High-light-transmittance polyester film and manufacturing method thereof

A polyester film and high light transmittance technology, applied in the field of biaxially oriented polyester film, can solve the problems that the transparency of the film cannot meet the application requirements, the undisclosed use of a third monomer, etc., and achieve the promotion of mechanical properties and processing performance, Solve the effect of easy agglomeration, difficult dispersion and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

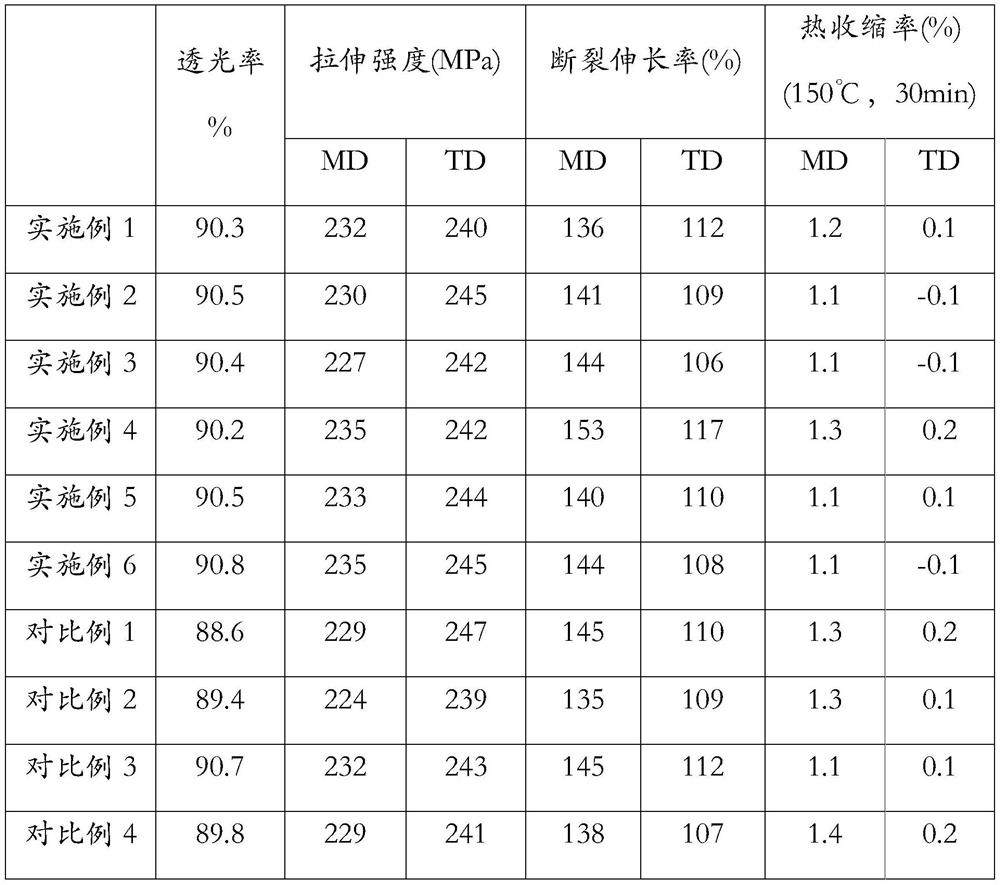

Examples

Embodiment 1

[0043] After the 1,4-cyclohexanediol with a molar ratio of 0.2:10 is mixed with ethylene glycol and a catalyst, it is then mixed with terephthalic acid, heated, and vacuumed to react. After the reaction is completed, the pressure is reduced, the material is discharged, and the cooling , dicing to make copolyester chips; grinding the copolyester chips into powder, mixing with barium sulfate with a particle size of 1.4 μm and dispersing agent, and then extruding and granulating through twin-screw to prepare optical opening masterbatch; The copolyester powder is mixed with 40nm nano-kaolin particles and dispersant, and then extruded and granulated by twin screw to prepare a crystal nucleating agent; in terms of mass percentage, 96% of copolyester chips and 3% of optical aperture masterbatch With 1% of the crystallization nucleating agent, it is sent to the corresponding silo of the main extruder through the suction system, and is fed into the extruder. After melting, vacuuming and...

Embodiment 2

[0045] After mixing 1,4-cyclohexanediol and isosorbide (the molar ratio of 1,4-cyclohexanediol and isosorbide is 1:10) with ethylene glycol and a catalyst in a molar ratio of 0.2:10, It is mixed with terephthalic acid, heated, and reacted with vacuum. After the reaction is completed, the pressure is reduced, the material is discharged, cooled, and diced to make copolyester chips; After mixing barium sulfate and dispersant, it is extruded and granulated by twin-screw to prepare optical open master batch; the copolyester powder is mixed with nano-kaolin particles with a particle size of 50nm and dispersant, and then extruded and granulated by twin-screw to prepare Obtain crystallization nucleating agent; in mass percentage, send 96% of copolyester chips, 2% of optical opening masterbatch and 2% of crystallization nucleating agent to the corresponding silo of the main extruder through the suction system , fed into the extruder, melted, vacuumed and filtered to remove the moisture...

Embodiment 3

[0047] After mixing 1,4-cyclohexanediol and isosorbide (the molar ratio of 1,4-cyclohexanediol and isosorbide is 1:1) with ethylene glycol and a catalyst in a molar ratio of 0.2:10, It is mixed with terephthalic acid, heated, and reacted with vacuum. After the reaction is completed, the pressure is reduced, the material is discharged, cooled, and diced to make copolyester chips; After mixing barium sulfate and dispersant, it is extruded and granulated by twin-screw to prepare optical open master batch; the copolyester powder is mixed with nano-kaolin particles with a particle size of 50nm and dispersant, and then extruded and granulated by twin-screw to prepare Obtain crystallization nucleating agent; in mass percentage, send 96% of copolyester chips, 2% of optical opening masterbatch and 2% of crystallization nucleating agent to the corresponding silo of the main extruder through the suction system , fed into the extruder, melted, vacuumed and filtered to remove the moisture,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com