Test method for simulating corrosion process of aluminum and aluminum alloy in industrially polluted atmospheric environment

A technology that pollutes the atmosphere and corrodes the environment. It is used in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc. It can solve the problems of difficult control of environmental factors, long experimental period and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

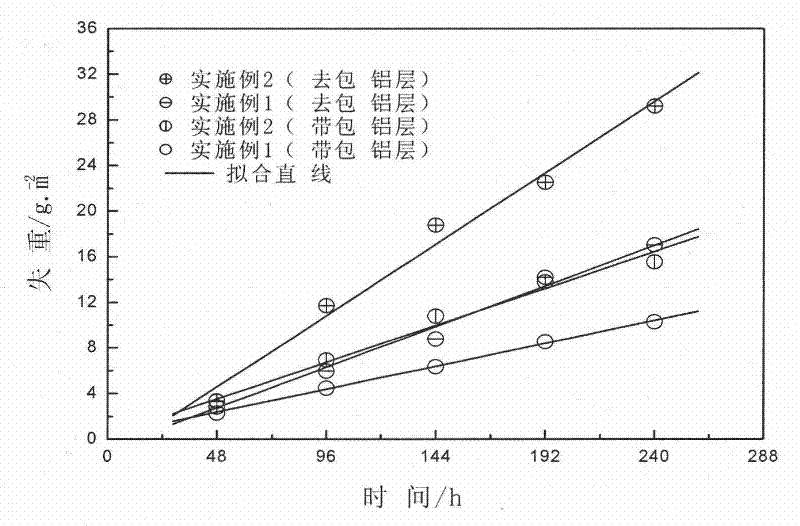

[0025] The test materials are the above-mentioned LC4 aluminum alloy with aluminum clad layer and the aluminum clad layer removed. The impregnation solution is 0.02mol / LNaHSO 3 , used to simulate Shenyang industrial pollution atmosphere environment. Cycle once every 15 minutes in the order of "dipping → drying → wetting", among which: dipping at 40°C for 2 minutes; drying at 50°C for 11 minutes; wet at 40°C for 2 minutes; the test time is 240 hours. For the relationship between corrosion weight loss and test time, see figure 1 , the corrosion of the LC4 aluminum alloy with and without the aluminum clad layer shows that the corrosion weight loss increases with the prolongation of the test time. Under the same corrosion medium conditions, the corrosion weight loss of the LC4 aluminum alloy with the aluminum clad layer removed Significantly greater than the corrosion weight loss of LC4 aluminum alloy with aluminum clad layer. This shows that the aluminum-clad layer on the surf...

Embodiment 2

[0031] The test materials are the above-mentioned LC4 aluminum alloy with aluminum clad layer and the aluminum clad layer removed. The impregnation solution is 0.02mol / LNaHSO 3 +0.006mol / L NaCl aqueous solution is used to simulate Shenyang's industrially polluted atmospheric environment. Cycle once every 15 minutes in the order of "dipping → drying → wetting", among which: dipping at 40°C for 2 minutes; drying at 50°C for 11 minutes; wet at 40°C for 2 minutes; the test time is 240 hours. For the relationship between corrosion weight loss and test time, see figure 1 , the corrosion of the LC4 aluminum alloy with and without the aluminum clad layer shows that the corrosion weight loss increases with the prolongation of the test time. Under the same corrosion medium conditions, the corrosion weight loss of the LC4 aluminum alloy with the aluminum clad layer removed Significantly greater than the corrosion weight loss of LC4 aluminum alloy with aluminum-clad layer, compared with...

Embodiment 3

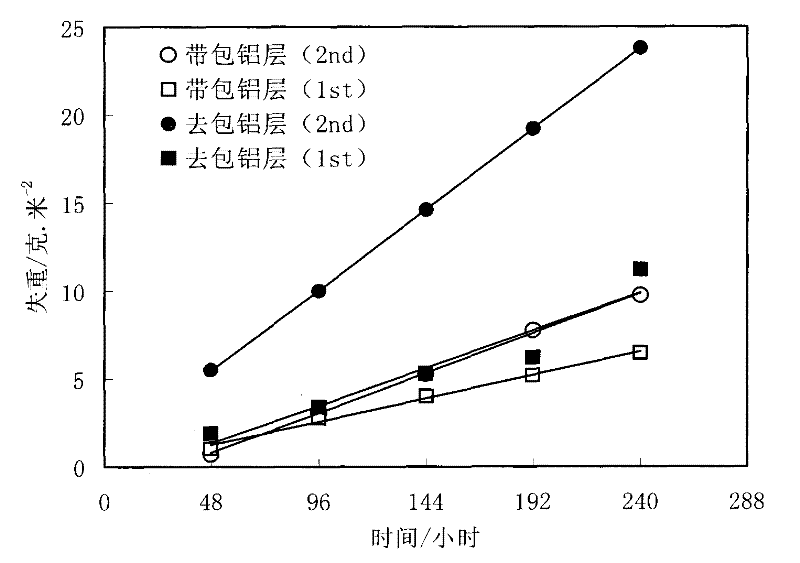

[0037] The test materials are the above-mentioned LY12 aluminum alloy with cladding and aluminum cladding removed. The soaking solution is 0.02mol / L NaHSO 3 Aqueous solution and 0.02mol / L NaHSO 3 +0.006mol / L NaCl aqueous solution, used to simulate industrial pollution atmosphere environment. Cycle once every 15 minutes in the order of "dipping → drying → wetting", among which: dipping at 40°C for 2 minutes; drying at 50°C for 11 minutes; wet at 40°C for 2 minutes; the test time is 240 hours.

[0038] image 3 The LY12 aluminum alloy with and without the aluminum clad layer is given in two corrosion media st : 0.02mol / L NaHSO 3 ,2 nd : 0.02mol / L NaHSO 3 The relationship between the corrosion weight loss in +0.006mol / L NaCl and the test time. The relationship between the corrosion weight loss and the test time of the LY12 aluminum alloy with and without the aluminum clad layer in the two corrosive media is linear, but the corrosion of the LY12 aluminum alloy with the alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com