Patents

Literature

398results about How to "Accurate printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

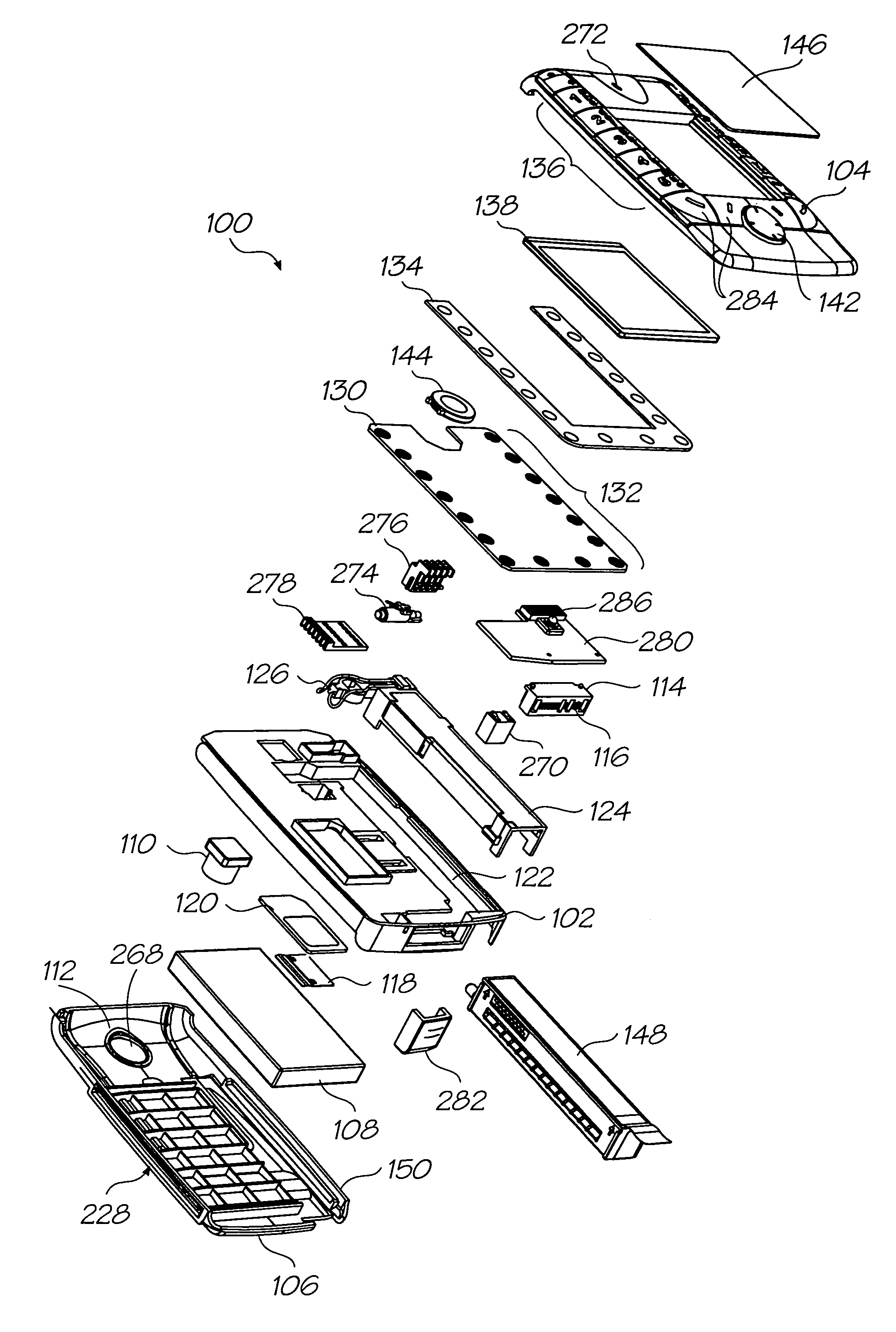

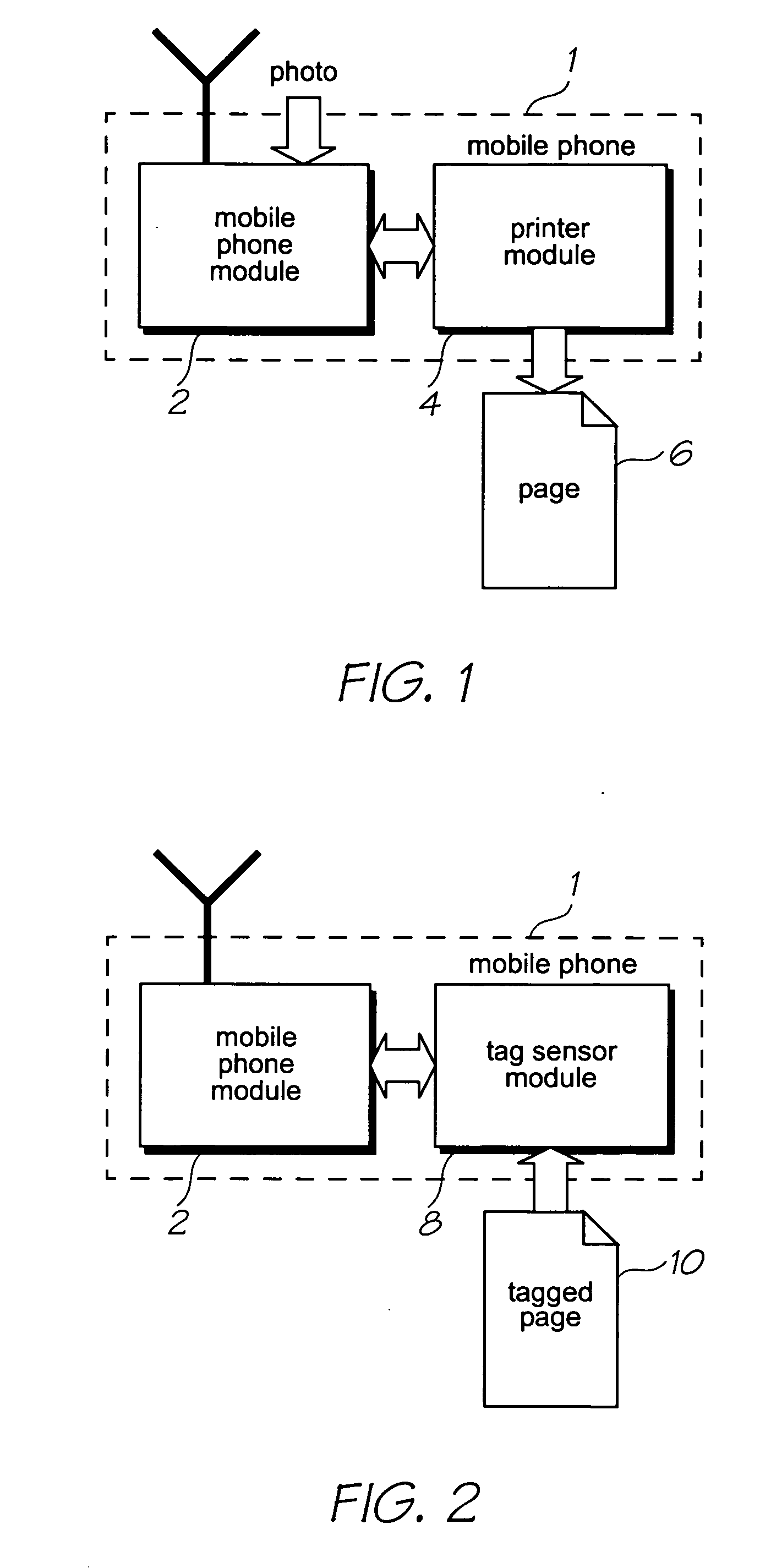

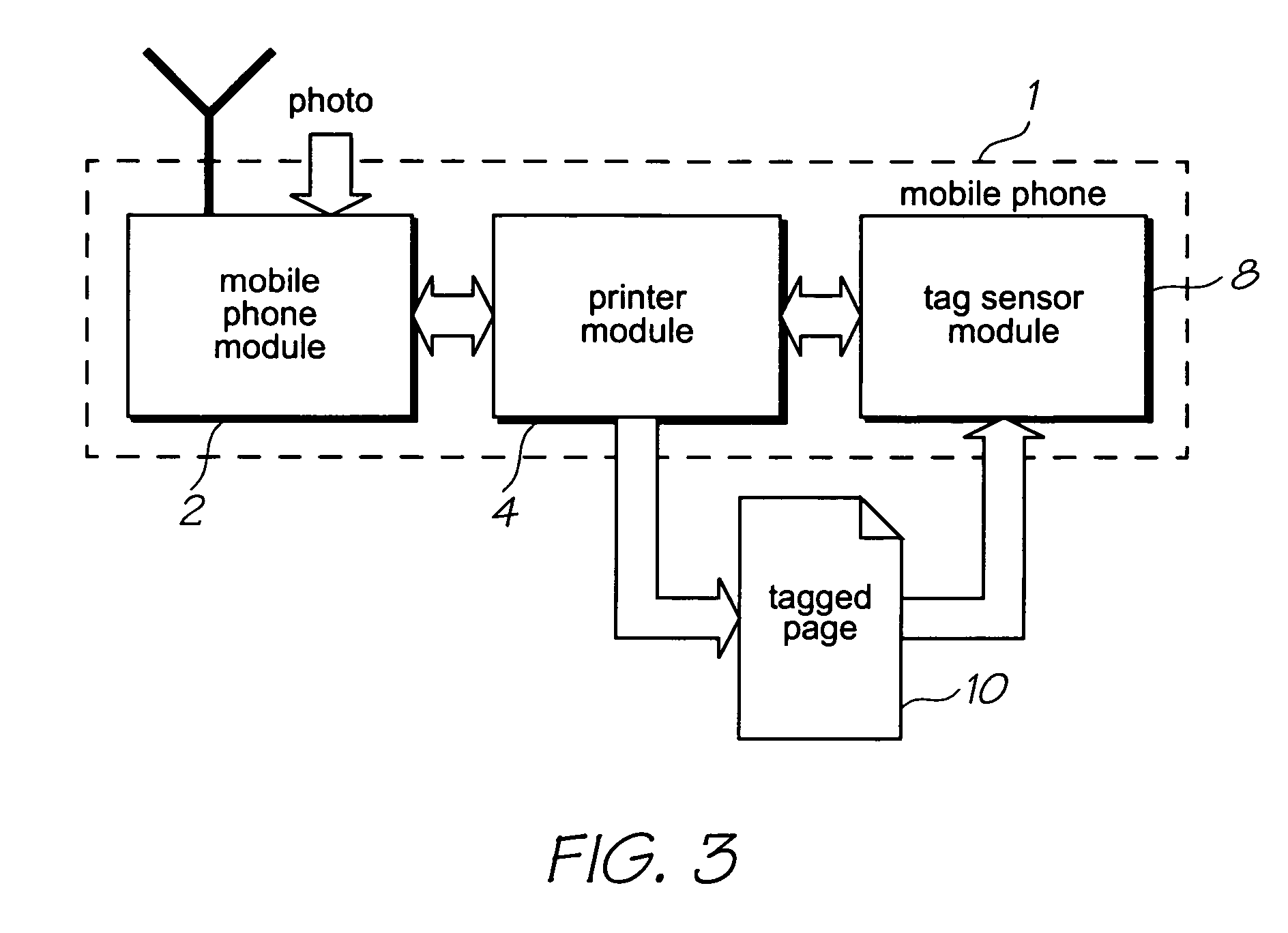

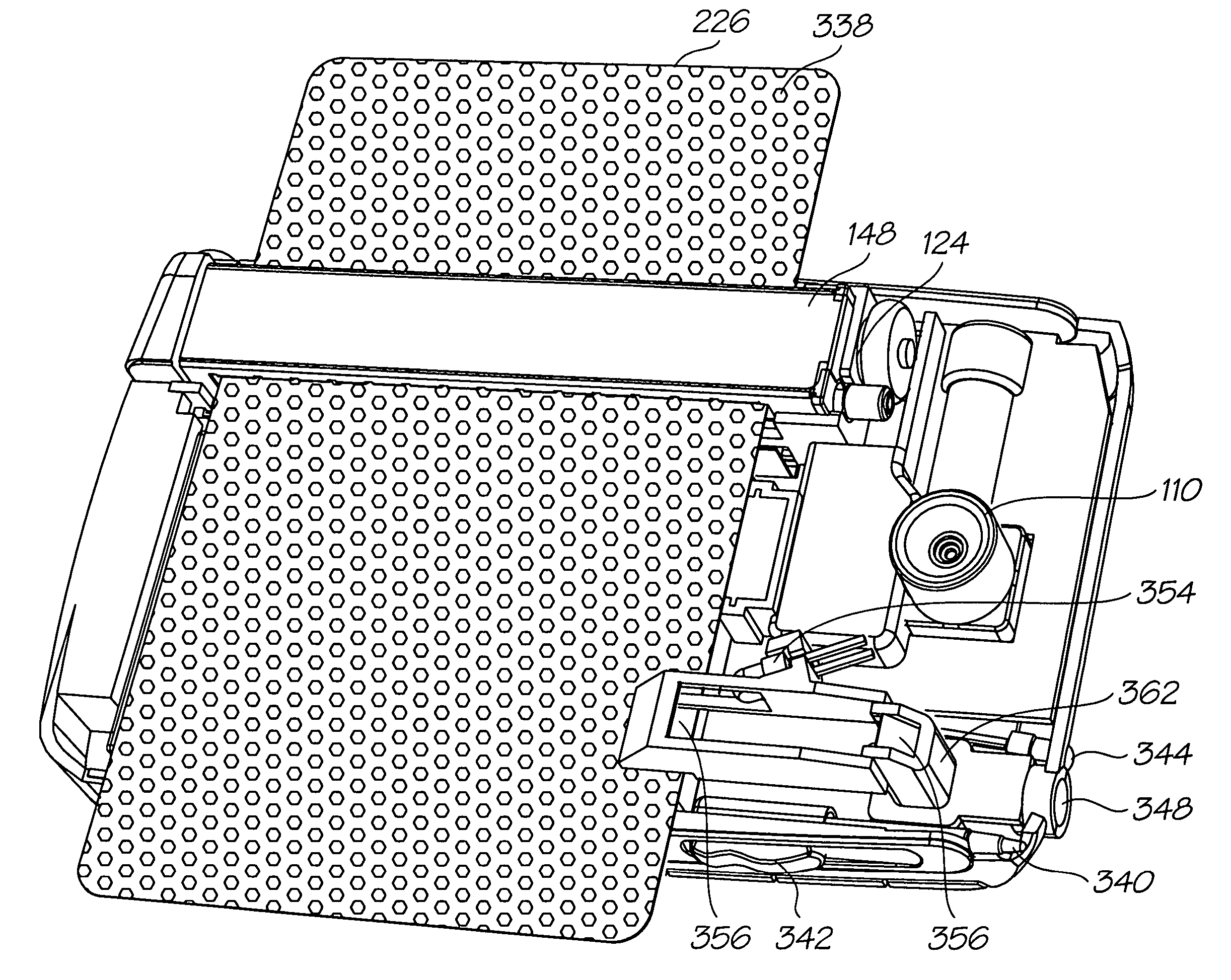

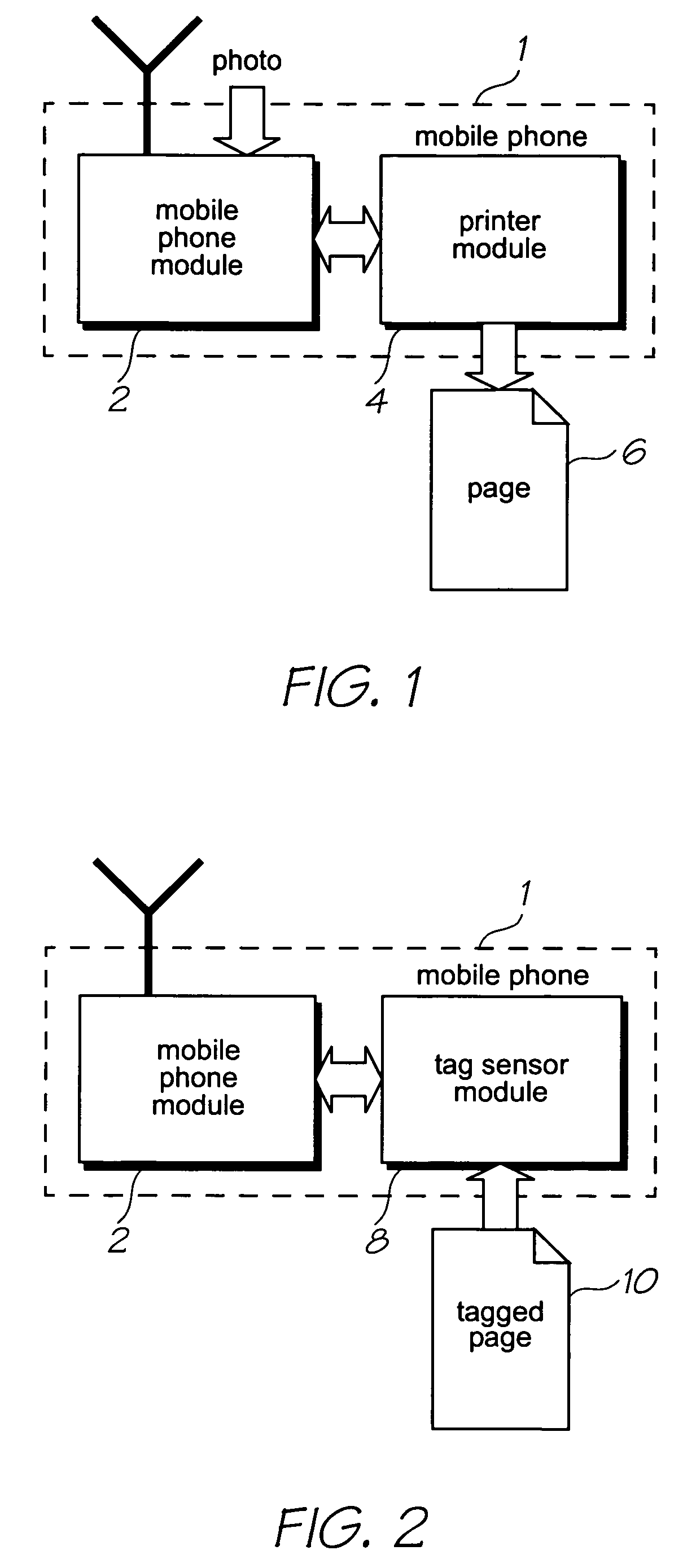

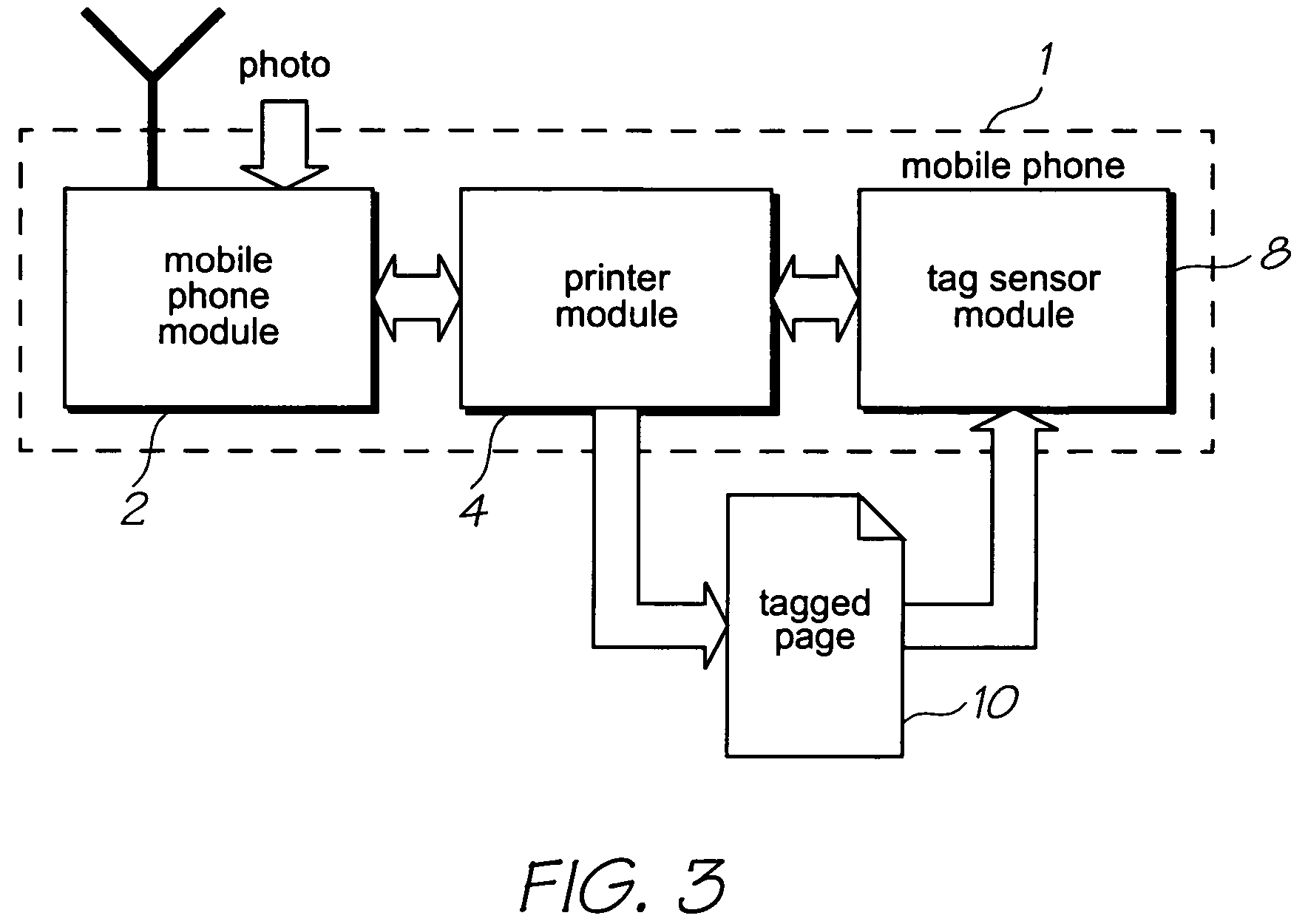

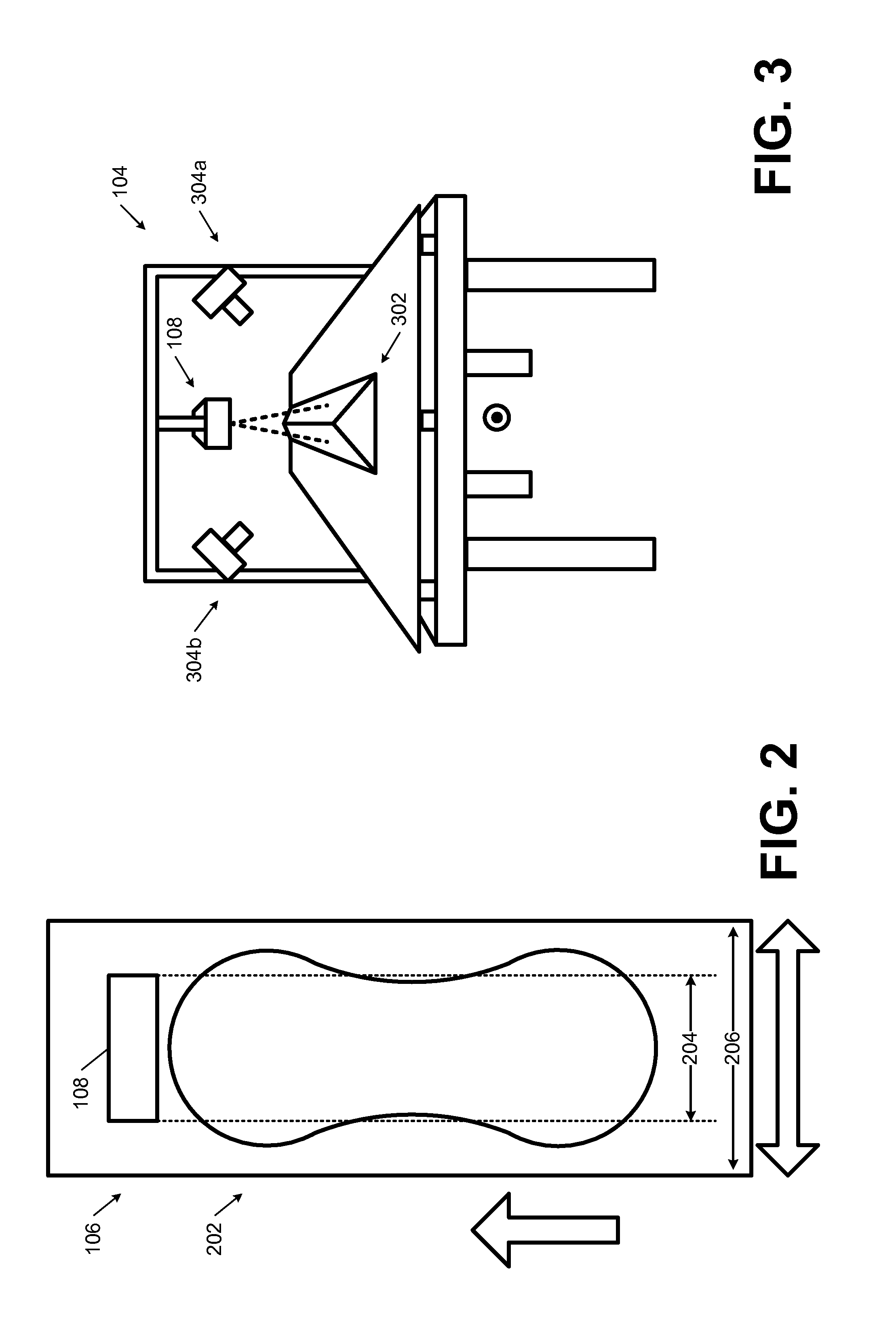

Mobile telecommunications device with media edge detection

InactiveUS20060250479A1Increased complexityIncrease in sizeTypewritersOther printing apparatusPaper sheetElectrical and Electronics engineering

A mobile telecommunications device comprising: a printhead for printing a sheet of media substrate, the sheet of media substrate having coded data on at least part of its surface; a media feed assembly for feeding the sheet of media substrate along a feed path past the printhead; a print engine controller for operatively controlling the printhead; and, a sensor for reading the coded data and generating a signal indicative of at least one dimension of the sheet, and transmitting the signal to the print engine controller; such that, the print engine controller uses the signal to initiate the printing when the sheet is at a predetermined position relative to the printhead.

Owner:SILVERBROOK RES PTY LTD

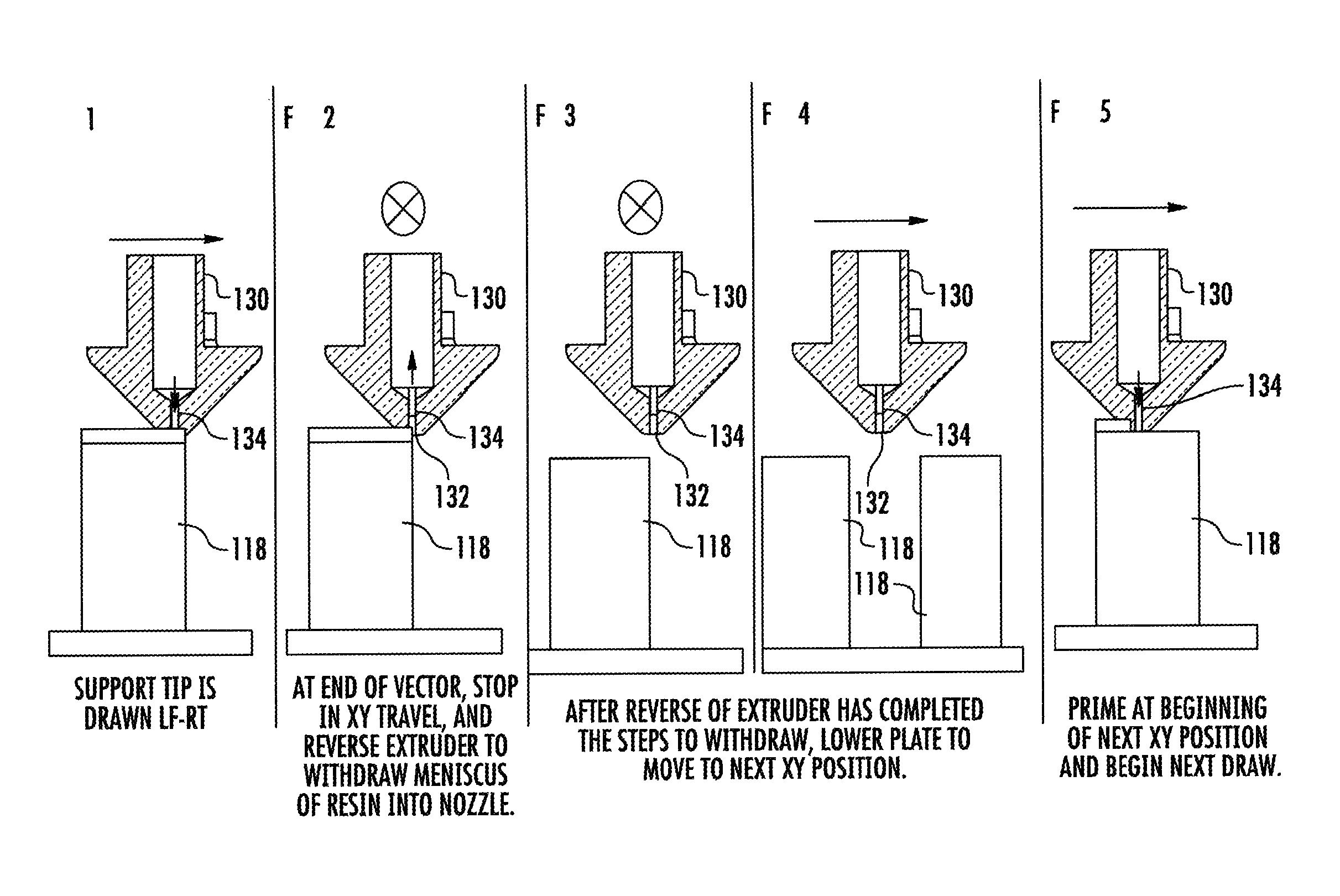

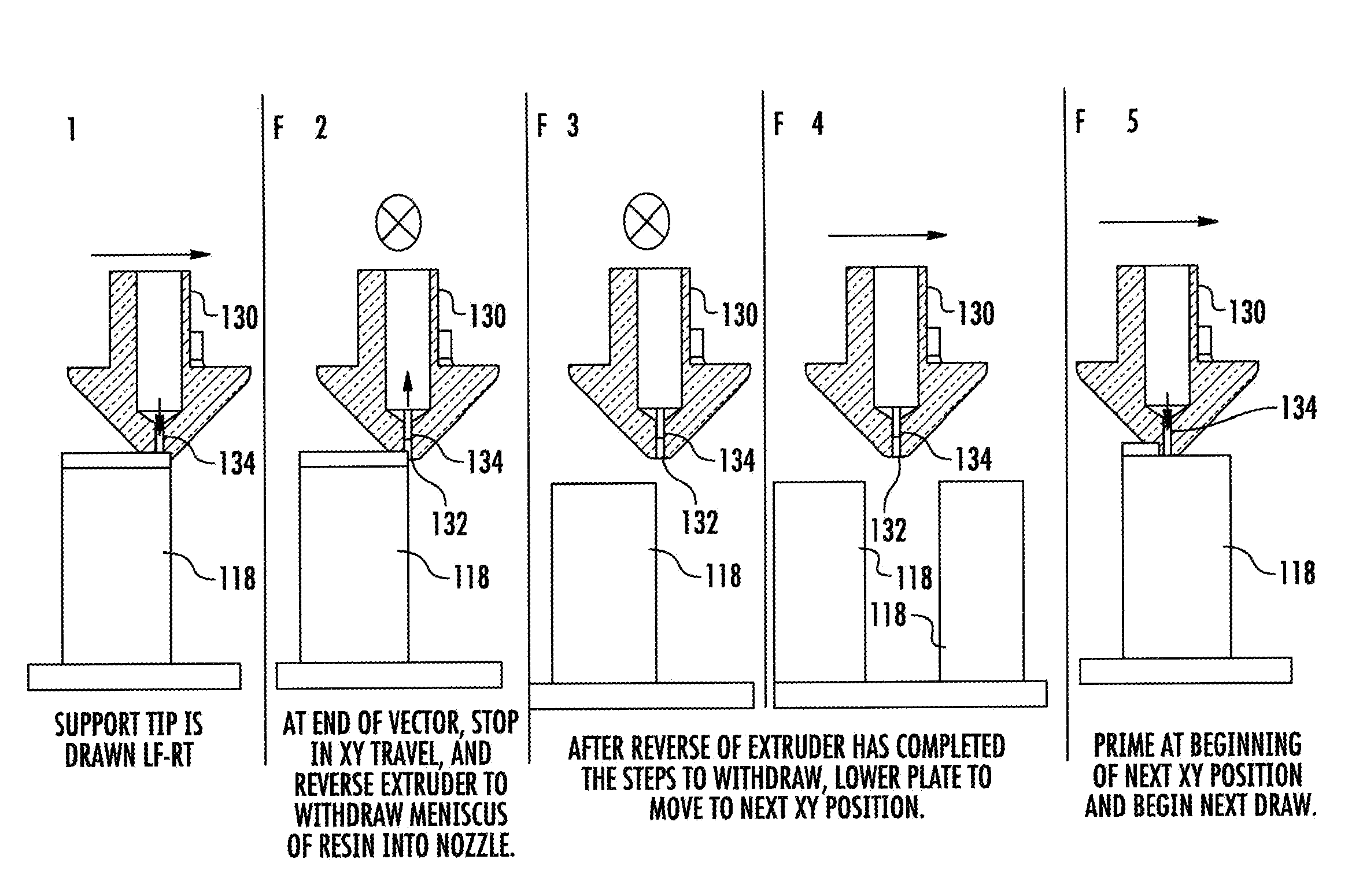

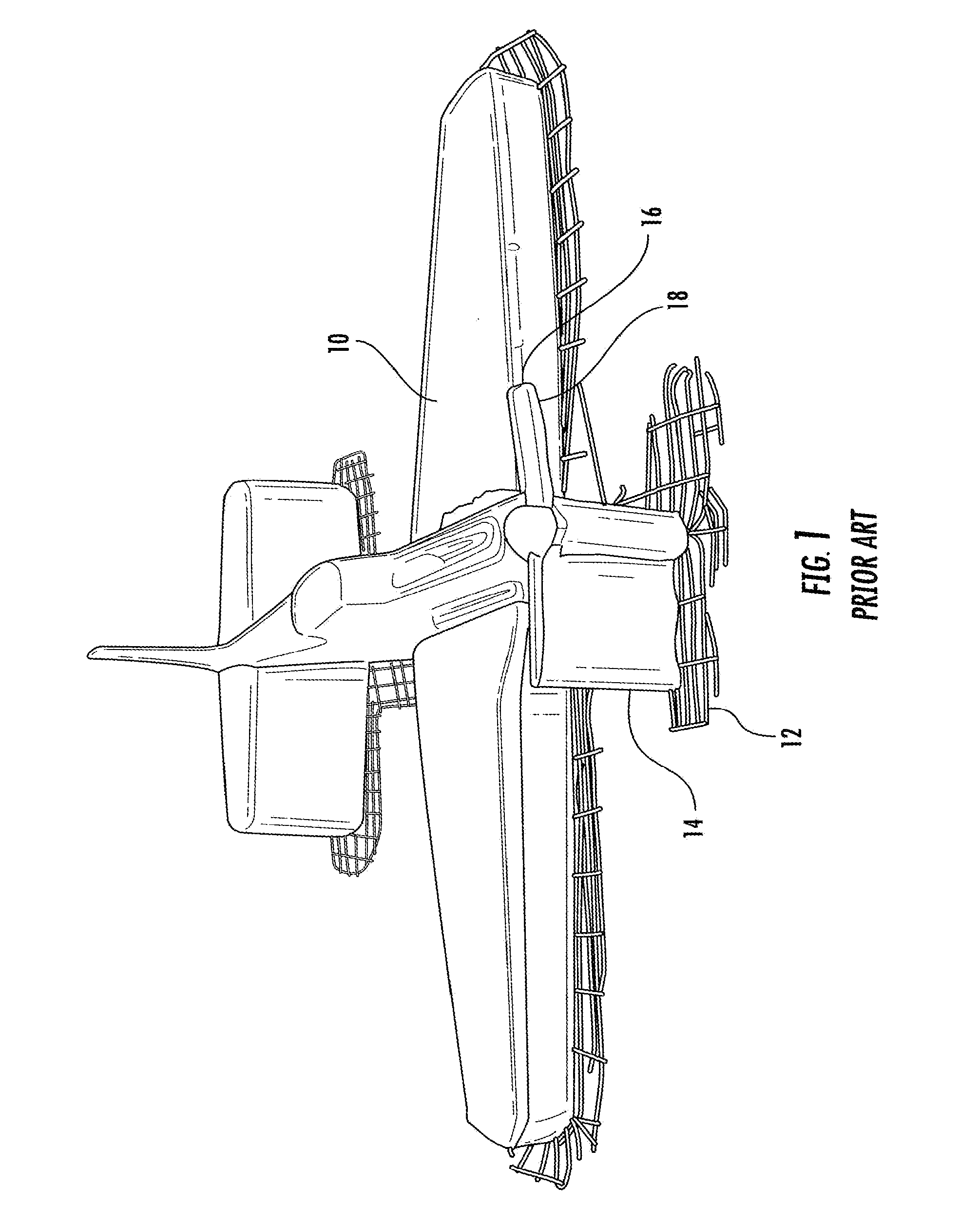

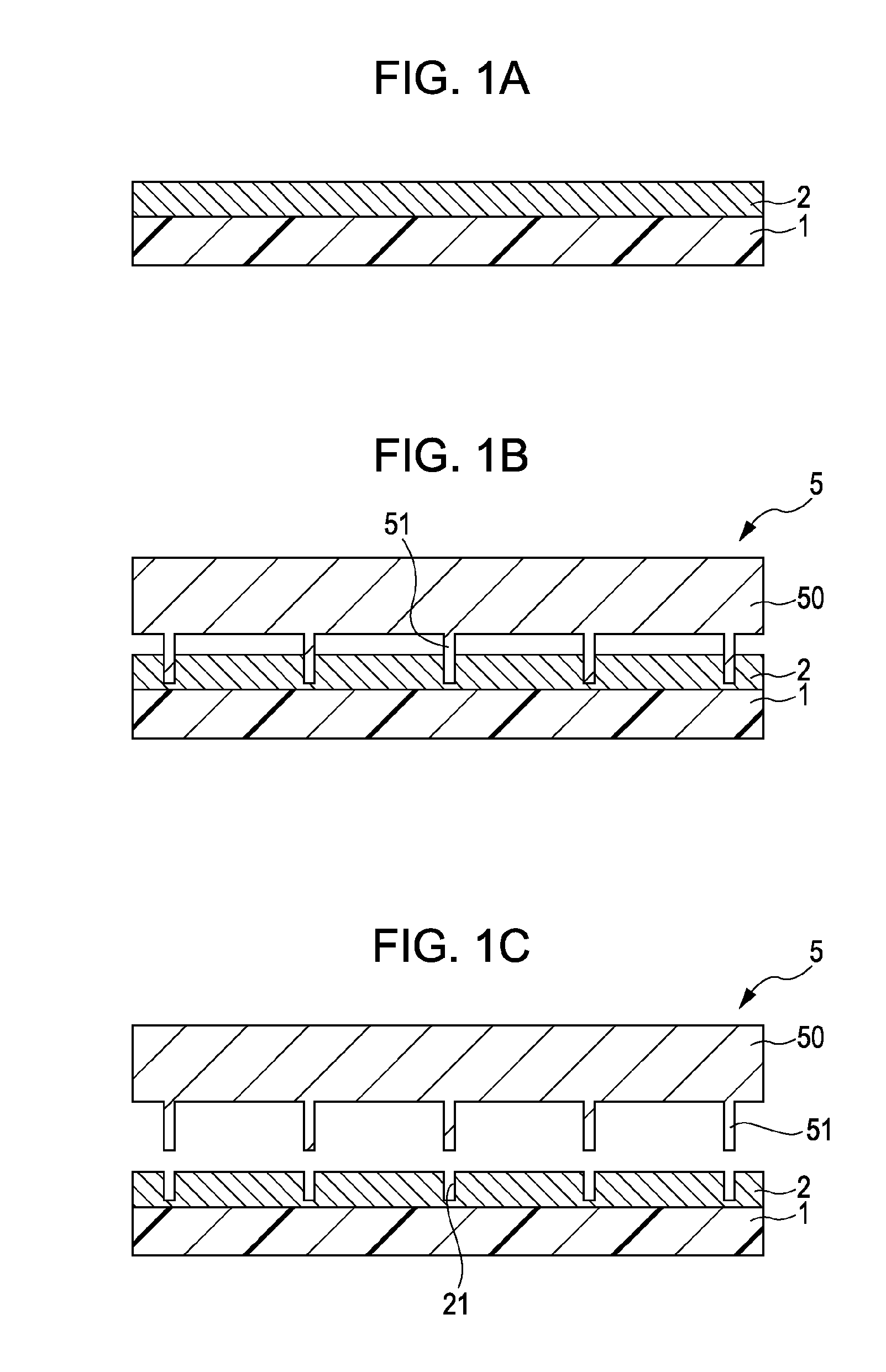

Support structures and deposition techniques for 3D printing

ActiveUS9469057B2Easy to separateFine surfaceManufacturing platforms/substratesUnsaturated ether polymer adhesivesComputer Aided DesignEngineering

Owner:3D SYST INC

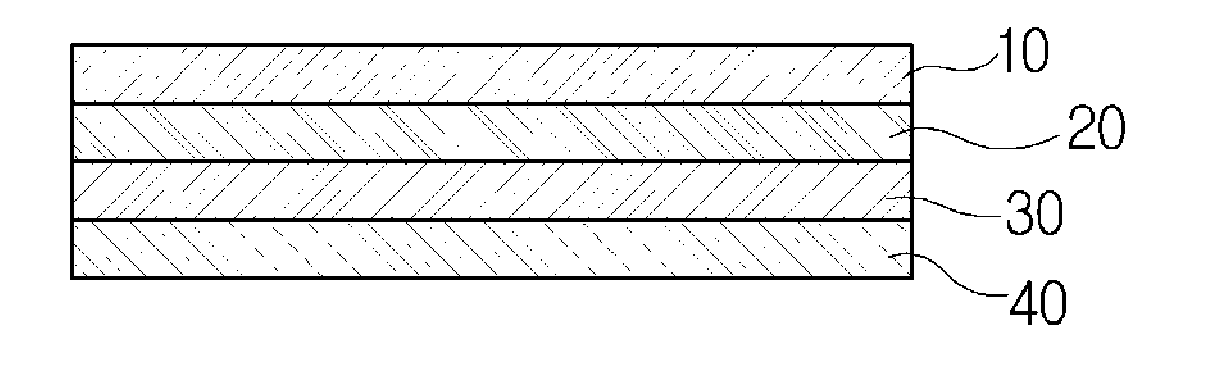

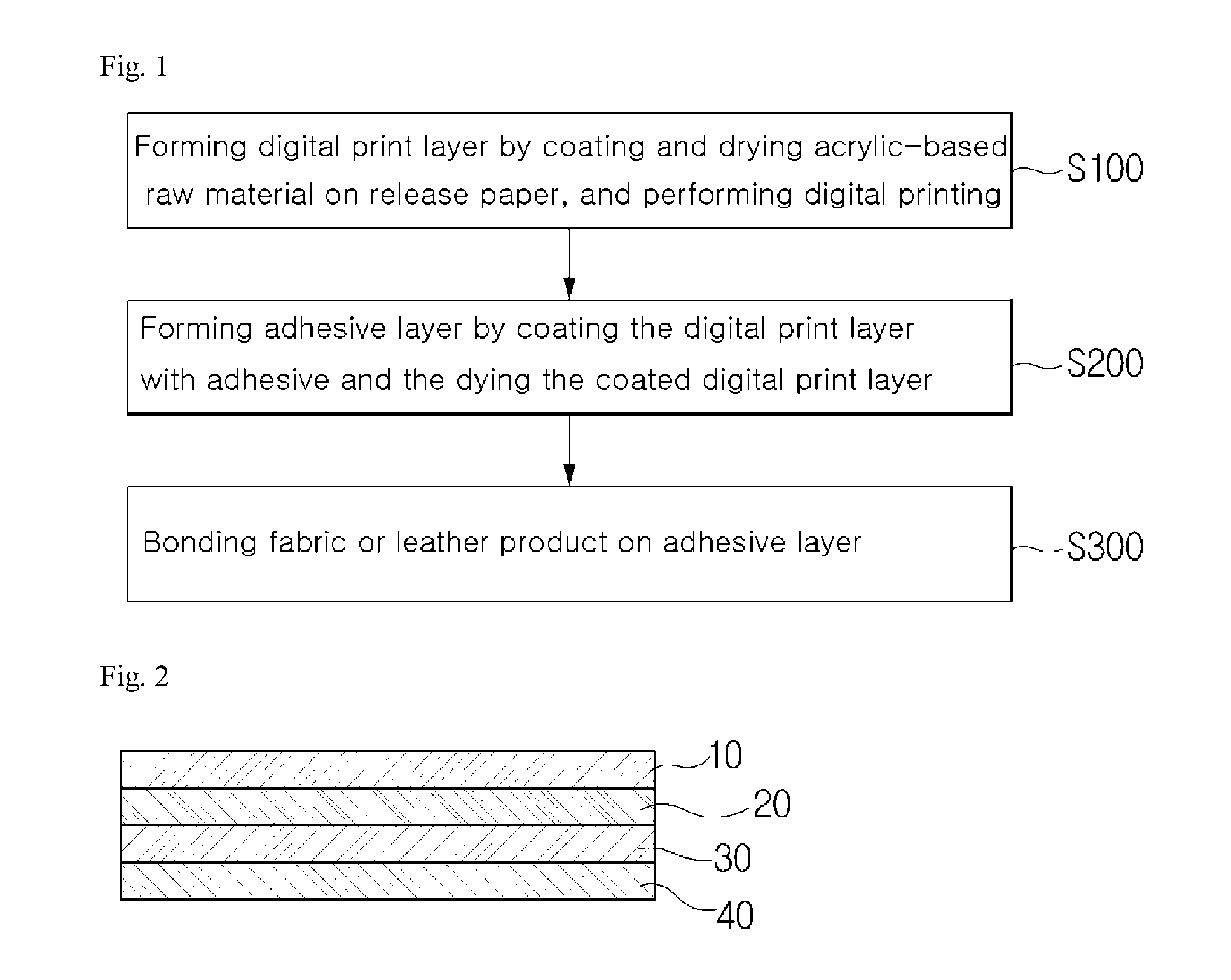

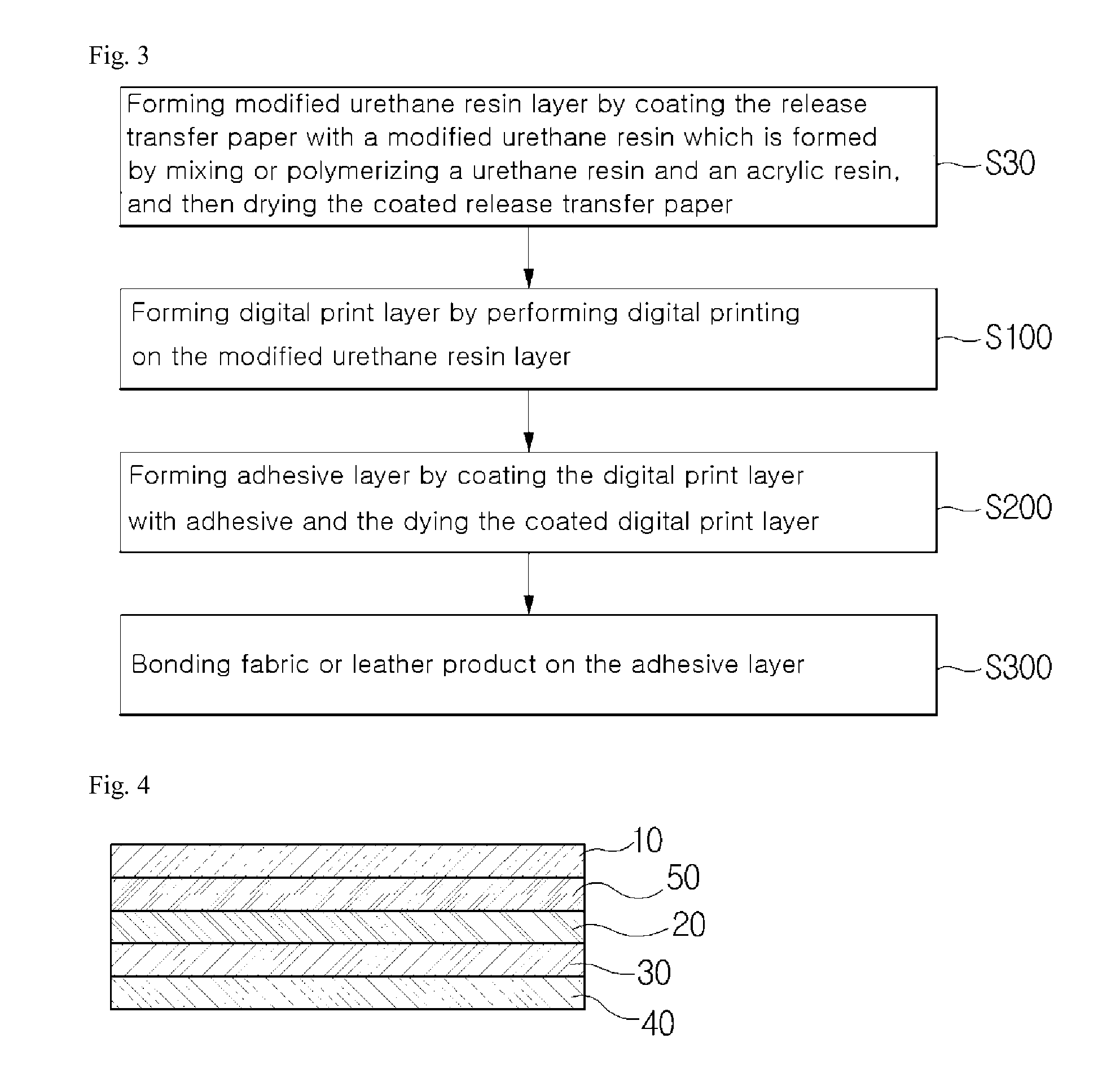

Method for printing fabric or leather product, and printed matter printed by using the same

ActiveUS20160067984A1Simple processReduce manufacturing costDecorative surface effectsDuplicating/marking methodsAdhesiveComputer printing

The present invention relates to a method for printing fabric or leather product, and printed matter printed by using the same, the method comprising the steps of: a) forming a digital print layer by performing digital printing on a release transfer paper by using an inkjet printer; b) forming adhesive layer by coating the digital print layer with an adhesive, and drying for a predetermined time; and c) bonding fabric or leather product to the adhesive layer. Thus, the present invention can precisely print fabric or leather product with high resolution and can enable customized printing so as to allow small quantity batch production.

Owner:CHUNG DOO HO

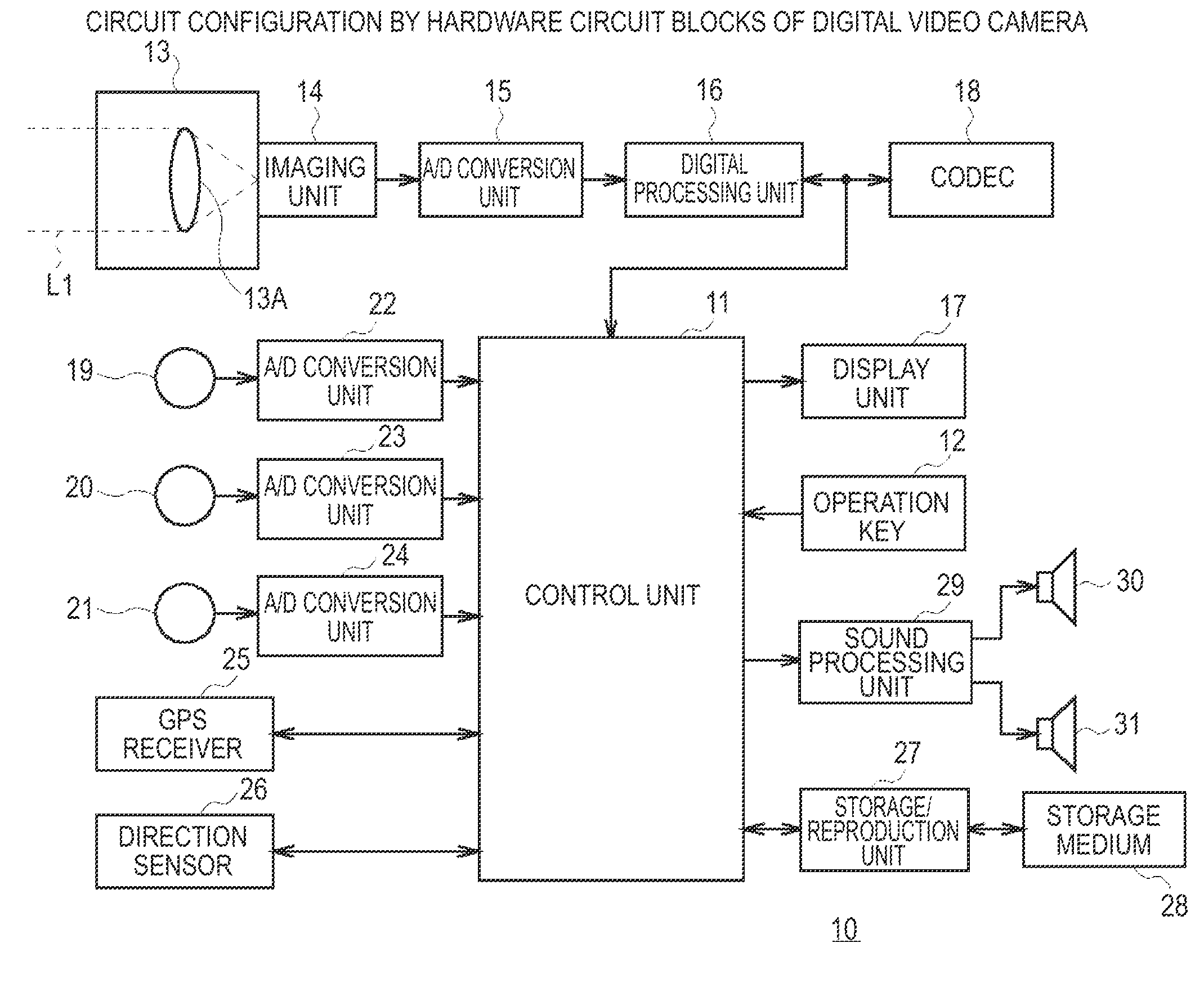

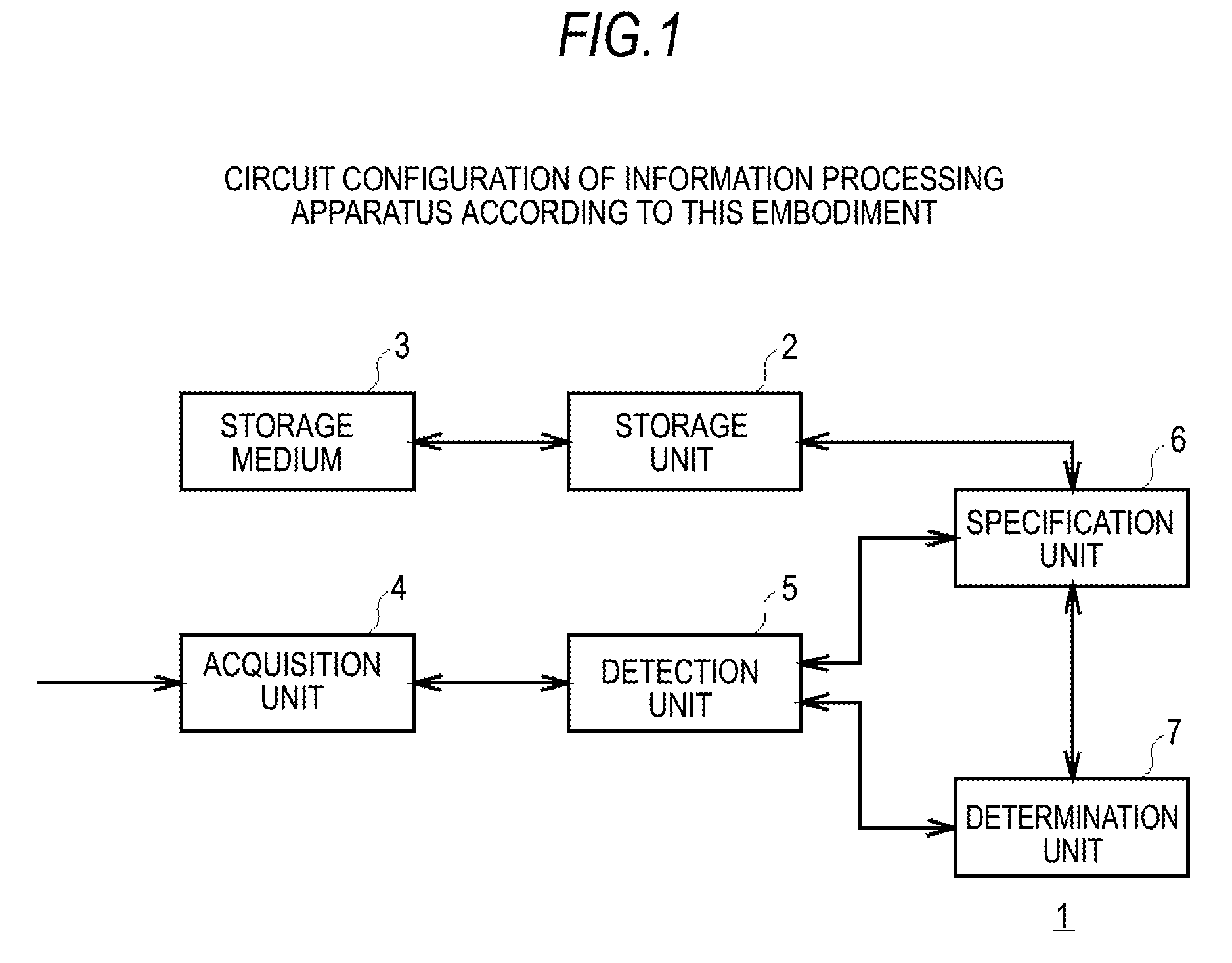

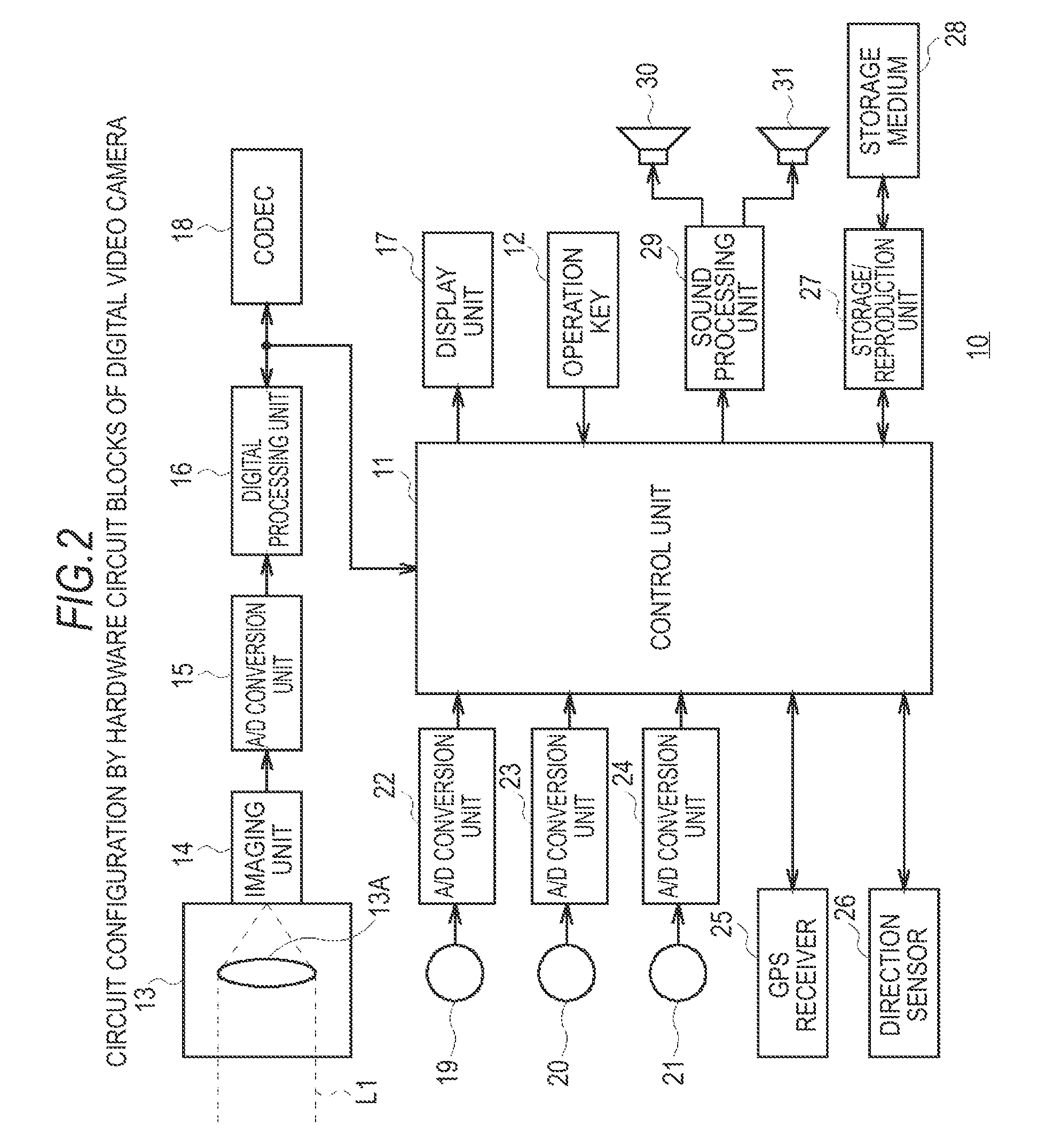

Information processing apparatus, information processing method, and information processing program

ActiveUS20110058028A1Avoid wastingExact searchCharacter and pattern recognitionColor television detailsInformation processingRadiology

An information processing apparatus includes: a storage unit which stores person relationship information representing the relationship between multiple people as a subject in a storage medium; an acquisition unit which acquires image data generated by imaging people as a subject; a detection unit which detects each person in an image based on image data acquired by the acquisition unit; a specification unit which specifies each person detected from the image by the detection unit; and a determination unit which determines the relationship between the multiple people detected from the image by the detection unit, wherein, when at least one person from among the multiple people detected from the image by the detection unit is specified and another person is unable to be specified, the specification unit specifies another person on the basis of the relationship between the multiple people determined by the determination unit and the person relationship information stored in the storage medium.

Owner:SONY CORP

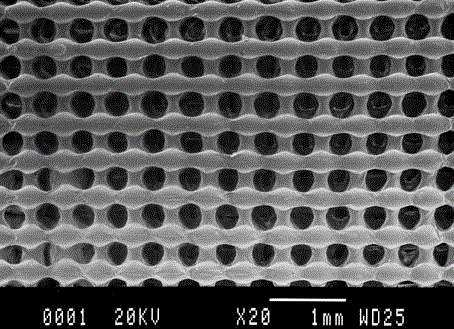

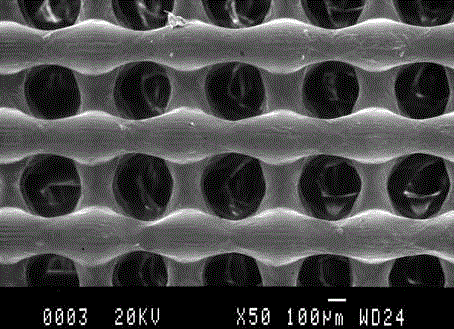

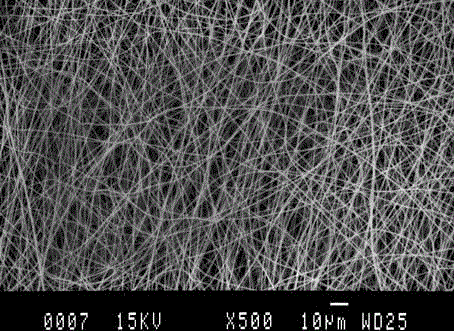

Cell-biological scaffold complex and 3D printing forming method thereof

ActiveCN104888277AAvoid immune rejectionContour controllableAdditive manufacturing apparatusProsthesisBiomedical engineeringNanofiber

The invention provides a cell-biological scaffold complex and a 3D printing forming method thereof. The cell biological scaffold complex comprises a biological scaffold with an actual deficit condition similar to the tissues and organs of patients, a nanometer fiber layer printed on the biological scaffold, capable of simulating natural extracellular matrixes, and beneficial for the adhesion, reproduction and growth of cells, and cell suspension printed on the nanometer fiber layer. According to the actual deficit condition of the tissues and organs of patients, the cell-biological scaffold complex needed by patients can be precisely printed by adopting the bioprinting forming method.

Owner:深圳尤尼智康医疗科技有限公司

Support Structures and Deposition Techniques for 3D Printing

ActiveUS20130307193A1Easy to separateImproved down-facing surfaceManufacturing platforms/substratesUnsaturated ether polymer adhesivesComputer Aided Design3d print

Owner:3D SYST INC

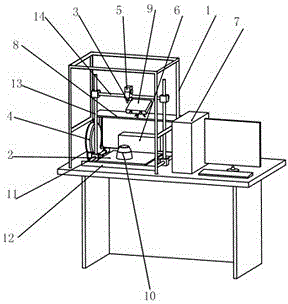

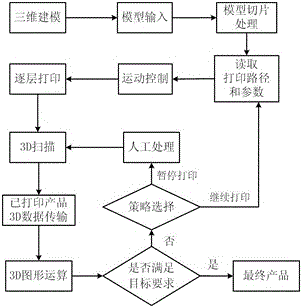

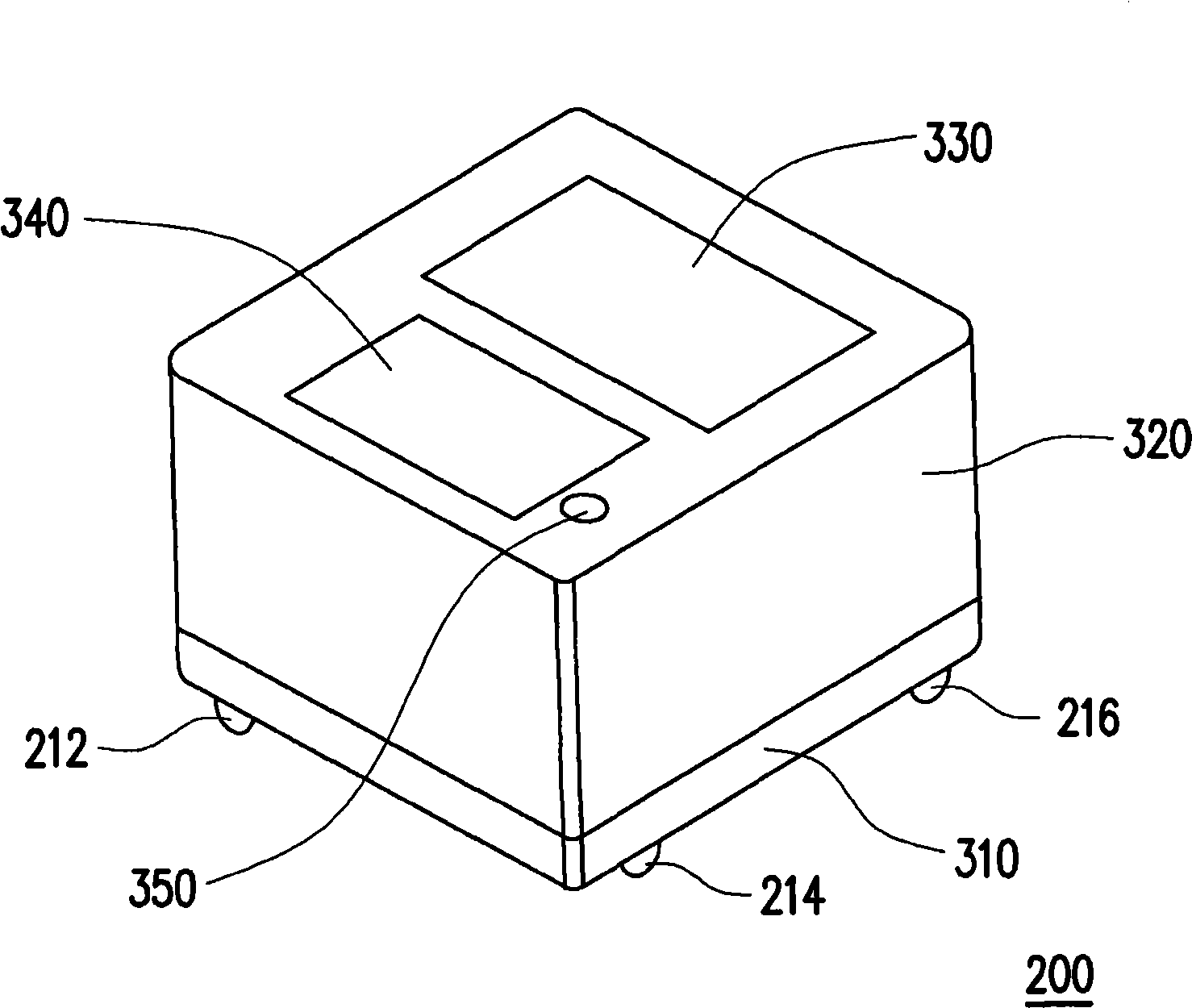

3D printing machine with three-dimensional figure feedback system and printing method of 3D printing machine

InactiveCN105666877AHigh precisionImprove printing efficiencyAdditive manufacturing apparatusGraphicsControl system

The invention discloses a 3D printing machine with a three-dimensional figure feedback system and a printing method of the 3D printing machine. The 3D printing machine comprises a rack, a printing platform, a printing spray head, a material box, a feeding device, a drive device, a control system, a computer, a support mounted on the outer side of the drive device and a 3D scanner which is arranged on the support and used for scanning a printed article. In the product forming process, the 3D scanner is used for scanning a semi-finished workpiece or a blank, the three-dimensional profile of the workpiece is obtained and compared with a three-dimensional model of a target product through graphics operation, the motion path and printing parameters of the printing machine are adjusted according to a result, and therefore feedback control of the printing process is achieved, and the 3D printing forming precision and the printing efficiency are improved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

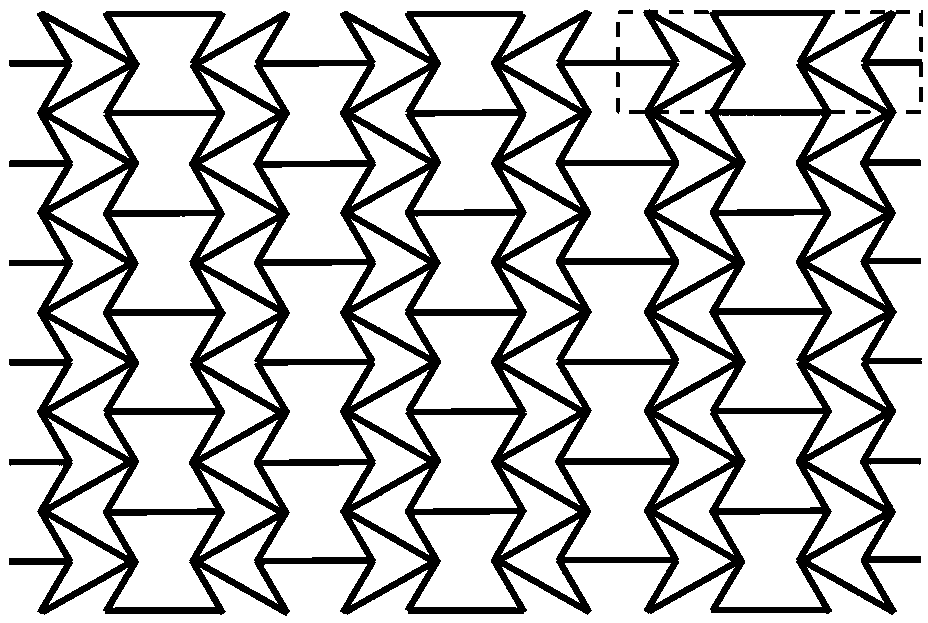

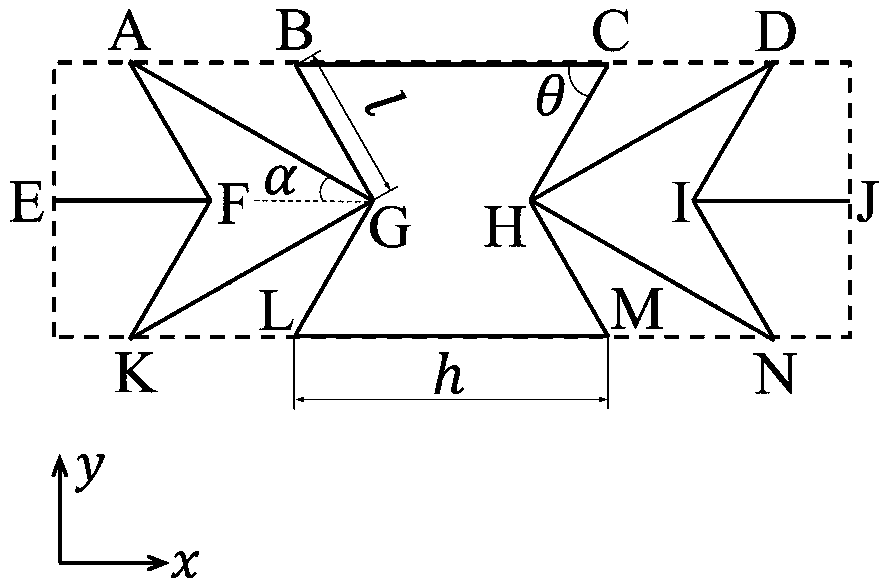

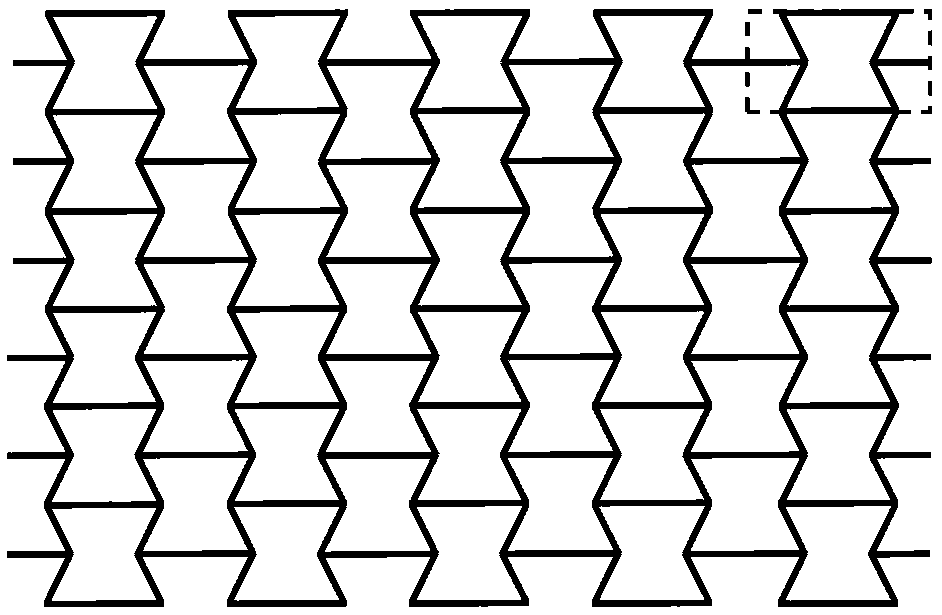

Pulled polycellular configuration and energy-absorbing structural member

InactiveCN108895108AImprove stress resistanceStrong impact resistanceElastic dampersShock absorbersShock resistanceEngineering

The invention discloses a pulled multicellular configuration and an energy-absorbing structure component, comprising a plurality of unit cell structures, wherein each unit cell is obtained by cleverlysplicing two typical concave characteristic structures and two arrow-shaped structures; the pulled multicellular configuration and the energy-absorbing structure component comprise a plurality of unit cell structures. The vertices of the concave corners on the left and right sides of the concave eigenstructure are connected with two arrow-shaped eigenstructures respectively, and the vertices of the concave corners of the two arrow-shaped eigenstructures are connected with half of the transverse bars of the other two concave eigenstructures, which together form a single cell structure with anexpanded multicellular configuration; the vertices of the concave corners of the left and right sides of the concave eigenstructures are connected with each other. Then the two-dimensional stretched polycyclic configuration is obtained by planar array. The polycellular material has negative Poisson's ratio property, which shrinks when compressed, thus locally densifying the compressed region. Thisunique deformation characteristic makes the polycellular material have stronger indentation resistance and impact resistance. In addition, by changing the slenderness ratio and inclination angle of the rod, the elastic properties and compression strength of the rod are adjusted.

Owner:BEIHANG UNIV

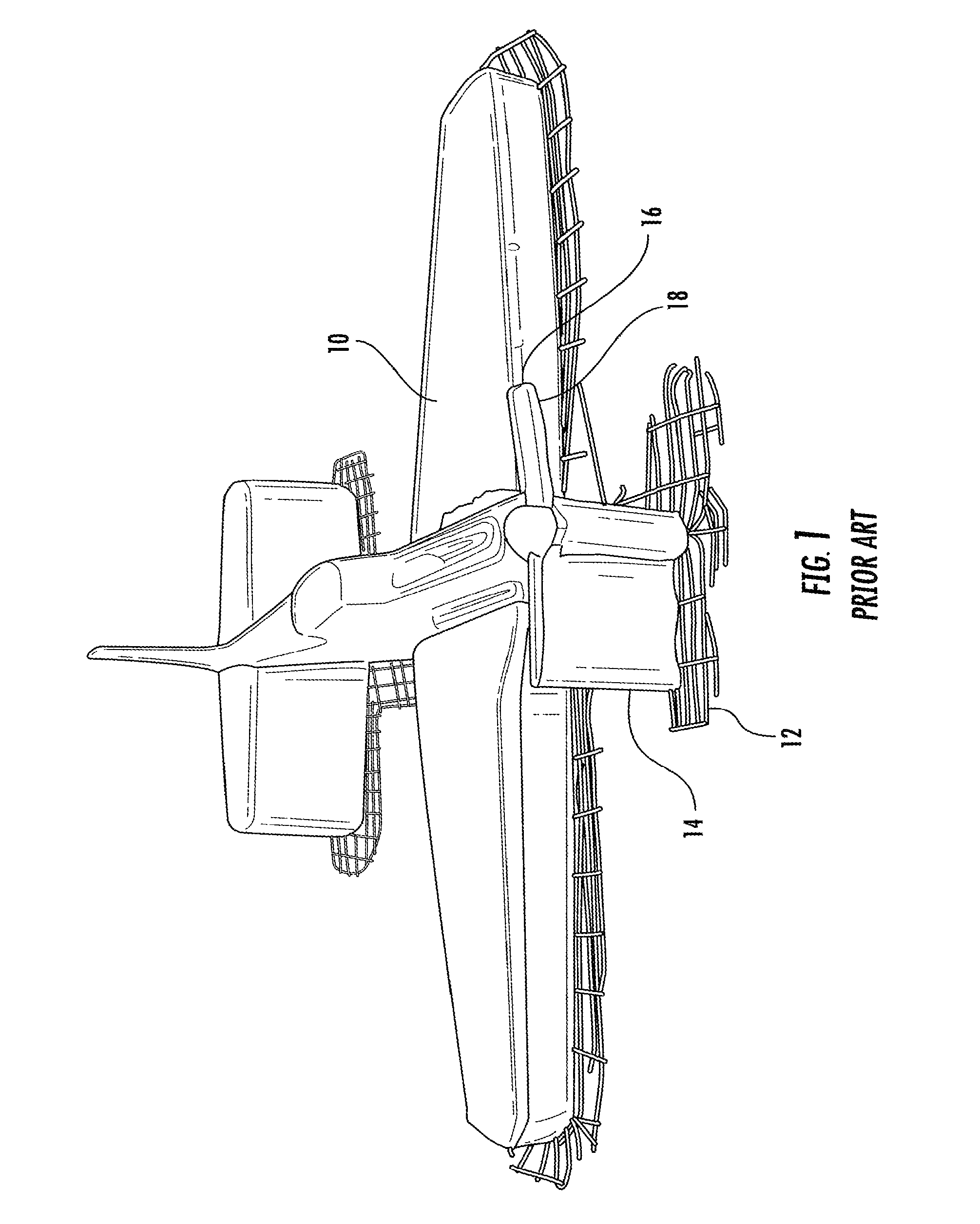

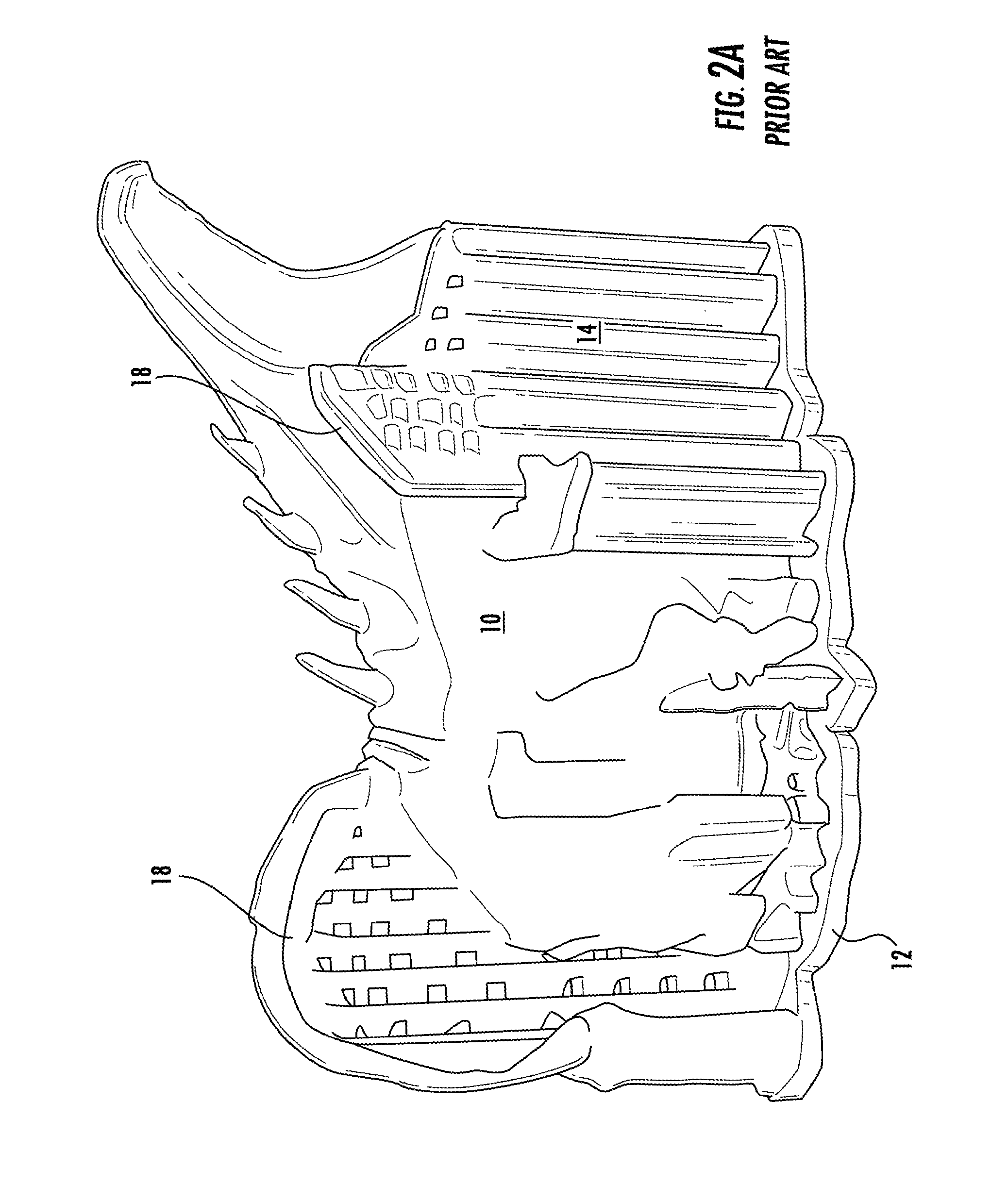

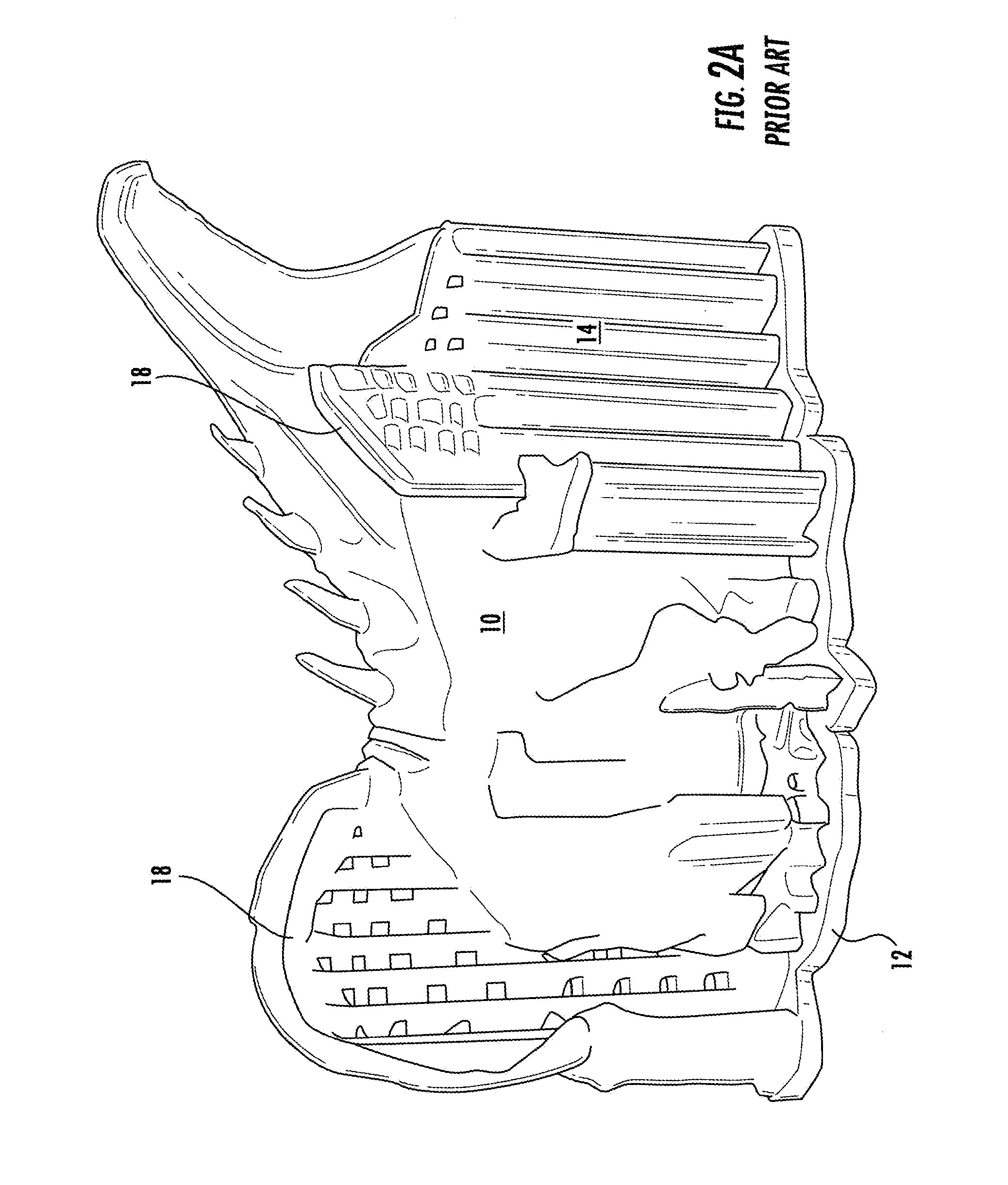

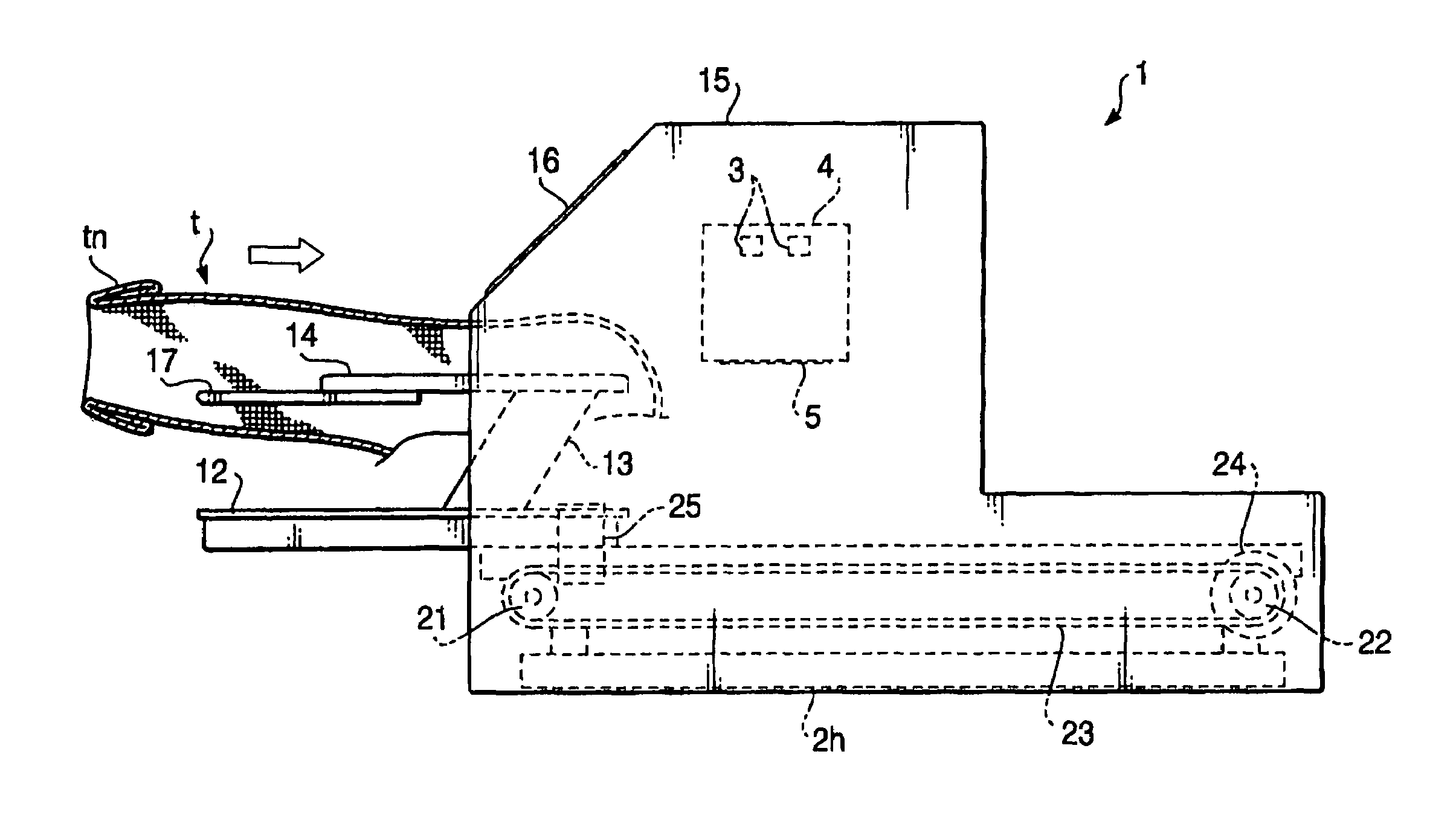

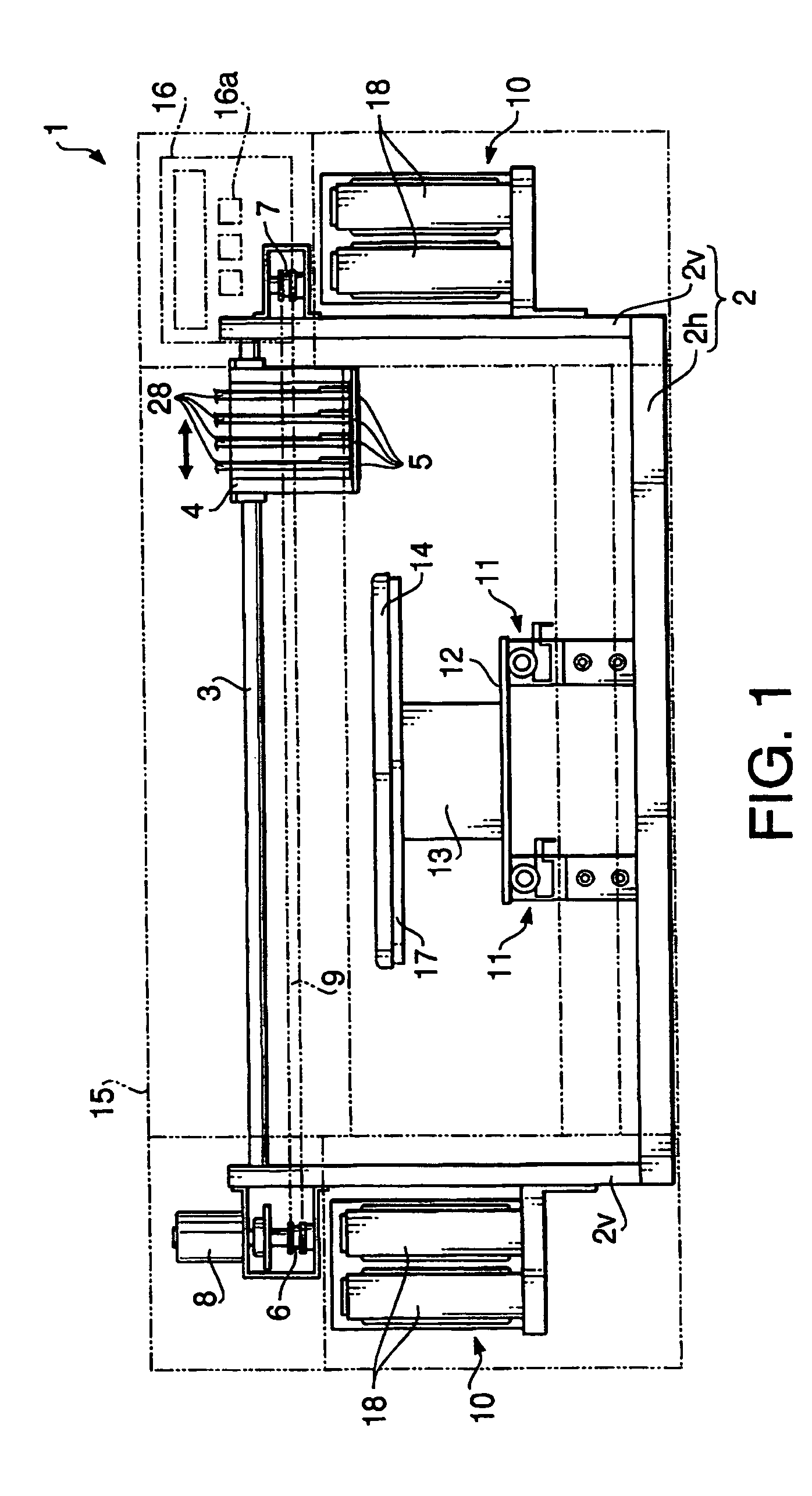

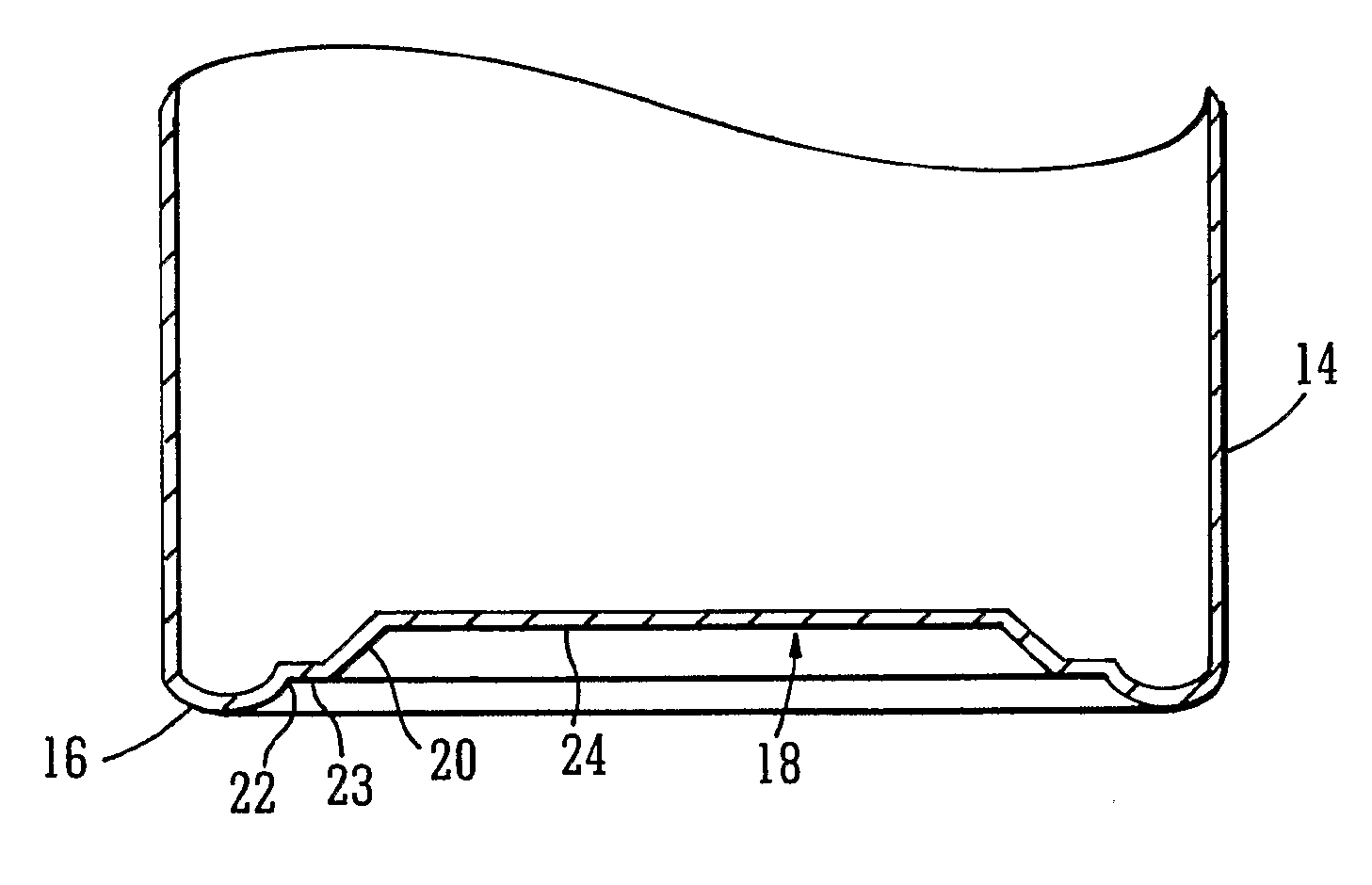

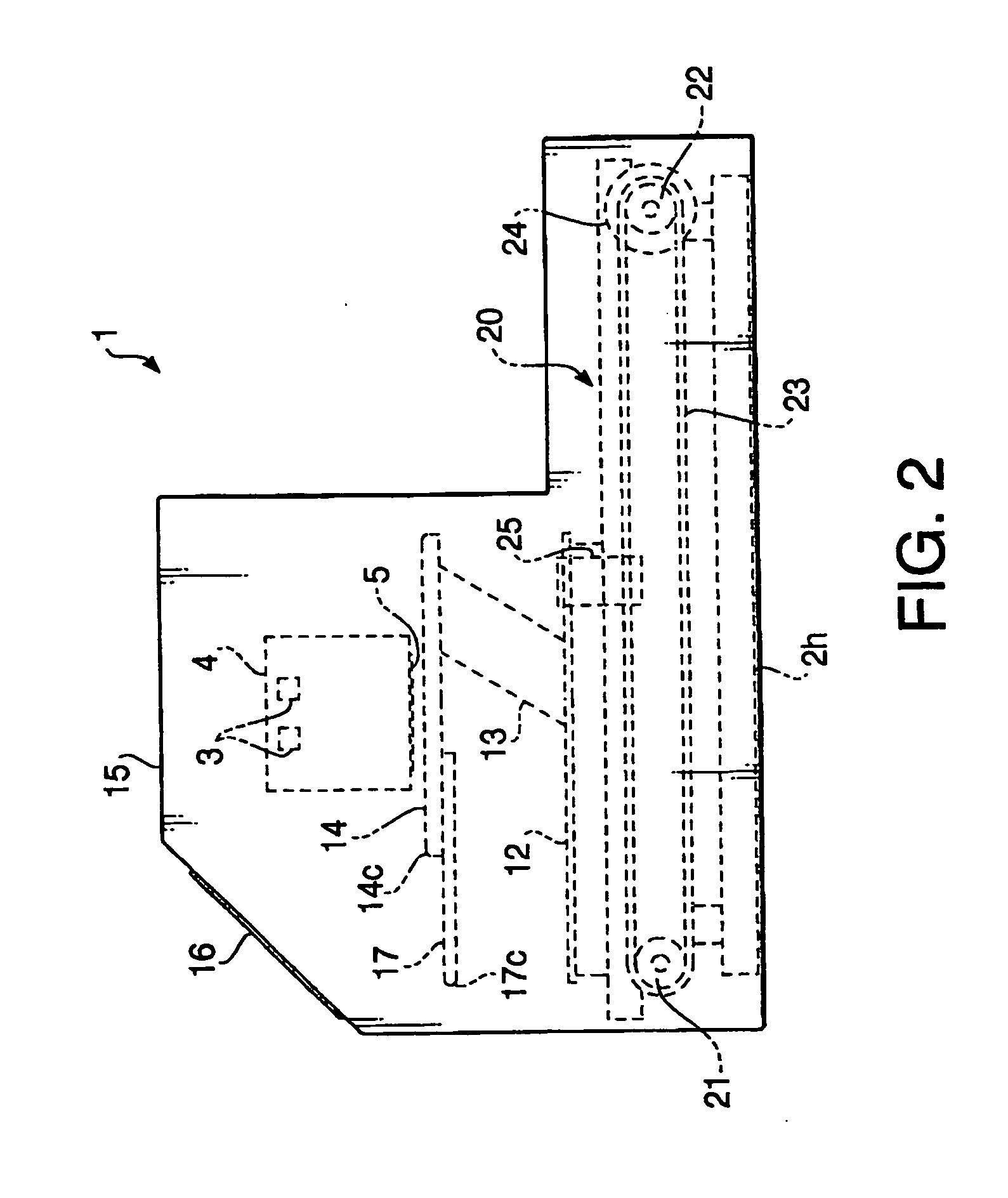

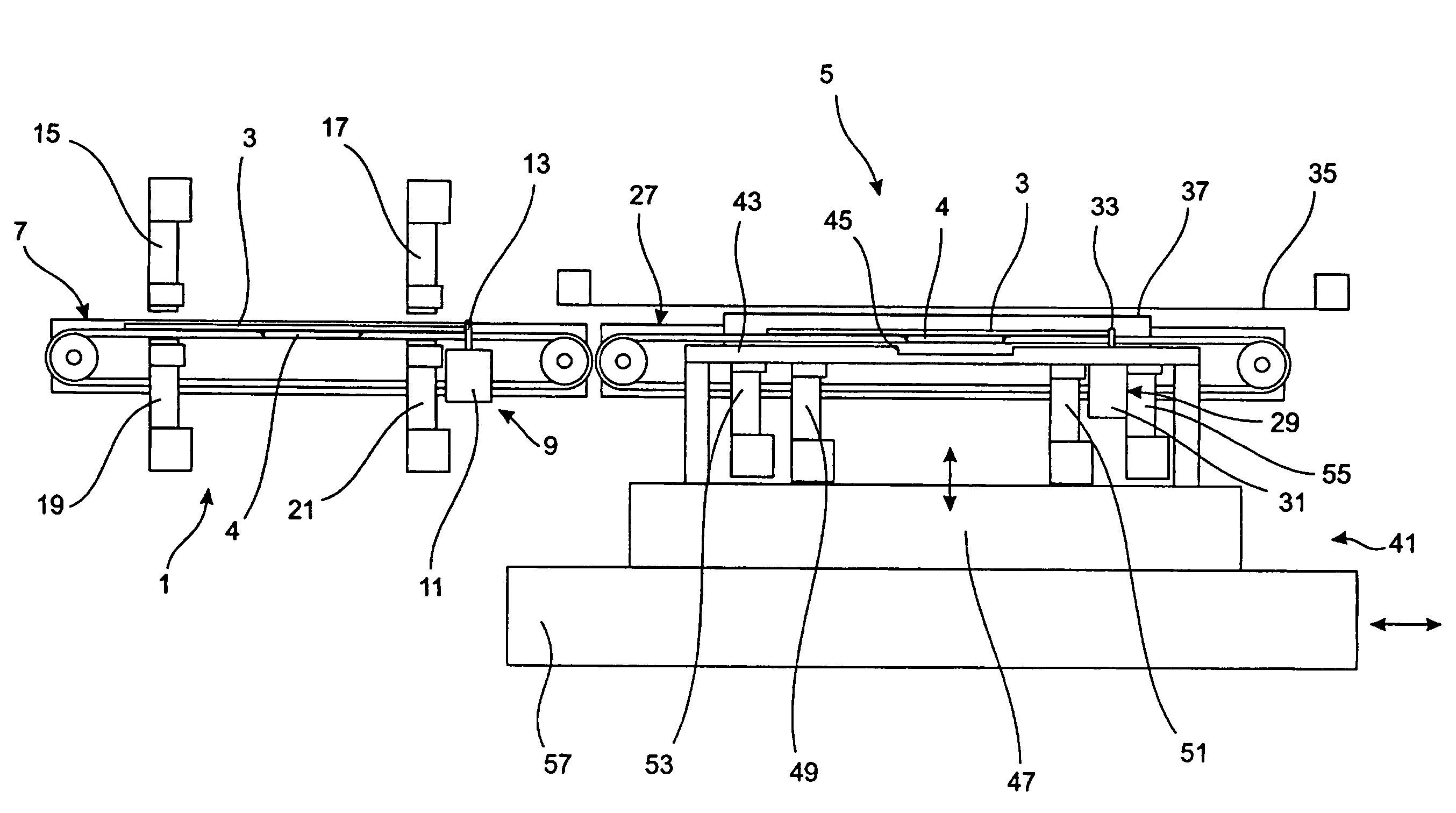

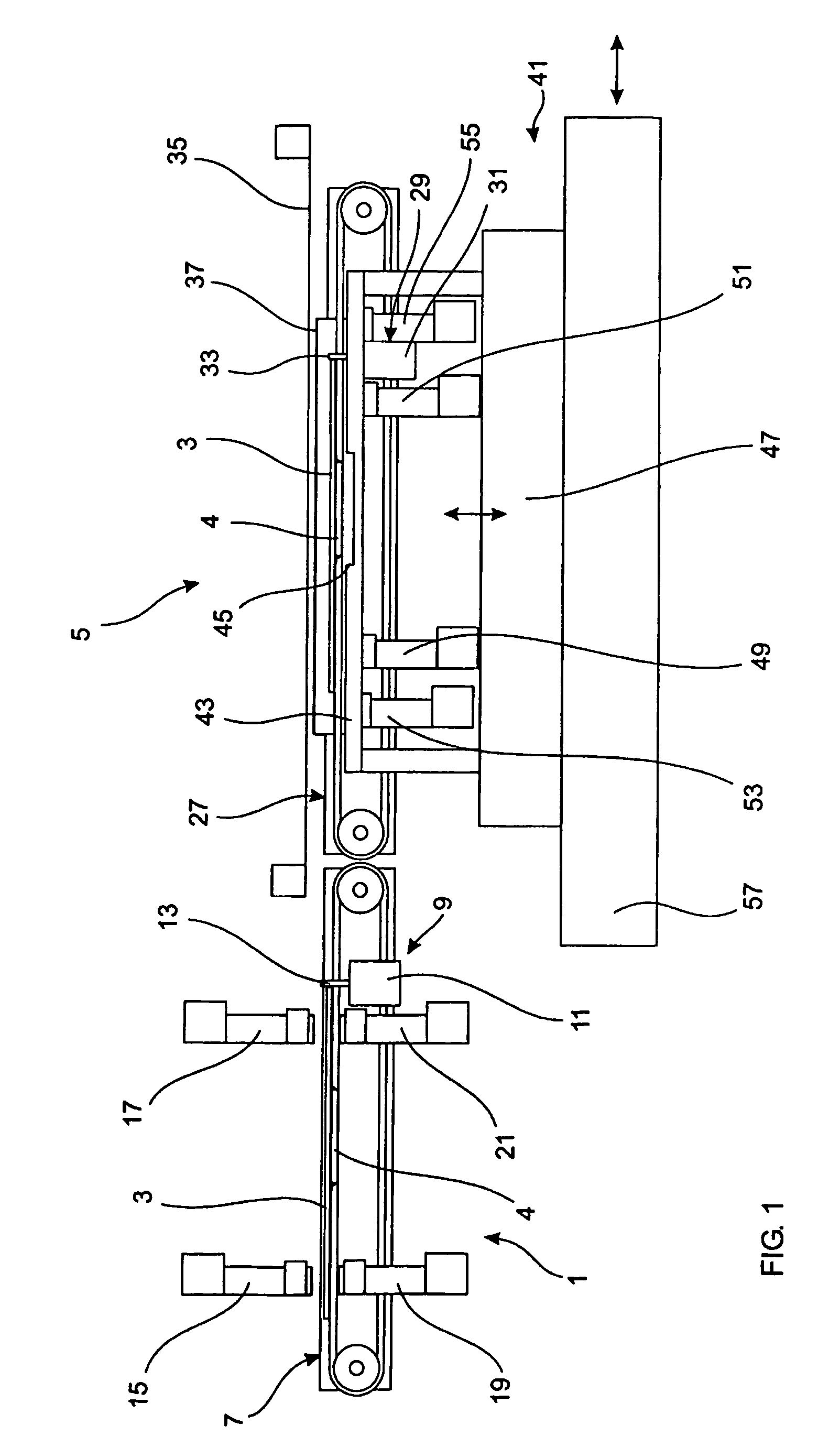

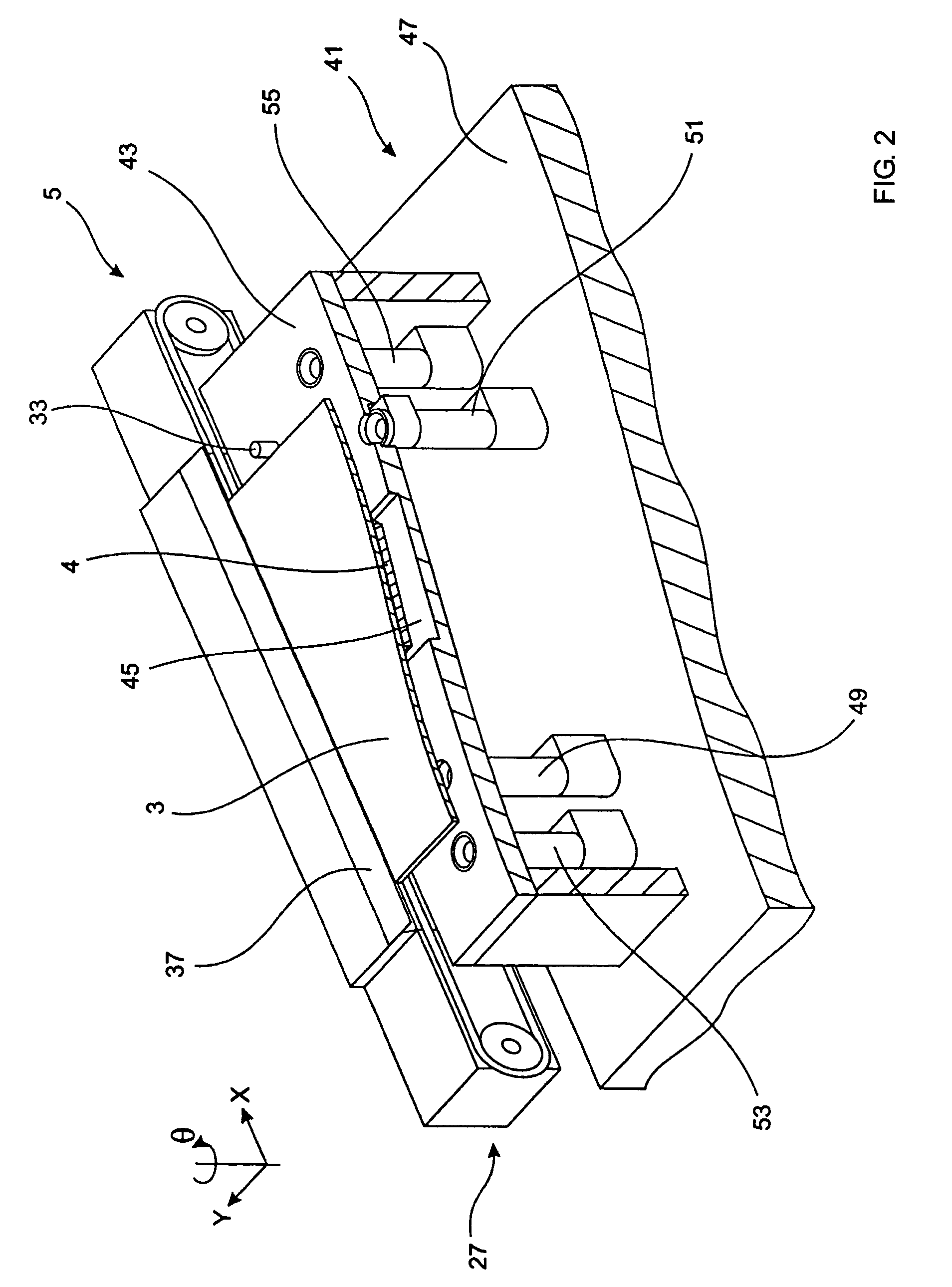

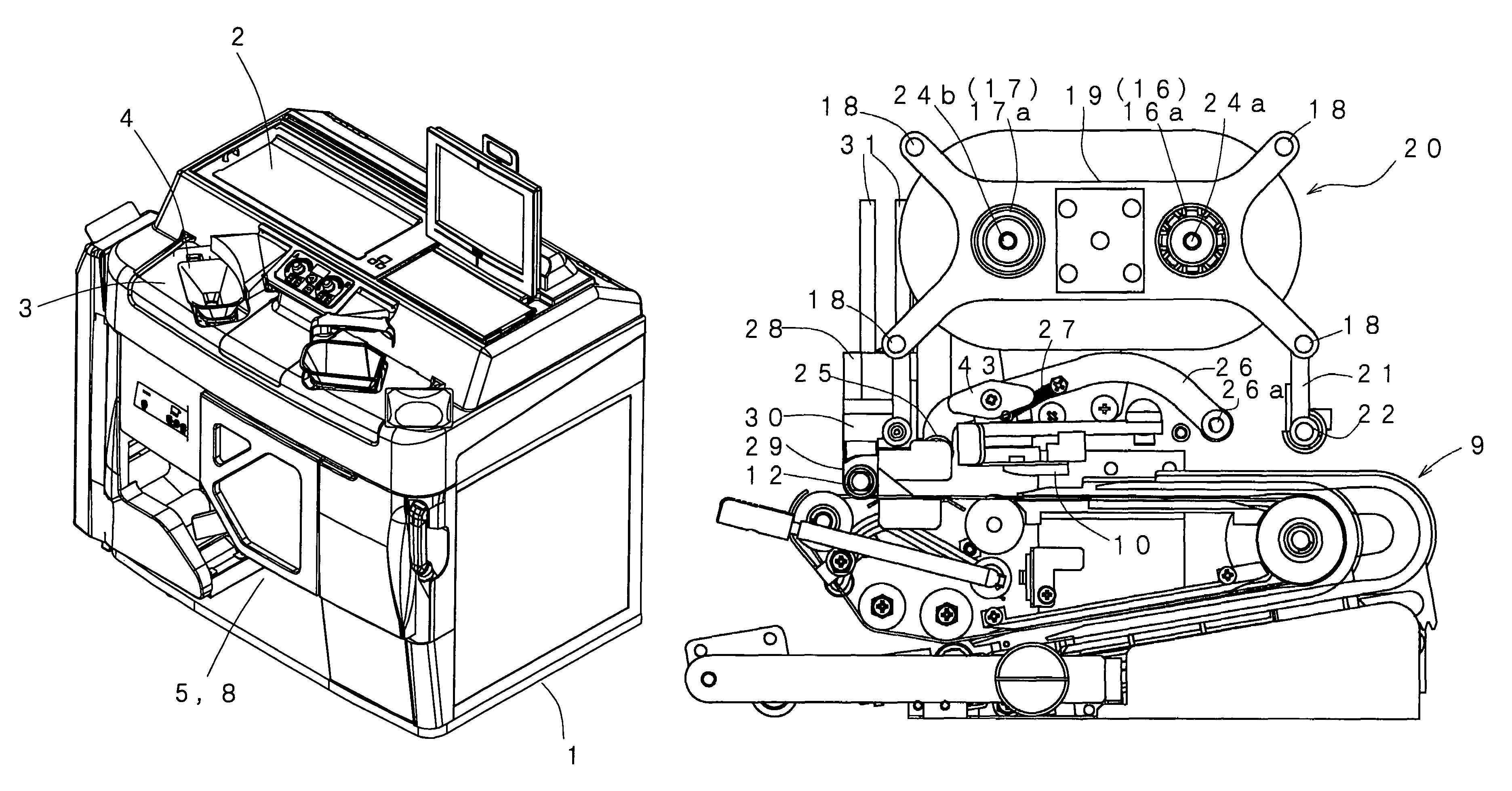

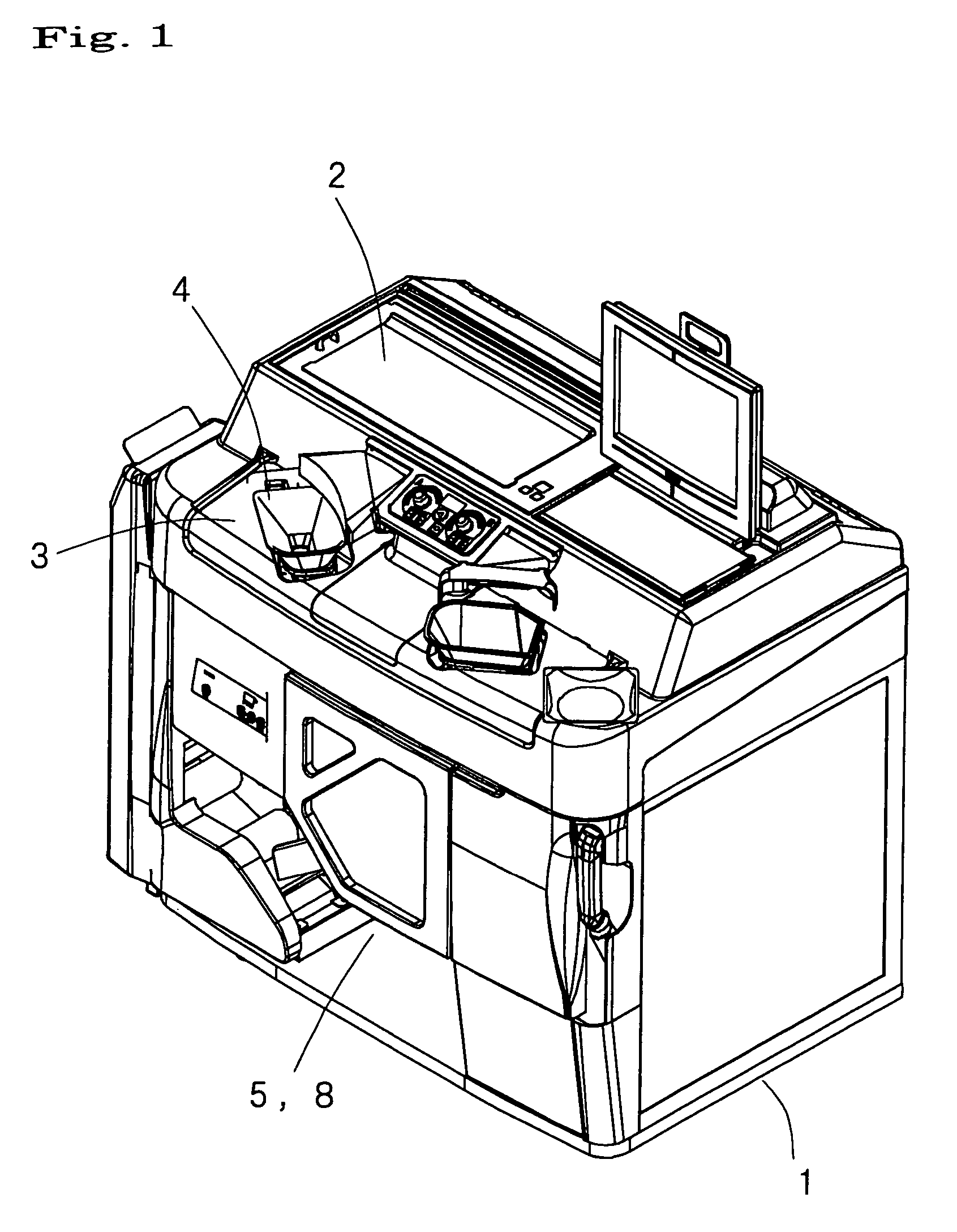

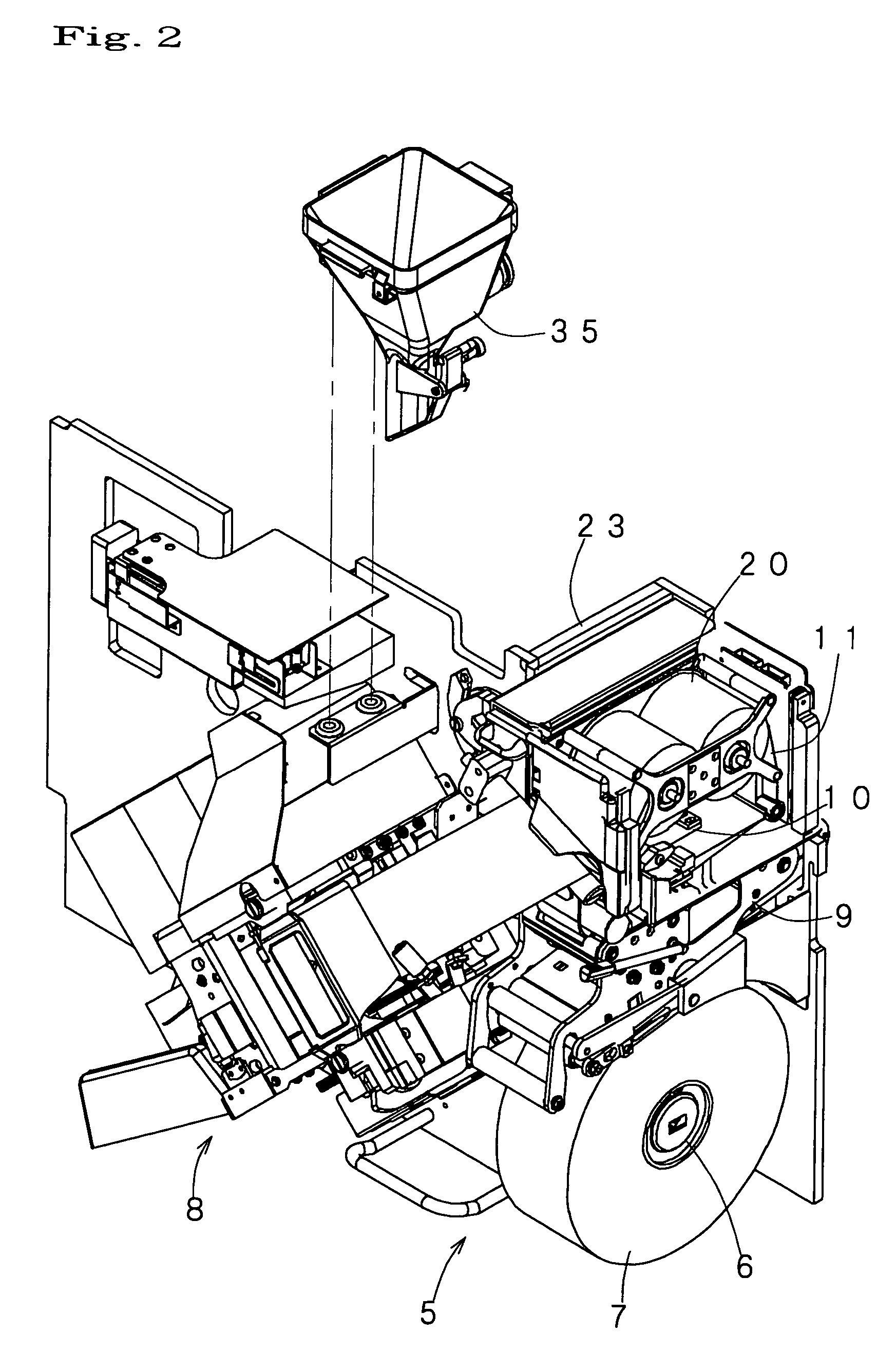

Inkjet printing apparatus

ActiveUS7040748B2Accurate printingLiquid surface applicatorsPlaten pressesDistance spaceMechanical engineering

An inkjet type fabric printing apparatus is provided with an inkjet head, a platen and a positioning member. The inkjet head reciprocally moves in main scanning direction and auxiliary scanning direction relative to a fabric (e.g., clothes). The platen holds the fabric to extend on a plane parallel with the main scanning direction and the auxiliary scanning direction with a first predetermined distance spaced from the inkjet head. On the positioning member, the fabric is set. The fabric is positioned on the platen in place in a direction parallel with the main scanning direction and the auxiliary scanning direction. The positioning member supports at least one of a neck portion and a shoulder portion of the fabric such that the neck portion and / or a shoulder portion is spaced from the inkjet head by a second predetermined distance.

Owner:BROTHER KOGYO KK

Mobile telecommunications device with media edge detection

InactiveUS7770995B2Increased complexityIncrease in sizeTypewritersOther printing apparatusEdge detectionTelecommunications Device

A mobile telecommunications device comprising: a printhead for printing a sheet of media substrate, the sheet of media substrate having coded data on at least part of its surface; a media feed assembly for feeding the sheet of media substrate along a feed path past the printhead; a print engine controller for operatively controlling the printhead; and, a sensor for reading the coded data and generating a signal indicative of at least one dimension of the sheet, and transmitting the signal to the print engine controller; such that, the print engine controller uses the signal to initiate the printing when the sheet is at a predetermined position relative to the printhead.

Owner:SILVERBROOK RES PTY LTD

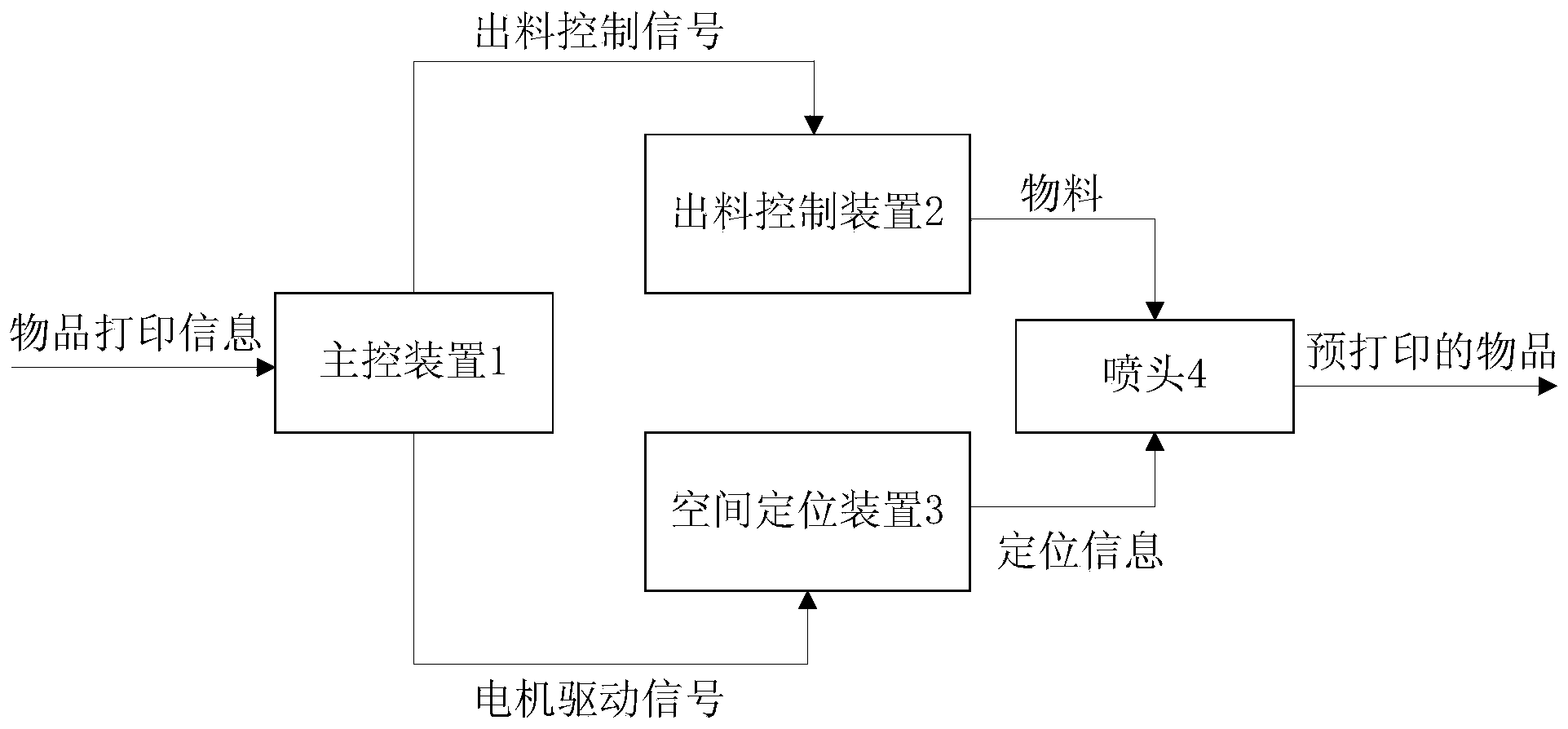

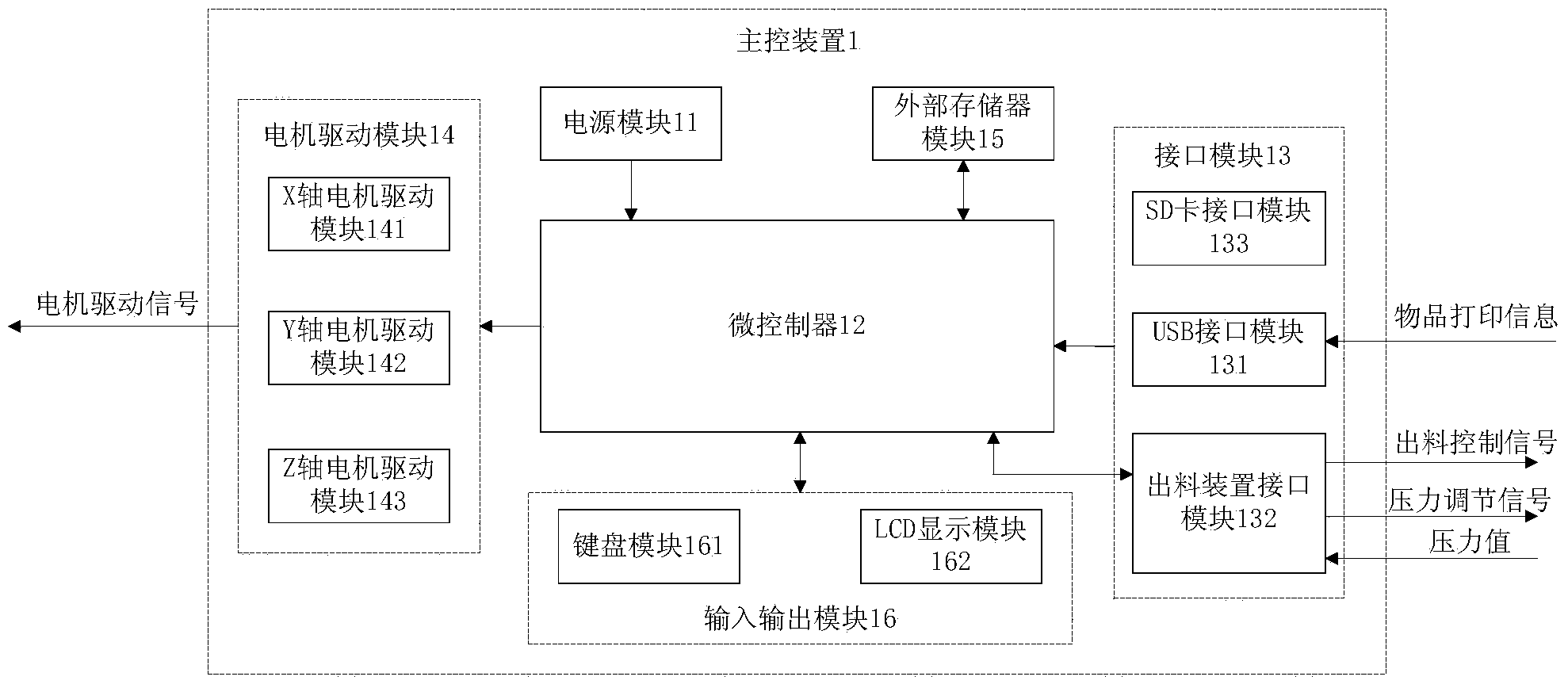

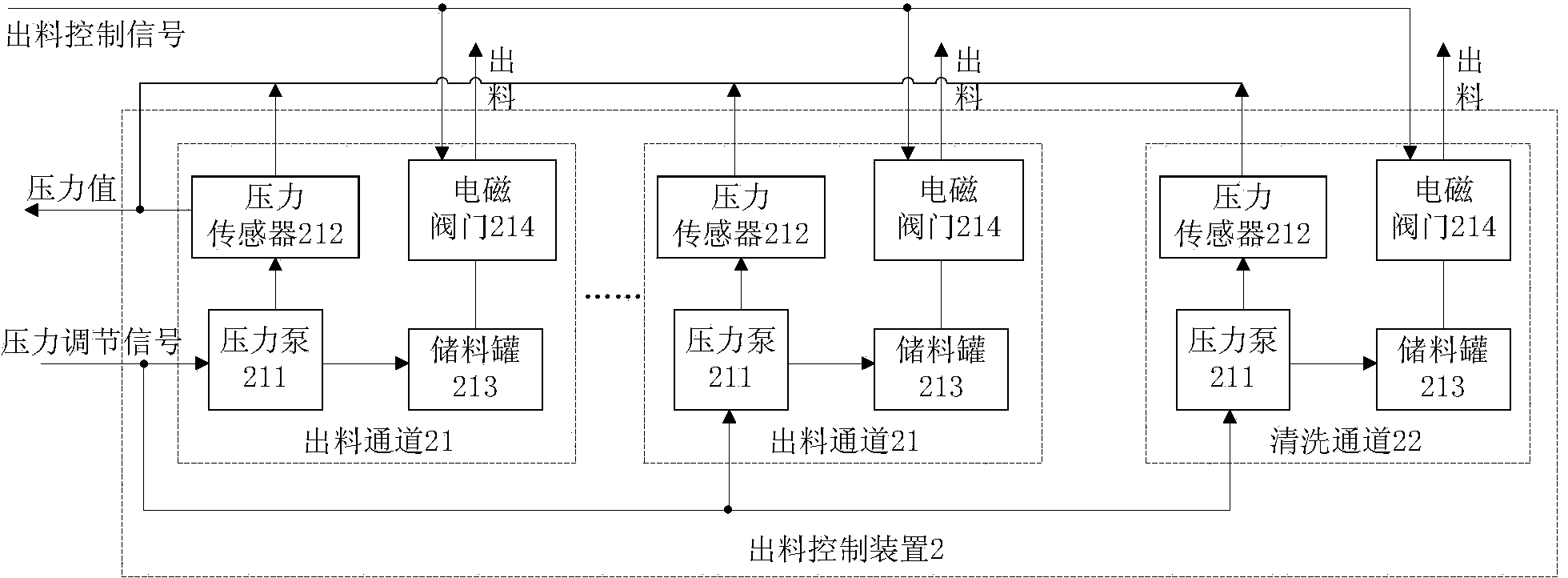

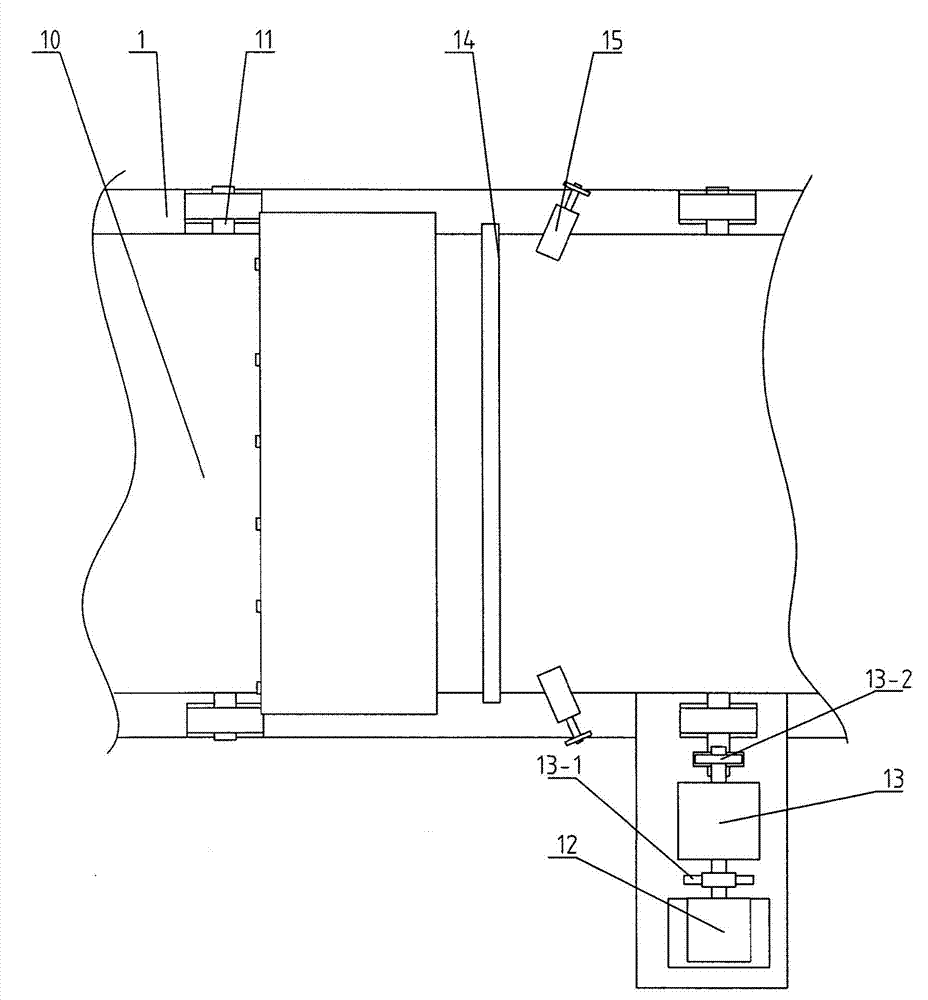

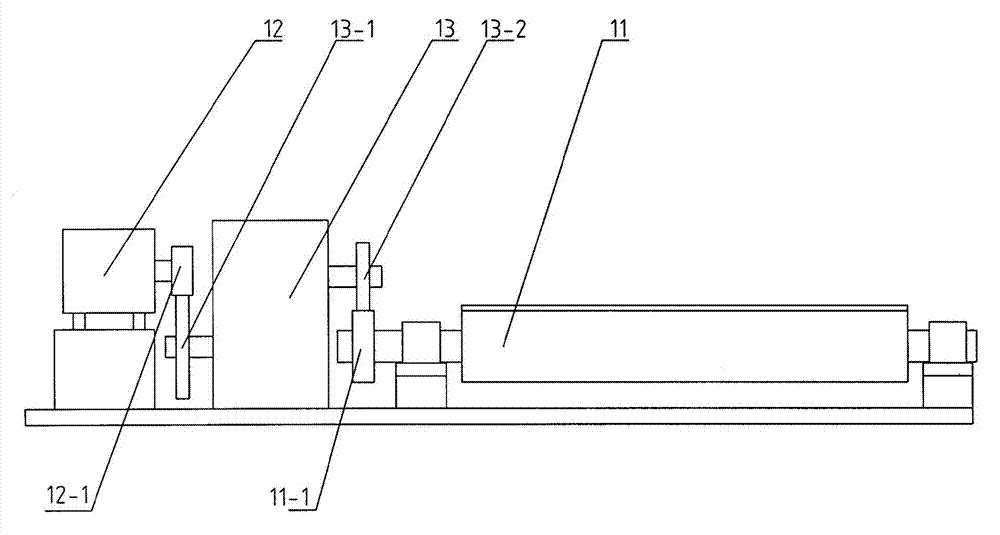

Single-spraying-head multi-channel three-dimensional printer and use method of single-spraying-head multi-channel three-dimensional printer

The invention relates to a single-spraying-head multi-channel three-dimensional printer and a use method of the single-spraying-head multi-channel three-dimensional printer. The single-spraying-head multi-channel three-dimensional printer is characterized by comprising a master control device, a discharging control device, a space positioning device and a spraying head, the master control device transmits a discharging control signal and a motor driving signal to the discharging control device and the space positioning device respectively according to preset object printing information, controls the discharging control device to deliver materials to the spraying head through a delivery pipe, and controls the space positioning device to determine the position of the spraying head in space, and the spraying head prints out an object to be printed. The use method of the single-spraying-head multi-channel three-dimensional printer includes the following steps: placing the needed materials and cleaning fluid in a discharging channel and a cleaning channel of the discharging control device respectively, presetting information of the object to be printed and a pressure limit value of the discharging control device in the master control device, controlling the discharging control device through the master control device to deliver the materials or the cleaning fluid to the spraying head, controlling the space positioning device to drive the spraying head to print out the object to be printed, and cleaning the spraying head through the cleaning fluid.

Owner:NORTH CHINA INST OF SCI & TECH

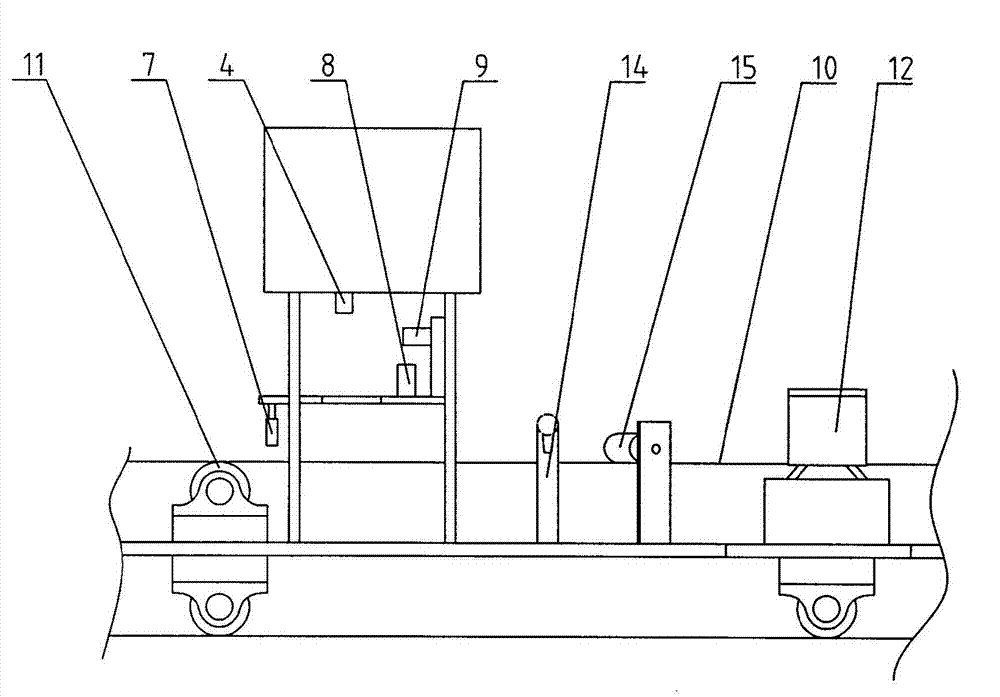

High-efficiency digital printing machine

InactiveCN102815092AAvoid confusionGuaranteed speedTypewritersOther printing apparatusControl systemPrinting ink

The invention discloses a high-efficiency digital printing machine comprising a frame, a cloth transportation device, an ink jet positioning and calibrating device and a printing ink jetting device. The cloth transportation device comprises a transportation control system, a cloth positioning mechanism, a power driving device and a transportation platform, wherein the cloth positioning mechanism is mounted on the frame and on two sides of the transportation platform, the power driving device is controlled by the transportation control system, and the transportation platform is driven by the power driving device. The printing ink jetting device is arranged above the transportation platform and comprises a jet nozzle assembly, an ink distribution assembly, an ink supply assembly and an ink control system. The high-efficiency digital printing machine is high in working efficiency, good in printing accuracy and capable of accurately printing complicated patterns.

Owner:CHANGZHOU YILIYASI TEXTILE +1

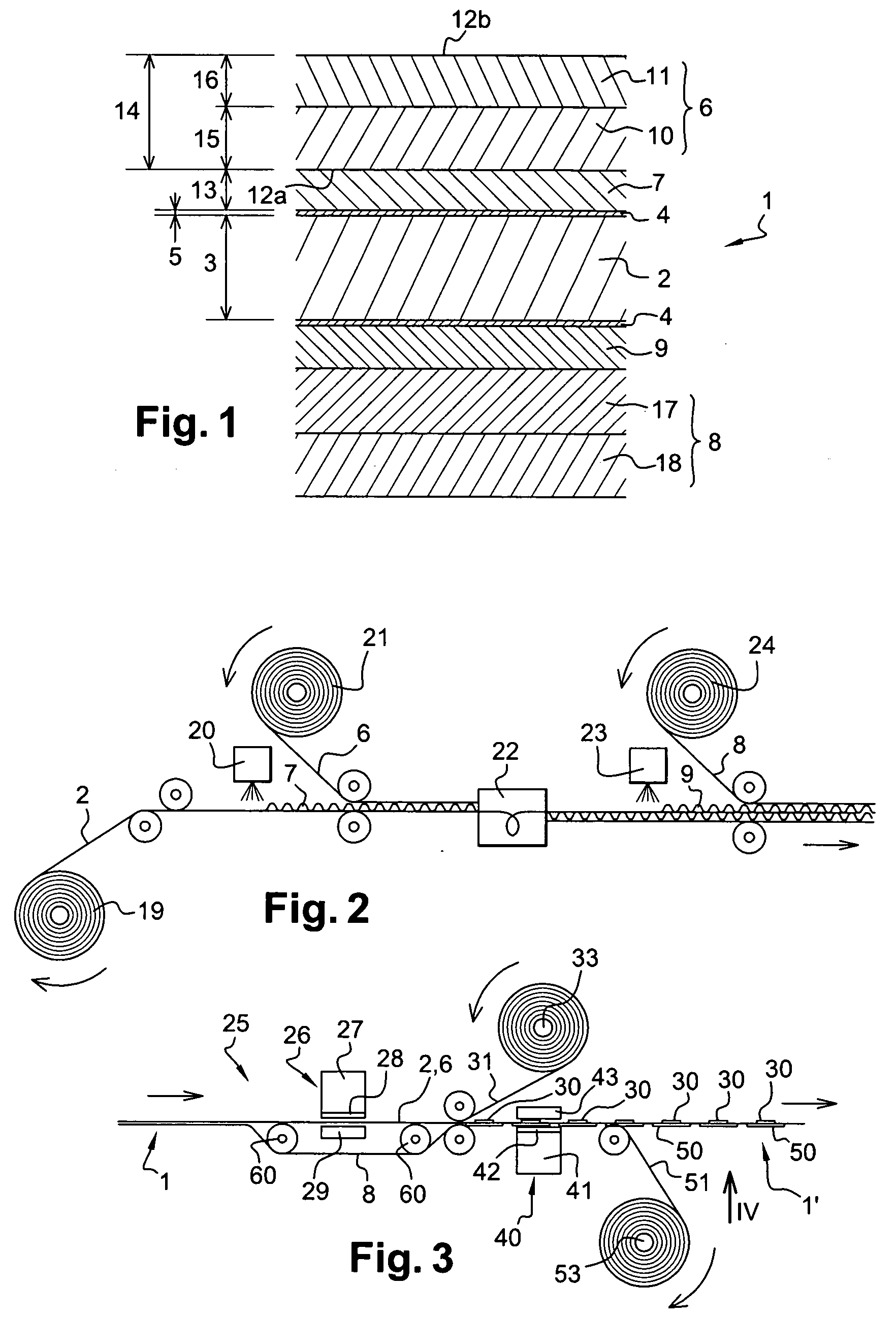

Support provided with two series of labels

InactiveUS20050255276A1Improve impermeabilityDurably printedStampsFlexible coversEngineeringElectrical and Electronics engineering

A support for labels includes a support tape provided on each of its two faces with first and second series of removable adhesive labels respectively. The labels of at least one of the first and second series include at least two layers of different coextruded materials. A method of forming the support is also provided, as well as a method of applying the labels.

Owner:LOREAL SA

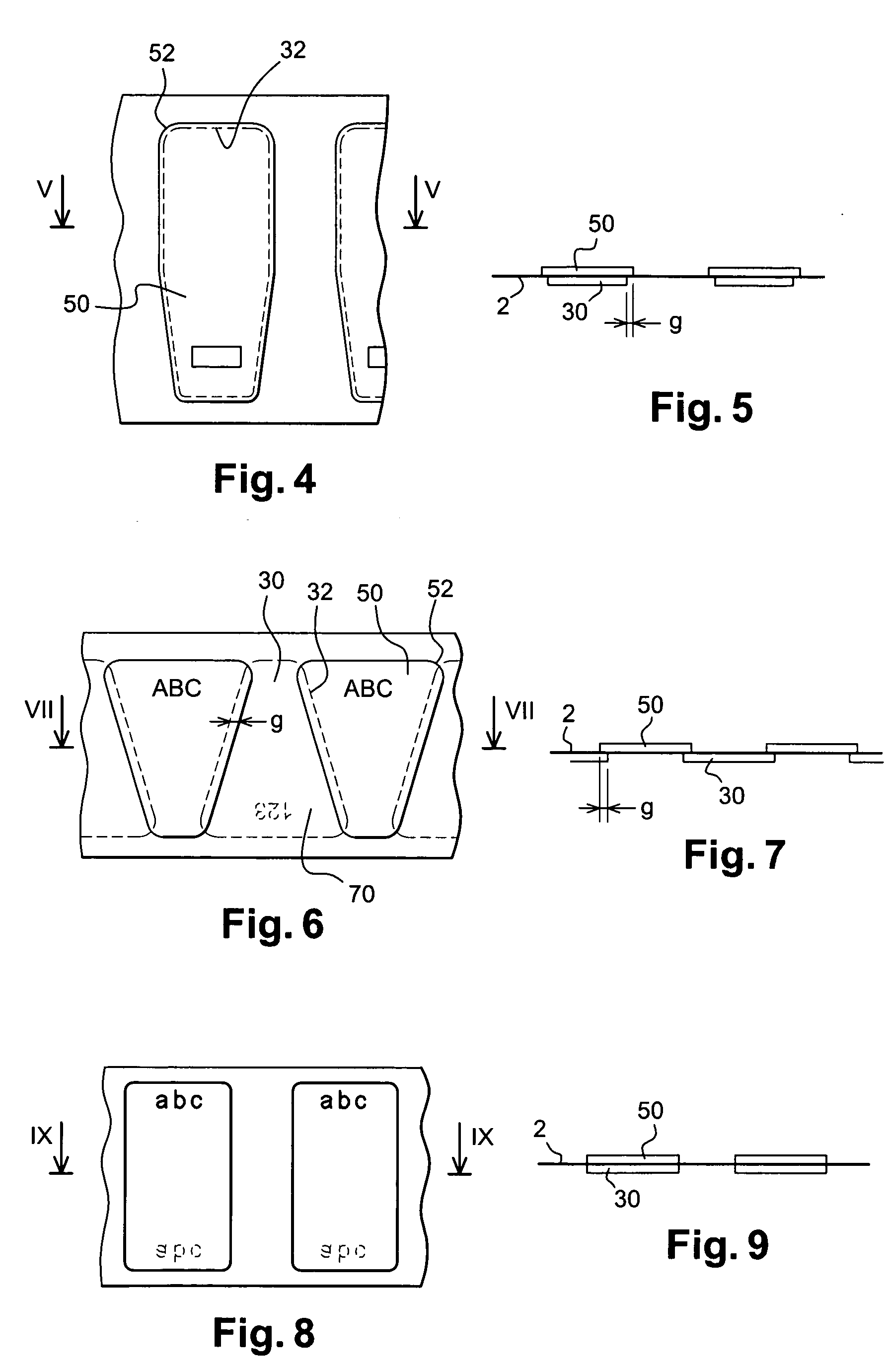

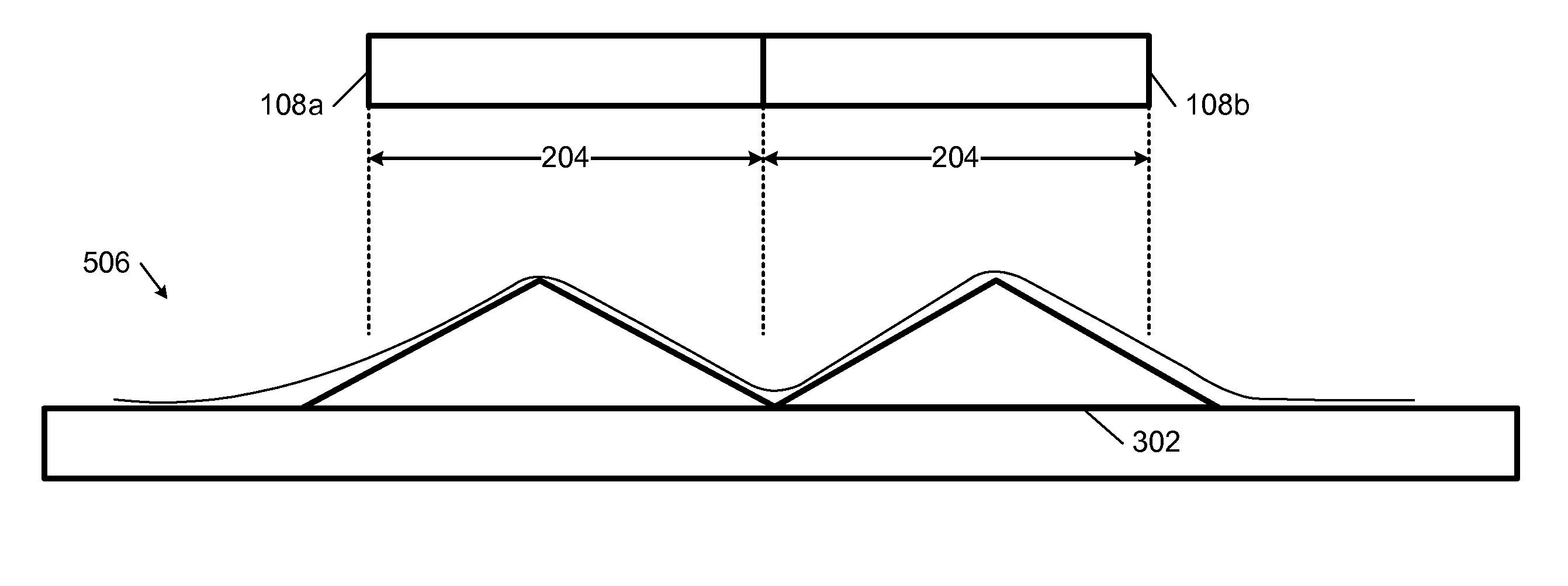

Systems and methods for image distortion reduction in web printing

ActiveUS9446586B2Accurate printingReduce widthOther printing apparatusPictoral communicationDistortion reductionEngineering

Included are embodiments for image distortion reduction in web printing. Some embodiments are configured for determining an ink drop speed of ink from a printer and determining a web travel speed of a web of material, where the web of material engages with a folding board during printing that manipulates a plane of the web of material such that a projection of the web width is effectively reduced. Some embodiments may be configured for determining an altered web geometry of the web of material while engaging with the folding board, receiving a desired image for printing on the web of material, and calculating a pixel displacement of the plurality of pixels. Some embodiments may be configured for creating an altered image that utilizes the pixel displacement from the desired image and sending data related to the altered image for printing on the web of material.

Owner:PROCTER & GAMBLE CO

Method of Attaching an Rfid Tag to a Component, a Component Comprising an Rfid Tag and Rfid Tag

InactiveUS20080309497A1Reduce the possibilityImproved protection against damageRecord carriers used with machinesBurglar alarm by hand-portable articles removalControl electronicsEmbedded system

A method of attaching an RFID tag to a component comprises locating the RFID tag on or in a section of a component, applying an ultrasonic welding process to melt a portion of the housing and a portion of the component contacting the housing and allowing the component and the RFID tag to cool to form a weld therebetween. There is also described a comprising an RFID tag for identification wherein the RFID tag is ultrasonically welded to a section of the component. The RFID tag has a housing encapsulating control electronics and an antenna, the RFID tag being located on or in the section of the component, and wherein a portion of the housing and a portion of the component contacting the housing have a weld therebetween.

Owner:BRYANT KEITH C

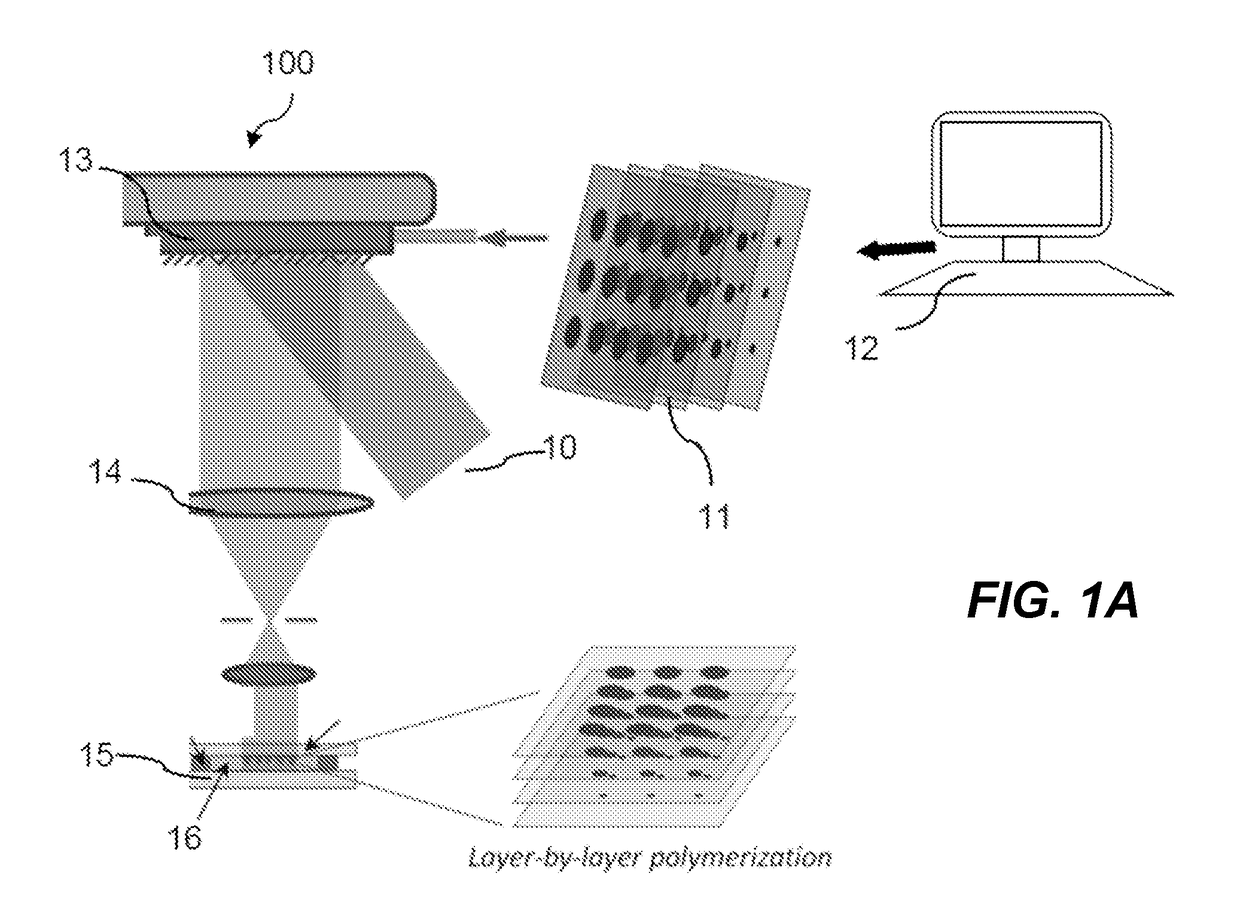

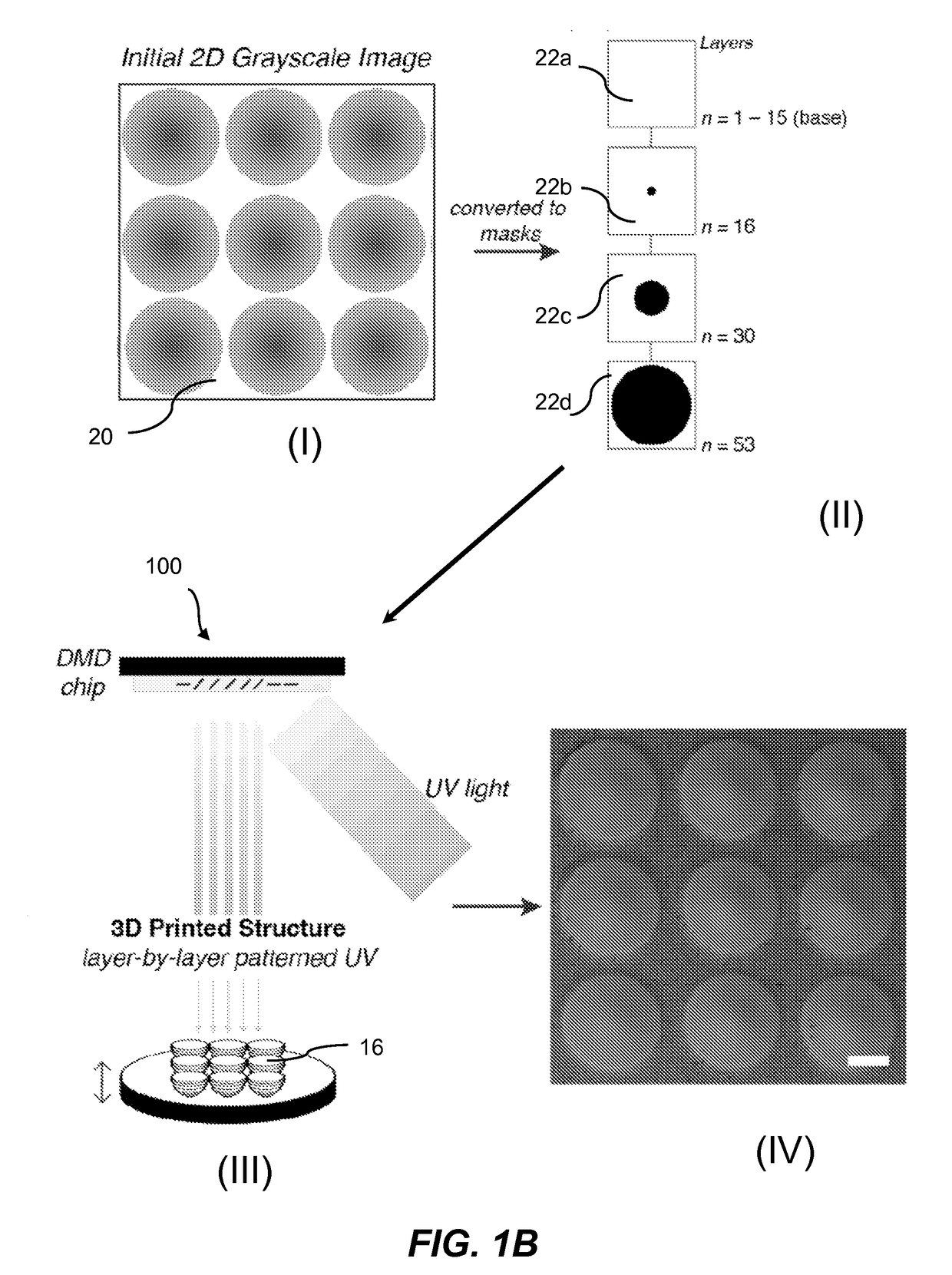

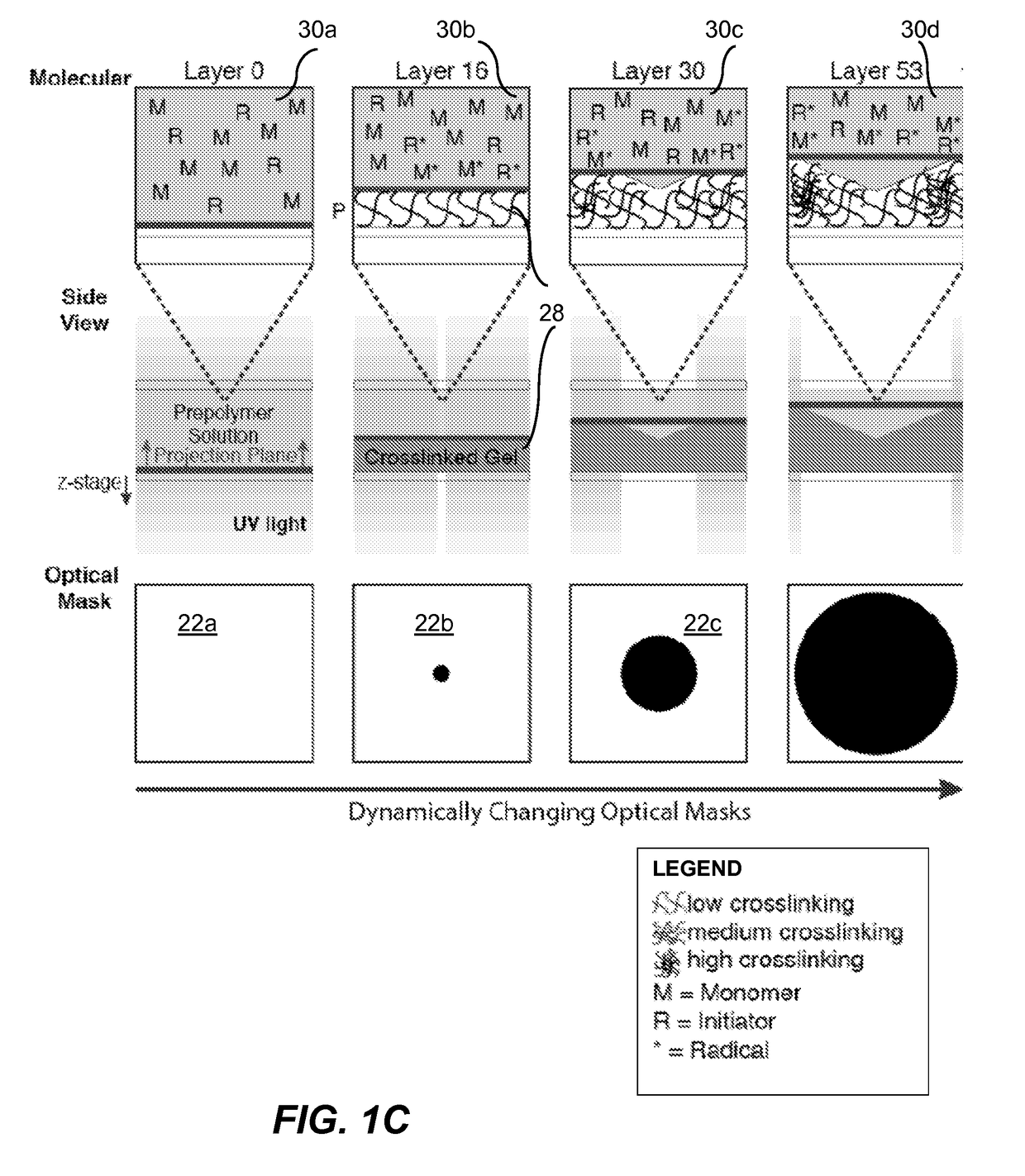

Method for fabrication of microwells for controlled formation of 3-dimensional multicellular-shapes

ActiveUS20170283766A1Increase heightCluster sizeBioreactor/fermenter combinationsBiological substance pretreatmentsExposure periodProjection plane

Using 3D printing, a microwell is formed by providing a plurality of masks, each mask representing a cross-section of a layer of the concave structure. Progressive movement of a projection plane exposes a pre-polymer solution to polymerizing radiation modulated by the masks to define the layers of the microwell, where each layer is exposed for a non-equal exposure period as determined by a non-linear factor. In a preferred embodiment, a first portion of the masks are base layer masks, which are exposed for a longer period than subsequent exposure periods. Shapes of the microwells, which may include circular, square, annular, or other geometric shapes, and their depths, are selected to promote aggregation behavior in the target cells, which may include tumor cells and stem cells.

Owner:RGT UNIV OF CALIFORNIA +1

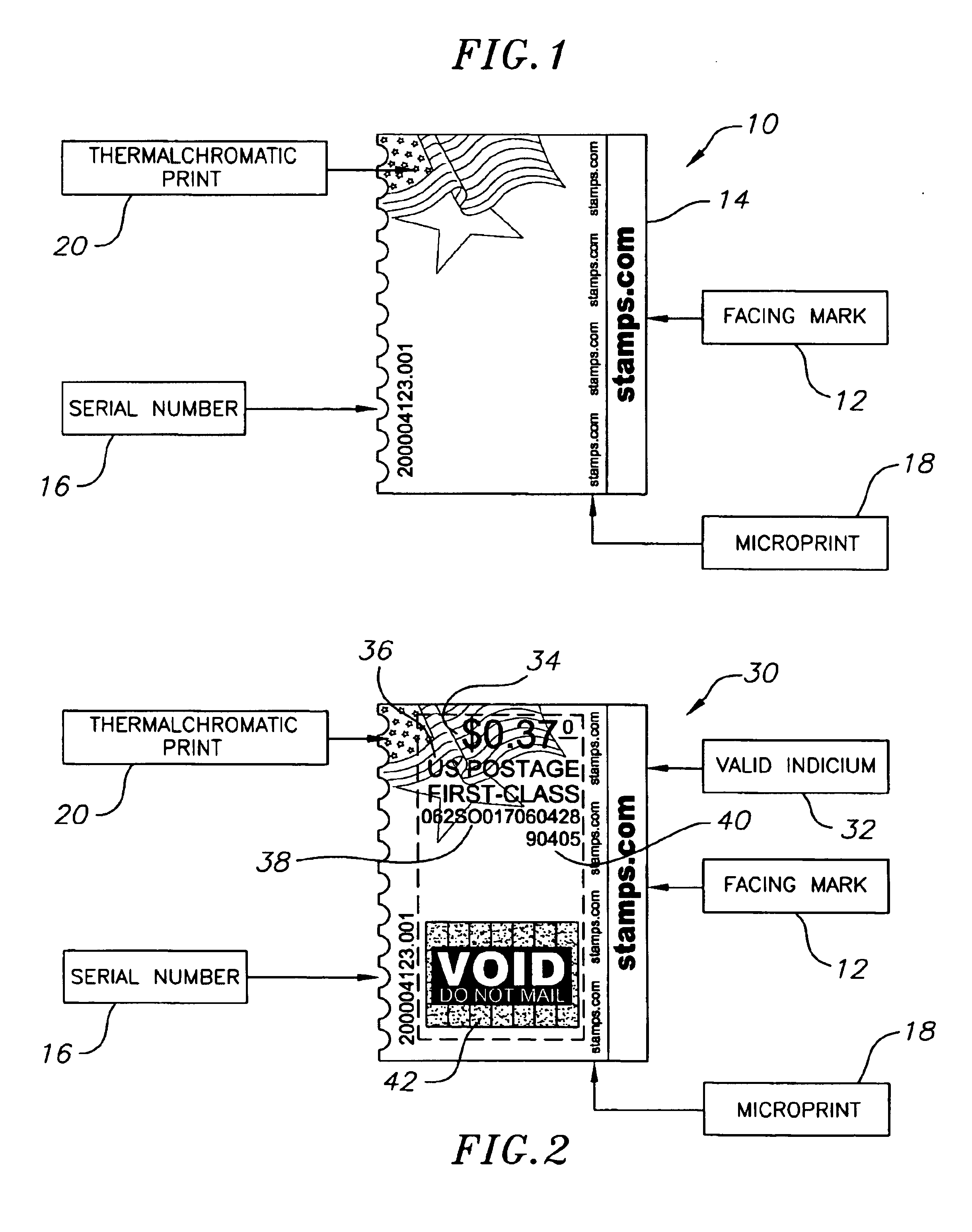

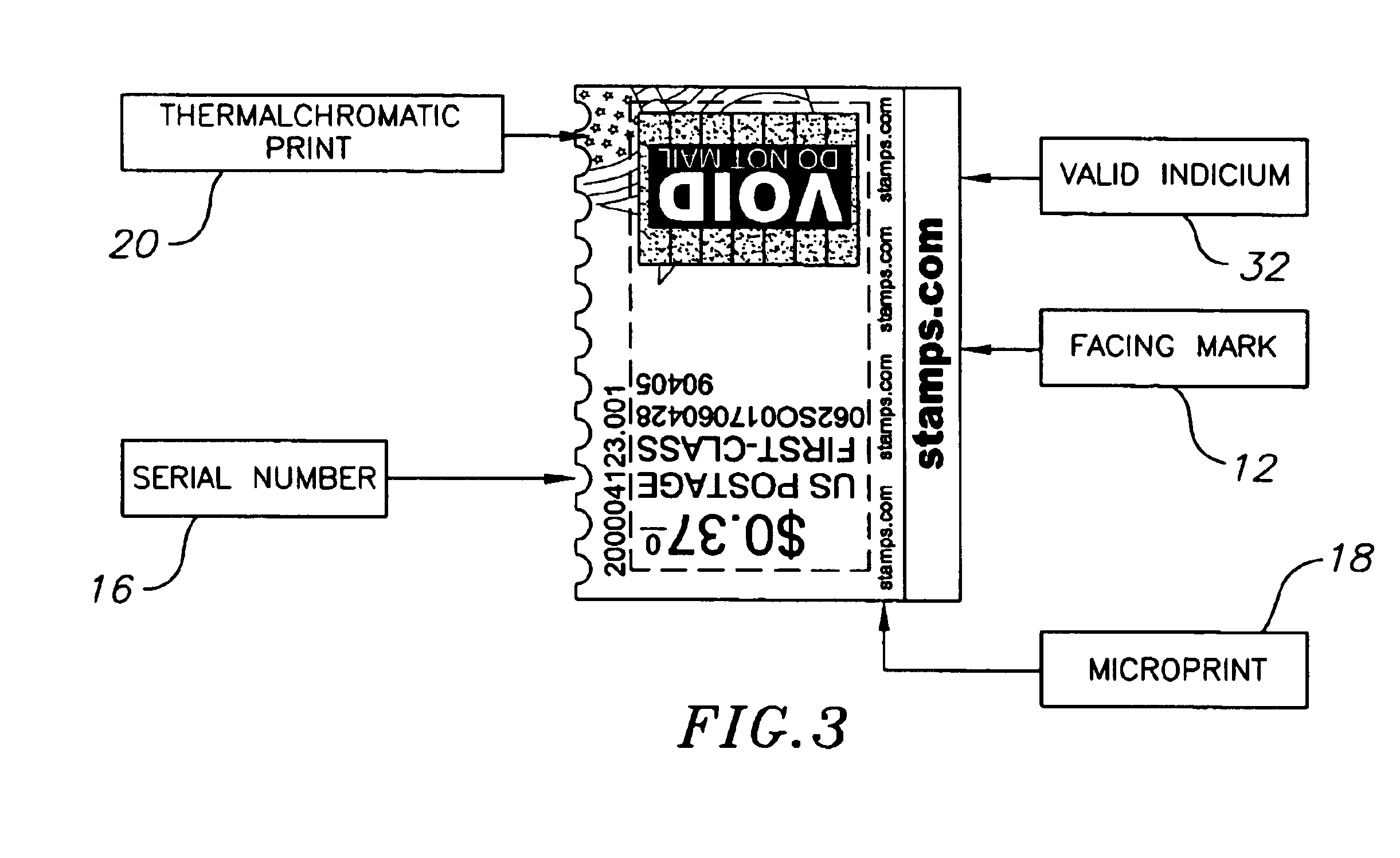

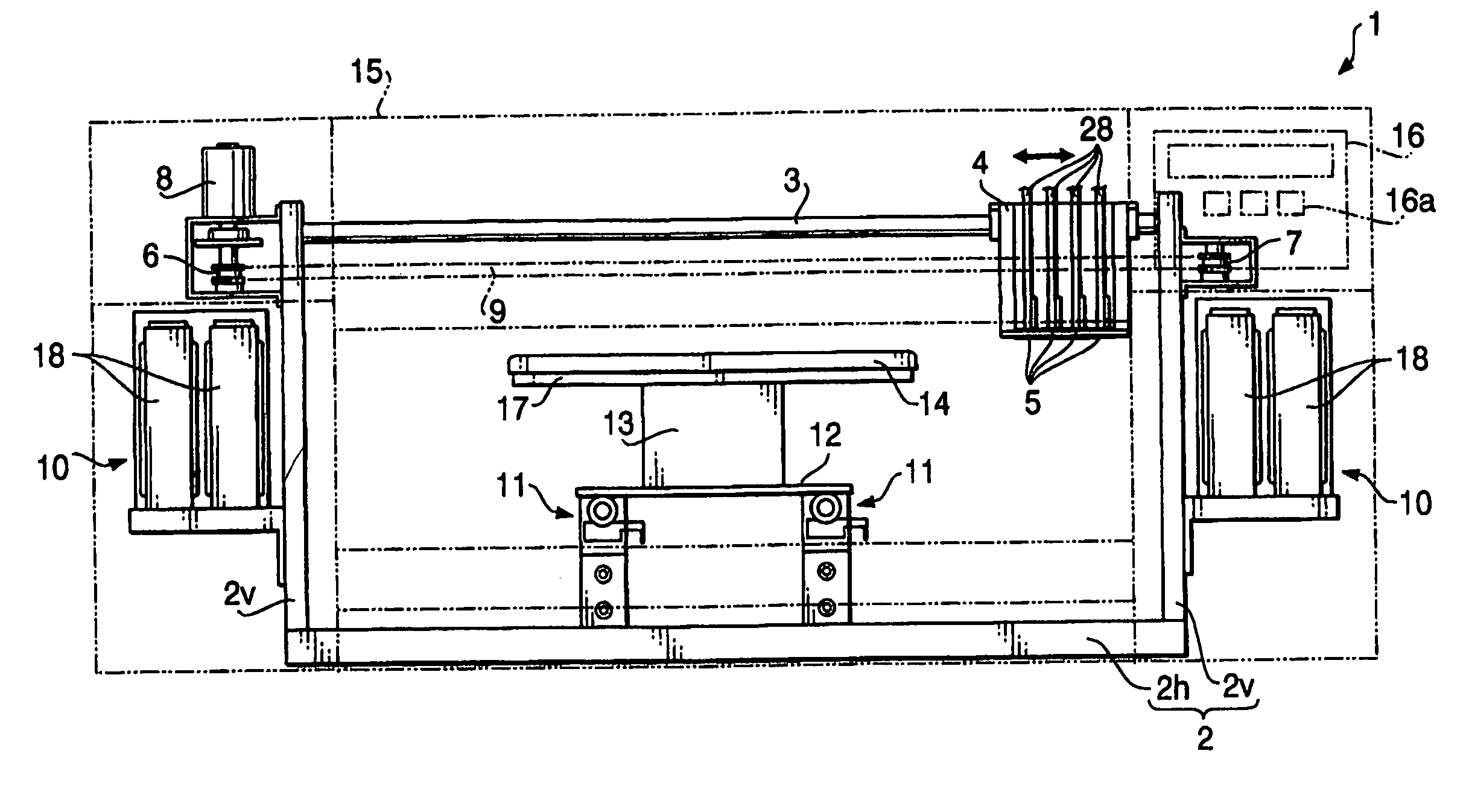

System and layout for proper printing of netstamps and other labels

InactiveUS6939062B2Accurate printingCharacter printing data arrangement from carrierError detection/correctionEngineeringComputer software

A system for assisting a user with the proper feeding of sheets of labels into a printer so that the labels may be properly printed with postage indicia. The system providing a sheet bearing pre-printed labels for further printing with postage indicia, the sheet having a target marker located thereon. Further provided is an interactive computer software that guides a user to feed a sheet of labels into the printer, directs the printer to print an indication mark on the sheet of labels, and queries the user as to where an indication mark appears on the sheet of labels. The invention further provides a sheet bearing pre-printed labels for further printing with postage indicia, having an area where a plurality of self-stick labels are located, wherein each label is pre-printed with a serial number, and a perimeter margin area having a target marker located thereon.

Owner:AUCTANE INC

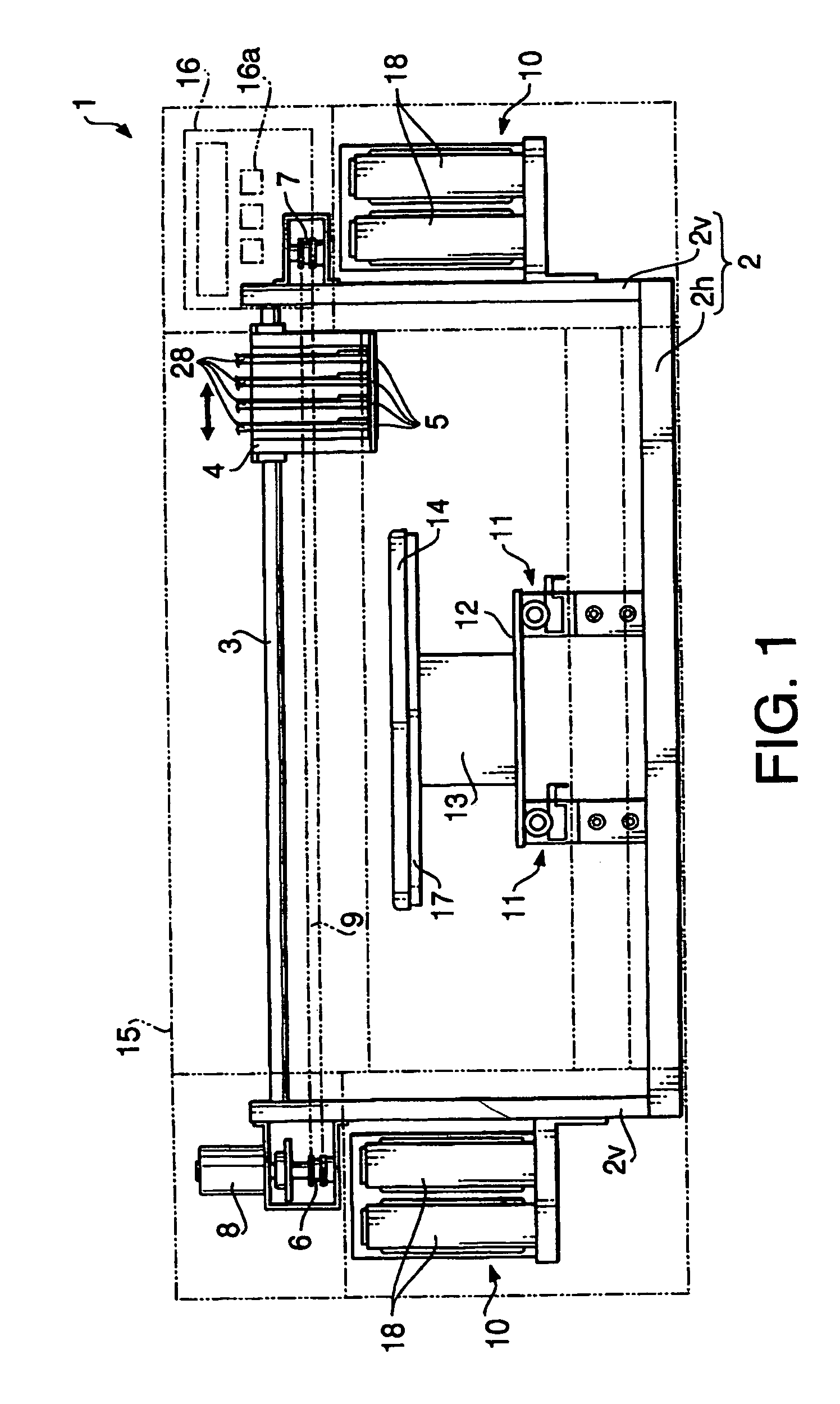

Inkjet printing apparatus

ActiveUS20060152568A1Accurate printingLiquid surface applicatorsPlaten pressesDistance spaceMechanical engineering

An inkjet type fabric printing apparatus is provided with an inkjet head, a platen and a positioning member. The inkjet head reciprocally moves in main scanning direction and auxiliary scanning direction relative to a fabric (e.g., clothes). The platen holds the fabric to extend on a plane parallel with the main scanning direction and the auxiliary scanning direction with a first predetermined distance spaced from the inkjet head. On the positioning member, the fabric is set. The fabric is positioned on the platen in place in a direction parallel with the main scanning direction and the auxiliary scanning direction. The positioning member supports at least one of a neck portion and a shoulder portion of the fabric such that the neck portion and / or a shoulder portion is spaced from the inkjet head by a second predetermined distance.

Owner:BROTHER KOGYO KK

Method for printing product features on a substrate sheet

ActiveUS20120321793A1Increased dimensional tolerancesLess artefactRotary intaglio printing pressPattern printingEngineeringImage object

Owner:ROLLING OPTIKS AB

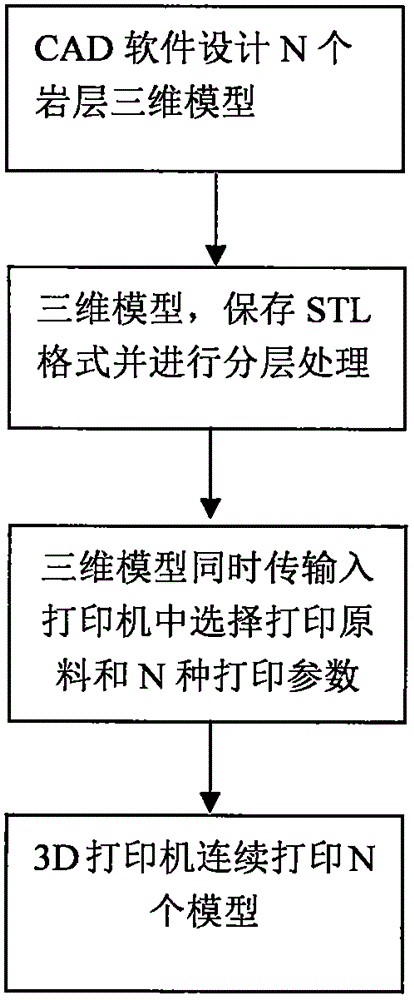

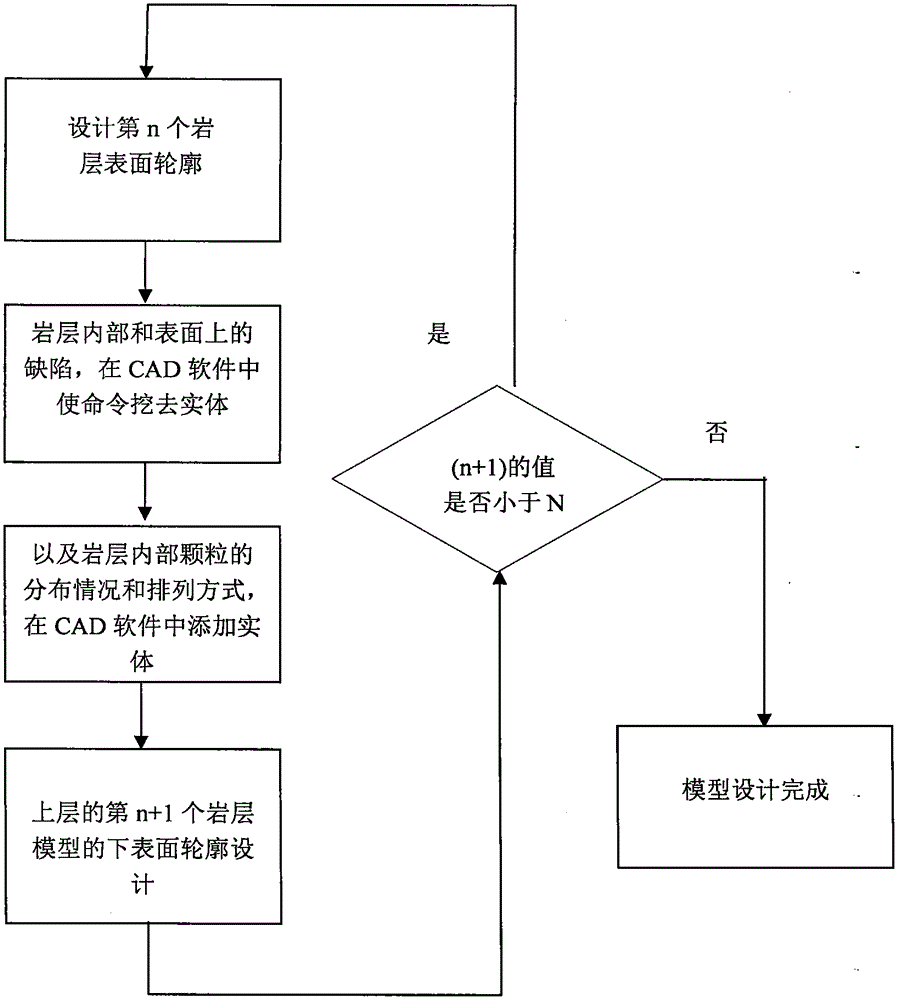

Method for making rock bedding structure model based on 3D printing technology

InactiveCN105599300AGuaranteed representationAvoid time costAdditive manufacturing apparatusVolumetric Mass DensityData transmission

The invention provides a method for making rock bedding structure model based on a 3D printing technology. The method includes the following steps that N rock stratum three-dimensional models of the same property are designed with CAN software; the obtained three-dimensional models are subjected to layered processing and saved in the format of STL; data are transmitted to a computer, and N printing parameters and printing raw materials are selected; N models are printed continuously with a 3D printer, control software controls a printer nozzle to melt the materials according to layered information, spraying is conducted point by point, one layer of printing is completed, and the printer controls a software control platform to ascend along the Z axis to continue curing of subsequent printing layers till the model is obtained. According to the method, the 3D printing technology is utilized to rapidly make the rock bedding structure model stratum by stratum, rock stratums representing different density, composite particles and particle arrangement modes are concentrated into one model, defects existing in the stratums are printed accurately, a rock prototype can be adjusted according to research requirements, and time and economic cost of a small number of customized models are reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

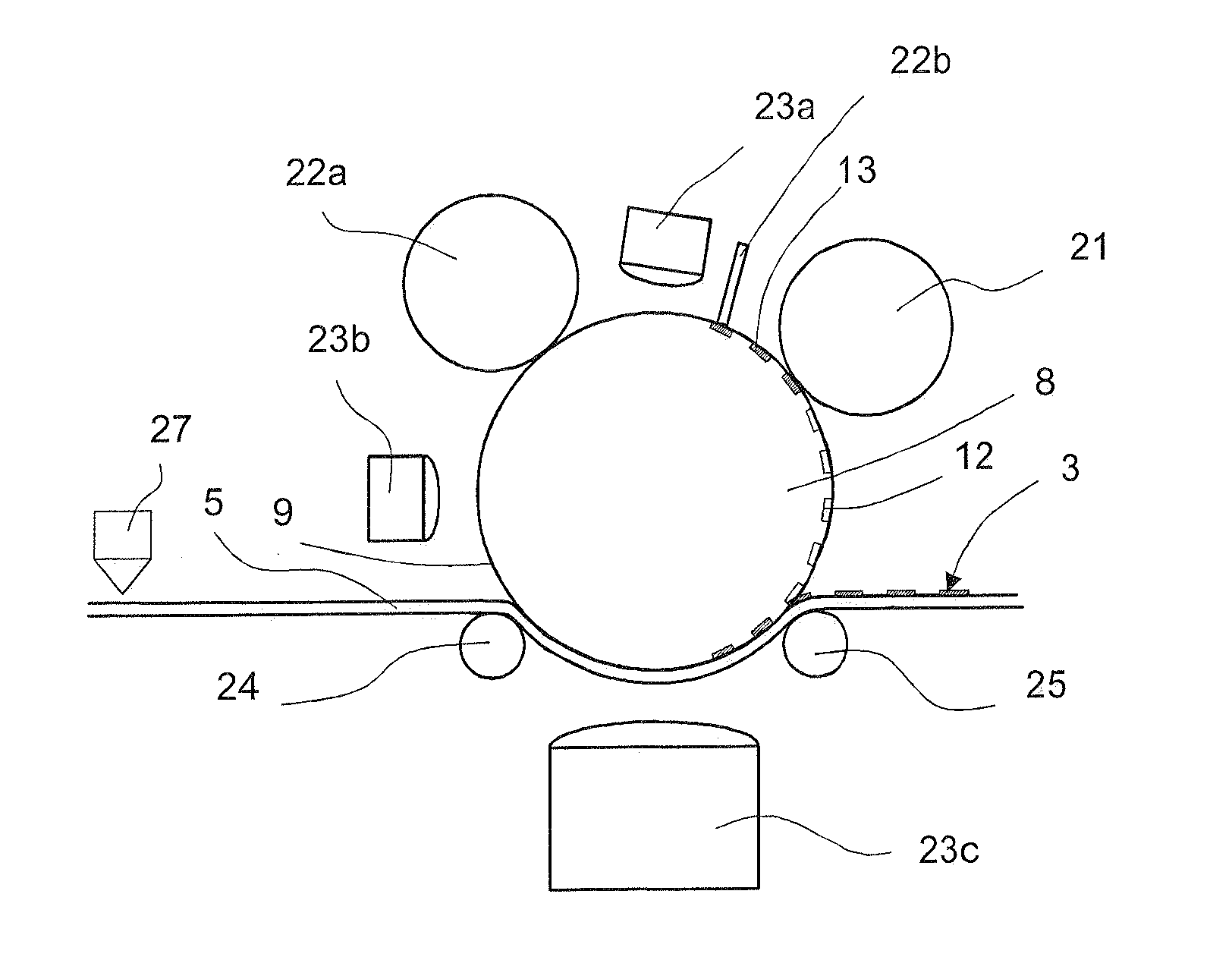

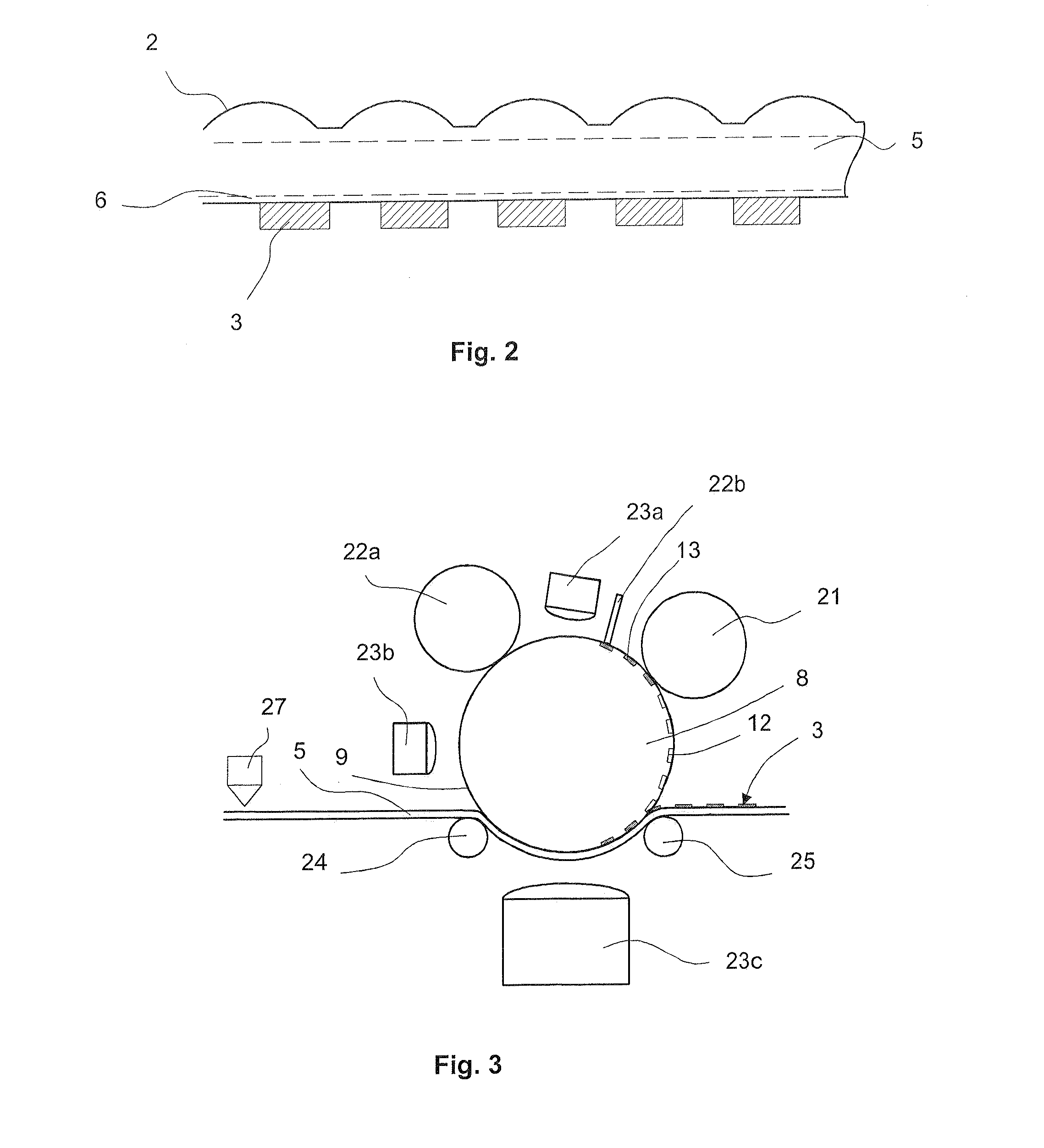

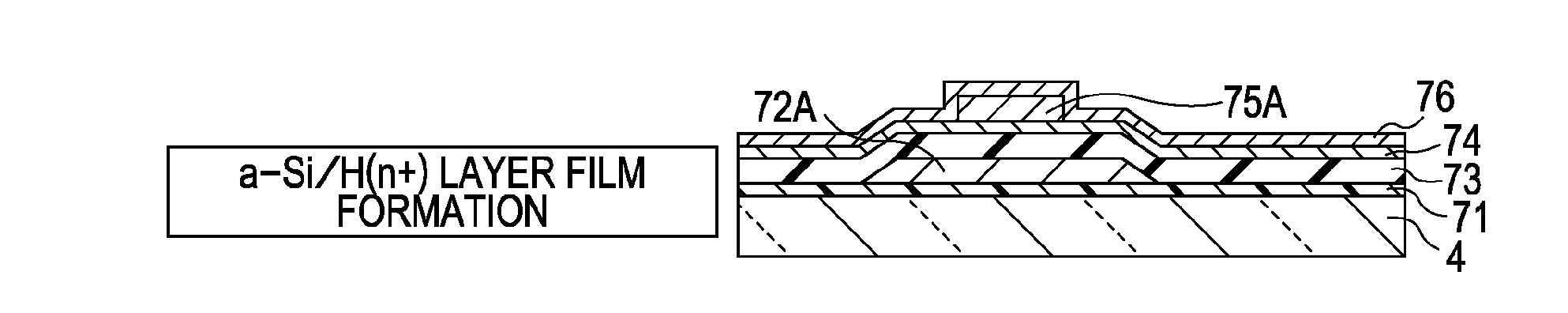

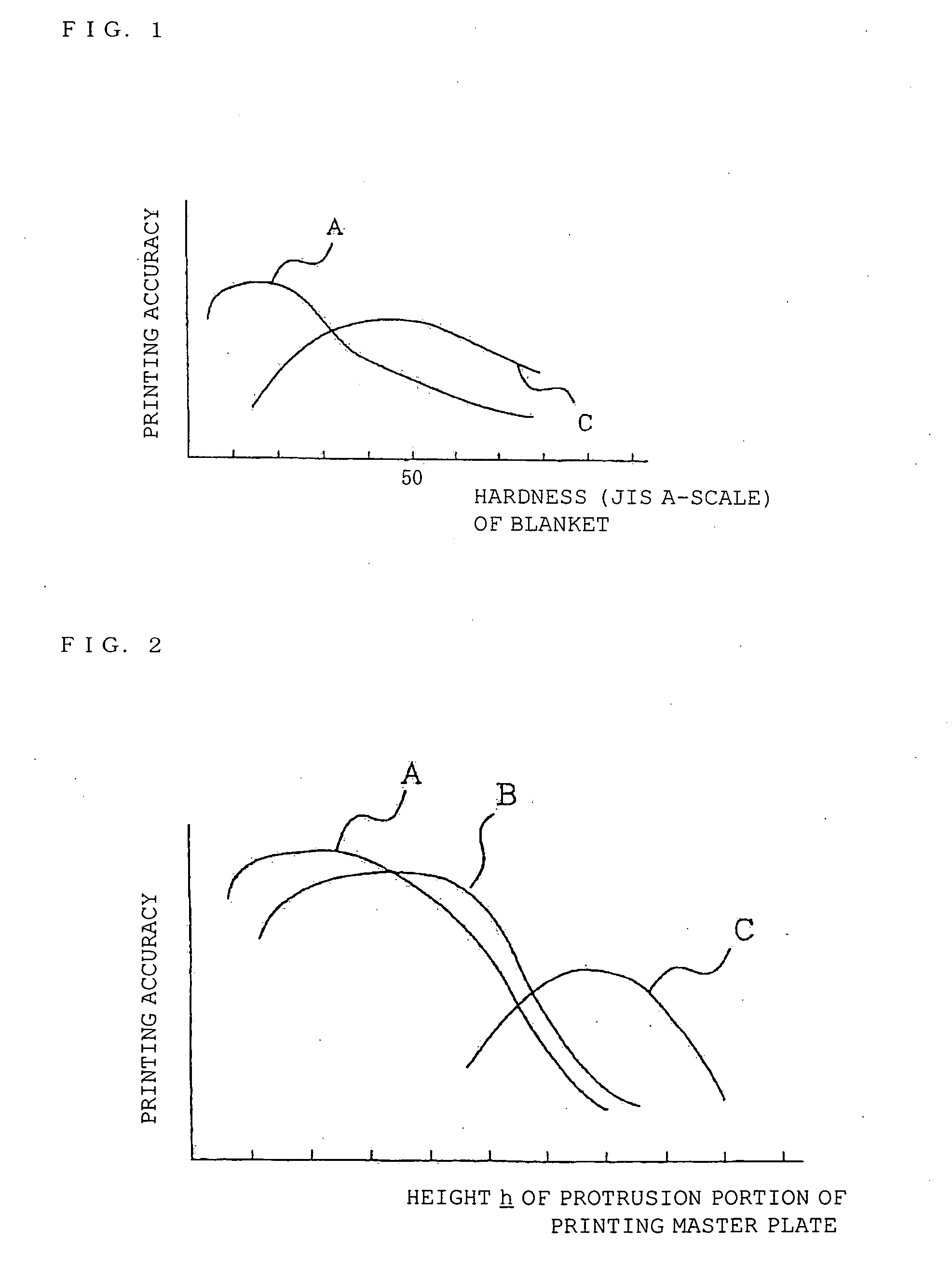

Printing method and display apparatus manufacturing method

InactiveUS20100173553A1Easy to cutAccurate printingCylinder pressesPlaten pressesRelief printingElectrical and Electronics engineering

A printing method including the steps of, forming a transfer layer on a blanket, forming a groove portion on the transfer layer by pressing a protrusion portion of a mold member including the protrusion portion having a predetermined pattern against the transfer layer, the groove portion having the pattern corresponding to the protrusion portion, forming a print pattern layer on the blanket by causing the transfer layer on the blanket and a relief printing plate including a convex portion having a pattern corresponding to a reverse pattern of the protrusion portion to face each other and pressure-contacting them so that a portion on the transfer layer corresponding to the convex portion is selectively eliminated, and transferring the print pattern layer onto a substrate to be printed by causing the print pattern layer on the blanket and the substrate to be printed to face each other and pressure-contacting them.

Owner:SONY CORP

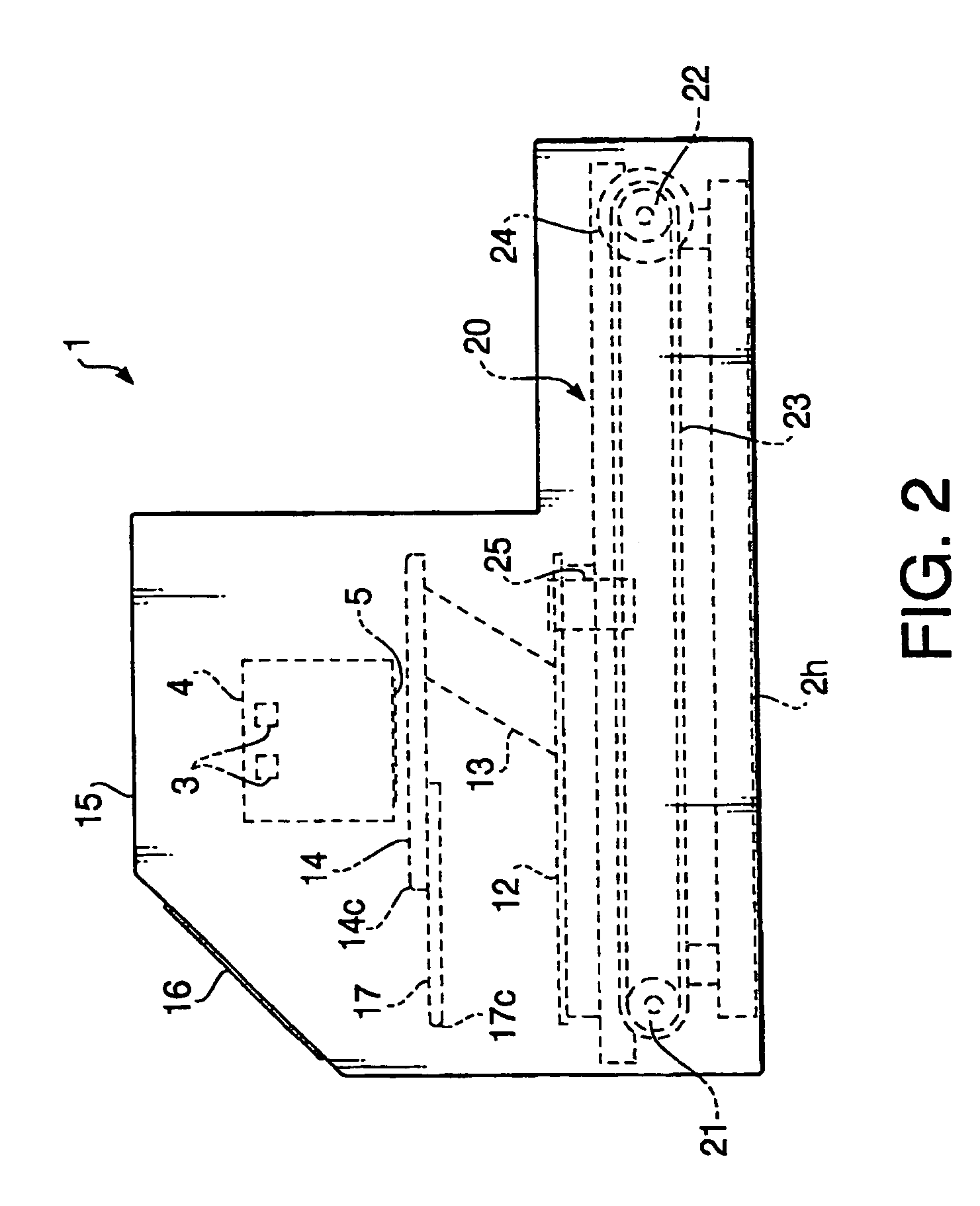

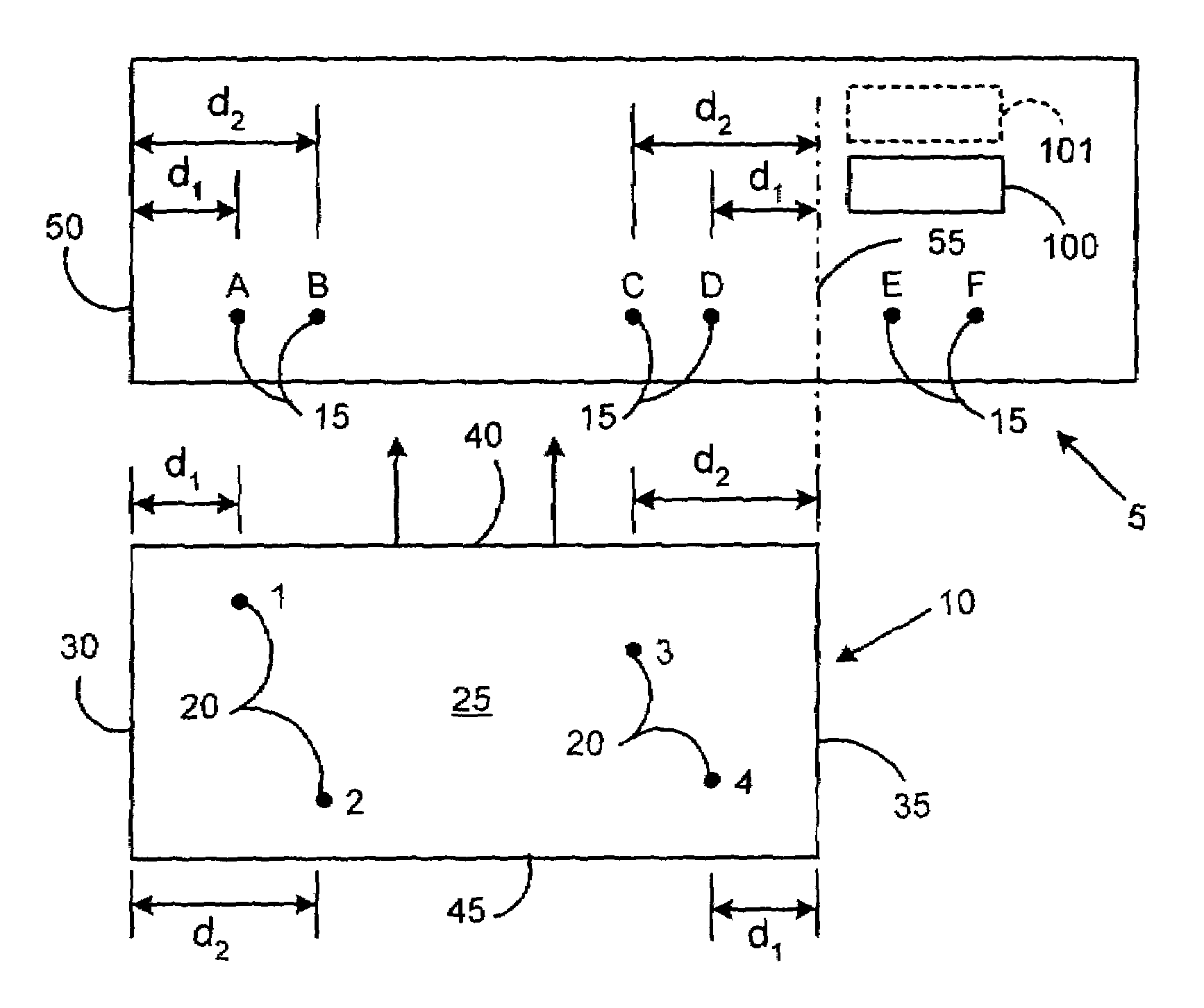

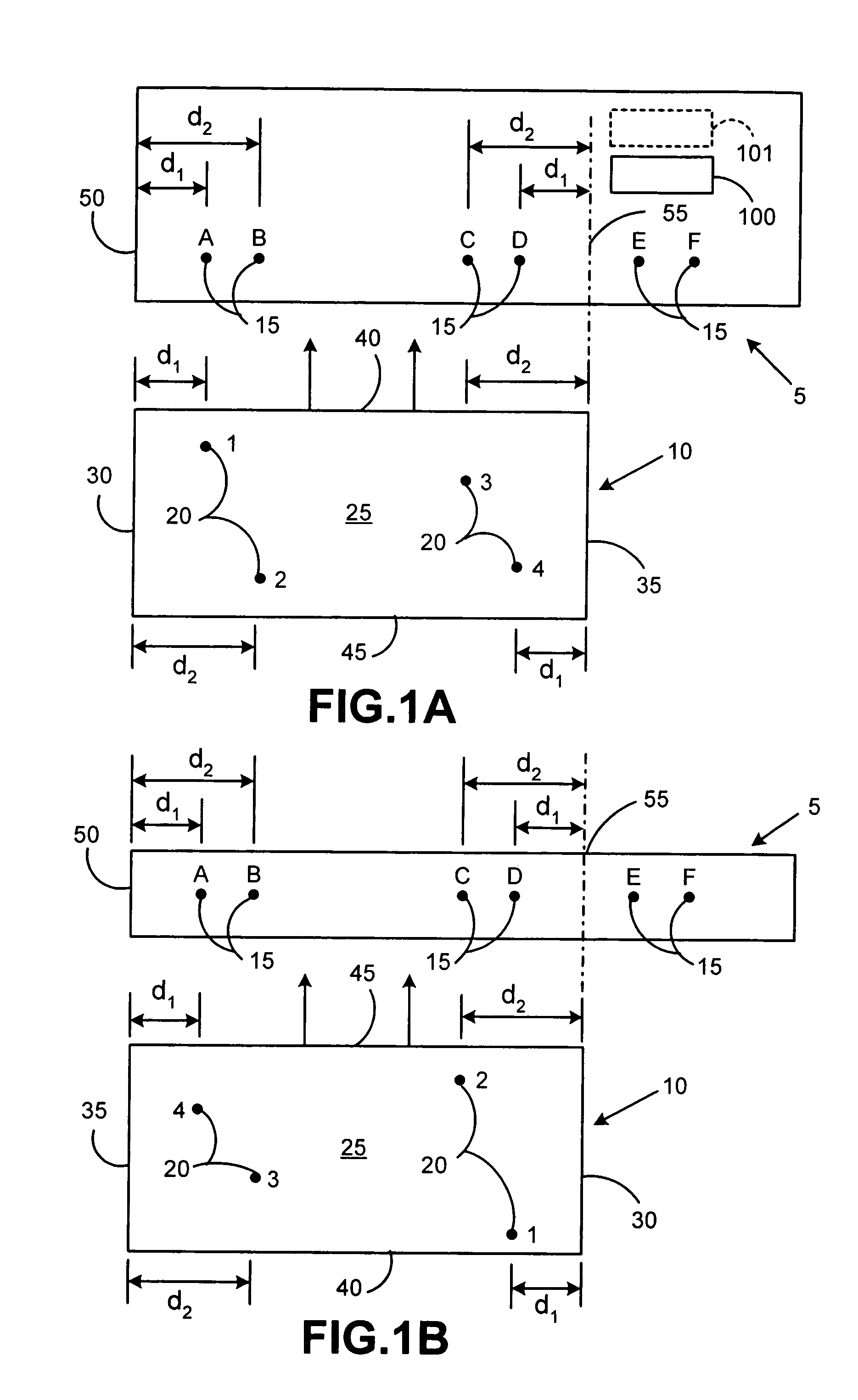

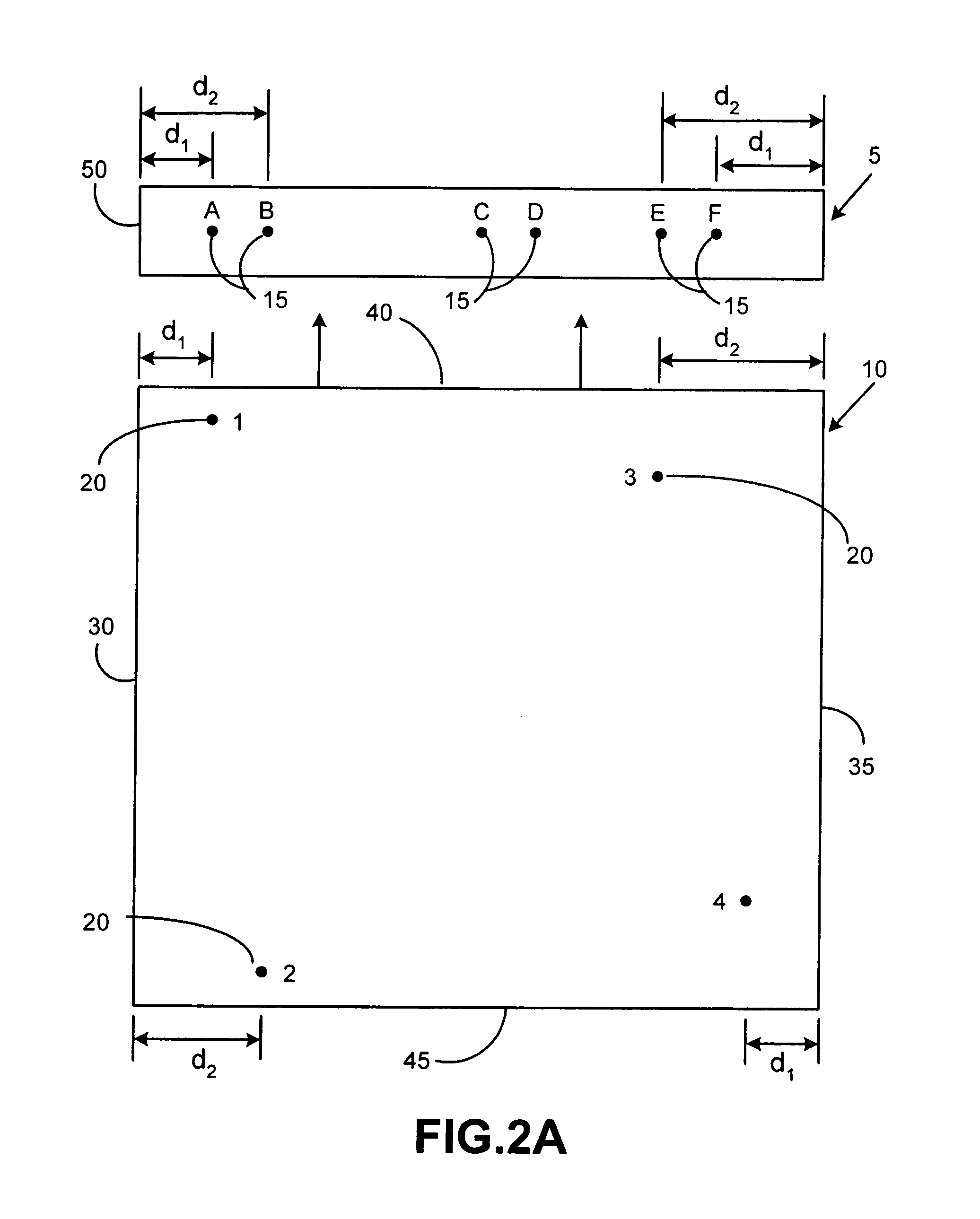

System for ensuring correct placement of printed matter on a tangible print medium

InactiveUS7056048B2Accurate printingPrecise positioningInking apparatusOther printing apparatusElectrical and Electronics engineeringTesting equipment

A system for ensuring that printed matter is properly printed on a print medium including a printer having a feeding device and a plurality of detecting devices disposed along a length of the feeding device. The print medium has a plurality of signaling components, and each of the detecting devices is able to detect the presence of each of the signaling components. The system determines a first feed orientation of the print medium based on an order in which the detecting devices detects the presence of the signaling components when the print medium is being fed into the printer. Alternatively, the first feed orientation may be based on identifying information contained in the signaling components. The printer causes the printed matter to be printed in a proper location and in a proper orientation on the print medium based on the first feed orientation.

Owner:PITNEY BOWES INC

Screen printing apparatus

ActiveUS7580558B2Tight toleranceAccurate printingScreen printersCharacter and pattern recognitionScreen printingEngineering

A screen printing apparatus and method for printing deposits of material onto a workpiece, the apparatus comprising an inspection station for determining a positional relationship of features on upper and lower surfaces of the workpiece. The inspection station comprises an imaging system for determining a positional relationship of features on upper and lower surfaces of the workpiece. The imaging system comprises at least two spaced imaging units for imaging features on an upper surface of the workpiece and at least two spaced imaging units for imaging features on a lower surface of the workpiece. A processing unit determines a positional relationship of the imaged features on the upper and lower surfaces of the workpiece. A printing station prints deposits of material onto the workpiece. Also described are a transport mechanism and an alignment system.

Owner:ASM ASSEMBLY SYST SINGAPORE PTE LTD

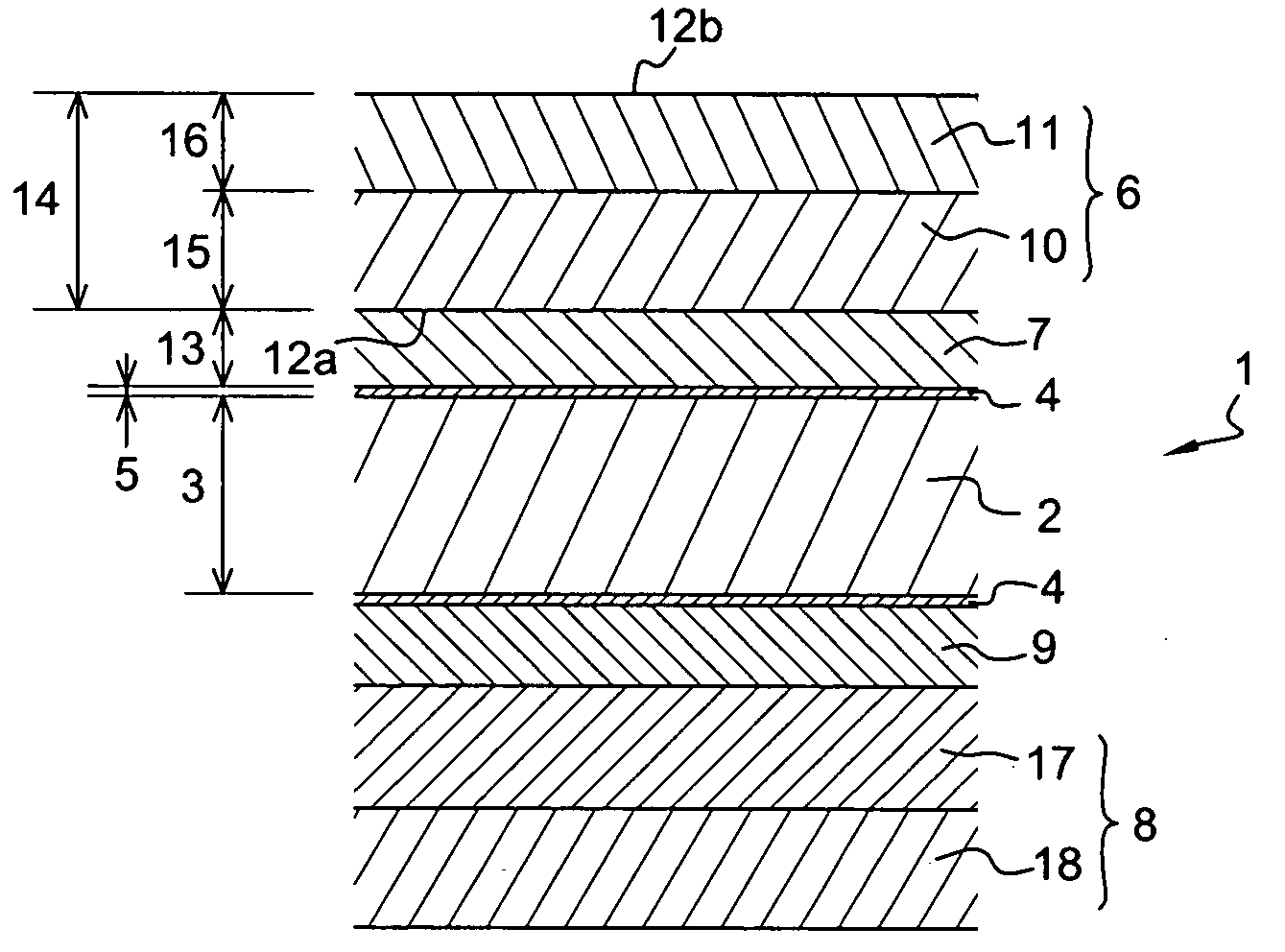

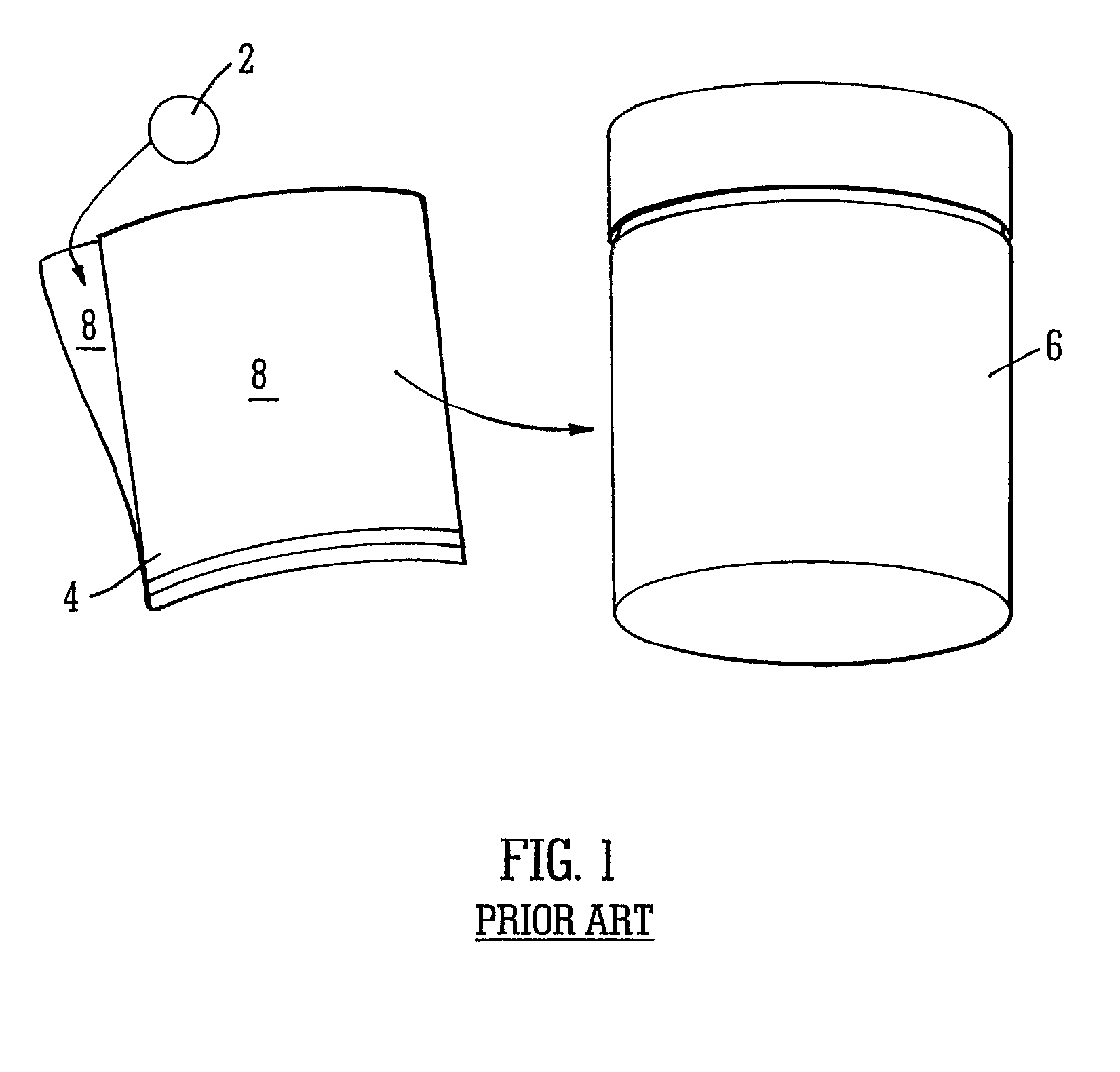

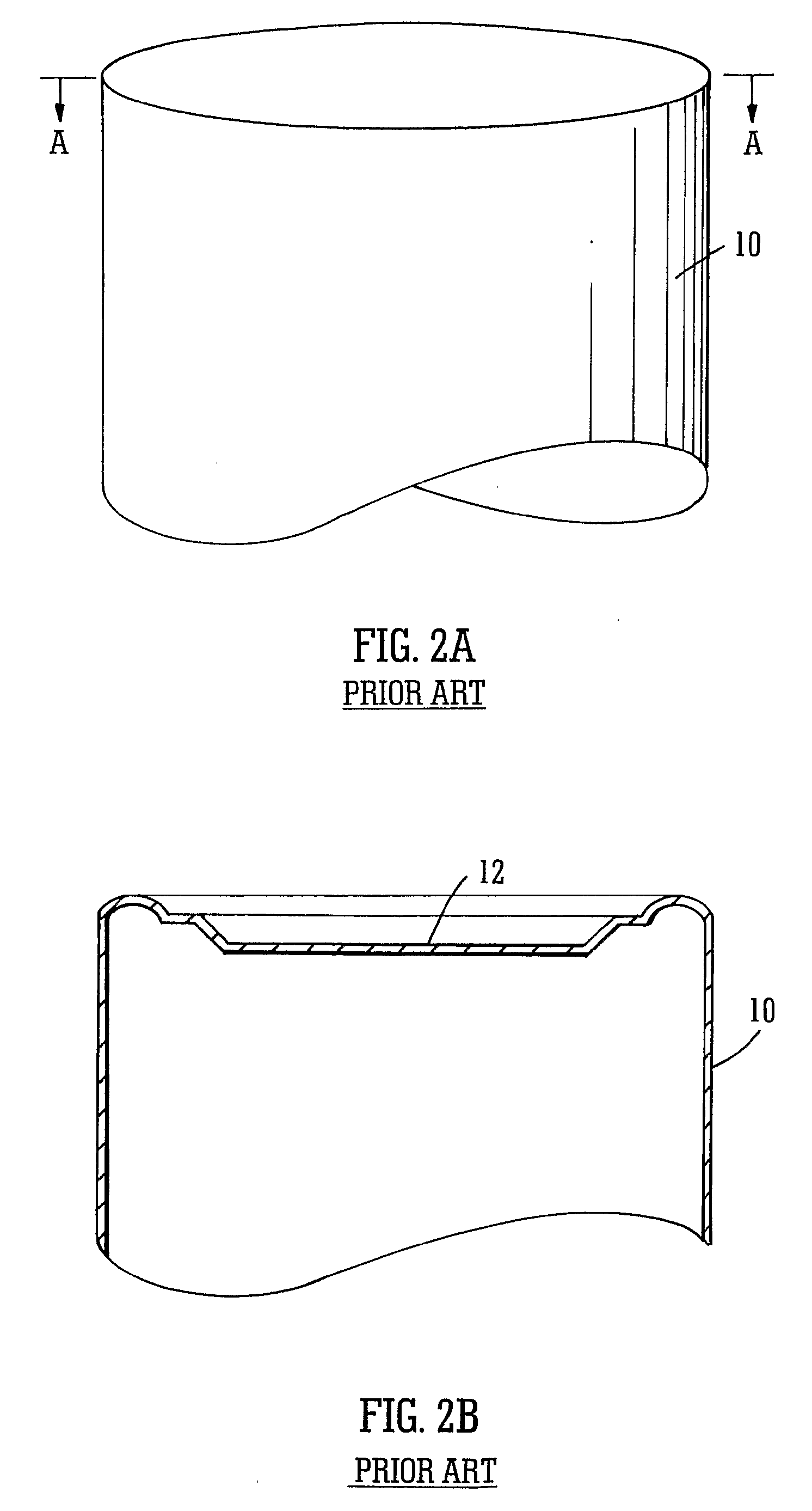

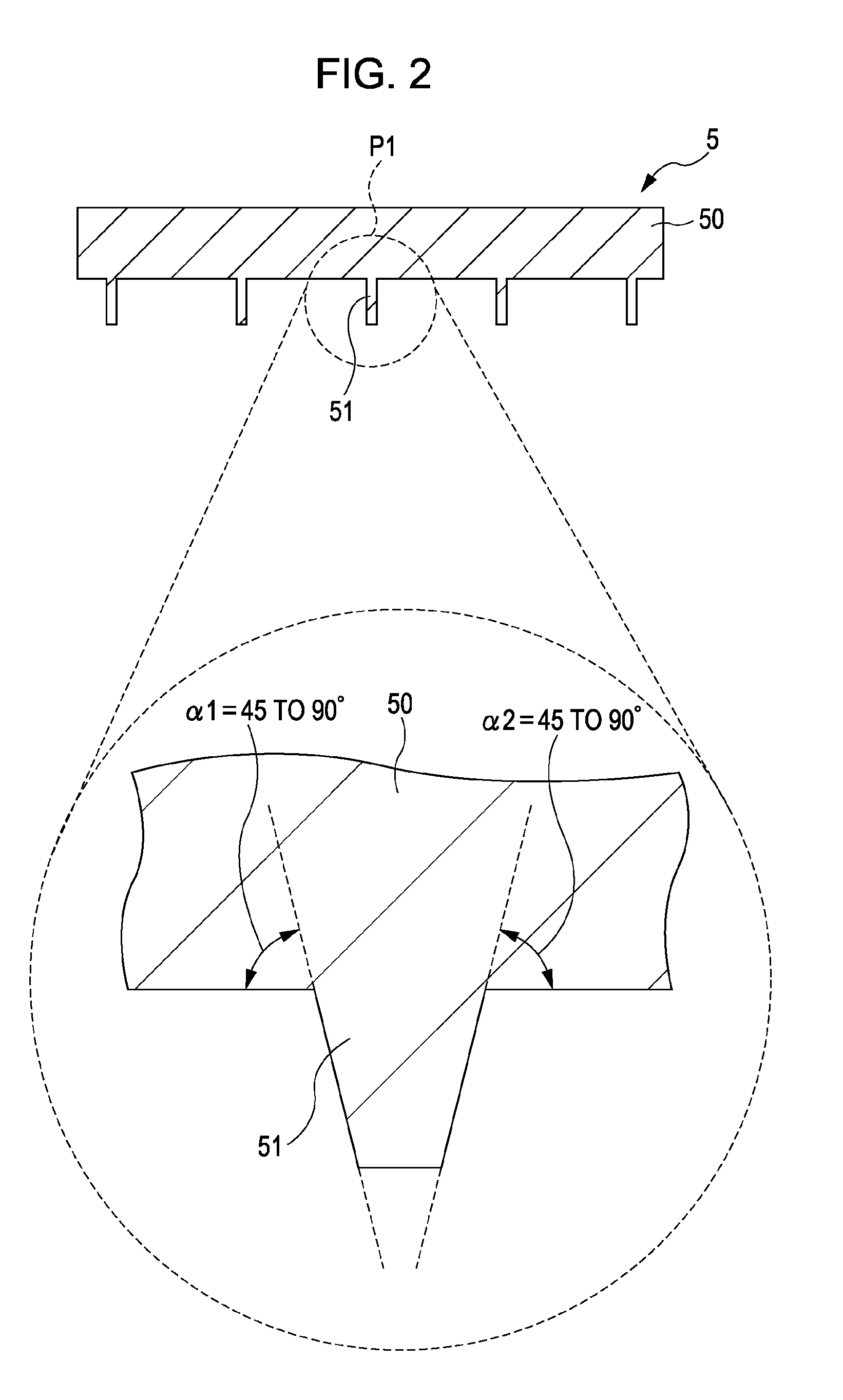

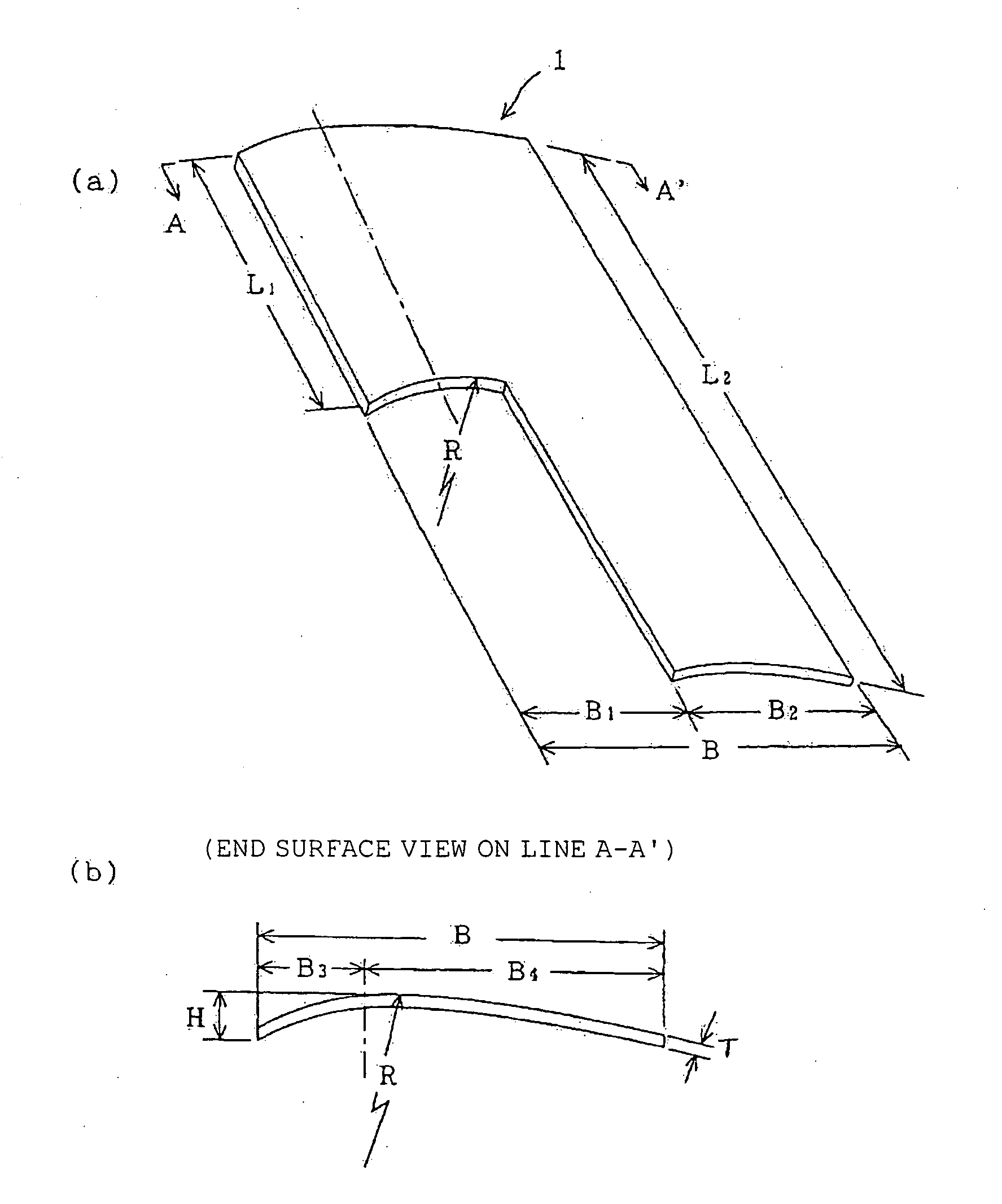

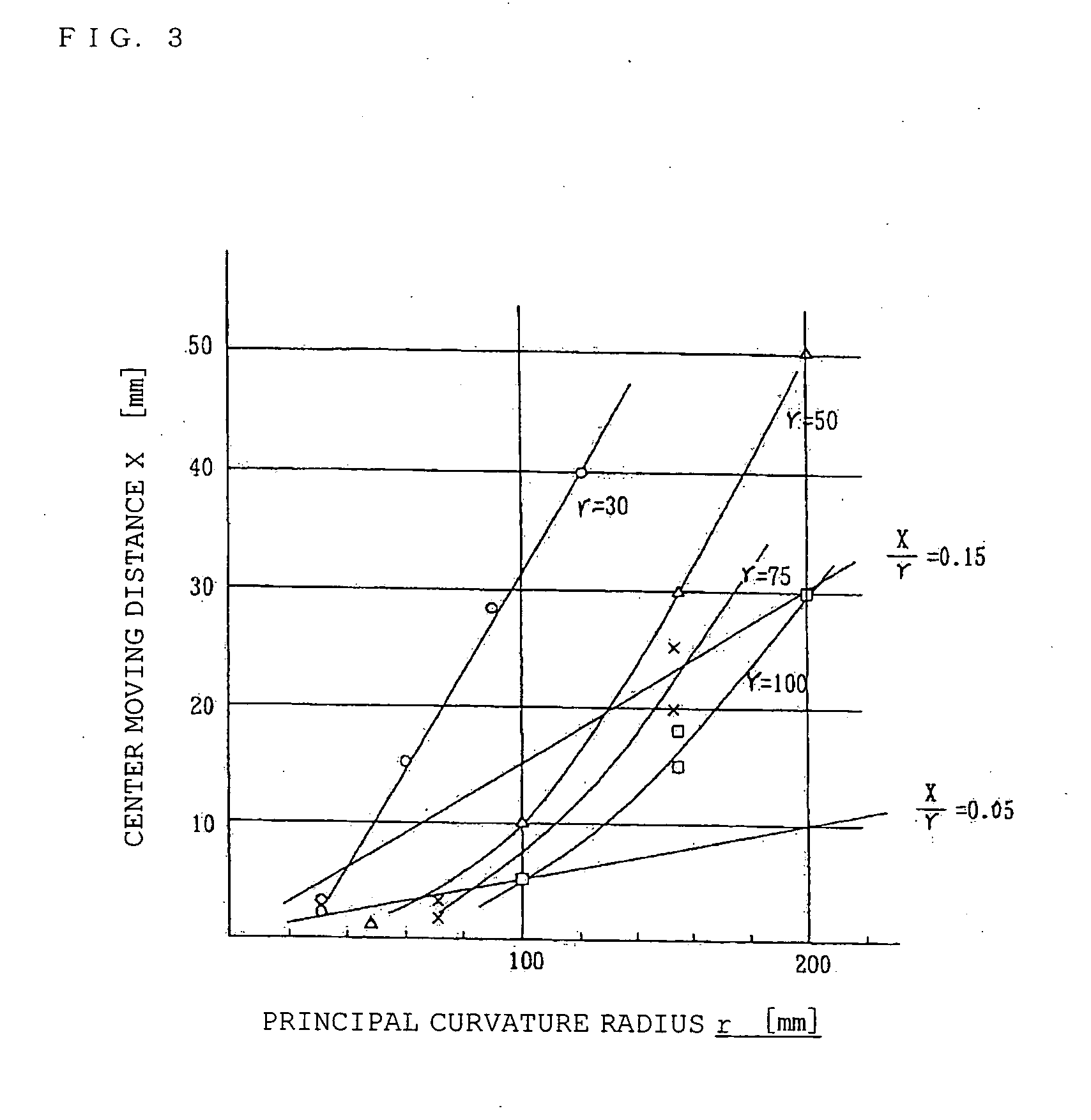

Printing Method on Curved Surface and Curved Surface Body Printed by that Method

A method for printing on a curved surface and a printed curved surface body using the method. The method includes the steps of: applying printing ink having a viscosity of 5-500 PaS, preferably 5-250 PaS, to a protrusion portion of a relief printing master plate 3 which is a flat plate with the protrusion portion 0.1-50 μm high, preferably 0.1-25 μm high in height h; pressing a rubber or rubbery roll-like elastic blanket 2 having an elastic portion whose thickness T has a relation of 2H≦T≦8H with respect to a level difference H of a to-be-printed curved surface body 10 and which has a hardness (JIS A-scale) of 3-40, preferably 3-20, onto the relief printing master plate 3 supplied with the printing ink while applying constant pressure to the roll-like elastic blanket 2 and smoothly rotating the roll-like elastic blanket 2, so as to transfer the printing ink to an outer circumferential surface of the roll-like elastic blanket 2; and moving the roll-like elastic blanket 2 having the printing ink transferred thereto, and bringing the roll-like elastic blanket 2 into rotational pressure contact with a surface of the to-be-printed curved surface body 10 so as to perform printing thereon.

Owner:SHUHOU

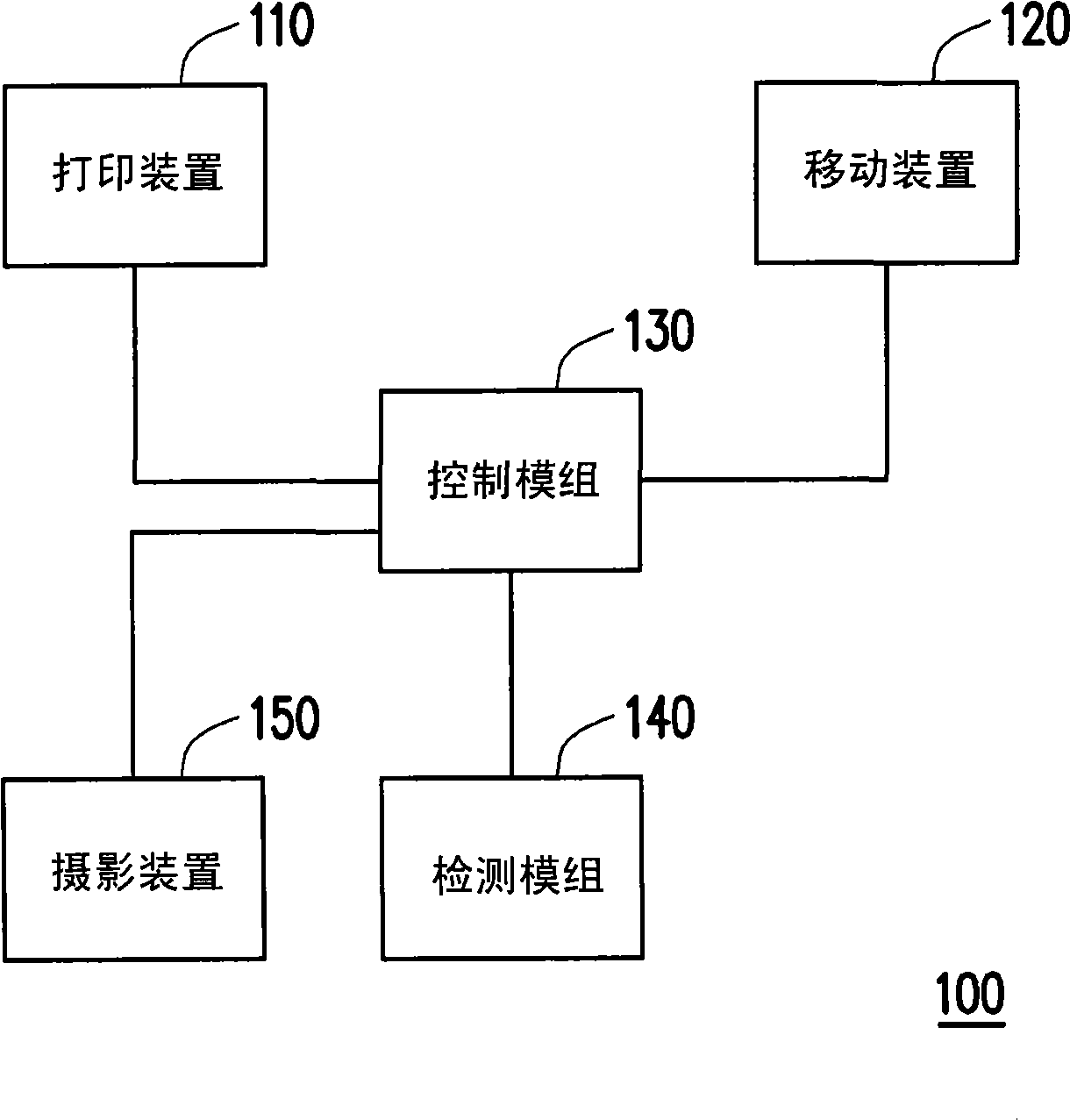

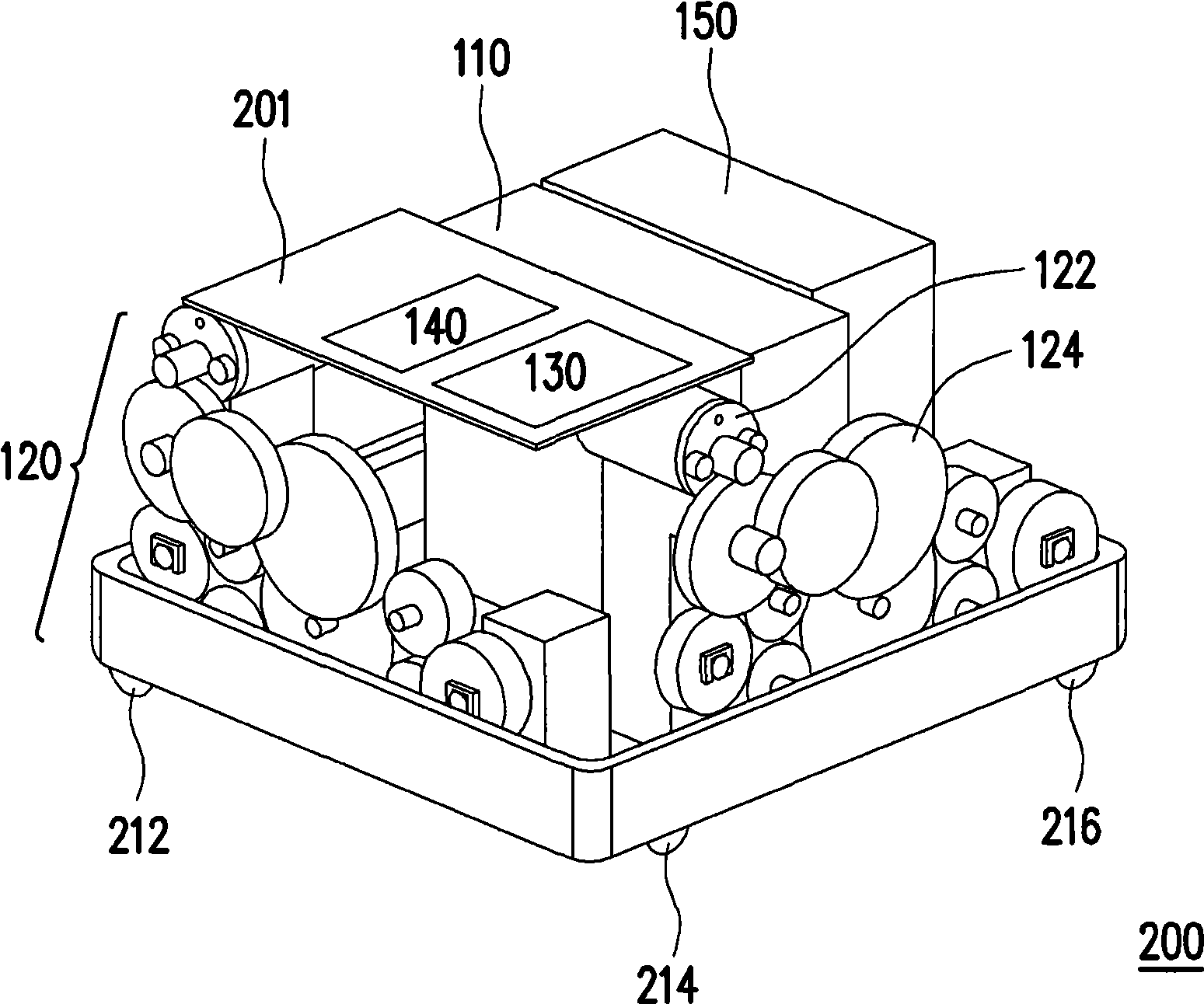

Self-propelled printer having orientation adjusting device and method for setting coordinate

InactiveCN101544132AHigh movement accuracyAccurate printingTypewritersOther printing apparatusComputer science

Owner:KINPO ELECTRONICS

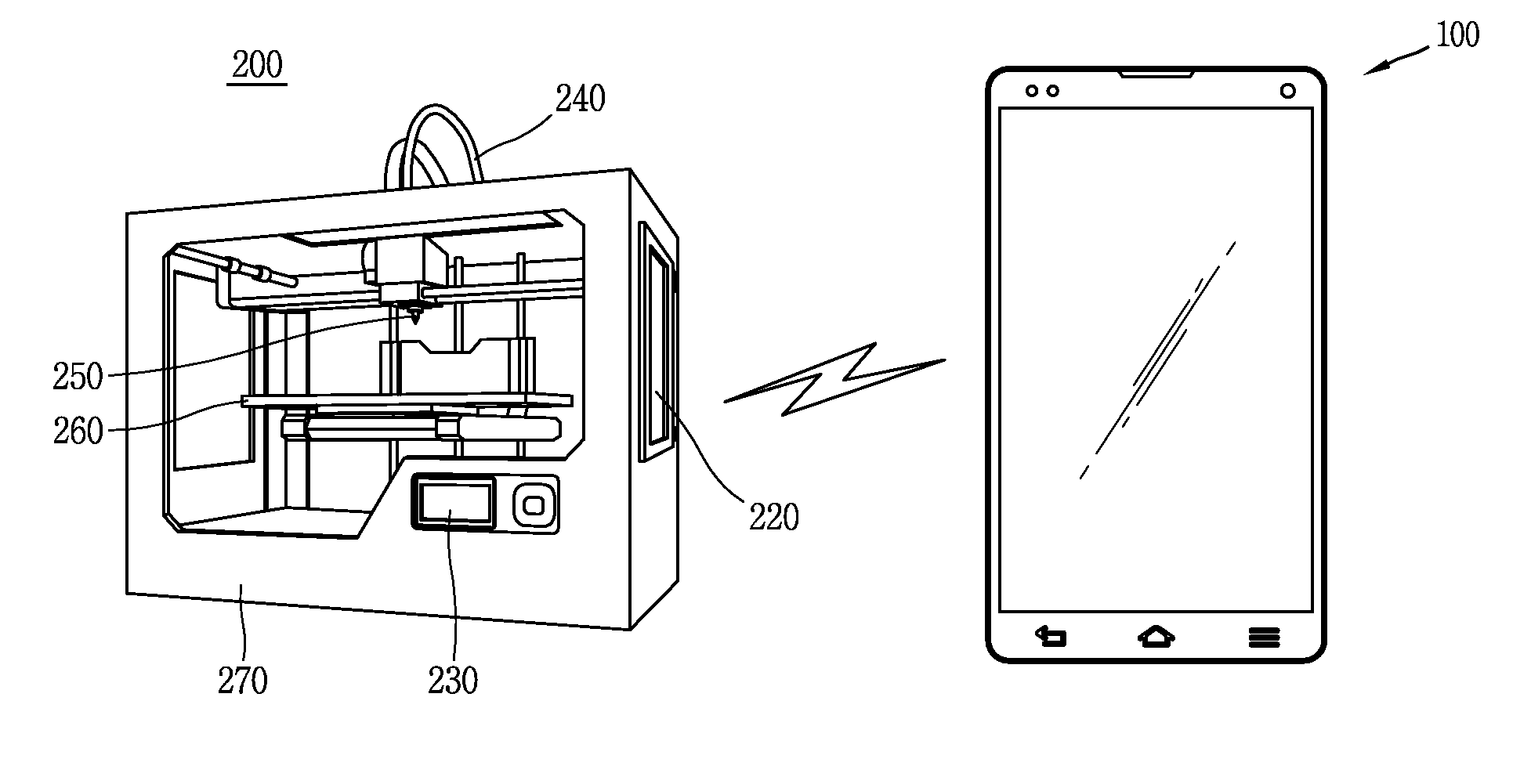

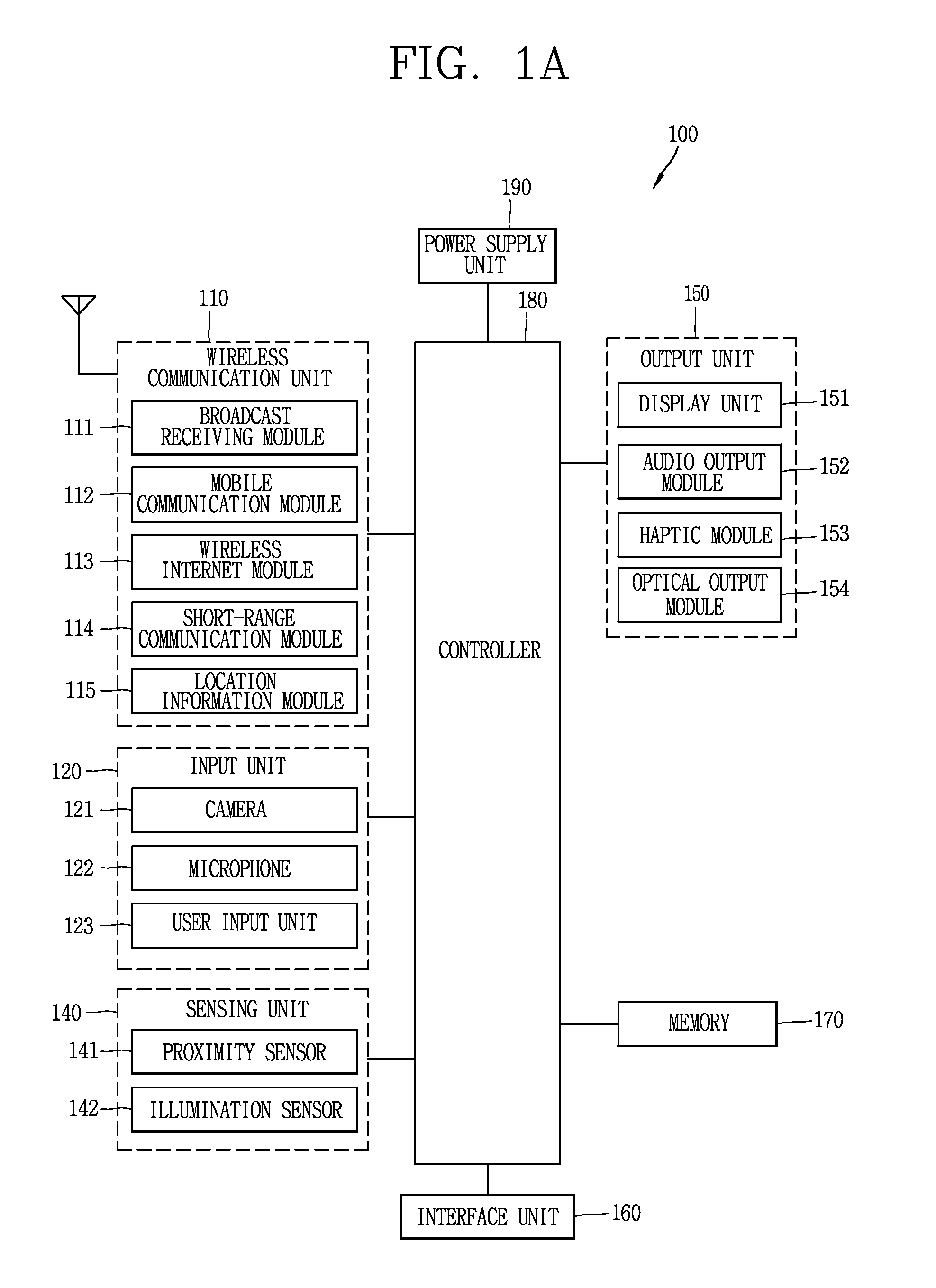

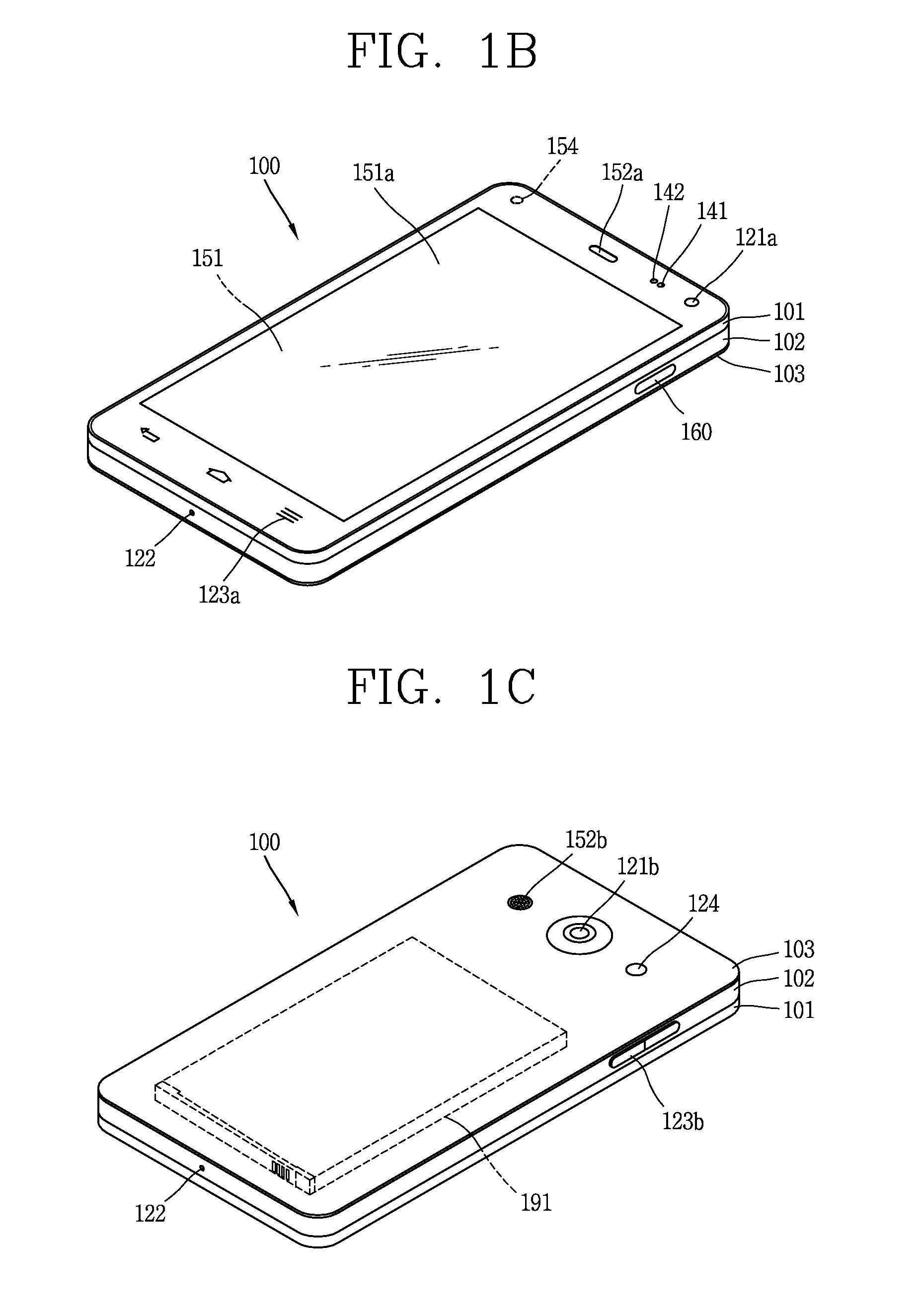

Mobile terminal and method for controlling the same

InactiveUS20160016362A1Accurate printingProgramme controlAutomatic control devicesCommunication unitControl signal

The present disclosure provides a mobile terminal including a wireless communication unit configured to perform wireless communication with a 3D printer configured to print a solid object, a display unit configured to divide the solid object into a plurality of modules based on a preset criteria, and display an image containing at least part of the plurality of modules, and a controller configured to control the wireless communication unit to transmit a control signal to the 3D printer so as to print at least one selected from the plurality of modules based on a control command applied to the display unit.

Owner:LG ELECTRONICS INC

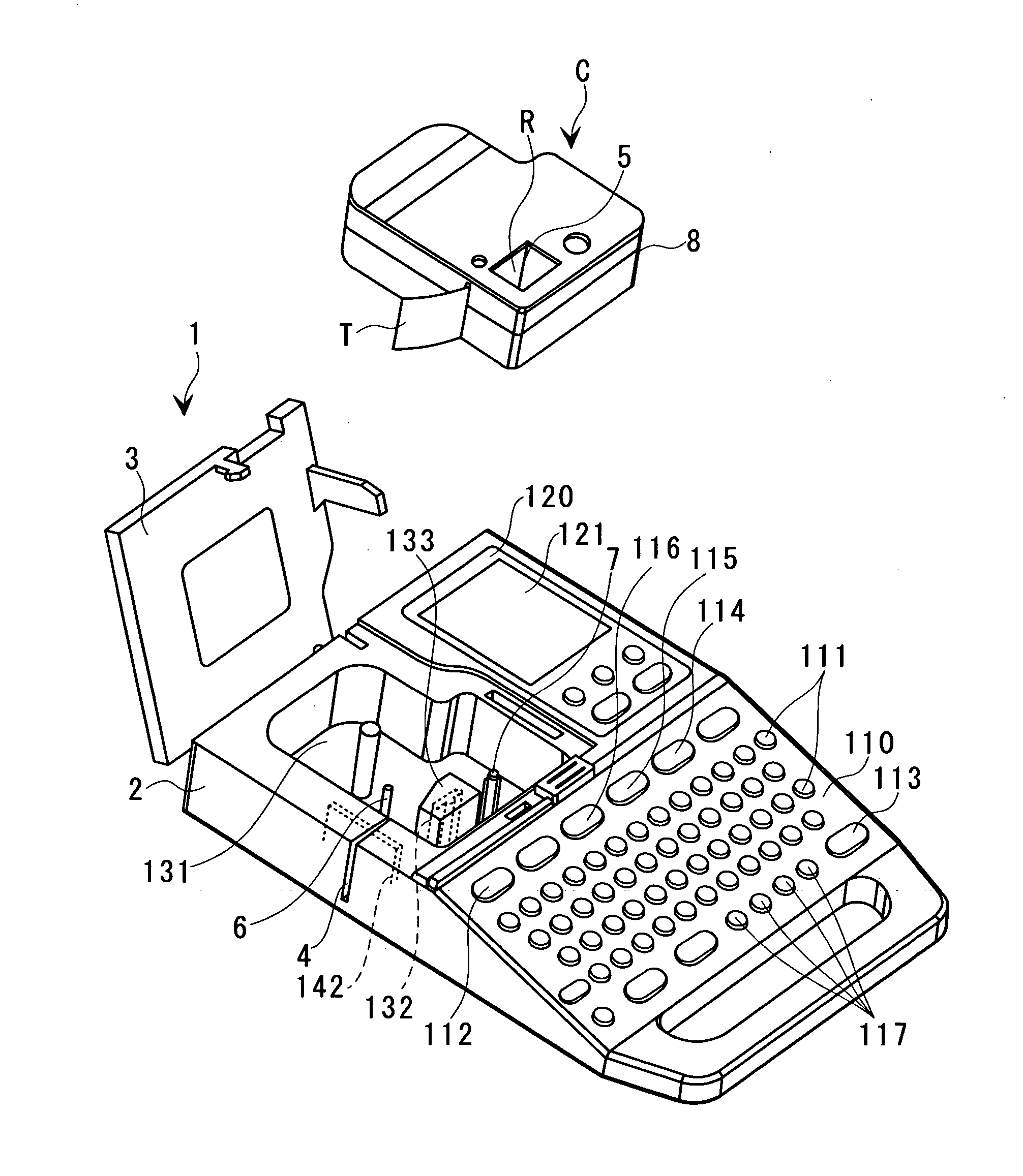

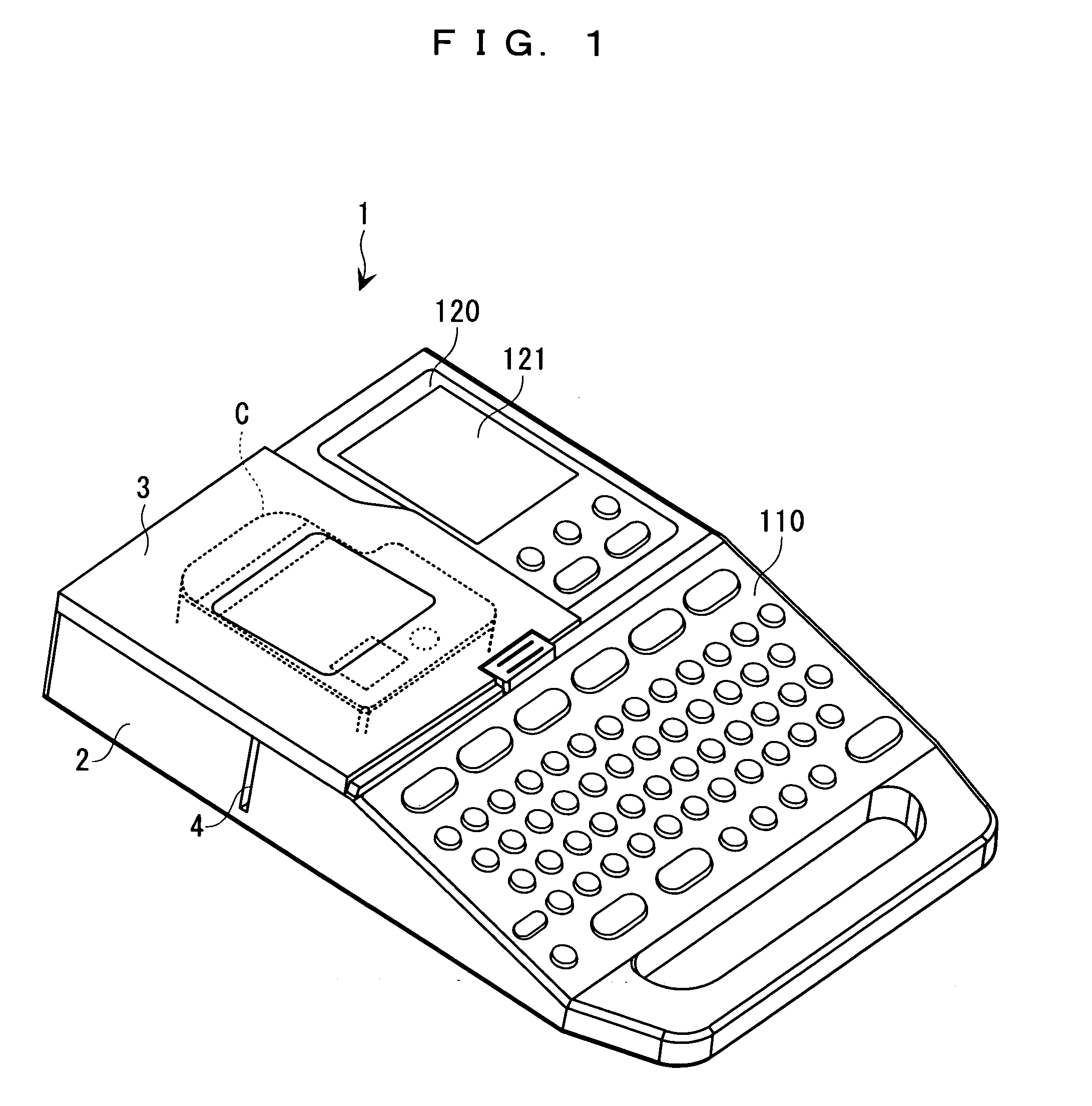

Tape printing apparatus and tape printing method

ActiveUS20050180795A1Attractive appearanceFinely adjust tape width of tapeStampsTypewritersComputer science

Owner:SEIKO EPSON CORP

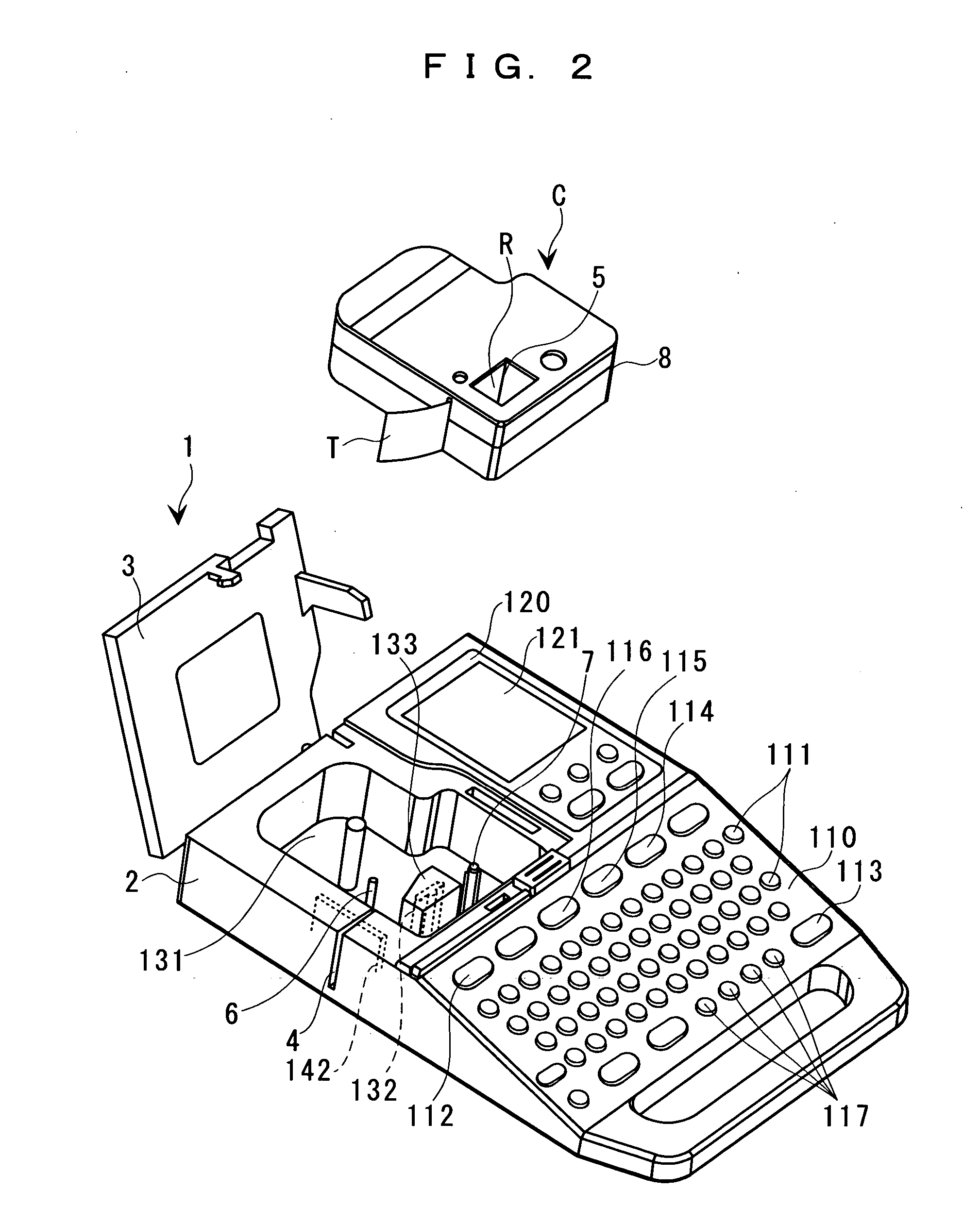

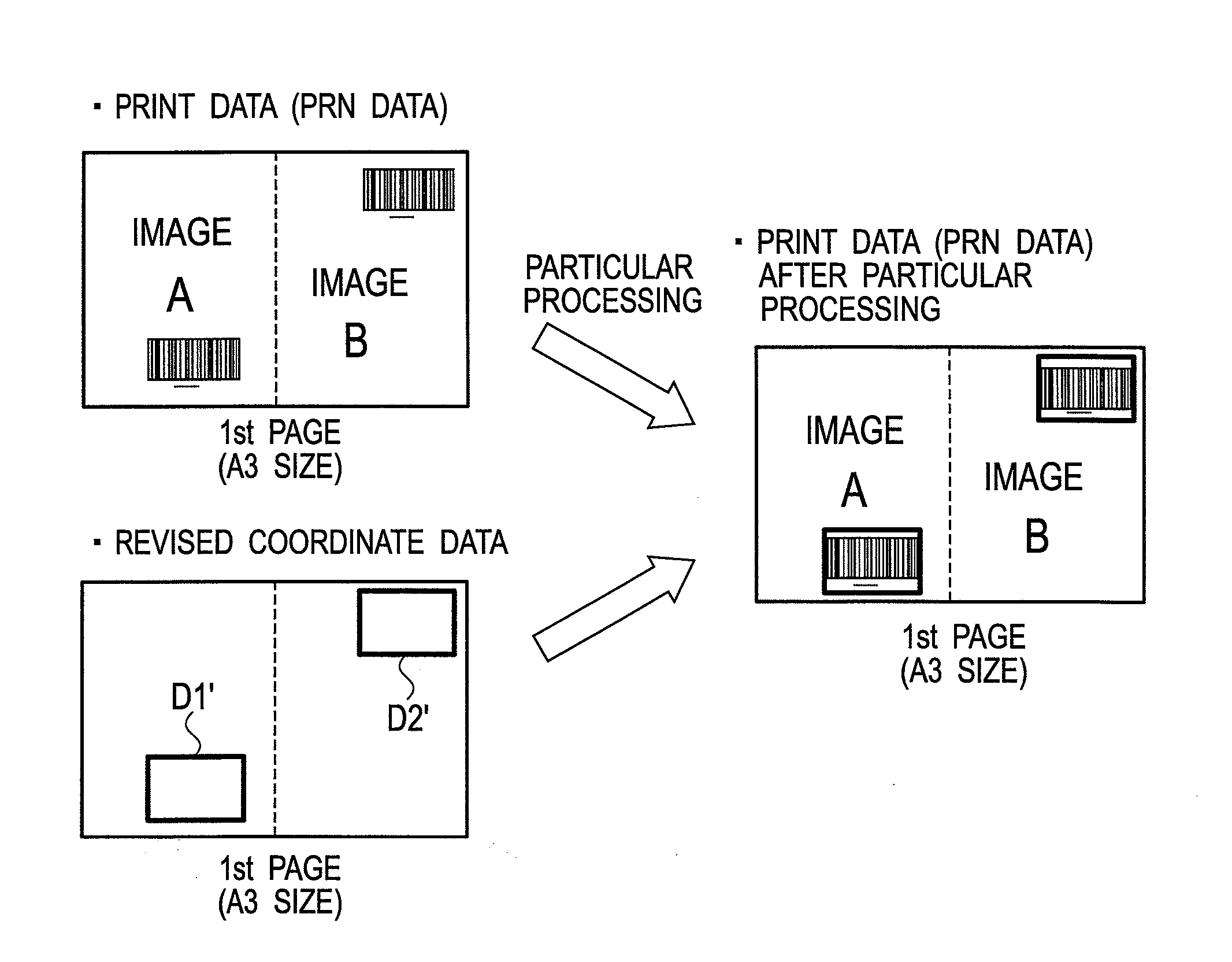

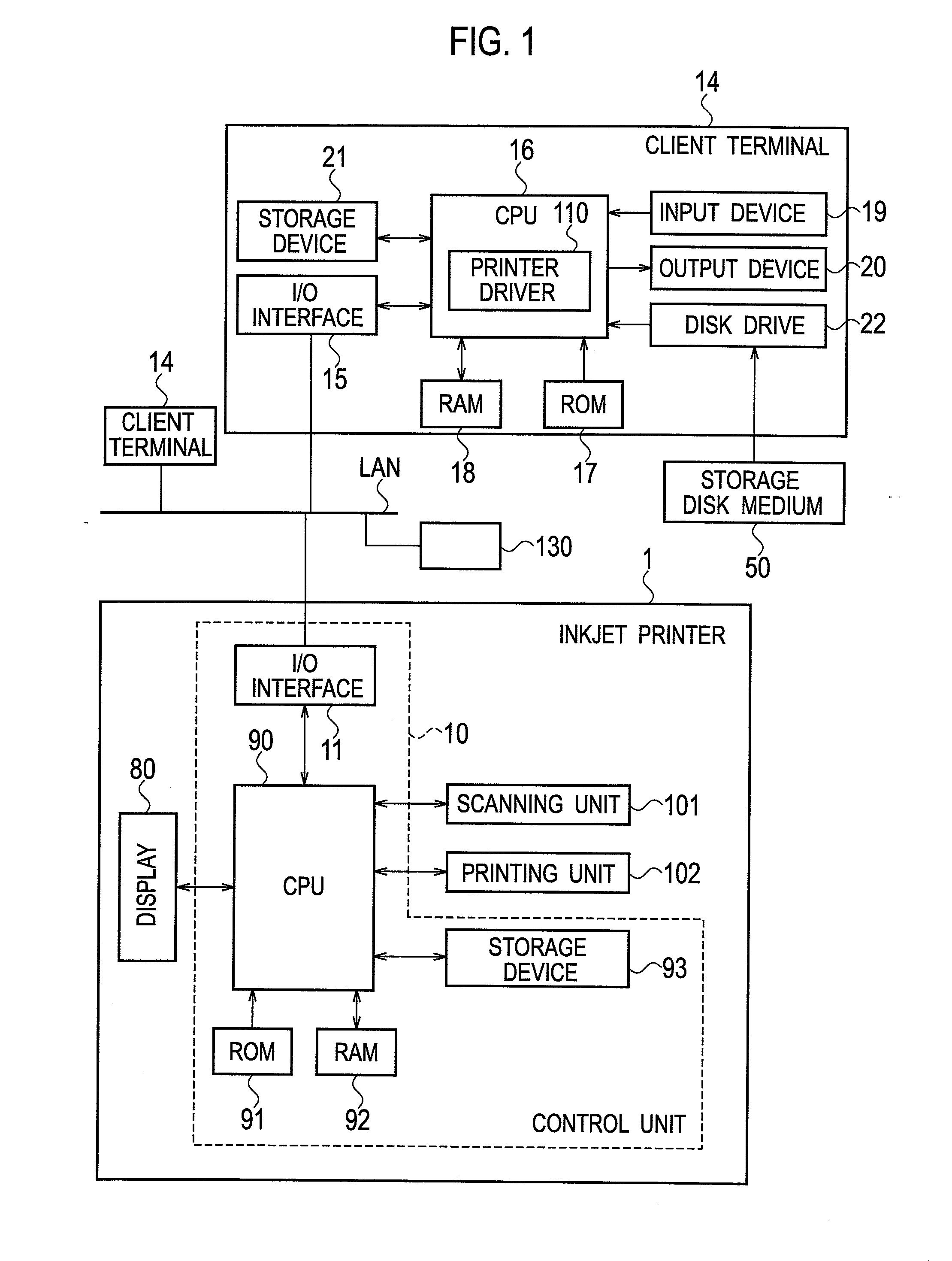

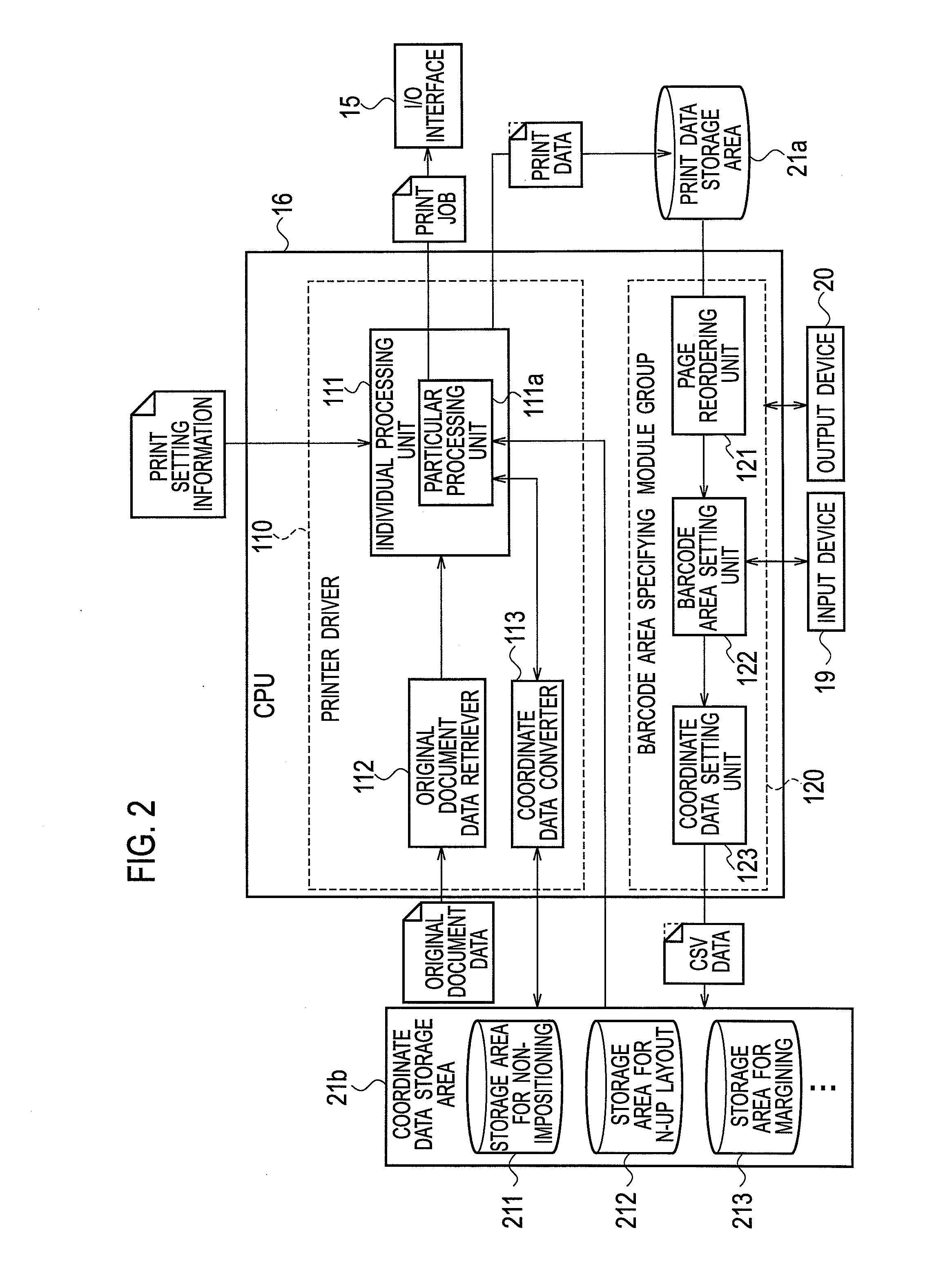

Printer control apparatus

InactiveUS20130222857A1Imaging of print image can be ensuredAccurate specificationsVisual presentation using printersDigital marking by printing code marksComputer scienceData conversion

A printer control apparatus includes an individual processing unit configured to retrieve layout setting information and generate print data that defines a print layout of the page images, a coordinate data converter configured to generate revised coordinate data by converting coordinate data of a target area based on the layout setting information, a particular processing unit configured to execute a particular processing to the target area based on the revised coordinate data and the print data, and a print job output unit configured to output the print data processed by the particular processing to the printer as a print job. According to the printer control apparatus, a user can specify the target area easily and accurately. The revised coordinate data is stored together with the layout setting information, so that the revised coordinate data can be utilized when a printing processing with the identical print layout will be executed.

Owner:RISO KAGAKU CORP

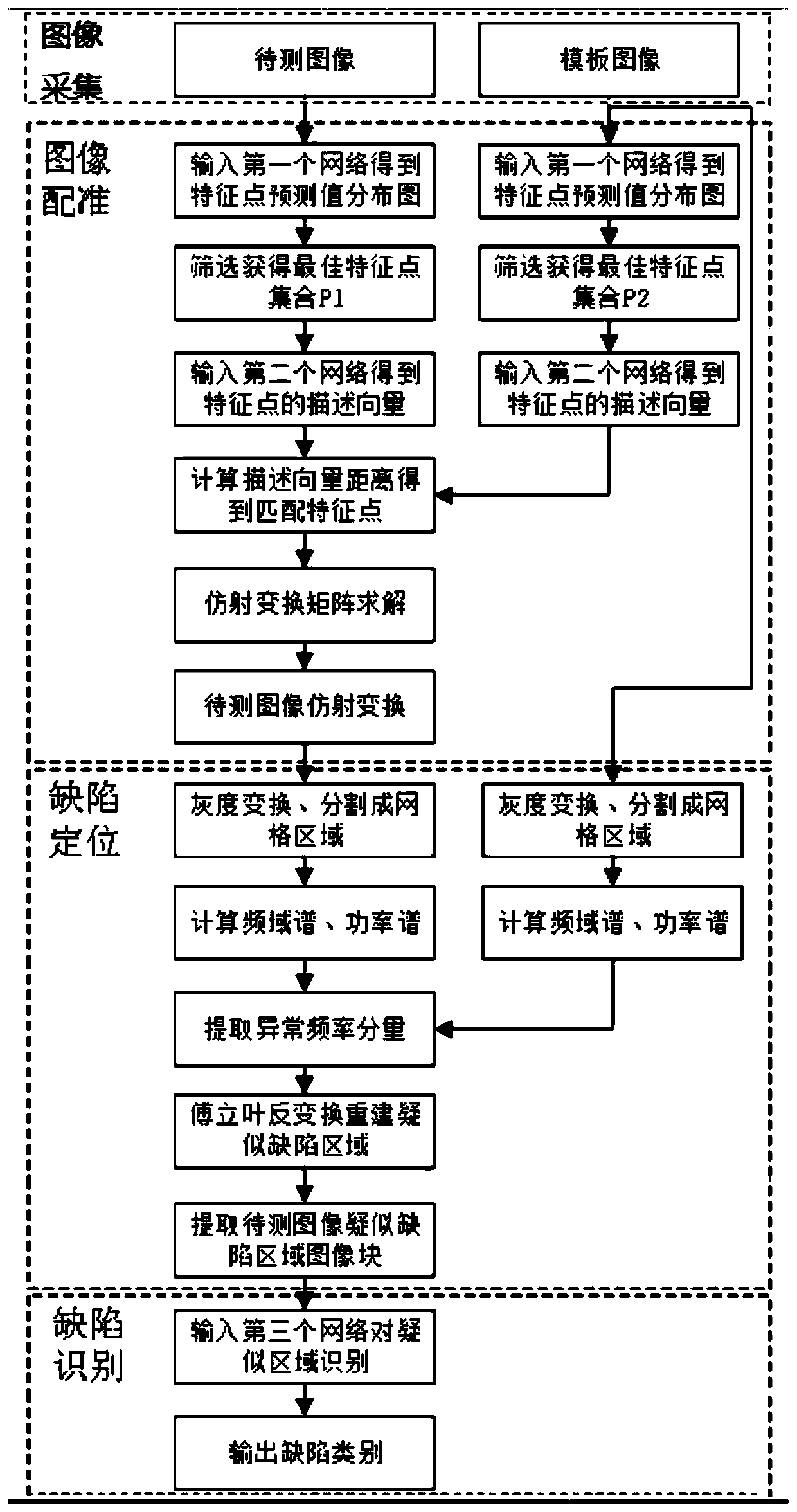

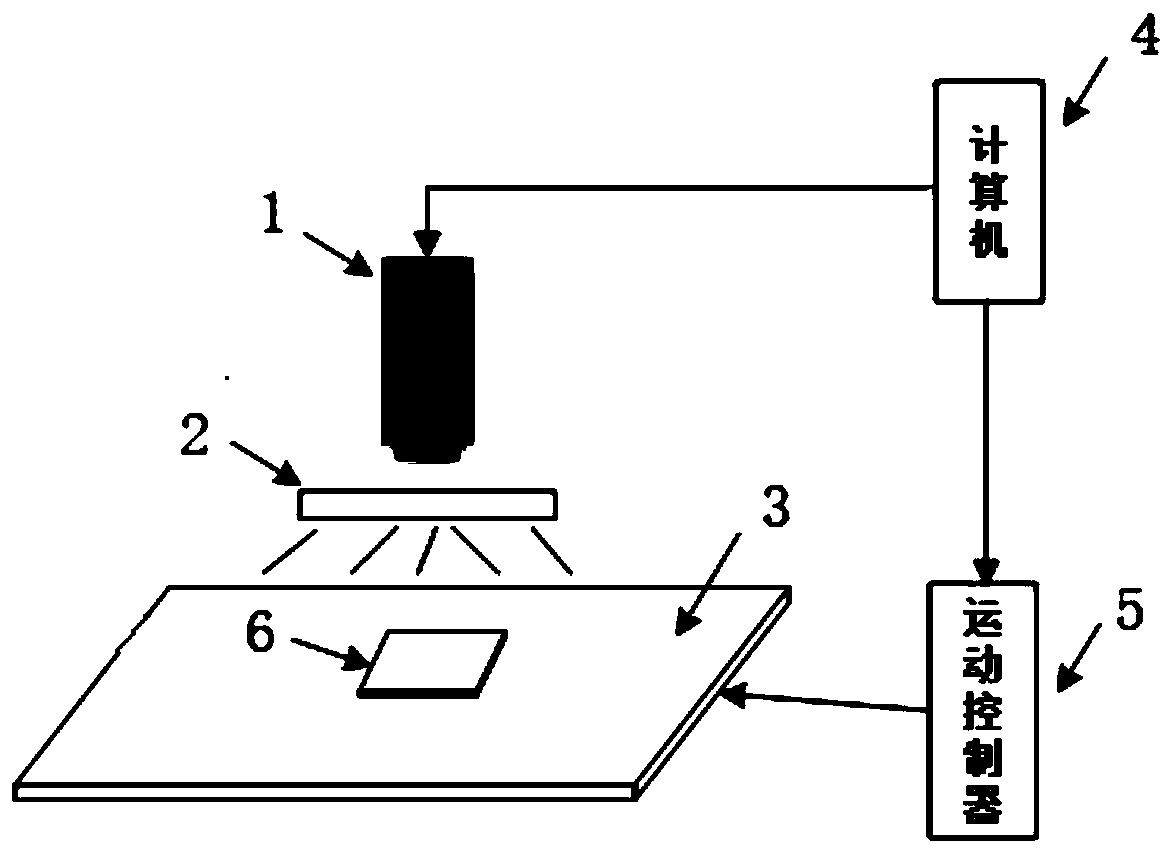

Printed circuit board surface defect positioning and identifying method

ActiveCN111260621AAccurate printingQuality assuranceImage enhancementImage analysisEngineeringComputer vision

The invention discloses a printed circuit board surface defect positioning and identification method. The method comprises the following steps: firstly, collecting a to-be-detected image and a template image of a printed circuit board; secondly, using a first convolutional neural network to obtain a feature point prediction distribution map, and screening to obtain an optimal feature point; then,calculating a description vector of the optimal feature point by using a second convolutional neural network, and matching the optimal feature points of the to-be-detected image and the template image; then, calculating an affine transformation matrix according to the matching points, and projecting the image to be measured onto the template image; thirdly, calculating a power spectrum of the projected to-be-detected image and the template image, obtaining an abnormal frequency component of the to-be-detected image according to the power spectrum difference, and obtaining a suspected defect area through inverse Fourier transform; and finally, identifying and classifying the suspected defect area by using a third convolutional neural network. According to the method, the surface defects ofthe printed circuit board can be accurately positioned and identified, the quality of the circuit board is guaranteed, and the method has certain robustness to environmental noise.

Owner:HUNAN UNIV

Medicine packaging device

InactiveUS7500337B2Accurate printingPrevent movementWrapping material feeding apparatusPharmaceutical product form changeEngineeringMechanical engineering

Owner:YUYAMA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com