Multi-station numerical control thermal forming machine

A molding machine and thermoforming technology, applied in the field of multi-station CNC thermoforming machines, can solve the problems of small size, generally only about 25 tons, reducing the range of sheet material selection, affecting the quality of product molding, etc., to achieve good molding quality and applicable Effect of wide range and improved clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

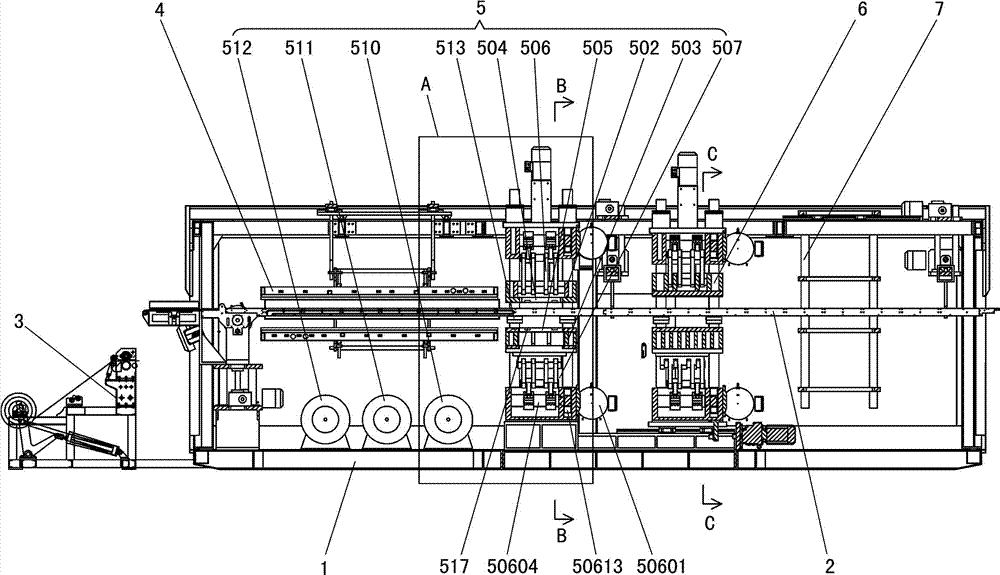

[0031] like figure 1 , figure 2 and image 3 As shown, this multi-station numerical control thermoforming machine includes a frame 1, a conveyor chain 2 arranged on the frame 1, an unwinding device 3 arranged on the frame 1 along the conveying direction of the conveyor chain 2, a heating Device 4, thermoforming device 5, punching and shearing device 6 and collecting device 7.

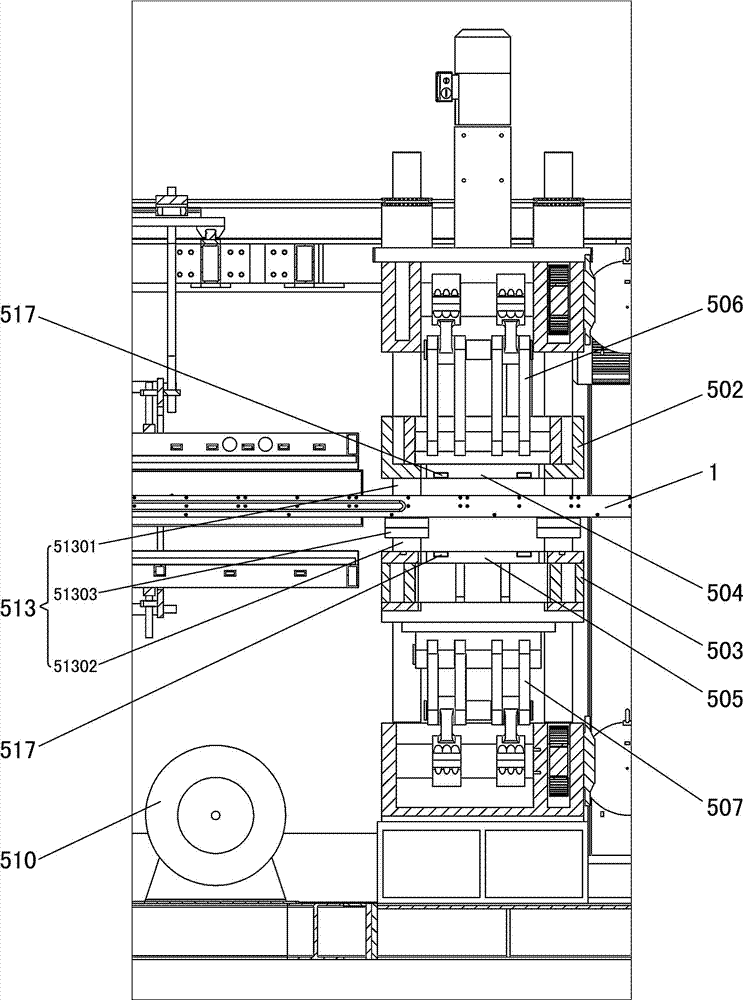

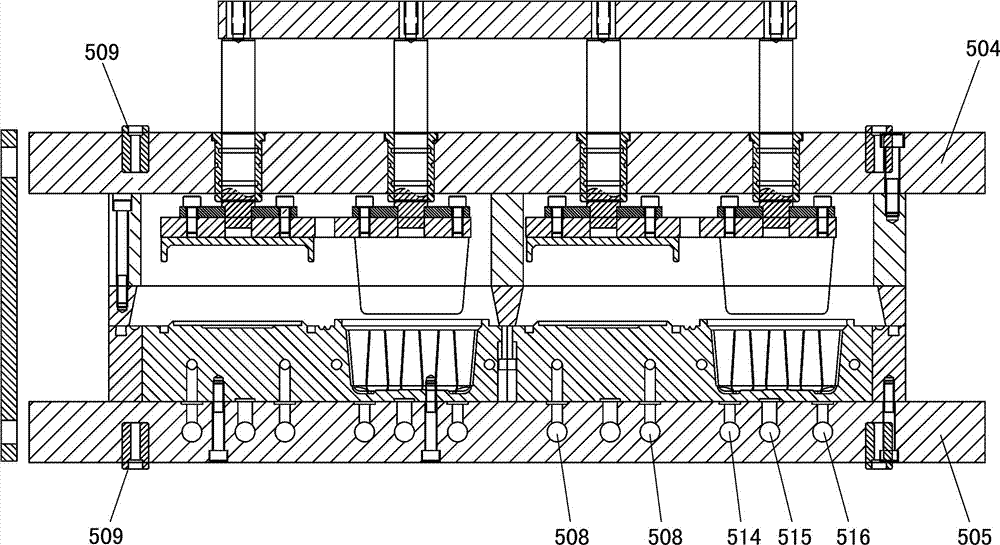

[0032] Thermoforming device 5 upper mold platform 502, lower mold platform 503, upper mold 504, lower mold 505, upper mold platform lifting mechanism 506, lower mold platform lifting mechanism 507, S-shaped metal pipeline 508, cold air supply device 510, positive pressure A supply device 511 and a negative pressure supply device 512; two guide posts 513 are respectively arranged on both sides of the frame 1, and the upper die table 502 and the lower die t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com