Bearing fault diagnosis method based on morphological top hat product filtering of optimal scale

A technology of optimal scale and fault diagnosis, applied in the testing of mechanical components, identification of patterns in signals, and testing of machine/structural components, etc., can solve the problem of low extraction accuracy, improve extraction performance, and enhance fault feature information. , the effect of suppressing Gaussian noise and uncoupled frequency components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

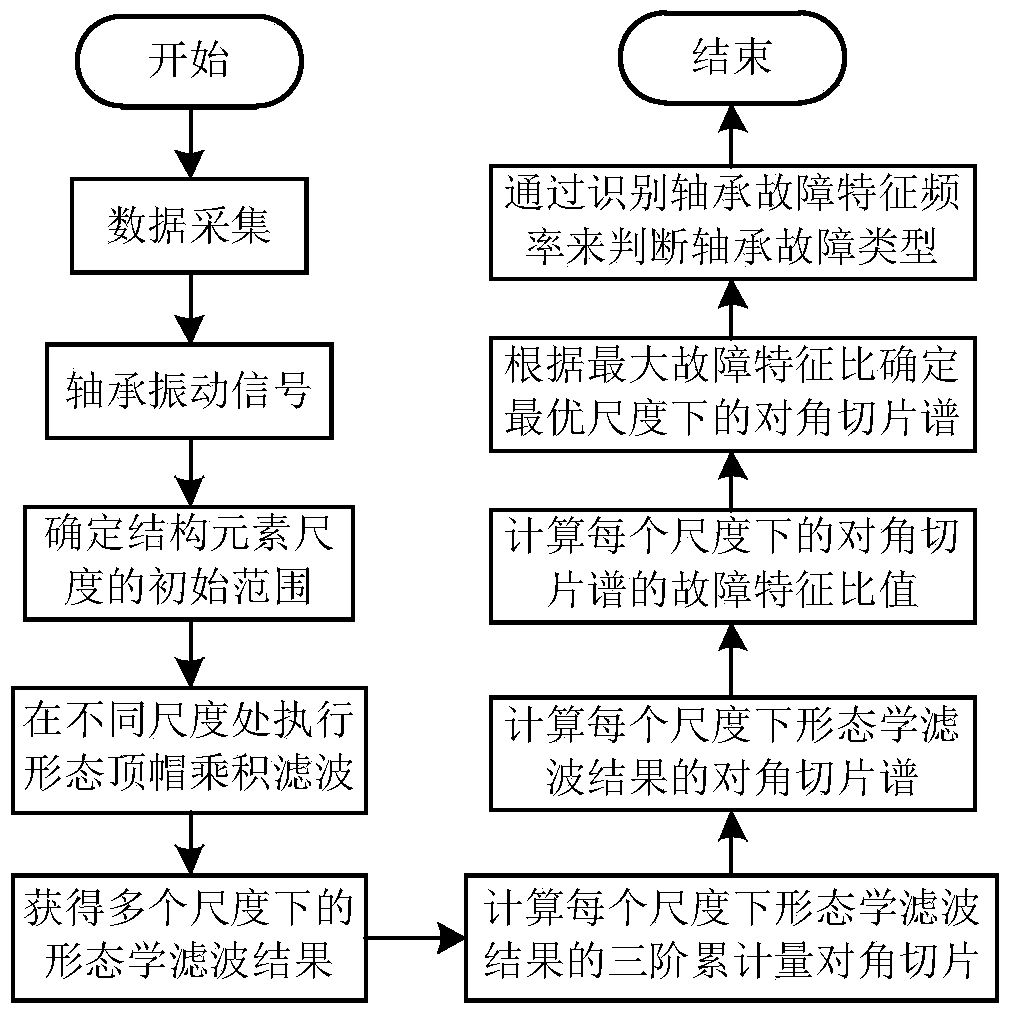

[0047] figure 1 is a flowchart of the present invention. The steps of the present invention will be described in detail below in conjunction with the flowchart.

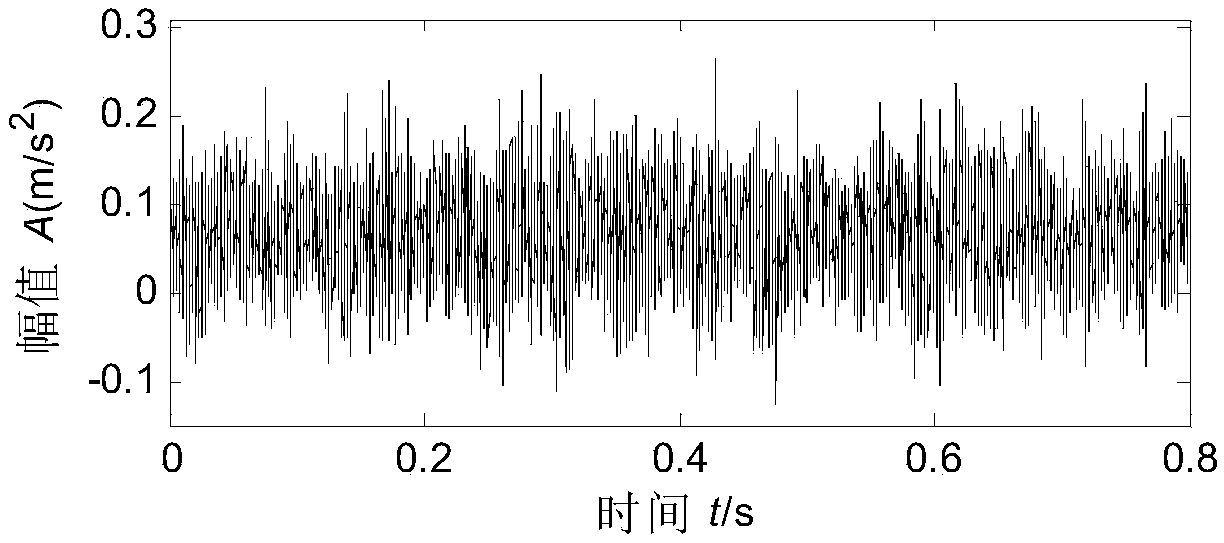

[0048] 1) Set the signal sampling frequency to f s , install the acceleration sensor near the bearing to collect the vibration signal of the bearing, and calculate the fault characteristic frequency f of different bearing components according to the bearing size parameters g , select a flat structural element g with a height H of 0 and a length of L, and set the minimum structural element length L min =3, that is, g={0,0,0}, and then according to the relational expression between the length L of the structural element and the scale λ, that is, λ=L-2, it is determined that the minimum structural element scale is 1, and the maximum structural element scale is L-2, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com