Method of accelerated corrosion test used for simulating corrosion process of copper and alloy thereof in atmosphere

An accelerated corrosion test, atmospheric corrosion technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of difficult operation, many control factors, etc. analog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

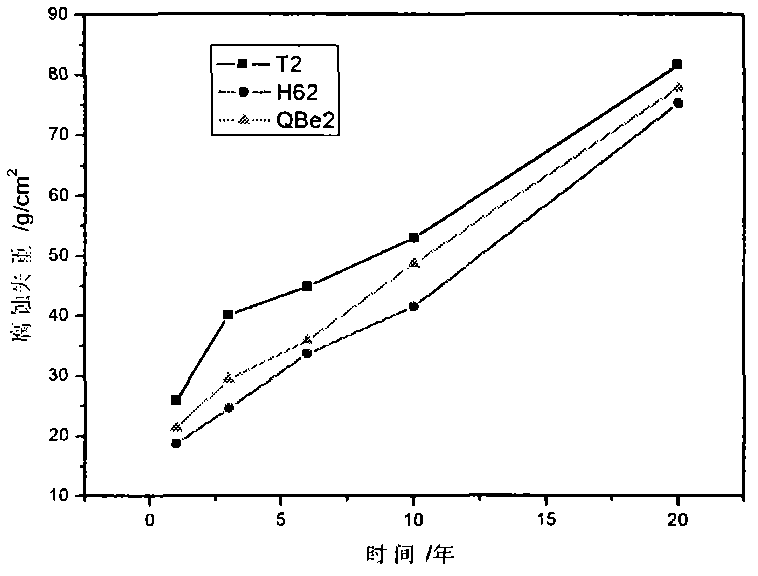

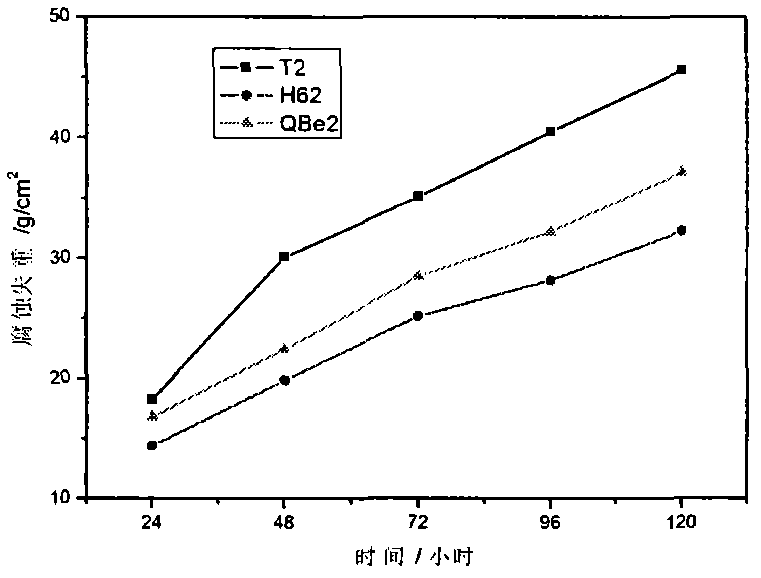

[0048] The test materials are the above-mentioned T2, H62, QBe2. With 0.2mol / L CuCl 2 +0.05mol / L(NH 4 ) 2 SO 4 +0.01mol / L NaHSO 3 For the dipping solution, cycle according to the order of "dipping→wetting→drying→", in which dipping is at 50°C, wetting is at 50°C, and drying is at 70°C; the cycle time refers to the following conditions: cycle once every 180 minutes, including dipping for 15 minutes; wet for 105 minutes; dry 60 minutes; total experiment time is 24 hours, 48 hours, 72 hours, 96 hours or 120 hours. In order to simulate the atmospheric corrosion process of the three materials, the corrosion weight loss and test time are listed in Table 4, and the relationship curve between corrosion weight loss and test time is shown in figure 2 , the regression analysis of corrosion weight loss and accelerated test time is shown in Table 5. Among the three kinds of copper and its alloys, T2 has the largest corrosion weight loss, followed by QBe2, and the smallest is H62; t...

Embodiment 2

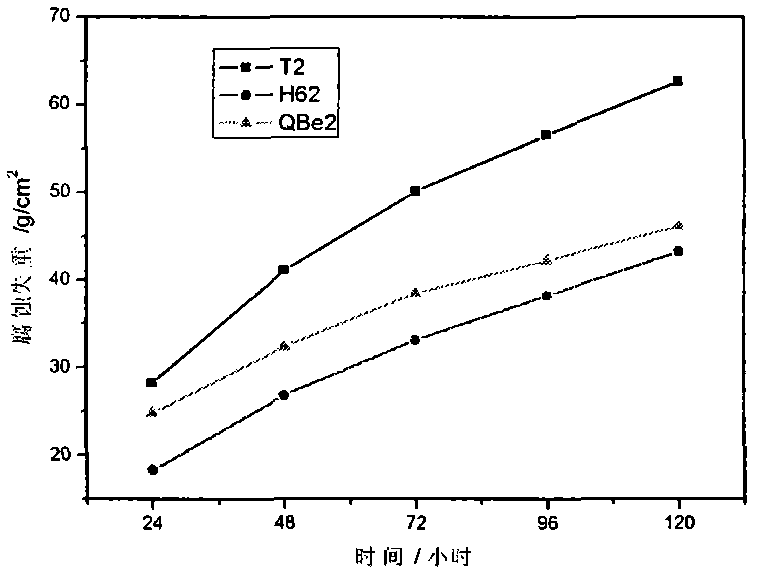

[0054] The test materials are the above-mentioned T2, H62, QBe2. With 0.01mol / L CuCl 2 +3mol / L(NH 4 ) 2 SO 4 +0.2mol / L NaHSO 3 For the dipping solution, cycle according to the order of "dipping→wetting→drying→", in which dipping is at 25°C, wetting is at 25°C, and drying is at 40°C; the cycle time refers to the following conditions: cycle once every 150 minutes, including dipping for 10 minutes; wet for 110 minutes; dry 30 minutes; total experiment time is 24 hours, 48 hours, 72 hours, 96 hours or 120 hours. This is used to simulate the atmospheric corrosion process of the three materials. The corrosion weight loss and test time are listed in Table 6. The relationship curve between corrosion weight loss and test time is shown in image 3 , the regression analysis of corrosion weight loss and accelerated test time is shown in Table 7. Among the three kinds of copper and its alloys, T2 has the largest corrosion weight loss, followed by QBe2, and the smallest is H62; the c...

Embodiment 3

[0060] The test materials are the above-mentioned T2, H62, QBe2. With 0.07mol / L CuCl 2 +2mol / L(NH 4 ) 2 SO 4 +0.1mol / L NaHSO 3 For the dipping solution, cycle according to the order of "dipping→wetting→drying→", in which dipping is at 25°C, wetting is at 25°C, and drying is at 50°C; the cycle time refers to the following conditions: cycle once every 60 minutes, including dipping for 5 minutes; wet for 35 minutes; dry 20 minutes; total experiment time is 24 hours, 48 hours, 72 hours, 96 hours or 120 hours. This is used to simulate the atmospheric corrosion process of the three materials. The corrosion weight loss and test time are listed in Table 8. The relationship curve between corrosion weight loss and test time is shown in Figure 4 , the regression analysis of corrosion weight loss and accelerated test time is shown in Table 9. Among the three copper and its alloys, T2 has the largest corrosion weight loss, followed by QBe2, and the smallest is H62; the corrosion la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com