Epoxy resin casted insulating material, and preparation method and application method thereof

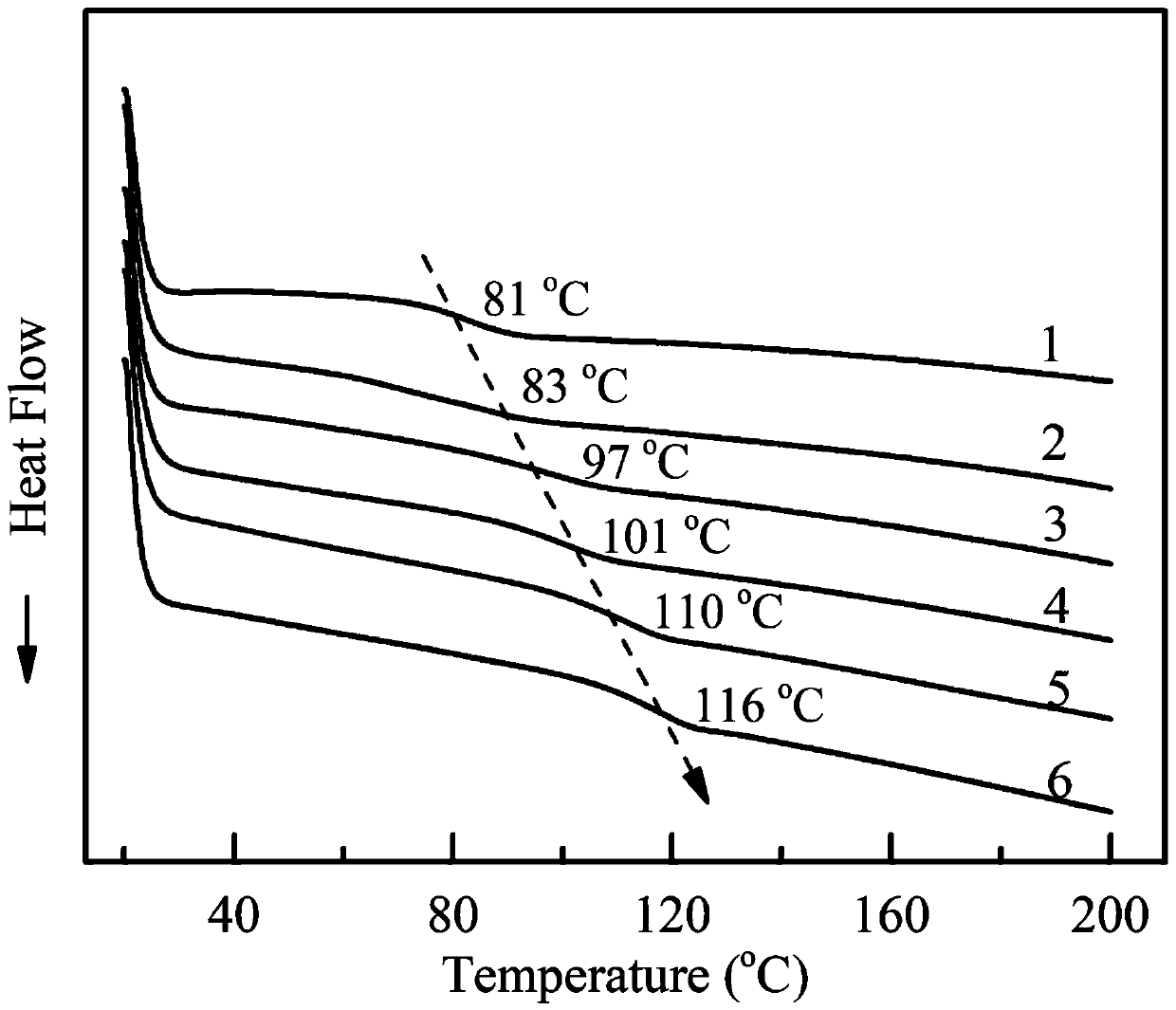

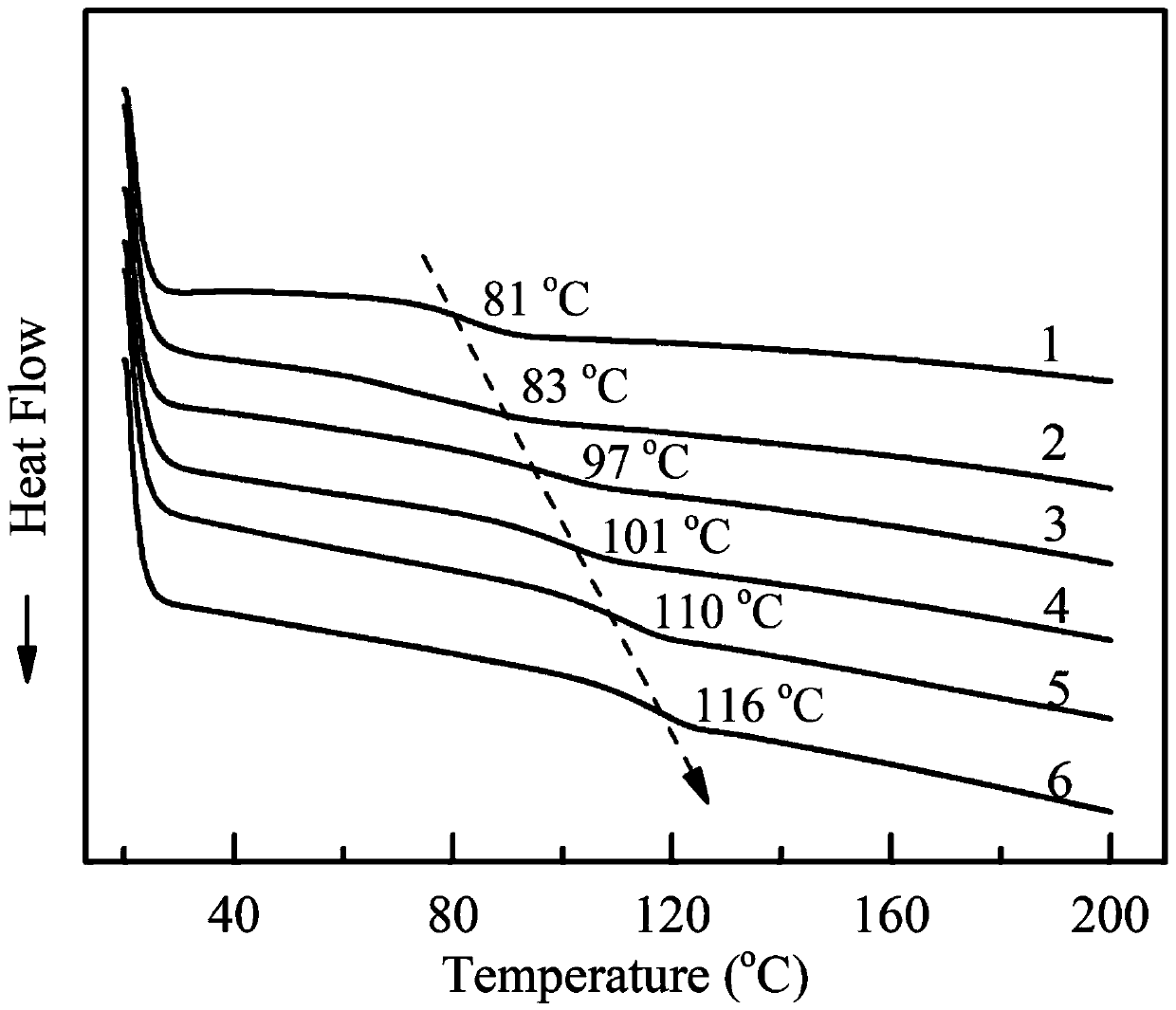

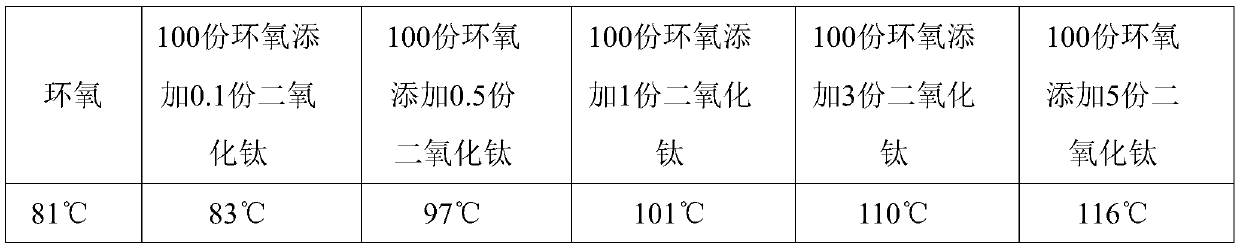

A technology for epoxy resin and casting material, which is applied to the field of epoxy resin casting insulating material and its preparation, can solve the problems of low high temperature resistance level and insufficient transition temperature, and achieve the effect of improving the temperature resistance level and glass transition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation process of the epoxy resin casting material of this embodiment is as follows:

[0031] Step 1. First, weigh 100 parts of epoxy resin, 80 parts of curing agent, 0.3 parts of accelerator, 0.1 part of nano-titanium dioxide filler and 0.0015 parts of coupling agent.

[0032] Step 2. Mix the weighed nano-titanium dioxide filler with absolute ethanol and perform ultrasonic dispersion, then add the coupling agent weighed in step 1 and mix evenly to obtain a mixed solution A. Heat the mixed solution A to 60°C and pass the homogenization Mixture B was obtained after machine treatment.

[0033] Step 3. Add the above mixed solution B into the weighed epoxy resin and mix evenly, then circulate and stir at 90°C until the ethanol is completely volatilized and then cool to room temperature to obtain the mixed solution C.

[0034] Step 4, then mix the obtained mixed solution C with the weighed curing agent and accelerator to obtain the mixture D, and carry out the vacu...

Embodiment 2

[0037] The preparation process of the epoxy resin casting material of this embodiment is as follows:

[0038] Step 1. First, weigh 100 parts of epoxy resin, 80 parts of curing agent, 3 parts of accelerator, 1 part of nano-titanium dioxide filler and 0.01 part of coupling agent by mass.

[0039] Step 2. Mix the weighed nano-titanium dioxide filler with absolute ethanol and perform ultrasonic dispersion, then add the coupling agent weighed in step 1 and mix evenly to obtain a mixed solution A. Heat the mixed solution A to 30°C and pass through the homogenizer Mixture B was obtained after machine treatment.

[0040] Step 3. Add the above mixed solution B into the weighed epoxy resin and mix evenly, then circulate and stir at 60°C until the ethanol is completely volatilized and then cool to room temperature to obtain the mixed solution C.

[0041] Step 4, then mix the obtained mixed solution C with the weighed curing agent and accelerator to obtain the mixture D, and carry out th...

Embodiment 3

[0044] The preparation process of the epoxy resin casting material of this embodiment is as follows:

[0045] Step 1. First, weigh 100 parts of epoxy resin, 80 parts of curing agent, 0.1 part of accelerator, 5 parts of nanometer titanium dioxide filler and 0.15 part of coupling agent.

[0046] Step 2, then mix the weighed nano-titanium dioxide filler with absolute ethanol and ultrasonically disperse, then add the coupling agent weighed in step 1 and mix evenly to obtain a mixed solution A, heat the mixed solution A to 80°C and pass Mixed liquid B is obtained after homogenization.

[0047] Step 3. Add the above mixed solution B into the weighed epoxy resin and mix evenly, then circulate and stir at 150°C until the ethanol is completely volatilized and then cool to room temperature to obtain the mixed solution C.

[0048] Step 4, then mix the obtained mixed liquid C with the weighed curing agent and accelerator to obtain the mixture D, and carry out the vacuum degassing treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com