Double-S-shaped double-curve thin-walled part manufacturing process

A manufacturing process and technology of thin-walled parts, which is applied in the field of double "S"-shaped hyperbolic thin-walled parts manufacturing technology, can solve the problem of wall thickness size, shape tolerance, high surface quality requirements, easy vibration, difficult to control processing deformation, etc. problems, to achieve the effect of enhancing clamping stability and processing rigidity, ensuring size and accuracy, and avoiding vibration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

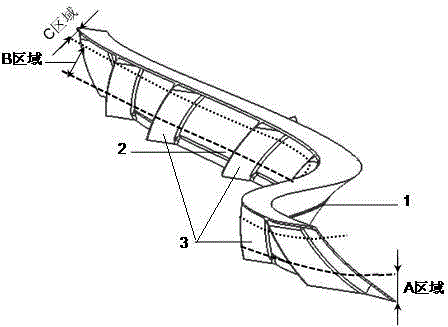

[0031] Example: see figure 1 .

[0032] A manufacturing process of a double "S"-shaped hyperbolic thin-walled part, using five-coordinate high-speed milling to perform rough machining of inner surface 1, rough machining of outer surface 2, semi-finishing and finishing of inner surface 1, outer surface 2 and The ribs 3 are semi-finishing and finishing, the inner surface 1 is the concave part of the part, and the outer surface 2 is the convex part of the part with ribs, and the clamping and positioning are carried out by adding step pad positioning and gypsum filling method, Its manufacturing process is as follows:

[0033] 1) Rough machining of inner surface:

[0034] The bottom surface of the process boss around the outer surface with ribs is positioned, and the clamping and positioning method is adopted with two holes on one side, and the pressure plate groove is opened around the blank, and the pressure plate is clamped. After rough machining, a 4mm process allowance is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com