Patents

Literature

401results about How to "Quick grip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

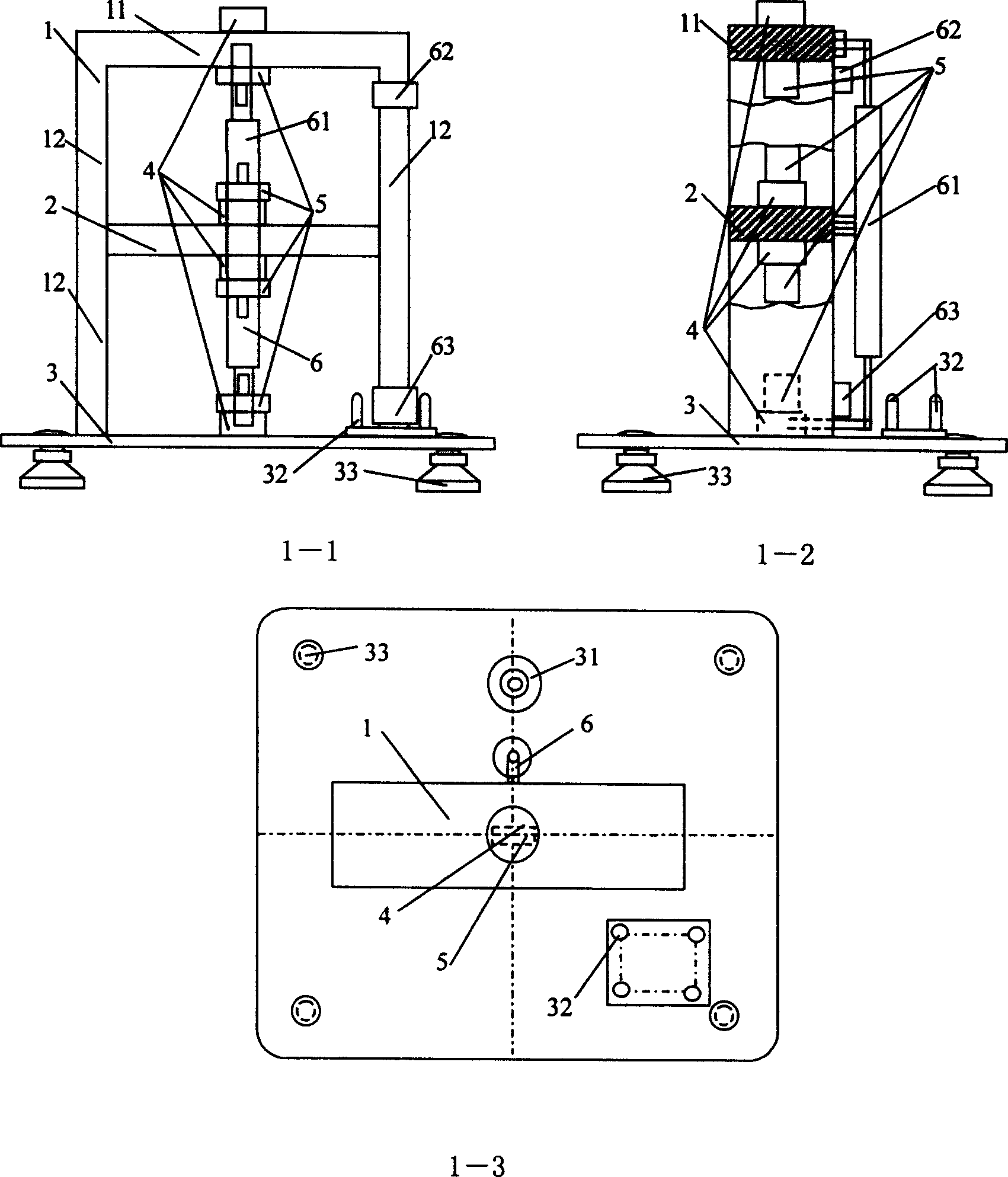

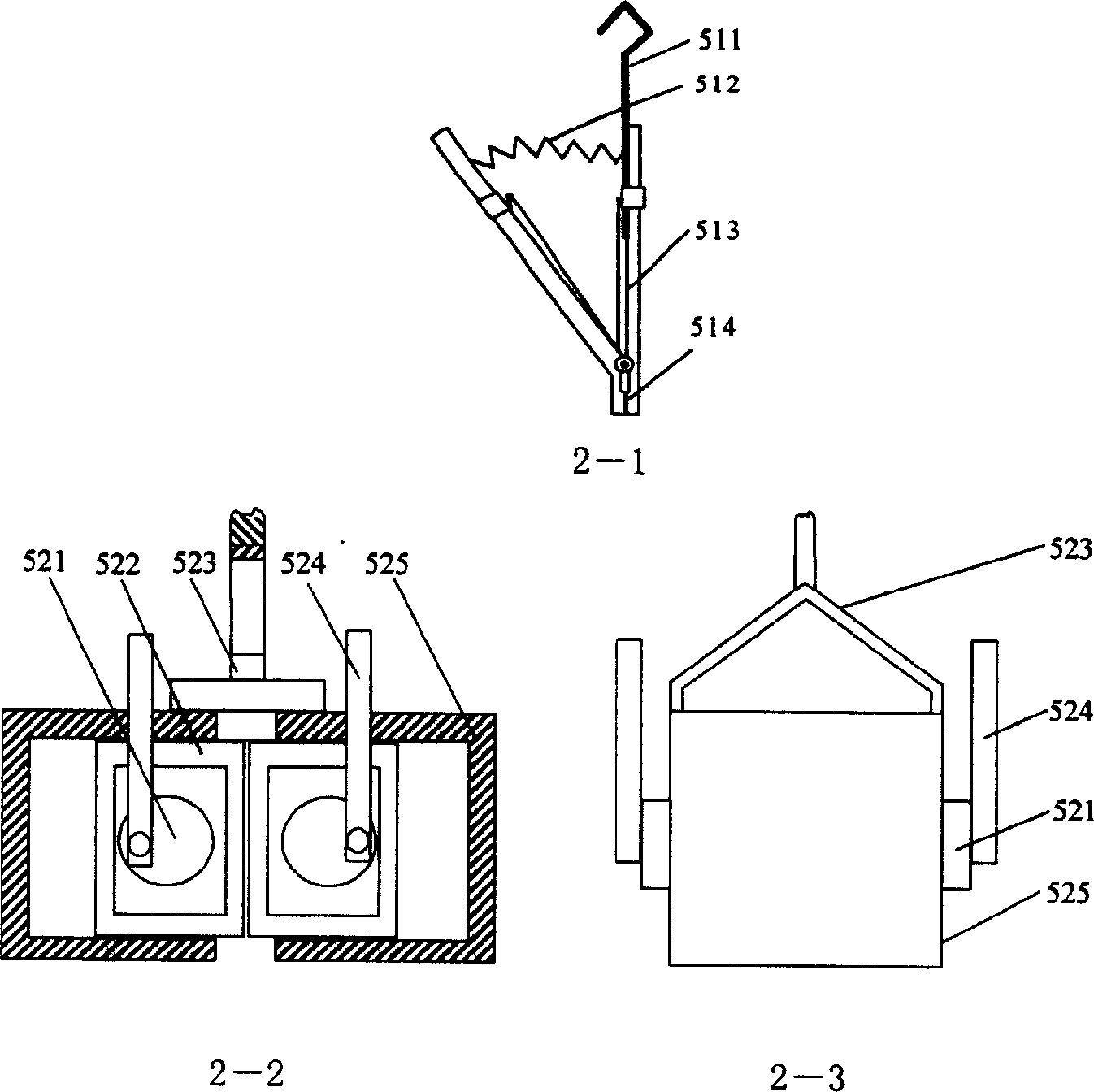

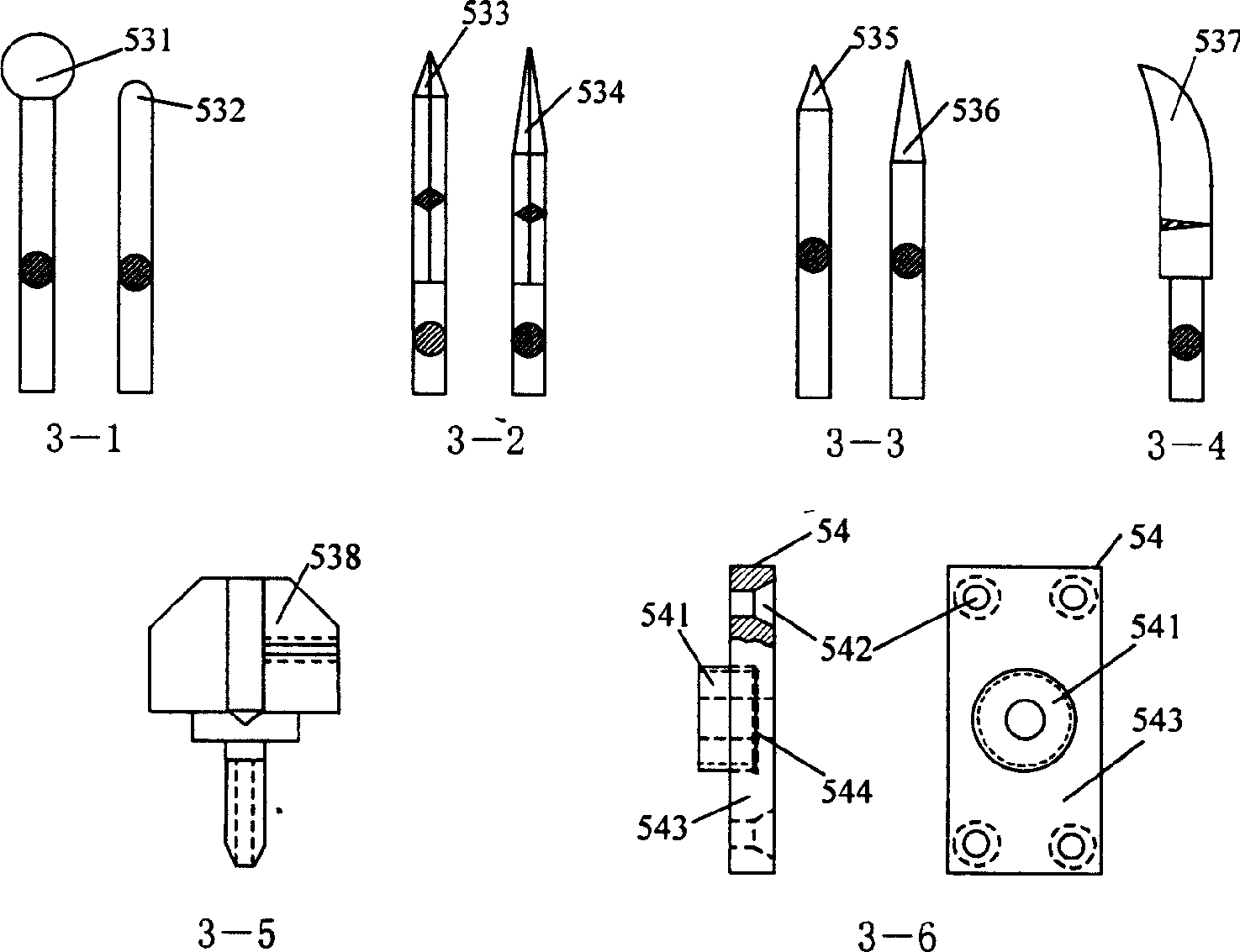

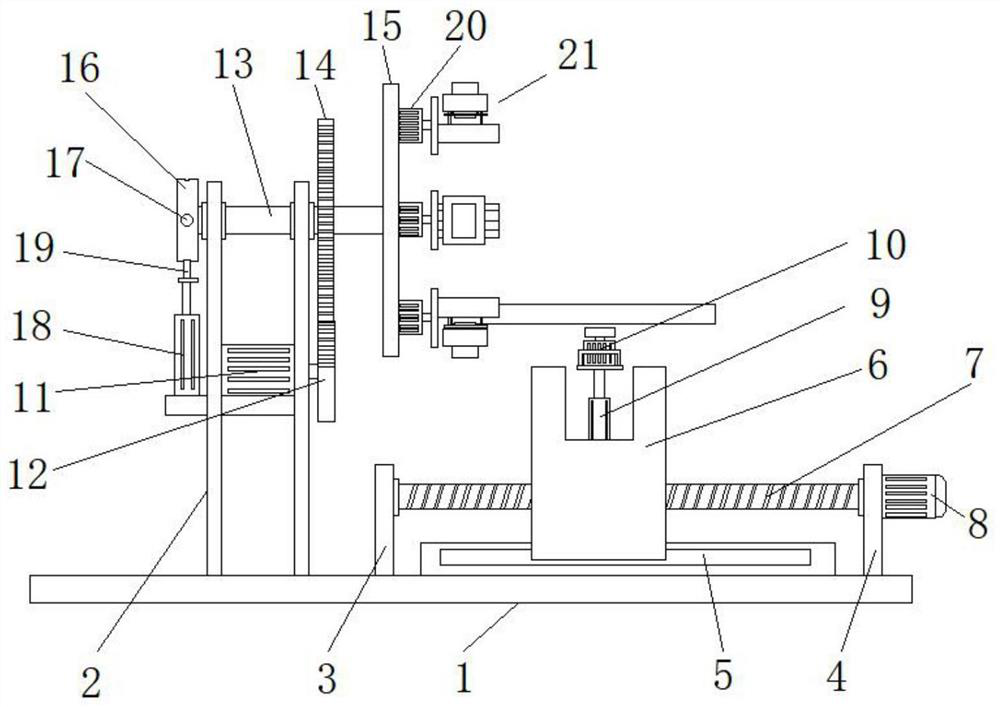

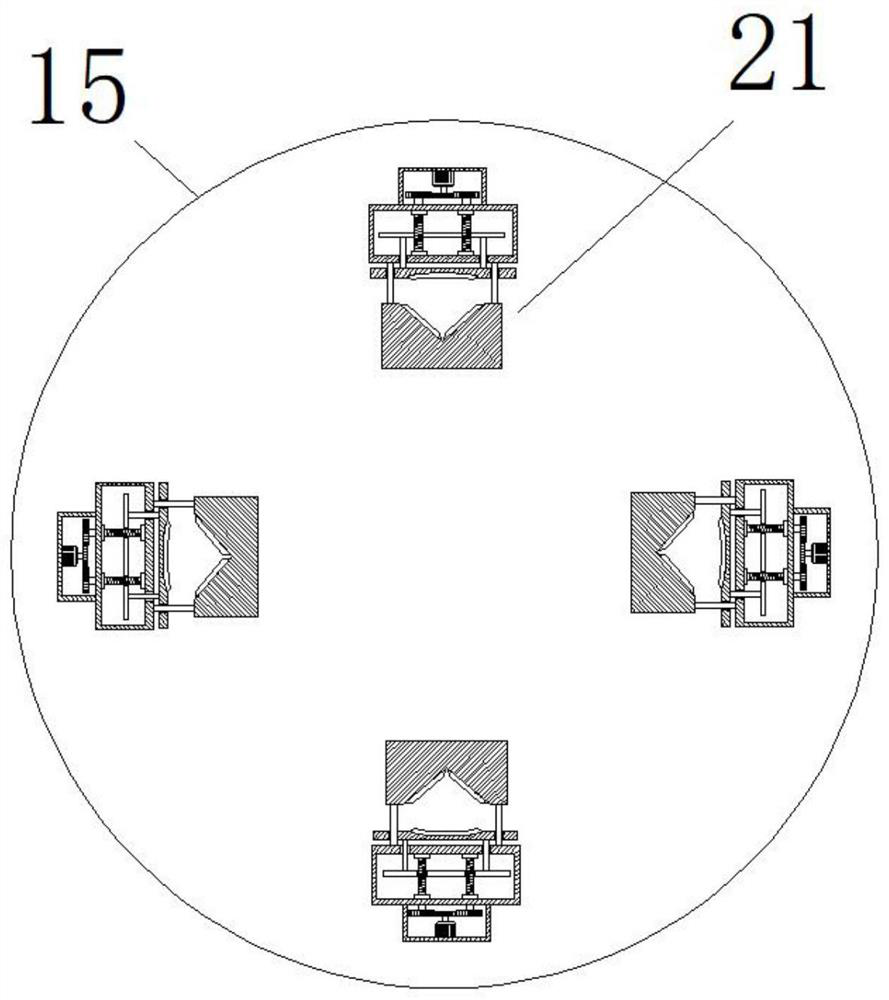

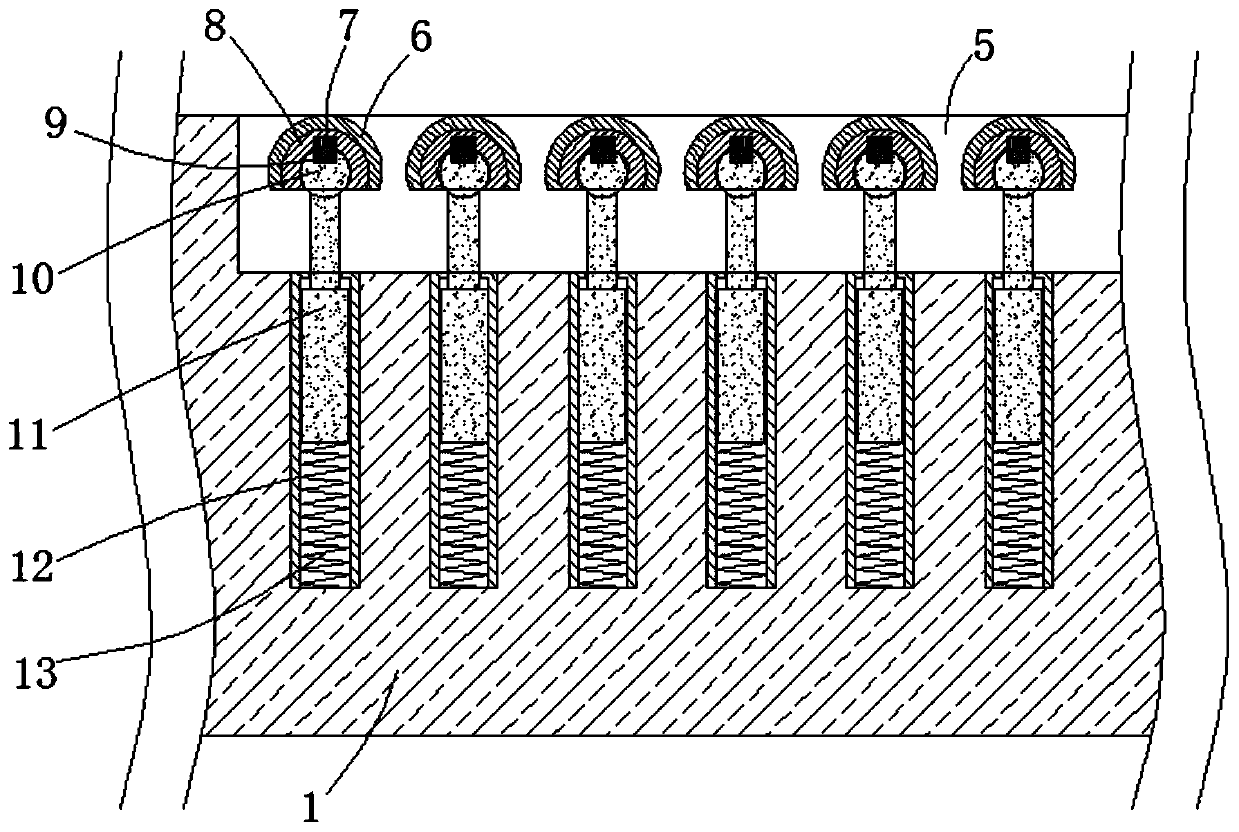

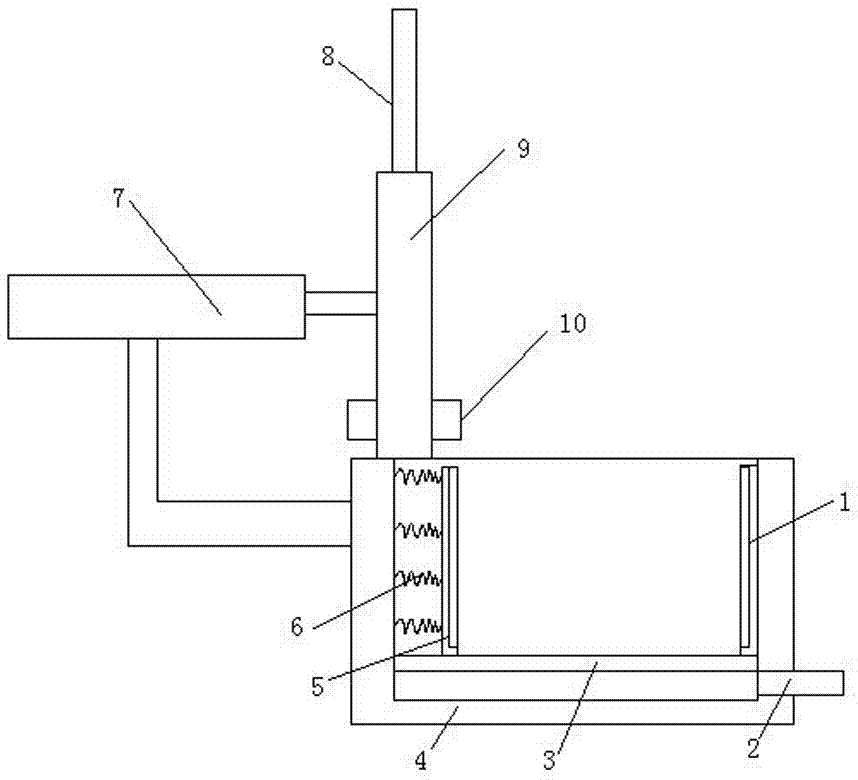

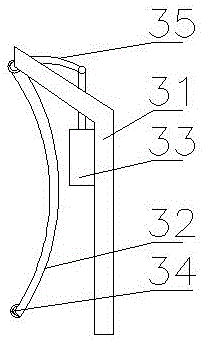

Combined measuring method and device for stretching, compressing, bursting and prick-cut

InactiveCN1587964AEasy to holdQuick gripMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesYarnFiber

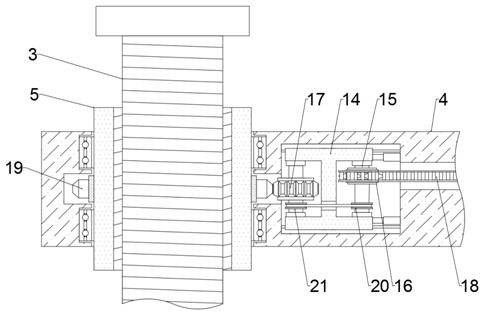

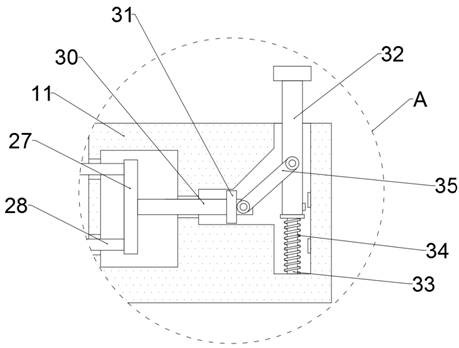

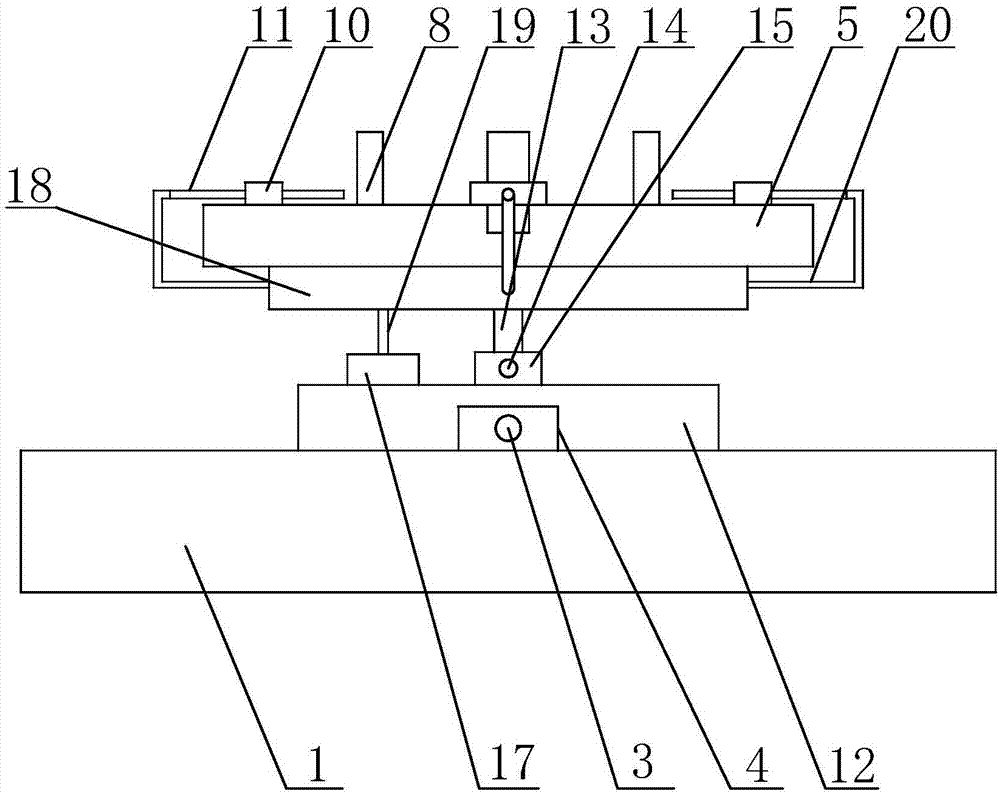

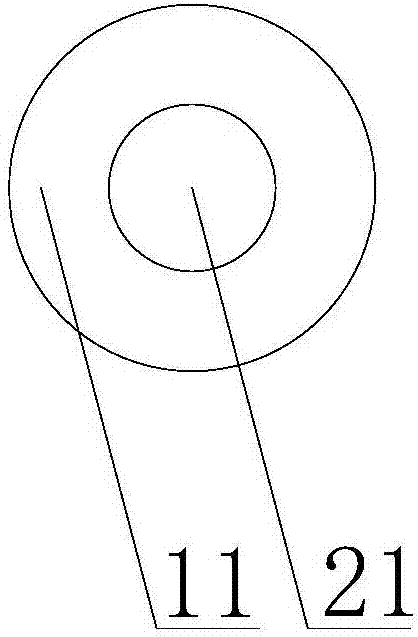

The invention relates to a combining ability and displacement measuring method and device of textile materials containing fiber, yarn, cloth, film and composite material, by which combining ability-displacement curve and stress-strain carve and measurement of associative characteristic value are obtained. The measuring device is consisted of multi-functional clamper suitable for textile materials, frame top beam, middle beam and under beam where sensor and multi-functional clamper can be installed, driving element controlled by middle beam, force and displacement signal collection card And computer with modules of program control and data processing. The invention includes the following properties that force sensor can be fitted on anywhere of the under beam, which can measure force value of moving terminal, and its structure is simple, operation is convenient and multi-functional clamper can be replaced fast and conveniently.

Owner:DONGHUA UNIV

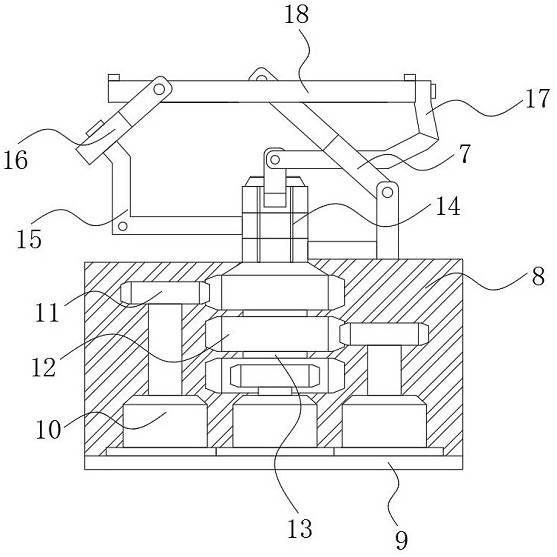

Portable material clamping mechanical arm

The invention discloses a portable clamping mechanical arm, which comprises a base, a supporting platform, a rotating disk, a mounting frame, a lifting slider, a mounting plate, a supporting beam, a sleeve and arc-shaped clamping teeth, and the right bottom surface of the supporting beam is opened. There are slide rails, the slide rails have a T-shaped structure, and there is a translation slider sliding inside the slide rail. The lower surface of the translation slider is fixedly installed with a connecting piece, and the bottom fixing frame of the connecting piece is equipped with a No. A sleeve with the opening facing downward is installed on the outer wall of the lower end of the cylinder. A hinge shaft is provided at the bottom of the output shaft of the No. 2 telescopic cylinder. Connected with tension spring. The invention is simple in structure, reasonable in design, flexible in use, can realize fast clamping of materials, facilitates the movement of the clamped materials in space, saves manpower and material resources, greatly improves work efficiency, and is suitable for popularization and use.

Owner:喻为科技服务(上海)有限公司

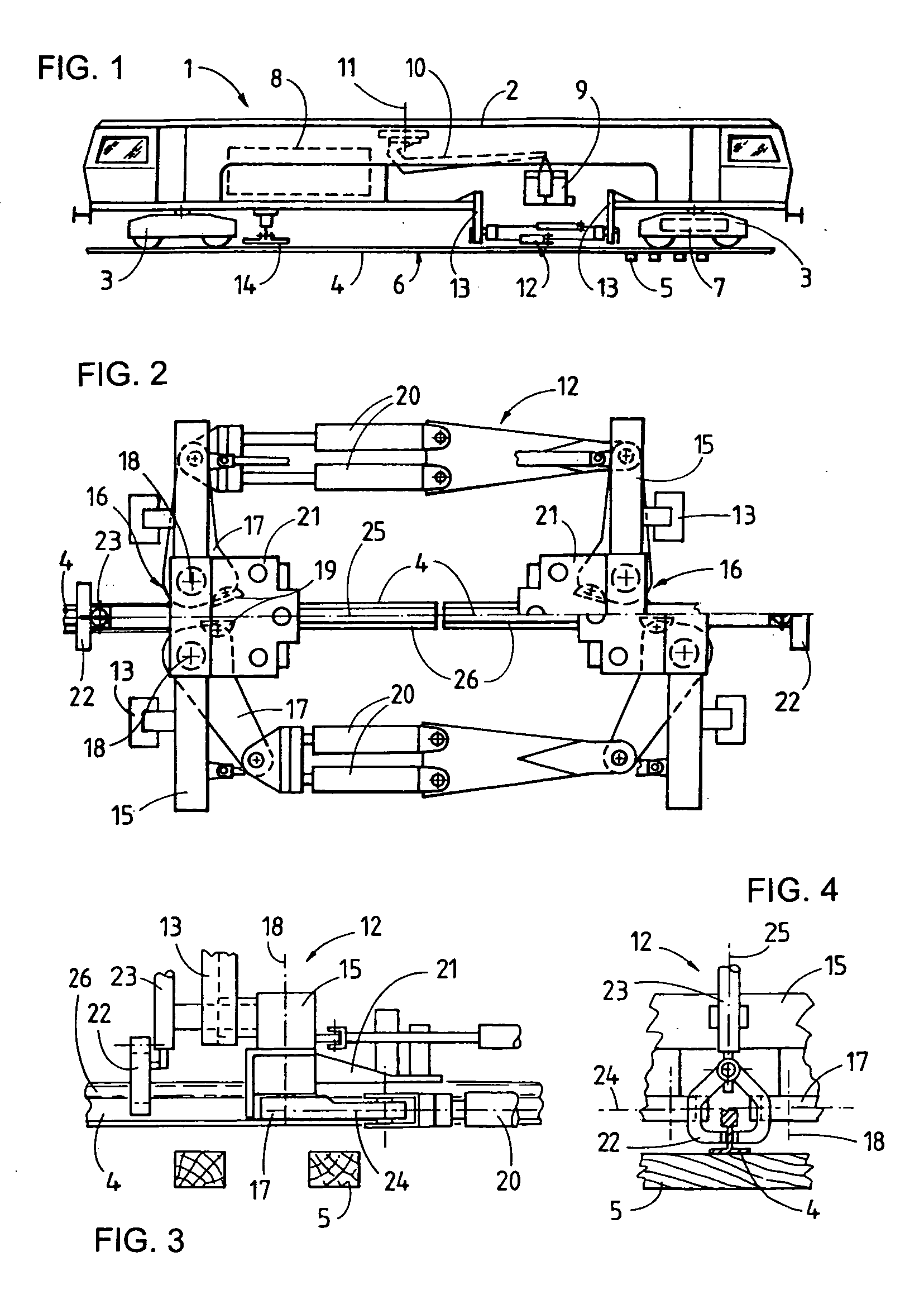

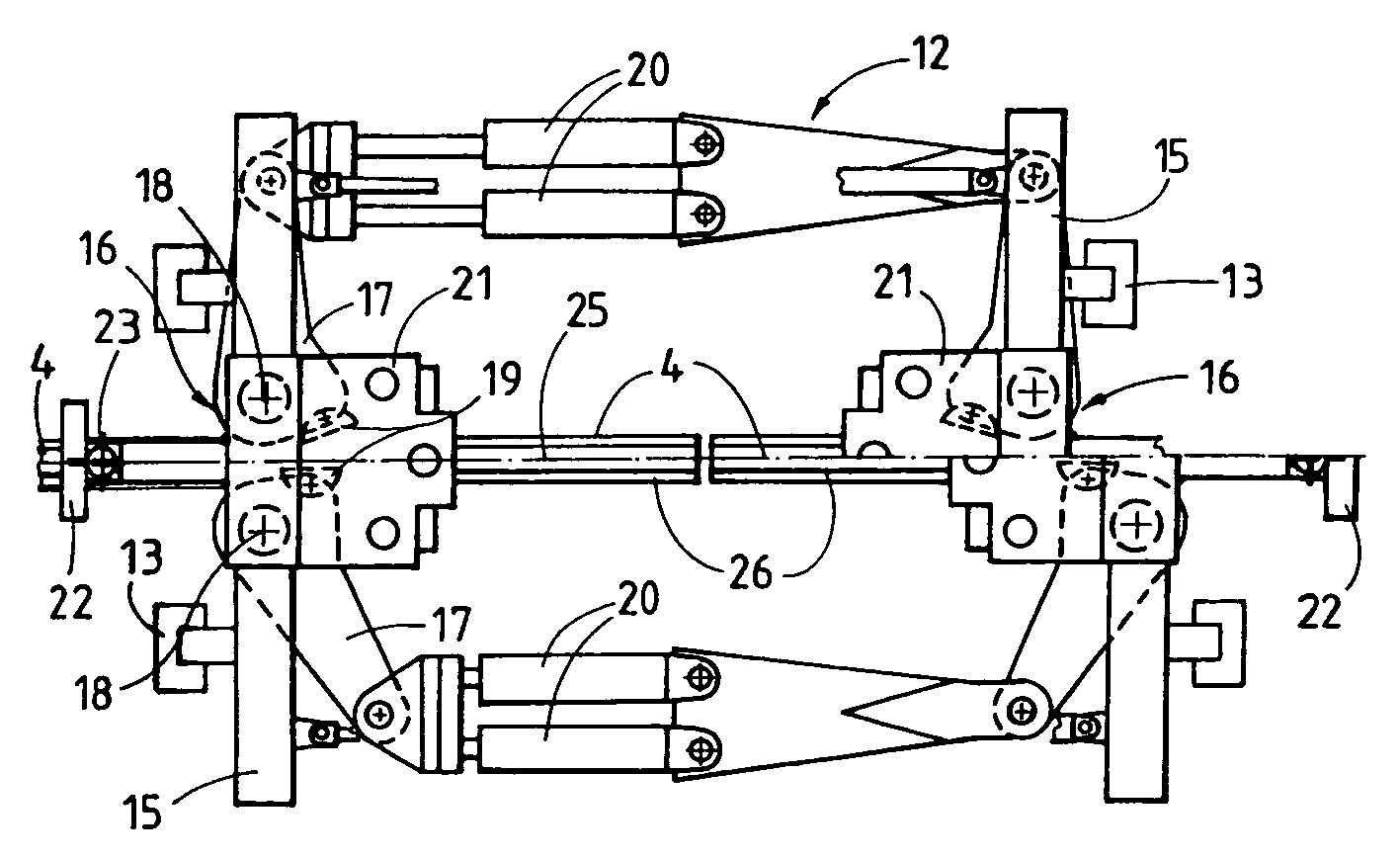

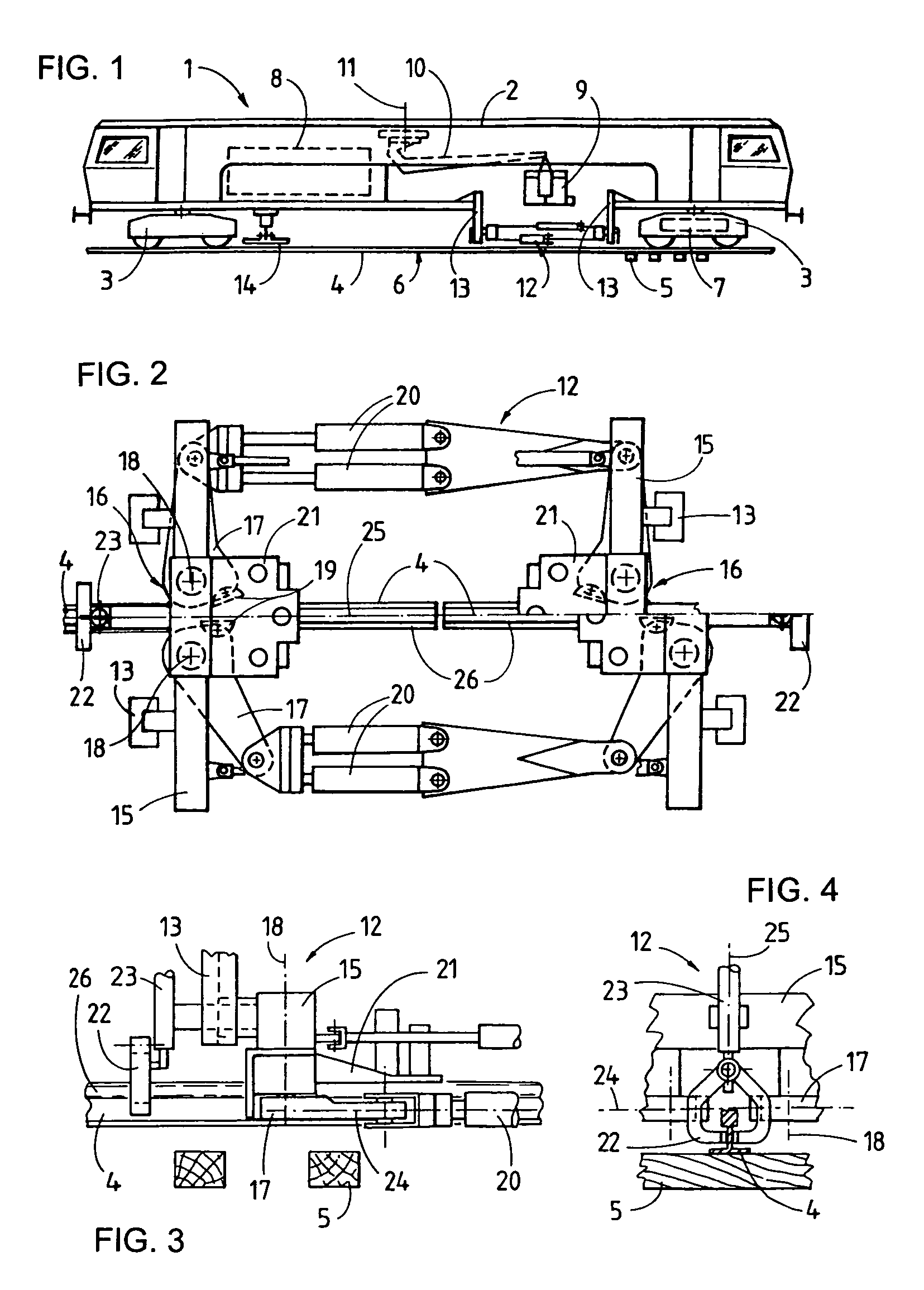

Machine and method for welding rails of a track

InactiveUS20060261044A1Simplify mannerQuick and precise and automatically executable grippingRailsBallastwayEngineeringMechanical engineering

A machine for welding the rails of a track includes a rail pulling device that grips the rail ends and pulls them together so that they can be welded to one another. Two rail clamps provided for gripping the rails are fastened to the rail pulling device. The rail clamps are each vertically adjustable in their position relative to the rail pulling device by way of a respective adjustment drive in a direction extending perpendicularly to a pulling device plane formed by hydraulic drives of the rail pulling device. With this, the rails can be lifted from ties in a simple manner in order to enable the clamping members of the rail pulling device to grip the rails.

Owner:FRANZ PLASSER BAHNBAUMASCHINEN IND GMBH

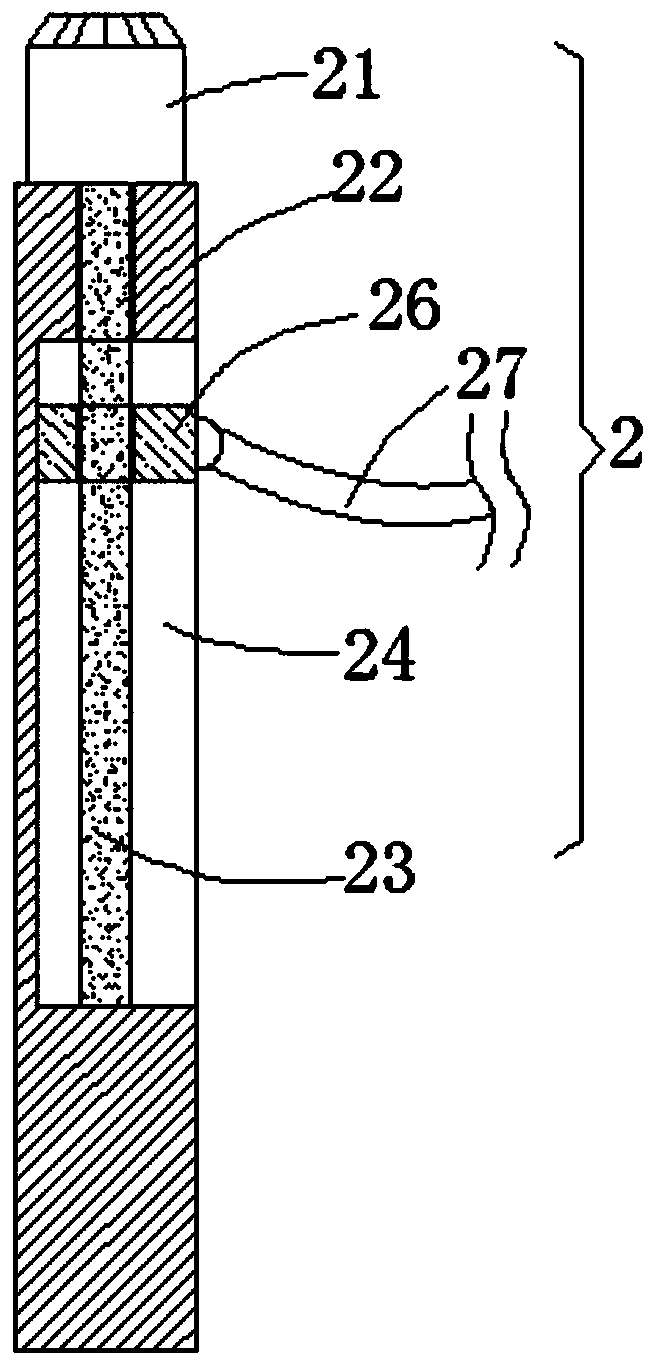

Pneumatic banana spike stem clamping device

InactiveCN104647231ACompact structureLight in massMachine part testingWork holdersEngineeringMechanical engineering

Owner:SOUTH CHINA AGRI UNIV

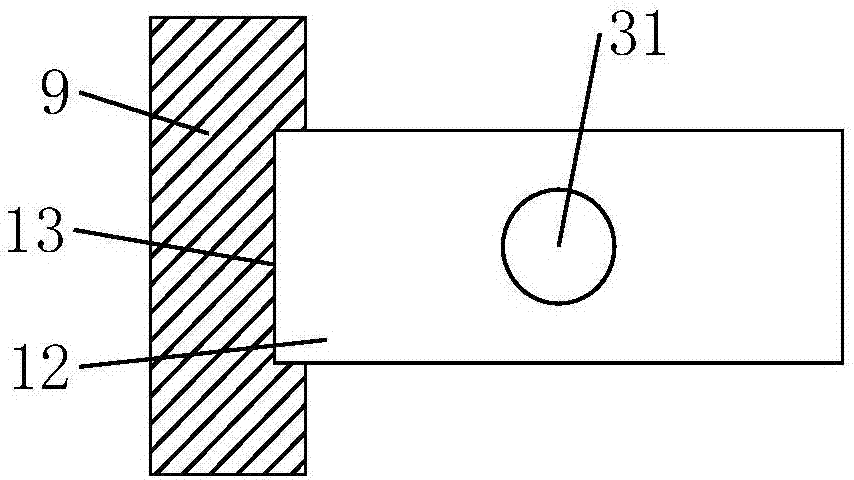

Edge contact clamping type wafer end actuator

InactiveCN101728302AQuick gripAccurate clampingPolishing machinesSemiconductor/solid-state device manufacturingUnresolved IssueThinning

The invention provides an edge contact clamping type wafer end actuator belonging to the technical field of chemical mechanical polishing equipment. The edge contact clamping type wafer end actuator comprises a wafer seat, the wafer seat is at least internally provided with two telescopic type edge contact clamping finger hooks which are connected with a telescopic device; and the wafer seat is at least provided with a third edge contact clamping contact. The invention well solves the problems which exist for a long time and are unsolved all the way in the prior art, clamps wafers in an edge contact way, fast, accurately and safely clamps the wafers without pollution, has simple structure, safe and convenient use and reduced cost, automatically determines the circle centers of the wafers and can be widely used for the processing, i.e. chemical mechanical polishing (CMP), grinding, thinning, and the like of the wafers.

Owner:THE 45TH RES INST OF CETC

Hardware pipe fitting surface polishing device

InactiveCN111730489AQuick gripImprove grinding efficiencyPolishing machinesGrinding drivesCircular discGrinding process

The invention discloses a hardware pipe fitting surface polishing device. A supporting base is included. The top end of the supporting base is fixedly provided with a supporting frame, a first vertical plate and a second vertical plate. A sliding block is arranged between the first vertical plate and the second vertical plate in a sliding manner. An installing groove is formed in the top end of the sliding block. A vertically-arranged first air cylinder is fixedly arranged in the installing groove. An output shaft of the first air cylinder is fixedly provided with a grinding machine. A first threaded rod is rotationally arranged between the first vertical plate and the second vertical plate. The sliding block is provided with a first threaded hole. The first threaded rod penetrates throughthe sliding block via the first threaded hole. The supporting frame is rotationally provided with a rotation shaft. The supporting frame is further fixedly provided with a rotation shaft drive mechanism. One end of the rotation shaft is fixedly connected with a rotation disc. The hardware pipe fitting surface polishing device is ingenious in structure and convenient to use, a plurality of pipe fittings can be rapidly fixed at the same time, the effects of automatic pipe fitting replacement and continuous grinding are achieved, the grinding efficiency is greatly improved, the pipe fittings cannot swing in the grinding process, and the grinding effect is better.

Owner:泉州台商投资区源平信息技术有限公司

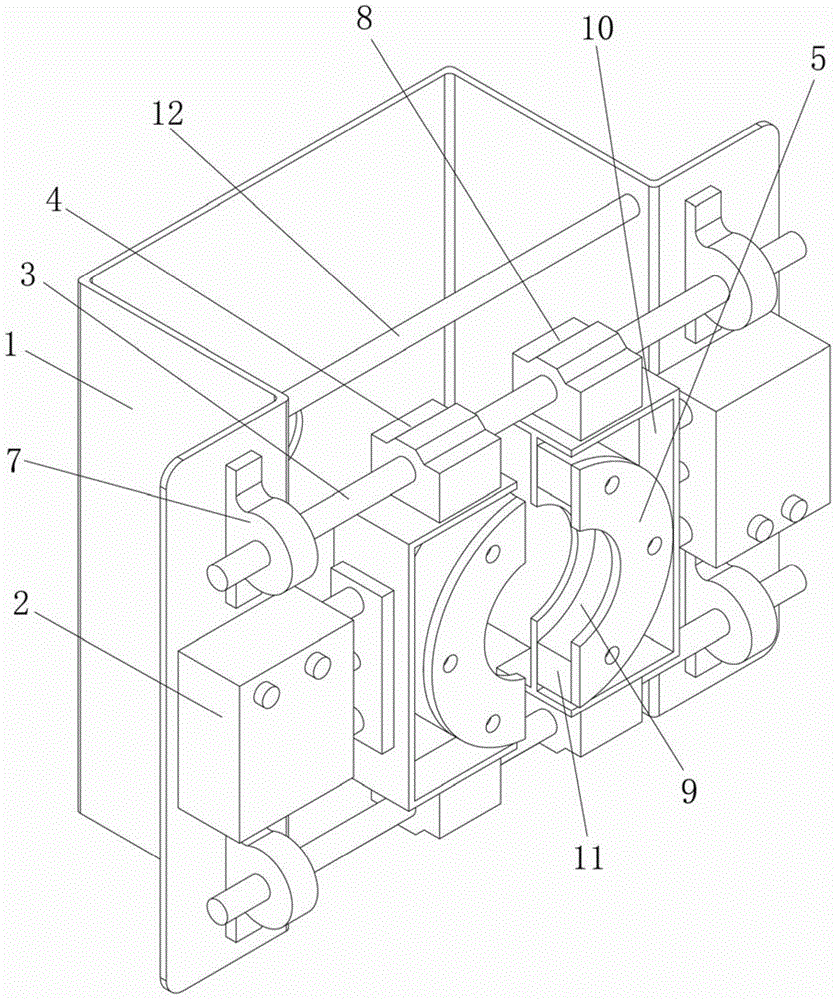

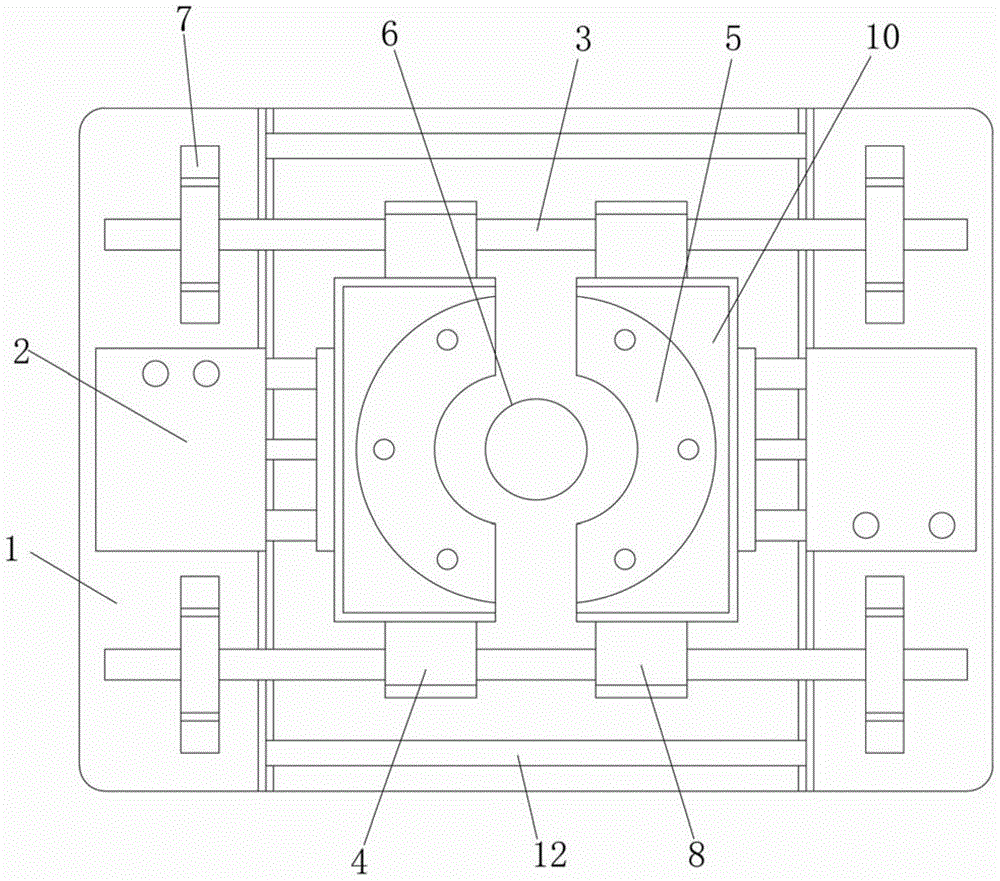

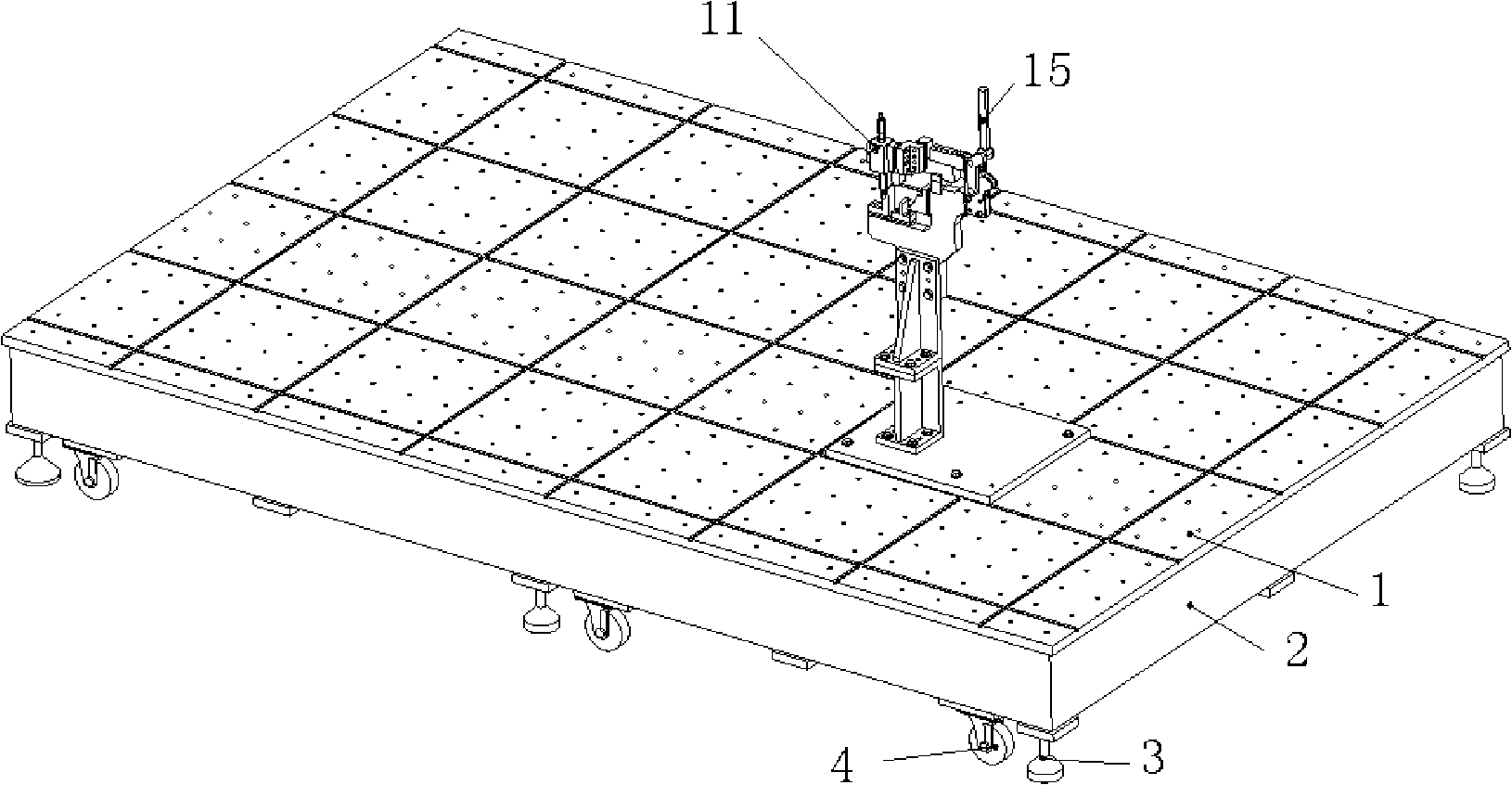

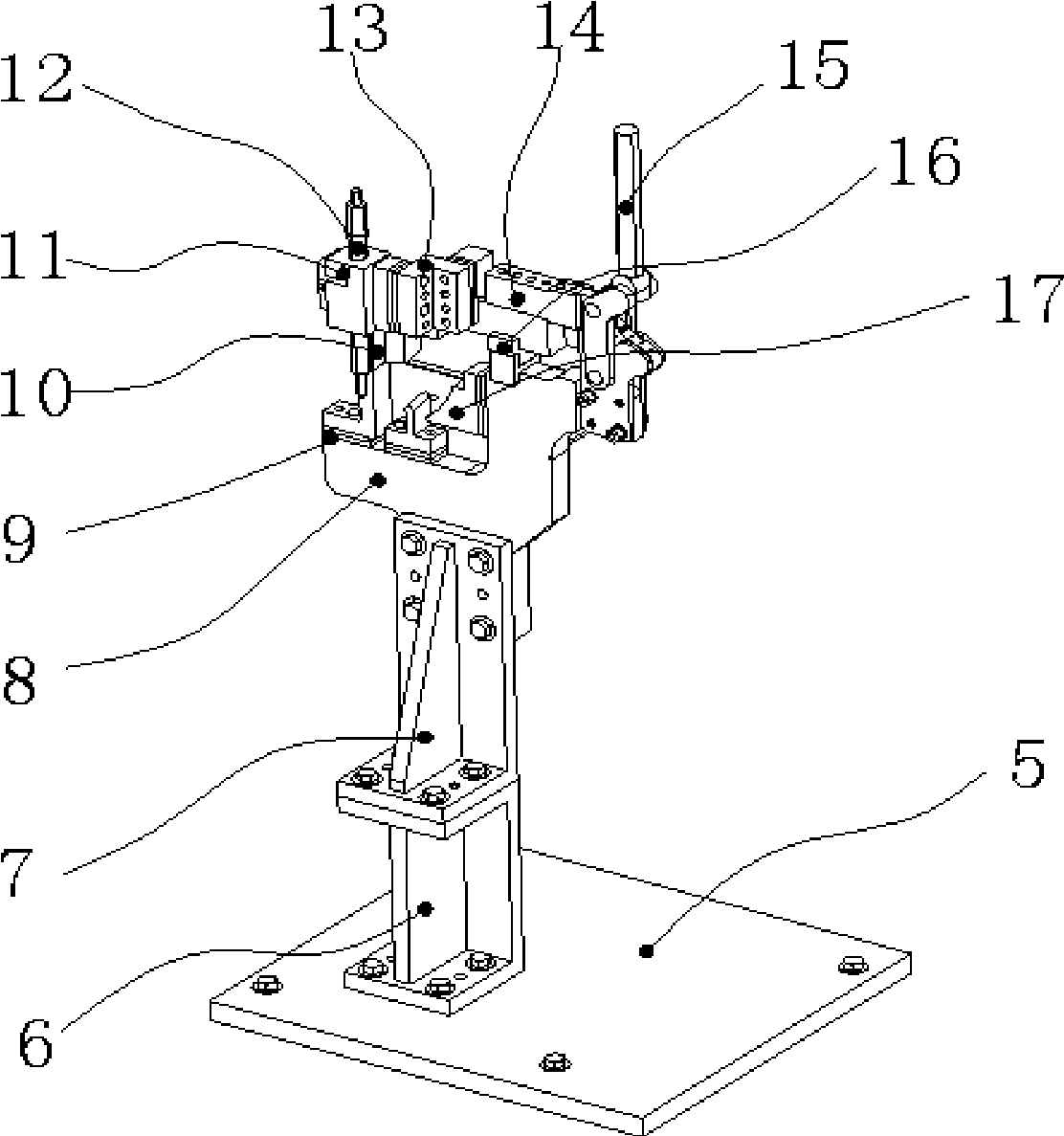

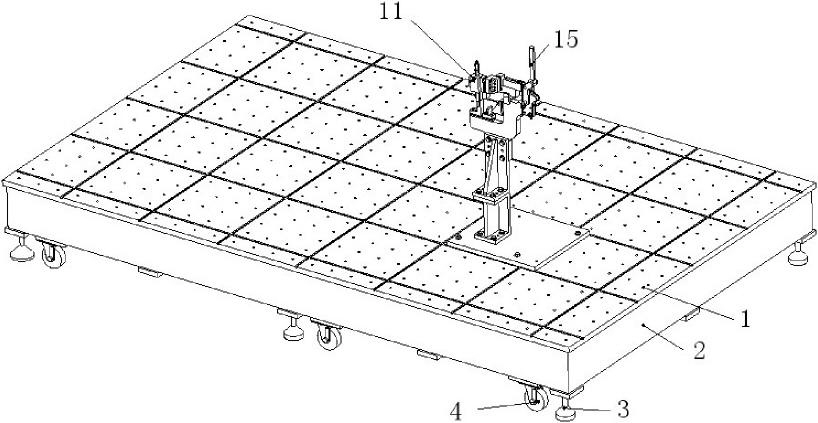

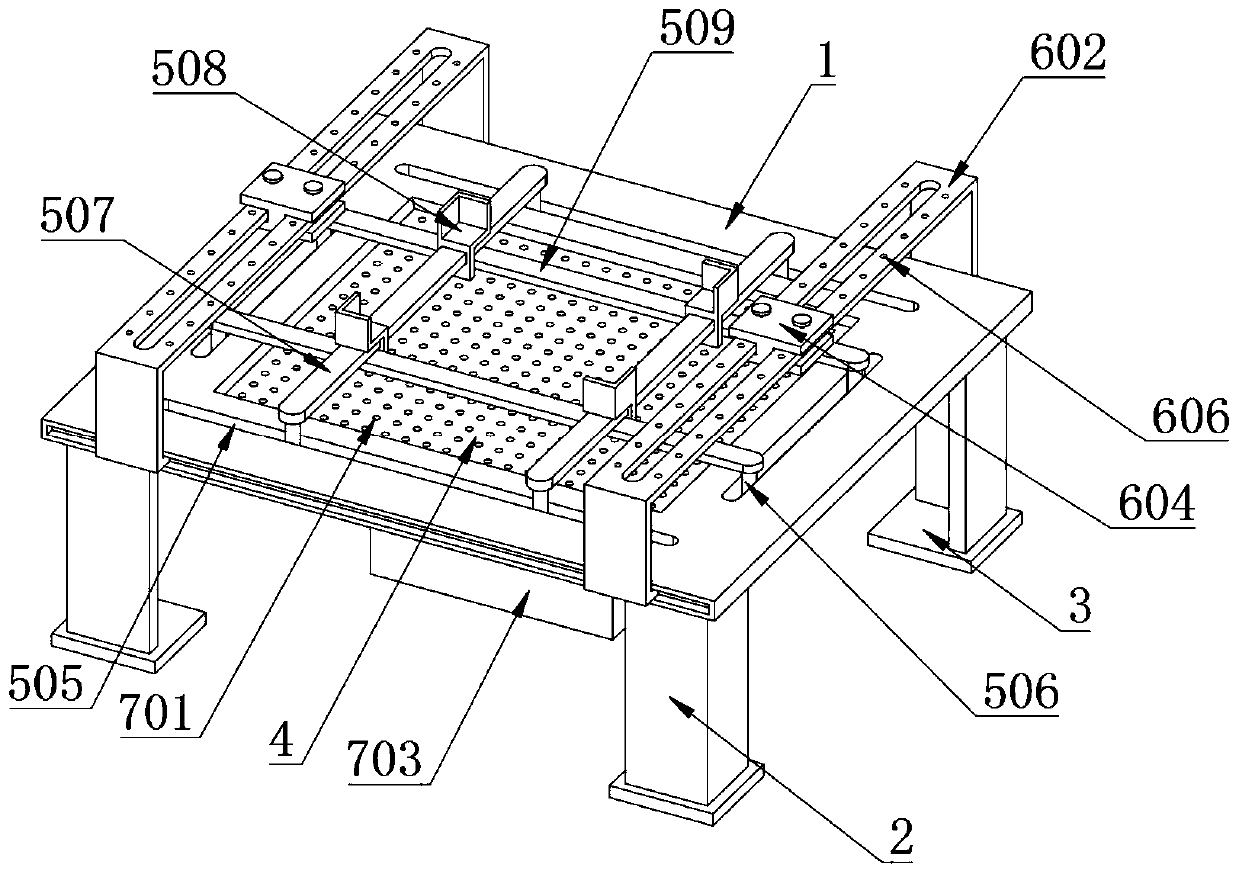

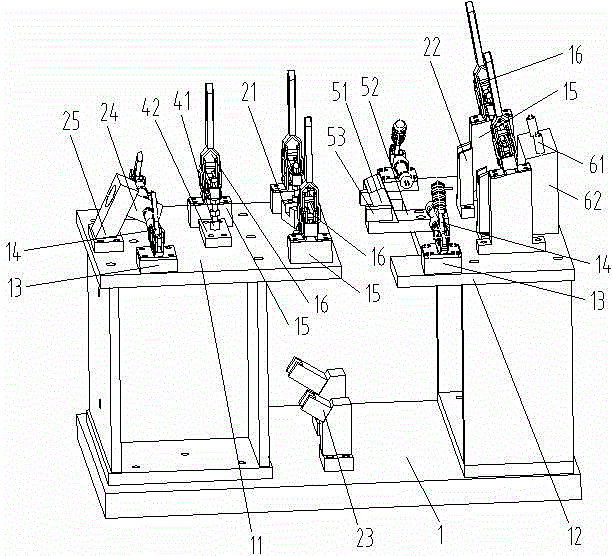

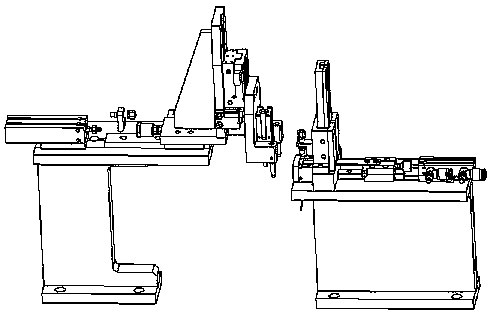

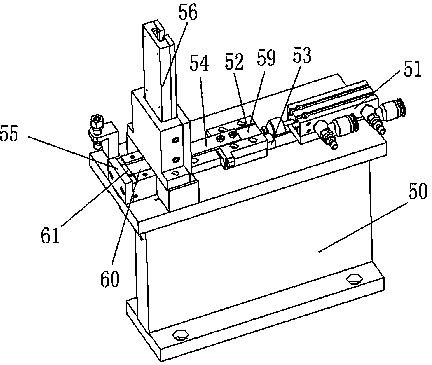

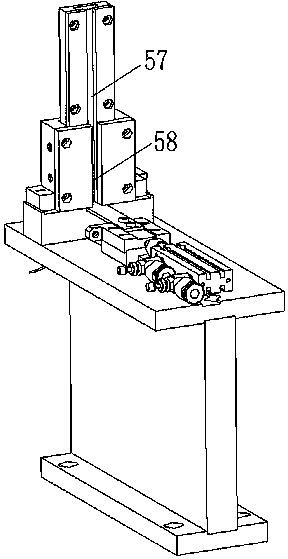

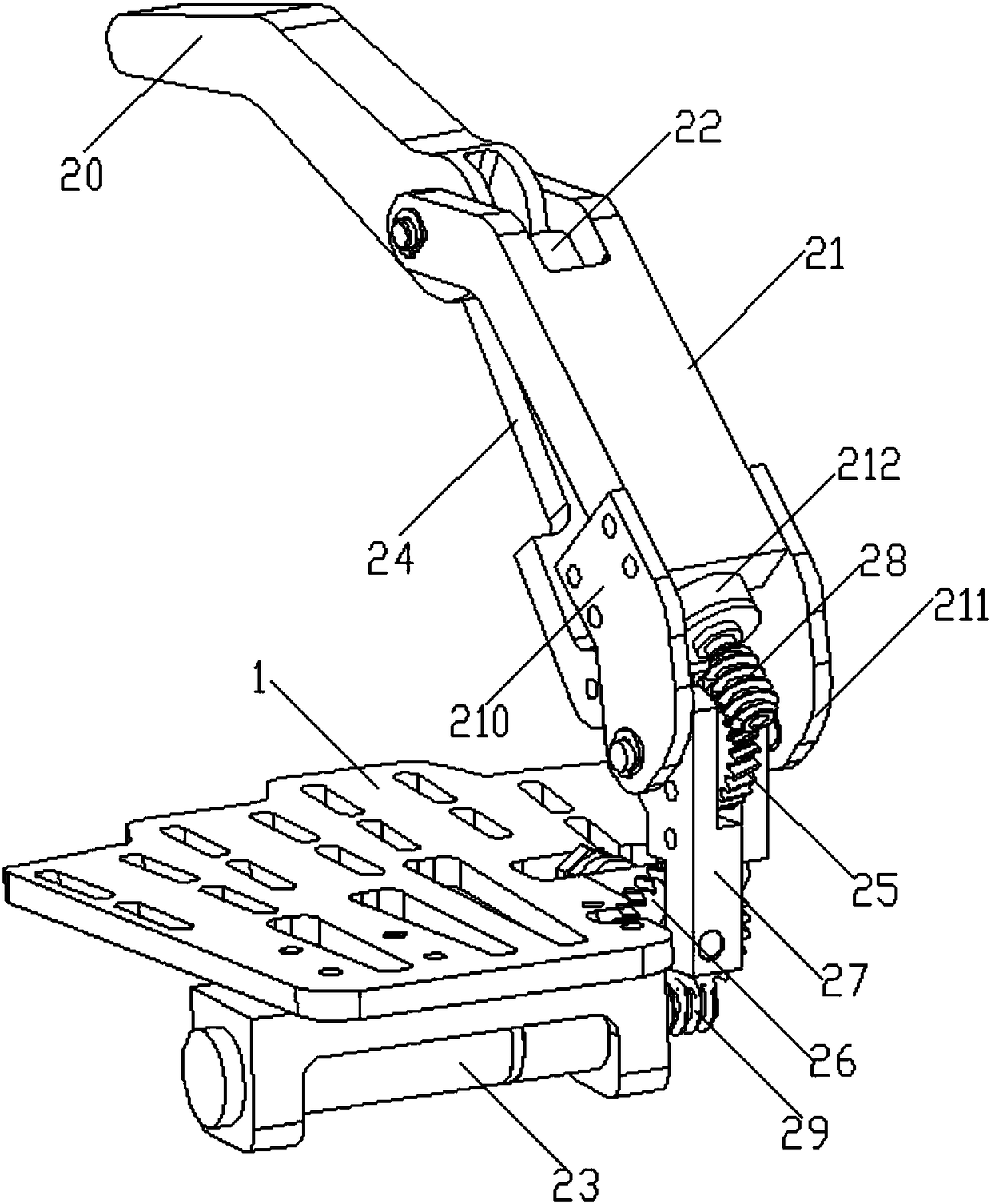

Modular design method and structure of welding fixture for trial-manufacture sample vehicles

ActiveCN101905403ASimple design methodShorten the design and production cycleWelding/cutting auxillary devicesAuxillary welding devicesModular designModularity

The invention relates to the technical field of automobile manufacturing equipment, in particular to a modular design method and a modular design structure of a welding fixture for trial-manufacture sample vehicles, which solve the problems of incapability of recycling, long design and manufacturing period and high manufacturing cost of sample vehicle trial-manufacture fixture parts of automobiles in the prior art. The welding fixture comprises a base and a fixture unit arranged on the base; structural members with the same functions in the welding fixture for the trial-manufacture sample vehicles are formulated into standard or standard series parts in the process of design and development to form a fixture module series, so that the standard or standard series parts are recycled in the development of the welding fixture for new type trial-manufacture sample vehicles and the welding fixture for small-lot vehicles, and non-standard parts in the fixture are subjected to structural design; and the standard parts and the non-standard parts in the welding fixture for the trial-manufacture sample vehicles are matched to form novel and complete welding fixture equipment for the trial-manufacture sample vehicles. Through the modular design method and the modular design structure, the aims of shortening the design and manufacturing period, recycling general and standard parts and reducing manufacturing cost are fulfilled.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

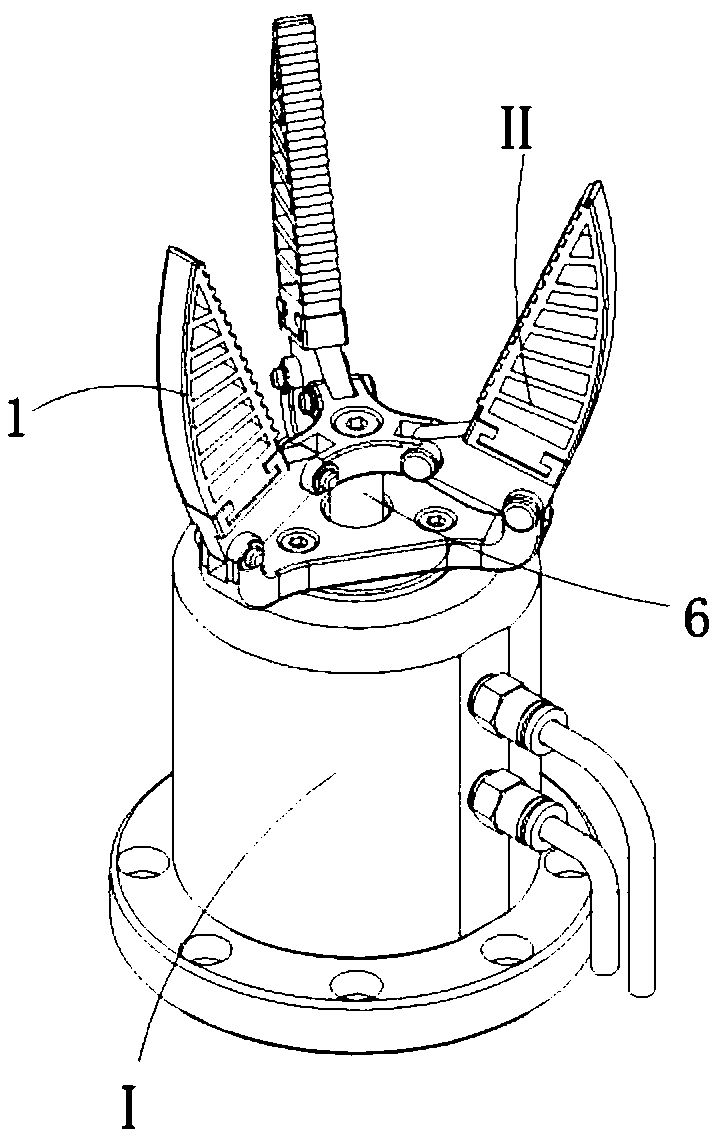

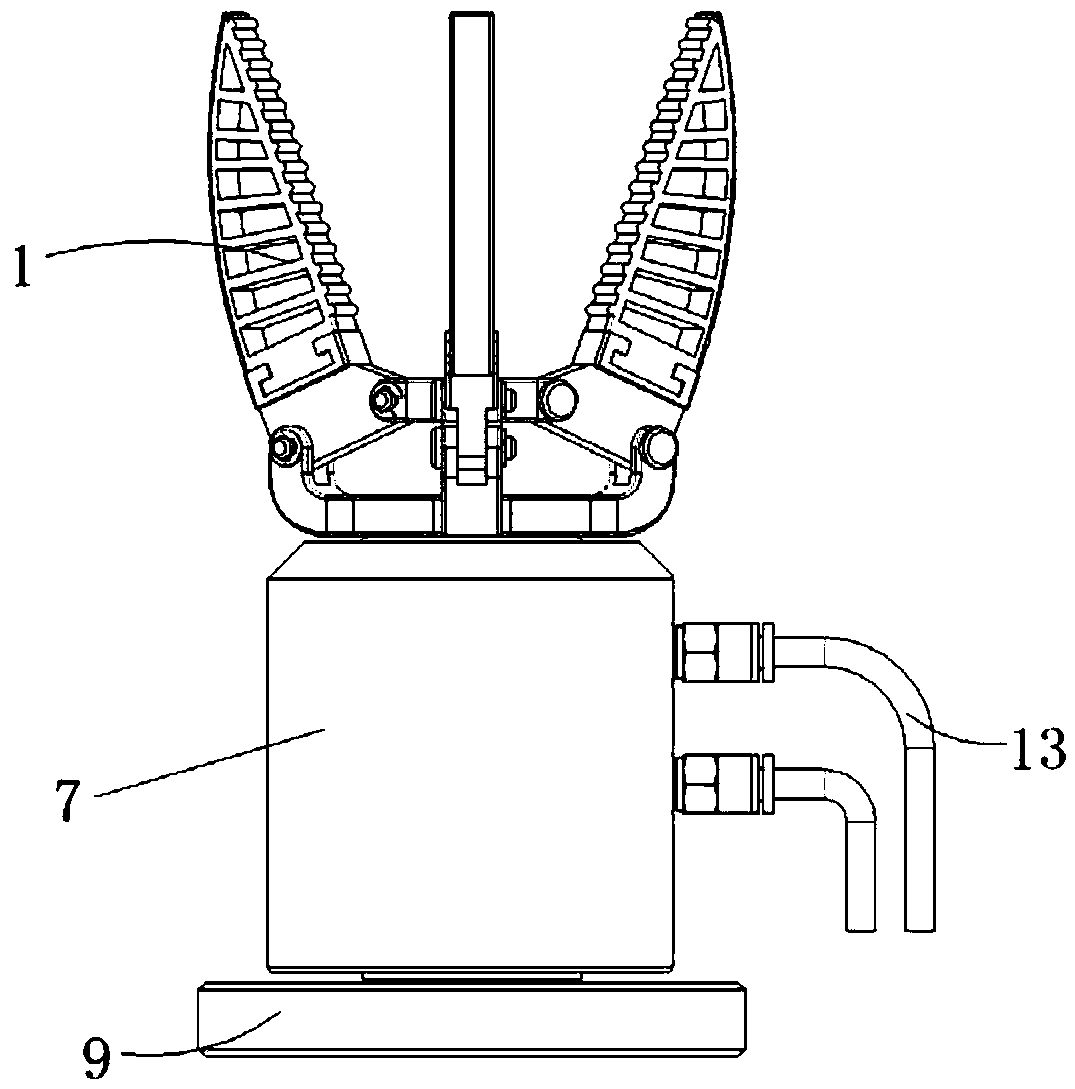

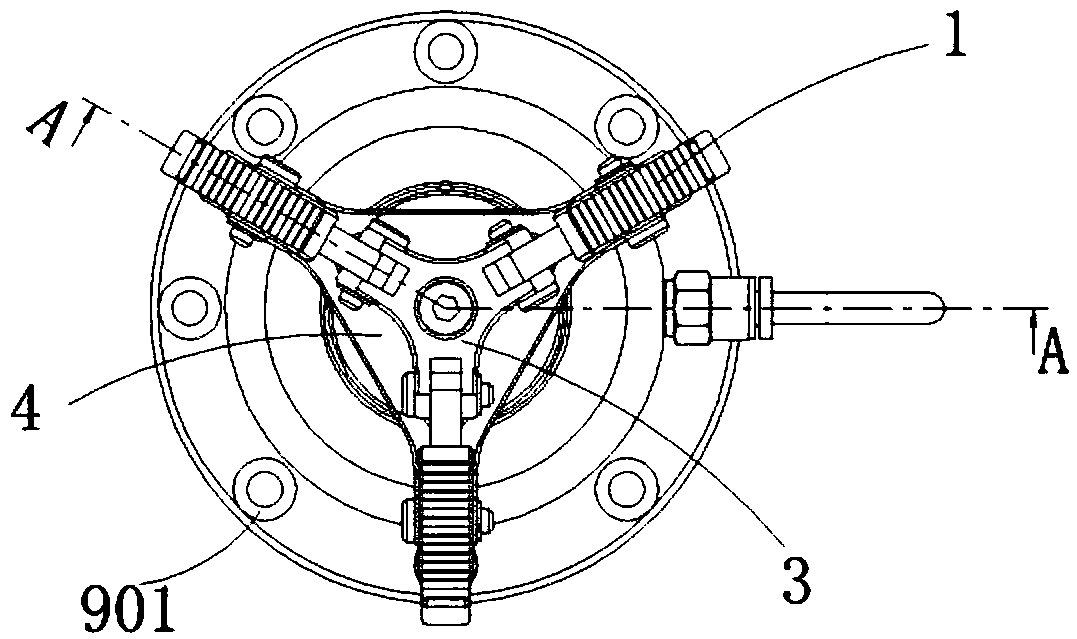

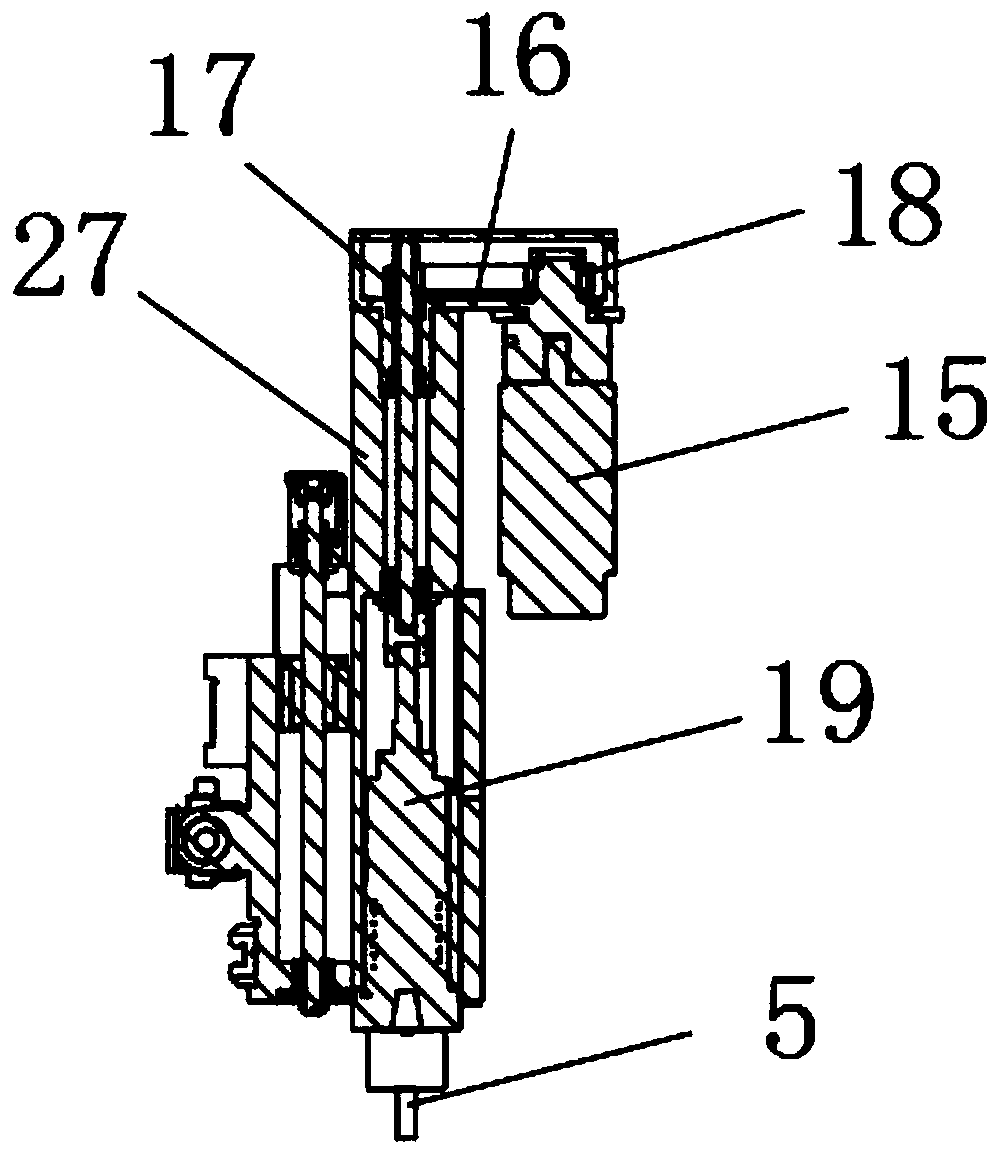

Flexible clamping jaw

The invention relates to a flexible clamping jaw comprising a cylinder driving mechanism and a clamping jaw assembly movably arranged on the cylinder driving mechanism. The cylinder driving mechanismcomprises a cylinder body and a gas guide ring rotationally arranged on the periphery of the cylinder body. A piston is arranged in the cylinder body. A support is arranged on the upper portion of thecylinder body, and the piston penetrates through the support. A connecting rod is connected to the upper end of the piston. The clamping jaw assembly comprises a clamping jaw fixing seat and clampingjaws. One end of the clamping jaw fixing seat is hinged to the support. The other end of the clamping jaw fixing seat is hinged to the connecting rod. An upper flow guide hole and a lower flow guidehole are formed in the cylinder body. The gas guide ring is provided with gas pipe connectors communicating with the upper flow guide hole and the lower flow guide hole. A valve-controlled gas channelis arranged outside the flexible clamping jaw to drive the clamping jaws to move, thus the rubber clamping jaws clamp an object, under the circumstance of extrusion, the clamping jaws generates self-adaptive deformation to be tightly attached to the surface of the grabbed object into a package state, meanwhile a pipeline on the gas guide ring is not wound due to rotation when the cylinder body rotates, and the original direction and state are maintained all the time.

Owner:SUZHOU QIAOYUE SOFTWARE

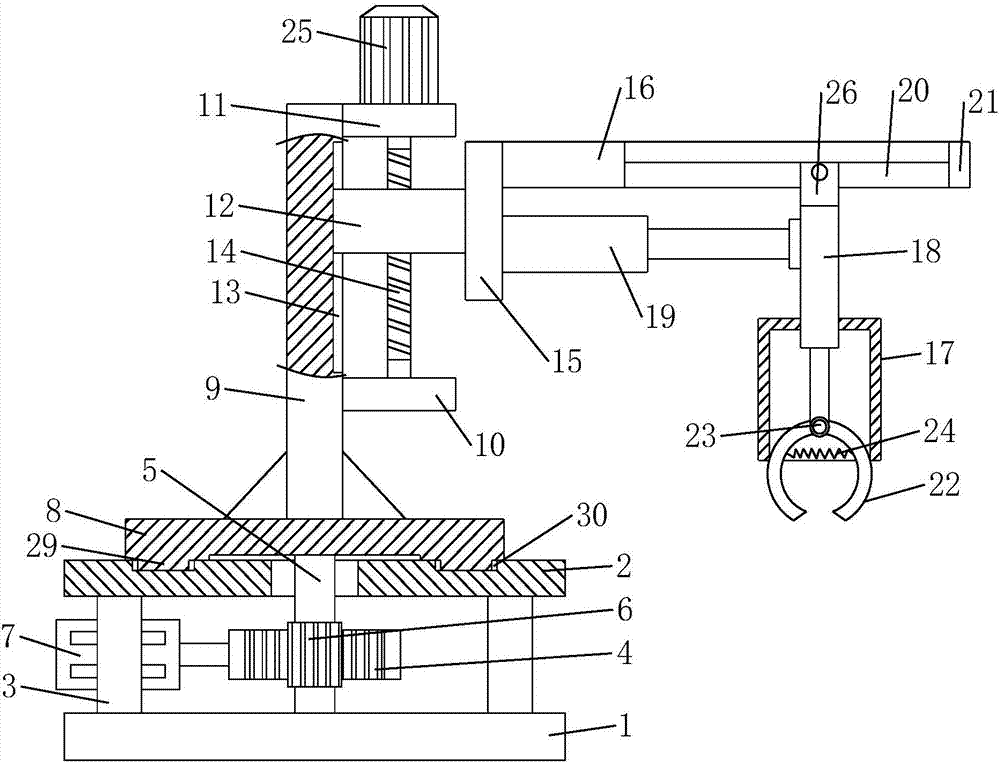

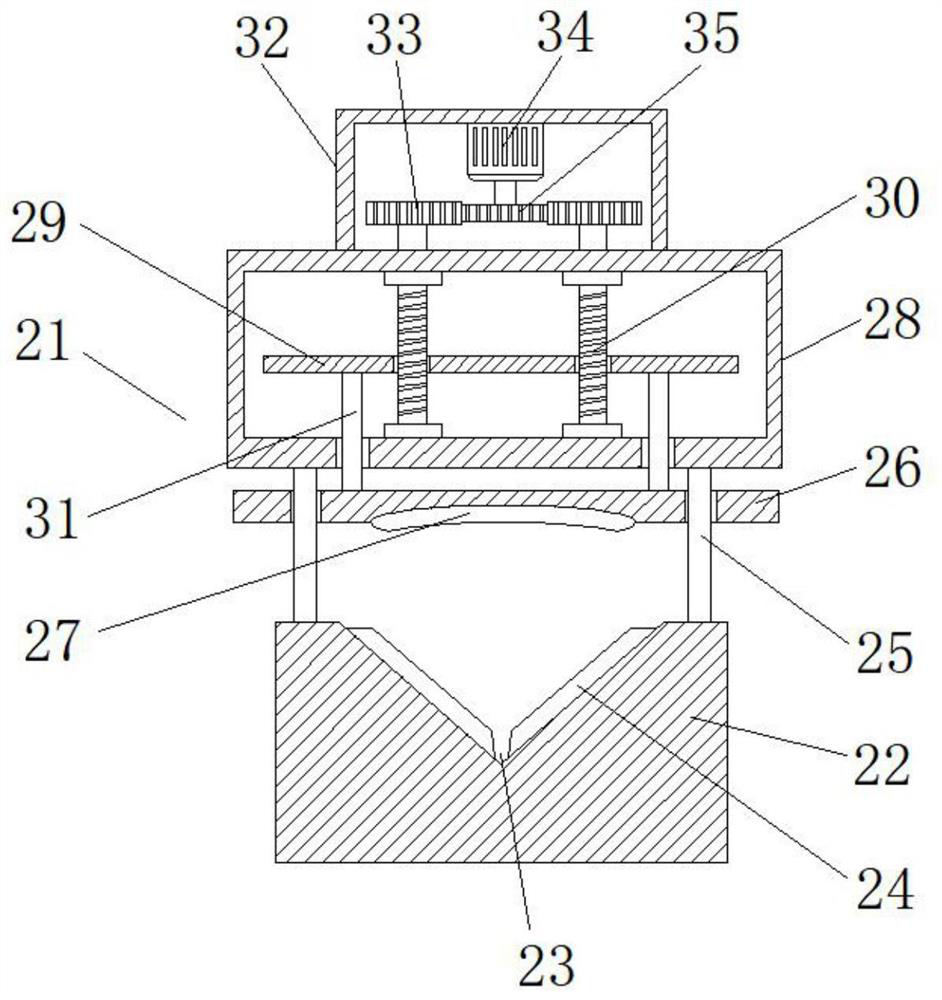

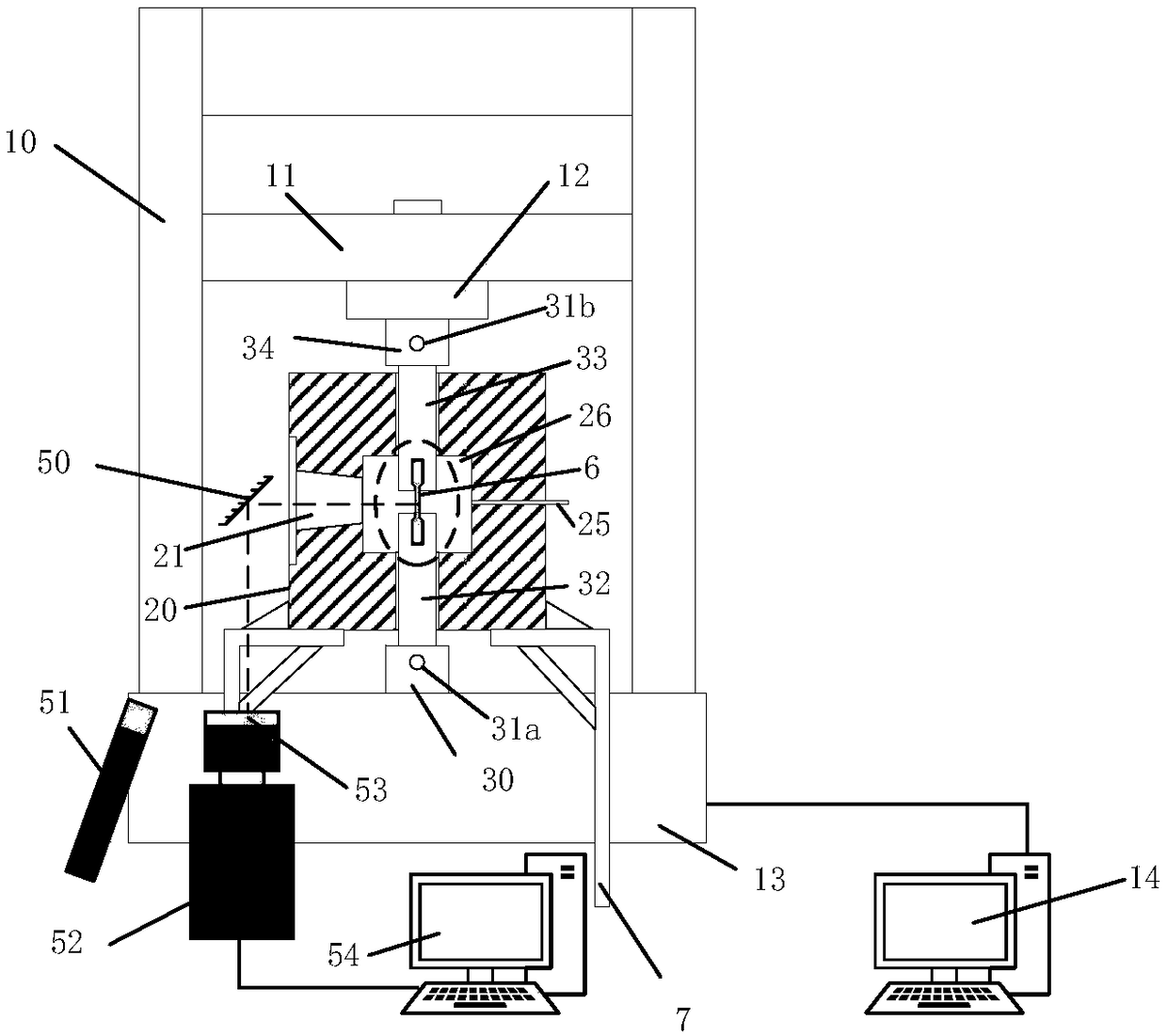

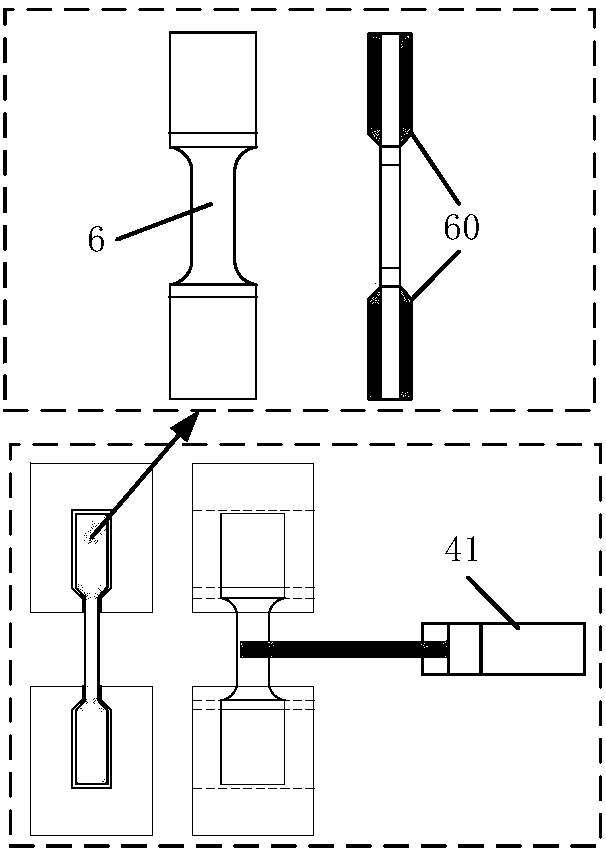

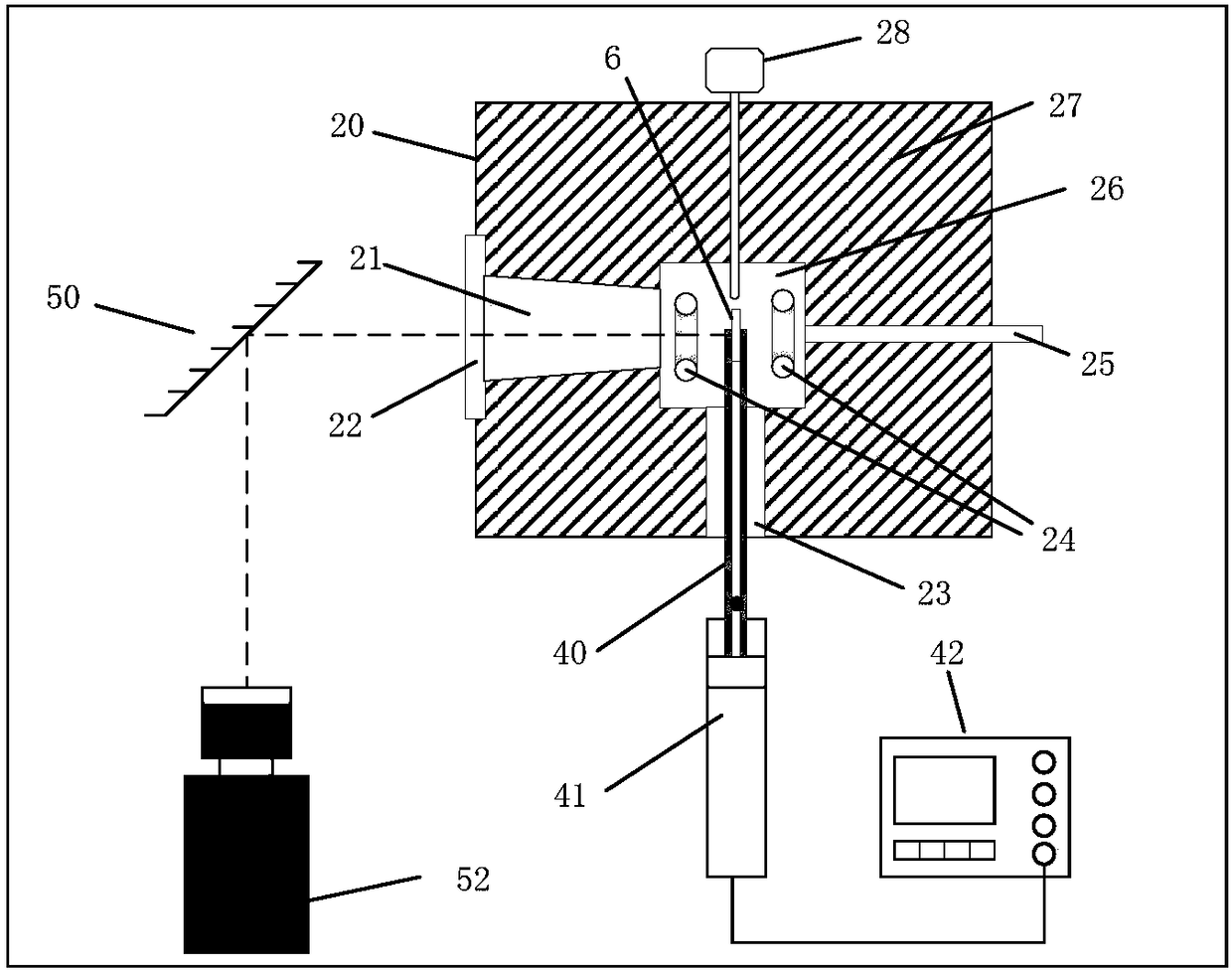

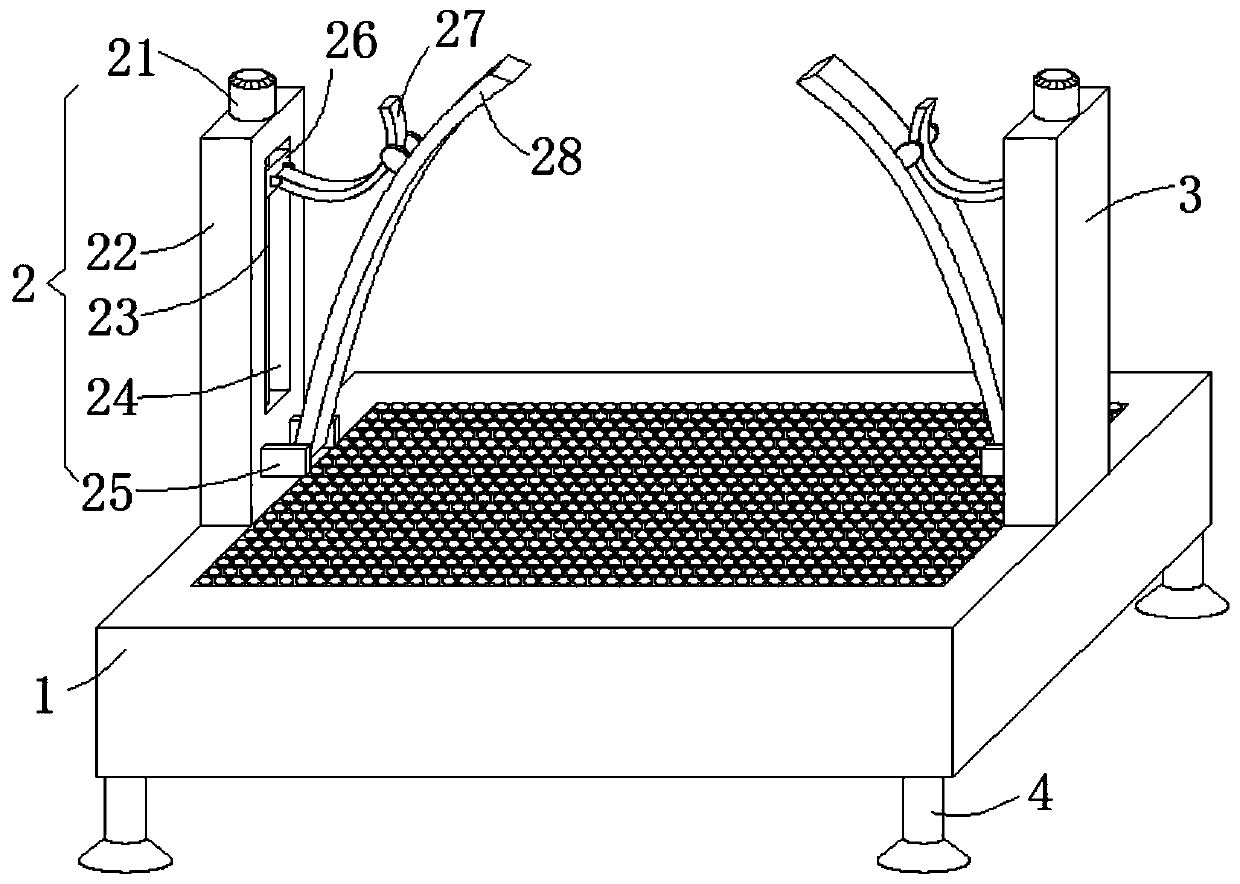

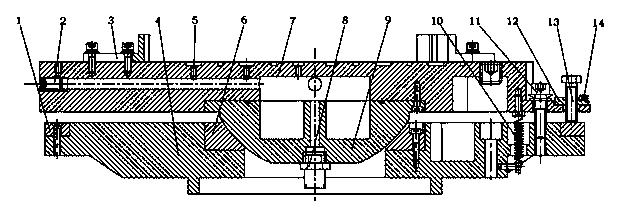

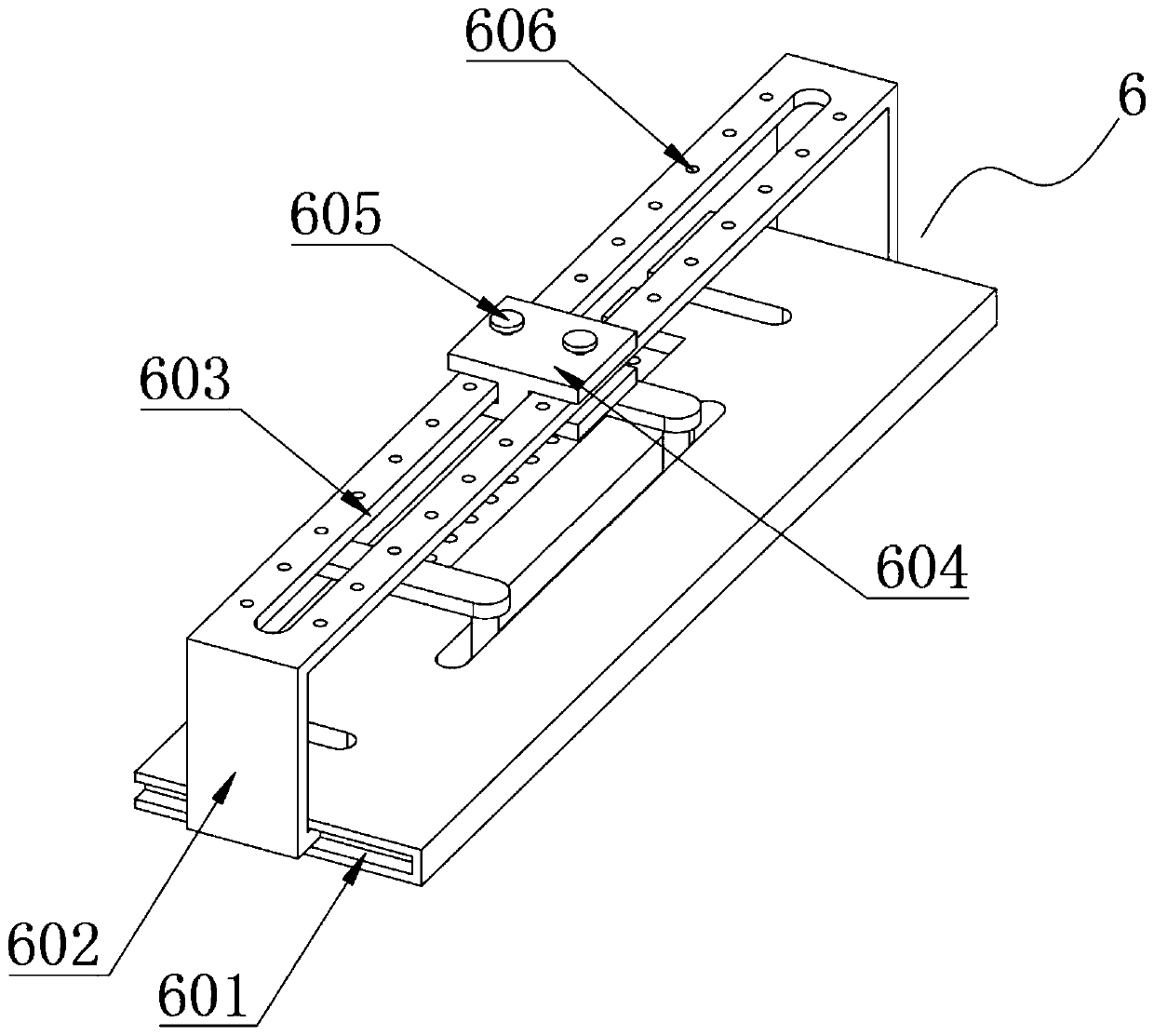

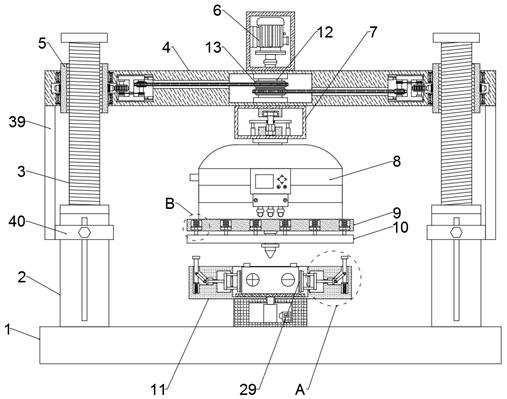

High-temperature tensile experiment device and method

ActiveCN108344644AHeating fastQuick gripMaterial strength using tensile/compressive forcesPlane mirrorShielding gas

The invention discloses a high-temperature tensile experiment device and method. The device comprises a static loading system, a sample clamping system, a sample heating system, a sample pushing system and an image collecting and processing system; the static loading system comprises an universal testing machine, a loading cross beam, a force sensor and a base; the sample sampling system comprisesa lower adapter, a lower clamp, an upper clamp and an upper adapter; the sample heating system comprises a heating furnace body, an observation window, quartz glass located outside the observation window, a sample channel, a heating element, a shielding gas inlet hole and a heating cavity; the sample pushing system comprises a sample clamping head, a guide rail and a controller; the image collecting and processing system comprises a plane mirror, a light source, a video camera, a filter lens and a second computer. A sample can be rapidly heated and warmed, the testing machine can be clamped,and meanwhile the deformation and damage process of the sample under the high-temperature tensile load can be captured.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Clamping mechanism for grinding and polishing robot system for high-temperature alloy mechanical parts of engine

InactiveCN110281111AImprove stabilityQuick gripGrinding drivesGrinding feed controlRobotic systemsSuperalloy

The invention discloses a clamping mechanism for a grinding and polishing robot system for high-temperature alloy mechanical parts of an engine. The clamping mechanism comprises a workbench and a data processing module, wherein the data processing module is embedded in an inner chamber of the workbench. A first supporting mechanism and a second supporting mechanism are vertically arranged at the middle segment positions of the left side and the right side of the top end face of the workbench respectively. The first supporting mechanism and the second supporting mechanism both comprise supporting columns, and servo motors are fixedly arranged on the top end faces of the two supporting columns. The two servo motors are connected with threaded rods respectively through power shafts, the outer walls of the two threaded rods are rotationally sleeved with lifting sliding blocks through external threads, and the lifting sliding blocks are respectively positioned in inner chambers of two rectangular lifting grooves. The positions, being 1 / 4 of the distance from the top end, of the outer walls of two arc-shaped clamping blocks are respectively hinged with the side walls at quarter of the tip ends of two hinged plates, and pressure sensors are embedded in the top ends of the opposite side walls of the two arc-shaped clamping blocks. The clamping mechanism is convenient to quickly clamp the parts to be ground and polished, can ensure the good clamping stability, can also ensure no slippage in the grinding and polishing process, and improves the grinding and polishing precision.

Owner:NANJING YUSHENG ROBOT CO LTD

Leveling tool

InactiveCN103522102AQuick gripImprove complianceAutomatic control devicesPositioning apparatusSupport pointMachining

The invention discloses a leveling tool, and belongs to the field of mechanical devices. The leveling tool needs using in the machining, assembling adjustment and checking processes to reliably clamp and position a workpiece. Leveling of an existing tool is completed by adjusting an adjustment screw or adjustable support of the tool; because different supporting points need adjusting and manufacturing errors exist in the leveling process, different leveling directions in the same plane interfere in one another, repeated adjusting is needed, and leveling efficiency is low; a single clamping method can not meet clamping requirements of workpieces of different surface shapes and different specifications. The leveling tool aims to overcome defects in the prior art, mainly comprises an embedded ring, an air passage sealing nail, a mechanical clamping block, a lower disc, an air channel sealing nail, a lower spherical concave part, an upper disc, a vacuum suction joint, an upper spherical convex part, a tension spring, a lock screw, an adjusting nut, an adjusting screw and a stop screw, and solves the problems that the existing leveling tool is low in working efficiency and can not meet the clamping requirements of the workpieces of different surface shapes and different specifications.

Owner:LUOYANG JIANHAO HEAVY MACHINERY LIMITED

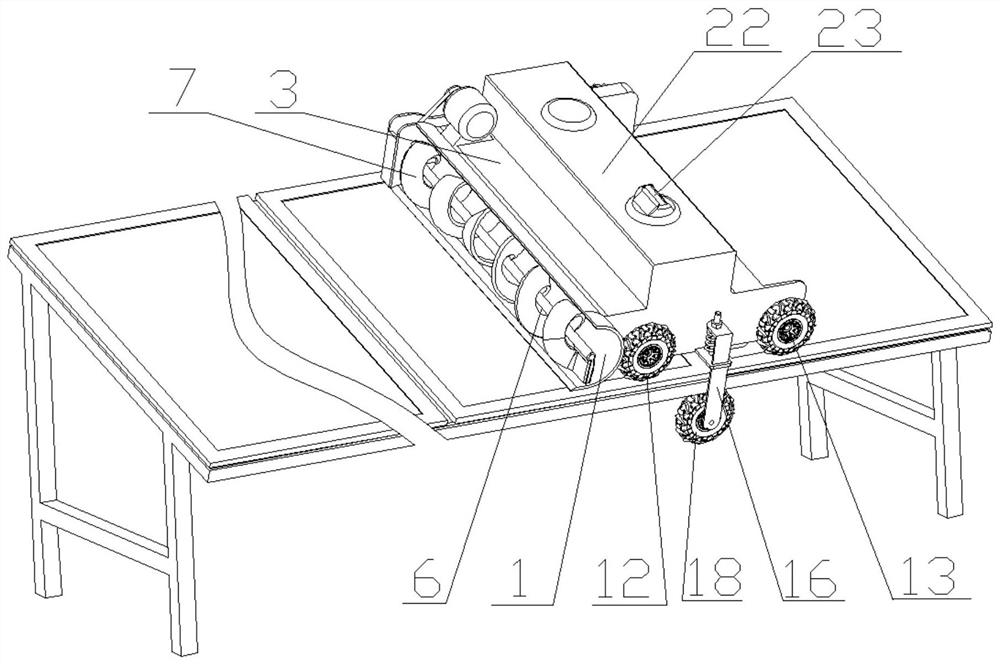

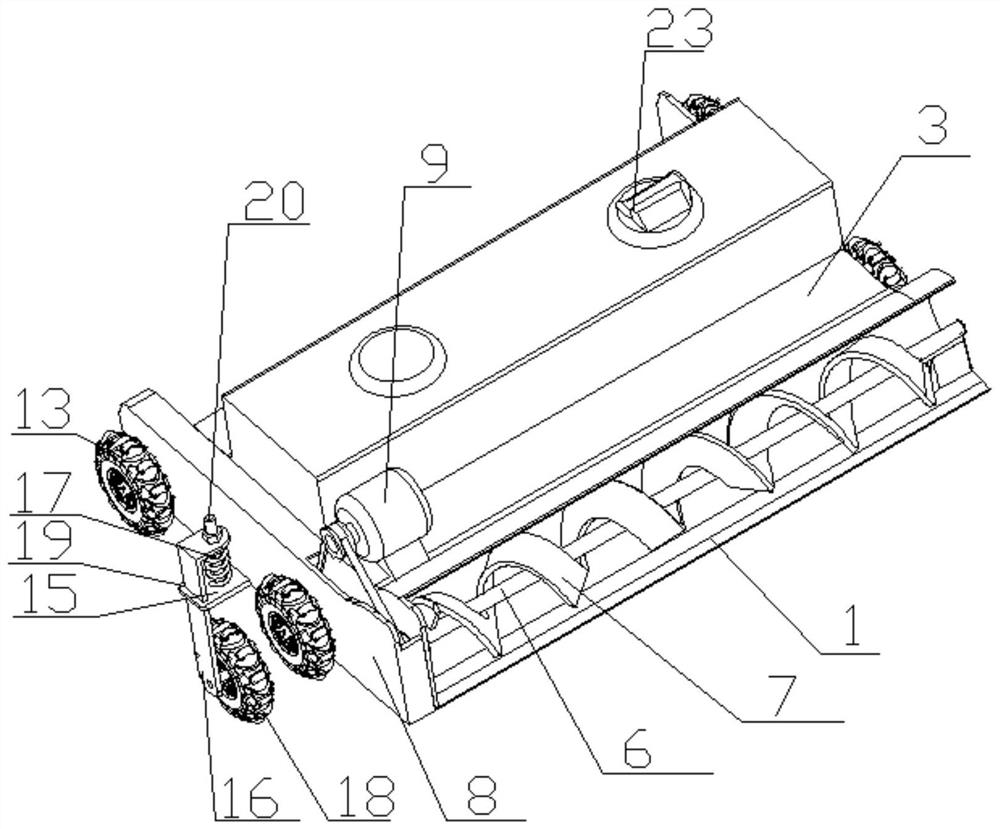

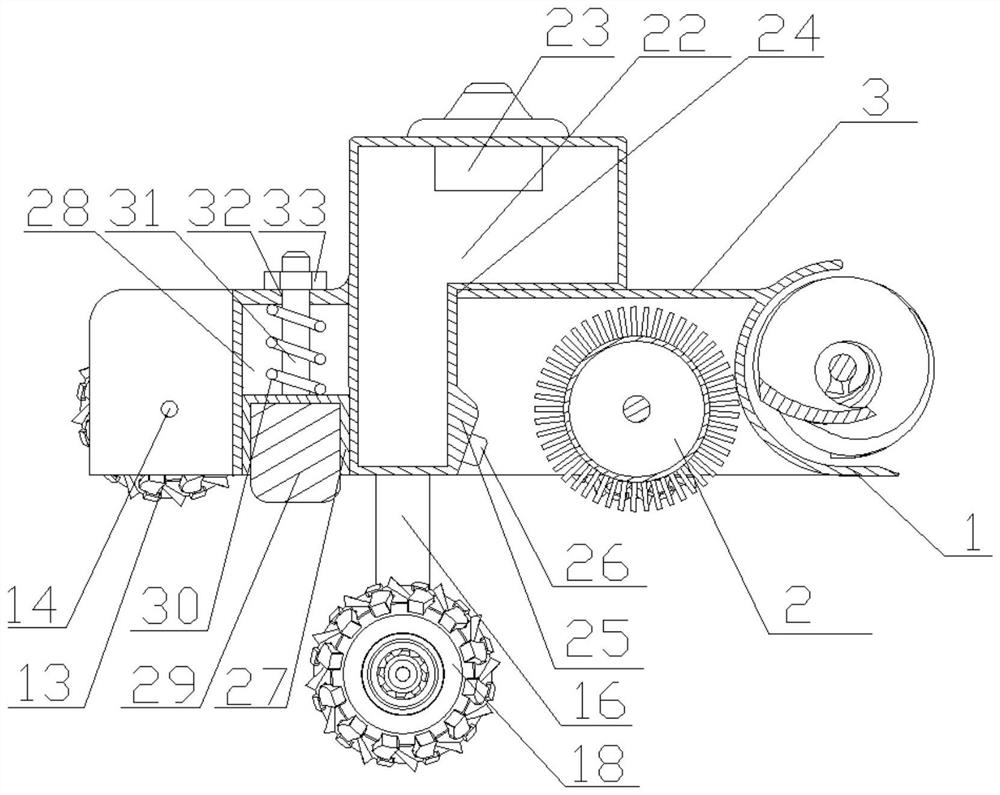

Cleaning device for solar photovoltaic panel

ActiveCN111790647AAchieve cleanAvoid scratchesPhotovoltaicsCleaning using toolsPower apparatusMaterials science

The invention discloses a cleaning device for a solar photovoltaic panel. According to the cleaning device, the cross section of a shovel plate is of an arc-shaped structure, a shell is of a box structure provided with a bottom opening, the shovel plate is fixedly connected with the side wall of the shell, a cleaning roller is mounted in the shell and can partially extend out of the opening of theshell, the cleaning roller can rotate around itself to make contact with the solar photovoltaic panel so as to clean the surface of the solar photovoltaic panel, an end plate is arranged on the end face at one side of the shovel plate, a first through hole is formed in the end plate, one end of a snow guide assembly penetrates through the first through hole so that the snow guide assembly is arranged in the shovel plate, the snow guide assembly also can rotate around the axis of the first through hole, walking devices are mounted at the two sides of the shell, the lowest plane of the shovel plate is higher than the walking surfaces of the walking devices so that the shovel plate can be not in contact with the solar photovoltaic panel, and a power device is mounted at the top of the shelland can drive the cleaning roller and the snow guide assembly to rotate through a transmission assembly. The device can realize rapid cleaning of the solar photovoltaic panel.

Owner:NANJING RUIQI ELECTRONICS TECH CO LTD

Quickly spliced workbench for civil air defense door frame

InactiveCN110524166AScientific and reasonable structureSafe to useWelding/cutting auxillary devicesAuxillary welding devicesSlagEngineering

The invention discloses a quickly spliced workbench for a civil air defense door frame. The workbench comprises a workbench top, and supporting columns are connected to the four corners of the bottomend of the workbench top. A protective bottom pad is mounted at the bottom end of each supporting column; a collecting groove is formed in the top end of the workbench top; according to the invention,the workbench is proper in structure, and safe and convenient to use; a longitudinal moving plate, a door frame placing plate, a telescopic rod and a clamping spring are arranged, so the position ofthe sliding plate can be limited; therefore, the door frame needing to be spliced can be quickly clamped, the clamping effect is good, and the time required for splicing the door frame can be reduced;through the arrangement of the collecting groove, the collecting leakage holes, the collecting bin and the storage bin, conduction can be conducted through the collecting bin, fallen welding slag canbe stored and stored; and the storage bin can be detached from the bottom end of the collecting bin through the fixing bolts after the workbench is used, and therefore the welding slag stored in thestorage bin can be rapidly cleaned.

Owner:QIANSHAN JIUDING PRECISION MACHINERY CO LTD

Rapid positioning and welding tool for automobile exhaust pipe

InactiveCN108500553APrevent looseningSmooth connectionWelding/cutting auxillary devicesAuxillary welding devicesInterference fitEngineering

The invention discloses a rapid positioning and welding tool for an automobile exhaust pipe. The rapid positioning and welding tool structurally comprises a free adjuster, an exhaust pipe, a movable rail, a movable bottom plate, a sliding rod, a base, a top supporting platform and an end head fixing frame, wherein a chuck inside the free adjuster is movably connected with the connecting pipe wallof the exhaust pipe, the shell of the free adjuster is fixed at the top of the movable bottom plate through a bolt and is parallel to the movable rail, and the movable rail is welded and fixed at thetop of the base; and a middle groove is in interference fit with the sliding rod, the top supporting platform is vertically fixed at the bottom of the end head fixing frame. According to the tool, theinvention provides a rapid positioning and welding tool for the automobile exhaust pipe, the improved rapid positioning and welding tool can quickly clamp the exhaust pipe by using a manner of rotating a handle, a tool is not required to be used for operation, so that the overall working efficiency can be further improved.

Owner:浙江光和园林有限公司

Lithium battery liquid injection device

ActiveCN112234325AIncrease the scope of applicationImprove work efficiencyFinal product manufactureCell component detailsPhysicsEngineering

The invention discloses a lithium battery liquid injection device which comprises a base, linkage mechanisms, clamping mechanisms, a driving assembly, a buffer assembly and a transmission assembly, fixing columns are fixedly connected to the middles of the two sides of the top surface of the base, threaded rods are fixedly connected to the top surfaces of the fixing columns, a cross beam is arranged between the threaded rods, and a threaded barrel is arranged in each mounting opening; the driving assembly is arranged in a driving cavity; a linkage mechanism is arranged in each linkage cavity;the transmission assembly is arranged in a transmission box; a liquid injection instrument is mounted at the bottom end of the fixed shaft; a fixed seat is fixedly connected to the top surface of thebase, and a clamping mechanism is arranged in each clamping cavity; the lithium battery liquid injection device is easy to operate, and the problem that the height and the angle of a liquid injectioninstrument are inconvenient to quickly adjust when an existing lithium battery liquid injection device is used is solved through the cooperative use of the driving assembly and the linkage mechanisms;and through cooperative use of the clamping mechanisms and a propelling assembly, the problem that when an existing lithium battery liquid injection device injects liquid, a lithium battery is inconvenient to automatically clamp through downward pressure is solved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

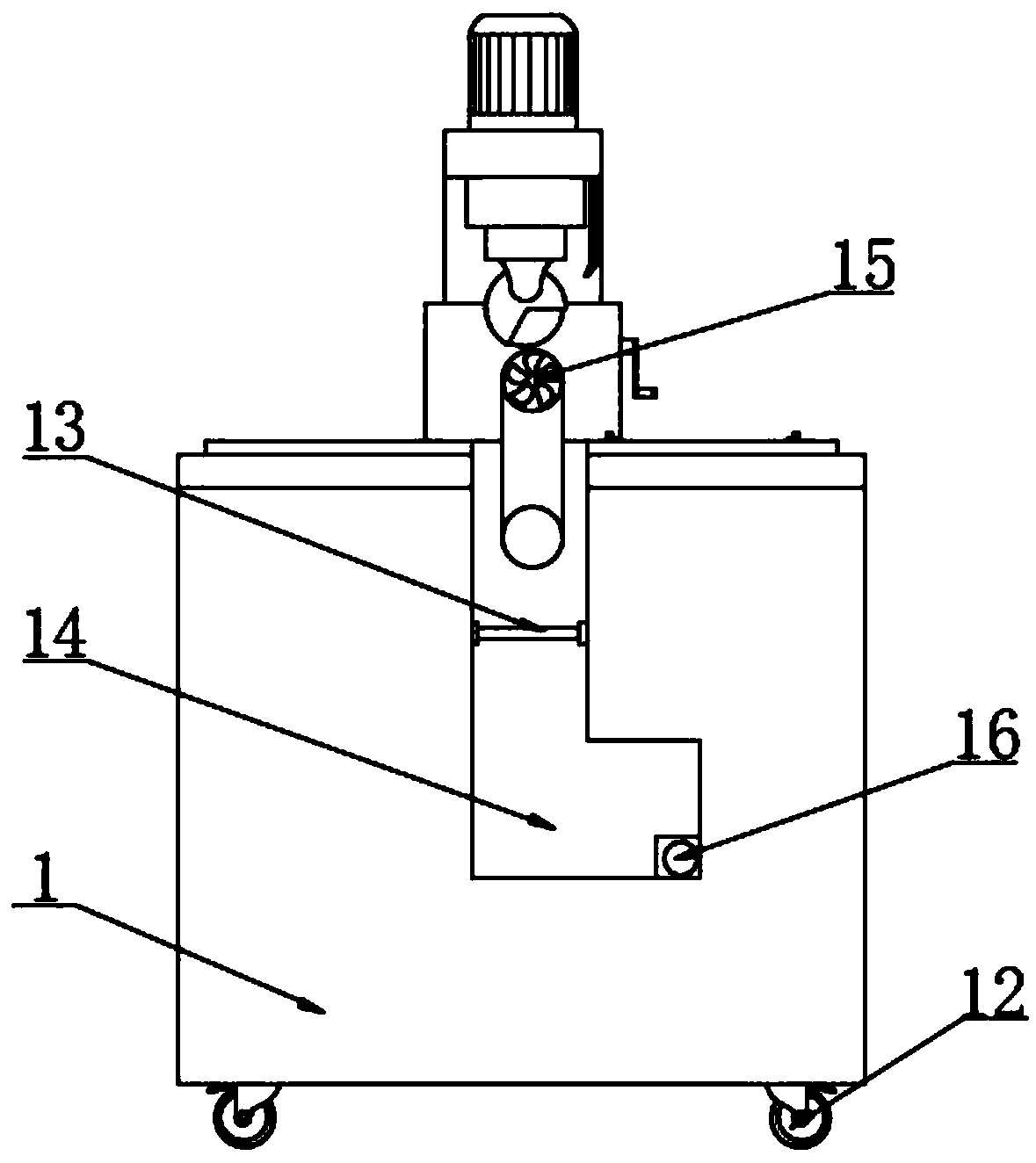

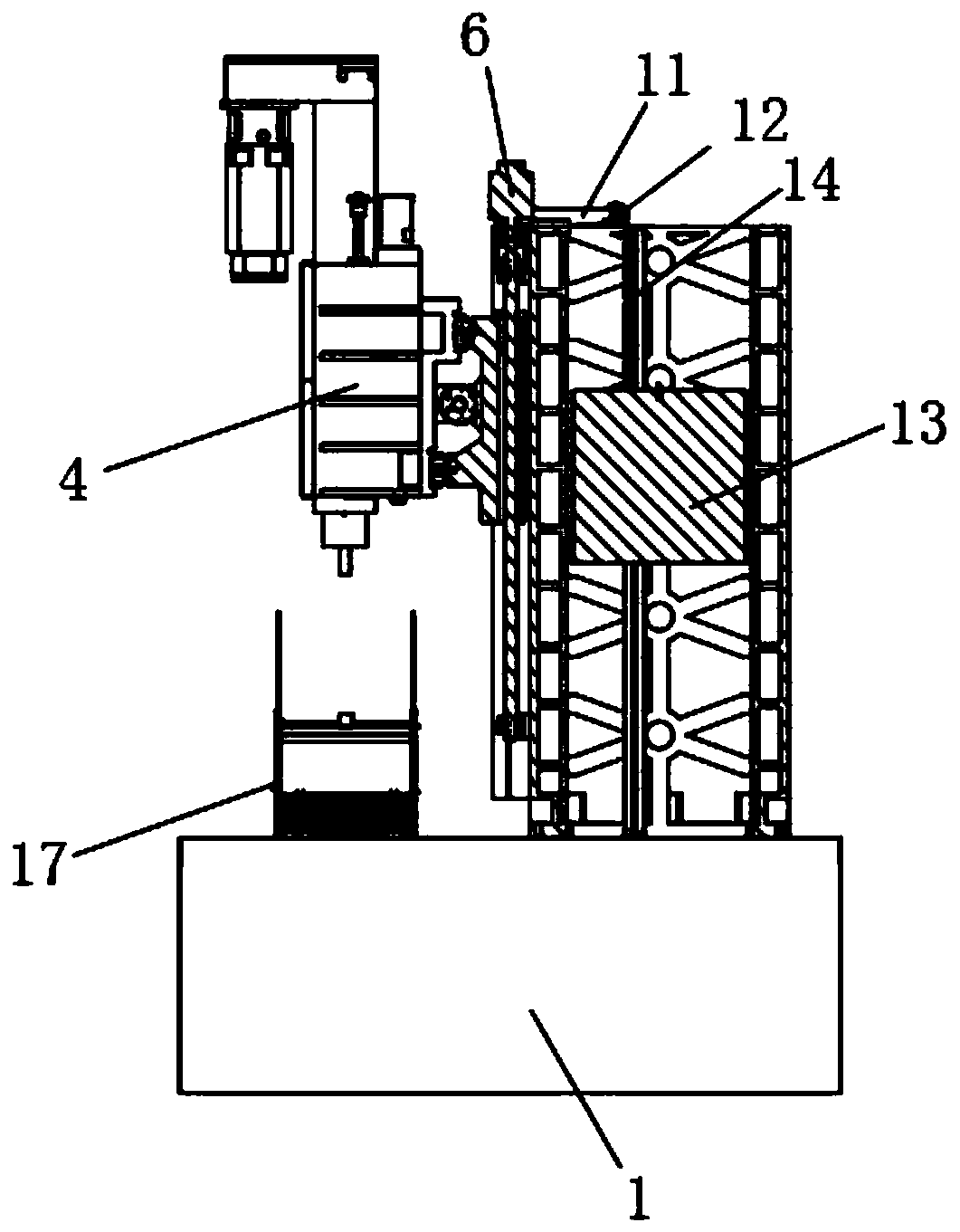

Automatic tool changing vertical machine tool and continuous machining method thereof

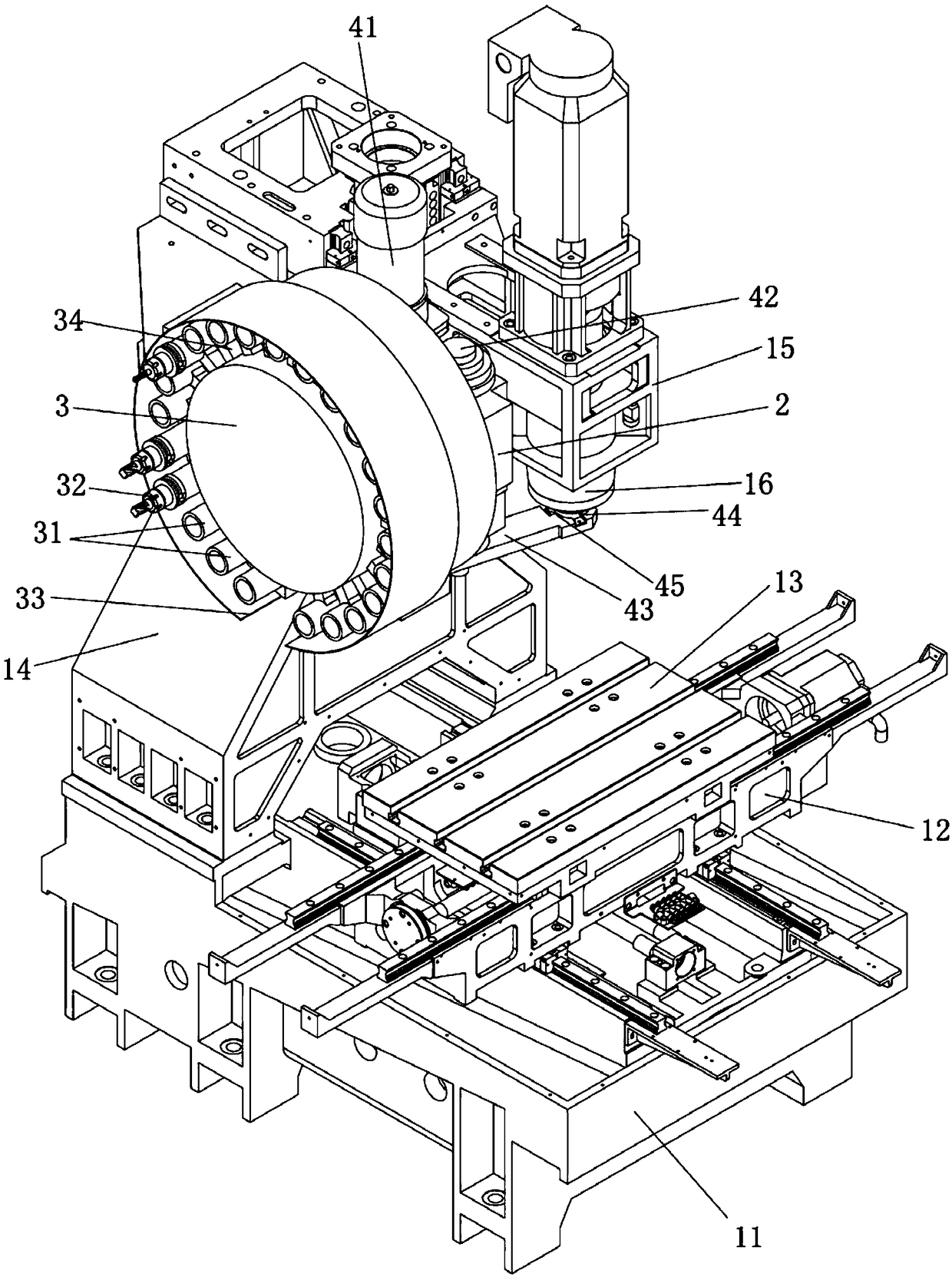

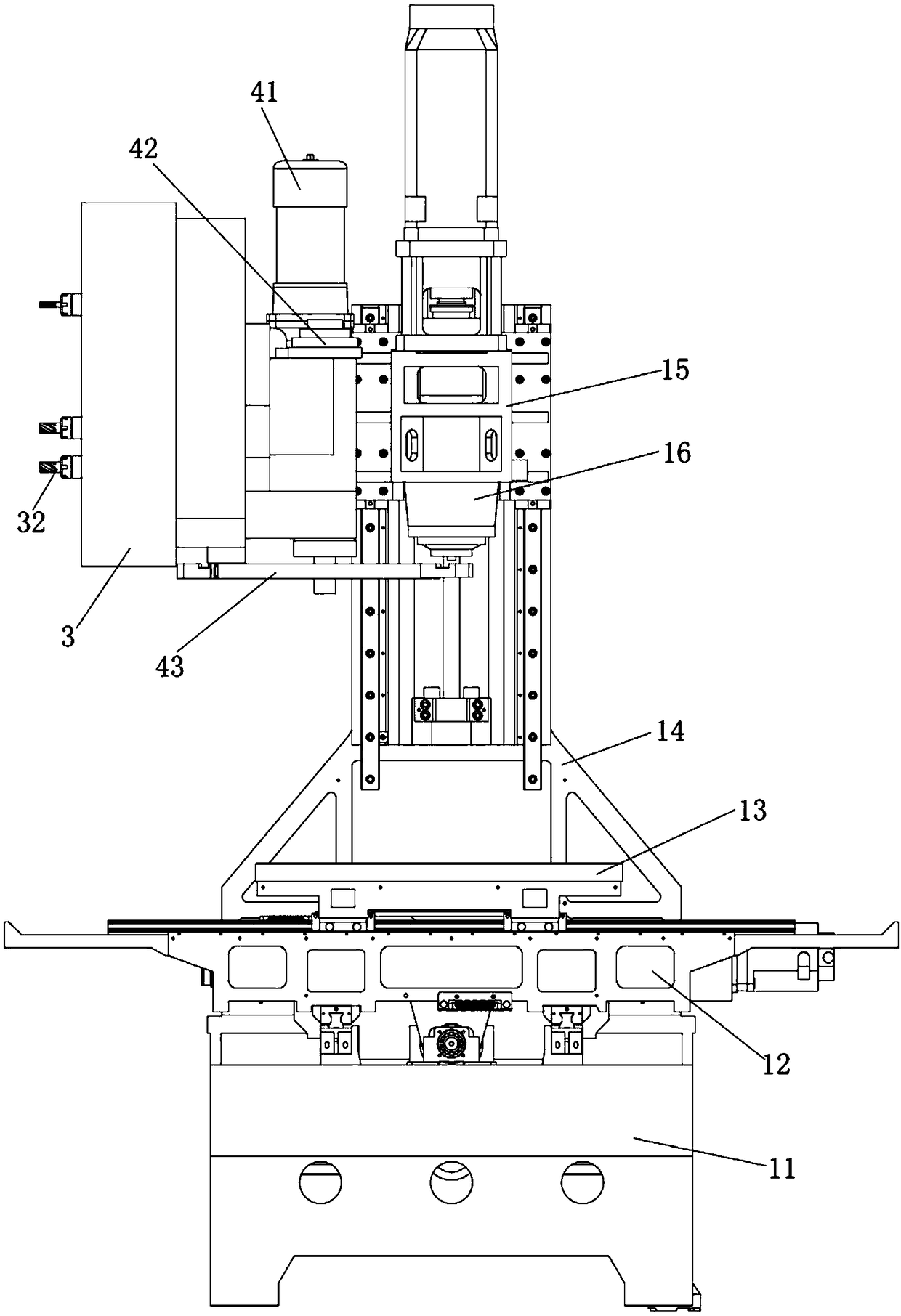

PendingCN108655798ARealize automatic tool change processIncrease productivityPositioning apparatusMetal-working holdersEngineeringDrive motor

The invention discloses an automatic tool changing vertical machine tool and a continuous machining method of the automatic tool changing vertical machine tool. The automatic tool changing vertical machine tool comprises a workbench, a slide saddle and a base, wherein the workbench, the slide saddle and the base are arranged from top to bottom in sequence. One side of the base is provided with a bracket arranging a main shaft to the workbench in an erecting manner, the bracket is provided with a fixing frame, the fixing frame is provided with a disc tool changer, and a tool changing device isarranged between the disc tool changer and the main shaft. The tool changing device comprises a tool changing drive motor and a lifting drive piece, wherein the tool changing drive motor is arranged on a tool changing rod and drives the tool changing rod to rotate, and the lifting drive piece drives the tool changing rod to move up and down. The middle of the tool changing rod is fixedly connectedwith the drive end of the lifting drive piece. The two ends of the tool changing rod are provided with C-shaped clamping slots for clamping tools, and the clamping slots are internally provided withjacking rods driven by clamping air cylinders. The automatic tool changing vertical machine tool is reasonable in structure, through the disc tool changer and the tool changing device, the automatic tool changing process of the vertical machine tool is realized, and the production efficiency of the machine tool is greatly improved; and through the clamping slots in the two ends of the tool changing rod, the tool at a tool changing opening and the tool in the main shaft are clamped rapidly, and the tool changing efficiency is improved.

Owner:东莞市同振五金机械有限公司

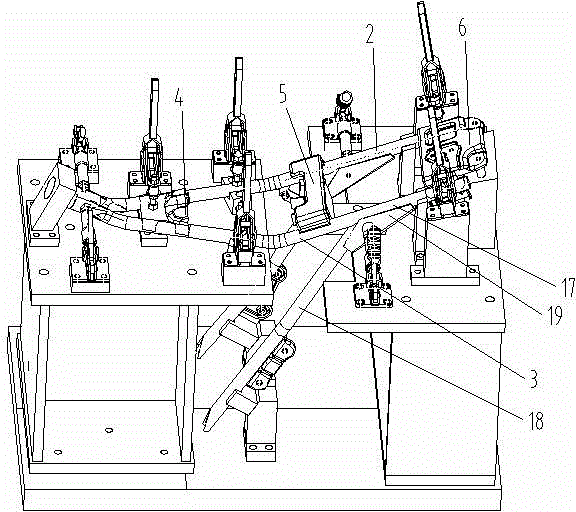

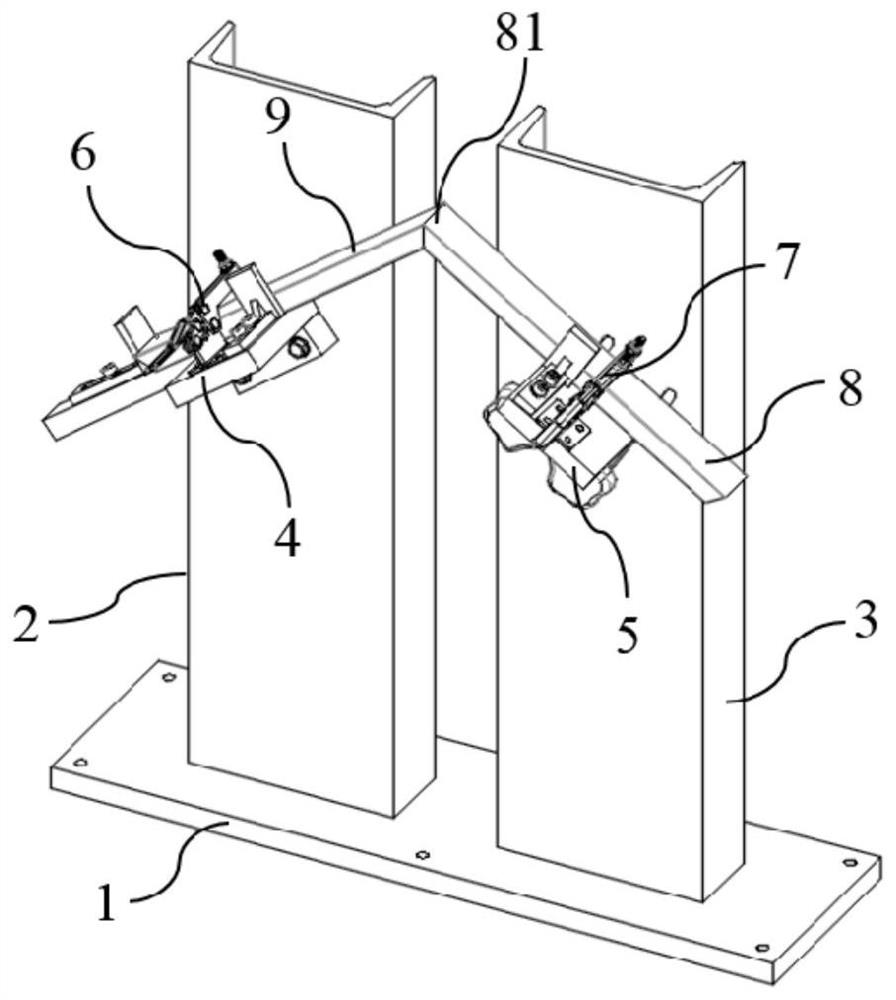

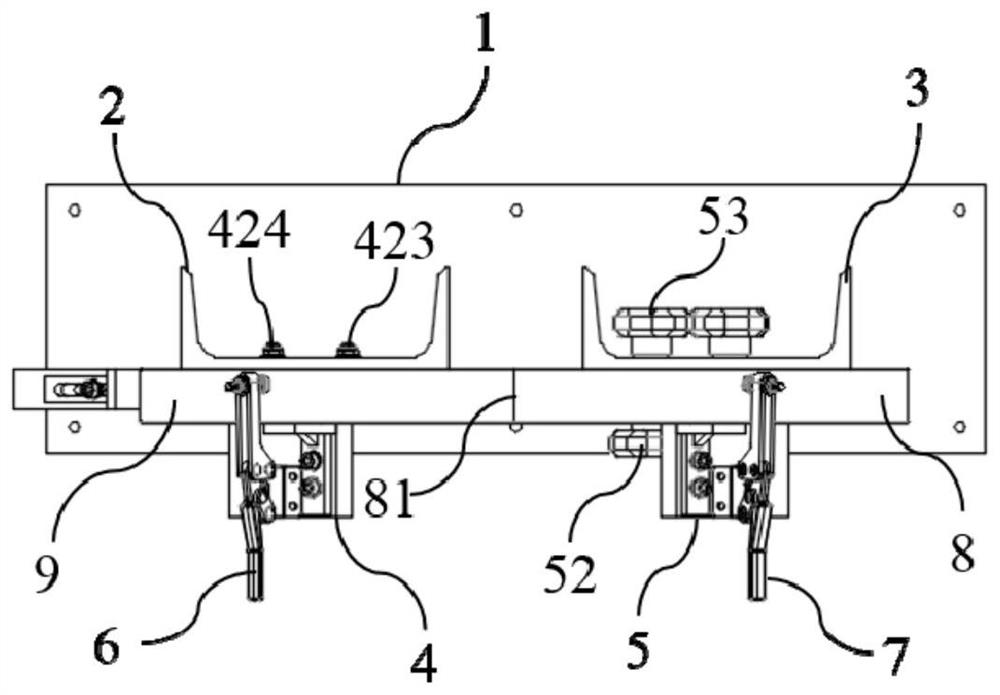

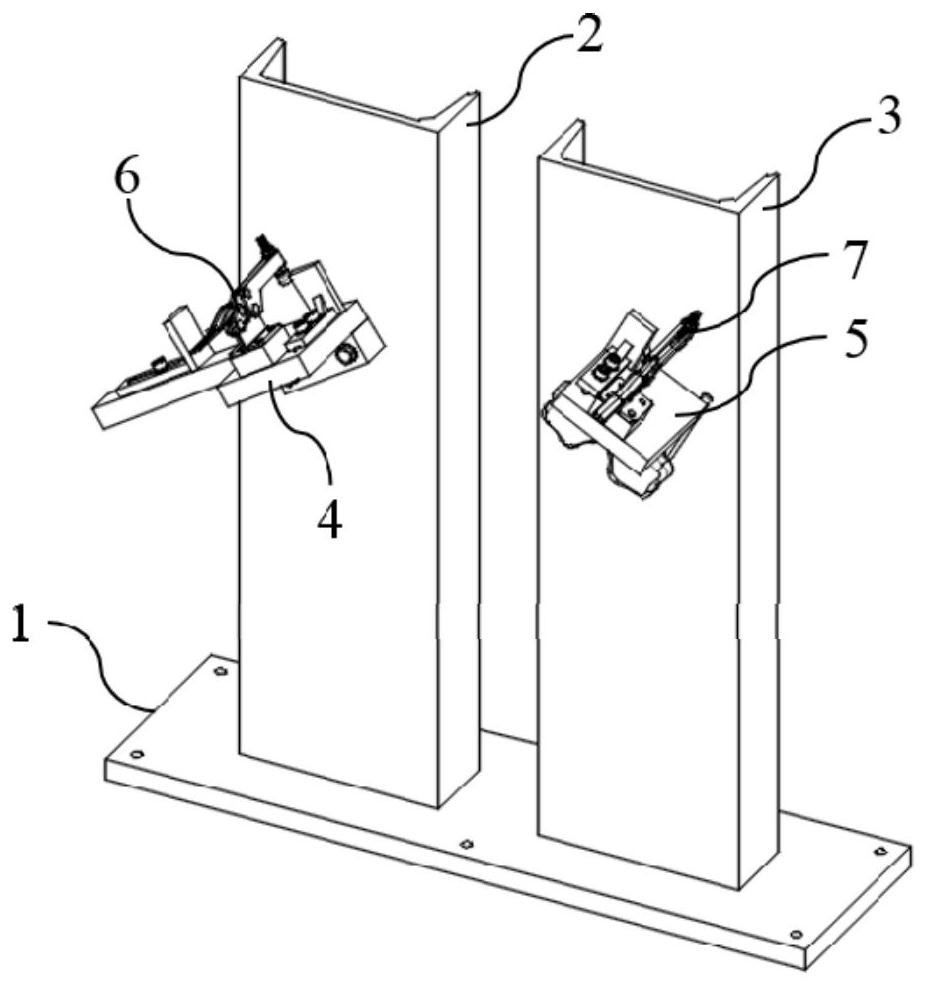

Motorcycle frame rear body assembly welding jig

InactiveCN104690472AMeets targeting requirementsSimple structureWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameLeft half

The invention discloses a motorcycle frame rear body assembly welding jig. The motorcycle frame rear body assembly welding jig is characterized in that a lower bottom plate is provided with a left half body assembly positioning mechanism, a right half body assembly positioning mechanism, a fuel tank rear mounting bracket component positioning mechanism, a left and right connecting plate positioning mechanism, and a seat lock mounting bracket component positioning mechanism; the left half body assembly positioning mechanism and the right half body assembly positioning mechanism are symmetrically arranged; an upper front bottom plate and an upper rear bottom plate are respectively arranged on the two sides of the lower bottom plate through support structures; a certain space is reserved between the upper front bottom plate and the upper rear bottom plate, so that a left half body assembly support pipe and a right half body assembly support pipe can pass in a downwardly inclined manner. The motorcycle frame rear body assembly welding jig provided by the invention has the advantages that clamp positioning of all parts of a motorcycle frame rear body assembly is integrated, so that the jig structure is simplified, fewer clamp positioning points and rapid clamping are achieved, accordingly, the product loading / unloading time for the jig is shortened, and the welding efficiency is improved; meanwhile, the positioning of all the parts is more accurate and precise, and the assembly positioning requirements are better met, so that the forming quality of the welded frame rear body assembly is higher.

Owner:力帆科技(集团)股份有限公司

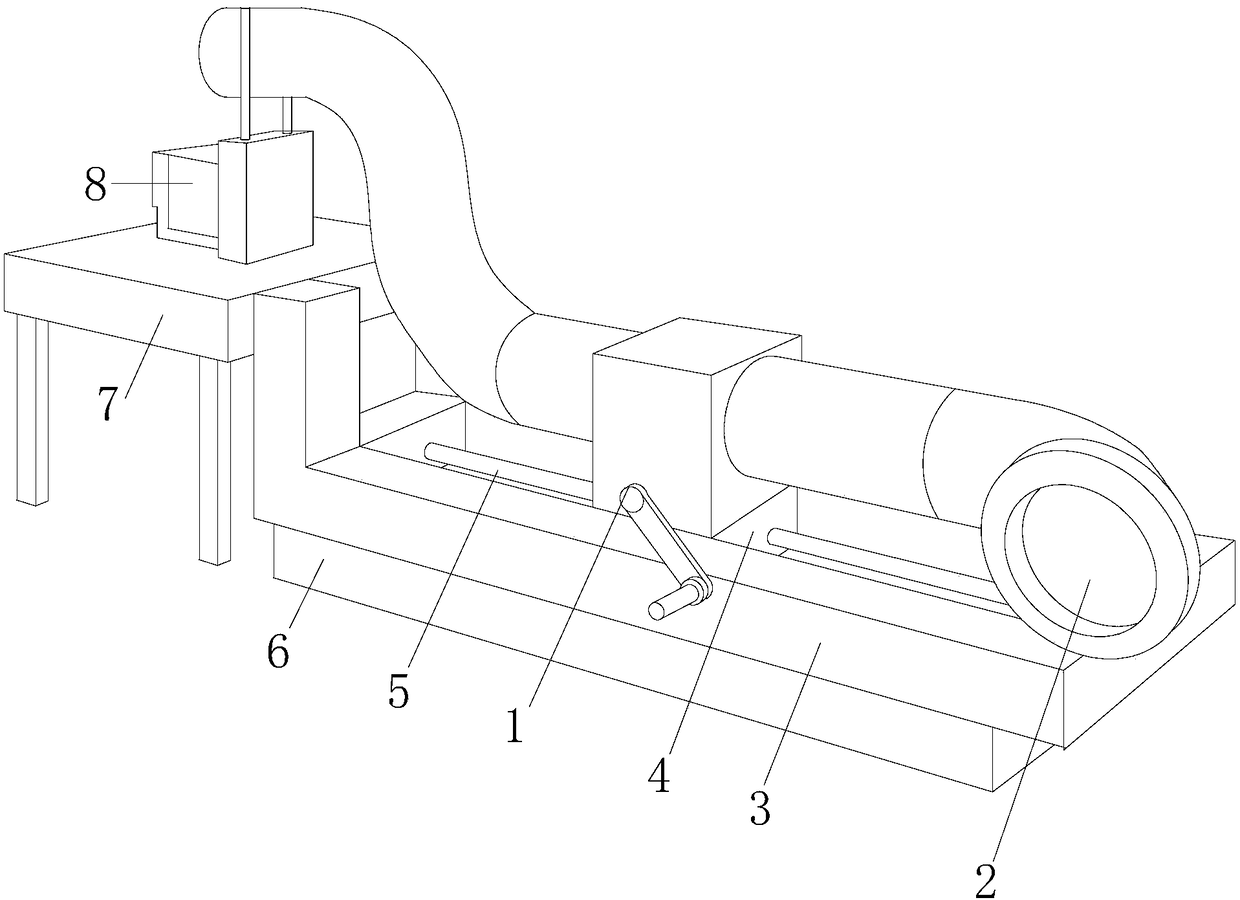

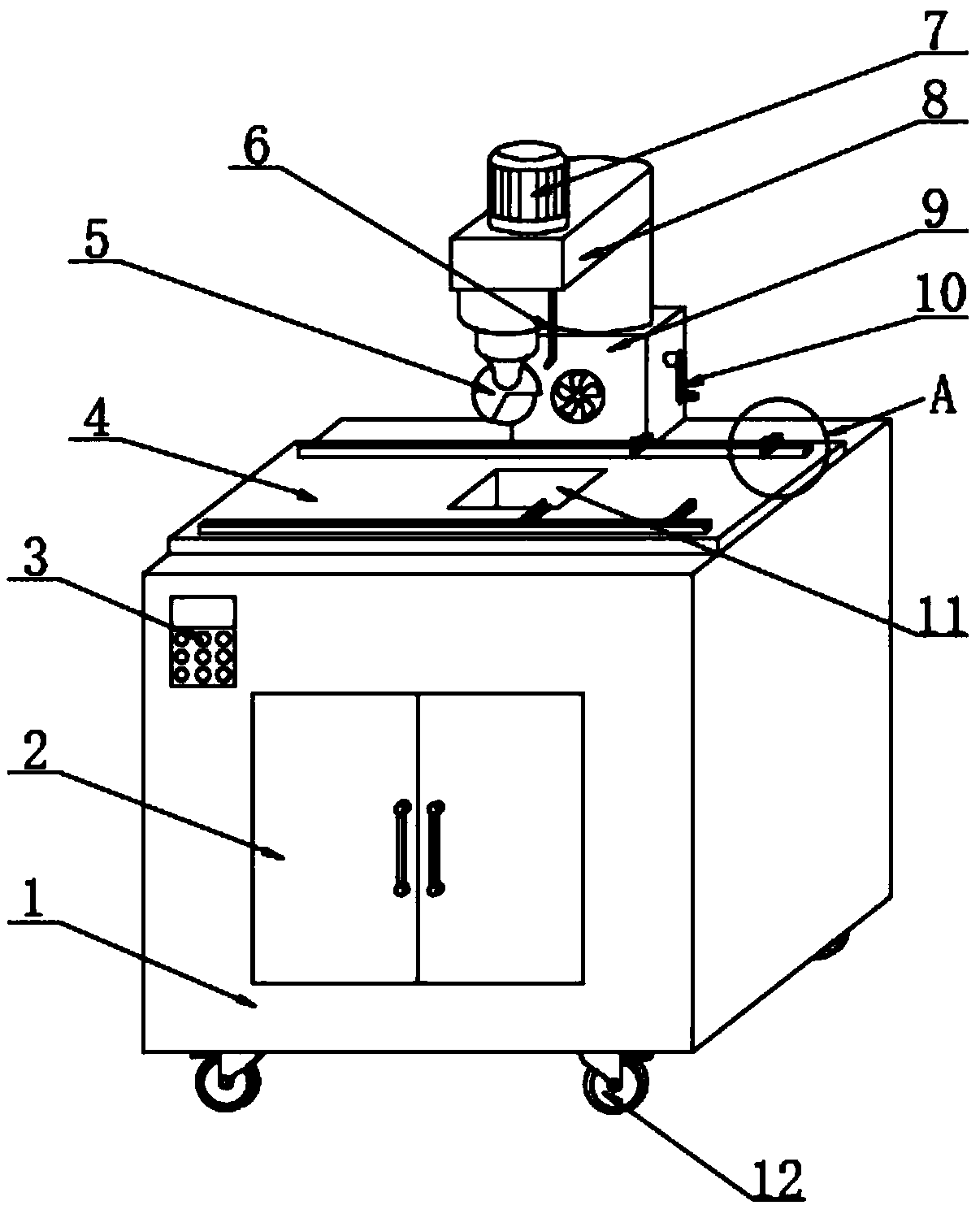

Environmental protection plate rapid cutting equipment

ActiveCN108673594AScientific and reasonable structureEasy to useMetal working apparatusSuspended particlesEngineering

The invention discloses environmental protection plate rapid cutting equipment. The environmental protection plate rapid cutting equipment comprises a box body, a fixing base, a rotating seat, a crank, a fan and telescopic clamping plates. The fixing base is installed at the top of the box body, and the rotating seat is arranged at the top of the fixing base. The fan is installed on one side of the fixing base in an embedded mode, and the crank is arranged on the other side of the fixing base. The telescopic clamping plates are arranged above the box body. The environmental protection plate rapid cutting equipment is scientific and reasonable in structure and safe and convenient to use, the length of the telescopic clamping plates can be adjusted according to the width of a plate, and rapid clamping of the plate is facilitated. Water is sprayed through a spray pipe to cool a cutter to avoid damage to the cutter caused by excessive temperature, and at the same time, debris and floatingdust can be wetted; and combined with the operation of the fan, the remaining debris and floating dust can be collected to avoid the occurrence of suspended particles during cutting; and the crank isshook to drive second transmission teeth to rotate, the rotating seat can be rotated, so the cutter is turned out of a working table, and replacement and installation of the cutter are facilitated.

Owner:台州市高典机电有限公司

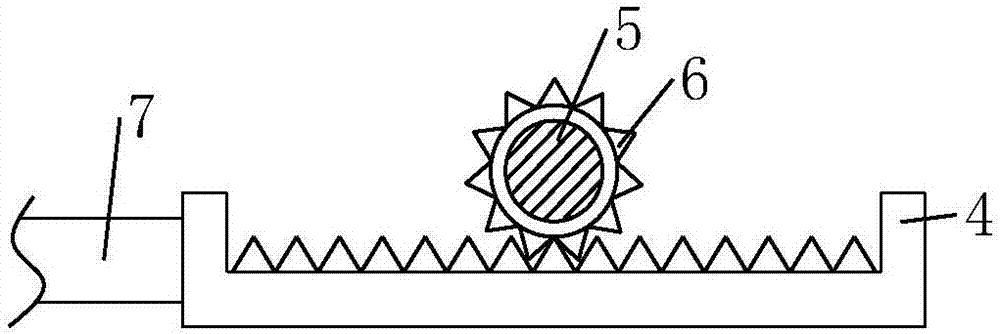

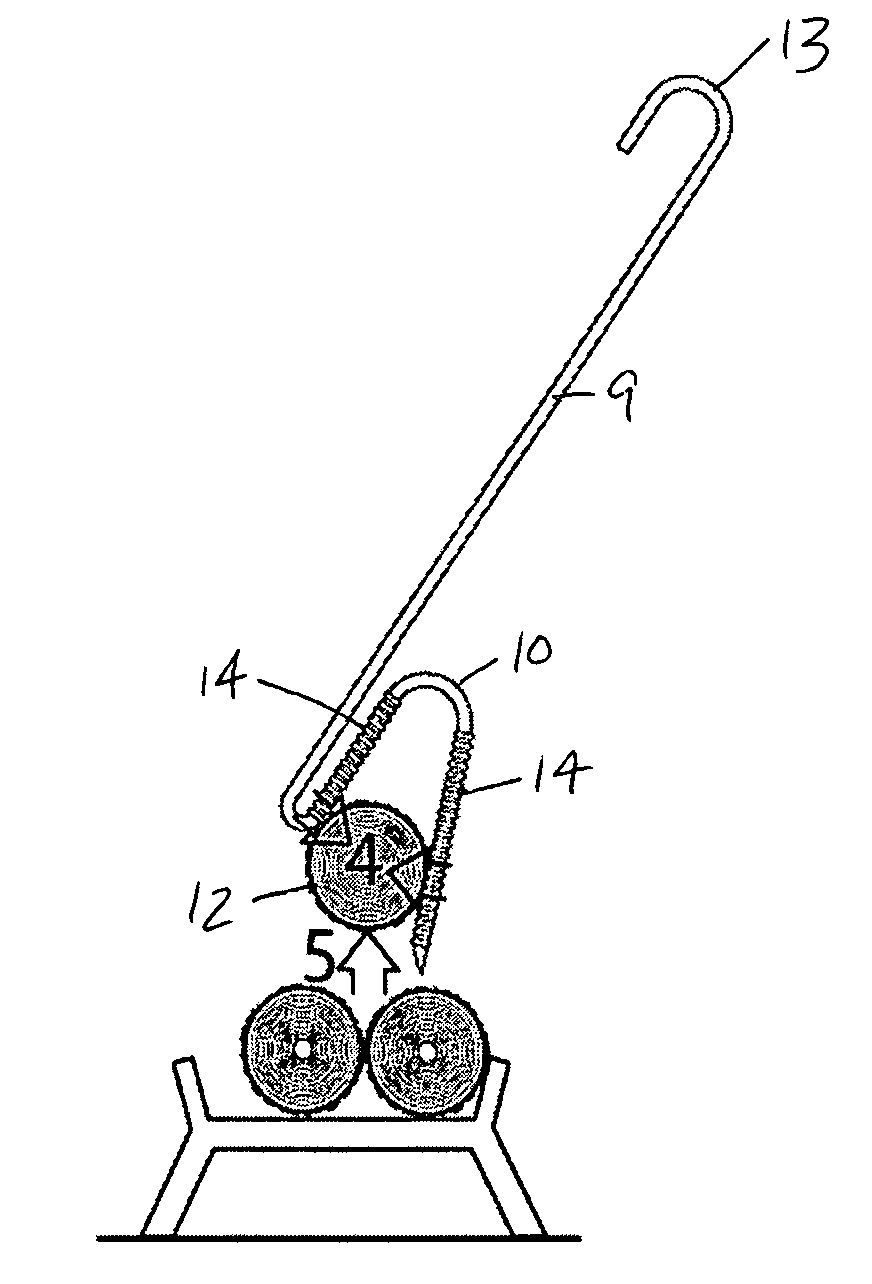

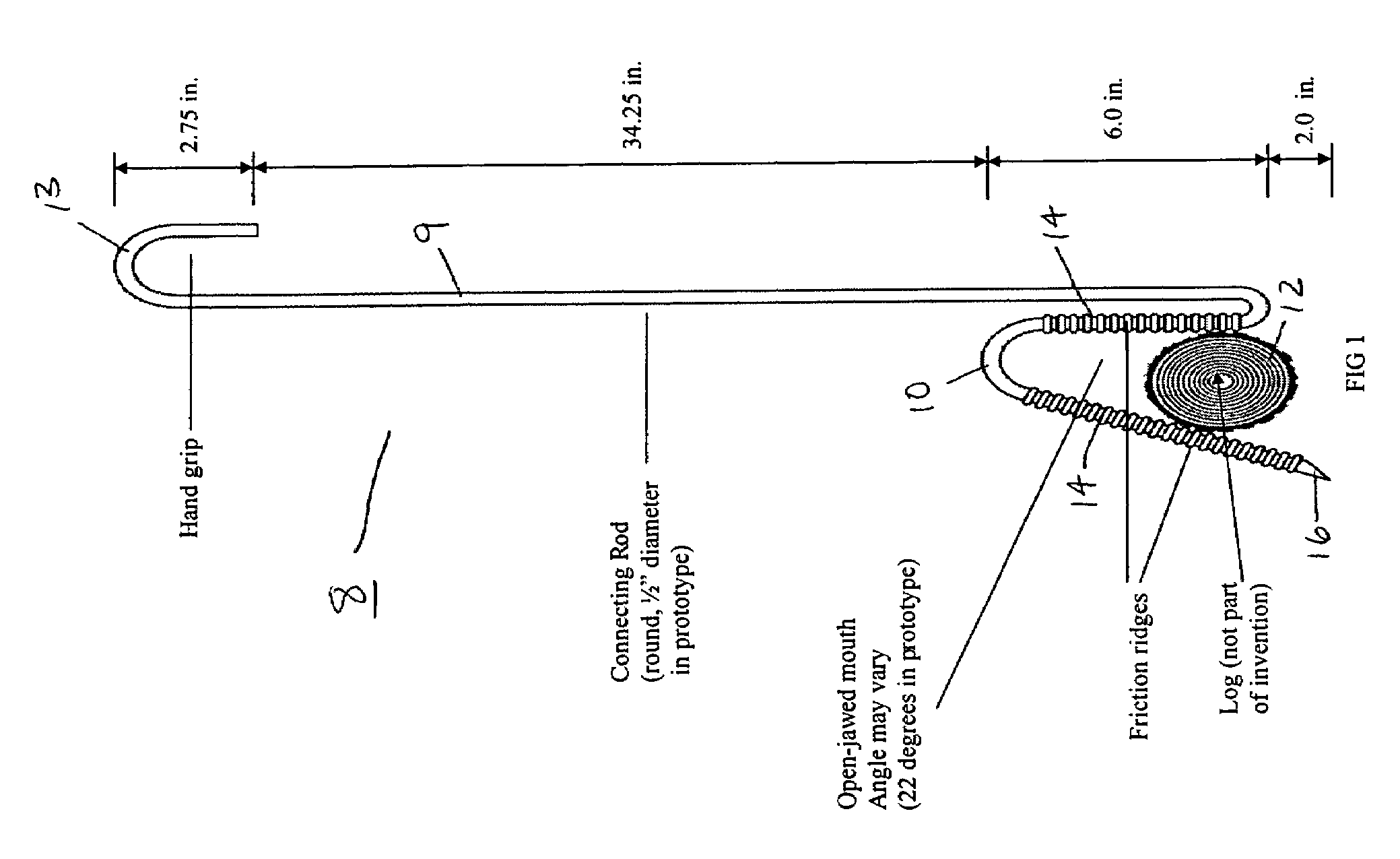

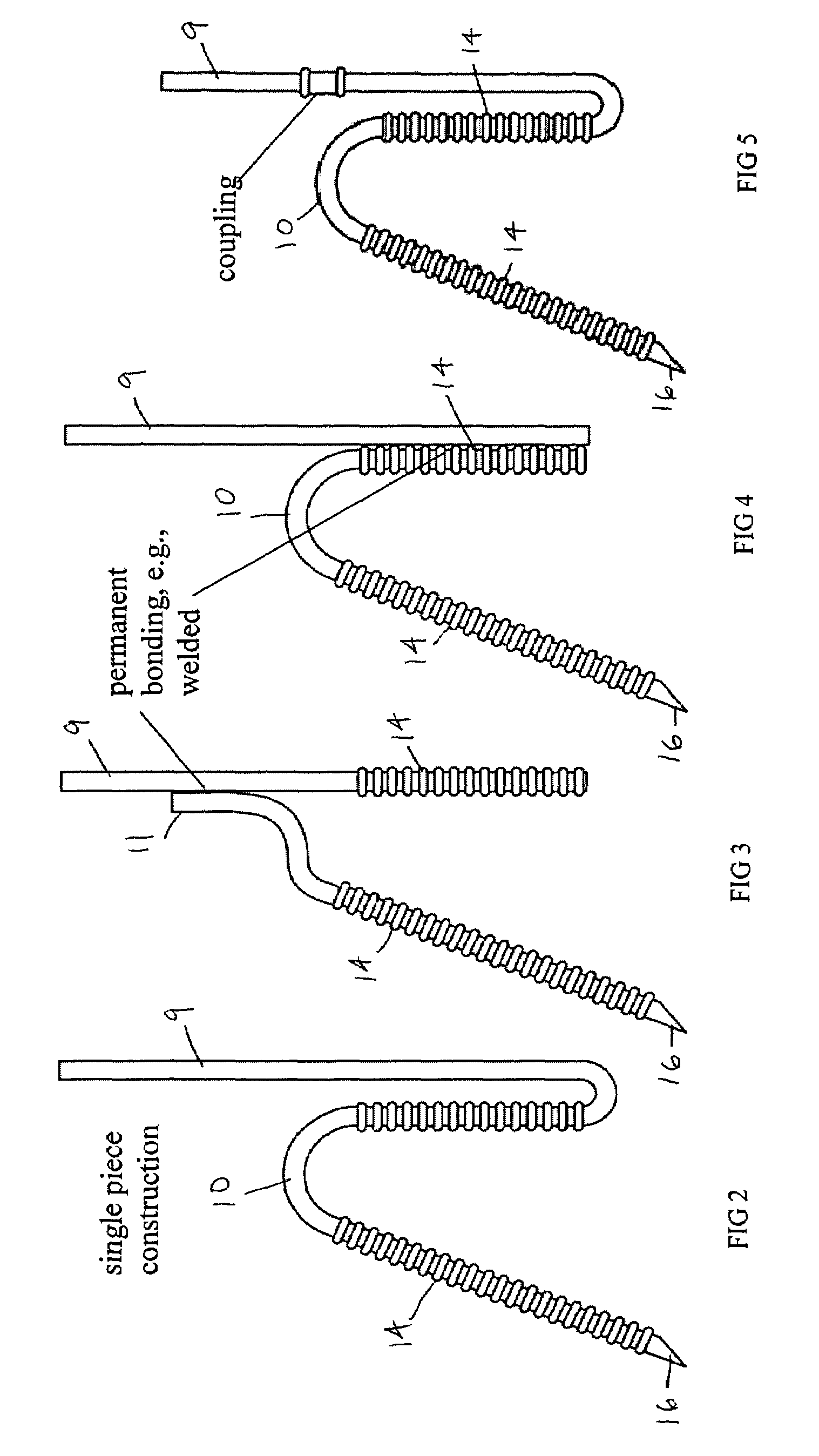

Friction grip fireplace tool

InactiveUS7344170B2Easy to useImprove gripDomestic stoves or rangesLighting and heating apparatusFriction effectEngineering

A friction grip fireplace tool comprising a rod or bar, having a hand grip on one end, and on the other end a resilient, unary, v-shaped open-jawed mouth to grip, lift and re-position logs in a fireplace. There are no moving parts, no hinges, or pivot points. The tool can be made of one solid piece of steel or material with similar properties of elasticity and fire resistance or can be fabricated from two or more parts. A log is held in place by friction, created by ridges within the open-jawed mouth of the tool and the spring effect of the open-jawed mouth being forced onto a log. The spring effect of the tool's mouth along with the friction effect of the ridges allow most burning logs to be completely lifted, held, and moved about safely.

Owner:INGRAM TODD RUSSELL

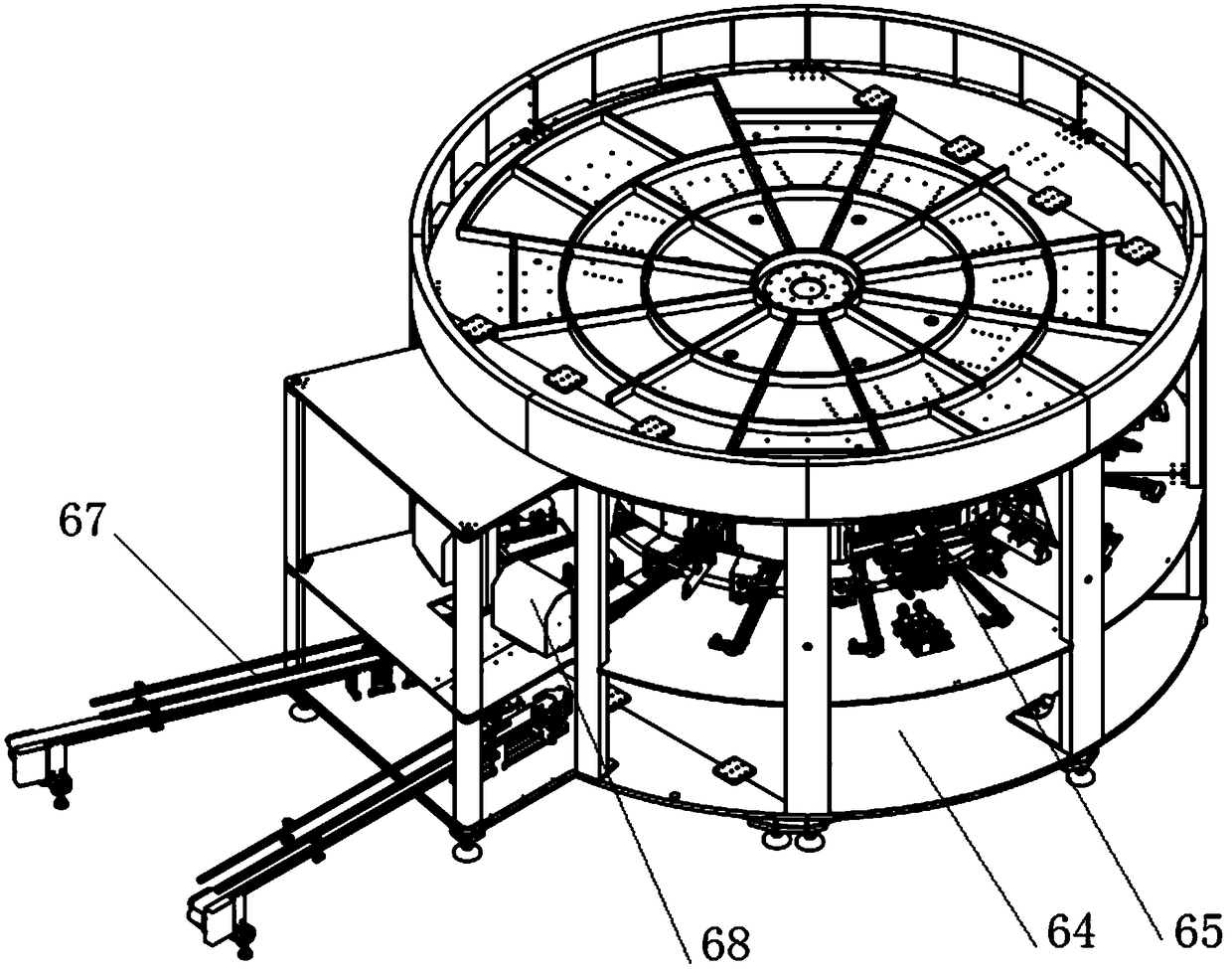

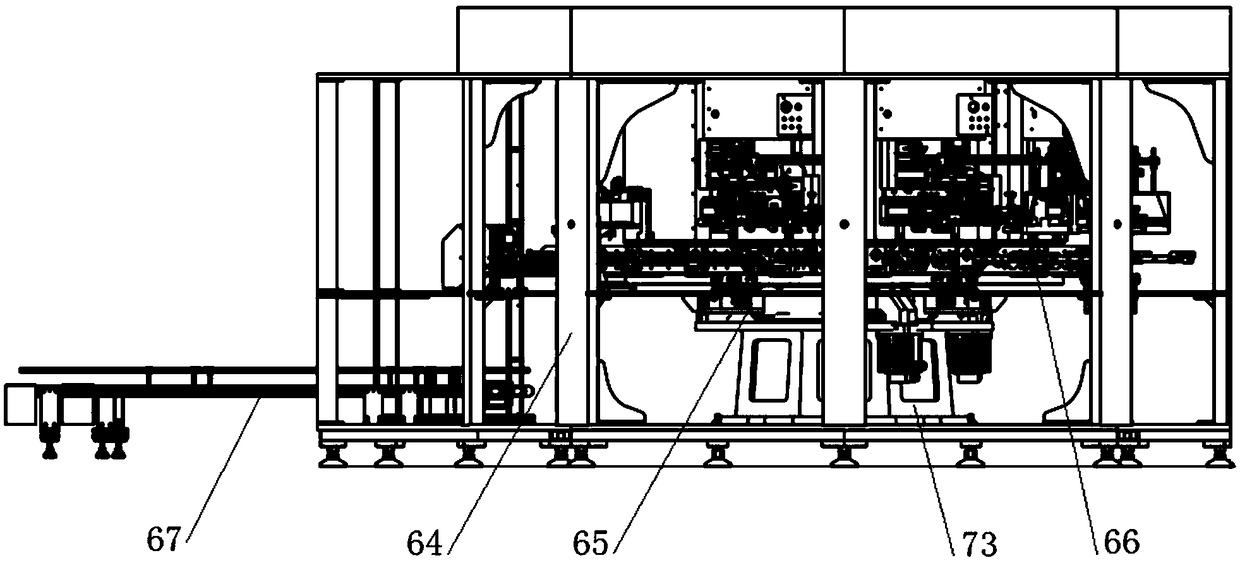

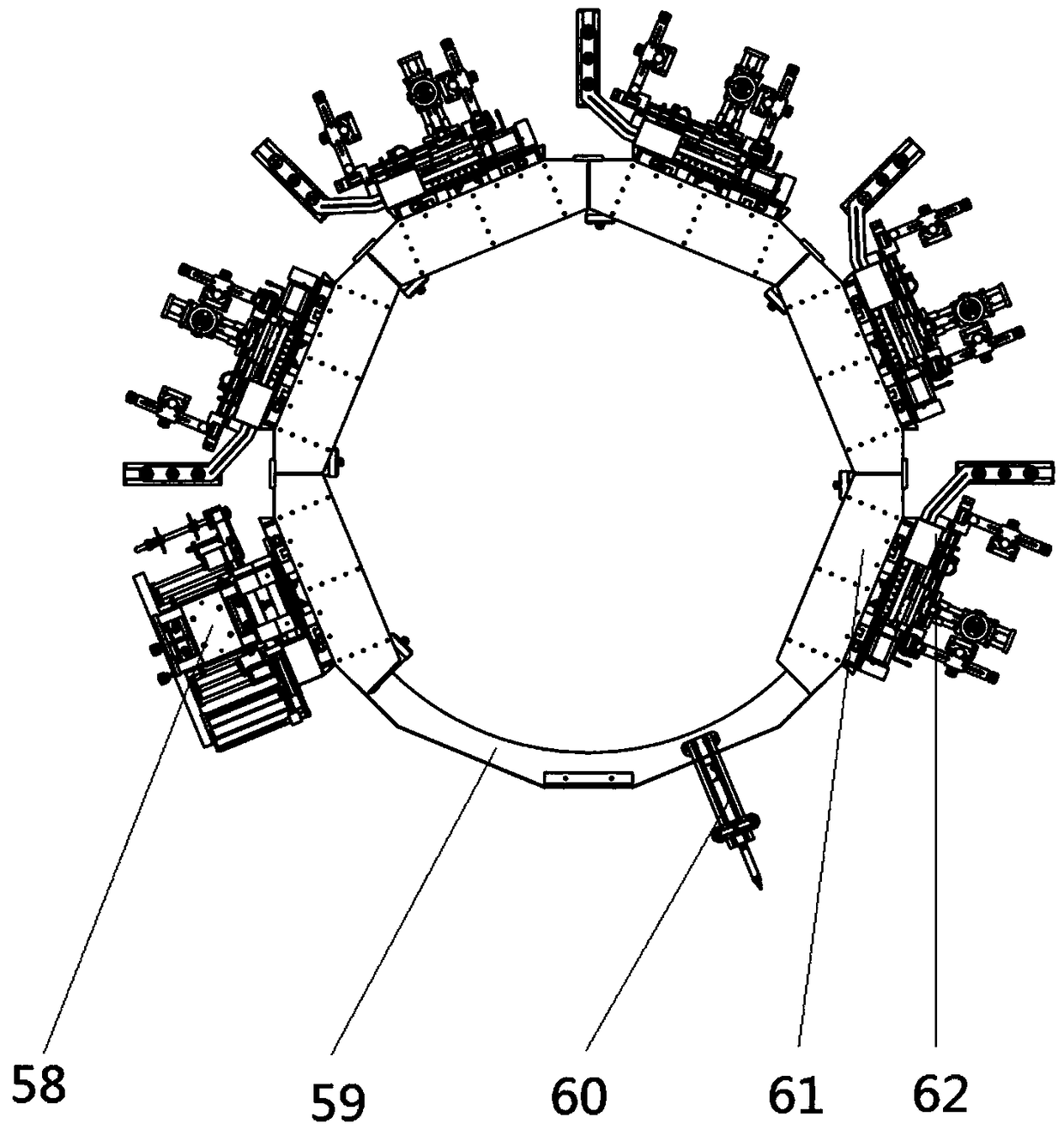

Total-servo silk-screen printing equipment

PendingCN109454980AAccurate printingIncrease surface tensionScreen printersScreen printingCharge and discharge

The invention discloses total-servo silk-screen printing equipment. The total-servo silk-screen printing equipment comprises a housing, a turning plate, a printing assembly and a charging and discharging device; the turning plate and the printing assembly are positioned inside the housing; the printing assembly is connected with the top of the turning plate; the turning plate is used for driving the printing assembly to rotate inside the housing; the charging and discharging device is positioned at the outer side of the housing and is used for conveying a to-be-printed material for the turningplate; the printing assembly comprises a plurality of printing lifting plates; the plurality of printing lifting plates are correspondingly provided with a fire burning component, a gold stamping component and a printing component; the turning plate comprises a base, a rotary disc, an index table and an electric slip ring; the rotary disc is arranged on the base and is rotationally connected witha pedestal; the index table is connected with the bottom of the rotary disc; the charging and discharging device comprises a conveying belt and a clamp; the conveying belt is positioned at the bottomof the housing; the clamp is arranged on the housing and is used for conveying the to-be-printed material to the turning plate.

Owner:SICHUAN XINGDA PACKAGING EQUIP MFG

Full-automatic electric appliance part and component cleaning device

InactiveCN107377453AQuick cleanEasy to cleanCleaning using toolsCleaning using liquidsEngineeringPiston rod

The invention discloses a full-automatic electric appliance part and component cleaning device which comprises a shell, and an opening is formed in the top end of the shell. A horizontally arranged supporting frame is installed in the shell. A fixed clamping plate is welded to the inner wall of one side of the shell and located at the top end of the supporting frame. One side of the top end of the supporting frame is slidably connected with a vertically arranged movable clamping plate. The side wall of the side, close to the fixed clamping plate, of the movable clamping plate is evenly provided with a plurality of clamping grooves. The side wall of the side, away from the fixed clamping plate, of the movable clamping plate is connected with a plurality of springs. One end of each spring is connected to the inner wall of the shell. A bracket is welded to the outer wall of one side of the shell. A horizontally arranged first air cylinder is welded to the bracket. A vertically arranged cleaning device is welded to a piston rod of the first air cylinder and slidably connected to the side wall of the top end of the shell. The full-automatic electric appliance part and component cleaning device can rapidly clamp a plurality of circuit boards and rapidly clean the surfaces of the multiple circuit boards simultaneously, and the cleaning effect is good.

Owner:合肥杰代机电科技有限公司

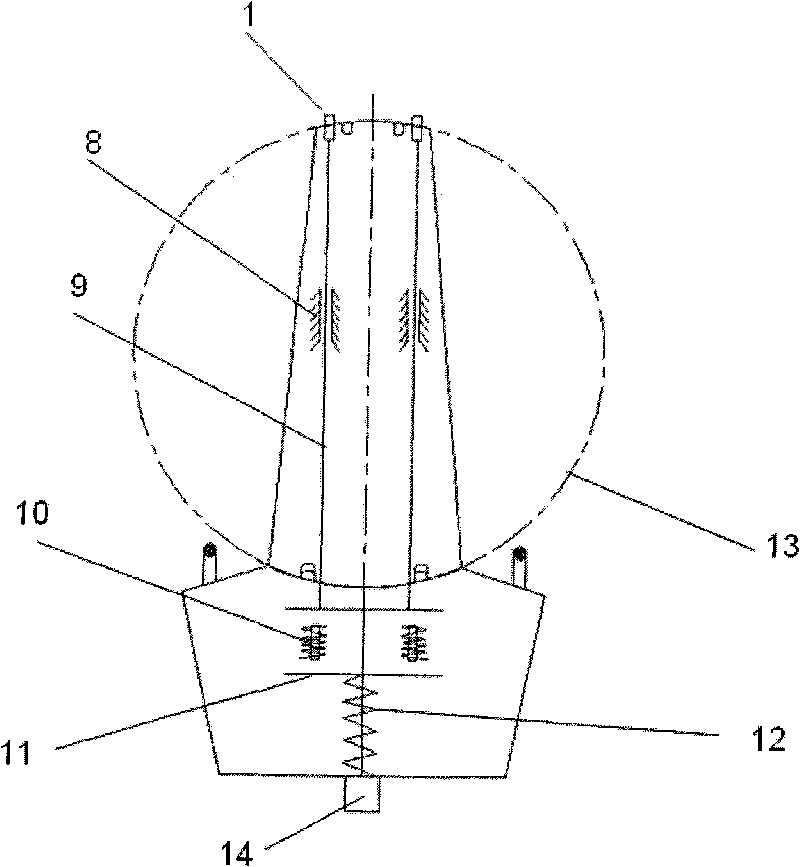

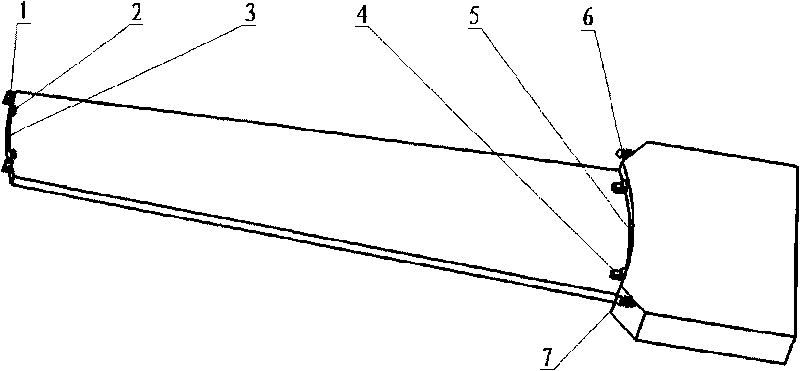

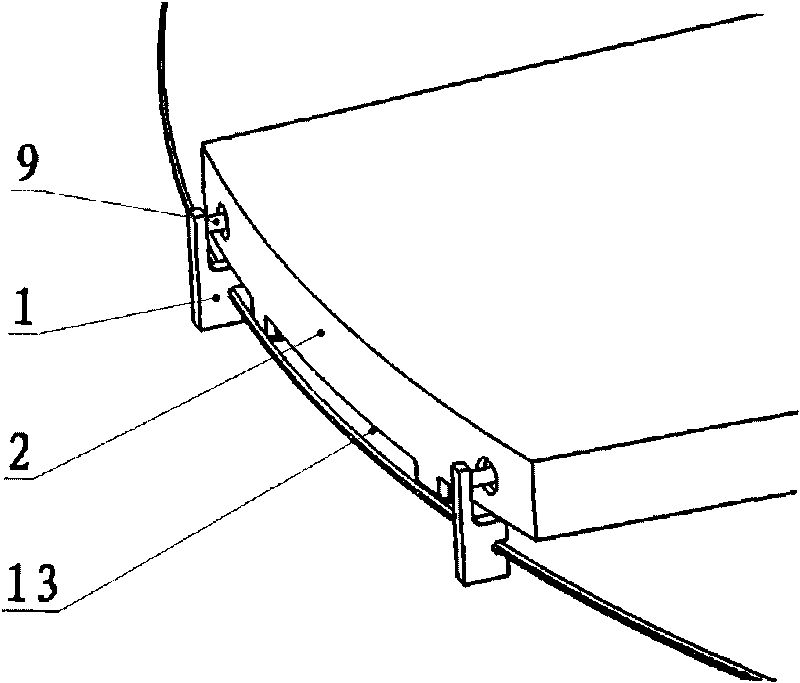

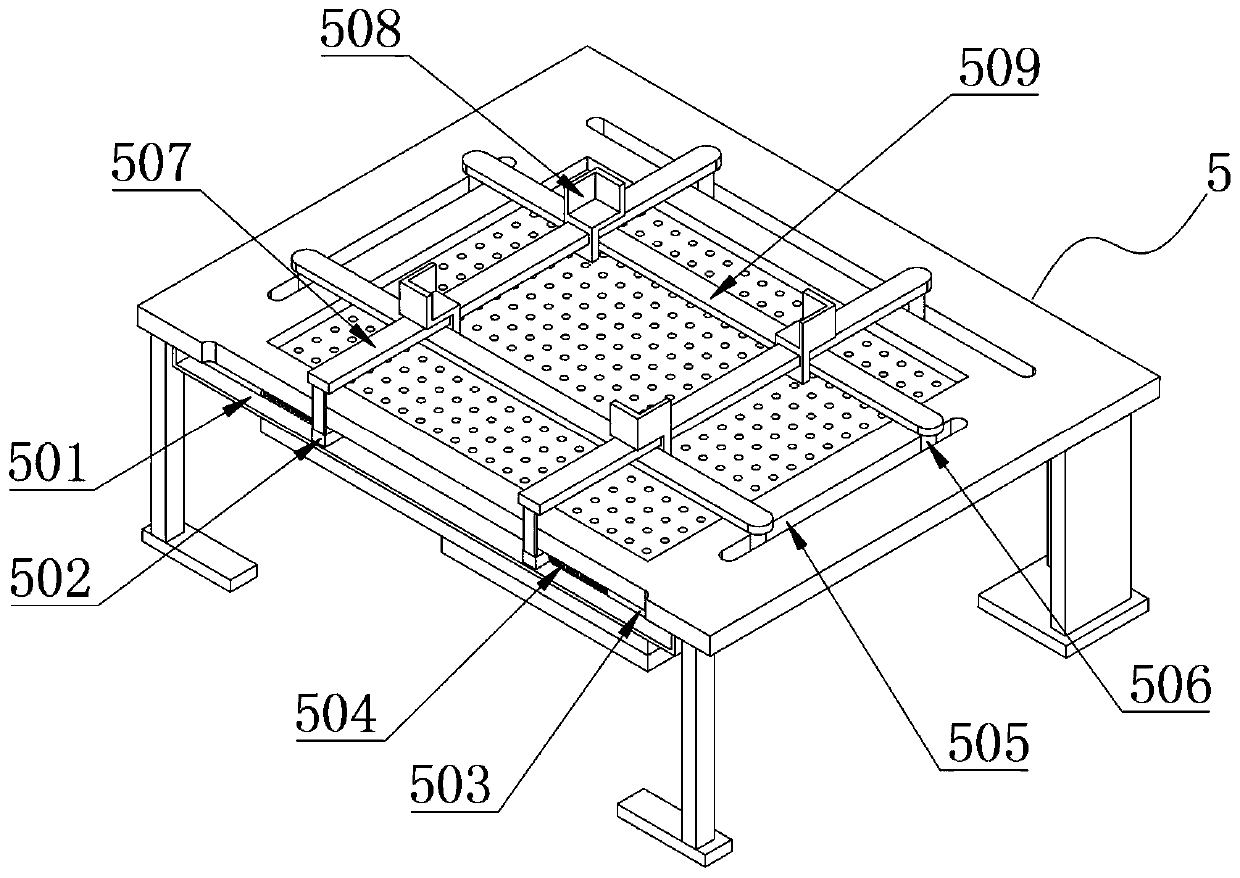

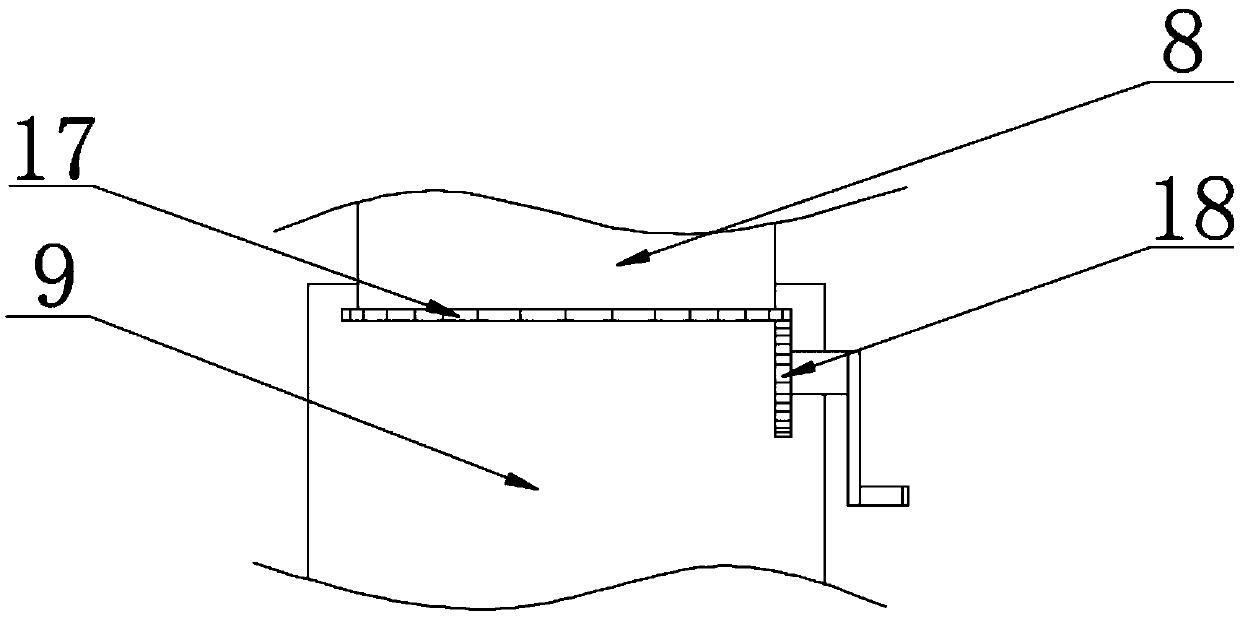

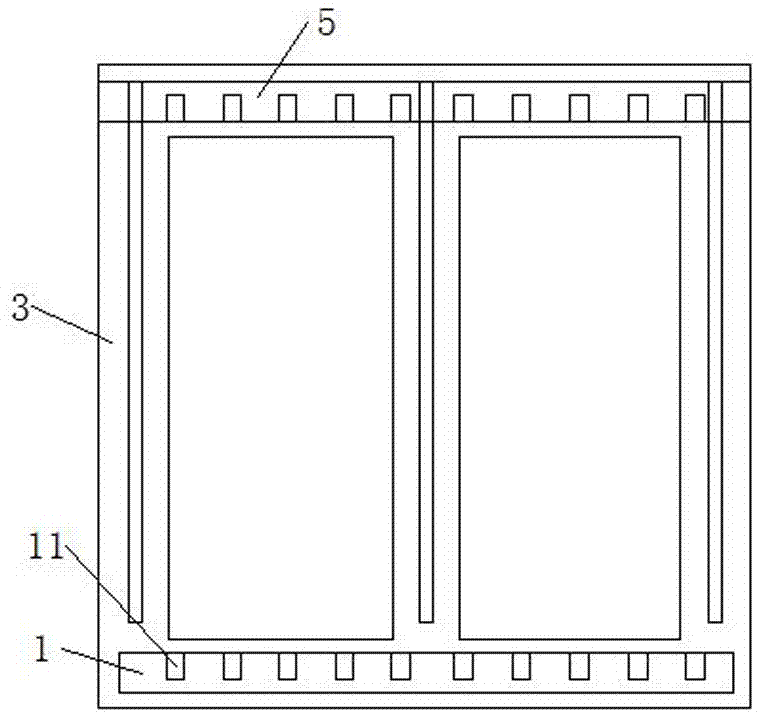

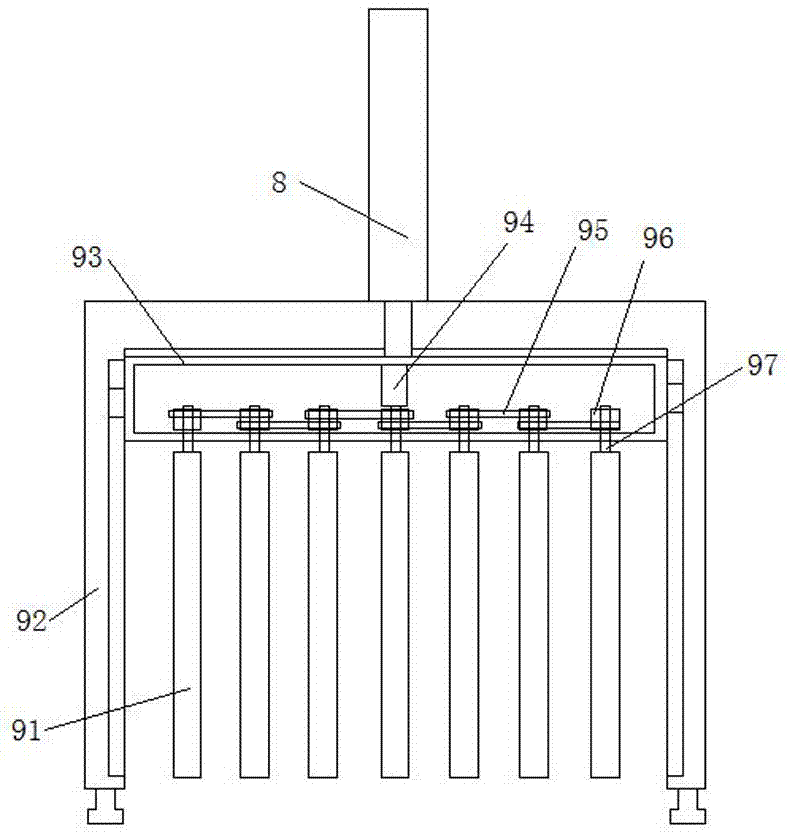

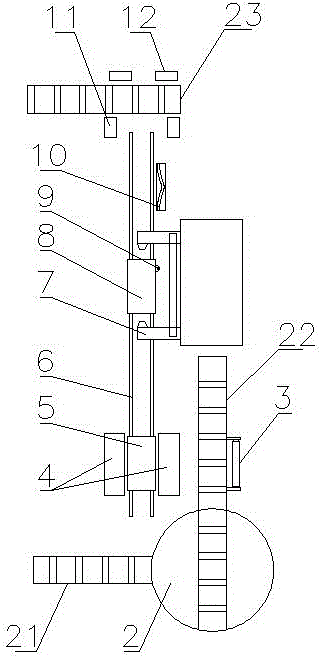

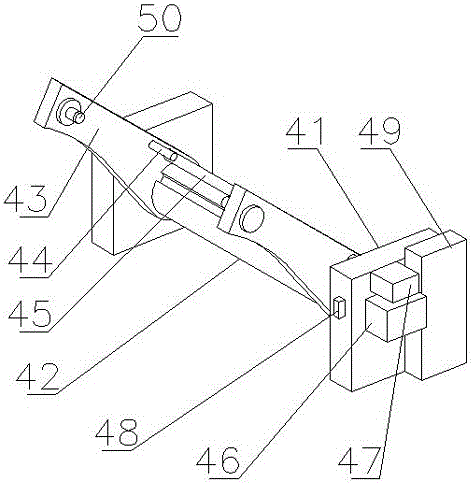

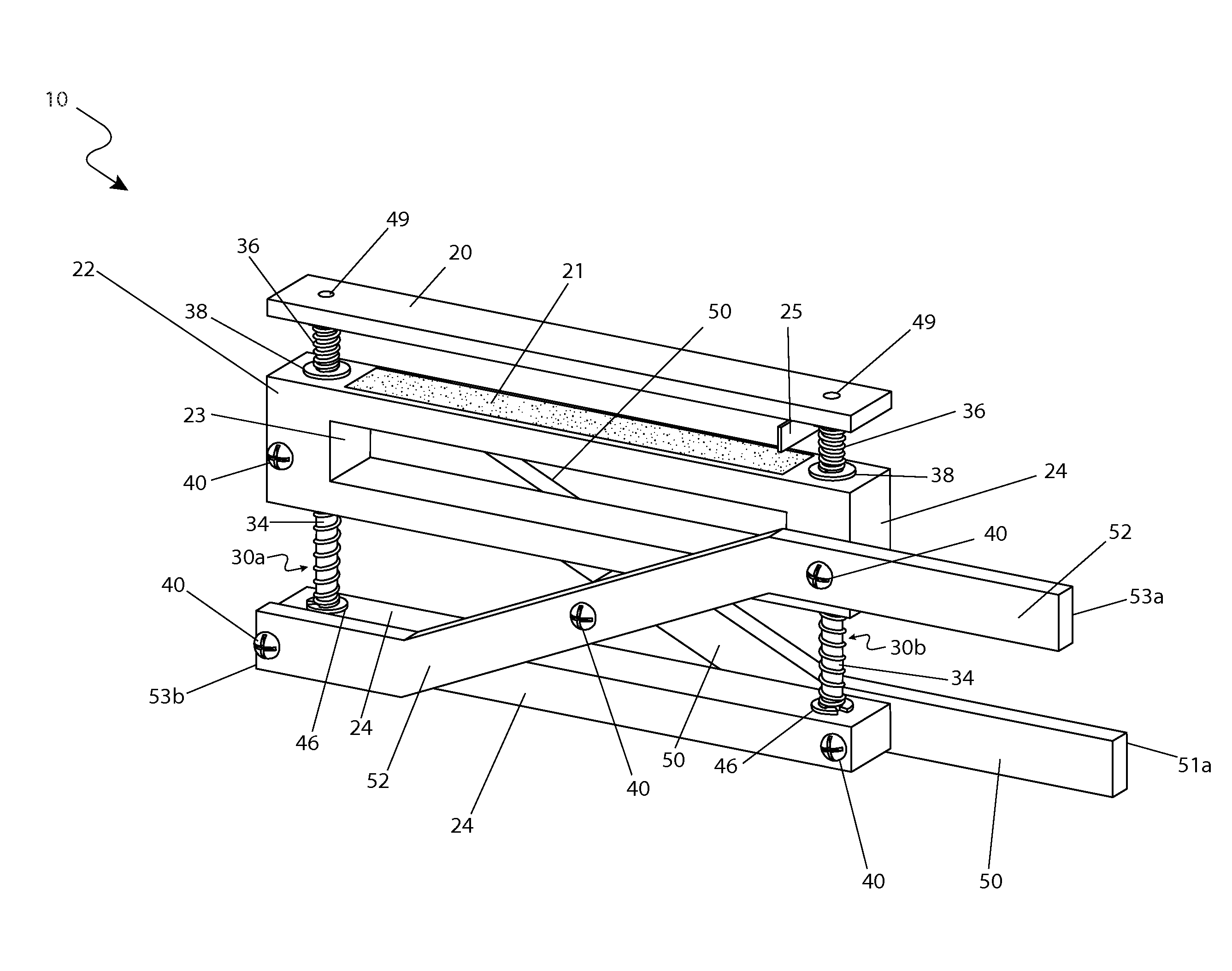

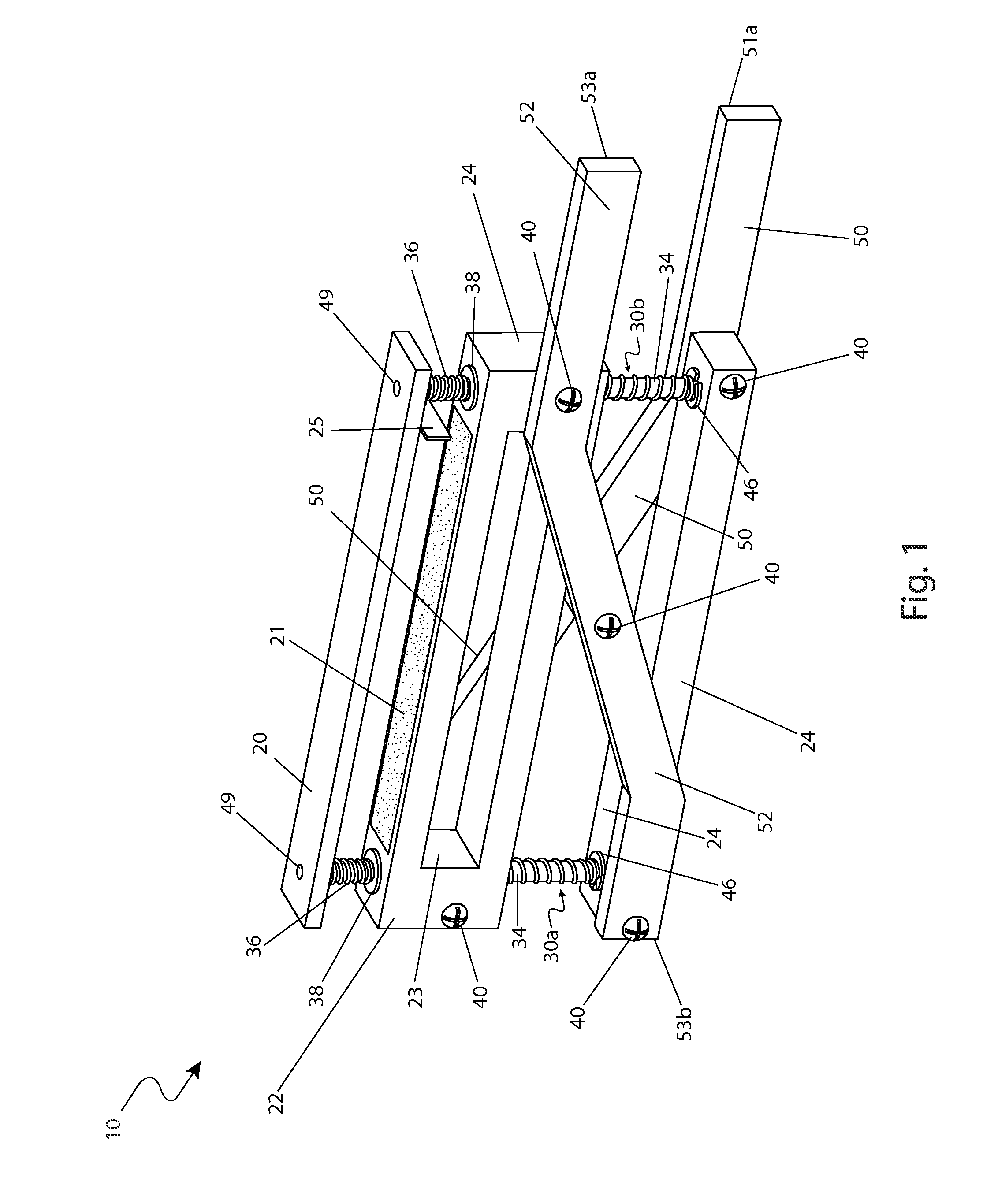

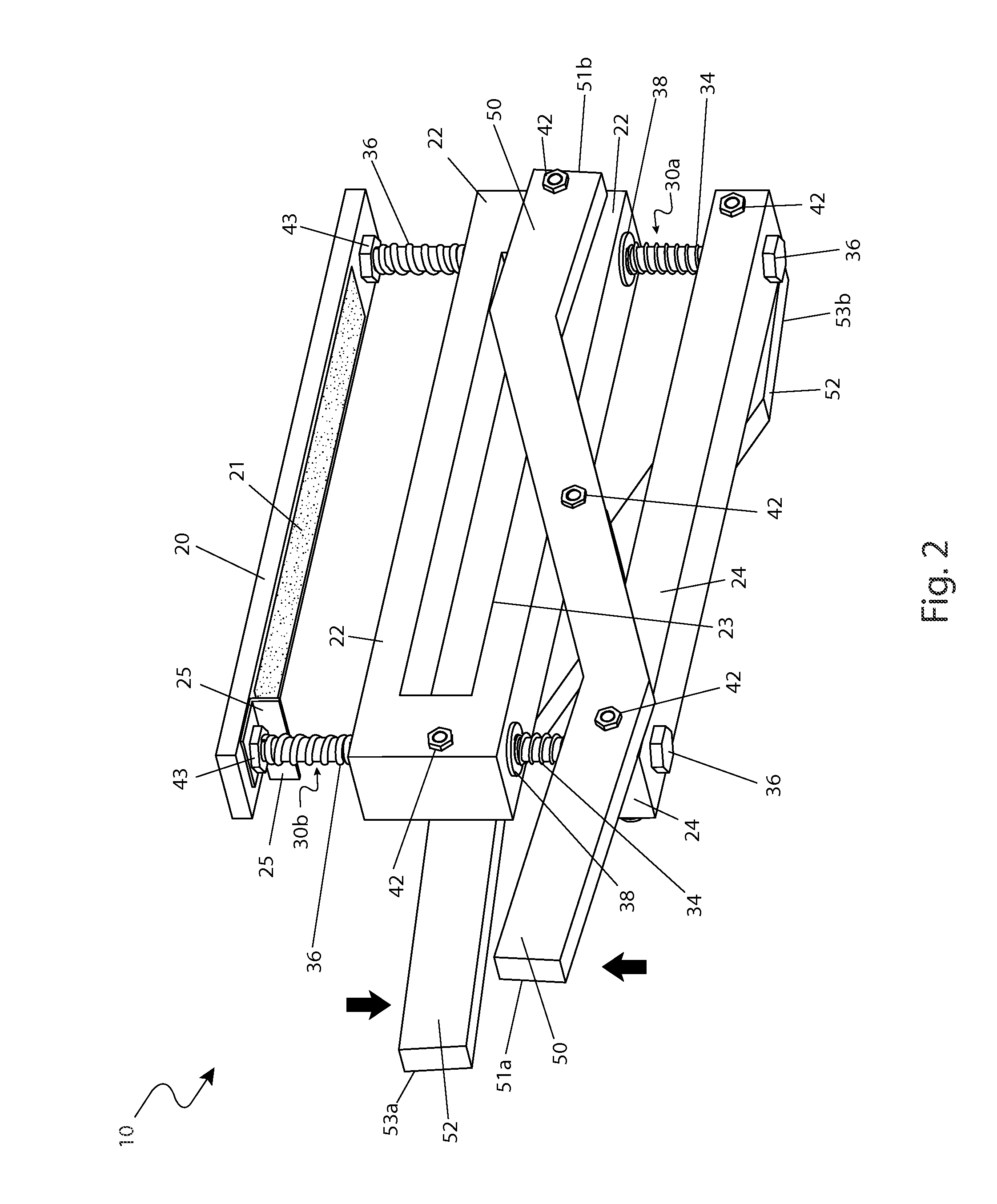

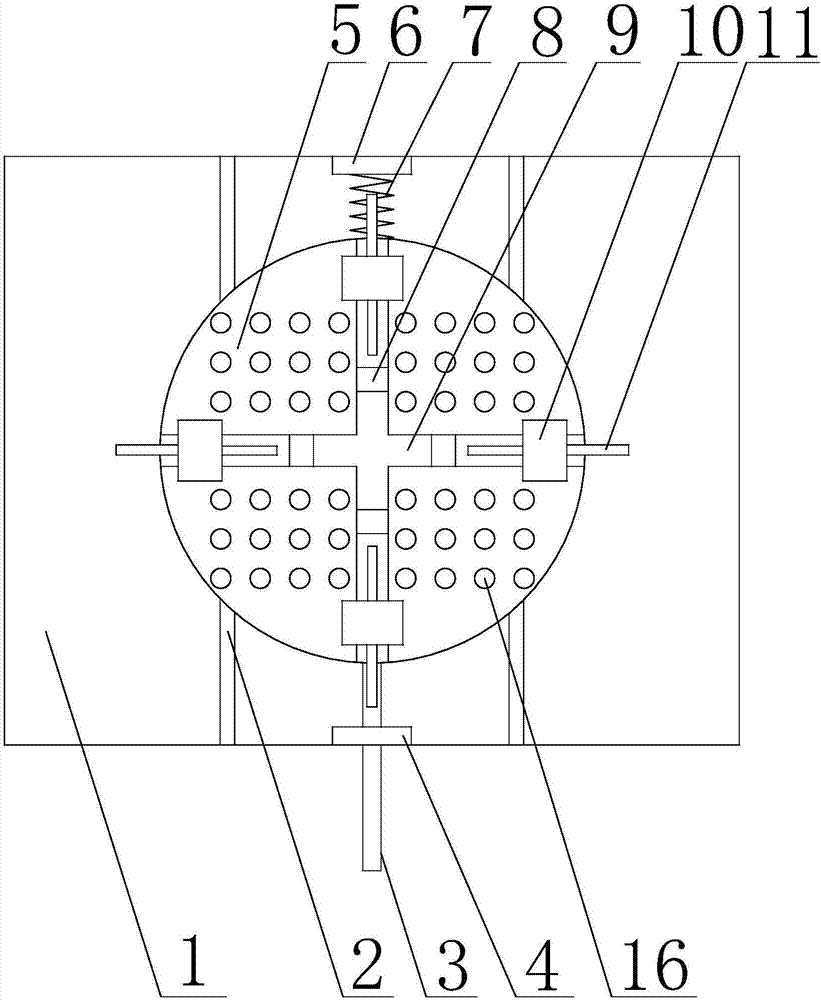

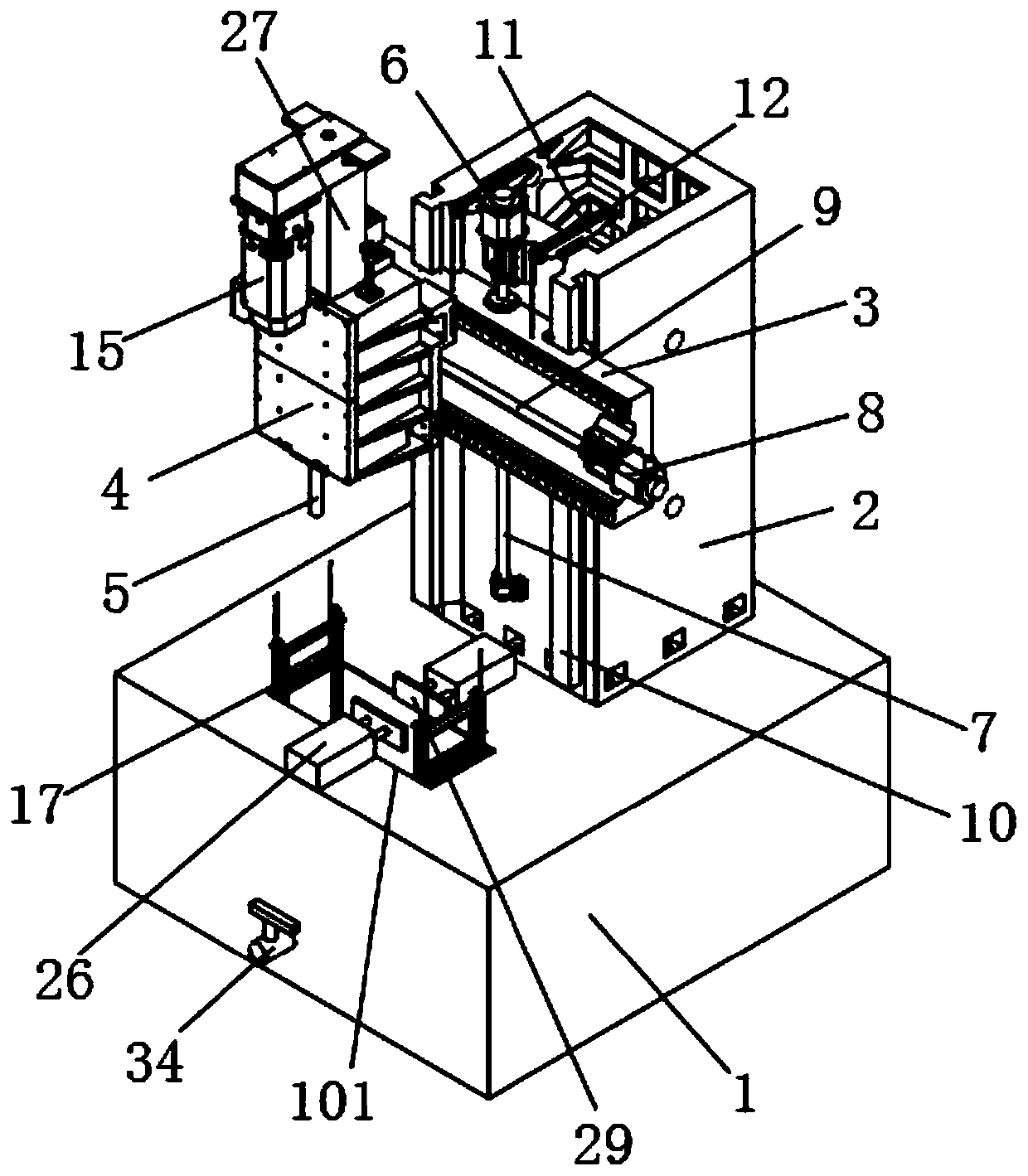

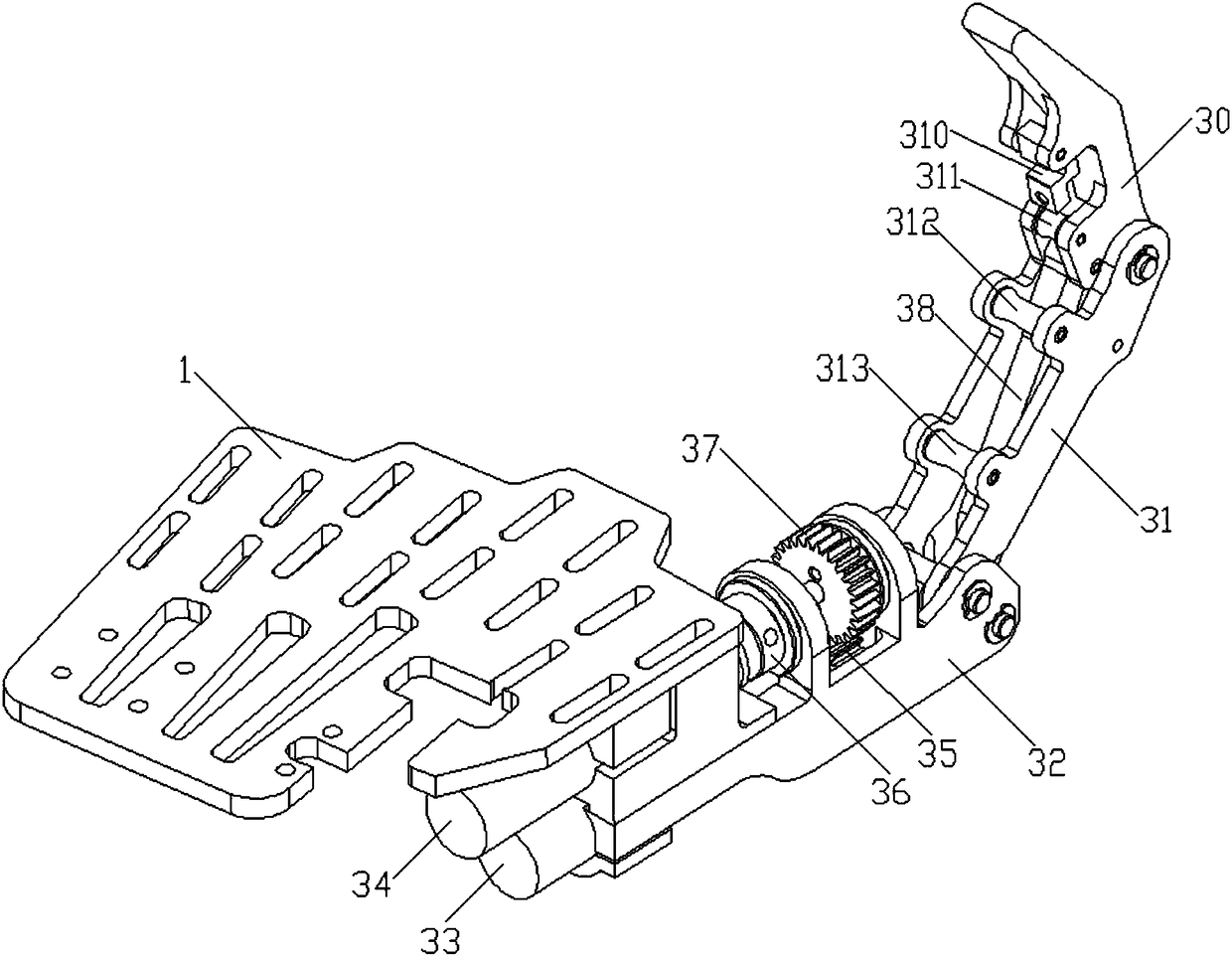

Automatic paper feeding system of corrugated paper board production line

ActiveCN106429570AQuick gripPrecise and convenient clamping and positioningWebs handlingProduction lineAutomatic control

An automatic paper feeding system of a corrugated paper board production line comprises a conveyor A (21), a conveyor B (22), a conveyor C (23), an electric rotary table (2), a paper kicking device (3), a pair of paper-feeding turning plates (4), a paper feeding trolley (5), a lifting arm (7), a paper withdrawing trolley (8) and a remaining roll turning and unloading device. The lifting arm (7) comprises a base (41), a rotary shaft (42), a pair of clamping arms (43), a lead screw (45), a motor A (46), a motor B (47), a distance measurement sensor (48) and a PLC (49). The automatic paper feeding system has the advantages that the width and the diameter of a paper roll are measured automatically through a set of sensors, a chuck of the lifting arm can rapidly clamp the paper roll and lift and put down the paper roll, clamping and positioning are accurate and convenient, mechanized automatic control can be achieved in the whole procedure from feeding of the paper roll to roll withdrawing, and labor is saved.

Owner:HUBEI JINGSHAN LIGHT INDAL MACHINERY

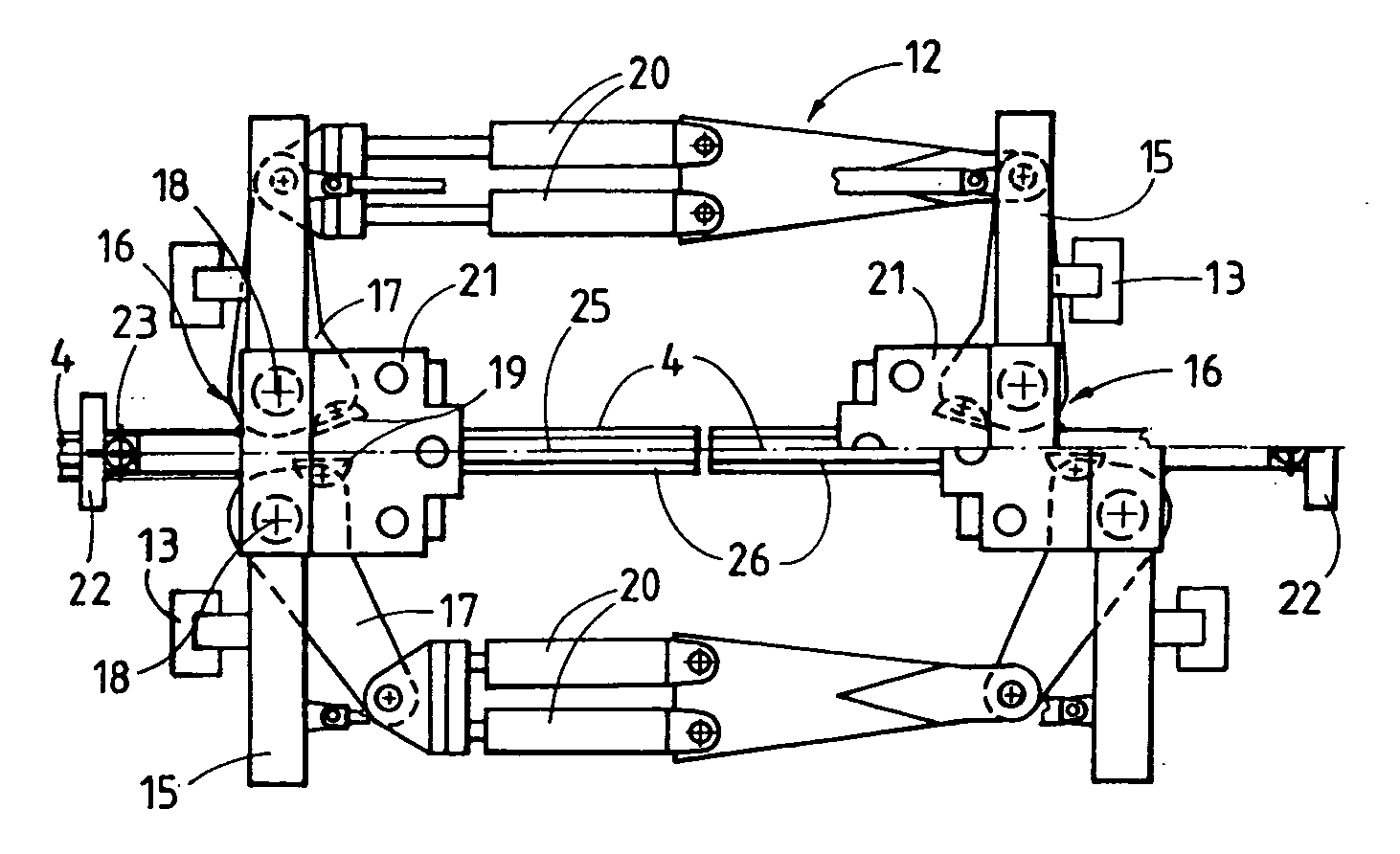

Machine and method for welding rails of a track

InactiveUS7523707B2Quick and precise and automatically executable grippingIncrease expensesRailsBallastwayEngineeringMechanical engineering

A machine for welding the rails of a track includes a rail pulling device that grips the rail ends and pulls them together so that they can be welded to one another. Two rail clamps provided for gripping the rails are fastened to the rail pulling device. The rail clamps are each vertically adjustable in their position relative to the rail pulling device by way of a respective adjustment drive in a direction extending perpendicularly to a pulling device plane formed by hydraulic drives of the rail pulling device. With this, the rails can be lifted from ties in a simple manner in order to enable the clamping members of the rail pulling device to grip the rails.

Owner:FRANZ PLASSER BAHNBAUMASCHINEN IND GMBH

Connector cover plate clamping conveying mounting mechanism

InactiveCN103746249AEasy to processQuick gripLine/current collector detailsEngineeringMechanical engineering

The invention discloses a connector cover plate clamping conveying mounting mechanism. The connector cover plate clamping conveying mounting mechanism comprises a conveying mechanism and a clamping moving mechanism, an air cylinder is arranged on the base, a guide rail is arranged in front of the air cylinder, a sliding seat connected with an air cylinder rod of the air cylinder is arranged on the guide rail, the top of the sliding seat is fixedly provided with a push plate, the front end of the guide rail is provided with a clamping plate, the clamping plate is internally provided with a vertical sliding groove for placing the cover plate, the push plate can penetrate through an opening located under the vertical sliding groove, and the front end of the opening is provided with a placing seat; and a propelling air cylinder is arranged on the top of a support table, the front end of the propelling air cylinder is provided with a sliding rail, a support is arranged on the sliding seat, a front surface of the support is provided with a sliding table air cylinder which controls a moving plate to move up and down, and a clamping air cylinder is arranged in front of the moving plate. The connector cover plate clamping conveying mounting mechanism provided by the invention is simple in structure, stable in clamping movement, fast in moving speed, and high in efficiency, and can be matched with subsequent processing production.

Owner:KUNSHAN FOR EASIER AUTOMATION TECH

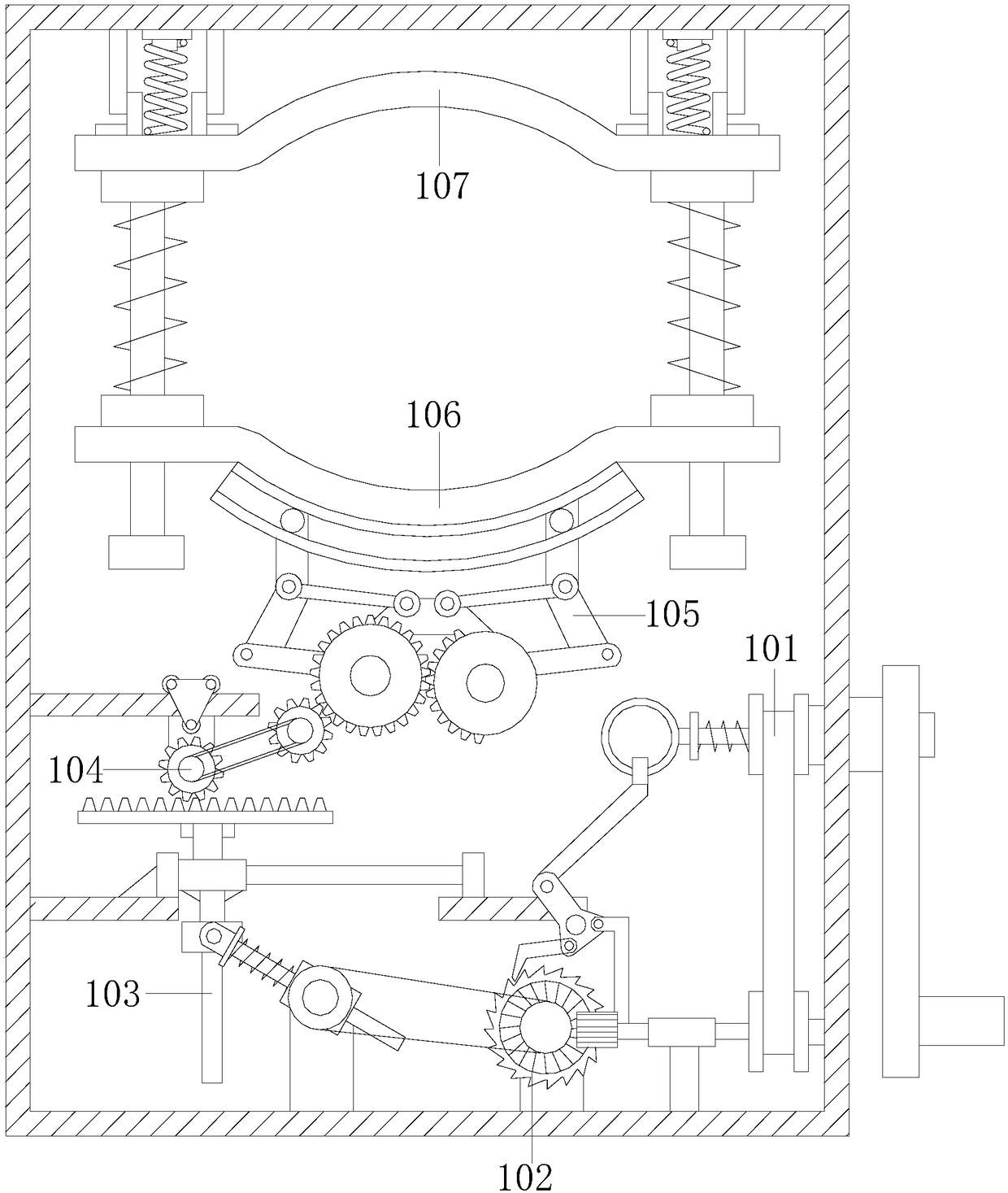

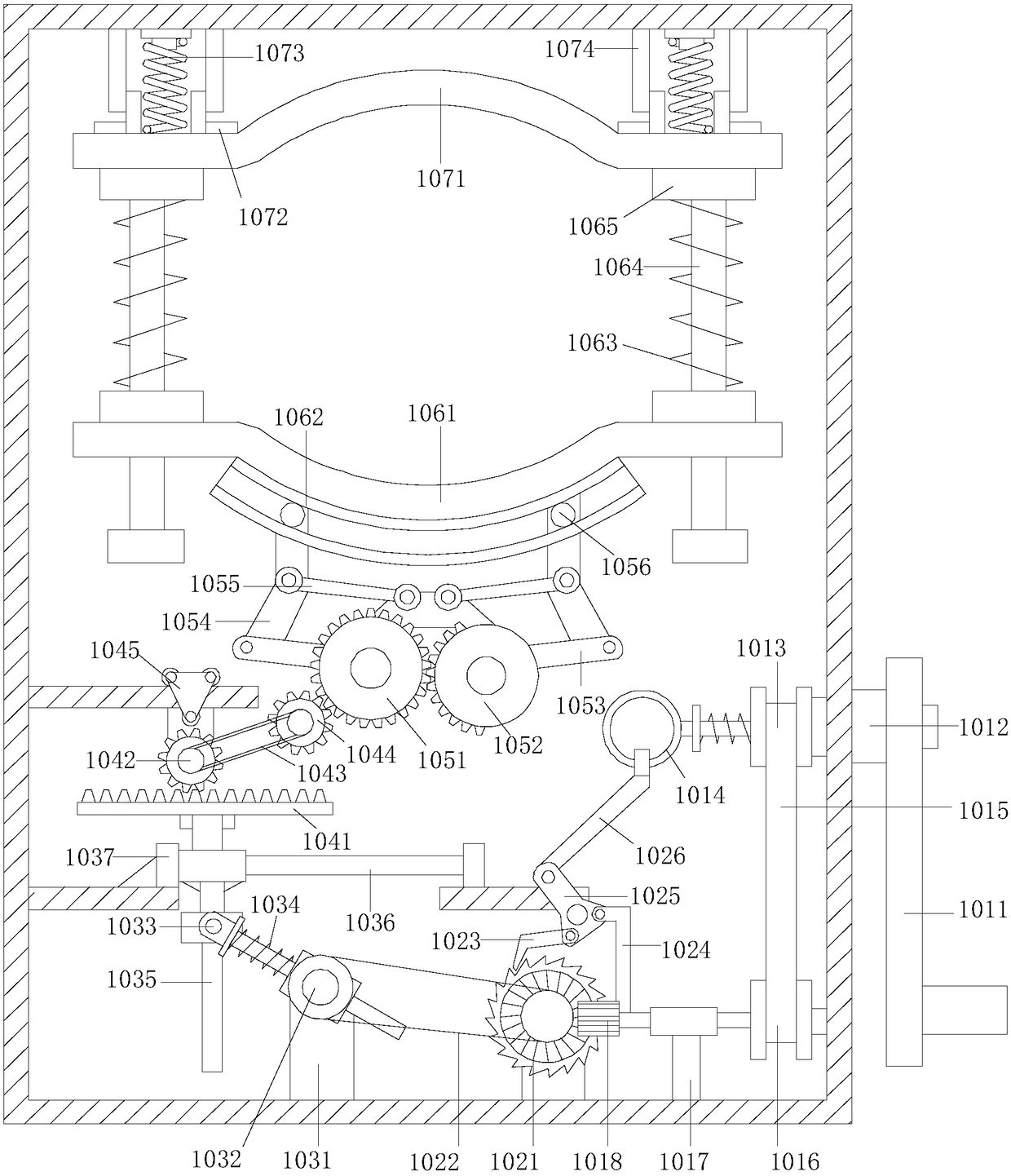

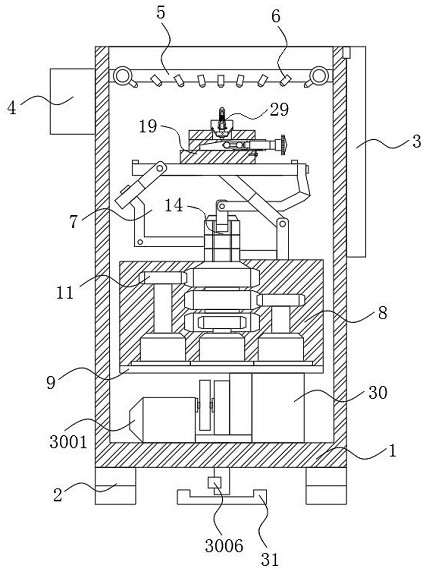

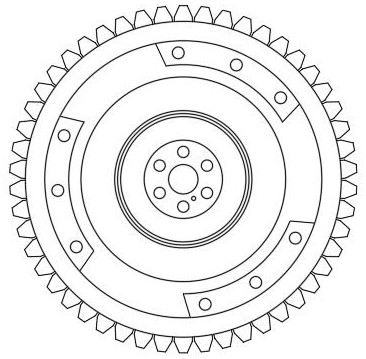

Flywheel assembly machining equipment with chipping cleaning function

InactiveCN112276659AWith debris cleaning functionWith cleaning functionMetal working apparatusPositioning apparatusMotor vehicle partGear wheel

The invention discloses flywheel assembly machining equipment with a chipping cleaning function, and relates to the technical field of automobile part machining. The flywheel assembly machining equipment specifically comprises a box body, a coaxial parallel mechanical platform, a wedge auxiliary rapid clamping mechanism, a self-locking supporting mechanism and an automatic overturning and discharging mechanism, wherein a damping base is arranged at the bottom end of the box body, and the automatic overturning and discharging mechanism is arranged on one side of the bottom end of the box body.According to the flywheel assembly machining equipment with the chipping cleaning function, the coaxial parallel mechanical platform is arranged, the mechanism is a spherical parallel mechanical platform with a coaxial input shaft, and the mechanism is controlled by three stepping motors through gear transmission and nine rotating joints, any angle position can be achieved in a three-dimensional space, the machining angle of a workpiece arranged in a loading platform at the top end of the coaxial parallel mechanical platform can be changed at will under the assistance of the coaxial parallel mechanical platform, and by matching with air nozzles arranged at the surface end of an annular air injection pipe in an array mode, the comprehensive chipping cleaning process of a flywheel assembly material clamped by the wedge auxiliary rapid clamping mechanism is realized.

Owner:DONGGUAN UNIV OF TECH

Adjustable cutting guide

InactiveUS8578827B1Simple and easy and quick repetitionQuick installationGang saw millsCircular sawsCutting guide

A clamping cutting guide to assist a carpenter in performing various wood techniques comprises a guide plate, a pair of guide rods, and a spring-loaded clamping portion. The guide rods extend perpendicularly downward along side areas and are inserted into respective springs to provide a clamping force to the stationary guide plate and a mobile clamping plate. The cutting guide also comprises a pair of pivoting handles open the clamp portions during loading / unloading of a desired object to be cut, thereby allowing a user to operate the guide using a single hand.

Owner:JAROCHE THOMAS

Welding fixture tool with adjustable angle

InactiveCN112427872AQuick gripAvoid affecting the welding strengthWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBilateral symmetry

The invention discloses a welding fixture tool with an adjustable angle, and belongs to the technical field of welding fixture tools. The welding fixture tool with the adjustable angle comprises a bottom plate, wherein a left stand column and a right stand column are vertically installed on the upper surface of the bottom plate in a bilateral symmetry mode, a left positioning module is detachablyinstalled on the front portion of the left stand column, and a workpiece II is clamped on the left positioning module through a positioning clamp I; and a right positioning module is detachably installed on the front portion of the right stand column, and a workpiece I is clamped on the right positioning module through a positioning clamp II. A positioning hole is transversely formed in the middleof the left stand column, and a plurality of sets of adjusting holes are further formed in the left stand column at equal intervals, so that the left positioning module fixed on the left stand columncan realize angle adjustment. An arc-shaped sliding groove is formed in the middle of the right stand column, the angle of the right positioning module is adjusted along the sliding groove through afront fastening knob and a rear fastening knob, and the position of the right positioning module is fixed, so that the angle adjustment is accurate, and the alignment degree of the front ends of the workpiece I and the workpiece II is good.

Owner:安徽省佳艺休闲用品有限公司

Method for improving machining efficiency of exhaust manifold air inlet flange

InactiveCN107443105AImprove work efficiencyImprove processing efficiencyWork clamping meansCleaning using gasesAirflowMachining process

The invention discloses a method for improving the machining efficiency of an exhaust manifold air inlet flange. The method comprises the following steps that 1, a to-be-machined flange is put at the top of a clamping disc; 2, adjusting rods are rotated in sequence, the tail ends of the adjusting rods enter air outlet channels of clamping plates, the clamping plates are pushed to move in grooves, and then, the to-be-machined flange is fastened; 3, in the flange machining process, a push rod is rotated to push a movable table to move in moving grooves, meanwhile, a threaded rod is loosened, the clamping disc is rotated, and the flange is machined flexibly; 4, in the flange machining process, a draught fan is started, airflow generated by the draught fan enters a fan cover, the airflow in the fan cover is blown into the grooves and the clamping disc, and iron filings generated during flange machining are removed; and 5, after machining of the flange is completed, the adjusting rods are adjusted again, so that the flange is not clamped by the clamping plates and taken down, and another to-be-machined flange is installed. Machining can continue to be conducted without removing the iron filings on the clamping disc.

Owner:CHENGDU LINGCHUAN SPECIAL IND

Five-cylinder plunger pump head body forging processing equipment and processing method thereof

ActiveCN111390292AFlexible adjustmentSolve technical problems with poor stabilityWork clamping meansPositioning apparatusElectric machineryLiquid tank

The invention discloses five-cylinder plunger pump head body forging processing equipment and a processing method thereof. The equipment comprises a support base, wherein a support column is fixedly installed on the upper surface of the support base, the outer wall at one side of the support column is moveably installed with a lifting mounting plate in a vertical direction, the lifting mounting plate is located above the support base, one side of the lifting mounting plate is movably installed with a movable seat in a horizontal direction, a processing cutter head is arranged under the movableseat, the lower wall at the inner side of the support base is fixedly installed with a cooling liquid tank, the bottom wall at the inner side of the cooling liquid tank is vertically fixed with two sets of support rods by welding, a holding plate is arranged between the two sets of support rods, the output shaft of a geared motor is connected to a rotating rod, and one end of a lifting chain is fixedly connected to a connecting plate. The pump head body forging processing equipment can automatically quickly cool the forgings, thereby improving work efficiency and ensuring the stability and safety of the plunger pump head body forgings during processing.

Owner:YANCHENG SUNDA PETROCHEMICAL MASCH CO LTD

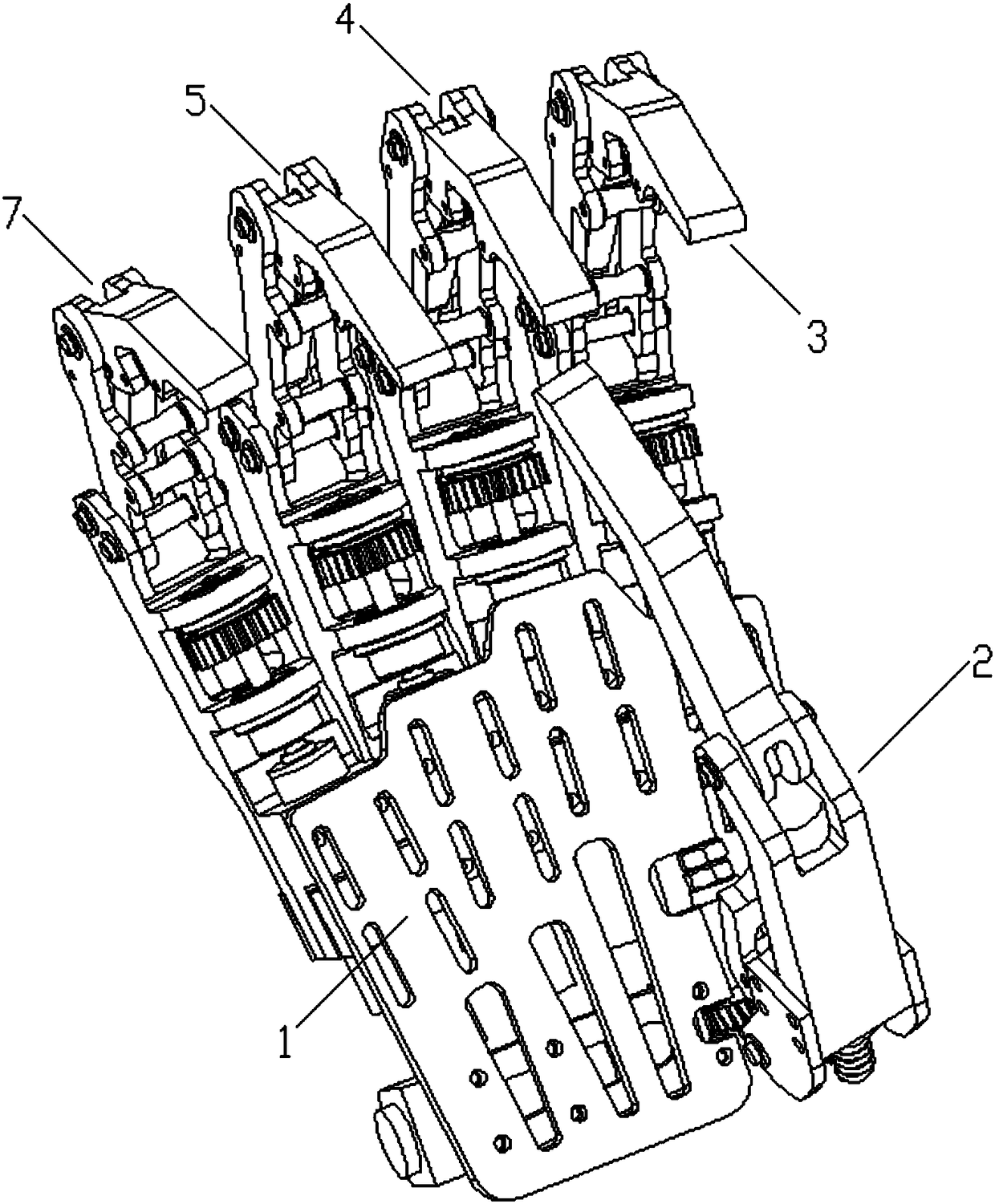

Active double-mode rope-driven five-finger dexterous manipulator

The invention relates to an active double-mode rope-driven five-finger dexterous manipulator. The manipulator comprises a palm assembly, a thumb assembly, an index finger assembly, a middle finger assembly, a ring finger assembly and a little finger assembly, wherein the thumb assembly, the index finger assembly, the middle finger assembly, the ring finger assembly and the little finger assembly are arranged on the palm assembly. The manipulator has the advantages that the structure is simple, the design is reasonable, and grabbing is flexible; the manipulator can grasp objects in a pluralityof ways through a thumb rotating motor; according to the manipulator, through two different driving modes, the problems that a manipulator is slow in object grabbling and the grabbing force of the manipulator is small are solved, the manipulator can grab an object quickly, and the generated grabbing force is large; and according to the manipulator, a four-bar mechanism is adopted, so that the number of finger driving motors is reduced under the condition that the basic daily life function of the manipulator is not affected, meanwhile, the complexity degree of the manipulator is reduced, then the manufacturing cost of the manipulator is reduced to a great extent, and the weight of the manipulator is correspondingly reduced at the same time, and therefore the manipulator has outstanding advantages in terms of the manufacturing cost and the quality and the size of the manipulator.

Owner:WUYI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com