Corrosion-resistant metallurgical composite bimetal longitudinal submerged-arc welded steel pipe and method for manufacturing same

A composite bimetallic and straight seam submerged arc technology, which is applied in metal rolling, arc welding equipment, metal processing equipment, etc., can solve the problems of easy generation of gaps, inclusion of stolen goods, and limited application, and achieve high accuracy of shape and size, Good corrosion resistance and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

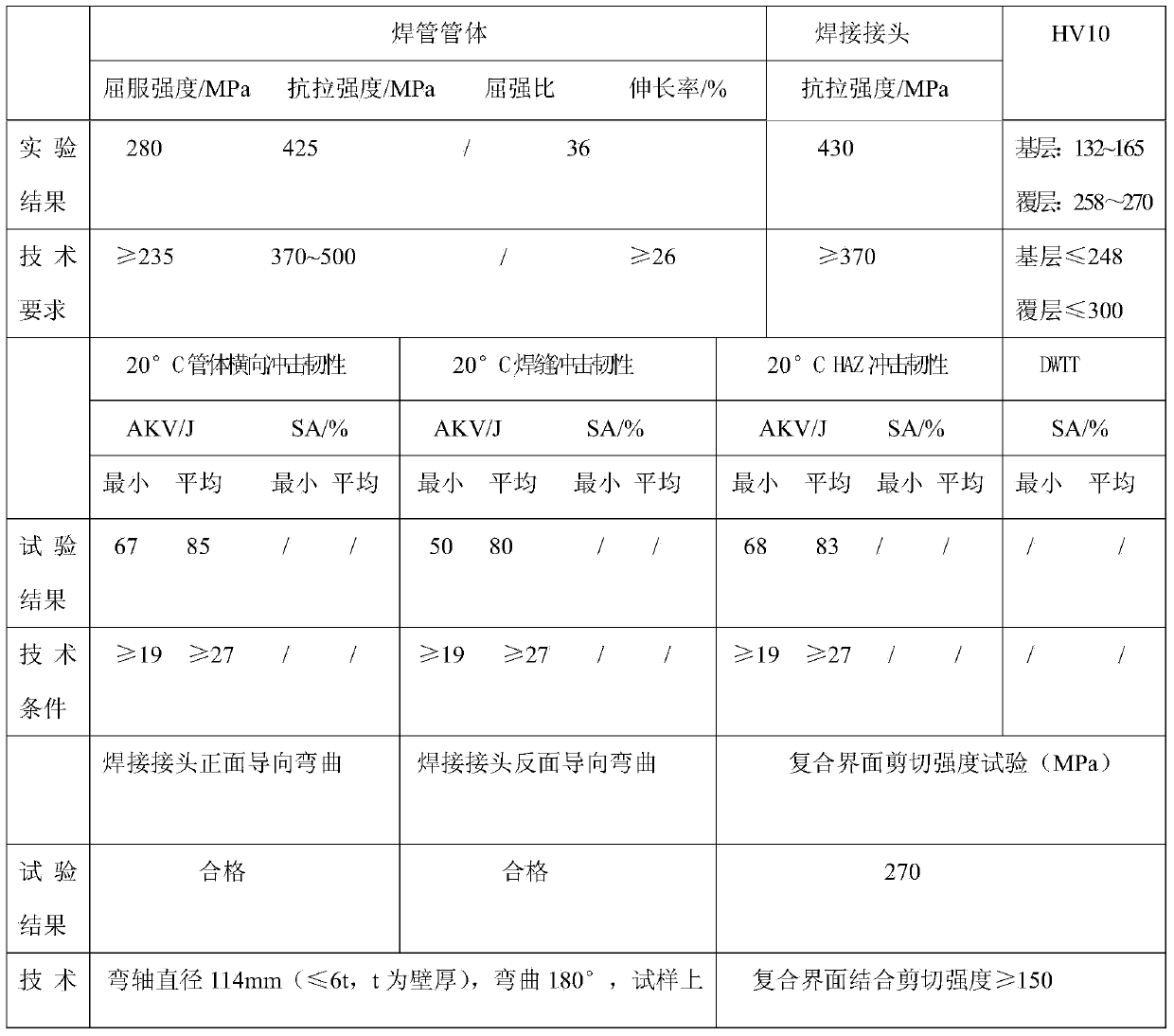

Embodiment 1

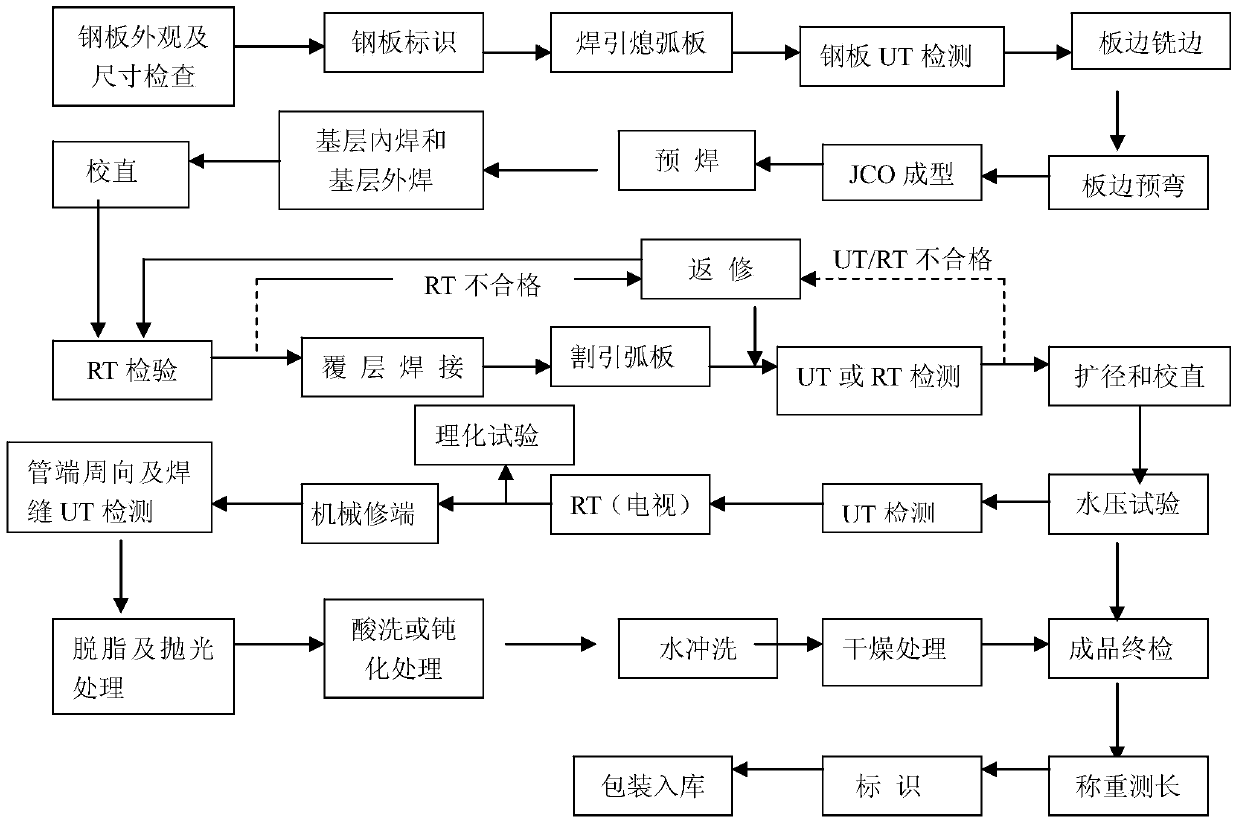

[0024] Manufacturing process see figure 1 .

[0025] (1) Raw material inspection: corrosion-resistant metallurgical composite bimetallic steel plate (the thickness of carbon steel is 19mm, the model is Q235B; the thickness of the corrosion-resistant layer is 304L (3mm), the model is 304L), after the appearance, size inspection and various mechanical and corrosion resistance properties Feed after passing the test and marking; to ensure that the raw materials meet the quality requirements;

[0026] (2) Arc extinguishing plate for welding: The arc extinguishing plate is made of the same material as the steel pipe Q235B and 304L, so that the arc starting and extinguishing of the steel pipe during welding are carried out on the arc igniting plate and the arc extinguishing plate. To ensure the quality of steel pipe welds.

[0027] (3) Steel plate UT (ultrasonic flaw detection) inspection: use automatic UT to conduct 100% inspection on the surface of the steel plate, and further ch...

Embodiment 2

[0049] (1) Raw material inspection: corrosion-resistant metallurgical composite bimetallic steel plate (carbon steel layer thickness 14mm, material model X60); corrosion-resistant layer thickness 3mm, model 316L, passed the inspection of appearance, size and various mechanical and corrosion resistance performance tests and passed the test Feed after marking; to ensure that the raw materials meet the quality requirements;

[0050] (2) Welding arc extinguishing plate: use the same material X60 as the steel pipe; the corrosion-resistant layer 316L is used to make the arc extinguishing plate, so that the arc starting and extinguishing of the steel pipe welding are carried out on the arc starting plate and the arc extinguishing plate.

[0051] (3) Steel plate UT (ultrasonic flaw detection) inspection: use automatic UT to conduct 100% inspection on the surface of the steel plate, and further check the internal quality of the steel plate to ensure that the materials used for pipe maki...

Embodiment 3

[0068] (1) Raw material inspection: corrosion-resistant metallurgical composite bimetallic steel plate (carbon steel layer thickness 20mm, material type Q345B; corrosion-resistant layer thickness 2mm, type 310S), passed the inspection of appearance, size, and various mechanical and corrosion resistance performance tests. Feed after marking; to ensure that the raw materials meet the quality requirements;

[0069] (2) Welding arc extinguishing plate: Q345B, which is the same material as the steel pipe; the corrosion-resistant layer 310S is used to make the arc extinguishing plate, so that the arc starting and extinguishing of the steel pipe welding are carried out on the arc starting plate and the arc extinguishing plate.

[0070] (3) Steel plate UT (ultrasonic flaw detection) inspection: use automatic UT to conduct 100% inspection on the surface of the steel plate, and further check the internal quality of the steel plate to ensure that the materials used for pipe making meet th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com