Accelerated corrosion testing method for simulating soil corrosion process

A test method and soil corrosion technology, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as limited acceleration ratio and difficult soil uniformity, and achieves wide application range, simulation, and significant Accelerates the corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

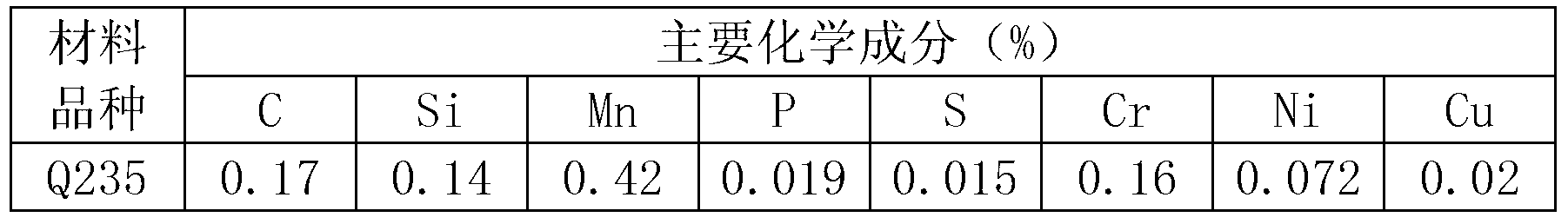

[0059] The test material is the above-mentioned Q235 steel. According to the physical and chemical properties of the target soil, 5Kg of test soil with a water content of 40%, a pH value of 4.5-4.7, and a total salt content of 3 times the target soil was prepared.

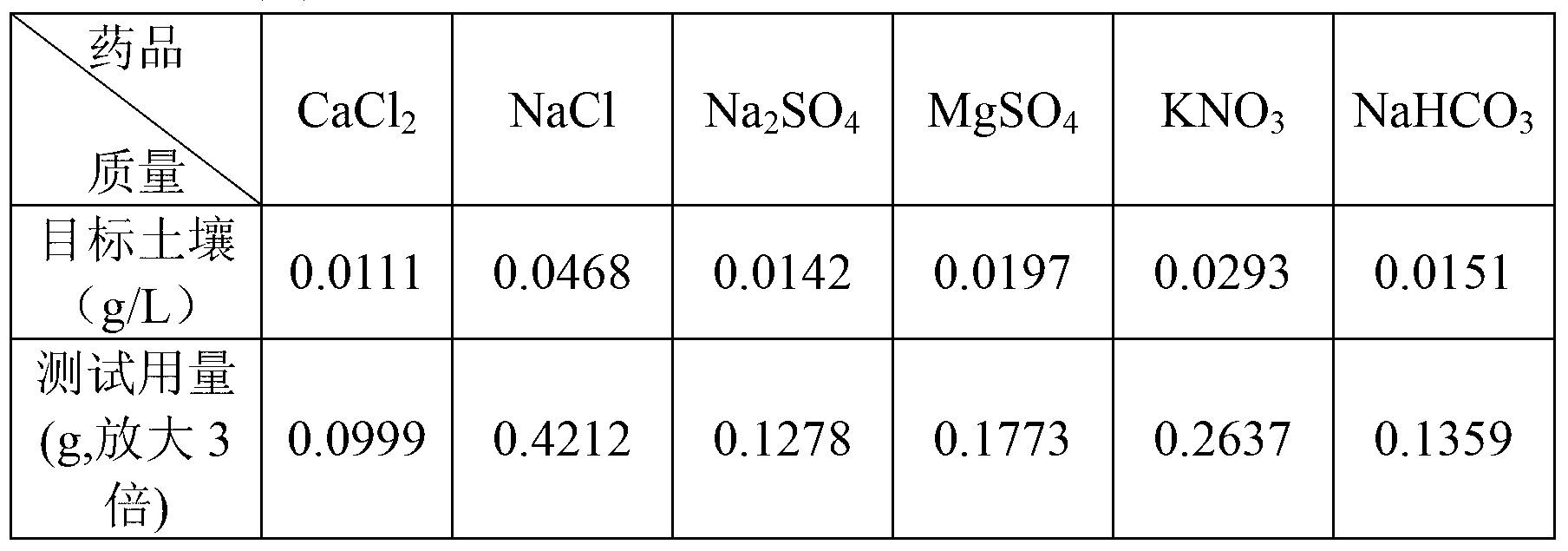

[0060] (1) The preparation content of each drug (ie, salt) is shown in Table 3. These drugs were dissolved in 2L of deionized water and stirred evenly.

[0061] Table 3 Test drug weighing amount

[0062]

[0063] with CaCl 2 For example, the calculation method of the test amount is:

[0064] m (CaCl 2 )=0.0111×5×60%×3=0.0999g.

[0065] Among them, the content of each chemical is the amount of the drug measured when the soil is dried and ground and mixed with 50% deionized water. In the calculation formula, 5×60%=3Kg means that the soil carrying salt in the test is 3Kg (correspondingly, 3 water is used for 1:1 leaching, so that the salt concentration remains unchanged); multiplied by 3 means the magnification...

Embodiment 2

[0072] The test material is the above-mentioned Q235 steel. According to the physical and chemical properties of the target soil, 5Kg of simulated soil with a water content of 40%, a pH value of 4.5-4.7, and a total salt content of 3 times the target soil was prepared.

[0073] (1) The preparation content of each drug is shown in Table 4. These drugs were dissolved in 2L of deionized water and stirred evenly.

[0074] Table 4 Test drug weighing amount

[0075]

[0076] (2) Adjust the pH value of the solution in (1) to 1.24-1.26 with 98% concentrated sulfuric acid.

[0077] (3) Weigh 200 mesh diatomite 1.2Kg, its bulk density is 0.42g / cm 3 , the 150 mesh sieve is less than 14%; weigh 1.8Kg of 20-40 mesh diatomite, and its bulk density is 0.37g / cm 3 , 150 mesh sieve is less than 6%; the solution is evenly mixed with two kinds of diatomaceous earth, and the test soil is prepared.

[0078] (4) Bury the long side of the Q235 sample vertically downwards into the test box, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com