient coating layer / basal body bonding force of traditional high-temperature wave absorption coating layers, difficult control of microscopic structures of the coating layers and incapability of guaranteeing electromagnetic performances. Nanoscale ferrite powder and nanoscale reductive metal powderare prepared as composite particles through a mixed granulation process; in a closed preparation cavity of 3D printing equipment, the composite particles are prepared as the high-temperature invisible coating layers on the surfaces of substrates through laser induced in-situ reaction. The preparation method is applied to high-temperature invisibility and electromagnetic pollution prevention of components.

Owner:HARBIN INST OF TECH

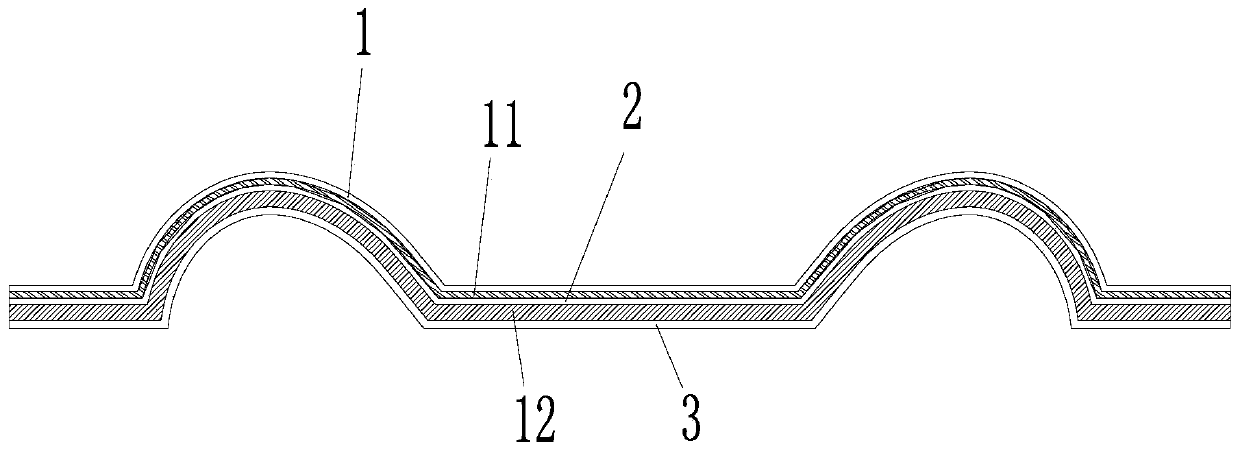

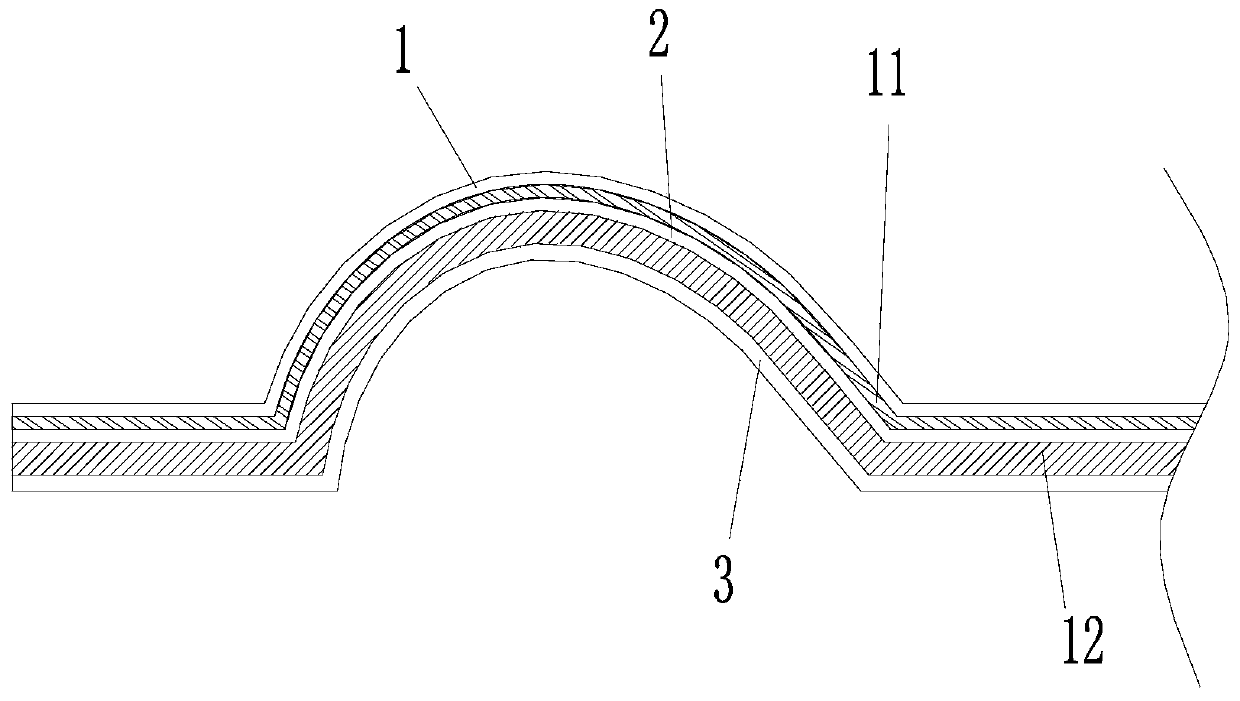

Composite vibrating diaphragm for sound production device and sound production device

ActiveCN110958544AGuaranteed resilienceIncrease elasticityPolymeric diaphragmsSynthetic resin layered productsEngineeringSound production

The invention discloses a composite vibrating diaphragm for a sound production device, and the composite vibrating diaphragm enables a rubber layer and an adhesive film layer to be compounded to forma composite structure, guarantees the temperature resistance and rebound resilience of the rubber layer, combines the advantages of high modulus and high damping of the adhesive film layer of the composite structure, and guarantees the rebound resilience, high temperature resistance and high damping performance of the composite vibrating diaphragm. The sound production device provided by the invention has better acoustic performance.

Owner:GOERTEK INC

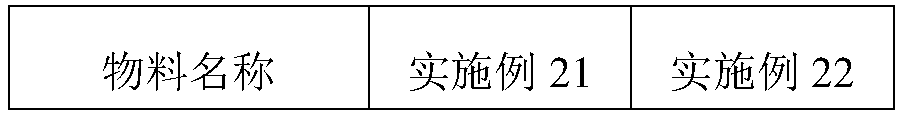

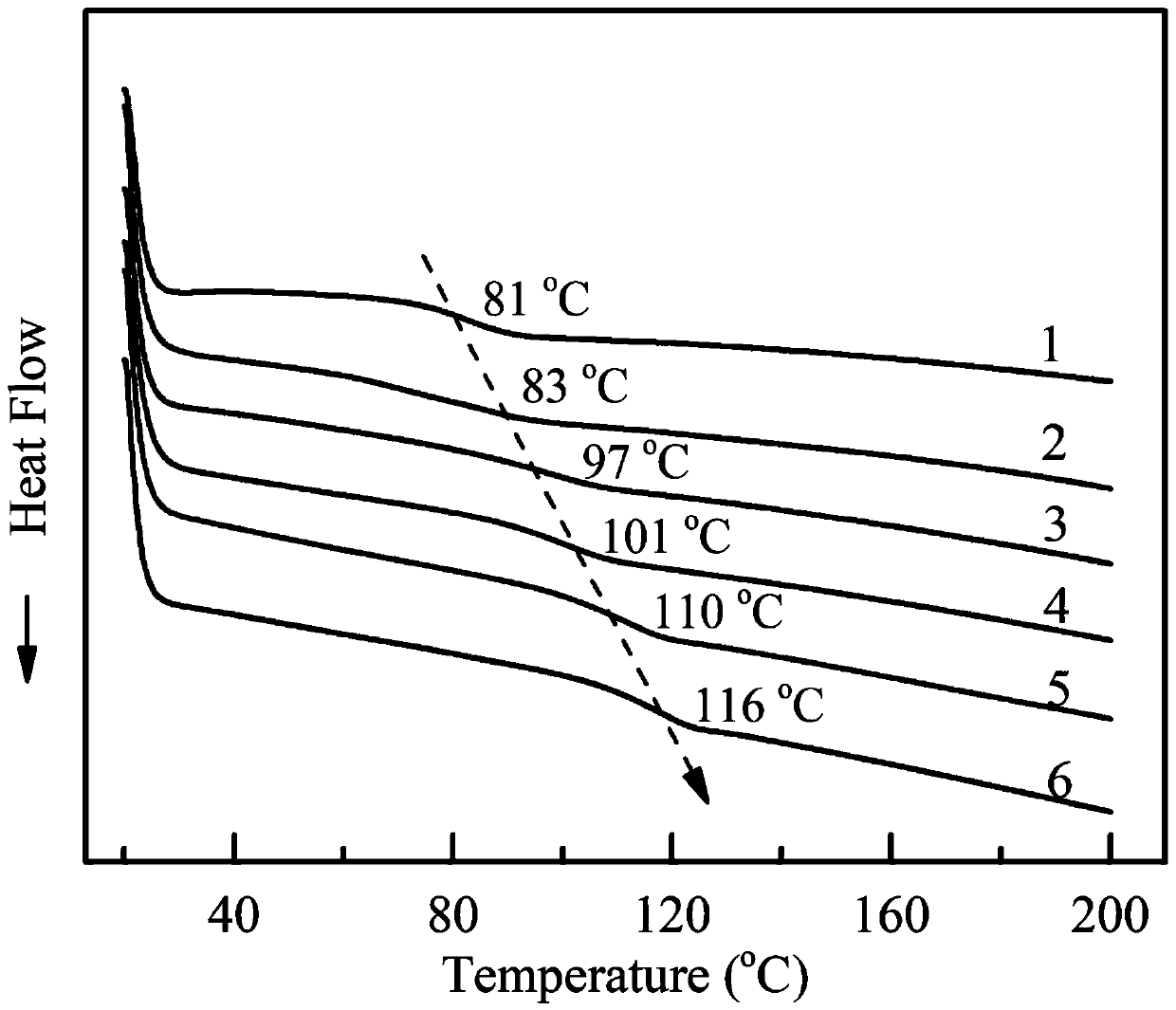

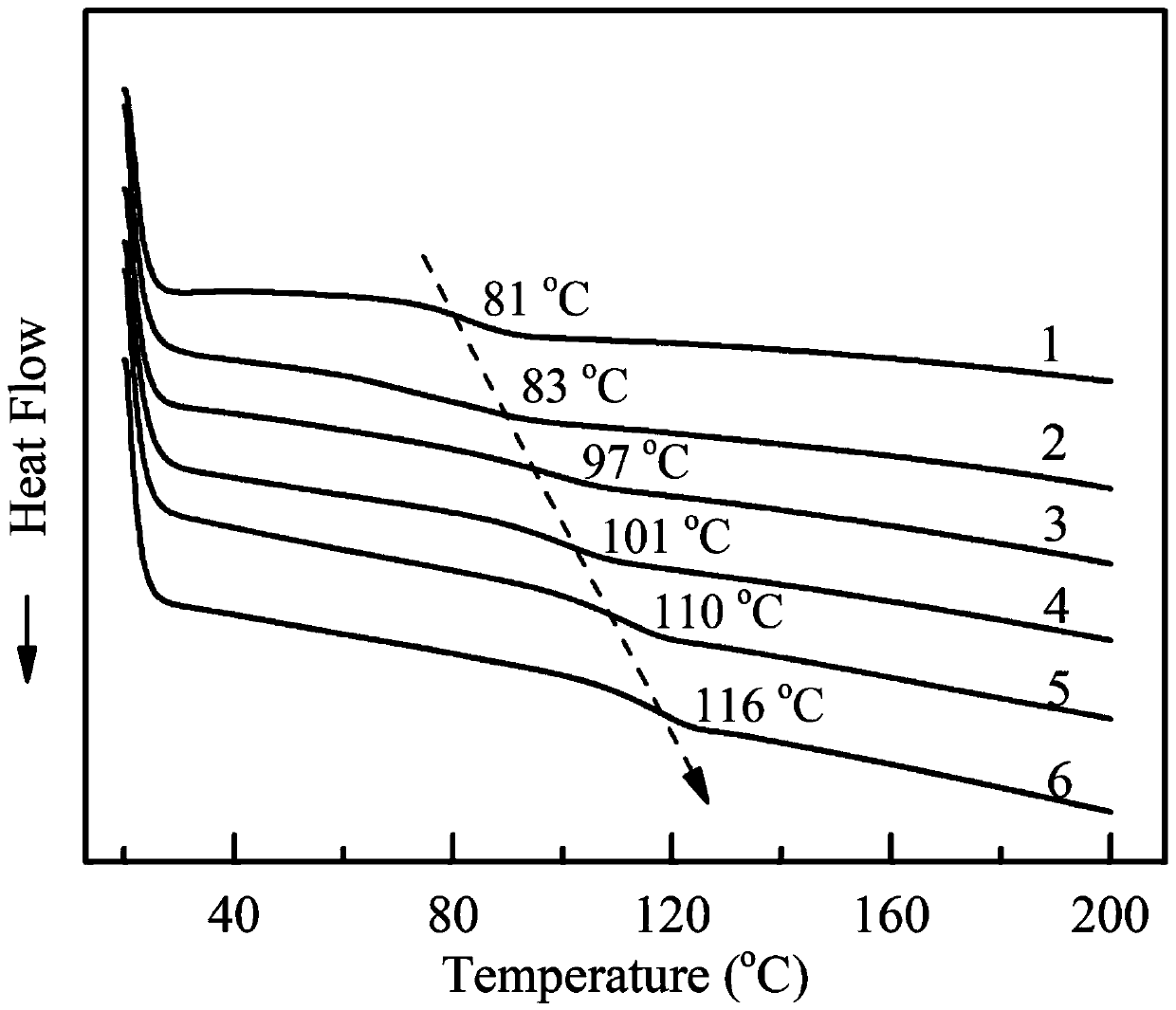

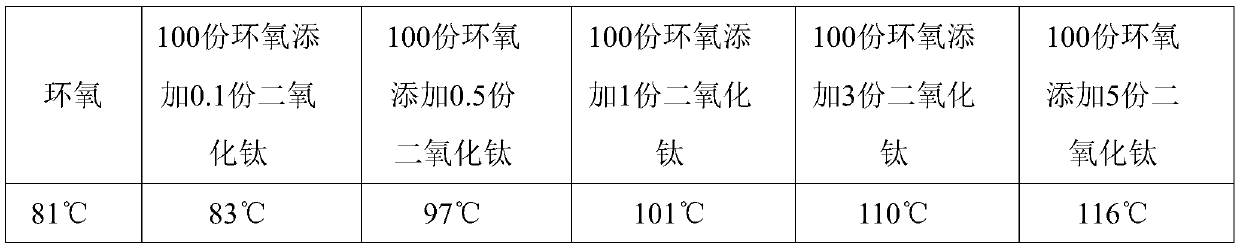

Epoxy resin casted insulating material, and preparation method and application method thereof

InactiveCN109705531AHigh glass transition temperatureHigh temperature resistanceGlass transitionInhibitory effect

The invention provides an epoxy resin casted insulating material, and a preparation method and an application method thereof. According to the preparation method, an appropriate amount of a nanometertitanium dioxide filling material processed through surface silane coupling agent modification processing is added before bisphenol A type epoxy resin curing; the surface modified nanometer titanium dioxide is capable of realizing bonding with epoxy resin main molecule chains through chemical bonds, so that inhibition effect on the heat motion of epoxy resin main molecule chains is achieved, and epoxy resin casted material glass-transition temperature is increased. The preparation method can be used for increasing of the heat resistant grade of electrical equipment epoxy resin casted insulating material. Pure epoxy resin casted material glass-transition temperature is 81 DEG C, and the glass-transition temperature of the epoxy resin casted insulating material prepared using the preparationmethod is increased to 116 DEG C.

Owner:XI AN JIAOTONG UNIV

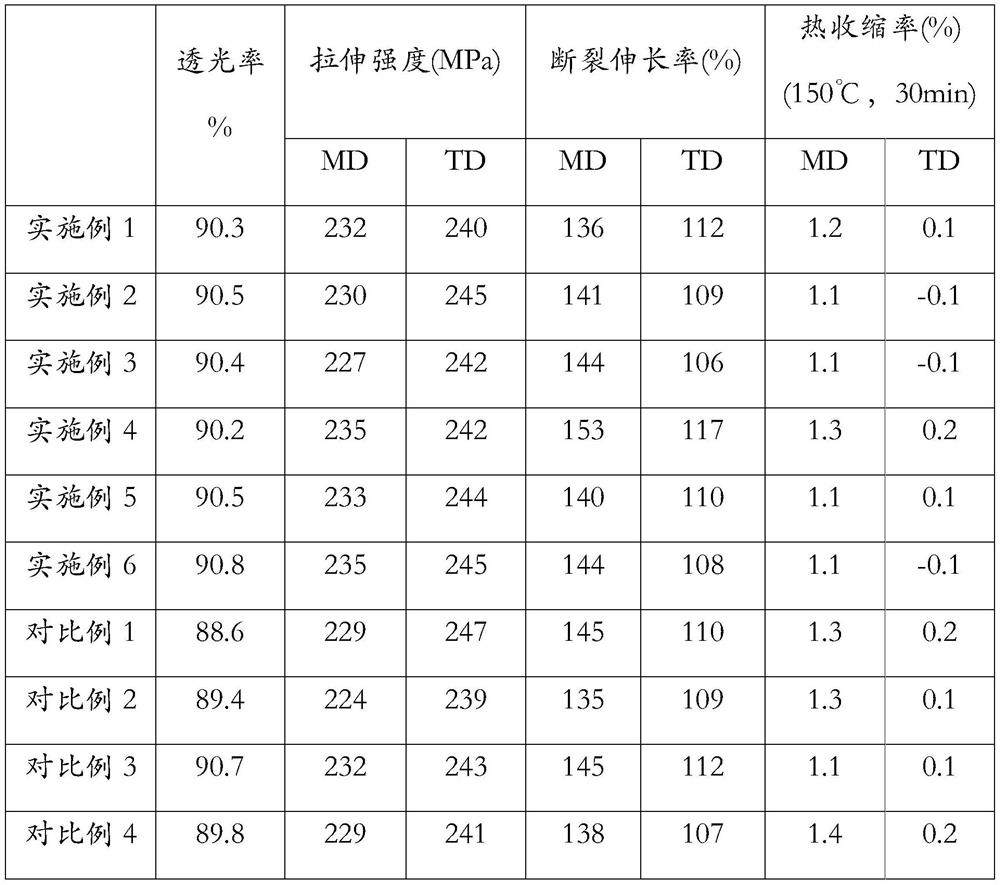

High-light-transmittance polyester film and manufacturing method thereof

PendingCN114702789ASimple production processEasy to reunite and difficult to disperseCopolyesterPolymer chemistry

The invention discloses a high-light-transmittance polyester film and a manufacturing method thereof, the high-light-transmittance polyester film comprises the following components in percentage by mass: 93-98% of copolyester chip copolymerized and modified by a third monomer, 1-5% of optical opening master batch and 1-2% of crystallization nucleating agent, and the high-light-transmittance polyester film with the thickness of 12-75 microns is obtained through melt extrusion and two-way stretching. The light transmittance is improved by reducing the scattering loss of visible light in the polyester film, and the polyester film has the characteristics of simple production process, low production cost and reservation of the thermal stability of a common polyester film, and can be applied to the field of electronic display.

Owner:HANGZHOU HESHUN TECH CO LTD +1

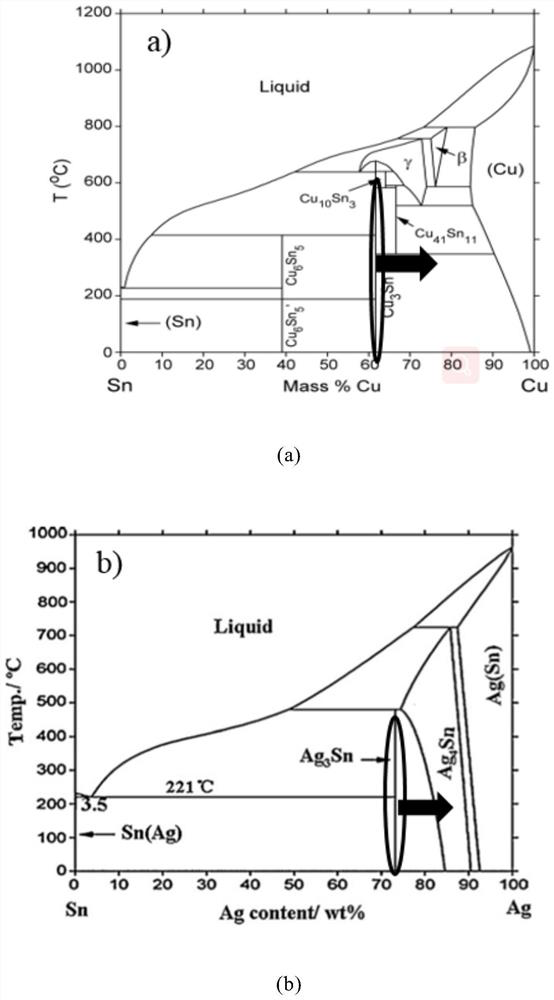

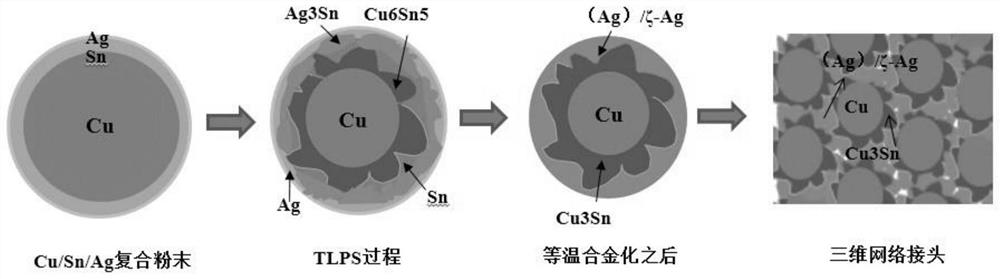

In-situ toughening method for tough integrated Cu/Sn/Ag welding material

ActiveCN112157257AGuaranteed temperature resistanceWill not melt downTransportation and packagingVacuum evaporation coatingElectroplatingMetal

The invention relates to an in-situ toughening method for a tough integrated Cu / Sn / Ag welding material. The method comprises the steps of step (1), uniformly electroplating a 2-3 [mu]m Sn plating layer on copper particles with different particle sizes, then, physically and uniformly depositing a 1 [mu]m Ag layer on the surface of Cu / Sn powder to obtain Cu / Sn / Ag powder; step (2), proportioning theCu / Sn / Ag powder prepared in the step (1), placing the Cu / Sn / Ag powder in a mixer, and performing mechanical mixing for 1 to 2 hours at the speed of 100 to 300 r / min to obtain powder with uniformly mixed particle sizes; step (3), performing pressure forming on the powder prepared in the step (2) on a high-pressure tablet press with the pressure range of 10 MPa to 30 MPa to obtain a Cu / Sn / Ag composite preformed welding chip with the thickness of 100 [mu]m to 400 [mu]m; and step (4), performing low-temperature transient liquid-phase diffusion welding on the composite preformed welding chip, and enabling Sn with a low melting point to be completely converted into a high-temperature-resistant Cu3Sn and Ag3Sn interface intermetallic compound through simultaneous diffusion reaction of Sn and Cu and simultaneous diffusion reaction of Sn and Ag at a point below the melting point of Sn, so as to prepare a Cu3Sn / Ag3Sn-clad Cu particle three-dimensional network structure joint.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com