A Friction Hinge for Large Outward Opening Window

A friction hinge and outward-opening window technology, which is applied in door/window fittings, buildings, building fastening devices, etc., can solve the problems of friction hinges that do not have much consideration in terms of load-bearing, and is not suitable for large outward-opening windows, etc. The effect of reducing the falling of the sash, reasonable force and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

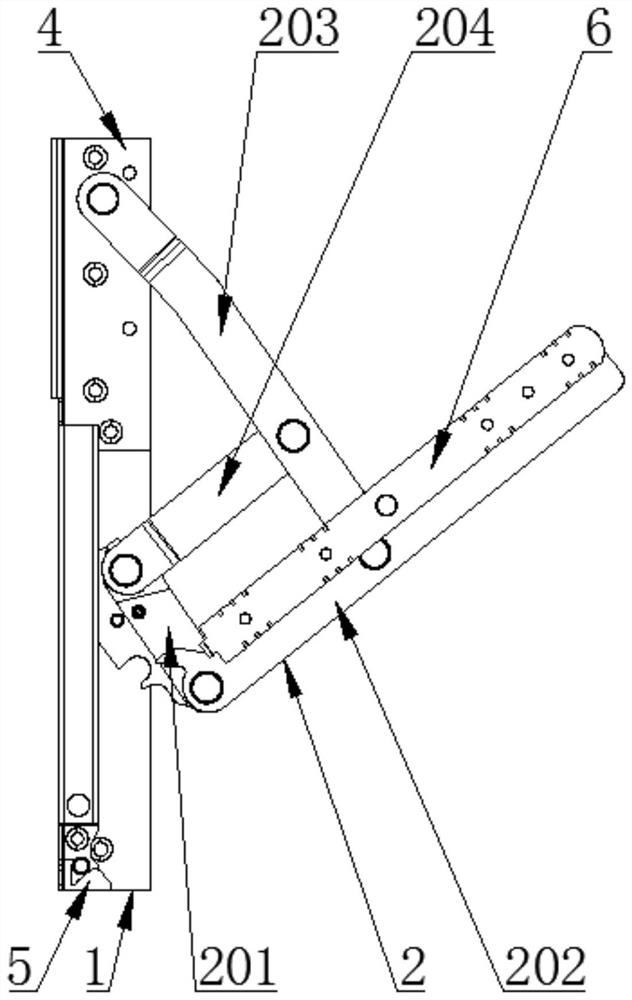

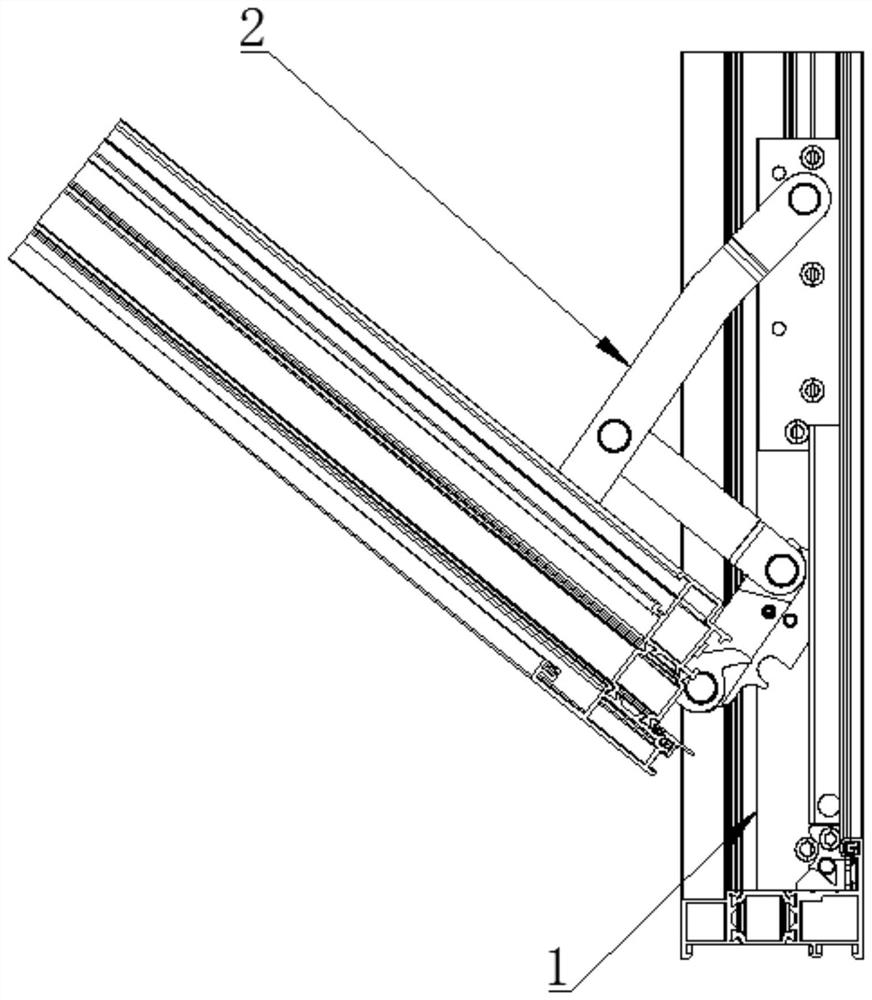

[0033] A friction hinge for a large outward-opening window, comprising a base plate 1 fixedly connected to the frame, a slider 3 slidably connected to the base plate 1, and a multi-link cantilever 2 rotatably connected to one end of the base plate 1. The connecting rod cantilever 2 slides on the bottom plate 1 by being rotationally connected with the slider 3 to realize opening and closing of the window sash.

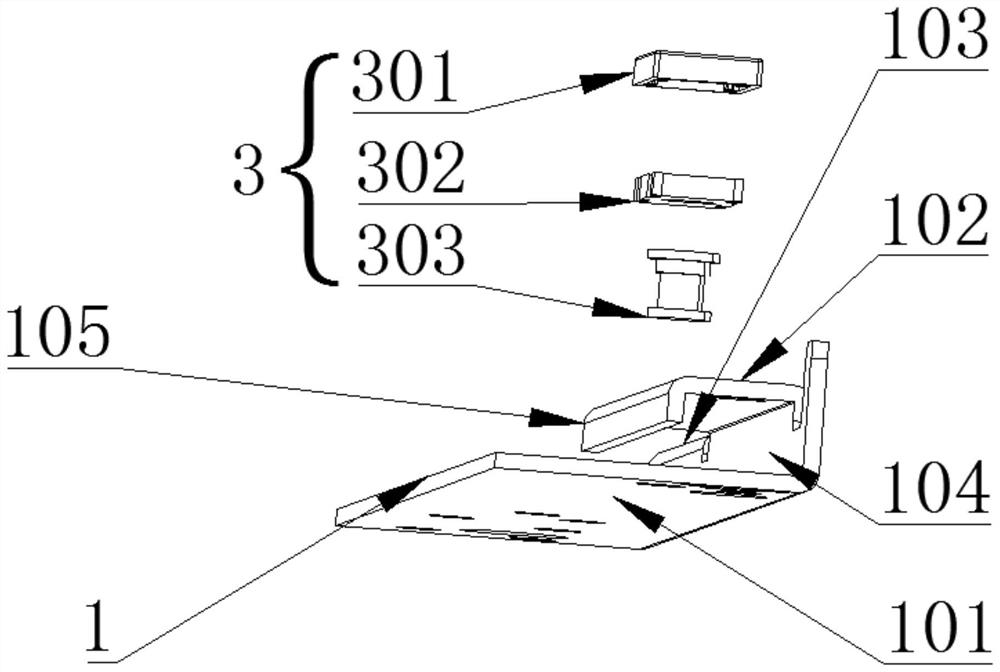

[0034] The base plate 1 includes a first straight portion 101 fixed to the frame, a second straight portion 102 parallel to the first straight portion 101 and above the first straight portion 101, and a third flat portion 101. The straight portion 103, the first vertical portion 104 connecting the second straight portion 102 and the third straight portion 103 with the first straight portion 101 and parallel to the first vertical portion 104 and passing through The second vertical portion 105 connected to the second straight portion 102; the second straight portion 102 e...

Embodiment 2

[0040] A large outward-opening window friction hinge, which can be used for large or heavy outward-opening windows of high-rise buildings, includes a bottom plate 1 fixedly connected to the frame, a slider 3 slidingly connected in the bottom plate 1, and a rotatable joint connected to the bottom plate 1 is a multi-link cantilever 2 at one end, and the multi-link cantilever 2 slides on the bottom plate 1 by being rotationally connected with the slider 3 to realize the opening and closing of the window sash. The connection between the multi-link cantilever 2 and the slider 3 and the bottom plate 1 is not the same connection.

[0041] The bottom plate 1 is generally L-shaped, including a first straight portion 101 fixed to the frame, a second straight portion 101 parallel to the first straight portion 101 and above the first straight portion 101. part 102 and the third straight part 103, the first vertical part 104 connecting the second straight part 102 and the third straight pa...

Embodiment 3

[0047] A large outward-opening window friction hinge, which can be used for large or heavy outward-opening windows of high-rise buildings, includes a bottom plate 1 fixedly connected to the frame, a slider 3 slidingly connected in the bottom plate 1, and a rotatable joint connected to the bottom plate 1 is a multi-link cantilever 2 at one end, and the multi-link cantilever 2 slides on the bottom plate 1 by being rotationally connected with the slider 3 to realize the opening and closing of the window sash. The connection between the multi-link cantilever 2 and the slider 3 and the bottom plate 1 is not the same connection.

[0048] The bottom plate 1 has been designed to be widened and utilizes the principle of leverage to increase the length of the moment arm near the indoor side, so that in the case of a long moment arm and high load-bearing on the outdoor side, the stress at the short arm 201 will not be very large. extreme and lead to failure of the fastener or the short a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com