Preparation method of nanoscale silicon carbide magnesium alloy material

A technology of nano-scale silicon carbide and silicon-magnesium carbide, which is applied in metal processing equipment, transportation and packaging, etc., can solve problems such as unsatisfactory performance, and achieve the effect of improving corrosion resistance and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

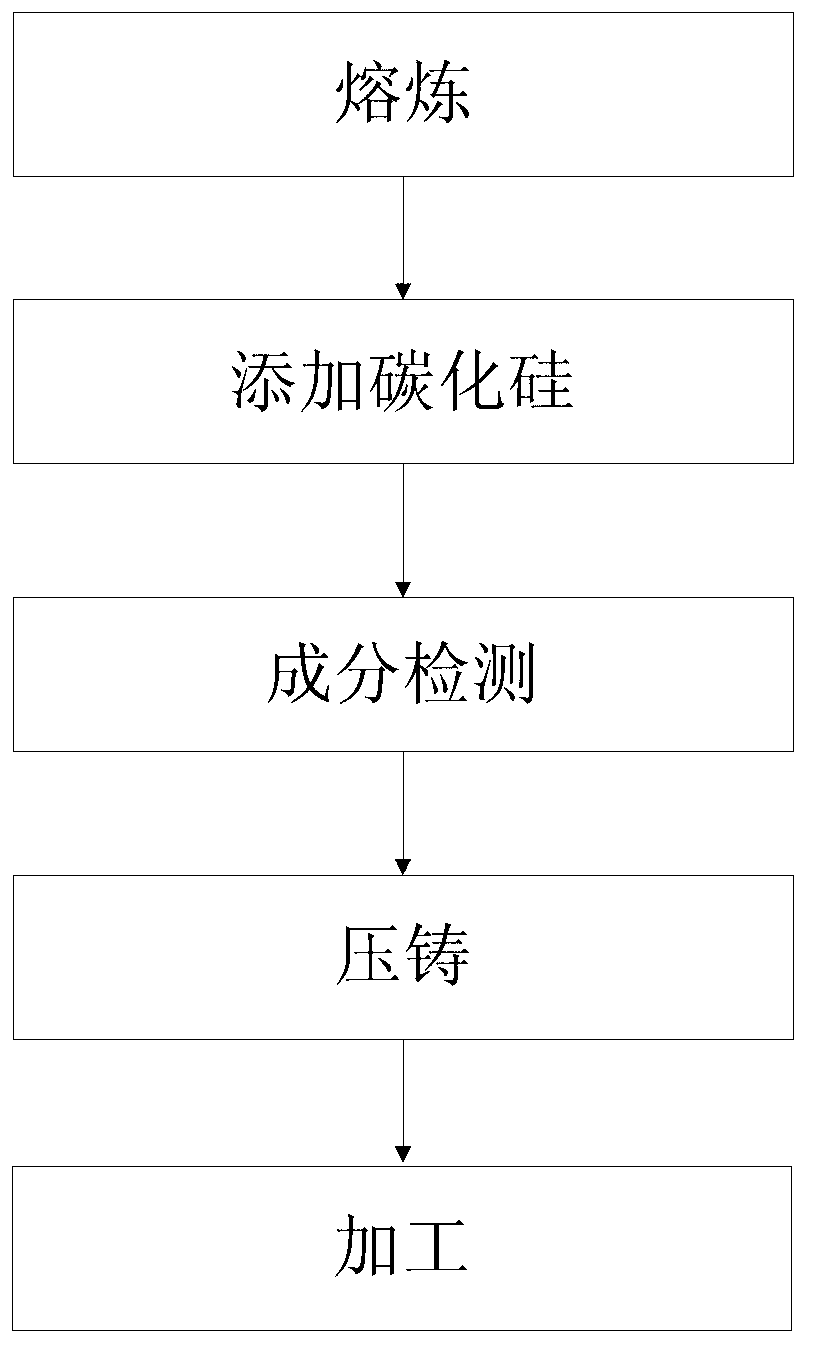

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of nanoscale silicon carbide magnesium alloy material:

[0025] Step 1: Ingredients: Weigh 1% of the total weight of nano-scale silicon carbide, 10% of the total weight of aluminum ingots, 1.2% of the total weight of zinc ingots, and 0.05% of the total weight of manganese ingots And magnesium ingots accounting for 87.75% of the total weight.

[0026] Step 2: Melting: Place the crucible in a gradient electric furnace, slowly adjust the voltage and preheat the surface of the crucible to remove impurities. The preheating temperature is 500°C; place the magnesium ingot in the crucible and slowly heat the magnesium The ingot melts slowly, the melting time is 1.5-2 hours, and the temperature is 700°C; after the magnesium ingot is completely melted, it is filled with inert gas, and after the temperature is raised to 760°C, add the aluminum ingot, zinc ingot and manganese ingot, and start the vibration Set it up for 15-20 minutes to form a fully fu...

Embodiment 2

[0033] A kind of preparation method of nanoscale silicon carbide magnesium alloy material:

[0034] Step 1: Ingredients: Weigh 1.5% of the total weight of nano-scale silicon carbide, 11.5% of the total weight of aluminum ingots, 1.8% of the total weight of zinc ingots, and 0.25% of the total weight of manganese ingots And magnesium ingots accounting for 84.95% of the total weight, and powdered aluminum ingots and zinc ingots.

[0035] Step 2: Melting: The crucible is placed in a power frequency electric furnace with gradients, the voltage is slowly adjusted and the surface of the crucible is preheated to remove impurities. The preheating temperature is 500°C; the magnesium ingot is placed in the crucible and slowly heated to make the magnesium The ingot melts slowly, the melting time is 1.5-2 hours, and the temperature is 700°C; after the magnesium ingot is completely melted, it is filled with an inert gas, and after the temperature is raised to 760°C, the above-mentioned powd...

Embodiment 3

[0042] A kind of preparation method of nanoscale silicon carbide magnesium alloy material:

[0043] Step 1: Ingredients: Weigh 1% of the total weight of nano-scale silicon carbide, 11.5% of the total weight of aluminum ingots, 1.5% of the total weight of zinc ingots, and 0.16% of the total weight of manganese ingots And magnesium ingots accounting for 85.84% of the total weight, and powdered aluminum ingots, zinc ingots and manganese ingots;

[0044] Step 2: Melting: The crucible with a capacity of 50 kg is placed in a gradient electric furnace with a capacity of 1500 mm in length x 1500 mm in width x 1000 mm in height. Slowly adjust the voltage and preheat the surface of the crucible to remove impurities. The preheating temperature is 500°C; the magnesium ingot is placed in the crucible and slowly heated to melt the magnesium ingot slowly. The melting time is 1.5-2 hours and the temperature is 700°C. °C; after the magnesium ingot is completely melted, fill it with inert gas,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com