Patents

Literature

260results about How to "Guaranteed Corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

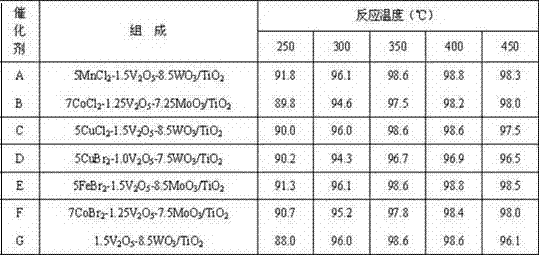

Denitrition catalyst with mercury removal effect and its preparation method

ActiveCN102366722ALess corrosiveReduce processing costsPhysical/chemical process catalystsDispersed particle separationHalogenCoal fired power plant

The invention relates to denitrition catalyst with a mercury removal effect. The catalyst has a chemical general formula of: MXn-V2O5-Y / TiO2, wherein, M is a metallic element selected from Fe, Cu, Mn or Co, X is halogen Cl or Br, Y is WO3 or MoO3, and n=2-4, and the elements are in a weight ratio of: 1-10 of M, 1-1.5 of V, 7.5-8.5 of W or Mo, and 75-100 of TiO2. The catalyst is prepared by the steps of: dipping V2O5-WO3 / TiO2 or V2O5-MoO3 / TiO2 with MCln or MBrn, then conducting frying and calcination. With the catalyst of the invention, catalytic reduction of NOx and catalytic oxidation of Hg<0> can be simultaneously completed in an original flue gas denitrition catalytic reactor, and the generated divalent mercury ions are washed and cured in desulfurized gypsum in a subsequent flue gas wet desulphurization process. Thus, cooperative control of the discharge of NOx and Hg<0> can be realized without increasing flue gas purification facilities of coal-fired power plants.

Owner:GUODIAN SCI & TECH RES INST

Welding method of duplex stainless steels

InactiveCN102019485ALess welding spatterBeautiful weld shapeArc welding apparatusWelding/cutting media/materialsCarbon dioxideCorrosion

The invention belongs to a welding method of duplex stainless steels, comprising the following steps of backing welding, filling welding and cosmetic welding. 99.99% of argon inert gas shield is used for performing the backing welding of the manual tungsten electrode argon tungsten-arc welding, or gas shield formed by adding 80% of argon and 20% of carbon dioxide gas is used for performing semi-automatic filling and cosmetic welding. The welding method of the duplex stainless steels has the advantages that mechanical properties and corrosion resistance of welding joints can be fully ensured, welding spatters are reduced, and weld shaping is beautiful.

Owner:宋卫国

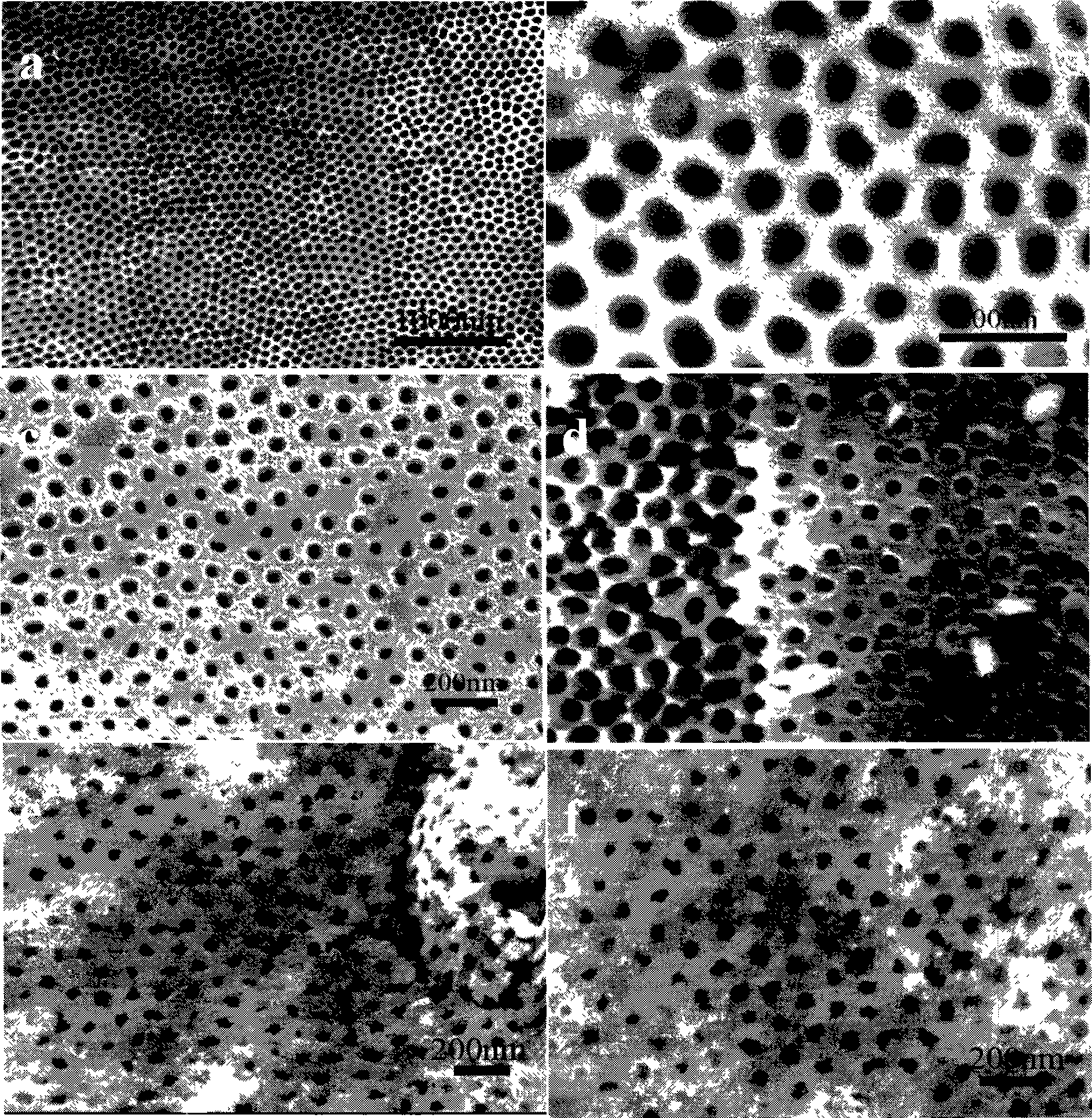

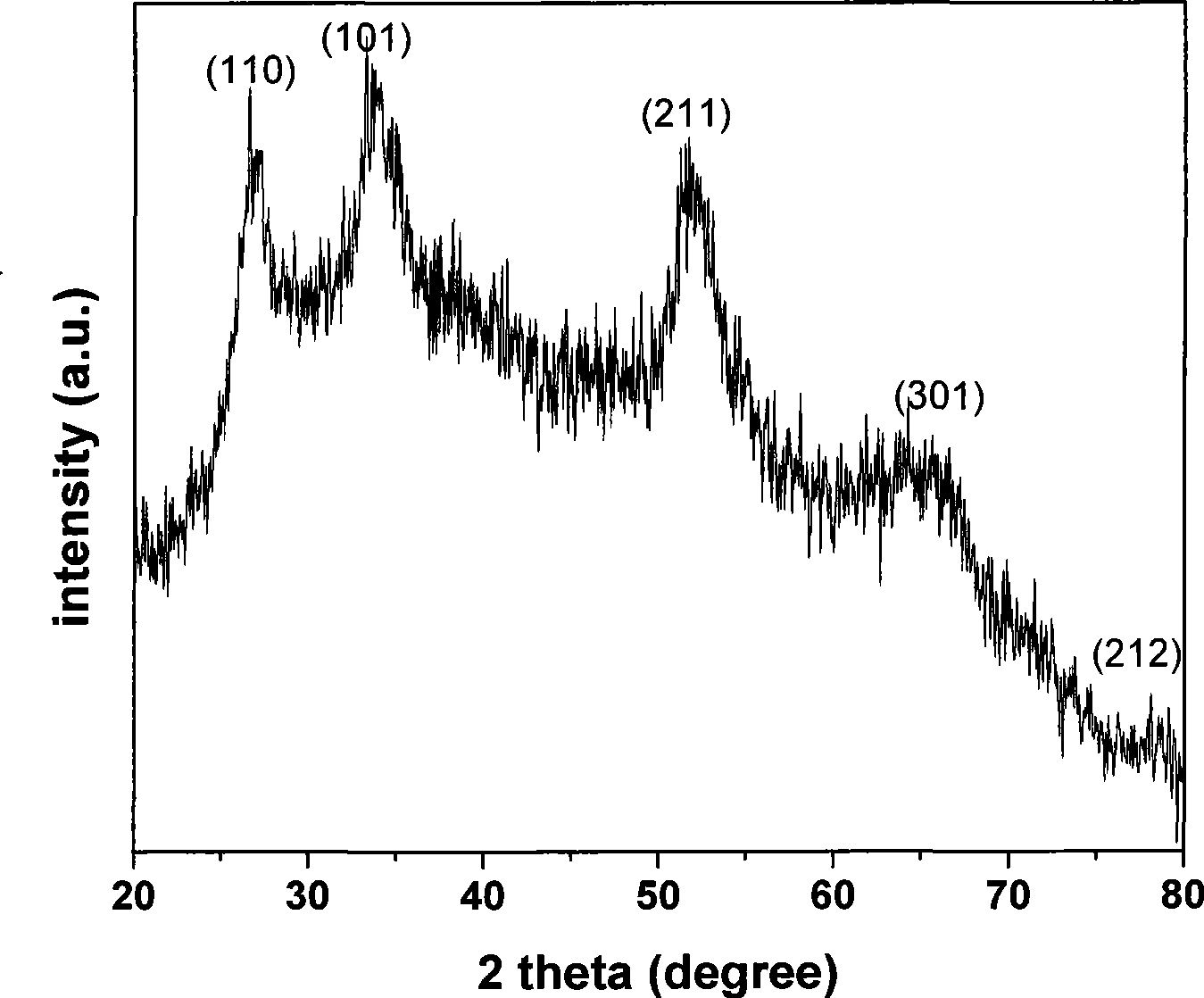

Titanium dioxide nano-pore array thin film and preparation thereof

InactiveCN101503211AEasy to peel and transferShort timePhysical/chemical process catalystsTitanium dioxidePorosityPolyethylene glycol

The invention discloses a titanium dioxide nanometer hole array film and a preparation method thereof. A hole in the film is an ordered through hole array; the diameter of the through hole thereof is 15 to 130 nm, the hole pitch thereof is 25 to 200 nm, and the porosity thereof is 30 to 40 percent; the thickness of the film is 10 to 1000 nm; the preparation method comprises the following steps: step 1, obtaining a porous aluminum oxide template with the hole diameter of 20 to 150 nm by using the secondary oxidation process; step 2, preparing precursor solution by using absolute ethyl alcohol, glacial acetic acid, butyl titanate and water, then adding polyethylene glycol into the precursor solution after the pH value of the precursor solution is adjusted to 2 to 3 by using nitric acid, and finally obtaining precursor sol; and step 3, firstly coating the precursor sol on the porous aluminum oxide template for at least one time and thermally insulating and drying the precursor sol for at least one time, then placing the aluminum oxide template coated with the precursor sol after being annealed into strong alkaline solution to corrupt the porous aluminum oxide template, and finally preparing the titanium dioxide nanometer-hole array film. The invention can be widely applied to the fields of sensors, catalysis, photo catalysis, photonic crystal, etc.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

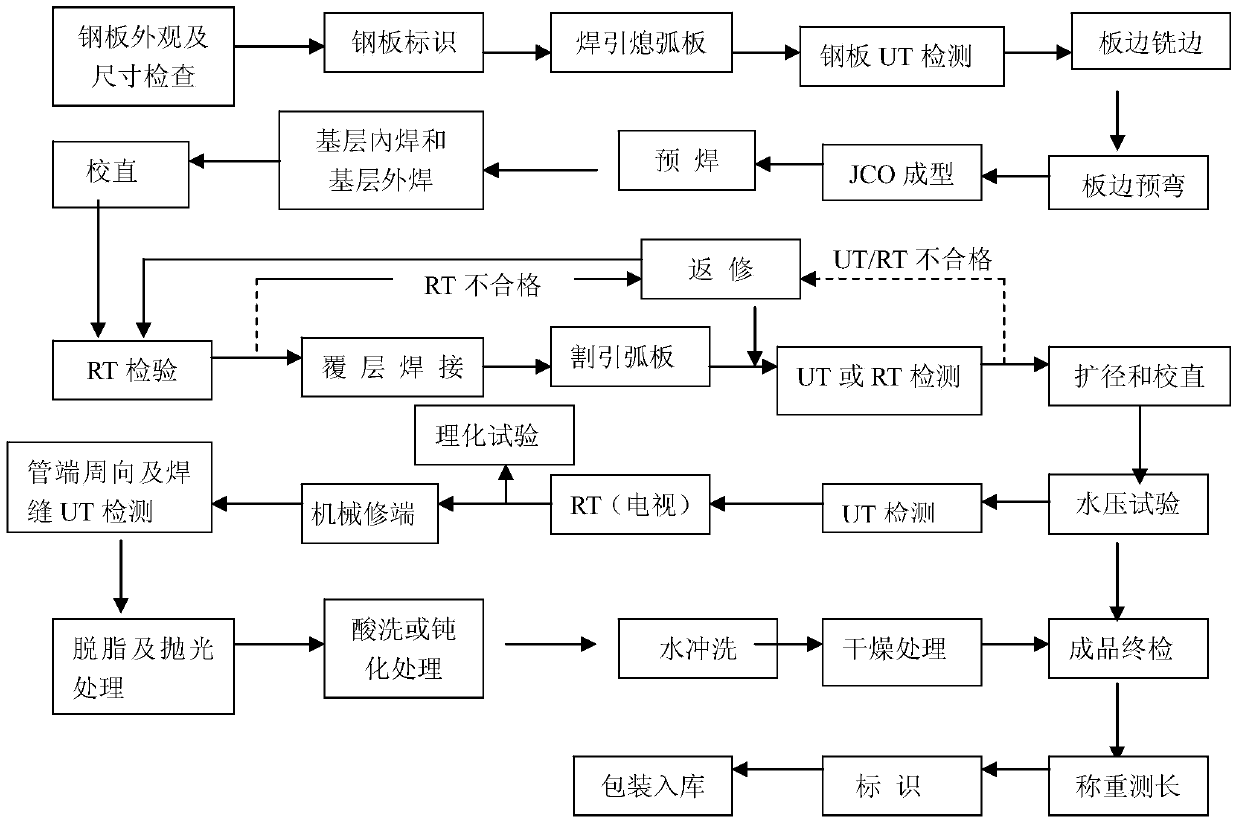

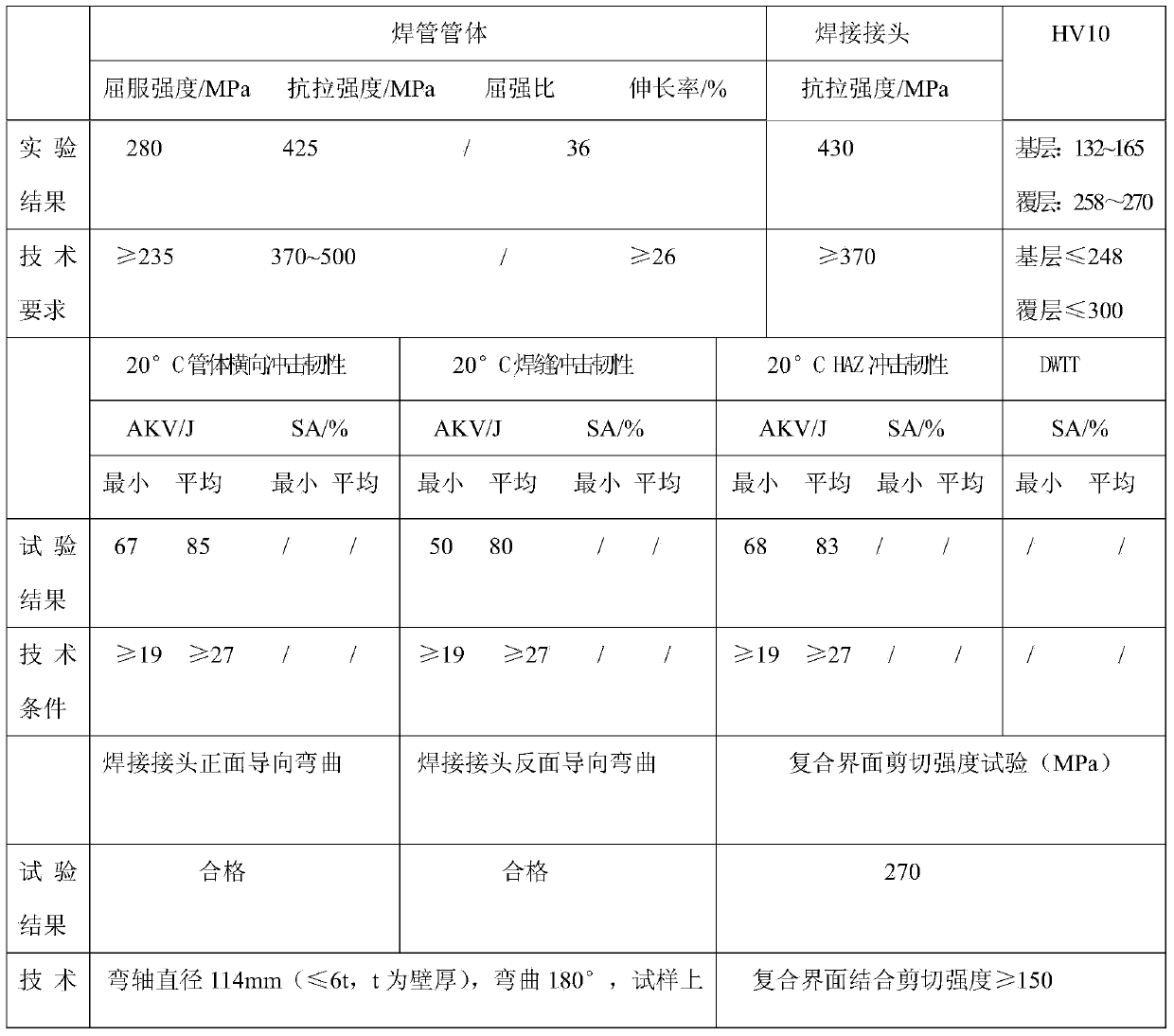

Corrosion-resistant metallurgical composite bimetal longitudinal submerged-arc welded steel pipe and method for manufacturing same

ActiveCN103722346AHigh strengthStrong integrityArc welding apparatusMetal rolling arrangementsSteel tubeSteel plates

The invention provides a corrosion-resistant composite bimetal longitudinal submerged-arc welded steel pipe and a method for manufacturing the same. The method includes steps of (1), manufacturing bimetal composite steel plates by a hot rolling process; (2), carrying out edge milling, pre-bending, JCO forming and pre-welding on the bimetal composite steel plates manufactured in the step (1); (3), welding weld joints of a steel pipe by a submerged-arc welding process, particularly, welding a carbon steel layer of a base layer at first when the weld joints are welded, and then welding metal of a clad layer of a corrosion-resistant layer. The steel pipe is obtained after JCO forming and pre-welding are carried out on the bimetal composite steel plates. The corrosion-resistant composite bimetal longitudinal submerged-arc welded steel pipe and the method have the advantages that the corrosion-resistant metallurgical composite bimetal longitudinal submerged-arc welded steel pipe is manufactured by a hot rolling metallurgical composite bimetal steel plate and JCOE pipe manufacturing process and the efficient automatic submerged-arc welding process, double layers of metal of the steel pipe can be metallurgically combined with each other, and accordingly the steel pipe is high in strength, integrity and corrosion resistance; the JCOE pipe manufacturing process is adopted, so that the steel pipe is high in mechanical degree, production efficiency and overall dimensional accuracy, and steel pipes with the lengths of 12 meters can be produced by the method.

Owner:江苏玉龙钢管科技有限公司

Large-diameter seamless steel tube for high-pressure gas cylinders and manufacturing method thereof

The invention belongs to the technical field of metallurgy, and provides a large-diameter seamless steel tube for high-pressure gas cylinders and a manufacturing method thereof. The large-diameter seamless steel tube for high-pressure gas cylinders comprises the following chemical components in percentage by mass: 0.30-0.60% of C, 0.20-0.50% of Si, 0.20-0.60% of Mn, at most 0.010% of P, at most 0.010% of S, 0.90-1.70% of Cr, 2.50-3.50% of Ni, 0.25-0.55% of Mo, 0.05-0.25% of V and the balance of Fe. The manufacturing method adopts spongy iron and scrap steel as raw materials for steelmaking. The large-diameter seamless steel tube has the advantages of high heat stability, high strength, impact toughness, stable enduring plasticity, high heat resistance, excellent corrosion resistance and excellent fatigue resistance, and the yield strength is not lower than 1000 MPa.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

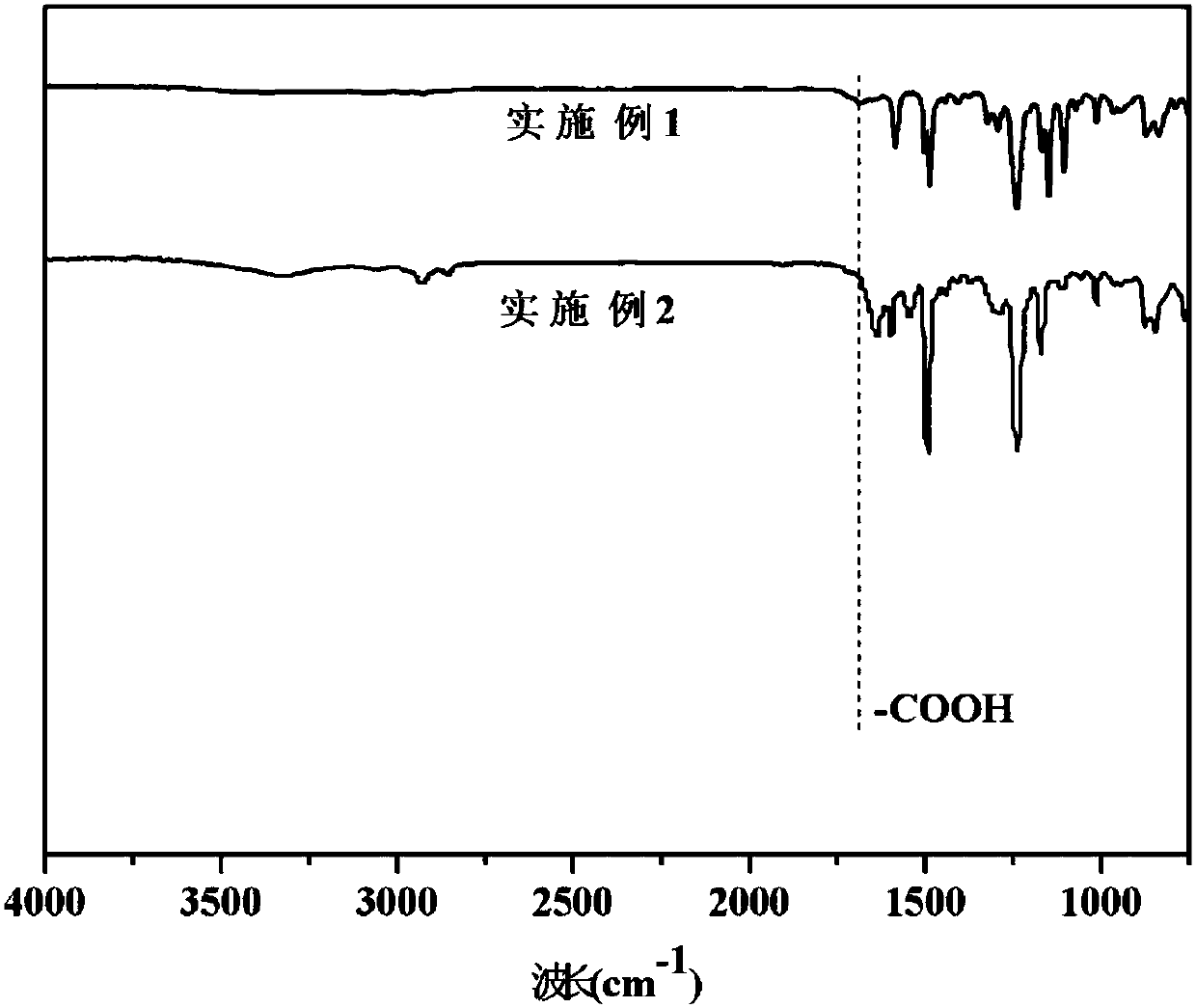

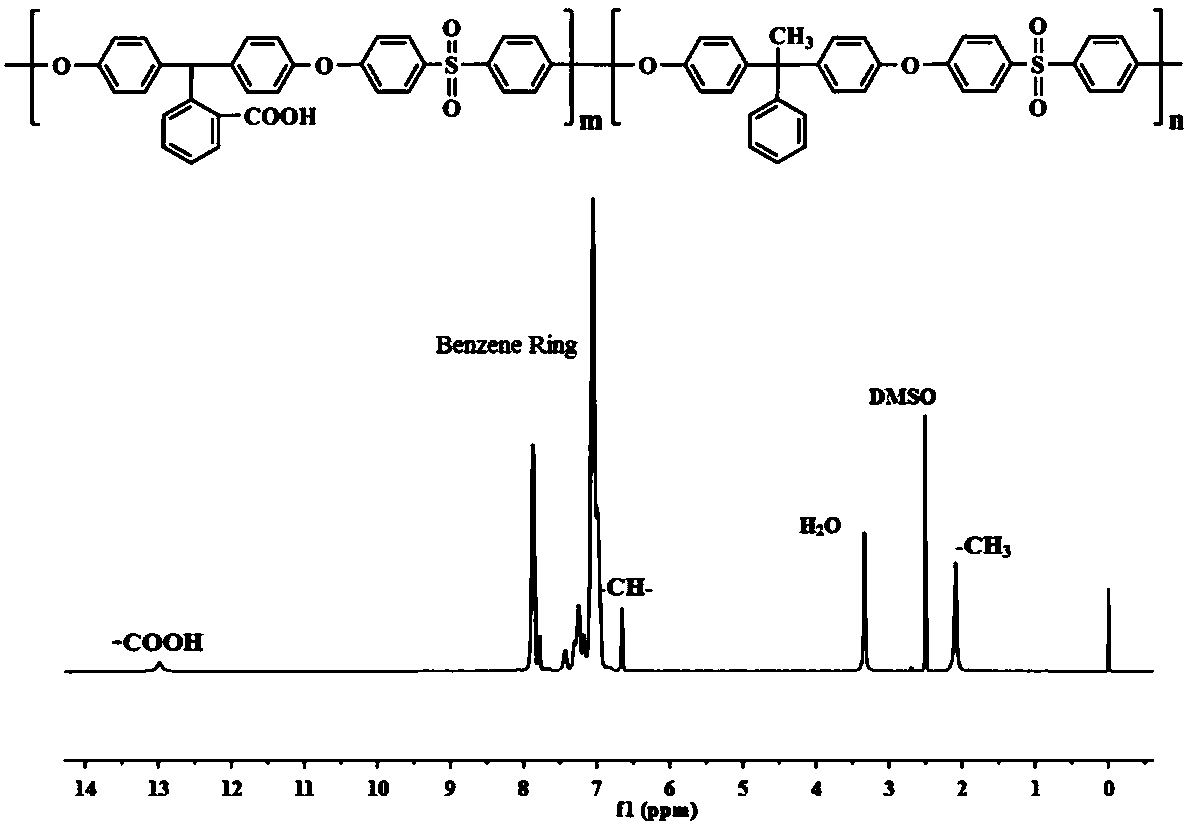

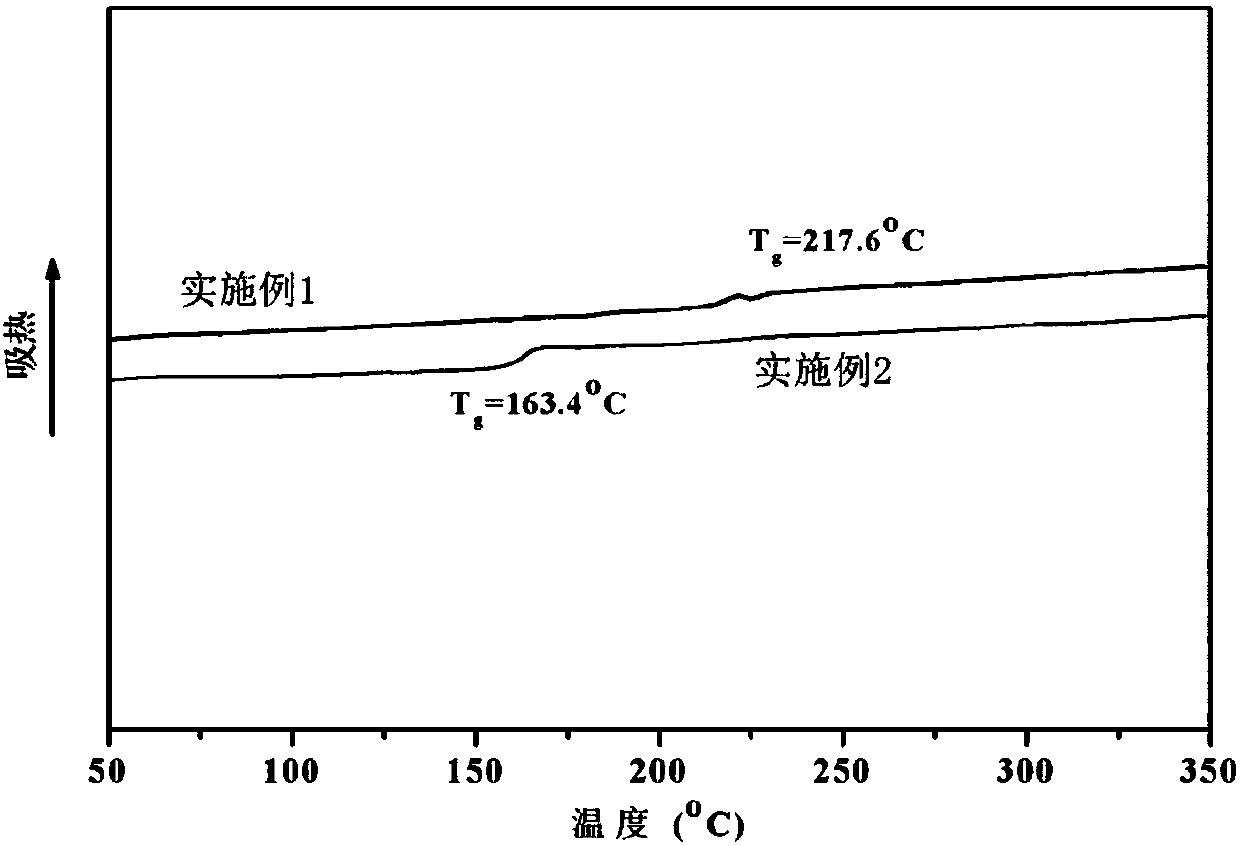

High-temperature-resistant organic-solvent-resistant separating membrane material, separating membrane, and preparation method thereof

ActiveCN107551825AImprove corrosion resistanceImprove temperature resistanceSemi-permeable membranesPolymer scienceOrganic solvent

The invention relates to a high-temperature-resistant organic-solvent-resistant separating membrane material, a separating membrane, and a preparation method thereof, and belongs to the field of highmolecular material. The high-temperature-resistant organic-solvent-resistant separating membrane material is composed of, by weight, 20 to 40 parts of a high-temperature-resistant aromatic ring matrixcontaining resin, 20 to 40 parts of a carboxyl-containing polymer, 0 to 60 parts of a matrix reinforcing material, 0.1 to 10 parts of a water soluble pore forming agent, and 100 to 300 parts of a solvent. The high-temperature-resistant organic-solvent-resistant separating membrane prepared from the high-temperature-resistant organic-solvent-resistant separating membrane material possesses excellent corrosion resistance, heat resistance, mechanical properties, pollution resistance, and high separating efficiency, is a high performance separating membrane, and is promising in application prospect.

Owner:安徽旭云商务咨询有限公司

Failure point positioning method for semiconductor power device failure analysis

InactiveCN102854429AConvenient to judge timeViolent reactionElectrical testingElectrical resistance and conductanceLight beam

The invention provides a failure point positioning method for semiconductor power device failure analysis. The failure point positioning method comprises the following steps of: performing chemical corrosion on a metal aluminum layer covering the surface of a power device by utilizing a chemical corrosion stripping technology, completely removing the aluminum layer, and completely keeping a barrier layer below the metal aluminum layer; positioning the front side of the power device by utilizing a micro light microscope and a light beam induced resistance variation technology, simulating electric conditions under the failure conditions, electrifying by using a point needle method, simulating the electric conditions, and finding possible failure points; and performing physical verification of electronic package assembly failure analysis by utilizing the positioning result of an electronic package assembly failure analysis tool on the previous steps, and finding the final physical failure point. The failure point positioning method has the advantages that the metal aluminum layer is effectively stripped, and the integrity of the barrier layer is kept; and moreover, the positioning speed and efficiency of the semiconductor power device failure point are greatly improved, and an extremely high precision is kept.

Owner:SHANGHAI FALAB TEST

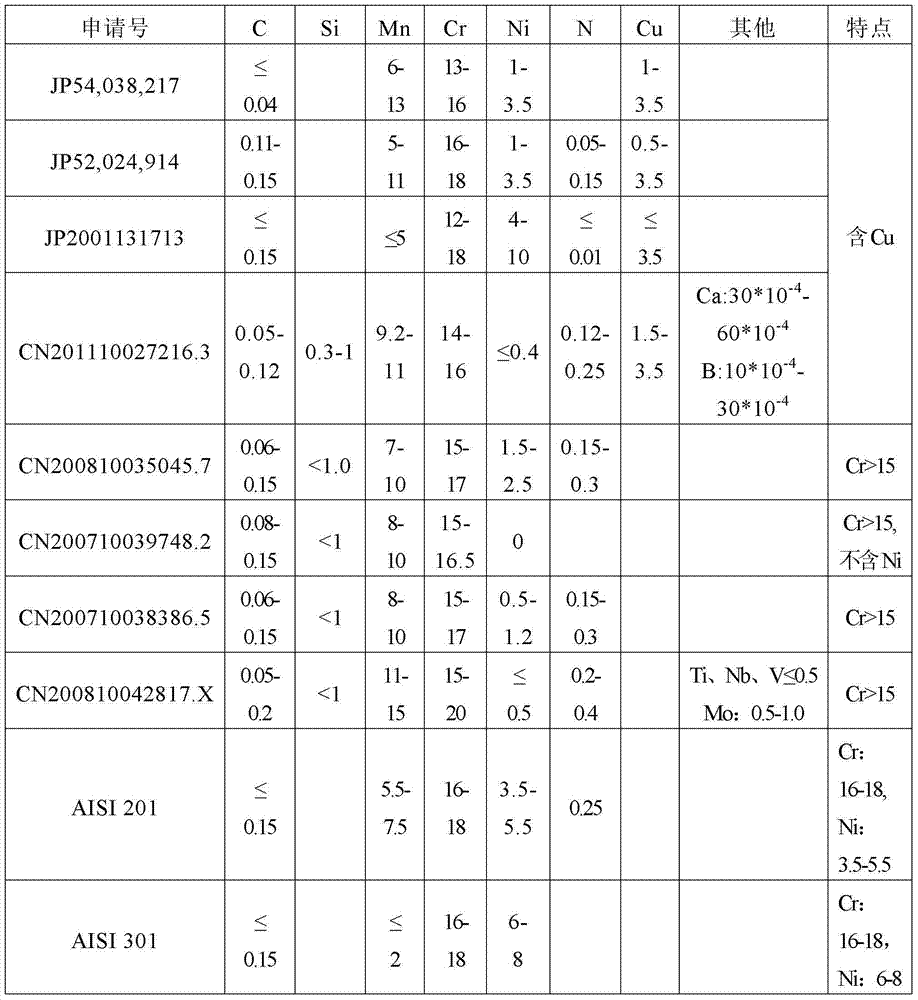

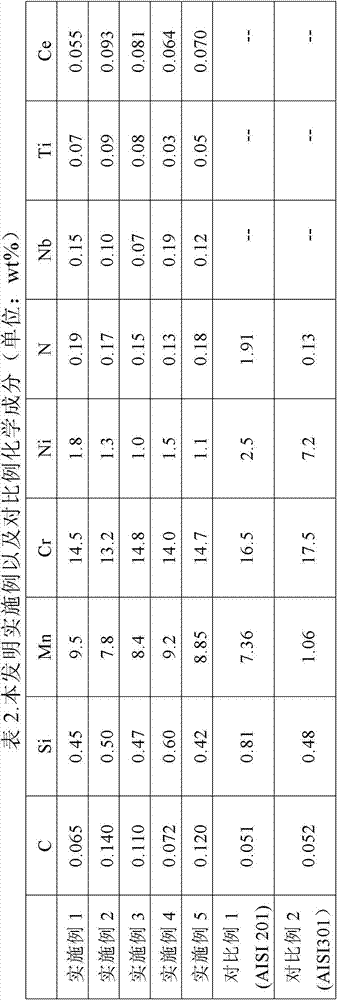

High-strength austenitic stainless steel for automobile frames and manufacturing method thereof

The invention relates to a high-strength austenitic stainless steel for automobile frames and a manufacturing method thereof. The austenitic stainless steel comprises the following chemical components in percentage by weight: 0.05-0.15% of C, 0.4-1% of Si, 7-10% of Mn, at most 0.03% of P, at most 0.01% of S, 13-15% of Cr, 1-2% of Ni, 0.1-0.2% of N, 0.05-0.2% of Nb, at most 0.1% of Ti, 0.05-0.1% of Ce, and the balance of Fe and inevitable impurities, wherein 0.1%<=Nb+Ti<=0.25%.In order to ensure the comprehensive mechanical properties to satisfy the requirements, the austenitic stainless steel manufacturing method adopts two different production techniques for producing high-strength stainless steel with different thicknesses. The yield strength of the finished austenitic stainless steel can reach 600 MPa above, the tensile strength is up to 1000 MPa above, and the elongation percentage is up to 28% above. The austenitic stainless steel is suitable for manufacturing automobile frames, anti-collision beams and other high-strength parts as well as other new-energy vehicle structural members.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

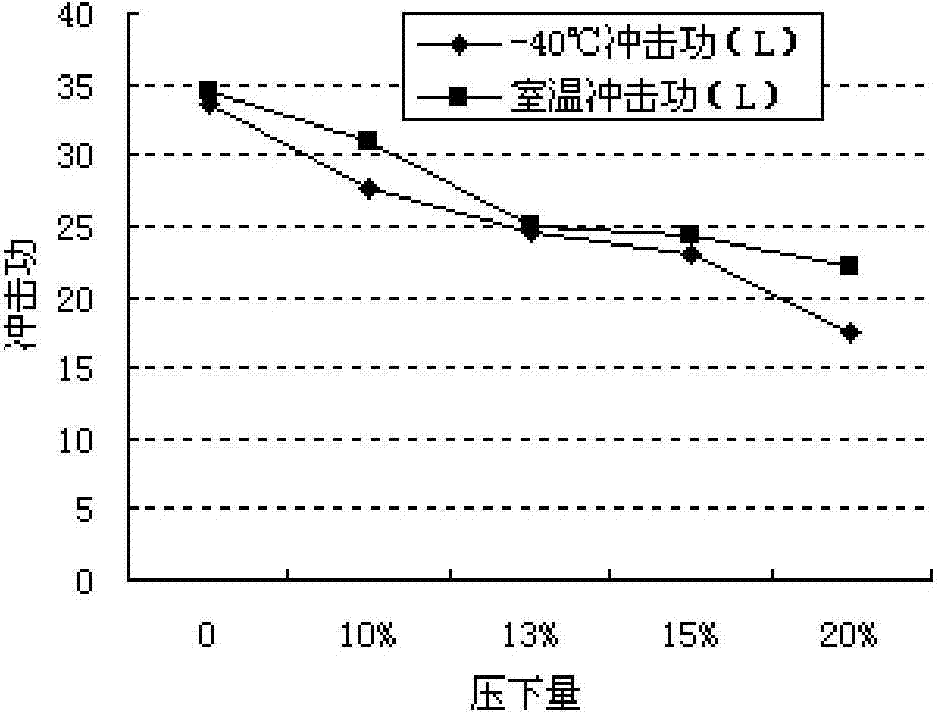

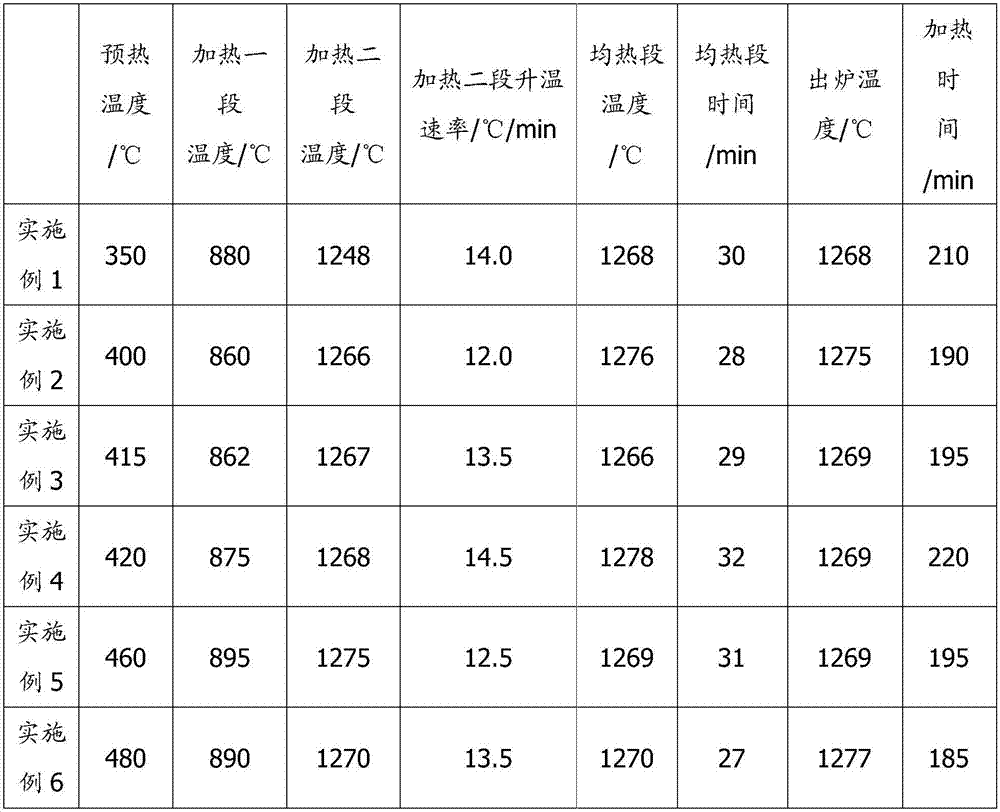

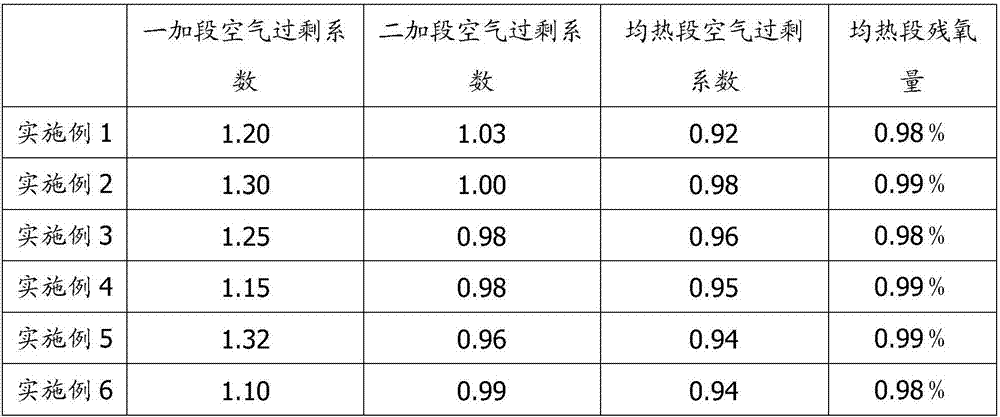

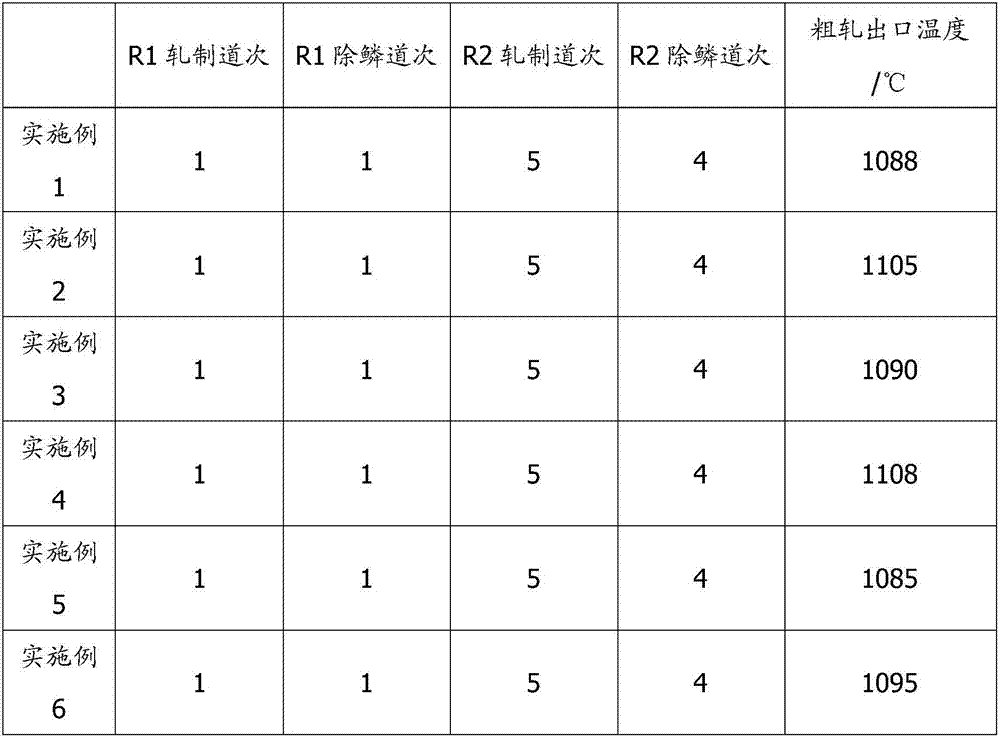

Oxide scale control method for improving corrosion resistance of hot rolled medium plate

ActiveCN103962386AImprove corrosion resistanceReduce contentTemperature control deviceWork treatment devicesScale structureMechanical property

The invention provides an oxide scale control method for improving the corrosion resistance of a hot rolled medium plate and belongs to the technical field of metallurgy. The control method comprises the steps that smelting molten steel is made into a plate billet in a continuous casting mode, and the plate billet is heated, subjected to heat preservation and then roughly descaled, wherein the rough descaling pressure is larger than or equal to 16 MPa, and the rough descaling time is 4-10 seconds; the plate billet is subjected to rough rolling and then finish rolling, and finish descaling is conducted before an odd number of secondary finish rolling stages, wherein the finish descaling pressure is larger than or equal to 16 MPa, and the finish descaling time is 4-10 seconds; after being subjected to finish rolling, the plate billet is placed onto a cooling bed and cooled to the room temperature at the speed of 10-25 DEG C per second. According to the control method, a hot rolling process adjustment scheme is proposed according to an oxide scale structure of the hot rolled medium plate; the cooling speed of the plate billet on the cooling bed is controlled, the oxide scale structure is controlled reasonably by controlling the eutectoid reaction degree of FeO, and therefore the corrosion resistance of the surface of the hot rolled medium plate is improved; since existing equipment and process conditions in a steel mill are utilized, investment cost and production cost are not increased, and the corrosion resistance of the hot rolled medium plate is improved on the basis of guaranteeing the mechanical properties of the hot rolled medium plate.

Owner:NORTHEASTERN UNIV

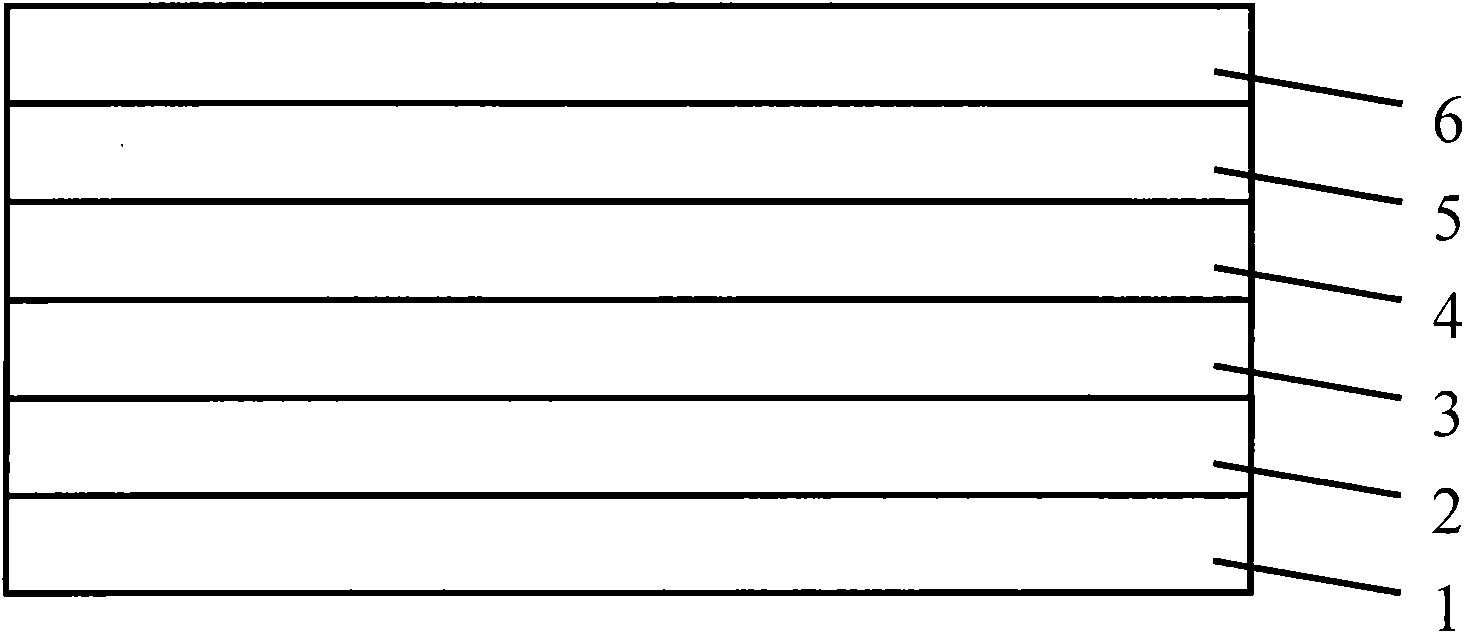

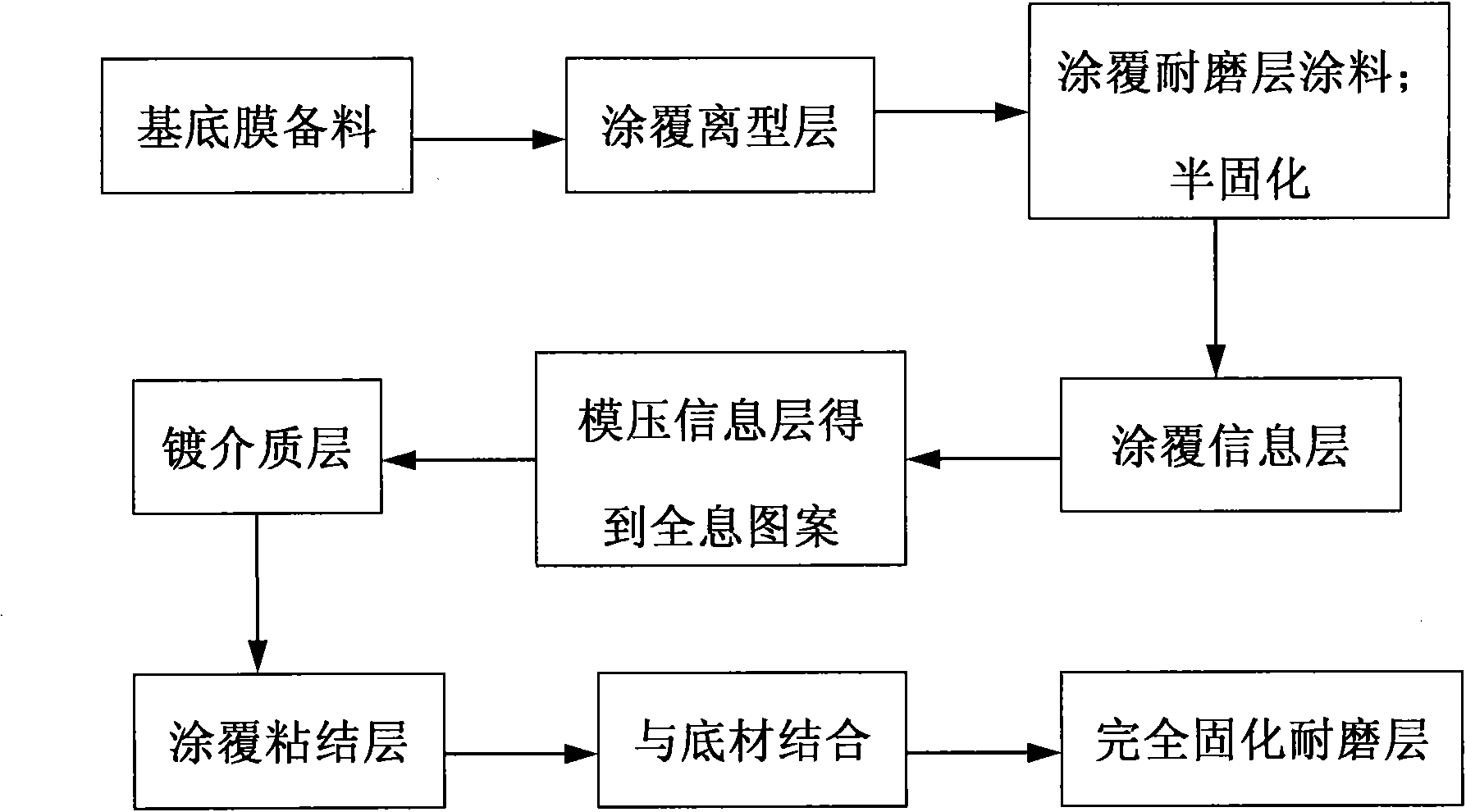

Method for preparing material with holographic patterns

InactiveCN101614954AGuaranteed wear resistanceGuaranteed CorrosionDecorative surface effectsPhotomechanical apparatusInformation layerWear resistance

The invention discloses a method for preparing a material with holographic patterns, which comprises the following steps: forming a releasing layer, an abrasion-resistant layer, an information layer and a dielectric layer on a basement membrane in turn to obtain a holographic transfer membrane, and combining the holographic transfer membrane and a base material at one side of the dielectric layer, wherein the abrasion-resistant layer is formed by coating an abrasion-resistant layer paint on the surface of the releasing layer and then semi-curing the abrasion-resistant layer paint; and fully curing the abrasion-resistant layer after the holographic transfer membrane is combined with the base material to obtain the material with the holographic patterns. The material with the holographic patterns prepared by the method avoids the deformation of the abrasion-resistant layer paint during curing on the premise of ensuring the abrasion resistance and corrosion resistance of the material so as to improve the quality of a product.

Owner:BYD CO LTD

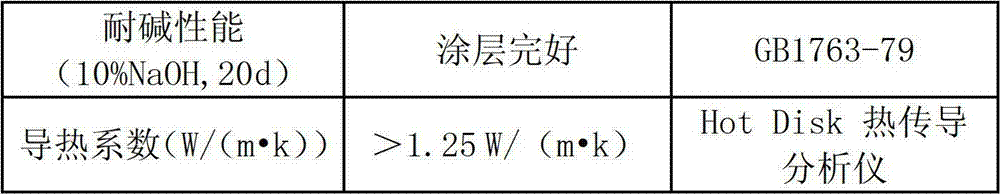

Anti-corrosion heat-conducting coating for heat exchanger and preparation method of coating

ActiveCN102964963AHigh thermal conductivityImprove heat transfer performanceAnti-corrosive paintsEpoxy resin coatingsChemistryTitanium dioxide

The invention discloses an anti-corrosion heat-conducting coating for a heat exchanger and a preparation method of the coating. The formula of the anti-corrosion heating conducting coating comprises the following raw materials by weight percent: 30%-40% of matrix resin, 40%-50% of filler, 0.5%-1% of auxiliaries and 15%-25% of diluting agent, wherein the matrix resin is a mixture of resin A and resin B, the resin A is a SH-023-7 type organic silicon modified epoxy resin product, the resin B is a 2130 type phenolic resin product, and the filler is a mixture of 40%-55% of aluminum nitride, 10%-15% of glass powder, 15%-25% of barium sulfate and 10%-15% of titanium dioxide. With the coating provided by the invention, better anti-corrosion performance and heat-conducting performance of the heat exchanger are realized; and in the filler range, the heat conductivity of the coating is maximally up to 3.912W / (m.k).

Owner:江苏四方威凯科技有限公司

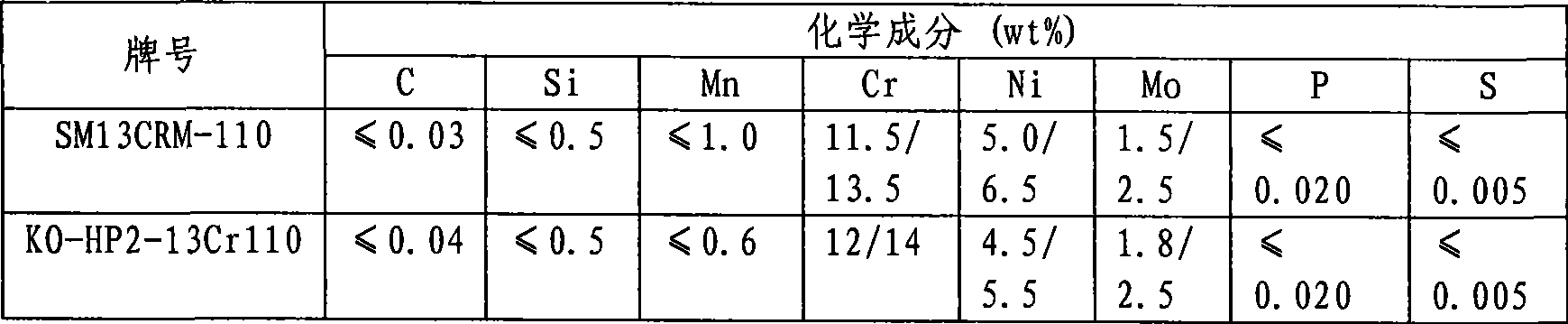

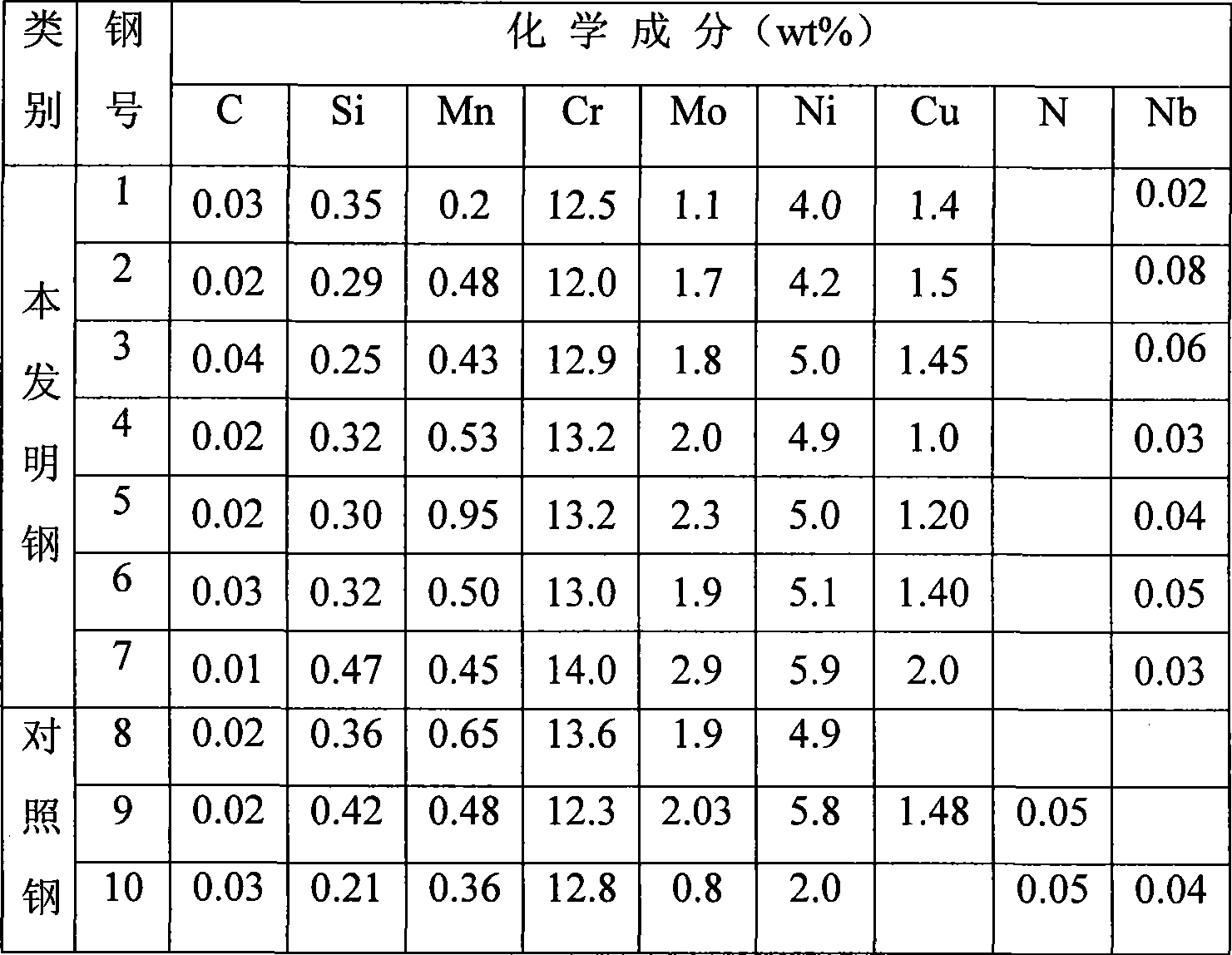

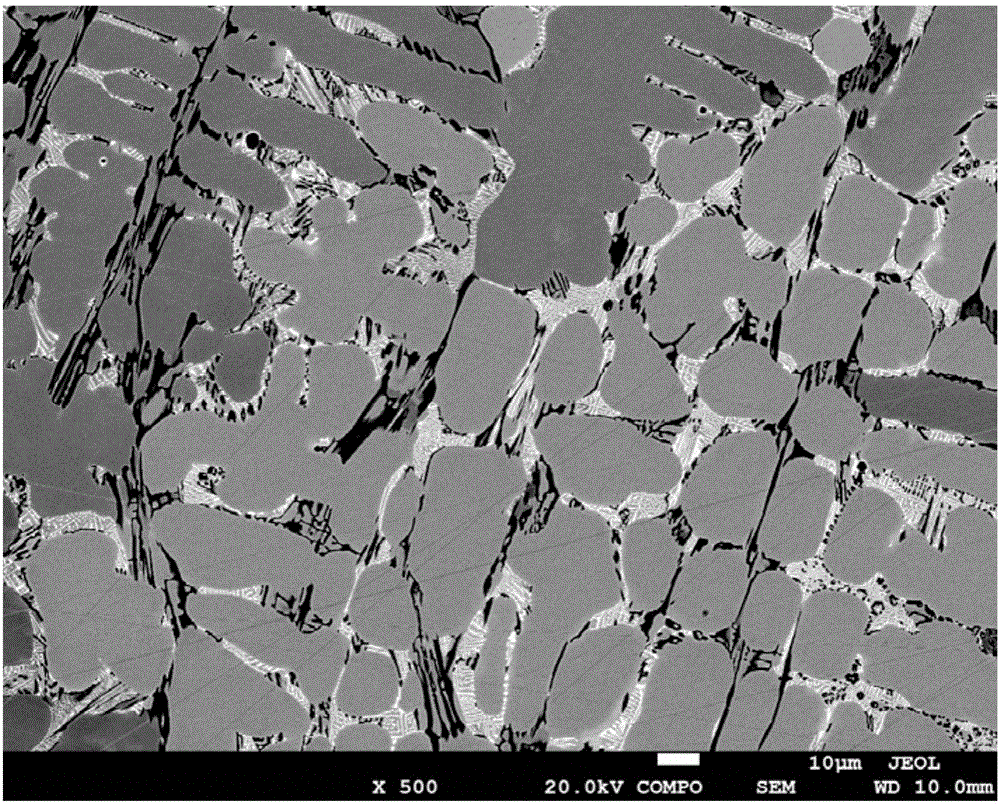

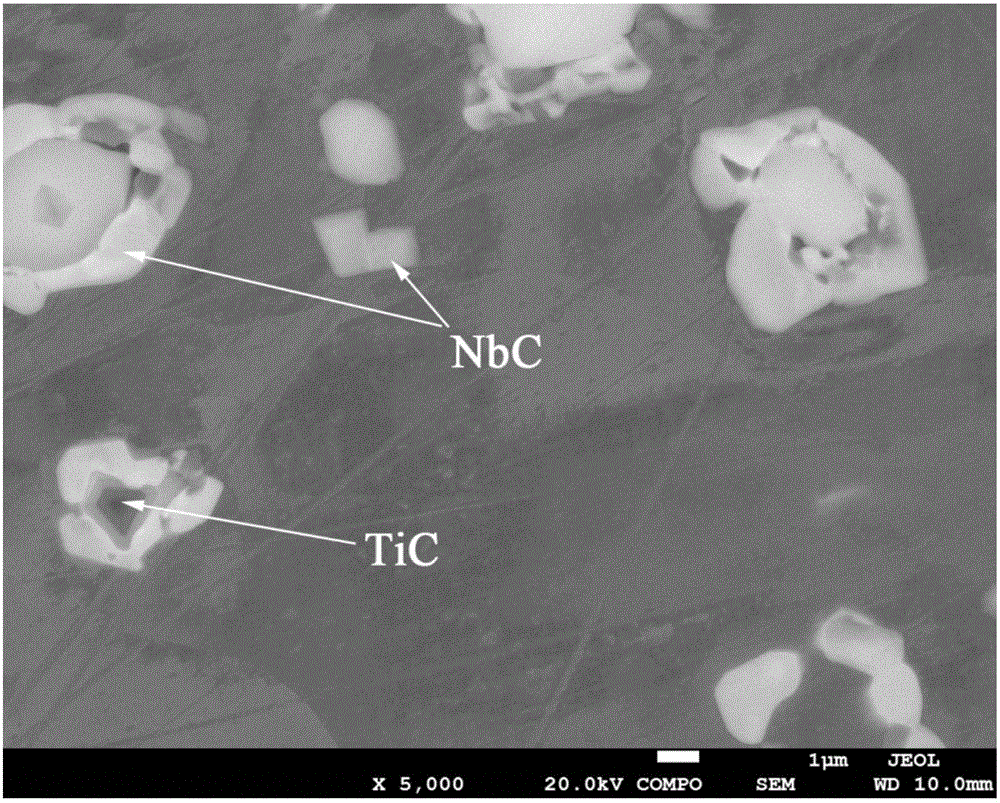

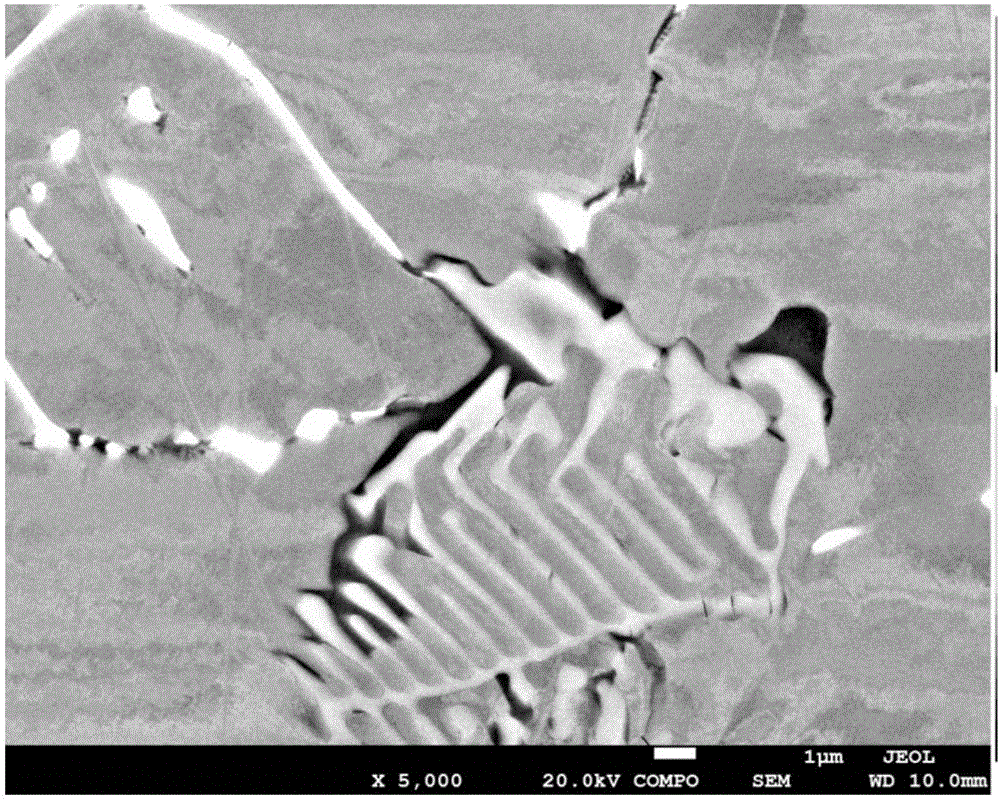

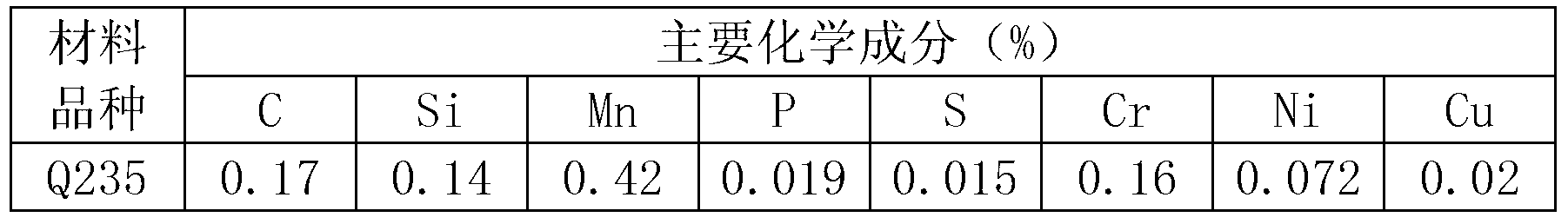

13Cr high anti-carbon dioxide and trace hydrogen sulfide corrosion tubing and casing steel and method for producing the same

ActiveCN101397637AGuaranteed CorrosionSimple ingredientsTemperature control deviceSteelmakingHigh resistance

The invention discloses a 13Cr oil bushing steel which has high resistance to carbondioxide and trace hydrogen sulfide corrosion and a manufacturing method thereof, wherein, the chemical constituents ratio according to weight percentage is as follows: C: 0.01 to 0.05 percent, Si: is less than or equal to 0.5 percent, Mn: 0.20 to 1.00 percent, Cr: 12 to 14 percent, Mo: 1.0 to 3.0 percent, Ni: 4.0 to 6.0 percent, Cu: 1.0 to 2.0 percent, Nb: 0.02 to 0.10 percent, and Fe and inevitable impurity as the rest, and the total amount of the impurity is lower than 0.05 percent. Non-API corrosion-resistant oil bushing can be obtained after electric furnace steelmaking, ingot casting, calcining, cogging, rolling, pipe-manufacturing and reasonable heat treatment. The resistance to hydrogen sulfide corrosion of the materials is obviously improved by copper-niobium alloying.

Owner:BAOSHAN IRON & STEEL CO LTD

Iron-nickel-based high-temperature alloy

The invention discloses iron-nickel-based high-temperature alloy which is resistant to glass corrosion. The alloy comprises components which satisfies the following range requirement in percentage by mass: 0.7% to 1.0% of C, 24% to 30% of Cr, 48% to 55% of Ni, 0.5% to 3.5% of Co, smaller than or equal to 0.5% of Mn, smaller than or equal to 0.5% of Si, 0.5% to 2.5% of Nb, smaller than or equal to 2.5% of Mo, 5% to 10% of W, 0.1% to 1.2% of Ti, 0.1% to 3.5% of Al and the balance Fe. The alloy can be used in an as-cast condition or in a solid solution state; the compressive yield strength of the alloy at 1000 DEG C and 1100 DEG C is respectively higher than 100MPa and 60MPa; the 500-hour deformation degree of the alloy under a 1050DEG C / 25MPa compression creep condition is not higher than 1.5%; the 180-hour deformation degree of the alloy under a 1050DEG C / 35MPa compression creep condition is not higher than 5.0%.

Owner:HUANENG POWER INTERNATIONAL +1

Aluminum matrix composite plate rolling method

ActiveCN106424196AImprove performanceImprove billet structureTemperature control deviceMetal rolling arrangementsHigh intensityLarge deformation

The invention discloses an aluminum matrix composite plate rolling method and belongs to the field of metal matrix composite molding machining. According to the method, on the basis that the density of a composite billet used for rolling is regulated, a plate blank is manufactured through multidirectional free forging and extruding, and the thickness of a rolled plate is 1-150 mm; sectional temperature rolling is adopted, cogging and reversing rolling are both conducted in a recrystallization temperature region so as to avoid detects generated in subsequent rolling, the rest of passes are subjected to large deformation rolling at a dynamic recovery temperature, and the rolling efficiency is improved; the regions of the rolling temperature and the rolling speed are narrowed so that organization can be precisely controlled and detects can be avoided; and medium and low temperature finish rolling is adopted so as to ensure the plate performance. In this way, the manufactured aluminum matrix composite plate has high strength and good corrosion resistance and fatigue resistance, and efficient rolling of large-size plates can be achieved.

Owner:中科复材(滨州)新材料有限公司

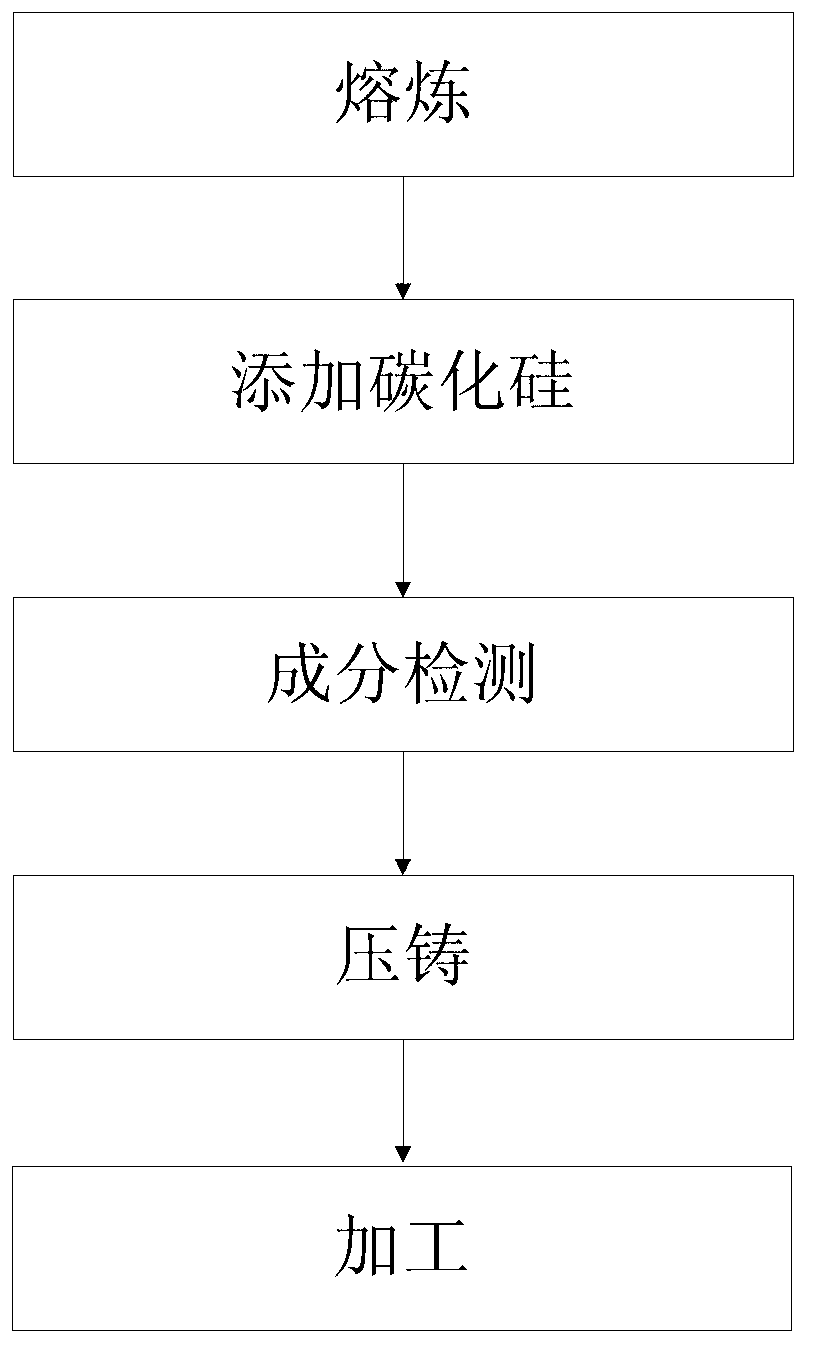

Preparation method of nanoscale silicon carbide magnesium alloy material

ActiveCN103320631AGuaranteed CorrosionGuaranteed ductilityTransportation and packagingMetal-working apparatusManganeseHardness

The invention provides a preparation method of a nanoscale silicon carbide magnesium alloy material. The nanoscale silicon carbide magnesium alloy material is prepared by uniformly dispersing and distributing a light nanoscale silicon carbide material through particle fine treatment in the magnesium alloy material. The nanoscale silicon carbide magnesium alloy material comprises the following components in percentage by weight: 1-1.5% of nanoscale silicon carbide, 10-11.5% of aluminum, 1.1-1.8% of zinc, 0.05-0.2% of manganese, less than or equal to 0.2% of inevitable impurities, and the balance of magnesium. According to the preparation method of the nanoscale silicon carbide magnesium alloy material provided by the invention, higher solid solubility is formed in a magnesium alloy substrate by means of characteristics of high hardness and wear resistance and the like of nanoscale silicon carbide, so that the stretching and compressing yield strength is enhanced while the welding performance, corrosion resistance and malleability of the nanoscale magnesium alloy material are ensured.

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

Spraying process for automobile hub

ActiveCN106622898AGuaranteed CorrosionGuaranteed wear resistancePretreated surfacesCoatingsEpoxySand blasting

The invention discloses a spraying process for an automobile hub. The spraying process for the automobile hub comprises the following steps of S1, pretreating the surface of the automobile hub: removing oil on the surface of the automobile hub, and then removing rust on the surface of the hub through sand blasting or sand papering; S2, soaking the hub in a diluted alkali solution, taking out the hub, and washing with water; S3, preparing a diluted silane coupling agent solution, soaking the hub into the silane coupling agent solution, taking out the hub, and drying in the air; S4, spraying epoxy resin paint on the surface of the hub, and solidifying at high temperature to form a paint layer; S5, spraying paint on the surface of the hub, and solidifying at high temperature; and S6, spraying gloss oil on the surface of the hub, drying in the air at the room temperature. According to the spraying process for the automobile hub, the metal surface of the hub and the paint are fastened and combined through a silane coupling agent, a hub base material, the coupling agent and a paint coating are combined through chemical bonds, the adhesive force of the paint coating is greatly improved, and in addition, the silane coupling agent forms a silane film layer on the surface of the hub, so that the hub is effectively coated, and the resistance to corrosion of the hub is improved.

Owner:GUANGDONG DCENTI AUTO PARTS STOCK LTD

Hot-rolling high-strength weather-resistant steel and manufacturing method thereof

The invention provides hot-rolling high-strength weather-resistant steel and a manufacturing method thereof. Chemical components of the hot-rolling high-strength weather-resistant steel comprise, by mass percentage, 0.05-0.07% of carbon, 0.5-0.6% of silicon, 0.80-1.0% of manganese, 0.03-0.07% of phosphorus, less than or equal to 0.005% of sulphur, 0.25-0.35% of chromium, 0.25-0.35% of copper, 0.09-0.11% of titanium and the balance iron and inevitable impurities. By means of the hot-rolling high-strength weather-resistant steel and the manufacturing method thereof, the ratio of nickel to copperequals to zero; in addition, technological steps are improved so that the functions of the element Ni can be replaced; the copper brittleness defect is inhibited; and good surface quality of a steelplate is guaranteed.

Owner:BEIJING SHOUGANG CO LTD

Nano metal ceramic electrodeposited composite coating at inner hole wall of oil drill pipe and preparation method thereof

The invention discloses a nano metal ceramic electrodeposited composite coating at an inner hole wall of an oil drill pipe and a preparation method thereof, and belongs to the technical field of modification of the inner hole wall of the oil drill pipe. The preparation method disclosed by the invention comprises the following steps: by taking electrocleaning and activating as pretreatment processes, firstly, coating a layer of nickel coating on the surface of the inner hole wall of an oil drill pipe by adopting a fast nickel plating liquid; carrying out brushing electroplating on a nano metal ceramic composite coating by adopting a brushing electroplating nano composite plating solution; and preparing a surface composite coating with compact tissue and excellent performance on the surface of an oil drill pipe sample. The nano metal ceramic electrodeposited composite coating has the advantages of being stable in process, high in coating hardness, good in abrasive resistance, good in corrosion resistance and the like, and plays an important role in development and application of the oil drill pipe.

Owner:JILIN UNIV +1

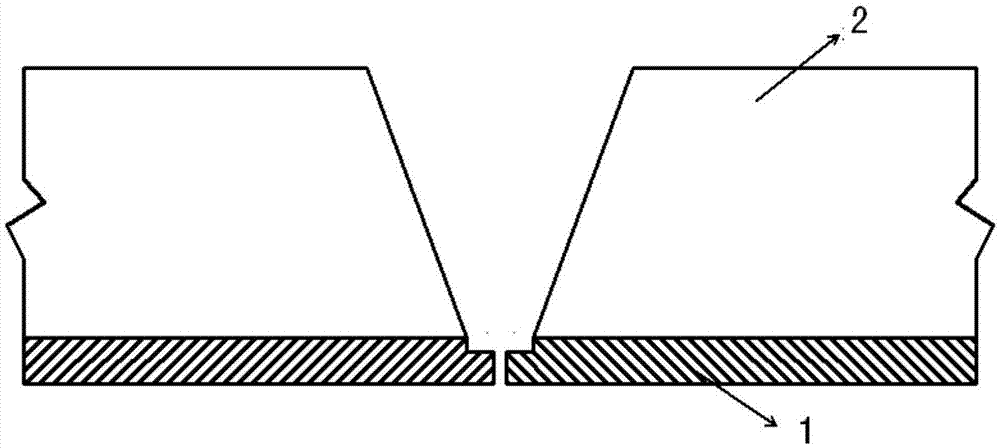

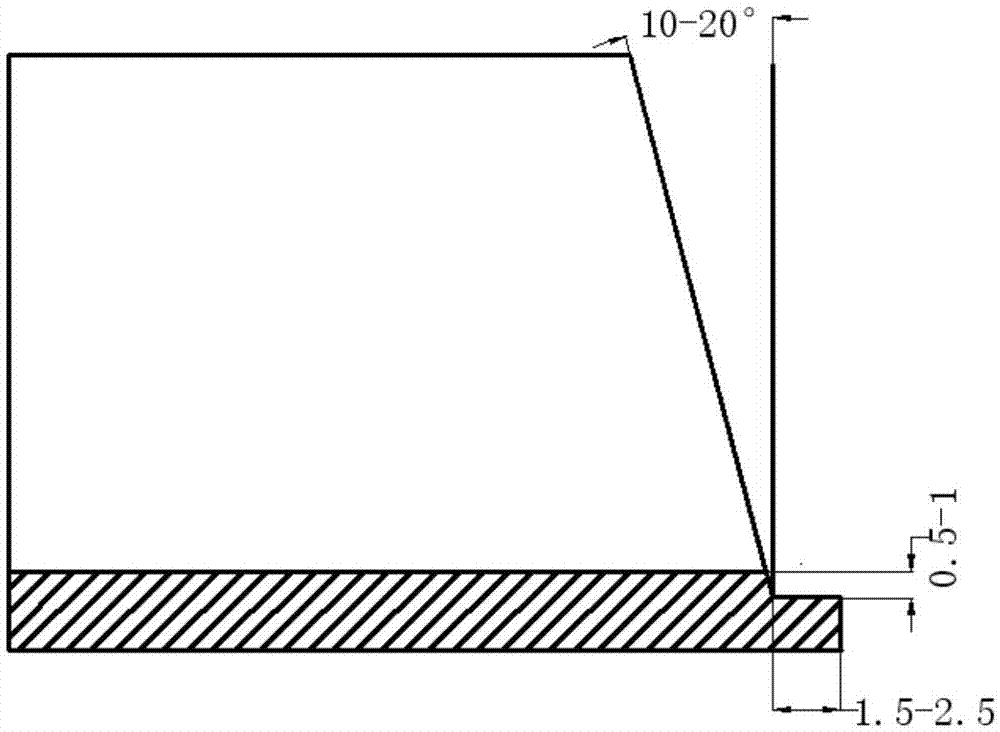

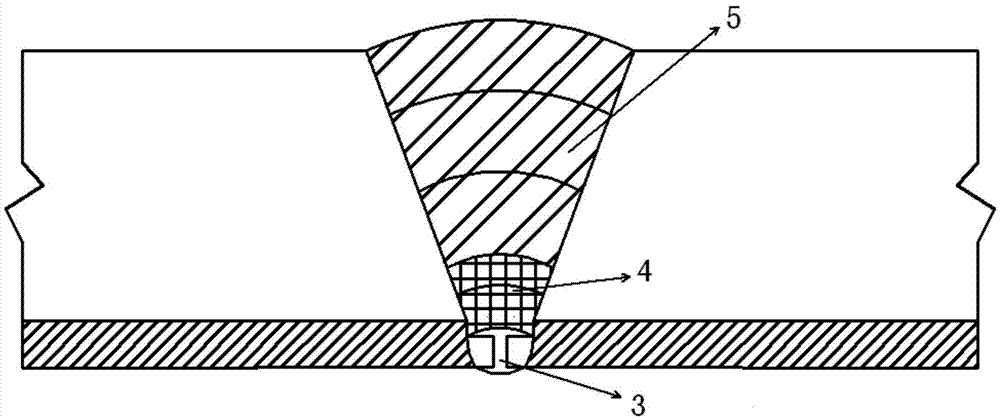

Nickel-based double-metal composite pipe all-position automatic welding method

ActiveCN106975819ALow costLow efficiencyArc welding apparatusMetal working apparatusButt jointEngineering

The invention discloses a nickel-based double-metal composite pipe all-position automatic welding method. The method includes the steps that (1), pipe ends of two composite pipes are machined into platform-shaped beveled edges; (2), the two composite pipes are in butt joint through internal clamps in the pipes; (3), coating layer backing welding and transition layer welding are performed in sequence through TIG welding or hot wire TIG welding; (4), base layer welding is performed through TIG or MIG welding. The same nickel-based alloy welding material is adopted for the coating layer welding, the transition layer welding and the base layer welding, and the Ni content of the nickel-based alloy welding material is higher than or equal to that of the coating layer. By means of the machined platform-shaped beveled edges, it is avoided that coating layer nickel-based metal and base layer metal dilute each other, and the corrosion performance of a nickel-based composite pipe circumferential weld is guaranteed; and the same nickel-based alloy welding material is adopted for all layers of welding, the requirements for coating layer metal corrosion and base layer toughness are met, and it is avoided that the nickel-based alloy base layer ring welding generates hot crack defects.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

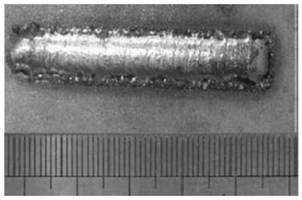

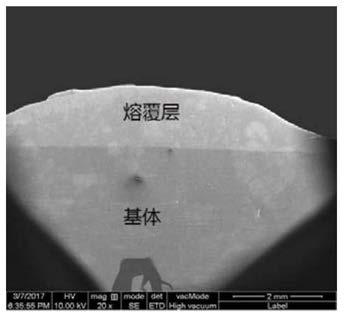

Nickel base alloy powder, corresponding corrosion-resisting coating and preparing method thereof

ActiveCN109988958AReduce contentReduce manufacturing costMetallic material coating processesSurface engineeringProcess equipment

The invention discloses nickel base alloy powder, a corresponding corrosion-resisting coating and a preparing method of the nickel base alloy powder and belongs to the technical field of surface engineering. The nickel base alloy powder comprises, by mass percent, 30.00%-35.00% of Cr, 15%-18% of Fe, 3.50%-4.00% of Mo, 1.50%-3.50% of Si, 1.50%-3.50% of Mn, 1.50%-3.50% of Cu, 1.00%-5.00% of Ti, 0.5%-2.0% of B, smaller than or equal to 0.03% of S, smaller than or equal to 0.04% of P, smaller than or equal to 0.04% of C and the balance Ni. By means of the nickel base alloy powder, after fusion covering of the nickel base alloy powder is conducted on a stainless steel and low carbon steel base body, the surface of a fusion covering layer is compact, the microscopic appearance is good, defects of air holes, cracks and the like do not exist, hardness is high, the corrosion resisting performance is good, existing high-temperature-resisting concentrated sulfuric acid alloy steel can be replaced, sulfuric acid manufacturing process equipment cost is effectively reduced, and the application prospect is wide.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

Sulfuric acid resistant ferritic stainless steel and manufacturing method thereof

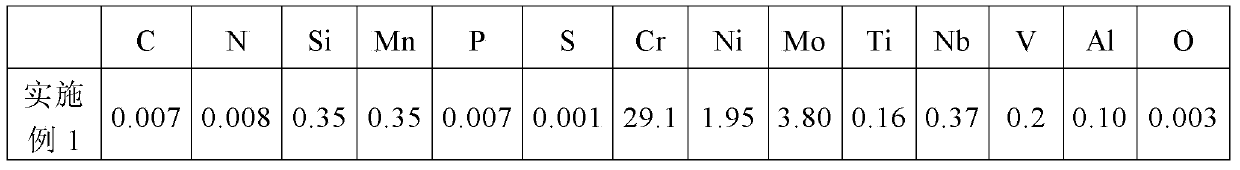

InactiveCN105506502AHigh sulfuric acid corrosion resistanceImprove low temperature impact toughnessAlloyAustenite

The invention relates to a sulfuric acid resistant ferritic stainless steel and a manufacturing method thereof. The sulfuric acid resistant ferritic stainless steel comprises the following chemical components by weight: 0.002-0.015% of C, 0.002-0.015% of N, 0.2-1.0% of Si, 0.2-0.5% of Mn, less than or equal to 0.030% of P, less than or equal to 0.003% of S, 28-30% of Cr, 1.5-3% of Ni, 2.0-4.0% of Mo, 0.1-0.3% of V, 0.10-0.30% of Ti, 0.2-0.5% of Nb, 0.05-0.1% of Al, with the sum of Cr+3.3*Mo being greater than or equal to 38%, and Ti+Nb being greater than or equal to 16(C+N), less than or equal to 0.005% of O, and the balance Fe and inevitable impurities. The ferritic stainless steel provided by the invention can tolerate the corrosion of various concentration sulfuric acids at a temperature of less than 60 DEG C and at a concentration of less than or equal to 98wt%, also has good impact toughness and welding performance. With a pitting resistance equivalent PREN of greater than or equal to 38, the ferritic stainless steel has corrosion resistance far superior to conventional ferritic stainless steel, and is equivalent to superaustenitic stainless steel and nickel based alloys.

Owner:BAOSTEEL STAINLESS STEEL

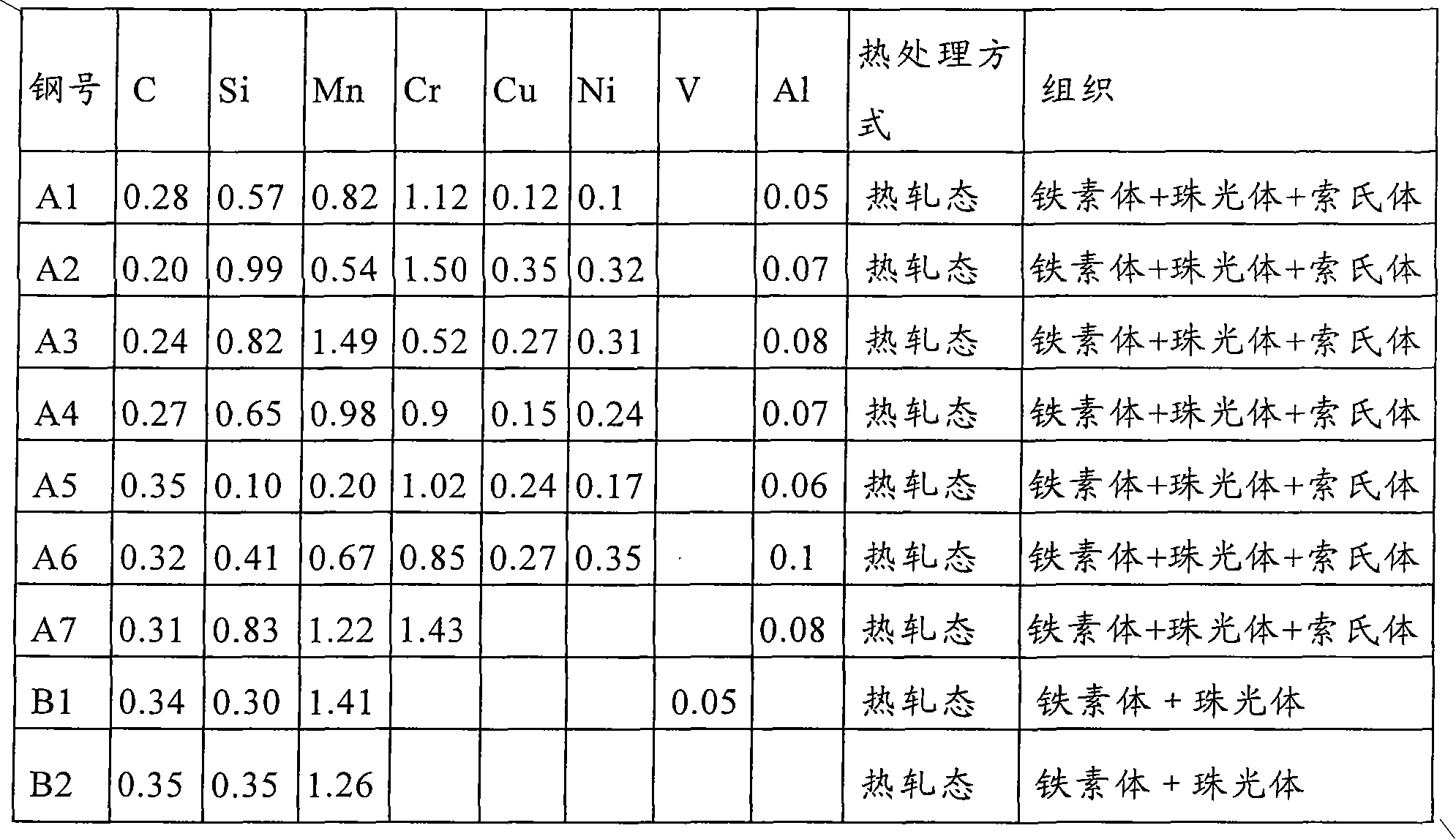

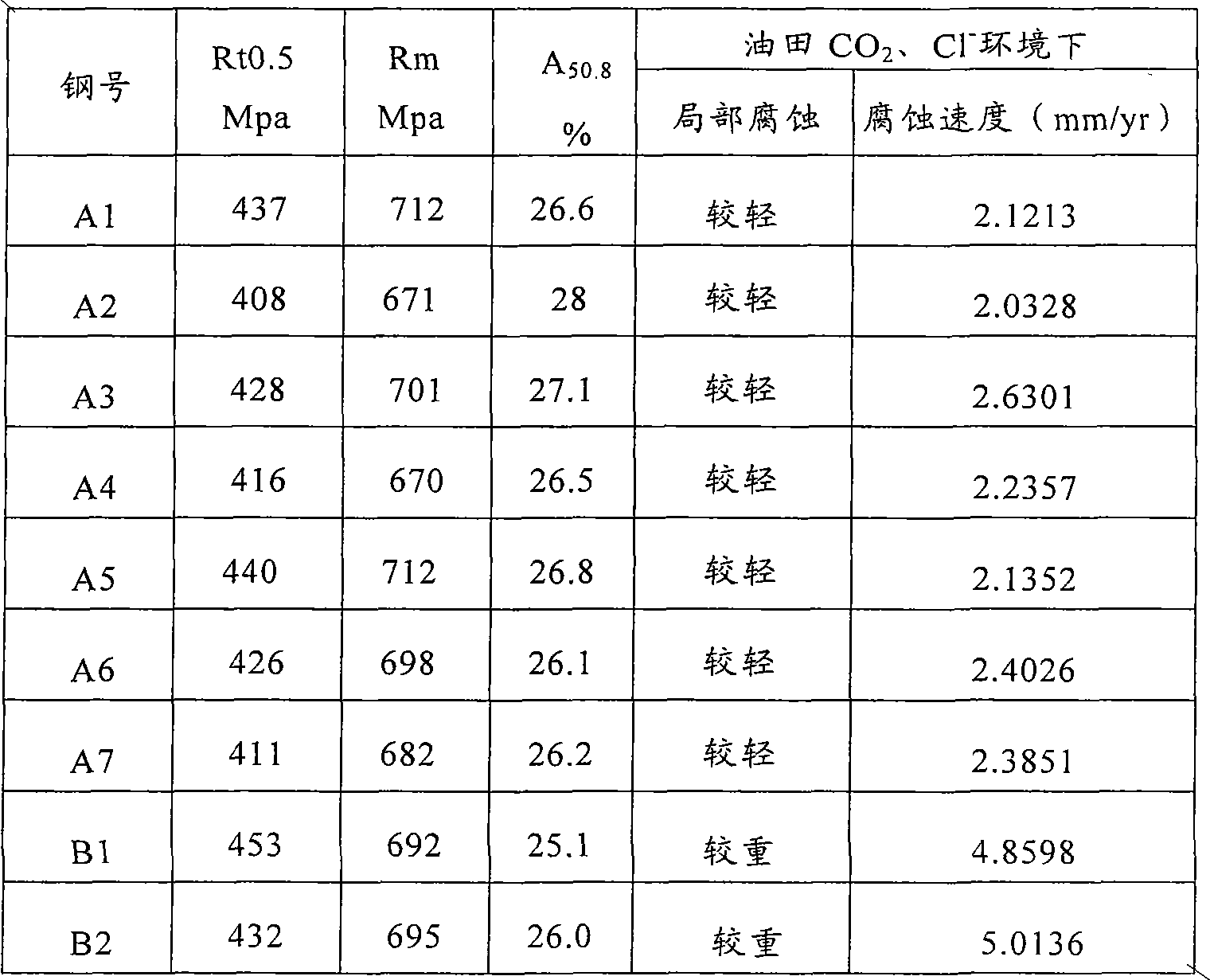

Low-alloy steel resistant to carbon dioxide corrosion

ActiveCN101928893ASimple preparation processOmit quenching and tempering heat treatment procedureDrilling rodsDrilling casingsChemical compositionCarbon dioxide corrosion

The invention relates to a low-alloy steel resistant to carbon dioxide corrosion, which comprises the following chemical components in percentage by weight: 0.20-0.35% of C, 0.10-1.0% of Si, 0.20-1.5% of Mn, 0.5-1.5% of Cr, being more than or equal to 0.35% of Ni, being more than or equal to 0.35% of Cu, 0.01-0.10% of Al, and the balance of Fe and inevitable impurities, wherein the total content of impurity elements is lower than 0.05 wt%. In manufacturing process of the alloy steel, heat treatment is not carried out after smelting, continuous casting, hot rolling and air cooling. The strength of the oil well pipe prepared by the alloy steel is 55 ksi, thus the oil well pipe prepared by the alloy steel is suitable for shallow wells resistant to carbon dioxide corrosion.

Owner:BAOSHAN IRON & STEEL CO LTD

Stainless steel welding method

ActiveCN103785931AGuaranteed mechanical propertiesGuaranteed CorrosionArc welding apparatusWelding/soldering/cutting articlesButt weldingShielding gas

The invention relates to a stainless steel welding method. The method comprises the following steps that a V-shaped groove is formed in a butt welding seam; welding is carried out on a bottoming welding seam, carbon dioxide with content larger than 99.9% is used as protecting gas for welding, gas flow is controlled to be 15-17 liters per minute, and the protecting gas does not pass through the back of the welding seam; welding is carried out on a front groove cover face welding seam, the carbon dioxide with the content larger than 99.9% is used as the protecting gas for welding, and gas flow is controlled to be 15-17 liters per minute; welding is carried out on a back welding seam, the carbon dioxide with the content larger than 99.9% is used as the protecting gas for welding, and gas flow is controlled to be 15-17 liters per minute. As the carbon dioxide is used as the protecting gas, by means of the three-welding-seam process comprising the bottoming welding seam, the cover face welding seam and the back welding seam, the mechanical property and the corrosion resistance of the welding seams are effectively ensured, and the problem that the quality of appearance of the welding seams can not be controlled easily is solved.

Owner:CRRC YANGTZE CO LTD

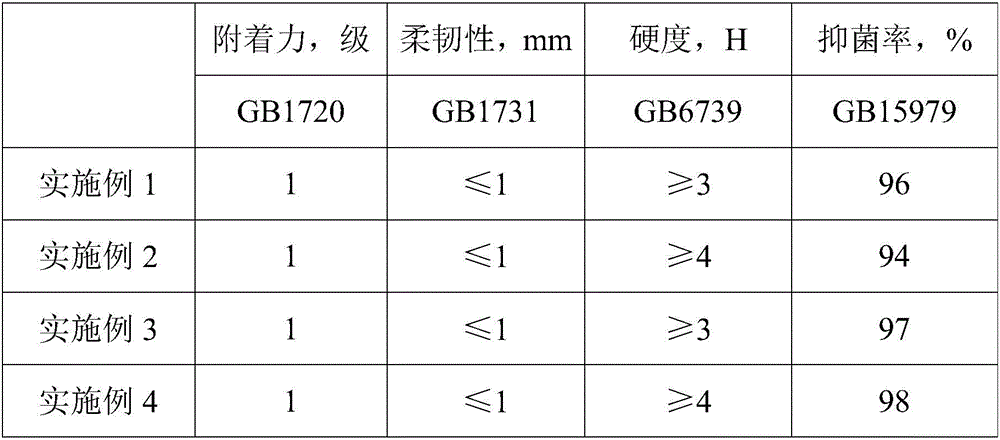

Kitchen ware dedicated electrostatic spraying powder coating and preparation method thereof

InactiveCN106609096AStorage Stability BalanceMelting balanceAntifouling/underwater paintsPaints with biocidesEpoxySorbent

The invention relates to a kitchen ware dedicated electrostatic spraying powder coating and a preparation method thereof, wherein the coating comprises the following raw materials in parts by weight: 60-90 parts of epoxy resin, 15-35 parts of fluororesin, 3-8 parts of phenolic hydroxyl resin, 5-25 parts of an antibacterial adsorbent, 2-6 parts of nano silicon dioxide, 1-5 parts of nano titanium dioxide, 1-5 parts of nano calcium carbonate, 5-15 parts of bauxite, 5-10 parts of precipitated barium sulfate, 10-20 parts of titanium dioxide, 2-5 parts of zinc stearate, 1-3 parts of benzoin, 2-6 parts of hydroxyethylmethylcellulose, 0.2-1 part of polyamide wax, 0.5-2 parts of a leveling agent, and 2-6 parts of an amine curing agent. According to the kitchen ware dedicated electrostatic spraying powder coating and the preparation method thereof disclosed by the invention, the construction requirements of electrostatic spraying can be met, moreover, the bacteriostatic and bactericidal effects can be played, and the coating also has the ability to adsorb odorous substances in kitchens.

Owner:TIANCHANG JINLING ELECTRONICS

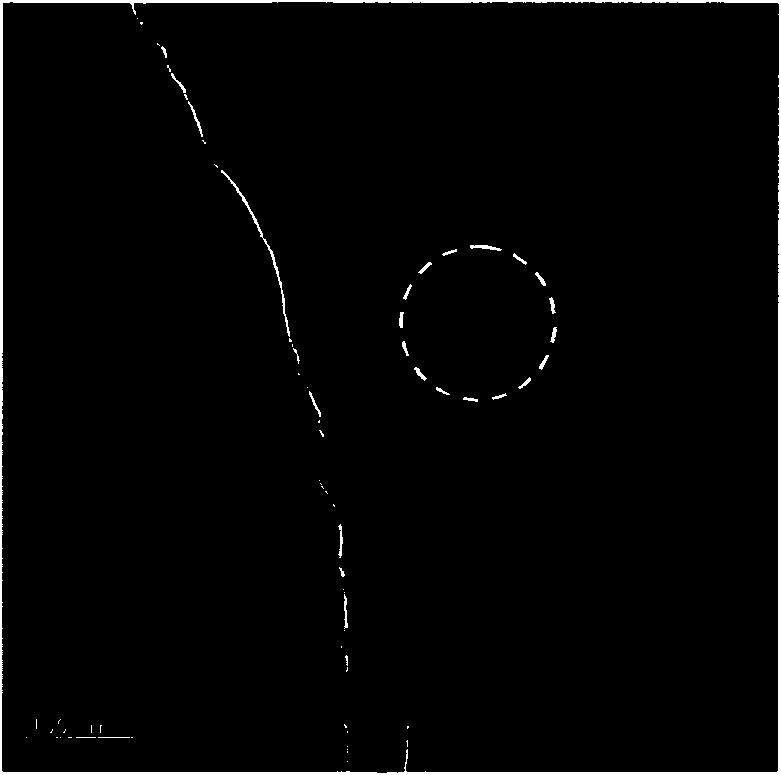

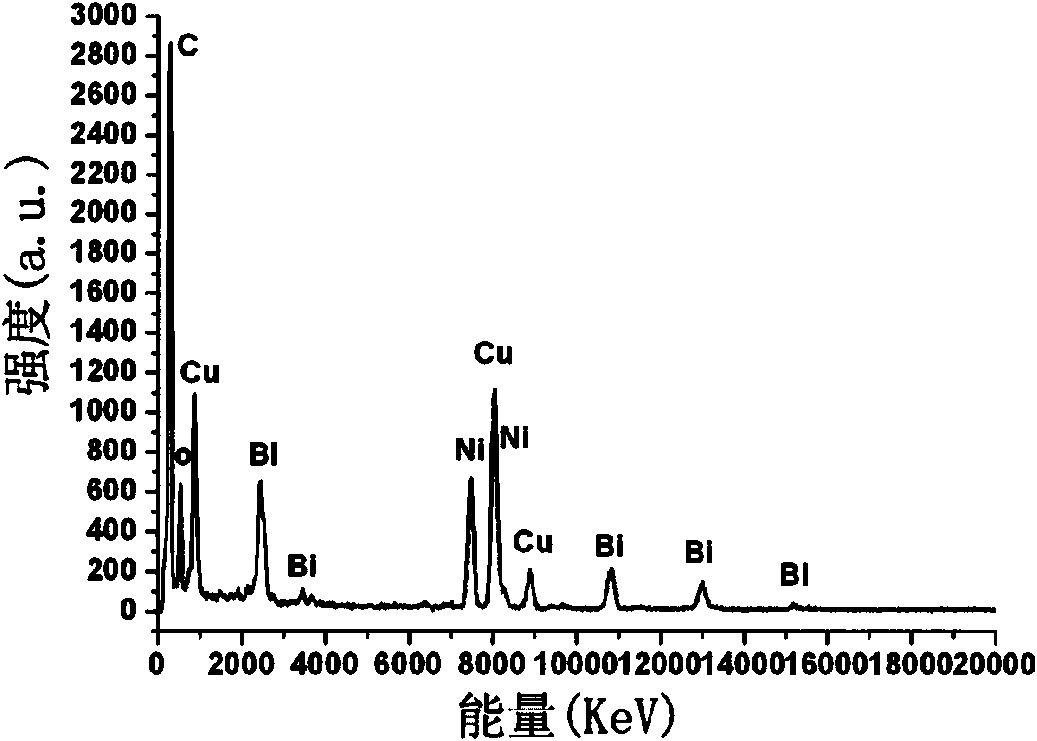

Nano cable made of magnetic material and half-metallic material and preparation method thereof

InactiveCN101937732AHigh surface contactSolve technical problemsAnodisationSingle bars/rods/wires/strips conductorsEngineeringNanometre

The invention relates to a nano cable made of a magnetic material and a half-metallic material and a preparation method thereof. The nano cable comprises a nano cable core and a cable shell layer, wherein the cable shell layer is coated outside the nano cable core, and the nano cable core and the cable shell layer are coaxial; the nano cable core is made of half-metallic bismuth, and the nano cable shell layer is made of magnetic metallic nickel; and the diameter of the nano cable core is 20-170nm, and the thickness of the nano cable shell layer is 10-80nm. The preparation method comprises the following steps of: obtaining a through-hole alumina template by adopting a secondary anode oxidation method, evaporating a metallic membrane on the alumina template, carrying out corroding to form a through hole, then depositing in electrolyte to realize the direct electrochemical deposition in the through hole of the alumina template to obtain a nickel (shell) and bismuth (core) nano cable, and finally placing a bismuth core wire and a nickel shell into the through hole thereof and placing into a strongly alkaline solution to corrode the alumina template to prepare the nano cable comprising the bismuth core wire and the nickel shell.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method for realizing edge insulation of solar cell by wet process

InactiveCN102623560ASolve the problem of overcuttingReliable methodFinal product manufactureSemiconductor devicesHydrofluoric acidSolar cell

The invention discloses a method for realizing edge insulation of a solar cell by wet process. The method comprises the following steps that: firstly, adding a hydrofluoric acid solution into a hydrofluoric acid tank so that part of an idler wheel is immersed into the hydrofluoric acid solution and a moderate amount of hydrofluoric acid solution is contained in tiny grooves of the idler wheel during rotation of the idler wheel; and arranging a silicon wafer on the idler wheel, removing phosphorosilicate glass on the back and edge of the silicon wafer through hydrofluoric acid, and remaining phosphorosilicate glass on the front surface of the silicon wafer; secondly, after the phosphorosilicate glass on the back and edge of the silicon wafer is removed, drying a bit of hydrofluoric acid solution seeping on the front surface of the silicon wafer by windward cutter; and thirdly, feeding the silicon wafer into an etching tank, and corroding PN (positive-negative) junctions on the back and edge of the silicon wafer by the mixed solution of hydrofluoric acid and nitric acid. The method is simple to operate and has good effects.

Owner:ZHEJIANG JINKO SOLAR CO LTD

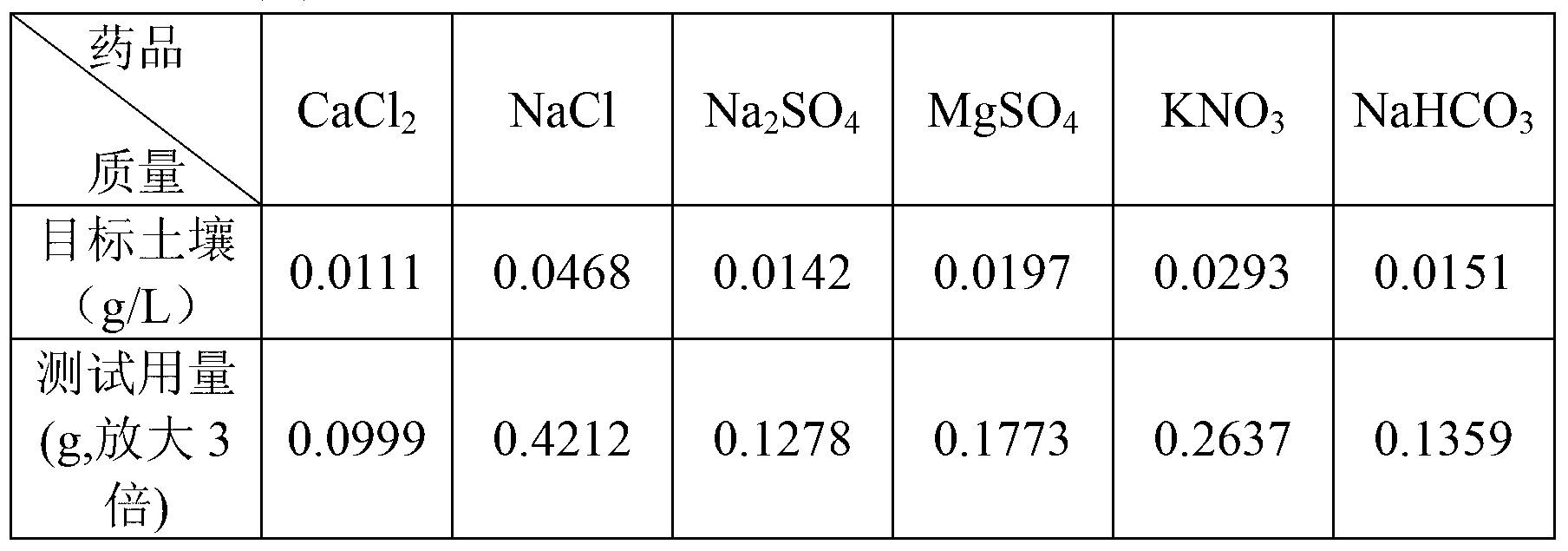

Accelerated corrosion testing method for simulating soil corrosion process

ActiveCN103308443ASoil Corrosion Resistance GuaranteeGuaranteed CorrosionWeather/light/corrosion resistanceHydrogenTest sample

The invention discloses an accelerated corrosion testing method for simulating a soil corrosion process. The method comprises the following steps of: (1) preparing a testing solution from salt and water according to components of target soil; (2) adjusting the pH (Potential of Hydrogen) value of the testing solution to a testing value by H2SO4 or NaOH, thus taking the testing solution as an impregnation medium for simulating soil corrosion, wherein the testing value is the same as the pH value of the target soil; (3) mixing diatomite, which is taken as a carrier, with an impregnation medium to prepare testing soil which is basically same as the target soil in physicochemical properties; and (4) testing a test sample in the testing soil according a pre-set testing temperature, relative humidity and testing period.

Owner:CENT IRON & STEEL RES INST

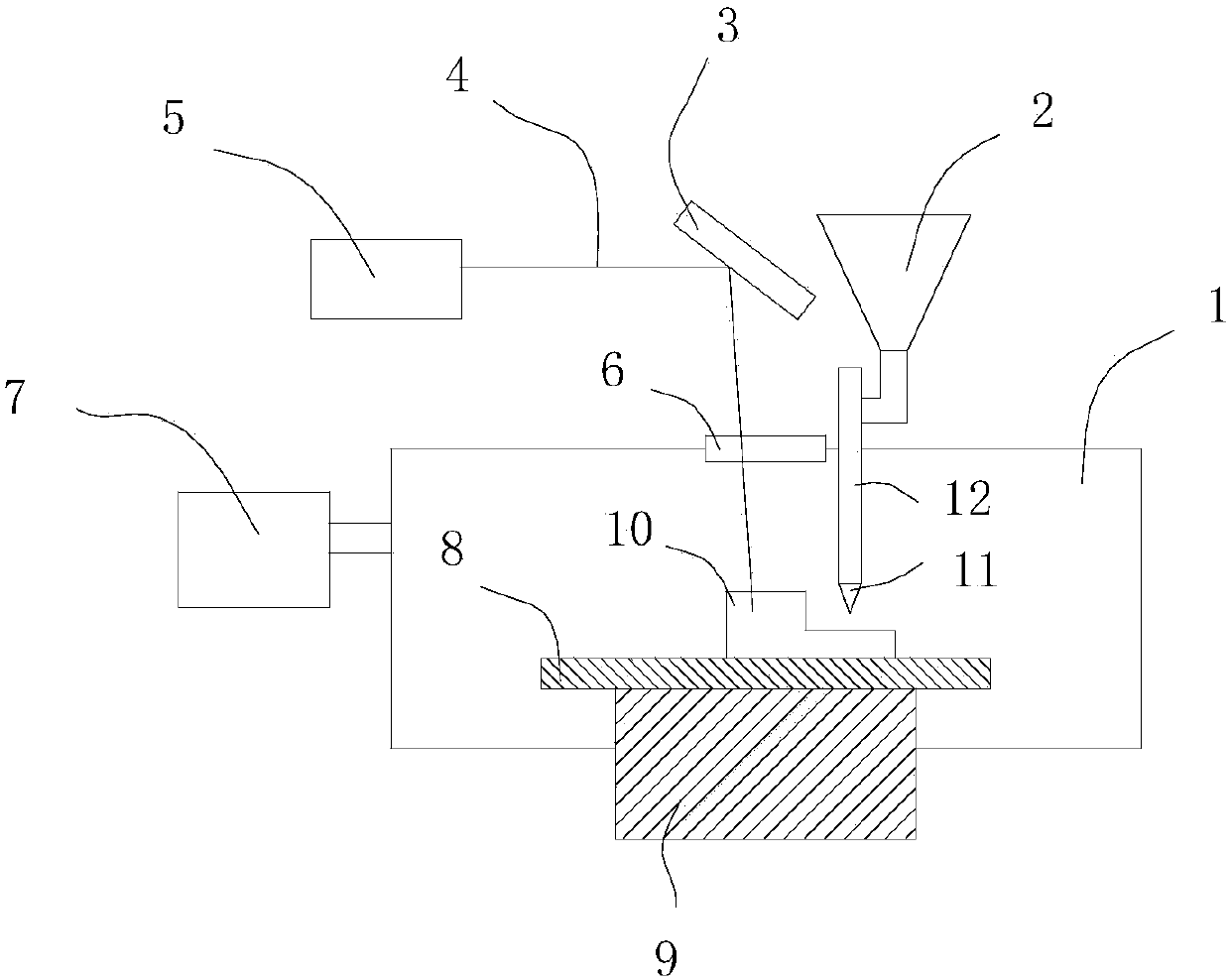

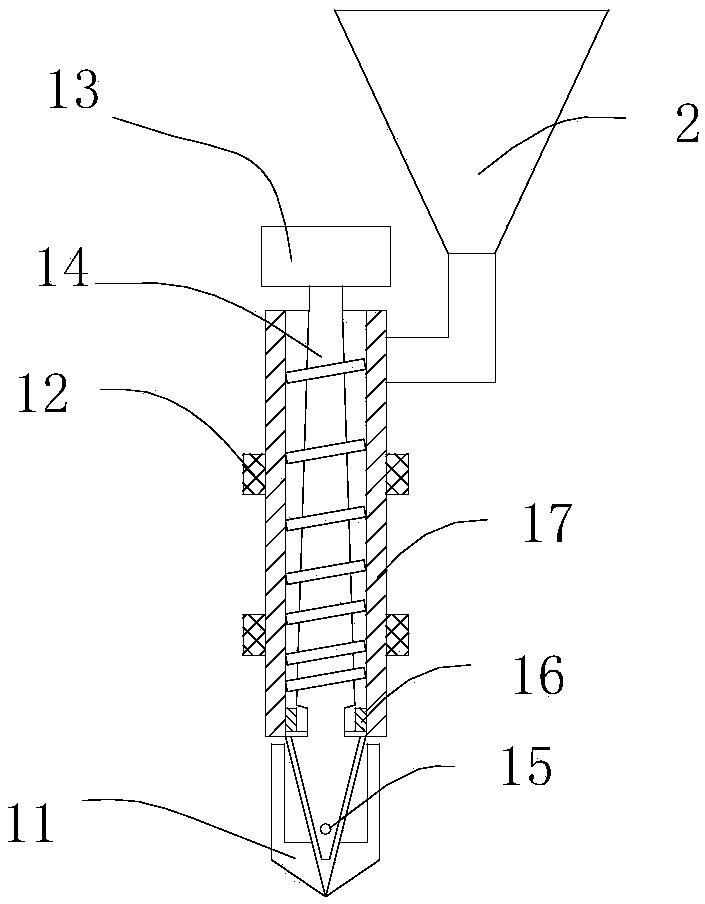

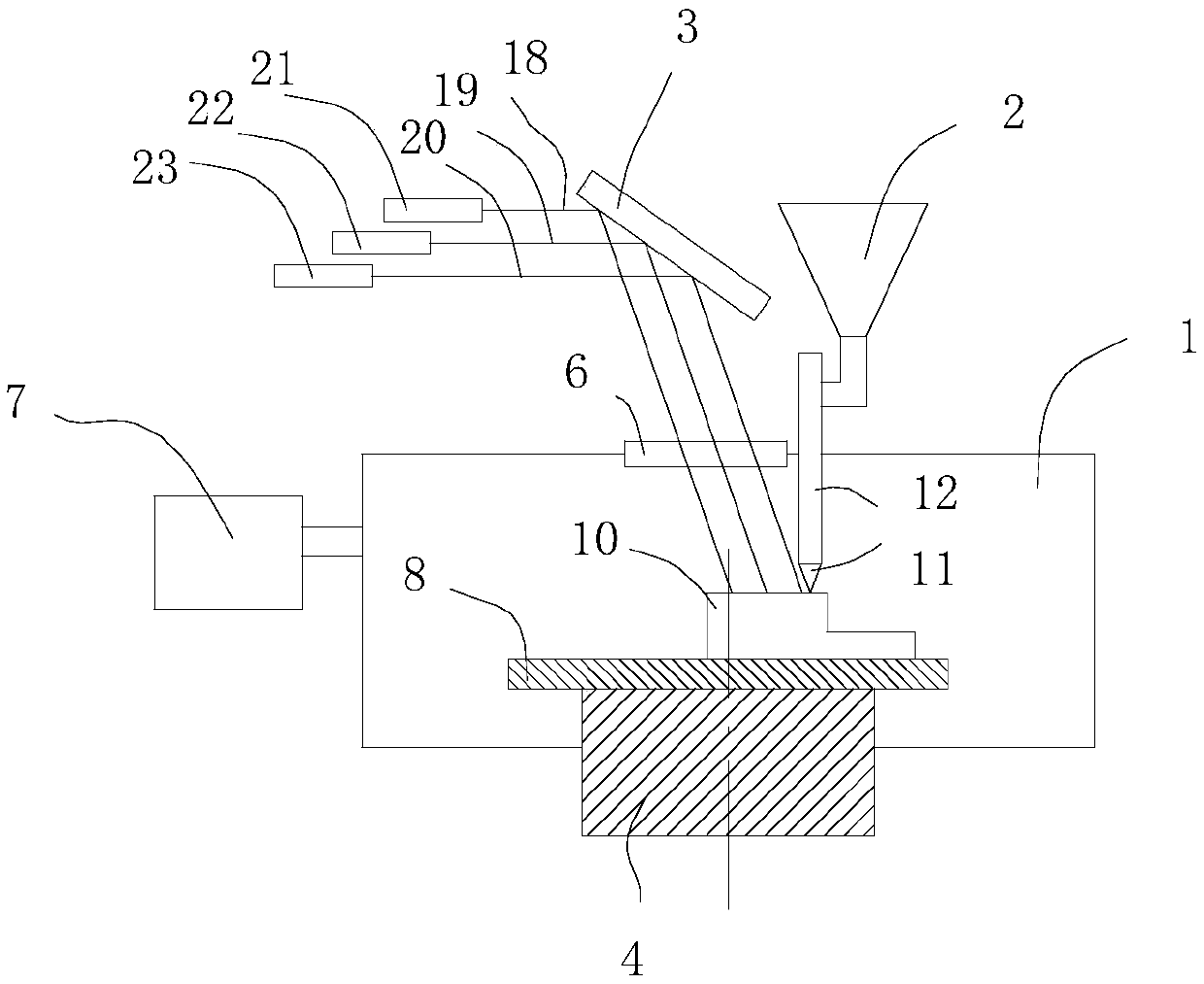

Metal part additive manufacturing method and corresponding equipment

InactiveCN109550959AGuaranteed dimensional control accuracyEasy to manufactureAdditive manufacturing apparatusIncreasing energy efficiencyControl systemEngineering

The invention discloses a metal part additive manufacturing method and corresponding equipment. The method comprises the following steps of inputting three-dimensional model data of a part into a control system of a 3D printing device, a control command of the spray head and the working platform planning path is generated; the control system controls a working platform and a spray head to move according to the planning path, mixed materials of the metal powder with the rheological property and the binding agent are sprayed out through a spray head and are adhered to the surface of the workingplatform or on the surface of the deposited model mixture; heating the mixture to a sintering temperature below the melting point of the metal powder by using a heat source, and finishing gasificationand degreasing of the binder and sintering of the metal powder; repeating the two steps until the metal part is printed and formed. According to the metal part additive manufacturing method, the metal powder with rheological property and the binder agent are subjected to injection molding and are subjected to degreasing and sintering synchronously, the size of the parts can be accurately controlled, the device is suitable for manufacturing metal parts with complicated shapes, the injection mold is not needed, the process is simple and practical, and the energy consumption is reduced.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

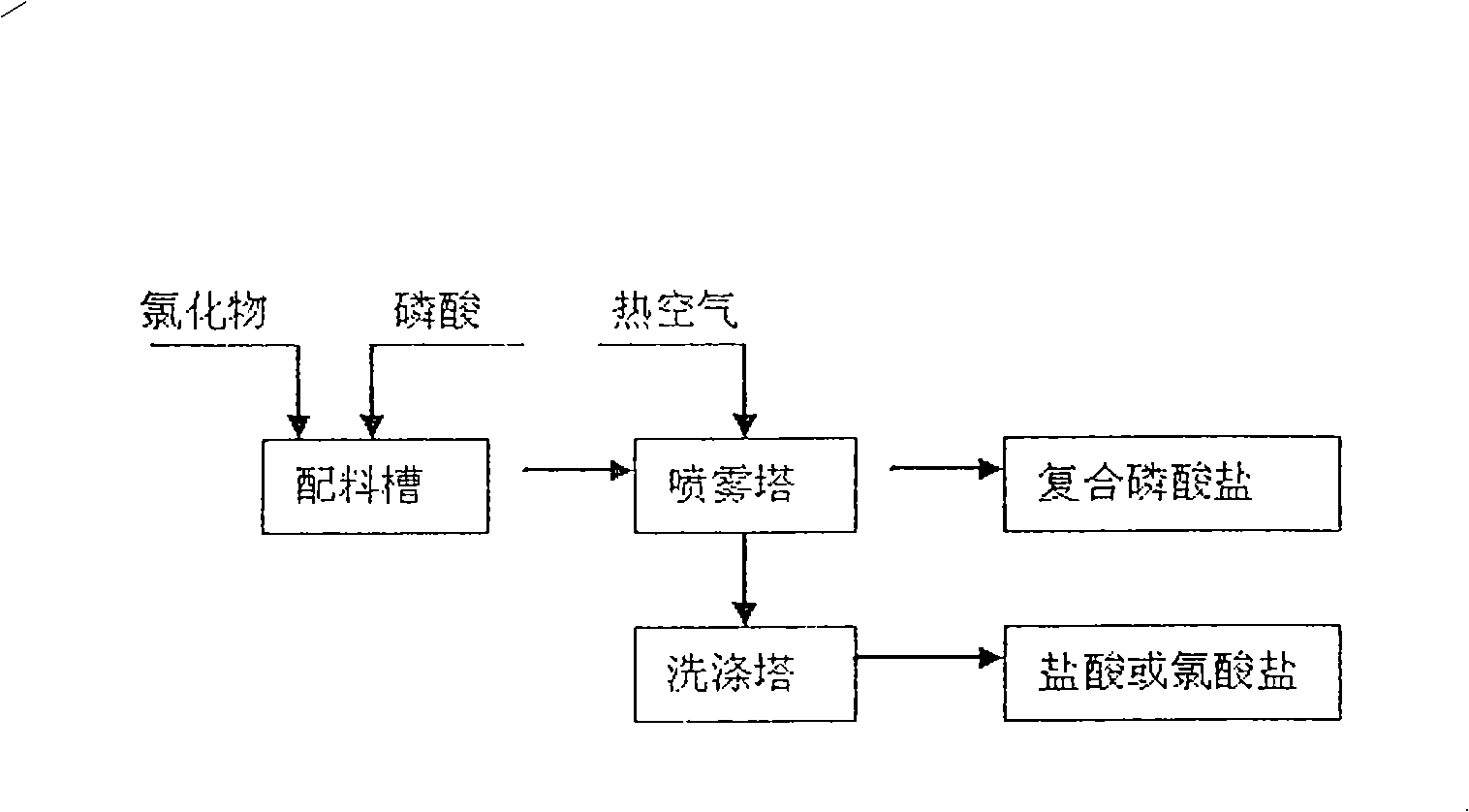

Method for preparing composite phosphate

ActiveCN101343053AReduce heat transfer rateLow mass transfer efficiencyPhosphatesState of artSmall droplet

The invention discloses a production method of composite phosphate, which essentially comprises steps as follows: firstly, chloride is mixed with excessive phosphoric acid in order to obtain material liquid; secondly, the material liquid is added into the spray dryer to atomize into tiny droplets; thirdly, the droplets are instantaneously contacted and heated with as much hot air as is sufficient to enable double decomposition reaction between chloride and phosphoric acid to happen, so that hydrogen chloride gas escapes, and the remaining things are reacted to obtain a compound phosphate product. The production method has technical advantages that the shortcomings of prior art can be overcome, the spray dryer is adopted as a core reactor to atomize the material liquid into small droplets to be contacted with the high-temperature hot air, the specific surface area of evaporation is maximum, so that the escaping time of HCl and the water vapor is 3 to 8 seconds only, the reaction conversion rate reaches up to 97 percent, the material liquid continues to be in and out, and large-scale industrialization production can be achieved.

Owner:GUIZHOU CHANHEN CHEM CO LTD

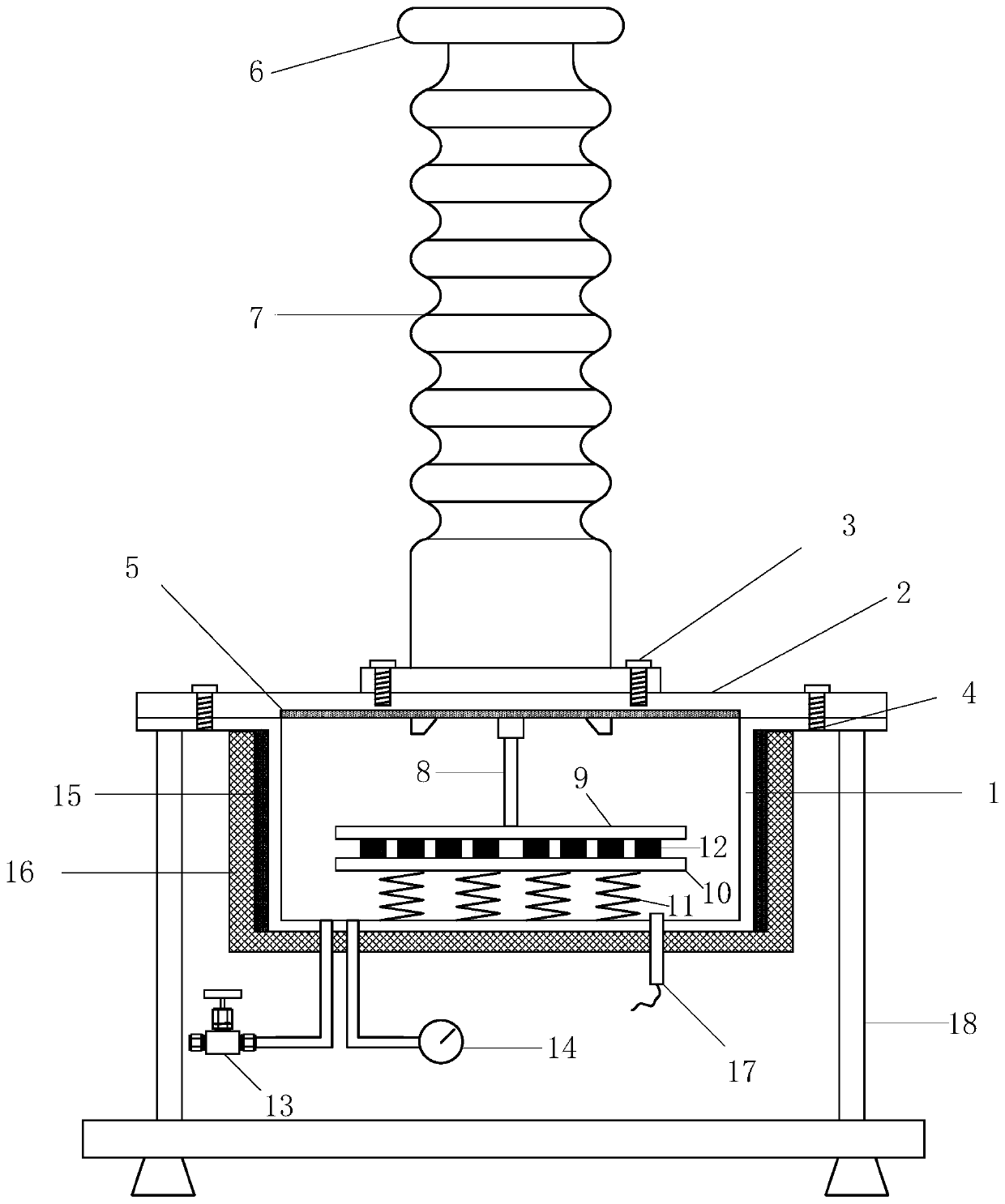

Combined heat-power test device for compatibility between gas and solid material

InactiveCN110501368AGuaranteed to withstand high voltageGuaranteed resistance to high pressureComponent separationMaterial analysis by electric/magnetic meansTransformerHigh voltage

The invention relates to insulation technology, in particular, to a combined heat-power test device for compatibility between gas and a solid material. The combined heat-power test device comprises asealed tank, a high-voltage generating system, an air charging device, and a heating device. The sealed tank includes a tank body with an open upper end and a top cover arranged at the top of the tankbody; and the top cover and the tank body form a sealed cavity. The high voltage generating system includes a metal guide rod connected to a transformer, an insulating casing tube, a grading ring, ahigh-voltage electrode connected to the metal guide rod, a ground electrode connected to the tank body, and a spring connected to the ground electrode, wherein the insulating casing tube and the grading ring are arranged outside the metal guide rod. The air charging device includes a valve and a barometer that are connected to the tank body. The heating device includes a heating belt arranged on the outer wall of the tank body. With the provided combined heat-power test device, high-atmospheric-pressure-resistant, high-temperature-resistant, corrosion-resistant, safe and reliable long-term compatibility testing of the tank body is realized; the local overheating in the sealed tank can be monitored; the high safety of the high voltage test is ensured. The provided device has advantages of small size, low power consumption, reduced test occupation area, and low cost.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com