Patents

Literature

165 results about "Morphological analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Morphological analysis or general morphological analysis is a method for exploring possible solutions to a multi-dimensional, non-quantified complex problem. It was developed by Fritz Zwicky.

Computer-assisted cell analysis

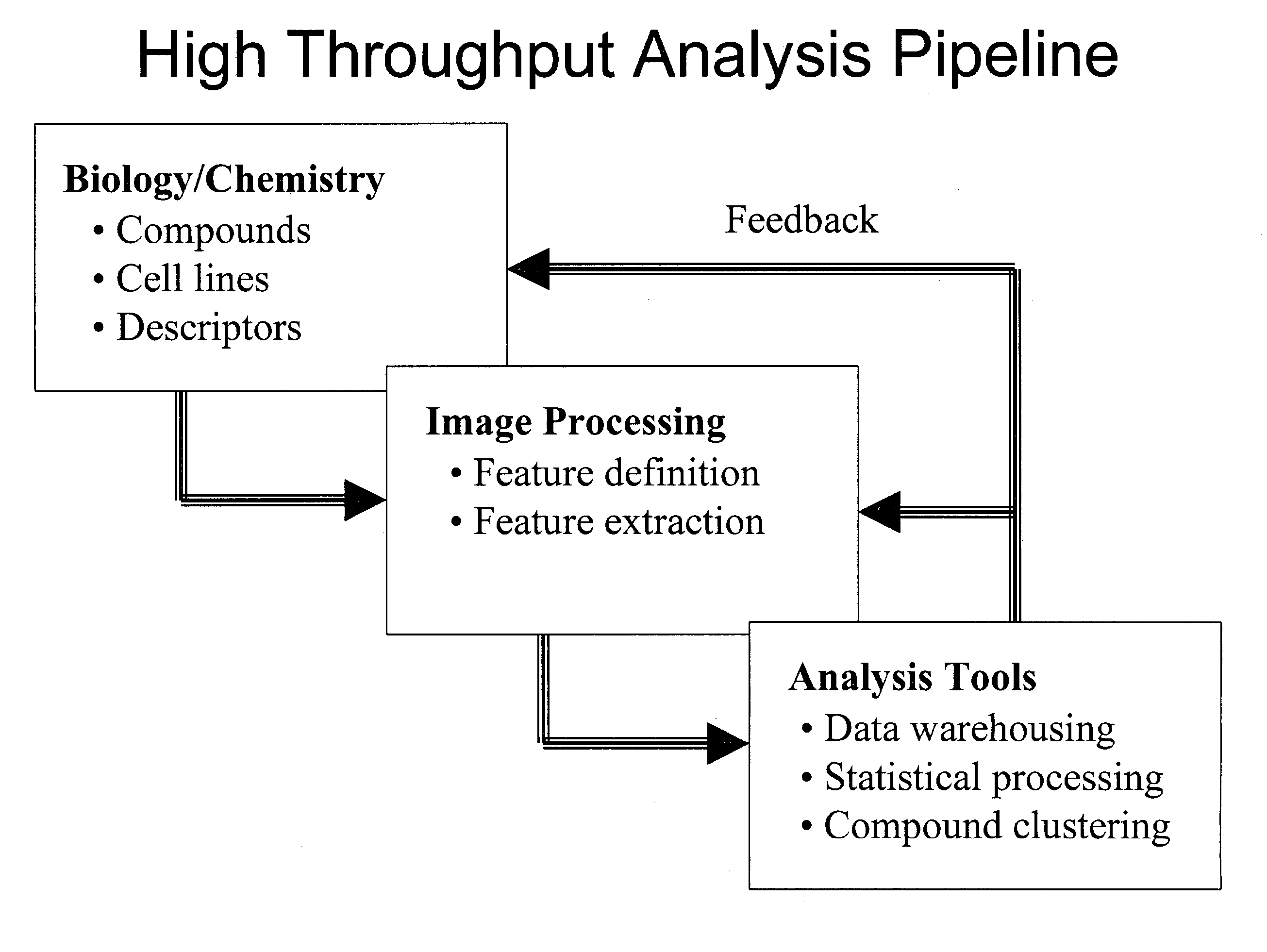

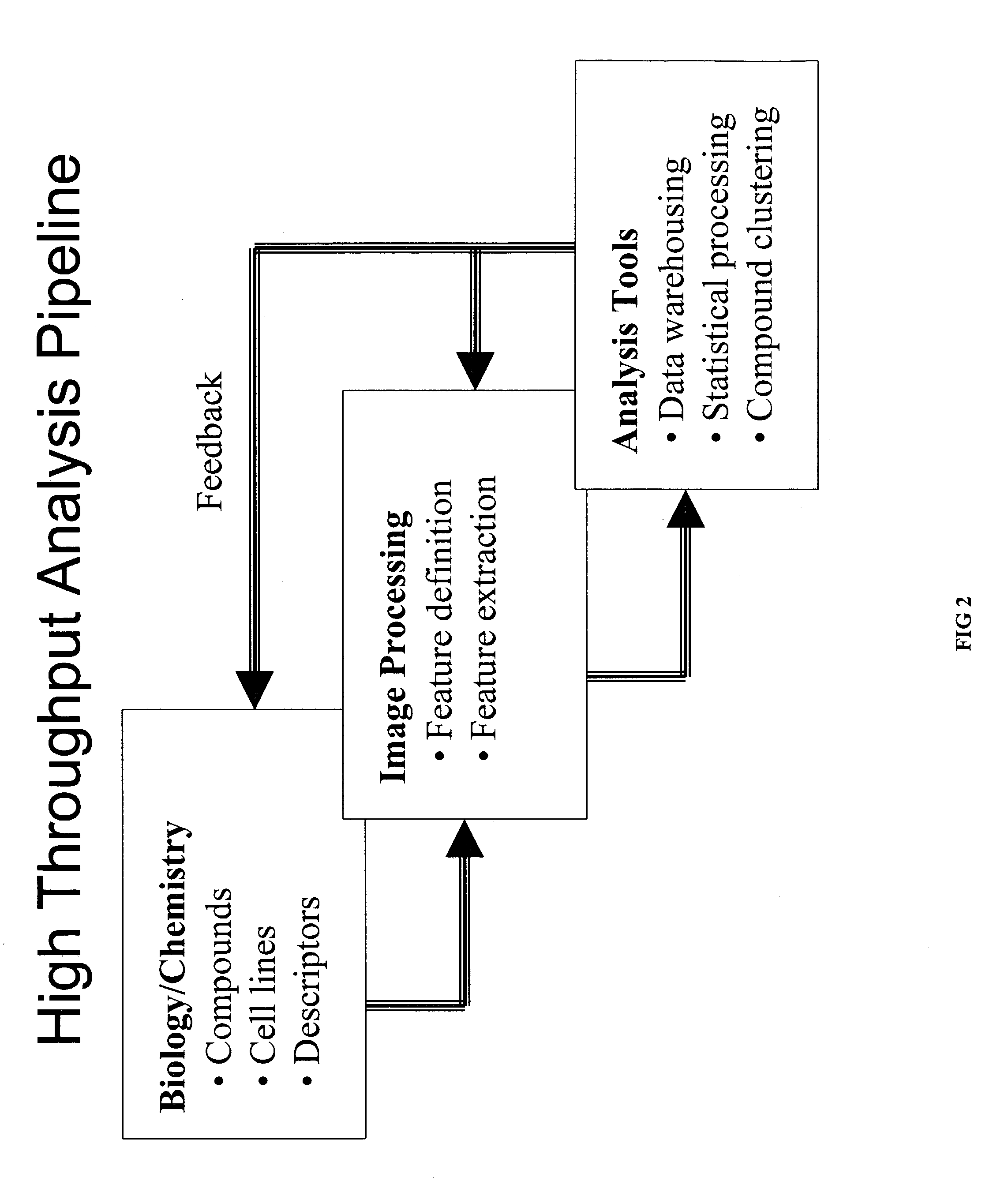

InactiveUS20060050946A1High throughput screeningReduce the number of cellsImage enhancementImage analysisStainingComputer-aided

The present invention provides methods and systems for automated morphological analysis of cells. The inventive methods are particularly useful in the rapid analysis of cells required in a biological screen. Agents which cause a particular phenotype in the cells can be identified using the inventive quantitative morphometric analysis of cells. The data gathered using the inventive method can also be quantified and analyzed later for various trends and classifications. Characteristics of cells which can be determined using this method include number of nuclei, size of cell, size of nuclei, number of the centrosomes, shape of cells, size of centrosomes, perimeter of nucleus, shape of nucleus, pattern of staining, and degree of staining.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

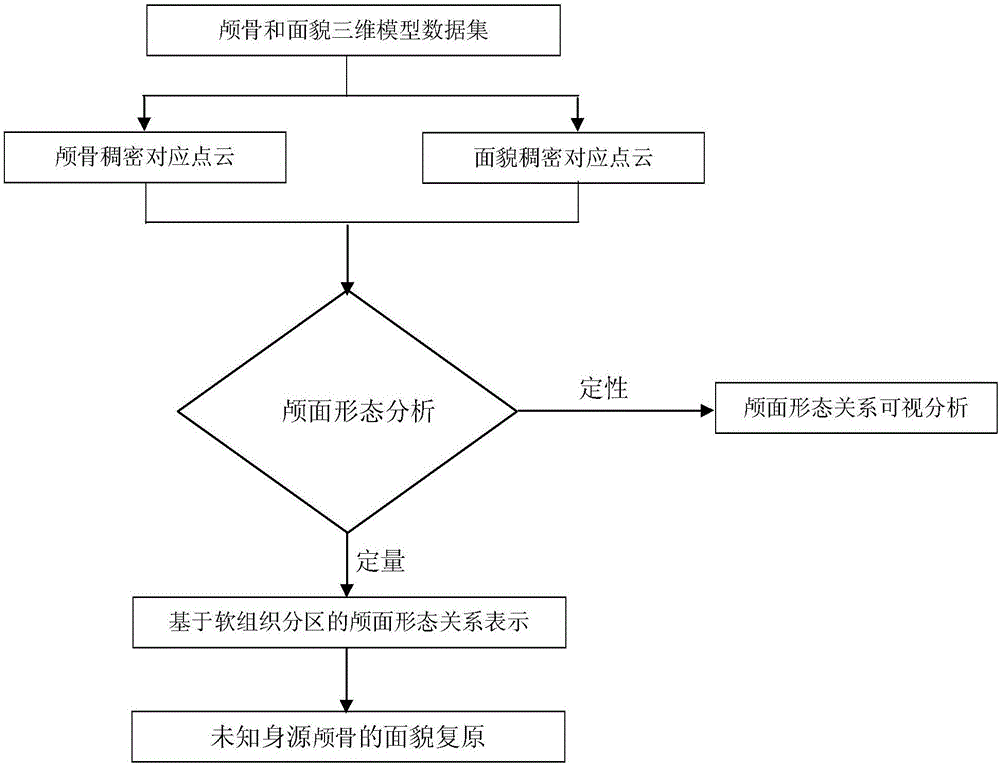

Craniofacial morphological analysis and facial restoration method based on craniofacial denseness corresponding point clouds

ActiveCN106780591AImprove accuracyConsistent craniofacial morphologyImage analysisPattern recognitionPoint cloud

The invention relates to a craniofacial morphological analysis and facial restoration method based on craniofacial denseness corresponding point clouds. The method comprises the steps of 1, acquisition of skull denseness corresponding point clouds; 2, acquisition of facial denseness corresponding point clouds; 3, visual analysis of a craniofacial morphological relation; 4, expression of the craniofacial morphological relation based on soft tissue partitioning; and 5, facial restoration of an unknown body source skull. According to the method, analysis of the craniofacial morphological relation is realized by use of visual analysis based on a principal component coefficient and a quantitative expression method of least square regression, and the problems that craniofacial point cloud data size is large, principal component geometrical significance cannot be easily determined, and the craniofacial morphological relation cannot be easily expressed quantitatively are solved; the problems that the craniofacial morphological relation is complicated, and the craniofacial morphological relation is inconsistent among different regions are solved by use of a craniofacial partitioning method based on soft tissue thickness, and the accuracy of the craniofacial morphological relation is improved; finally, facial restoration of the unknown body source skull is realized by use of the craniofacial morphological relation based on partitioning.

Owner:BEIJING NORMAL UNIVERSITY

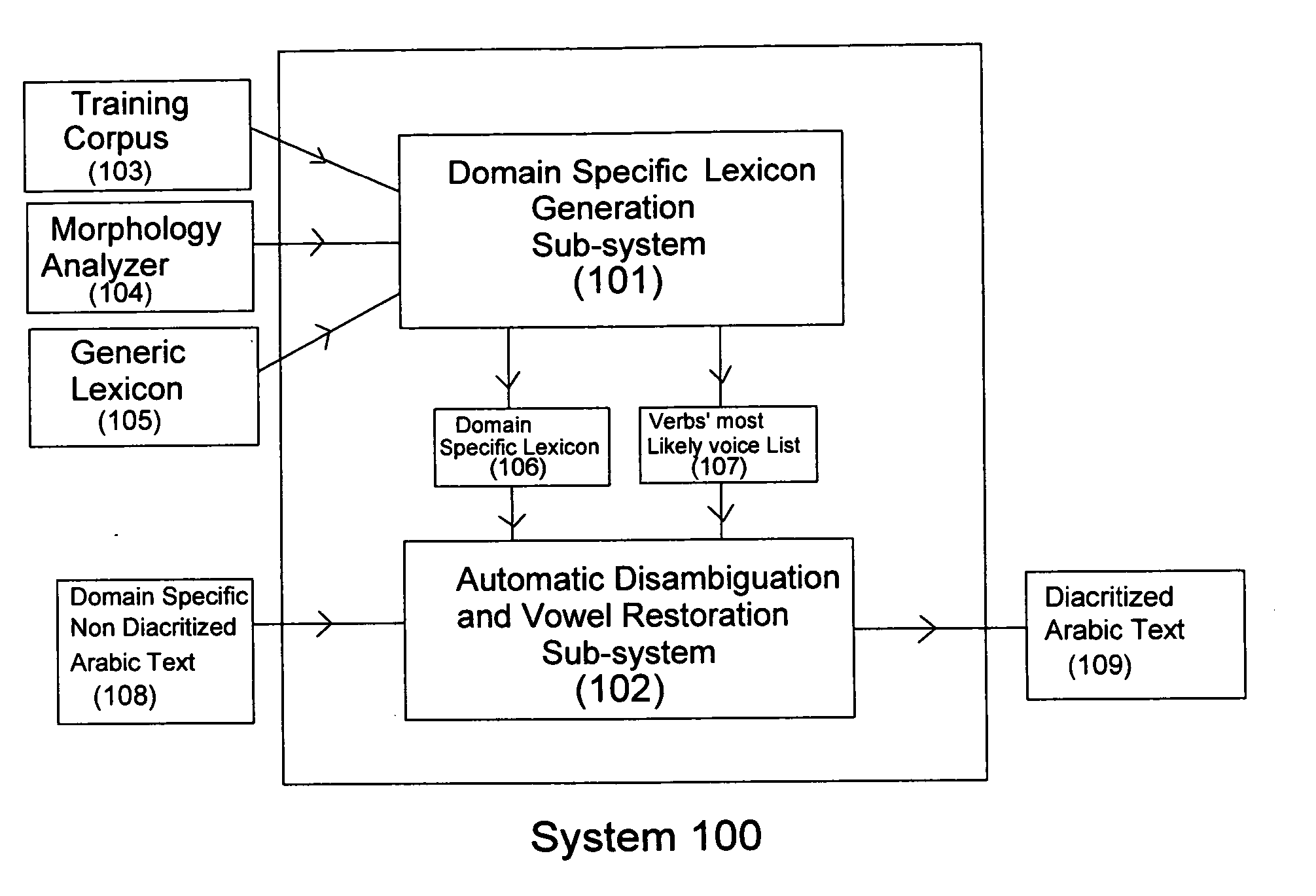

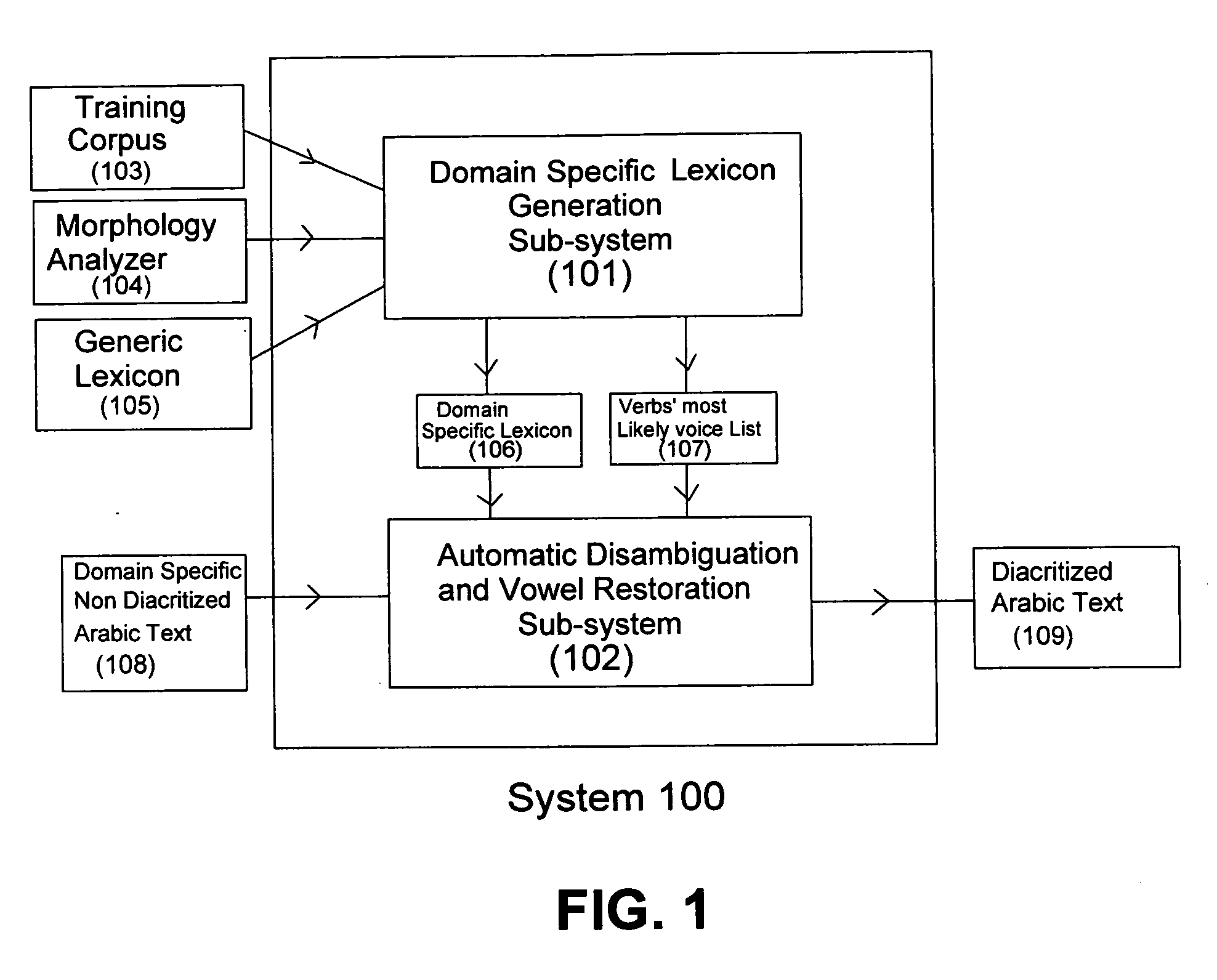

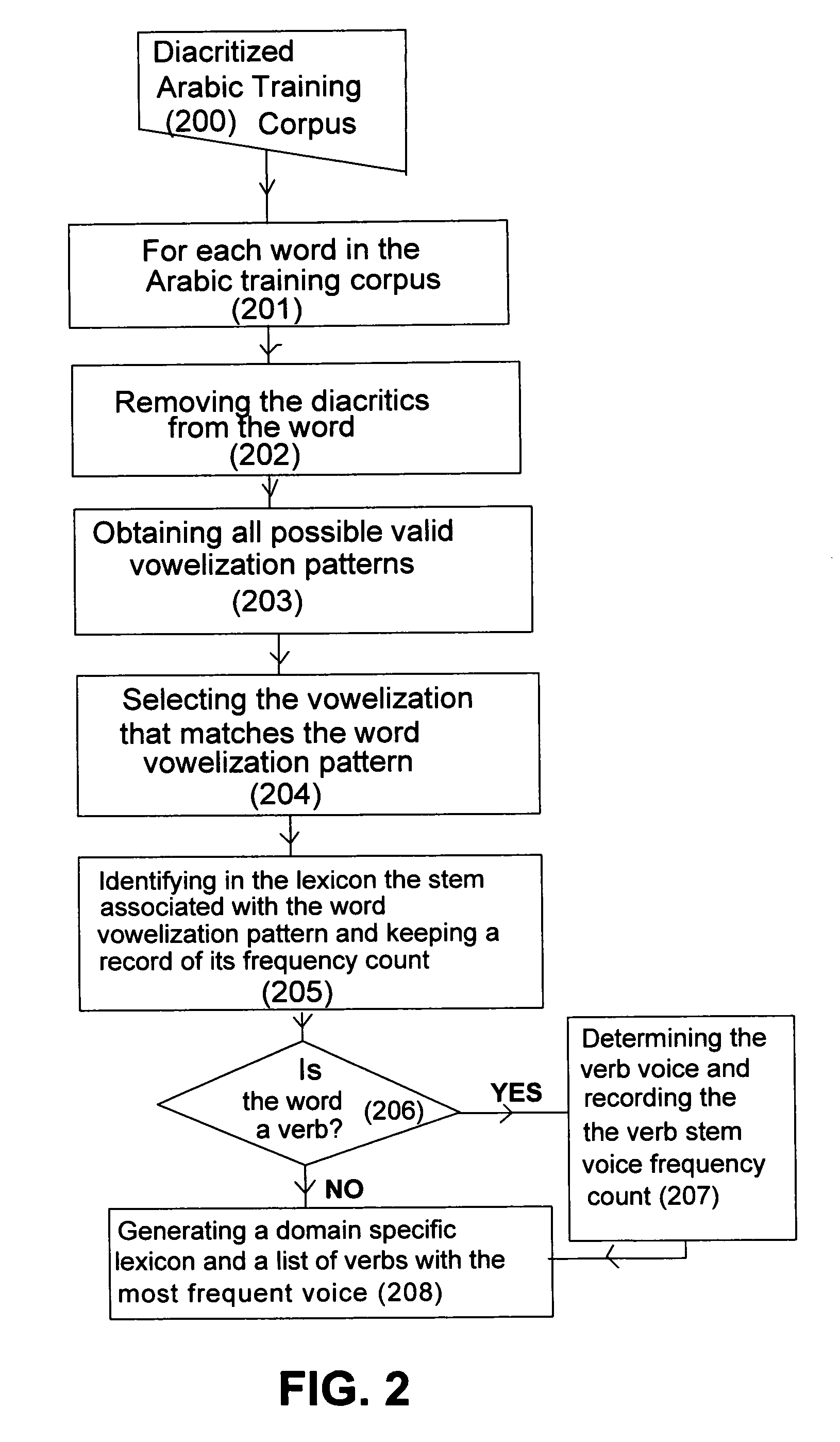

System and method for disambiguating non diacritized arabic words in a text

ActiveUS20060129380A1Improve accuracyCorrect vowel pattern can be identifiedNatural language translationSpecial data processing applicationsAmbiguityA domain

The present invention proposes a solution to the problem of word lexical disambiguation in Arabic texts. This solution is based on text domain-specific knowledge, which facilitates the automatic vowel restoration of modern standard Arabic scripts. Texts similar in their contents, restricted to a specific field or sharing a common knowledge can be grouped in a specific category or in a specific domain (examples of specific domains; sport, art, economic, science . . . ). The present invention discloses a method, system and computer program for lexically disambiguating non diacritized Arabic words in a text based on a learning approach that exploits; Arabic lexical look-up, and Arabic morphological analysis, to train the system on a corpus of diacritized Arabic text pertaining to a specific domain. Thereby, the contextual relationships of the words related to a specific domain are identified, based on the valid assumption that there is less lexical variability in the use of the words and their morphological variants within a domain compared to an unrestricted text.

Owner:MACHINES CORP INT BUSINESS

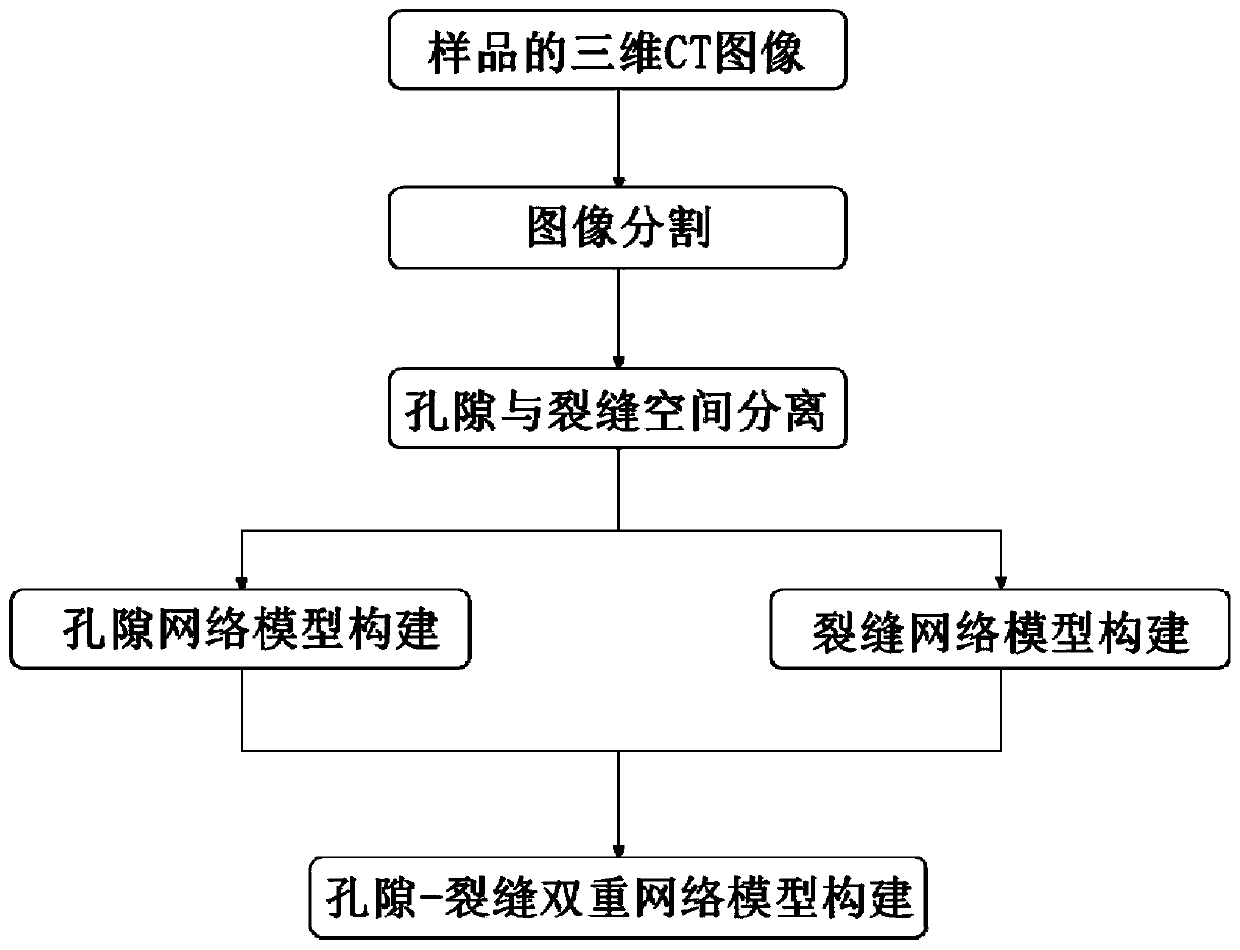

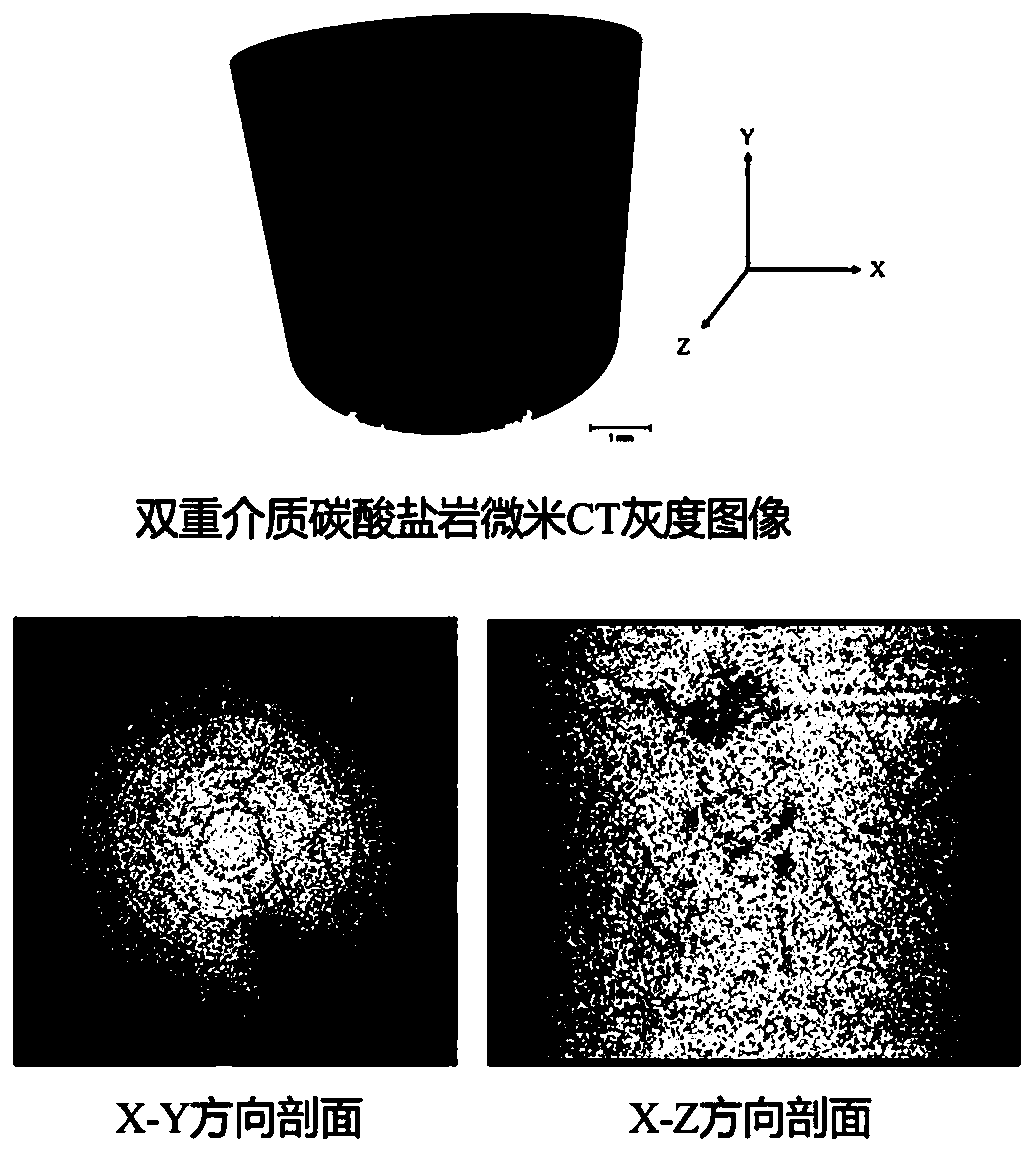

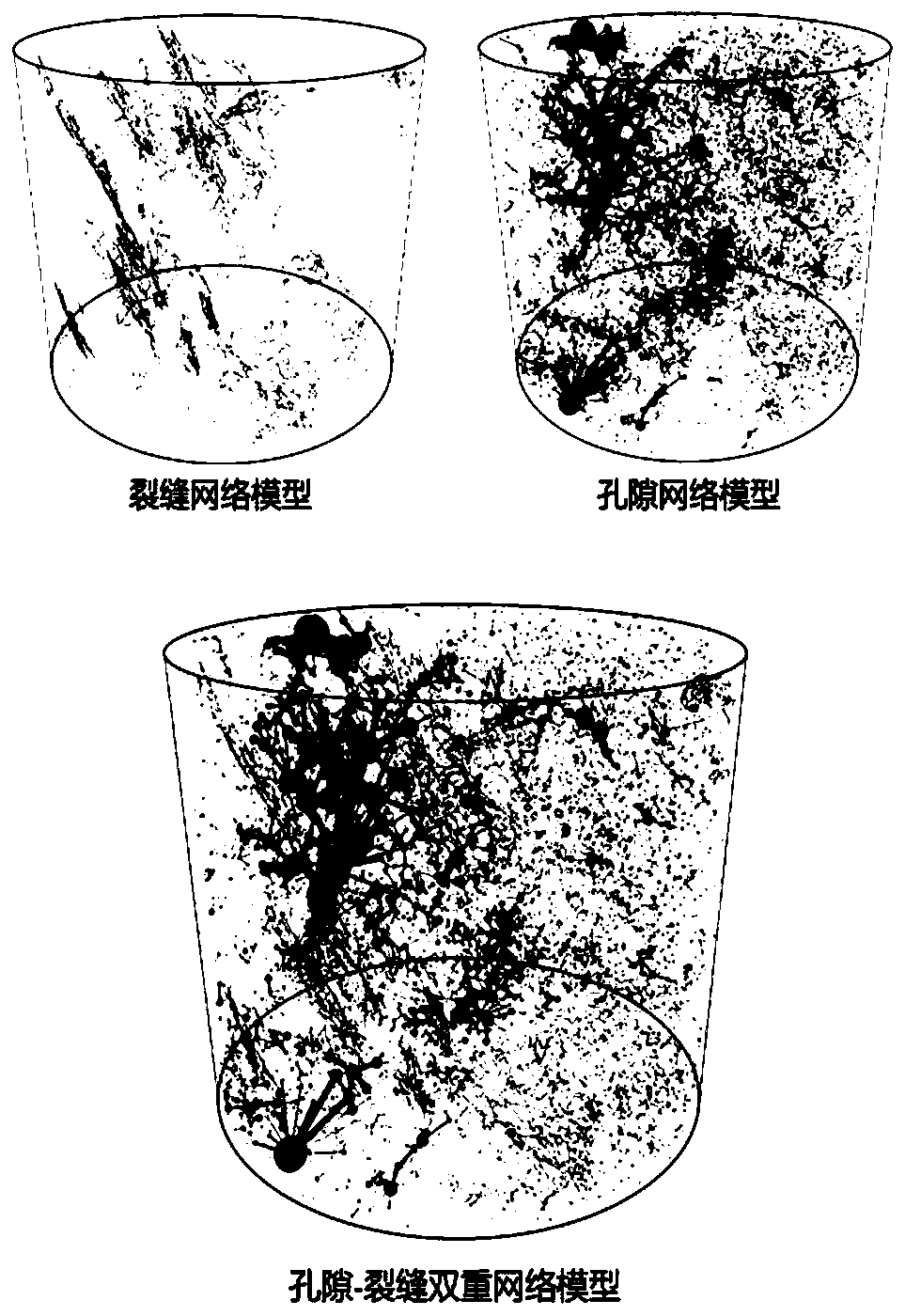

Dual-medium carbonate rock pore-crack dual-network model construction method

ActiveCN110853138ABuild accuratelyIgnore the singularity problemDetails involving processing stepsImage enhancement3d imageImage segmentation

The invention relates to the technical field of oil and gas development, in particular to a dual-medium carbonate rock pore-fracture dual-network model construction method. The method comprises the following steps: scanning a dual-medium carbonate rock sample to obtain a three-dimensional image; performing image segmentation processing on the three-dimensional image, and extracting a to-be-identified space; performing morphological analysis on the to-be-identified space, and completing separation of a pore space and a crack space according to a morphological analysis result; respectively carrying out network model construction on the separated pore space and crack space by adopting a sphere filling method to obtain a pore network model and a crack network model; and adding a communicationthroat between the pore network model and the crack network model to complete construction of a pore-crack dual-network model. According to the method, when the dual-medium carbonate rock network model is constructed, the pore network model and the crack network model can be accurately constructed, and meanwhile, the pore network model and the crack network model are fused into the pore-crack dual-network model.

Owner:科吉思石油技术咨询(北京)有限公司

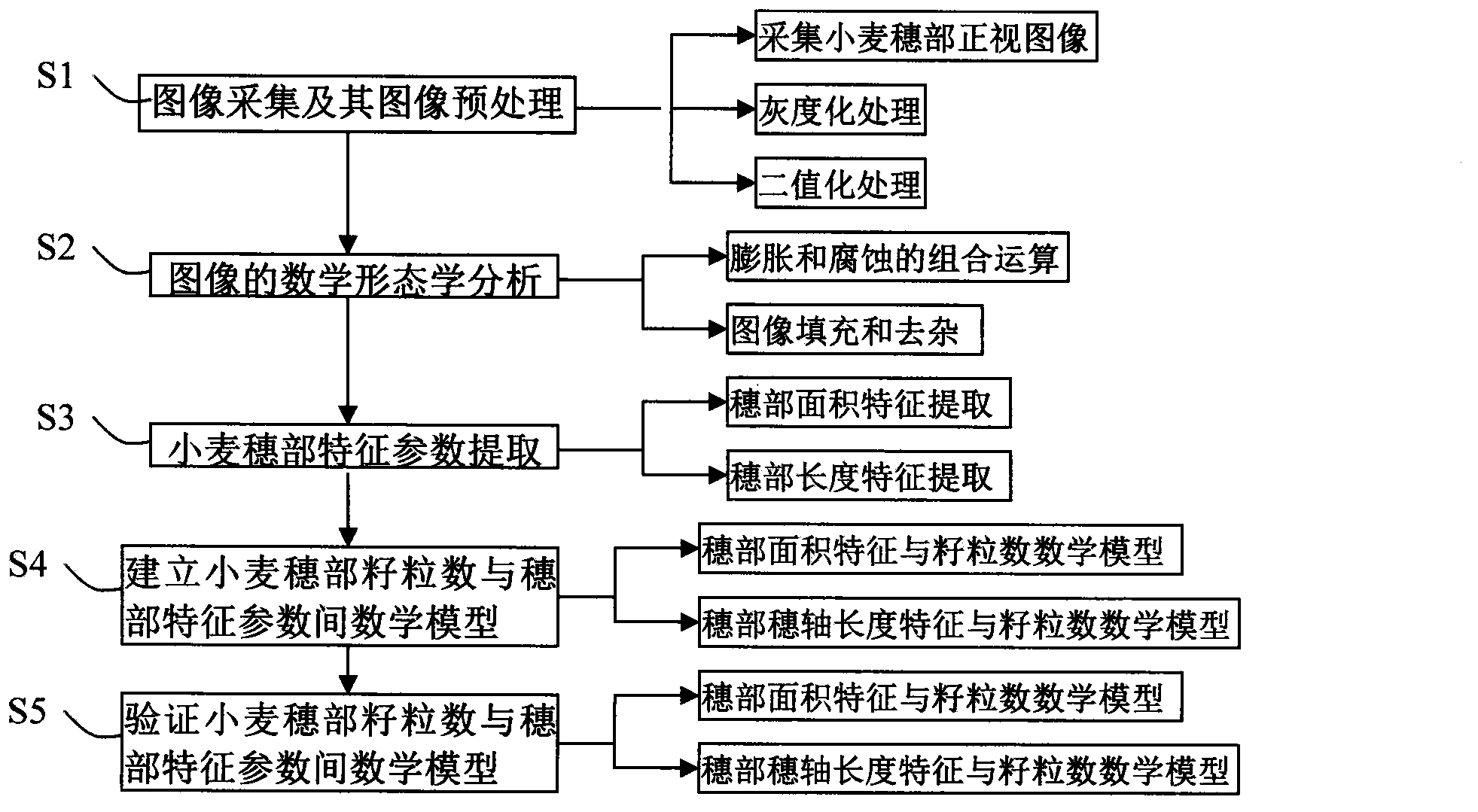

A method for counting seeds of a wheatear portion per wheat

The invention discloses a method for counting seeds of a wheatear portion per wheat. The method comprises the following steps: S1, collecting a front view of the wheatear portion by utilizing a CCD camera and performing pretreatment on the collected front view; S2, carrying out mathematical morphology analysis, wherein the mathematical morphology is a new method applied to the field of image processing and pattern recognition; S3, extracting wheatear portion characteristic parameters, wherein the characteristics of the wheatear portion are extracted so as to establish correlationship between correlated characteristic parameters of the wheatear portion and the number of the seeds; and S4, performing mathematic model testing, which is for testing the correlationships between area characteristics as well as long axis characteristics of the wheatear portion and the number of the seeds so as to ensure the practicality of the two models. Through the method, mathematic models between the wheatear portion image area characteristics as well as long axis length characteristics and the number of the seeds are established through extracting the wheatear portion image area characteristics as well as long axis length characteristics, so that the number of the seeds of the wheatear portion can be accurately, rapidly and objectively counted, and compared with the manual work, the method greatly helps to improve the efficiency of seed counting.

Owner:NANJING AGRICULTURAL UNIVERSITY

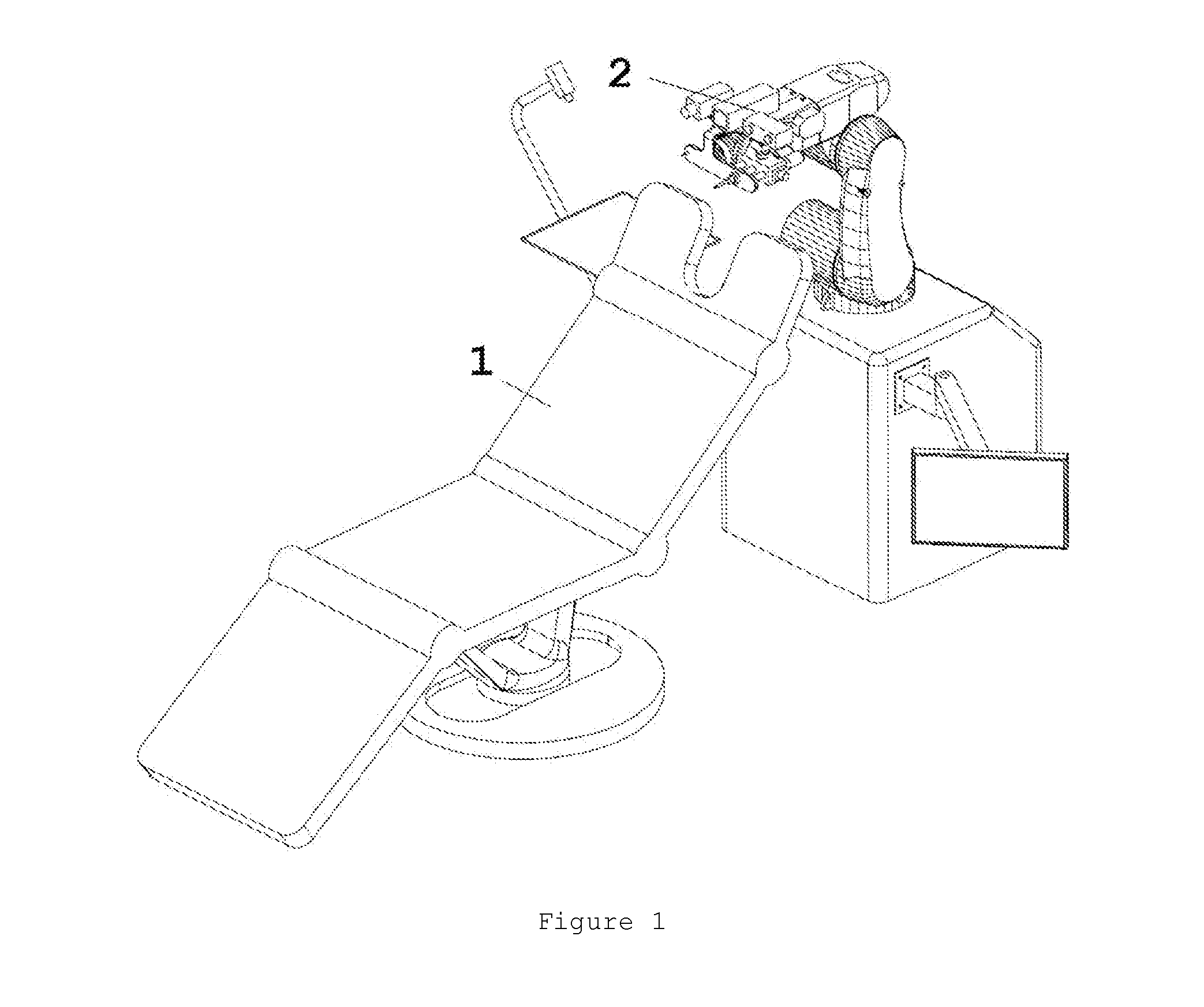

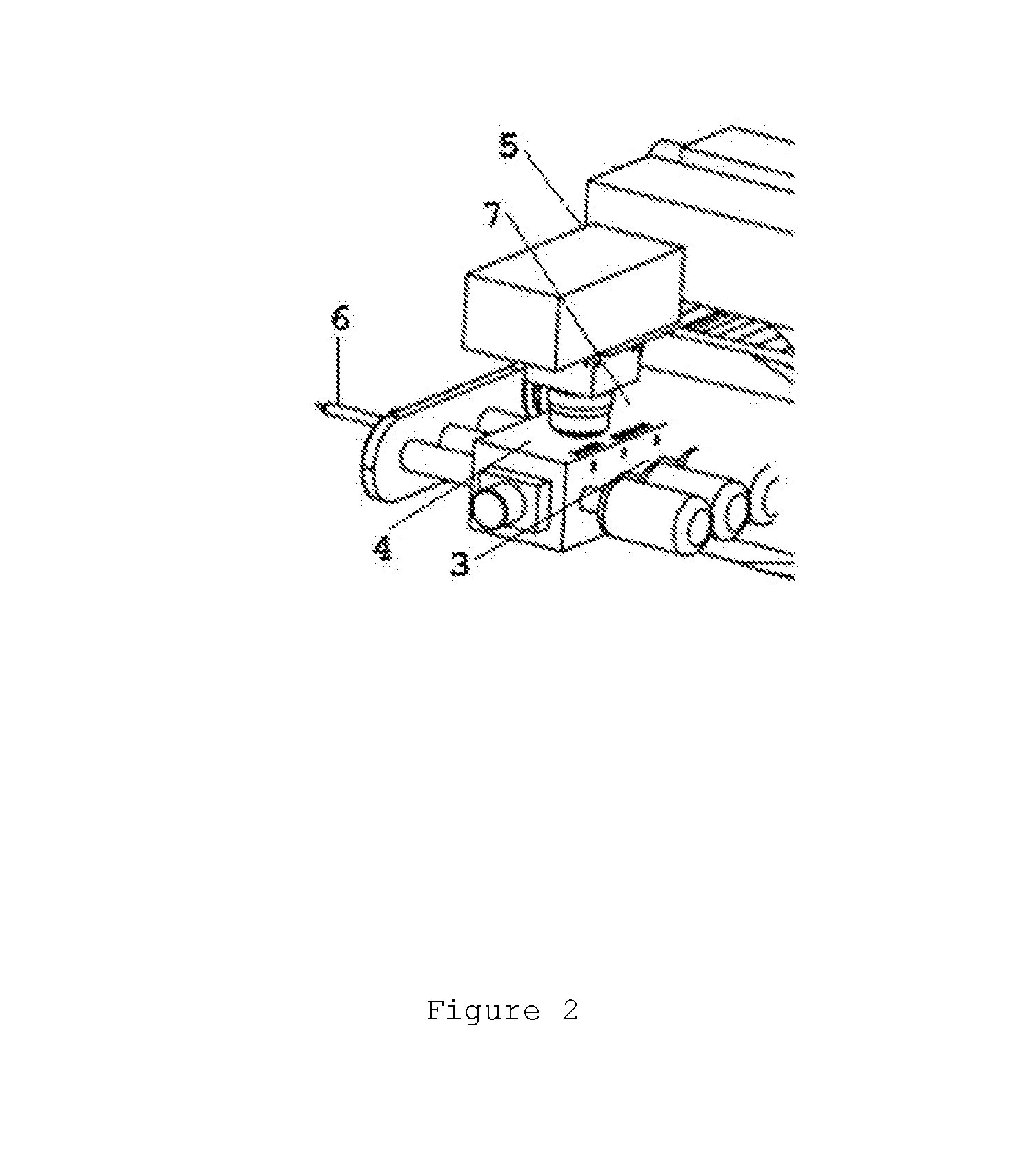

Apparatus for automated differential hair transplant

ActiveUS20160193035A1Reduce expensesShorten the timeSkin implantsDiagnosticsGraft transplantMorphological analysis

The present invention relates to an apparatus for automated hair transplantation through the well-known extraction technique of capillary units or FUE, comprising the morphological analysis of hair follicles in real-time by means of artificial vision, mapping of points for extraction and implant, simulation of the final result, a system of local anaesthesia, global, simultaneous or in sequential phases, at least one articulated mechanical arm associated with a tool for differentially extracting and implanting hair follicles.The present invention is useful to reduce the time and cost associated with the intervention, improve the quality of the operation and the final result, in terms of capillary density, contemplating the study of cell differentiation of follicles with the required estimate of time required regarding the growth. Minimizes the positional discomfort of the patient, the pain associated with the administration of anaesthesia, among other inconveniences usually experienced by the patient in this type of intervention. The present invention is useful for diagnosis, treatment and hair transplantation procedures.

Owner:SAUDE VIAVEL LDA

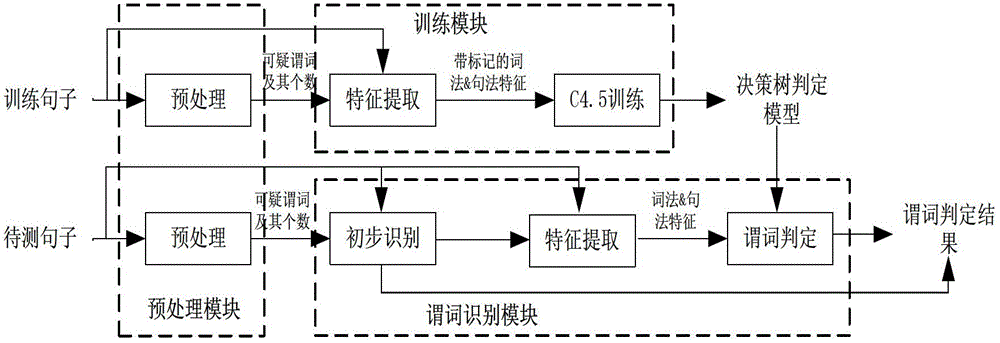

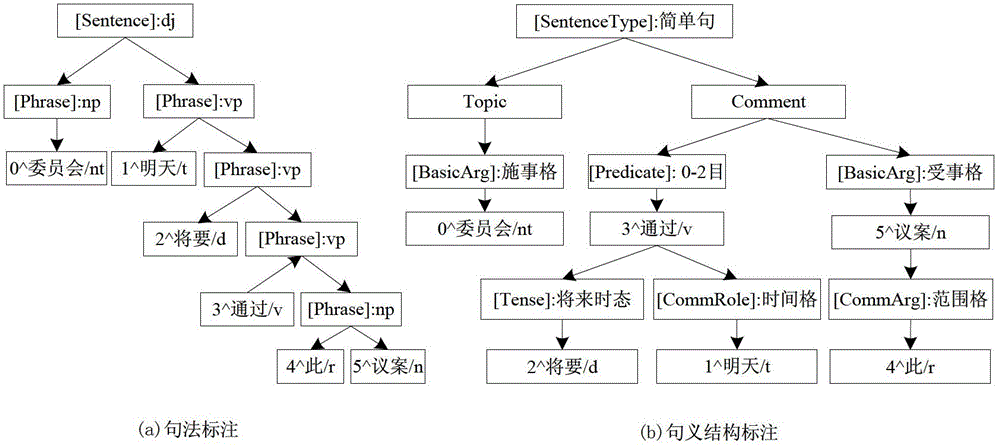

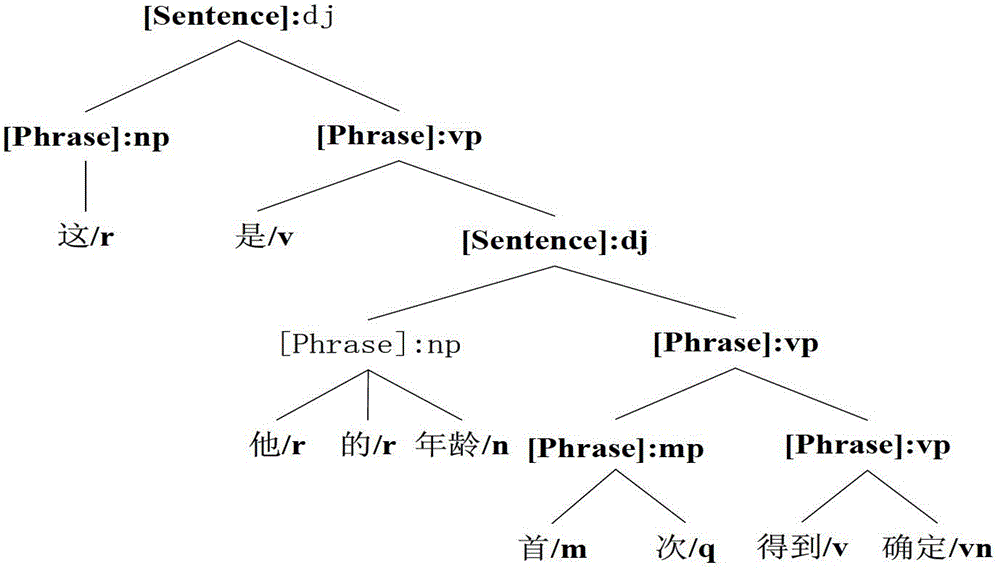

High-precision Chinese predicate identification method

InactiveCN103150381AImprove accuracyImprove recognition efficiencySpecial data processing applicationsLexical analysisHigh effectiveness

The invention relates to a predicate identification method based on a combination of rules and statistics, and belongs to the field of natural language processing and machine learning. The identification method aims at achieving high-precision and high-efficiency predicate identification. The stepped identification method identifies predicates from morphology and syntax labeled sentences, and comprises the steps of conducting morphological analysis on the sentences to be detected, obtaining suspicious predicates and a number thereof, preliminarily identifying the predicates by using preliminary identification judgment conditions, extracting relevant morphological and syntactic characteristics of the suspicious predicates dissatisfying the preliminary identification judgment conditions, judging the predicates with a decision-making tree judgment model obtained from C4.5 training, and finally summarizing identification results in the two steps to present the predicates of the sentences to be detected. The identification method has the characteristics of high accuracy rate, identification speed and identification rate for the non-verbal predicates, and the like, is applicable to the field requiring high-precision Chinese predicate identification, greatly promotes development of sentence meaning analysis, and has high application and popularization values.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

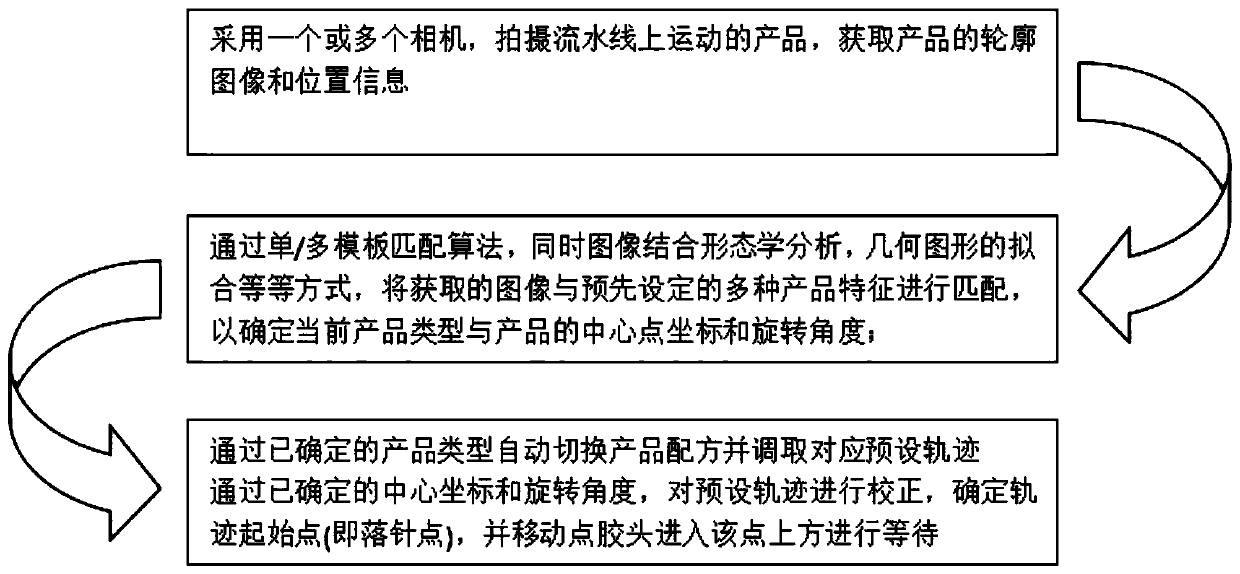

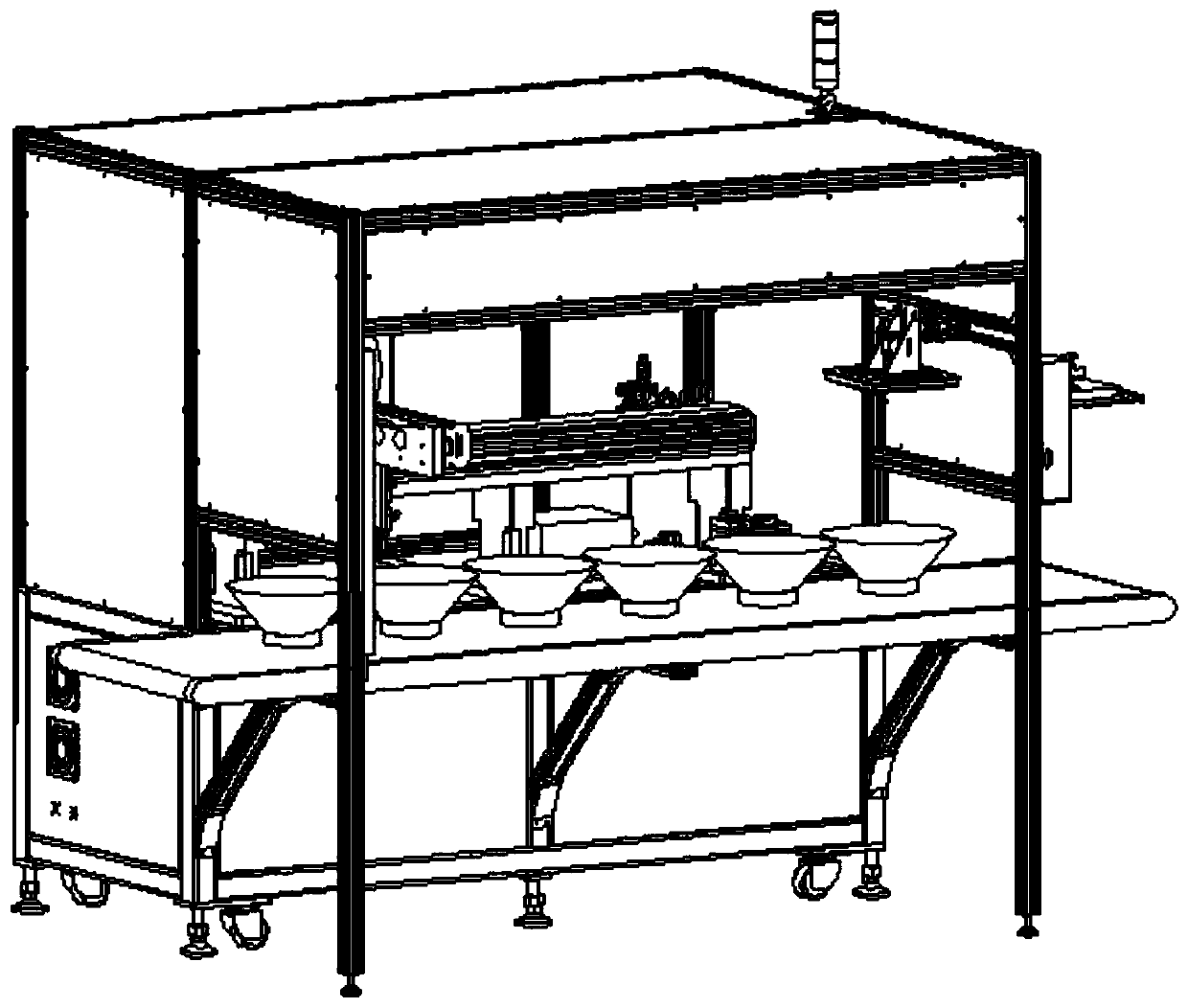

Image recognition and processing system on automatic tracking dispensing equipment

InactiveCN111460955AImprove adaptabilitySatisfy pain pointsImage enhancementImage analysisImaging processingComputer graphics (images)

The invention discloses an image recognition and processing system on automatic tracking dispensing equipment. The system is adapted to an uninterruptible feeding assembly line, and monitors or captures image information of assembly line feeding in real time through one or more image acquisition devices. The system comprises: an image acquisition module which monitors or captures the image information of assembly line feeding in real time through one or more image acquisition devices;an image processing module which is used for establishing a template based on contour image information of an incoming material and fitting a template model of a corresponding product through a model matching algorithm and a morphological analysis method, associating the image coordinate system with the equipment motion coordinate system through a five-point calibration method based on the position image of the incoming material, and determining the coordinate and angle of the current incoming material inthe equipment motion coordinate system; and a track editing module which is used for carrying out simulation teaching on the machining process of an incoming material model through a preset dispensingtrack or a manual operation track, and correcting the dispensing track according to the coordinate and angle of an incoming material.

Owner:飓蜂科技(苏州)有限公司

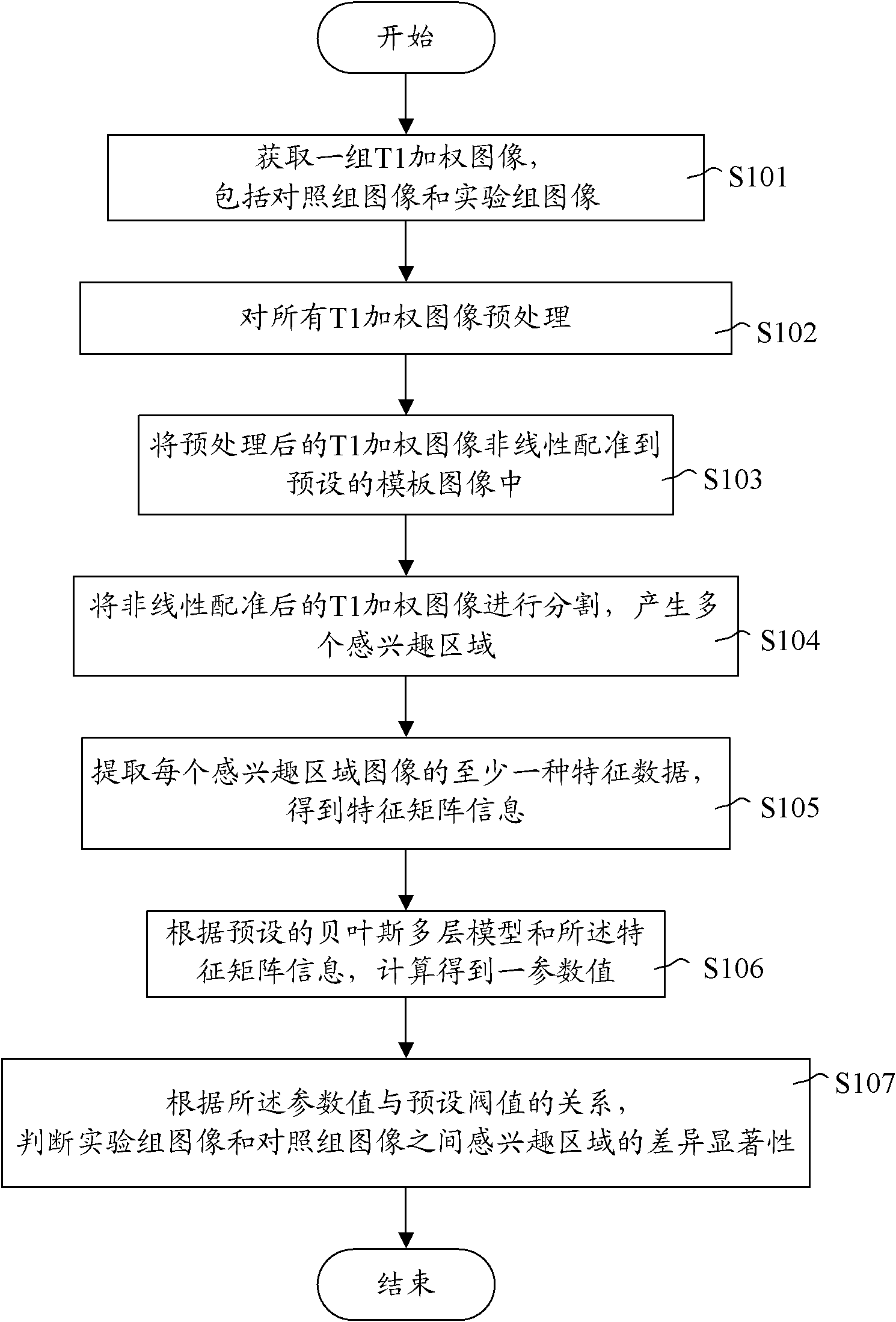

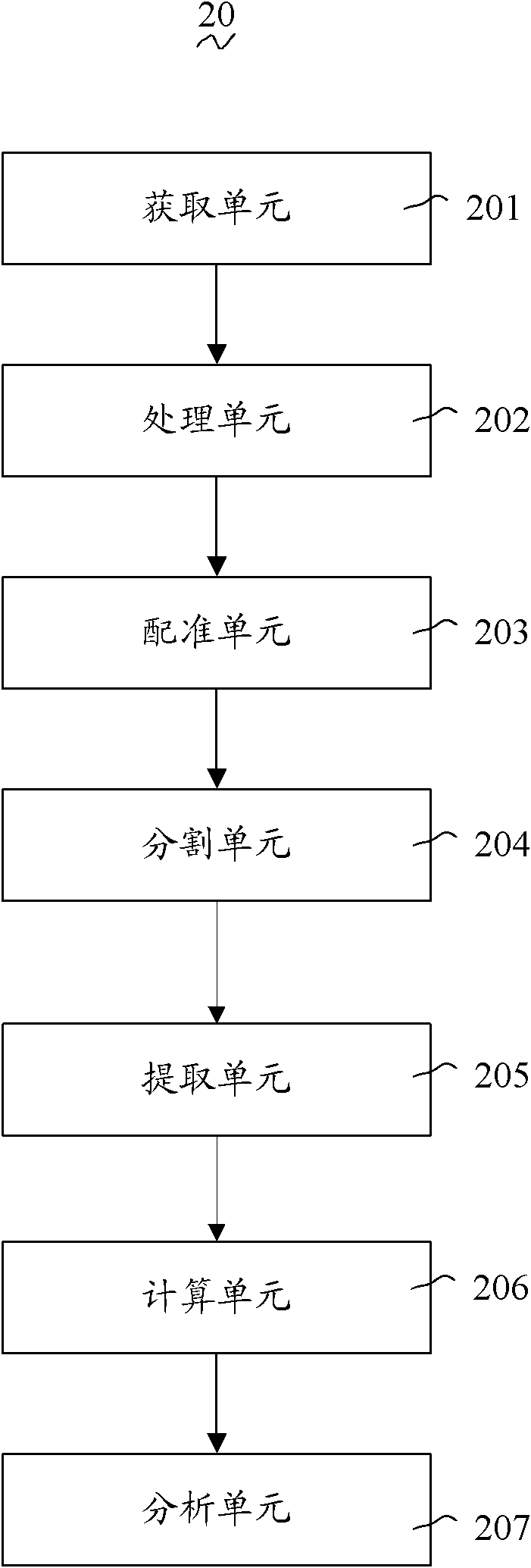

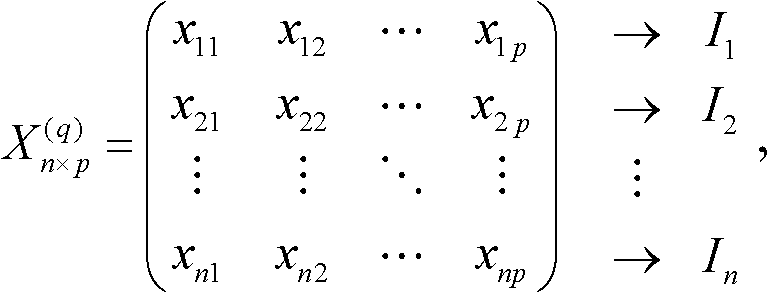

Image analysis method and system

The invention discloses an image analysis method, which comprises the steps of: obtaining a group of T1 weighted images including a control group image and an experimental group image, pre-processing all T1 weighted images, carrying out non-linear registration on preprocessed T1 weighted images into a preset template image, dividing the non-linear registered T1 weighted images to generate a plurality of interest regions, extracting at least one feature data of each interest region to obtain feature matrix information, calculating to obtain a reference value according to a preset Bayesian multi-layer model and the feature matrix information, and judging difference significance of the interest regions between the experimental group image and the control group image according to the relation between the reference value and a preset threshold value. The invention also provides a corresponding image analysis system. The image analysis method and the system can extract more and richer parameters to be analyzed and more diverse information in comparison with the conventional technology, and can simultaneously process multi-region multi-feature significance statistical test so that morphology analysis is more complete.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

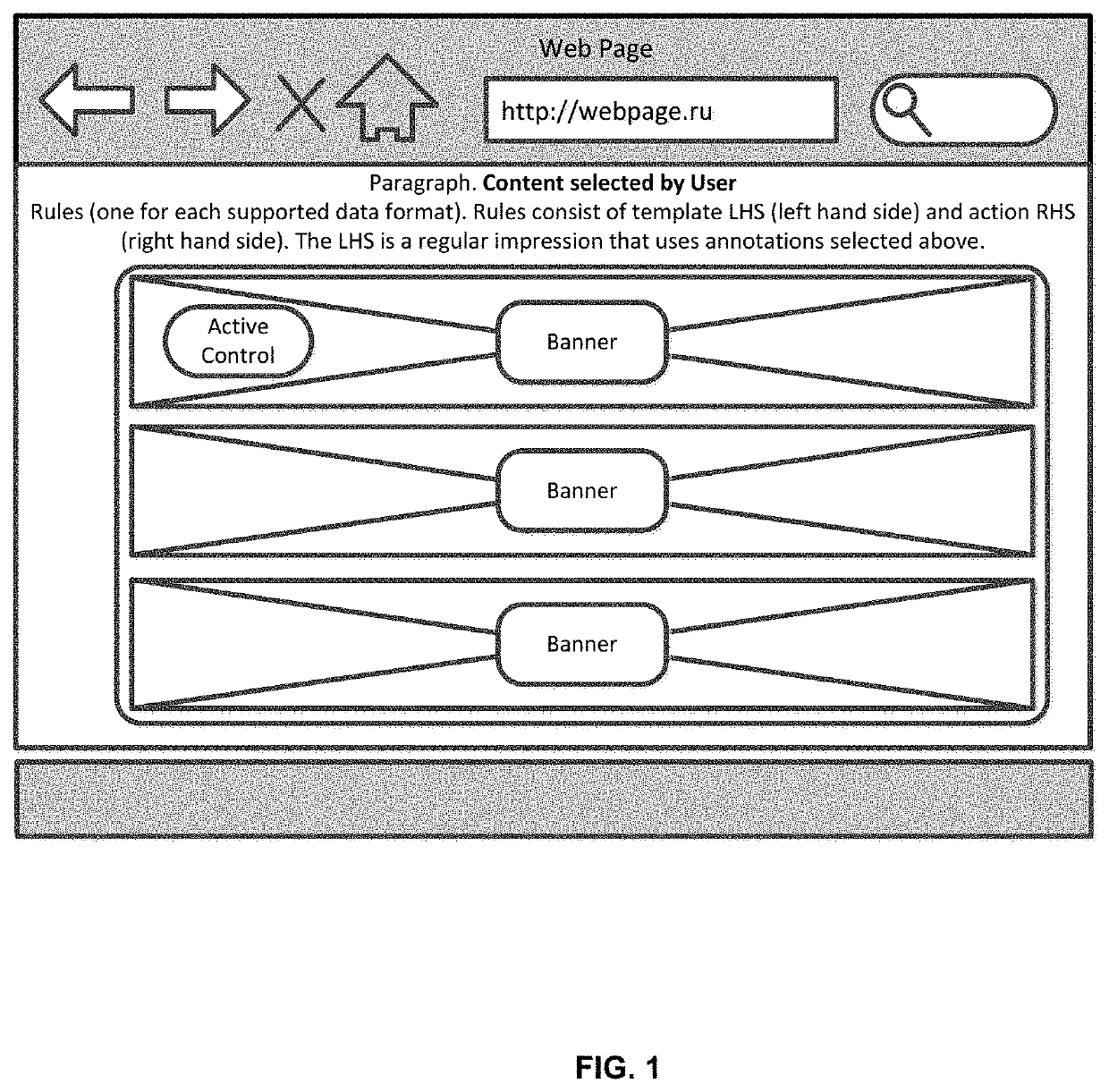

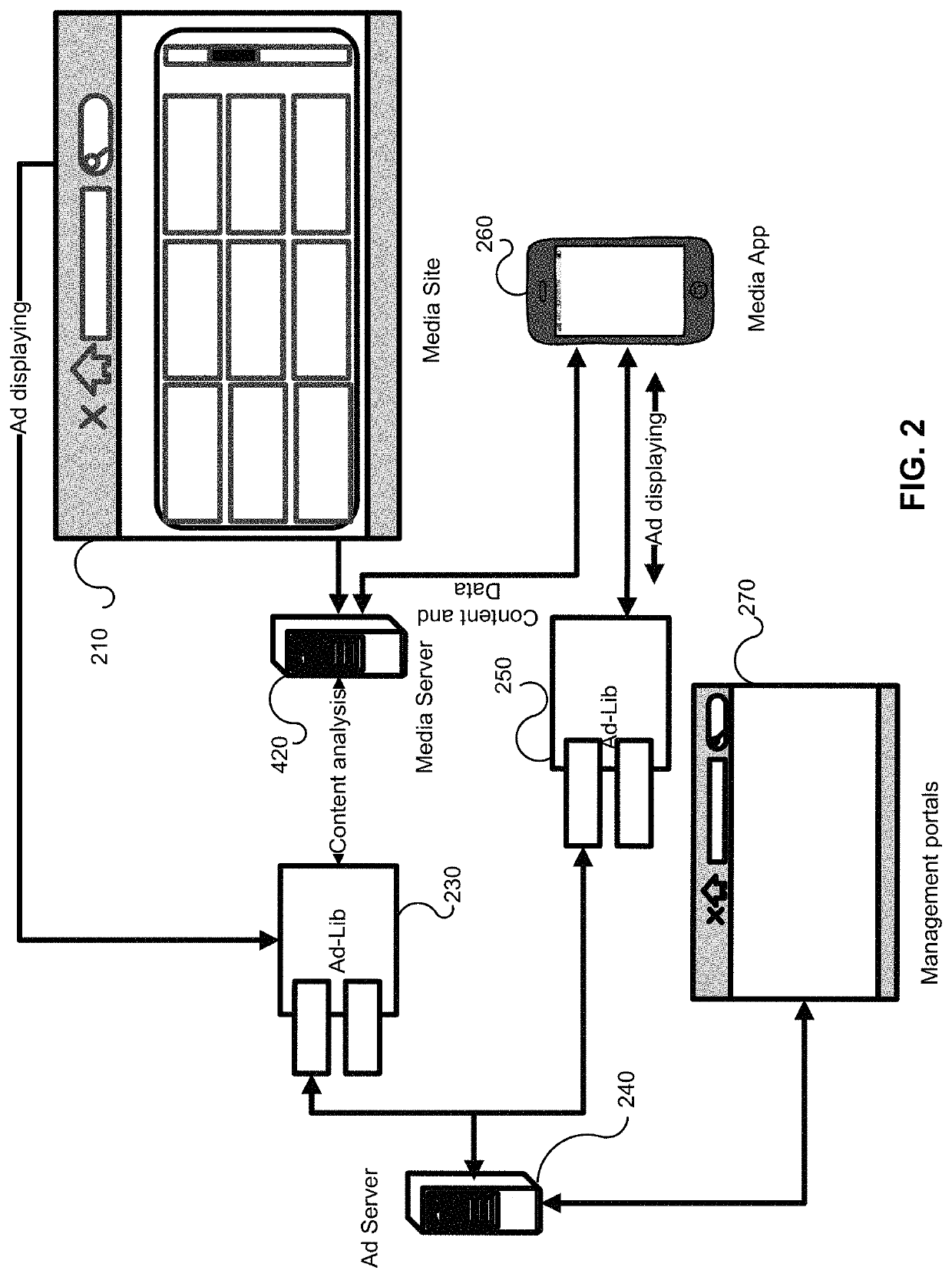

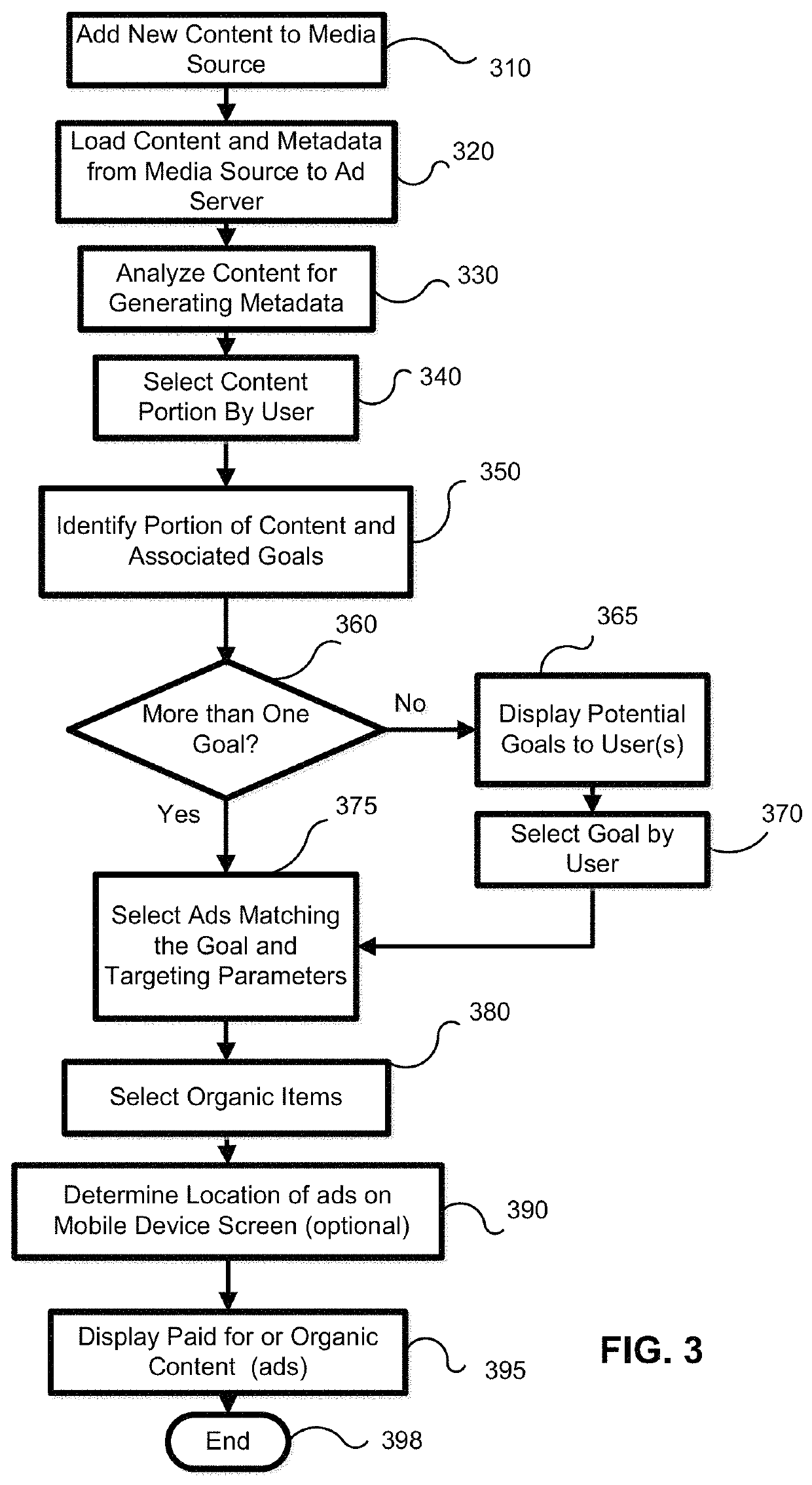

System and method for selection of meaningful page elements with imprecise coordinate selection for relevant information identification and browsing

ActiveUS10810357B1Choose accuratelySemantic analysisText processingPart of speechRelevant information

Method for identifying search candidates, including receiving a content that includes unprocessed content, markup elements and element styles; identifying raw content; applying content styles to the markup elements to determine which sequence of parts of content produces compact logically linked and visually bounded parts of the content; performing syntactic analysis to generate parsing trees; performing morphological analysis to determine parts of speech and word morphology in bounded parts; performing stemming on the parts of speech and constructing chains that meet grammar rules; identifying zests and calculating weights of the zests; applying weights to the chains to determine zests; adjusting the weights based on a distance from a point of user interaction with the content; selecting zests with the highest weight and degree of belonging to a region around the point of interaction; adjusting zests near the point of interaction and using it for selection of information to display.

Owner:SLICKJUMP

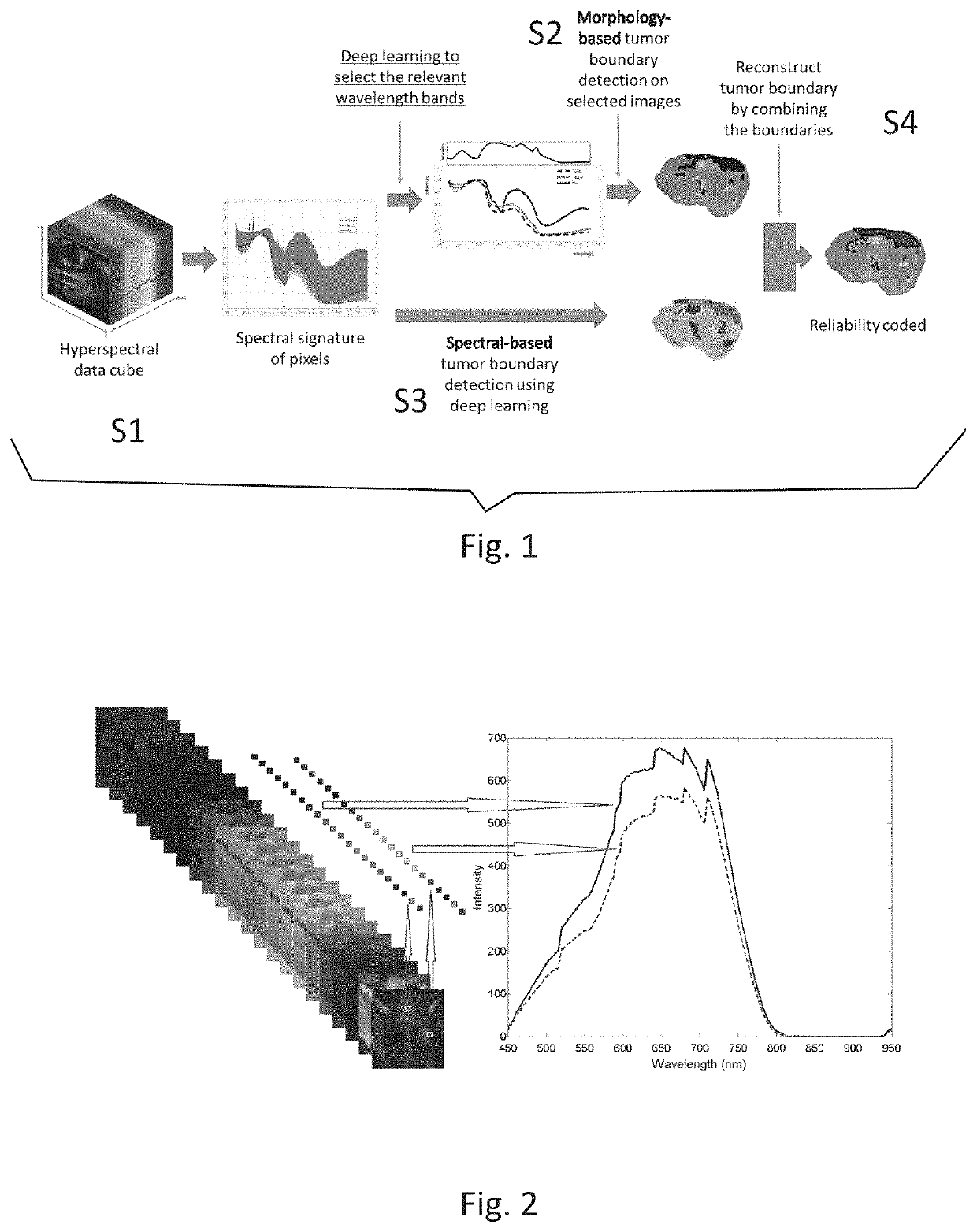

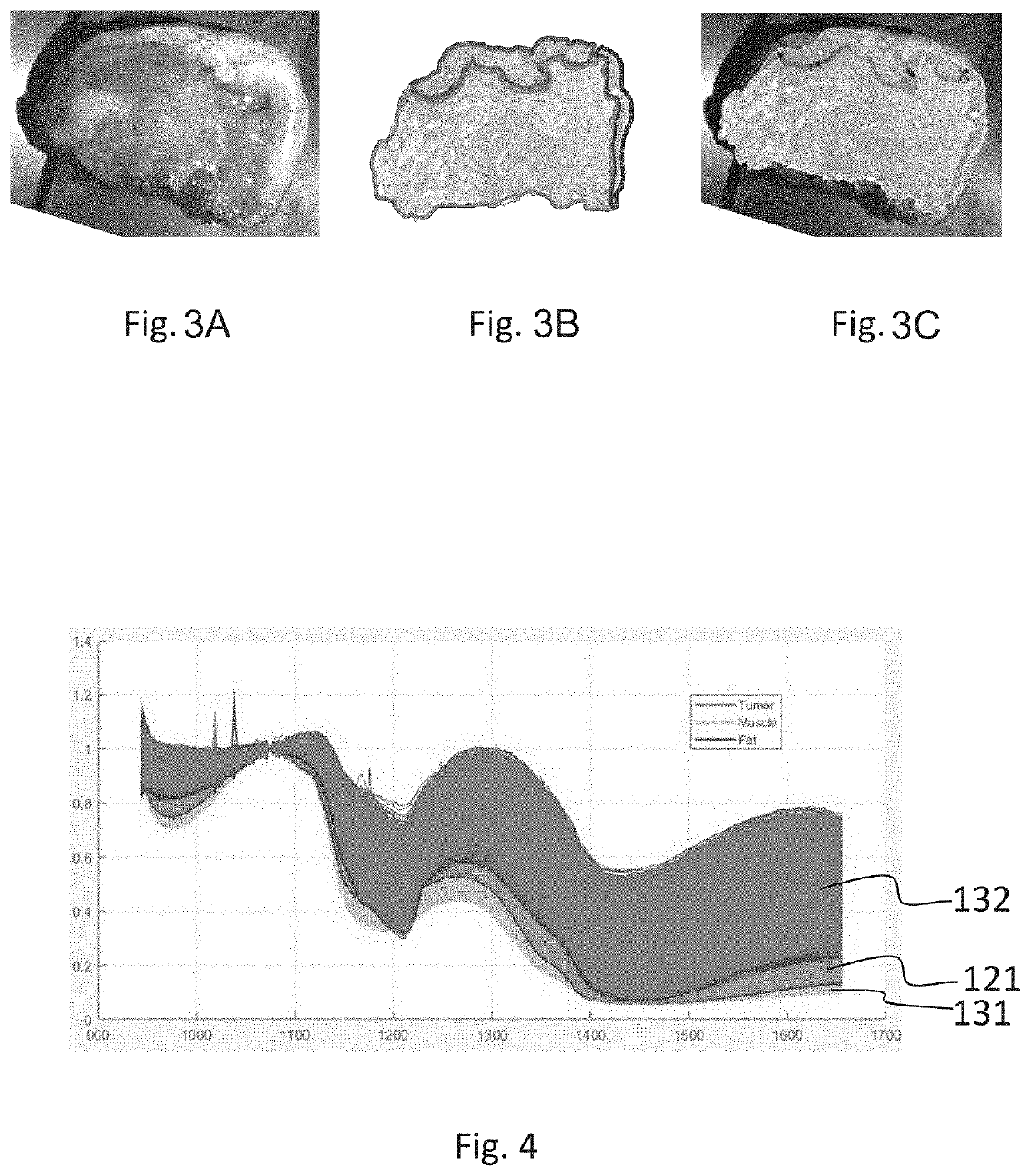

Tumor boundary reconstruction using hyperspectral imaging

In a computer implemented method of determining a boundary of a tumor region or other diseased tissue, hyper- or multispectral image data of a tissue sample including a tumor region or other diseased tissue is taken. The analysis includes a morphological analysis and a spectral analysis of the hyper- or multispectral image data resulting in a morphological tumor boundary and a spectral tumor boundary or a morphological diseased tissue boundary and a spectral diseased tissue boundary. These two boundaries are combined resulting in a combined tumor boundary or combined diseased tissue boundary, wherein an indication of reliability of the combined tumor boundary or combined diseased tissue boundary is given.

Owner:KONINKLJIJKE PHILIPS NV

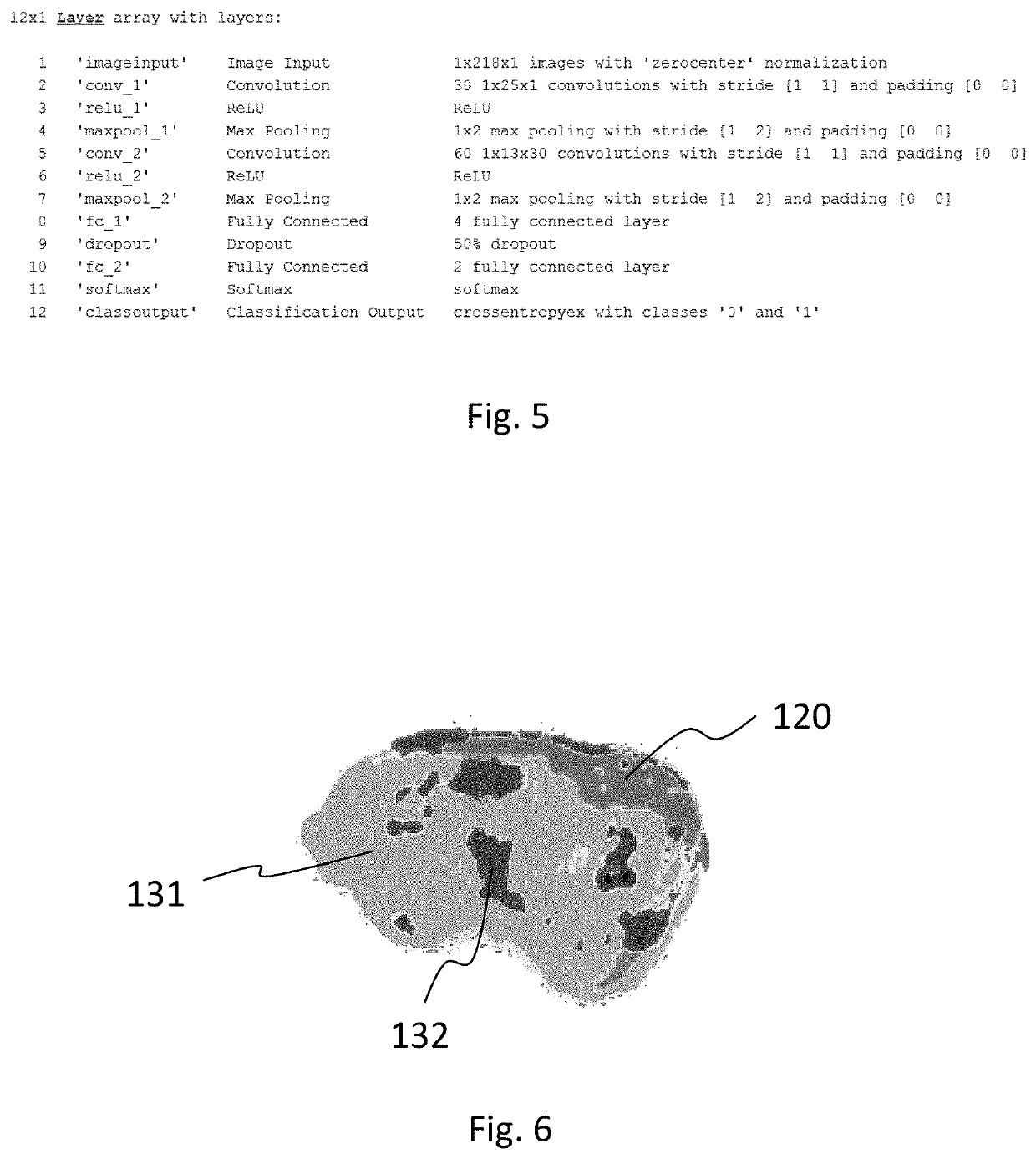

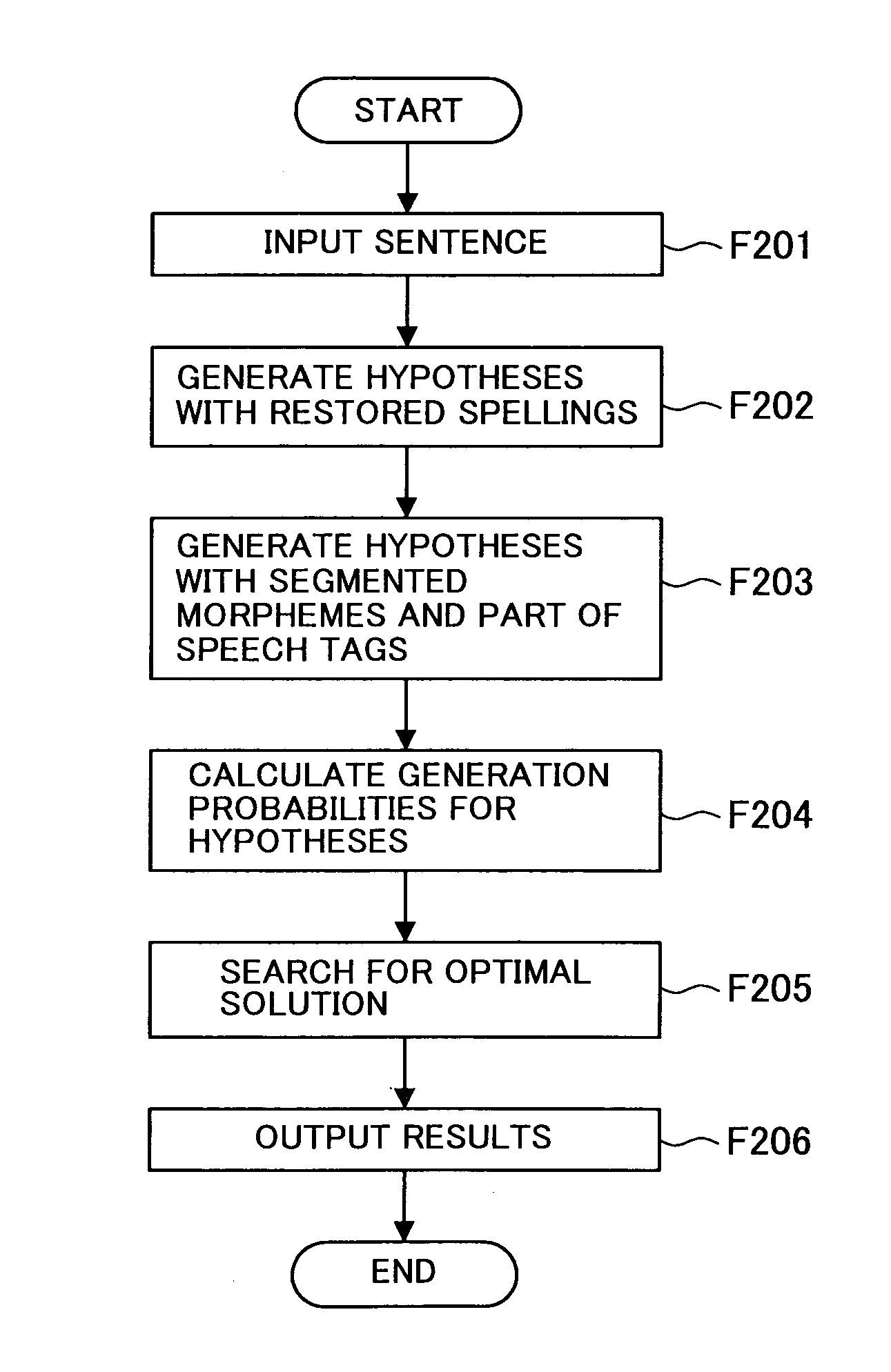

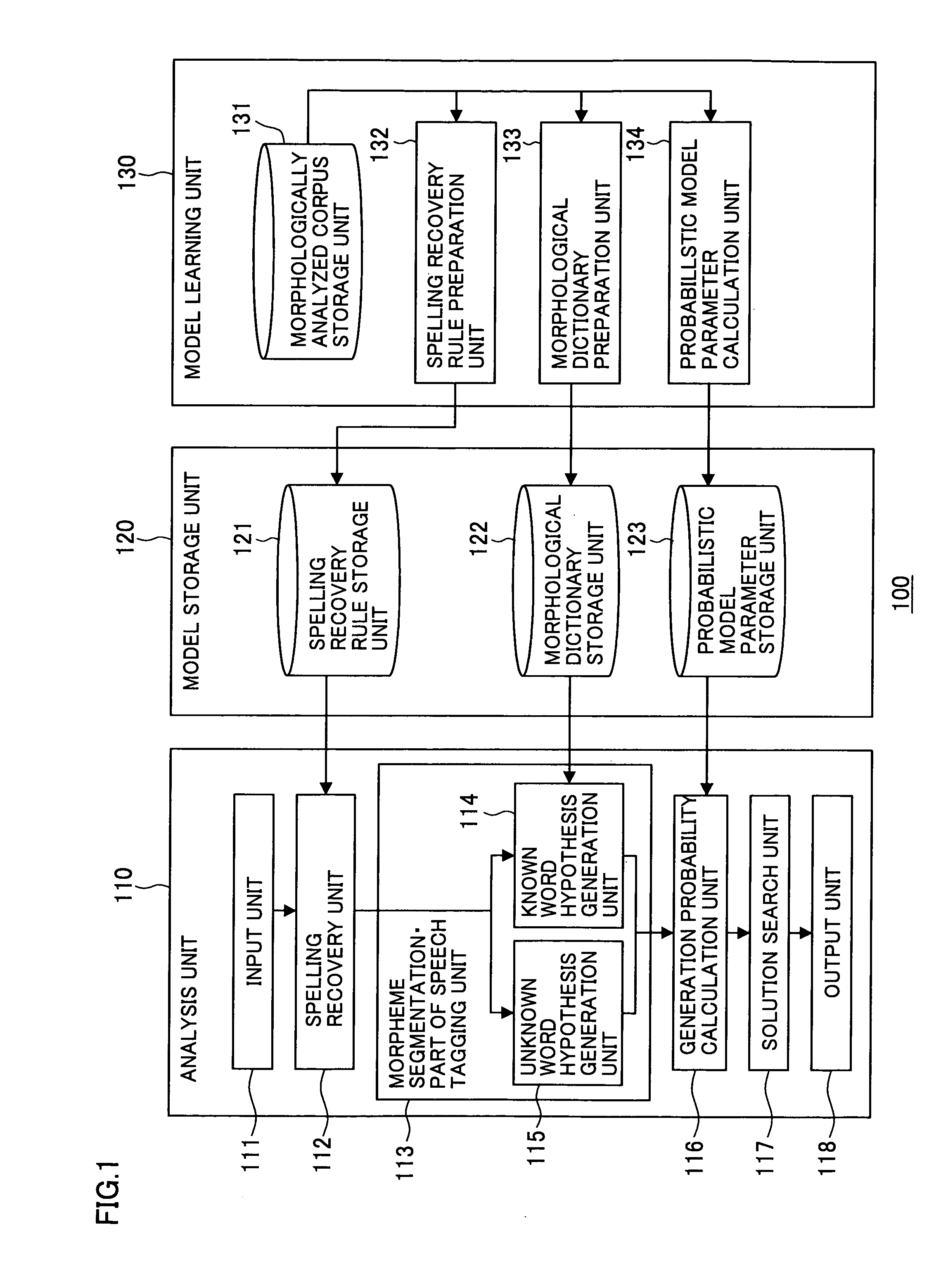

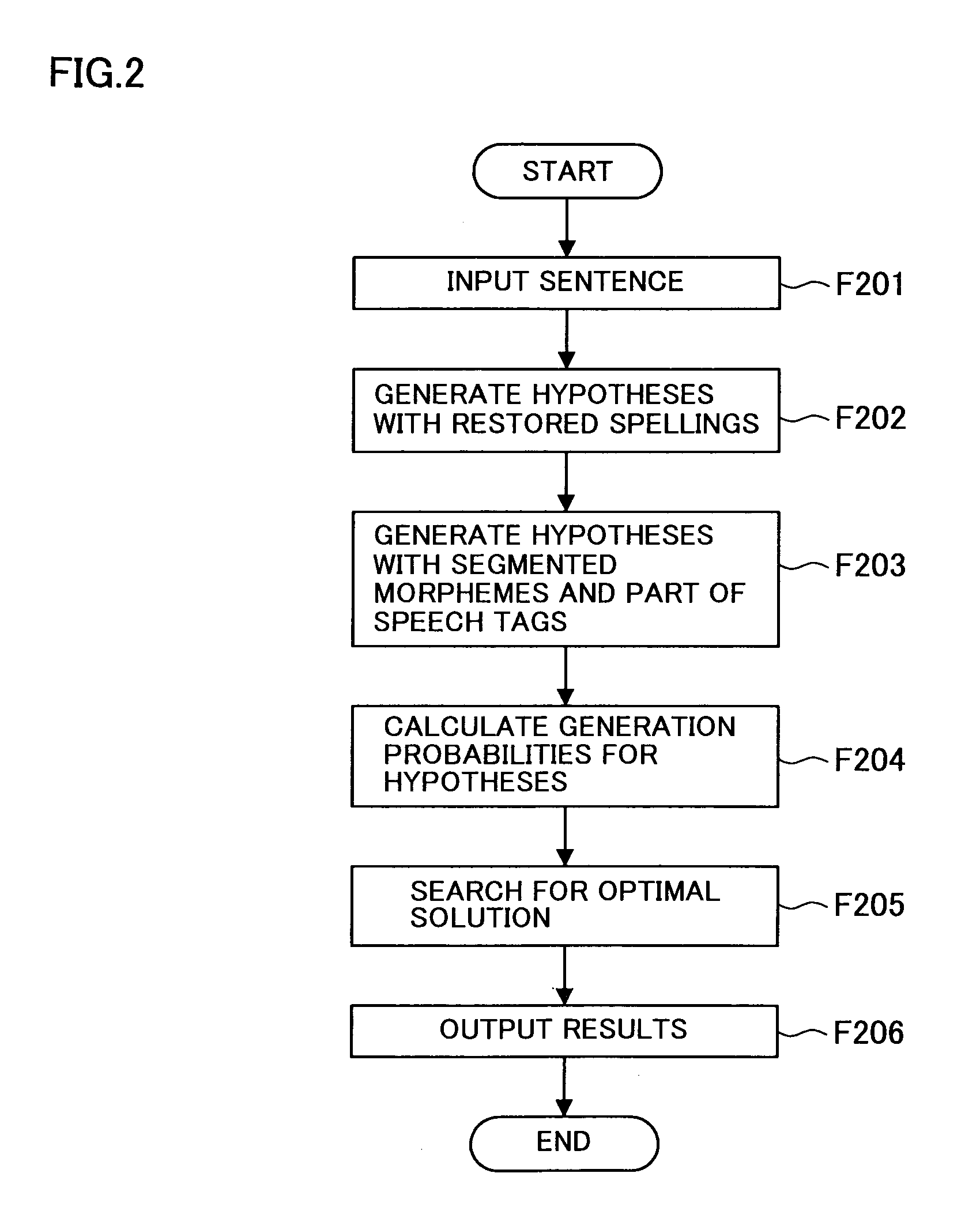

Morphological analysis apparatus, morphological analysis method and morphological analysis program

InactiveUS20070067153A1Exact searchEfficient preparationNatural language translationSpecial data processing applicationsMorphemeMorphological analysis

The morphological analysis apparatus according to the present invention, comprises a spelling recovery unit that recovers the spellings of words, a morphological analysis candidate generation unit that segments a word sequence composed of words, the spellings of which have been recovered, into morphemes, appends POS tags to the morphemes and generates a single morphological analysis candidate or a plurality of morphological analysis candidates, a generation probability calculation unit that calculates a generation probability for each morphological analysis candidate having been generated based upon the product of the probability of the pre-spelling recovery word being converted to the post-spelling recovery word and the probability of a morpheme sequence and a POS sequence being generated from the post-spelling recovery word sequence and a solution search unit that selects through a search the most likely candidate as a solution from all the morphological analysis candidates for which the generation probabilities have been calculated by the generation probability calculation unit.

Owner:OKI ELECTRIC IND CO LTD

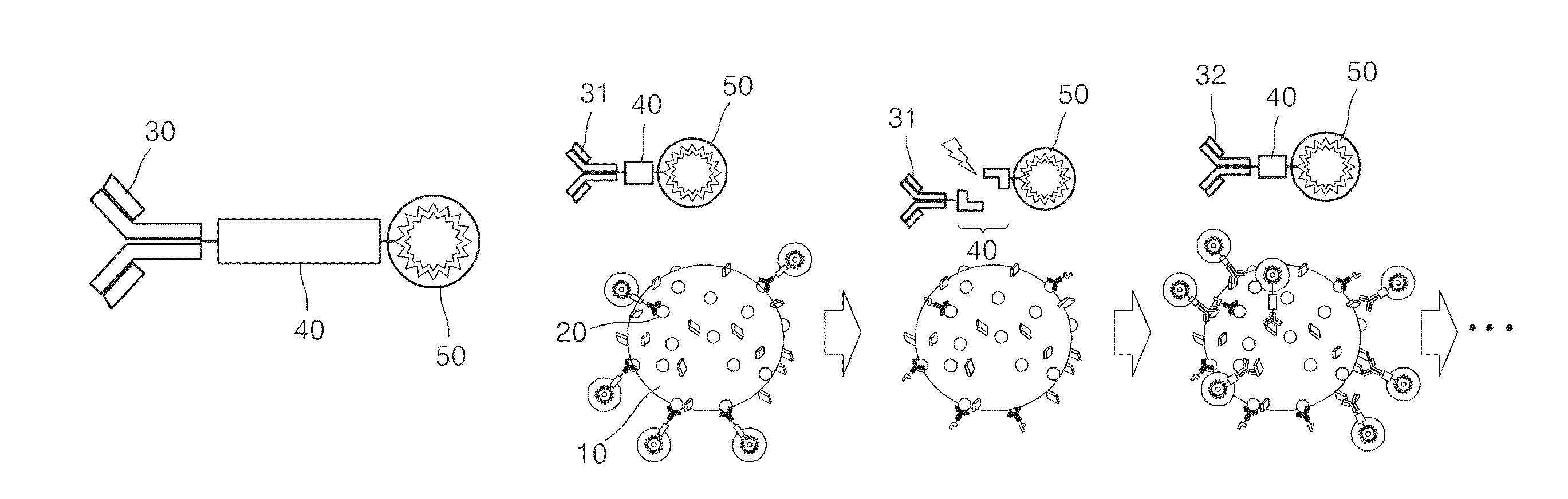

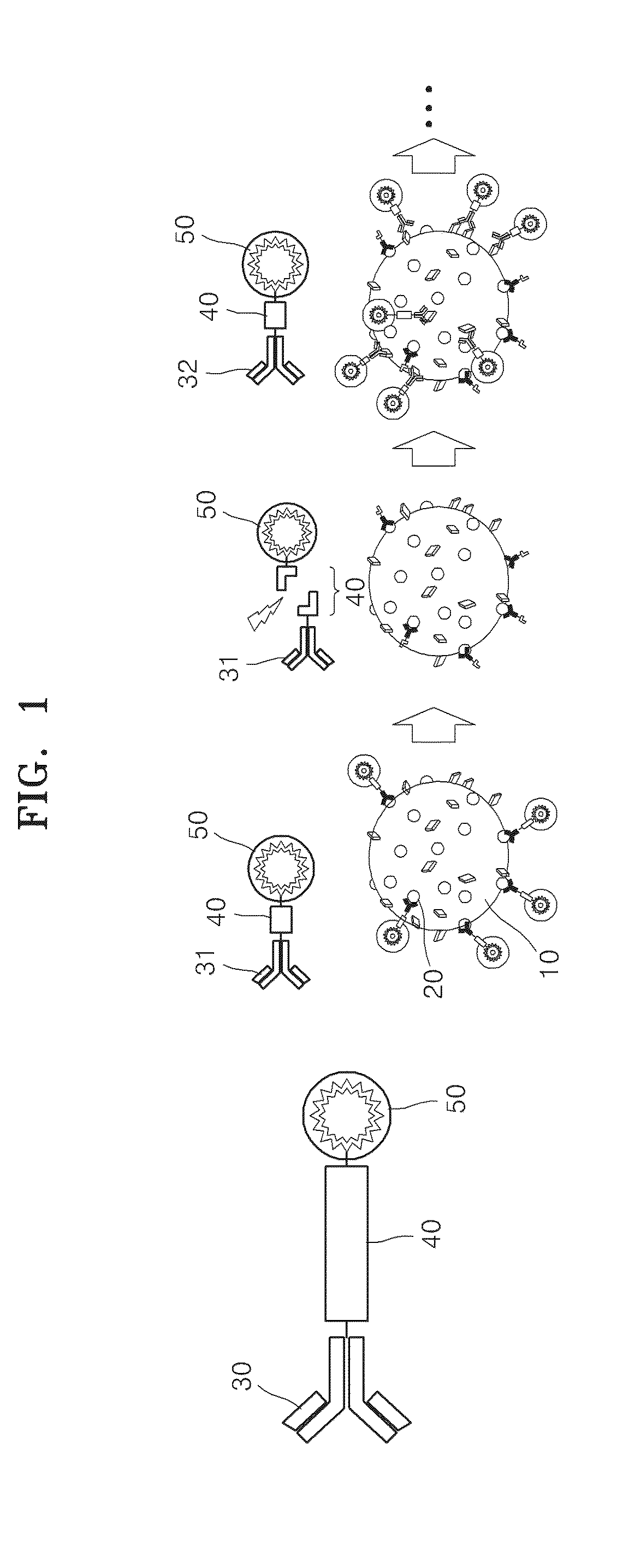

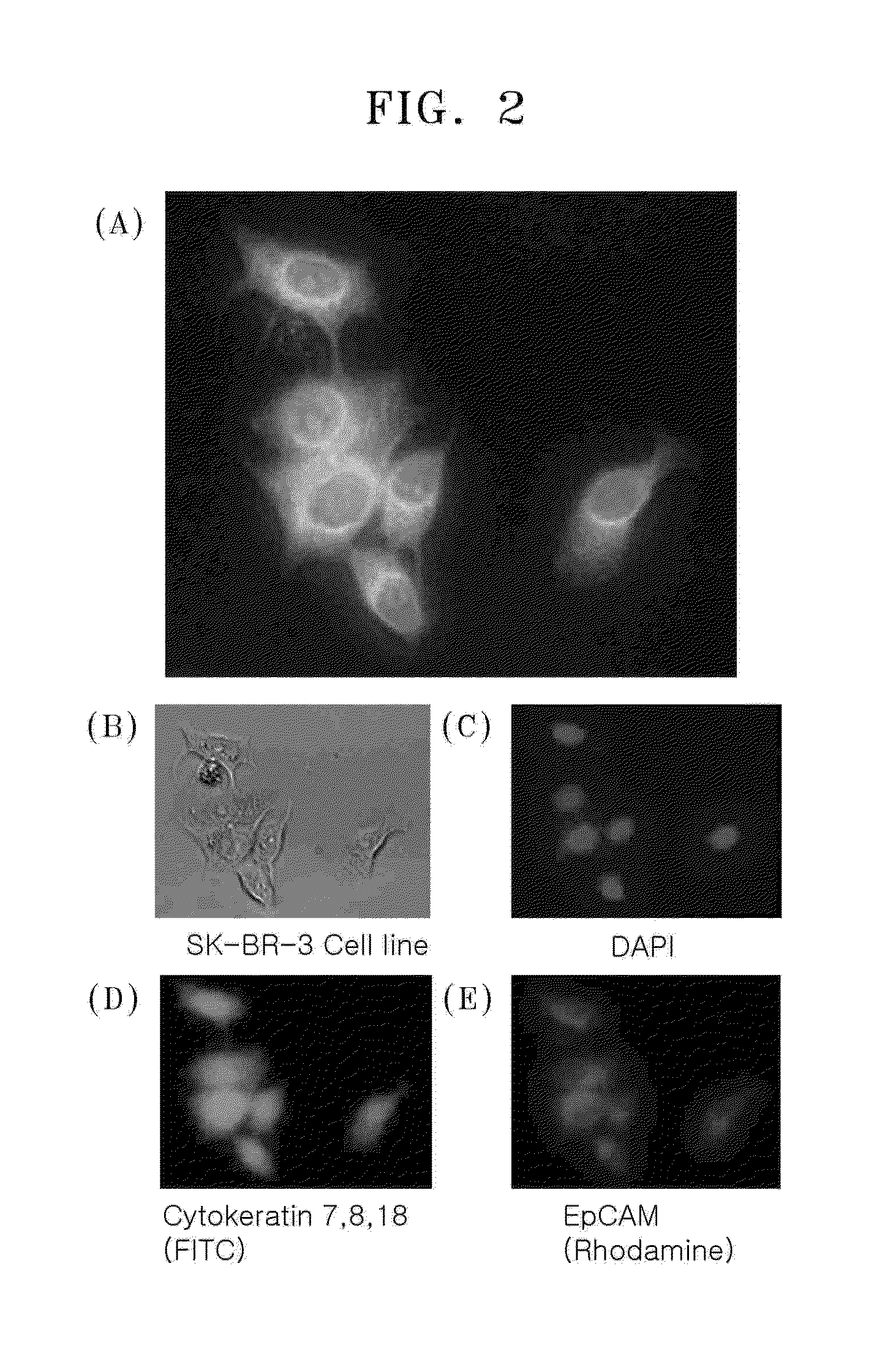

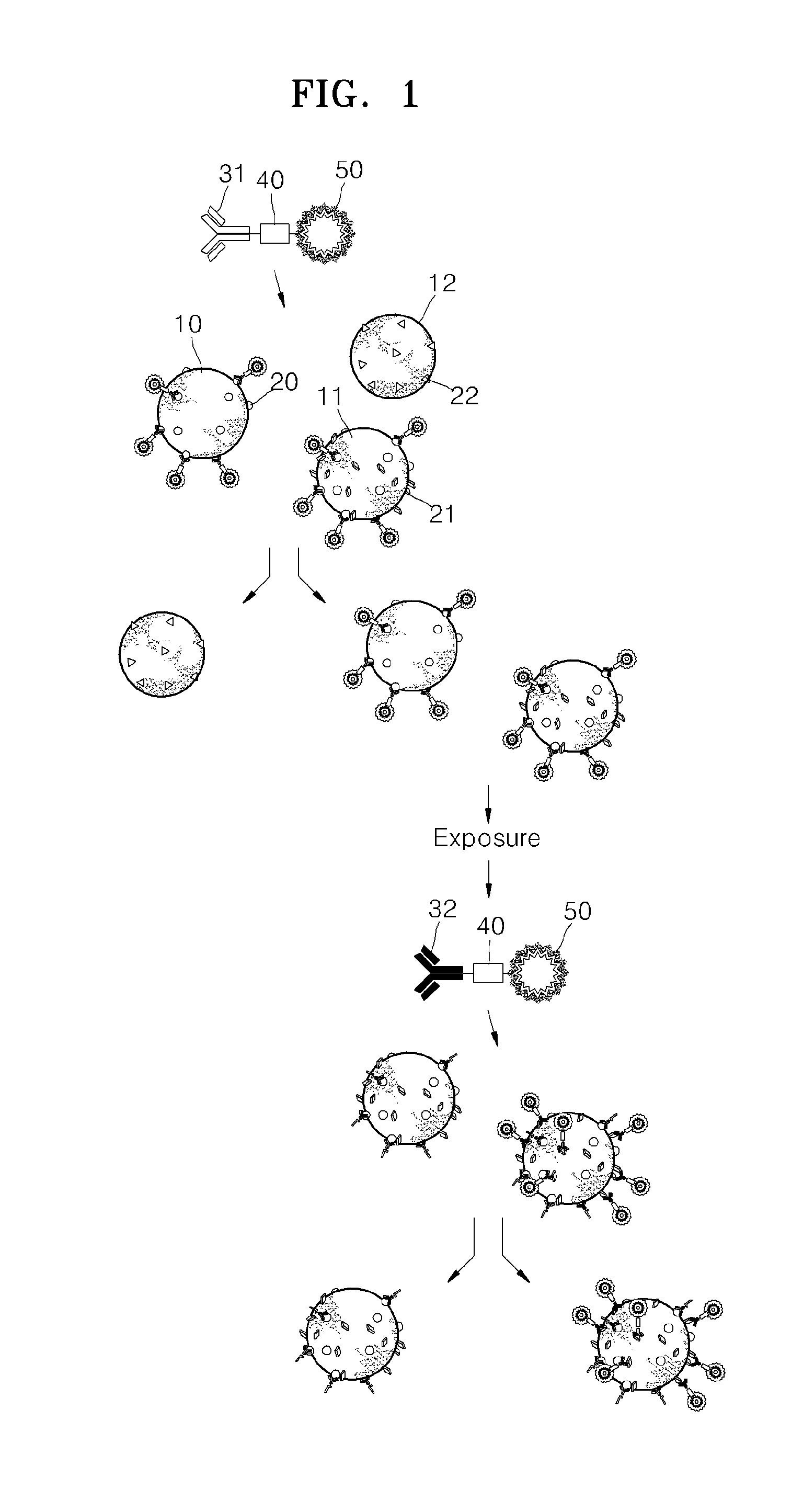

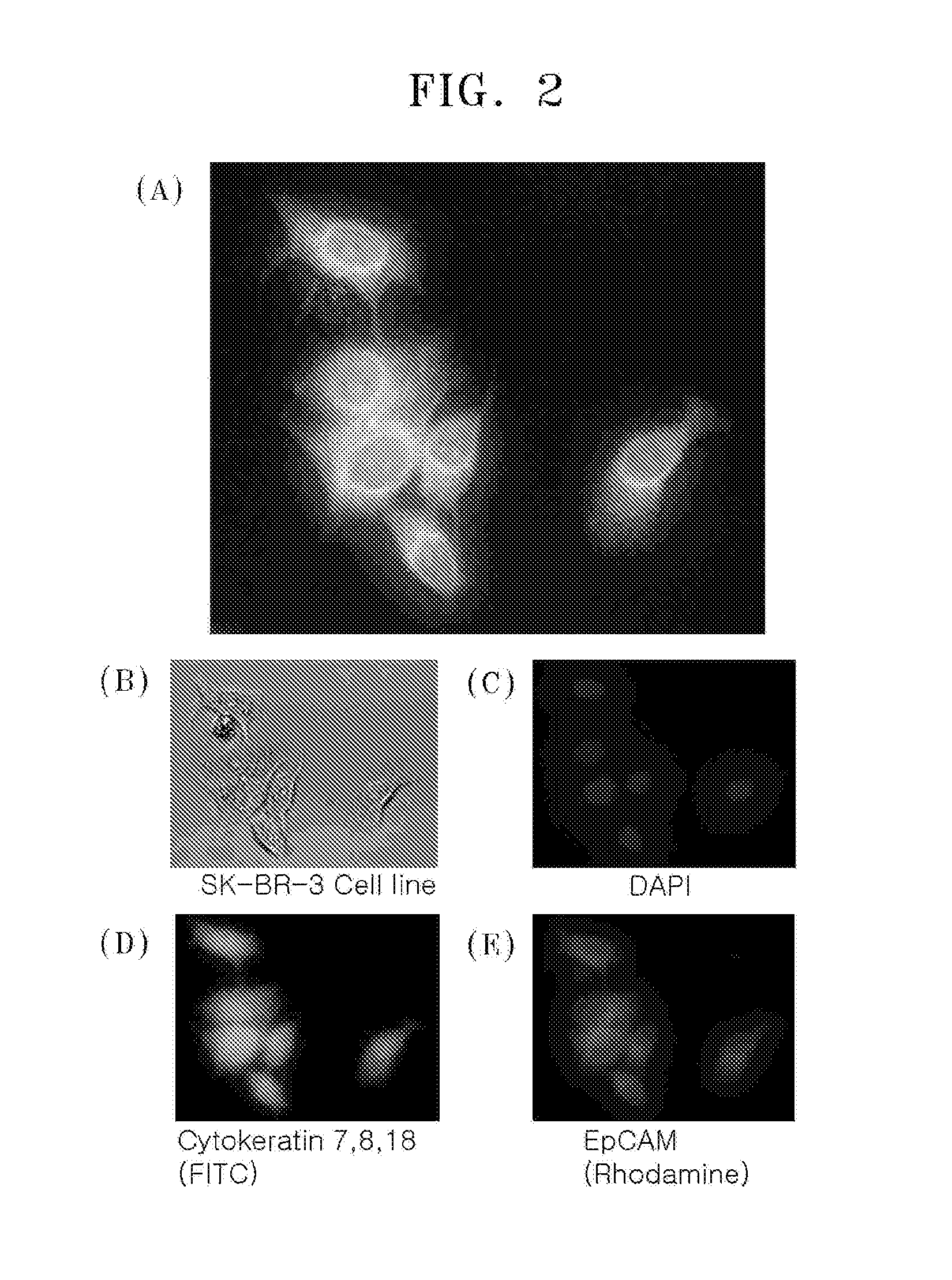

Method of sequential and multiple immunostaining for detection of various antigens in the same specimens

ActiveUS20140120532A1Sugar derivativesMicrobiological testing/measurementAntigenMorphological analysis

Provided herein is a method of sequential and multiple immunostaining for detection of various antigens in the same specimens, which may be used for qualitative or quantitative analysis of proteins expressed, gene analysis, and morphological analysis even in specimens where only a small amount is available.

Owner:SAMSUNG ELECTRONICS CO LTD

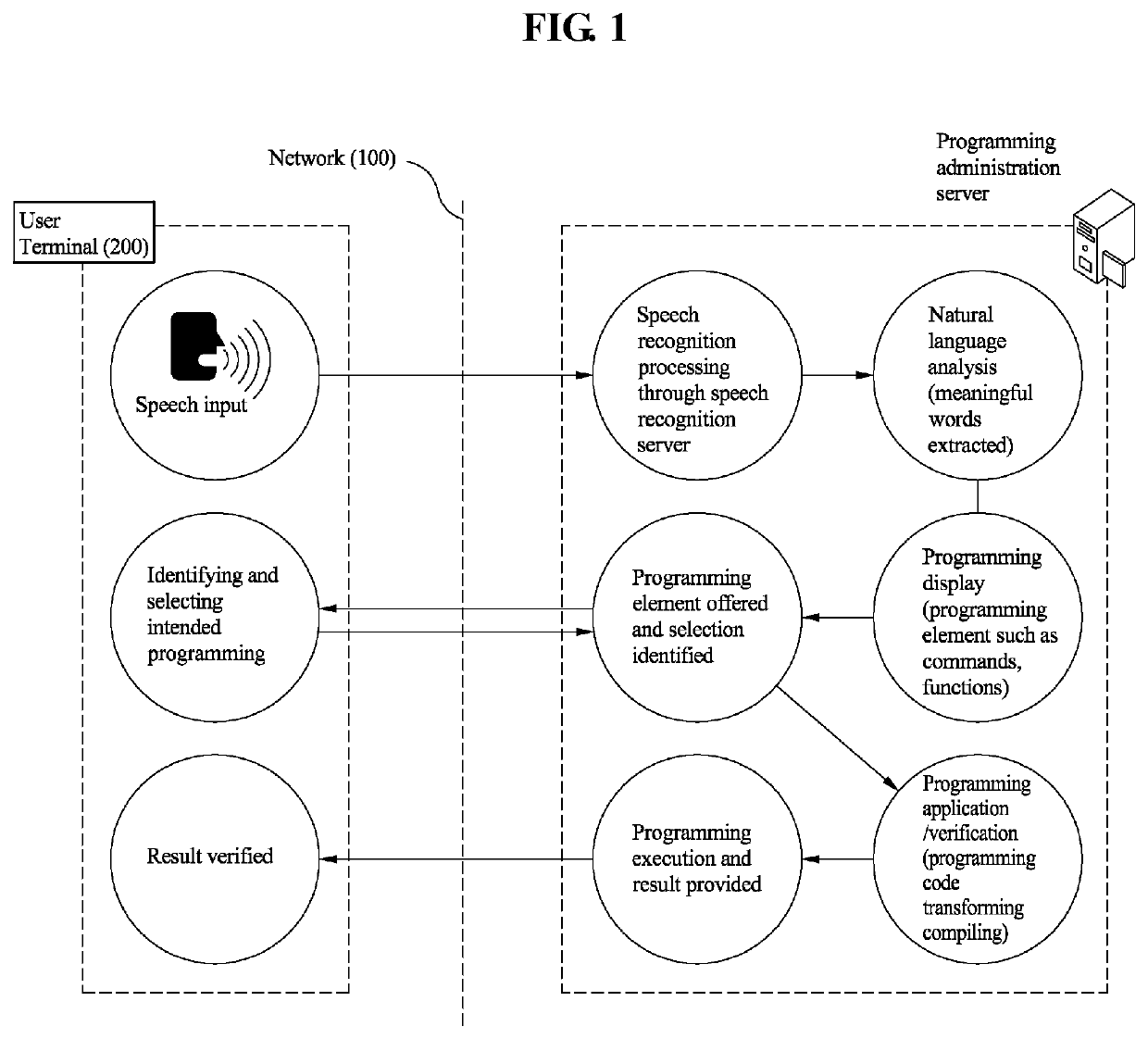

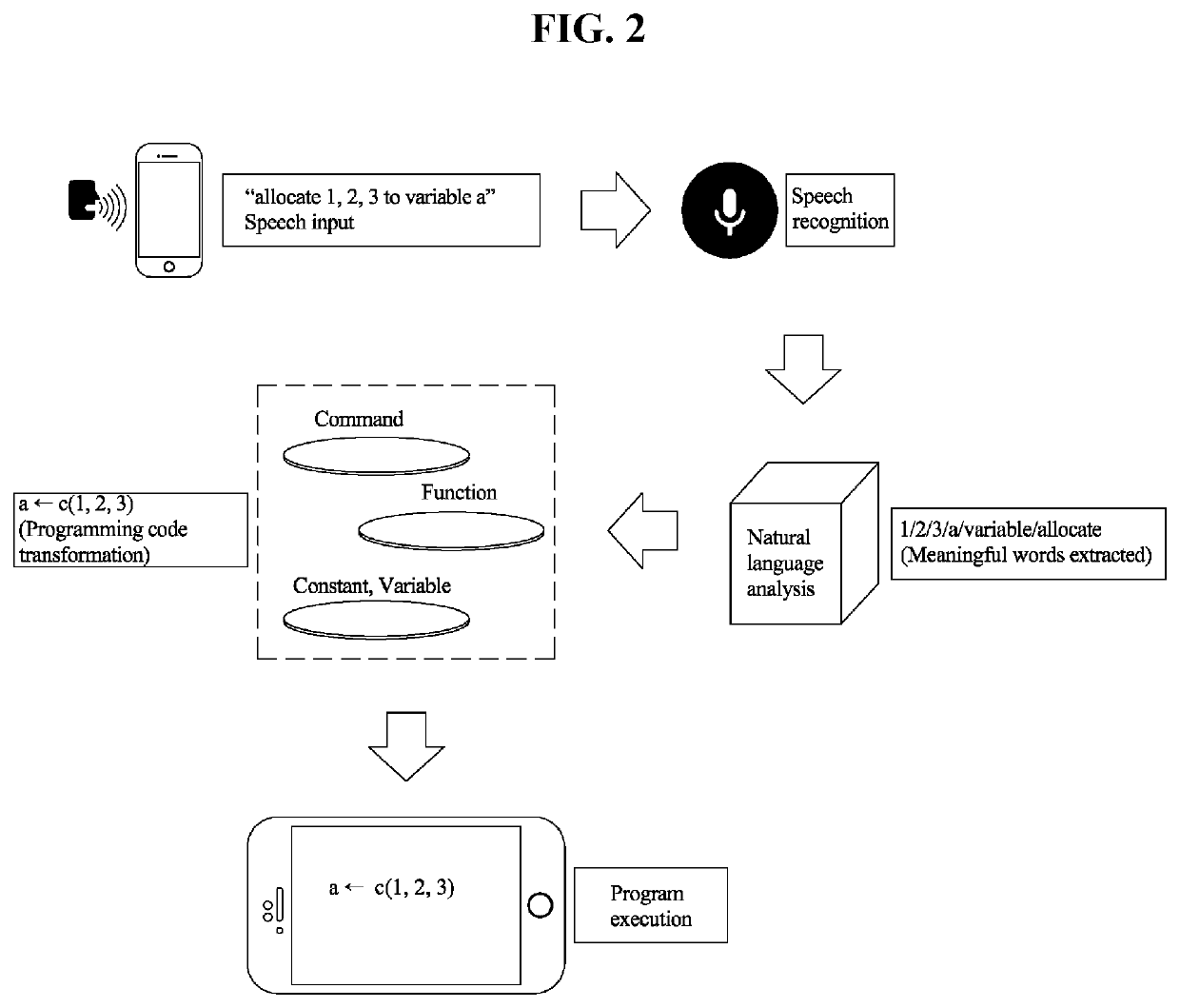

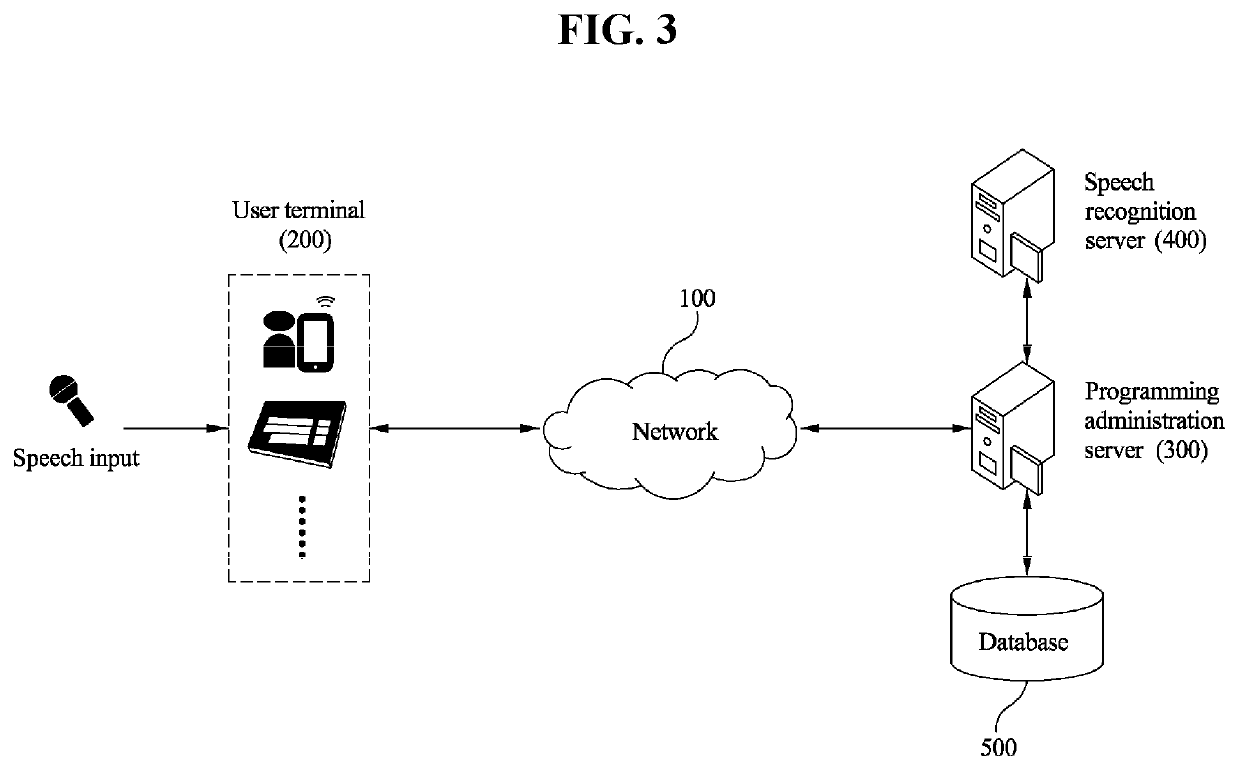

Coding system and coding method using voice recognition

ActiveUS20200026488A1Carry-outSimply carry-outSoftware testing/debuggingIntelligent editorsMorphological analysisHuman–computer interaction

The present invention relates to a system and a method for coding. In the present invention, the user may simply process the work of coding using various programming languages on Cloud without a need for the user to use a separate input device, by recognizing oral commands spoken by the user and carrying out the natural language processing comprising morphological analysis, syntactic analysis, semantic analysis, discourse analysis or combinations thereof, and creating and executing the programming code based thereon.

Owner:DATAEDU INC

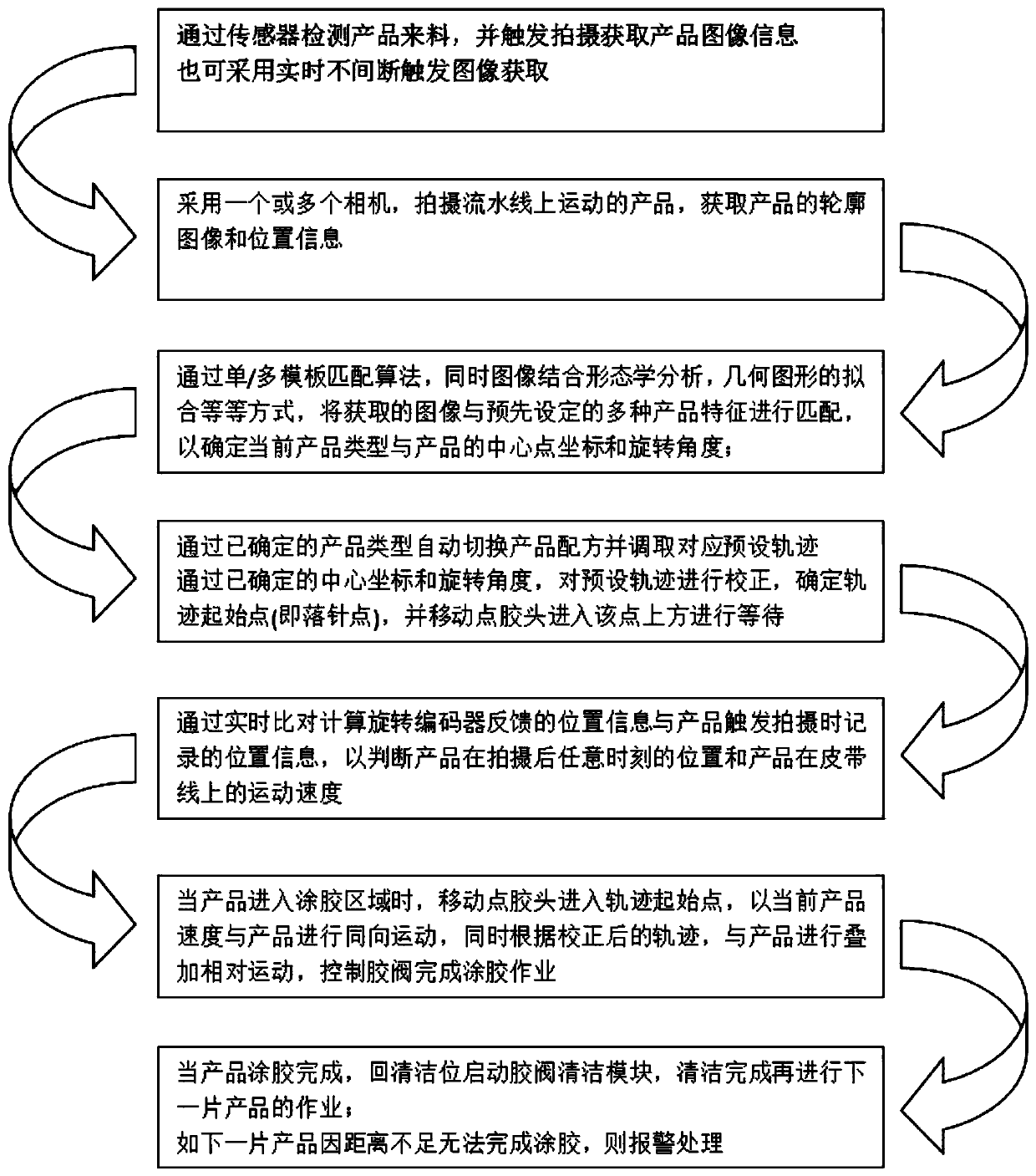

Automatic tracking and dispensing method based on production line

InactiveCN111299078AReduce processImprove time and efficiencyLiquid surface applicatorsSpraying apparatusProduction lineEngineering

The invention discloses an automatic tracking and dispensing method based on a production line. The method comprises the following steps: firstly, a sensor or image acquisition is triggered to capturean image of an incoming material; secondly, the contour and position of the incoming material are shot by at least one image acquisition device; thirdly, a template and an image coordinate system areestablished based on images of the incoming material, a product is matched by a template matching method, an incoming material model is fitted in combination with morphological analysis, the image coordinate system is associated with an equipment motion coordinate system by a five-point calibration method, and coordinates and angles of the incoming material are determined; fourthly, an actual starting point corresponding to a machining track is determined based on the machining track and coordinates and angle of the incoming material; fifthly, a dispensing device is displaced to the actual starting point, and the position of the incoming material at any time after image capture and the running speed of the incoming material are judged by sensing; sixthly, the incoming material enters theactual starting point, and the dispensing device is controlled to move synchronously with the incoming material to perform dispensing; seventhly, the incoming material is glued, and a glue valve is cleaned to wait for the next incoming material.

Owner:飓蜂科技(苏州)有限公司

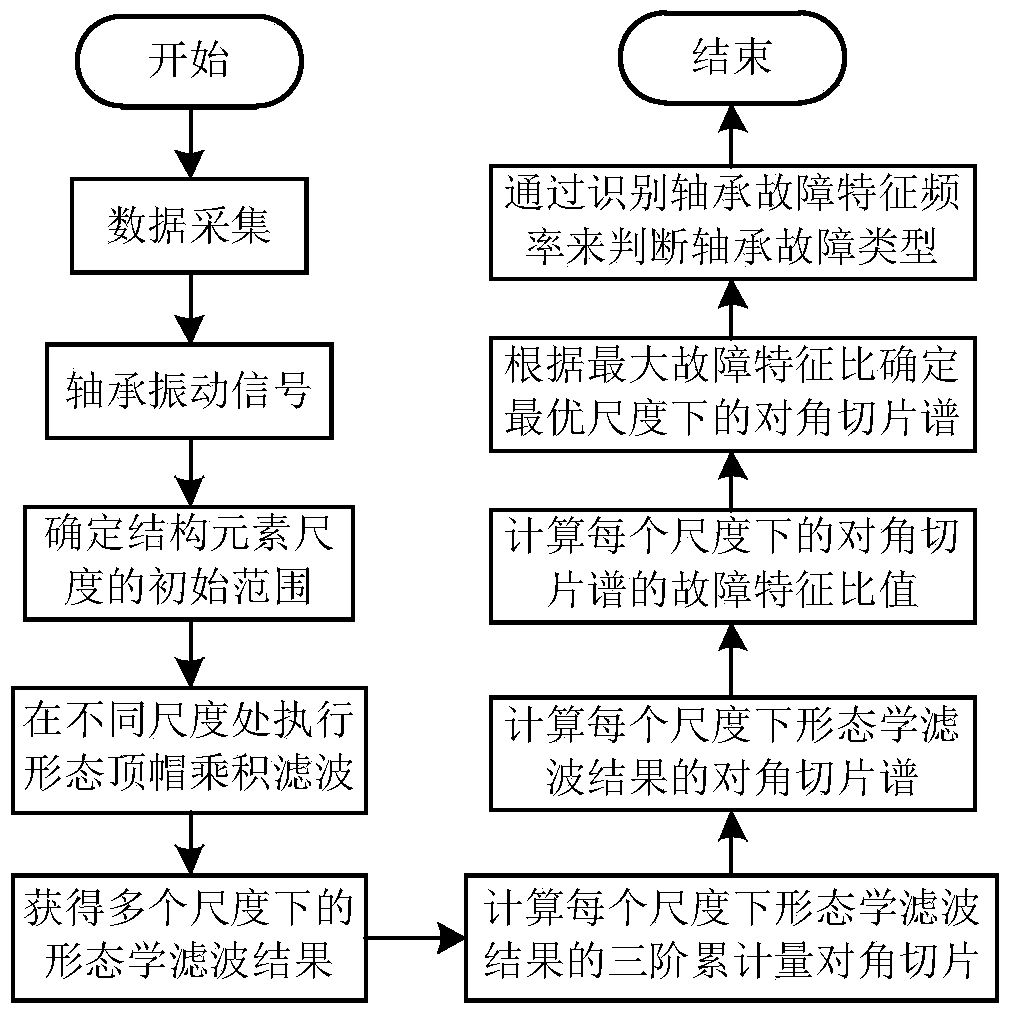

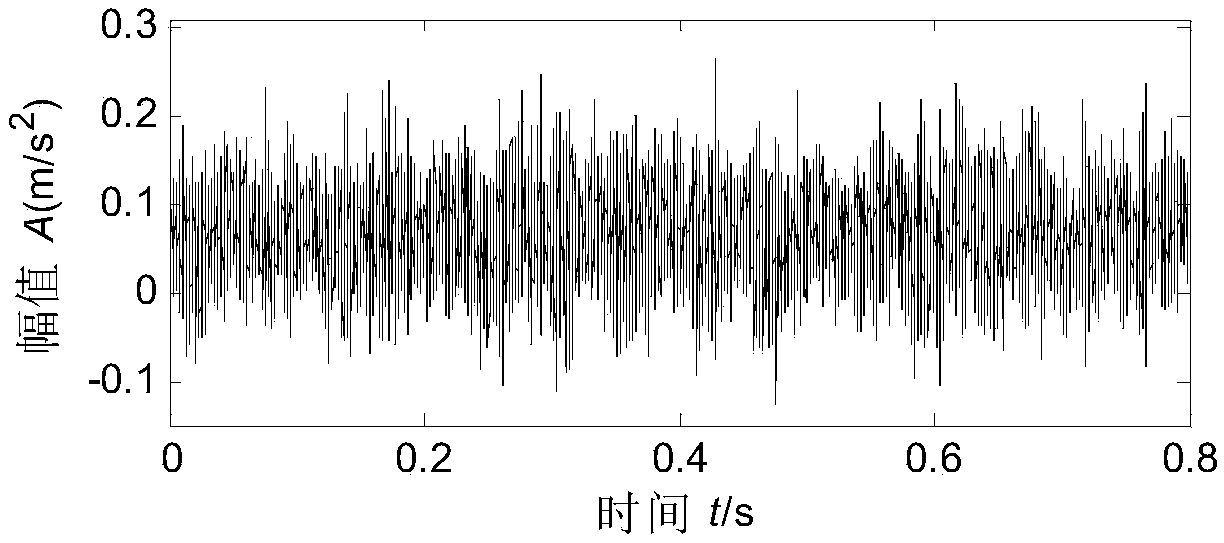

Bearing fault diagnosis method based on morphological top hat product filtering of optimal scale

InactiveCN109297712AEfficient extractionOvercome the disadvantage of not having multi-resolution analysisMachine part testingCharacter and pattern recognitionMorphological filteringDiagnosis methods

The invention discloses a bearing fault diagnosis method based on morphological top hat product filtering of an optimal scale. The diagnosis method comprises: mounting an acceleration sensor near thebearing to acquire bearing vibration signals and determine the initial range of the structural element scale; performing morphological top hat product filtering on the bearing vibration signals at each structural element scale to obtain morphological filtering results of a plurality of scales; calculating the third-order accumulation amount diagonal slice and the diagonal slice spectrum of the morphological filtering result of each scale to obtain third-order accumulative amount diagonal slices and diagonal slice spectra of a plurality of scales; calculating the fault characteristic ratio of the diagonal slice spectrum of each scale and determining a diagonal slice spectrum of the optimal scale according to the maximum fault characteristic ratio criterion; extracting the bearing fault feature information from the diagonal slice spectrum of the optimal scale to realize the accurate discrimination of bearing fault types. The bearing fault diagnosis method based on morphological top hat product filtering of an optimal scale is simple and feasible, overcomes the defects of traditional multi-scale morphology analysis, and can improve the diagnosis precision of bearing faults.

Owner:SOUTHEAST UNIV

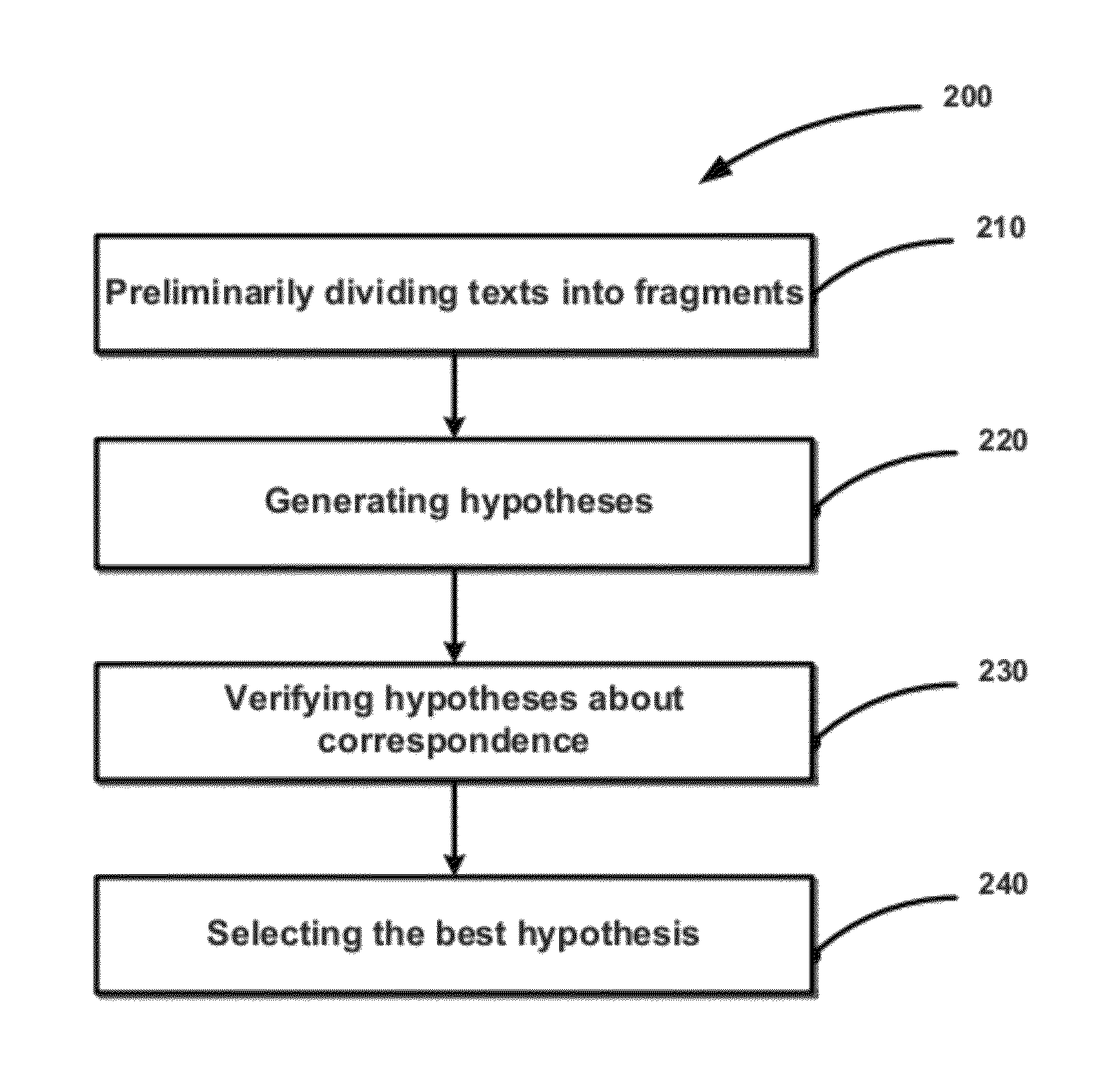

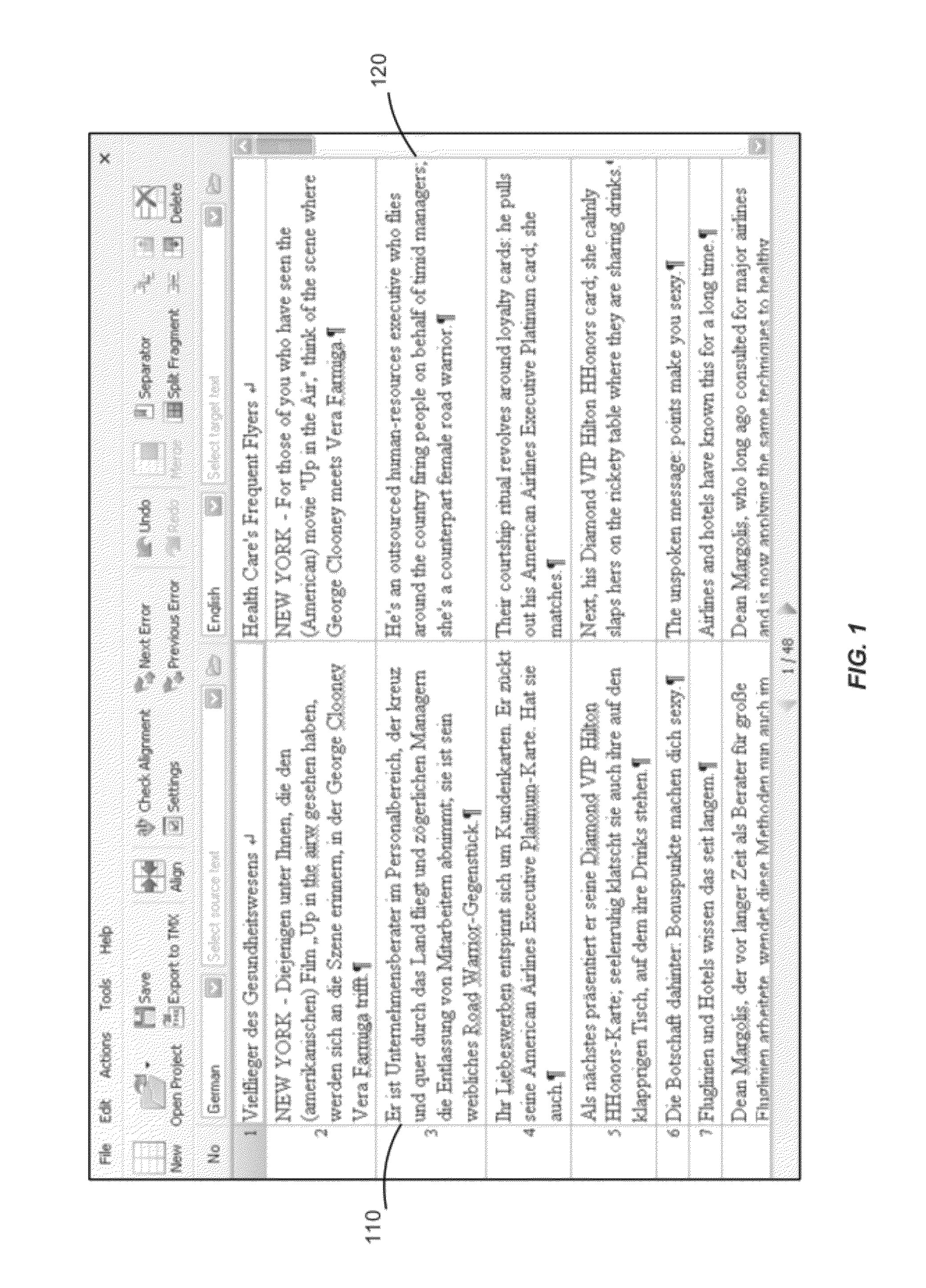

Methods and systems for alignment of parallel text corpora

InactiveUS9047275B2Efficiently employedResolve ambiguityNatural language translationSemantic analysisHypothesisMorphological analysis

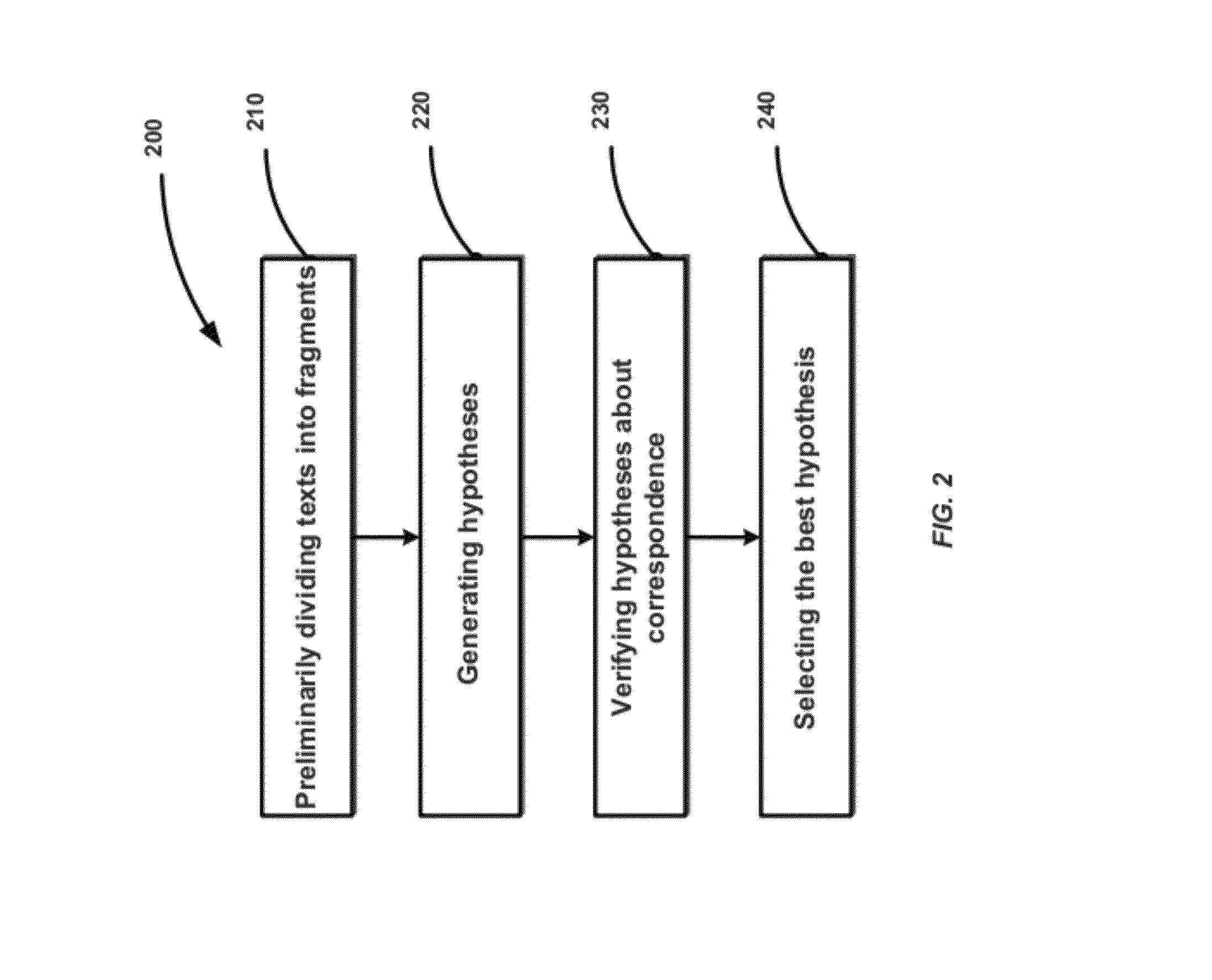

Computer-implemented systems and methods align fragments of a first text with corresponding fragments of a second text, which is a translation of the first text. One preferred embodiment preliminarily divides the first and second texts into fragments; generates a hypothesis about the correspondence between the fragments of the first and second texts; performs a lexico-morphological analysis of the fragments using linguistic descriptions; performs a syntactic analysis of the fragments using linguistic descriptions and generates syntactic structures for the fragments; generates semantic structures for the fragments; and estimates the degree of correspondence between the semantic structures.

Owner:ABBYY PRODUCTION LLC

Electrocardiosignal automatic analysis method based on deep learning

PendingCN111460951AImprove accuracyImprove compatibilityCharacter and pattern recognitionNeural architecturesData setMorphological analysis

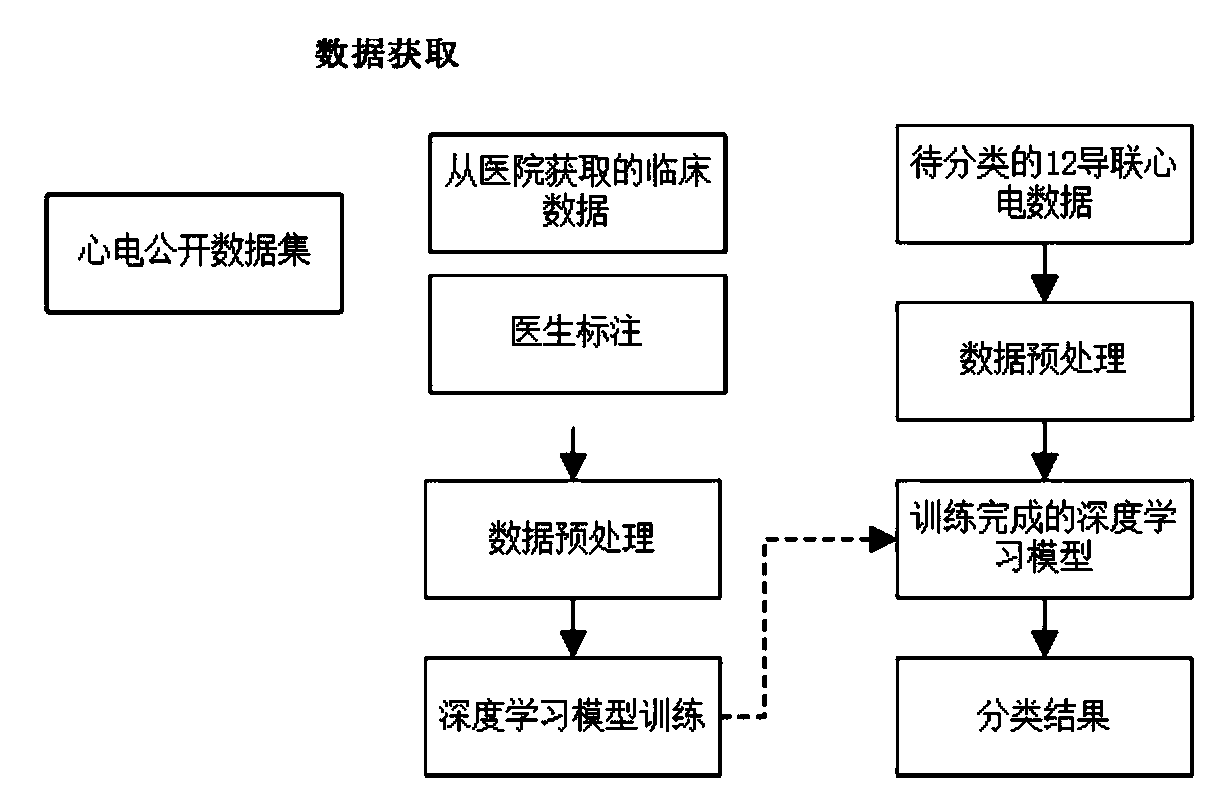

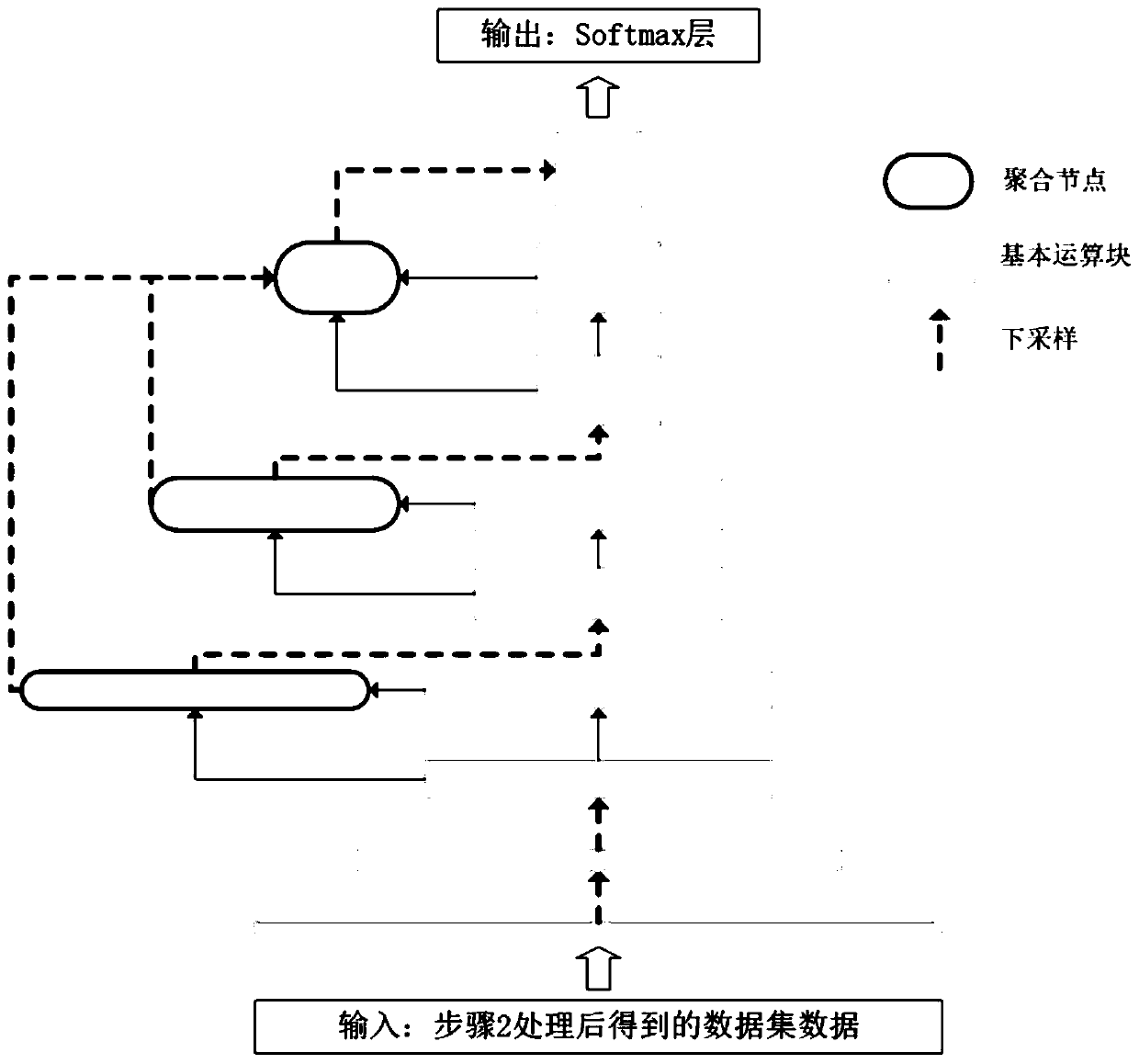

An electrocardiosignal automatic analysis method based on deep learning comprises the steps: downloading labeled electrocardiosignal data from a public data set, processing the electrocardiosignal data to obtain a data set, and dividing the data set into a training set, a verification set and a test set; constructing a deep learning model according to the DLA structure, and performing training toobtain a trained deep learning model; adjusting hyper-parameters, and selecting a model with the best classification effect on the verification set and the test set; and processing 12-lead electrocardiogram data to be classified to obtain a data set, and inputting the data of the data set into the model with the best classification effect to obtain the classification to which the electrocardiogramsignals of the electrocardiogram data belong. According to the method, low-level waveform structure features are extracted through one-dimensional convolution, shallow and deep layers are aggregated,the space and semantic features of the electrocardiosignal are obtained, morphological analysis is completed, correlation between morphologies is obtained, and the method can be applied to classification of electrocardiograms or one-dimensional time series electrocardiograms.

Owner:XI AN JIAOTONG UNIV

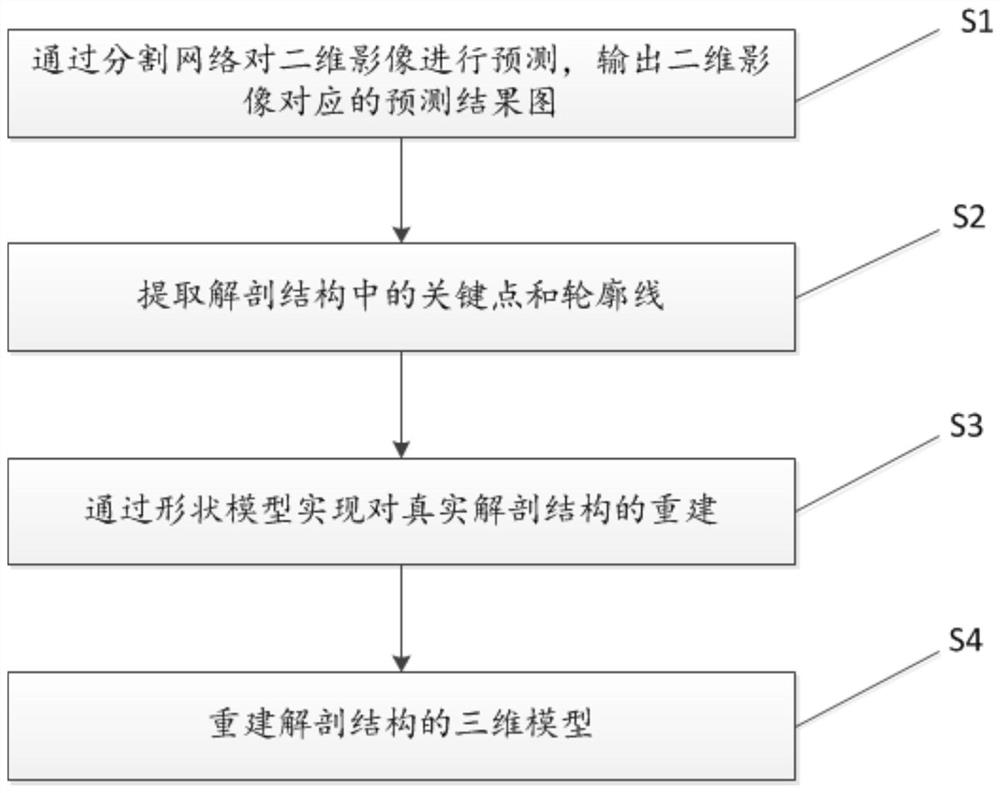

Automatic identification and model reconstruction method for anatomical features in medical image

PendingCN112037200ARealize automatic identificationShorten the timeImage enhancementImage analysisAnatomical structuresModel reconstruction

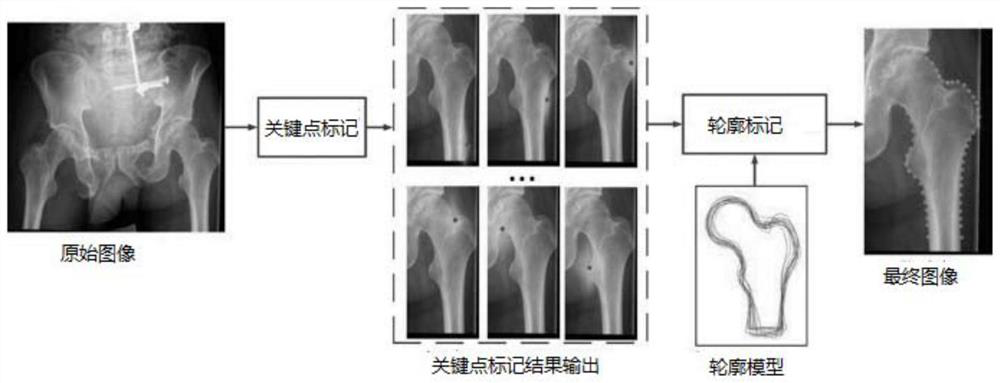

The invention relates to the technical field of medical image intelligent analysis, and provides a medical image anatomical feature automatic identification and model reconstruction method comprisingthe following steps: S1, inputting a two-dimensional image into a segmentation network for prediction, and outputting a prediction result graph corresponding to the two-dimensional image; S2, performing morphological analysis on each anatomical structure segmented from the prediction result graph, and extracting positions and contour lines of key points; S3, reading the contour line and comparingthe contour line with the shape model: when the projection contour simulated by the shape model is close to the contour line, the current shape model is the reconstruction of the real anatomical structure; S4, executing the steps S1-S3 by using at least two two-dimensional images at different visual angles, so as to reconstruct the three-dimensional model of the anatomical structure. According tothe technical scheme, the anatomical feature points and the contour lines of the two-dimensional images can be automatically recognized, and the optimal three-dimensional model can be reconstructed through at least two two-dimensional images at different visual angles.

Owner:SHANGHAI TAOIMAGE MEDICAL TECH CO LTD

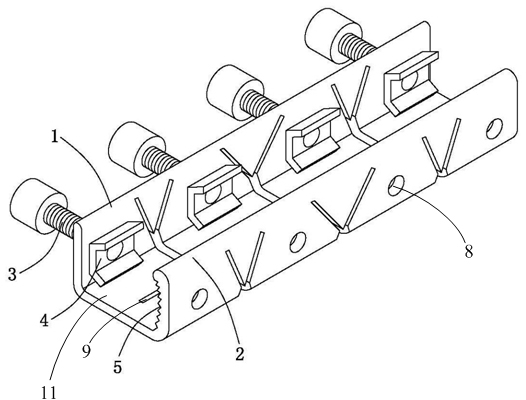

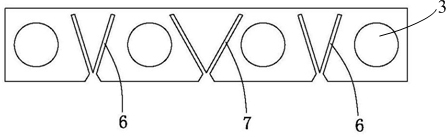

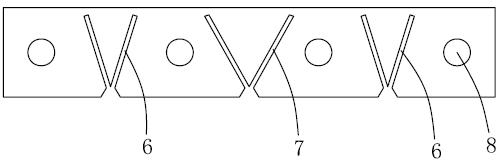

Fibula shaping board for use in mandibular reconstruction

The invention discloses a fibula shaping board for use in mandibular reconstruction, which comprises an arc-shaped groove and a regulating screw, wherein the regulating screw passes through the front side face of the arc-shaped groove; the end, which extends out of the front side face of the arc-shaped groove, of the regulating screw is provided with a bracket; the arc-shaped groove has three osteotomy slots, and the sizes and positions of the three osteotomy slots are prescribed in the description; the middle slot is a chin angle osteotomy slot, and the size of a chin angle is 55 to 65 degrees; the slots at the two ends are mandible angle osteotomy slots, and the size of an mandible angle is 35 to 45 degrees and the distance between a front side face and a rear side face is 2.5 to 3.5 centimeters. Through morphological analysis on the mandible of common adults, an intrinsic common law is found, and the shaping parameters of the horizontal part of the mandible are determined; on the basis of the parameters, common fibula shaping plate is designed; and thus, the four-section shaping of a transplanted fibula in the reconstruction of the horizontal part of the mandible can be realized.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

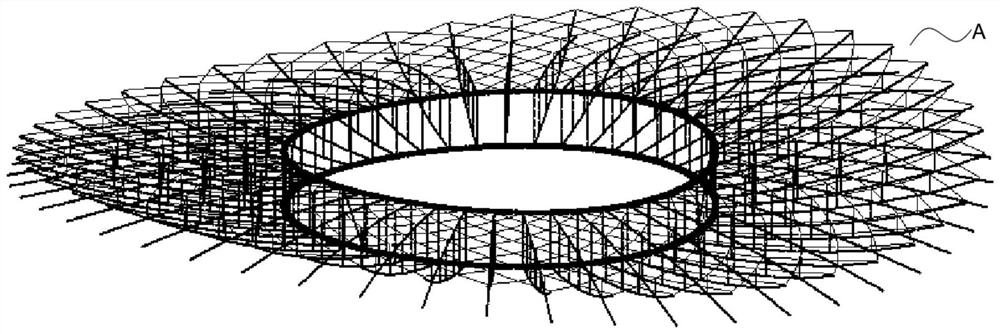

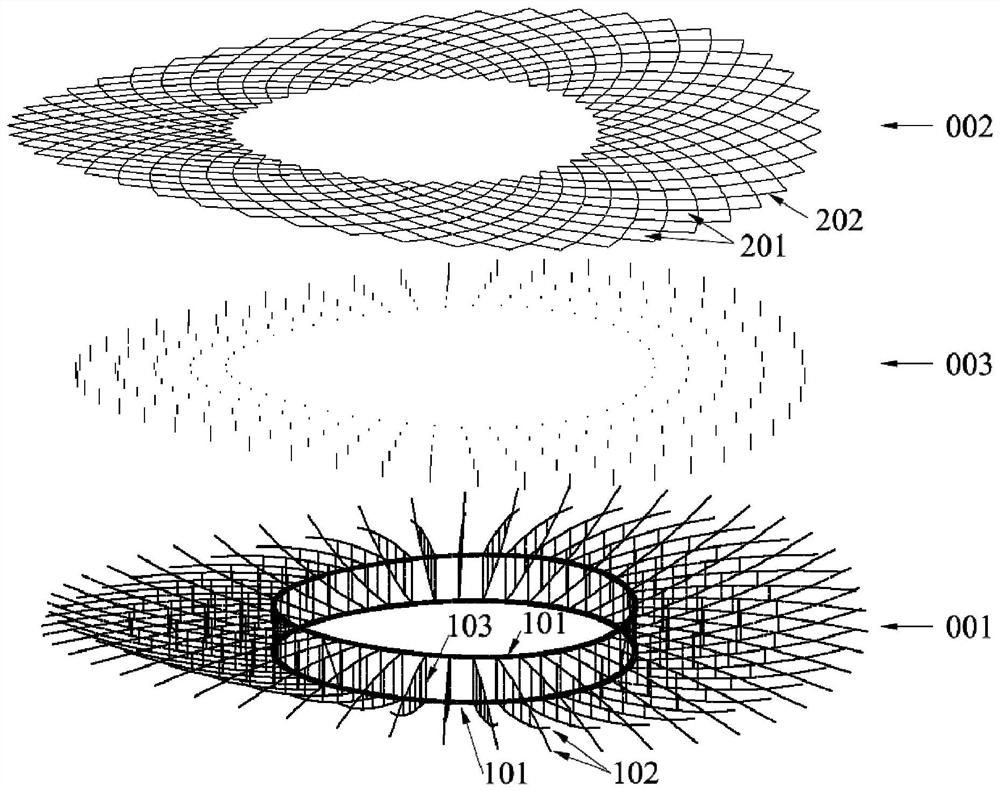

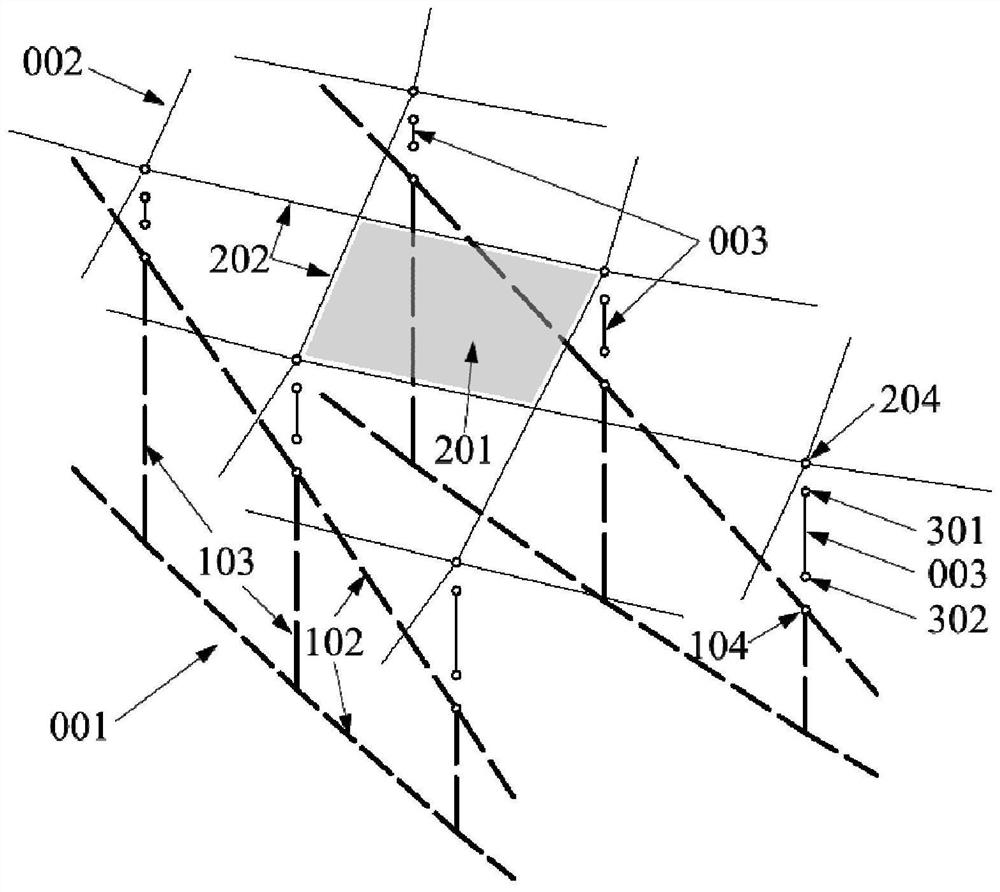

Superimposed cable structure system and morphological analysis method thereof

PendingCN112252477AEfficient bearingGood mechanical propertiesBuilding roofsDesign optimisation/simulationMorphological analysisBuilding modeling

The invention relates to the technical field of structural design and analysis of constructional engineering, in particular to a superimposed cable structure system and a morphological analysis methodthereof. According to the system, on the premise that the characteristics of lightness and permeability of the cable structure are reserved, a free and complex geometric curved surface and grids canbe formed, so that the problem that an existing cable structure system greatly restricts building modeling is solved, and the application range of the cable structure is greatly widened; and the corresponding morphological analysis method is used for solving the initial state of the superimposed cable structure system, the prestress distribution meeting the building modeling requirement, namely the target configuration, can be obtained, and the core problem of engineering application of the system is solved.

Owner:BEIJING INST OF ARCHITECTURAL DESIGN

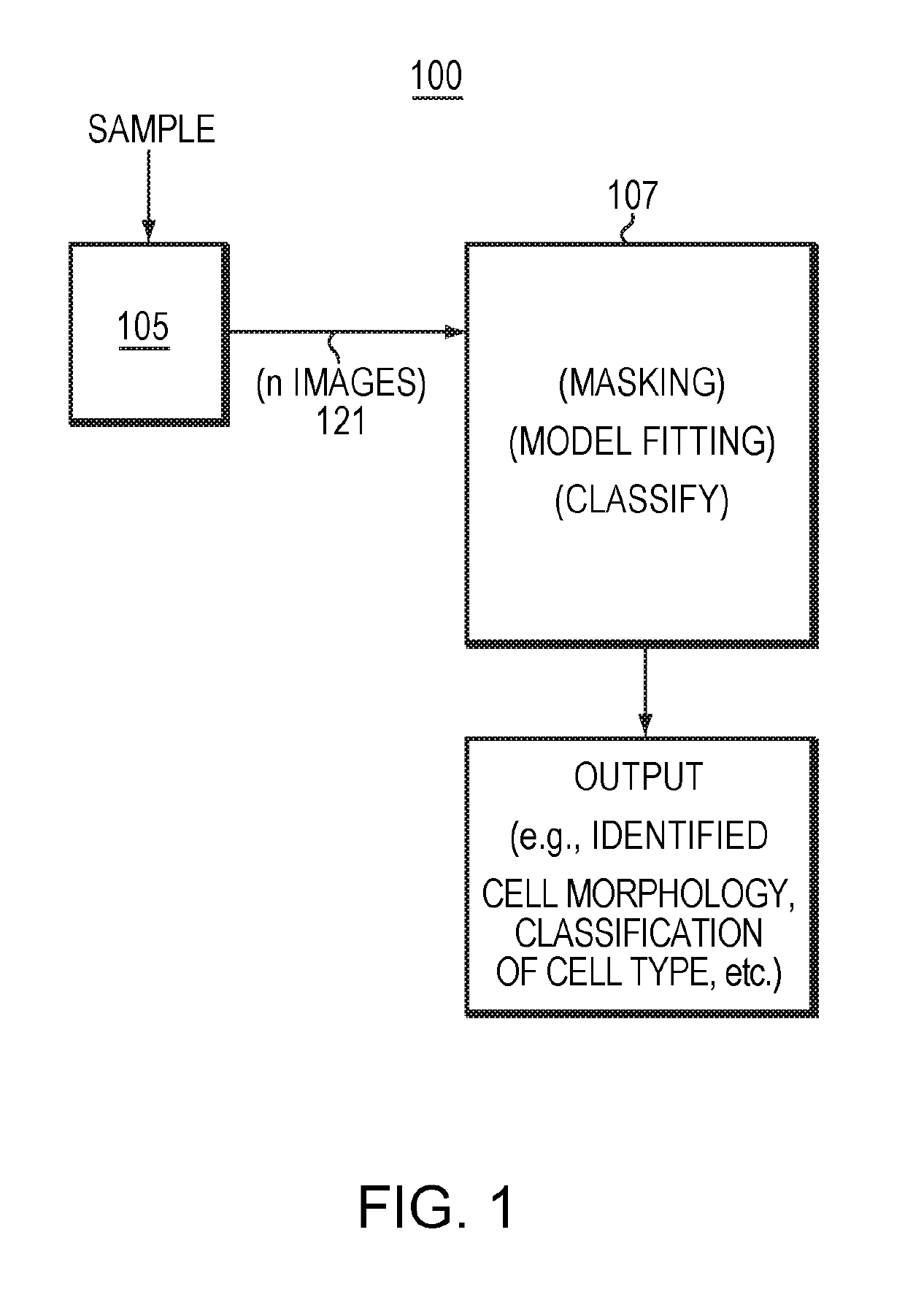

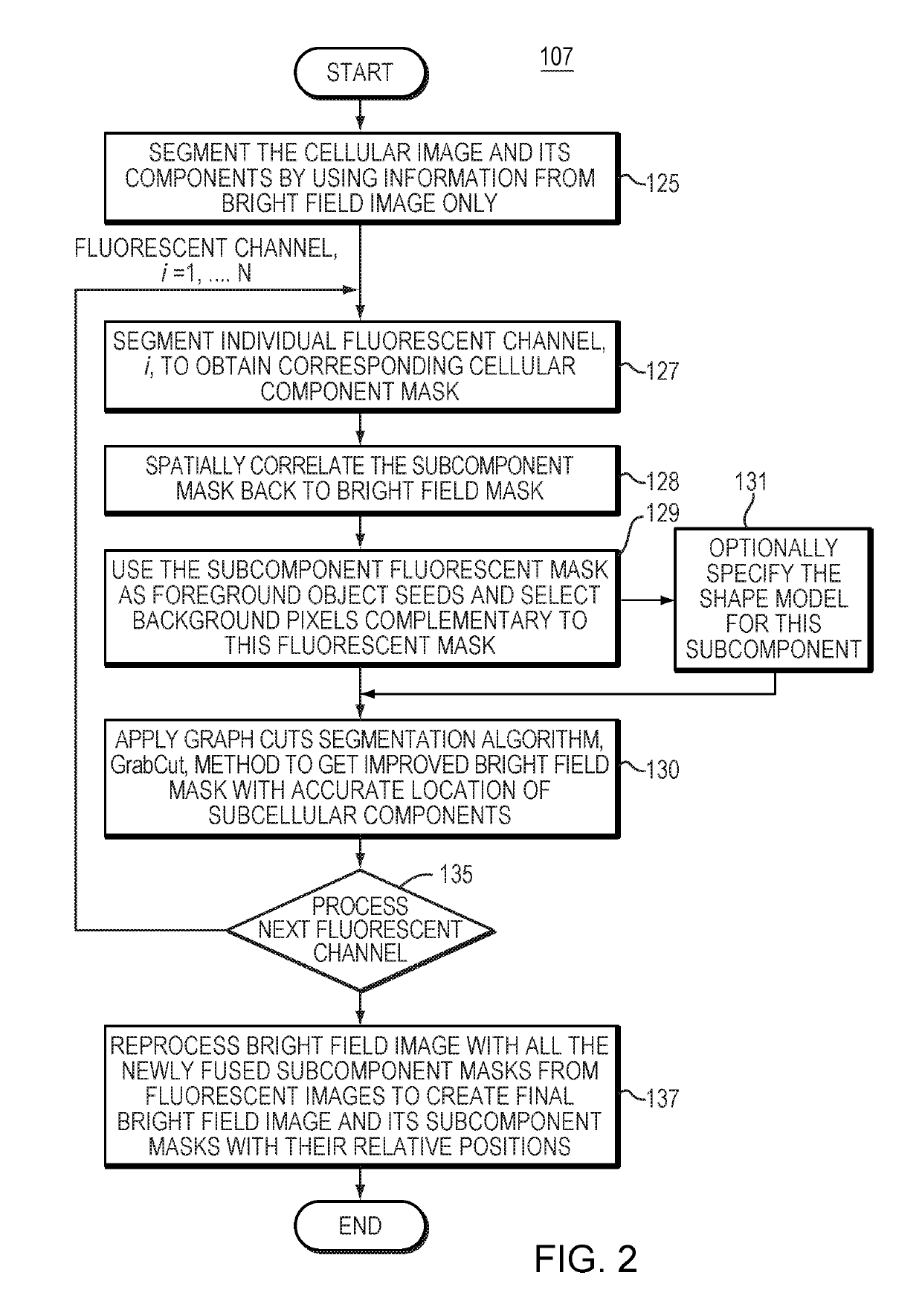

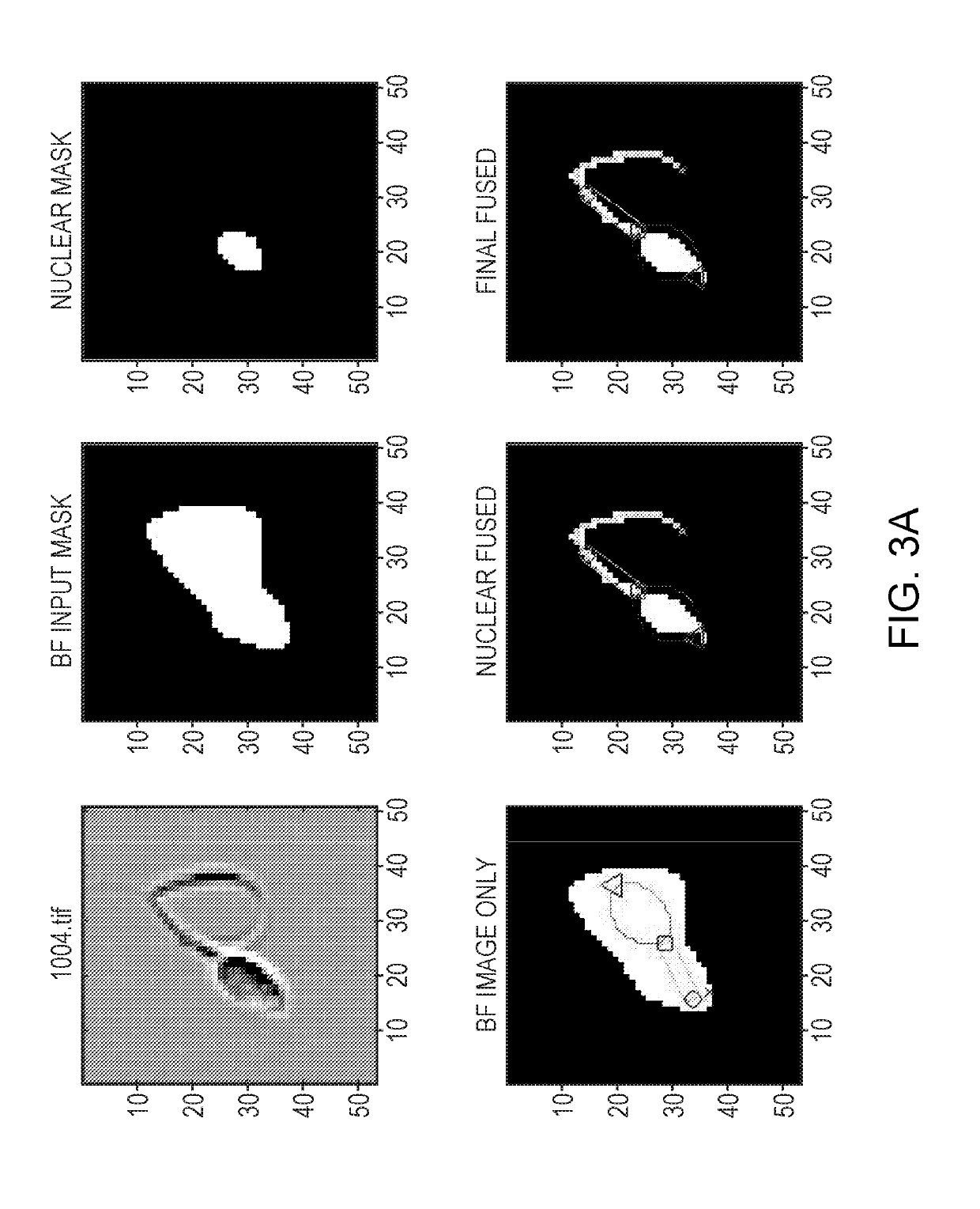

A Method To Combine Brightfield And Fluorescent Channels For Cell Image Segmentation And Morphological Analysis Using Images Obtained From Imaging Flow Cytometer (IFC)

ActiveUS20190163956A1High resolutionIncrease speedImage enhancementImage analysisPattern recognitionFluorescence

A classifier engine provides cell morphology identification and cell classification in computer-automated systems, methods and diagnostic tools. The classifier engine performs multispectral segmentation of thousands of cellular images acquired by a multispectral imaging flow cytometer. As a function of imaging mode, different ones of the images provide different segmentation masks for cells and subcellular parts. Using the segmentation masks, the classifier engine iteratively optimizes model fitting of different cellular parts. The resulting improved image data has increased accuracy of location of cell parts in an image and enables detection of complex cell morphologies in the image. The classifier engine provides automated ranking and selection of most discriminative shape based features for classifying cell types.

Owner:LUMINEX

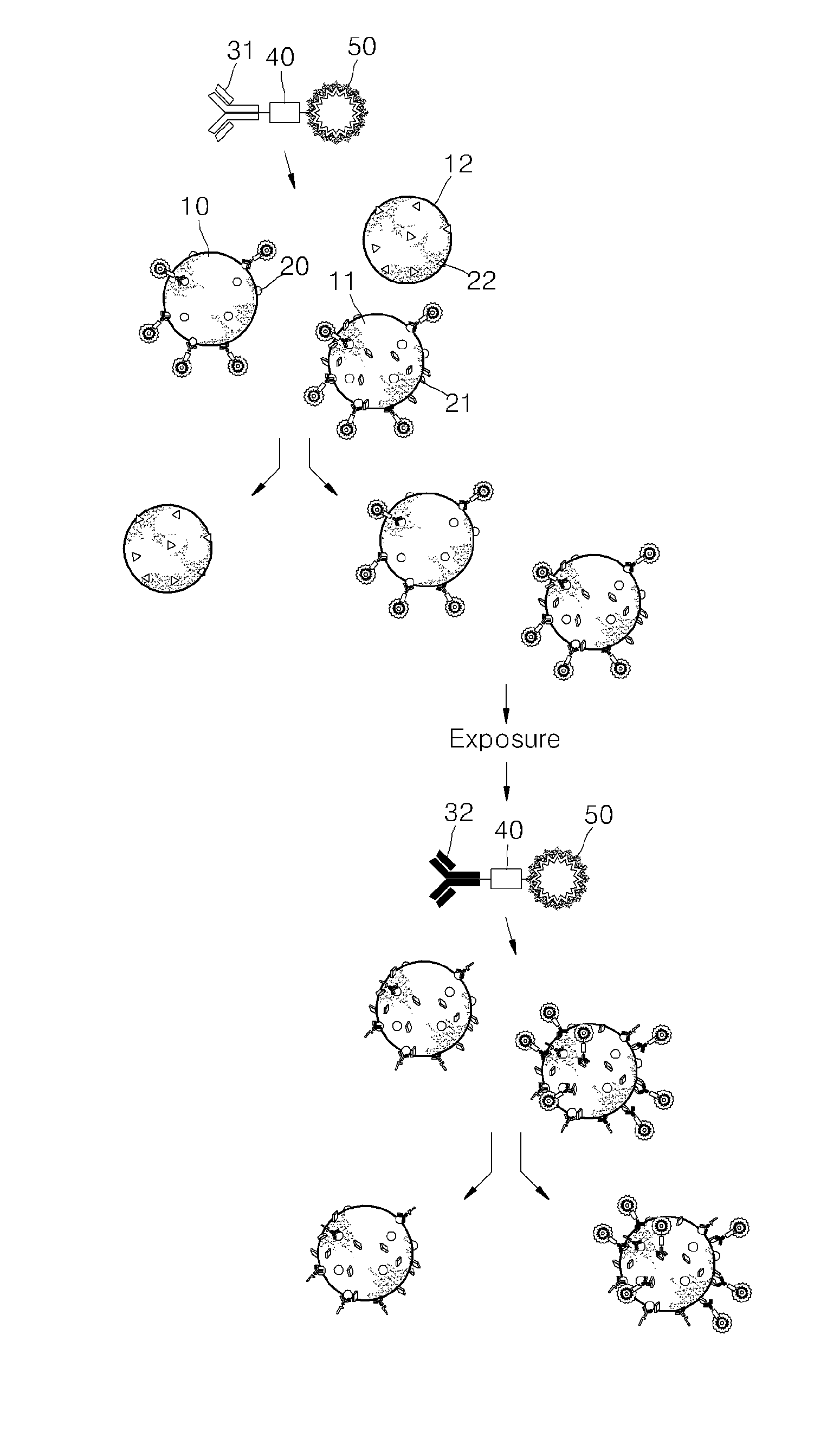

Method of isolating or counting target cells by using photocleavable linker coupled with fluorescent dye

InactiveUS20140134645A1Microbiological testing/measurementBiological testingMorphological analysisGene

A method of isolating or counting target cells using photocleavable linkers coupled with fluorescent dyes, for qualitative or quantitative analysis of protein, gene analysis, and / or morphological analysis after removing the dye.

Owner:SAMSUNG ELECTRONICS CO LTD

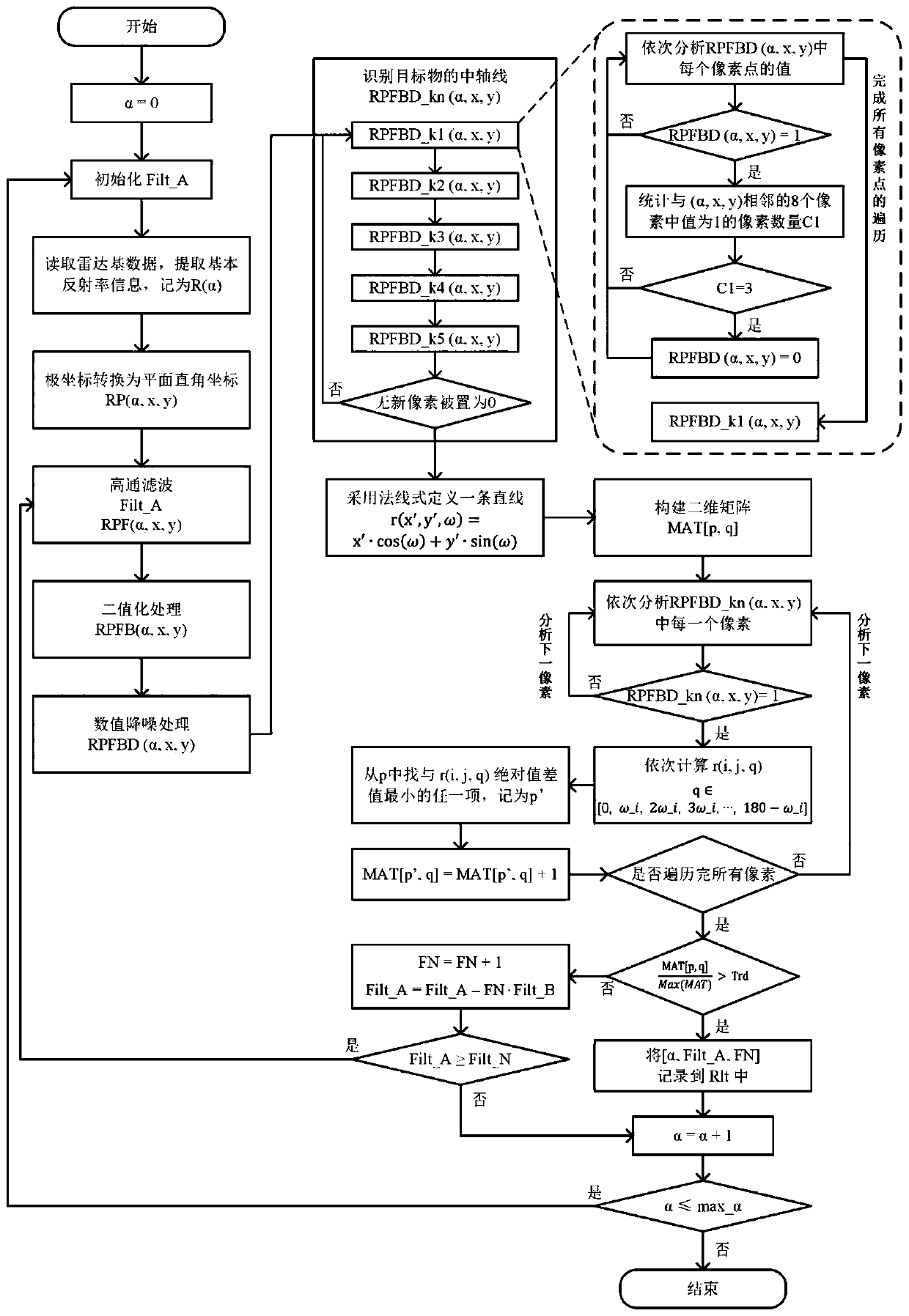

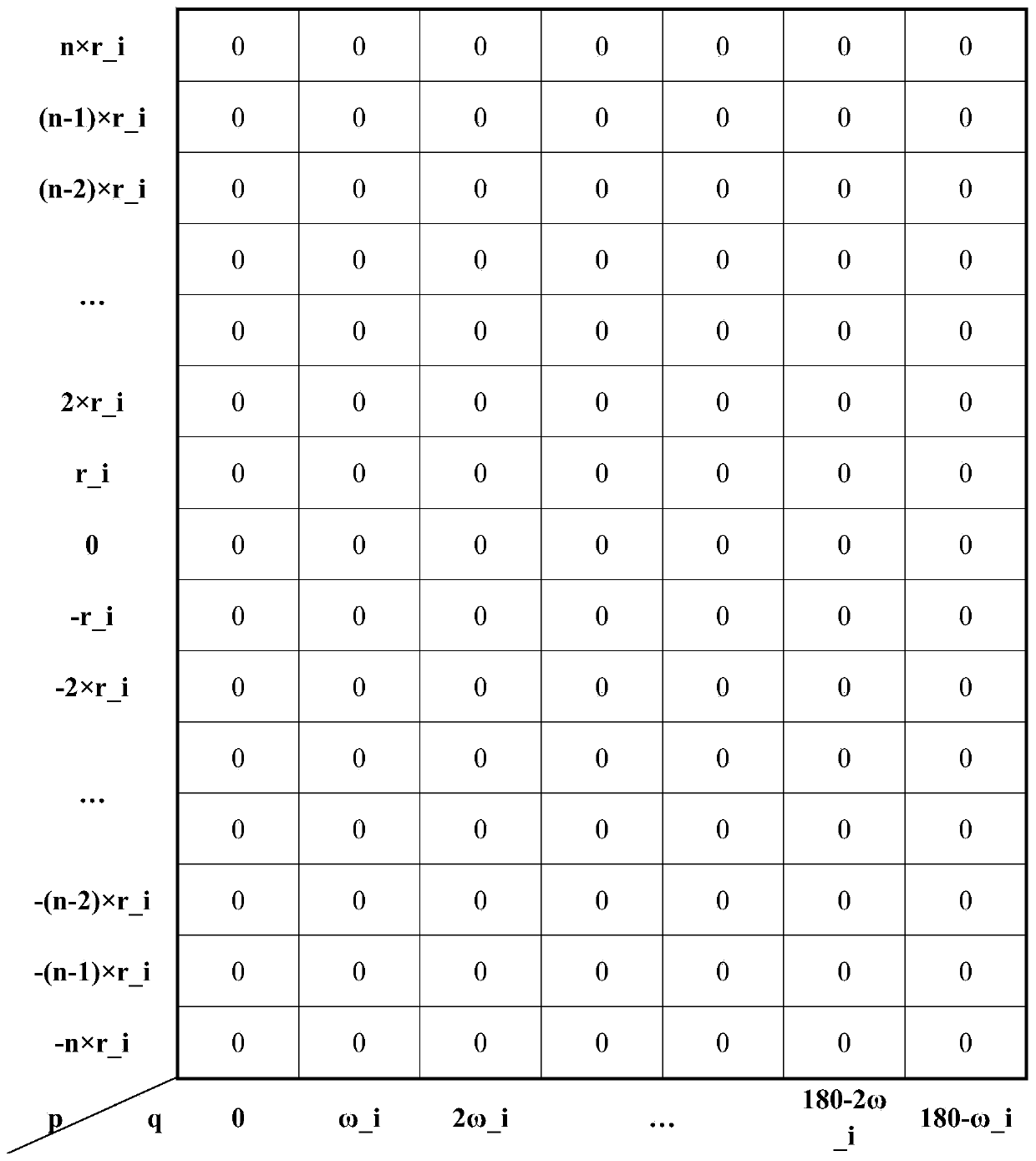

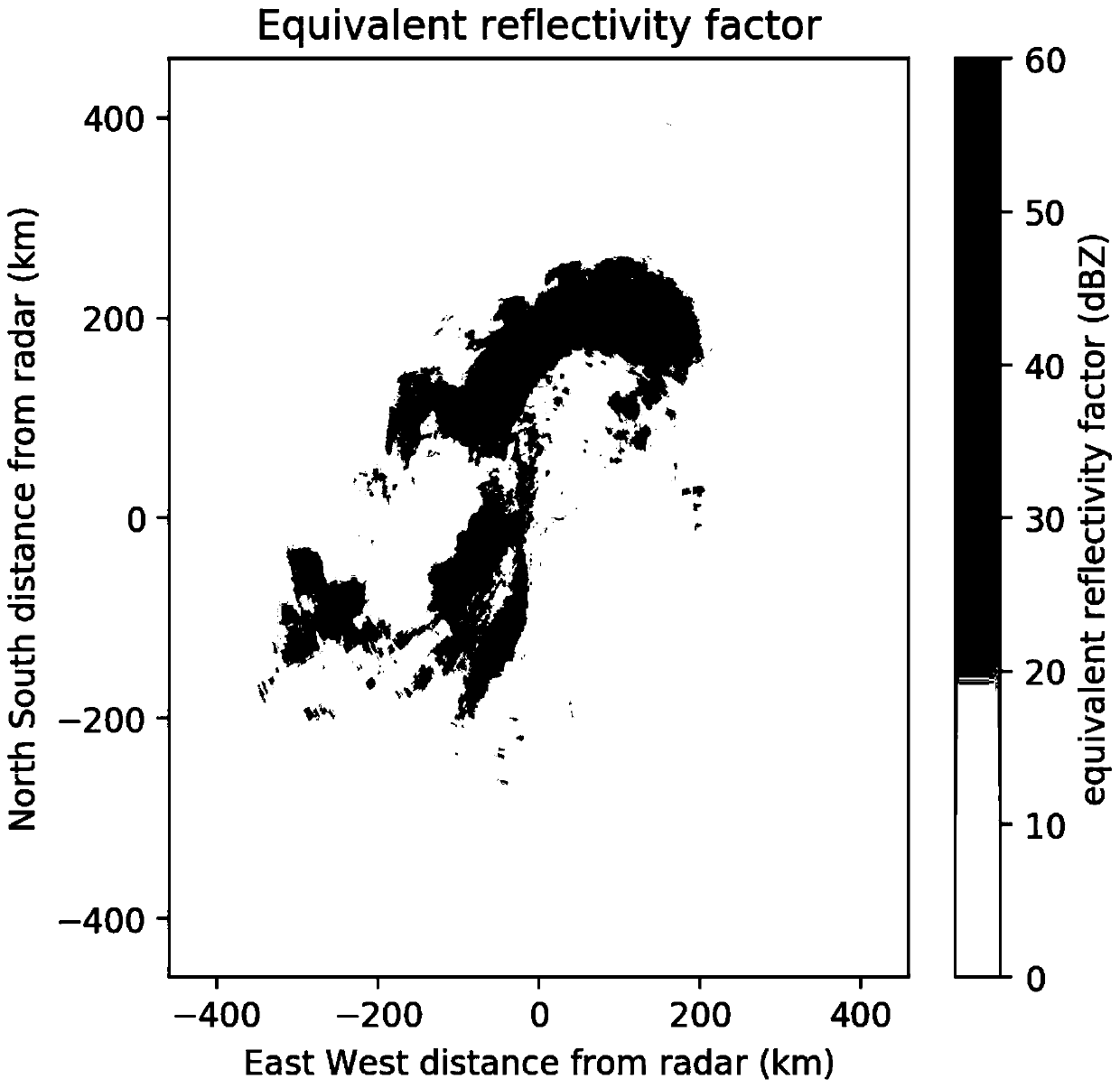

Intelligent identification and early warning method for squall line features in radar echo image

ActiveCN110988883ARealize intelligent identificationRealization of intelligent identification and early warningRadio wave reradiation/reflectionICT adaptationWeather radarFeature extraction

The invention provides an intelligent identification and early warning method for squall line features in a radar echo image. Doppler weather radar detection data is used as a main data source, spatial distribution and intensity of basic reflectivity detected by a radar are analyzed, and intelligent identification and early warning of squall line features of the radar are realized through a seriesof steps of numerical preprocessing, filtering, image feature extraction, central axis analysis of a target object, squall line morphological analysis and the like. By applying the method, the work of subjectively analyzing and interpreting radar echo images by meteorological professionals in the past can be automated and objectified, and then the accuracy and timeliness of squall line identification and severe convection weather alarm related services are improved.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

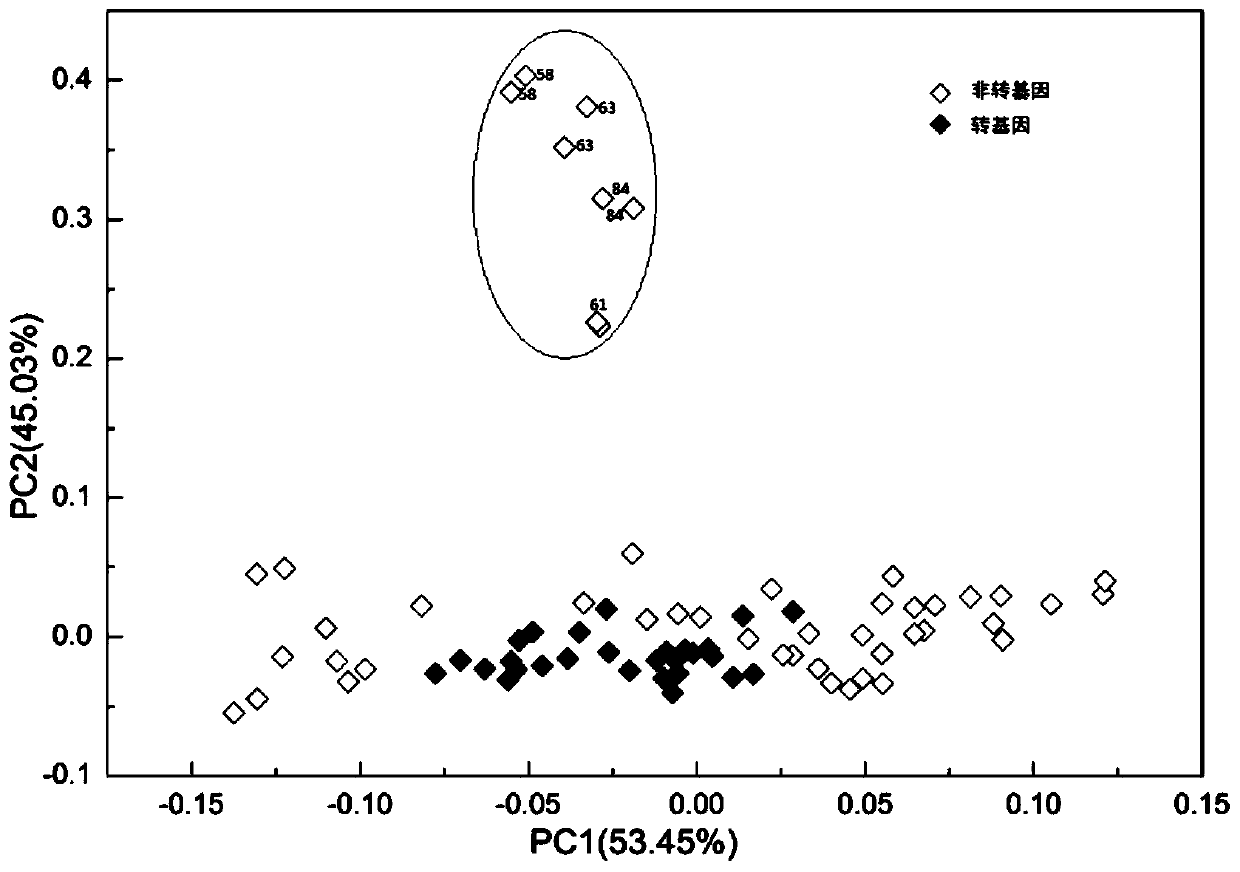

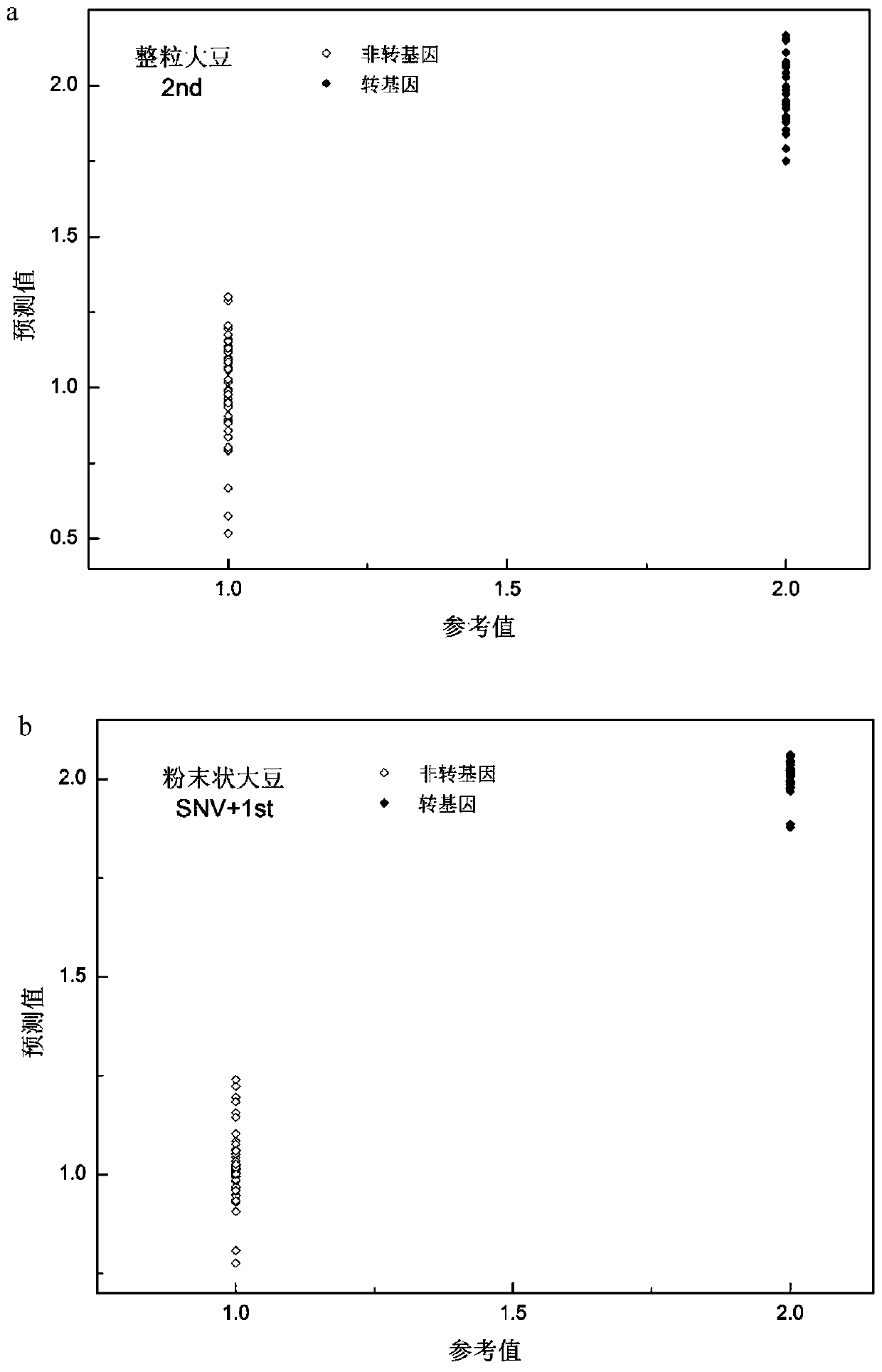

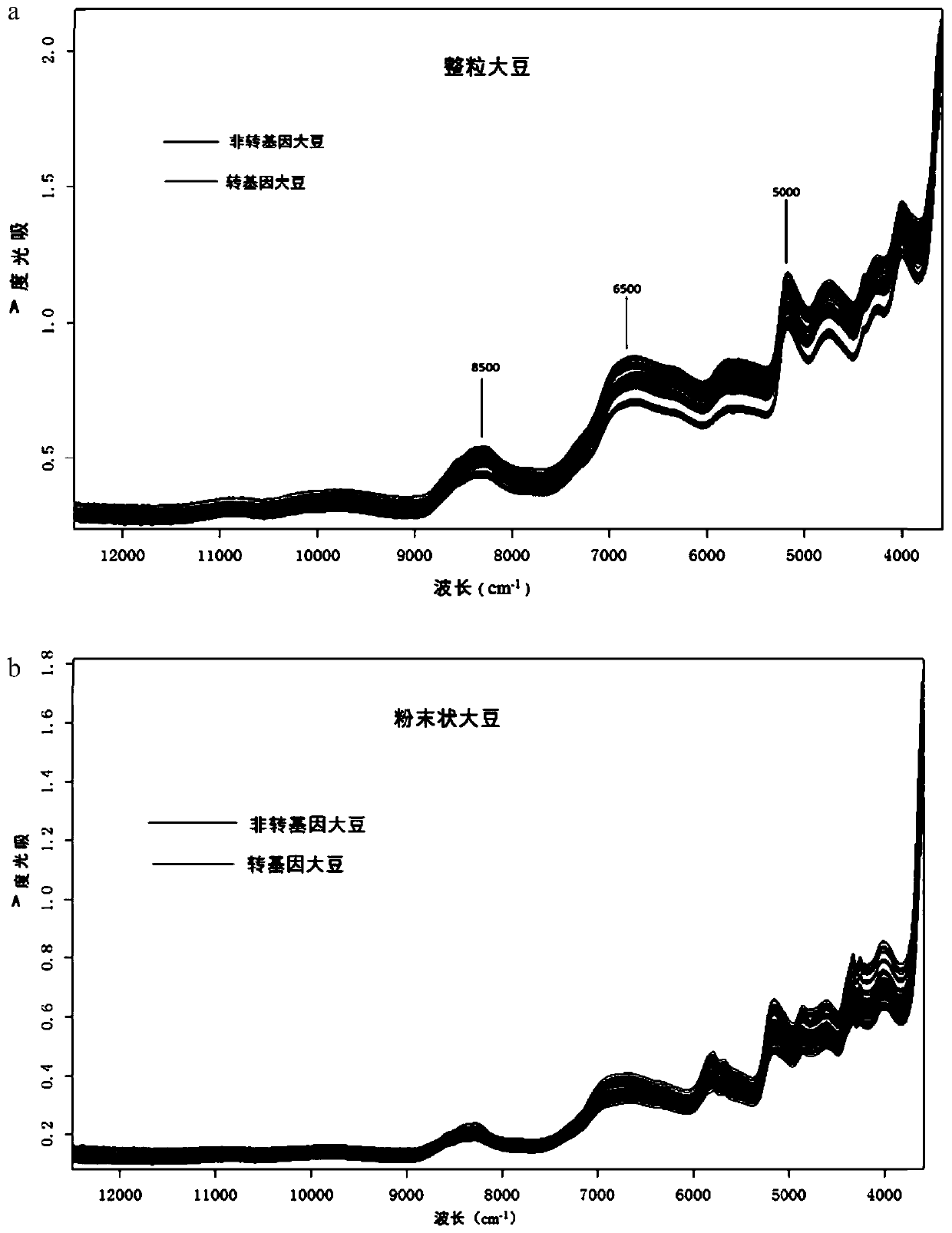

Optimized model for rapid identification of transgenic soybeans based on morphological analysis

InactiveCN110632017AHigh identification accuracyMaterial analysis by optical meansBiostatisticsPretreatment methodRapid identification

The invention provides an optimized model for rapid identification of transgenic soybeans based on morphological analysis. According to the invention, firstly, an establishment method of the optimizedmodel for rapid identification of the transgenic soybean based on morphological analysis is provided; for whole soybeans, spectral information under a characteristic wave band of 9403-5438cm<-1> is selected, the spectrum is preprocessed by adopting a second derivative, and a PLS-DA model is established by adopting a partial least squares-discrimination method; and for powdery soybeans, spectral information under a characteristic waveband of 7505-4597cm<-1> is selected, the spectrum is preprocessed by adopting vector normalization and a first derivative, and a PLS-DA model is established by adopting a partial least squares-discrimination method. According to the invention, the transgenic soybeans are identified by combining the near-infrared spectrum with a discriminant analysis method, and the identification accuracy of the discrimination model can be improved by selecting the sample form, the wavelength range and the spectrum pretreatment method, so that the optimal model is selectedto be applied to actual production.

Owner:NAT INST FOR NUTRITION & HEALTH CHINESE CENT FOR DISEASE CONTROL & PREVENTION

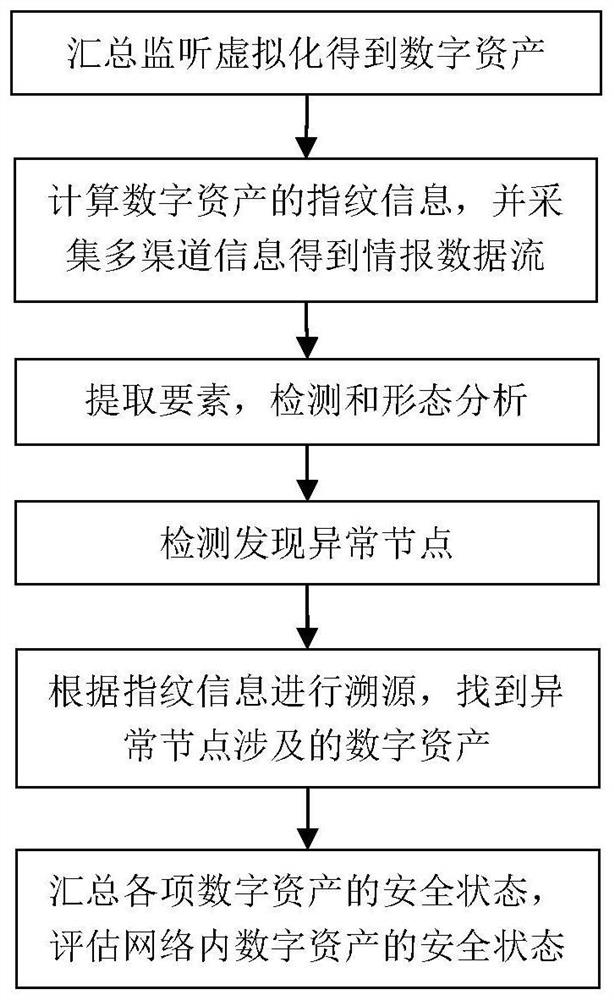

Asset safety assessment method and system based on intelligence analysis

The invention provides an asset safety assessment method and system based on intelligence analysis. Digital assets are obtained through an edge layer, summarizing equipment information and monitoringchannel data virtualization, fingerprint information of the digital assets is calculated, data information of multiple ways is collected, information data streams are obtained, feature vectors and morphological analysis of the information data streams are detected, tracing is conducted according to the fingerprint information of the digital assets, and therefore the digital assets in the network are evaluated, and an administrator can deploy defense strategies conveniently.

Owner:武汉思普崚技术有限公司

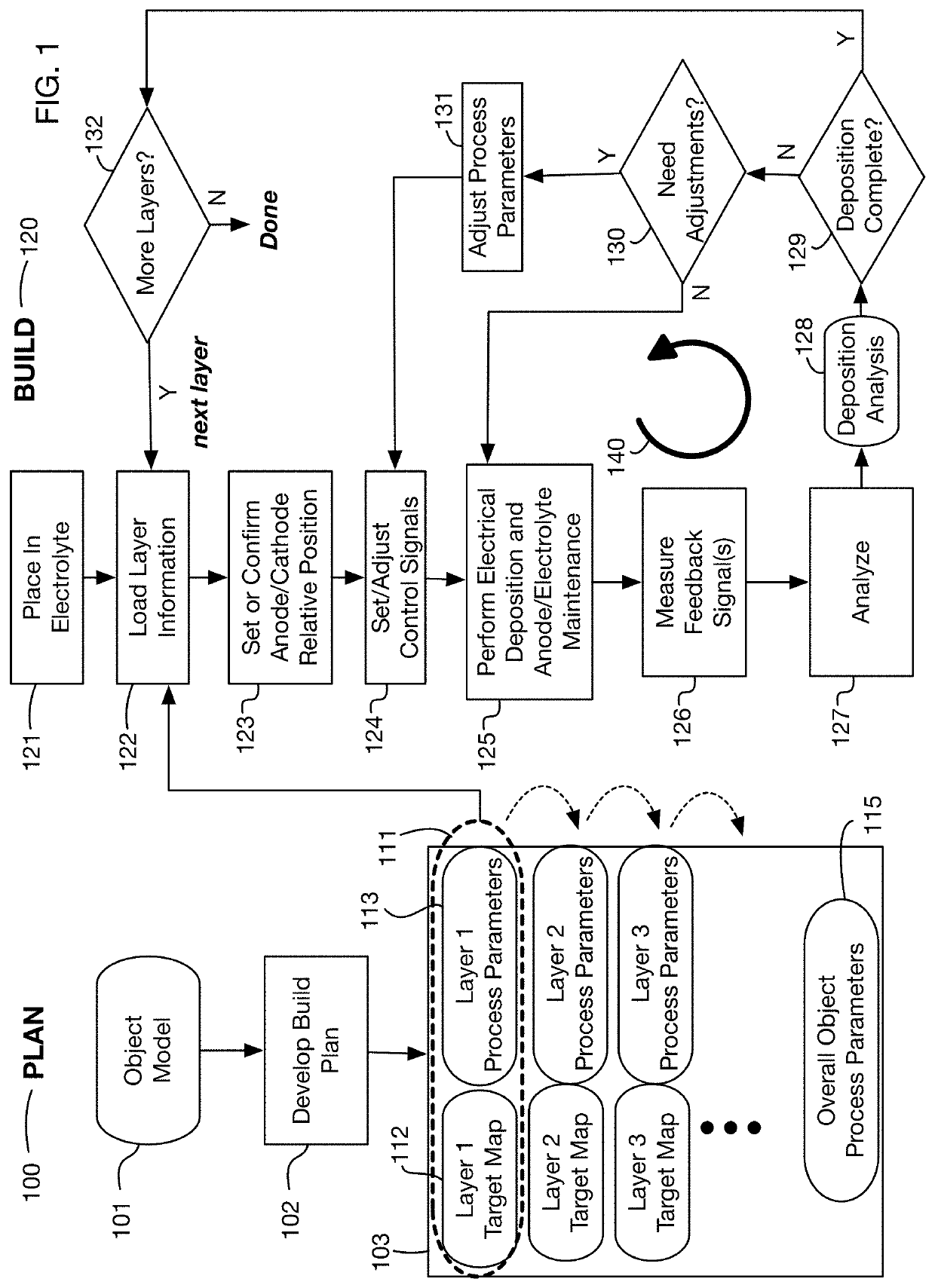

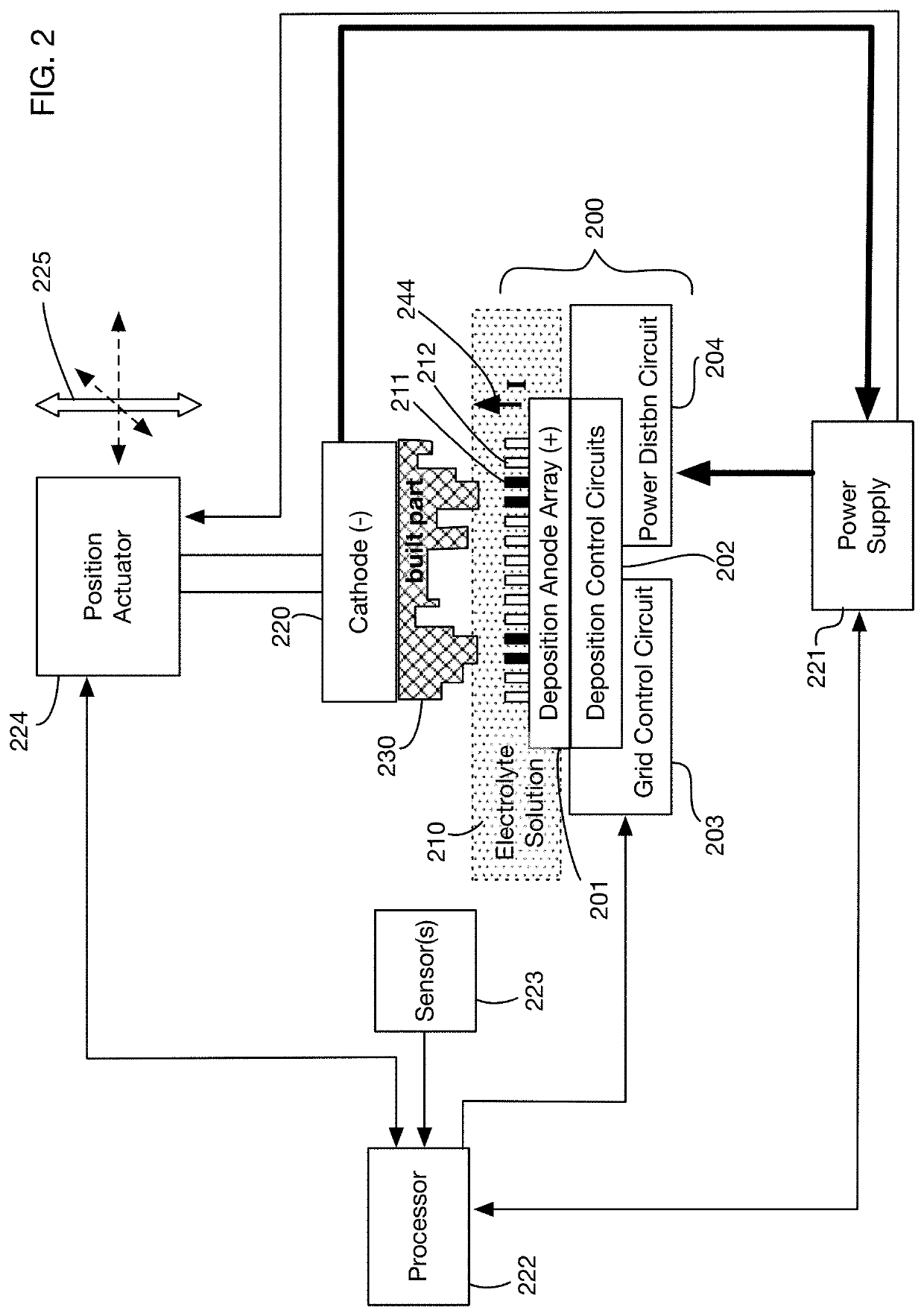

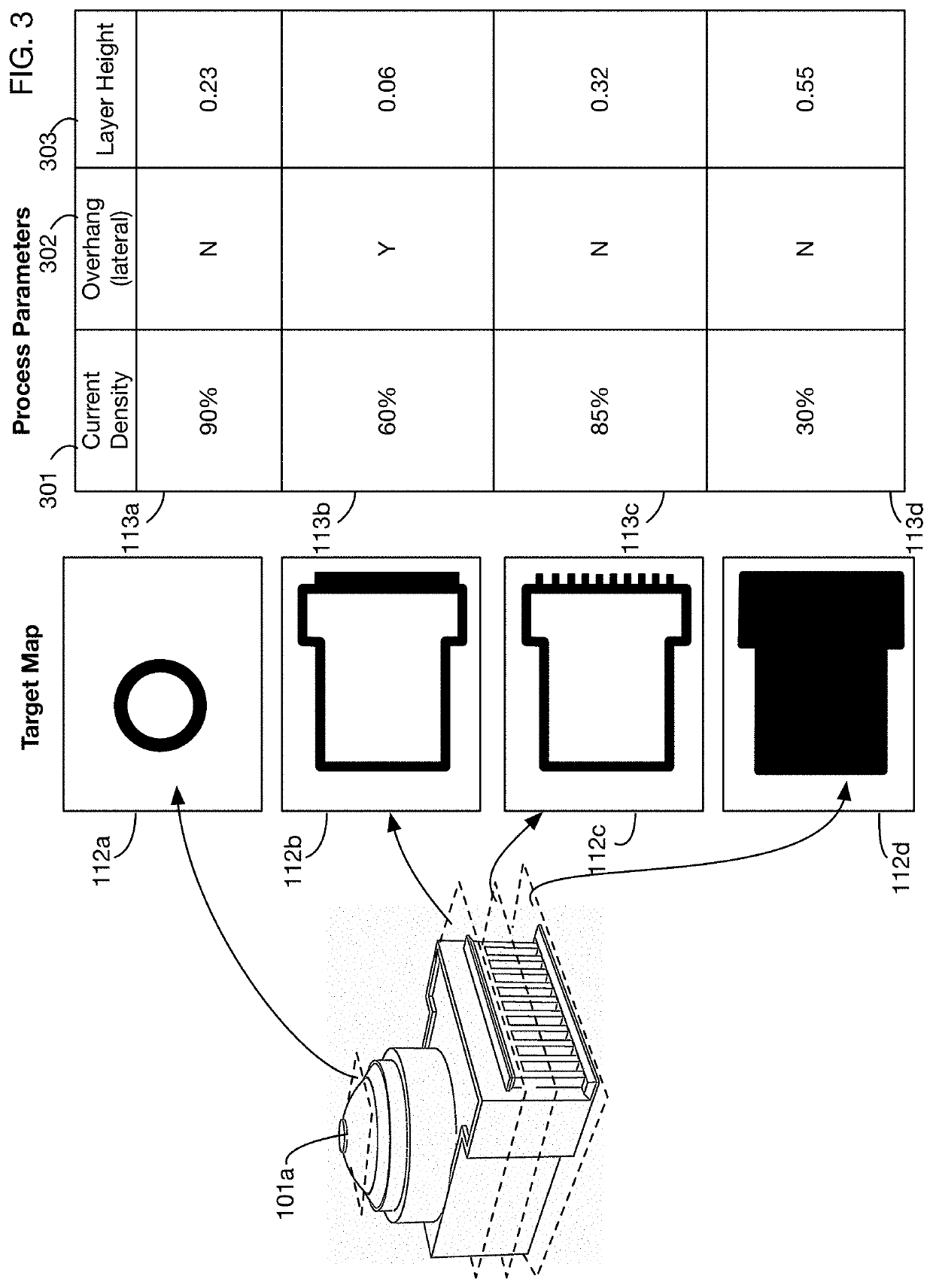

Electrochemical additive manufacturing method using deposition feedback control

ActiveUS10947632B1Additive manufacturing apparatusAdditive manufacturing with liquidsThin membraneEngineering

A method of additive manufacturing that deposits material onto a cathode by transmitting current from an anode array through an electrolyte to the cathode; the method uses feedback to control the manufacturing of successive layers of a part. For example, feedback signals may be a map of current across the anode array; this current map may be processed using morphological analysis or Boolean operations to determine the extent of deposition across the layer. Feedback data may be used to determine when a layer is complete, and to adjust process parameters such as currents and voltages during layer construction. Layer descriptions may be preprocessed to generate maps of desired anode current, to manipulate material density, and to manage features such as overhangs. Feedback signals may also trigger execution of maintenance actions during the build, such as replenishment of anodes or removal of films or bubbles.

Owner:FABRIC8LABS INC

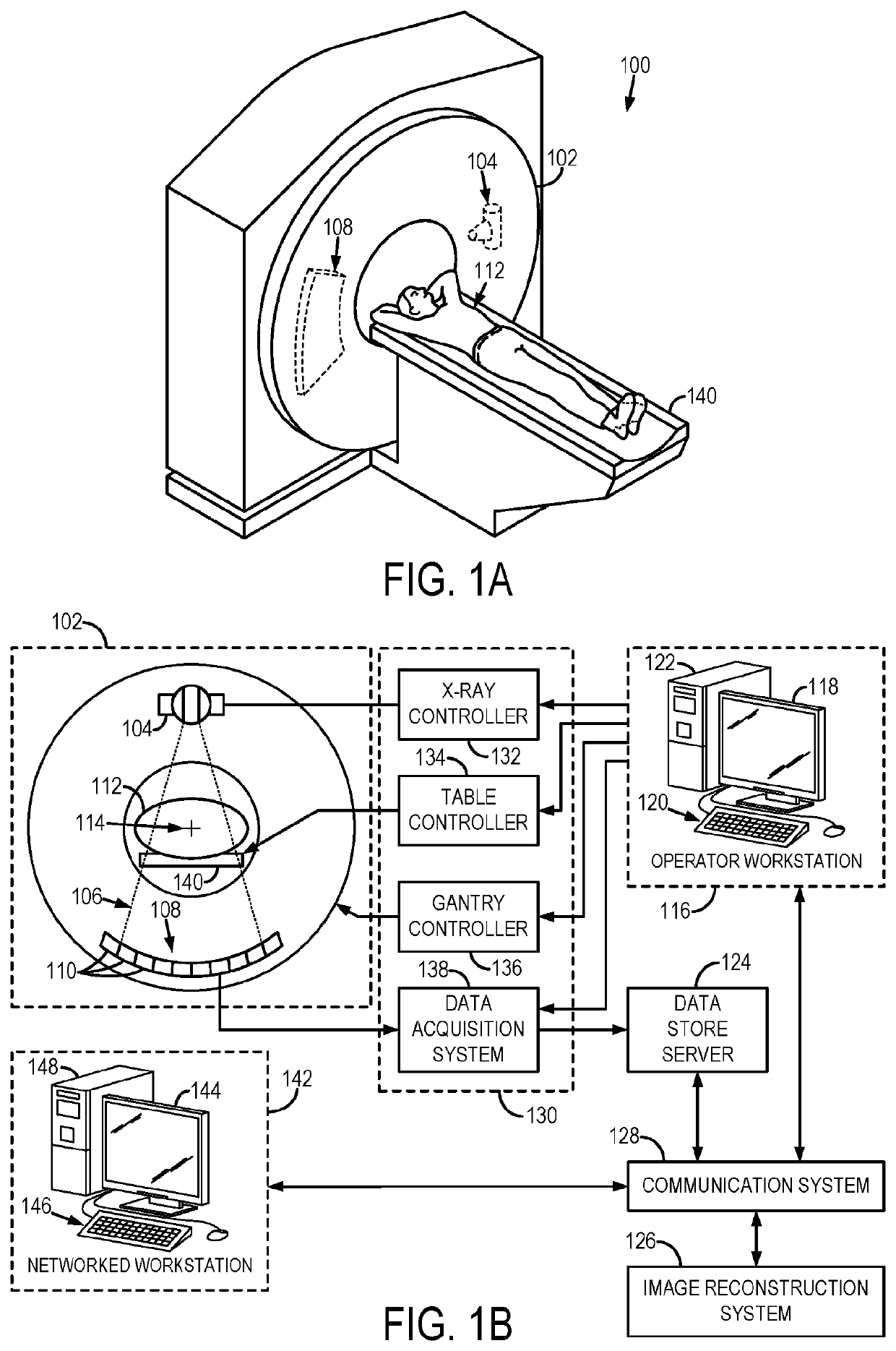

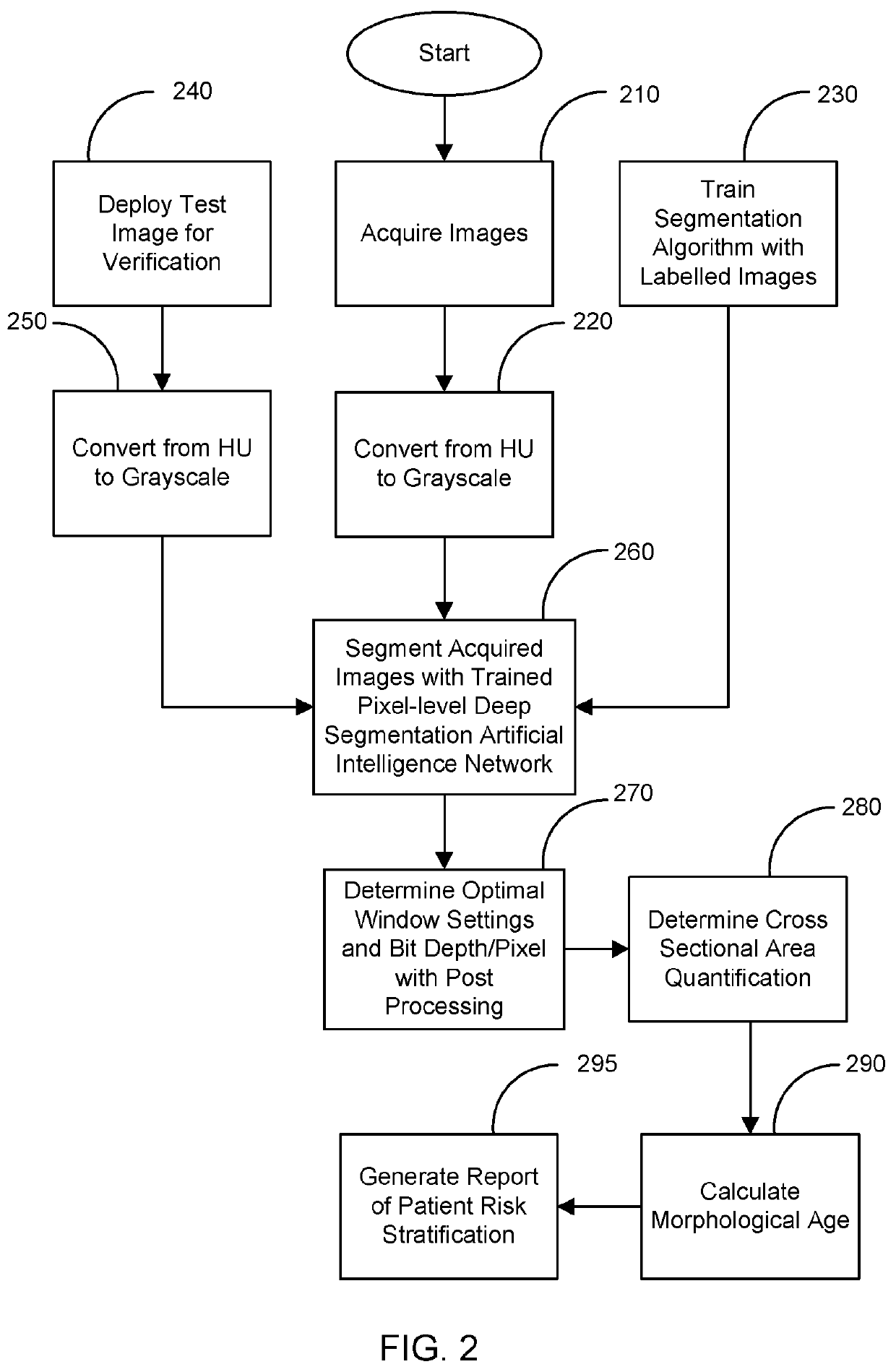

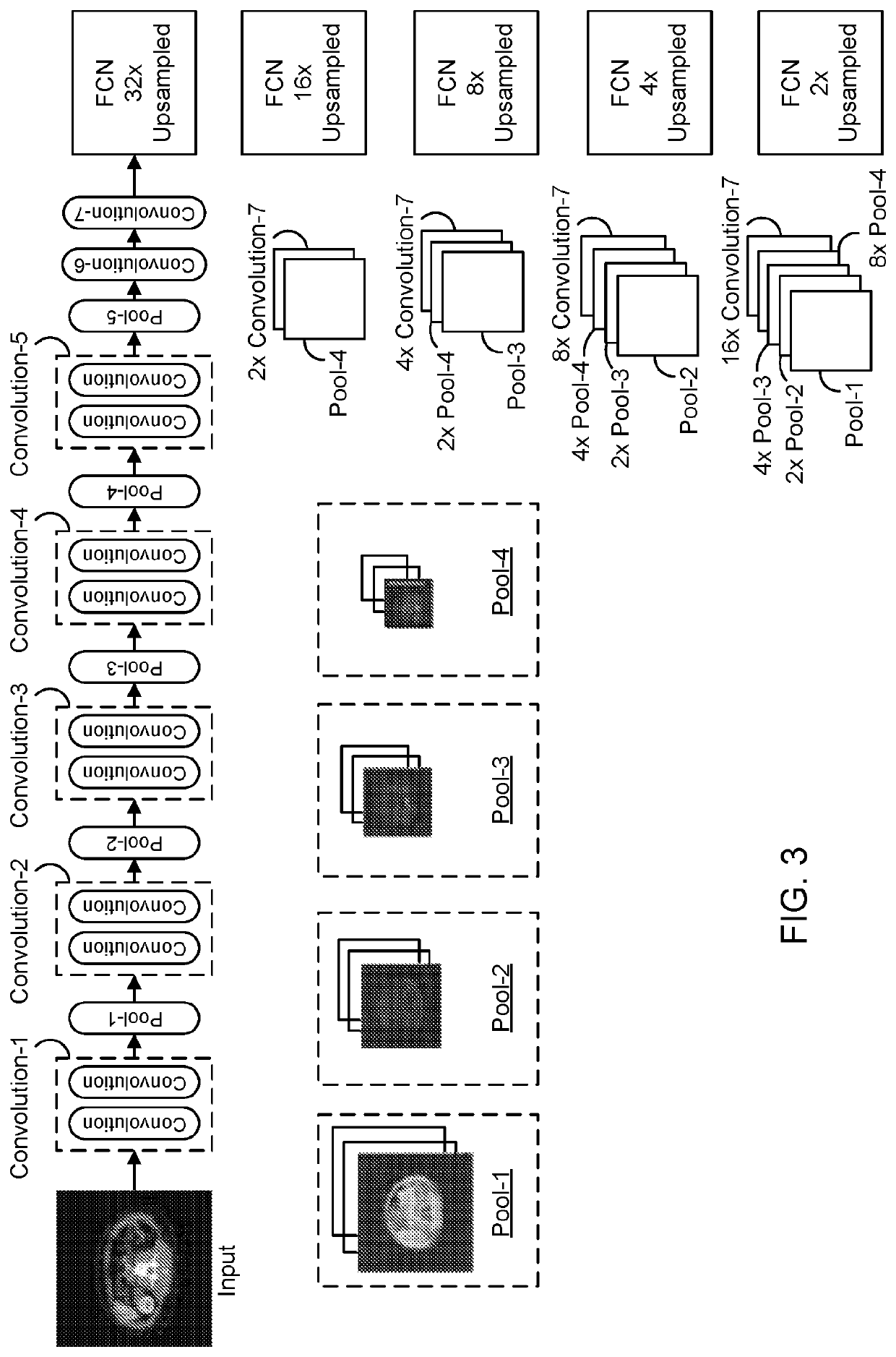

Patient risk stratification based on body composition derived from computed tomography images using machine learning

ActiveUS20200211710A1Accurate analysisConvenient for clinical operationImage enhancementImage analysisPatient riskComputed tomography

A system and method for determining patient risk stratification is provided based on body composition derived from computed tomography images using segmentation with machine learning. The system may enable real-time segmentation for facilitating clinical application of body morphological analysis sets. A fully-automated deep learning system may be used for the segmentation of skeletal muscle cross sectional area (CSA). Whole-body volumetric analysis may also be performed. The fully-automated deep segmentation model may be derived from an extended implementation of a Fully Convolutional Network with weight initialization of a pre-trained model, followed by post processing to eliminate intra-muscular fat for a more accurate analysis.

Owner:THE GENERAL HOSPITAL CORP

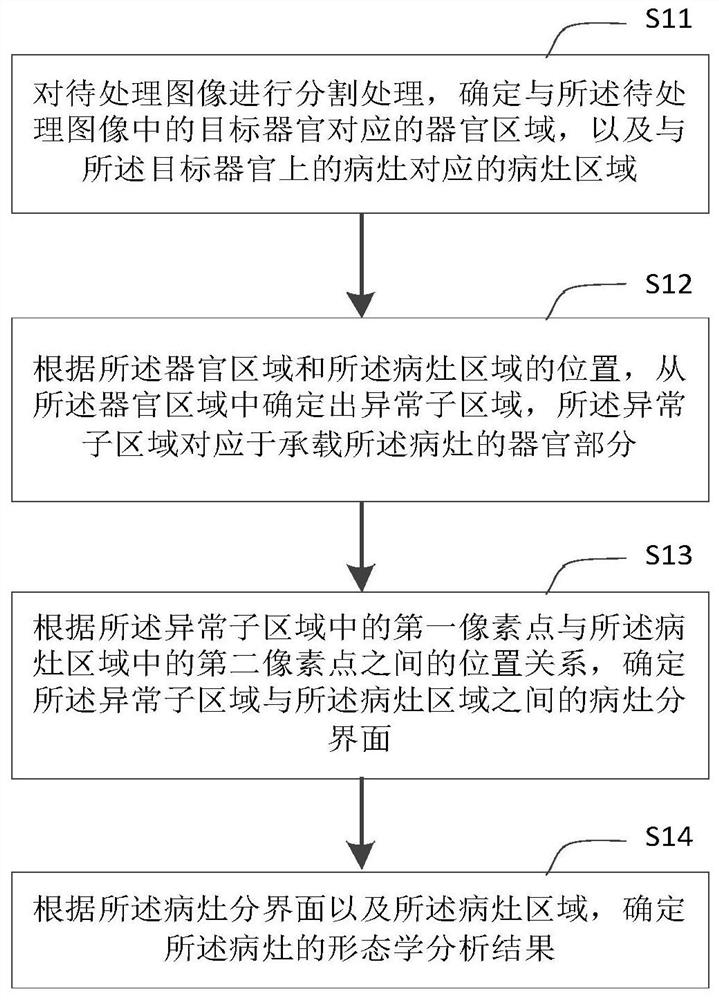

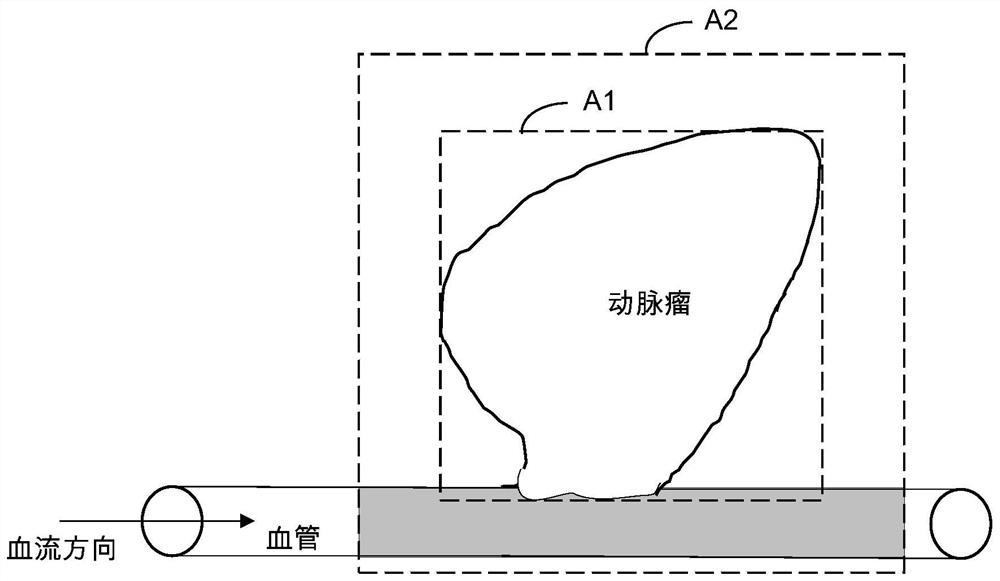

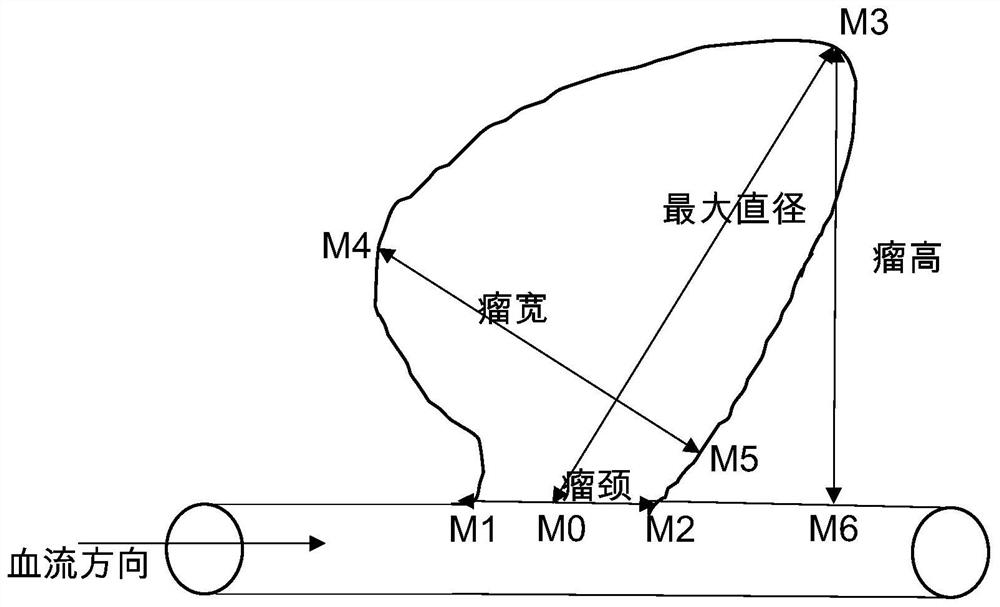

Image processing method and device, electronic equipment and storage medium

ActiveCN112967291ADetermine automatic and accurateReduce workloadImage enhancementImage analysisImaging processingOrgan region

The invention relates to an image processing method and device, electronic equipment and a storage medium, wherein the method comprises the steps: carrying out the segmentation processing of a to-be-processed image, and determining an organ region corresponding to a target organ in the to-be-processed image, and a focus region corresponding to a focus on the target organ; according to the positions of the organ region and the focus region, determining an abnormal sub-region corresponding to the part bearing the focus organ from the organ region; determining a lesion interface between the abnormal sub-region and the lesion region according to a position relationship between a first pixel point in the abnormal sub-region and a second pixel point in the lesion region; and according to the focus interface and the focus area, determining a morphological analysis result of the focus. According to the embodiment of the invention, the morphological analysis result of the focus in the image can be automatically and accurately determined, so that the workload of medical staff is reduced, and the working efficiency of the medical staff is improved.

Owner:BEIJING ANDE YIZHI TECH CO LTD

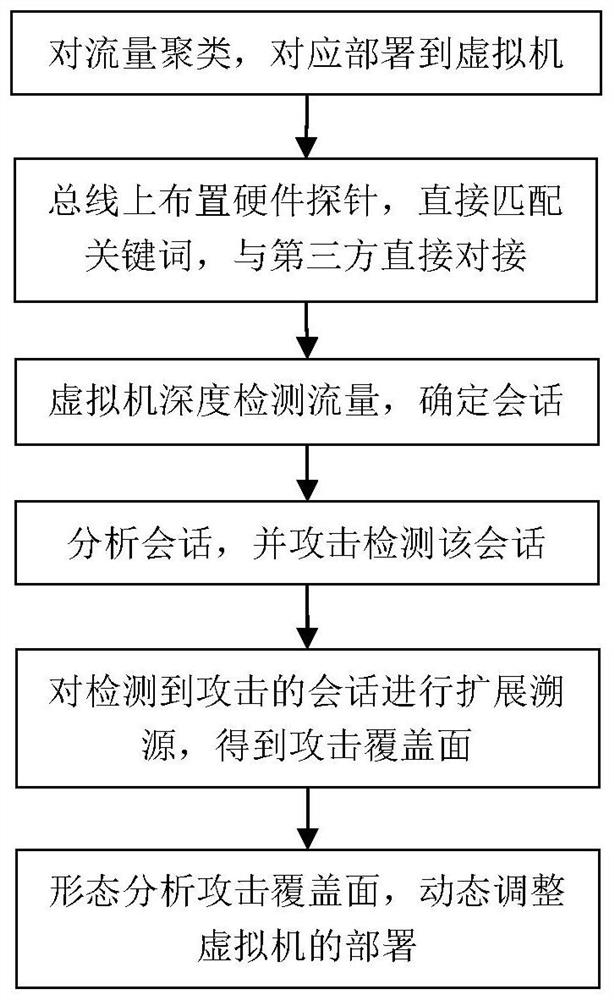

Hardware independence method and system for realizing network traffic security analysis

ActiveCN111935145ASolve problems that cannot be effectively deployedEfficient deploymentMachine learningData switching networksThird partyInternet traffic

The invention provides a hardware independence method and system for realizing network traffic security analysis. The problems are solved that existing flow analysis is limited by a hardware platform,and effective deployment cannot be achieved. The method comprises the steps of: physically clustering the flow, and deploying a plurality of virtual machines on the platform to execute a traffic security analysis process, wherein the virtual machine can be distributed according to the speed of clustering flow; dynamically deploying a special virtual machine to process the specified flow; and meanwhile, arranging hardware probes on the bus, so that preliminary keyword matching can be directly carried out on the flow message, the flow message serves as an interface in butt joint with other third parties, abnormal points are found through deep detection of the flow by the virtual machine, tracing and morphological analysis comparison are carried out on the abnormal points to obtain an attackcoverage surface and virtual machine distribution, and effective deployment of a defense strategy is realized.

Owner:武汉思普崚技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com