Thermal recovery compensation sealed pipe column

A pipe string and thermal recovery technology, applied in the field of compensation pipe string, can solve the problems of easy scaling and poor sealing on the outer wall of the inner pipe, achieve the effect of ensuring temperature resistance and corrosion resistance, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

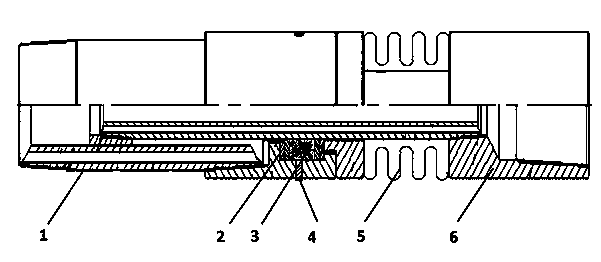

[0016] Refer to attached figure 1 , a heat recovery compensation seal pipe string, the pipe string includes an outer pipe 1, an inner pipe 6, a stainless steel corrugated sealing pipe 5, and a combined sealing system. The outer pipe 1 is a high-vacuum heat-insulated oil pipe, and the inner pipe 6 is an oil pipe to ensure that the fluid does not throttling in the flow channel. The corrugated sealing pipe 5 is connected to the outer pipe 1 and the inner pipe 6 by welding. The sealing system is sealed by two perfluoroether rubber sealing rings 2 at the front and rear and the sealing grease in the sealing chamber 3. The sealing groove of the sealing ring 2 is independent from the sealing chamber 3. The sealing grease is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com