Chemical plating liquid of high-phosphor chemical plating Ni-P alloy for use on 304 stainless steel surface

A 304 stainless steel, electroless plating technology, applied in the field of electroless plating solution, can solve the problems of insufficient mechanical strength, poor corrosion and wear resistance, etc., and achieve the goal of improving corrosion and wear resistance and expanding the application field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

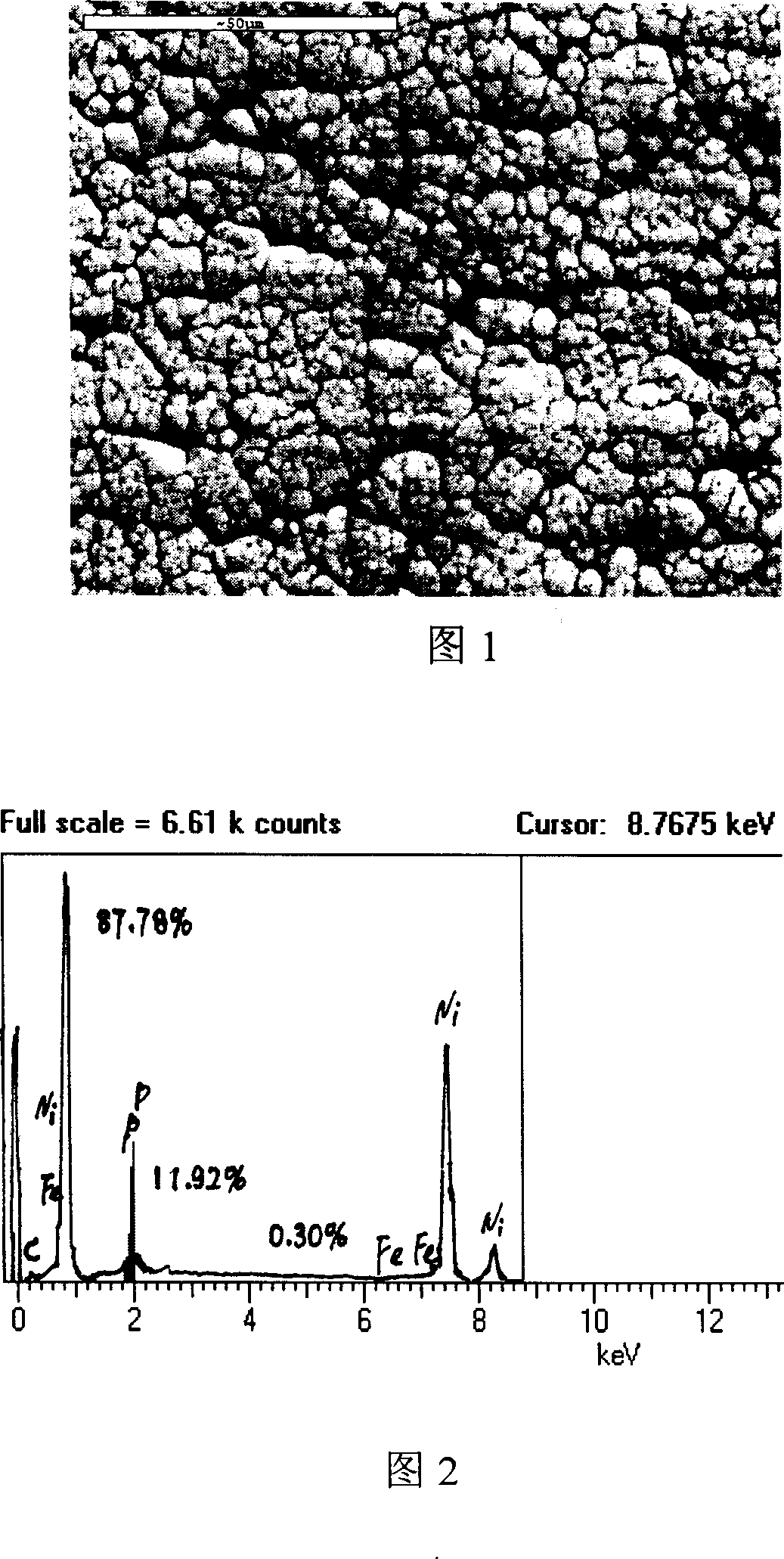

Image

Examples

Embodiment Construction

[0028] The present invention will be specifically described below in conjunction with specific embodiments.

[0029] The implementation process of the present invention is strictly controlled according to the technological process. After the pre-treatment of the stainless steel is qualified, flash nickel plating is carried out, and then chemical nickel plating is carried out. The preparation method of the chemical plating phosphating solution is carried out strictly according to the preparation principle of the chemical plating solution, and the addition of the plating solution is carried out every 0.5 to 1 hour.

[0030] Concrete implementation process formula of the present invention is:

[0031] Nickel Sulfate (NiSO 4 ·6H 2 O) 25g / L

[0032] Sodium hypophosphite (NaH 2 PO 2 ·H 2 O) 30g / L

[0033] Main complexing agent lactic acid 19g / L

[0034] Auxiliary complexing agent citric acid 6g / L

[0035] Auxiliary complexing agent EDTA disodium 7.5g / L

[0036] Auxiliary c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com