Superimposed cable structure system and morphological analysis method thereof

A form analysis and cable structure technology, which is applied to building components, building structures, and special data processing applications, can solve problems such as large constraints on architectural shapes, achieve good mechanical properties, high-efficiency stress, and broaden the application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

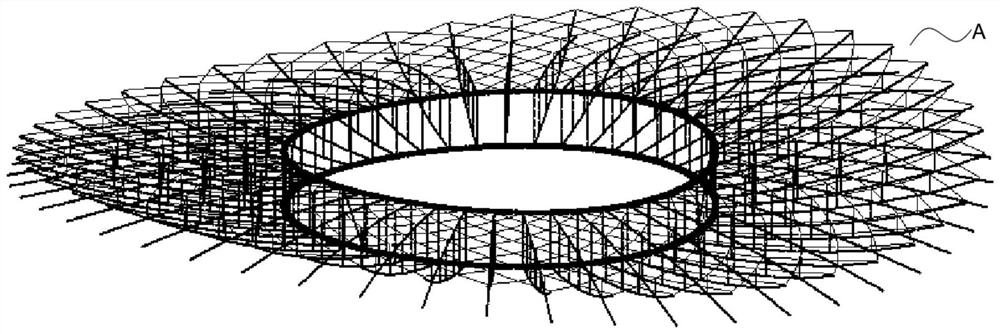

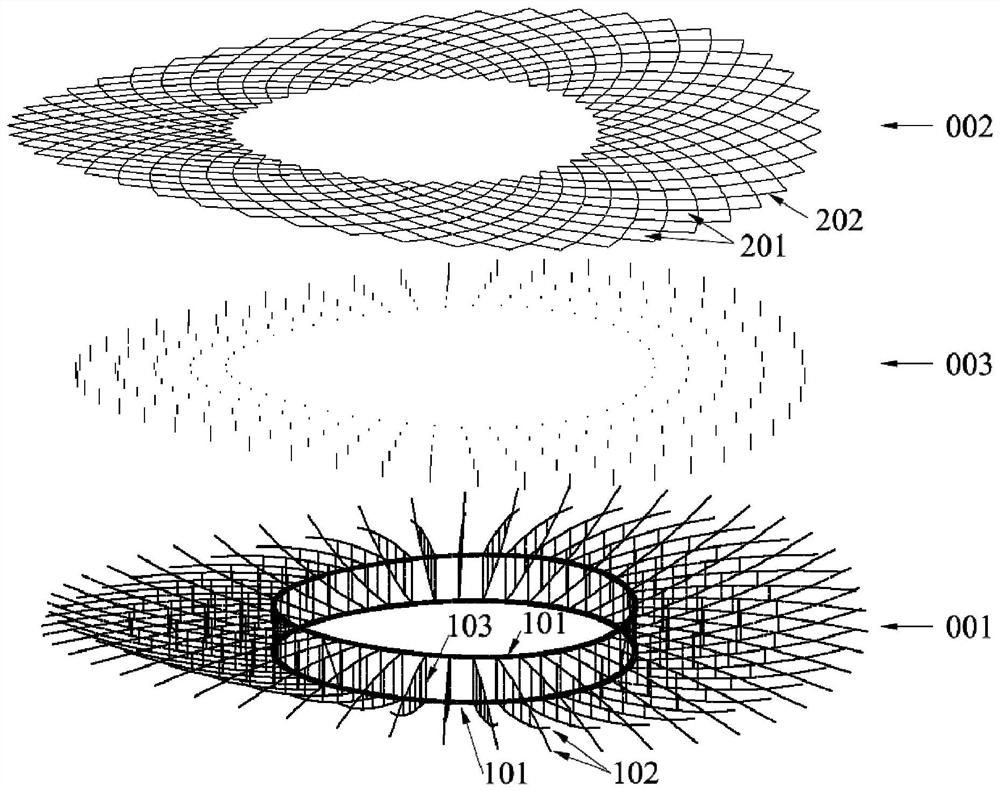

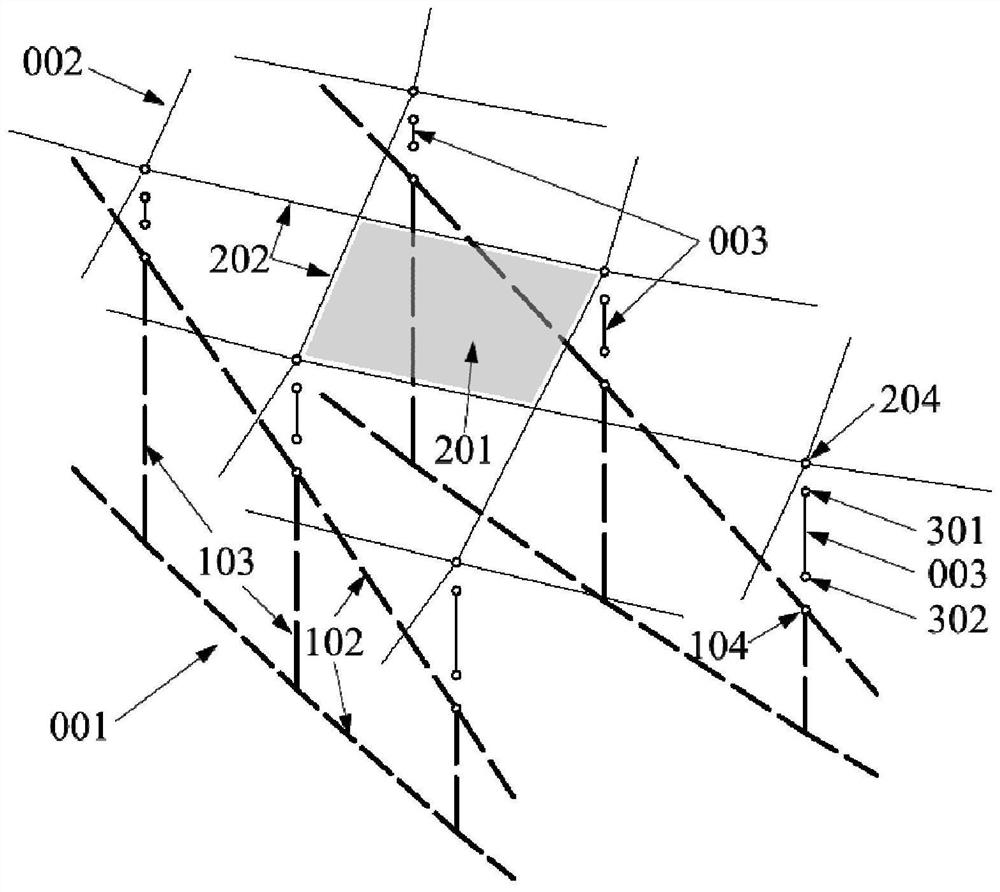

[0062] In this example, Figure 1-Figure 3 The present invention will be described by taking the superimposed cable structure system of saddle-shaped curved surface and rhombus grid as an example (the overall structure shown in A in the figure).

[0063] combine Figure 1 to Figure 3 as shown, figure 1 Shown is a schematic diagram of the composite cable structure system A provided in this embodiment, the upper surface of which is a saddle-shaped surface composed of a series of rhombus grids. figure 2 The composition of the composite cable structure system A is schematically illustrated in the form of an exploded view, which consists of a load-bearing structure 001 , a molding structure 002 and a connecting member 003 . In order to more clearly show the composition of the composite cable structure system A, image 3 A detailed exploded schematic of the system is given.

[0064] The load-bearing structure 001 is located below the composite cable structure system A, providin...

Embodiment 2

[0070] In this example, Figure 4-Figure 6 The present invention will be described by taking the superimposed cable structure system of saddle-shaped curved surface and space triangular grid as an example (the overall structure shown in B in the figure).

[0071] combine Figure 4 to Figure 6 as shown, Figure 4 Shown is the schematic diagram of the superimposed cable structure system B provided in this embodiment, the upper surface of which is a saddle-shaped curved surface, which is composed of a series of spatial triangular grids, and two of the sides of each spatial triangle are straight sides using cables. The third edge is an arc edge with a steel arch. Figure 5 The composition of the composite cable structure system B is schematically illustrated in the form of an exploded view, which consists of a bearing structure 001 , a molding structure 002 and a connecting member 003 . In order to more clearly show the composition of the composite cable structure system B, I...

Embodiment 3

[0078] In this example, Figure 7-Figure 10 The present invention will be described by taking the superimposed cable structure system with slightly convex curved surface and rib ring mesh as an example (the overall structure shown in C in the figure).

[0079] combine Figure 7 to Figure 10 as shown, Figure 7 Shown is the schematic diagram of the composite cable structure system C provided in this embodiment, Figure 8 It is a side view of the composite cable structure system C, the upper surface of which is a slightly convex surface with positive Gaussian curvature, and is arranged in a rib ring grid. Figure 9 The composition of the composite cable structure system C is schematically illustrated in the form of an exploded view, which consists of a bearing structure 001 , a molding structure 002 and a connecting member 003 . In order to more clearly show the composition of the composite cable structure system C, Figure 10 A detailed exploded schematic of the system is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com