Silane halogen-free flame retardant cross-linking polyolefine cable and manufacturing method thereof

A technology of cross-linking polyolefin and silane cross-linking, which is applied in the direction of insulated cables, cable/conductor manufacturing, and conductor/cable insulation. High polymer strength and elongation decrease, etc., to achieve stable electrical and mechanical properties, easy cross-linking, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

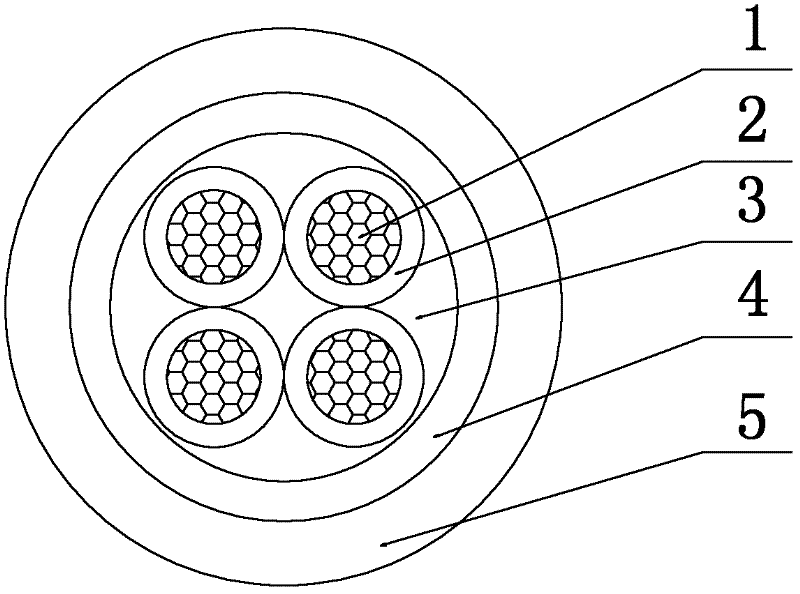

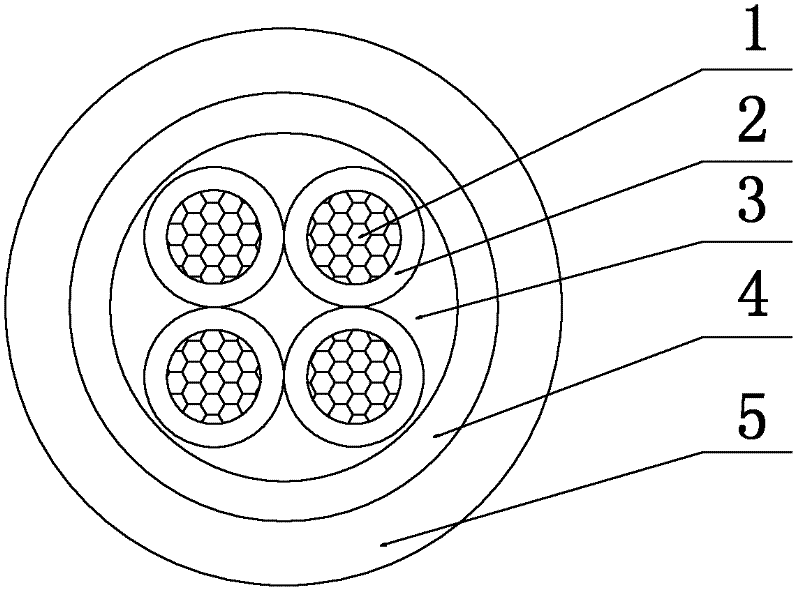

[0023] Taking Figure 1 as an example, the processing process of the cable is:

[0024] Single wire drawing-annealing-conductor stranding-LSZH flame retardant cross-linked polyolefin insulation-spark test-cable-flame retardant oxygen barrier layer-thermoplastic LSZH flame retardant polyolefin sheath-spray printing- inspection package

[0025] (1) Single wire drawing

[0026] The Φ8.00mm copper rod is drawn into a round copper single wire after multi-step drawing, and the drawing process is the same as that of general cable production.

[0027] (2) Annealing process

[0028] After the round copper single wire is drawn, it undergoes annealing and recrystallization, and the annealing temperature control range is precise.

[0029] (3) Conductor stranding

[0030] The conductors are properly stranded to ensure the stability of the conductor structure. Reasonably design the pitch ratio of each twisted layer to ensure the bending performance and tightness of the conductor. The su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com