Method for planning five-axis numerical control to process safety shortest cutting tool length

A tool length and tool technology, which is applied in the field of planning the safest shortest tool length in five-axis CNC machining, can solve problems such as not considering the impact of tool length, and achieve high calculation efficiency and simple programming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are not intended to limit the present invention.

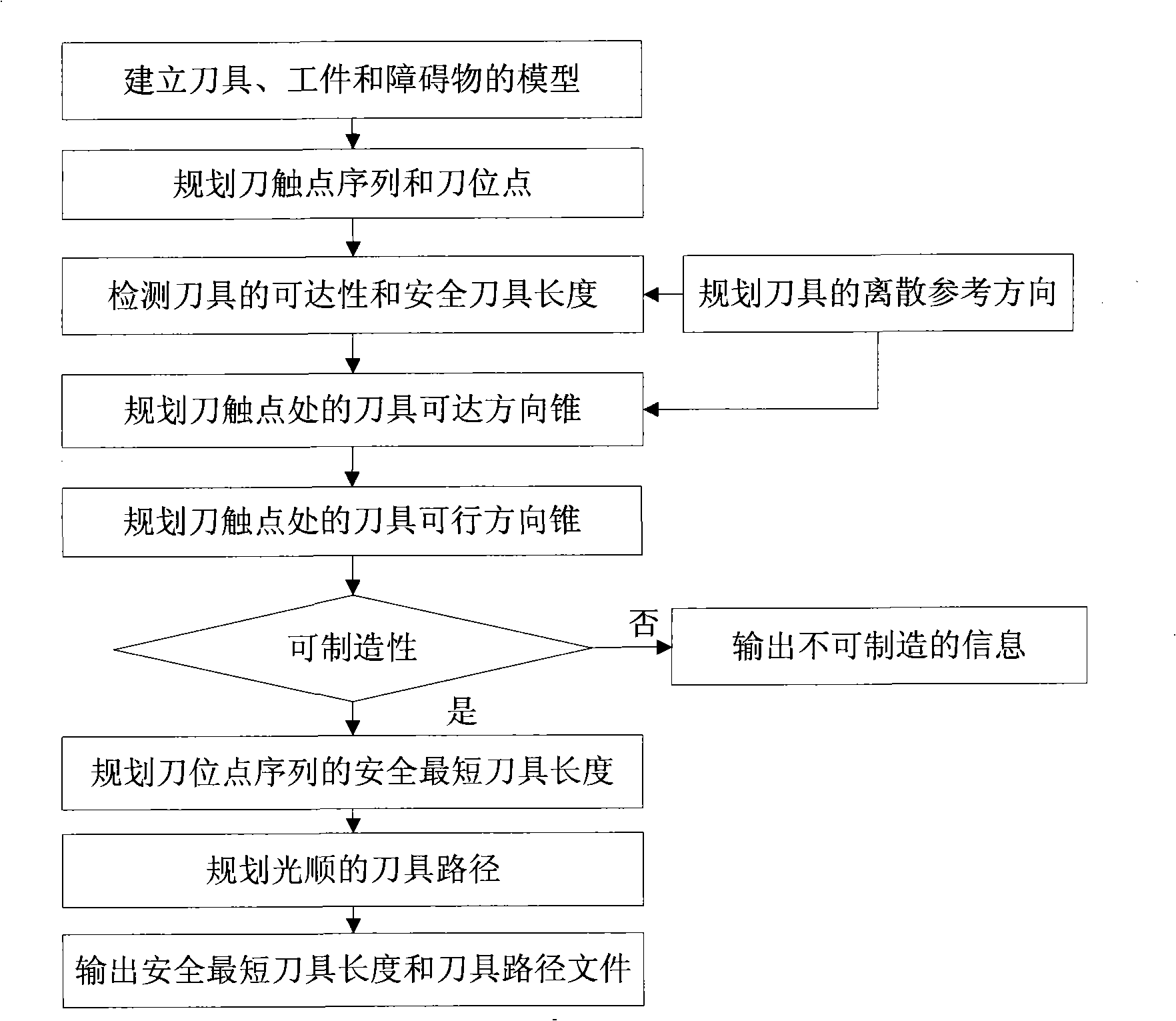

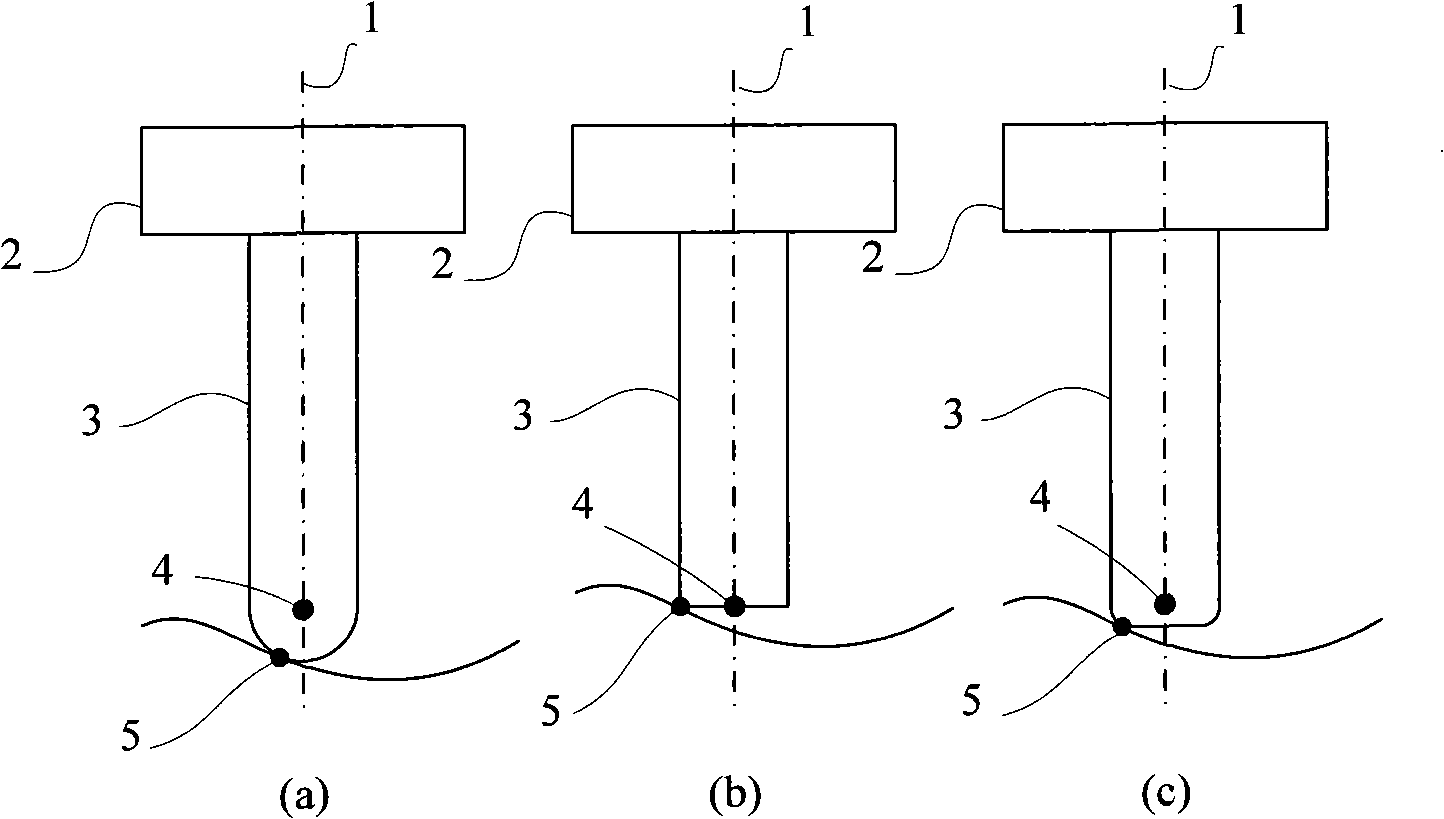

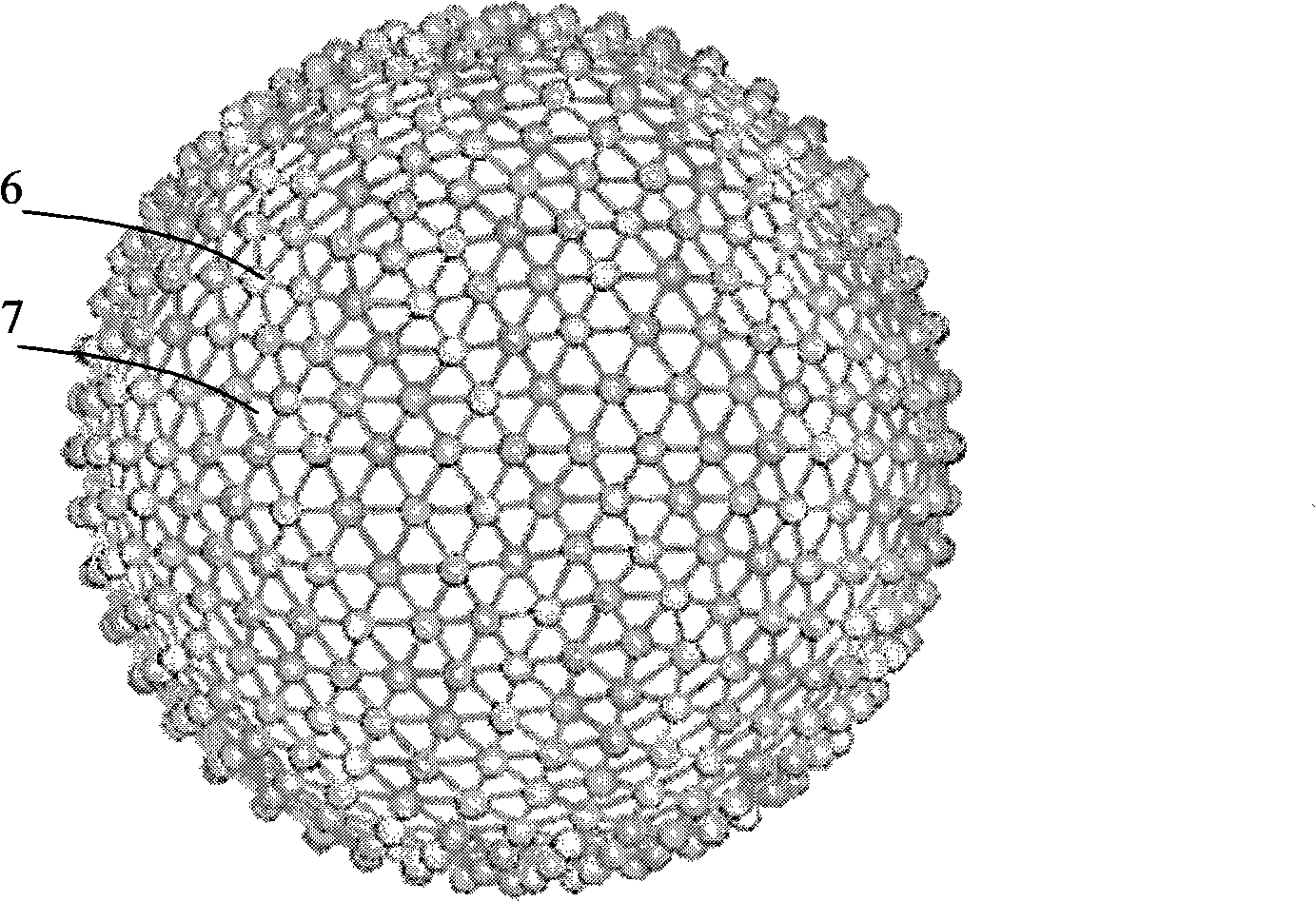

[0046] The process flow of the planning method for the safe shortest tool length in five-axis numerical control machining proposed by the present invention is as follows: figure 1 As shown, first establish the geometric model of the tool, the workpiece and the obstacle, the obstacle includes the fixture of the workpiece and the objects that may interfere with the tool around the workpiece; calculate the distance between the tool and the workpiece by using the equal residual height method, section method or equal parameter method Contact points, get the tool contact sequence, determine the position of the tool point according to the tool contact sequence and tool shape; uniformly discretize the Gaussian sphere to plan the discrete reference directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com