Patents

Literature

237results about How to "Avoid repeated adjustments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

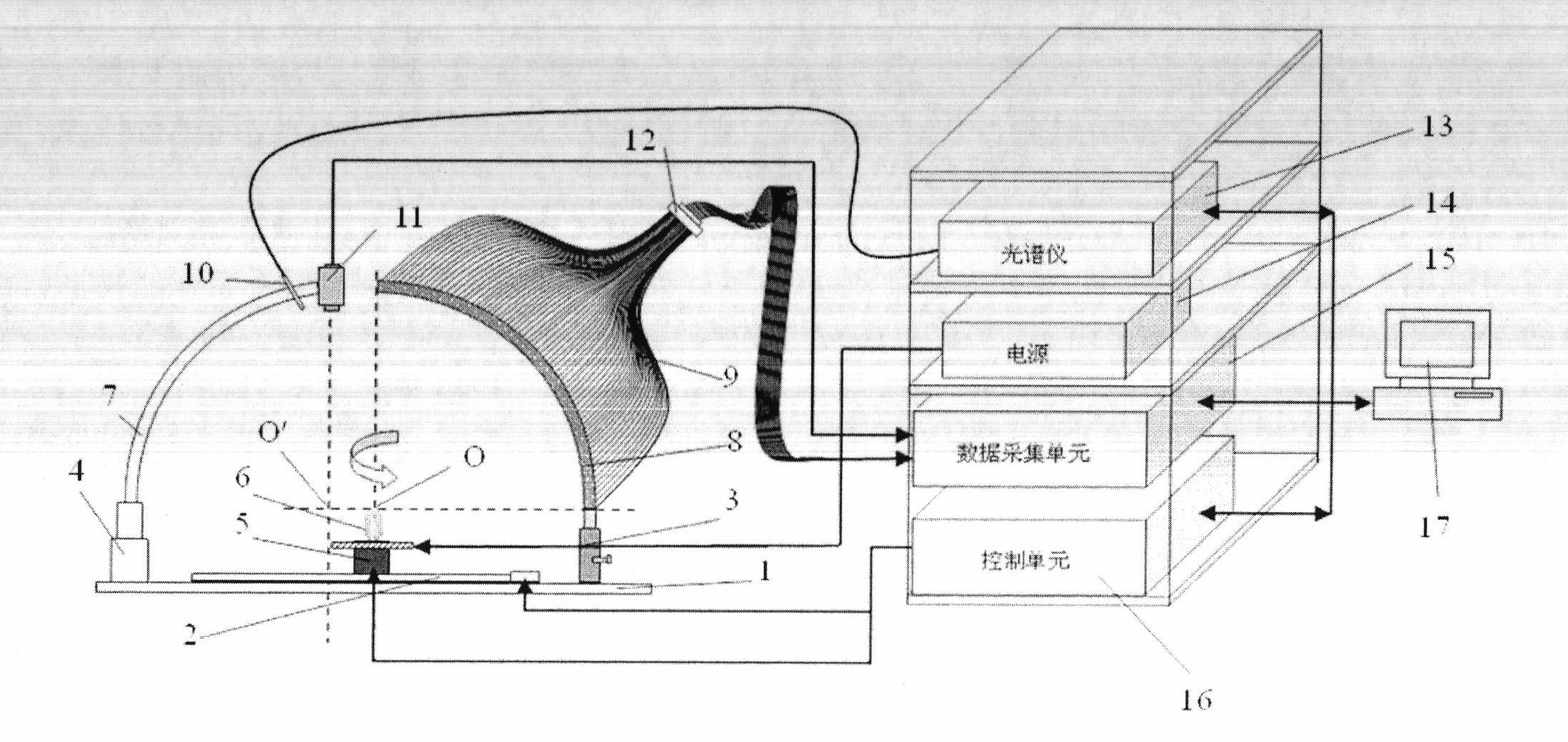

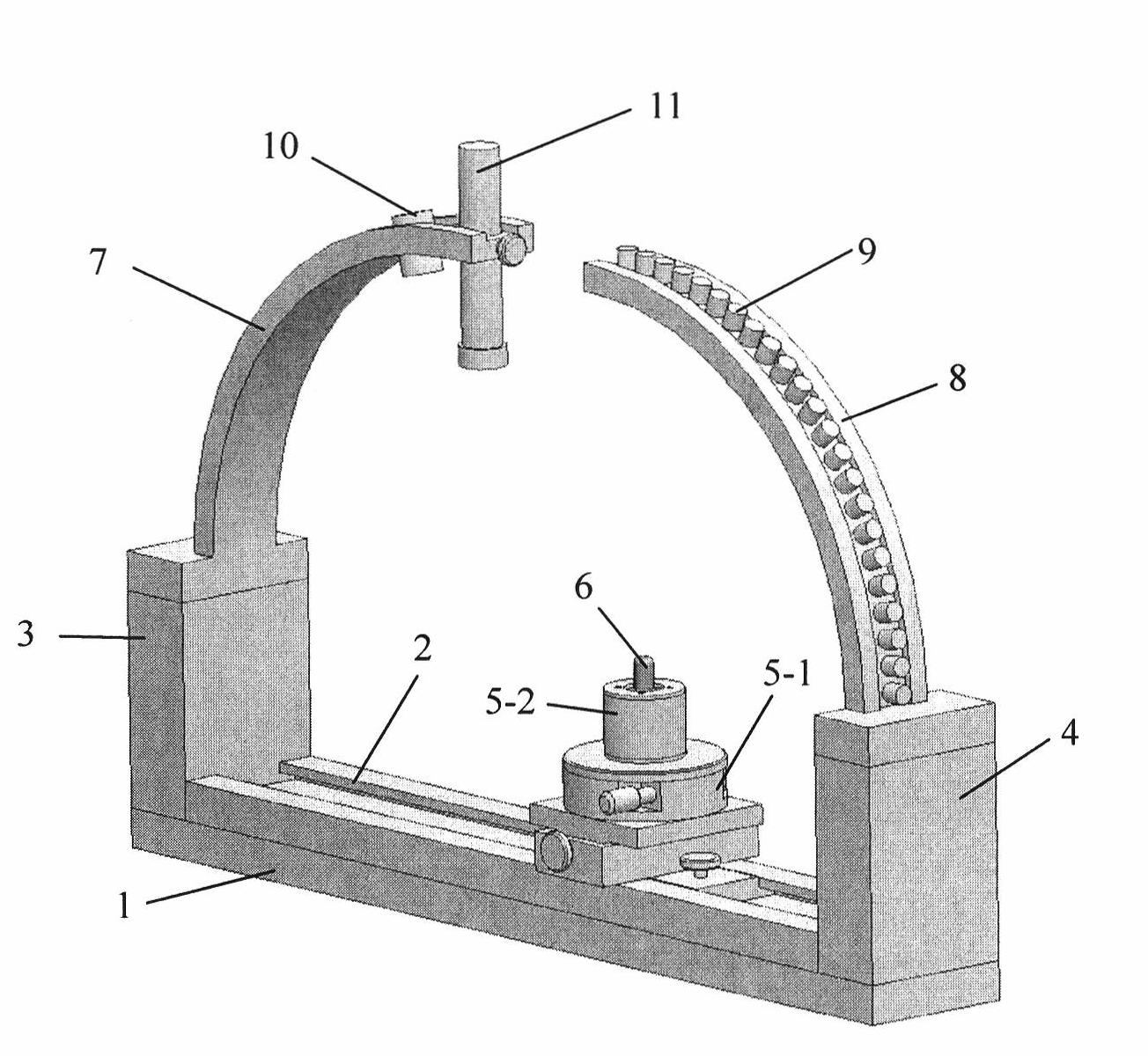

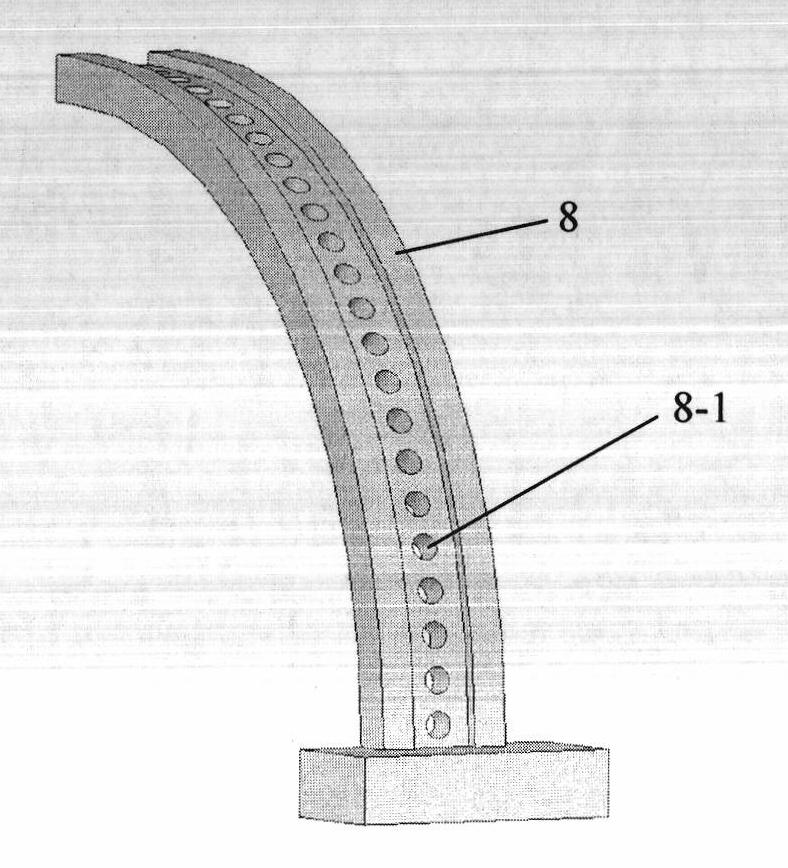

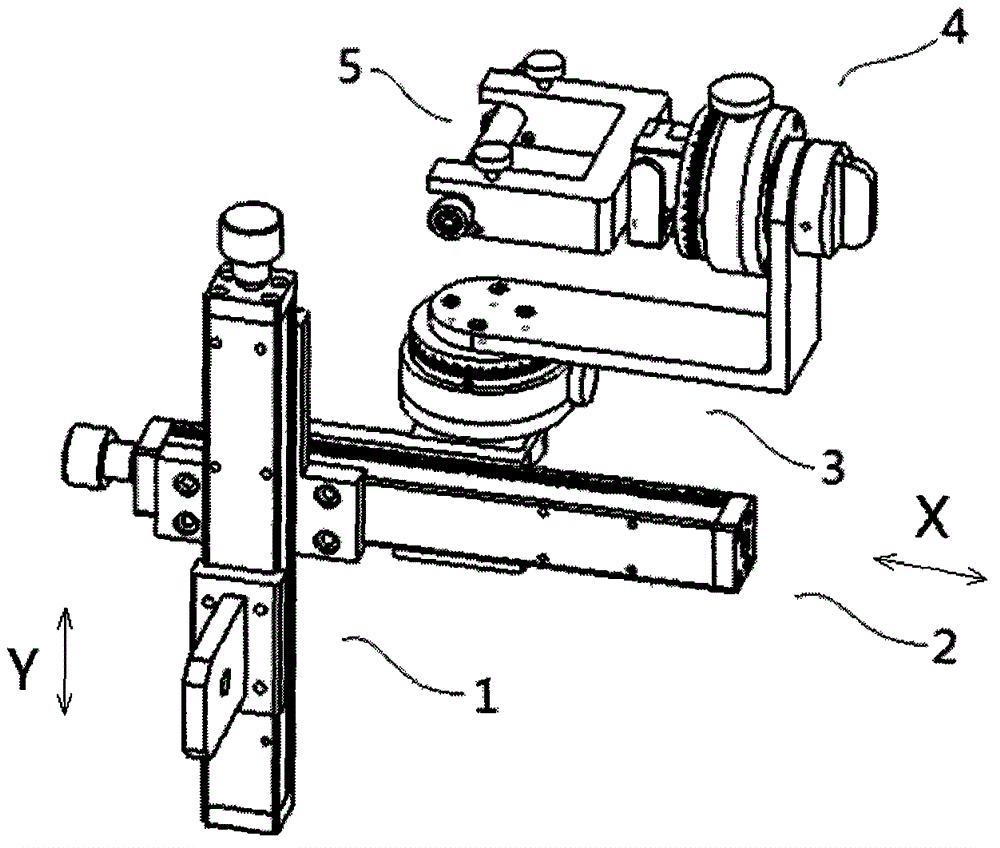

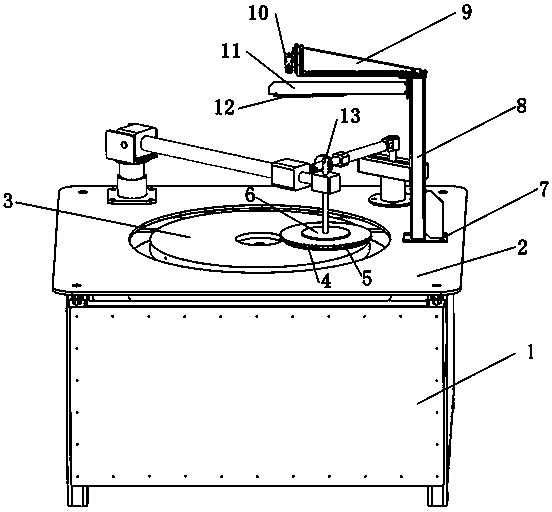

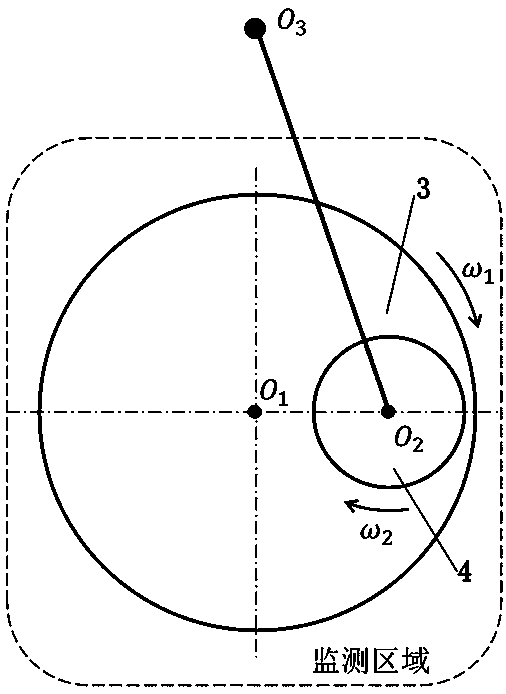

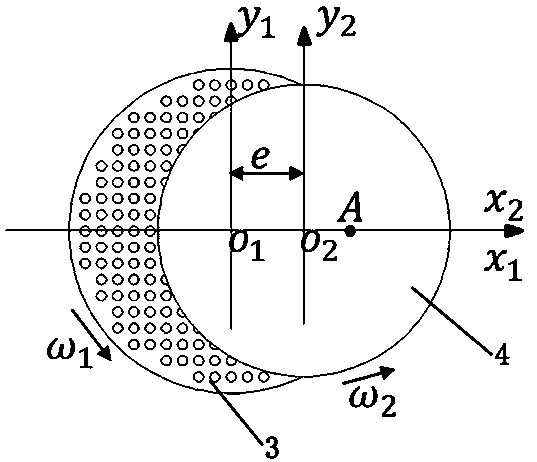

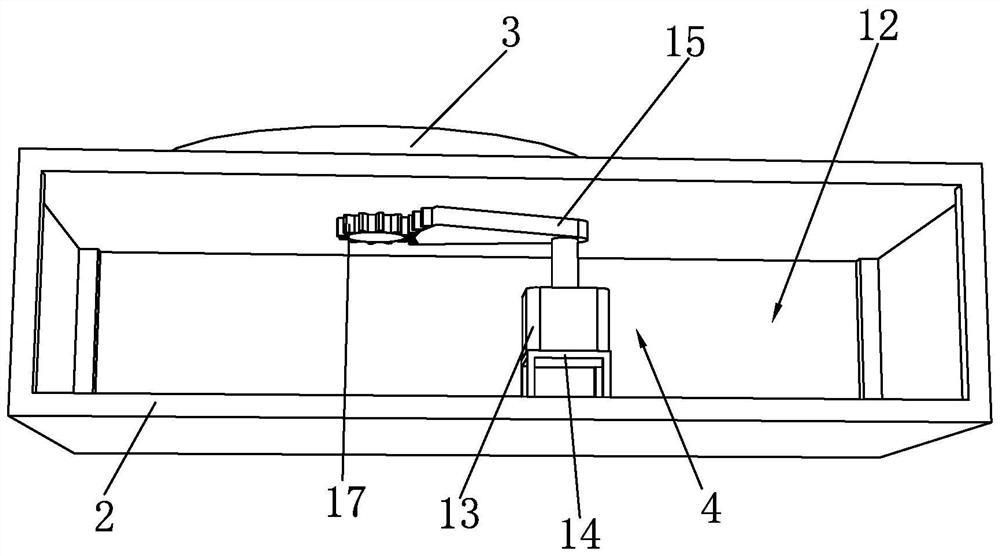

LED optical parameter comprehensive testing device

ActiveCN102213615AEfficient use ofAccurate measurementSpectrum investigationColor measuring devicesFiberMeasuring instrument

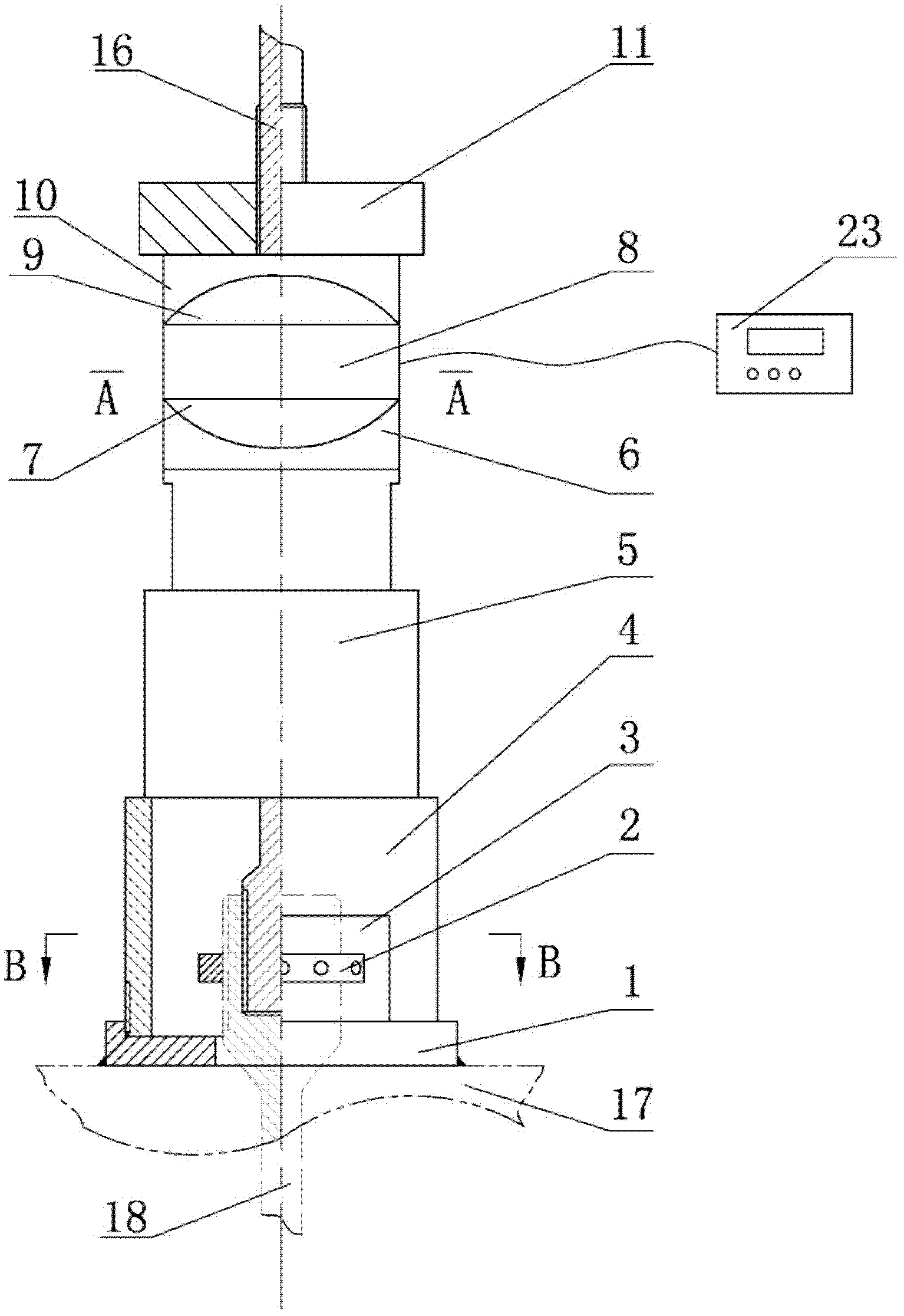

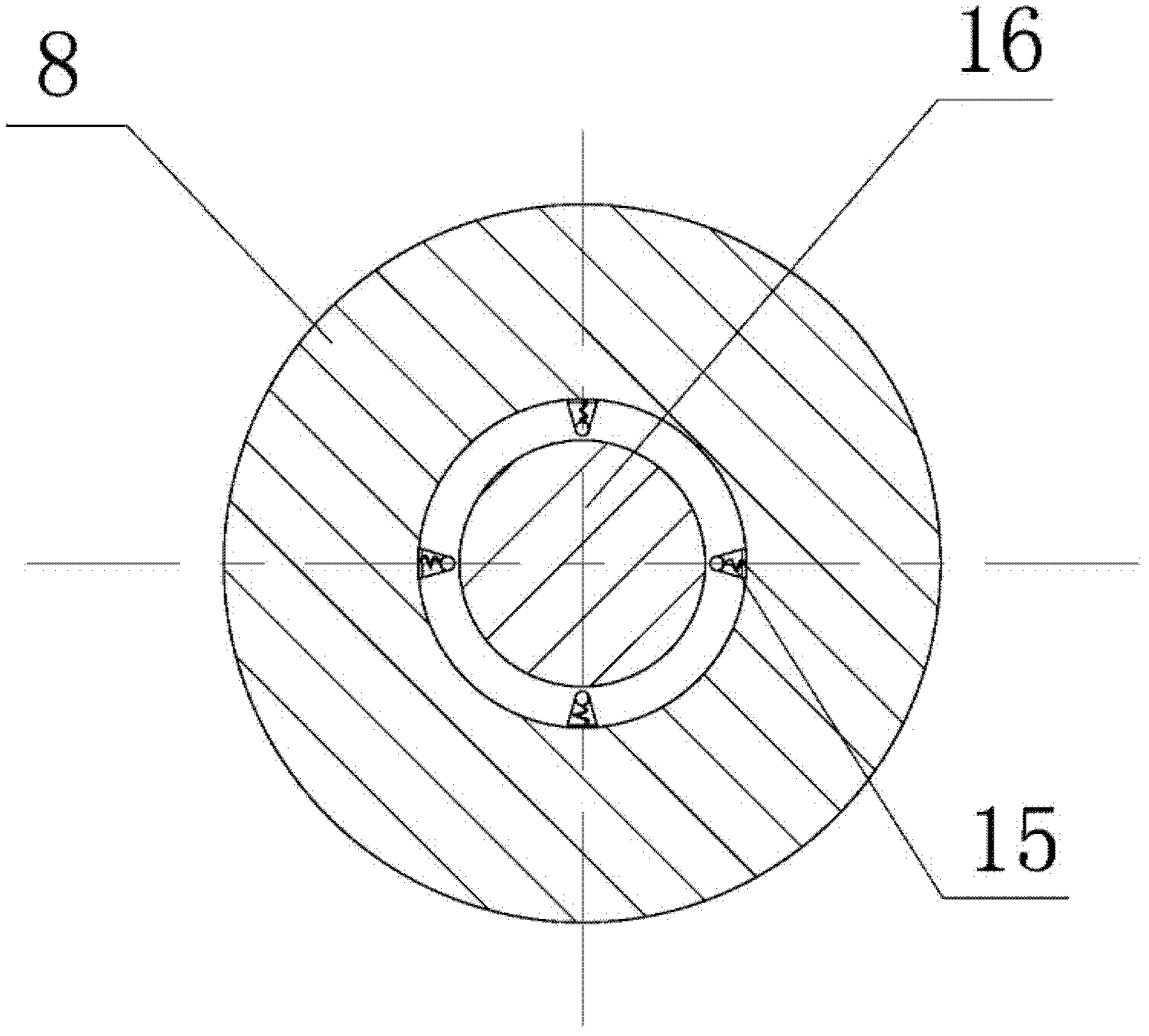

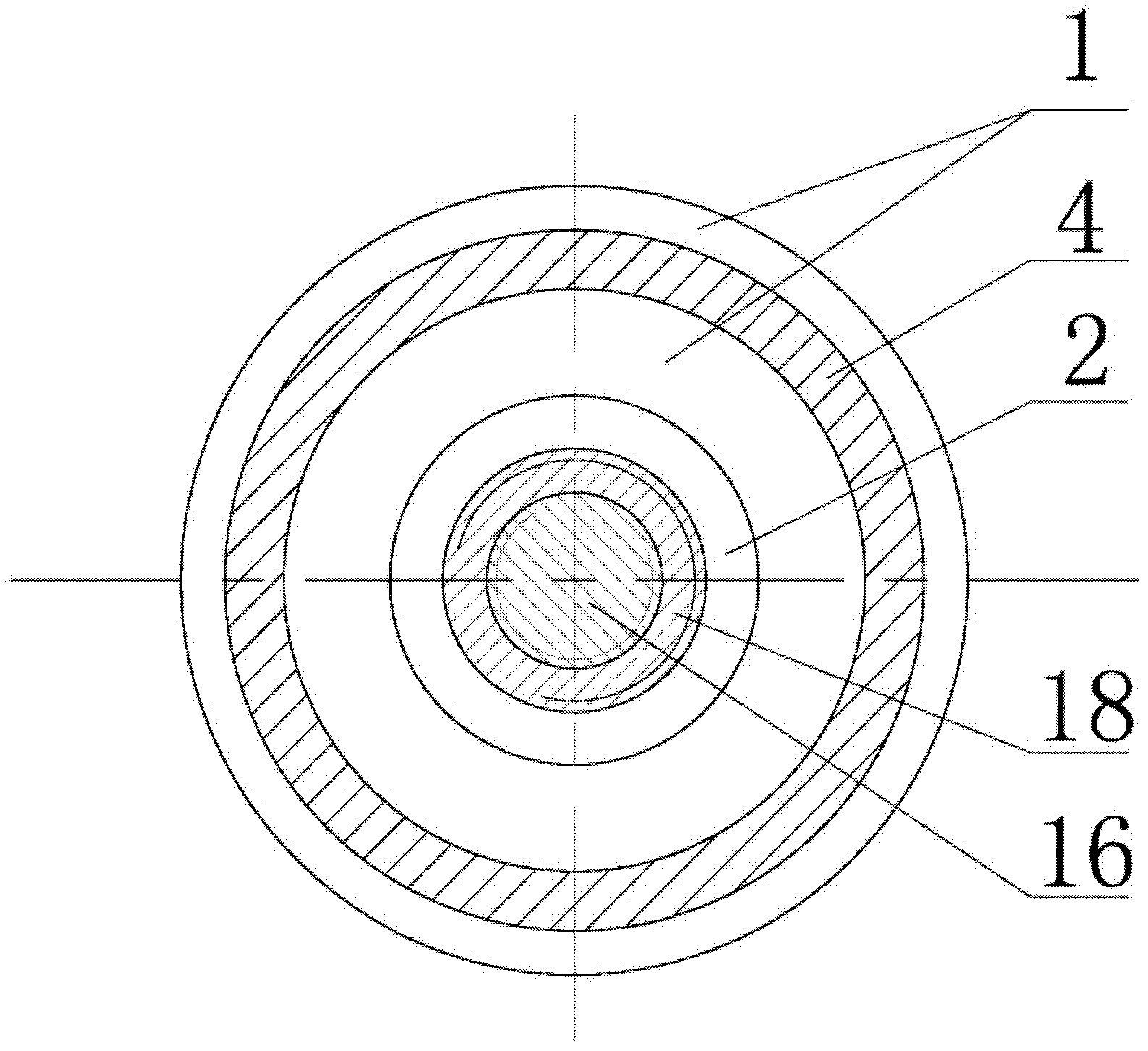

The invention discloses an LED optical parameter comprehensive testing device, belonging to the technical field of optical parameter measurement. The LED optical parameter comprehensive testing device is technically characterized in that one end of a horizontal base provided with a one-dimensional mobile platform is fixedly provided with an arc-shaped clamp provided with a fiber-optic probe and astandard luminosity probe, the other end of the horizontal base is fixedly provided with an arc-shaped light collector consisting of an arc fiber-optic array and a linear array CCD (Charge Coupled Device), and a rotary clamping table for holding an LED to be tested is arranged on the one-dimensional mobile platform; light information acquired by the fiber-optic probe is converted into a spectrum band by a spectrograph and then is sent into a computer, outputs of the standard luminosity probe and the linear array CCD are sent to the computer through the data acquisition unit, the computer performs corresponding processing and operation on measurement data through measurement software to finally obtain the luminescence characteristics of the LED to be tested. According to the invention, theproblem on comprehensively measuring the LED on a single measurement instrument is solved; and the LED optical parameter comprehensive testing device has the characteristics of simplicity for operation, compact structure, fastness for measurement, easiness for realization and the like.

Owner:CHINA NORTH IND NO 205 RES INST

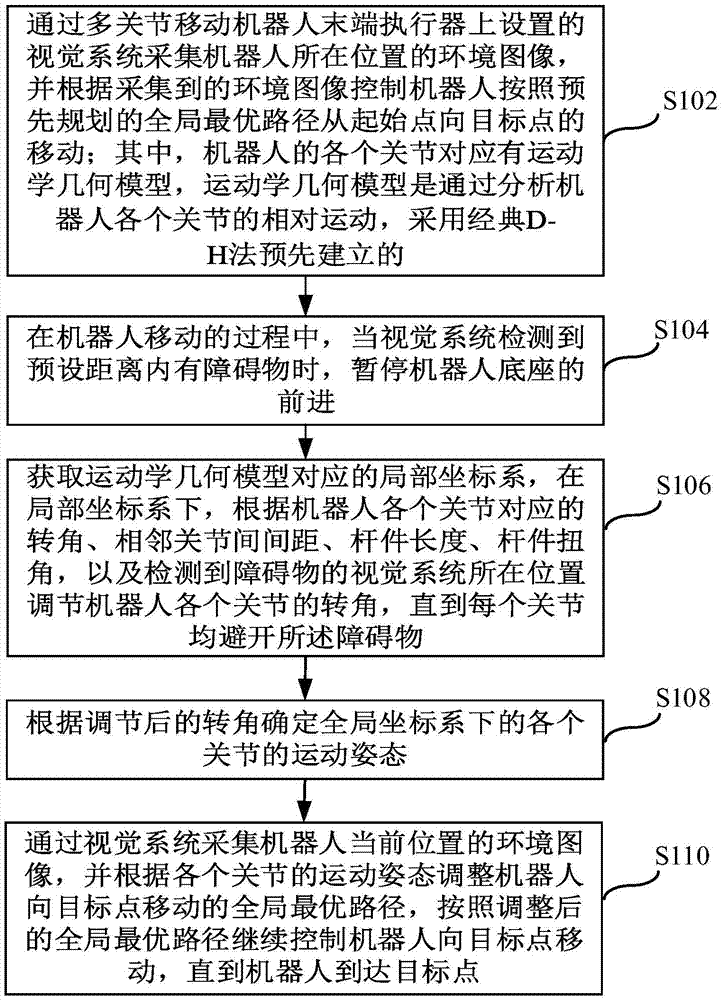

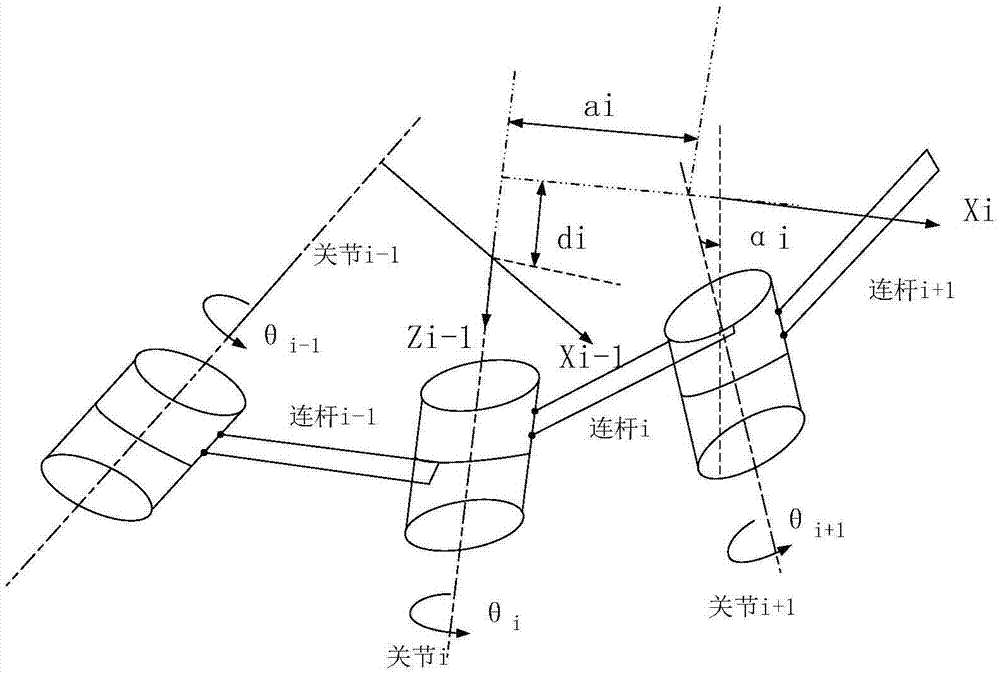

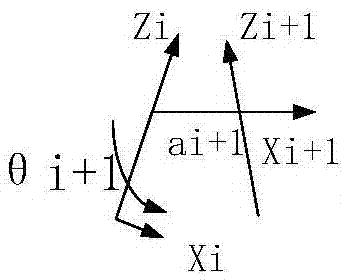

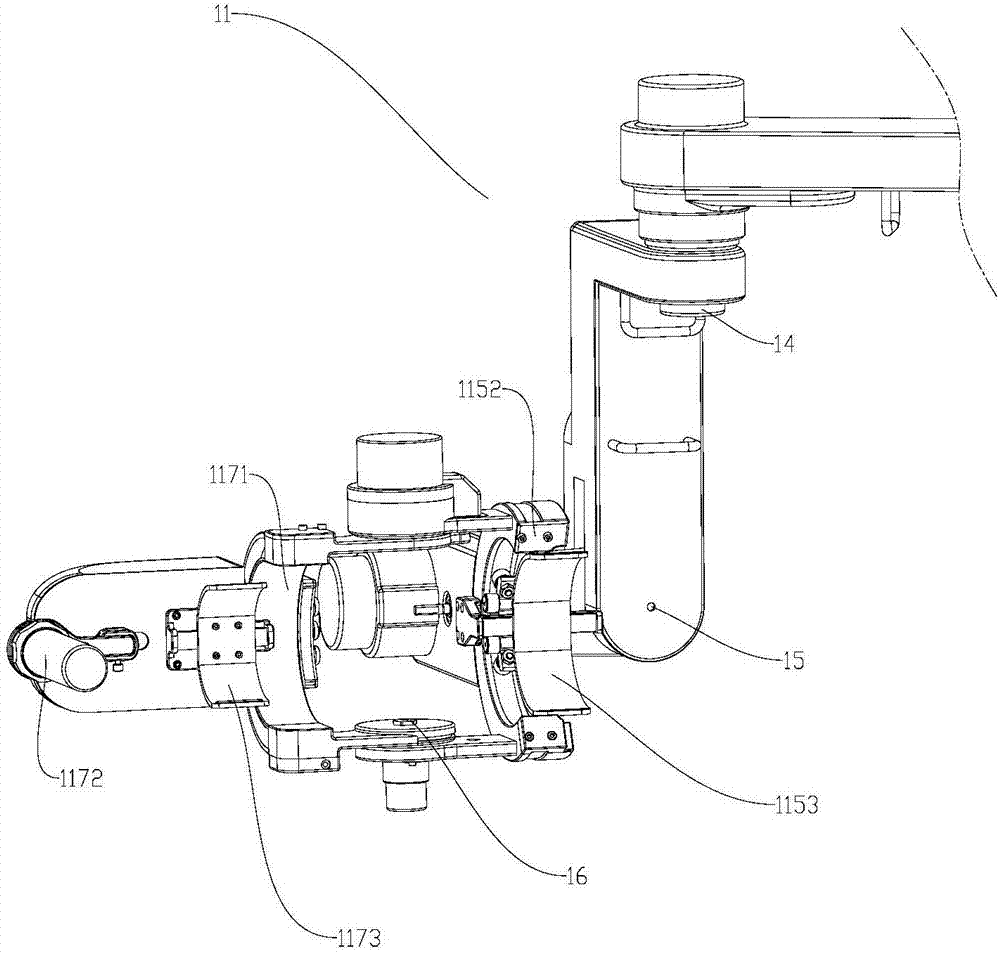

Method and device for controlling multi-joint moving robot to avoid obstacle

ActiveCN105437232AImprove obstacle avoidance efficiencyAvoid repeated adjustmentsProgramme-controlled manipulatorKinematicsGeometric modeling

The invention provides a method and device for controlling multi-joint moving robot to avoid an obstacle. The method is characterized in that a vision guidance device and the infrared obstacle avoidance device are mutually coordinated to control the robot to move during the process that the robot moves from a starting point to a target point along a pre-planned global optimal route; when a vision system detects the obstacle in the preset distance, a robot base is stopped marching, the movement posture of each joint can be automatically adjusted by grade on the basis of a pre-constructed kinematic geometric model of each joint, and the joints can be swung, from a tail end performer to the base, within a feasible region of each joint, so as to avoid the obstacle by grade; a servo system can control the pose position of each joint and the chassis movement direction, so as to continuously control the robot to move toward the target point until the robot reaches the target point; the movement postures of each joint and the base can be synchronously adjusted during the infrared obstacle avoiding process, thereby avoiding subsequent repeated adjusting, and as a result, the obstacle avoiding efficiency of the multi-joint moving robot can be improved.

Owner:HUNAN VISUALTOURING INFORMATION TECH CO LTD

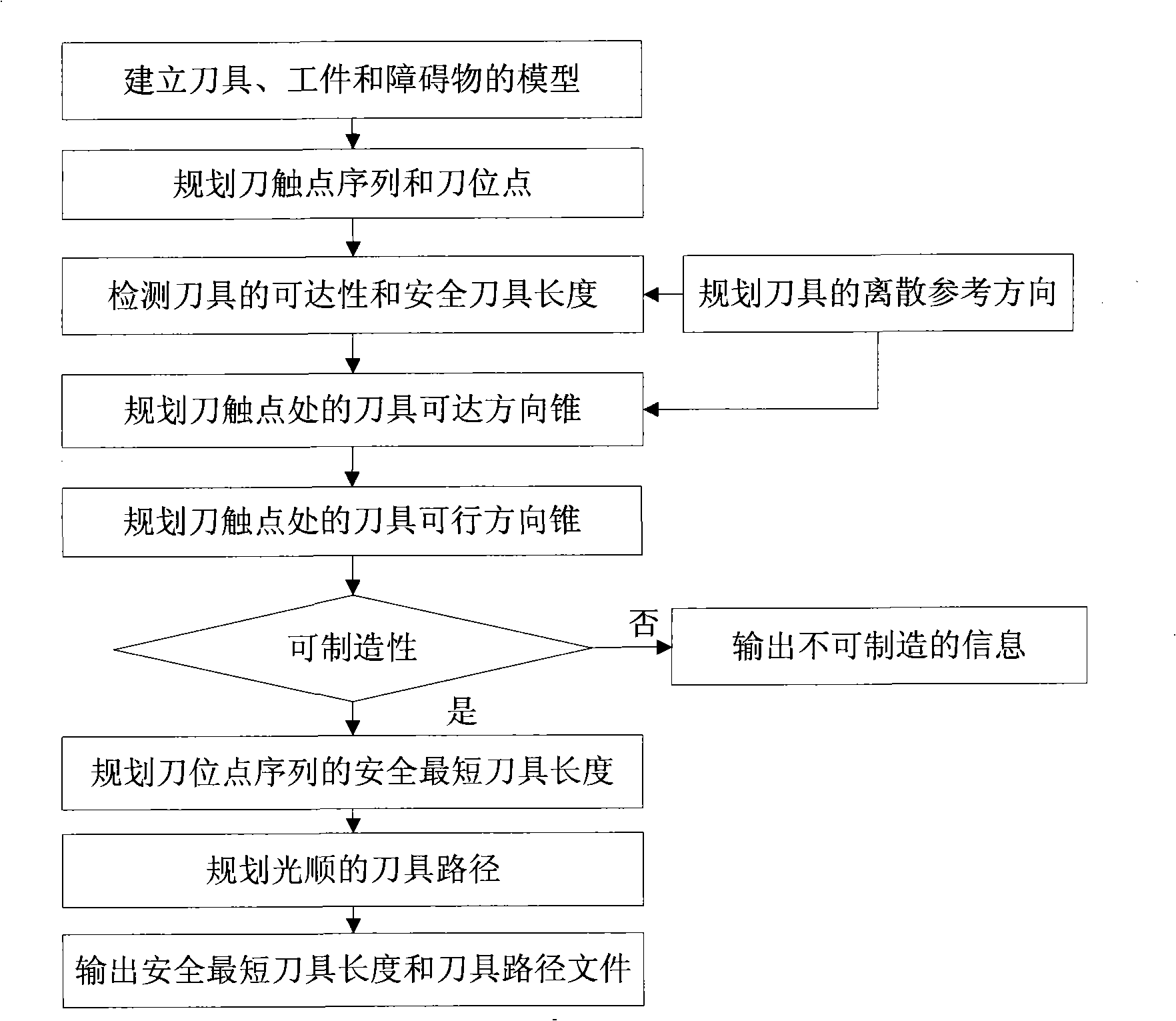

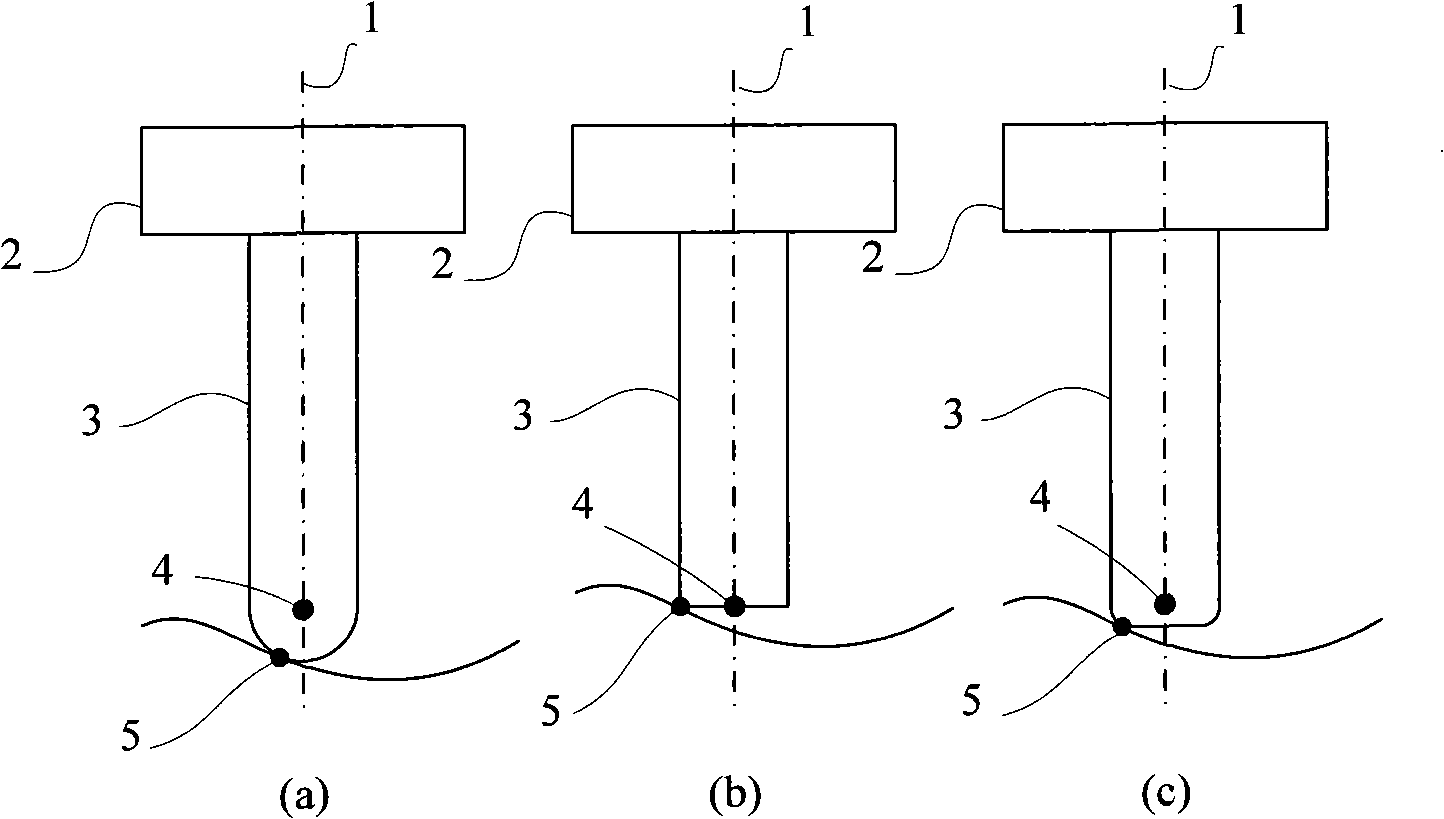

Method for planning five-axis numerical control to process safety shortest cutting tool length

InactiveCN101303583AAvoid repeated adjustmentsImprove computing efficiencyProgramme controlComputer controlCircular discNumerical control

The invention relates to a planning method for processing the length of a safe and shortest knife by adopting five-axle numerical control, analyzing component manufacturability and programming a smooth cutter path. Firstly, a maximum value of the cutter length is set within the range allowed in the technology; disc of the cylindrical surface for the knife rotation at the positions of knifepoint and a barrier are gridded, and through the depth testing of video card and the function of blocking and querying, the reachable information and safe shortest length of the knife in a reference direction can be obtained, and the reachable direction cone of the knife is programmed; then according to the restriction to direction continuity and processing environment, the feasible direction cone is calculated and the manufacturability is judged. If the programmed knife is manufacturable, the length of safe and shortest knife of a knifepoint sequence is programmed in the feasible direction cone in a dynamic planning method, and then a smooth knife path is programmed. The method of the invention has high efficiency, simply realized programming, can be applied to 3 plus 2 axle numerical control processing of complex components or knife choosing and path planning of five-axle linkage numerical control processing.

Owner:SHANGHAI JIAO TONG UNIV

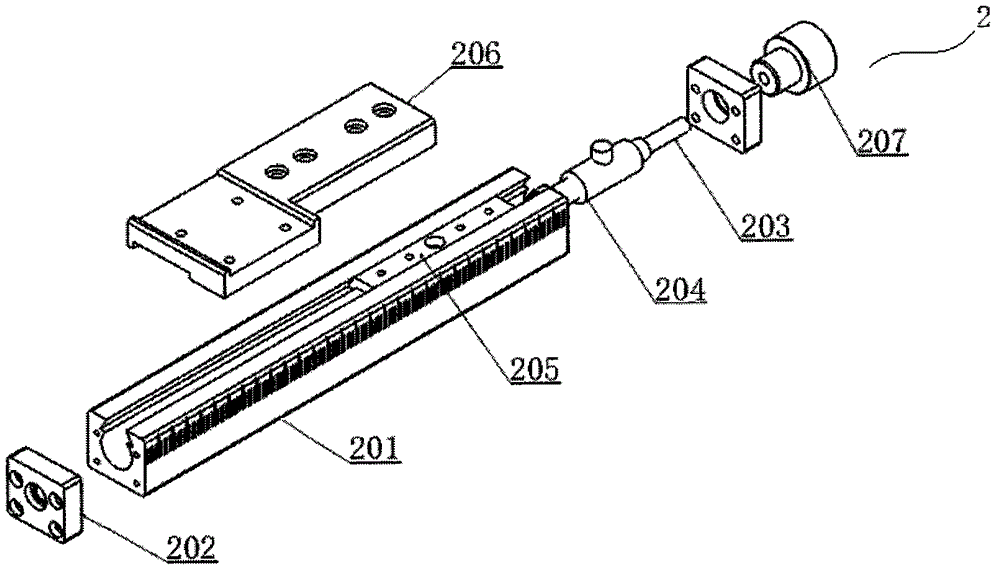

Active power control device and control method for distributed photovoltaic power station

InactiveCN103928940AAvoid repeated adjustmentsAvoid frequent switchingSingle network parallel feeding arrangementsPhotovoltaic energy generationTime informationControl system

The invention provides an active power control device and control method for a distributed photovoltaic power station. The control device comprises a communication management module, a command processing module, an AGC module, a data management module and an information displaying module. The data management module is in charge of storing all data information related to an active power control system and in charge of history base and real-time base management. The information displaying module is in charge of displaying the operation information of the active power control system. The AGC module carries out active power distribution on all inverters through the equal-margin distribution strategy according to the latest real-time information received at present, so that the active power of the current power station meets the requirement of power grid dispatching.

Owner:STATE GRID CORP OF CHINA +3

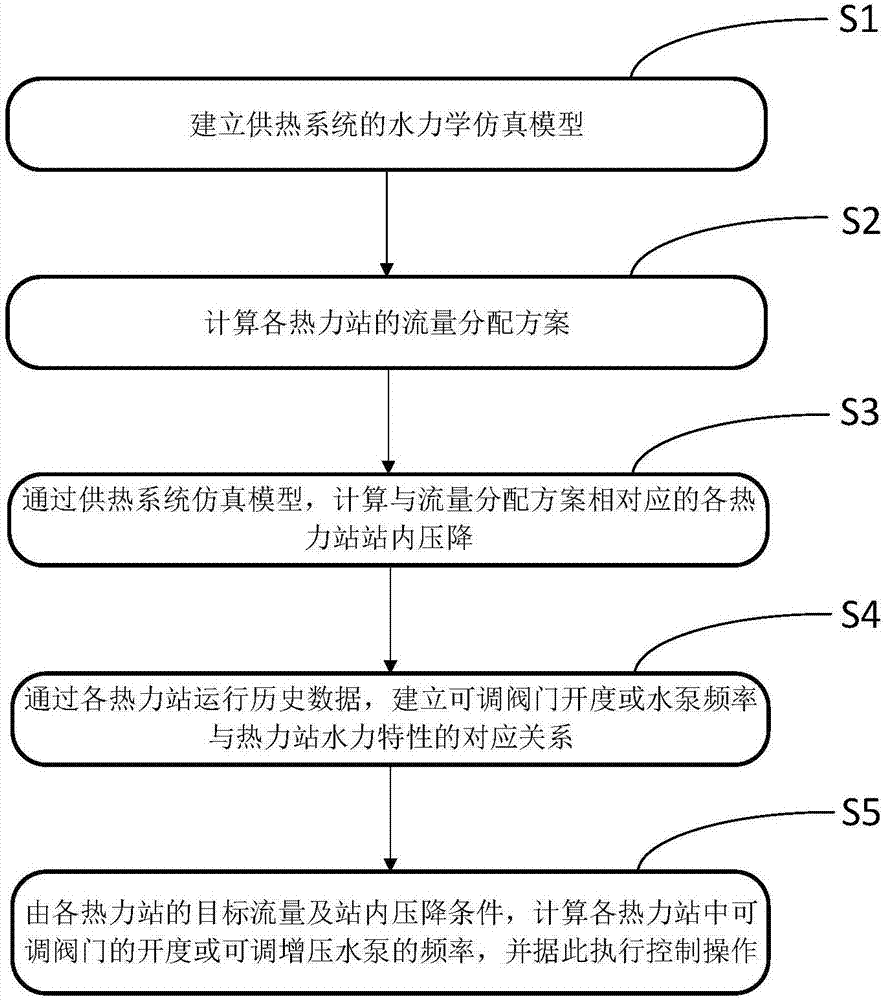

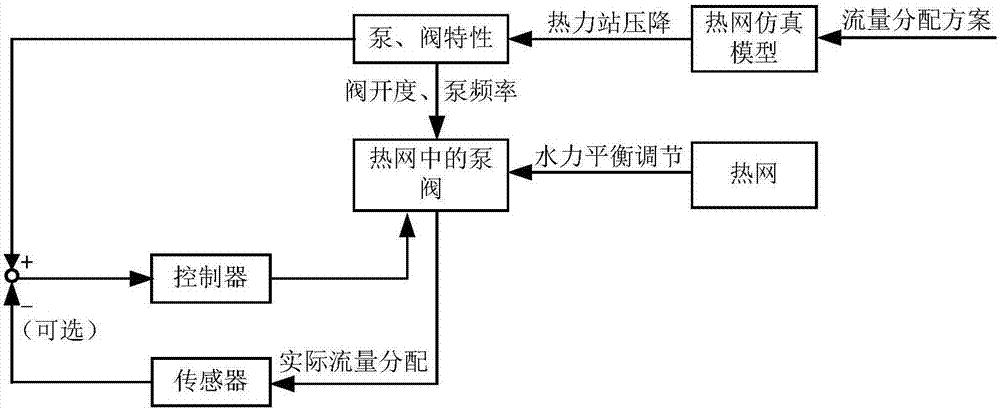

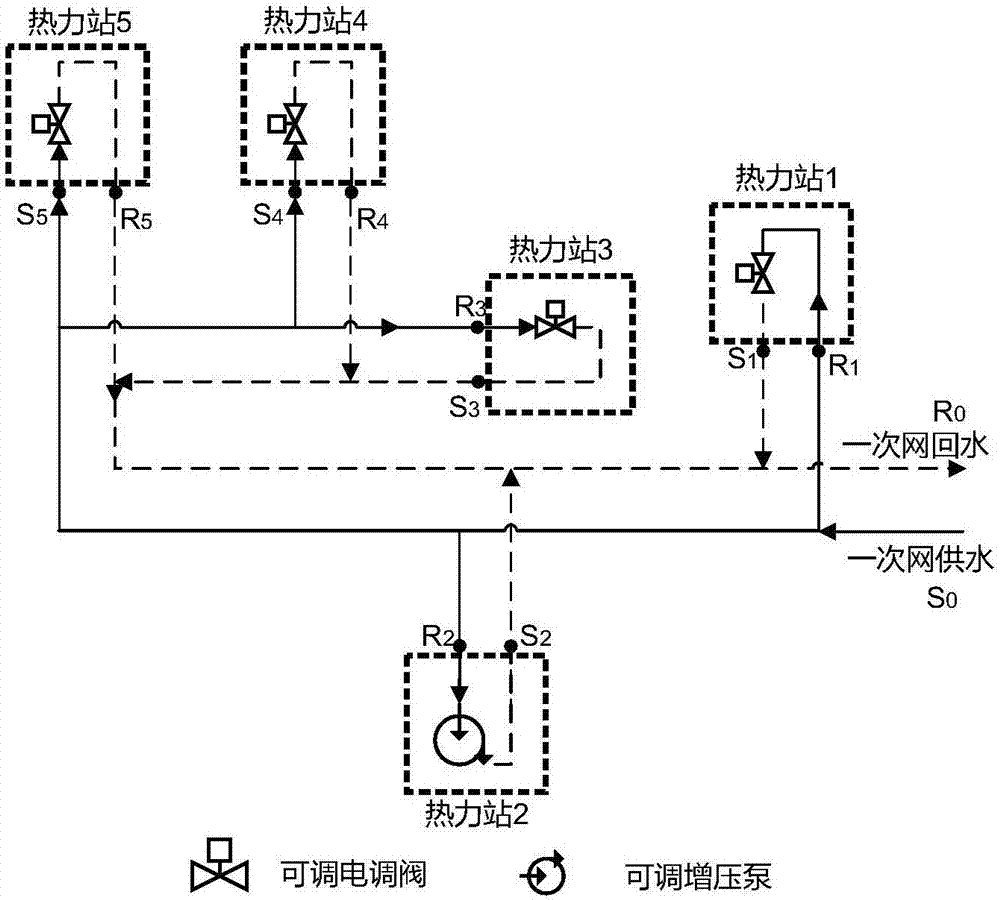

Heating supply system hydraulic equilibrium model prediction control method and system

ActiveCN106958855AAvoid repeated adjustmentsIncreased level of controlLighting and heating apparatusFluid distribution meansTraffic capacityEngineering

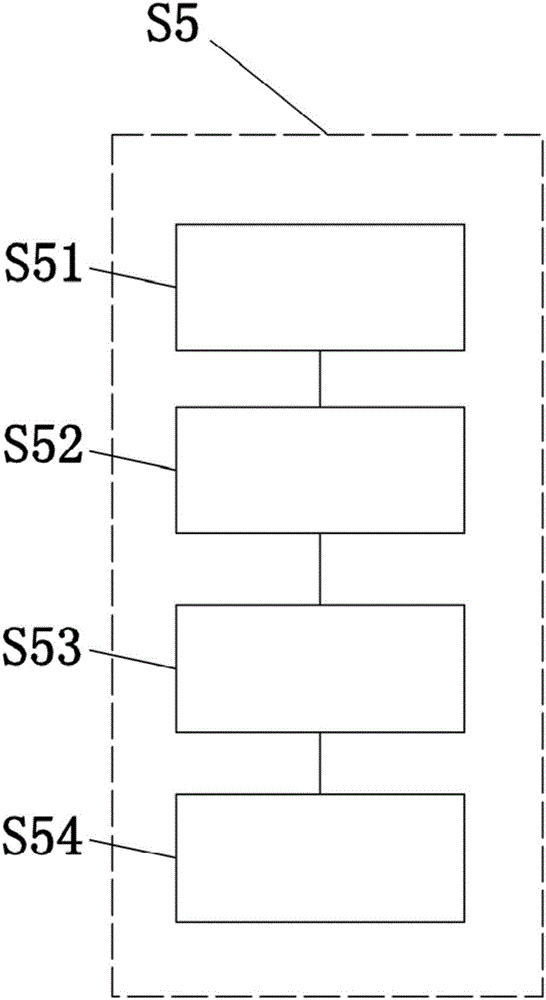

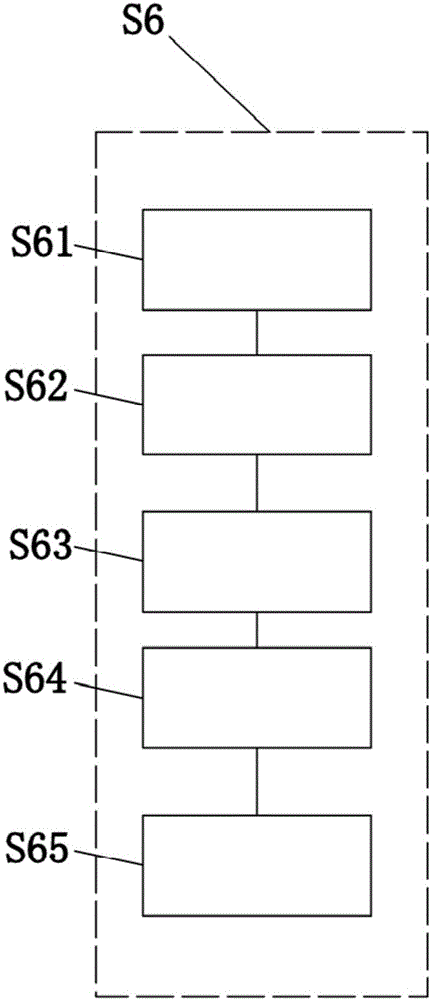

The invention relates to a heating supply system hydraulic equilibrium model prediction control method and system. The model prediction control method comprises the following steps that S1, a heating supply system hydraulics simulation model is built; S2, flow distribution schemes of all heating stations are calculated; S3, through the heating supply system hydraulics simulation model, in-station pressure drop of all heating stations corresponding to the flow distribution schemes is calculated; S4, through all heating station running historical data, the congruent relationship between the adjustable valve opening degree or water pump frequency and the heating station hydraulic characteristic is built; and S5, according to target flow and in-station pressure drop conditions of all heating stations, the adjustable valve opening degree or adjustable booster pump frequency in all heating stations are calculated, and control operation is accordingly executed.

Owner:CHANGZHOU ENGIPOWER TECH

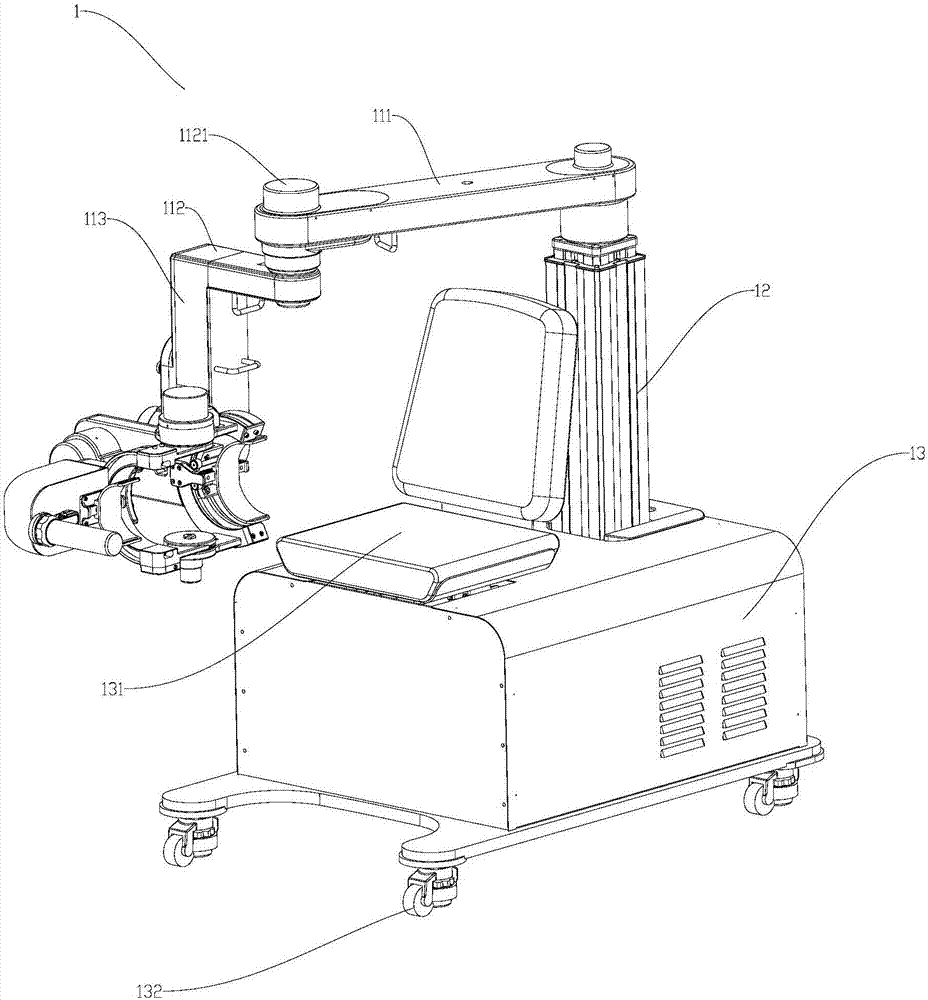

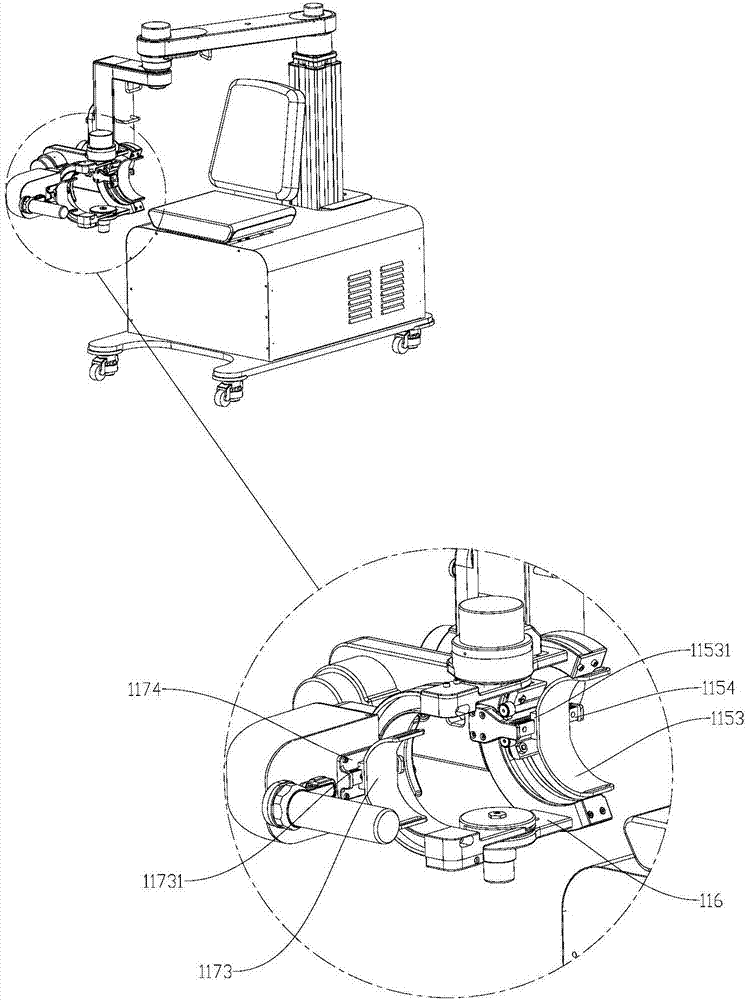

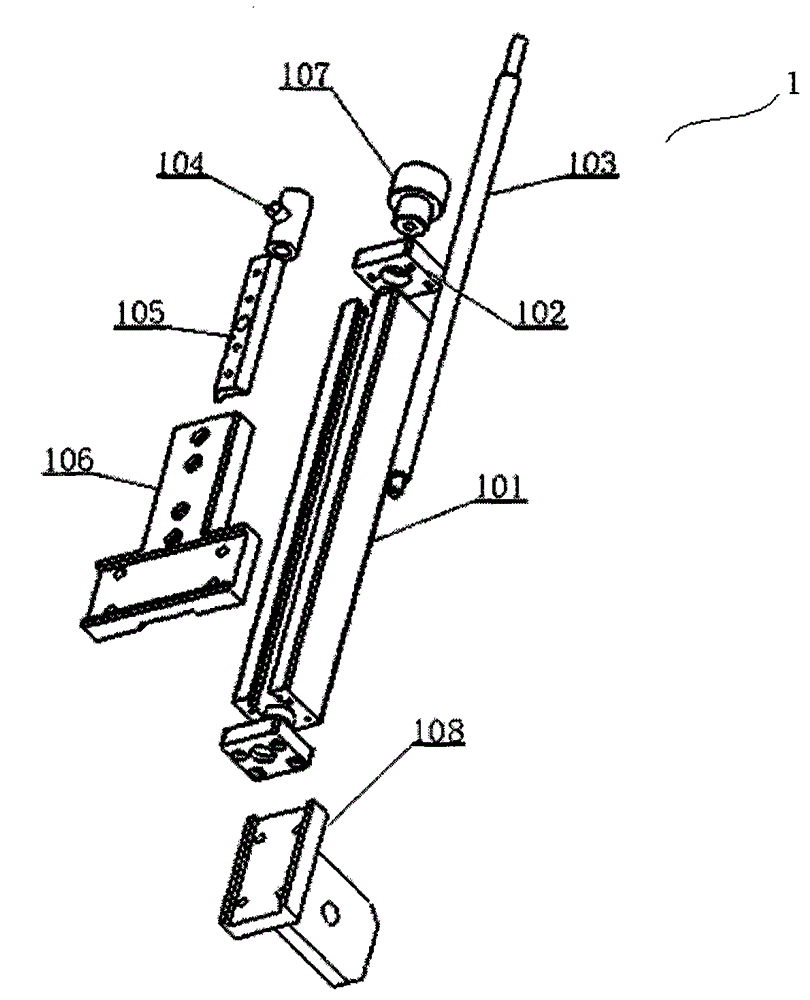

Upper limb training mechanical arm, upper limb training robot and training method

PendingCN107260489ASmooth movementEliminate pulling feelingChiropractic devicesManipulatorArm exerciseUpper limb training

The invention discloses an upper limb training mechanical arm, an upper limb training robot and a training method, wherein a forearm structural piece of the upper limb training mechanical arm is provided with a forearm bent rail and a rear arm structural piece is provided with a rear arm bent rail, and the forearm bent rail and the rear arm bent rail are connected to an elbow joint structural piece; a forearm bandage, which corresponds to the forearm bent rail, is arranged on the forearm structural piece; a forearm sliding piece is arranged on a part where the forearm bandage and the forearm structural piece are connected; a rear arm bandage, which corresponds to the rear arm bent rail, is arranged on the rear arm structural piece; and a rear arm sliding piece is arranged on a part where the the rear arm bandage and the rear arm structural piece are connected. According to the upper limb training mechanical arm provided by the invention, the forearm sliding piece, which is arranged on the part where the forearm bandage and the forearm structural piece are connected, and the rear arm sliding piece, which is arranged on the part where the rear arm bandage and the rear arm structural piece are connected, so that the forearm bandage and the rear arm bandage can slide oppositely along the forearm structural piece and the rear arm structural piece in a motion process of an arm, so that the arm is more smooth in motion, and pulling feeling of the forearm bandage and the rear arm bandage on the arm is eliminated.

Owner:GUANGZHOU YIKANG MEDICAL EQUIP INDAL

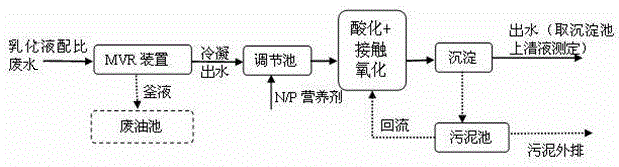

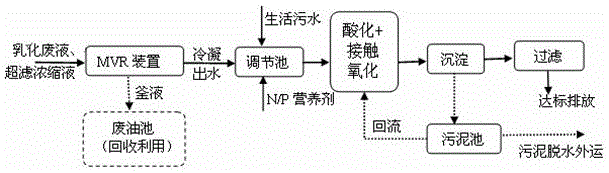

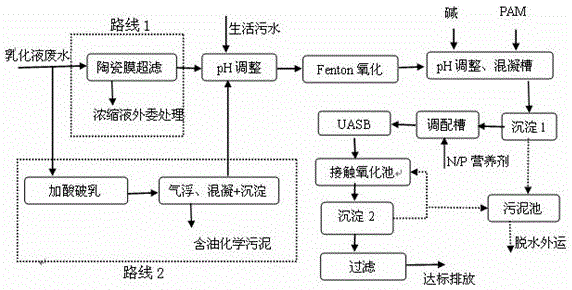

MVR technology-based machining emulsified wastewater treatment method

InactiveCN105036462AReasonable ideaSimple processMultistage water/sewage treatmentWater/sewage treatment by heatingUltrafiltrationProcess engineering

The invention relates to an MVR technology-based machining emulsified wastewater treatment method. The method comprises the following steps: realizing oil-water separation of emulsified wastewater by adopting an MVR technology, allowing condensed water generated after evaporation to enter an equalizing tank, and carrying out biochemical treatment; adding supplemented nutrients needed by subsequent biological treatment to the equalizing tank in order to realize subsequent biological treatment; carrying out hydrolysis acidifying treatment on wastewater to convert non-biodegradable organic matters in the wastewater into soluble organic matters, carrying out aerobic decomposition on the organic matters in the wastewater, and discharging outlet water to a next treatment technology; discharging water discharged from a contact aerobic tank to a secondary sedimentation tank in order to carry out mud-water separation; and filtering water separated through the secondary sedimentation tank to remove residual suspensions in water. The method has the advantages of simple process flow, stable control of the biochemical treatment impact load, guaranteeing of standard reaching of treatment outlet water, and solving of the secondary treatment problem of concentrate and ultrafiltration concentrate in traditional technologies.

Owner:湖北山鼎环境科技股份有限公司 +1

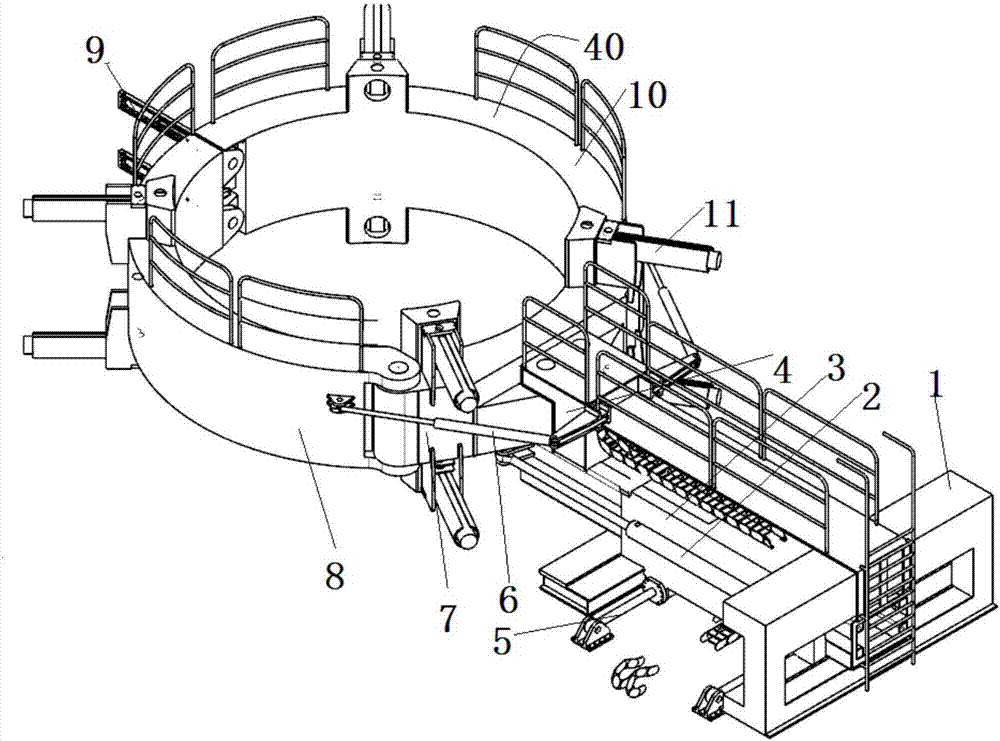

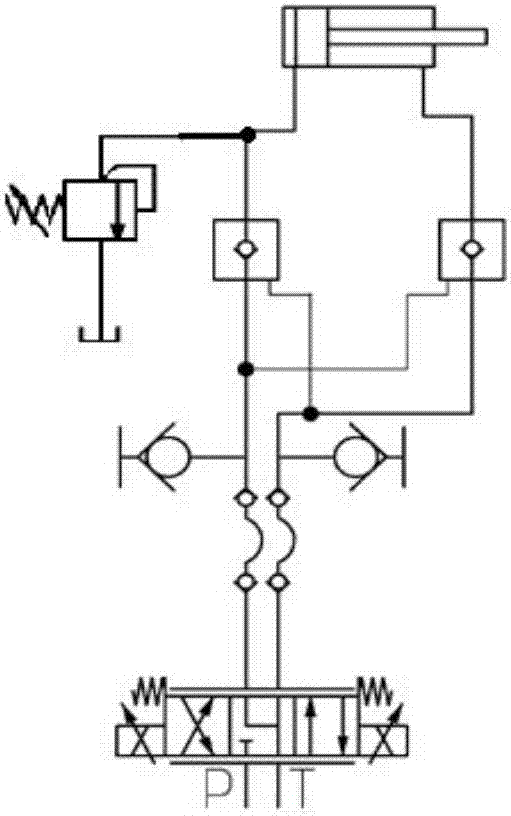

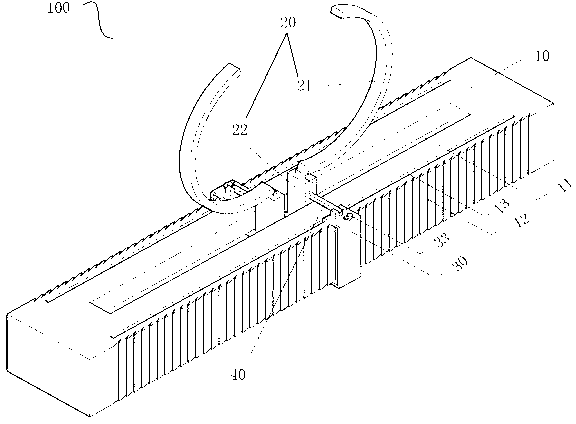

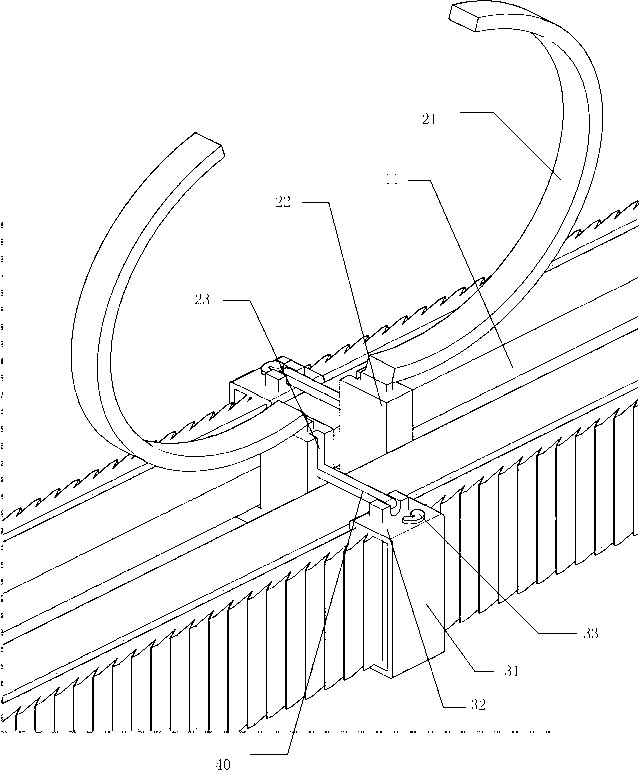

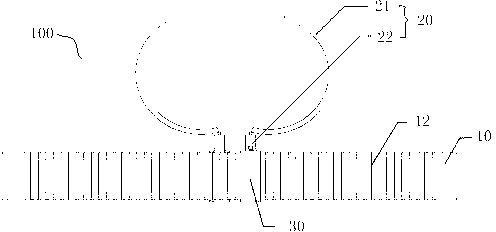

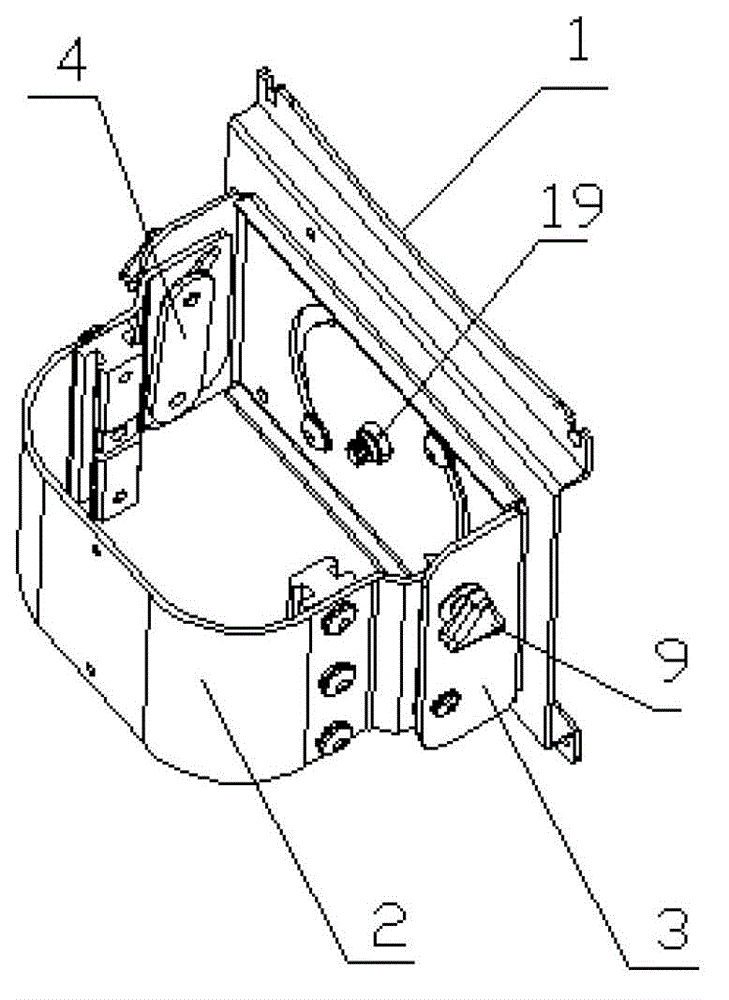

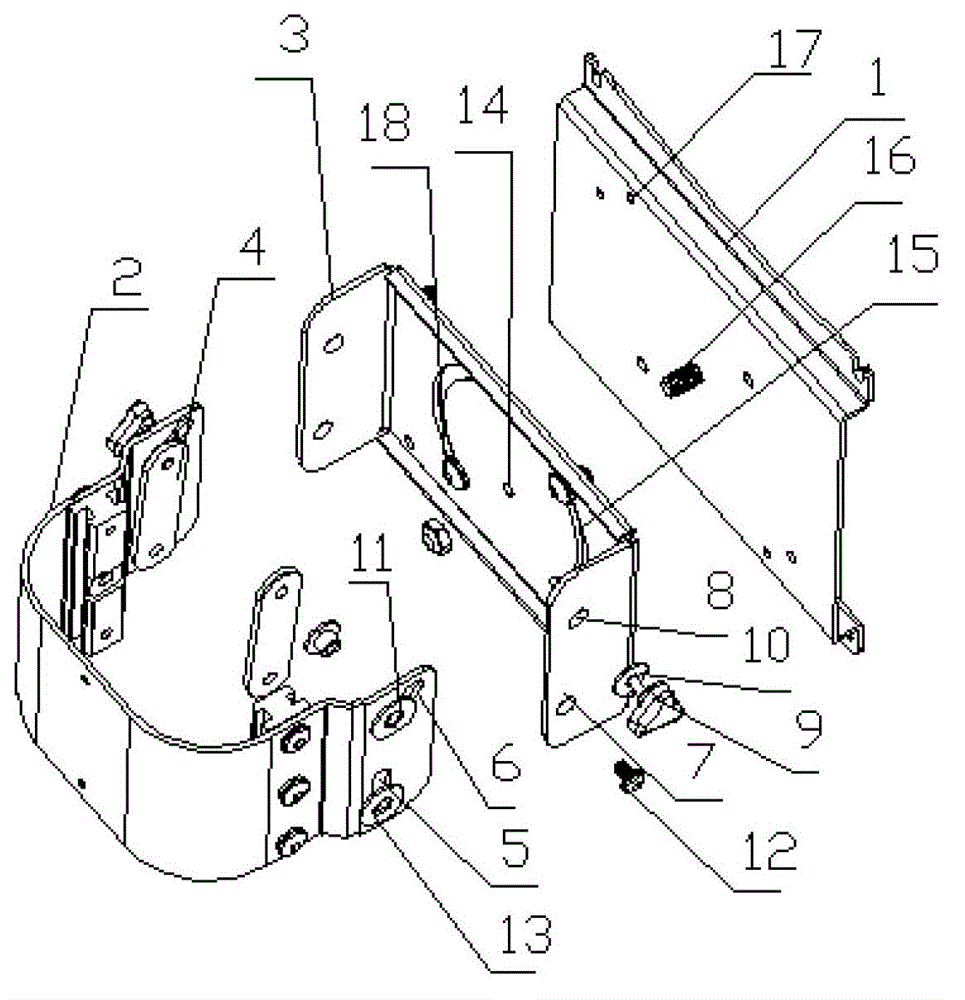

Pile gripper for offshore piling

The invention relates to a pile gripper for offshore piling. The pile gripper for offshore piling is composed of a pile gripper mechanism system, a hydraulic system and an electrical control system. A large base is connected with a sliding base through a sliding rail. A cross beam is installed in a sliding groove of the sliding base. A lateral thrust cylinder is installed on the portion, between a deck and the sliding base, of a mounting base. A main thrust cylinder is installed on the portion, between the sliding base and the cross beam, of the mounting base. A hoop is installed at the front end of the cross beam. The left side and the right side of the front end of a hoop base are connected with a left hoop body and a right hoop body separately. The left hoop body and the right hoop body are connected with the two sides of the cross beam through hoop opening and closing cylinders correspondingly. The hoop is provided with a pile gripping and clamping mechanism. Two sets of locking mechanisms are installed at the front end of the left hoop body. The right hoop body is provided with pin holes corresponding to taper pins of the locking mechanisms. Each pile gripping cylinder is connected with a proportional valve and controlled to act by the proportional valve. A programmable logic controller (PLC) performs closed-loop control over the opening degree and direction of the proportional valves according to a feedback signal of a magnetostrictive displacement sensor, so that the pile gripping cylinders are controlled to perform pile jacking guidance on steel piles and keep guidance on the steel piles within a required range.

Owner:SHANGHAI HUNTER MARINE EQUIP CO LTD +1

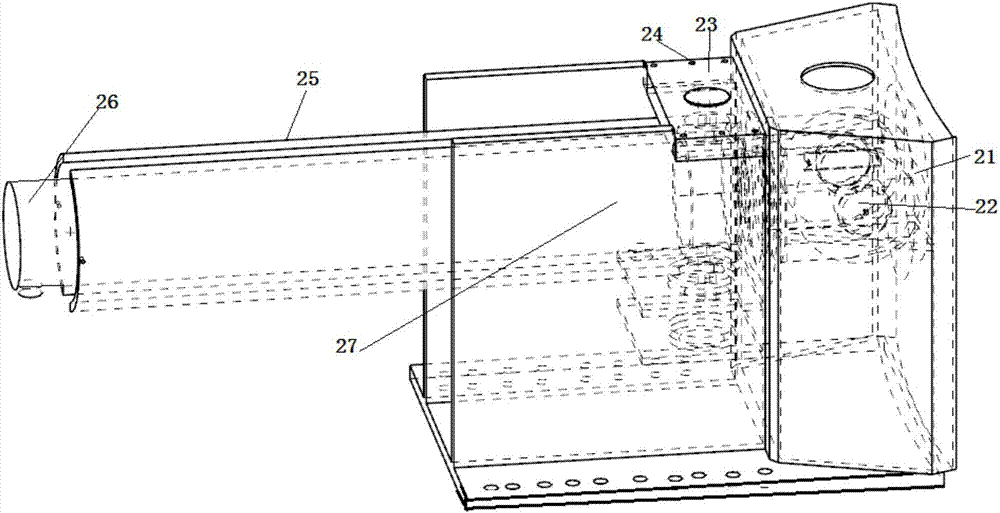

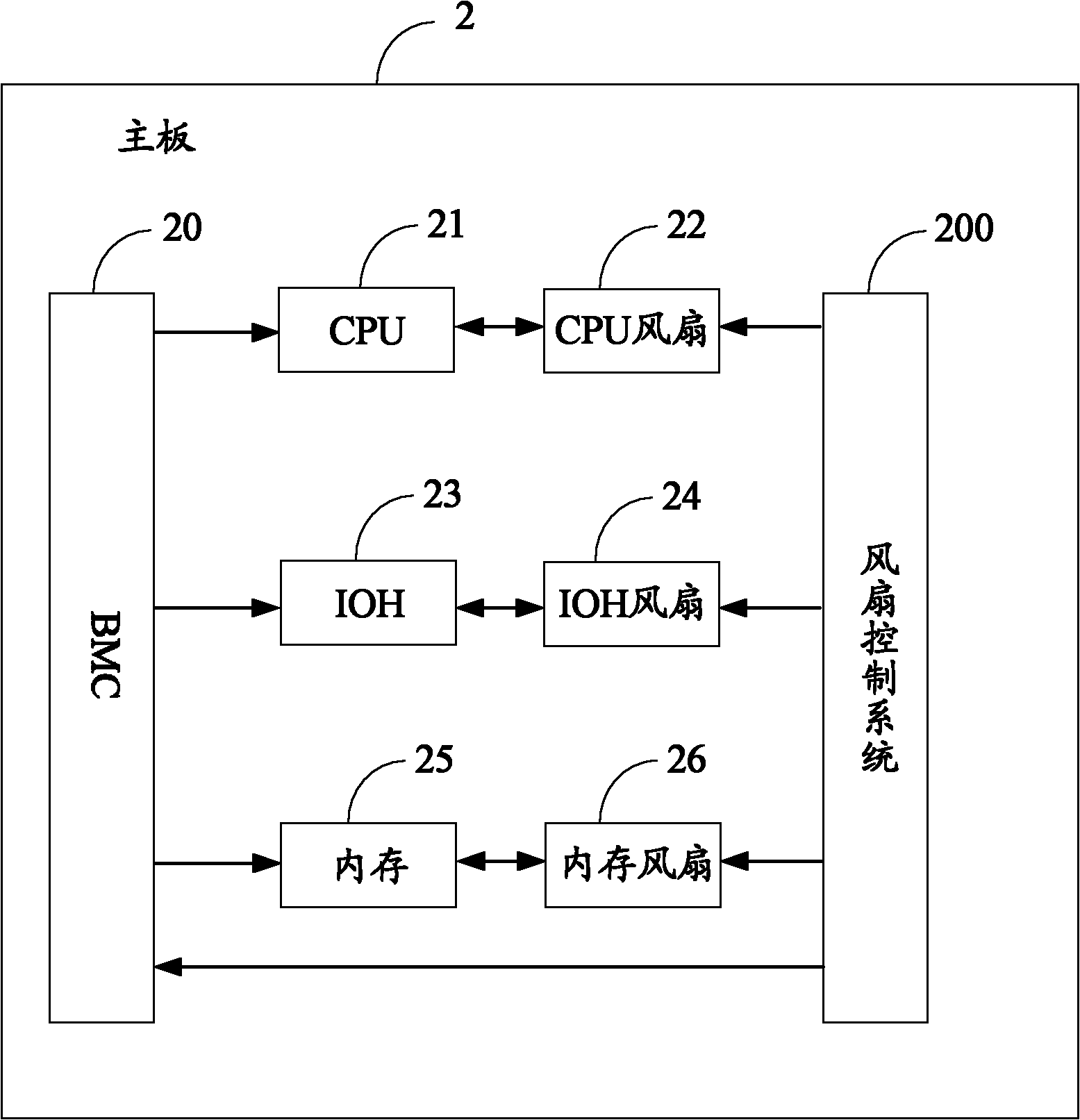

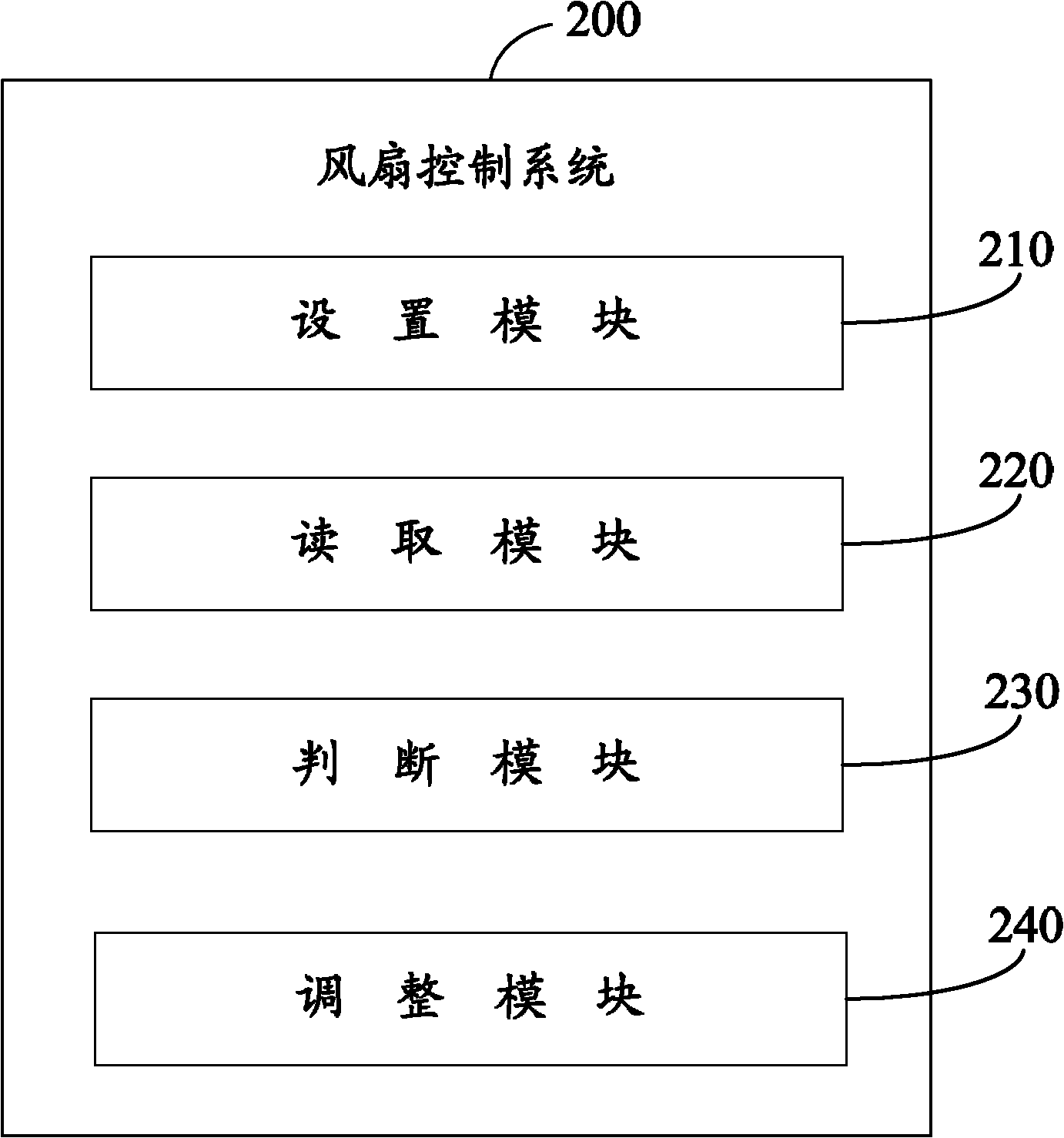

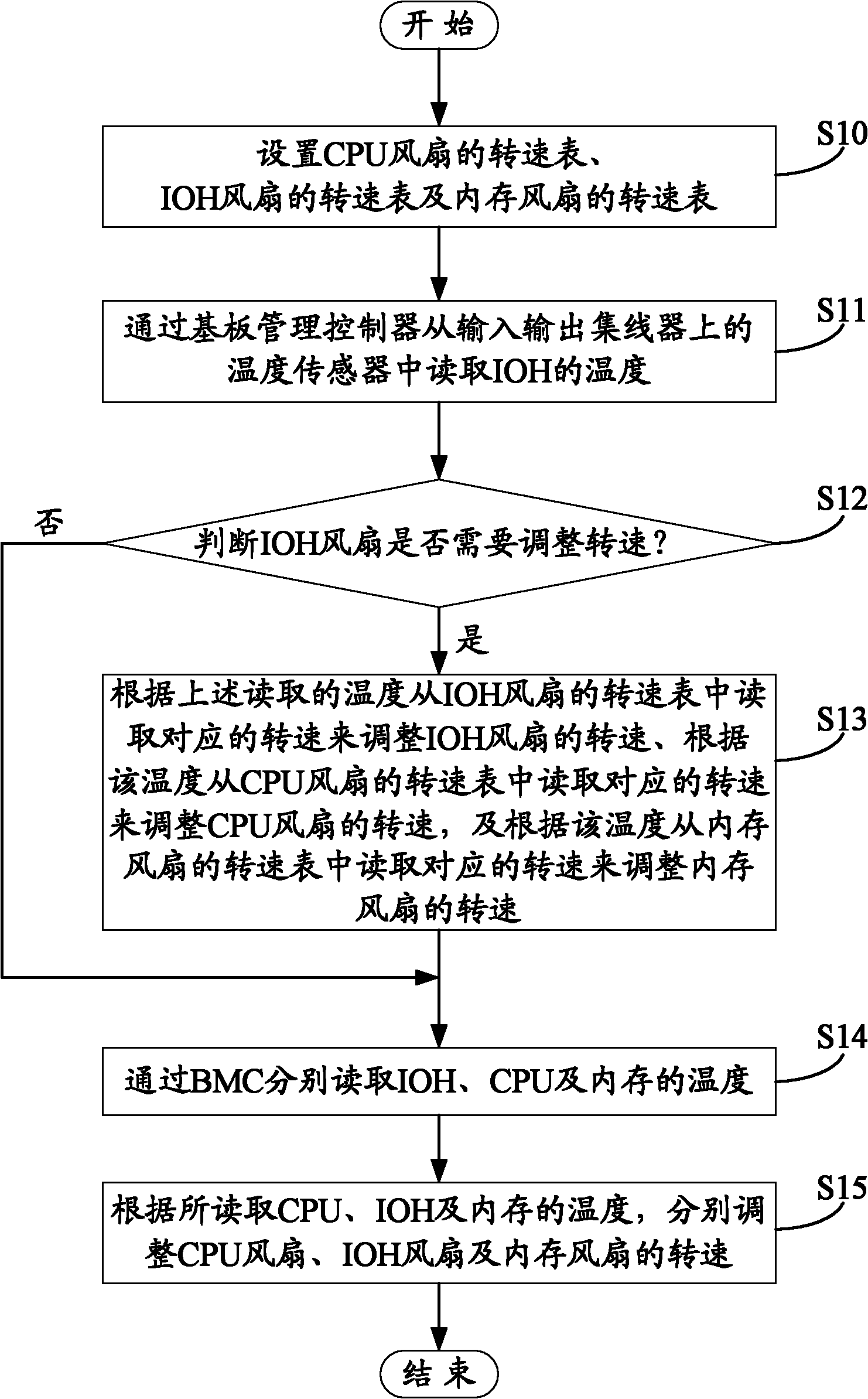

Control system and control method of fan

InactiveCN102486180AAvoid repeated adjustmentsReduce noiseEnergy efficient ICTDigital data processing detailsControl systemEnergy consumption

The invention discloses a control system and a control method for a fan. The control method comprises the following steps of: setting a tachometer of a CPU (Central Processing Unit) fan, a tachometer of an IOH (Input Output Hub) fan and a tachometer of a memory fan; reading the temperature of the IOH; judging whether the rotating speed of the IOH fan is required to be adjusted or not; reading corresponding rotating speed from the tachometer of the IOH fan according to the read temperature to adjust the rotating speed of the IOH fan and taking the temperature as the temperature of the CPU and the temperature of the memory; reading corresponding rotating speed from the tachometer of the CPU fan according to the temperature to adjust the rotating speed of the CPU fan; reading corresponding rotating speed from the tachometer of the memory fan to adjust the rotating speed of the memory fan; respectively reading the temperature of the CPU, the temperature of the IOH and the temperature of the memory; and respectively adjusting the rotating speed of the CPU fan, the rotating speed of the IOH fan and the rotating speed of the memory fan. According to the control system and the control method disclosed by the invention, repeated adjustment for the fans near a threshold value can be avoided, energy consumption is reduced and noises of the fans are reduced.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

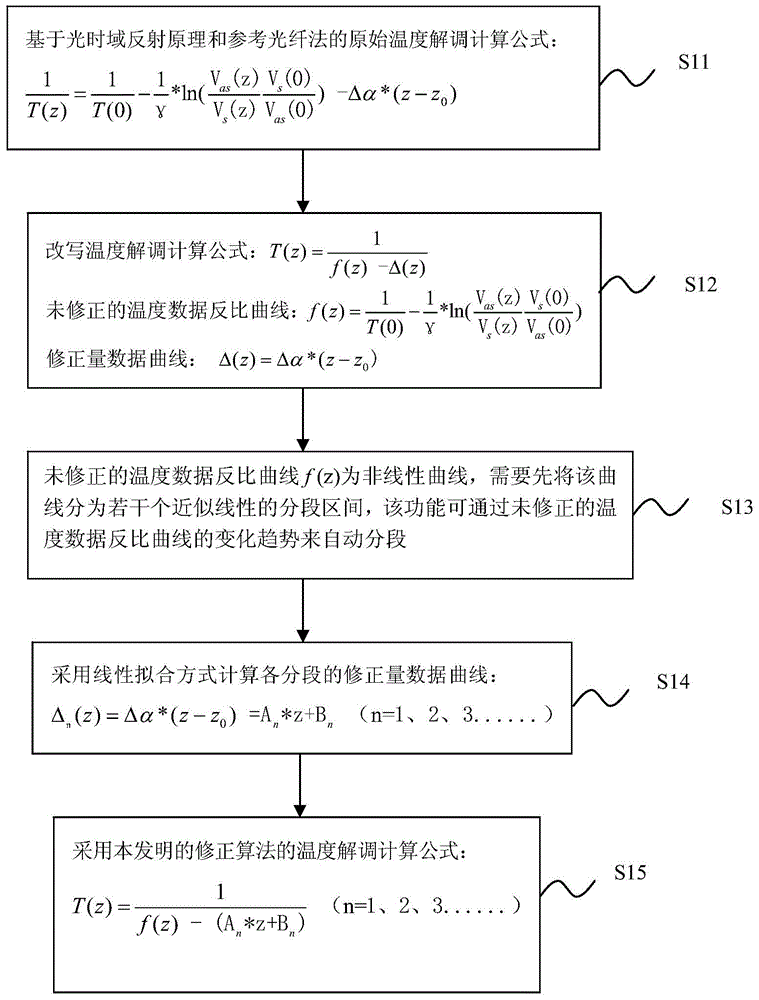

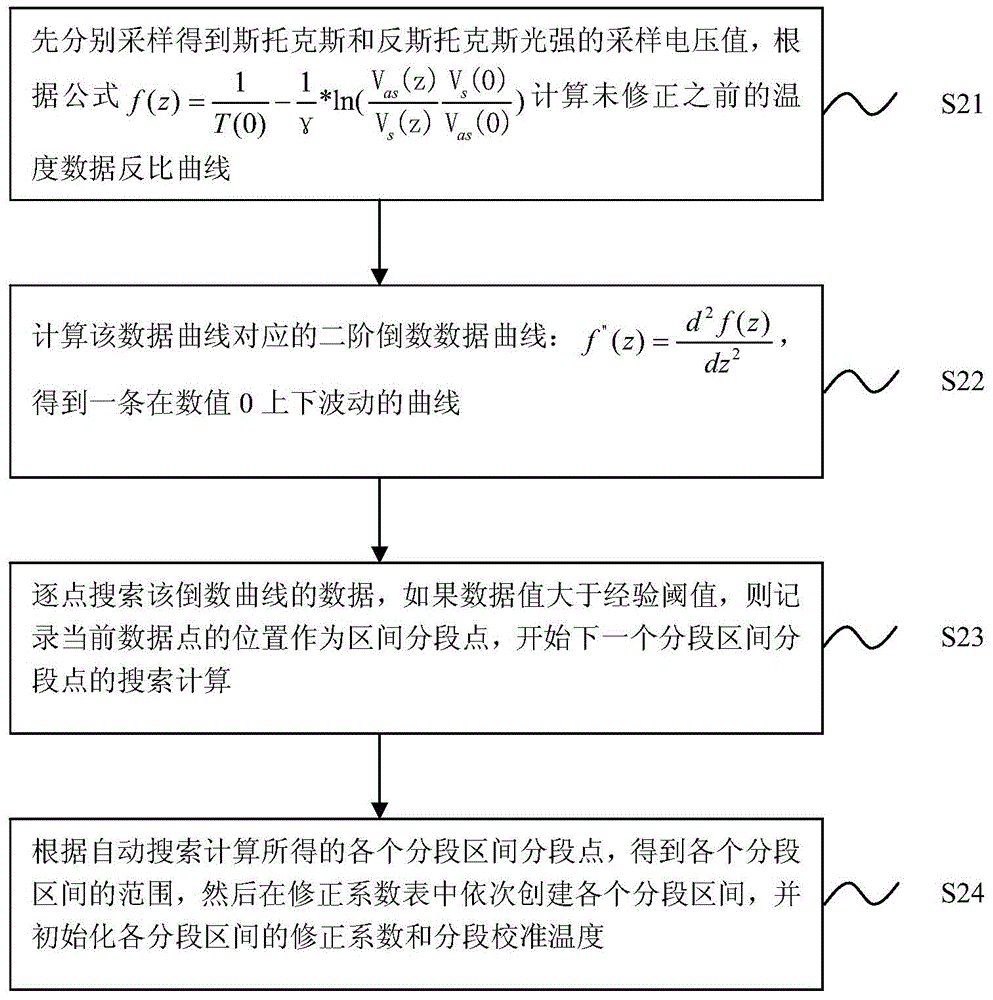

Temperature curve self-correcting algorithm and system for distributed optical fiber temperature sensing system

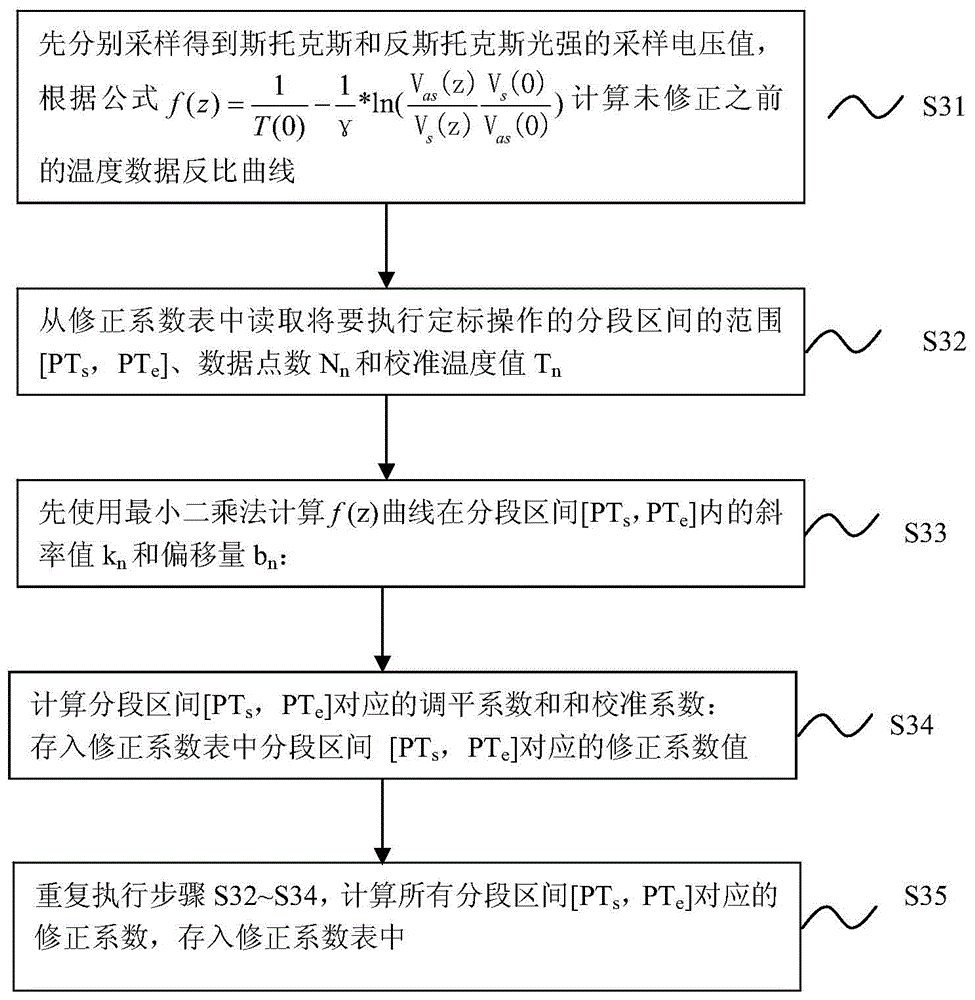

ActiveCN104535223AAccelerate the progress of installation and commissioningAuto-fix fastThermometers using physical/chemical changesThermometer testing/calibrationTemperature senseTemperature sensing

The invention discloses a temperature curve self-correcting algorithm and system for a distributed optical fiber temperature sensing system. The temperature curve self-correcting algorithm comprises the following steps: obtaining a reference optical fiber temperature, a Stokes light intensity data curve and an anti-Stokes light intensity data curve through sampling, obtaining an uncorrected temperature data inverse ratio curve f(z) through calculating, and reading corrected parameters of all piecewise intervals from a correction factor table, wherein the corrected parameters comprise the range of the piecewise intervals and correction factors, and correction factors comprise leveling factors and calibration factors; calculating an allowance of each piecewise interval, sequentially connecting the allowances of the piecewise intervals to obtain an allowance data curve delta(z) corresponding to the uncorrected temperature data inverse ratio curve, and a corrected temperature data curve is calculated. The temperature curve self-correcting algorithm and system for the distributed optical fiber temperature sensing system are capable of performing quick temperature curve self-correction during the production commissioning process and construction site automatically, accelerating the installing and commissioning progress and preventing a huge consumption of time caused by manual correcting operation resulted form repeatedly adjusting a temperature correcting curve.

Owner:WUHAN WUTOS

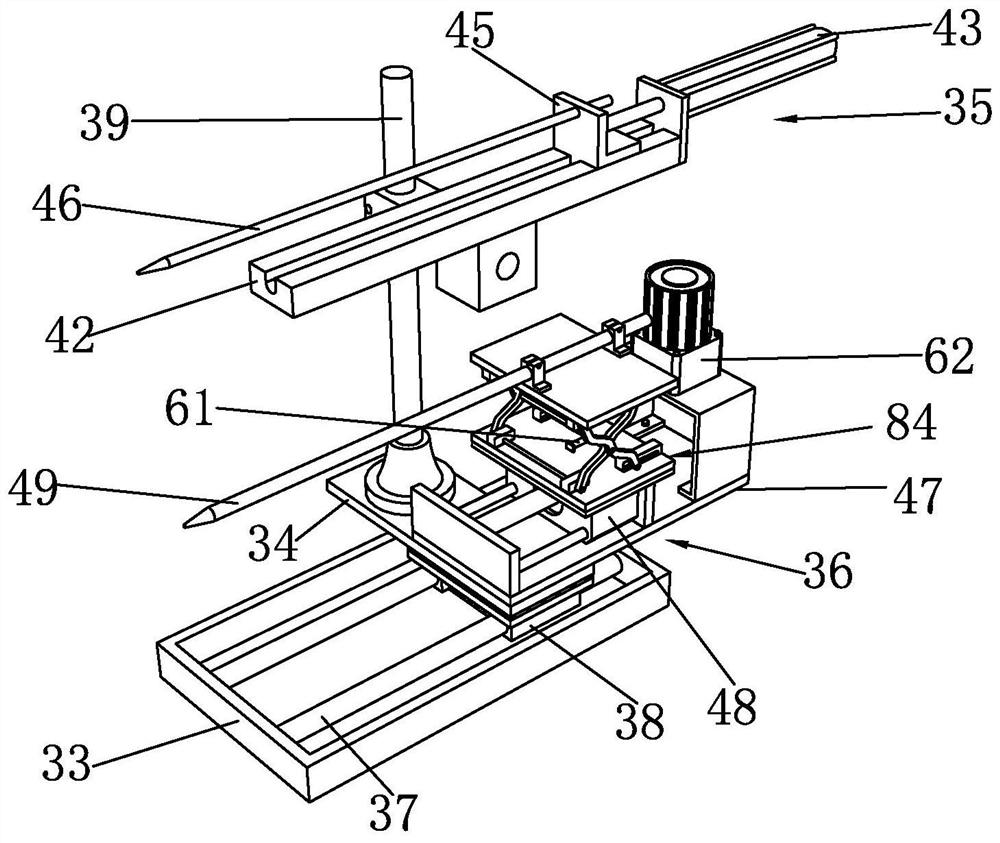

Method for tensioning boom and measuring tension, and device for method

The invention discloses a method and a device for accurately measuring a bridge boom and tensioning the boom. The device consists of an anchor backing plate with a central hole, a sleeve with an adjustment window, fixing nuts, a through lifting jack, a through force sensor, a dynamometer, a limit nut, and a tension rod; and the method comprises the following steps of: determining the through force sensor according to a Hooke's law and the maximum design tension of the boom, calculating the maximum stress of the tension rod, selecting the materials of a tension rod body according to the maximum stress, determining the lectotype of the through force sensor, sequentially assembling, and tensioning the boom by using the through lifting jack, reading the dynamometer, and displaying the force value of the through force sensor. The device has a simple structure, is high in accuracy and low in cost, and is detachable, and can be used repeatedly.

Owner:JIANGSU UNIV OF SCI & TECH

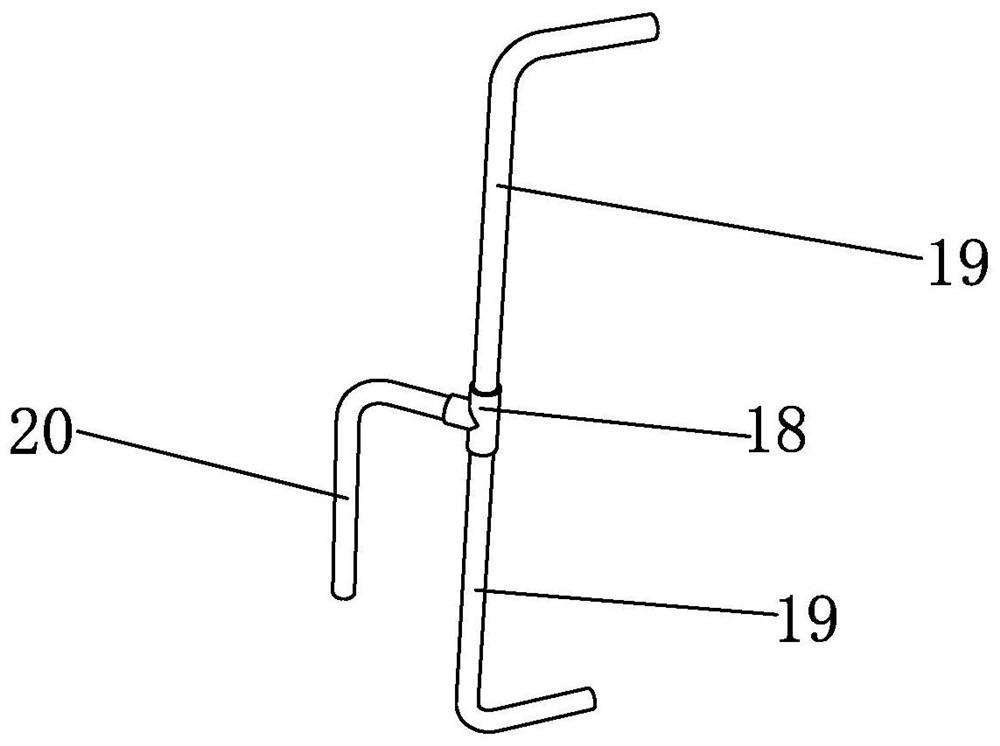

Body position fixator for locating limbs

InactiveCN103301000AEasy to placeInstalled and disassembledOperating tablesBody positionsEngineering

The invention is applicable to the field of medical instruments and provides a body position fixator for locating limbs in a surgery. The body position fixator comprises a baseplate, a first slide slot arranged on the baseplate, and at least one pair of arc locating rings, wherein the locating rings are arranged in the first slide slot in a sliding manner, one pair of locating rings can locate the position through a pair of locating locks arranged on the side edge of the baseplate, the concave sides of the pair of the locating rings are oppositely arranged to limit the limb between the pair of locating rings, and the number of locating rings is the same as that of the locating locks. Therefore, the body position fixator can regulate the fixation position according to the requirement of body position in the surgery to meet the requirement of maintaining the body position, the structure is simple, the manual operation is replaced, and the body fixator is convenient to use, install and dismount.

Owner:潘晓华

Positioning device for distal locking of intramedullary nail

InactiveCN104688322ASimple and fast operationPose has no effectInternal osteosythesisTransverse axisIntramedullary rod

The invention relates to a positioning device for distal locking of an intramedullary nail. The positioning device comprises a positioning mechanism and an adjusting mechanism, wherein the positioning mechanism comprises a first positioning ring and a second positioning ring which are arranged at intervals and are concentrically arranged; a guide needle penetrates through the first positioning ring and the second positioning ring in sequence and is positioned by the first positioning ring and the second positioning ring; the adjusting mechanism comprises a longitudinal rotation assembly used for rotating around a longitudinal axis so as to drive the positioning mechanism to rotate around the longitudinal axis, a transverse rotation assembly used for rotating around a transverse axis so as to drive the positioning mechanism to rotate around the transverse axis, a longitudinal translational component used for driving the positioning mechanism to move along the longitudinal direction and a transverse translational component used for driving the positioning mechanism to move along the transverse direction; the positioning mechanism is detachably or fixedly connected to at least one of the four components; an intersection of the longitudinal axis and the transverse axis is arranged on a connection line of a circle center of the first positioning ring and a circle center of the second positioning ring; an included angle is formed between the plane formed by the longitudinal direction and the transverse direction and the penetrating path of the guide needle. The positioning device is capable of assisting a doctor to quickly and accurately positioning far-end lock holes under the conditions without extra iatrogenic wounds and low radiation frequency.

Owner:安徽埃克索医疗机器人有限公司

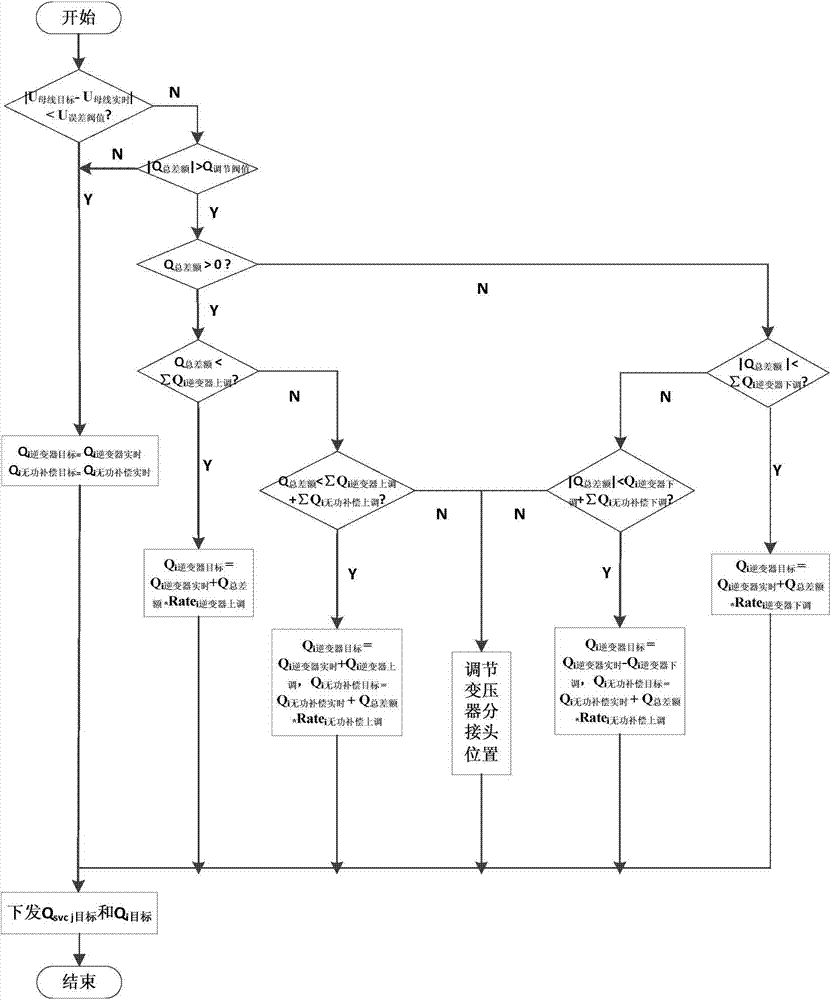

Automatic voltage control device and control method for distributed photovoltaic power station

InactiveCN103928984ALow running costAvoid repeated adjustmentsFlexible AC transmissionReactive power adjustment/elimination/compensationTime informationTransformer

The invention provides an automatic voltage control device and a control method for a distributed photovoltaic power station. The control device comprises a communication management module, a command processing module, an AVC module, a data management module and an information displaying module. The communication management module is in charge of receiving and transmitting real-time information with a connected device. The command processing module is in charge of converting formats of remote regulation and remote control orders received and transmitted by the communication management module. The AVC module is used for carrying out reactive power control on photovoltaic inverters of the whole station and an SVC / SVG system through the preference control strategy of the inverters according to the real-time information received at present and can control tap positions of a transformer substation, and therefore the busbar voltage of the current power station meets the requirement of power grid dispatching.

Owner:STATE GRID CORP OF CHINA +3

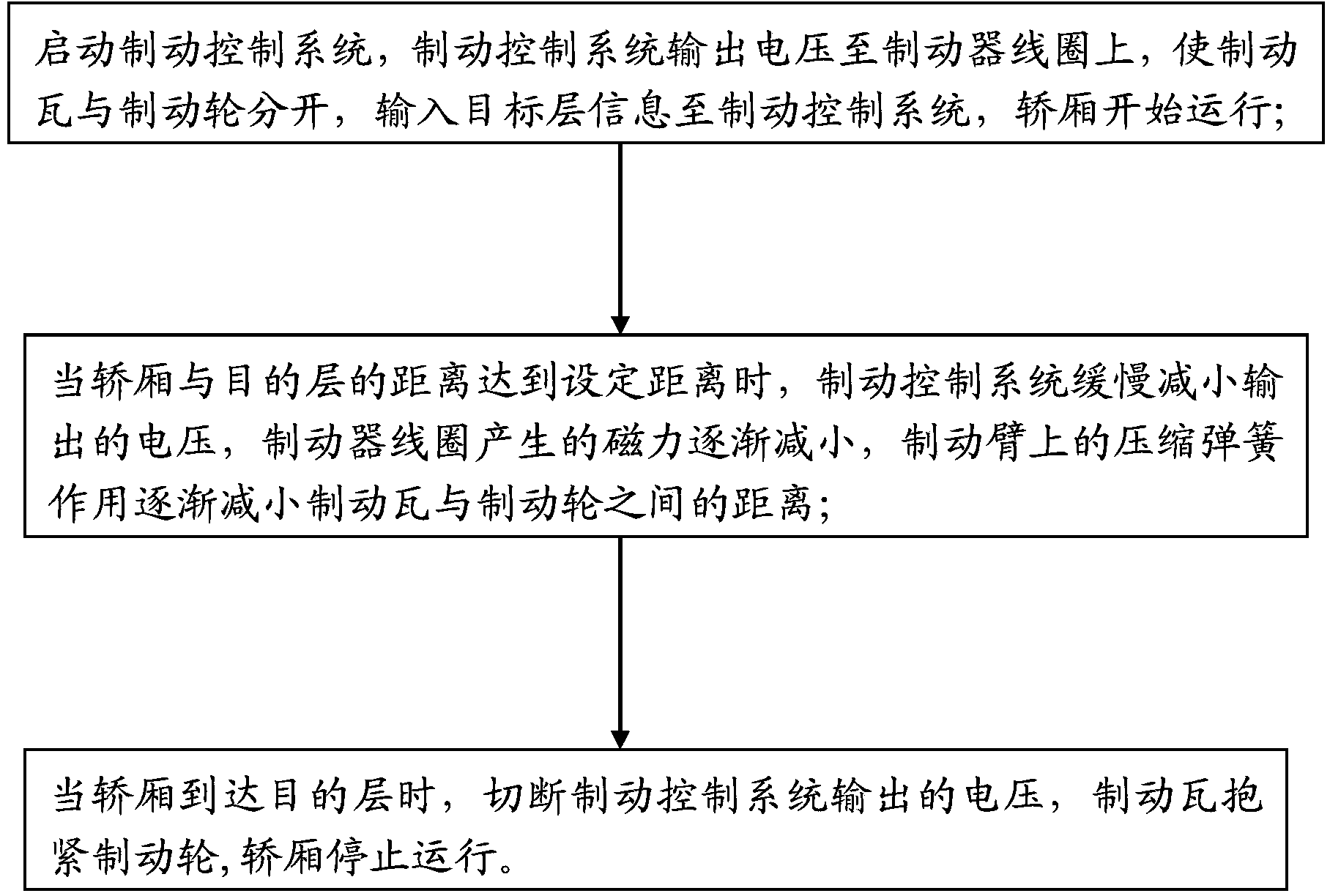

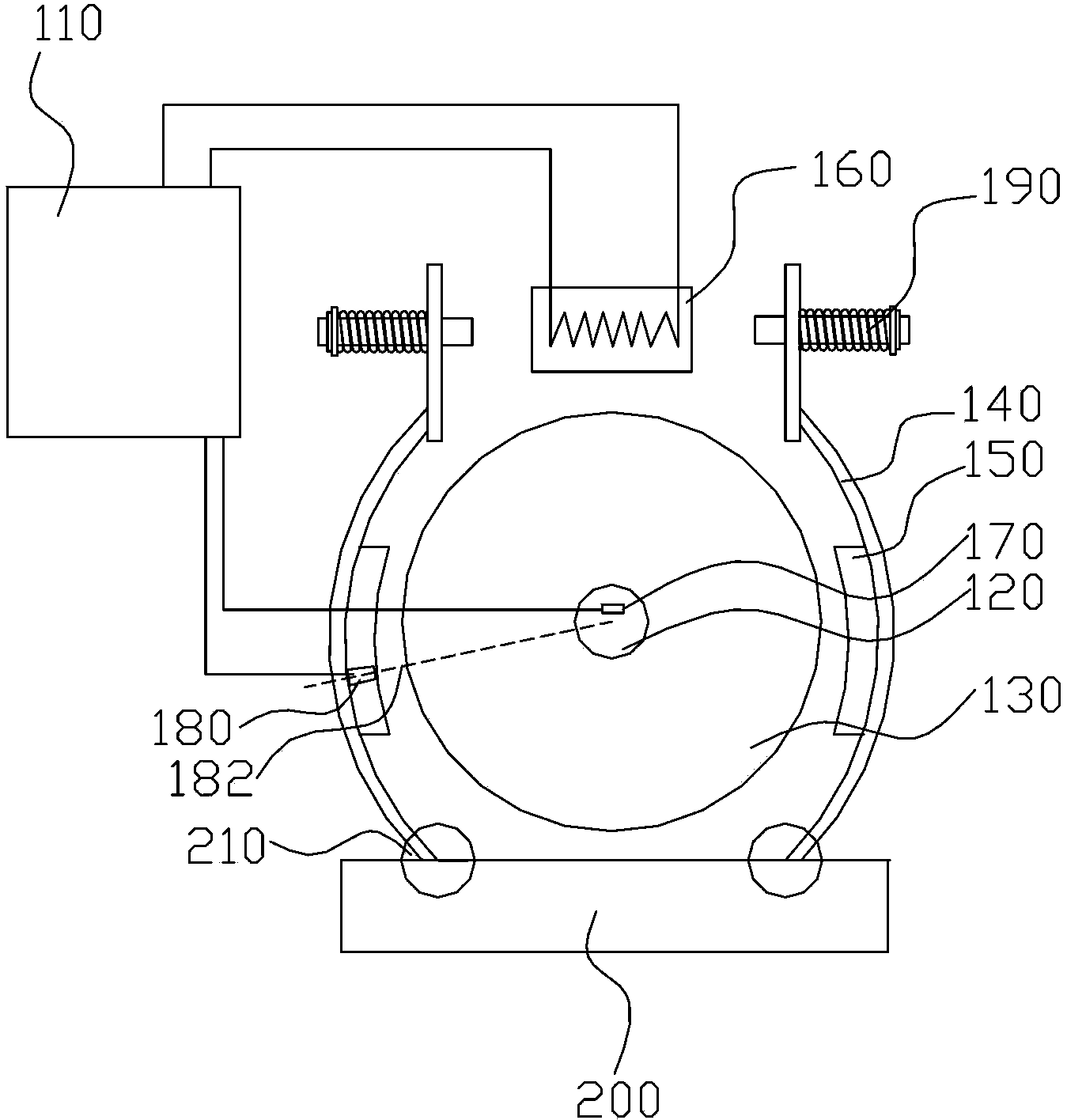

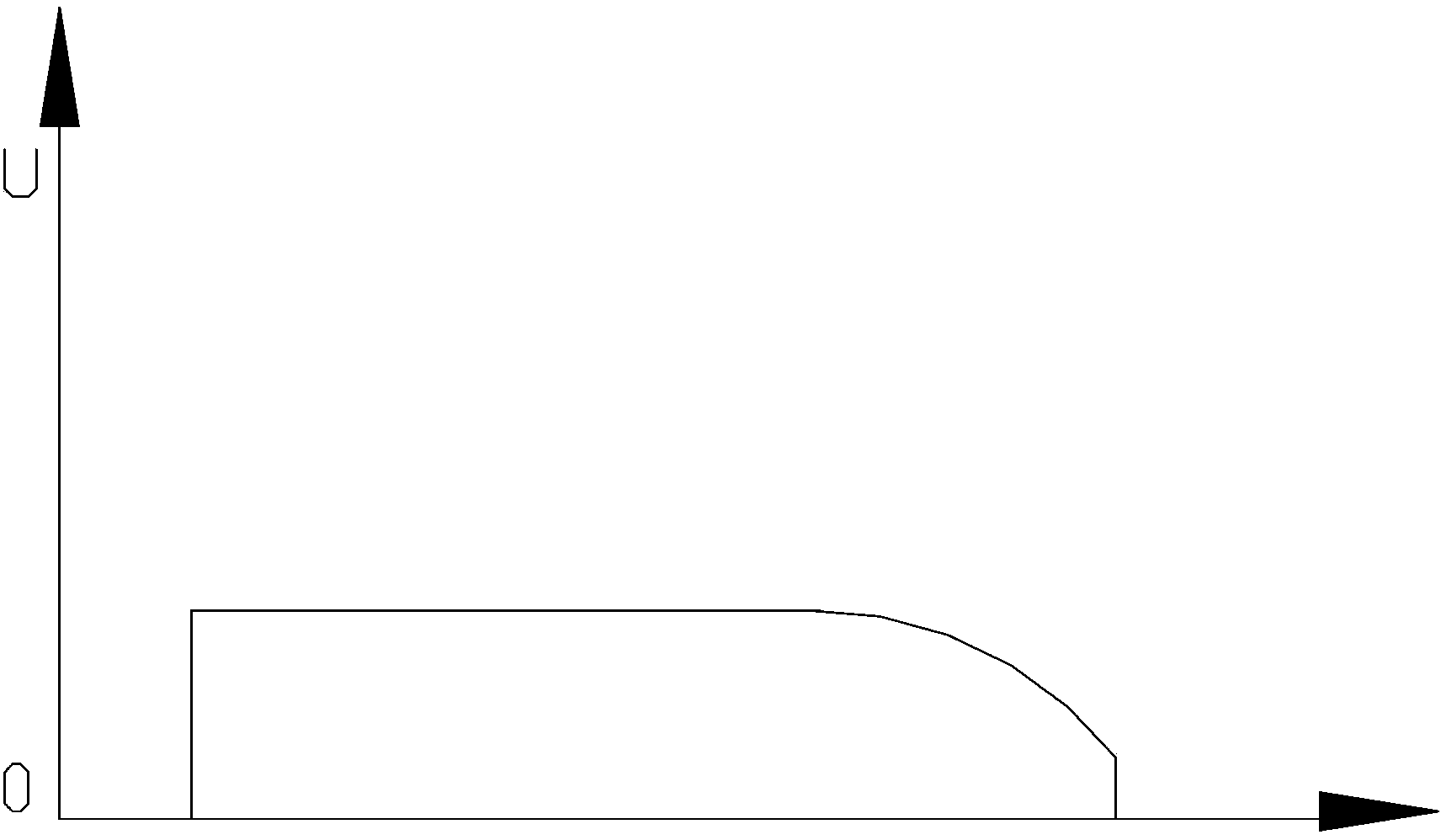

Elevator intelligent brake control method and device

ActiveCN103407850AAvoid repeated adjustmentsEasy maintenanceElevatorsMagnetic tension forceControl system

The invention discloses an elevator intelligent brake control method and device. The control method includes: a brake control system which outputs voltage to a brake coil to allow a brake shoe to be separated form a brake wheel is started, and target floor information is input to the brake control system to allow an elevator car to operate; when the distance between the elevator car and the target floor reaches the preset distance, the brake control system slowly reduces voltage output, magnetic force generated by the brake coil reduces gradually, and a compression spring on the brake arm gradually reduces the distance between the brake shoe and the brake wheel; when the elevator car reaches the target floor, voltage output by the brake control system is cut off, the brake shoe tightly holds the brake wheel, and the elevator car stops operating. By the method, brake time during elevator stopping is reduced, and safety hazards such as sliding when the elevator control system fails. Due to the fact that the distance between the brake shoe and the brake wheel is reduced, noise caused by collision of the brake shoe and the brake wheel is reduced. The invention further provides an elevator intelligent brake control device.

Owner:HITACHI ELEVATOR CHINA

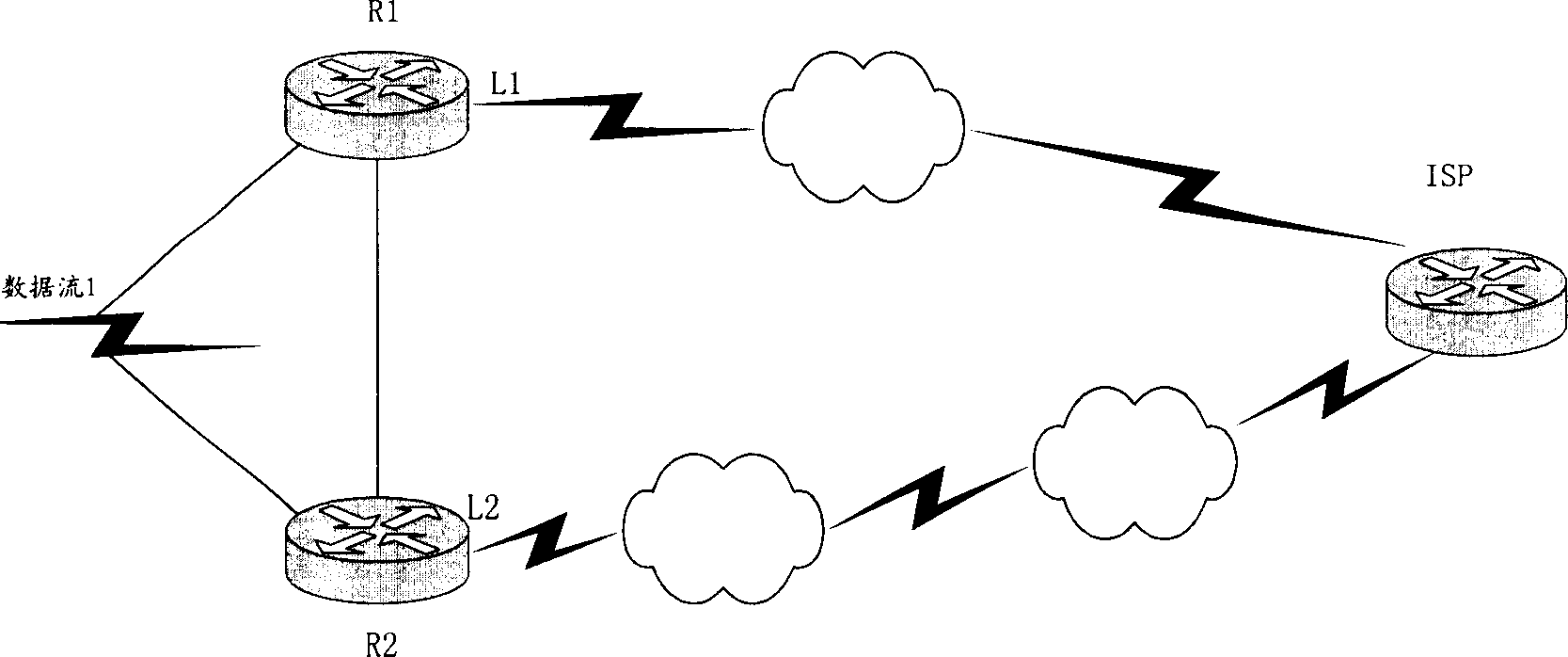

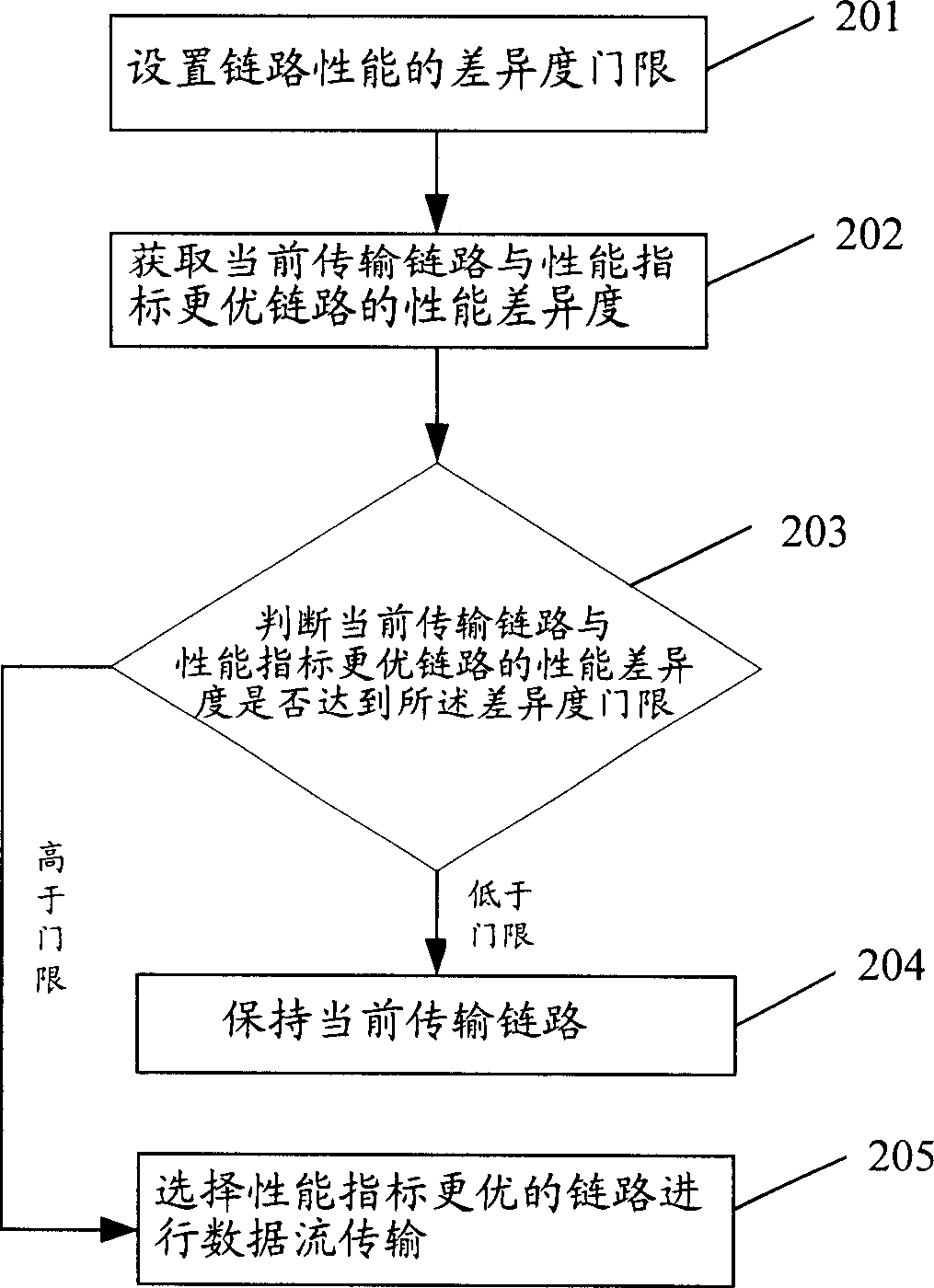

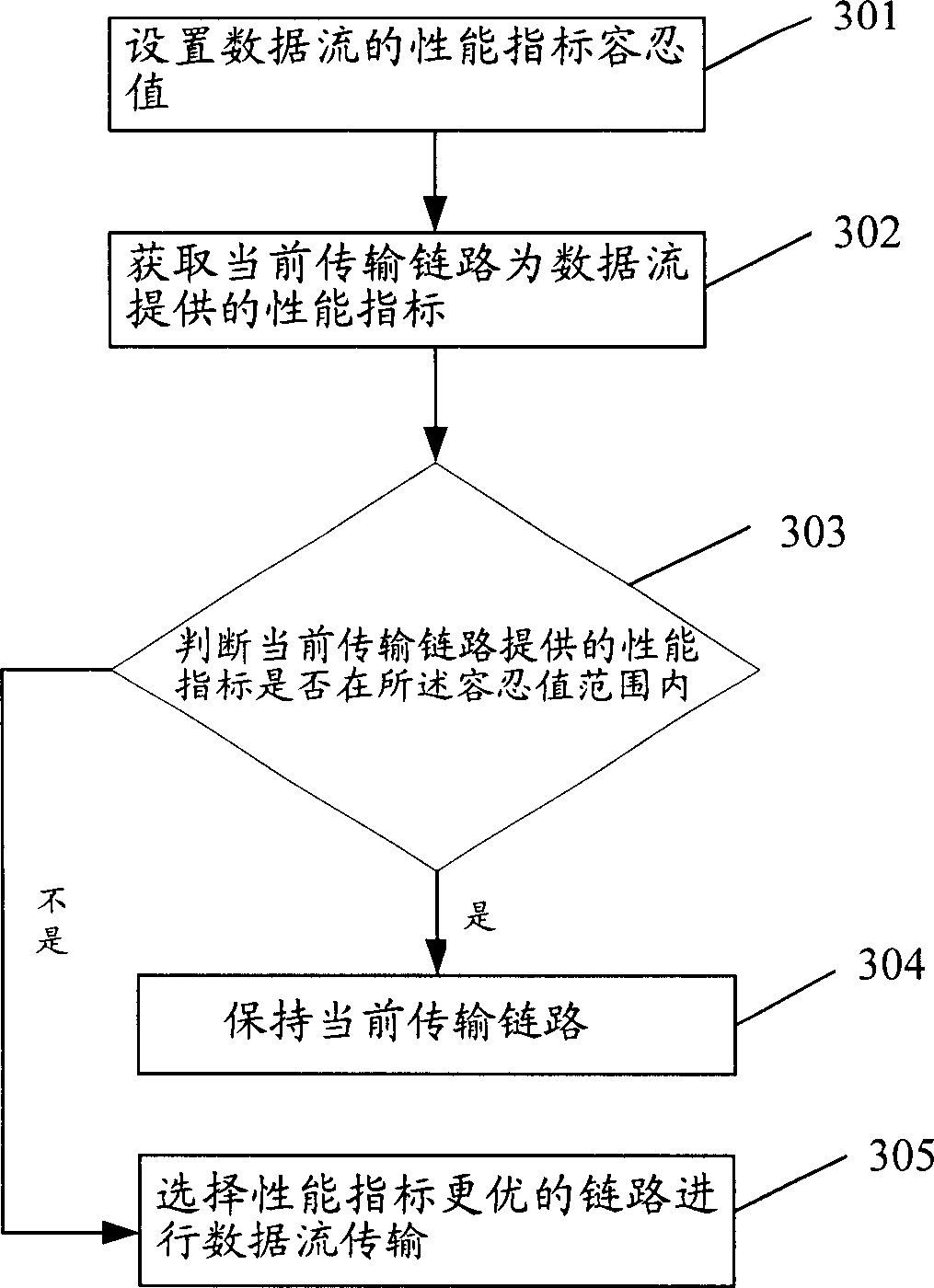

Method for adjusting data stream transmission link and its realizing device

ActiveCN1767523AAvoid repeated adjustmentsPrevent flow oscillating phenomenonTransmissionEngineeringData stream

Owner:NEW H3C TECH CO LTD

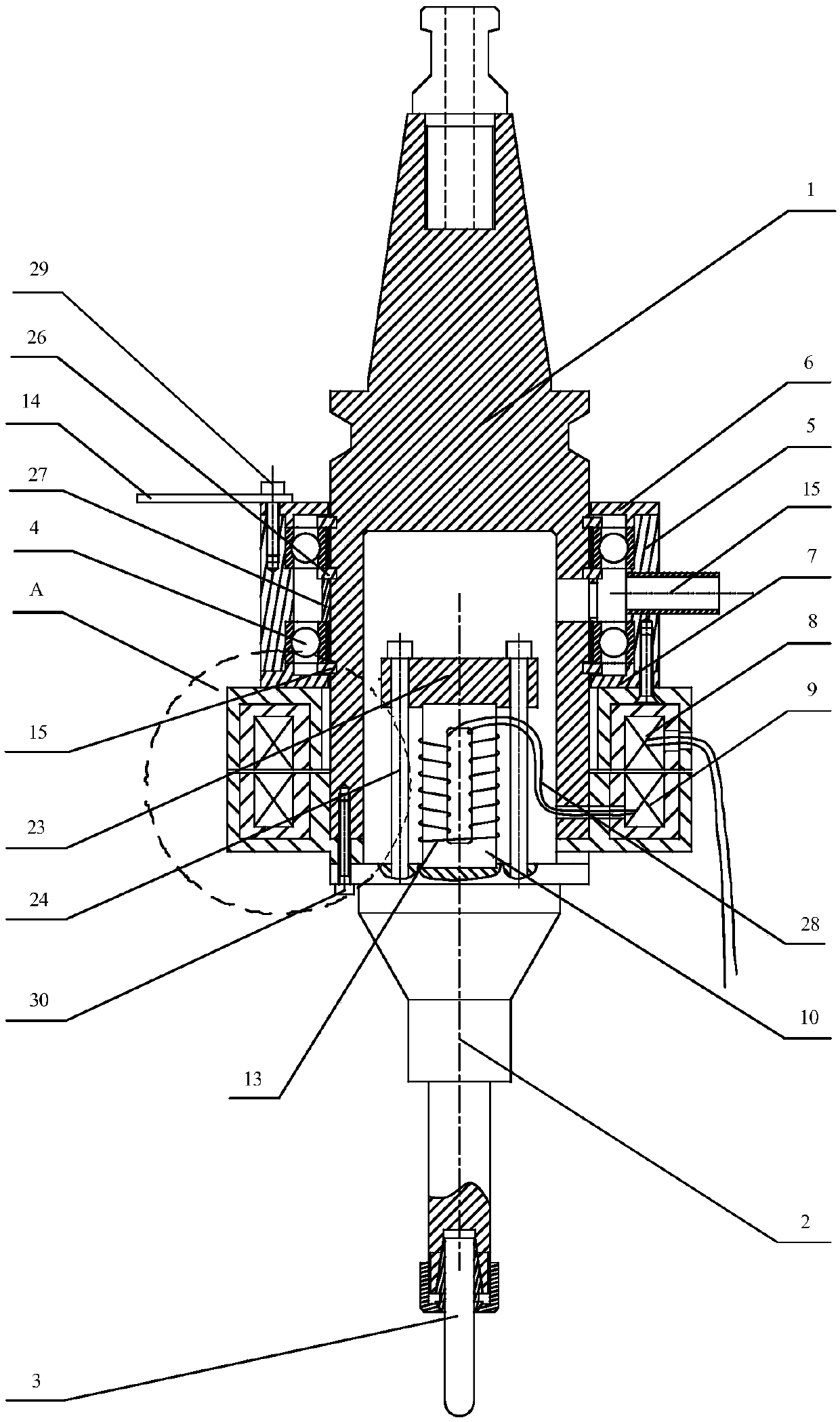

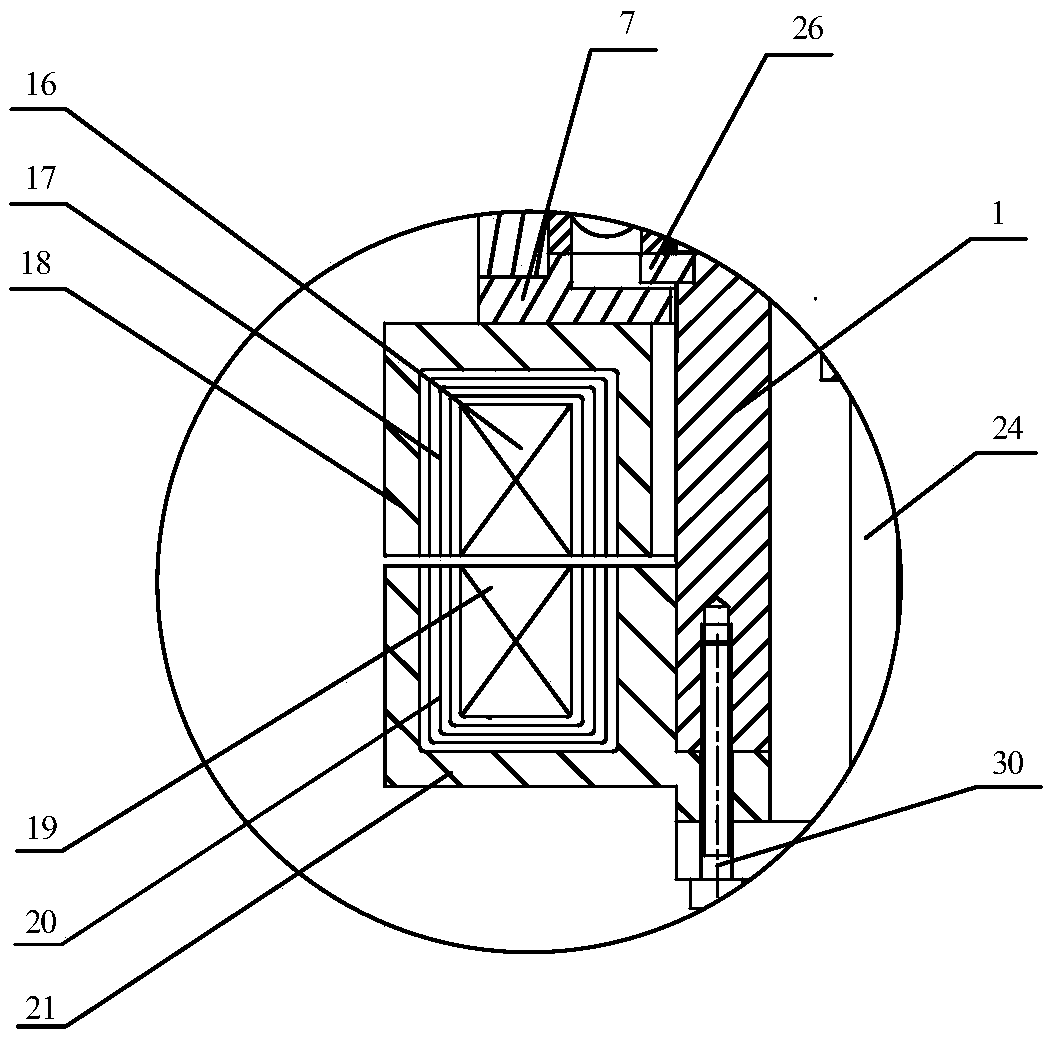

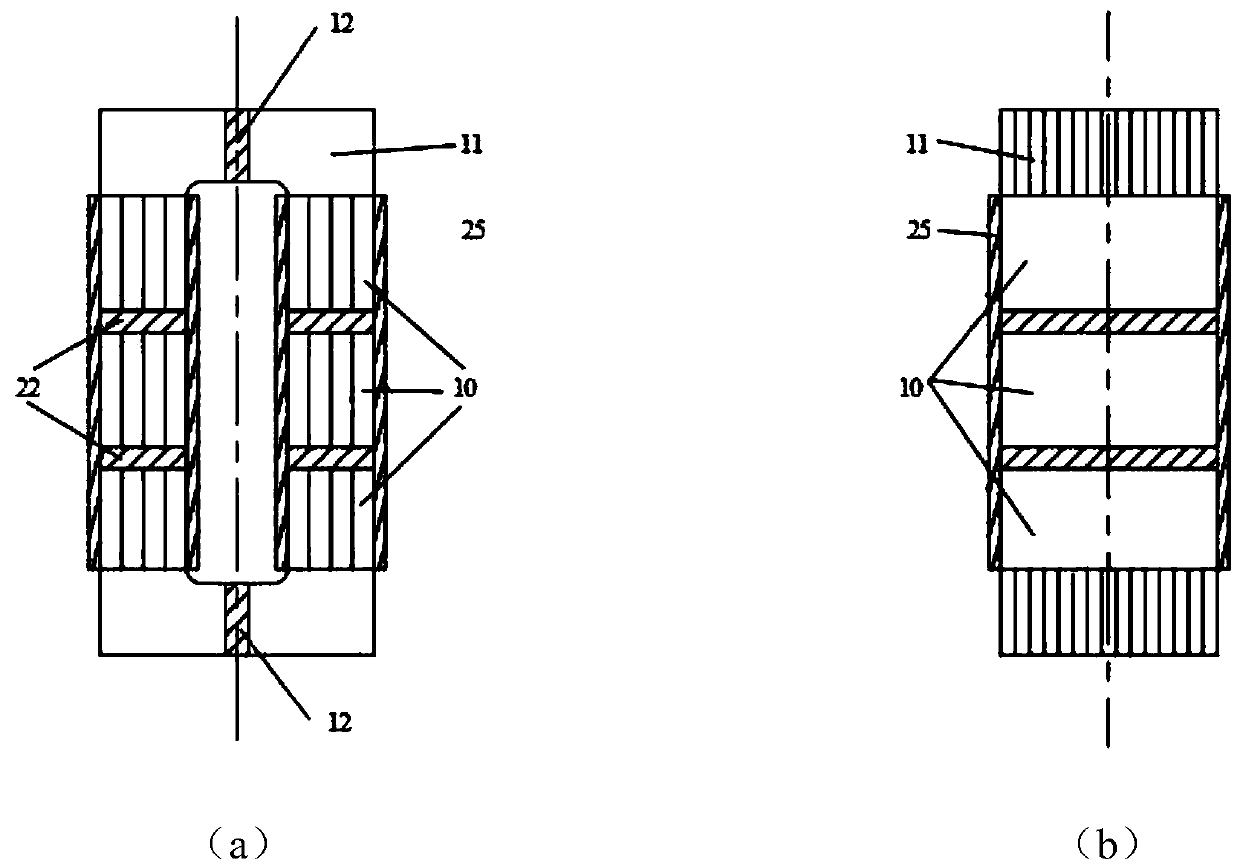

Double-rod type giant magnetostriction ultrasonic vibration device

The invention discloses a double-rod type giant magnetostriction ultrasonic vibration device. The device comprises a knife handle, a variable amplitude rod and a tool head are sequentially connected to the lower end of the knife handle, a cavity is formed in the lower part of the knife handle, a giant magnetostriction transducer is arranged in the cavity, a sealing bearing, an elastic check ring and a sleeve are arranged on the outer side wall of the knife handle, the elastic check ring and the sleeve are used for fixing the sealing bearing, a shell is arranged outside the sealing bearing, anupper end cover and a lower end cover are arranged at the upper end and the lower end of the shell respectively, the outer side of the knife handle is also provided with a primary side winding and a secondary side winding, and the primary side winding and the secondary side winding are located below the shell in sequence. According to the double-rod type giant magnetostriction ultrasonic vibrationdevice, the problem of magnetic flux leakage of the giant magnetostriction transducer is solved.

Owner:XIAN UNIV OF TECH

Rotor for television frame with improved structure

ActiveCN104061412ANo change in pitch angleAvoid repeated adjustmentsStands/trestlesTelevision setCable television

The invention discloses a rotor for a television frame with an improved structure. Both a first connecting plate and a second connecting plate are U-shaped; the second connecting plate sleeves the outer side of the first connecting plate; a first connecting hole and a second connecting hole are formed in the side wall of the first connecting plate; the first connecting hole is a vertical or horizontal elongated straight hole; the second connecting hole is an elongated inclined hole; a first circular hole and a second circular hole corresponding to the positions of the first connecting hole and the second connecting hole are formed in the two opposite side walls of the second connecting plate; a first connecting piece penetrates in the first connecting hole and the first circular hole and is finally connected with one end of a connecting sheet in a fastening way; a second connecting piece penetrates in the second circulating hole and the second circular hole and is finally connected the other end of the connecting sheet in the fastening way; the second connecting piece can be kept at any position in the second connecting hole; the hanging plate is connected with one side, back to the first connecting plate, of the second connecting plate; a mounting structure for mounting a television is arranged on the hanging plate. According to the rotor for the television frame with the improved structure, a pitch angle of the television in a long-term using process can be kept unchanged all the time, and repeated adjustment is avoided.

Owner:KUNSHAN HONGJIE ELECTRONICS CO LTD

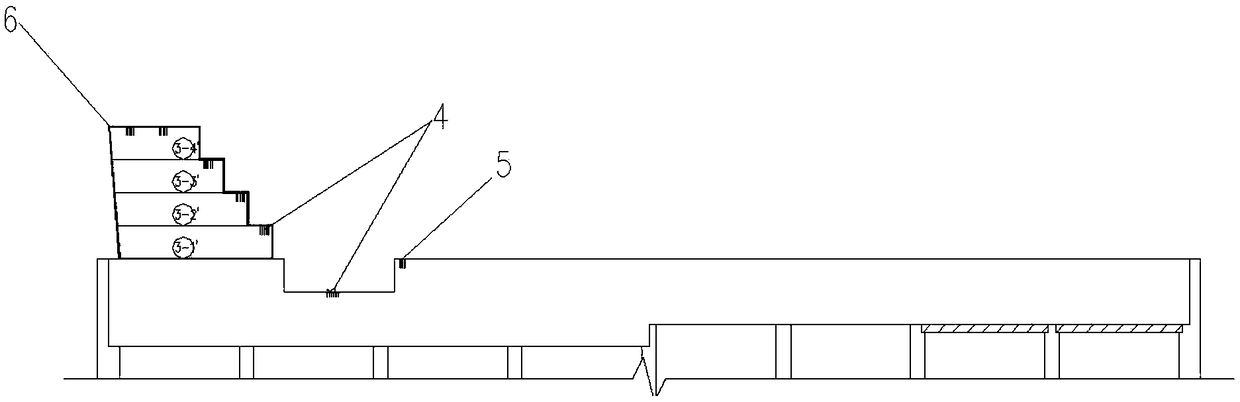

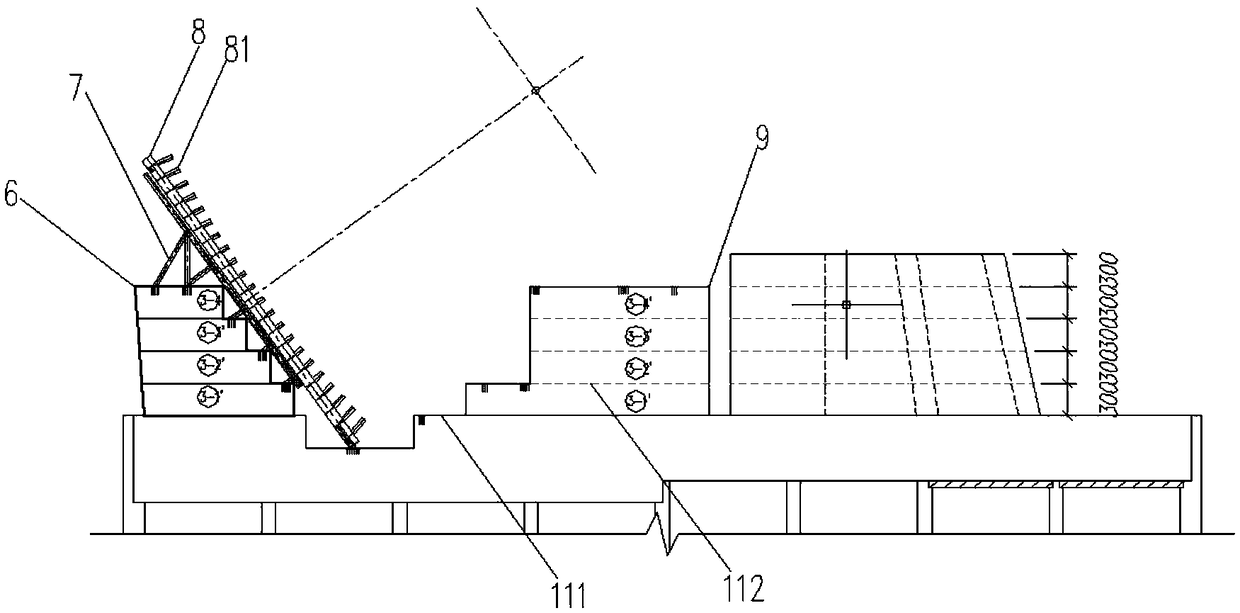

Construction method of anchorage anchoring system

ActiveCN109468954AIncrease stiffnessEliminate cumulative deformation effectsBridge structural detailsBridge erection/assemblyDeformation effectBuilding construction

The invention discloses a construction method of an anchorage anchoring system. The construction method comprises the following steps of (1) constructing a well cover of a sinking well; (2) pouring concrete in a step area of an anchor beam bracket layer by layer; (3) installing the anchor beam bracket; (4) installing an anchor beam and an anchor rod bracket; (5) installing anchor rods and pouringanchor block concrete layers one by one; (6) continuing anchor block construction. According to the construction method, a mixed anchoring bracket system is formed, and a construction mode of installing the anchor rods during pouring is adopted at the same time. According to the method, the mixed anchoring bracket system is formed, the rigidity of the anchoring bracket is enhanced correspondingly,the cumulative deformation effect is eliminated, repeated operation caused by deformation of the bracket is effectively prevented, the construction efficiency is improved, the use amount of section steel is reduced, and the input cost is reduced.

Owner:CCCC SHEC FOURTH ENG +2

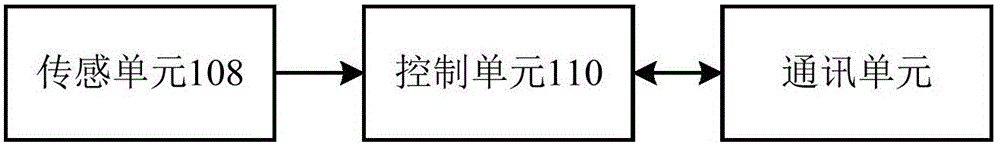

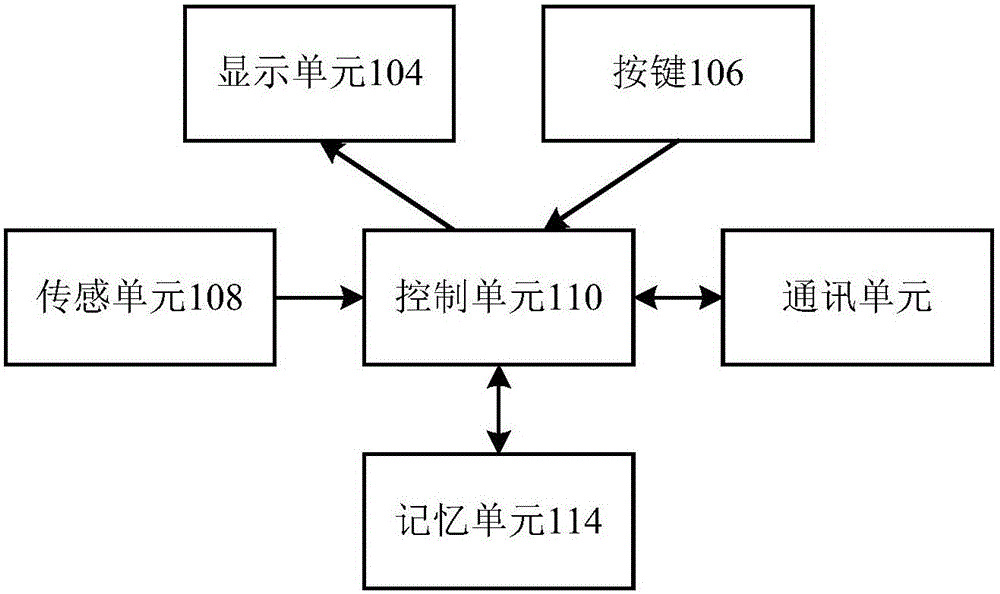

Control device for water heater, water heater and control method for water heater

InactiveCN106196617AAvoid repeated adjustmentsReduce stepsFluid heatersCommunication unitEngineering

The invention discloses a control device for a water heater, the water heater and a control method for the water heater. The device comprises a sensing unit (108), a control unit (110) and a communication unit; the sensing unit (108) is used for obtaining identity information of a user using the water heater; the control unit (110) is used for determining water consumption information of the user according to the identity information; and the communication unit is used for receiving and transmitting the identity information and / or the water consumption information. According to the scheme adopted by the invention, the defects such as a complex regulating process, inconvenience in use, poor user experience and the like in the prior art can be overcome, so that beneficial effects of a simple regulating process, convenience in use and good user experience are realized.

Owner:GREE ELECTRIC APPLIANCES INC

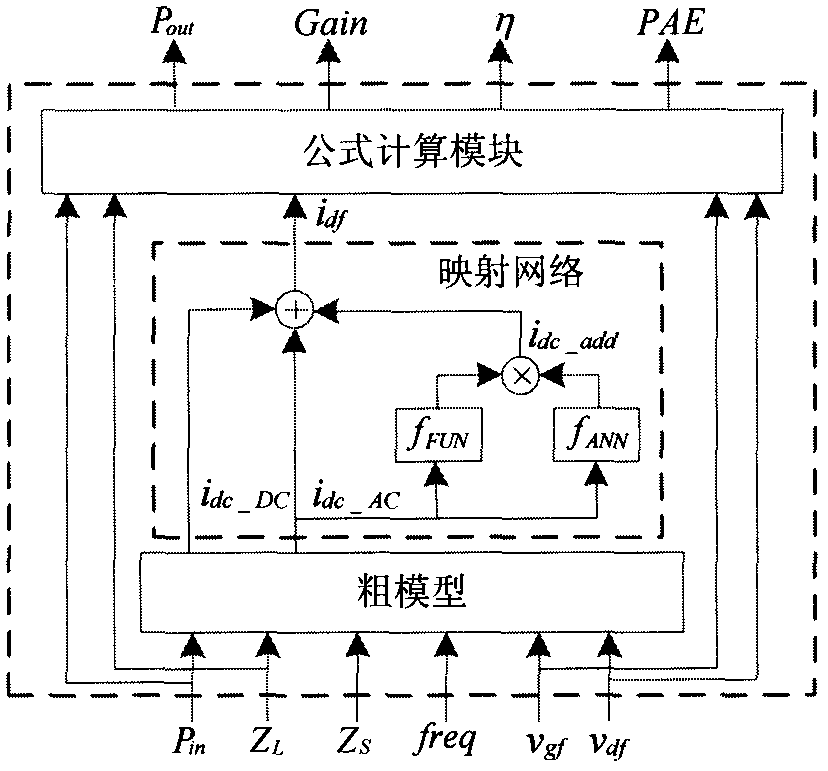

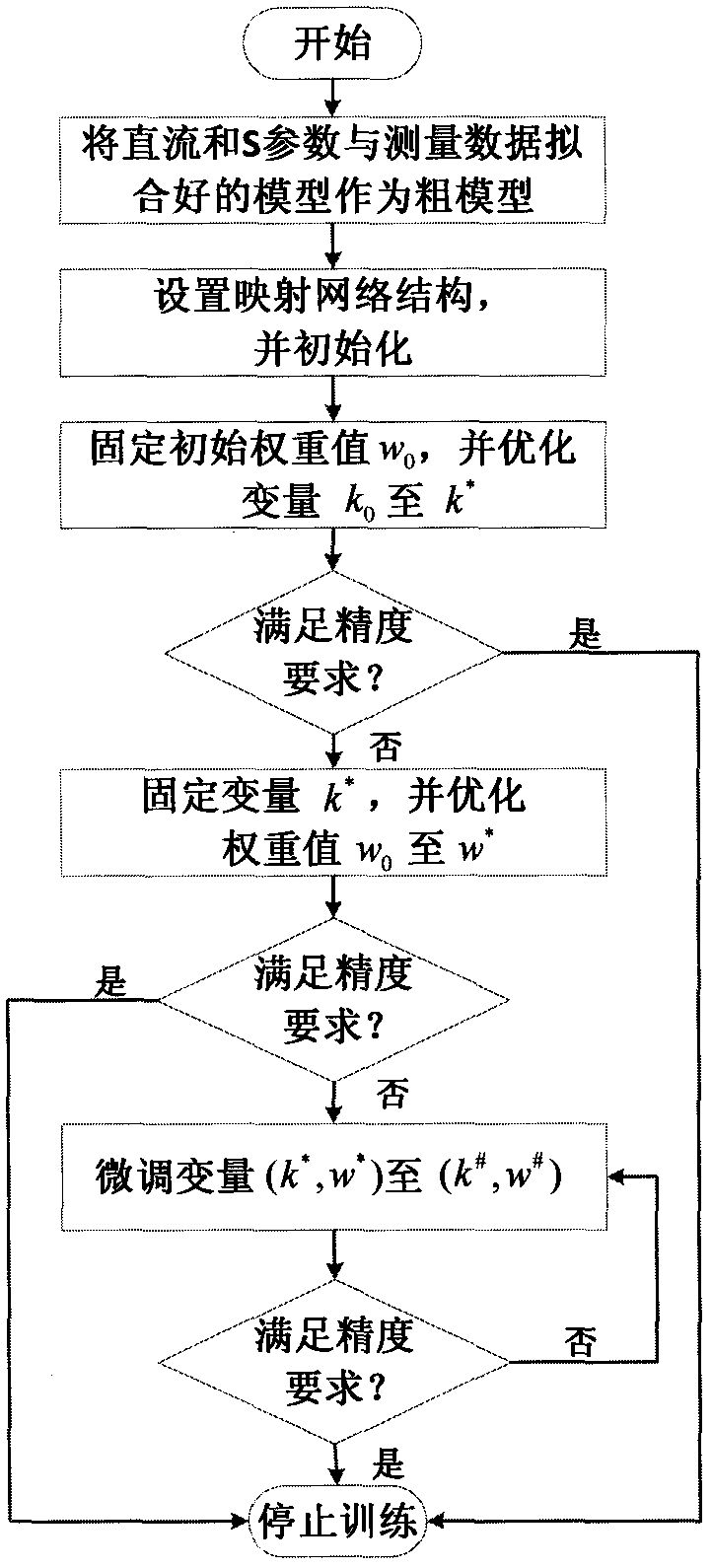

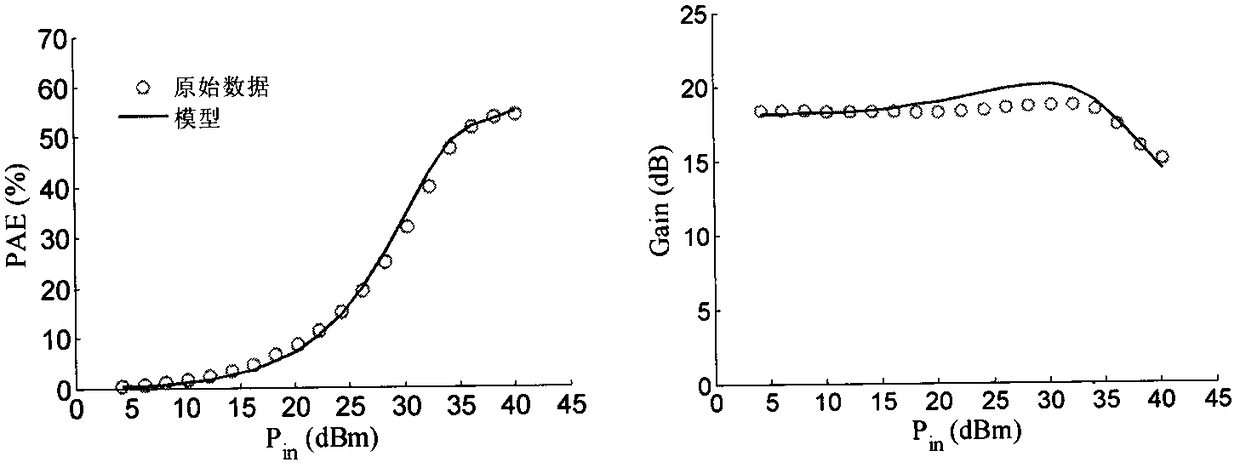

Neural network space mapping modeling method used for large signal power transistor

ActiveCN108549767ASimple structureAvoid repeated adjustmentsNeural architecturesSpecial data processing applicationsCapacitanceEngineering

The invention belongs to the field of microwave circuit and device modeling, and provides a neural network space mapping modeling method used for a large signal power transistor. The method comprisesthe steps of firstly building a neural network space mapping model with capacitors and inductors, and changing direct current and alternating current characteristics of the model; secondly extractingadditional current signals by adopting a novel nonlinear function to improve large signal characteristics of an existing device model, and meanwhile, keeping an S parameter unchanged; and finally quickly training the built neural network space mapping model by adopting a stepwise training method. Therefore, variables are prevented from being repeatedly adjusted and the modeling cycle is shortened.

Owner:成都手创科技有限公司

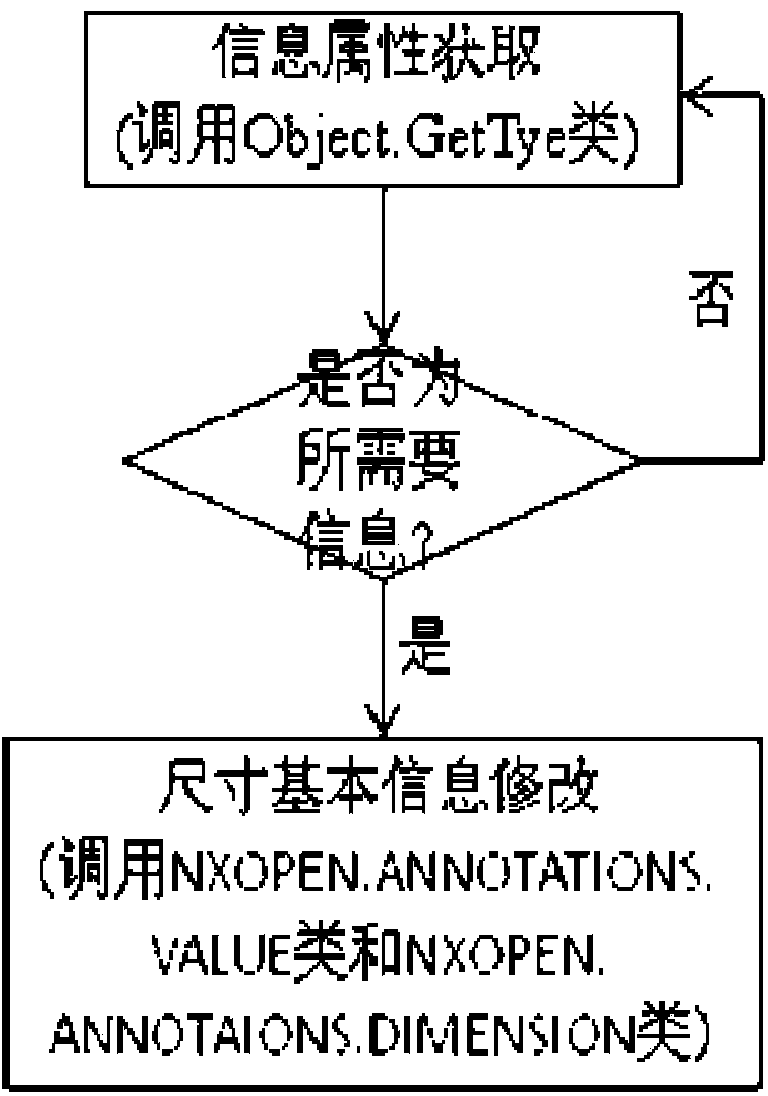

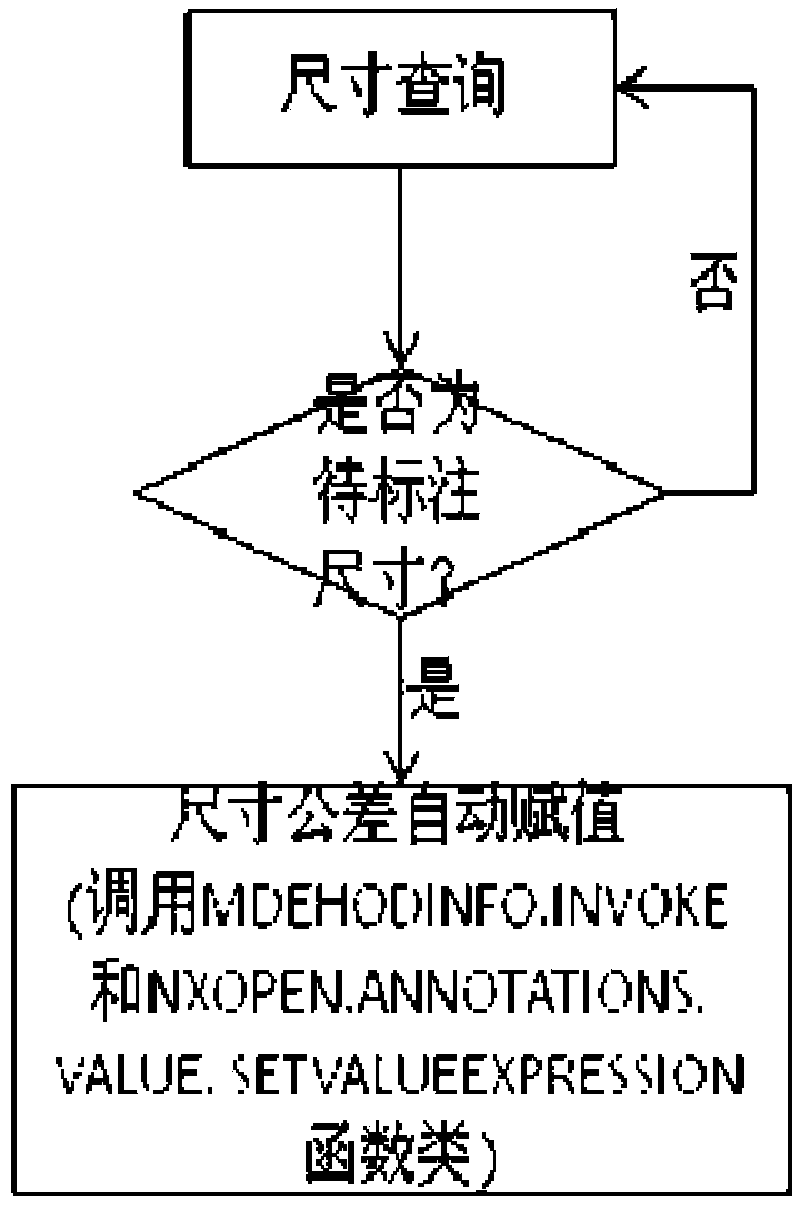

Part machining method for automatically obtaining dimensional tolerance

InactiveCN104375463AImprove efficiencyQuality improvementProgramme controlComputer controlComputer scienceMachining

The invention discloses a part machining method for automatically obtaining dimensional tolerance and belongs to the technical field of machining. According to the method, information in tolerance data is integrated in UG NX7.5 software, an accurate and fast tolerance information marking tool is provided for model information marking people by recognizing and judging model dimensions and retrieving the tolerance data, errors caused by manual operation are reduced, the part machining and production efficiency and quality are improved, and the project quality requirements are met. Besides, the method not only can complete accurate dimensional tolerance value entry, but also can adjust tolerance marking styles automatically according to dimensional tolerance types, and the dimensional tolerance marking styles are prevented from being repeatedly adjusted.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

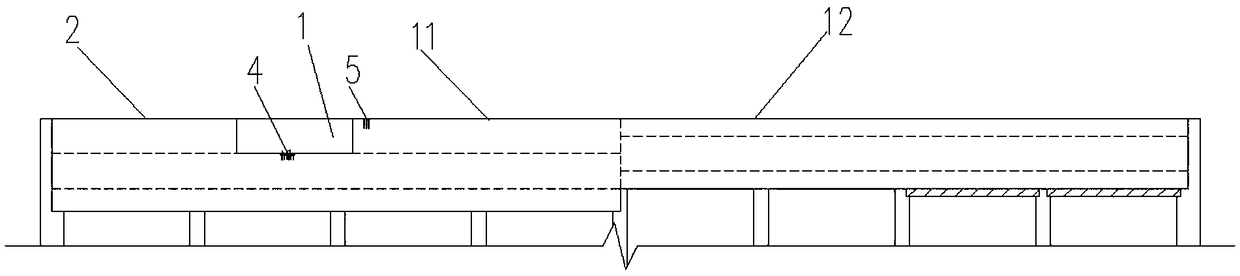

Mounting method for sill anchor combined support frame for steel structure shear wall and outer frame column base of super high-rise building

ActiveCN105926958AEasy docking installationEasy to adjustBuilding material handlingSteel columnsHigh rise

The invention discloses a mounting method for a sill anchor combined support frame for a steel structure shear wall and an outer frame column base of a super high-rise building. The method comprises the following steps of: S1, paying off at the position of the sill anchor combined support frame after civil foundation bed construction is finished; S2, mounting a transition rack at a proper position; S3, assembling an anchor bolt stock, an anchor bolt and an anchor bolt penetrating rack into an anchor bolt component, and placing the anchor bolt component on the transition rack; S4, preserving slot templates on a steel plate wall or a steel column foot base anti-shear component; S5, performing a primary calibration on the perpendicularity, the planimetric position and the anchor bolt top elevation of the overall anchor bolt component; S6, performing a secondary calibration on the perpendicularity and the elevation of the anchor bolt in the anchor bolt component before pouring concretes; and S8, pouring building foundation concretes. The mounting method has the advantages of assembling the sill anchor combined support off site so as to reduce in-site cross operation, flexibly adjusting the sill anchor combined support according the practical situation on site, greatly improving the construction efficiency and the like.

Owner:北京市机械施工集团有限公司 +1

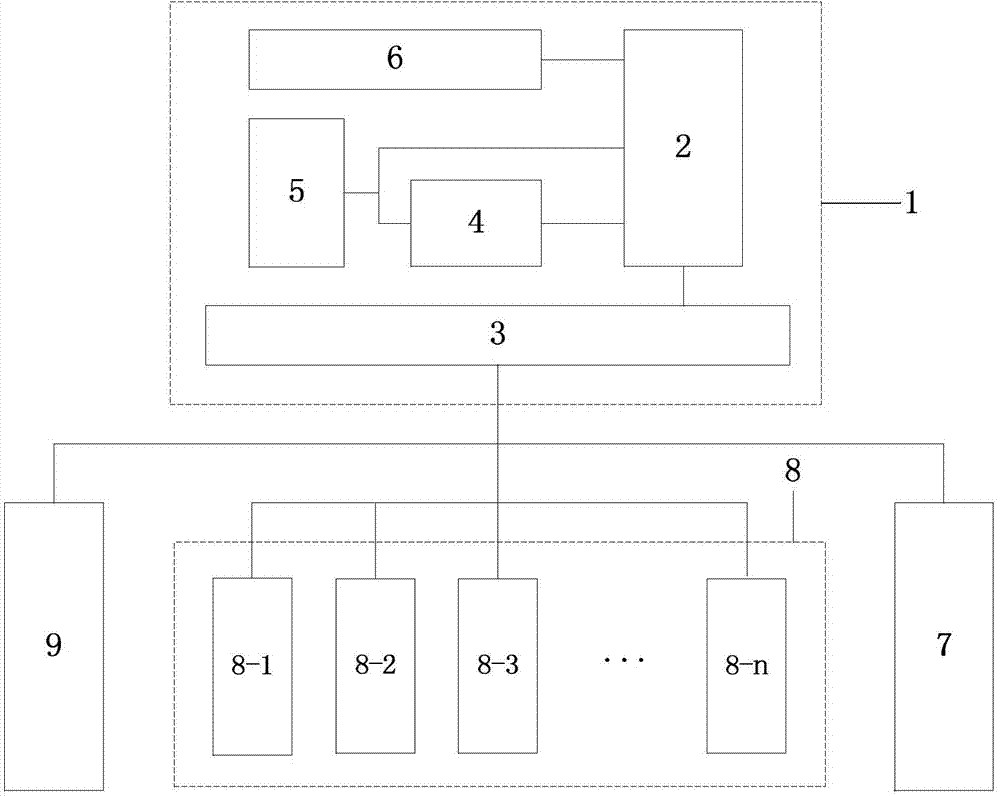

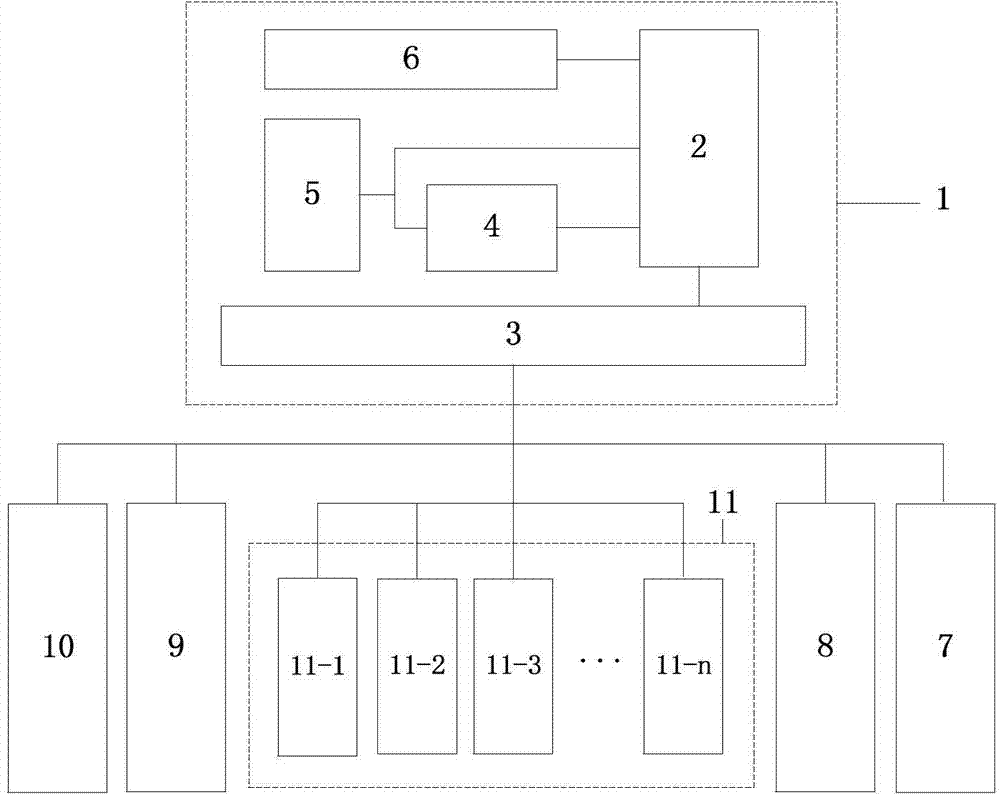

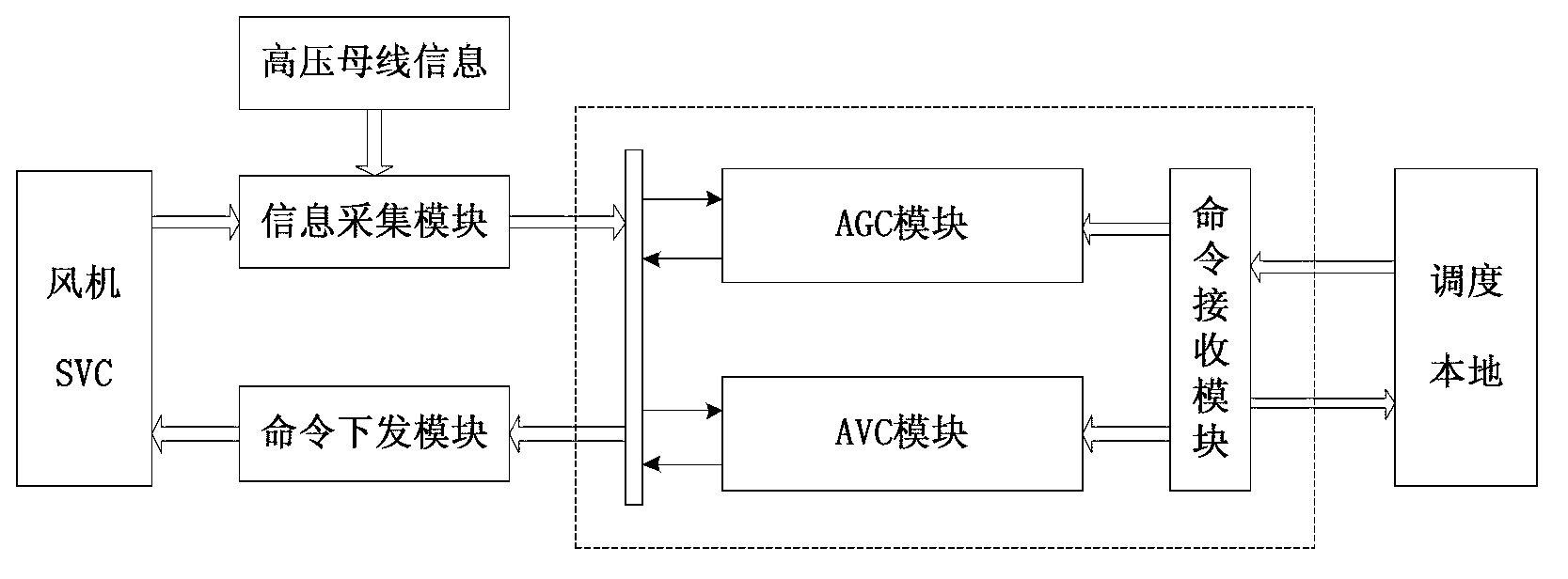

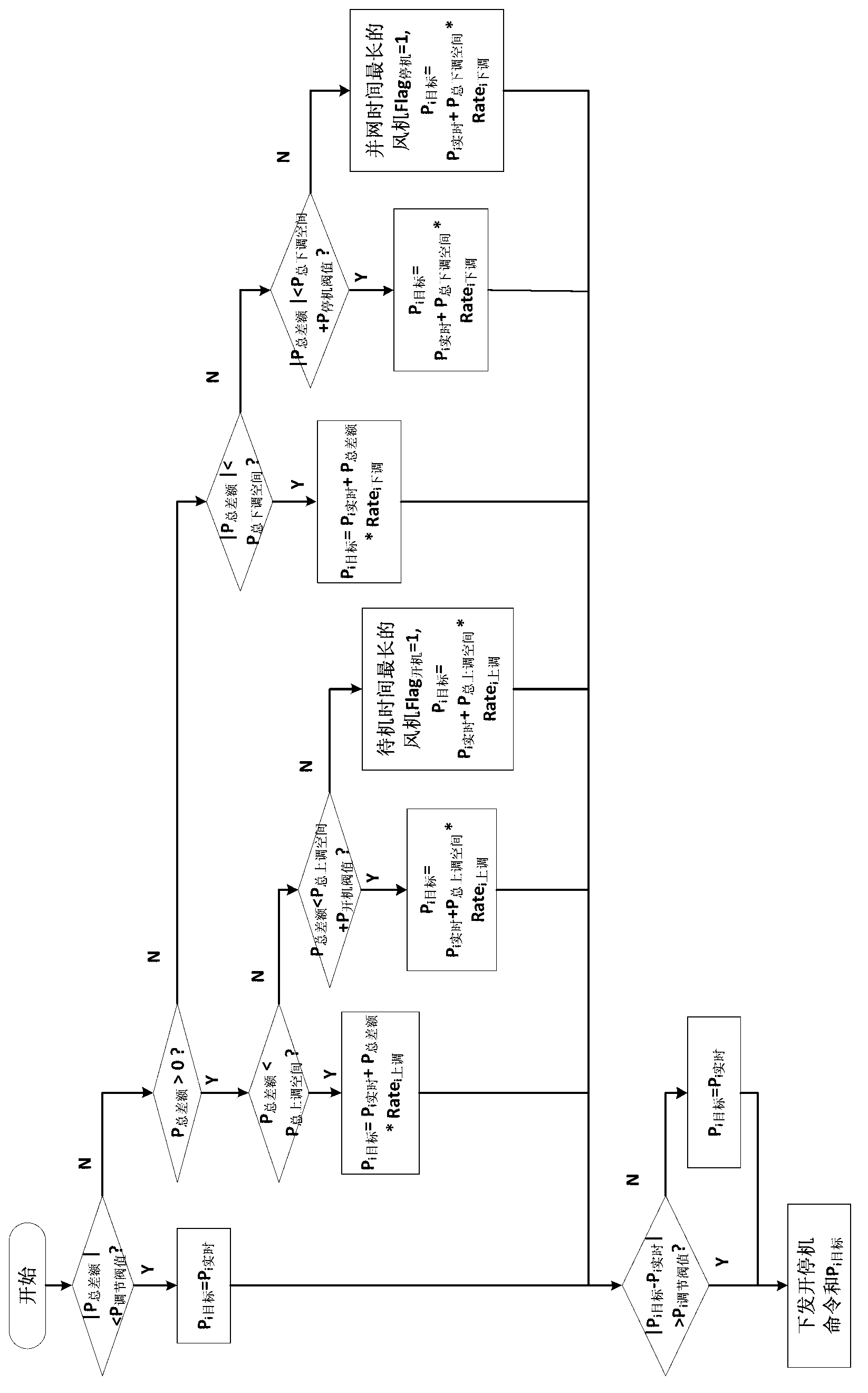

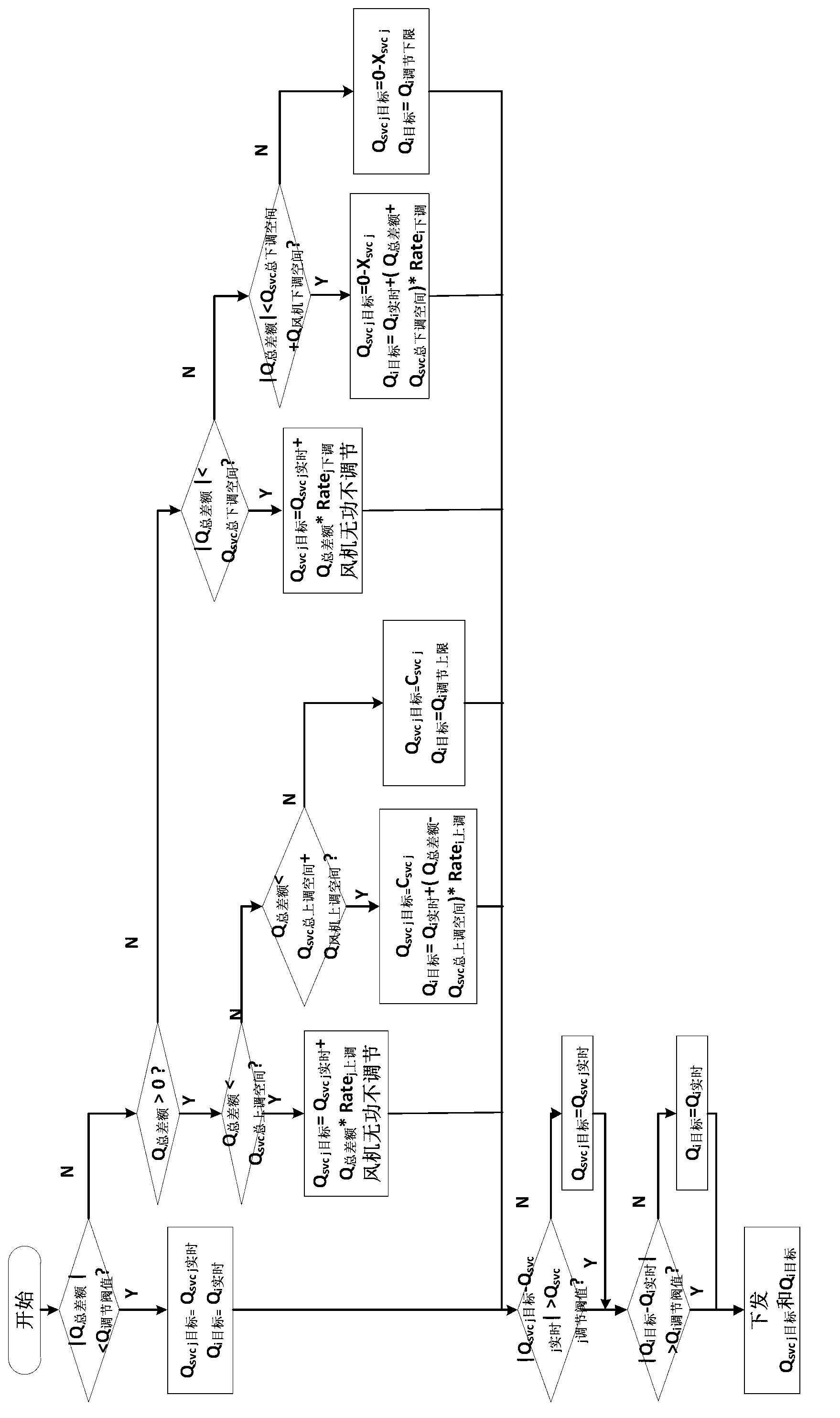

Active/reactive power control system of intelligent wind power station

ActiveCN103023041AQuick responseAccurate responseReactive power adjustment/elimination/compensationReactive power compensationReal-time dataPower grid

The invention provides an active / reactive power control system of an intelligent wind power station. The active / reactive power control system comprises an information collection module, an order receiving module, an AGC (Automatic Gain Control) module, an AVC (Automatic Volume Control) module and an order issuing module; a power grid dispatching system respectively issues orders to the AGC module and the AVC module through the order receiving module; and the AGC module and the AVC module respectively calculate an active target value of an air blower and reactive target values of the air blower and a static reactive compensating device by respectively collecting remote-metering and remote-signaling information and a dispatch issuing order of the equipment through the information collection module, and issuing a calculation result to the air blower and the static reactive compensating device through the order issuing module. The active / reactive distribution distributes according to regulation capability of the single air blower; reactive regulation uses the strategy that the static reactive compensating device is prior to the air blower; the static reactive compensating device is much faster and more accurate than the air blower in the response speed, so that the reactive regulation can be rapidly and accurately responded; and moving average is carried out on real-time data, so as to filter values with large fluctuation. Therefore, the algorithm is more accurate.

Owner:CHINA ELECTRIC POWER RES INST +3

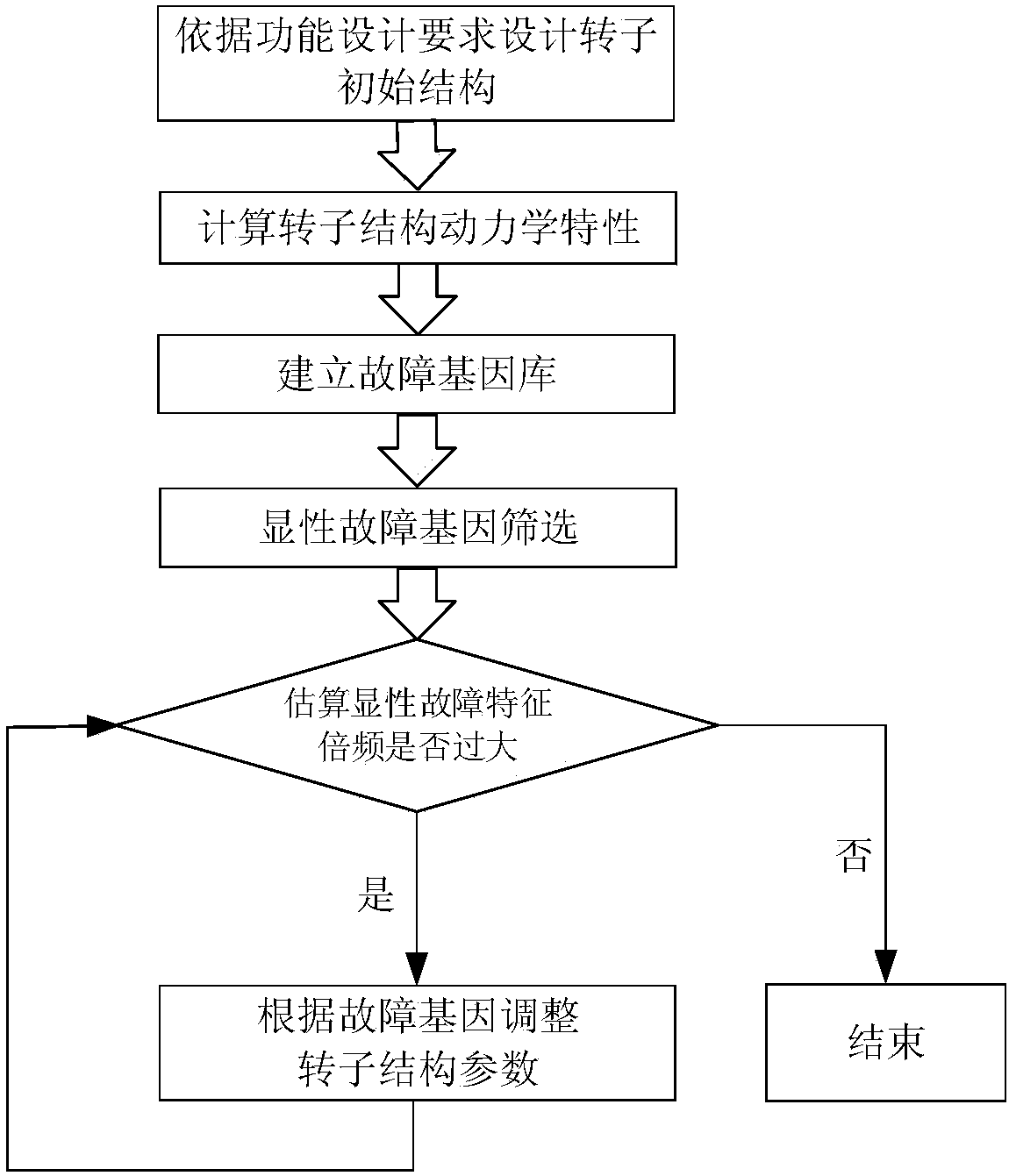

Reverse design method of rotor structure dynamics based on failure genes

ActiveCN107066725AImprove toleranceIncrease inclusivenessGeometric CADSustainable transportationAviationSupporting system

The invention discloses a reverse design method of rotor structure dynamics based on failure genes. The method comprises the steps of designing an initial rotor structure according to rotor speed and power function design requirements to obtain a critical speed and a vibration mode, performing failure gene screening, establishing a failure gene pool of a rotor-supporting system, determining a dominant gene of the initial rotor structure and an expression of the dominant gene, estimating failure response of a dominant failure of the initial rotor structure, adjusting rotor structure parameters according to genetic factors if the failure response is prominent, and estimating the failure response again till a requirement is met. According to the method, a potential vibration failure is preestimated in a design process, and structure adjustment and optimization are performed on a specific failure, so that the possibility of failure occurrence is reduced to the greatest extent; the containment capacity of a design result of aeroengine structure dynamics to a typical failure is improved; a direction is pointed for characteristic optimization of rotor dynamics; a development cycle of a rotor system is shortened; and the development cost is saved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Device and method for predicting removal effect of grinding and polishing processing process in real time

InactiveCN110587484AHigh degree of automationAvoid repeated adjustmentsGrinding feed controlComplex mathematical operationsComputer moduleMachining process

The invention provides a device and a method for predicting a removal effect of a grinding and polishing processing process in real time. The method comprises the following steps: (1) monitoring a processing area by adopting a machine vision method to acquire real-time image characteristic information; and (2) carrying out grinding and polishing model removal processing and calculating on the real-time image characteristic information to output a predicated removal effect. The device comprises a machine vision system, a mainframe, a predicted removal software module and an auxiliary supportingmechanism. The method is high in automatic intelligent degree, and improves the processing precision and processing efficiency of a workpiece. By comprehensively considering the actual condition of the workpiece in the grinding and polishing processing process, the processing removal effect can be predicted in real time, so that the device and the method have positive guiding significance to grinding and polishing processing.

Owner:苏州超徕精工科技有限公司

Rotating disc type automatic flame welding machine and welding method thereof

PendingCN111715973AImprove clamping stabilityAvoid jitterWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCam

The invention discloses a rotating disc type automatic flame welding machine and a welding method thereof. The rotating disc type automatic flame welding machine comprises a machine body, the machinebody is provided with a welding frame, a rotating disc is arranged at the top of the welding frame, a driving assembly is arranged at the bottom of the welding frame and drives the rotating disc to rotate, a feeding device is arranged on one side, located on the rotating disc, of the welding frame, a welding device is arranged on the other side of the welding frame, clamping devices are evenly arranged at positions, corresponding to the feeding device and the welding device, of the rotating disc, each clamping device is provided with a clamping frame, a high-speed precise cam divider is arranged at the top of each clamping frame, each high-speed precise cam divider is rotationally connected with a clamping table, each high-speed precise cam divider controls the corresponding clamping tableto rotate intermittently, an a clamping assembly is arranged on one side, away from the circle center of the rotating disc, of each clamping table and used for fixing a workpiece; and the welding method comprises the following steps of a, preparing before welding; b, feeding; c, welding; and d cyclic batch processing. According to the rotating disc type automatic flame welding machine and the welding method thereof, the welding precision of the workpiece is improved, and meanwhile the phenomena of insufficient welding and missing welding are eliminated.

Owner:嵊州市金东源机电设备有限公司

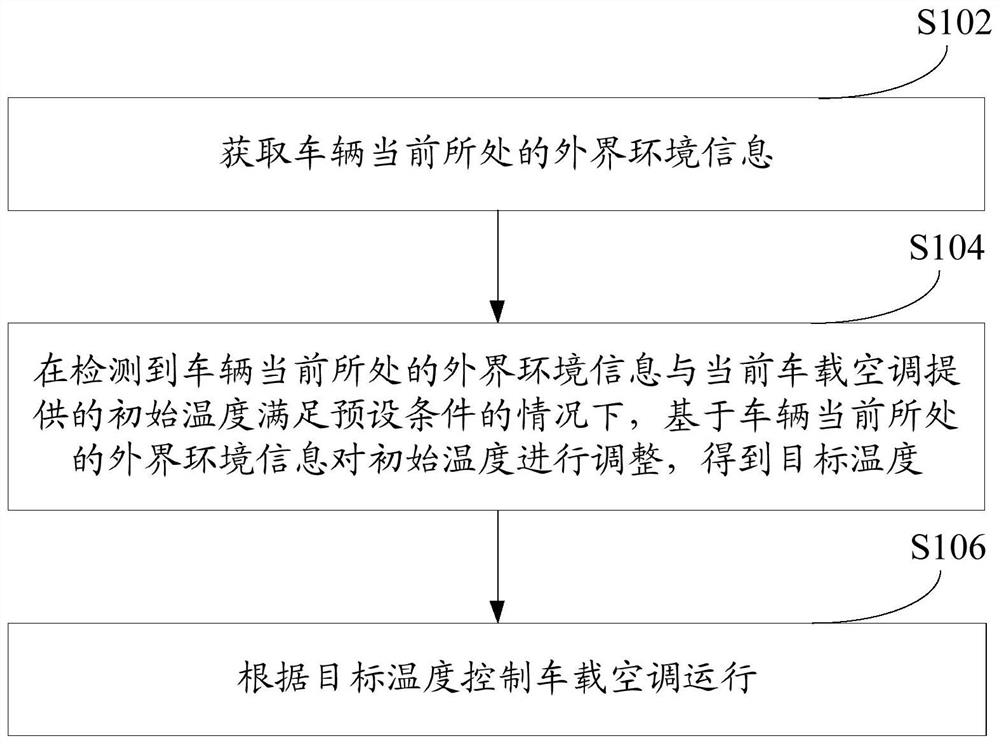

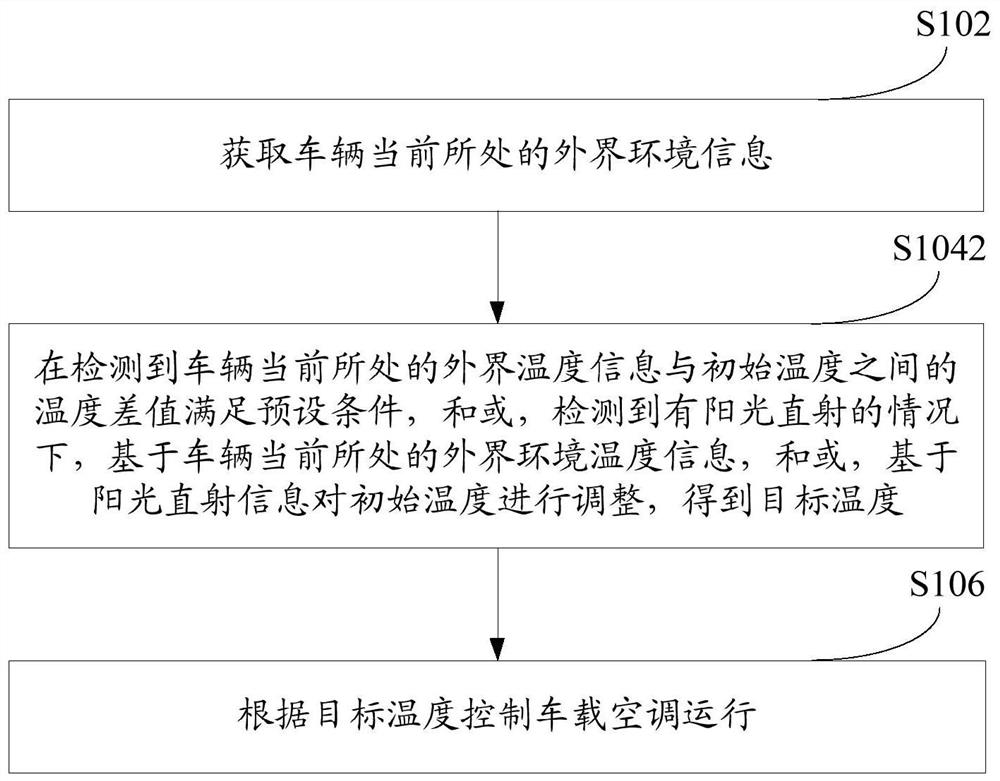

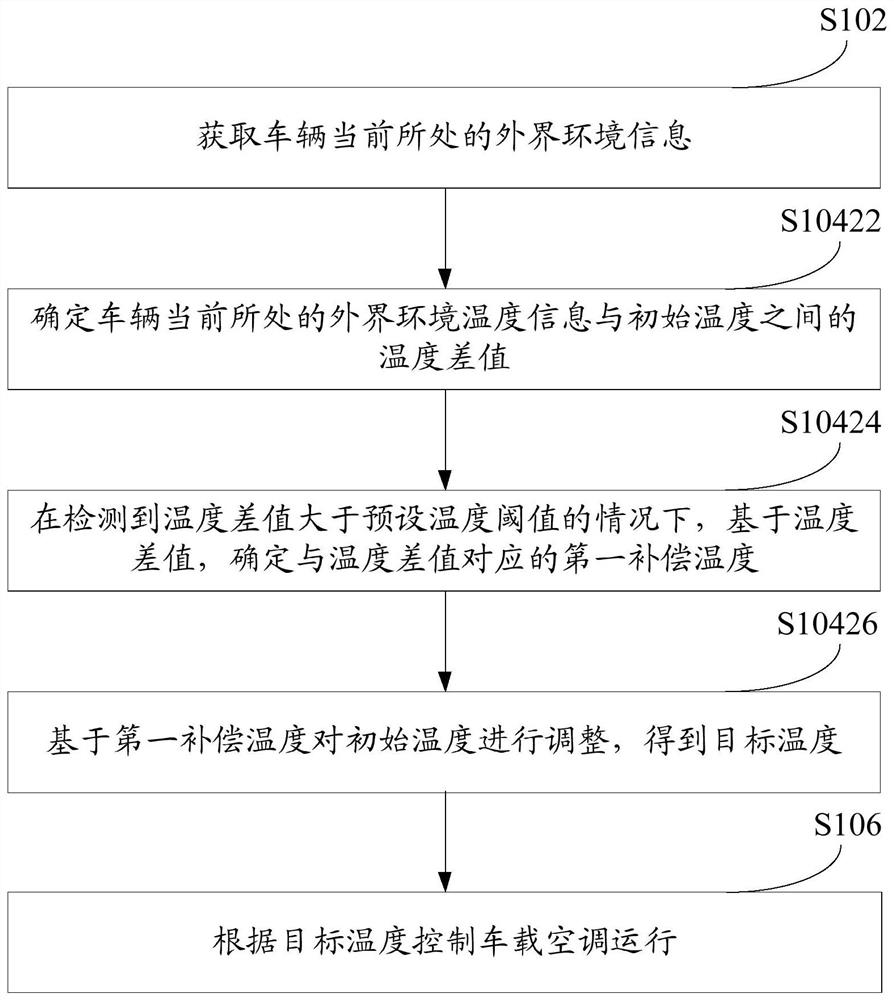

Vehicle-mounted air conditioner temperature control method and device, vehicle-mounted air conditioner and vehicle

PendingCN112874266AImprove regulation efficiencyAvoid repeated adjustmentsAir-treating devicesVehicle heating/cooling devicesTemperature controlIn vehicle

The embodiment of the invention provides a vehicle-mounted air conditioner temperature control method and device, the vehicle-mounted air conditioner and a vehicle. The method comprises the steps that information of the current external environment of the vehicle is obtained, and when it is detected that the information of the current external environment of the vehicle and the initial temperature provided by the current vehicle-mounted air conditioner meet preset conditions, the initial temperature is adjusted based on the information of the current external environment of the vehicle, the target temperature is obtained, and then the vehicle-mounted air conditioner is controlled to operate according to the target temperature. According to the method of the invention, in the running process of the vehicle, a user does not need to adjust the temperature of the vehicle-mounted air conditioner in a mode of manually touching a key or an intelligent voice mode, so that the problem that the temperature of the vehicle-mounted air conditioner needs to be repeatedly adjusted in the process of adjusting the temperature of the vehicle-mounted air conditioner to the comfortable temperature is effectively avoided, and the temperature adjusting efficiency of the vehicle-mounted air conditioner is further improved, and the use experience of a user is improved.

Owner:EVERGRANDE NEW ENERGY AUTOMOTIVE INVESTMENT HLDG GRP CO LTD

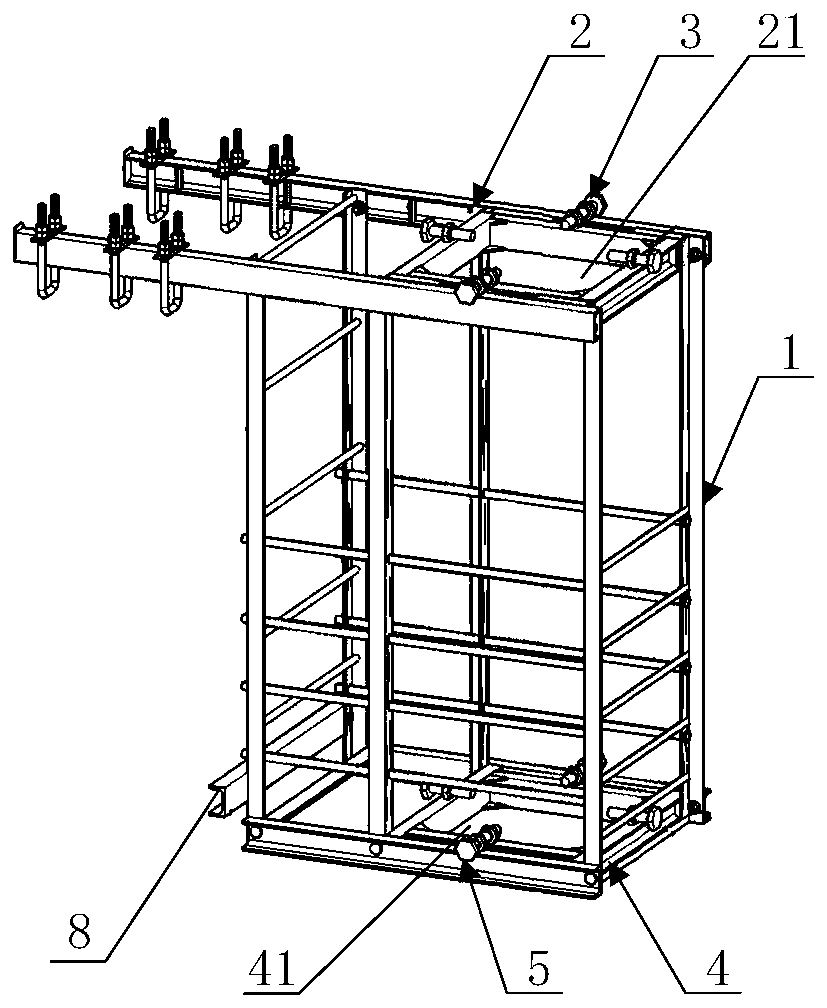

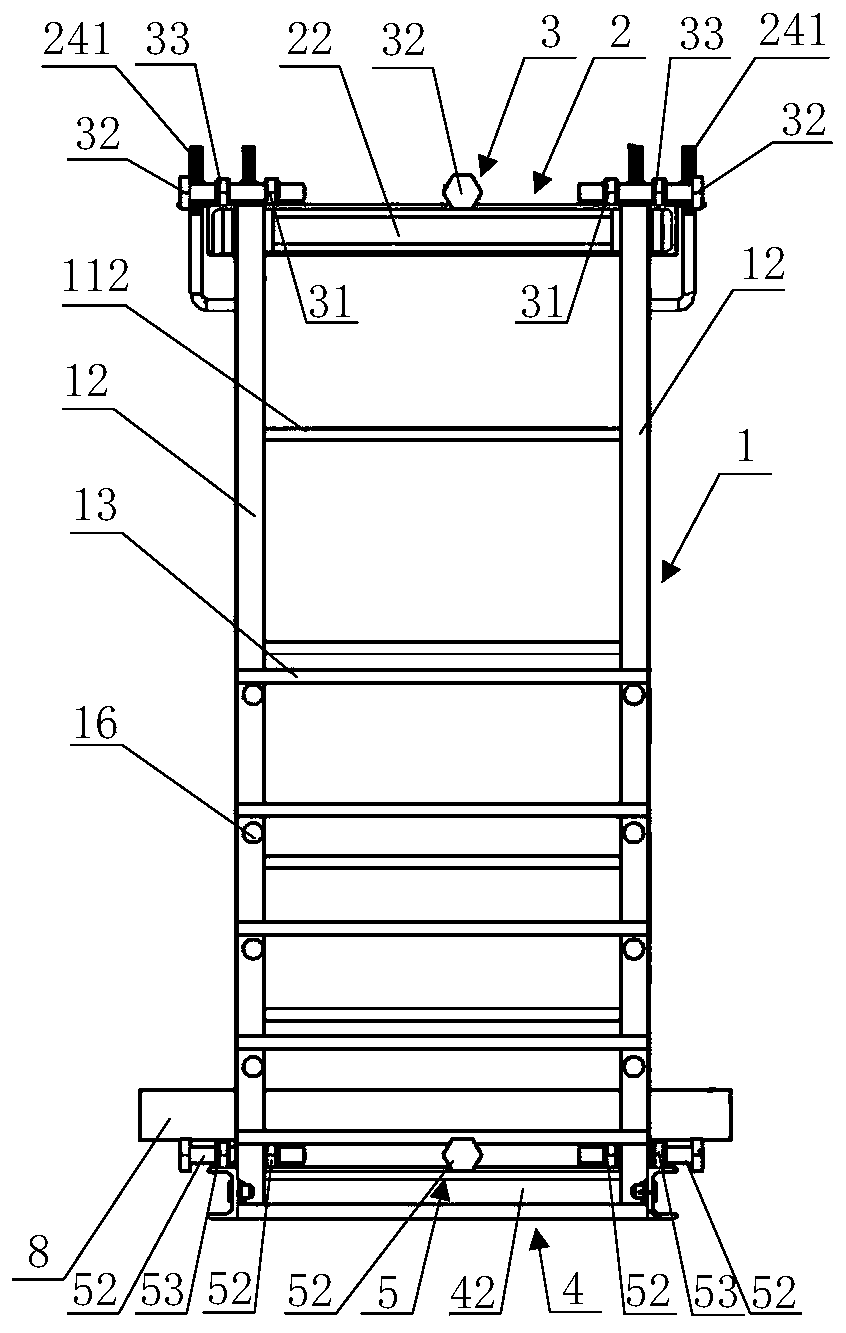

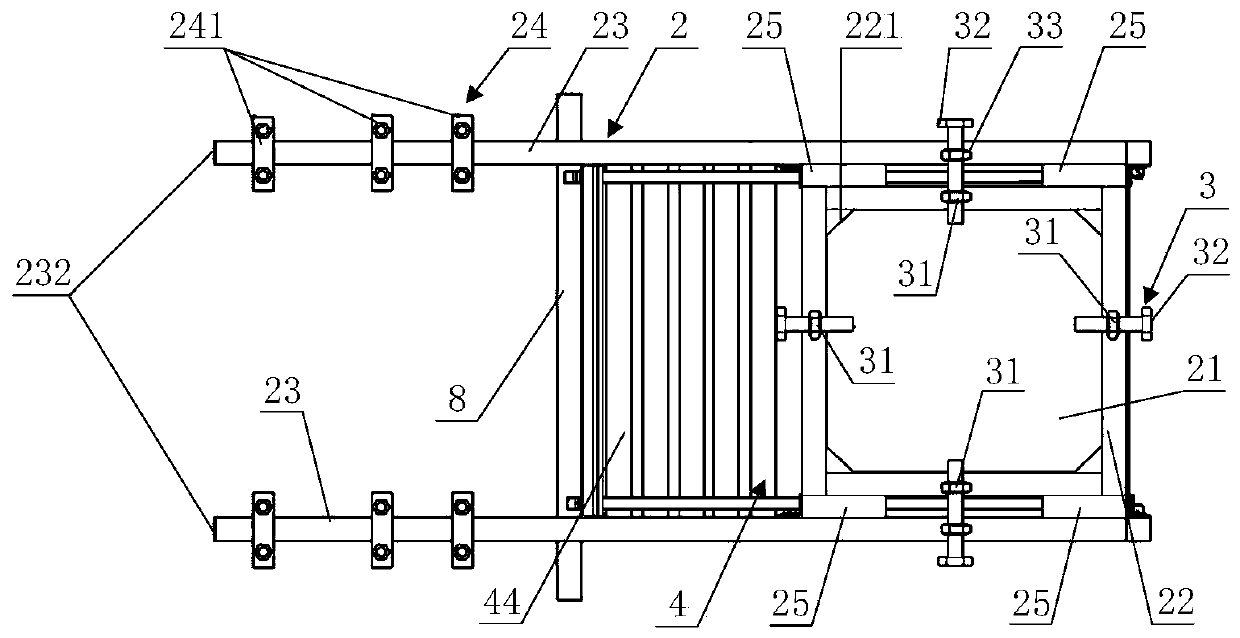

Guide positioning operation frame for steel pipe pile construction

PendingCN110158596AFast implementation of vertical correctionAchieving Vertical CorrectionBridge erection/assemblyBulkheads/pilesArchitectural engineeringBuilding construction

The invention provides a guide positioning operation frame for steel pipe pile construction. The operation frame comprises an operation cage, a first guide frame, a first positioning mechanism, a second guide frame and a second positioning mechanism. The first guide frame is connected with the top of the operation cage, and the first guide frame is provided with a first channel for a steel pipe pile to penetrate; the first positioning mechanism is arranged on the first guide frame and used for adjusting the size of the first channel; the second guide frame is connected to the bottom of the operation cage, the second guide frame is provided with a second channel for the steel pipe pile to be penetrate, and the second channel and the first channel are completely coincided with each other inthe penetrating direction of the steel pipe pile; and the second positioning mechanism is arranged on the second guide frame and is used for adjusting the size of the second channel, and the second positioning mechanism and the first positioning mechanism are completely coincided in the penetrating direction of the steel pipe pile. The guide positioning operation frame can quickly realize verticalcorrection of the steel pipe pile, improves the precision of the verticality of the steel pipe pile, prevents displacement of the steel pipe pile and improves the positioning efficiency and the positioning quality of the steel pipe pile.

Owner:CHINA MCC 2 GRP CO LTD

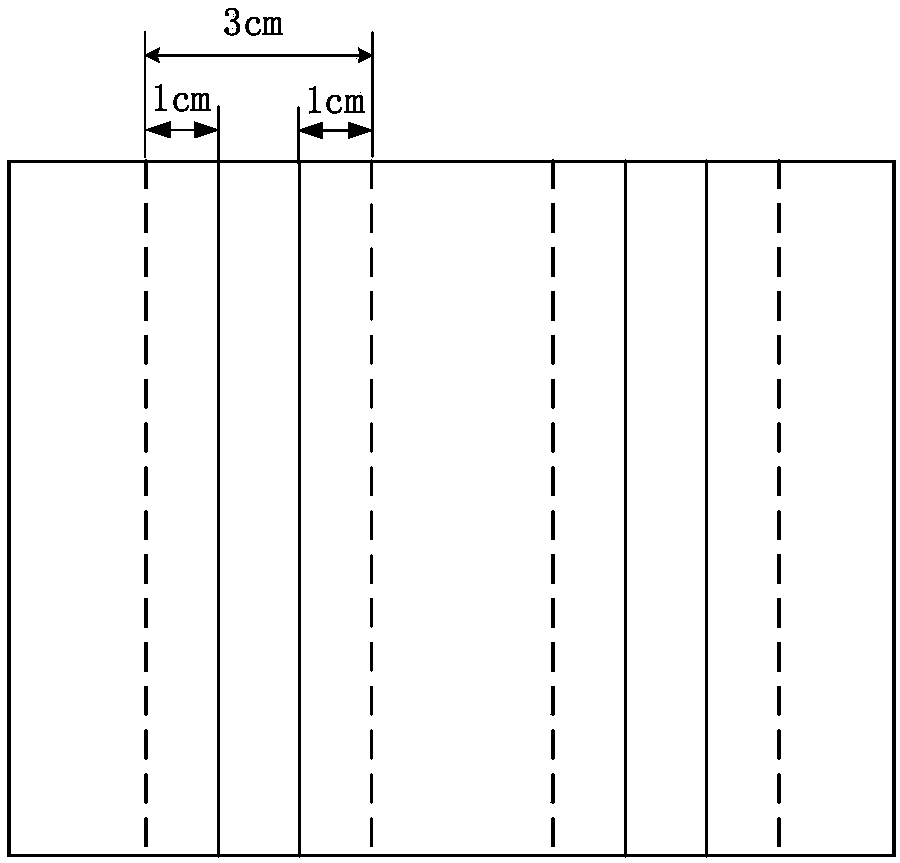

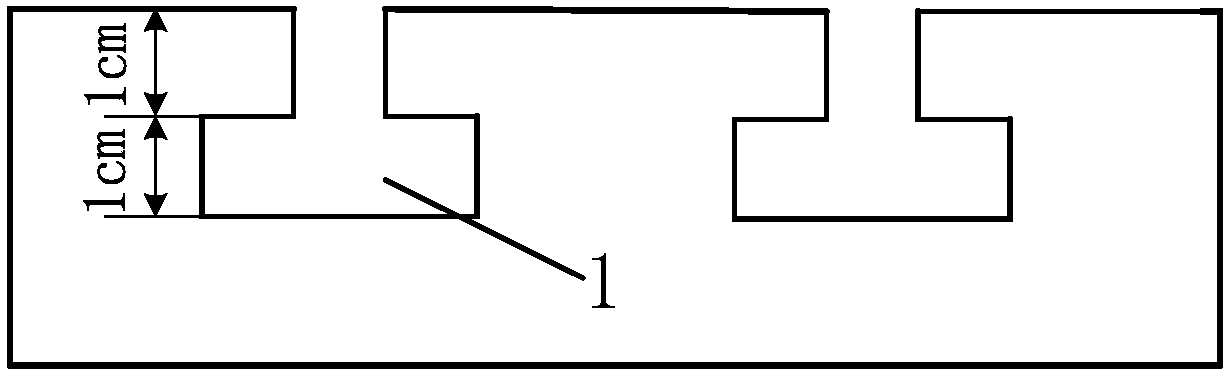

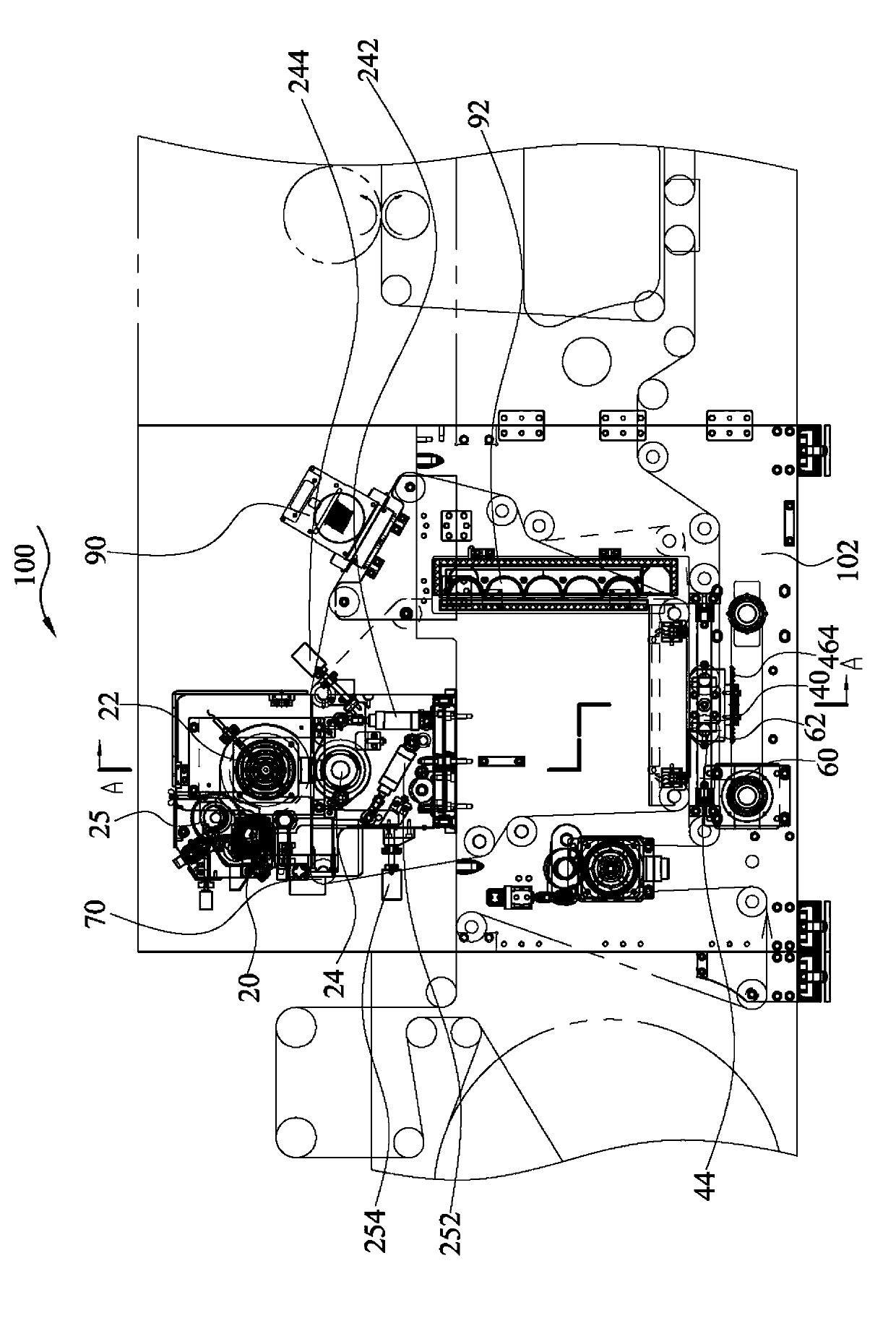

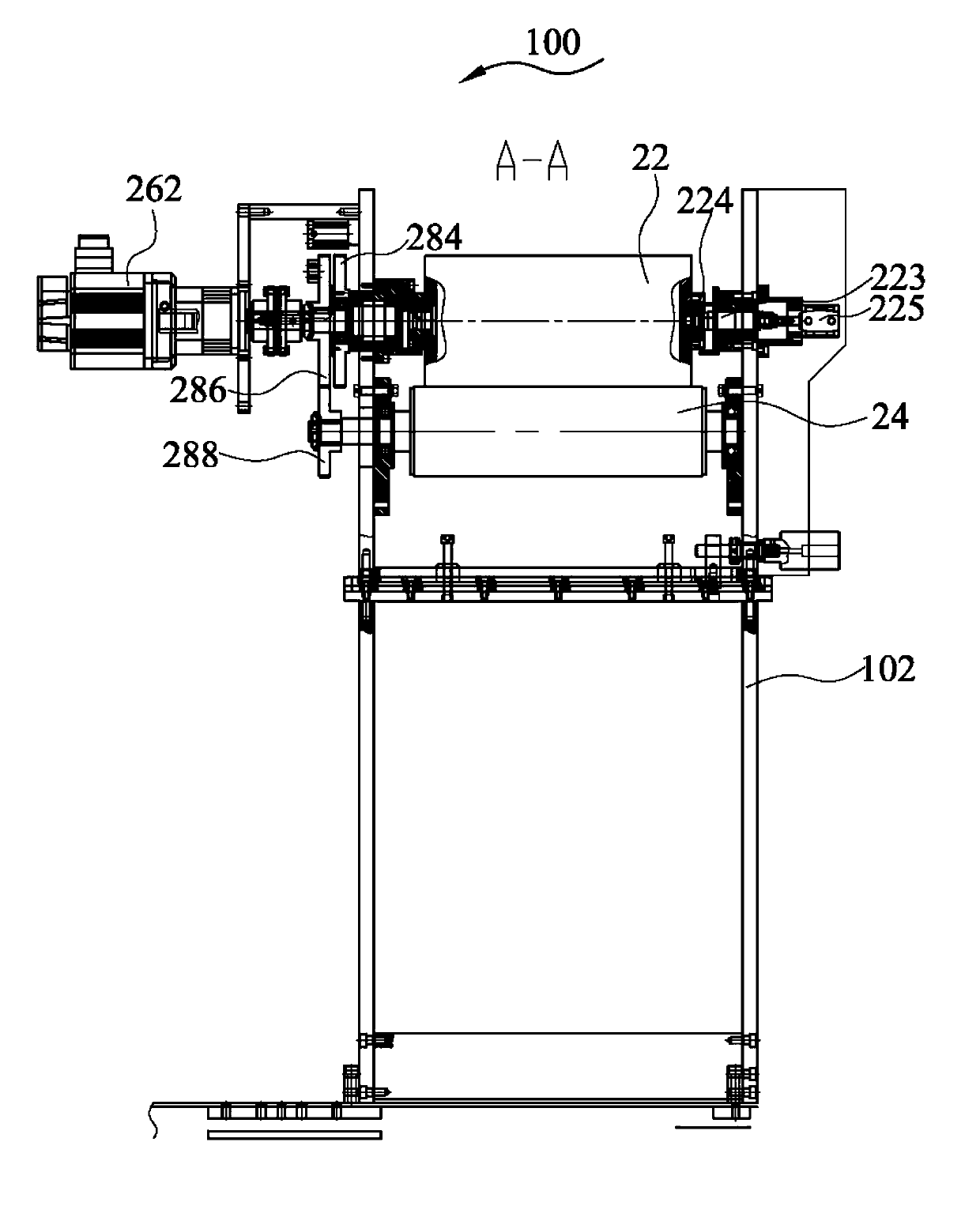

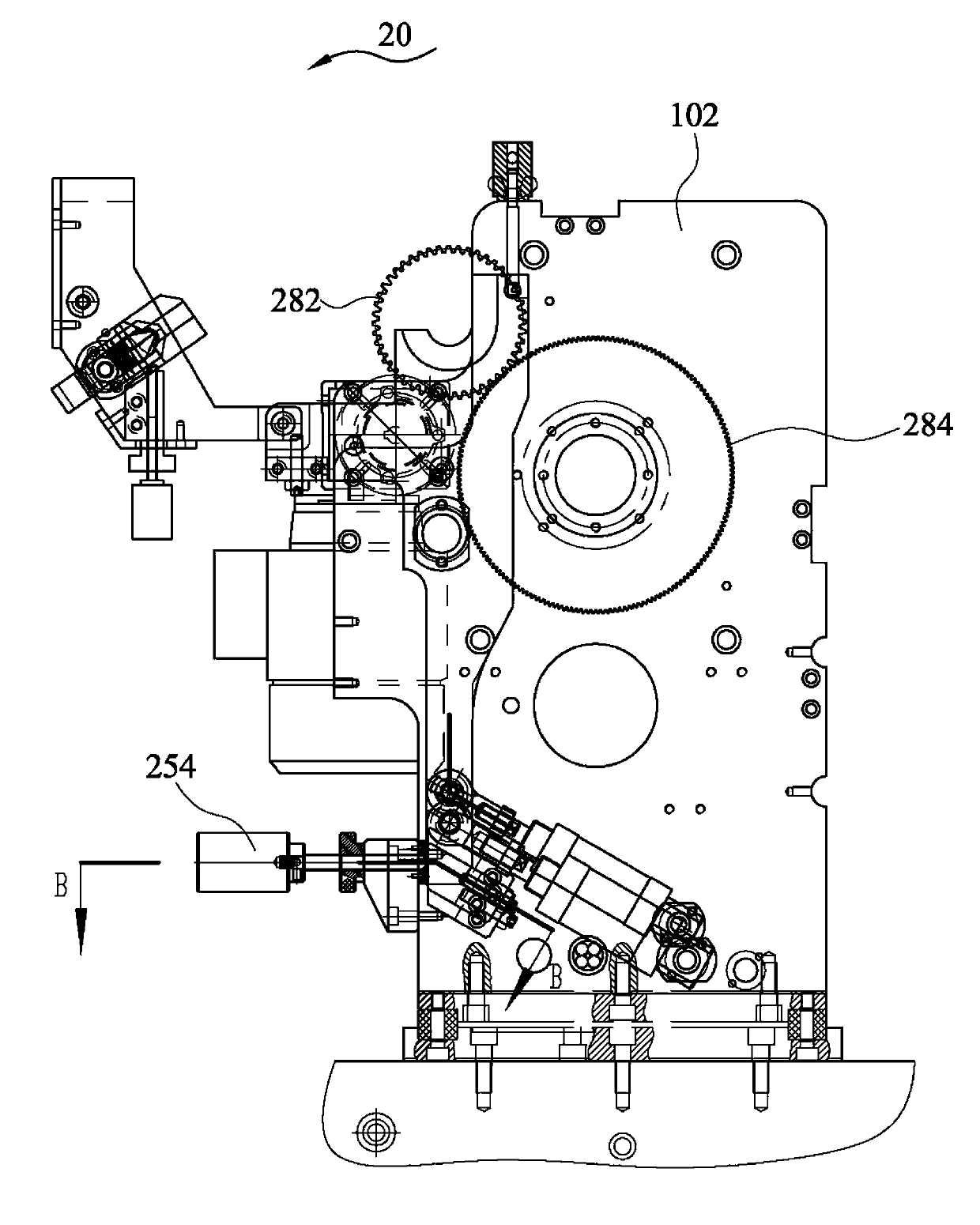

Batch-type flexible printing device

InactiveCN103101290AAvoid replacementAvoid repeated adjustmentsRotary letterpress machinesPower componentEngineering

A batch-type flexible printing device comprises a rack and a batch-type flexible printing unit. The batch-type flexible printing unit comprises a printing plate roller and a printing roller, a flexible printing power component and flexible printing transmission unit, wherein the printing plat roller and the printing roller are matched with each other to carry out printing, the flexible printing power component provides driving power, and the flexible printing transmission unit is connected with the flexible printing power component and is driven by the flexible power component to provide the power of the flexible printing power component for the printing plate roller or the printing roller. The printing plate roller is provided with a printing area and a non-printing area according to the arranging positions of printing plates. Through the arrangement of the batch-type flexible printing unit, the printing plate roller is provided with the printing area and the non-printing area according to the arranging positions of the printing plates, the needs of printing objects and printing plates with different sizes are met, and manufacture cost is saved. The printing plate roller is prevented from being replaced due to the replacement of the printing plates, pressure and positions are prevented from being adjusted repeatedly in a replacement process, manufacture time is saved, and the batch-type flexible printing device is especially suitable for the printing of the printing objects with a small quantity and different specifications.

Owner:BROTECH GRAPHIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com