Patents

Literature

890results about How to "Improve clamping stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing process for high-curvature full-profile thin-wall part

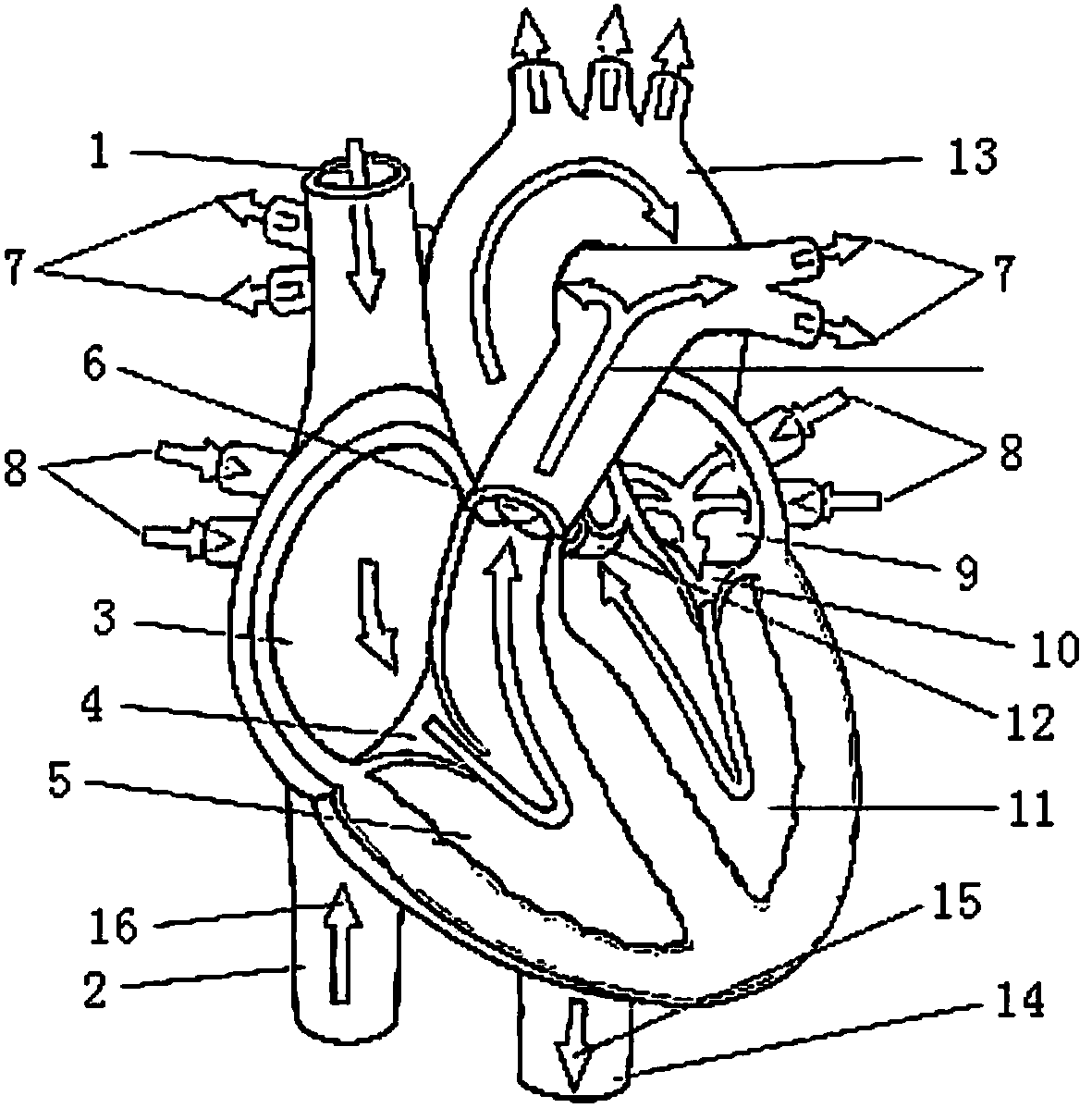

ActiveCN103639655ASolve Vibration ProblemsGuaranteed sizeAircraft componentsWorkpiecesMaterial removalNatural aging

The invention provides a manufacturing process for a high-curvature full-profile thin-wall part so as to solve the problem of processing deformation and vibration of an ultra-complex spatial thin-wall curved surface. By reasonable process layout, a segmented layer-by-layer processing mode is adopted, an appropriate cutter and a cutter handle are selected, working allowance of every process is set, natural aging time is set, cutting process parameters and feeding strategies are optimized, the uniform material removal amount of the part is guaranteed, an adding cushion block location and gypsum filling method is adopted simultaneously, the problem of clamping difficulty and vibration in part processing is solved, processing rigidity and clamping stability of the part are improved, deformation in the part processing process is controlled, and the part size and precision are guaranteed.

Owner:江西洪都航空工业股份有限公司

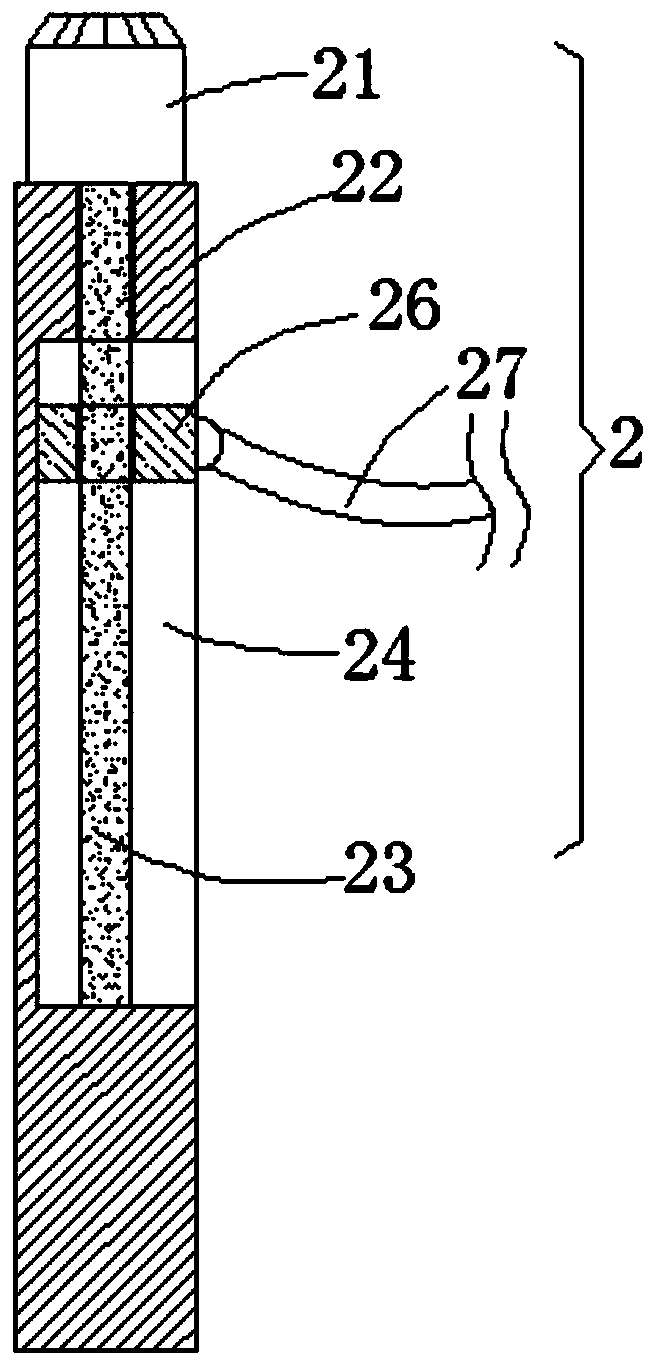

Nail taking device used in orthopedics department

InactiveCN107485442AEffective clampingTake it out and save effortOsteosynthesis devicesCouplingOrthopedic department

Owner:SHANGHAI TENTH PEOPLES HOSPITAL

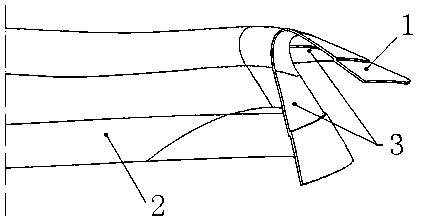

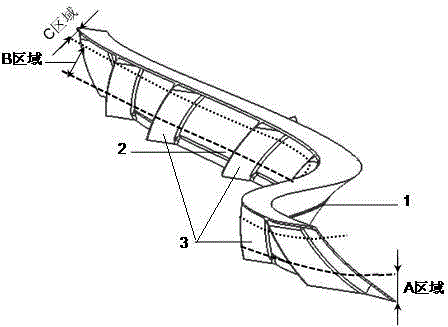

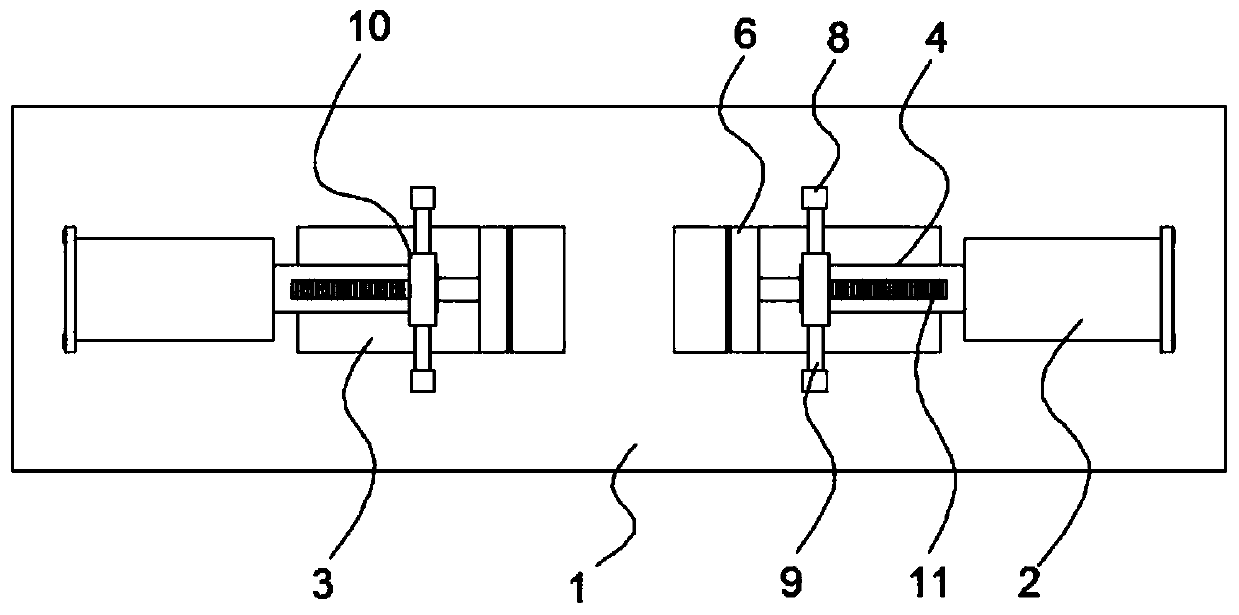

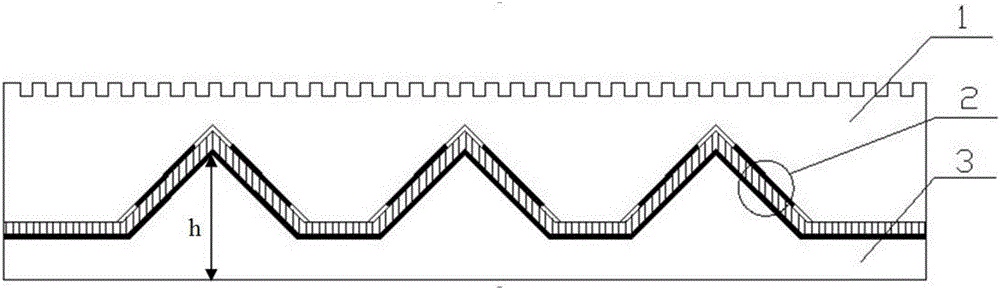

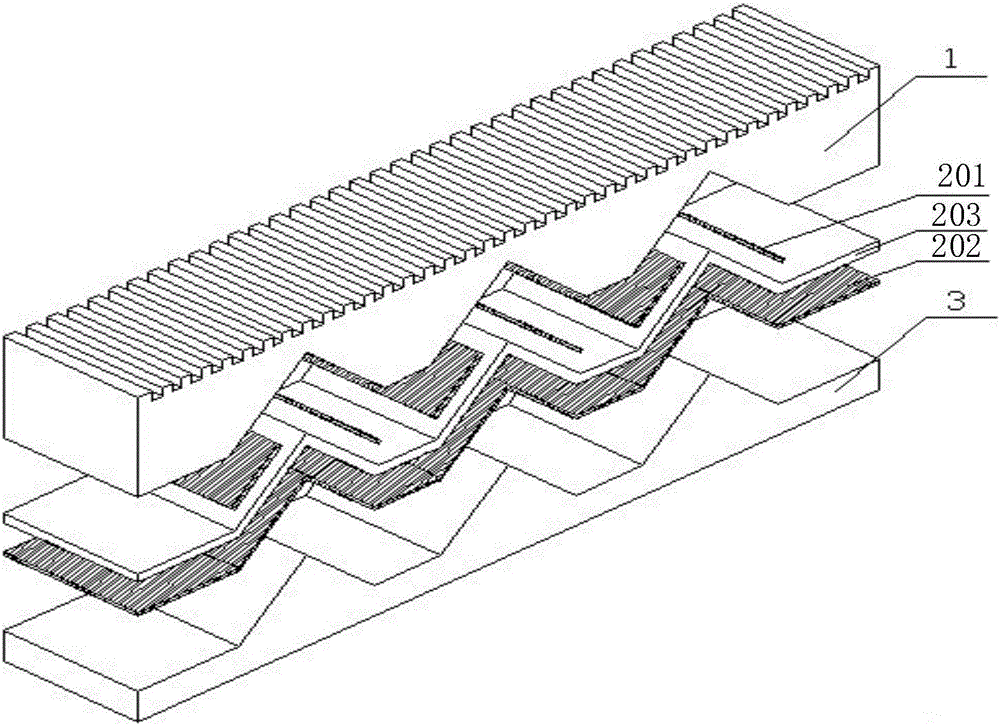

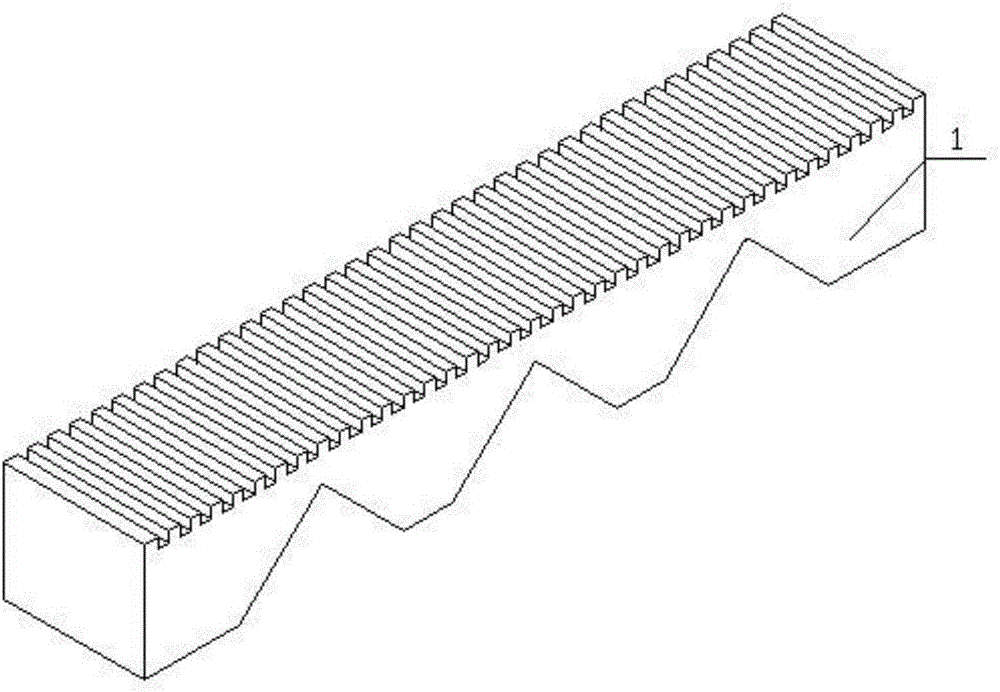

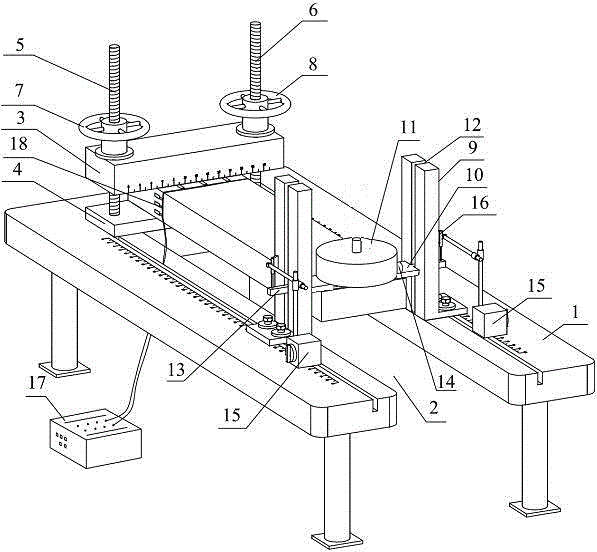

Double-S-shaped double-curve thin-walled part manufacturing process

ActiveCN104526270AImprove clamping stabilityImprove processing rigidityMachining deformationVibration Problem

The invention relates to the technical field of mechanical machining, in particular to a double-S-shaped double-curve thin-walled part manufacturing process. A five-coordinate high-speed mill is adopted to conduct rough machining on an inner curve and an outer curve with ribs and conduct semi-finish machining and finish machining on the inner curve and the outer curve with ribs, and a step cushion block positioning and gypsum filling method is adopted to perform clamping and positioning. The part clamping and positioning problems are solved, and part clamping stability and machining rigidity are improved. Regional segmented and layered machining is adopted for parts, machining deformation of ultra-complicated thin-walled curved surfaces is effectively controlled, the vibration problem in the machining process is avoided, and part size and accuracy are ensured.

Owner:JIANGXI HONGDU AVIATION IND GRP

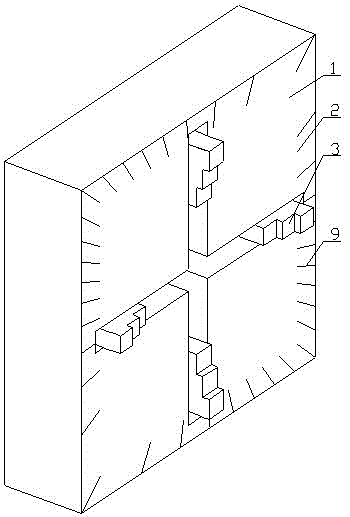

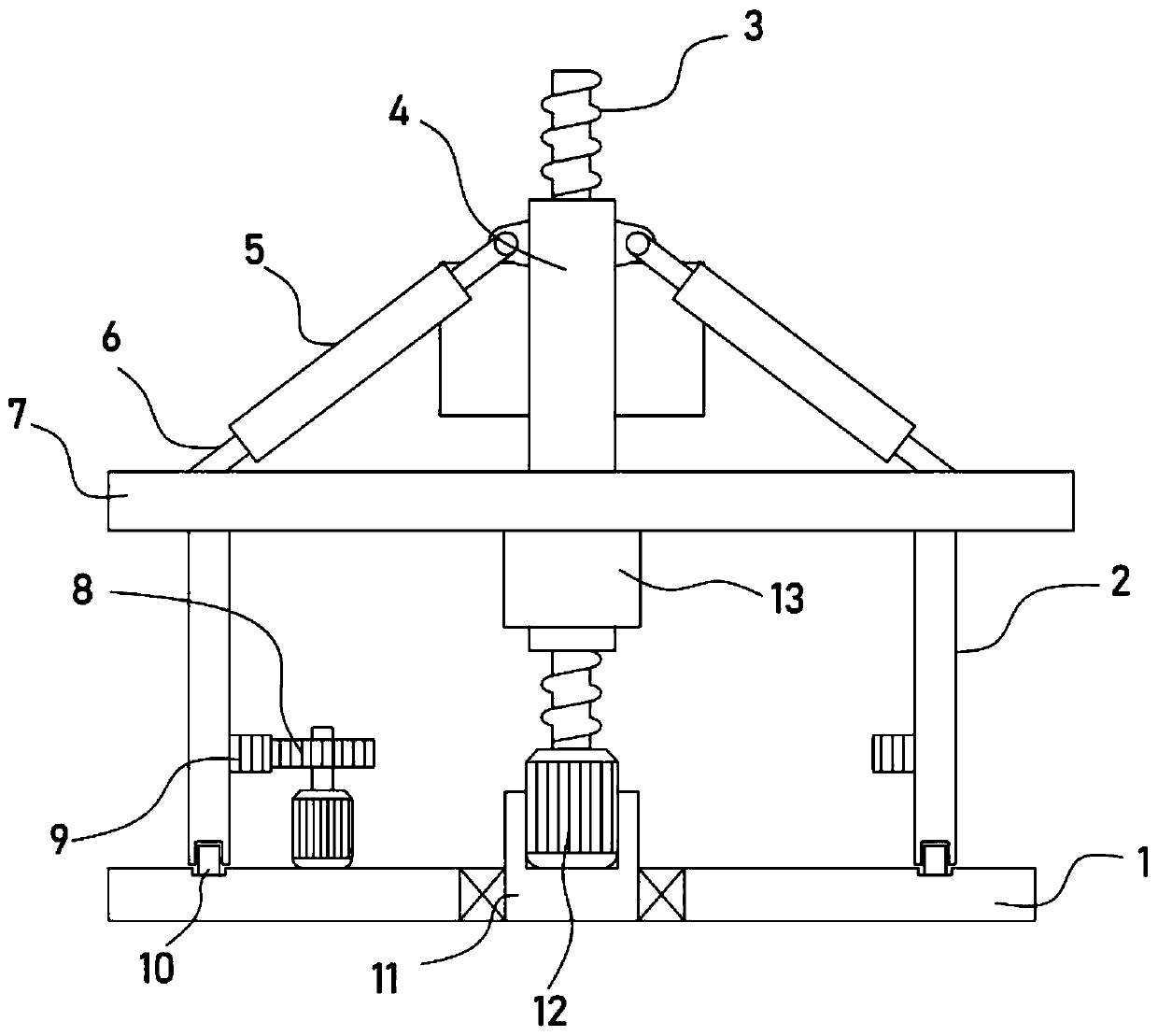

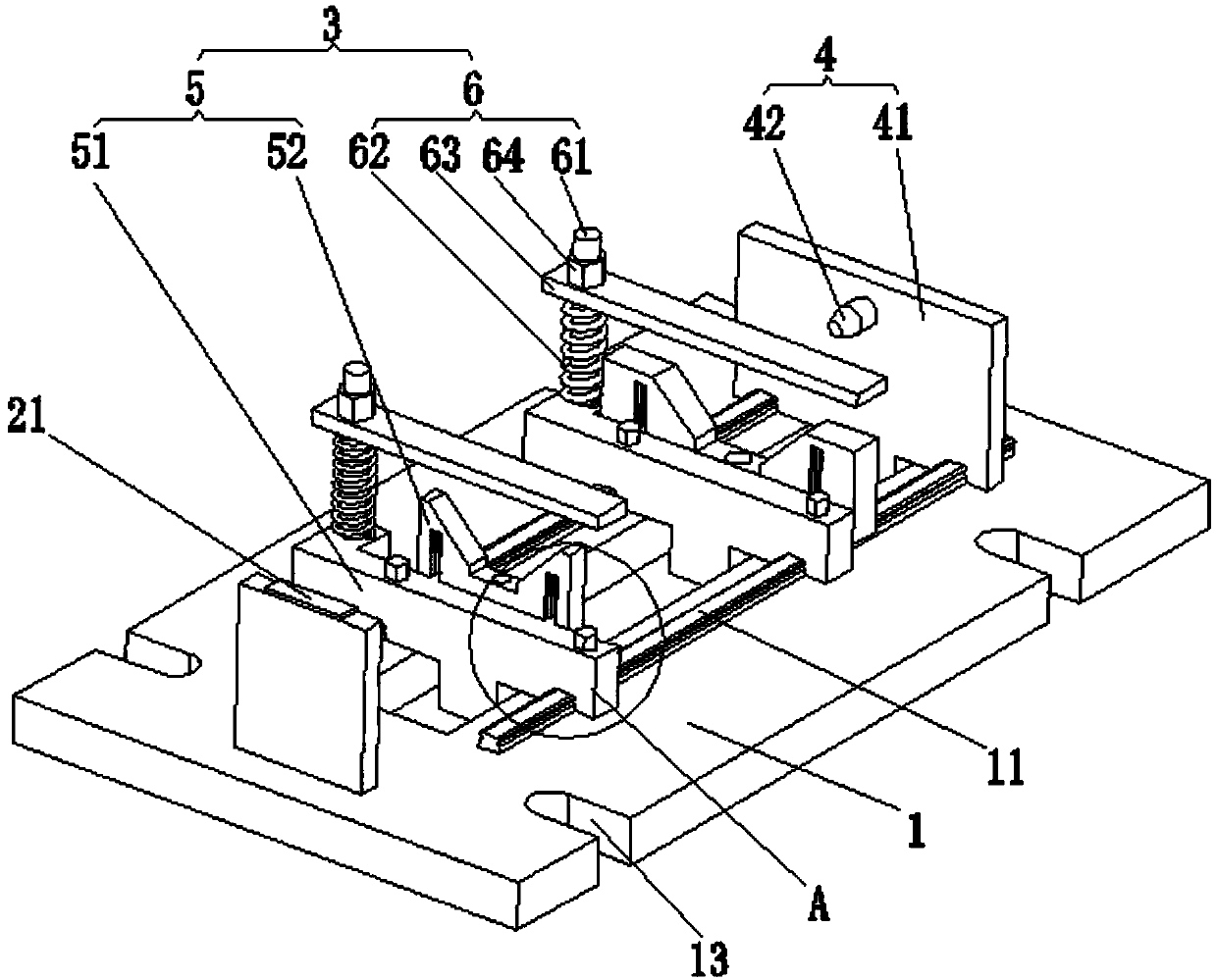

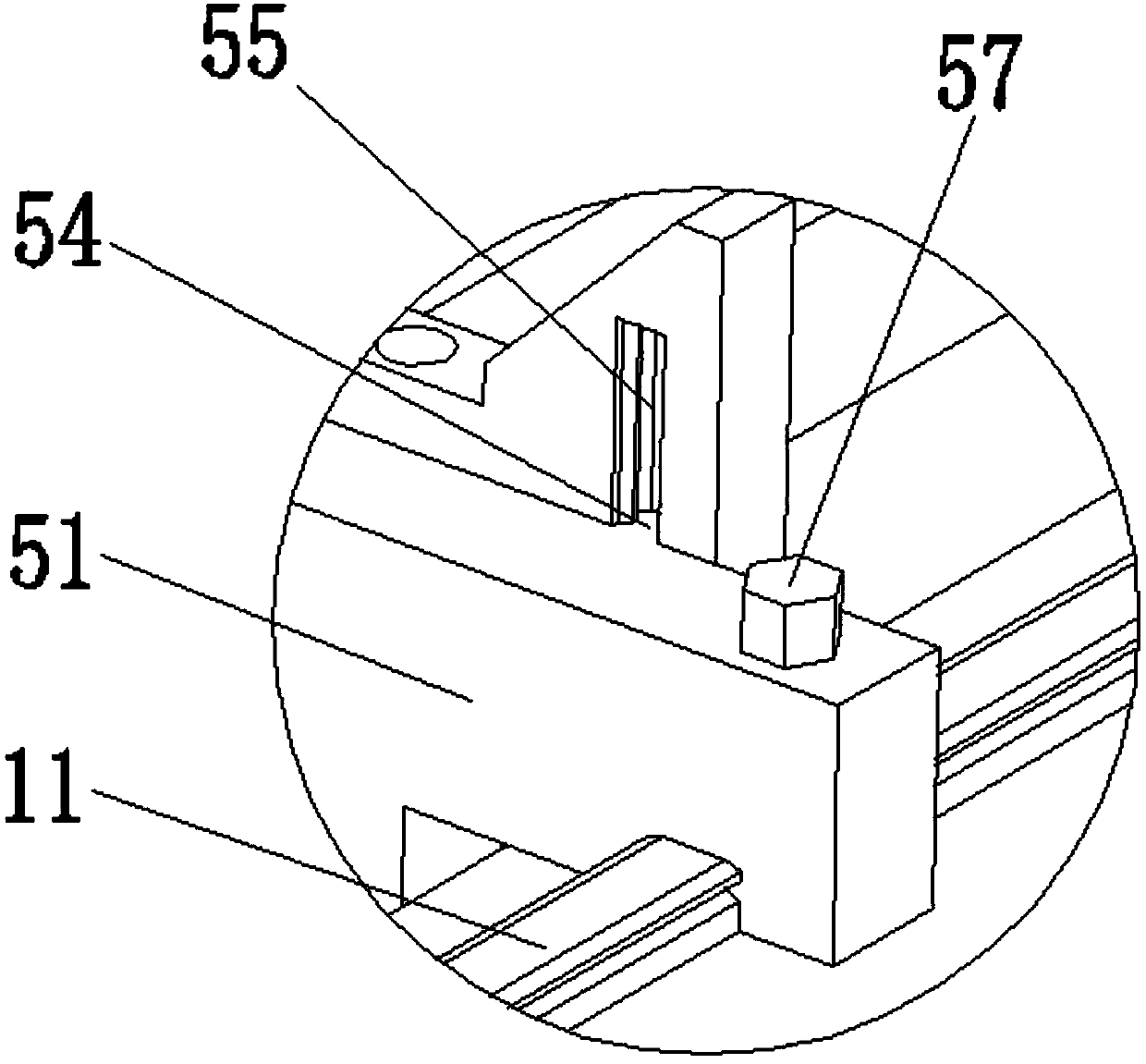

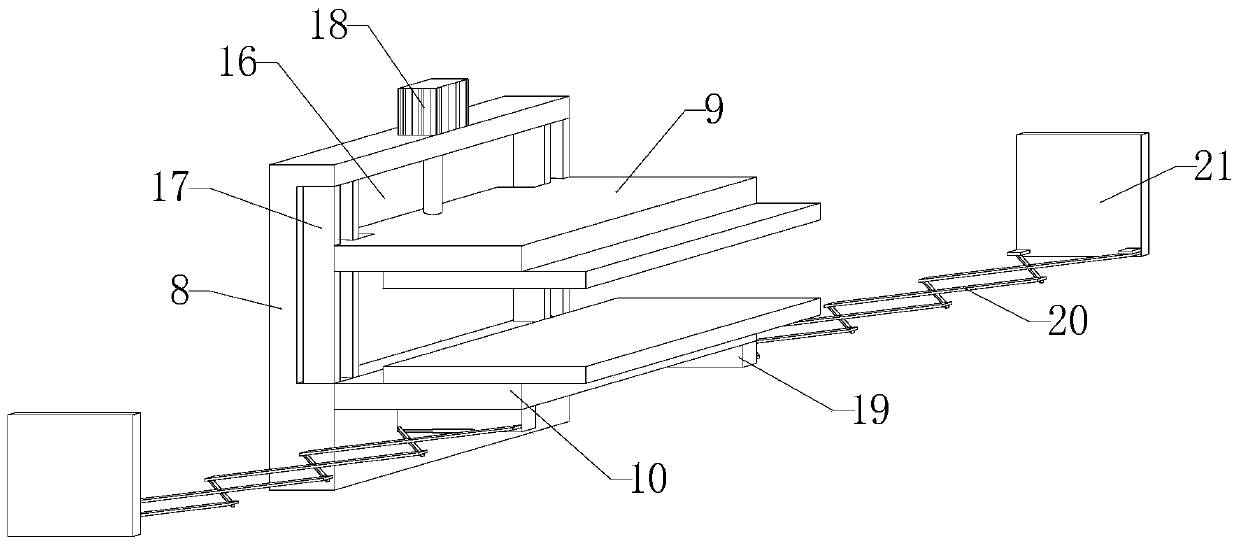

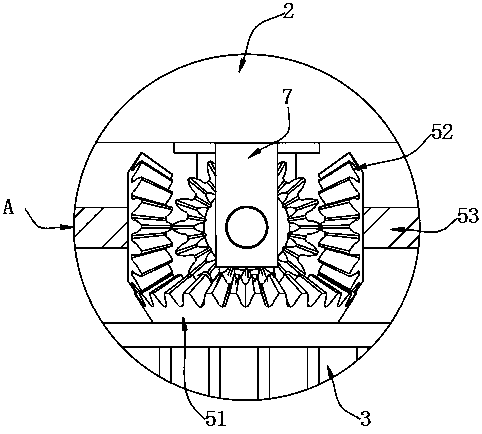

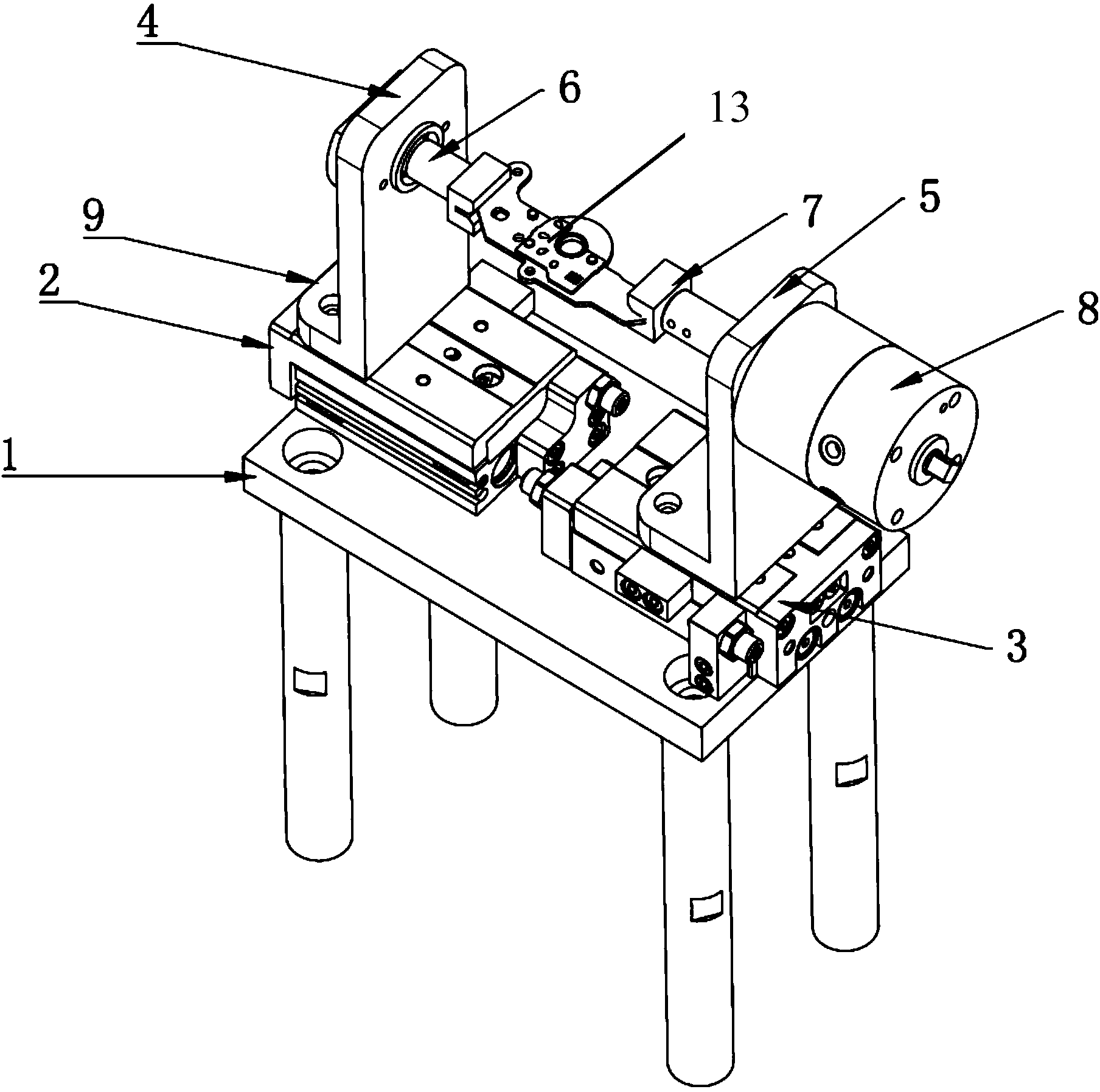

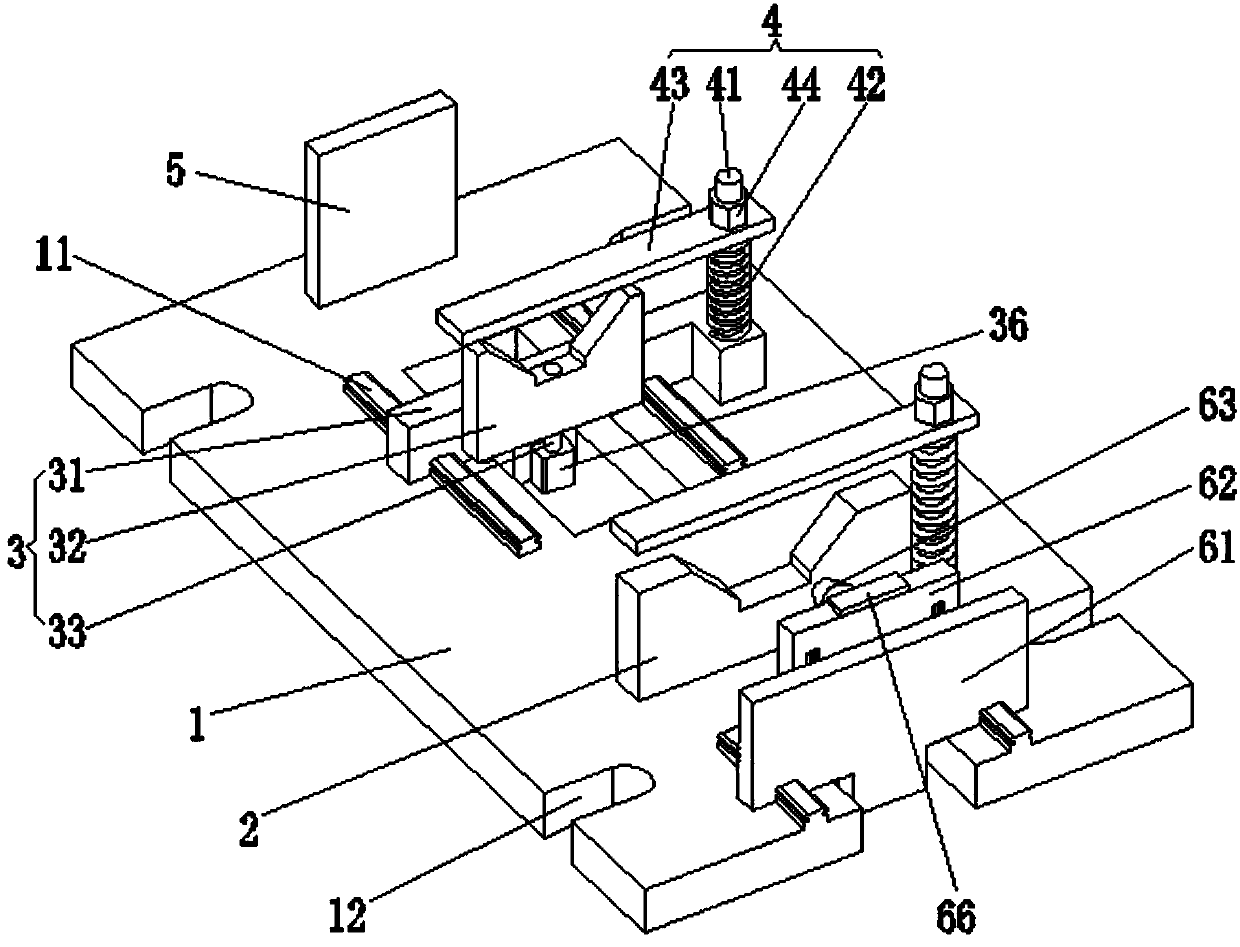

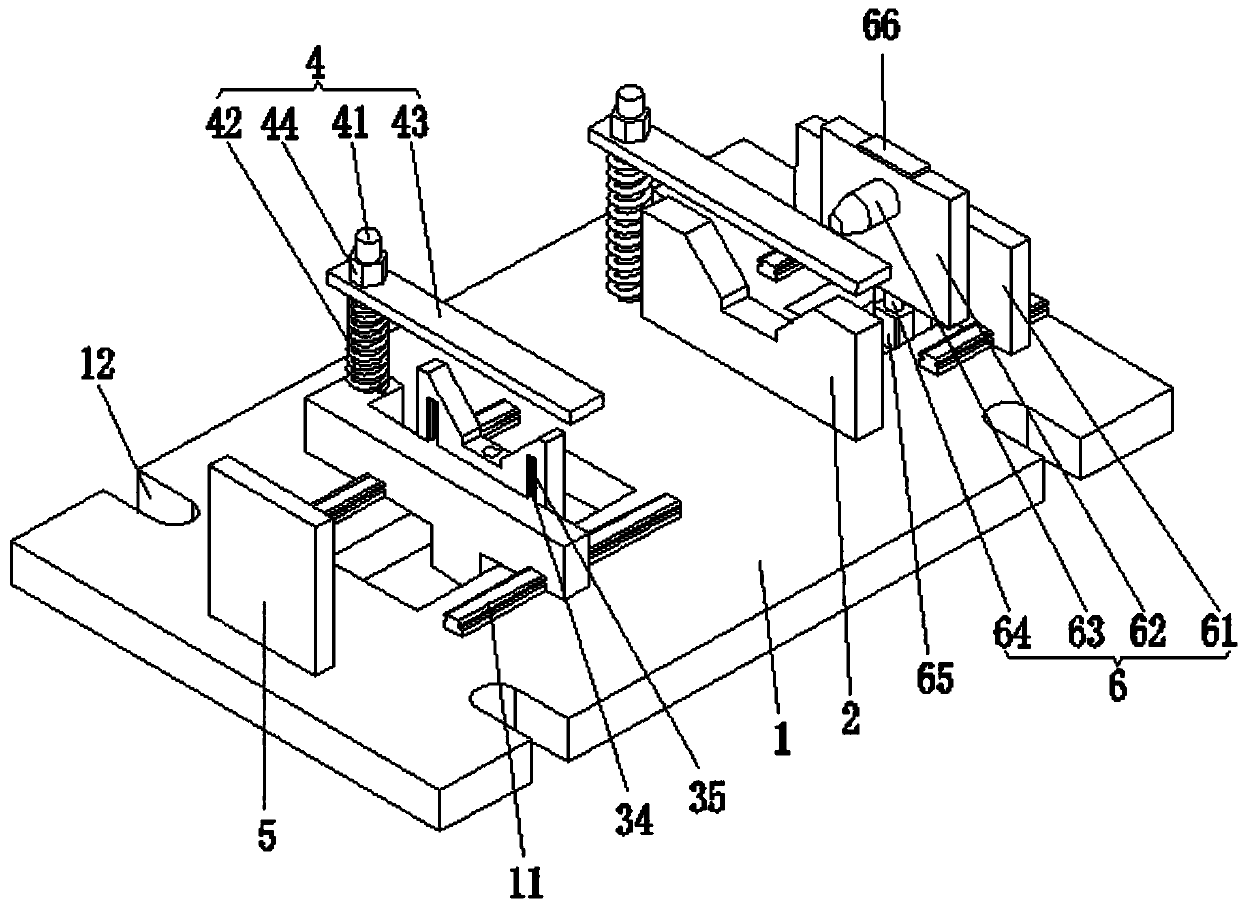

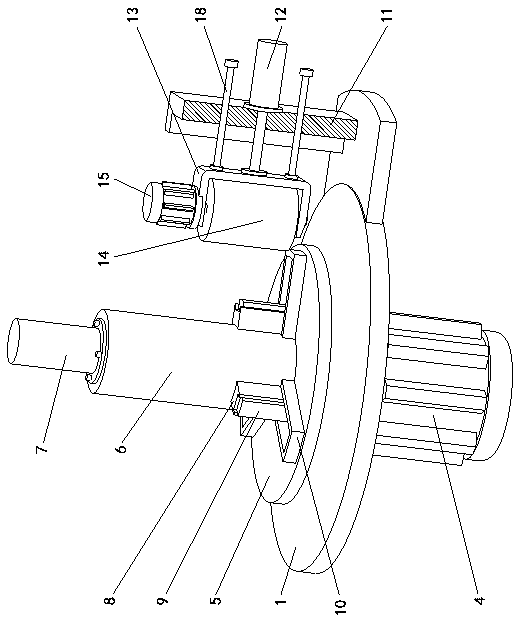

Precise indexing clamp special for turning

InactiveCN105583421AImprove clamping efficiencyEasy to holdMeasurement/indication equipmentsChucksEngineeringMachining

The invention discloses a precise indexing clamp special for turning, and belongs to clamps special for turning in the technical field of machining equipment. According to the precise indexing clamp special for turning, multipoint stress is achieved, and the clamp is suitable for clamping workpieces of multiple sizes. According to the technical scheme, the clamp comprises a clamp body, and a cross sliding groove is formed in the clamp body; a clamping jaw is arranged in each sliding groove body of the cross sliding groove, and a clamping jaw drive mechanism is arranged on the back face of the clamp body and comprises a large conical gear and a plurality of sets of lead screws; the large conical gear is mounted on the clamp body, and each lead screw is arranged at the position corresponding to the position of the corresponding clamping jaw; the lead screws are sleeved with threaded holes of the clamping jaws, and are in threaded connection with the clamping jaws; and a small conical gear is arranged on one side, close to the large conical gear, of each lead screw, and the small conical gears on the lead screws are meshed with the large conical gear. The precise indexing clamp is suitable for being used in turning.

Owner:新都区大丰鹏宇机械厂

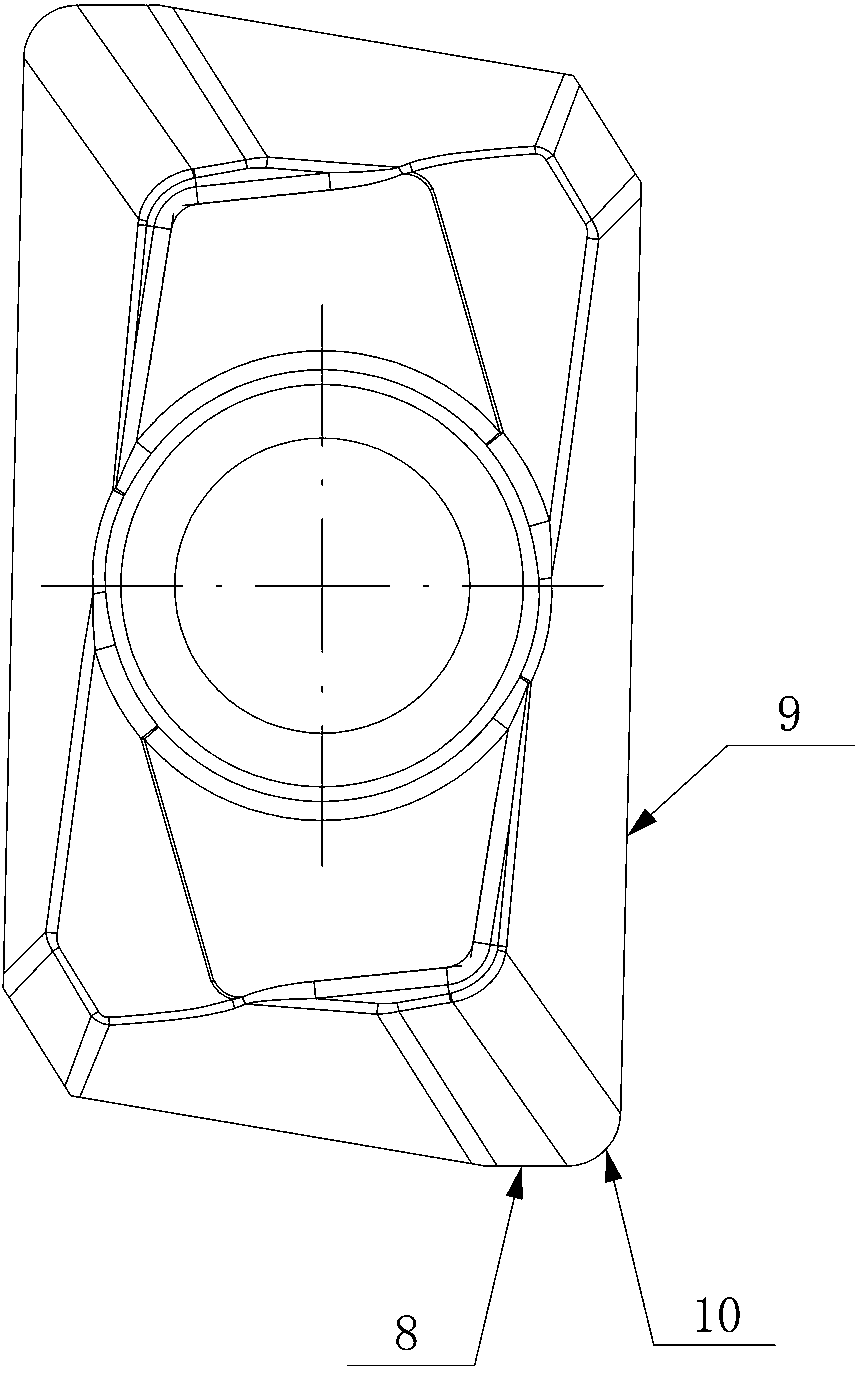

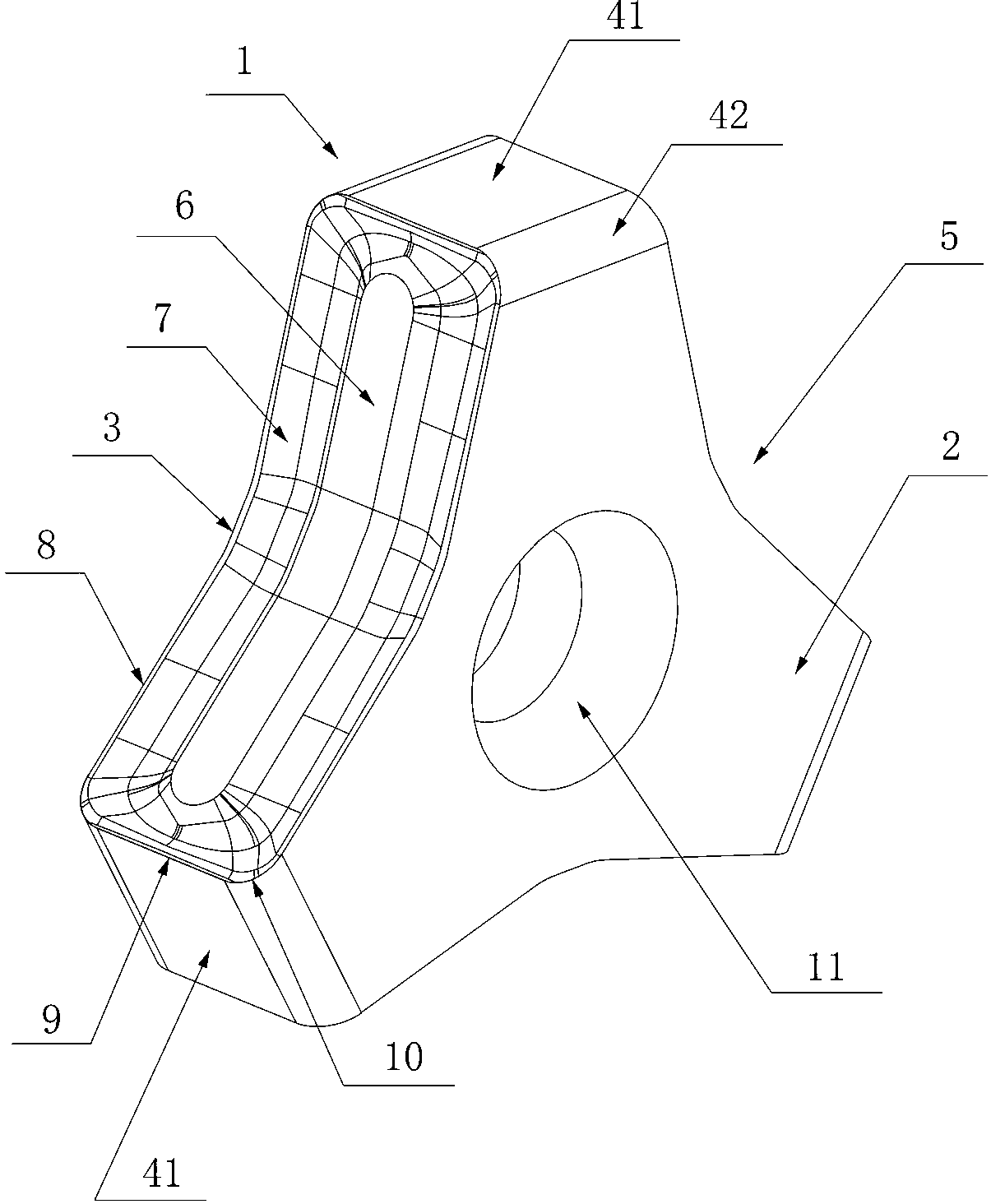

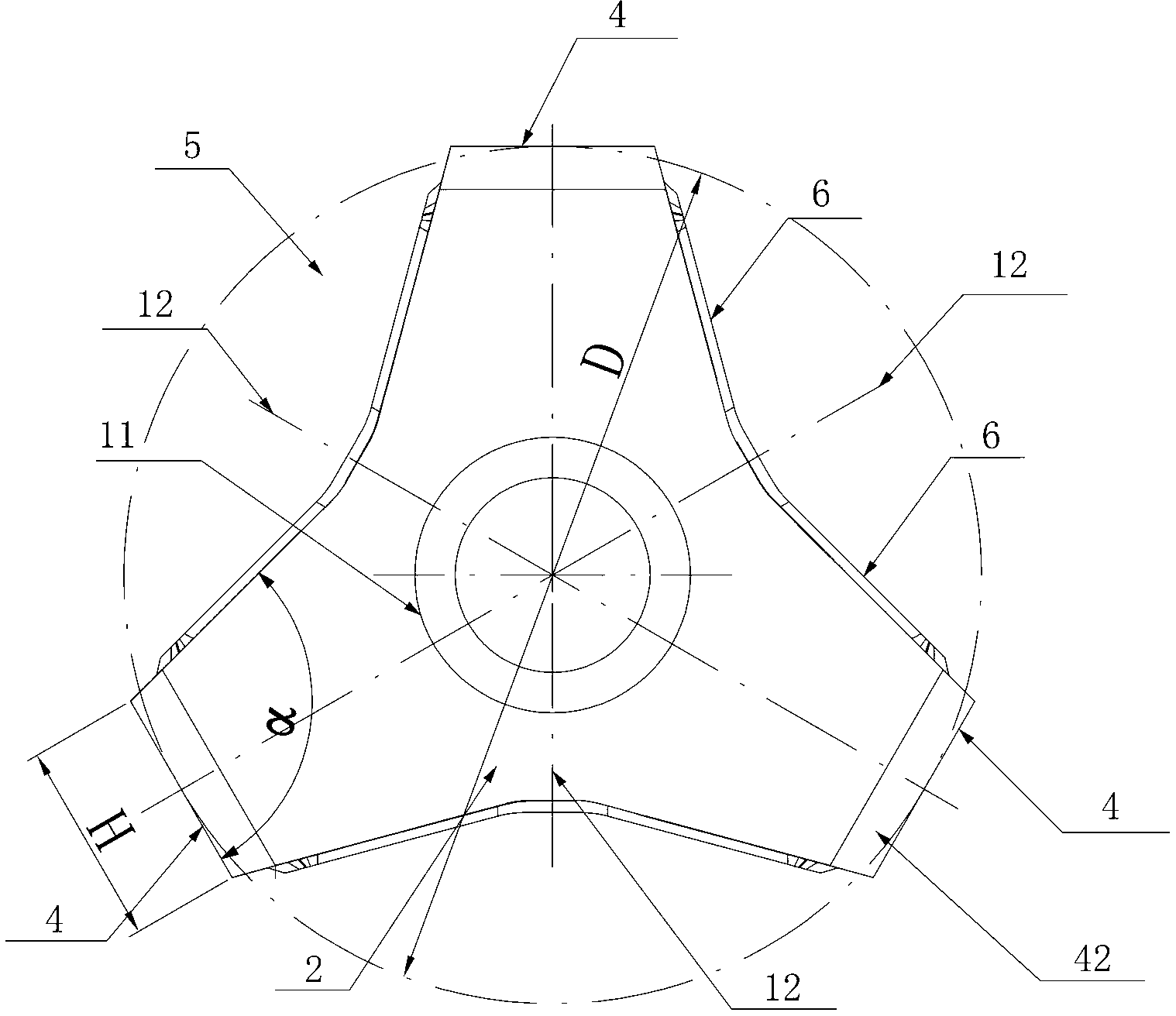

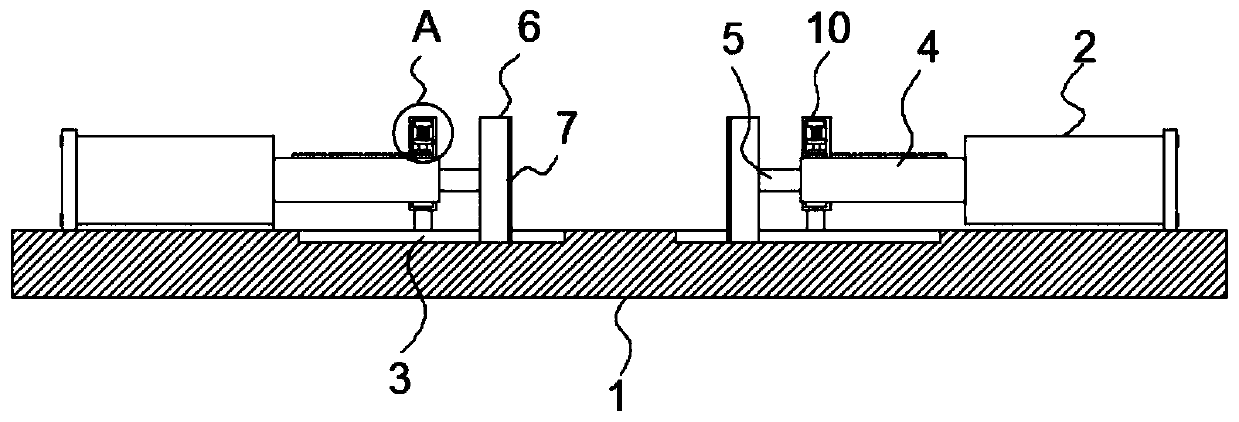

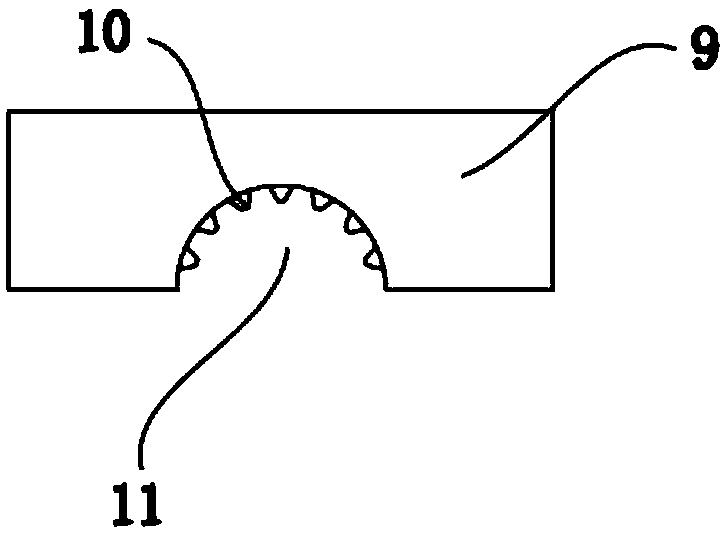

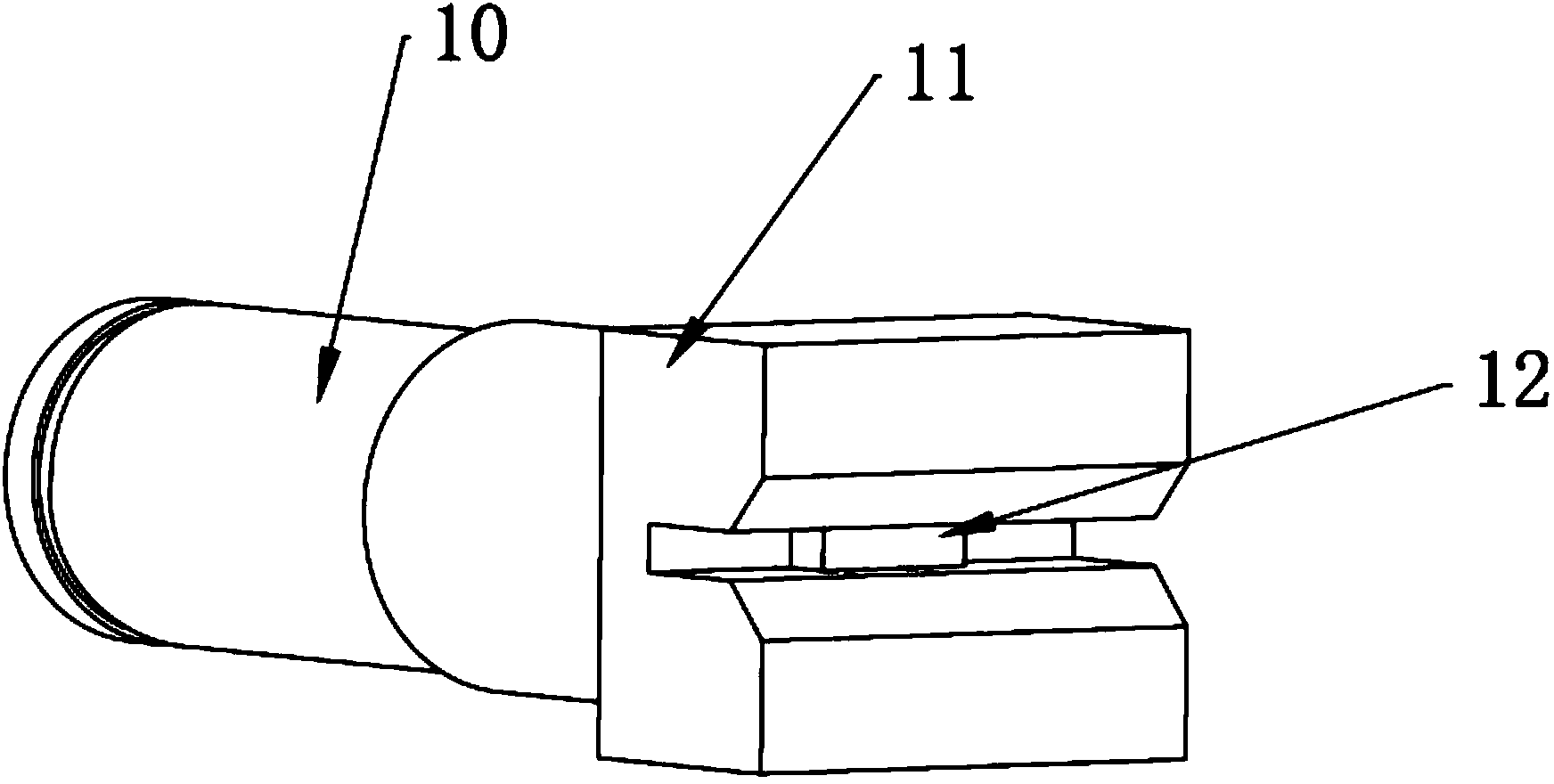

Cutting blade and cutting tool

The invention discloses a cutting blade and a cutting tool. The cutting blade comprises a platelike blade main body, the blade main body is formed by encircling an upper surface, a lower surface, side surfaces and concaves, the quantity of the side surfaces and the quantity of the concaves are respectively three, the three side surfaces and the three concaves are respectively arranged at intervals, each side surface and each concave are respectively arranged between the upper surface and the lower surface, each concave consists of a circumferential positioning surface and cutter grooves which are respectively arranged on two opposite corners of the circumferential positioning surface, each cutter groove is intersected with the upper surface or the lower surface to form a main cutting edge, each cutter groove is intersected with each side surface to form a side cutting edge, and the main cutting edges are connected with the side cutting edges to form cutting edge groups. The cutting blade and the cutting tool have the advantages of simplicity and compactness in structure, strong universality, convenience in use and high cost performance. The cutting tool comprises a cutter body and a cutter blade tightening element, and the cutter body is fixedly provided with the cutting blade through the cutter blade tightening element.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

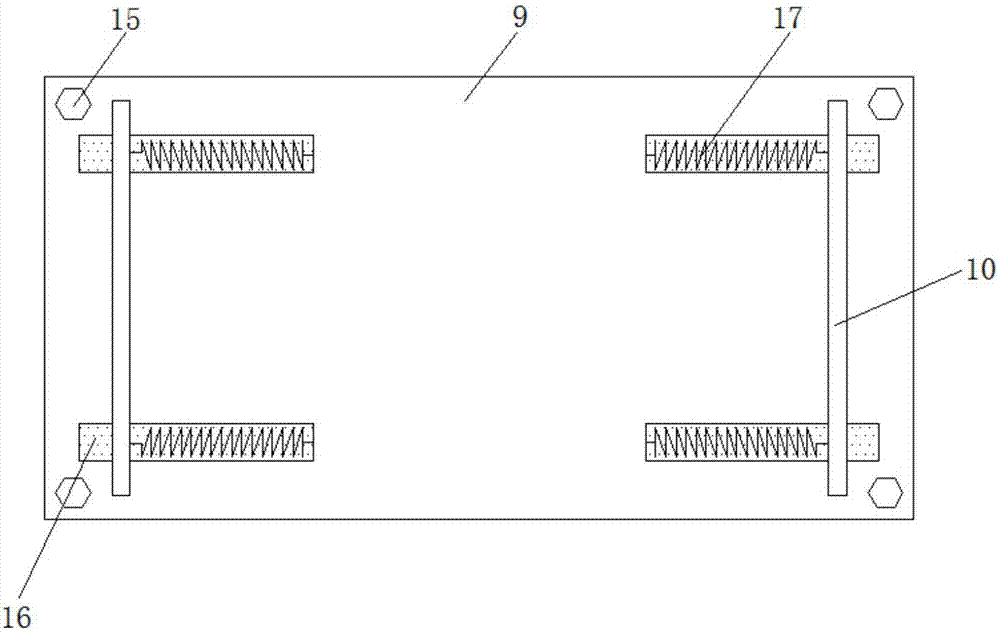

Machining fixture locking device

The invention discloses a machining fixture locking device. The machining fixture locking device comprises a base plate; two extension cylinders are symmetrically and fixedly mounted on the base plate; piston rods are arranged on the two extension cylinders, and are fixedly connected with tooth plates; buffer cavities are formed in the piston rods; piston blocks are slidingly connected into the buffer cavities; moving rods are fixedly connected to one sides of the piston blocks; the ends, far from the piston blocks, of the moving rods are fixedly connected with clamping plates; the other sidesof the piston blocks are fixedly connected with second springs; and the ends, far from the piston blocks, of the second springs are fixedly connected to the side walls of the buffer cavities. Tooth blocks adaptively slide up, and meanwhile, drive first springs to compress; and under the elastic effect of the first springs, the tooth blocks are engaged with the tooth plates again, and meanwhile, end surfaces B abut against the tooth plates to prevent retreating of the tooth plates, so that the locking effect on the piston rods is achieved, and the influence on the clamping effect of the pistonrods by instable air pressure of the extension cylinders is prevented.

Owner:浙江零捷网络科技有限公司

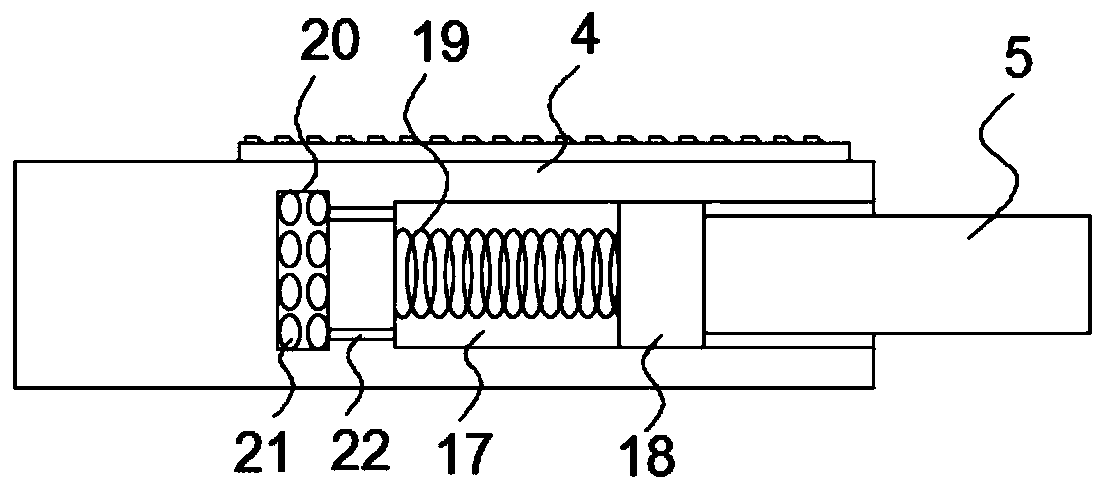

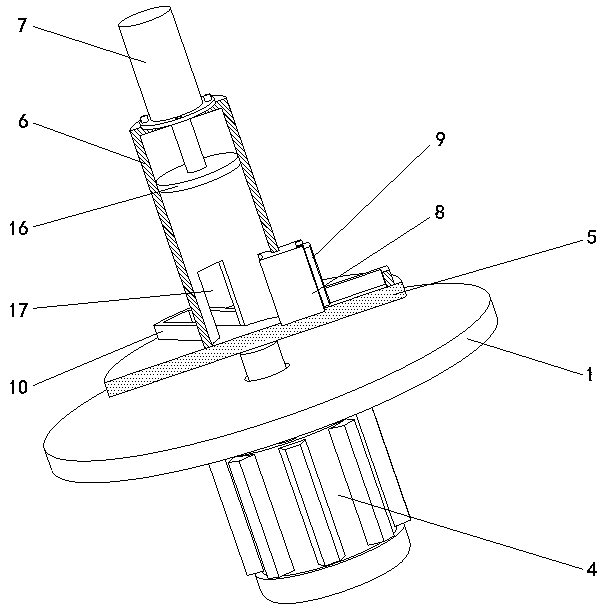

Flexible vector tactile and slip composite sensor

ActiveCN106802200AStable slip signal outputObtain mechanical information in real timeForce measurementConvex structurePositive pressure

The invention discloses a flexible vector tactile and slip composite sensor, and relates to the field of robot flexible tactile sensors and intelligent surgical instruments. The flexible vector tactile and slip composite sensor comprises an upper flexible substrate, a force sensitive structure layer and a lower flexible substrate which are closely fit from the top to the bottom. The force sensitive structure layer comprises an upper electrode layer, a flexible piezoresistive material layer and a bottom electrode layer which are arranged from the top to the bottom. The upper surface of the upper flexible substrate is provided with an equidistant microstructure array. The force sensitive structure layer is closely fit with the upper surface of the lower flexible substrate. The lower flexible substrate is provided with periodic symmetrical convex structures along the thickness direction of the sensor. Symmetrical force sensitive units are respectively arranged at the two sides of the symmetrical convex structures. The slip situation can be judged and the positive pressure, the frictional force and the slip speed can be measured through the simple internal symmetrical convex structures; and the microstructure array is arranged on the upper surface of the sensor so as to enhance the clamping stability and safety.

Owner:BEIHANG UNIV

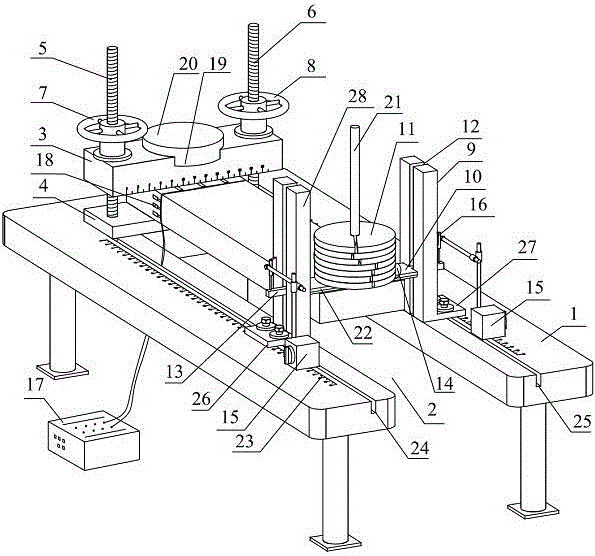

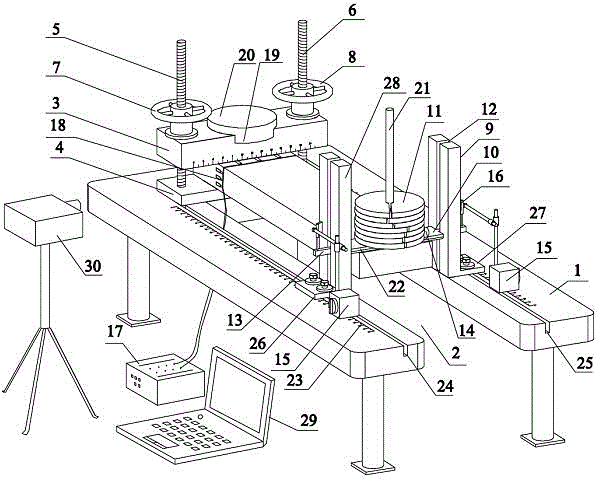

Rock beam sample cantilever type bending test device

ActiveCN106442112AImprove clamping stabilityImprove accuracyMaterial strength using steady bending forcesElectricityEngineering

The invention discloses a rock beam sample cantilever type bending test device, and belongs to the technical field of rock beam bending test equipment. The device comprises a supporting platform and a loading component and further comprises a pressing component and a data collecting component; the pressing component comprises an upper pressing block, a lower pressing block, a first screw, a second screw, a first rotary wheel and a second rotary wheel; the loading component comprises a load support, a contact block and a balance weight sheet, vertical clamping grooves are formed in the two sides of the load support, the two ends of the contact block are connected with clamping strips respectively, a limiting groove is formed in the contact block, the balance weight sheet is arranged in the limiting groove, and the load support is in sliding connection with the supporting platform. The data collecting component comprises a magnetic gauge stand, an electronic dial indicator, a data collector and a strain gage, and the strain gage is connected with the data collector. Rock beam cantilever type loading is adopted, aiming at an anti-dip bedded rock slope, the testing accuracy of the device is greatly improved, and reference can be provided for study of the stability of the anti-dip bedded rock slope in water and electricity slope engineering.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

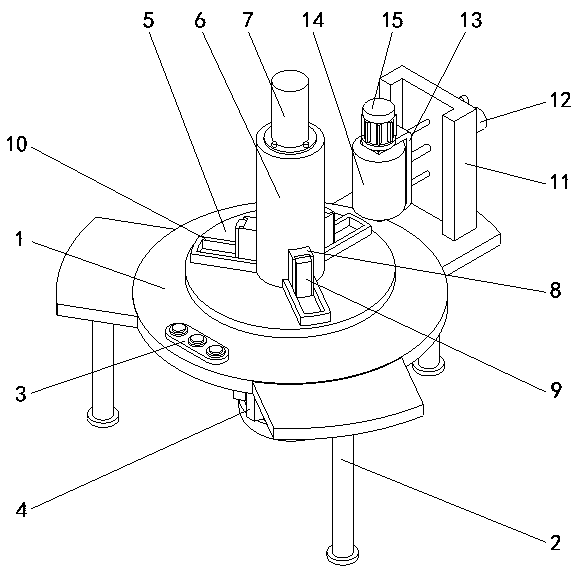

Display device for visual communication design

InactiveCN110250819ARealize all-round display effectIncrease the number ofShow shelvesShow hangersDisplay boardDisplay device

The invention discloses a display device for visual communication design, and relates to the technical field of display devices. The display device comprises a bottom plate, the bottom plate is provided with a platform, a display mechanism is mounted on the platform and comprises a plurality of circumferentially-distributed display plates, a threaded pipe is mounted at the center of the platform in a lifting mode, connecting rods slidably connected with the platform are fixed to the other ends of the display plates, and clamping mechanisms are arranged on the display plates. According to the display device, exhibits are supported through the arranged display plates, through rotating of the platform, the omni-directional display effect of circumferential rotating of the exhibits is achieved, an additionally-arranged servo motor can drive a threaded rod to rotate, height lifting of the threaded pipe is achieved, the display angles of the display plates are adjusted, the adjusting process is stable and efficient, through the arranged clamping mechanisms, the display device can adapt to the different exhibits, the great clamping and stabilizing effects are achieved, the multiple arranged display plates are used for storing and supporting the exhibits, and the display number of the exhibits displayed once is improved.

Owner:ZHONGBEI UNIV

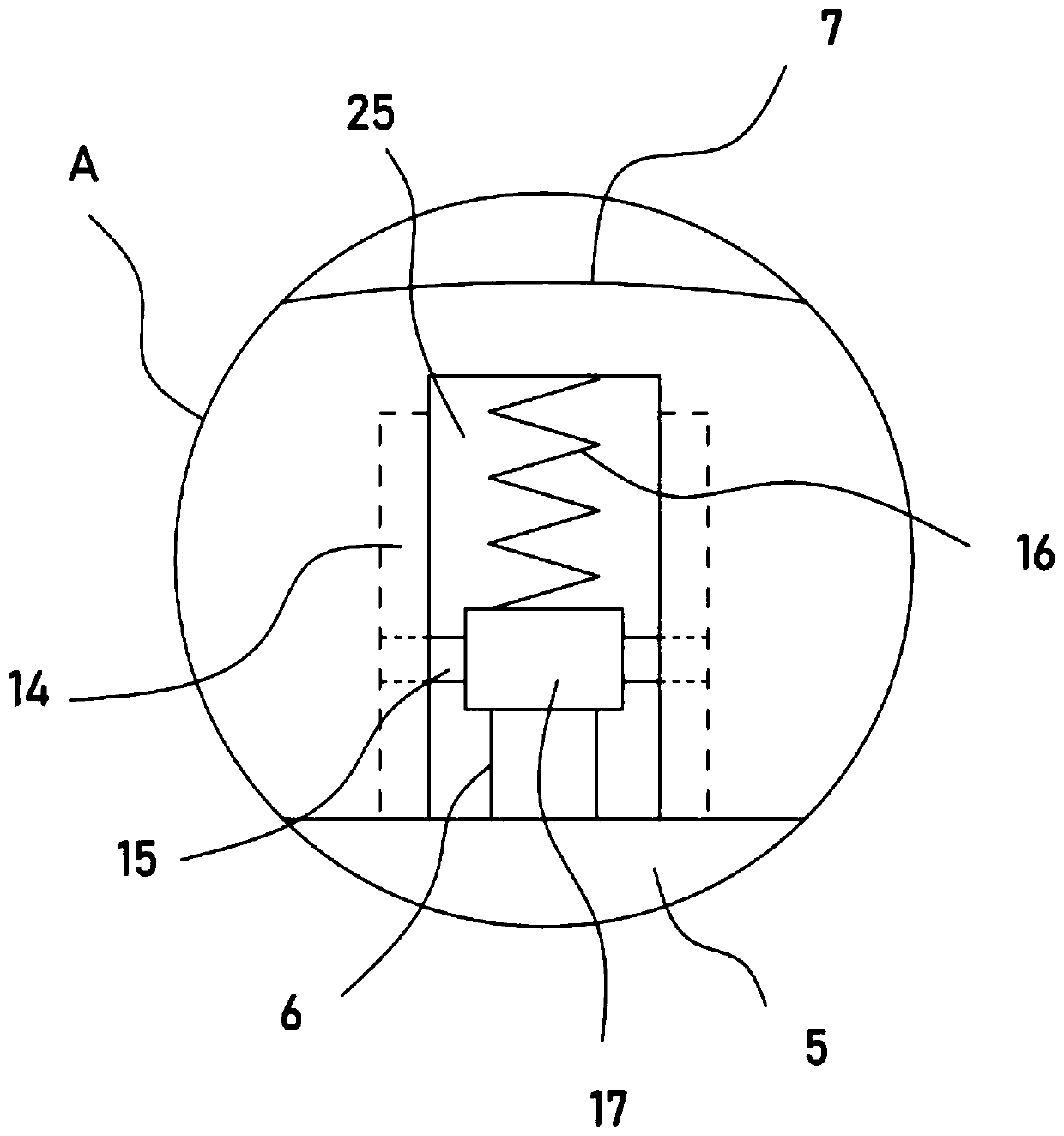

Shaft milling key slot fixture

InactiveCN107931686AEnsure machining symmetryImprove clamping stabilityMilling equipment detailsPositioning apparatusEngineeringScrew press

The invention discloses a shaft milling keyway fixture, which comprises a bottom plate, static thimbles arranged on the bottom plate in sequence along the axial direction, two V-shaped positioning mechanisms and a moving thimble assembly; the static thimble is fixedly connected to the bottom plate; the moving thimble assembly It includes a support seat, a moving thimble and a driving device. The driving device controls the support seat to drive the thimble to move axially; the axis lines of the static thimble and the moving thimble are located on the same straight line, and the directions are opposite; the V-shaped positioning mechanism includes an adjustable V-shaped The positioning assembly and the pressing mechanism, the adjustable V-shaped positioning assembly includes a traversing bracket, a V-shaped block and a fine-tuning screw, the pressing mechanism includes a threaded column, a spring sleeved outside the threaded column, and a pressure threaded on the threaded column. Tightening plate and compression nuts for compressing the compression plate. This fixture has high clamping stability and high positioning accuracy. It can adapt to step-shaped rotating shafts of various sizes by adjusting the position of the V-shaped position. It can reliably ensure the accurate positioning of the shaft and ensure the machining symmetry of the key groove of the shaft.

Owner:SUZHOU ZHENJIACHEN PRECISION MACHINERY CO LTD

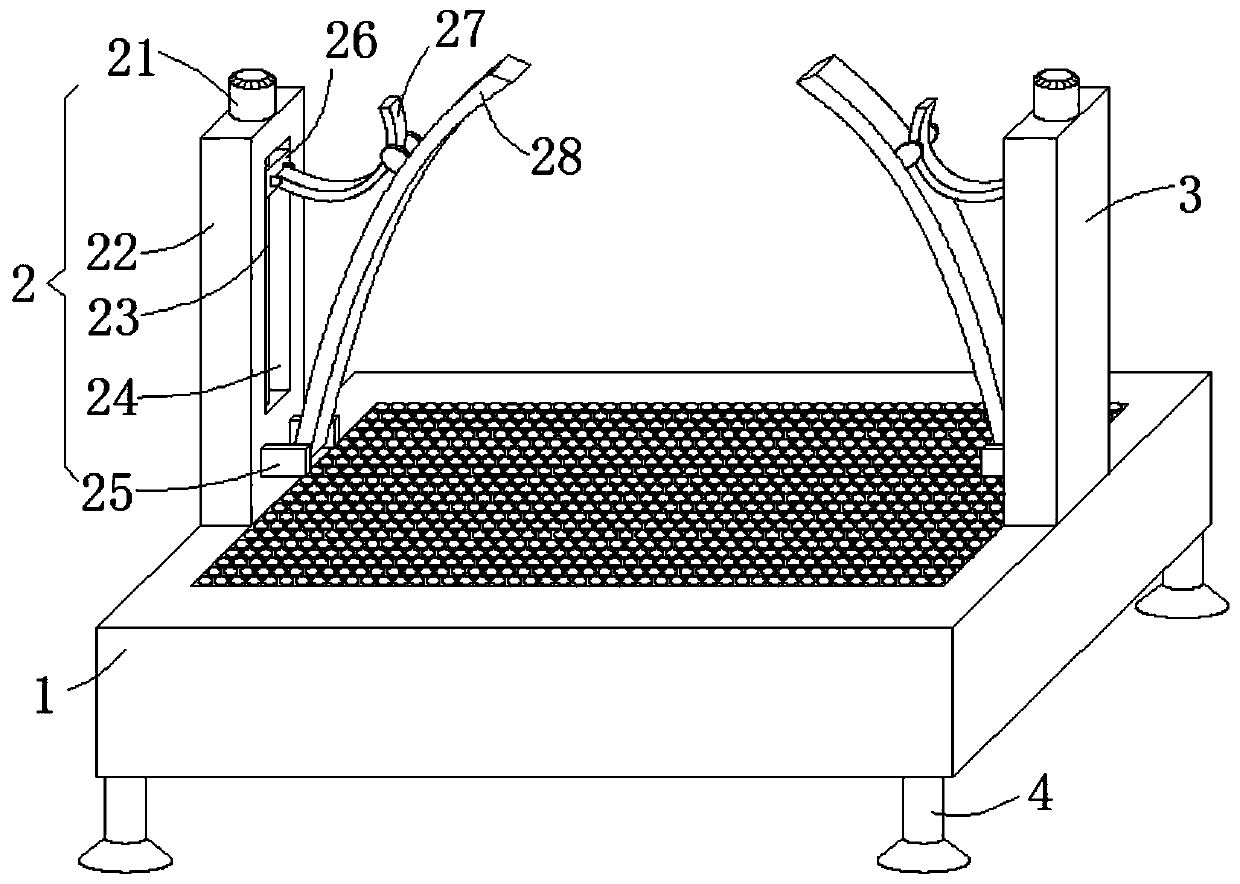

Overturning mechanism for mattress processing

ActiveCN110142729AEasy flipImprove practicalityWork holdersWork benchesHydraulic cylinderEngineering

The invention discloses an overturning mechanism for mattress processing. The overturning mechanism comprises two overturning bodies. Each overturning body comprises a base, universal wheels, a door frame and a rotating frame. A movable block is arranged inside the door frame. A rotating shaft is mounted on the movable block through a bearing. One end of the rotating shaft is fixedly connected with the rotating frame in a bolt fixing or welding manner, and the other end of the rotating shaft is fixedly connected with a rotating motor through a coupling. A hydraulic cylinder is arranged betweenthe movable block and the top of the base. According to the overturning mechanism for mattress processing, during the overturning process of a mattress, the mattress does not need to be raised to a height in which the mattress can be turned over and then clamped on the rotating frame, and the manpower is saved; and in the process of clamping the mattress, an upper clamping plate, a lower clampingplate and buckle plates cooperate with one another, so that the vertical and horizontal sides of the mattress are simultaneously clamped, the stability of the mattress clamping is improved greatly, and the situation that the mattress slips during the overturning process is avoided.

Owner:ANHUI YINGSHANG COUNTY TIANCHENG PRINTING PACKAGING CO LTD

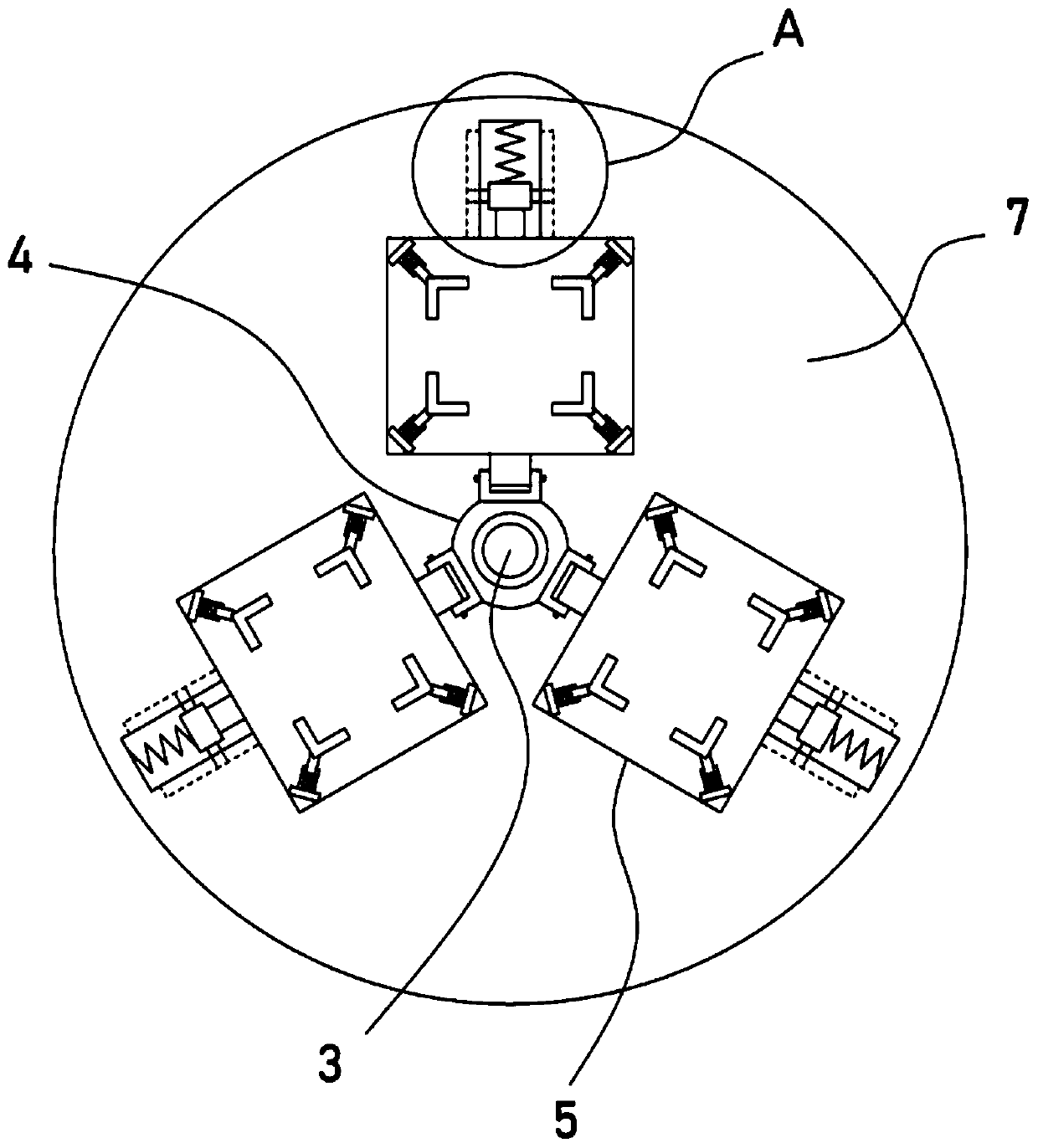

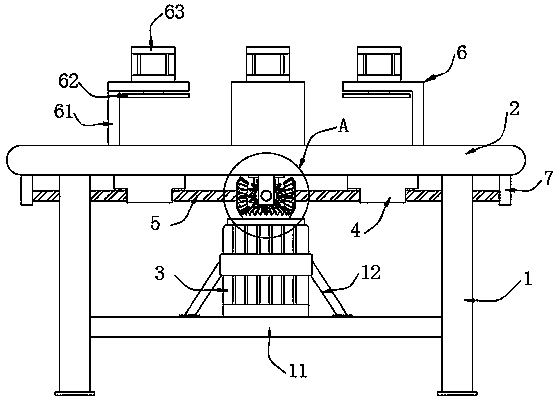

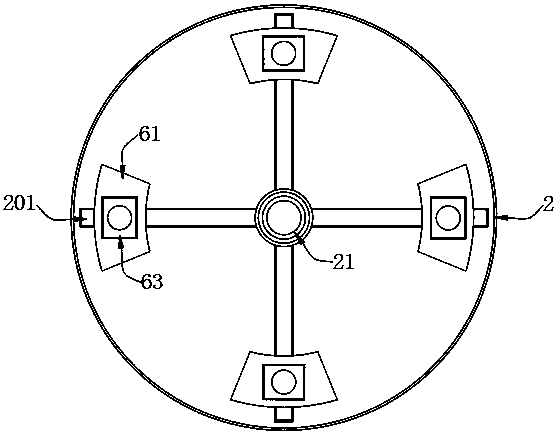

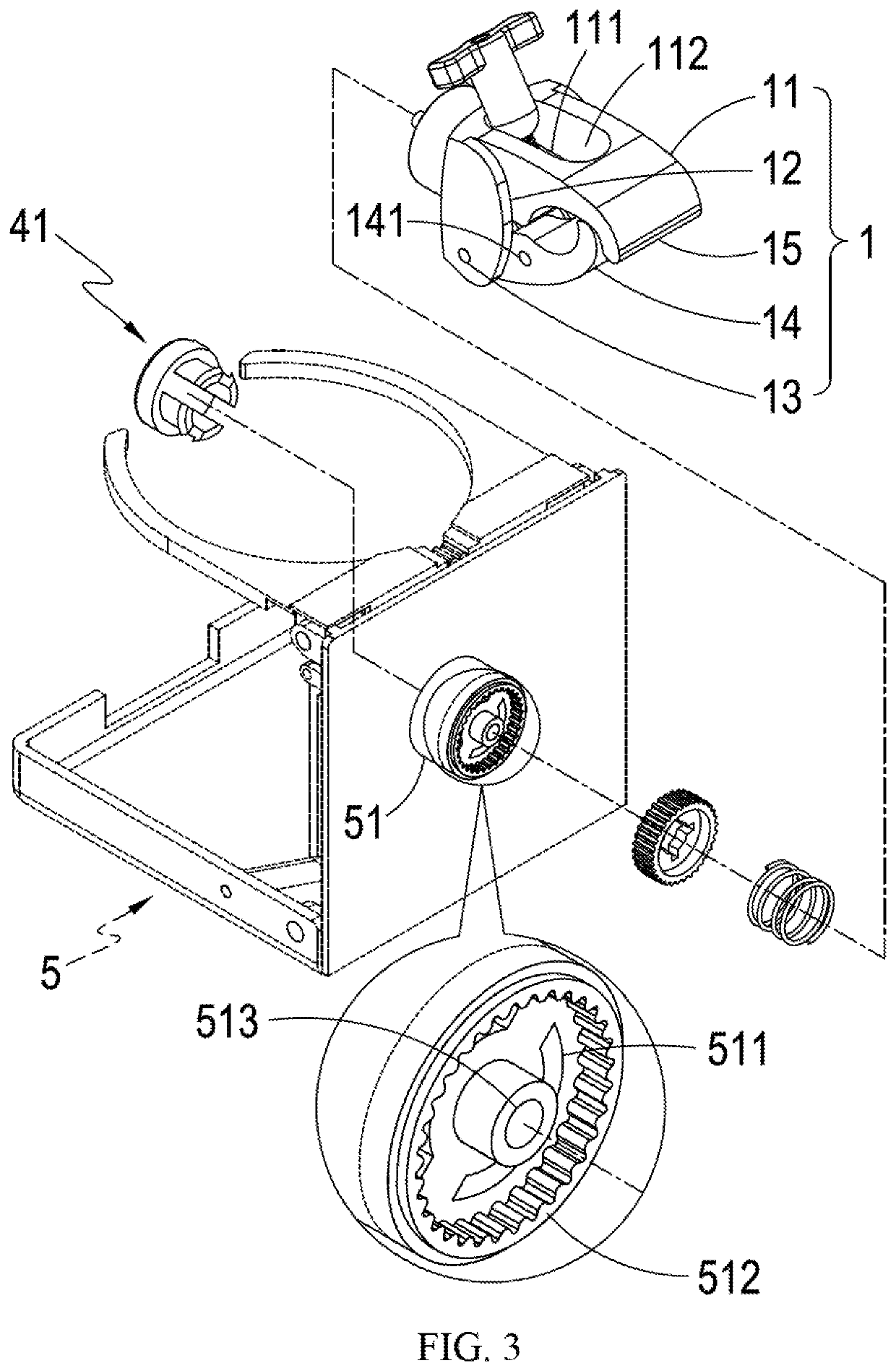

Aluminum alloy hub positioning clamp

InactiveCN111390854AReduce labor intensityAvoid wastingWork holdersWork benchesGear wheelElectric machinery

The invention belongs to the technical field of hub machining, and particularly relates to an aluminum alloy hub positioning clamp. The aluminum alloy hub positioning clamp comprises a support and a positioning workbench which is fixed to the top end of the support by threaded connection. A mounting base is fixedly arranged on the inner side of the bottom end of the support, and a servo motor is fixed to the middle of the top end of the mounting base through a motor mounting frame by threaded connection. Sliding grooves used for radial movement of clamping mechanisms are formed in the workbench. The servo motor is used for driving a driving gear to rotate at a high speed, so that four driven gears are driven to rotate. A screw rod is driven to rotate through the rotation of the driven gears, so that a linkage seat on the screw rod is driven to move on the screw rod. The four clamping mechanisms can axially move outwards or inwards on the positioning workbench. A hub placed on the positioning workbench is transversely clamped and positioned, and an air cylinder is used for driving a limiting clamping plate to move downwards, so that the hub is longitudinally clamped and positioned.The clamping stability is high, the clamp can be suitable for clamping and positioning hubs of different sizes, and the application range is wide.

Owner:王光银

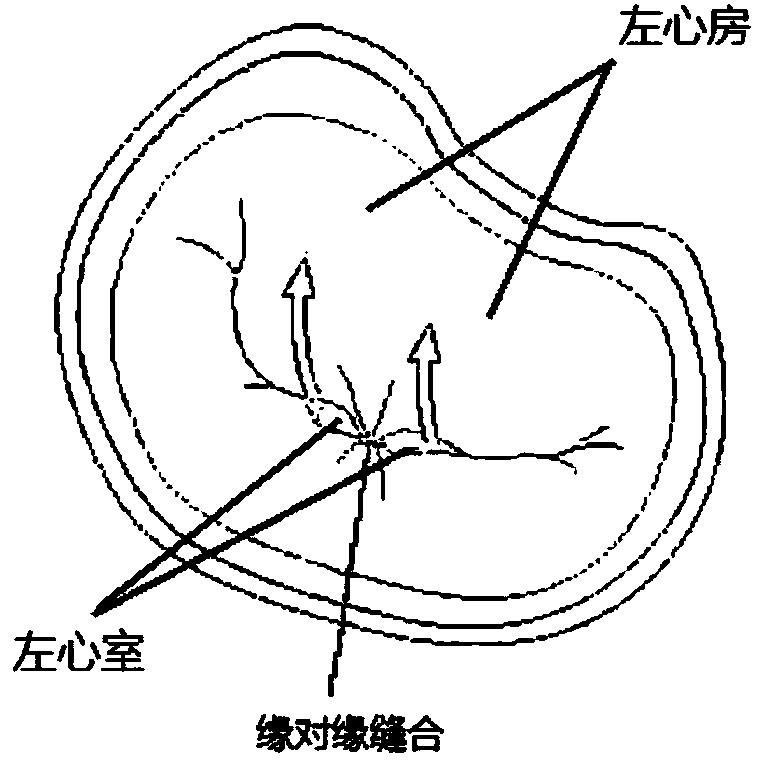

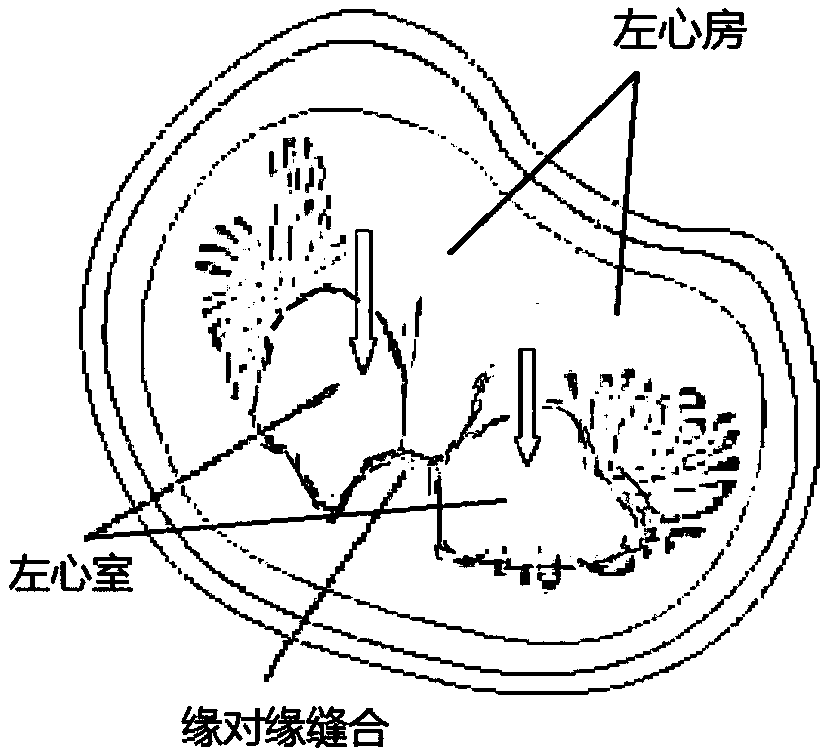

Valve clamping device

The invention discloses a valve clamping device. The valve clamping device comprises a first clamping component, a second clamping component and a fixing component. The fixing component is used for fixing the first clamping component and the second clamping component. The first clamping component comprises at least two first clamping arms. The second clamping component comprises a corresponding number of second clamping arms. A pair of clamps can be formed by each first clamping arm and the corresponding second clamping arm. The valve clamping device has the advantages that the valve clampingdevice can employ the smooth-transition top design, the high-clamping-stability clamping tooth design and the 'one-stripe-for-dualpurpose' fixing ring deign, so that damage to valves during movement of the clamping device is reduced, users capture the valves conveniently, and clamping performance is improved while damage to the valves is reduced; the overall structure of the clamping device has high machinability, and production and manufacture of factories are facilitated.

Owner:SHANGHAI HANYU MEDICAL TECH CO LTD

Fixture for drilling of PCB

ActiveCN107972105AGood clamping stabilityGood qualityMetal working apparatusEngineeringMechanical engineering

The invention provides a fixture for drilling of a PCB, and relates to the technical field of electronic product production. The fixture for drilling of the PCB comprises a mounting base, and two rotating seats are fixedly mounted on the top of the mounting base. According to the fixture for drilling of the PCB, through matching of the mounting base, the rotating seats, transverse rods, rotating handles, clamping rods, adjusting rotary knobs, pressing blocks, rubber blocks and a drilling plate, the relative positions of the transverse rods and the clamping blocks on the top of the drilling plate can be adjusted through the rotating handles and the adjusting rotary knobs, and after adjusting is completed, the top surface of the to-be-drilled PCB can be clamped by utilizing the pressing blocks and the rubber blocks; by arranging the clamping blocks, grooves and clamping springs, the positions of the clamping blocks on the two sides of the top of the drilling plate are adjusted through telescopic springs, and thus the two sides of the to-be-drilled PCB can be clamped; and in conclusion, through matching of two kinds of different clamping modes, the fixture for drilling of the PCB is good in clamping stability, and drilling of the PCB is more accurate, so that the produced PCB is good in quality.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Cutting machine for mechanical processing of building engineering

InactiveCN109226867AImprove usabilityEasy to useTube shearing machinesPositioning apparatusSteel tubeHydraulic pressure

The invention discloses a cutting machine for mechanical processing of construction engineering, including a dust collecting chamber with a body frame on the top of the dust collecting chamber. A first motor is installed on the left side of the top of the body frame. The output end of the first motor is connected with a screw rod through a coupling. Two moving blocks are provided through the guiderod and screw rod, and the bottom of the two moving blocks are connected with a first hydraulic cylinder. The output end of the first hydraulic cylinder is connected with the compression block through the piston rod. Start the first hydraulic cylinder and drop so that the pressure nail is in close contact with the steel pipe to effectively prevent skidding, so as to greatly improve the clamping stability. Drop the second hydraulic cylinder by starting the second motor to, cut the steel pipe, Due to the fact that the high temperature may be caused by circular cutter during the cutting process,so a micro water pump and a valve on the first water pipe need to be start to make the water in the water tank spray through the jet hole to the circular cutter for cooling, which can greatly extendthe service life of the circular cutter.

Owner:淮北市腾威机械设备有限公司

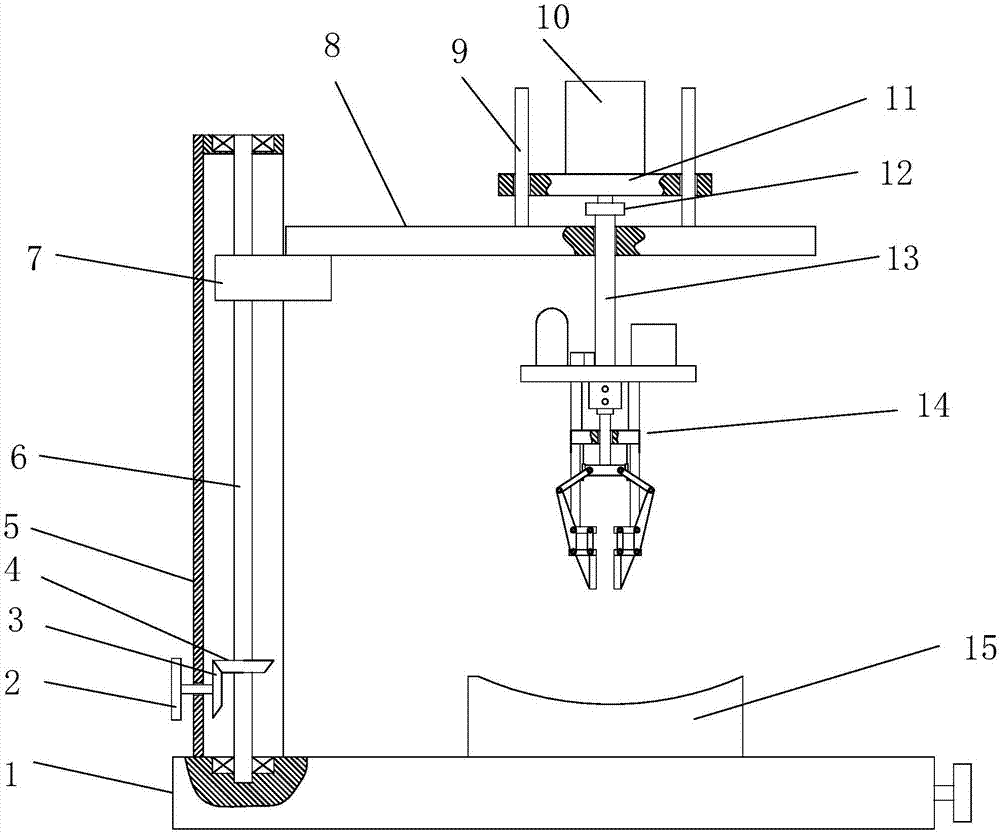

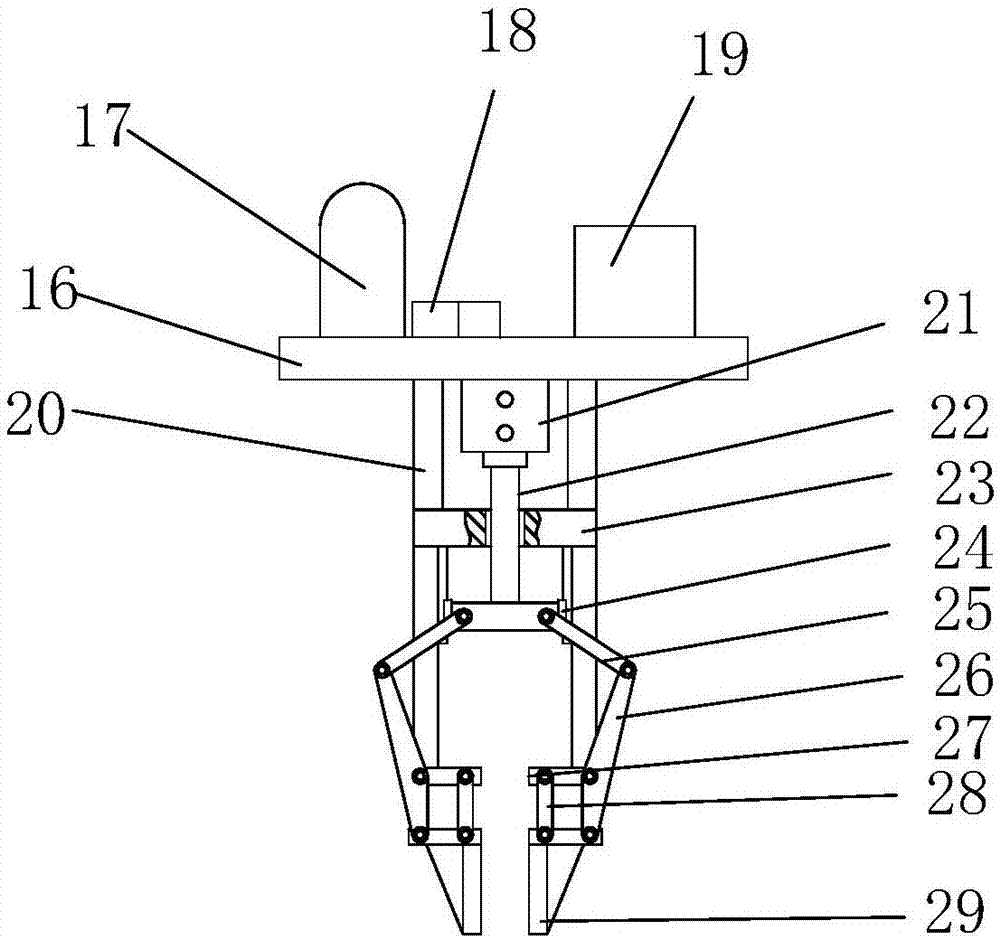

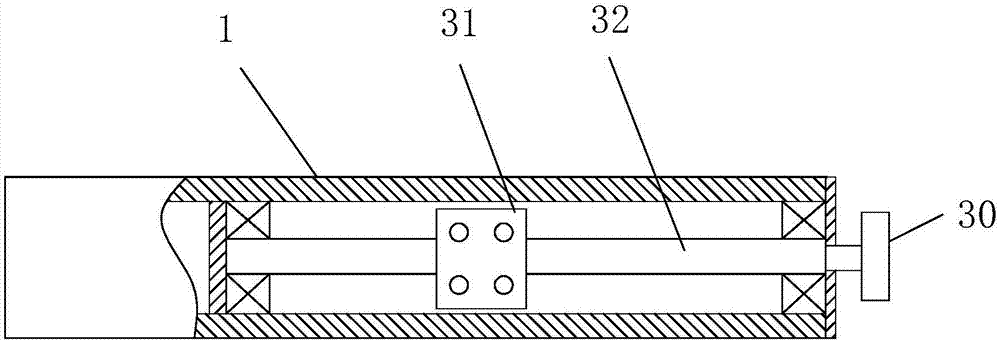

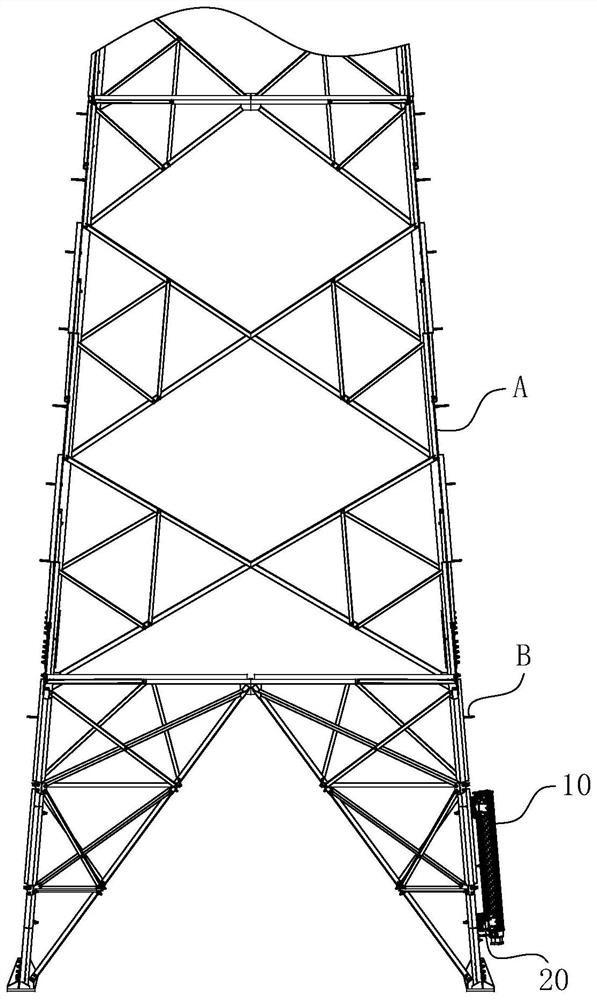

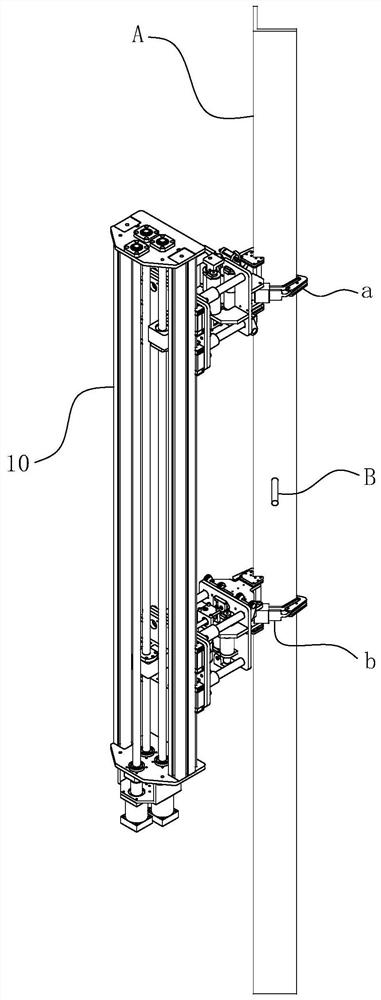

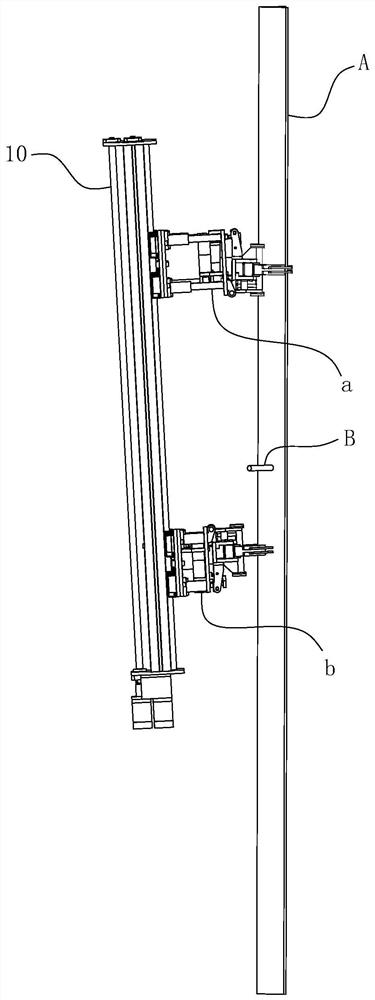

Climbing robot for angle steel tower

ActiveCN112356940AGuaranteed efficient obstacle clearanceGuaranteed clamping effectManipulatorVehiclesControl engineeringMachine

The invention belongs to the technical field of climbing robots for electric power operation, and particularly relates to a climbing robot for an angle steel tower. The robot comprises a main machineand clamping assemblies, the clamping assemblies comprise the upper clamping assembly and the lower clamping assembly, and at least one set of clamping assemblies can do reciprocating displacement motion parallel to the advancing path of the main machine relative to the main machine; each clamping assembly comprises a clamping jaw, an angle adjusting assembly and a lifting assembly, wherein the angle adjusting assembly is installed on the clamping jaw and can enable the main machine to generate pitching angle adjustment relative to the angle steel, and the lifting assembly can enable the clamping jaw to generate approaching and departing actions relative to the angle steel. The hinge axis of the angle adjusting assembly is horizontally arranged and is perpendicular to the length directionof the angle steel. The robot has high obstacle crossing capability and high climbing efficiency, and can synchronously guarantee the action stability and action reliability of climbing operation, sothat the manpower inspection cost can be greatly saved, the maintenance efficiency is improved, and the safe and reliable operation of a power transmission system is guaranteed.

Owner:STATE GRID ANHUI ELECTRIC POWER +1

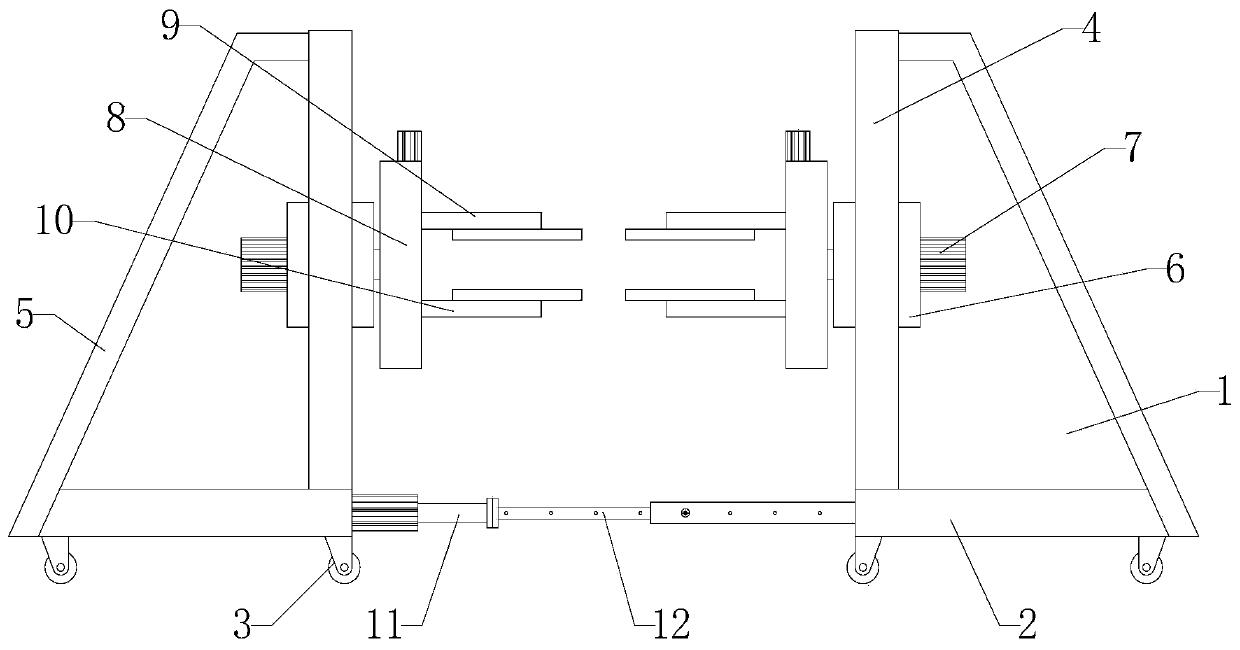

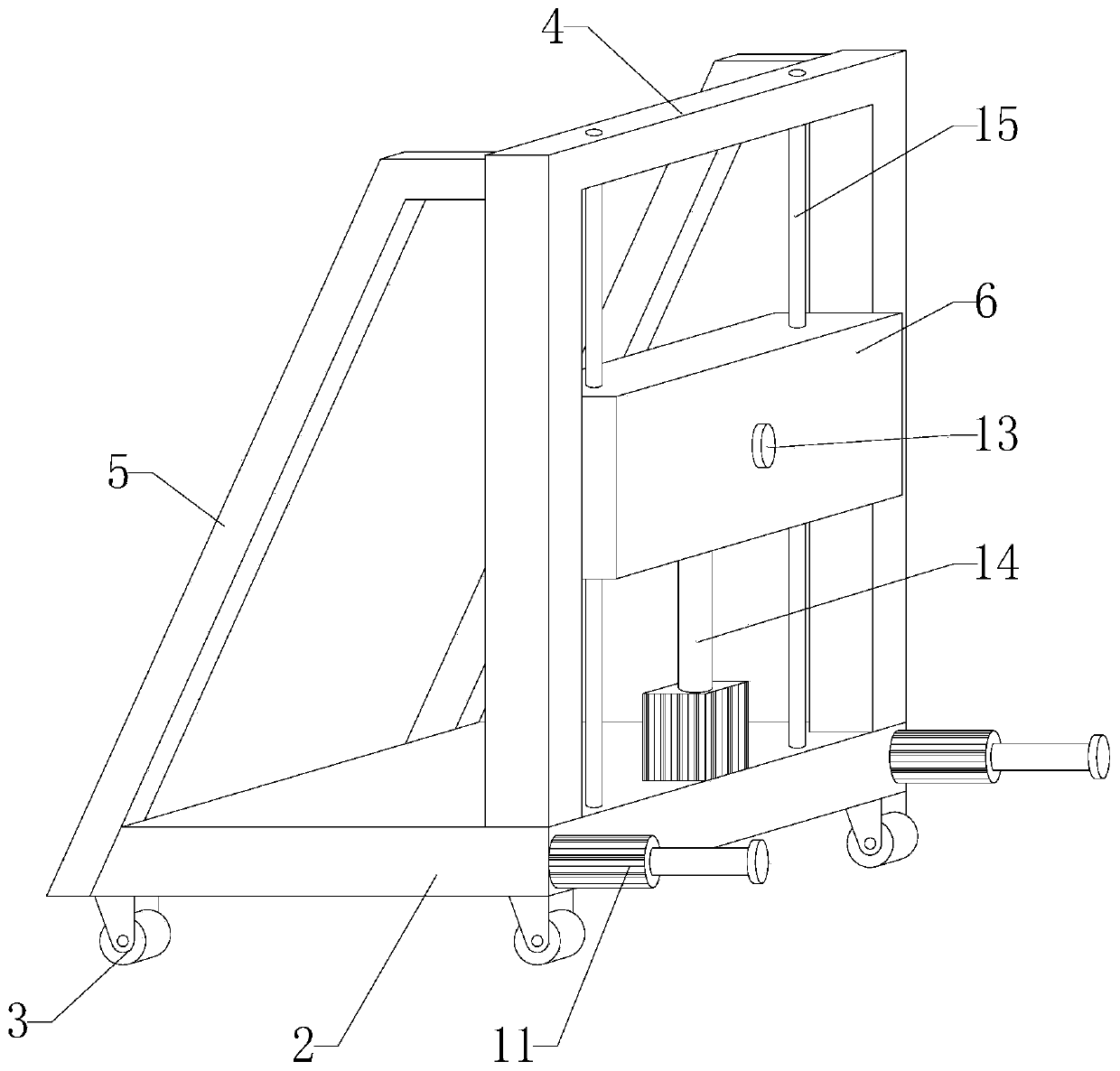

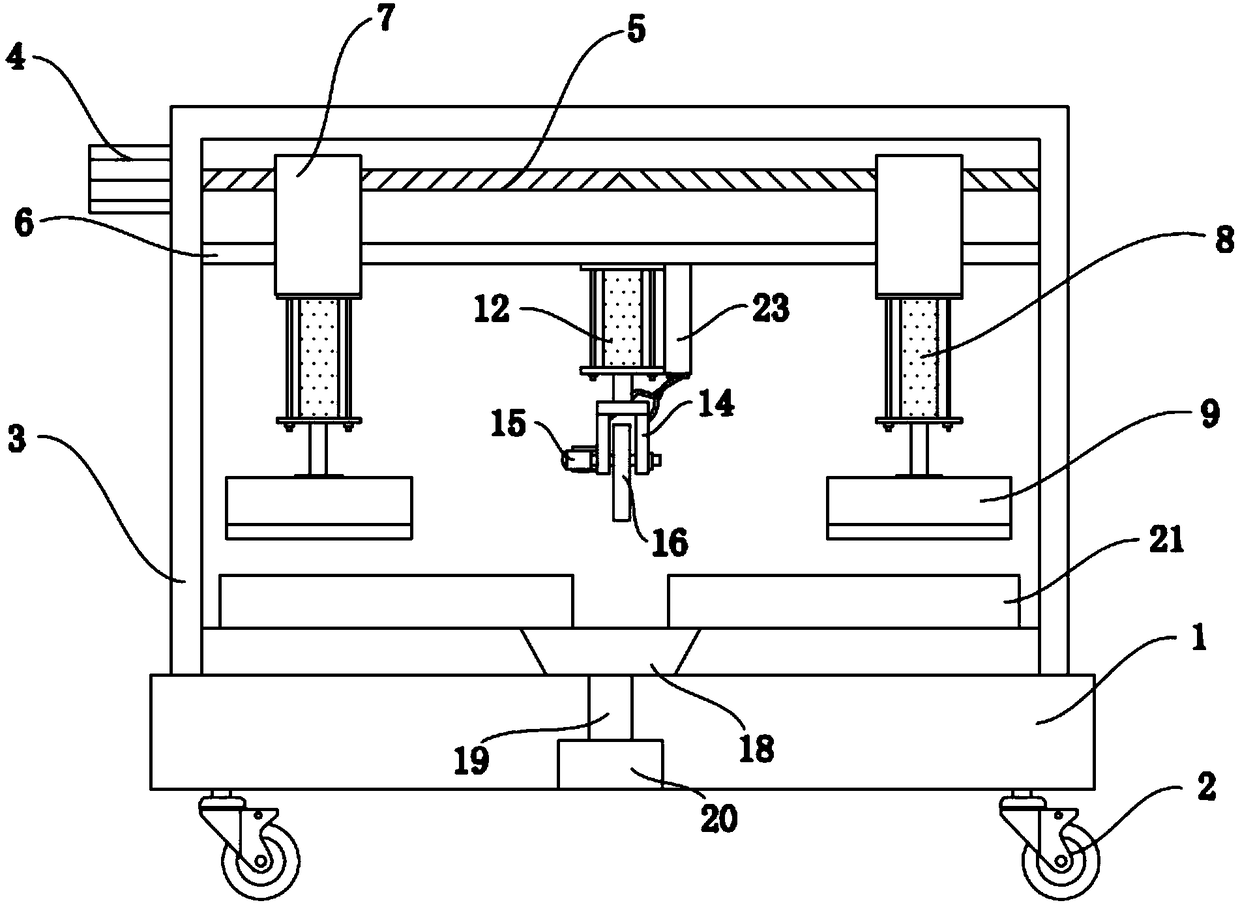

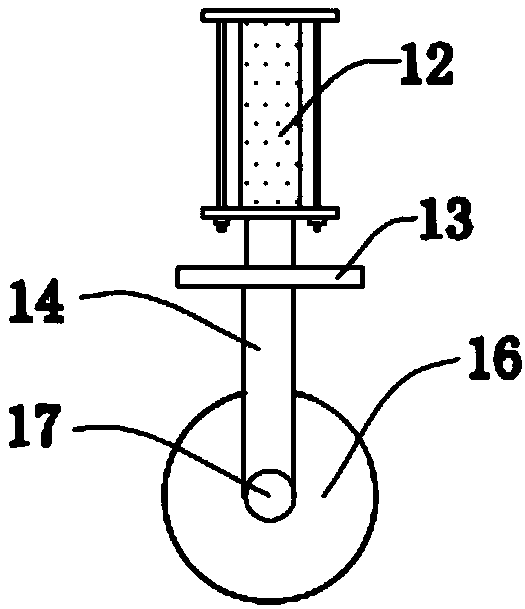

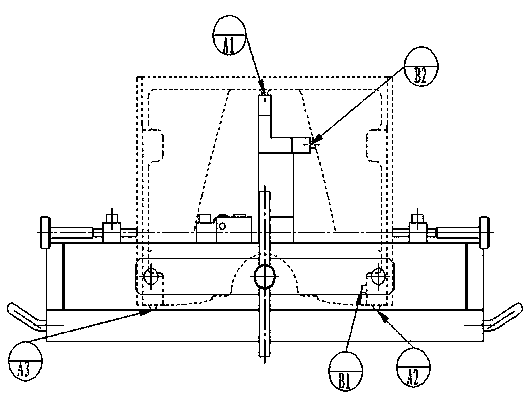

Automatic turnover mechanism

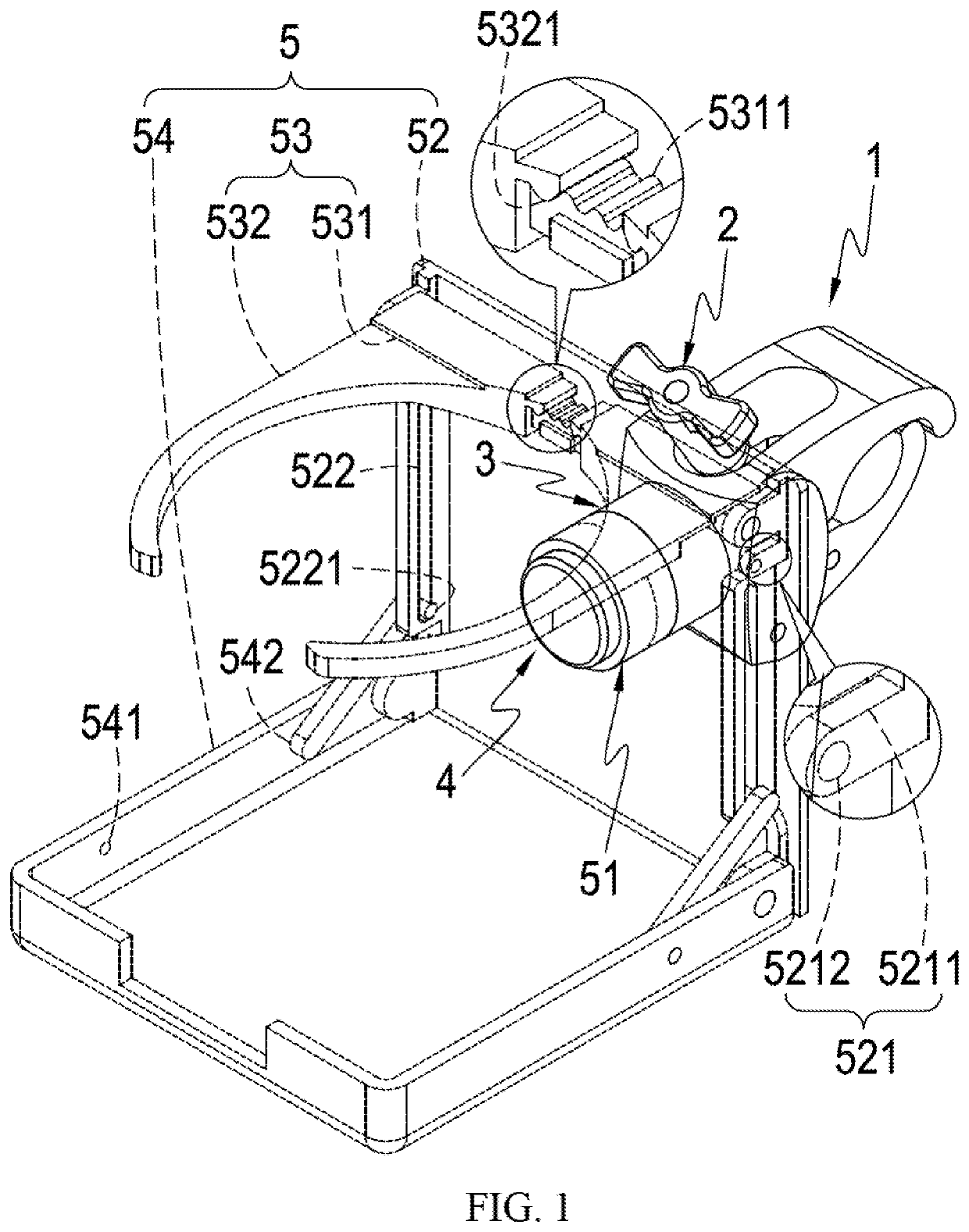

InactiveCN103707120AChange center of gravityHigh precisionMetal working apparatusRotary conveyorsEngineeringSupport plane

The invention discloses an automatic turnover mechanism. The automatic turnover mechanism comprises a base, an ejecting device and a device for clamping workpieces to be machined. The ejecting device is composed of a left ejecting block and a right ejecting block, wherein the left ejecting block and the right ejecting block can horizontally move. Supporting frames are fixed to the left ejecting block and the right ejecting block respectively, and shaft sleeve holes are formed in the supporting frames. The device for clamping the workpieces to be machined comprises a left clamping shaft and a right clamping shaft, one end of the left clamping shaft penetrates through the shaft sleeve hole in the corresponding supporting frame and can horizontally move along with the supporting frame, one end of the right clamping shaft penetrates through the shaft sleeve hole in the corresponding supporting frame and then is connected with a rotating air cylinder, and the right clamping shaft can rotate along with the rotating air cylinder and horizontally move along with the corresponding supporting frame. The rotating axis of the device for clamping the workpieces to be machined is fixed creatively, it is guaranteed that the gravity of the workpieces to be machined does not change after the workpieces to be machined are rotated, and therefore machining accuracy is improved. The automatic turnover mechanism can be turned over at any angle, and turnover efficiency is high. The appearance quality of the workpieces to be machined cannot be affected in the turnover process.

Owner:SANKYO PRECISION HUIZHOU

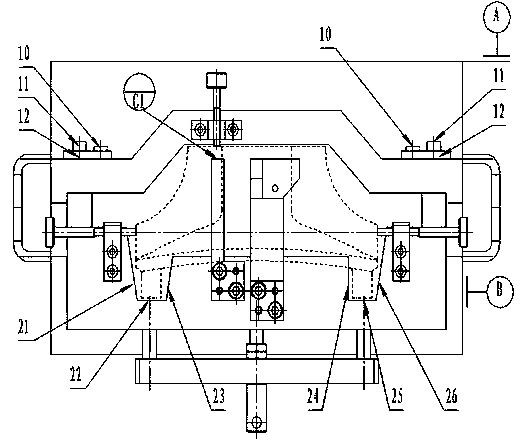

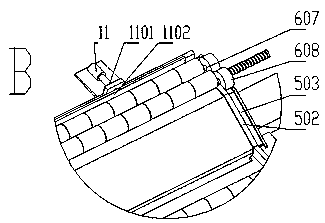

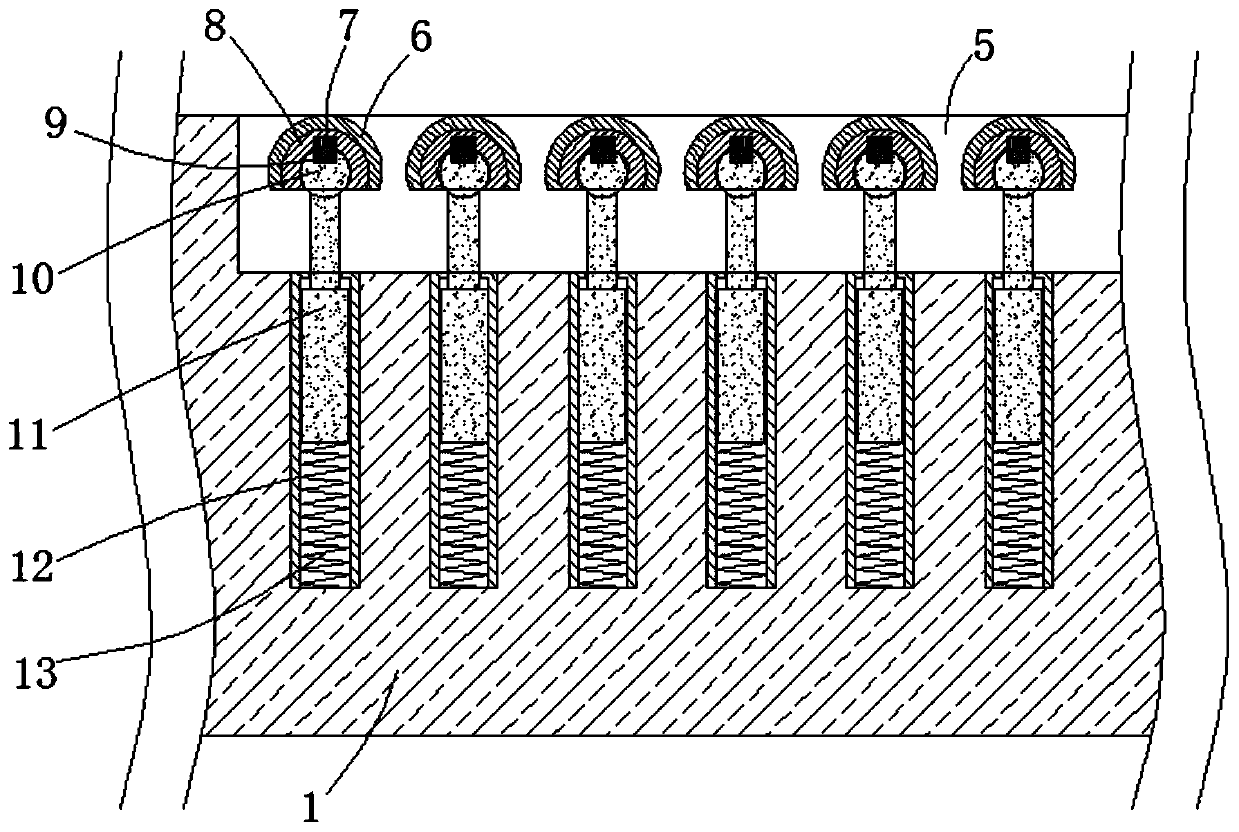

Low melting point alloy casting clamp for processing thin-walled parts, and use method thereof

The invention relates to a low melting point alloy casting clamp for processing thin-walled parts, and a use method thereof. By adoption of the clamp, the rigidity during the processing of the parts can be increased, so that the parts are high in efficiency and stable in quality during cutting; the clamp is compact in structure, reliable in positioning, and convenient and fast in operation. According to the technical scheme, the clamp comprises a base; a sub-module I and a sub-module II are arranged on the upper surface of the base; an opening end of the sub-module I is opposite to the opening end of the sub-module II; a tight-propping block I is arranged on each of the upper surfaces of the two sides of the sub-module II; a tight-propping pin I perpendicular to the tight-propping block I is arranged on each tight-propping block I; a positioning I and a Z-shaped positioning support are arranged at the center of the upper surface of the sub-module II; a positioning II is arranged at the extending end of the upper surface of the positioning support; a tight-propping block II is arranged on the sub-module I; a tight-propping pin II, opposite to the positioning blocks I, is arranged on the tight-propping block II; a support seat is arranged on the other side of the sub-module II, and is connected with the sub-module II through a shaft; a rotating lever is arranged on the outer side of the shaft.

Owner:西安西航集团莱特航空制造技术有限公司

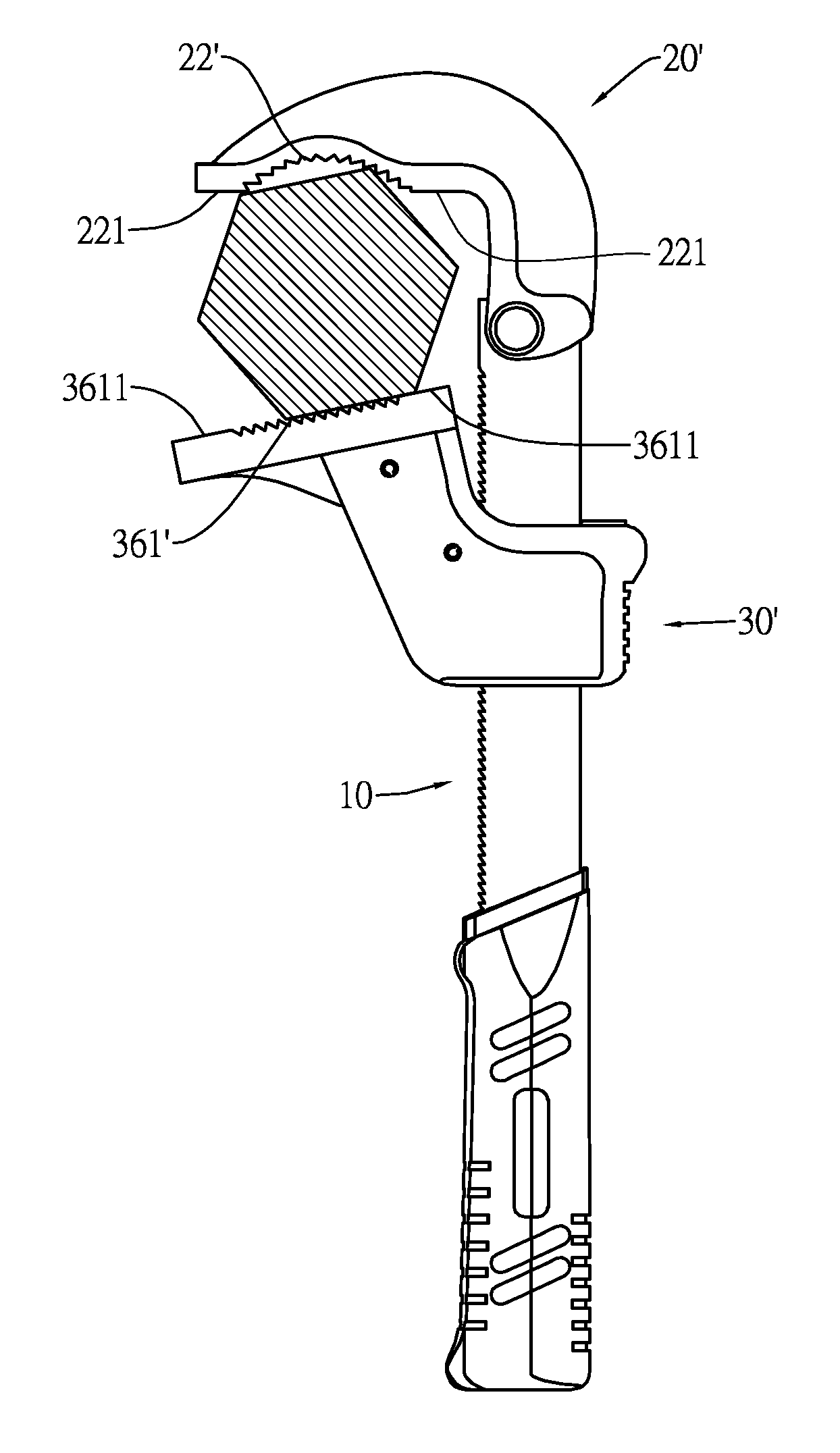

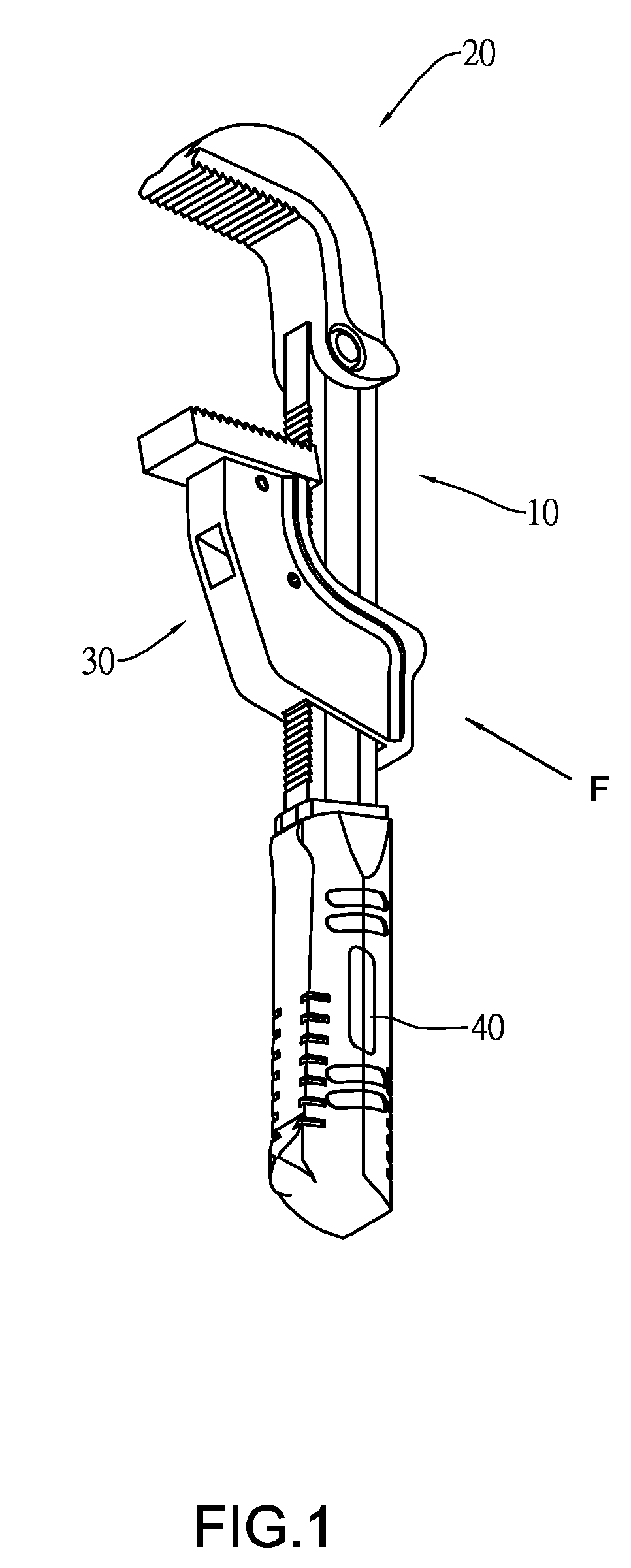

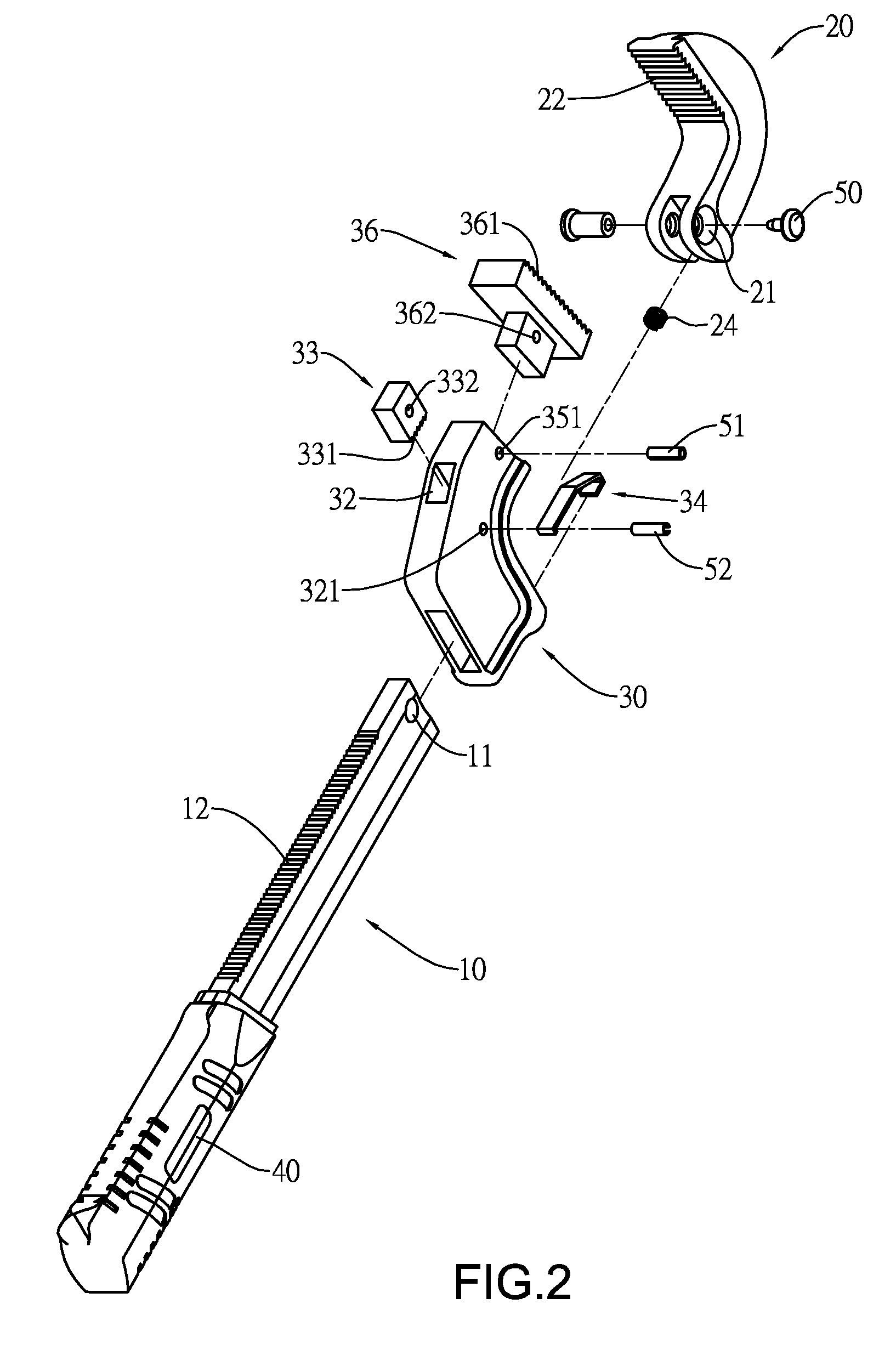

Jaw pipe wrench with resilient member

InactiveUS20090193940A1Improve convenienceIncrease competitionSpannersWrenchesPipe wrenchEngineering

The present invention pertains to a jaw pipe wrench with resilient member comprising a wrench body penetrating through an actuating jaw, where a resilient member mounted and provides with one flat surface leans against said wrench body, so as to drive a serrated section of the wrench body firmly contacting with a serrated section of actuating jaw. While in manipulation, users initially propel the actuating jaw and synchronically compress the resilient member, the serrated section of the wrench body thus moves away from the serrated section of the actuating jaw, whereby users can freely raise or descend the actuating jaw in time of clamping, thus increasing the convenience of using.

Owner:KUO SHAO FAN

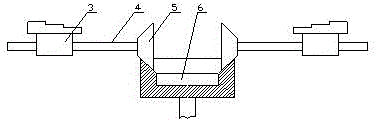

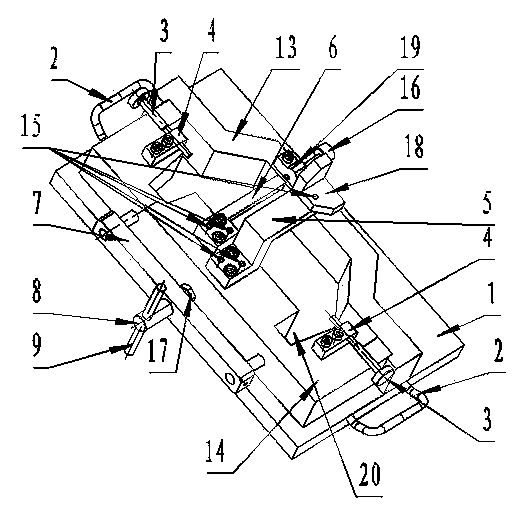

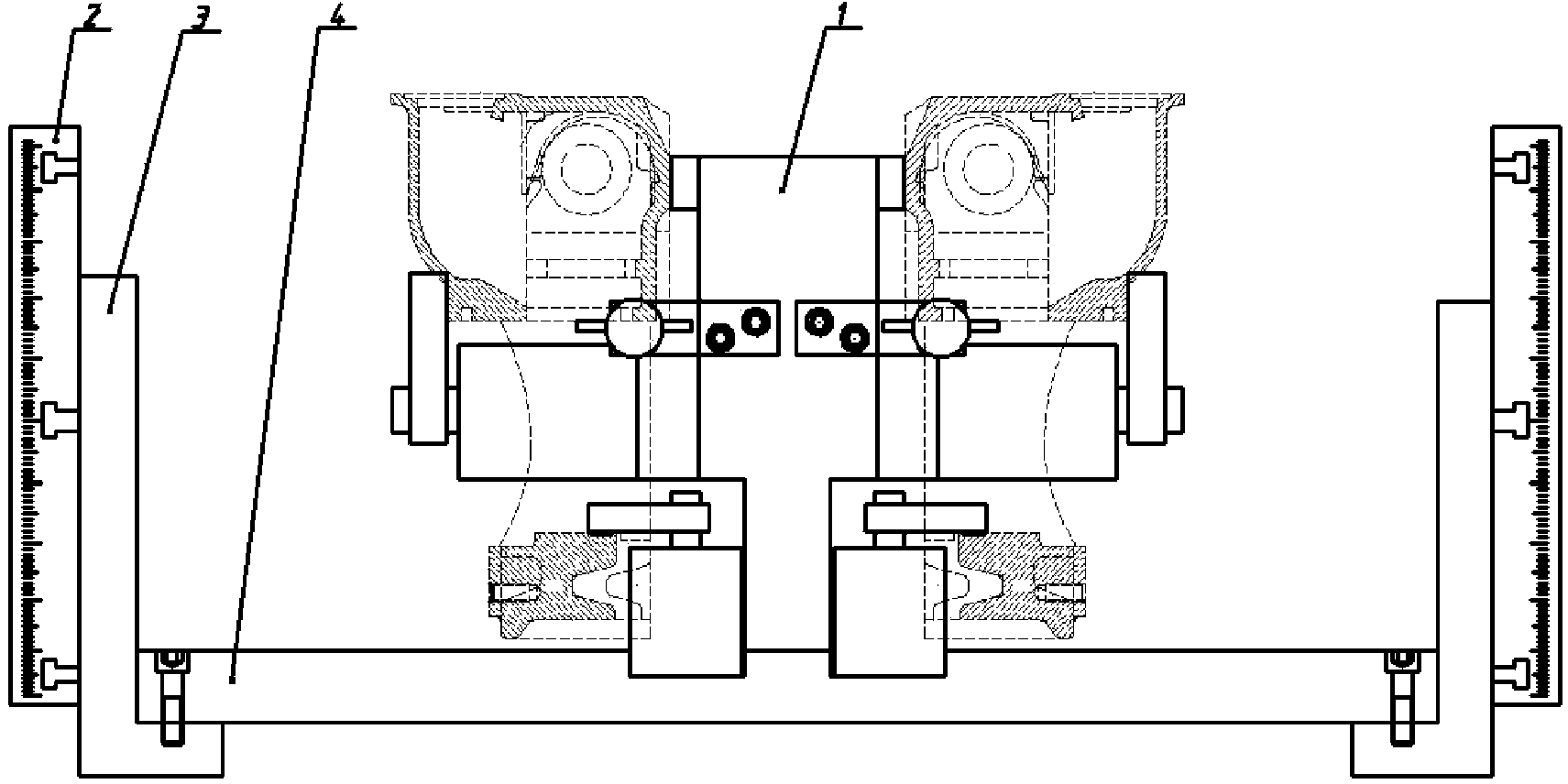

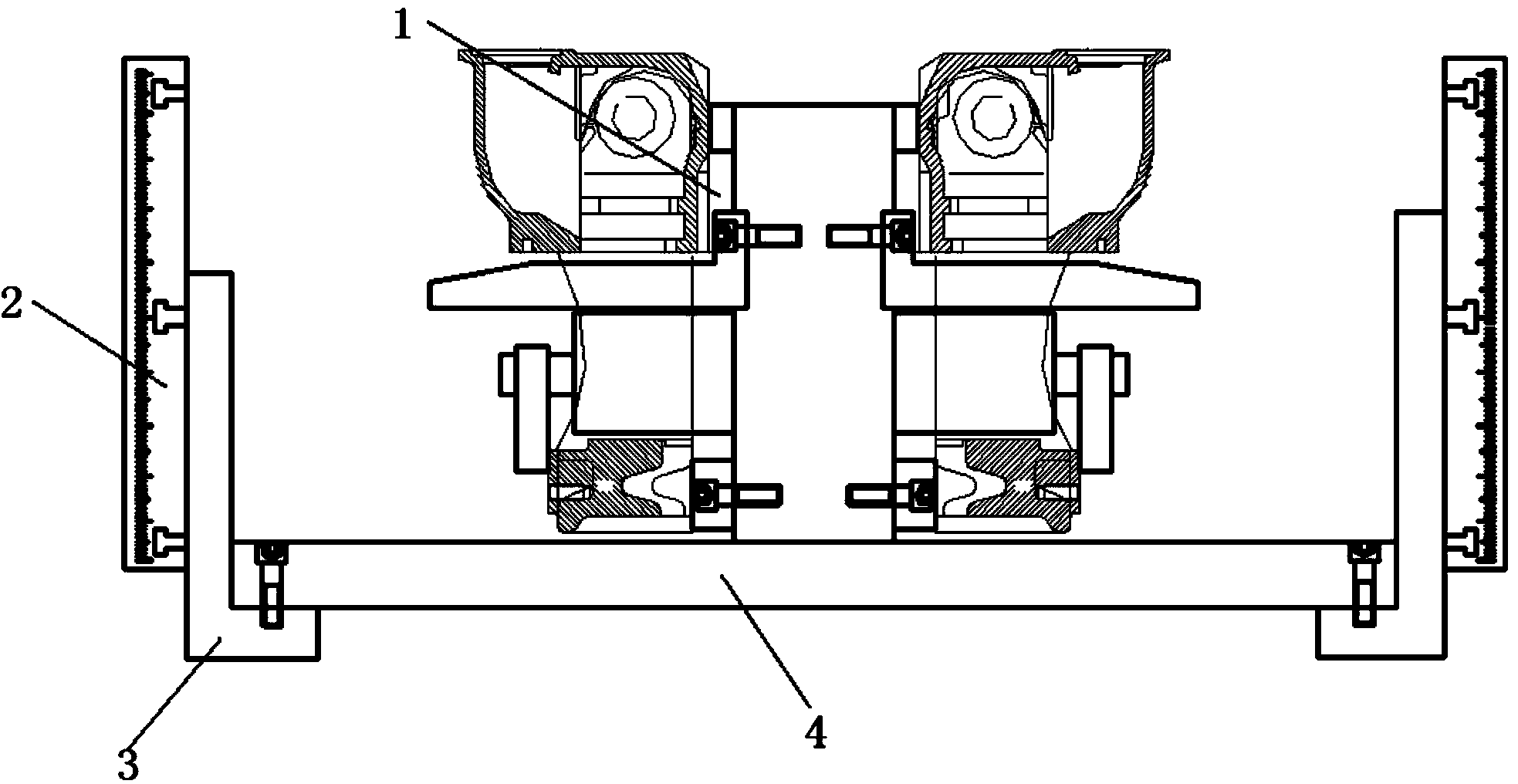

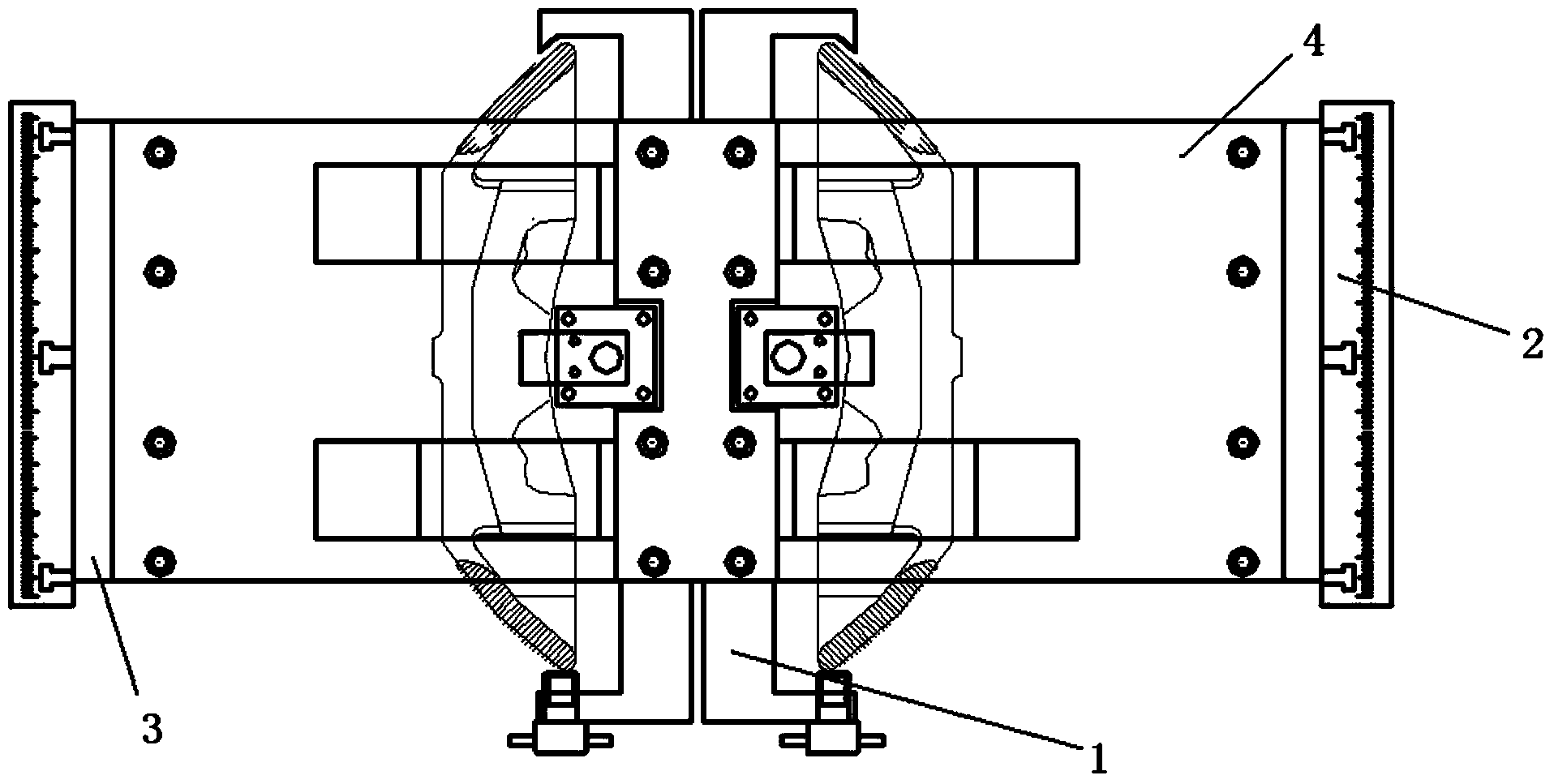

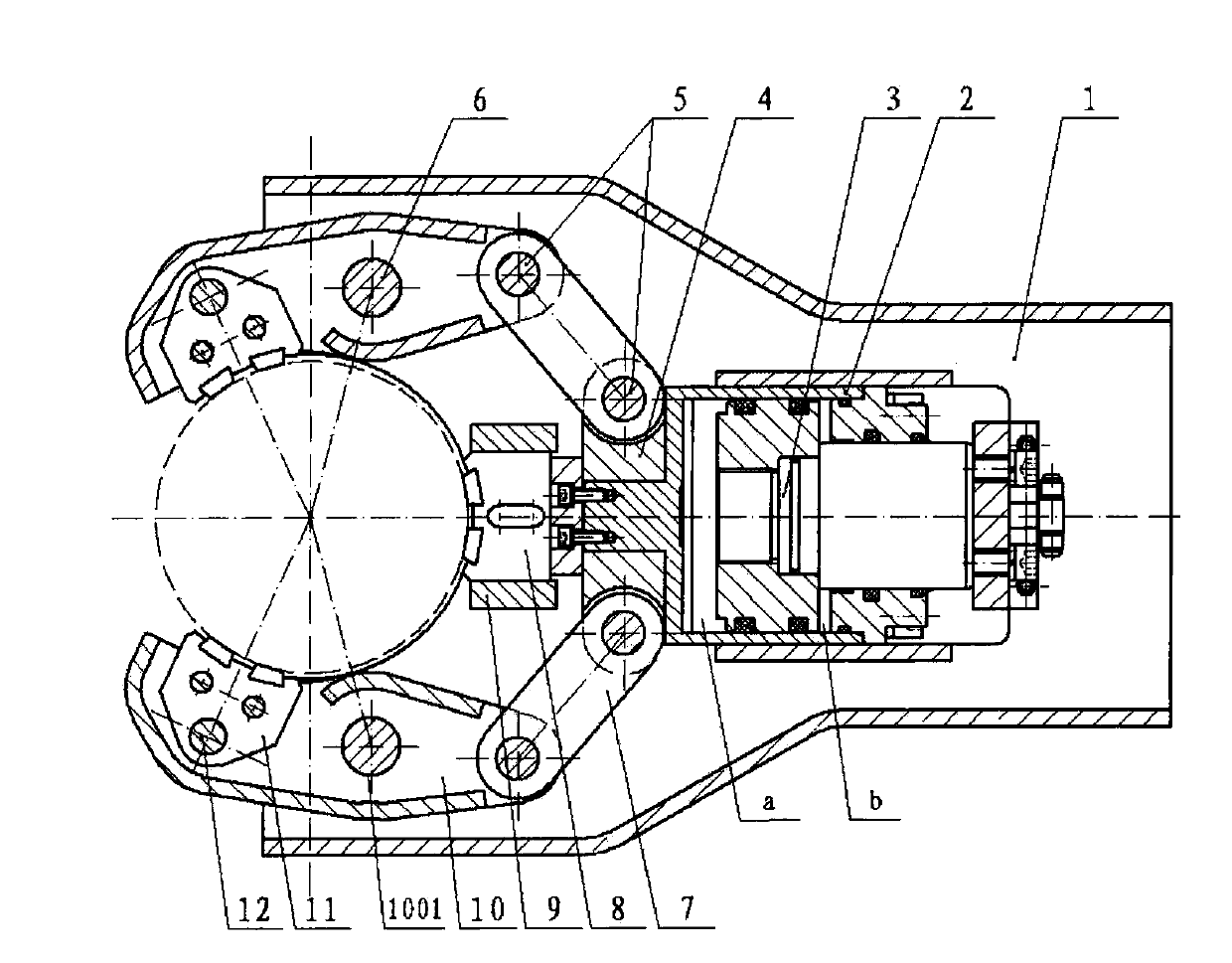

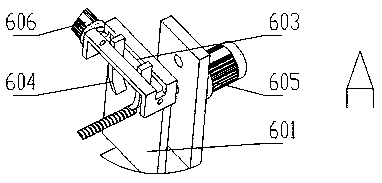

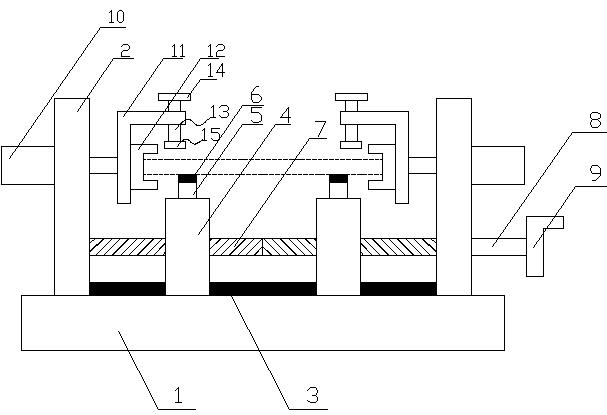

Clamping device for machining and positioning of pincers of disc brakes

ActiveCN103878615AAchieve rotationImprove machining accuracyWork clamping meansPositioning apparatusDegrees of freedomMachining

The invention discloses a clamping device for machining and positioning of pincers of disc brakes. The clamping device comprises an intermediate plate, two groups of clamping mechanisms are symmetrically arranged on two lateral sides of the intermediate plate respectively, index plates and L-blocks are symmetrically arranged on two sides of a bridge plate which is arranged at the bottom of the intermediate plate, and the index plates are fixed onto the bridge plate through the L-blocks. Each clamping mechanism comprises a supporting block, an upper rotary cylinder, a lower rotary cylinder, a clamping unit and a positioning unit in sequential distribution from top to bottom, and a wedged support, a middle rotary cylinder and a positioning block are sequentially distributed from top to bottom and symmetrically arranged on two sides of each upper rotary cylinder and the corresponding lower rotary cylinder. The wedged supports are used for supporting and positioning the pincers of the disc brakes, and the upper rotary cylinders, the lower rotary cylinders and the middle rotary cylinders control moving degrees of freedom of the pincers of the disc brakes in the X-axial, Y-axial and Z-axial directions. The clamping units are positioned on the front side of the intermediate plate, and the positioning units are positioned on the rear side of the intermediate plate. The clamping device is capable of clamping two pincers at one time and realizing workpiece rotation to machine different surfaces and is high in machining precision and effectiveness and good in application prospect.

Owner:JIANGSU HENGLI BRAKE MFG +1

Linkage multi-jaw hydraulic power back-up wrench

InactiveCN103375139AReasonable designThe principle is simpleDrilling rodsDrilling casingsHydraulic cylinderEngineering

The invention relates to a linkage multi-jaw hydraulic power back-up wrench. Acting force of a hydraulic cylinder directly acts on a clamped string by the aid of a movement pair between a translation jaw assembly and a back-up wrench body of the linkage multi-jaw hydraulic power back-up wrench, at the moment, linear movement of a cylinder body or a piston rod of the hydraulic cylinder is converted into rotation of clamping arms by the aid of a fixed hinge form of two rotary pairs and a movable hinge form of two other rotary pairs, the rotary pairs are arranged among the hydraulic cylinder and rotary jaw assemblies, and the acting force outputted by the hydraulic cylinder acts on the clamped string, so that the purpose of clamping the clamped string in a three-point linkage manner is achieved. The linkage multi-jaw hydraulic power back-up wrench has the advantages of reasonable design, simple principle, compact structure, convenience in manufacture, good clamping stability and low quantity of easily damaged parts.

Owner:盐城特达钻采设备有限公司

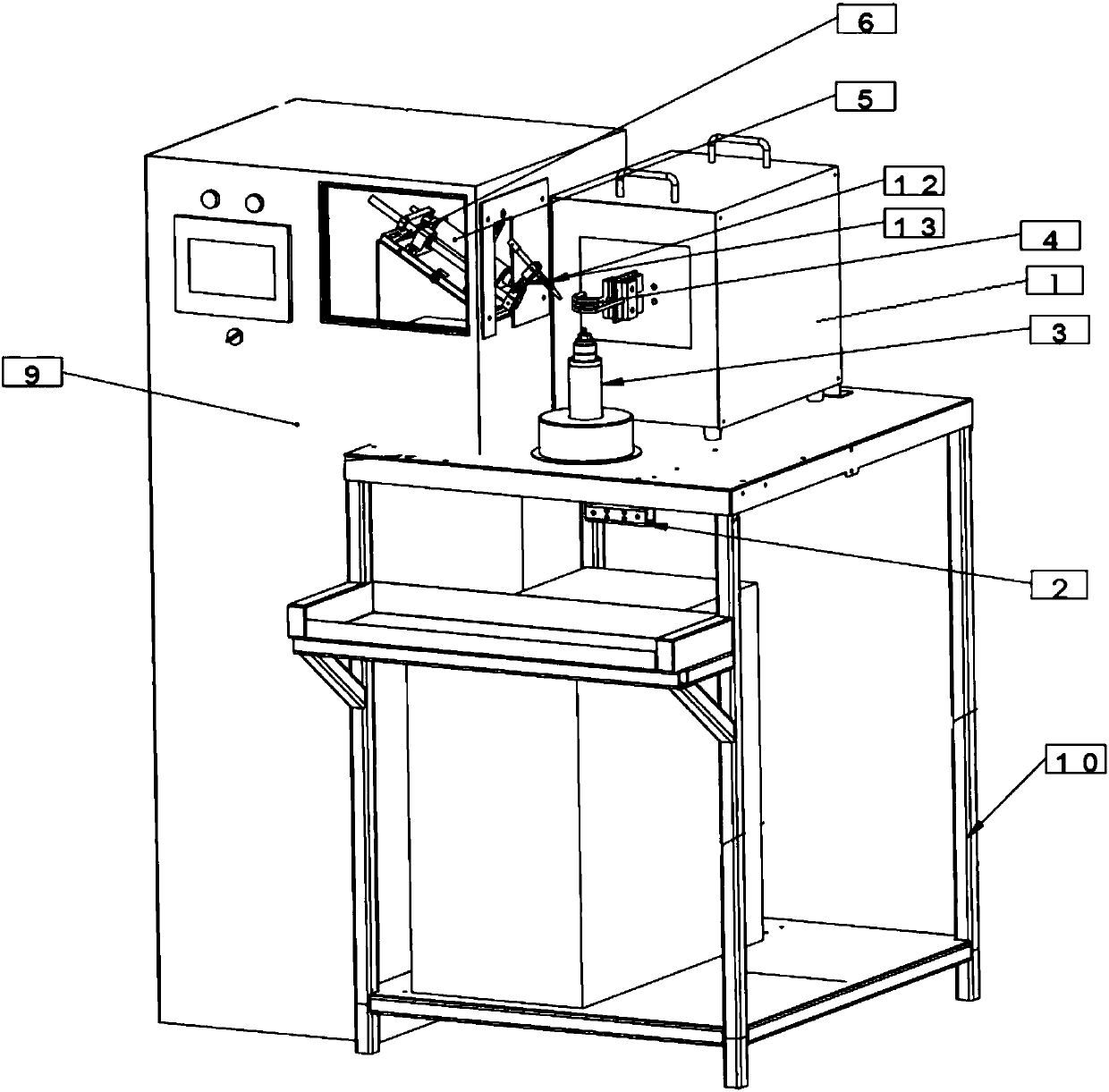

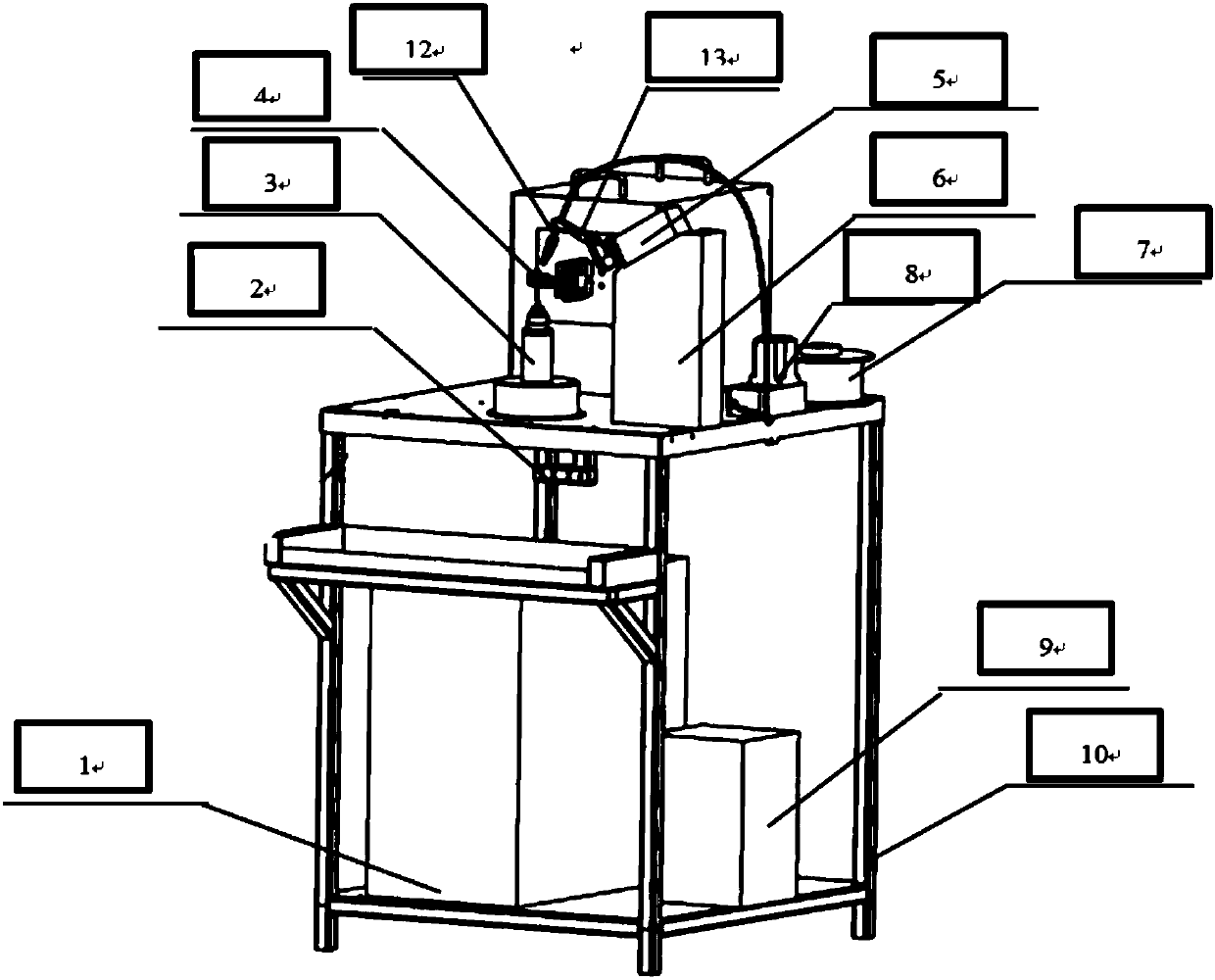

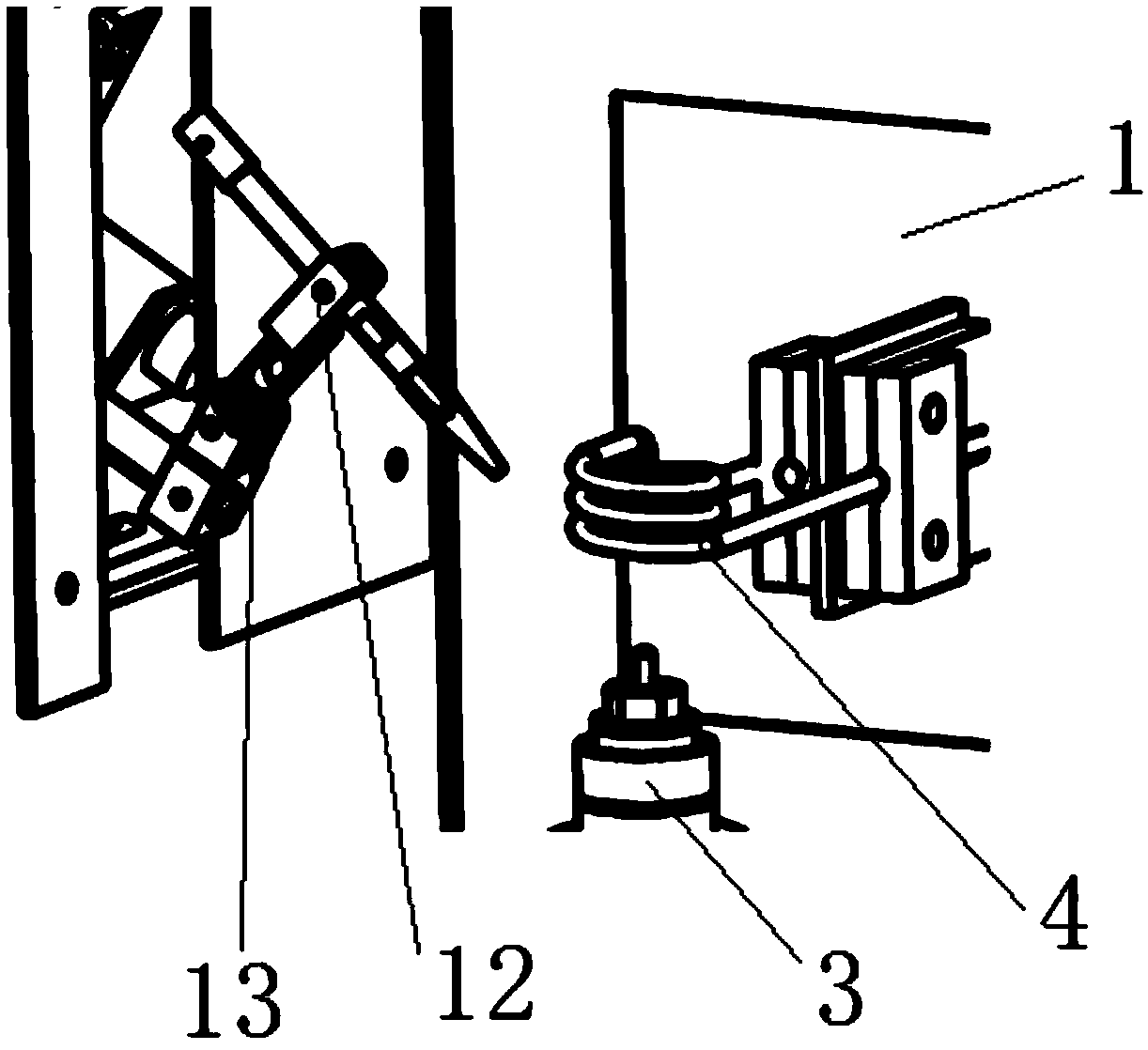

High-frequency welding mechanism and method of wire feeding machine

ActiveCN107617801AFully automatedImprove work efficiencyIncreasing energy efficiencySolder feeding devicesControl systemSingle station

The invention discloses a high-frequency welding mechanism and a method of a wire feeding machine. A workpiece tool, a cylinder adjusting mechanism, a wire feeding mechanism and a brazing device are arranged on a worktable; workpieces to be machined are fixed on the workpiece tool positioned at the lower end of an induction coil; the electromagnetic induction heating is performed on the workpiecesto be machined through the induction coil on the brazing device; a control system controls a cylinder device on the cylinder adjusting mechanism to feed a wire feeding nozzle onto the workpieces to be machined; a force sensor induces if welding wires are molten to achieve accurate wire feeding; the wire feeding mechanism, the brazing device and the force sensor are matched to realize precise matching between the welding wires and welded parts, so that the operation efficiency and the convenience are improved; a control system is adopted to replace manual control, so that full automation of all actions is guaranteed; the welded parts and the welding wires are precisely matched to reach optimal product quality; and the mechanism can adopt single-station and multi-station welding operations,can perform mated use according to actual scene conditions, and solves the product welding problems.

Owner:深圳市北辰亿科科技有限公司

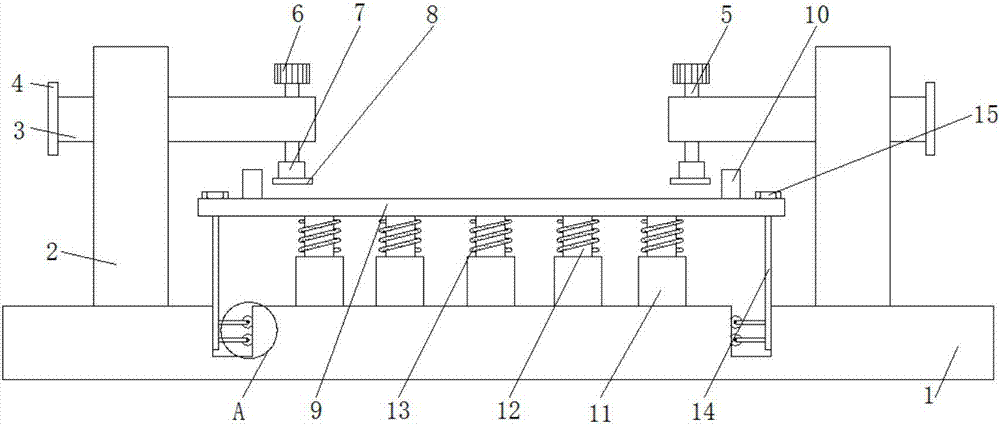

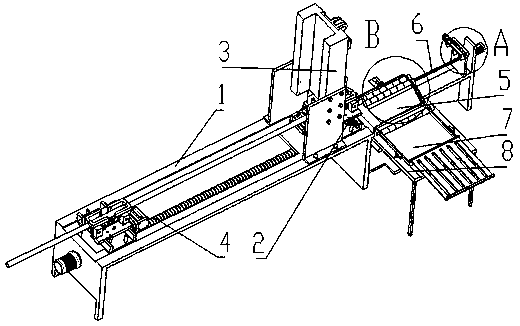

Pipe cut-off machine with automatic clamping mechanism

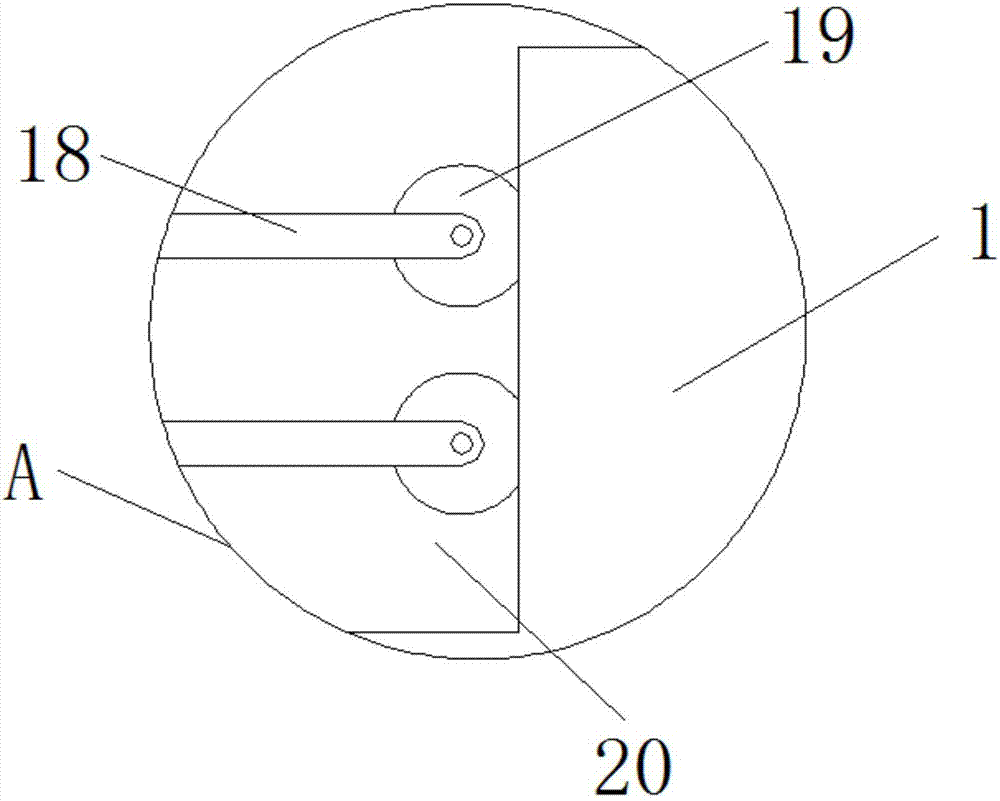

ActiveCN110977009AImprove clamping stabilityImprove securityTube shearing machinesMetal working apparatusSafety coefficientIndustrial engineering

The invention provides a pipe cut-off machine with an automatic clamping mechanism, and belongs to the technical field of machining. According to the technical scheme, a clamping mechanism is fixedlyarranged on one end of a rack, and a cutting mechanism is arranged on the rack and located above the clamping mechanism; a rotating shaft is rotationally arranged in the middle of the base; a short connecting rod is rotationally arranged at the upper end of the rotating shaft; long connecting rods are rotationally arranged at the two ends of the short connecting rod and located under the short connecting rod; side plates are arranged on the two sides of the base; clamp bottom plates are arranged above the two side plates and located on the two sides of the short connecting rod in a sliding mode; the other ends of the long connecting rods are arranged on the clamp bottom plates in a rotating connection mode; mounting blocks are arranged on the clamp bottom plates; and clamping plates are symmetrically arranged on the inner sides of the two opposite mounting blocks; and the two clamp bottom plates are connected through a telescopic mechanism. The pipe cut-off machine has the beneficial effects that a pipe can be clamped, the clamping stability is good, and the safety coefficient is high.

Owner:山东金润德新材料科技股份有限公司

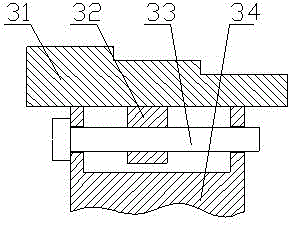

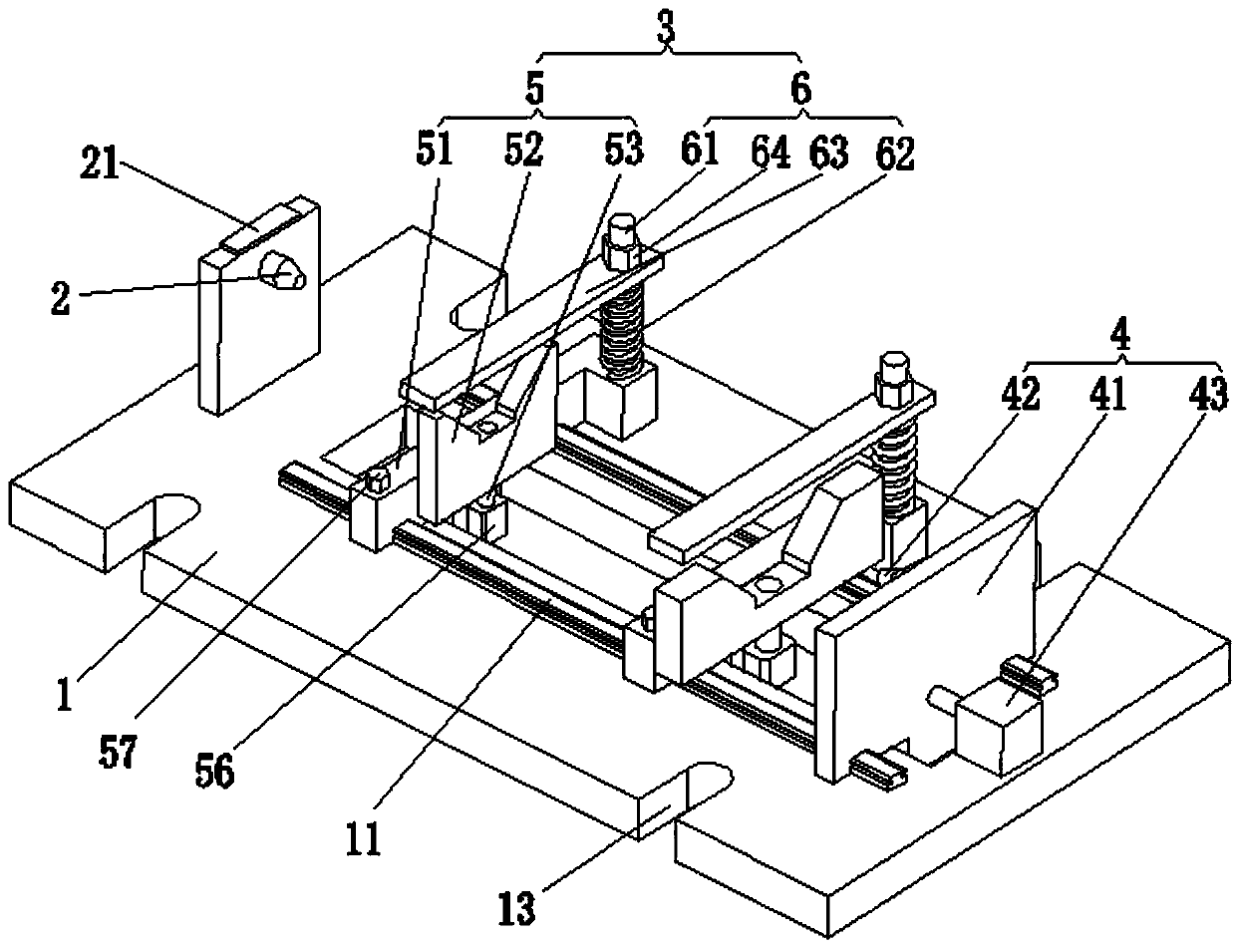

Fixture for shaft keyway processing

InactiveCN107900735AImprove clamping stabilityHigh positioning accuracyPositioning apparatusMetal-working holdersMachiningEngineering

The invention discloses a fixture for shaft keyway processing, which comprises a bottom plate, a fixed V-shaped positioning block fixedly connected to the bottom plate, an adjustable V-shaped positioning assembly slidably connected to the bottom plate, and a fixed V-shaped positioning block arranged on the bottom plate. And the two pressing mechanisms on the adjustable V-shaped positioning block, the limiting plate arranged on one side of the bottom plate and the thimble assembly arranged on the other side of the bottom plate relative to the limiting plate; the limiting plate is fixed by screws Connected to the bottom plate; the thimble assembly includes a support seat, a thimble bracket, a thimble and a transmission screw, and the thimble can be adjusted to move axially and move up and down. This fixture has high clamping stability and high positioning accuracy. It can be adapted to step-shaped shafts of various sizes by adjusting the position of the adjustable V-shaped positioning component, which can reliably ensure the accurate positioning of the shaft and ensure the symmetry of the machining of the key groove of the shaft. Spend.

Owner:SUZHOU ZHENJIACHEN PRECISION MACHINERY CO LTD

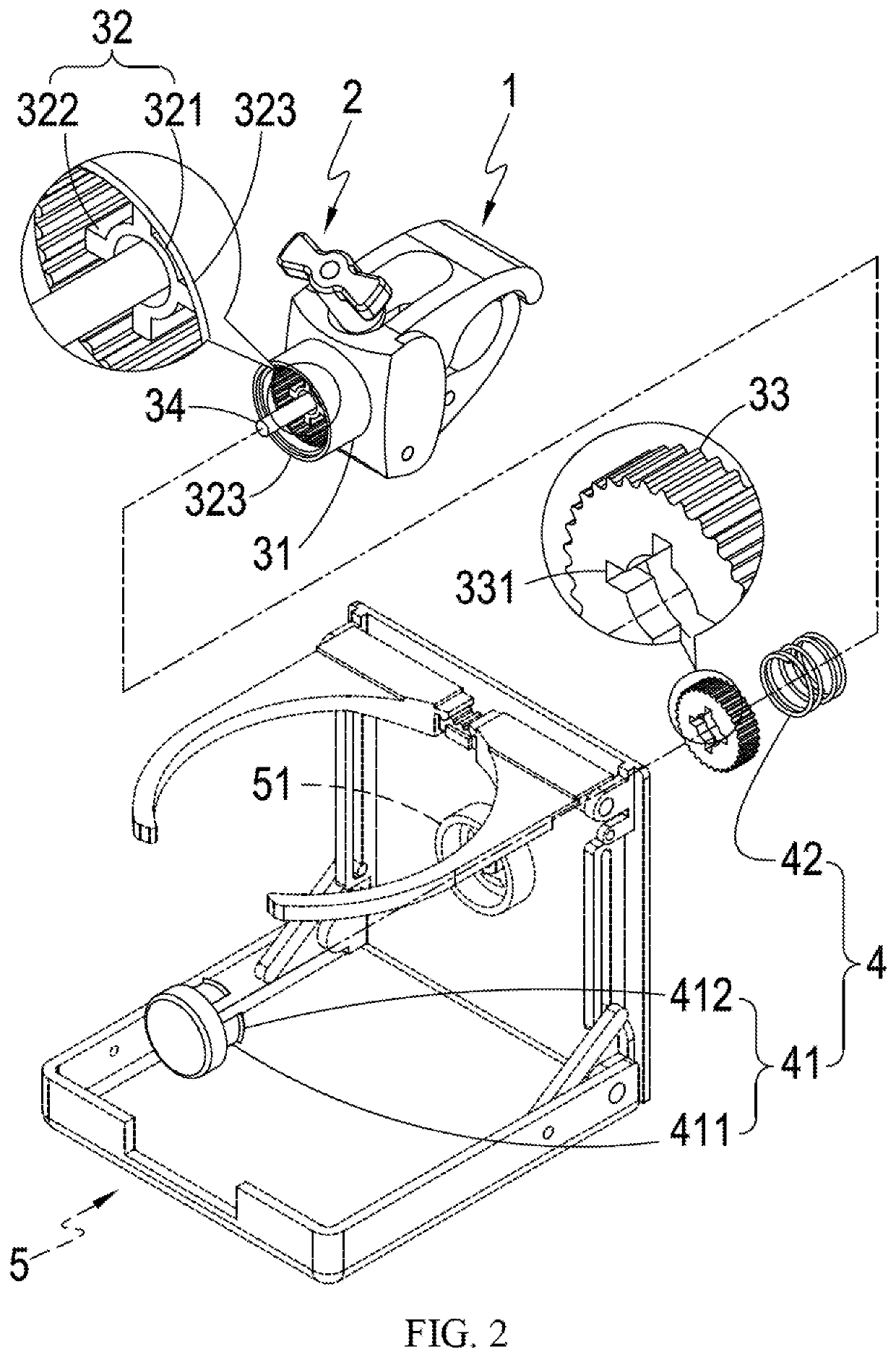

Drink holder mounting structure for attaching to various tubular objects

ActiveUS10531755B1Improve clamping stabilityOperational safety is enhancedNutsSheet joiningClassical mechanicsStructural engineering

A clamp body includes a first clamping member and a clamping seat that are integrally formed together, a pivot hole formed in the clamping seat, and a second clamping member pivotally connected to the pivot hole. Also included are an elongated through hole formed in the first clamping member, a circular arc wall extending from the elongated through hole and gradually shallowing from a depth, a position-limiting axle between inside wall surfaces of the second clamping member, a tightness adjusting assembly including a rounded-head pushing rod, and a rotation assembly for coupling the clamp body and the holder. As such, the clamp body that has one arm to fix and one arm to move could improve stability of clamping. The arrangement of the elongated through hole and the circular arc wall gradually shallowing from a depth is used to reduce a size of the tightness adjusting assembly projecting to outside.

Owner:HUANG PEI HSIU

Grinding mechanism for machining rotary bracket type bearing

InactiveCN110434689AImprove grinding efficiencyReduce workloadGrinding carriagesRevolution surface grinding machinesRotating discPlunger

The invention discloses a grinding mechanism for machining a rotary bracket type bearing. The grinding mechanism comprises a workbench, a grinding roller and a grinding machine, wherein a vertically distributed servo motor is arranged in the middle of the lower end surface of the workbench, an output shaft of the servo motor is in transmission connection with a rotating disc above the workbench, aplunger cylinder which is vertically distributed is fixedly connected to the middle of the upper end face of the rotating disc, and a first electric telescopic rod which is vertically distributed isarranged in the middle of the upper end surface of the plunger cylinder. According to the grinding mechanism, a full-automatic rotary grinding structure is adopted, so that a bearing outer ring can beautomatically polished, the workload of operators is reduced, and the bearing grinding efficiency is also improved; and a bracket-type clamping structure is arranged in the bearing, so that the bracket-type clamping processing of the bearings with different inner diameters is facilitated, the applicability of the grinding mechanism is improved, and the clamping stability of the clamping structureis also improved.

Owner:云和县凯毅德电子设备厂

Tool clamp

InactiveCN108927750AStable clampingImprove clamping stabilityWork holdersPositioning apparatusEngineeringPiston rod

The invention discloses a tool clamp. A guide rail is horizontally and fixedly connected between two side supporting plates, the left side and the right side of the guide rail are each provided with asliding base in a sliding manner, supporting columns are evenly arranged on the upper end faces of the sliding bases, the top end of each supporting column is bonded with a rubber pad, the two ends of a dual-way screw are rotatably connected with the side supporting plates on the left side and the right side through bearings, the dual-way screw horizontally penetrates the two sliding bases, the sliding bases are in threaded connection with the dual-way screw through thread holes, the left end of a connecting rod is fixedly connected with the right end of the dual-way screw, the right end of the connecting rod is fixedly connected with a first handle, upper portions of end faces, away from one side of the center of a base, of the two side supporting plates are each provided with an air cylinder, tail ends of piston rods of the air cylinders are fixedly connected with an L-shaped plate, a U-shaped clamping block is fixedly connected to the end face, facing one side of the center of thebase, of the vertical part of the L-shaped plate, a screw rod is in threaded connection to the horizontal part of the L-shaped plate, a second handle is fixedly connected to the upper end of the screwrod, and a pressing block is fixedly connected to the lower end of the screw rod. The tool clamp has the beneficial effects of being convenient to use and high in clamping stability.

Owner:张多梅

Clamping mechanism for grinding and polishing robot system for high-temperature alloy mechanical parts of engine

InactiveCN110281111AImprove stabilityQuick gripGrinding drivesGrinding feed controlRobotic systemsSuperalloy

The invention discloses a clamping mechanism for a grinding and polishing robot system for high-temperature alloy mechanical parts of an engine. The clamping mechanism comprises a workbench and a data processing module, wherein the data processing module is embedded in an inner chamber of the workbench. A first supporting mechanism and a second supporting mechanism are vertically arranged at the middle segment positions of the left side and the right side of the top end face of the workbench respectively. The first supporting mechanism and the second supporting mechanism both comprise supporting columns, and servo motors are fixedly arranged on the top end faces of the two supporting columns. The two servo motors are connected with threaded rods respectively through power shafts, the outer walls of the two threaded rods are rotationally sleeved with lifting sliding blocks through external threads, and the lifting sliding blocks are respectively positioned in inner chambers of two rectangular lifting grooves. The positions, being 1 / 4 of the distance from the top end, of the outer walls of two arc-shaped clamping blocks are respectively hinged with the side walls at quarter of the tip ends of two hinged plates, and pressure sensors are embedded in the top ends of the opposite side walls of the two arc-shaped clamping blocks. The clamping mechanism is convenient to quickly clamp the parts to be ground and polished, can ensure the good clamping stability, can also ensure no slippage in the grinding and polishing process, and improves the grinding and polishing precision.

Owner:NANJING YUSHENG ROBOT CO LTD

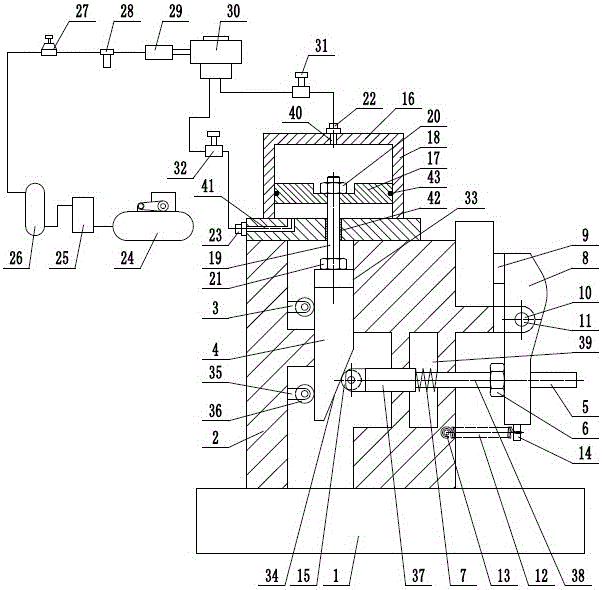

Pneumatic clamping device

ActiveCN106799611AAchieve clampingEasy clampingPositioning apparatusMetal-working holdersAir compressorCylinder block

The invention provides a pneumatic clamping device, and belongs to the technical field of mechanical processing. The pneumatic clamping device comprises a wedge block, a piston, and a connecting rod, wherein the wedge block is arranged on a wedge block chute by sliding up and down; a guide roller of a wedge block guide component is rotationally arranged on a guide supporting seat; a supporting roller is always matched with a sloping bench of the wedge block under the action of a compression spring; a threaded section of the right end of a sliding rod is in threaded connection with the lower end of a press plate; the piston is arranged in a pneumatic cylinder body by sliding up and down; the connecting rod is arranged on a cylinder body supporting seat by sliding up and down; an air compressor is connected with a rear cooler, a gas tank, a pressure control valve, an atomized lubricator, a logic element, and a direction control valve sequentially; and the other two ends of the direction control valve are connected with an upper valve port and a lower valve port through an upper flow control valve and a lower flow control valve respectively. The pneumatic clamping device provided by the invention automatically realizes clamping and releasing of a workpiece, and is reasonable in structure, high in degree of automation, same in clamping force each time, good in reliability and improved in clamping stability.

Owner:盐城捷恒仓储有限公司

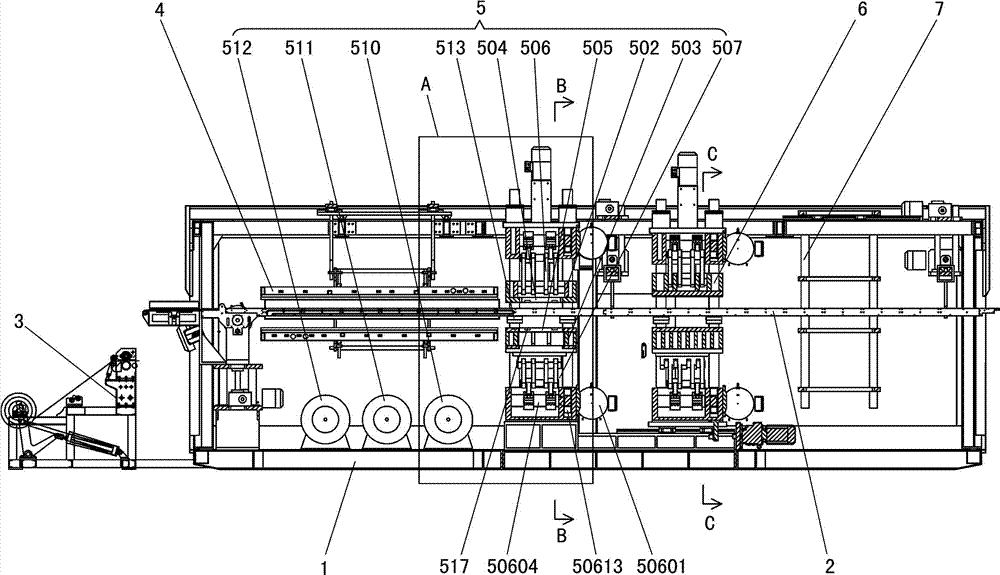

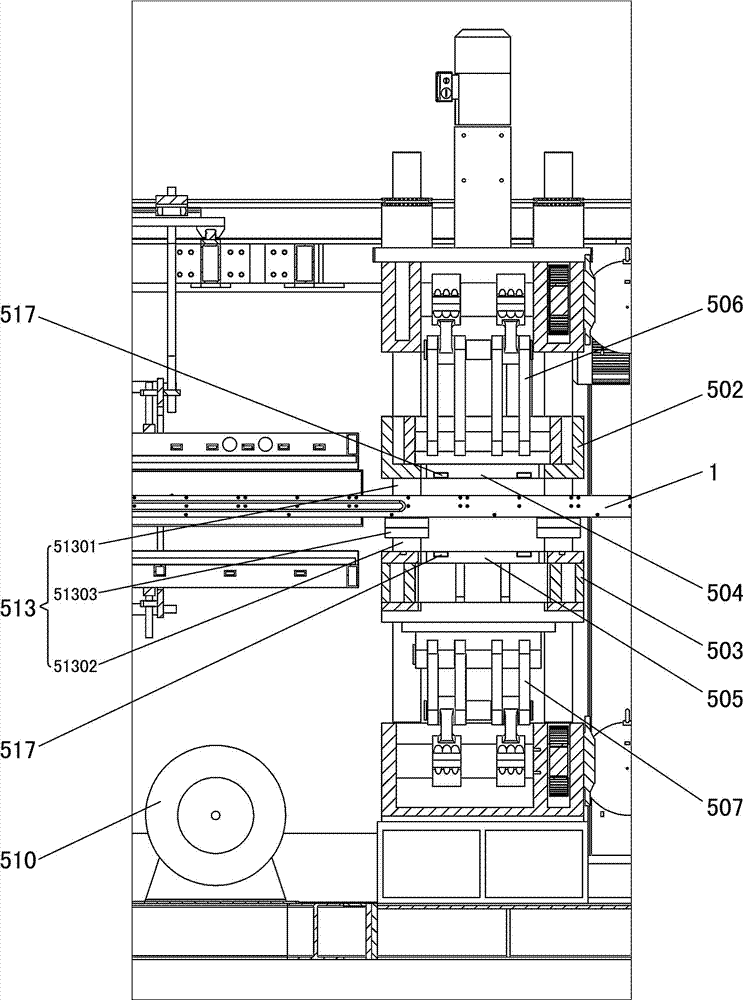

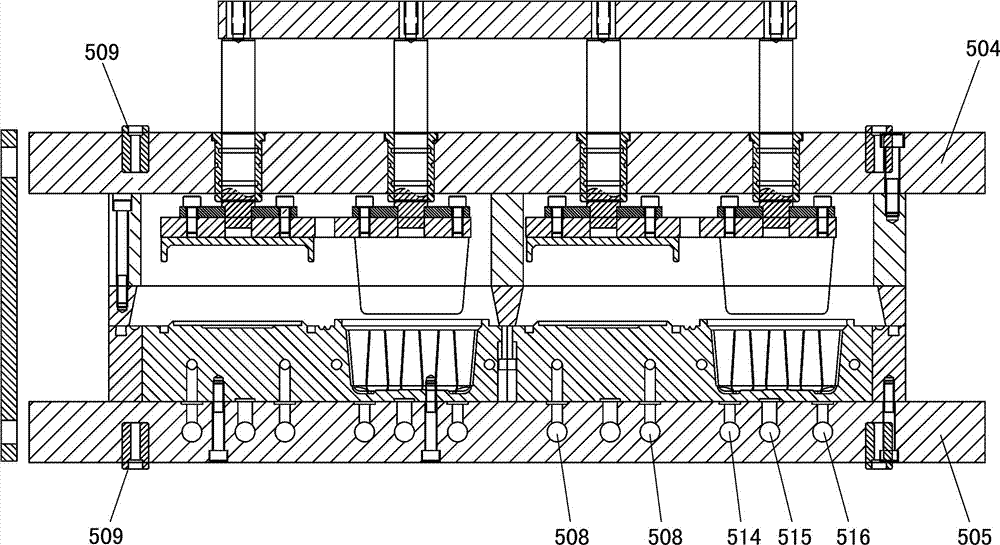

Multi-station numerical control thermal forming machine

The invention relates to a multi-station numerical control thermal forming machine. Each of an upper die platform lifting mechanism and a lower die platform lifting mechanism comprises a lifting motor, a speed reducer, a driving shaft, a reversing shaft, a first rotary shaft, a second rotary shaft, a pinion, a reversing gear, a first gearwheel, a second gearwheel, at least one first connecting rod mechanism and at least one second connecting rod mechanism. When the lifting motor is started, the speed reducer drives the driving shaft to rotate, so the pinion is driven to rotate; and the first rotary shaft and the second rotary shaft oppositely rotate by mutual meshing to drive the first connecting rod mechanism and the second connecting rod mechanism to simultaneously move, so the lifting of an upper die platform and a lower die platform is realized, and the assembly of an upper die and a lower die is realized. Power output by the lifting motor is converted into the locking force of the upper die and the lower die under the action of three-stage amplification, so the locking force during die assembly exceeds 75 tons and is tripled as compared to the locking force of the conventional thermal forming machine.

Owner:广东金兴机械股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com