Combined heat-power test device for compatibility between gas and solid material

A technology of solid material and combined heat and electricity, applied in the field of insulation, can solve the problems of inconvenient inflation and vacuuming, large volume, etc., and achieve the effects of reducing heat loss, small volume, and avoiding frequent start and stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

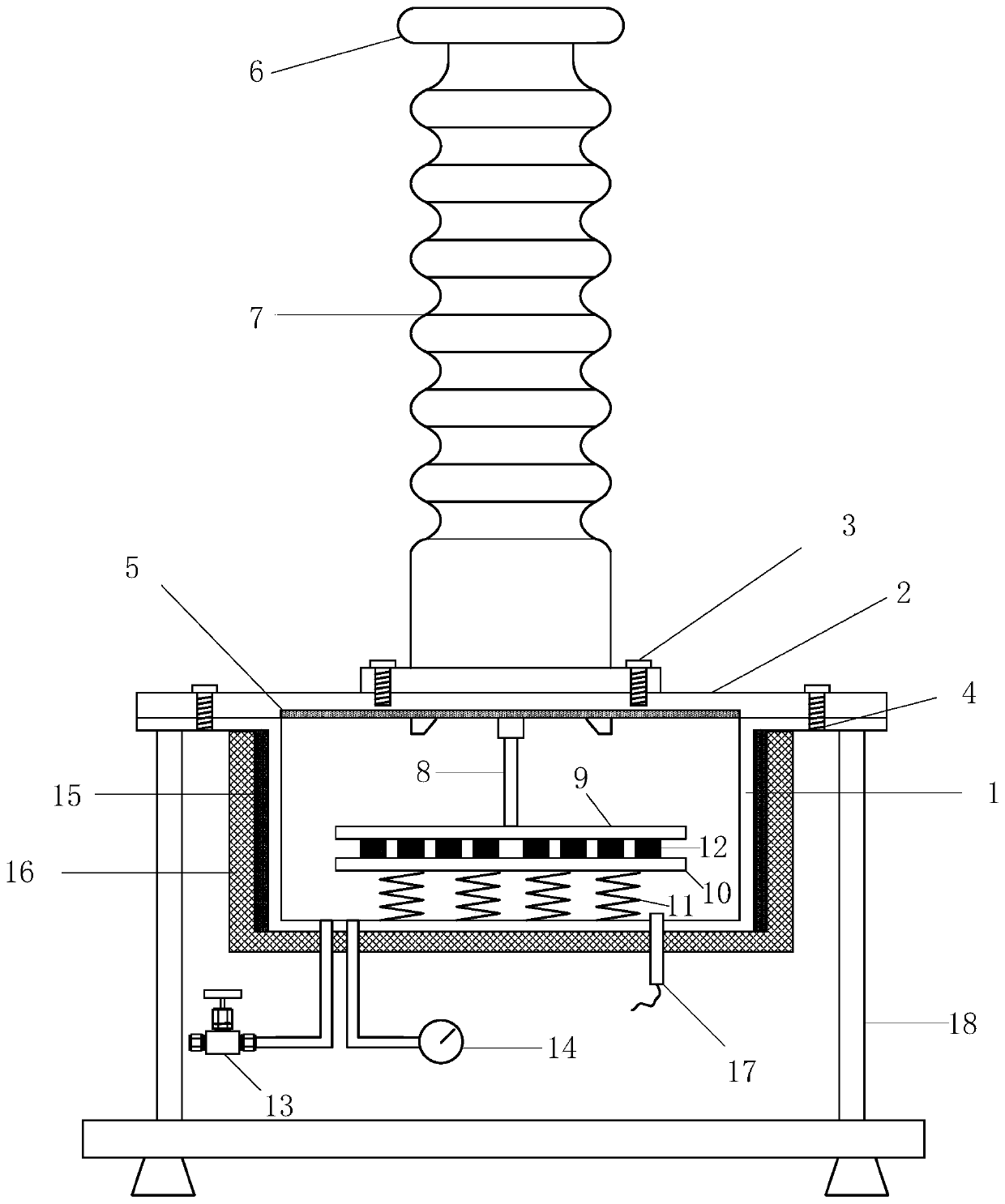

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] This embodiment is achieved through the following technical solutions, a thermoelectric combined test device for the compatibility of gas and solid materials, including: a sealed tank, a high voltage generation system, an inflator and a heating device. The sealed tank includes: a tank body with an open upper end and a top cover arranged on the top of the tank body. The top cover is provided with screws, the edge of the upper opening of the tank body is provided with threads, and a sealing ring is embedded in the bottom of the top cover. Tighten the tank body, the top cover and the sealing ring to realize the tightness of the tank body. The high-voltage generation system includes: a metal guide rod connected to the transformer, an insulating sleeve and a voltage equalizing ring arranged outside the metal guide rod, a high-voltage electrode connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com