Manufacturing method for welding round, square and flat pipes into *-shaped reinforced through beam columns

A technology of through-core beams, columns and flat tubes, which is applied in the field of through-core tubes, can solve the problems such as the inability to expand the use of bridge trusses and the inability of tube holes to be used as bridge columns and bridge girders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

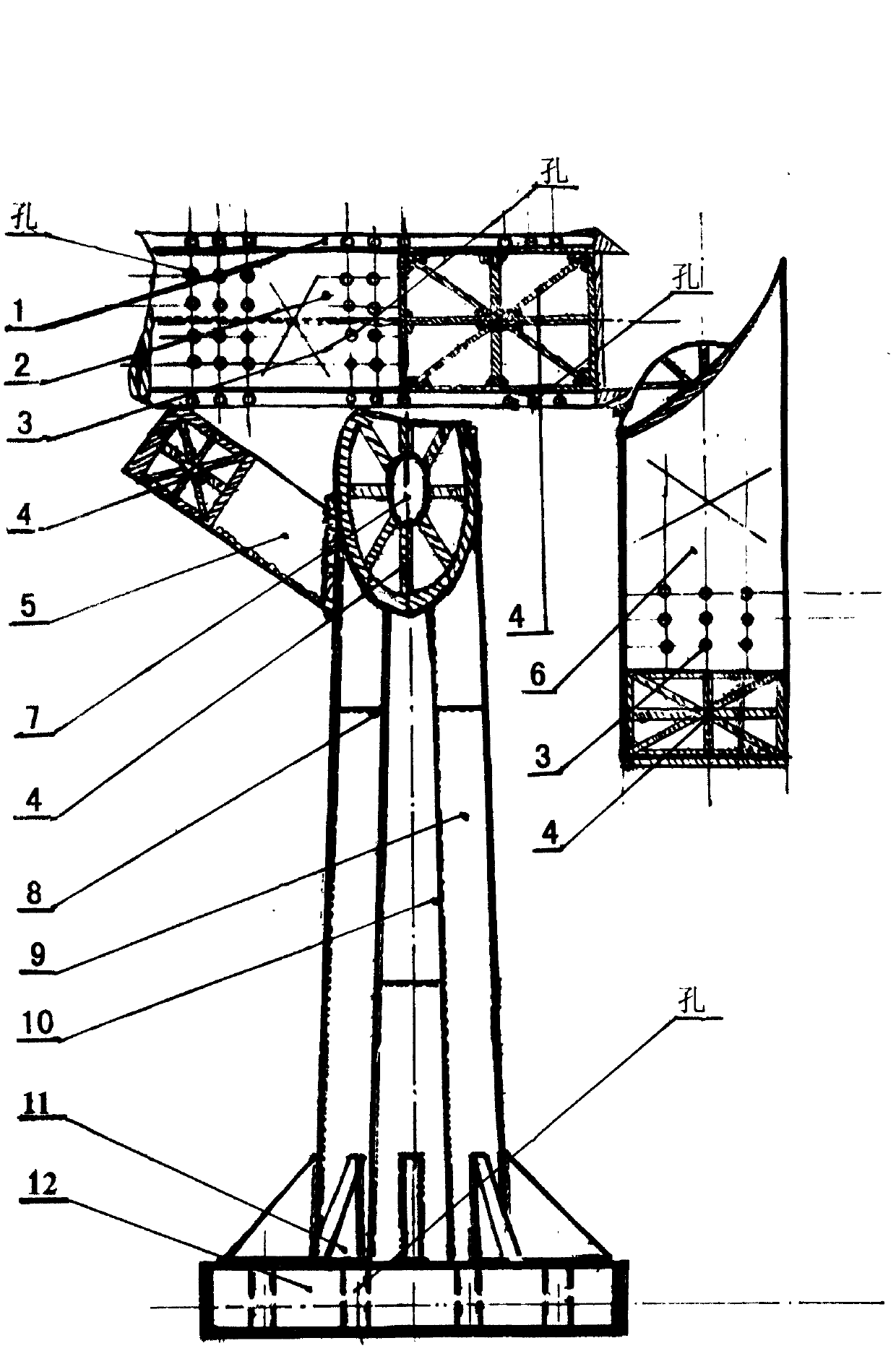

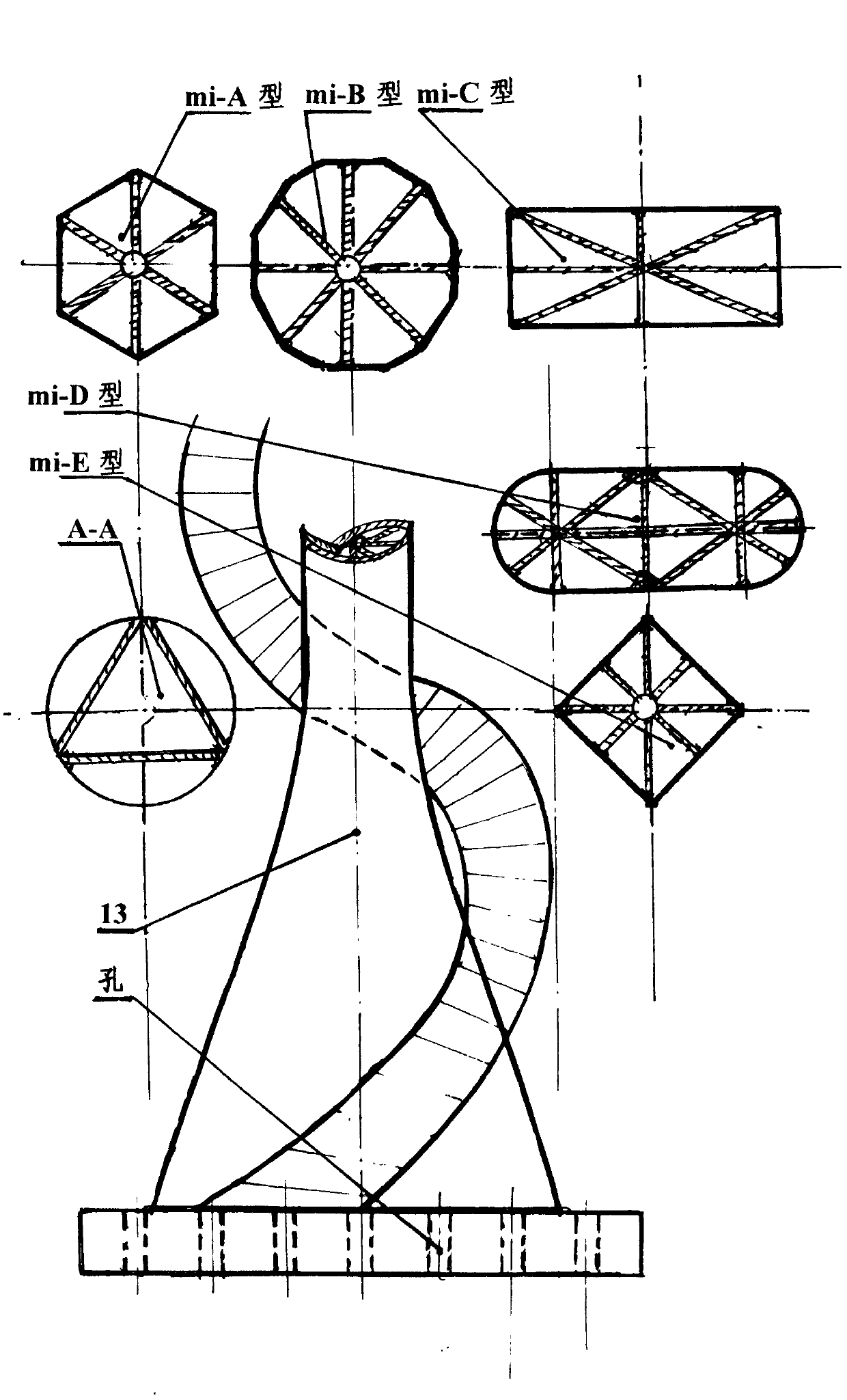

[0014] exist figure 1 Middle bridge crossbeam cut-to-length connecting plate (1), bridge cross girder according to needs such as the connecting plate of bridge column. Reinforced crossbeam (2) with meter-shaped fixed length, the finished crossbeam required to be manufactured. Connecting holes of beams and beams (3), columns, beams, and beams connected by screws to form a flat square meter-shaped reinforcement core (4), cross-sectional view of the reinforced meter-shaped heart in oblate square hollow holes, cross-arm beams and support beams (5) , The utility of the cross-arm beam of the utility pole and the connection bracket beam of the bridge column. The fixed-length reinforcement bridge girder (6) is a bridge girder finished product made according to regulations. The rice word heart reinforcement inner pipe (7) is that in the middle of the rice word reinforcement heart of octagonal pipe, multi-party pipe, big flat square pipe, there is a rice word heart welded by a masonry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com