Novel heat-resistant salt-resistant polyacrylamide and synthesis method thereof

A polyacrylamide, temperature-resistant and salt-resistant technology, which is applied in the field of new temperature-resistant and salt-resistant polyacrylamide and its synthesis. Oil displacement ability and other issues, to achieve the effect of ensuring shear degradation and temperature resistance, and improving salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

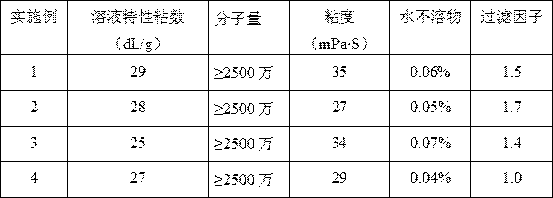

Examples

Embodiment 1

[0015] Add 739.8g of distilled water to a 1L jar, then add 7g of caustic soda sodium hydroxide, dissolve evenly, slowly add 50g of functional monomer AMPS, dissolve completely in a constant temperature water bath below 15°C, then add 0.5g of vinylpyrrolidone, stir well and then add Refined 200g of acrylamide monomer AM, adjusted the pH value to 12, then added 1g of sodium chloride, 1.5g of urea and cooled down to -2°C; moved it into a Dewar bottle, and passed 99.999% high-purity nitrogen to deoxygenate for 10min , add 0.01g of EDTA, continue to pass nitrogen gas for deoxygenation for 20min, then add 0.2g of azobisisoheptanonitrile, and then pass nitrogen gas for deoxygenation for 20min, then add 0.002g of tert-butyl hydroperoxide, and then add ferrous ammonium sulfate 0.01 g, then continue to pass nitrogen until the solution becomes viscous and then seal.

[0016] After the temperature of the solution rises to the highest value and cools down naturally for 2 hours, take out th...

Embodiment 2

[0018] First add 771.3g of distilled water to a 1L jar, then add 10g of granular alkali sodium hydroxide, and slowly add 35g of functional monomer AMPS after dissolving evenly. Refined 180g of acrylamide monomer AM, adjusted the PH value to 12.5, then added 1.5g of sodium chloride, 1g of urea and cooled down to 0°C; moved it into a Dewar bottle, and passed 99.999% high-purity nitrogen to remove oxygen for 10 minutes, Add 0.05g of EDTA, continue to pass nitrogen gas for deoxygenation for 20 minutes, then add 0.15 g of azobisisoheptanonitrile, and then pass nitrogen gas for deoxygenation for 20 minutes, then add 0.004 g of tert-butyl hydroperoxide, and then add ferrous ammonium sulfate 0.008 g after 2 minutes , and then continue to pass nitrogen until the solution becomes viscous and then seal.

[0019] After the temperature of the solution rises to the highest value and cools down naturally for 2 hours, take out the colloid from the Dewar bottle, granulate it into particles wit...

Embodiment 3

[0021] First add 771.3g of distilled water to a 1L jar, then add 10g of granular alkali sodium hydroxide, and slowly add 35g of functional monomer AMPS after dissolving evenly. Refined 180g of acrylamide monomer AM, adjusted the pH value to 12.2, then added 1.5g of sodium chloride, 1g of urea and cooled down to -1°C; moved it into a Dewar bottle, and passed 99.999% high-purity nitrogen to remove oxygen for 10 minutes , add 0.05g of EDTA, continue nitrogen deoxygenation for 20min, then add 0.15g of azobisisoheptanonitrile, then add 0.004g of tert-butyl hydroperoxide after nitrogen deoxygenation for 20min, then add ferrous ammonium sulfate 0.008 g, then continue to pass nitrogen until the solution becomes viscous and then seal.

[0022] After the temperature of the solution rises to the highest value and cools down naturally for 2 hours, take out the colloid from the Dewar bottle, granulate it into particles with a diameter of 3-5mm, take out 100g of the granulated colloid parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com