Patents

Literature

30results about How to "Simulated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

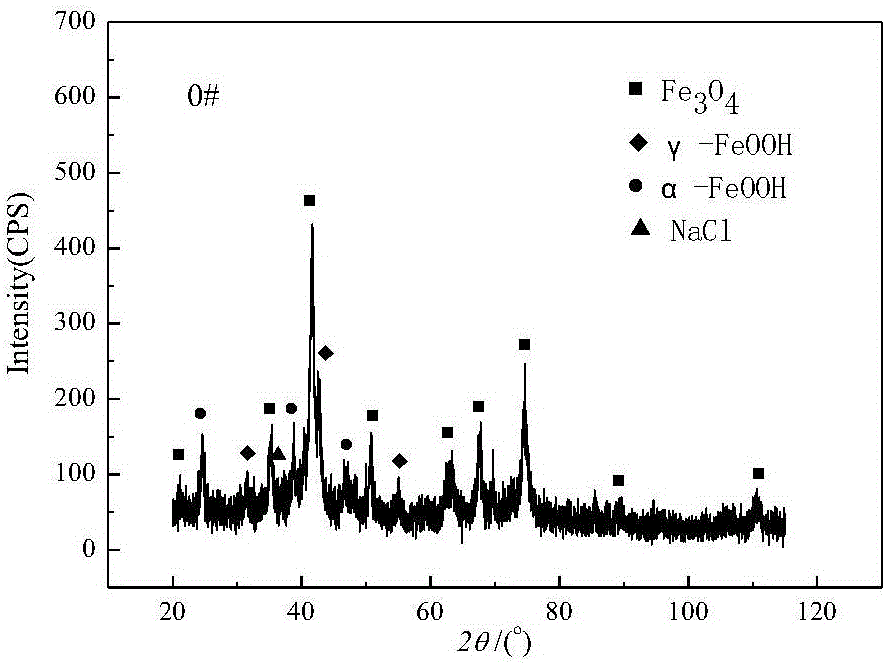

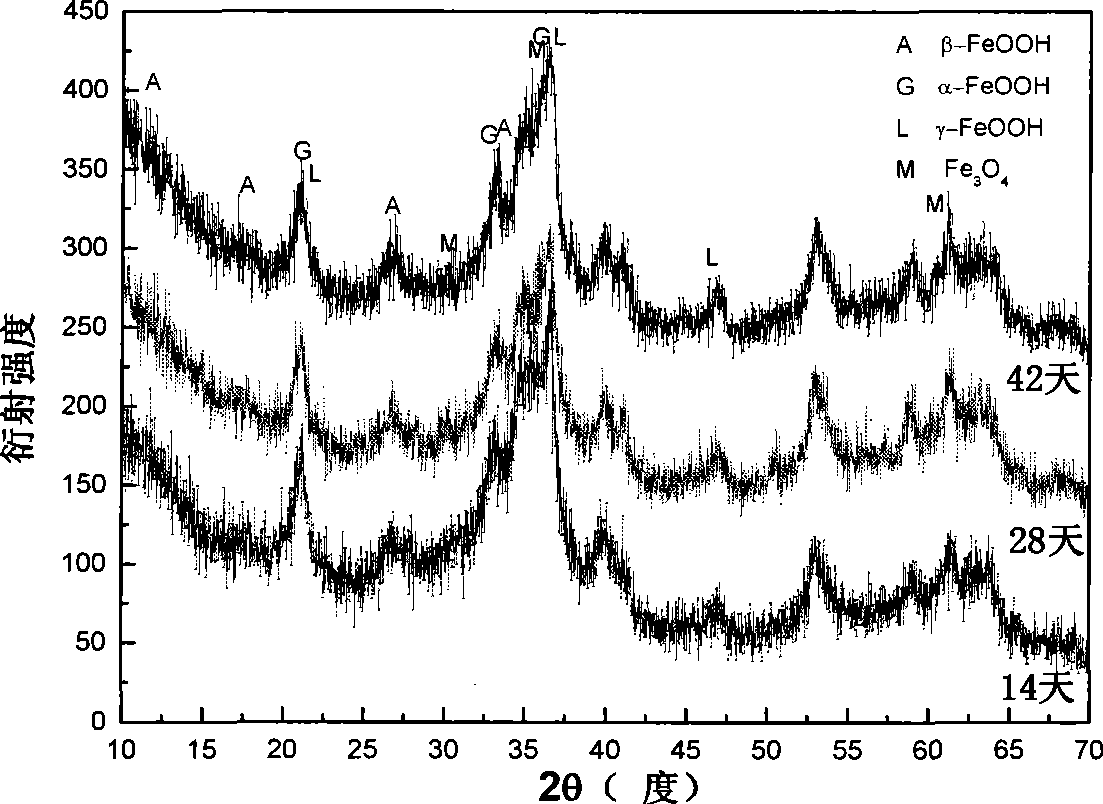

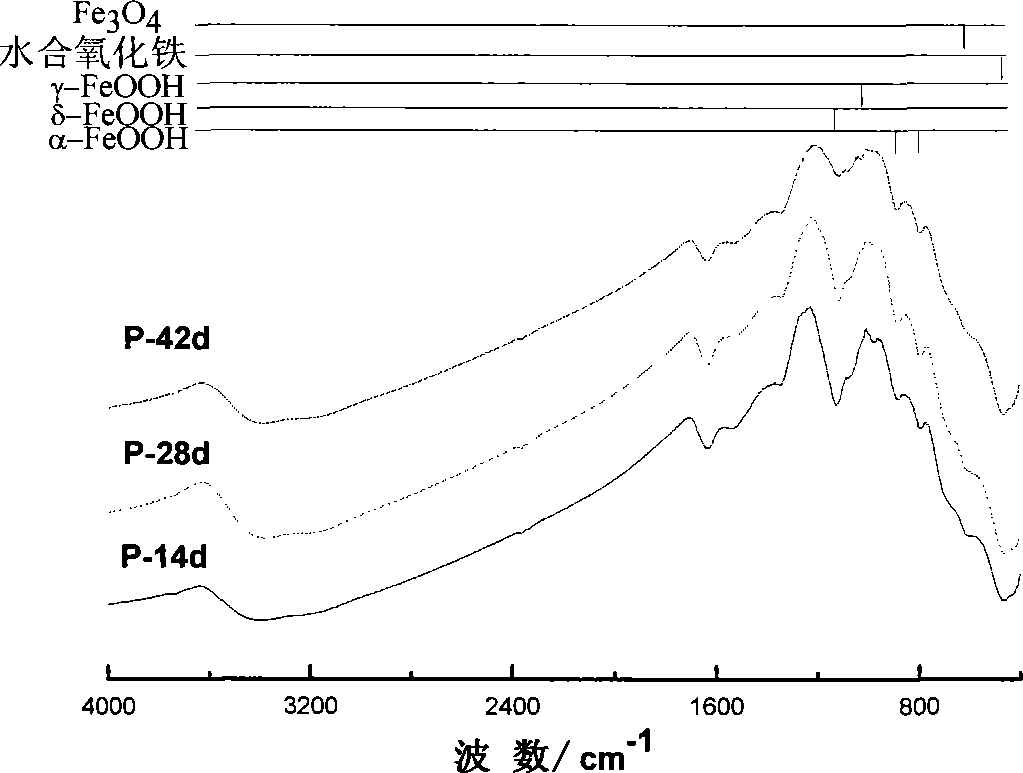

Test method for simulating corrosion course of low alloy steel under marine industrial atmospheric environment

InactiveCN102207446AGood reproducibilitySimulatedWeather/light/corrosion resistanceRelative humidityAlloy steel

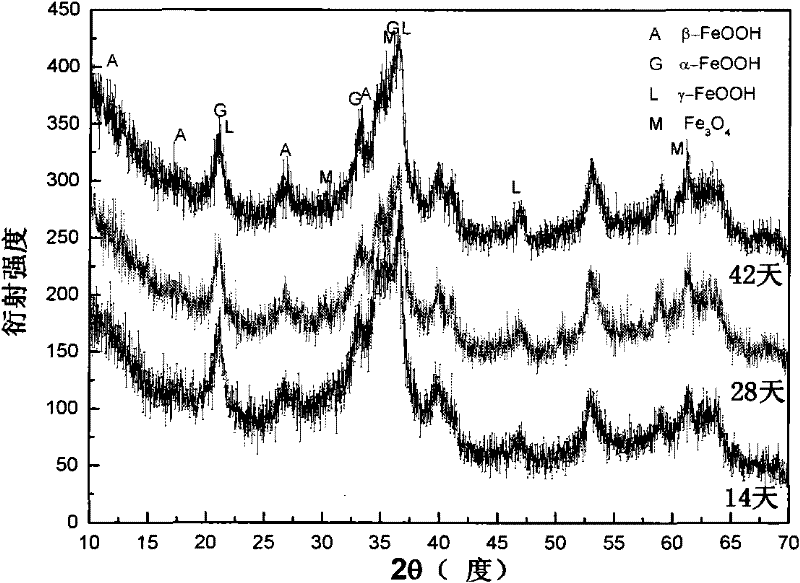

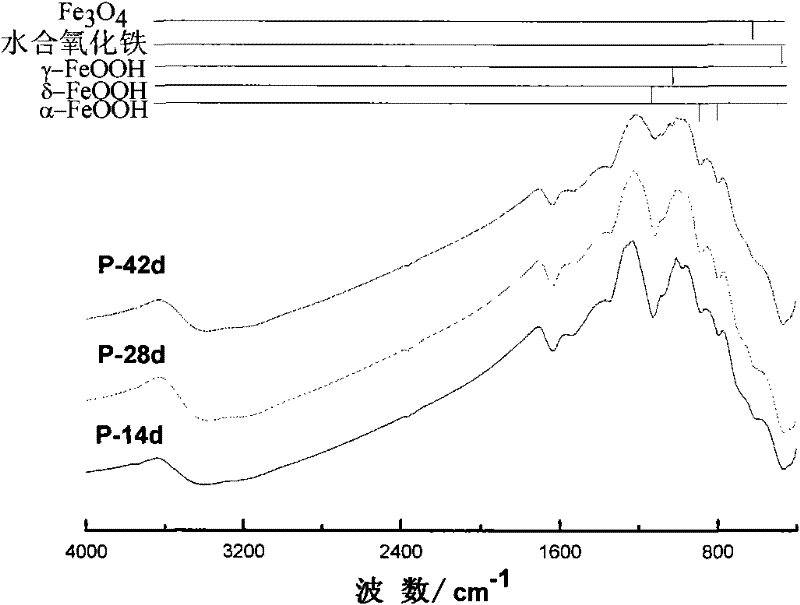

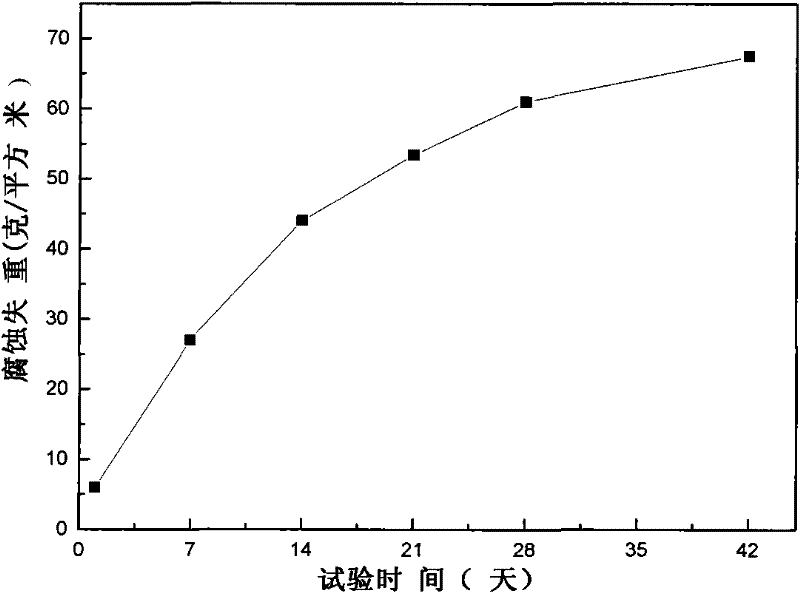

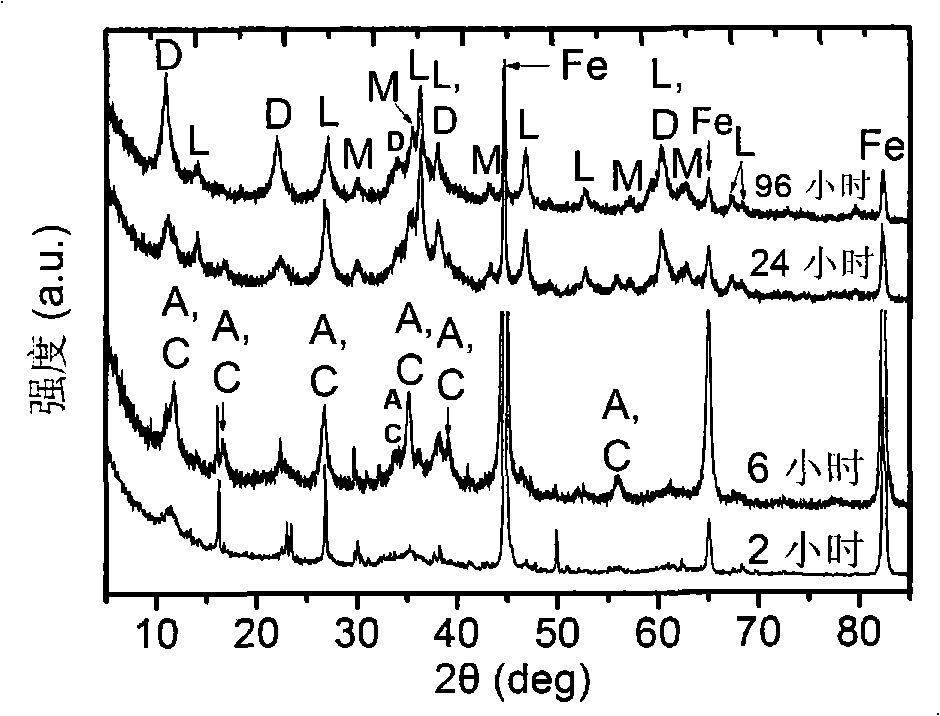

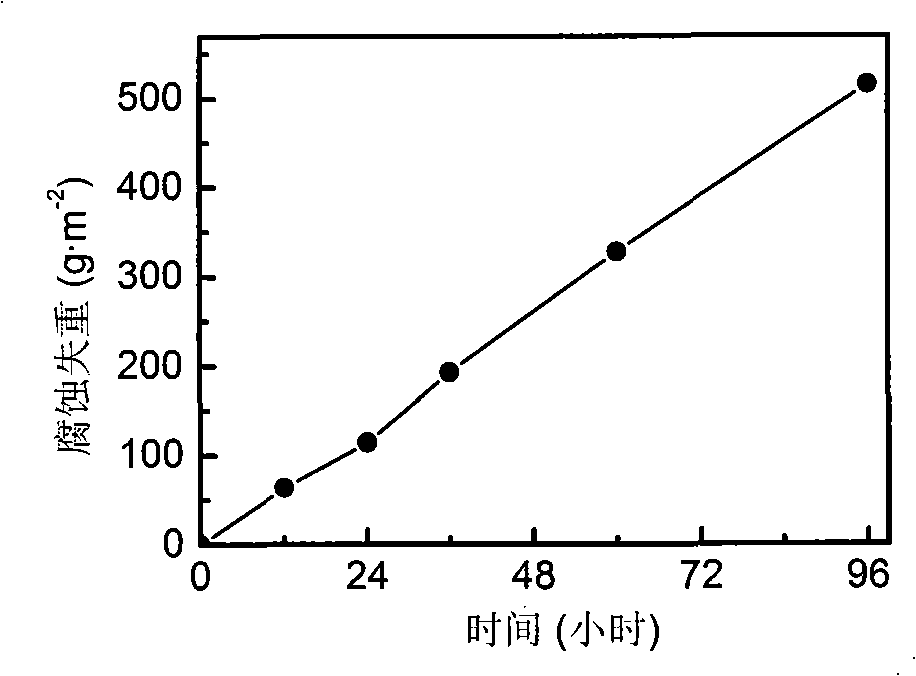

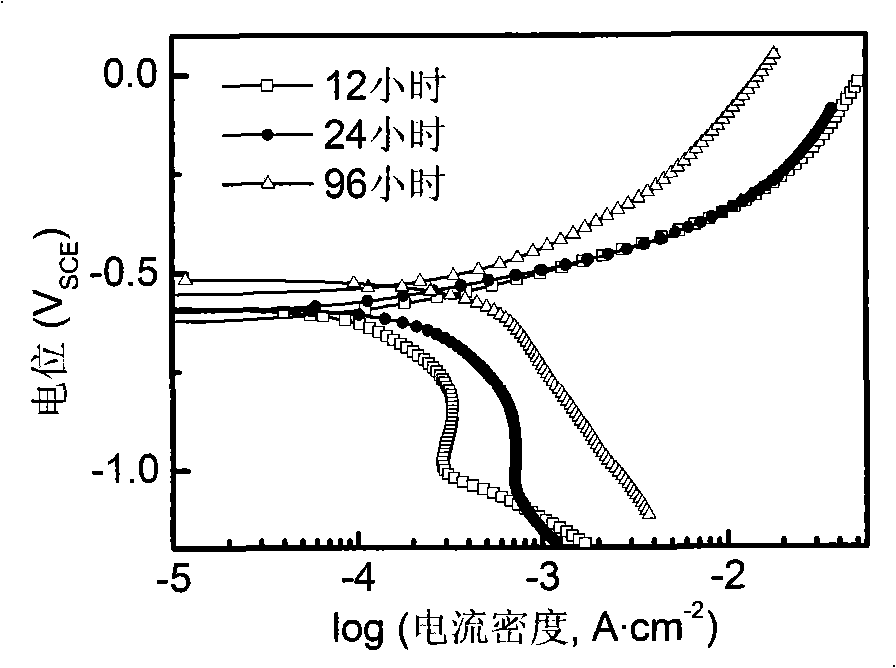

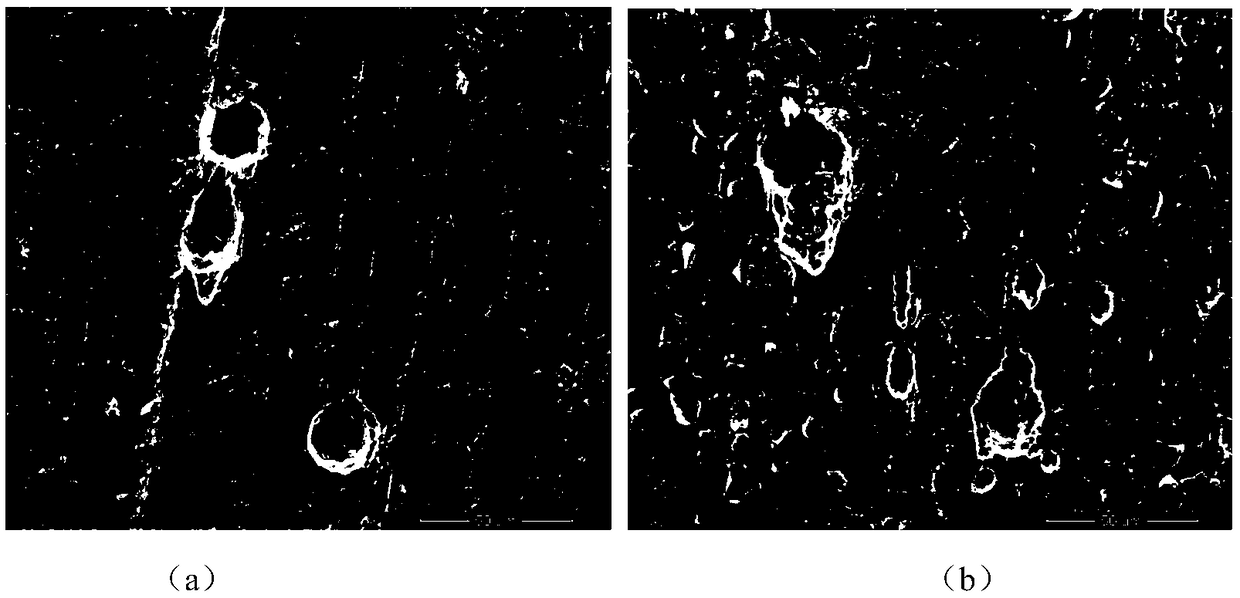

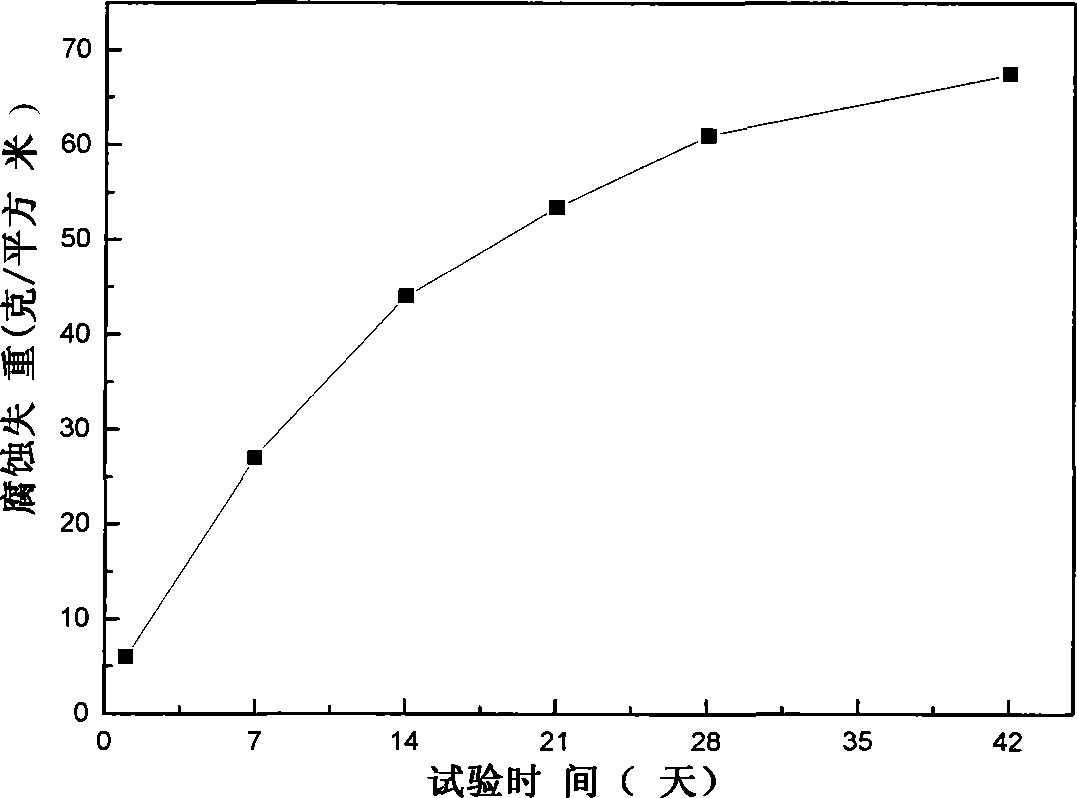

The invention relates to simulation technology of atmospheric corrosion of low alloy steel, and particularly provides a test method for simulating corrosion course of low alloy steel under marine industrial atmospheric environment. According to the invention, low alloy steel is used as a test material, and NaHSO3 and NaCl of different concentration ratios are deposited on the surface of a sample to be tested in advance, and alternate dry and wet tests are carried out according to the order of a wet test first and a dry test next, wherein test temperature is 30 DEG C, a wet test and a dry testboth last for 12 hours, relative humidity of the wet test and the dry test are 80% and 10% respectively, and the whole test lasts for 1 to 42 days. The test method provided in the invention has the characteristics of simulation, acceleration capability and reproducibility, and can be used to simulate marine industrial atmospheric corrosion course, to study corrosion behavior of various low alloy steel under an environment similar to the atmospheric environment and to evaluate and predict corrosion resistance of low alloy steel to marine industrial atmosphere, providing the basis for reasonable selection of low alloy steel and selection of appropriate protection methods.

Owner:中广核工程有限公司 +1

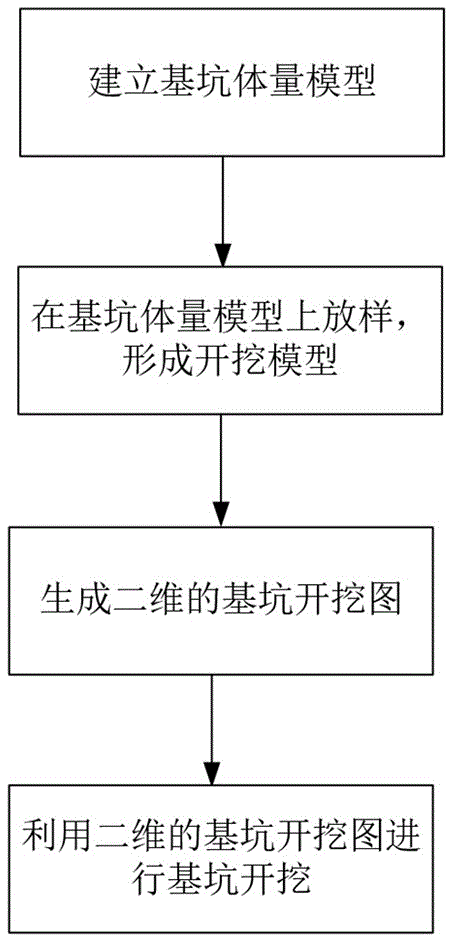

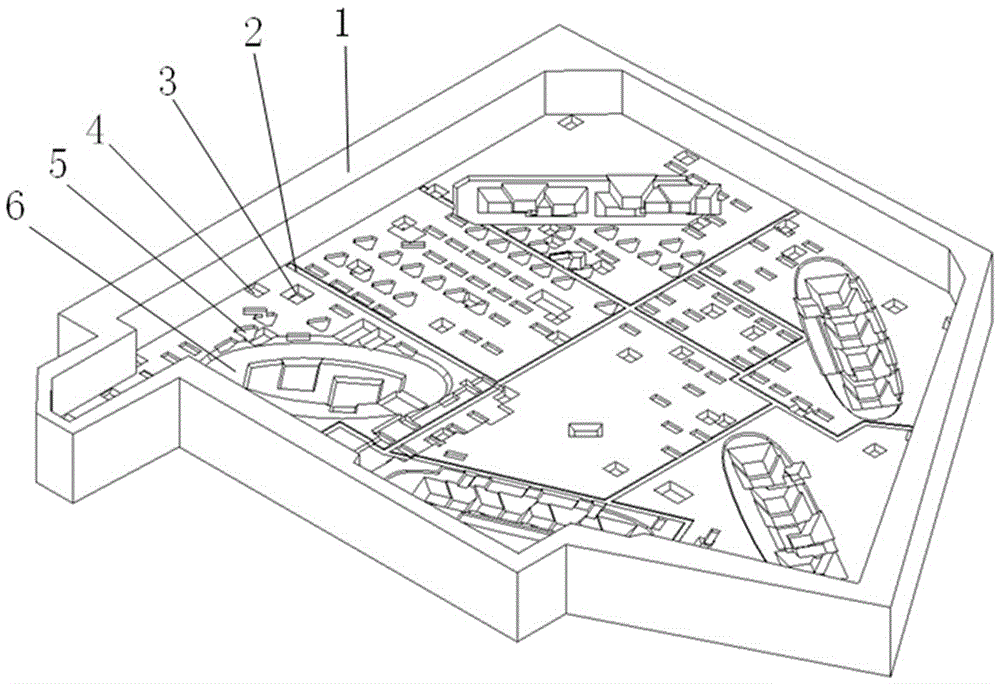

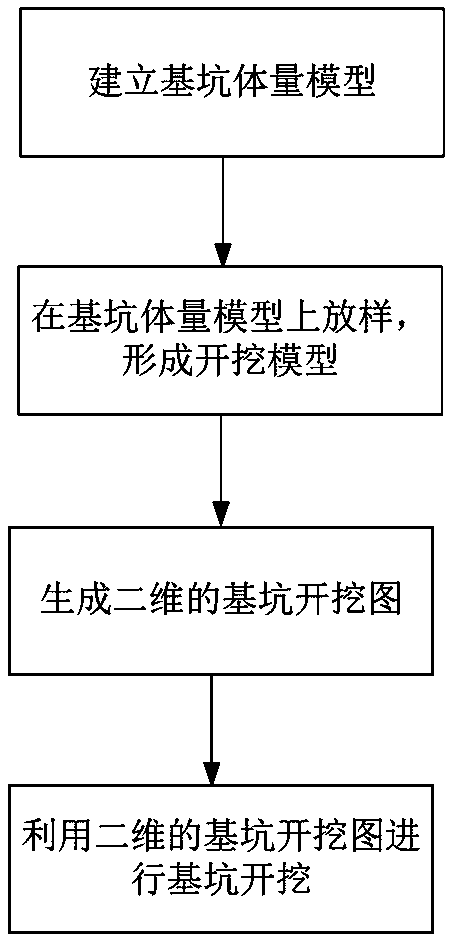

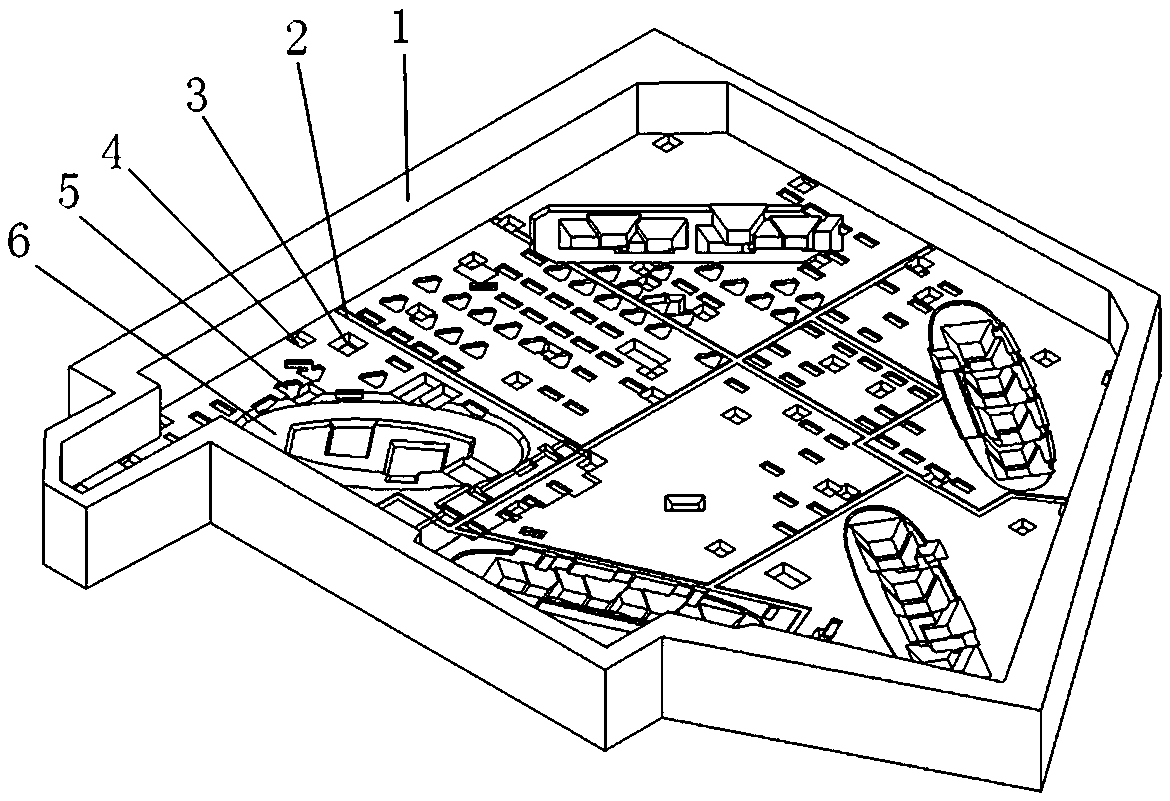

Method for drawing foundation pit excavation drawing

The invention discloses a method for drawing a foundation pit excavation drawing. The method comprises the following steps: step 1, according to a basic plane drawing of a building, applying building information model software to establishment of a foundation pit mass model, and enabling the foundation pit mass model to be consistent with the design dimension proportion in the basic plane drawing; step 2, laying off on the foundation pit mass model according to the building construction drawing, and forming an excavation model; step 3, applying the software to creation of a two-dimensional foundation pit excavation drawing according to the excavation model; step 4, based on the two-dimensional foundation pit excavation drawing, carrying out foundation pit excavation, and meanwhile, utilizing the three-dimensional foundation pit mass model to assist understanding and review. The method, disclosed by the invention, can effectively solve the problem that the excavation drawing is difficult to draw because when a large-scale foundation pit is excavated, the location and lay-out is complicated; compared with the regular drawing method for the excavation drawing, the method can greatly reduce drawing workload and drawing time to shorten the work period; compared with the regular excavation drawing, in the exported excavation drawing, size marking is realized via the software automatically, so that the phenomena of marking missing and mis-marking can be greatly reduced, and the drawing is high in accuracy.

Owner:THE THIRD CONSTR OF CHINA CONSTR FIRST GROUP +1

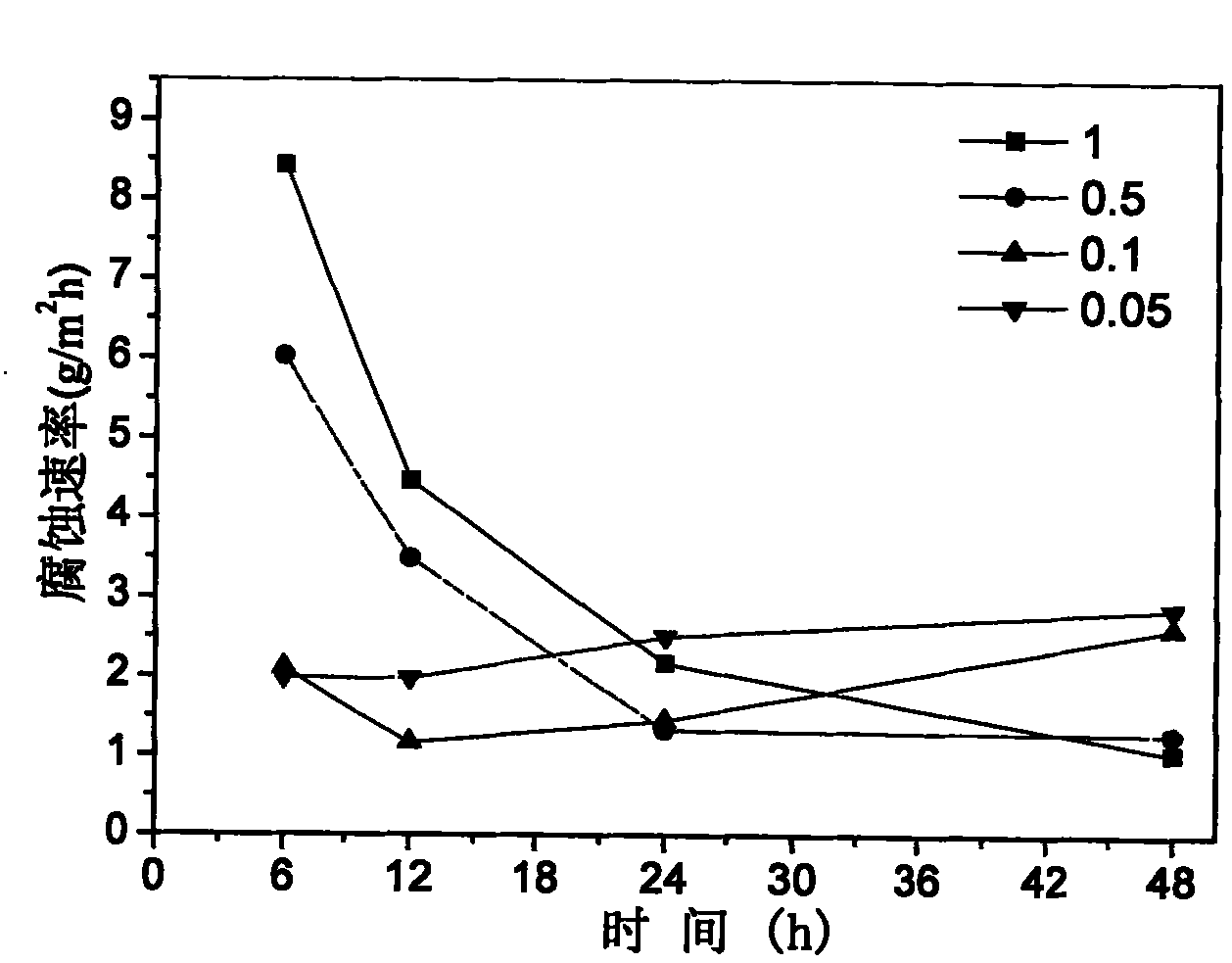

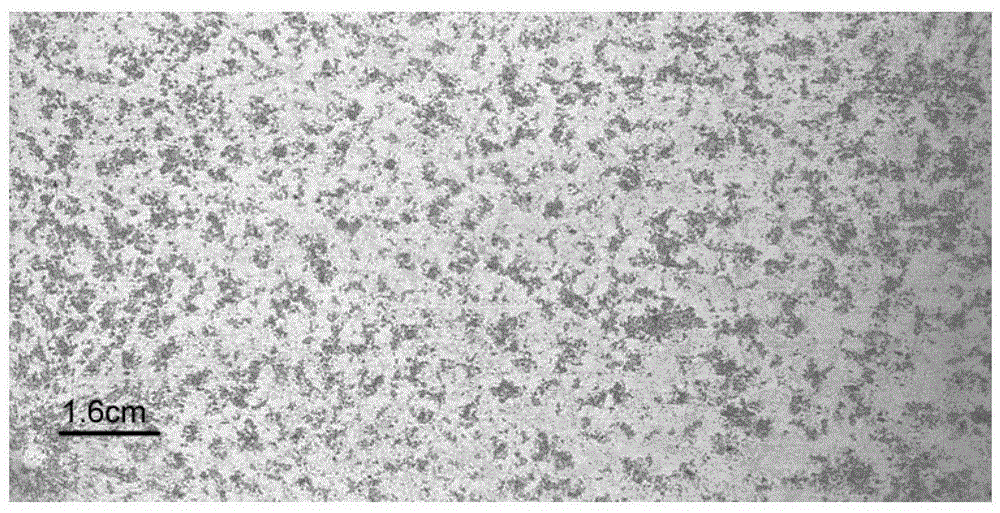

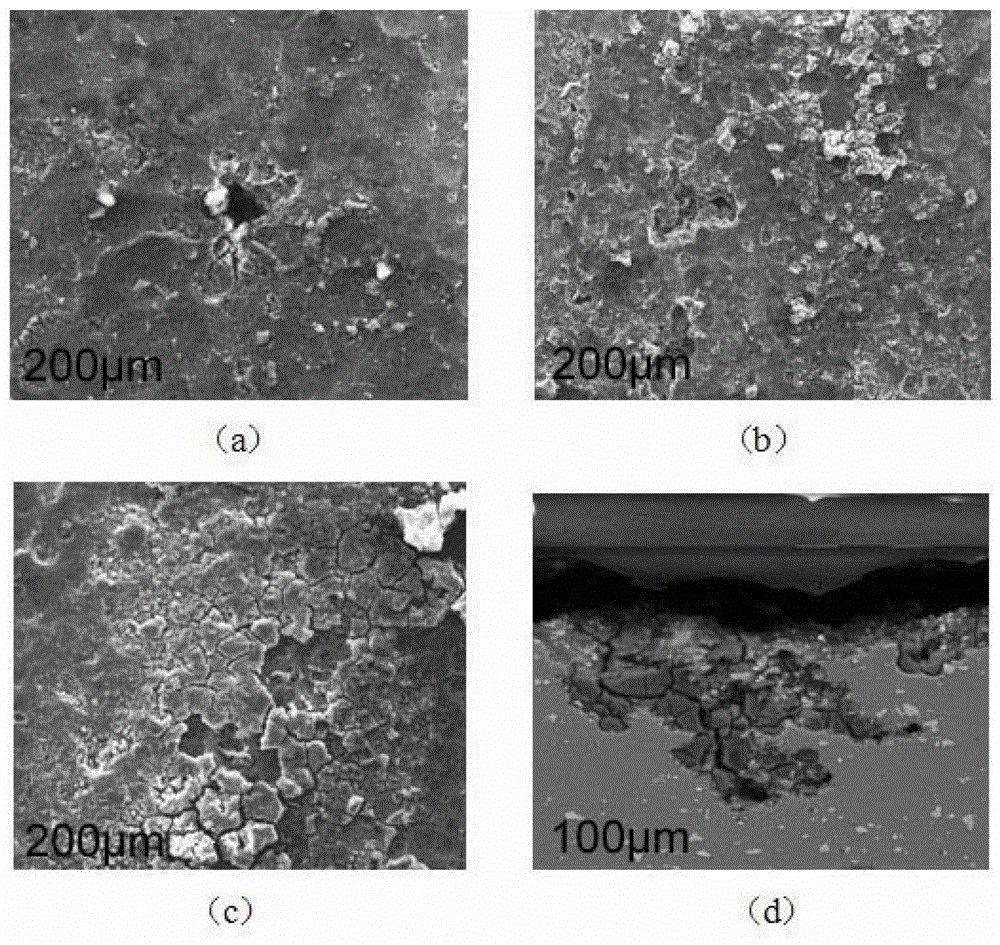

Corrosion simulation method and corrosion resistance evaluation method of galvanized steel coating in industrial atmosphere environment

InactiveCN105277478AQuickly evaluate corrosion resistanceSimulatedWeather/light/corrosion resistanceRational useDistilled water

The present invention discloses a corrosion simulation method and a corrosion resistance evaluation method of a galvanized steel coating in industrial atmosphere environment, and belongs to the technical field of atmospheric corrosion of galvanized steel. The galvanized steel as a test material is used for simulation of an industrial atmosphere corrosion medium spraying solution comprising 10.41g / L of NaHSO3, 0.585g / L of NaCl, and the balance of distilled water; and spraying / drying cycle corrosion is used for simulation of industrial atmosphere corrosion process. When in the evaluation of the corrosion resistance of the galvanized steel coating, in the phase with no red rust on the coating surface, the corrosion resistance of the galvanized steel coating can be determined by the corrosion rate; and when the red rust appears on the galvanized steel coating, the protective effect of the galvanized steel coating can be determined by the red rust appearance time. The corrosion simulation method and the corrosion resistance evaluation method can be used to simulate the industrial atmosphere corrosion process, has simulation, acceleration and reproducibility properties, and can be used for rapid evaluation of the corrosion resistance of the galvanized steel coating in the industrial atmosphere environment, and the basis for rational use of galvanized protection and prediction of the protection life is provided.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

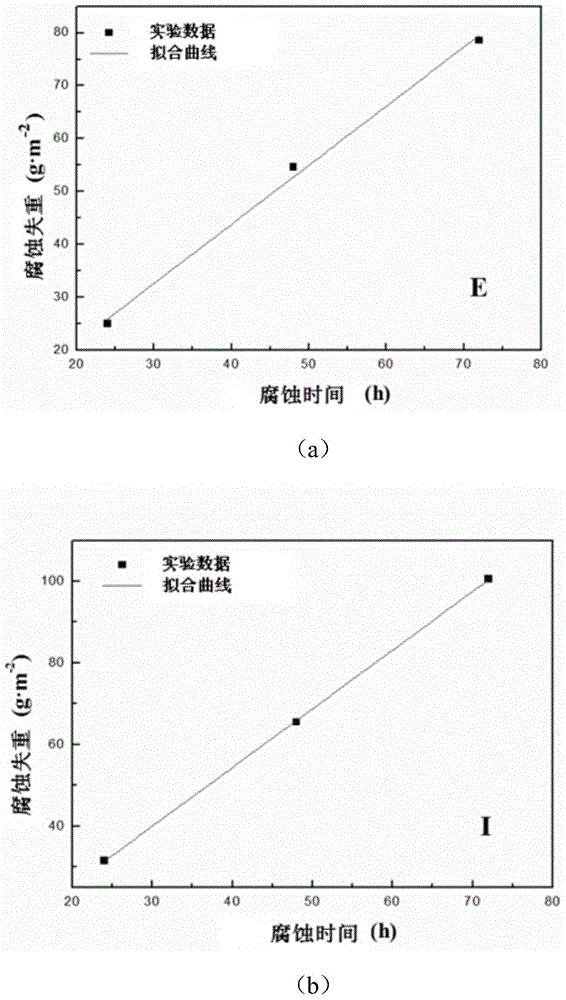

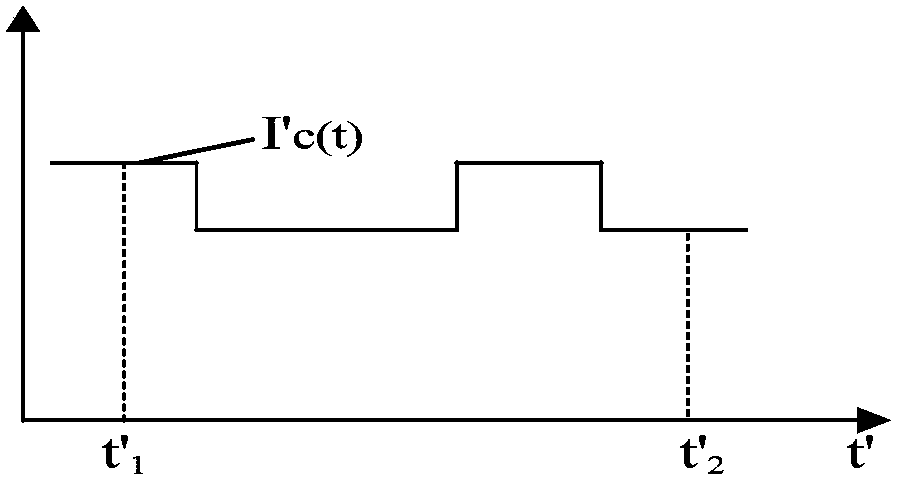

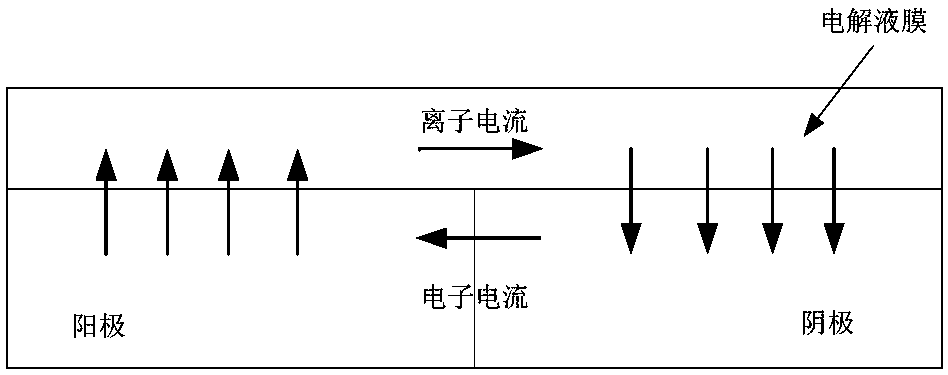

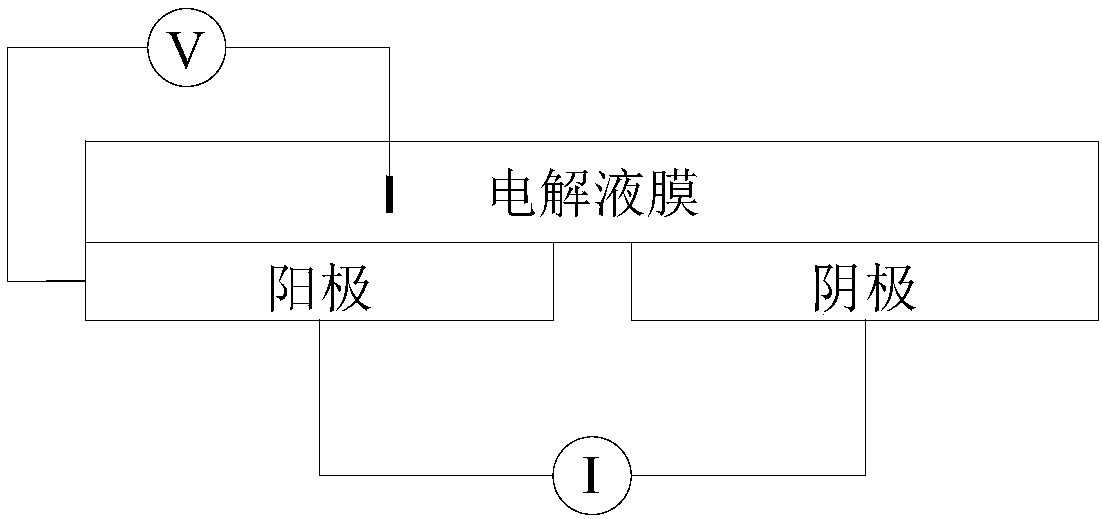

Compilation method for accelerated environment spectrum of dissimilar metal material combination structure

InactiveCN108256139AReproducibleSimulatedGeometric CADDesign optimisation/simulationPower flowConversion coefficients

The invention relates to aircraft environment spectrum and equivalence technology researches, in particular to a compilation method for an accelerated environment spectrum of a dissimilar metal material combination structure. The method comprises the steps of deriving an environment conversion coefficient formula of the combination structure according to a single metal environment conversion coefficient principle, and establishing an environment conversion coefficient database; based on a simulation method, building a galvanic corrosion model during dissimilar metal contact, obtaining information of potential distribution, a total current and the like of galvanic corrosion, verifying the correctness of the galvanic corrosion model, and supplementing the environment conversion coefficient database of the metal combination structure; selecting a typical dissimilar metal combination contact structure of an aircraft to perform a test, and according to a corrosion damage characterization quantity, correcting an accelerated equivalent environment spectrum of the dissimilar metal combination structure; and finally establishing accelerated corrosion equivalence theory and engineering methods of the combination structure.

Owner:CHINA SPECIAL TYPE FLIER RES INST

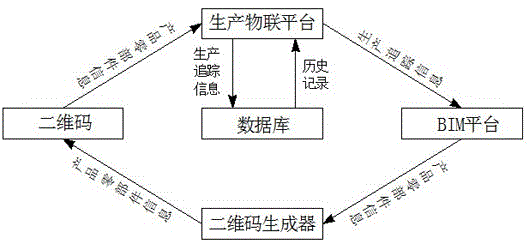

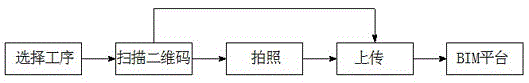

Production internet of things management method

InactiveCN105654318AIncrease storage capacityImprove confidentialityCommerceRelevant informationUser management

The invention relates to a production internet of things management method. The method comprises the steps of: generating a two-dimension code of a product by a two-dimension code generator, and fixing the two-dimension code to a corresponding component; scanning the two-dimension code of the component by adopting a production internet of things platform, photographing the component and obtaining production tracking data; transmitting the production tracking data to a BIM platform, and visually observing the production state of the component. The production internet of things management method has advantages that the production internet of things method combines the two-dimension code, the production internet of things platform and the BIM platform together and visually feeds back the production tracking data to a three-dimension information model; the two-dimension code is applicable to the field of production tracking; the production internet of things platform is mainly used for user management, process management, two-dimension code scanning, photographing, data uploading and historical data checking; and the BIM takes relevant information data of a construction project as a base of the model, has five advantages of visualization, harmony, simulation, optimization and mappability, and is wider and wider in application.

Owner:SHANGHAI ZHENHUA HEAVY IND +1

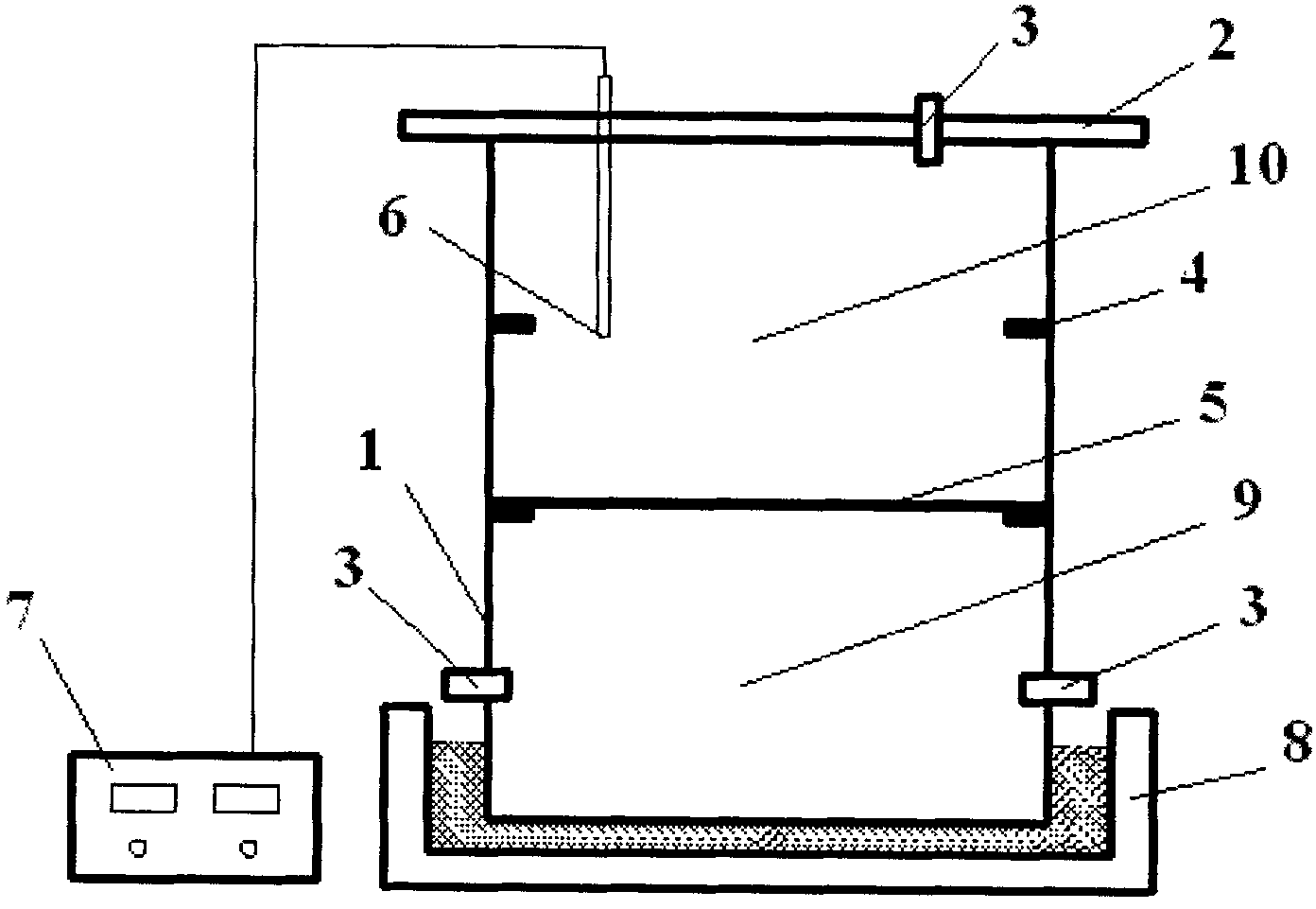

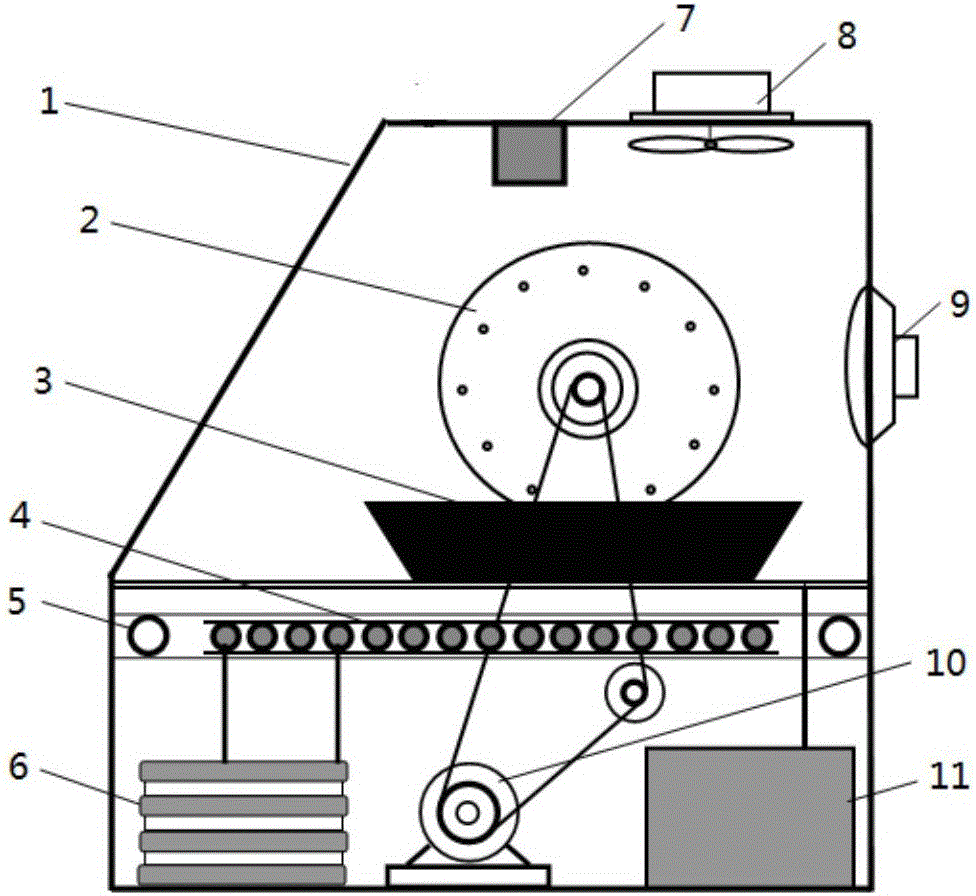

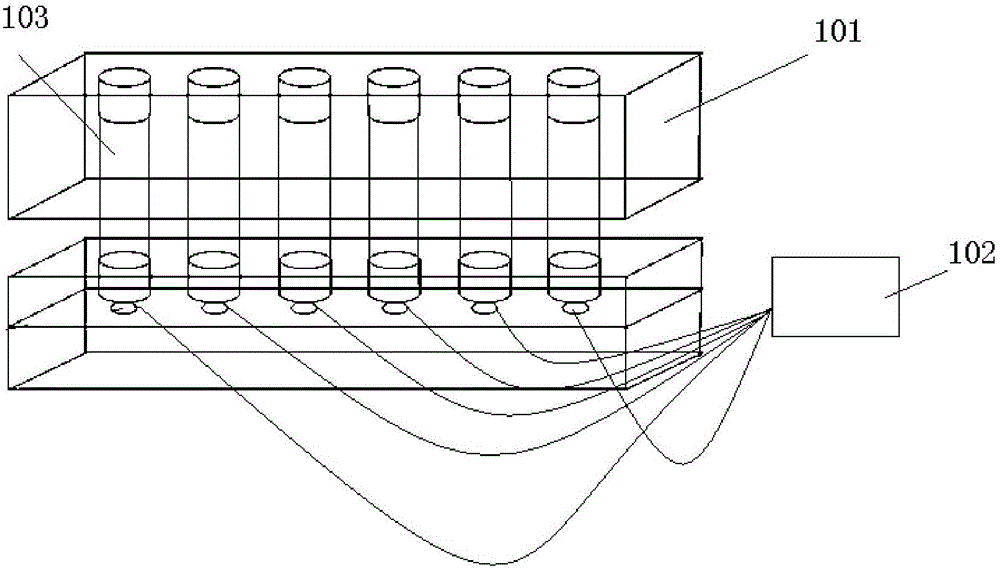

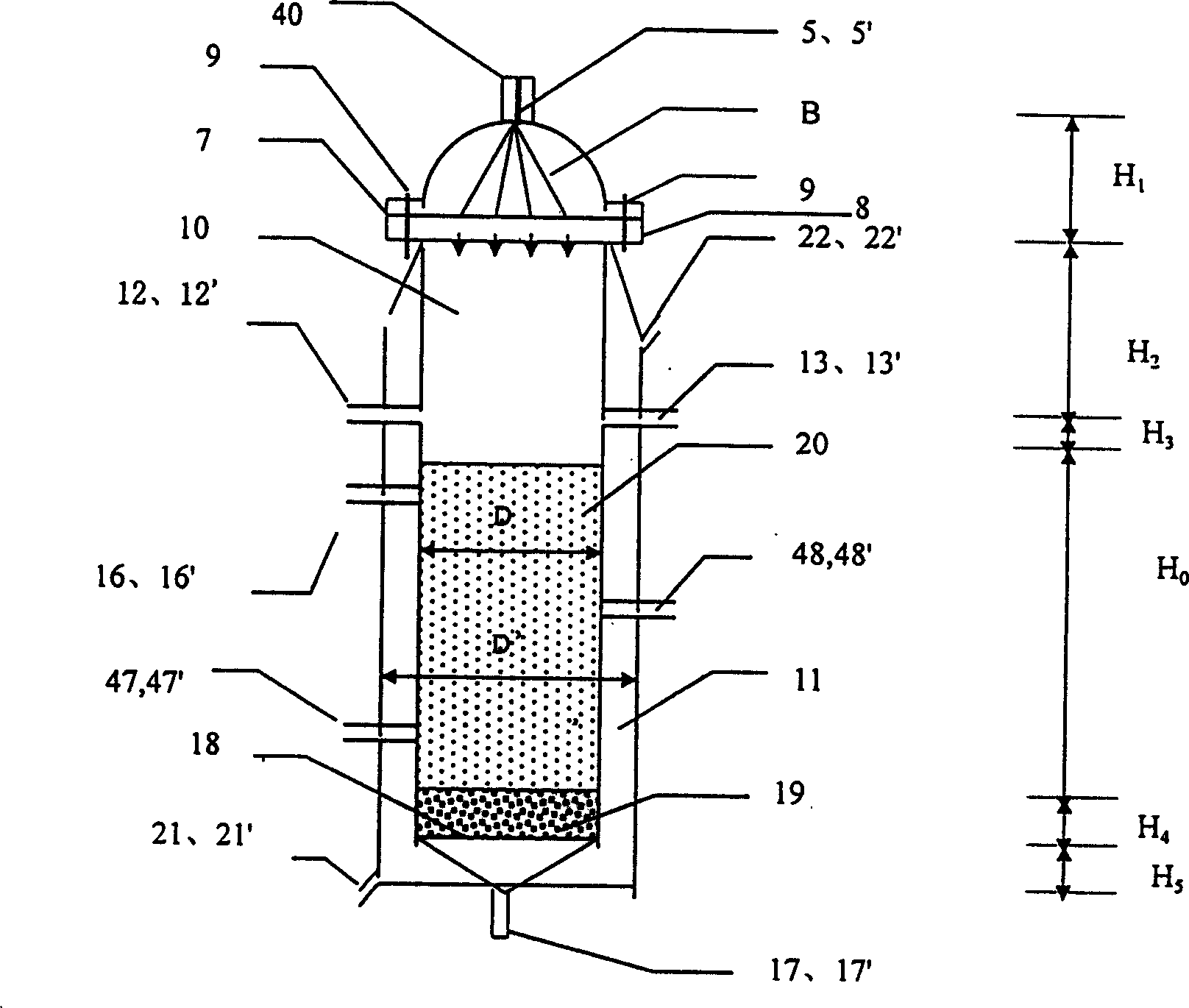

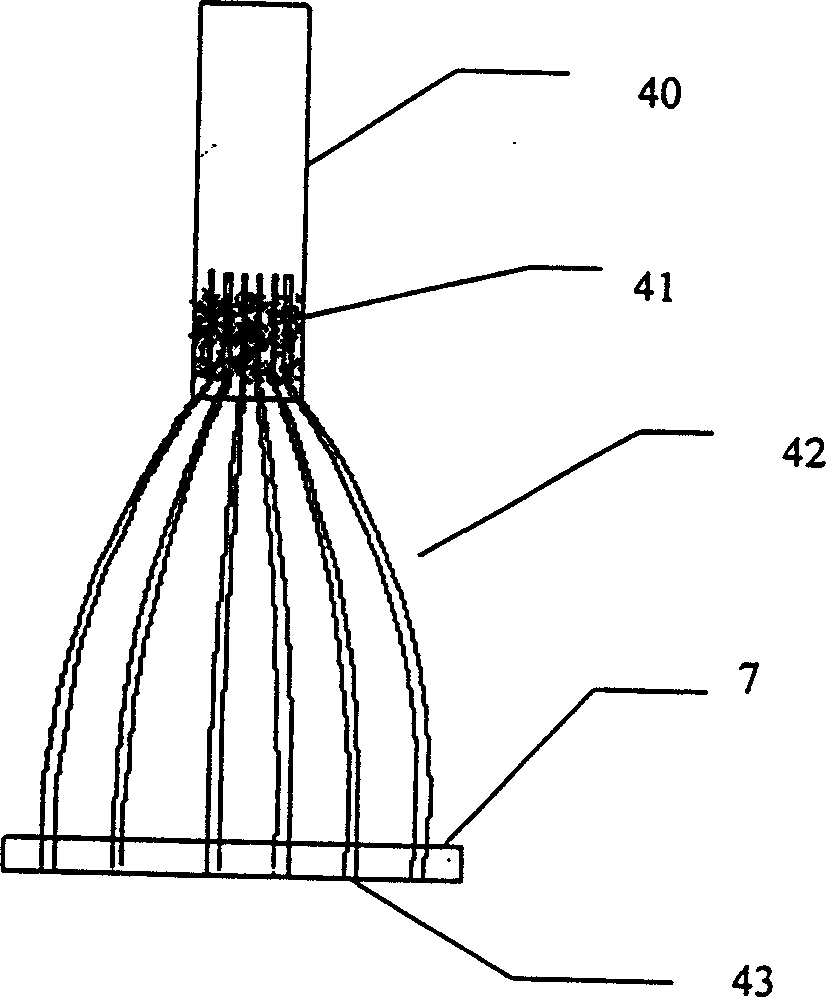

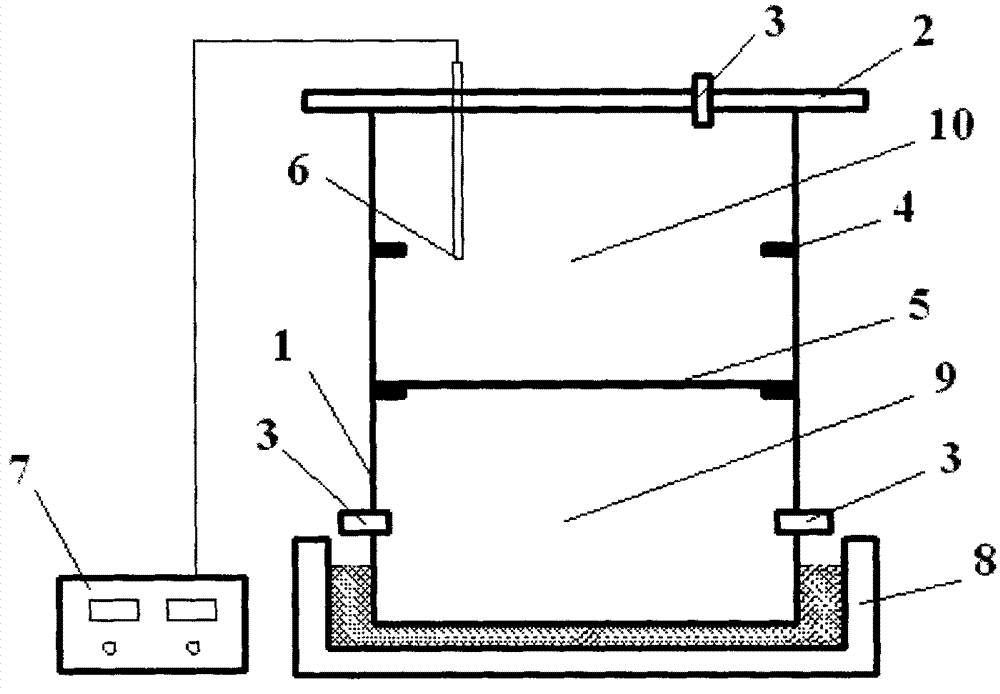

Accelerated testing apparatus for simulation of corrosion by industrially polluted atmosphere

InactiveCN102169083ASolve the problem of single dependence on external air sourceImprove good performanceWeather/light/corrosion resistanceAtmospheric airEngineering

The invention relates to a simulation technology of atmosphere corrosion on material and anticorrosion paint, and especially provides an accelerated testing apparatus for the simulation of the corrosion by industrially polluted atmosphere. The apparatus is provided with a reaction box, a box cover, an air inlet and outlet pipe, and a humiture monitoring probe. Besides, an inner chamber of the reaction box is divided into an upper layer chamber and a lower layer chamber, and the upper layer chamber is a corroding chamber and the lower layer chamber is an atmosphere generating chamber; the box cover is movably arranged on the top of the reaction box, and the air inlet and outlet pipe and the humiture monitoring probe are inserted into the box cover; and the air inlet and outlet pipe is inserted into the sidewall of the reaction box which has the atmosphere generating chamber. The apparatus has two methods of generating corrosive atmosphere: the chemical method and the external connection of gas source method, and a problem of relying on the single external connection of gas source to generate the corrosive atmosphere is solved. Simulation of the corrosion by polluted atmosphere especially by heavy-industry polluted atmosphere with the invention could be used for researching and evaluating the corrosion action of metal material and the anticorrosion paint in the heavy-industry polluted atmosphere, so as to provide evidence for reasonably choosing the material and choosing the appropriate protection method.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

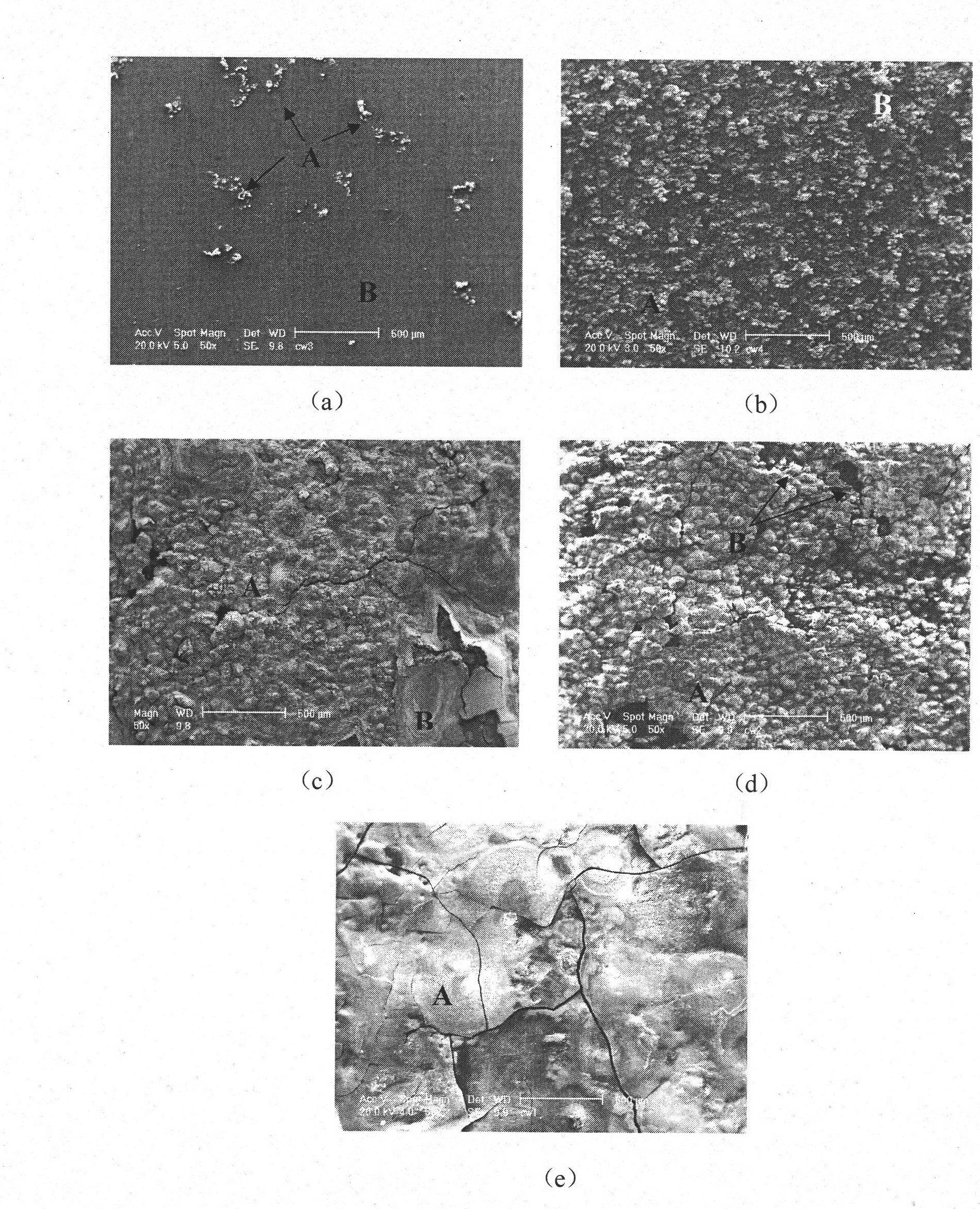

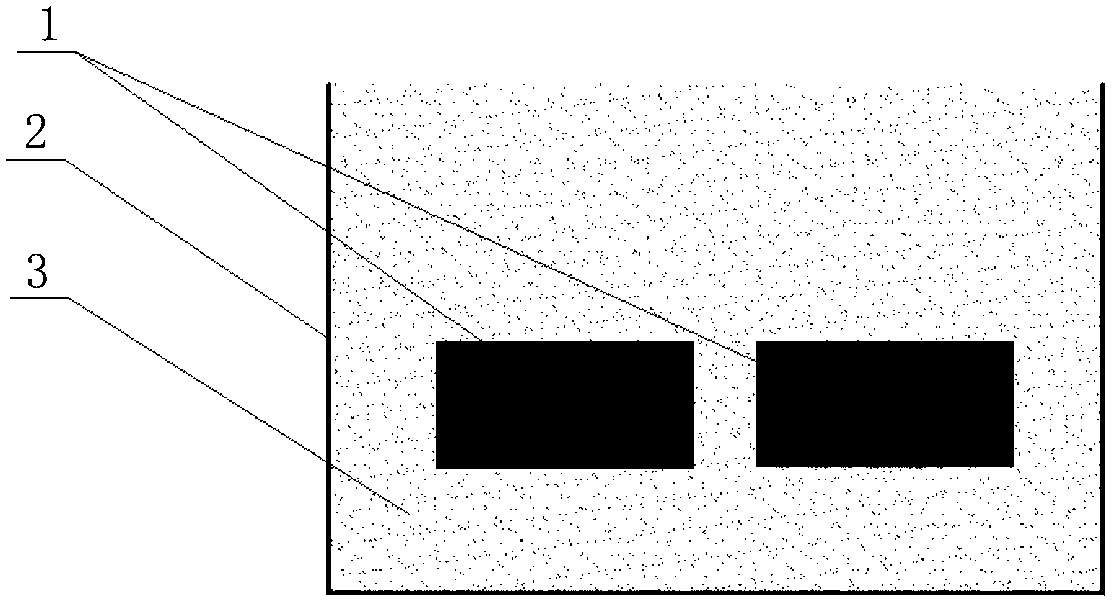

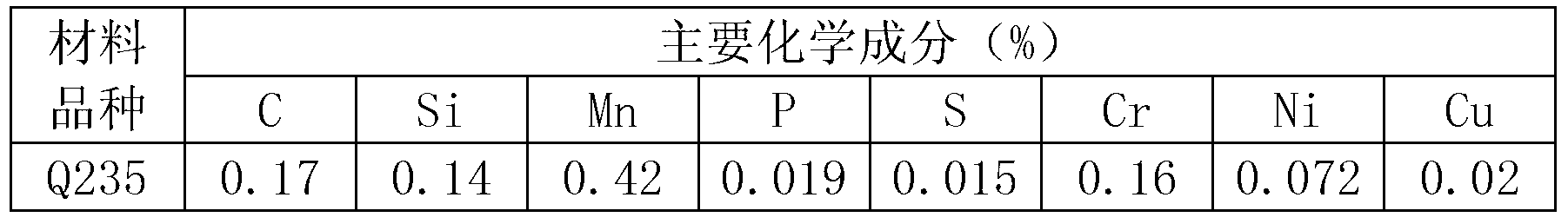

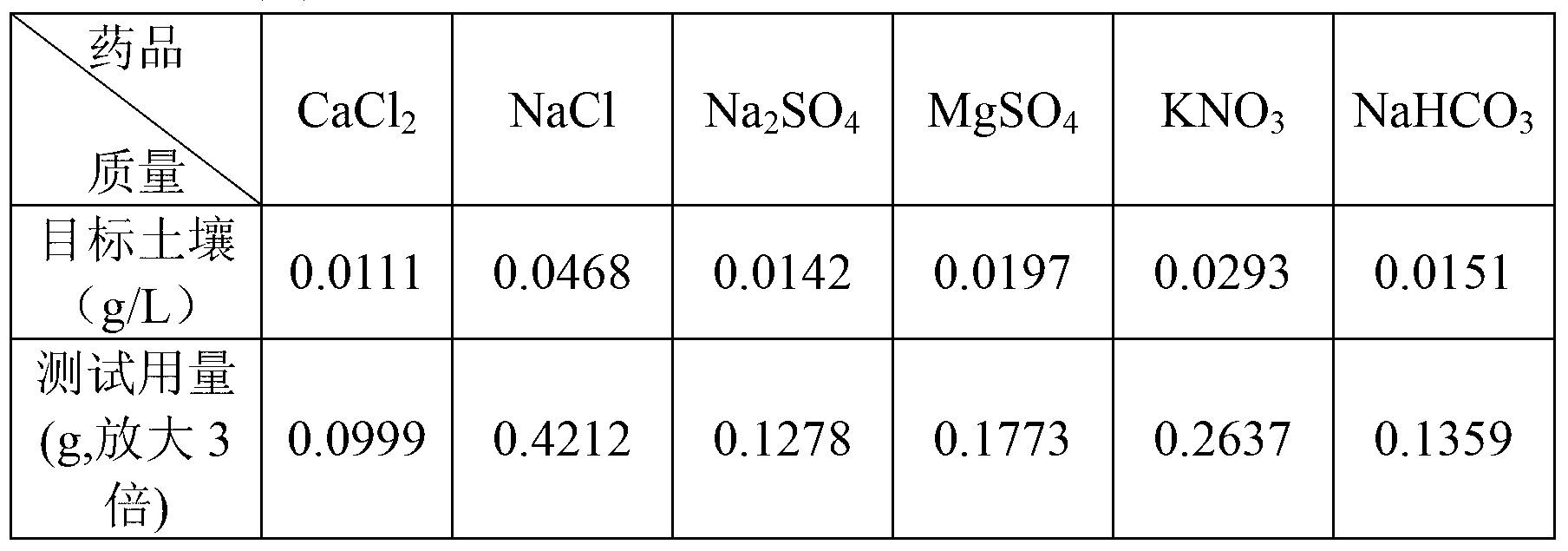

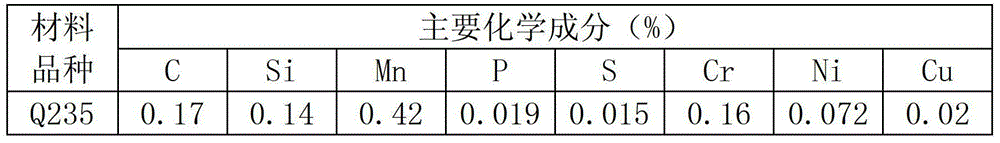

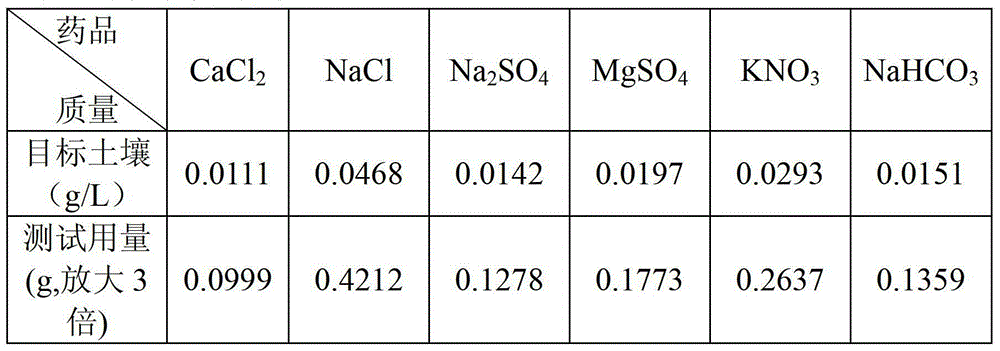

Accelerated corrosion testing method for simulating soil corrosion process

ActiveCN103308443ASoil Corrosion Resistance GuaranteeGuaranteed CorrosionWeather/light/corrosion resistanceHydrogenTest sample

The invention discloses an accelerated corrosion testing method for simulating a soil corrosion process. The method comprises the following steps of: (1) preparing a testing solution from salt and water according to components of target soil; (2) adjusting the pH (Potential of Hydrogen) value of the testing solution to a testing value by H2SO4 or NaOH, thus taking the testing solution as an impregnation medium for simulating soil corrosion, wherein the testing value is the same as the pH value of the target soil; (3) mixing diatomite, which is taken as a carrier, with an impregnation medium to prepare testing soil which is basically same as the target soil in physicochemical properties; and (4) testing a test sample in the testing soil according a pre-set testing temperature, relative humidity and testing period.

Owner:CENT IRON & STEEL RES INST

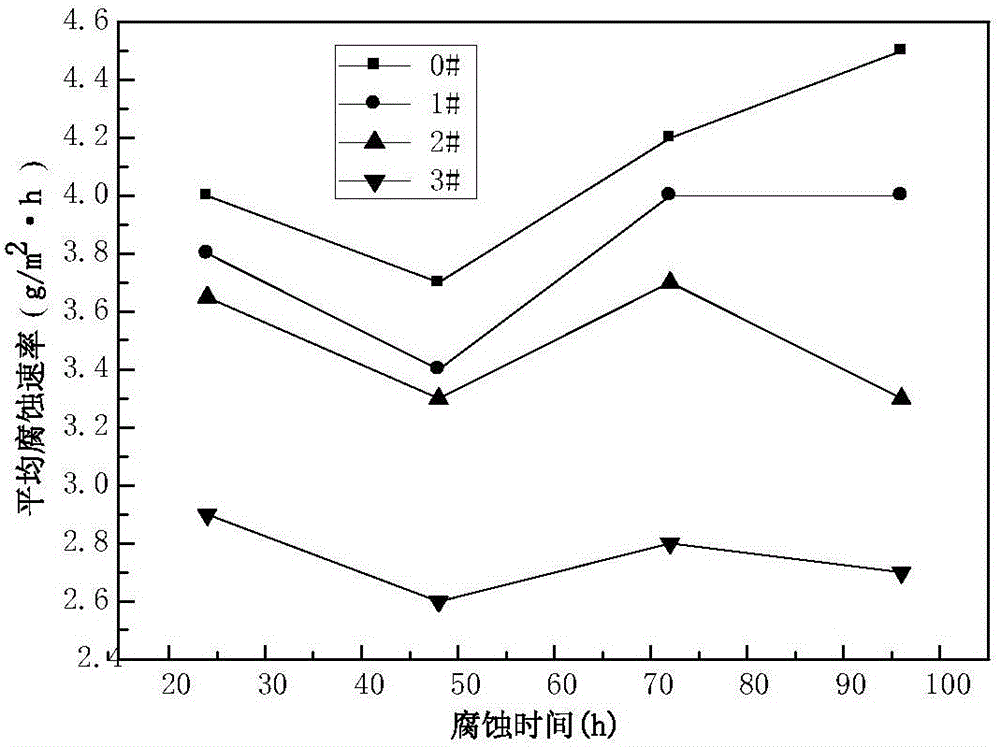

Method for simulating corrosion of weathering resistant steel in high-moist-heat marine atmosphere

InactiveCN105699280AConsistent corrosion resistanceThe same order of corrosion resistanceWeather/light/corrosion resistanceCyclic processSteeping

The invention relates to a method for simulating corrosion of weathering resistant steel in high-moist-heat marine atmosphere. The method comprises the following test parameters that a weathering resistant steel test specimen is subjected to the circulation processes of steeping, moistening and drying in an alternate immersion corrosion testing machine; the circulation period is 60min+ / -5min; the steeping time is 2min+ / -1min; the moistening time is 10min+ / -2min; a dipping solution is a NaCl solution; the NaCl solution concentration is 2.00 percent+ / -0.05 percent; the steeping solution temperature is 35 DEG C+ / -2 DEG C; the humidity in the alternate immersion corrosion testing machine is 80 percent RH+ / -5 percent RH; the total corrosion time of the weathering resistant steel test specimen in the alternate immersion corrosion testing machine is greater than or equal to 72h; a baking lamp in the alternate immersion corrosion testing machine is kept open. The method has better simulation performance, acceleration performance and reproducibility, and provides bases for studying the corrosion rule and the corrosion resistance of the weathering resistant steel in high-moist-heat marine environment.

Owner:CENT IRON & STEEL RES INST +1

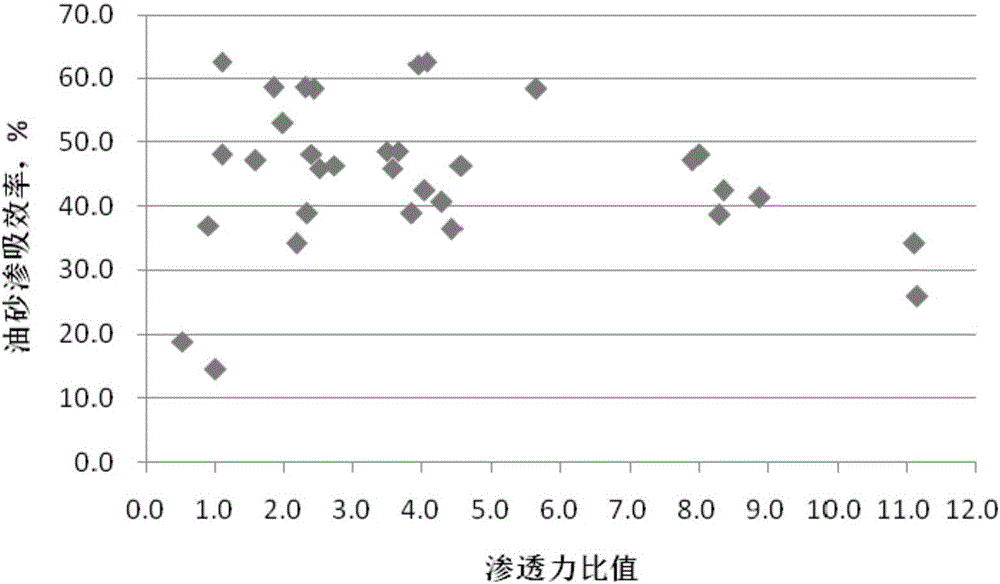

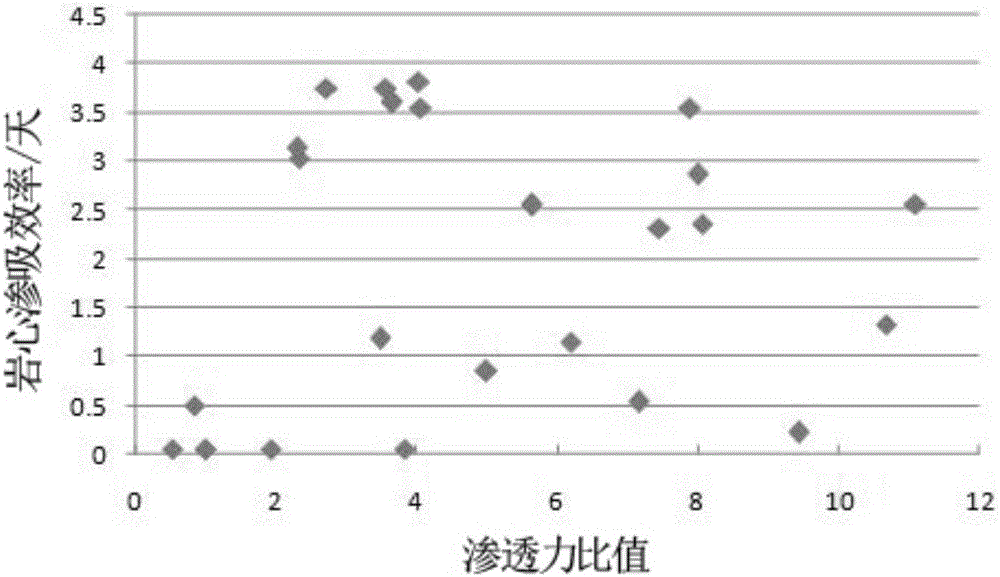

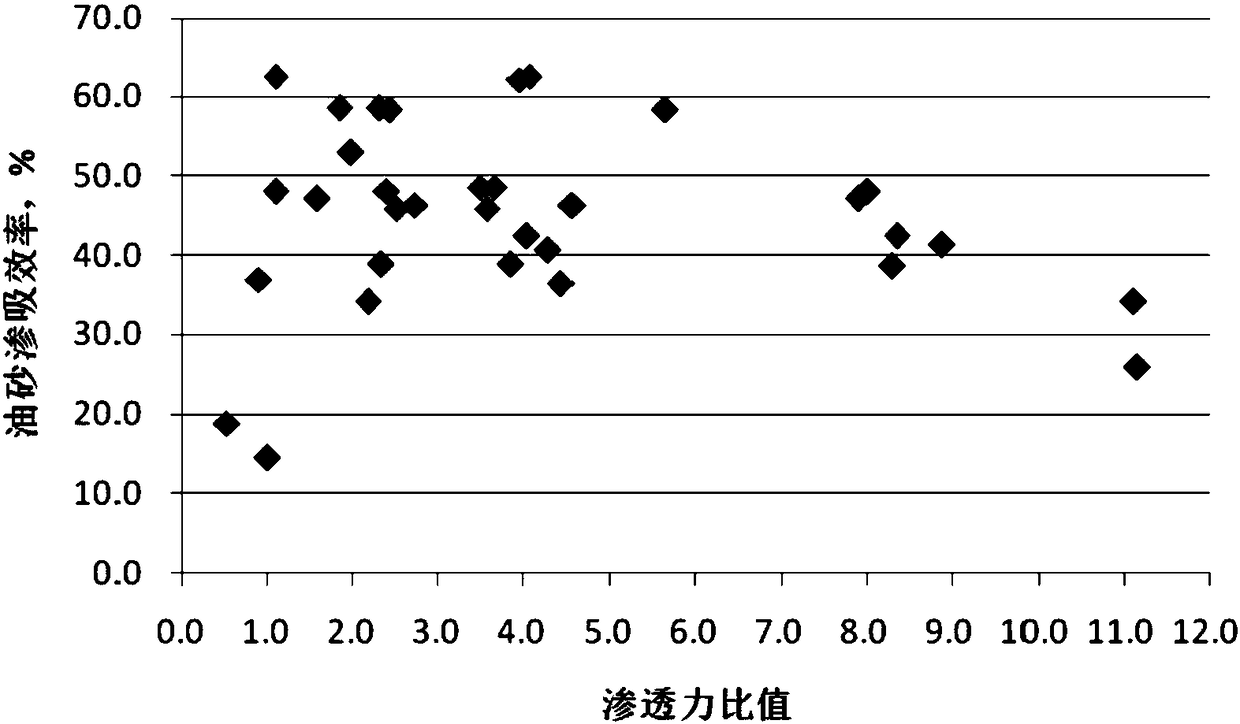

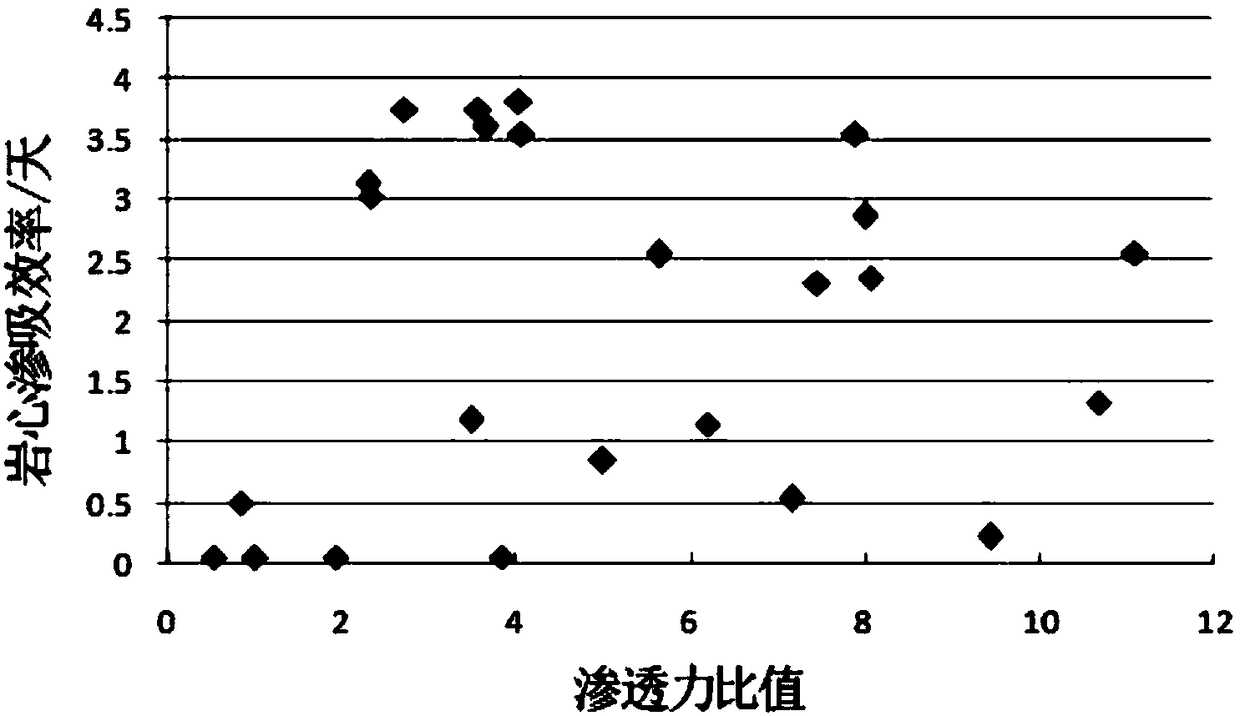

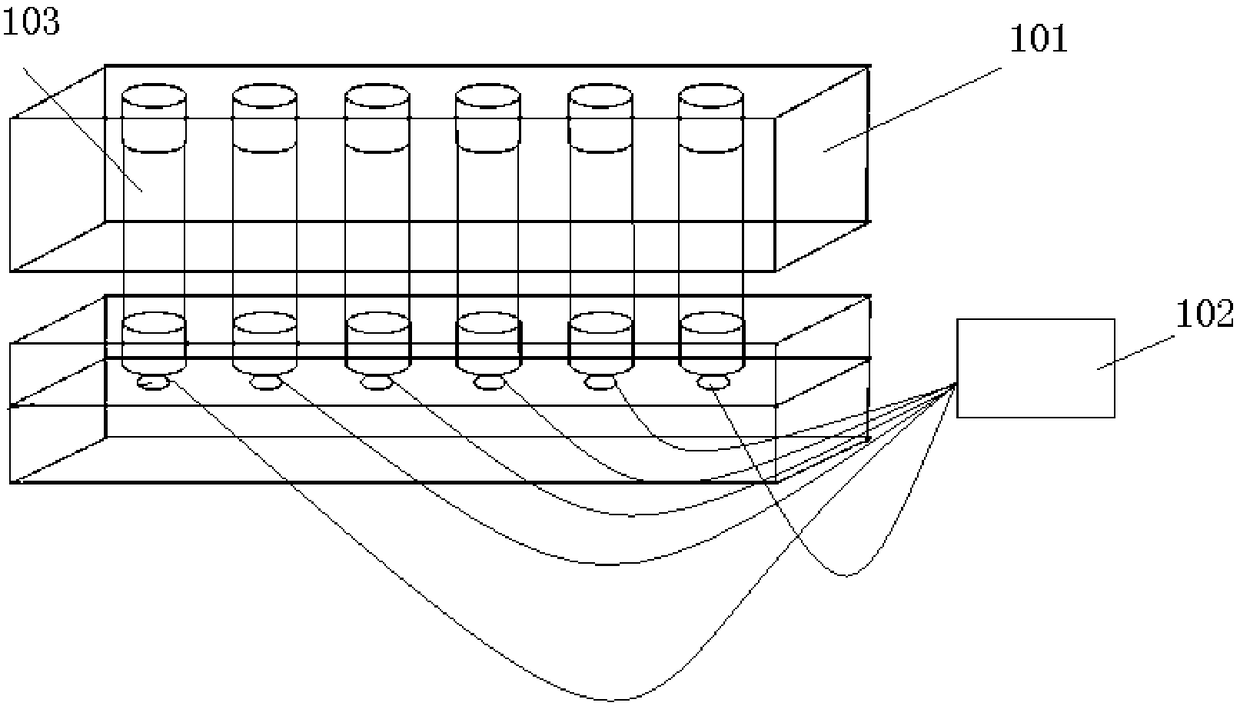

Method for evaluating permeating performance of chemical imbibition agent

ActiveCN105938084AConvenient for indoor testingQuick indoor testPermeability/surface area analysisPermeationOil sands

The invention provides a method for evaluating the permeating performance of a chemical imbibition agent. According to the evaluation method, the elevating coefficient Sc and permeation speed Sp of a capillary can be measured, thus the permeation force Fp can be calculate according to a formula: Fp=Sc*Sp; the performance of a chemical imbibition agent can be evaluated through a ratio (R) of the permeation force Fp of a chemical imbibition agent to a simulated water permeation force, and if the R is greater than 1.0, the chemical imbibition agent has a good imbibition effect. The method can be used to quantitatively evaluate the permeating performance of a chemical imbibition agent for low permeability reservoir. The method has the advantages that the indoor tests become convenient and fast, the comparison and quantitation become more convenient; the permeating performance and diffusion property of different chemical imbibition agents can be effectively compared; corresponding oil sand and capillary that are similar to oil reservoirs are used to simulate the oil reservoirs, at the same time, the experiment temperature is identical with the temperature of stratum, and thus the experiment is closer to the actual state.

Owner:PETROCHINA CO LTD

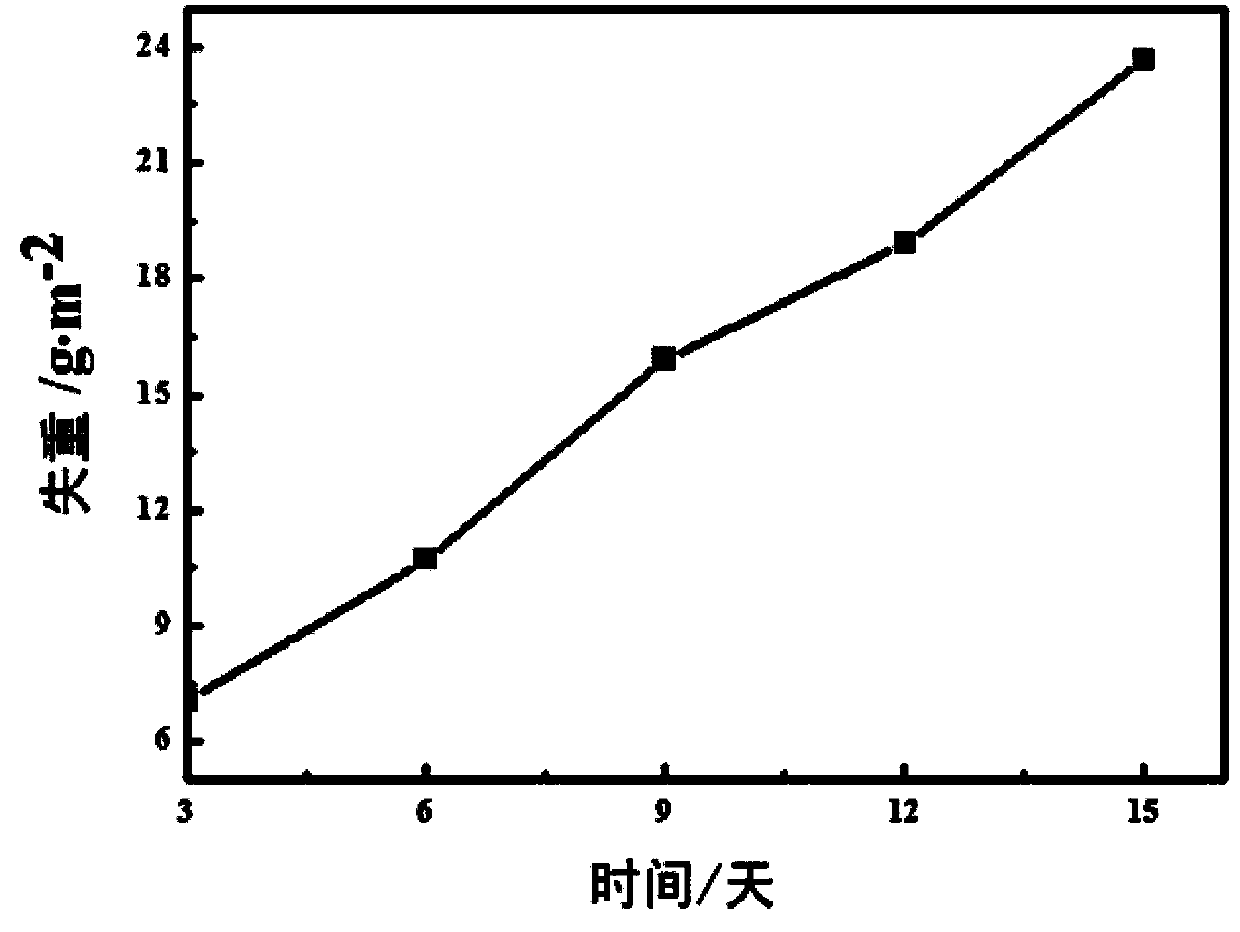

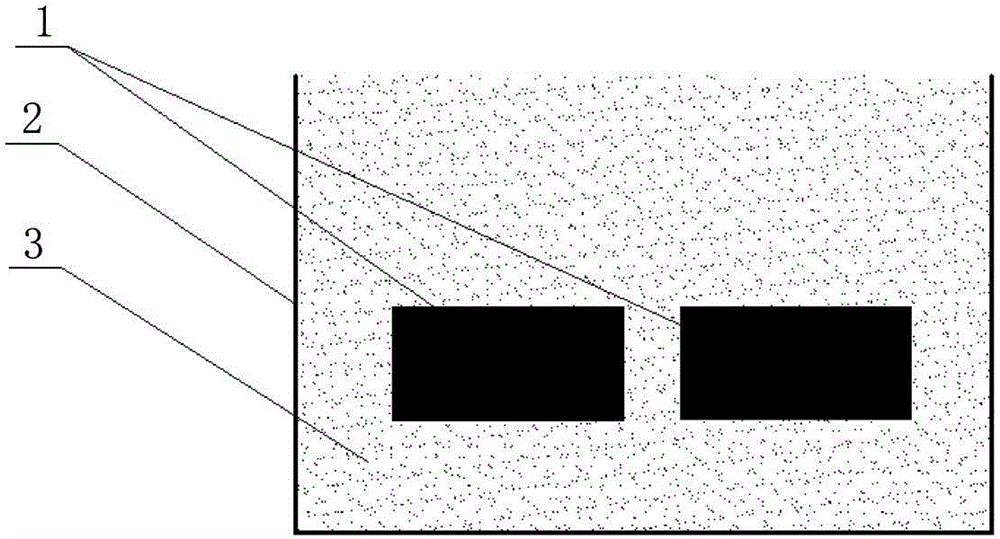

Test method for simulating corrosion process of aluminum alloy in salt-rich salt lake in atmospheric environment

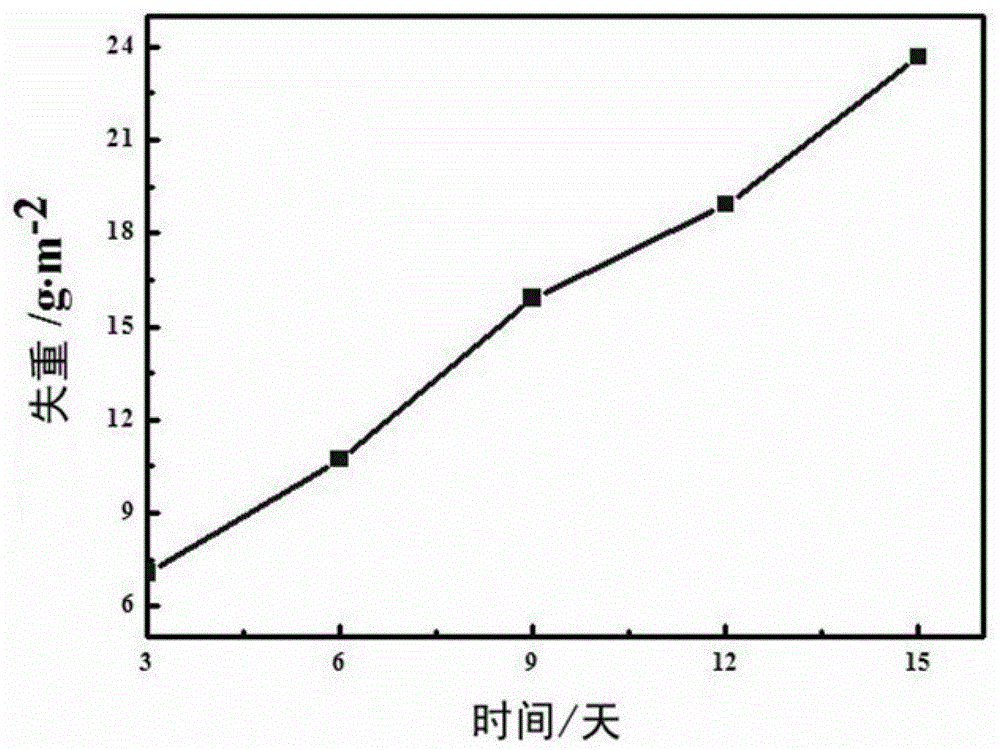

ActiveCN103969173AGood reproducibilityUniform Discontinuous DispersionWeather/light/corrosion resistanceDrying timeCorrosion behavior

The invention discloses a test method for simulating corrosion process of an aluminum alloy in a salt-rich salt lake in an atmospheric environment. According to the method, the aluminum alloy is used as a test material, salt lake water collected on site is used as a corrosion medium, salt solution drops are deposited on a sample surface in virtue of an aerosol generator, deposition is carried out once every three days, and the amount of deposited salt each time is 100 mu g / cm2; wetting and drying are alternately carried out, and a cycle of wetting and drying is carried out every three hours, wherein the temperature during wetting is 30 DEG C, wetting time is 1 h (wherein relative humidity is linearly increased to 80% from 20%), the temperature during drying is 40 DEG C, and drying time is 2 h (wherein relative humidity is linearly decreased to 20% from 80%); test time is 3 to 15 d. Test results obtained in the invention have the characteristics of simulation, acceleration and repeatability, and the method can be used for research on corrosion behaviors of the aluminum alloy in the salt-rich salt lake in the atmospheric environment and can realize rapid evaluation and prediction of atmospheric corrosion of the aluminum alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

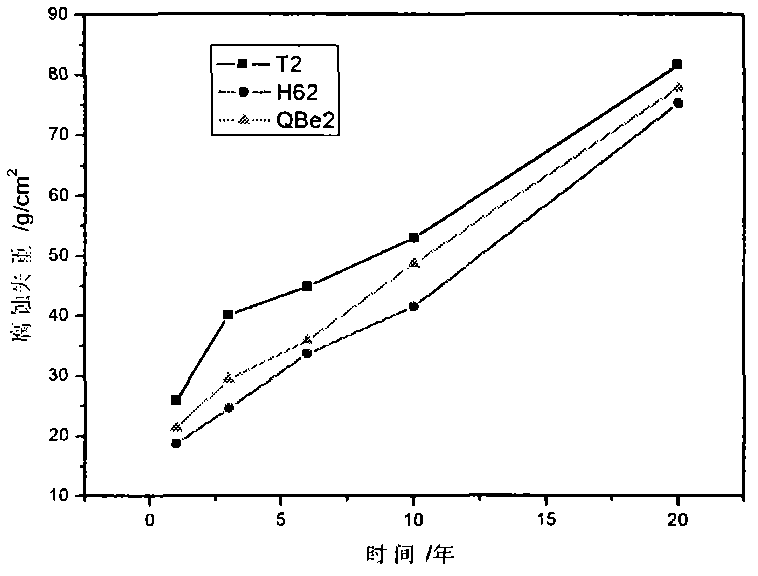

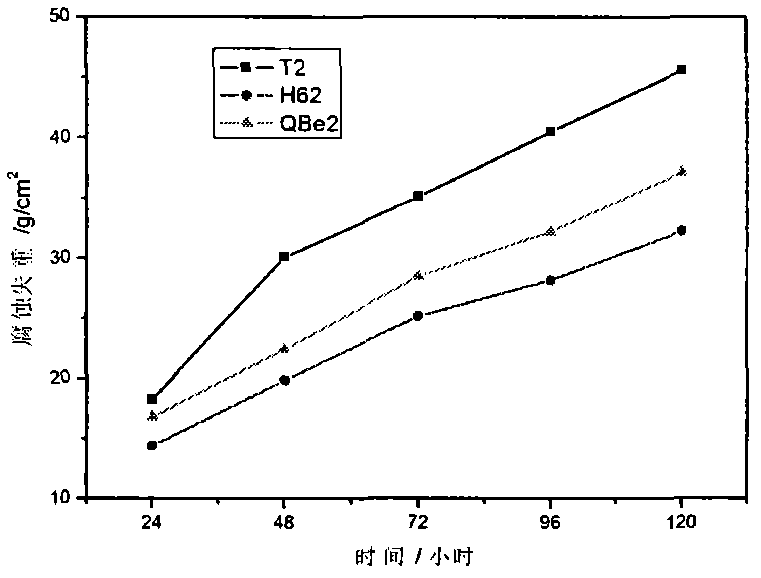

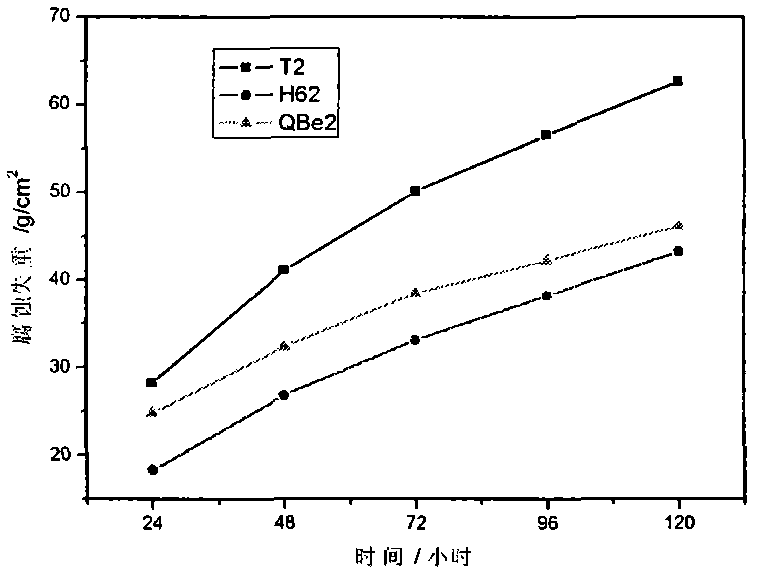

Method of accelerated corrosion test used for simulating corrosion process of copper and alloy thereof in atmosphere

InactiveCN102466613ARapid evaluation of atmospheric corrosion resistanceHighly corrosiveWeather/light/corrosion resistanceTest sampleTested time

The invention relates to a method of an accelerated corrosion test used for simulating a corrosion process of copper and alloy thereof in the atmosphere. The method comprises steps that: (1) copper or copper alloy is prepared into a test sample; (2) an aqueous solution of CuCl2, (NH4)2SO4 and NaHSO3 is adopted as an impregnation solution; (3) the sample is subject to a circulated test according to a sequence of impregnating, moisturizing, and drying; and single-time and total test times are determined according to specific requirements; (4) the sample obtained from the step (3) is treated, and researches such as corrosion weight loss, corrosion products and morphological analysis are carried out. The method provided by the invention is used for simulating the corrosion process of copper and alloy thereof in different environments such as a damp and hot environment and a marine environment. The test method has a simulating capacity, an accelerating capacity, and repeatability. The method can be used in the researches of atmosphere corrosion behaviors and rules of copper and alloy thereof in different environments, and can be used in rapid evaluations of corrosion resistances of various copper and alloy thereof.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Test method for stimulating corrosion process of low-alloy steel in atmospheric environment in salt lake

InactiveCN101571474AImprove good performanceAccelerated corrosionWeather/light/corrosion resistanceSalt lakeTested time

The invention relates to an atmospheric corrosion simulation technology for low-alloy steel, in particular to a test method for stimulating the corrosion process of low-alloy steel in the atmospheric environment in a salt lake. The method comprises the following steps: the low-alloy steel is taken as the test material, the salt lake water diluted by 20-50times is used as the corrosive medium, the low-alloy steel is dipped, dried and humidified in sequence every 20-30 minutes, wherein the low-alloy steel is dipped for 2-4 min at 40-50 DEG C; the low-alloy steel is dried for 15-20 min at 50-70 DEG C; the low-alloy steel is humidified for 3-6 min at 40-50 DEG C; and the test time is 6-96 h. The invention has the imitativeness, the acceleration capability and the reproducibility so as to stimulate the atmospheric corrosion process in the slat lake, can be used for studying the corrosion behavior of the low-alloy steel in the atmospheric environment in the salt lake, can perform evaluation and predication and provides the basis for reasonably selecting the material and using the proper protection method.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Test method for simulating corrosion process of stainless steel in industrial marine atmosphere

PendingCN109253966AGood reproducibilitySimulatedWeather/light/corrosion resistanceTested timeTest material

The invention provides a test method for simulating a corrosion process of stainless steel in an industrial marine atmosphere, and belongs to the technical field of metal corrosion atmosphere simulation. The method comprises the following steps: firstly performing ultraviolet irradiation test on a sample by using stainless steel as the test material, wherein the irradiation intensity is (60+ / -10)W / m2, the temperature is (50+ / -10) degrees centigrade, and the test time is 50 hours; then using the mixed solution of 1% to 5% NaCl added with 0.1% to 0.3% NaSO as an impregnation solution, performing alternate wetting and drying test on the sample in the order of "dipping to drying" in a periodic infiltration test machine every 30 minutes, wherein the solution is dipped for 7-8 minutes and driedfor 22-23 minutes, the temperature of the dipping solution is (40+ / -5) degrees centigrade, the relative humidity in the test machine used is 90% RH+ / -5% RH, and the test time is 50 hours. The invention has the characteristics of simulation, acceleration and reproducibility, and can be used to study the corrosion behavior rule of stainless steel in industrial marine atmosphere, and quickly evaluate and predict its resistance to industrial marine atmospheric corrosion, which provides a basis for rational material selection.

Owner:UNIV OF SCI & TECH BEIJING

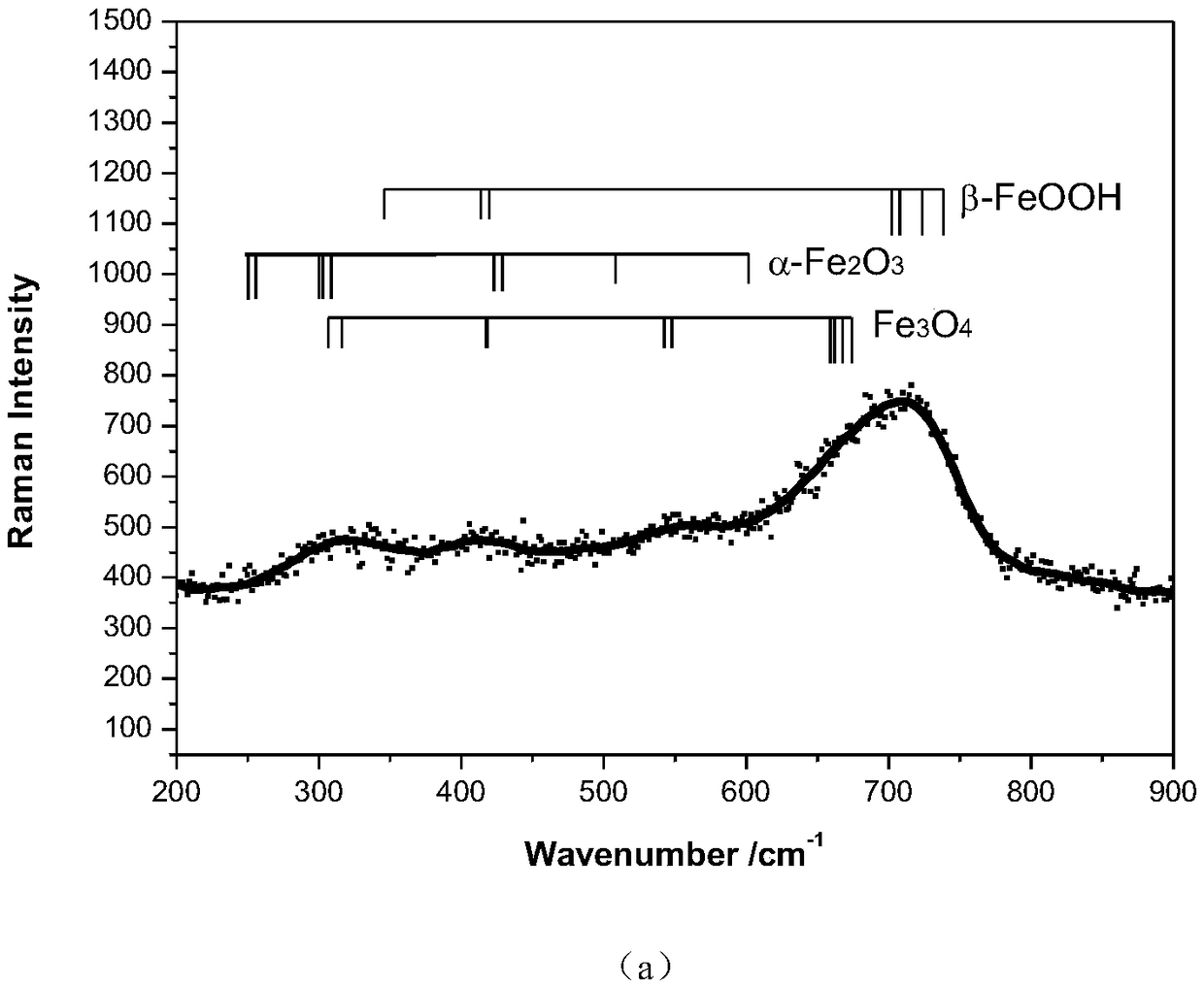

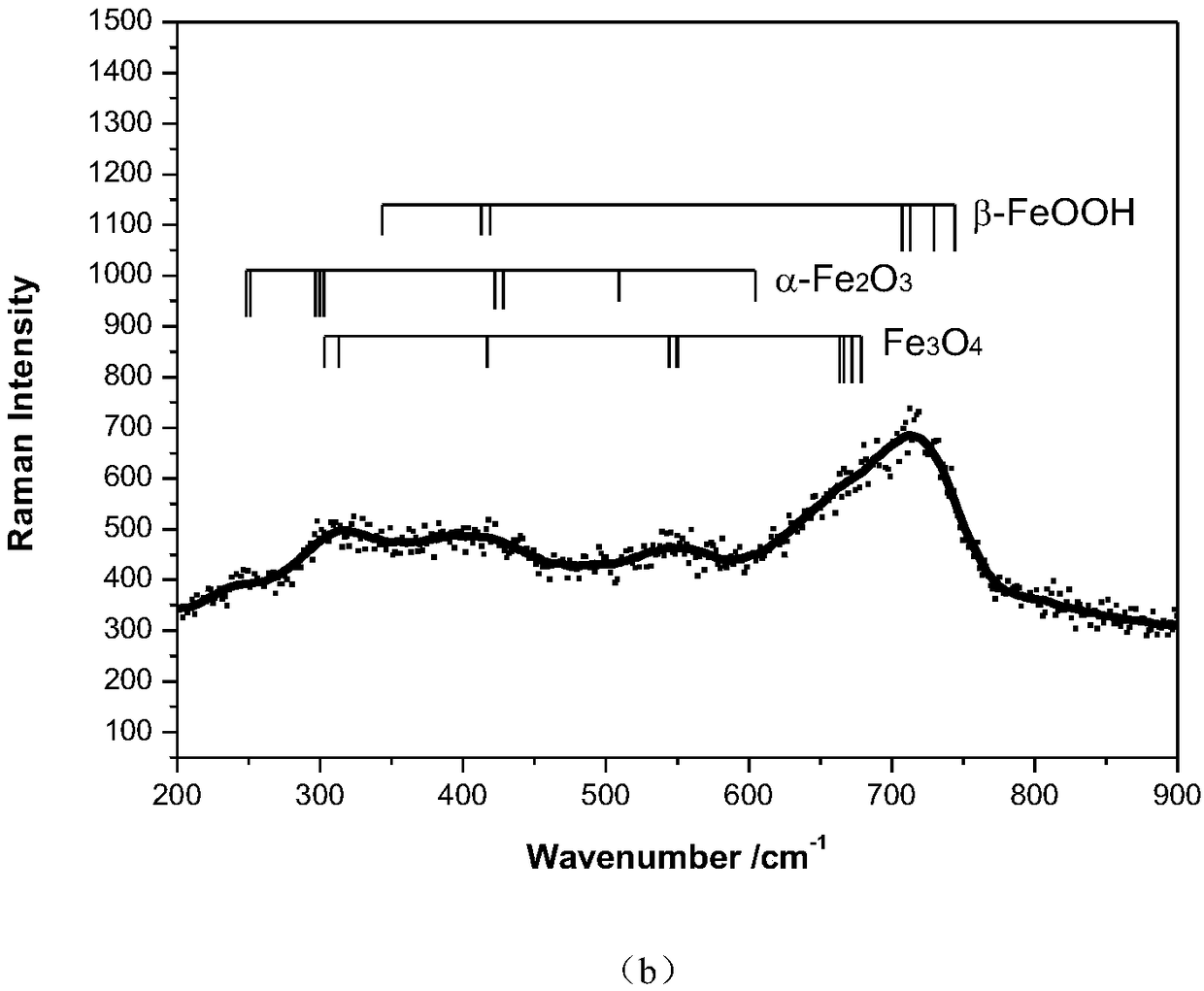

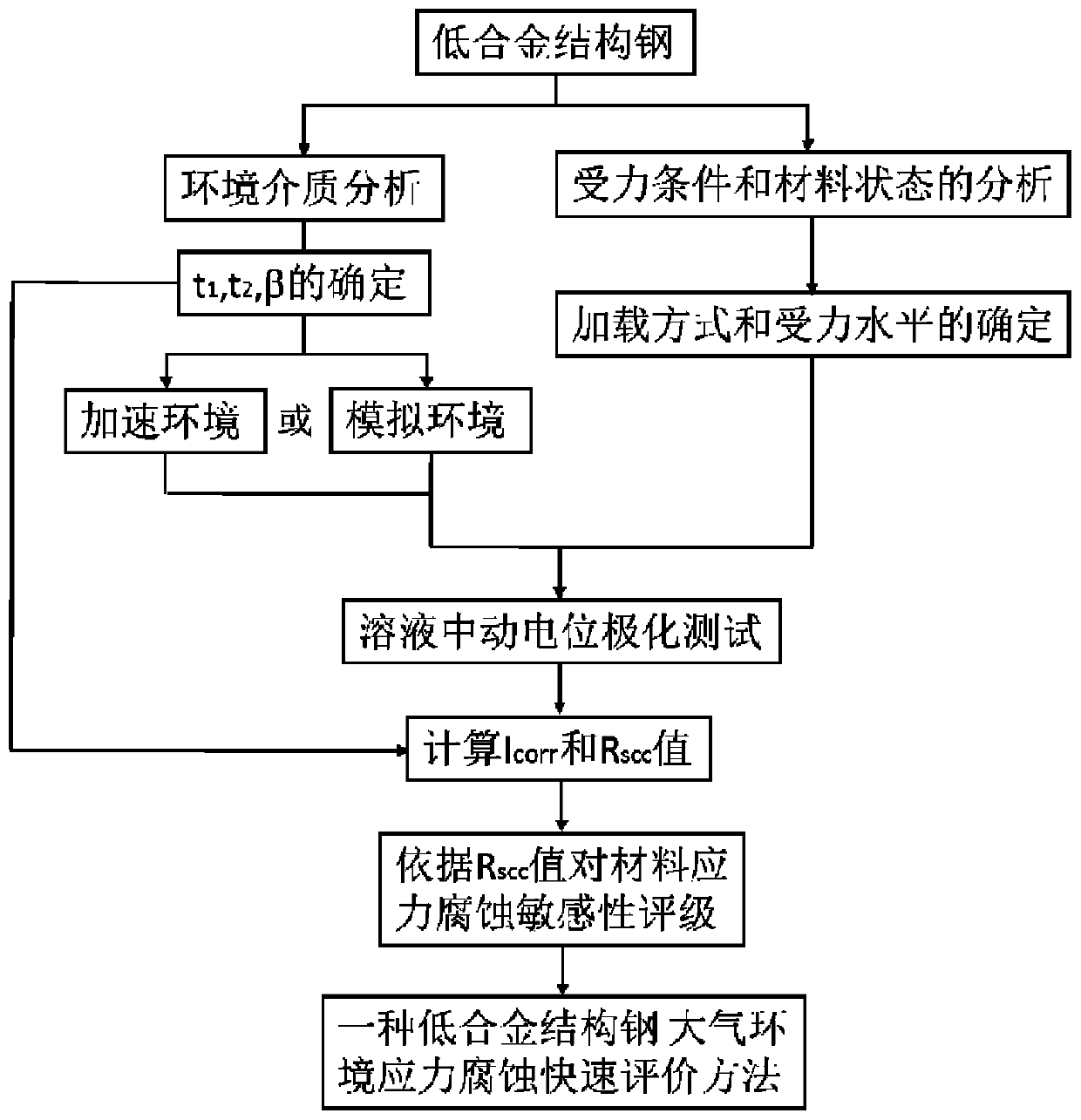

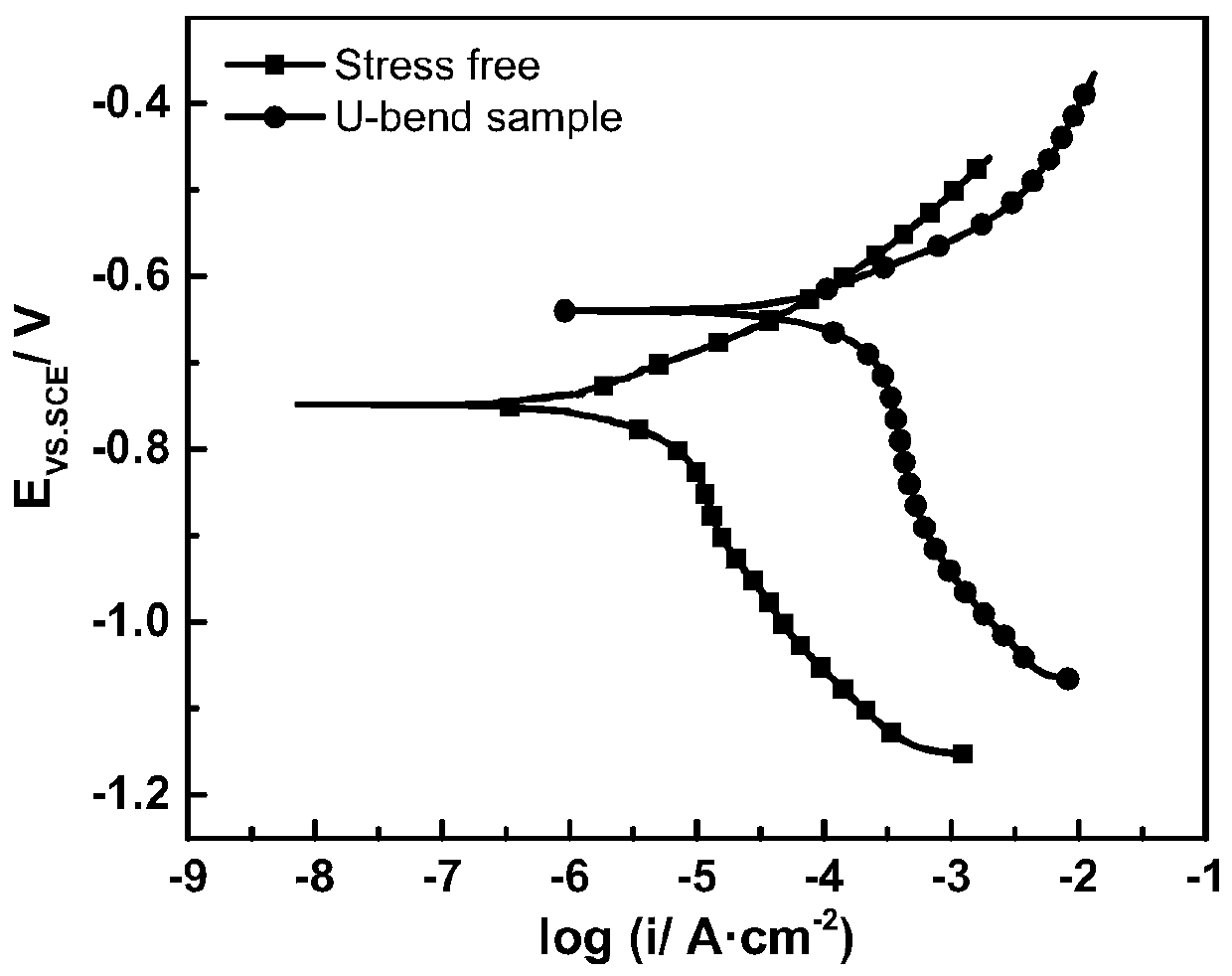

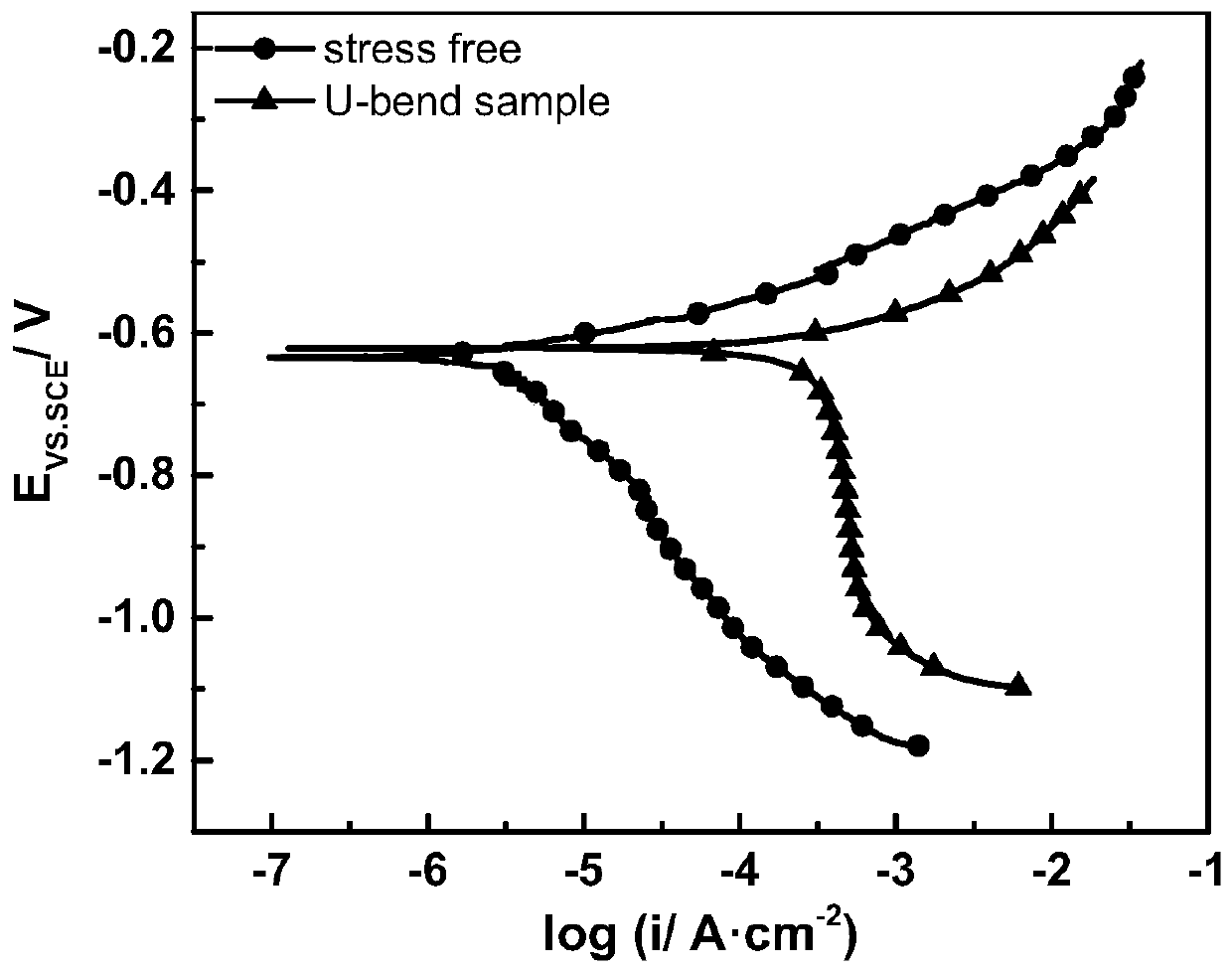

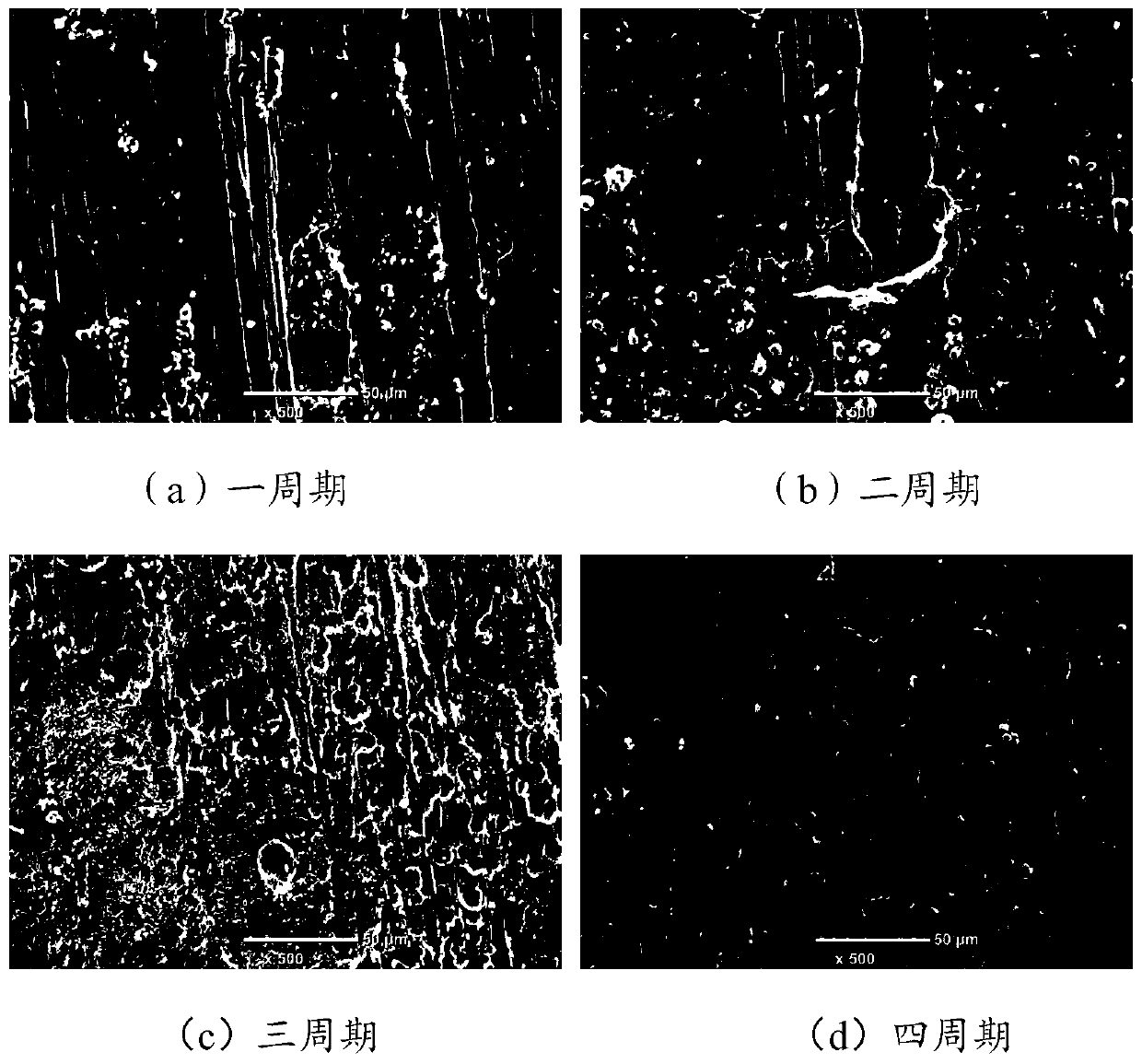

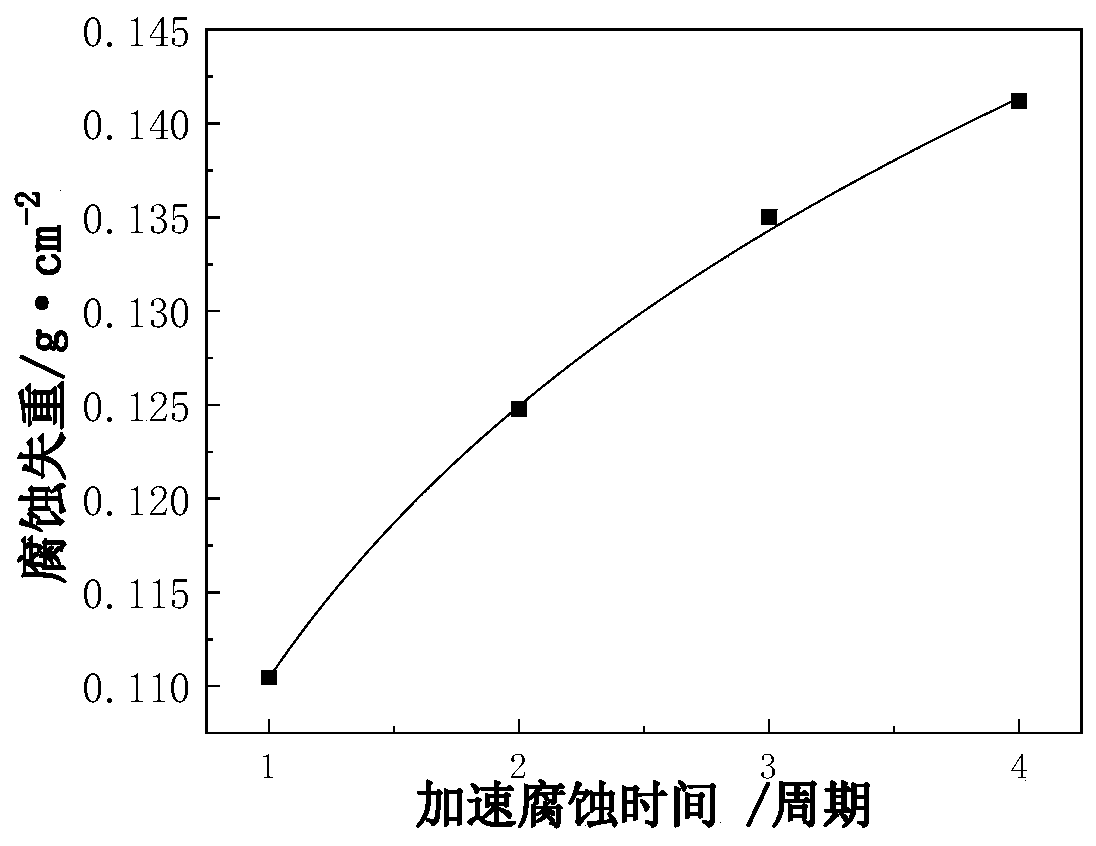

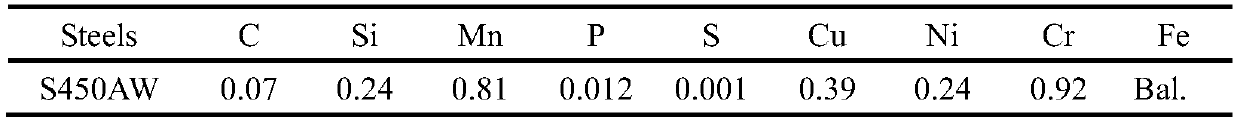

Rapid evaluation method for stress corrosion sensitivity of low-alloy structural steel in atmospheric environment

PendingCN110823690AEasy to operateImprove surface qualityWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesResearch dataPhysical chemistry

The invention discloses a rapid evaluation method for stress corrosion of low-alloy structural steel in an atmospheric environment. The rapid evaluation method is a stress corrosion sensitivity evaluation method constructed based on electrochemical tests and based on atmospheric environment stress corrosion indoor and outdoor simulation and acceleration research data and a stress corrosion electrochemical mechanism thereof. Compared with a traditional outdoor atmospheric exposure test method, the rapid evaluation method has high operability in indoor tests and short test time, the evaluation of stress corrosion performance of the low-alloy steel can be realized, and the rapid evaluation method can be further used for the research and development, production and relevant evaluation and testing in the material selection process of the low-alloy structural steel. The rapid evaluation method has the characteristics of simulation, acceleration and effectiveness, a new method is provided forthe evaluation study of the stress corrosion sensitivity of the low-alloy structural steel in the atmospheric environment, and thus an advantageous basis is provided for the use and protection of materials.

Owner:NANJING IRON & STEEL CO LTD

Corrosion test method for simulating truck body steel in coal leachate medium

The invention provides a corrosion test method for simulating truck body steel in a coal leachate medium and belongs to the metal corrosion atmospheric simulation technology field. Truck body steel istaken as a test material, a mixed solution which contains, by weight, 3.5% of NaCl, 0.25% of MgCl2, 1% of CaCl2, 0.25% of KCl and 10% of Na2SO4 is taken as a dipping solution, and a pH value is 3. Asample is subjected to a dry and wet alternating test in an order of ''infiltration-drying-hot and humid condition'' in a periodic infiltration testing machine, and a cycle is repeated every 60 minutes, where the sample is infiltrated for 15 minutes and dried for 15 minutes; and the hot and humid condition maintains for 30 minutes, a temperature of the dipping solution is (40+ / -5)DEG C, a drying temperature is (70+ / -5)DEG C, and a hot and humid temperature is (40+ / - 5)DEG C. The method has simulation, acceleration and reappearance performance, can be used to study a corrosion behavior rule ofcoal truck body steel during a service process, and can be used to quickly evaluate and predict corrosion resistance performance in the coal leachate medium, and a basis can be provided for rational material selection.

Owner:UNIV OF SCI & TECH BEIJING

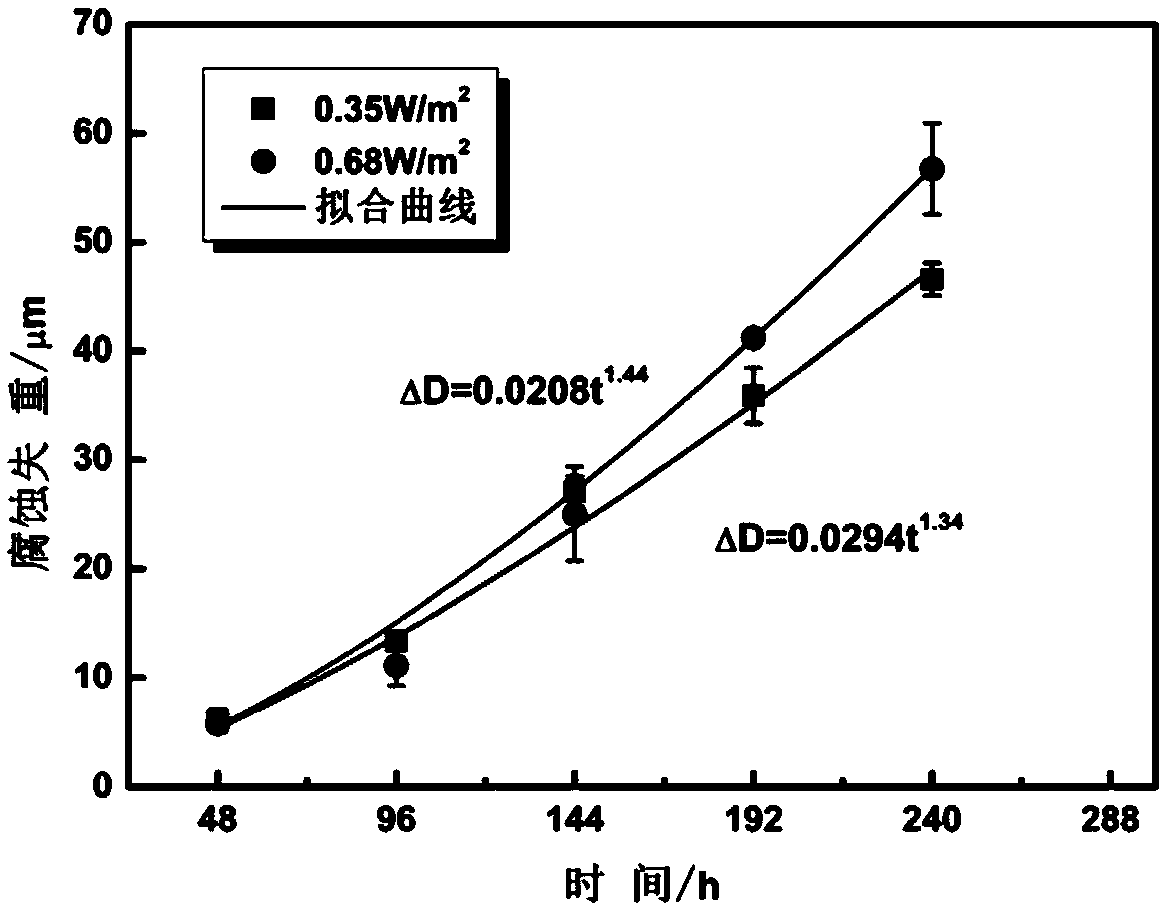

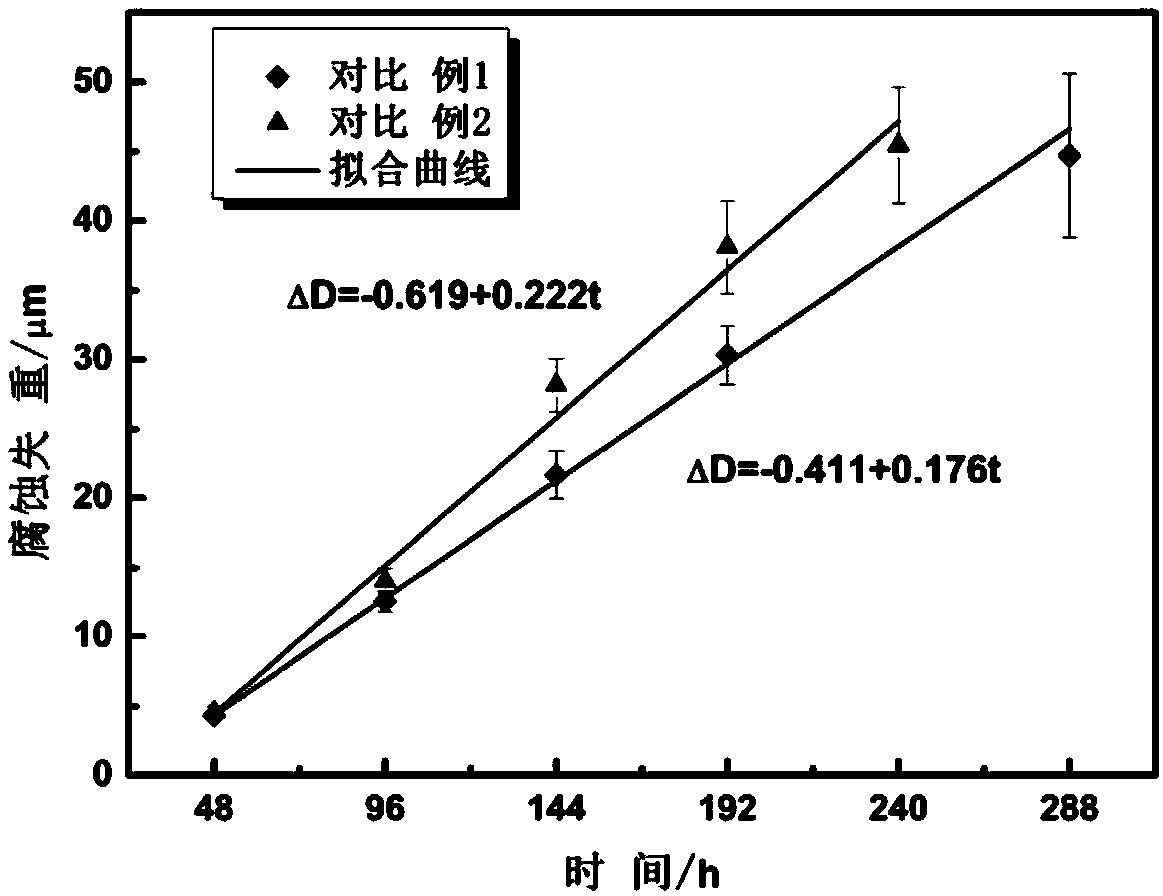

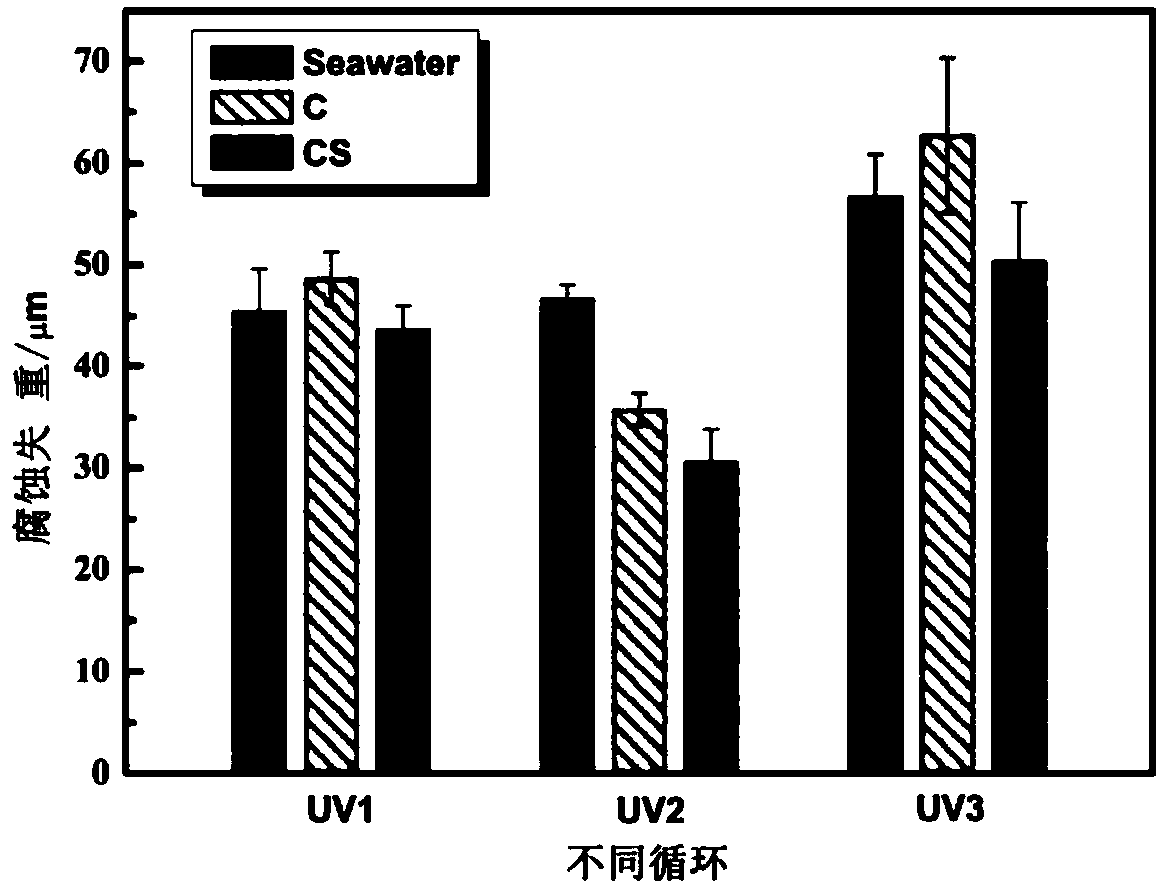

Testing method for simulating corrosion process of carbon steel in atmospheric environment with different ultraviolet radiation intensities

InactiveCN108627453AIncrease authenticitySimulatedWeather/light/corrosion resistanceAtmospheric airTest sample

The invention discloses a testing method for simulating a corrosion process of carbon steel in an atmospheric environment with different ultraviolet radiation intensities, and belongs to the technicalfield of atmosphere corrosion simulation. The testing method comprises the following steps: taking carbon steel as a testing material, depositing a corrosion liquid on the surface of a test sample inadvance, drying, repeating procedures of 'condensation for two hours and radiation for 4 hours' once every six hours, and setting testing temperatures, namely 40-60 DEG C in the condensation procedure and 45-80 DEG C in the radiation procedure. By adjusting the ultraviolet radiation intensities of the radiation procedure, the influence of high, medium and low ultraviolet radiation intensities upon the corrosion process of the carbon steel is simulated. The temperature of the radiation procedure is controlled to be higher than the room temperature, and thus an actual temperature on the surfaceof the sample is ensured. The testing method has simulation, acceleration quality and reproducibility, and can be used for studying corrosion behaviors of different types of carbon steel in atmospheric environments with different ultraviolet radiation intensities, the service life of a material can be also evaluated and predicted, and a basis can be made for reasonably selecting materials and appropriate protection methods.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

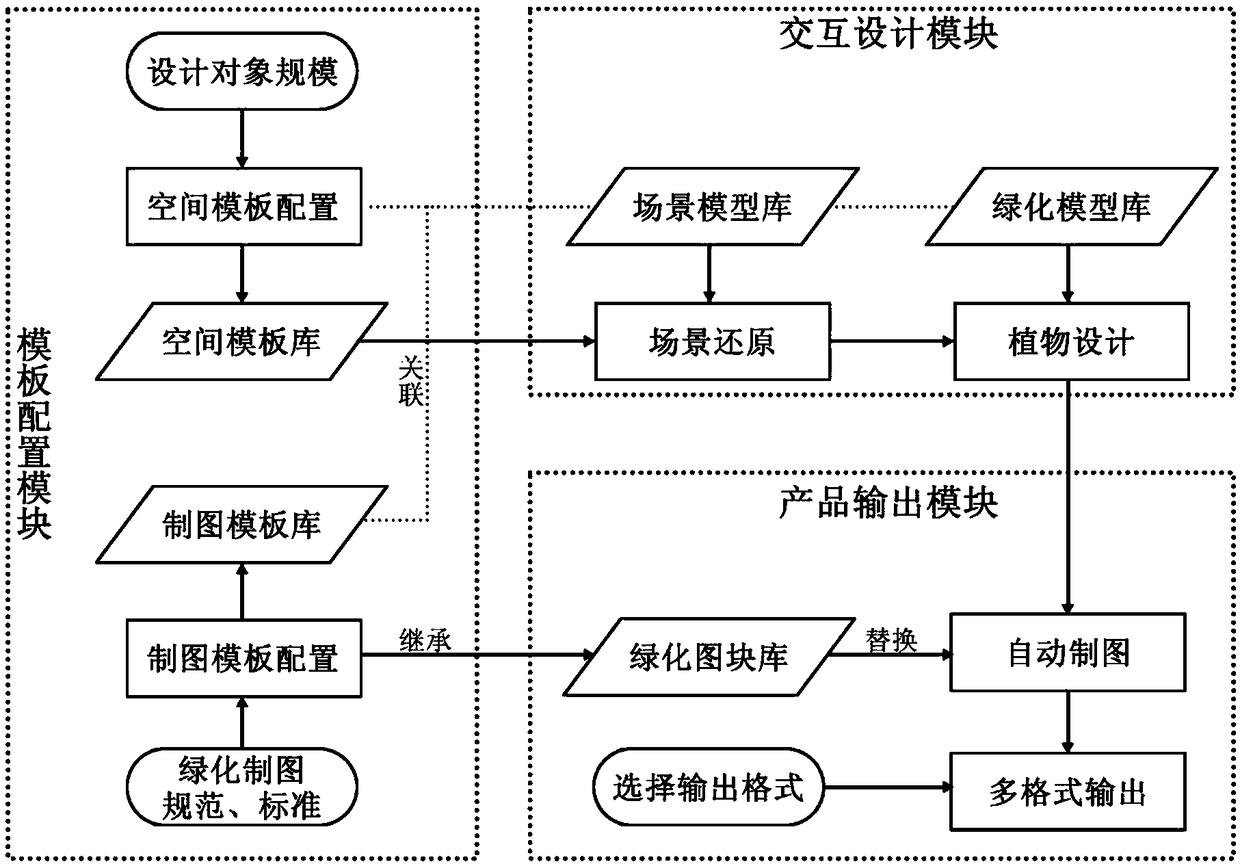

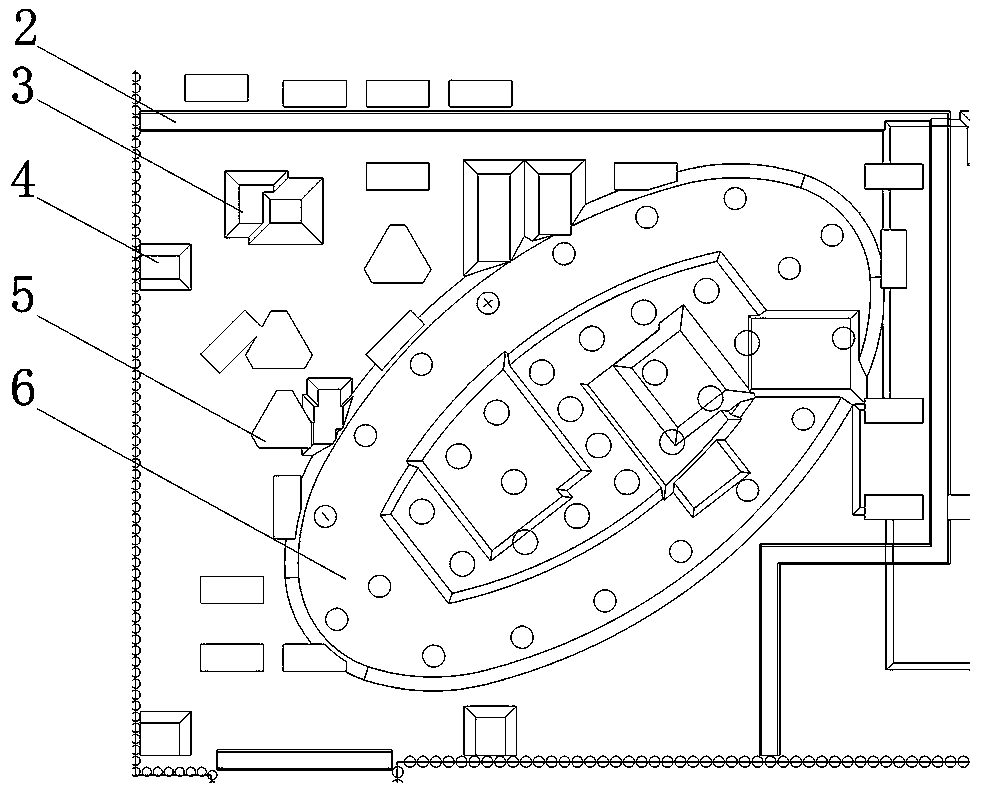

Informationalization design method for green planting

InactiveCN108304669AImprove guidanceProduct quality is easy to controlDesign optimisation/simulationSpecial data processing applicationsInteractive designBiology

The invention relates to an informationalization design method for green planting. The method comprises the steps that a template library is established and templates are configured; a scene model library, a greening model library and a greening map block library are established; interactive design is carried out; auto-drafting is carried out; and multi-format outputting is carried out. Accordingto the informationalization design method for green planting, design products has multiple formats, two-dimensional or three-dimensional design products can be output, and the expression of the three-dimensional design products is intuitive; the design process is visualized, the effect after green planting can be reflected immediately, and the evaluation of a greening scheme and the guiding of construction have a significant effect; the output two-dimensional products conform to the established format, style and rule, and the quality of the products can be controlled; the design has simulation, the greening sunlight analysis, later maintenance and other dynamic effects can be simulated; efficient collaboration of all parties involved in green planting design can be achieved, the quality ofthe design products is high, the efficiency of the design process is high, and the needs of practical application can be met well.

Owner:JIANGSU SURVEYING & DESIGN INST OF WATER RESOURCES

A large-scale building property management platform

InactiveCN109271729AWith visualizationCoordinatedGeometric CADData processing applicationsBuilding energyMonitoring system

The invention discloses a large-scale building property management platform. The management platform comprises a BIM database module, a BIM platform module and an intelligent property management platform module. The intelligent property management platform module is constructed based on the BIM database module and the BIM platform. The function module of the property management platform comprisesan operation information release system, a building space and equipment operation and maintenance management system, a public safety operation and maintenance management system, and a building energyconsumption and environment monitoring system, wherein the function module comprises an operation information release system, a building space and equipment operation and maintenance management system, a public safety operation and maintenance management system and a building energy consumption and environment monitoring system. The invention has the beneficial effects that the system is applied to the large-scale building property management and can be used as a standardized platform for different property management projects, greatly improving the project management efficiency and service level of the property management enterprise.

Owner:大连锐进科技发展有限公司

Test method for simulating corrosion process of stainless steel in atmospheric environment of salt lake

InactiveCN110068531AEasy to transformImprove the simulation effectWeather/light/corrosion resistanceSalt lakeTest sample

The invention discloses a test method for simulating a corrosion process of stainless steel in an atmospheric environment of a salt lake, and belongs to the technical field of atmospheric corrosion simulation of the stainless steel. Firstly, an ultraviolet lamp is installed in a room of a high-low temperature thermal-humidity test chamber, and a lamp wire is led out from the chamber body and is connected with an ultraviolet lamp switch. The stainless steel is used as a test material, an etching solution is deposited on the surface of a test sample by using a micro-injector and is deposited onthe surface of the test piece once after every two days. The test is alternately performed according to "wet-dry". The relative humidity in a wetting process is 70-90%, the wetting time is 1-2 hours,and the ultraviolet lamp is in a turned off state; and the relative humidity in a drying process is 10-35%, the drying time is 2-4 hours, and the ultraviolet lamp is in a turned on state. The resultsobtained by the test method provided by the invention have the characteristics of simulation, acceleration and reproducibility, and can be used for studying the corrosion behavior and corrosion mechanism of the stainless steel in the atmospheric environment of the salt lake, and evaluating and predicting the atmospheric corrosion resistance of the stainless steel in the salt lake.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

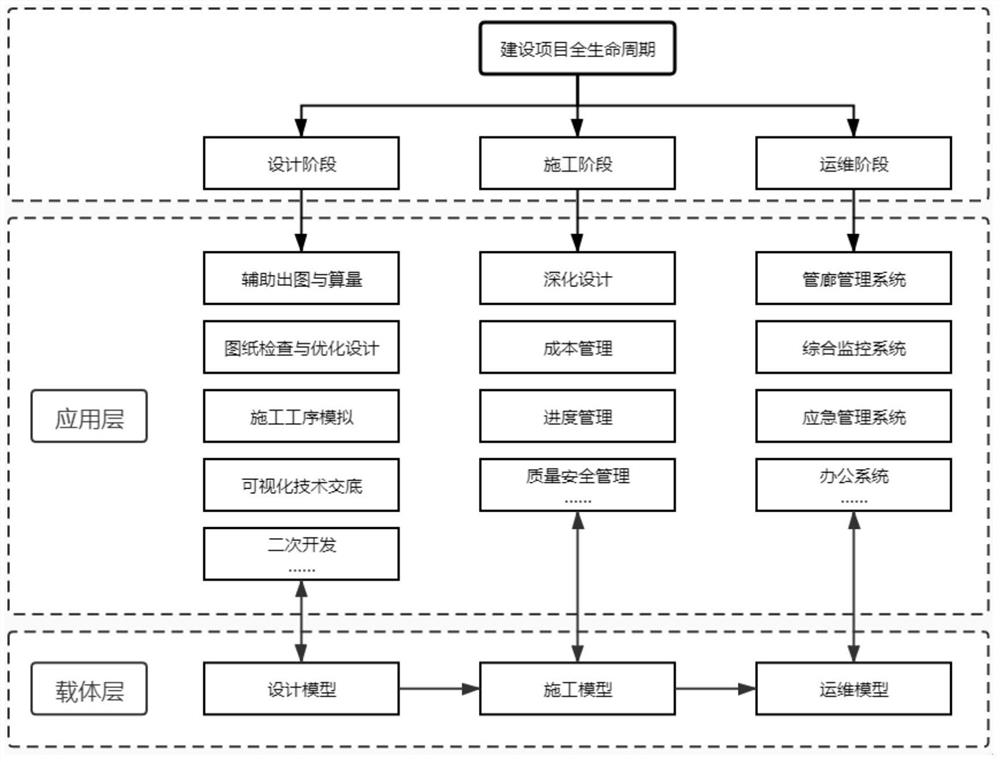

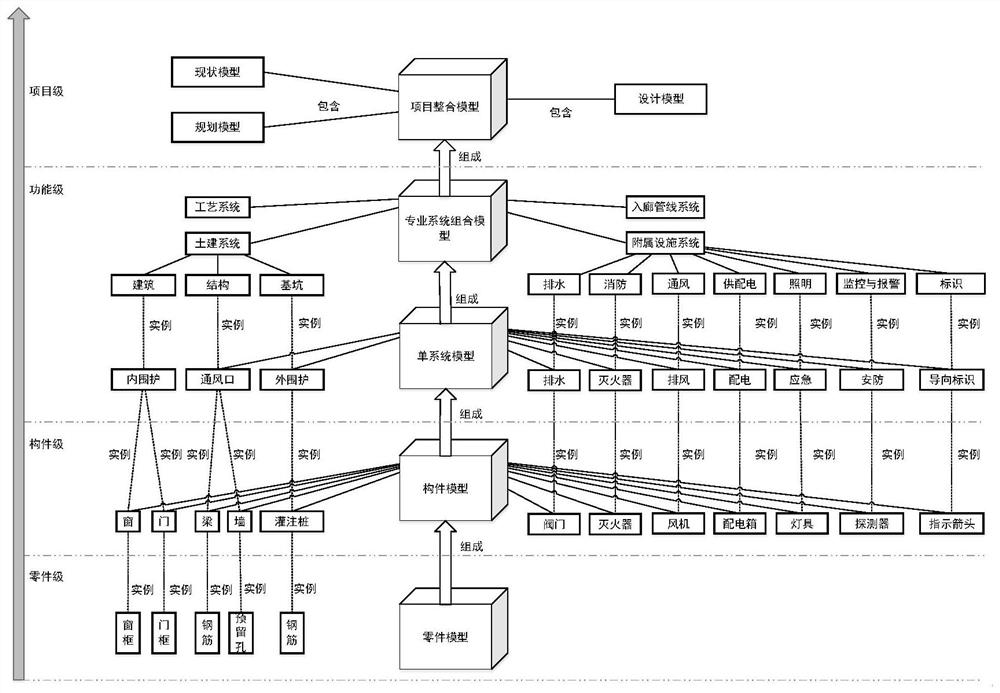

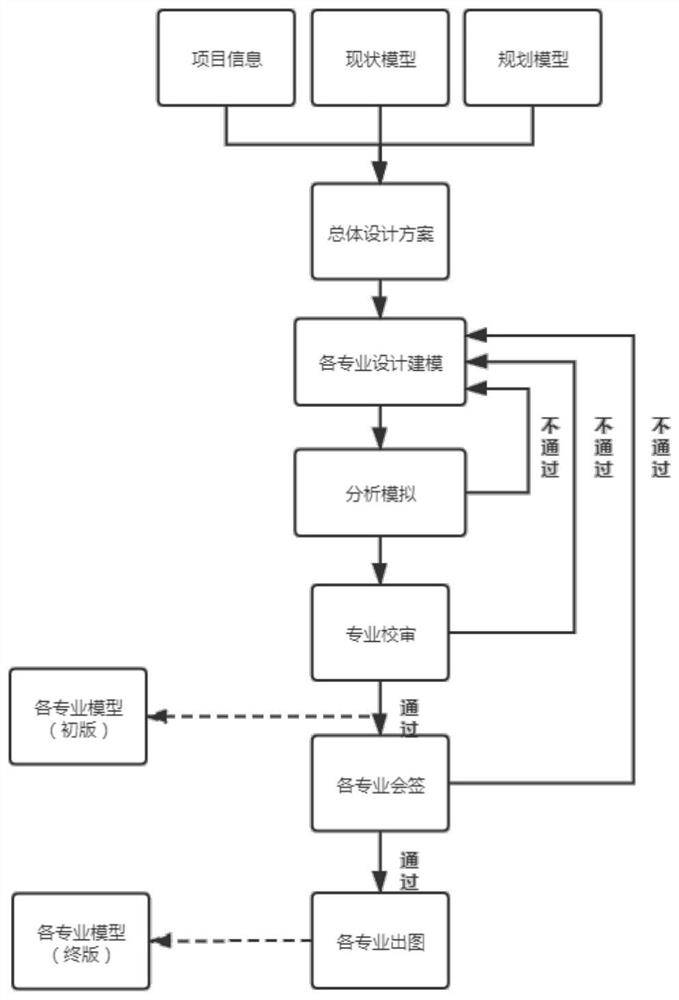

Geometric model lightweight processing method in BIM for operation and maintenance management

PendingCN113901569AComplete coherenceImprove the rationality of the planGeometric CADOffice automationConstruction managementVisualization

The invention discloses an operation and maintenance management-oriented geometric model lightweight processing method in a BIM, and the method comprises a full-life-cycle framework which is composed of an application layer and a carrier layer, and the application layer and the carrier layer communicate with each other; the carrier layer is a key layer of full-life-cycle application of a project and is divided into a design model, a construction model and an operation and maintenance model according to the full-life-cycle stage, and the design model layer is a source of whole basic data. Under the cooperation of the application layer and the carrier layer, deep optimization is carried out through the design model, the construction model and the operation and maintenance model, the complete continuity of the platform architecture is perfected, the scheme rationality is improved, and errors and missing collision are reduced, so that the design quality is improved; the construction stage has the characteristics of visualization, coordination, simulation, optimization, accurate cost, controllability and the like, and has the characteristics of avoiding or reducing construction conflicts, controlling site conditions as early as possible, better performing construction management, improving working efficiency and the like while what you see is what you get.

Owner:悉地(苏州)勘察设计顾问有限公司

A kind of foundation pit excavation drawing method

ActiveCN105678006BTroubleshooting Difficult Drawing SituationsImprove accuracyGeometric CADExcavationsArchitectural engineeringShop drawing

The invention discloses a method for drawing a foundation pit excavation drawing. The method comprises the following steps: step 1, according to a basic plane drawing of a building, applying building information model software to establishment of a foundation pit mass model, and enabling the foundation pit mass model to be consistent with the design dimension proportion in the basic plane drawing; step 2, laying off on the foundation pit mass model according to the building construction drawing, and forming an excavation model; step 3, applying the software to creation of a two-dimensional foundation pit excavation drawing according to the excavation model; step 4, based on the two-dimensional foundation pit excavation drawing, carrying out foundation pit excavation, and meanwhile, utilizing the three-dimensional foundation pit mass model to assist understanding and review. The method, disclosed by the invention, can effectively solve the problem that the excavation drawing is difficult to draw because when a large-scale foundation pit is excavated, the location and lay-out is complicated; compared with the regular drawing method for the excavation drawing, the method can greatly reduce drawing workload and drawing time to shorten the work period; compared with the regular excavation drawing, in the exported excavation drawing, size marking is realized via the software automatically, so that the phenomena of marking missing and mis-marking can be greatly reduced, and the drawing is high in accuracy.

Owner:THE THIRD CONSTR OF CHINA CONSTR FIRST GROUP +1

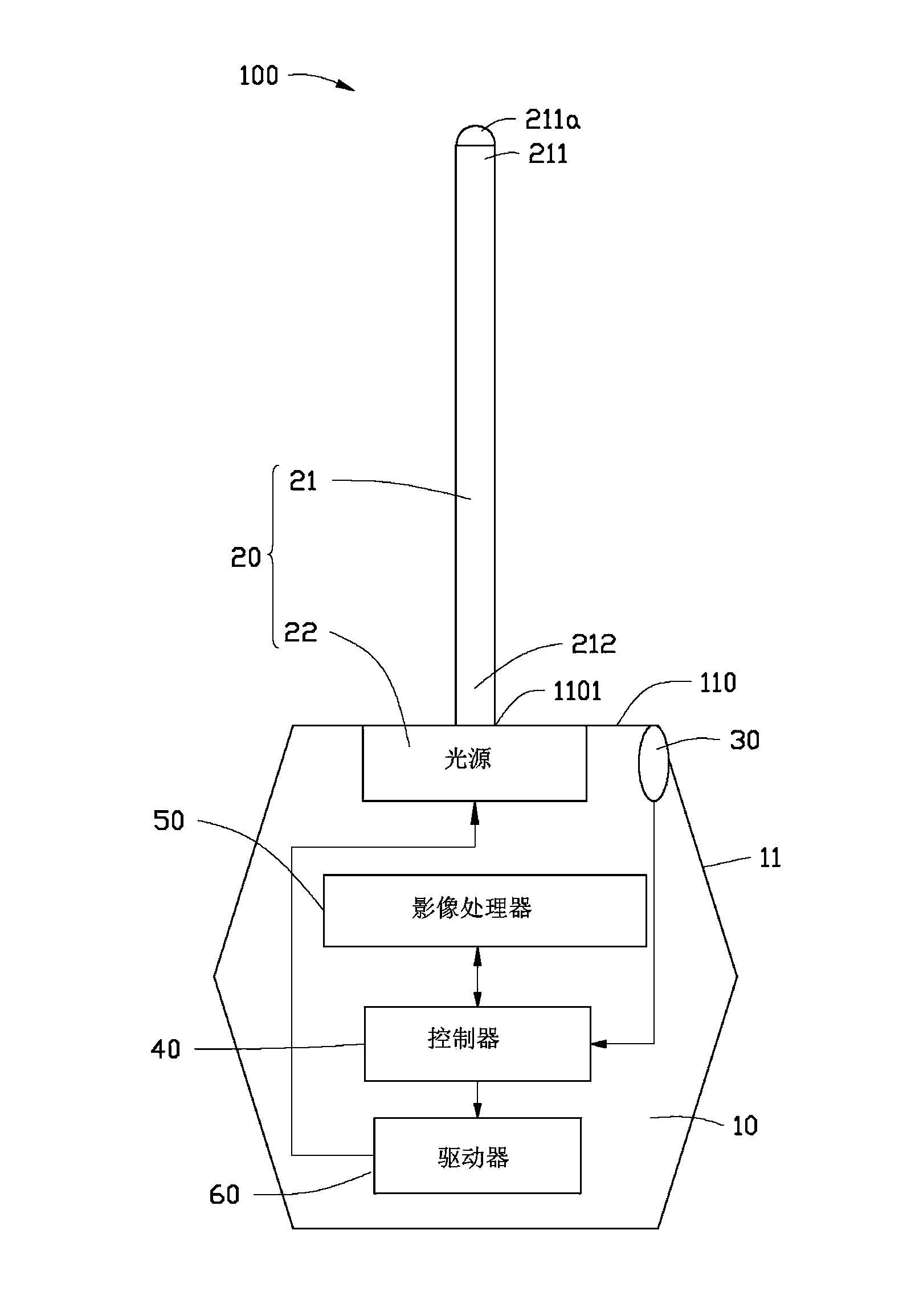

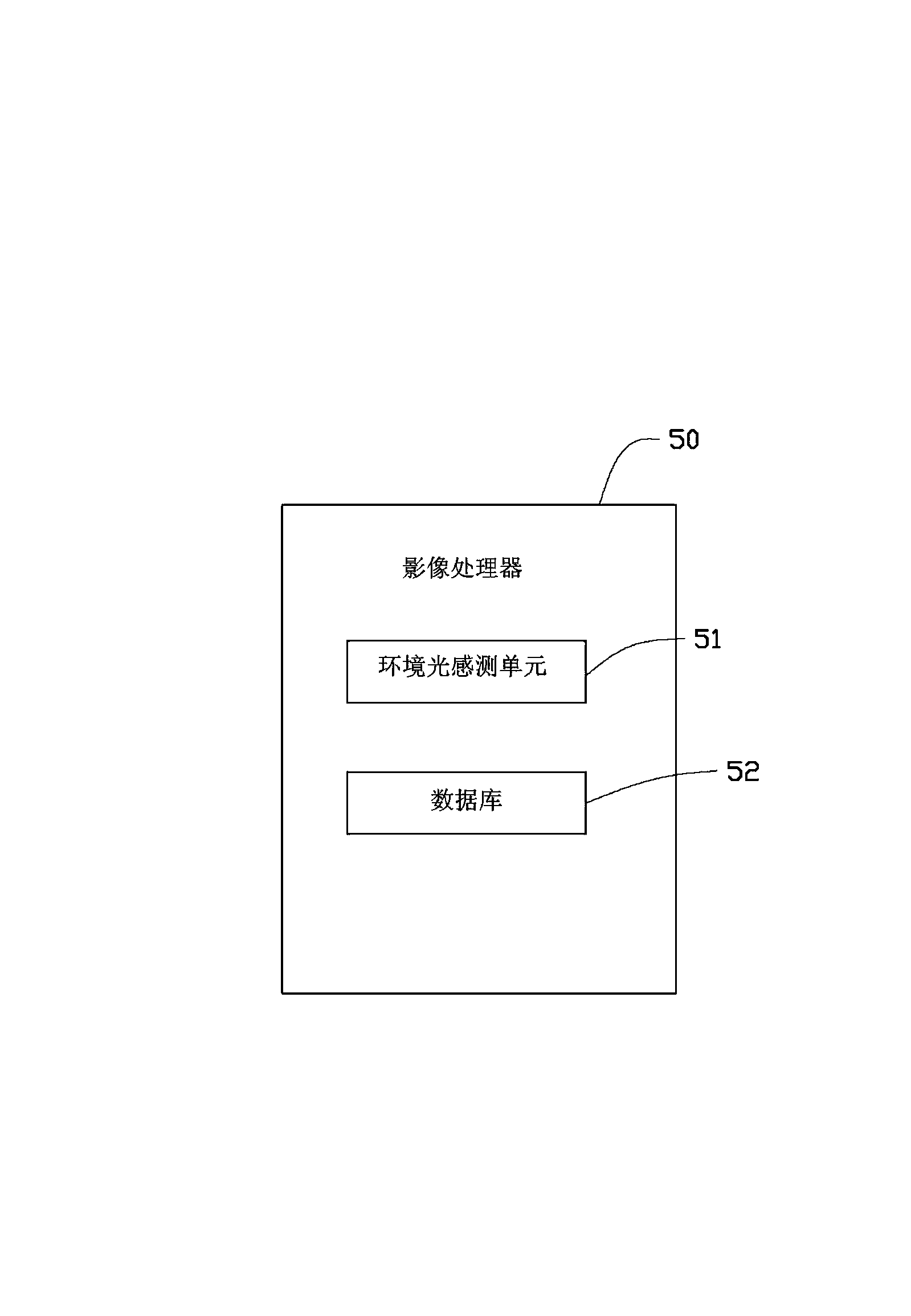

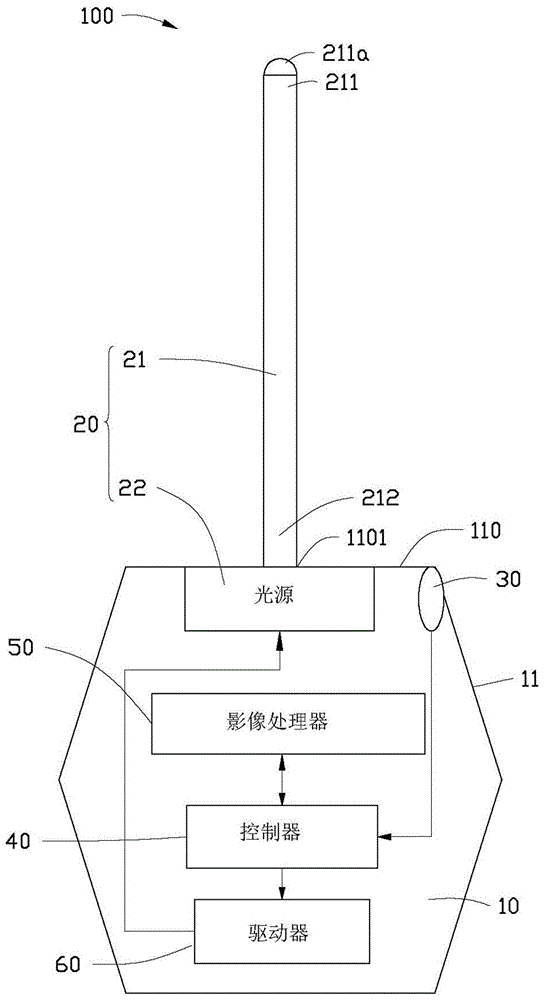

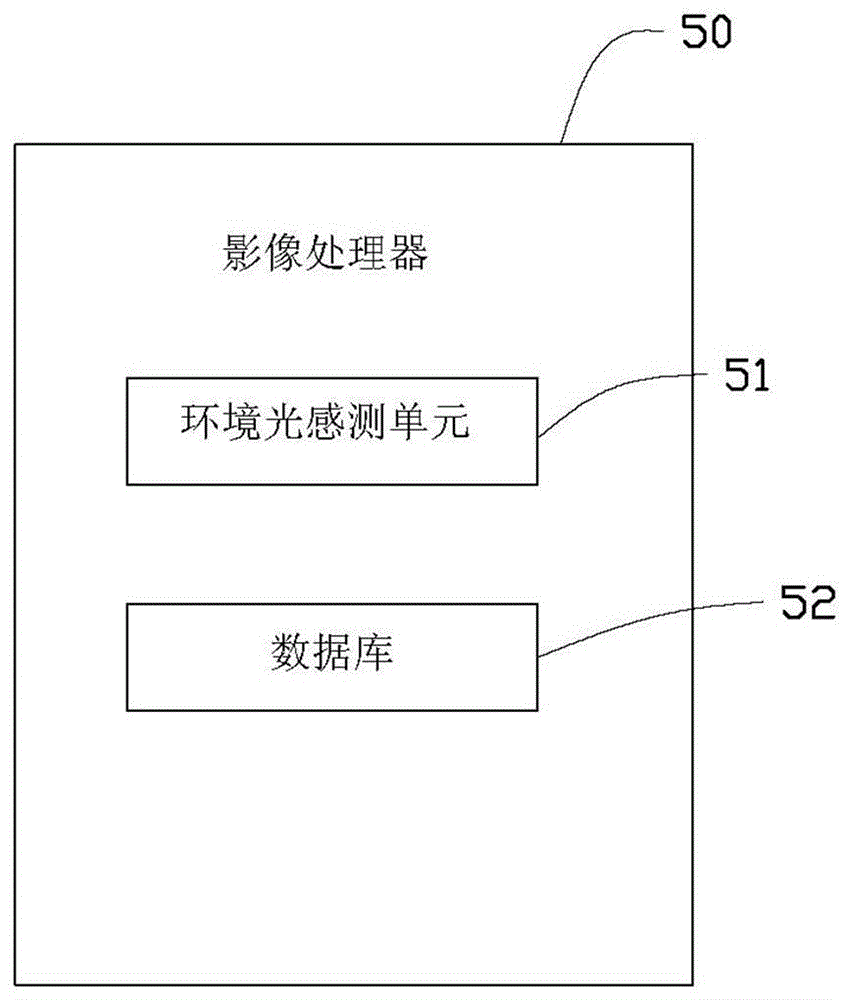

Electronic censer

An electronic censer comprises a censer body, and an electronic incense and a driver which are disposed in the censer body. The electronic incense comprises a light guide bar and a light source. The driver is electrically connected with the light source. The electronic censer further comprises a camera module, a controller and an image processor. The camera module is disposed on one side wall of the censer body and user for shooting images of the periphery environment of the electronic censer. The controller is electrically connected to the camera module, the image processor and the driver and used for transmitting the images shot by the camera module to the image processor. The image processor comprises an environmental light sensing unit which is used for sensing the environmental light brightness of the images shot by the camera module. The controller is used for receiving the environmental light brightness sensed by the environmental light sensing unit and controlling the driver to drive the light source to emit appropriate light according to the environmental light brightness.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

An accelerated corrosion test method for simulating soil corrosion process

ActiveCN103308443BSoil Corrosion Resistance GuaranteeGuaranteed CorrosionWeather/light/corrosion resistanceHydrogenTest sample

The invention discloses an accelerated corrosion testing method for simulating a soil corrosion process. The method comprises the following steps of: (1) preparing a testing solution from salt and water according to components of target soil; (2) adjusting the pH (Potential of Hydrogen) value of the testing solution to a testing value by H2SO4 or NaOH, thus taking the testing solution as an impregnation medium for simulating soil corrosion, wherein the testing value is the same as the pH value of the target soil; (3) mixing diatomite, which is taken as a carrier, with an impregnation medium to prepare testing soil which is basically same as the target soil in physicochemical properties; and (4) testing a test sample in the testing soil according a pre-set testing temperature, relative humidity and testing period.

Owner:CENT IRON & STEEL RES INST

Electronic incense burner

An electronic censer comprises a censer body, and an electronic incense and a driver which are disposed in the censer body. The electronic incense comprises a light guide bar and a light source. The driver is electrically connected with the light source. The electronic censer further comprises a camera module, a controller and an image processor. The camera module is disposed on one side wall of the censer body and user for shooting images of the periphery environment of the electronic censer. The controller is electrically connected to the camera module, the image processor and the driver and used for transmitting the images shot by the camera module to the image processor. The image processor comprises an environmental light sensing unit which is used for sensing the environmental light brightness of the images shot by the camera module. The controller is used for receiving the environmental light brightness sensed by the environmental light sensing unit and controlling the driver to drive the light source to emit appropriate light according to the environmental light brightness.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

A method for evaluating the permeability of chemical absorbents

ActiveCN105938084BConvenient for indoor testingQuick indoor testPermeability/surface area analysisDiffusionBiochemistry

The invention provides a method for evaluating the permeating performance of a chemical imbibition agent. According to the evaluation method, the elevating coefficient Sc and permeation speed Sp of a capillary can be measured, thus the permeation force Fp can be calculate according to a formula: Fp=Sc*Sp; the performance of a chemical imbibition agent can be evaluated through a ratio (R) of the permeation force Fp of a chemical imbibition agent to a simulated water permeation force, and if the R is greater than 1.0, the chemical imbibition agent has a good imbibition effect. The method can be used to quantitatively evaluate the permeating performance of a chemical imbibition agent for low permeability reservoir. The method has the advantages that the indoor tests become convenient and fast, the comparison and quantitation become more convenient; the permeating performance and diffusion property of different chemical imbibition agents can be effectively compared; corresponding oil sand and capillary that are similar to oil reservoirs are used to simulate the oil reservoirs, at the same time, the experiment temperature is identical with the temperature of stratum, and thus the experiment is closer to the actual state.

Owner:PETROCHINA CO LTD

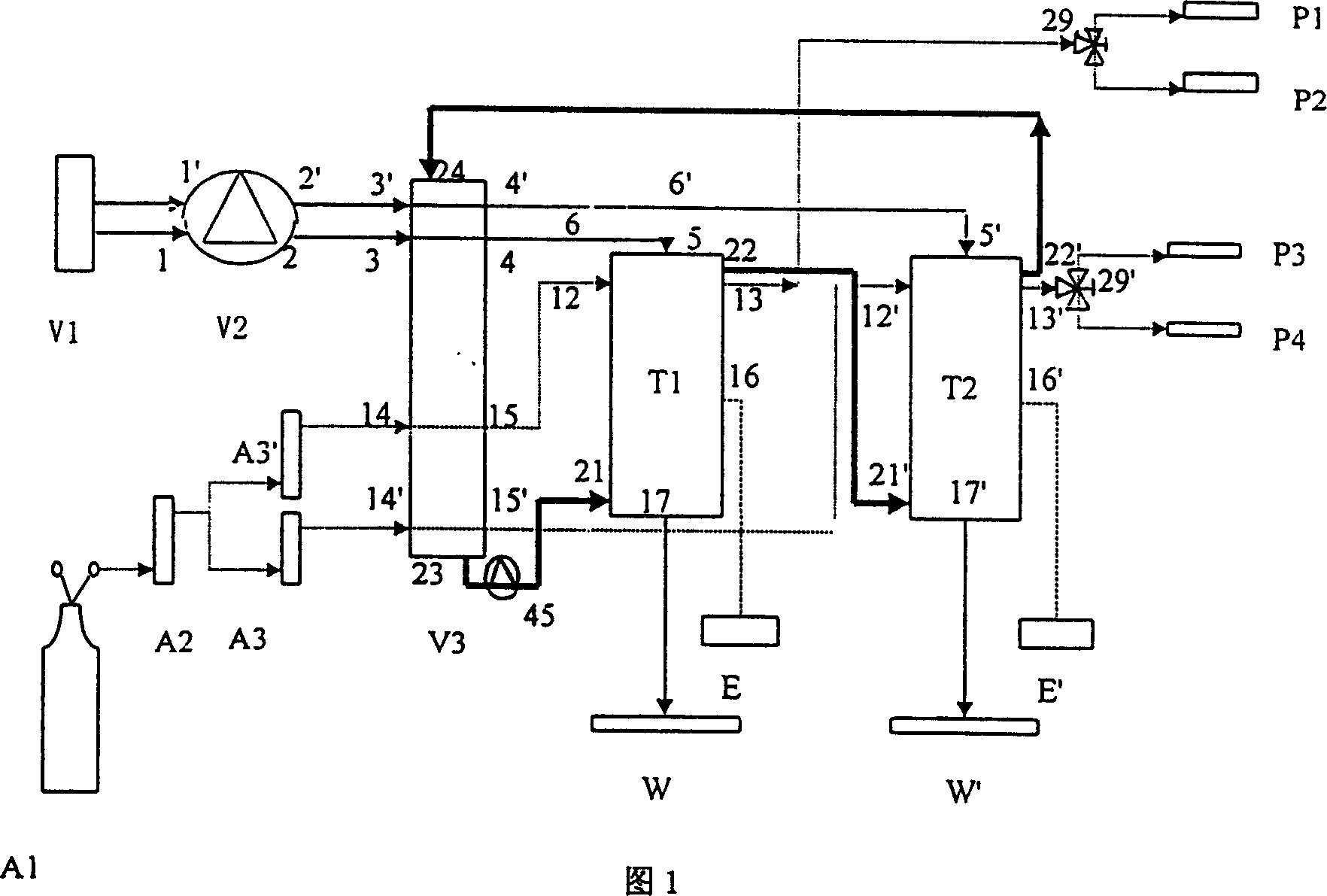

Method for researching nigration and conversion of pollutant in soil and its equipment

InactiveCN1127382CEasy to carry outAchieve percolationContaminated soil reclamationWater bathsPeristaltic pump

The present invention relates to a method for researching migration and conversion of pollutant in soil and its equipment. It is characterized by utilizing constant temp. circulating water bath to control soil temp. at 5 deg.C-35 deg.C; utilizing air flowmeter to measure and regulate air flow rate at 15-90 ml / min; using peristaltic pump to provide precipitation and control liquid flow rate at 0-20 ml / min; real-time collecting gas phase sample and liquid phase sample, and under the condition of simultaneously controlling temp., wind speed and precipitation, researching the behaviours of volatilization, in filtration, degradation and stagnation, etc. of pollution in soil, their interrelation and influence of various environmental factors to these behaviours. Said invented equipment has good closed property.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Test method for simulating corrosion course of low alloy steel under marine industrial atmospheric environment

InactiveCN102207446BGood reproducibilitySimulatedWeather/light/corrosion resistanceConcentration ratioTest material

The invention relates to simulation technology of atmospheric corrosion of low alloy steel, and particularly provides a test method for simulating corrosion course of low alloy steel under marine industrial atmospheric environment. According to the invention, low alloy steel is used as a test material, and NaHSO3 and NaCl of different concentration ratios are deposited on the surface of a sample to be tested in advance, and alternate dry and wet tests are carried out according to the order of a wet test first and a dry test next, wherein test temperature is 30 DEG C, a wet test and a dry testboth last for 12 hours, relative humidity of the wet test and the dry test are 80% and 10% respectively, and the whole test lasts for 1 to 42 days. The test method provided in the invention has the characteristics of simulation, acceleration capability and reproducibility, and can be used to simulate marine industrial atmospheric corrosion course, to study corrosion behavior of various low alloy steel under an environment similar to the atmospheric environment and to evaluate and predict corrosion resistance of low alloy steel to marine industrial atmosphere, providing the basis for reasonable selection of low alloy steel and selection of appropriate protection methods.

Owner:中广核工程有限公司 +1

A test method for simulating the corrosion process of aluminum alloys in the atmospheric environment of rich salt lakes

ActiveCN103969173BGood reproducibilityUniform Discontinuous DispersionWeather/light/corrosion resistanceDrying timeCorrosion behavior

The invention discloses a test method for simulating corrosion process of an aluminum alloy in a salt-rich salt lake in an atmospheric environment. According to the method, the aluminum alloy is used as a test material, salt lake water collected on site is used as a corrosion medium, salt solution drops are deposited on a sample surface in virtue of an aerosol generator, deposition is carried out once every three days, and the amount of deposited salt each time is 100 mu g / cm2; wetting and drying are alternately carried out, and a cycle of wetting and drying is carried out every three hours, wherein the temperature during wetting is 30 DEG C, wetting time is 1 h (wherein relative humidity is linearly increased to 80% from 20%), the temperature during drying is 40 DEG C, and drying time is 2 h (wherein relative humidity is linearly decreased to 20% from 80%); test time is 3 to 15 d. Test results obtained in the invention have the characteristics of simulation, acceleration and repeatability, and the method can be used for research on corrosion behaviors of the aluminum alloy in the salt-rich salt lake in the atmospheric environment and can realize rapid evaluation and prediction of atmospheric corrosion of the aluminum alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Accelerated testing apparatus for simulation of corrosion by industrially polluted atmosphere

InactiveCN102169083BSolve the problem of single dependence on external air sourceImprove good performanceWeather/light/corrosion resistanceAtmospheric airEngineering

The invention relates to a simulation technology of atmosphere corrosion on material and anticorrosion paint, and especially provides an accelerated testing apparatus for the simulation of the corrosion by industrially polluted atmosphere. The apparatus is provided with a reaction box, a box cover, an air inlet and outlet pipe, and a humiture monitoring probe. Besides, an inner chamber of the reaction box is divided into an upper layer chamber and a lower layer chamber, and the upper layer chamber is a corroding chamber and the lower layer chamber is an atmosphere generating chamber; the box cover is movably arranged on the top of the reaction box, and the air inlet and outlet pipe and the humiture monitoring probe are inserted into the box cover; and the air inlet and outlet pipe is inserted into the sidewall of the reaction box which has the atmosphere generating chamber. The apparatus has two methods of generating corrosive atmosphere: the chemical method and the external connection of gas source method, and a problem of relying on the single external connection of gas source to generate the corrosive atmosphere is solved. Simulation of the corrosion by polluted atmosphere especially by heavy-industry polluted atmosphere with the invention could be used for researching and evaluating the corrosion action of metal material and the anticorrosion paint in the heavy-industry polluted atmosphere, so as to provide evidence for reasonably choosing the material and choosing the appropriate protection method.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

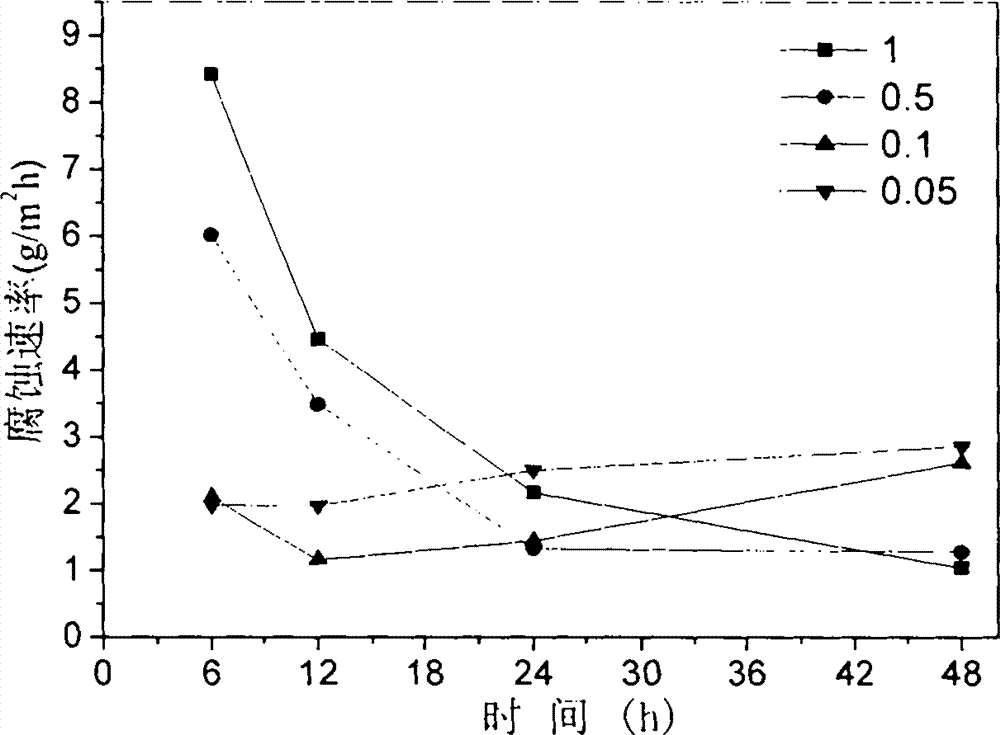

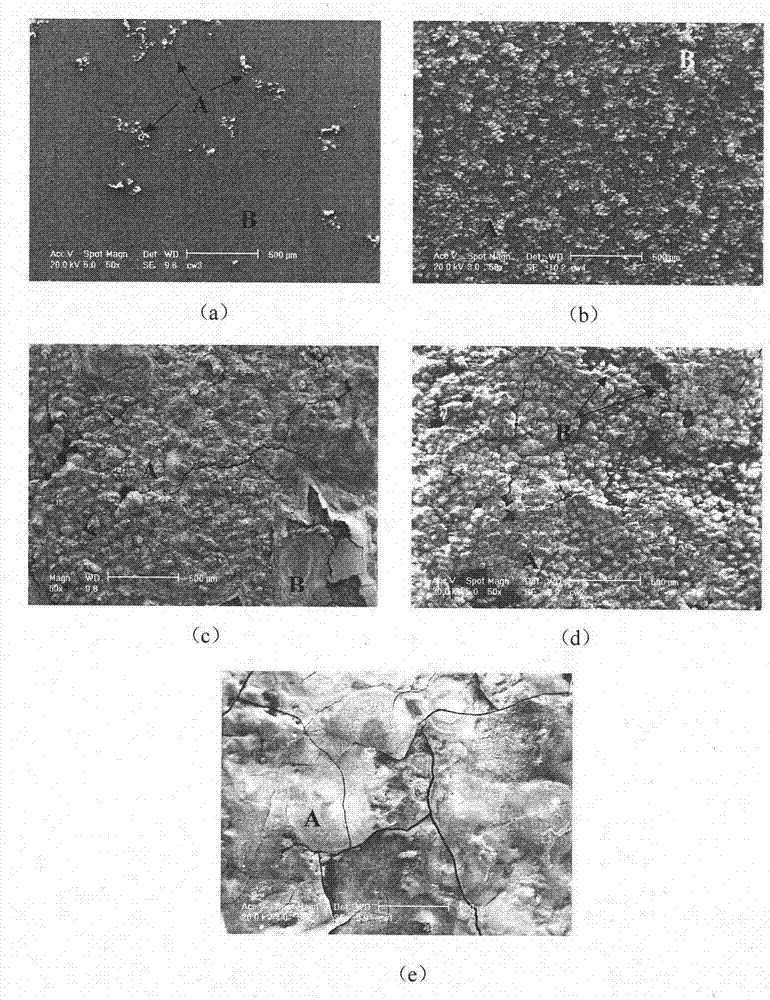

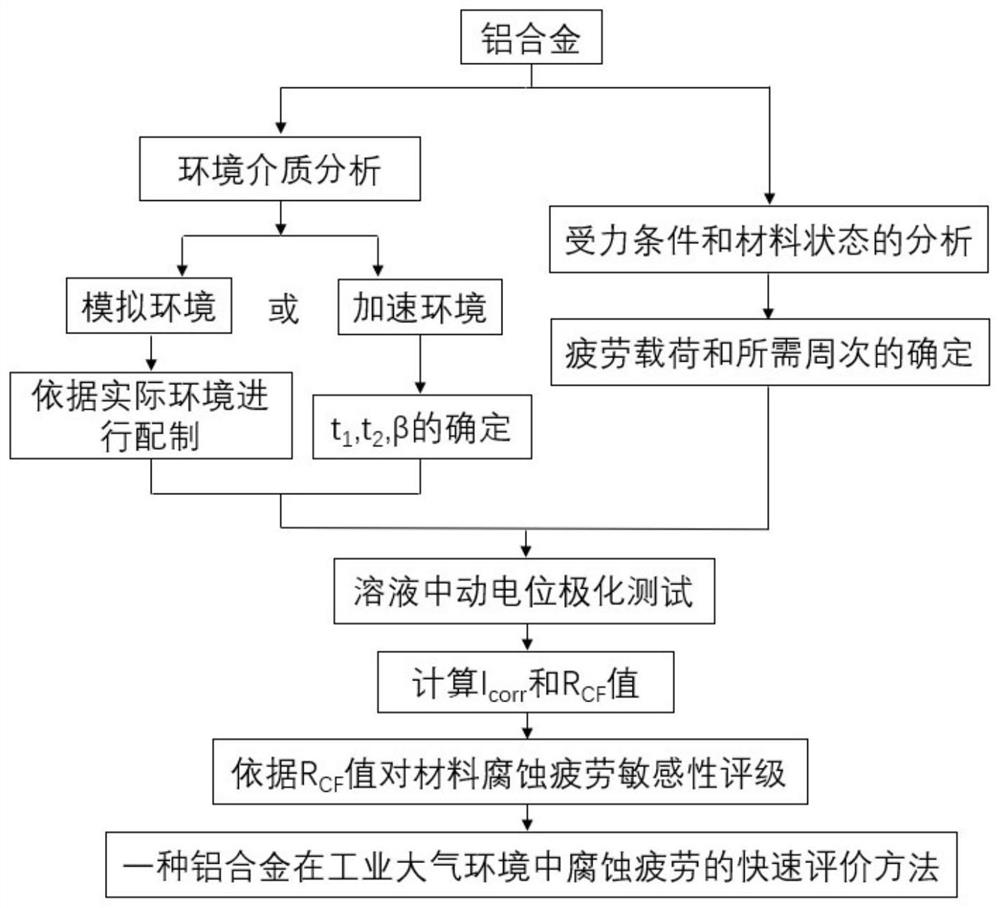

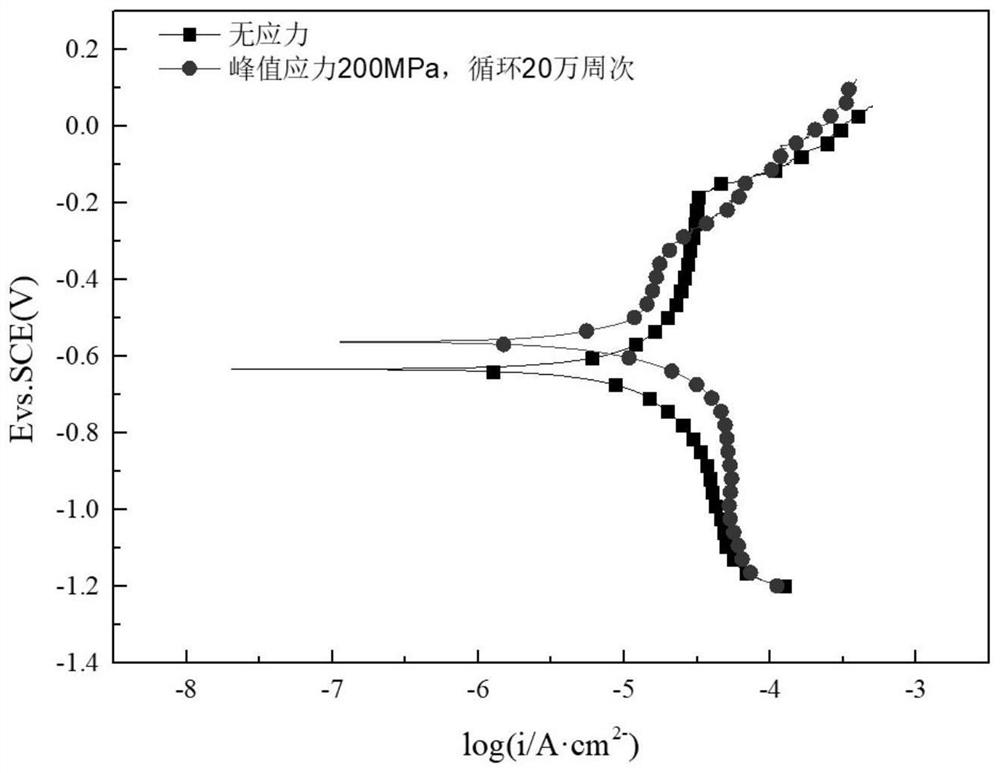

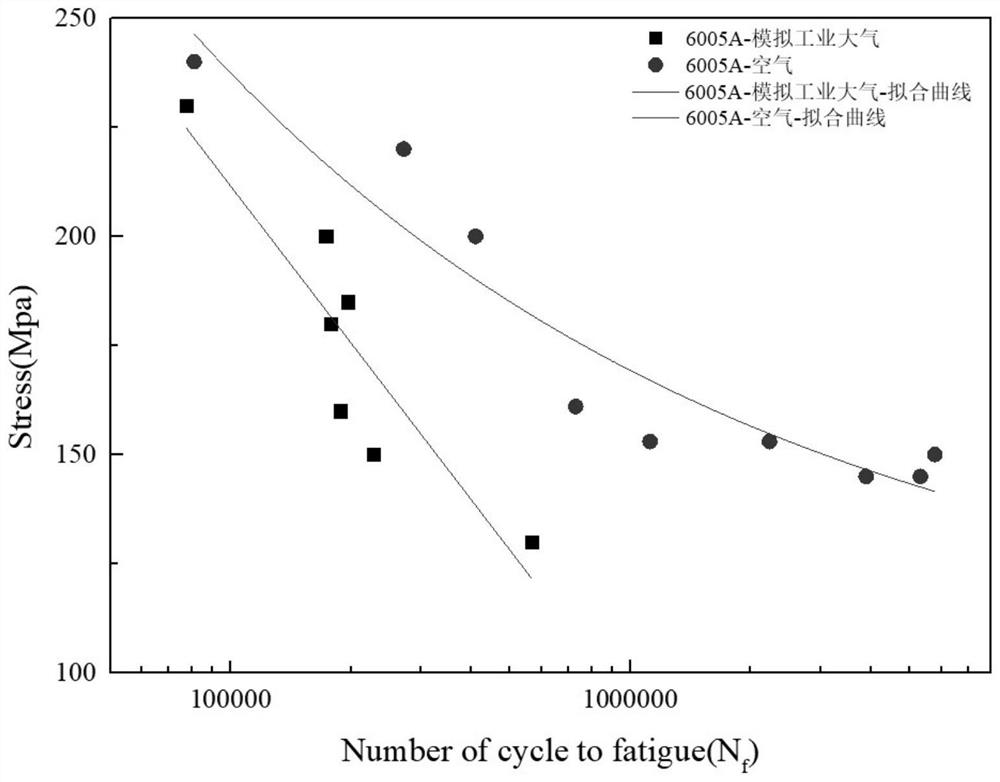

Rapid evaluation method for corrosion fatigue of aluminum alloy in industrial atmospheric environment

InactiveCN113252546ASimulatedAcceleratedWeather/light/corrosion resistanceMetallic materialsCorrosion fatigue

The invention relates to the technical field of metal material corrosion fatigue evaluation, and particularly relates to a rapid evaluation method for corrosion fatigue of an aluminum alloy in an industrial atmospheric environment. According to the evaluation method for corrosion fatigue of the aluminum alloy, the corrosion fatigue sensitivity grade of the aluminum alloy in the industrial atmospheric environment is evaluated by taking the relative difference degree of the corrosion current density of the aluminum alloy under different stress conditions as an index. The evaluation method provided by the invention has the advantages of strong indoor test operability, short test time consumption, rapidness and accuracy; and the method not only can realize rapid evaluation of the corrosion fatigue performance of the aluminum alloy, but also is suitable for related evaluation and test in the research and development, production and material selection processes of the aluminum alloy. A new method is provided for evaluating the corrosion fatigue sensitivity of the aluminum alloy in the industrial atmospheric environment, and a favorable basis is provided for use and protection of materials.

Owner:CRRC QINGDAO SIFANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com